Page 1

WSS 100

WST 100 DV

Instructions for Use Manual

C332-I-GB-F-D-E

09/2009

Page 2

WSS100 - WST100 DV

Table of contents

Instructions for use .........................................................................................................2

Operator’s safety ............................................................................................................................. 2

General recommendations .............................................................................................................. 2

Vacuum cleaner description...........................................................................................3

Labels .............................................................................................................................................. 3

Packing and unpacking ................................................................................................................... 3

Setting up - connection to the power supply ................................................................................... 4

Vacuuming liquids ........................................................................................................................... 5

Maintenance and repairs ................................................................................................................. 5

Technical specications ................................................................................................................... 5

Dimensions ...................................................................................................................................... 5

Controls, indicators and connections .............................................................................................. 6

Inspection prior to starting ............................................................................................................... 6

Starting up ....................................................................................................................................... 6

Starting the vacuum cleaner ......................................................................................................................6

Stopping - Emergency stopping ................................................................................................................. 6

Liquid vacuum stopping (g. 1) .................................................................................................................. 6

Emptying the containers .................................................................................................................. 6

Emptying the liquid container ..................................................................................................................... 6

Emptying the liquid container with the diverter valve ................................................................................. 6

Emptying the chip basket ........................................................................................................................... 7

At the end of a cleaning session ..................................................................................................... 7

Maintenance, cleaning and decontamination .................................................................................. 7

Cleaning the containers ................................................................................................................... 8

Chip basket ................................................................................................................................................ 8

Liquid container .......................................................................................................................................... 8

Cleaning or replacement of the safety lters ................................................................................... 8

Seal inspection ................................................................................................................................ 8

Vacuum cleaner disposal ................................................................................................................ 9

Wiring diagrams .............................................................................................................................. 9

Wiring diagram list - g. 14 ......................................................................................................................... 9

Troubleshooting .............................................................................................................10

1

09/2009

Page 3

WSS100 - WST100 DV

Instructions for use

Read the operating instructions and comply with the important safety recommendations identied by the word WARNING!

Operator’s safety

WARNING!

Before starting the vacuum cleaner, it is

absolutely essential to read these operating

instructions and to keep them ready at hand

for consultation.

Before using the vacuum cleaner, operators must be

informed, instructed and trained on how to work it and

for which substances its usage is permitted including

the safe method for removing and disposing of the

vacuumed material.

Proper uses

Any other use is considered improper.

This vacuum cleaner has been designed to be used by one

operator at a time. Do not carry out any operation that could

jeopardize the safety of people, property and the environment.

Comply with the safety indications and prescriptions in this

instruction manual.

General recoinendations

WARNING!

Risk of re outbreaks and explosions.

• The vacuum cleaner can only be used when active

sources of ignition are not going to be vacuumed.

• It is forbidden to vacuum the following materials:

• burning materials (embers, hot ashes, lighted

cigarettes, etc.);

• flainable liquids, aggressive fuels (e.g.

gasoline, solvents, acids, alkaline solutions,

etc.).

• It is forbidden to vacuum the following materials:

explosive dust or dust liable to spontaneous

ignition (such as magnesium or aluminium dusts,

etc.).

• The vacuum cleaner is not suitable for vacuuming

explosive or similar substances, as established

by the laws governing explosive substances,

particularly: liquid fuels and mixtures of ainable

dust and liquids.

WARNING!

Turn off the vacuum cleaner, unplug it and ask for

assistance from qualied personnel in the event of the

following:

• lter breakage;

• re outbreak;

• short-circuit;

• motor failure;

• electric shock;

WARNING!

The vacuum cleaner must not be used or stored

outdoors, or in damp places.

WARNING!

If foam or liquid spills from the vacuum cleaner, switch

it off iinediately and check for the cause.

09/2009

2

Page 4

Labels

WSS100 - WST100 DV

Vacuum cleaner description

Figure 1

1 Identication plate:

Code of the model, technical specications, serial

number, CE marking, year of manufacture

2 Liquid container

3 Controls (switches)

4 Inlet

5 Vacuum motors

6 Liquid container closing band

7 Diverter valve control (WST 100 DV only)

8 Liquid level indicator tube

9 Drain valve

10 Safety lters

11 Float for stopping liquids (located under chip basket)

Vacuuming of liquids and shavings

When the machine vacuums shavings and liquids produced

during the machining process, the solid shavings are captured

in the chip basket. Liquids ow into the container underneath

(2).

Before turning on the vacuum cleaner, t the vacuum hose

into the inlet (4) and then t the required tool to the end of the

hose.

The oat (11) stops the vacuuming operation (the vacuuming

units remain activated) when the liquid container (2) is full; it

is then necessary to turn off the vacuum cleaner and to empty

the liquid container (2).

Packing and unpacking

Dispose of the packing materials in compliance with the laws

in force.

Figure 2

Model A (in) B (in) C (in) Lbs

WSS 100 28 34 59 143

WST 100 DV 28 47 59 165

3

09/2009

Page 5

WSS100 - WST100 DV

Setting up - connection to the power

supply

WARNING!

• Make sure that the vacuum cleaner is in good

condition before starting work.

• Before plugging the vacuum cleaner into the

electrical mains, make sure that the voltage rating

indicated on the data plate corresponds to that of

the electrical mains.

• Plug the vacuum cleaner into a socket with a

properly installed ground connection. Make sure

that the vacuum cleaner is off.

• The plugs and connectors of the connection

cables must be protected against splashing water.

• Make sure that connections to the electrical mains

and plug are correct.

• Use the vacuum cleaner only when the cables

that connect to the electrical mains are in good

condition (damaged cables could lead to electric

shocks!).

• Regularly check that the electric cable does not

show signs of damage, excessive wear, cracks or

aging.

WARNING!

The vacuum cleaner’s power socket must be protected

by a differential circuit-breaker with surge current

limitation, that shuts off the power supply when the

current discharged to the ground exceeds 30 mA for

30 msec. or an equivalent protection circuit.

WARNING!

Never spray water on the vacuum cleaner: this could

be dangerous for persons and could short circuit the

power supply.

WARNING!

When the vacuum cleaner is operating:

• Do not crush, pull, damage or tread on the cable

that connects to the electrical mains.

• Only disconnect the cable from the electrical

mains by removing the plug (do not pull the cable).

• Only replace the electric power cable with one of

the same type as the original (H05 VV-F); the same

rule applies if an extension is used.

• The cable must be replaced by the manufacturer’s

Service Centre staff or by equivalent qualied

personnel.

09/2009

4

Page 6

WSS100 - WST100 DV

Vacuuming Liquids

WARNING!

Comply with the safety regulations governing the

materials for which the vacuum cleaner is used.

WARNING!

• Before vacuuming, check that the oat is present.

• If foam forms, turn off the vacuum cleaner

iinediately and empty the container.

• Warning: switch off the vacuum cleaner iinediately

if foam or liquid leaks out.

• Warning: the dirty liquid collected by the vacuum

cleaner must be considered conductive.

WARNING!

Do not use the vacuum cleaner without the oat!

If it’s used without the oat, the vacuum cleaner may

be seriously damaged.

Maintenance and repairs

WARNING!

Disconnect the vacuum cleaner from its power

source before cleaning, servicing, replacing parts or

converting it to obtain another variant.

• Carry out only the maintenance operations

described in this manual.

• Use only original spare parts.

• Do not modify the vacuum cleaner in any way.

Failure to comply with these instructions could

jeopardize your safety. Moreover, such action

would iinediately void the EC declaration of

conformity issued with the vacuum cleaner.

WARNING!

To carry out maintenance operations which are not

described in this manual contact the manufacturer’s

Service Centre or our sales network.

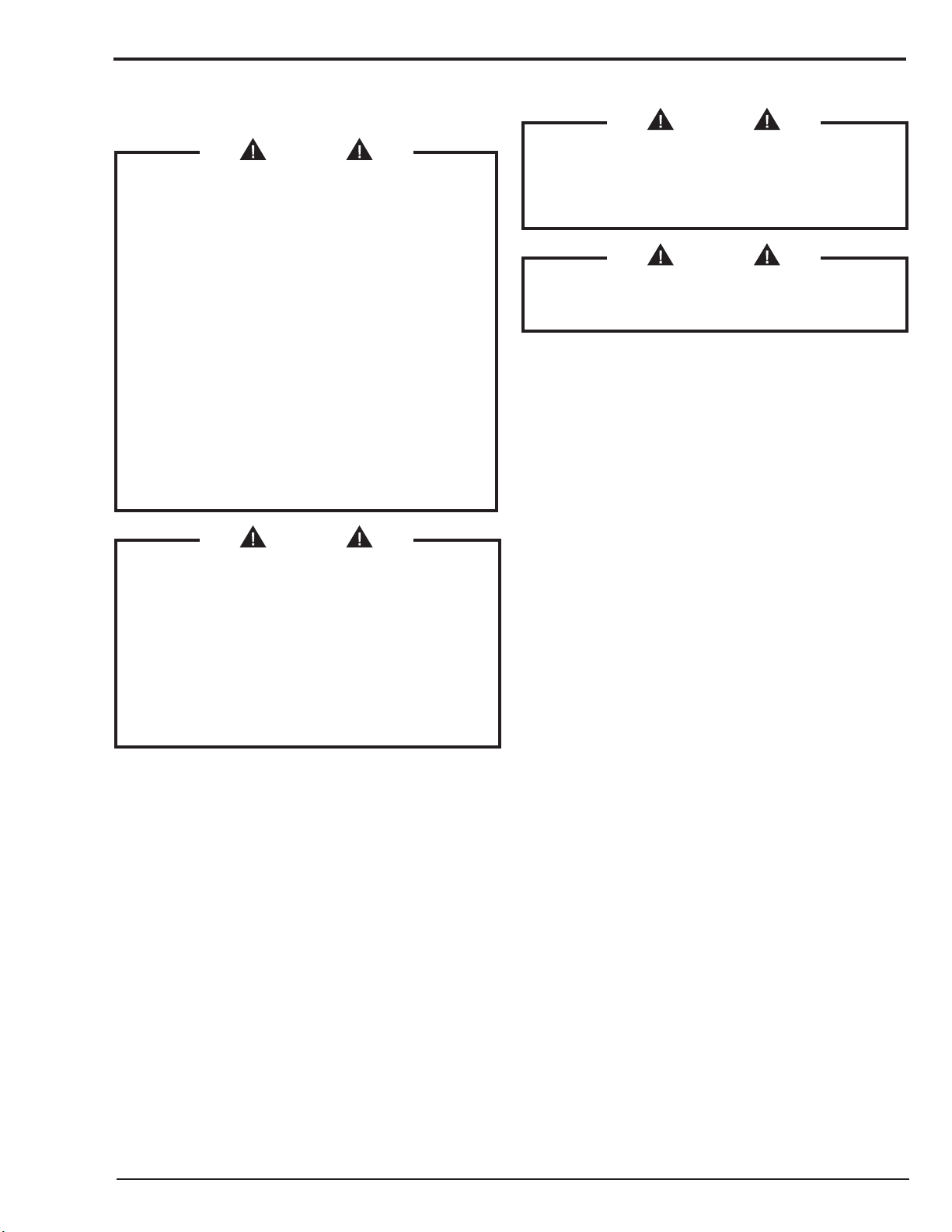

Technical specications

Parameter Units

Voltage / frequency V/Hz 120/60

Power rating kW 1.6

Noise level dB(A) 73

Protection IP 44

Insulation Class I

Shaving capacity

(optional)

Max liquid capacity gallons 26

Inlet (diameter) in 2

Max vacuum in H2O 70

Maximum air ow rate

(without hose and reductions)

gallons 6.6

cfm 150

WSS 100 /

WST 100 DV

Dimensions

Figure 3

Model WSS 100 WST 100 DV

A (in) 22.8 22.8

B (in) 31.5 34.7

C (in) 48.4 48.4

.

lbs

• Storageconditions:

Temperature:-10°C÷+40°C

Humidity:≤85%

• Operatingconditions:

Maximumaltitude:800m

(Upto2,000mwithreducedperformances)

Temperature:-10°C÷+40°C

Humidity:≤85%

110 132

[ NOTE ]

5

09/2009

Page 7

WSS100 - WST100 DV

Controls, indicators and connections

Figure 4

1 ON/OFF switches

2 Diverter valve (WST 100 DV only)

Inspection prior to starting

Figure 5

1 Inlet

Prior to starting, check that:

• All latches are tightly closed;

• The vacuum hose and tools have been properly tted into

the inlet (1);

• The chip basket is present,

• The liquid container is not full.

• The oat inside the liquid container is present and

installed correctly

Starting up

Figure 6

1 Castor brakes

Lock the castor brakes before starting the vacuum cleaner (1).

• Activate the diverter valve (2), and move it to position A,

in order to reverse the ow of air.

• Push both switches (1) to start the machine.

• Holding the drain hose rmly, open the valve on the drain

hose to start the ow of liquid.

• At the end of the emptying operation push both switches

(1) to stop the vacuum units.

• To start the vacuum operation, close the drain valve (3),

take the valve (2) to B position, then push both switches

(1).

WARNING!

Do not operate the diverter valve “2” when the vacuum

units are activated.

If the ow is inverted when the vacuum units are

activated, the machine may be damaged.

Starting the vacuum cleaner

• Push one of the switches or both of them (1 - gure 4) to

start the vacuum cleaner. The related warning lights will

turn on.

Stopping - Emergency stopping

• Push the switches (1 - gure 4) once again to stop the

vacuum cleaner.

Emptying the containers

Figure 7

1 ON/OFF switches

2 Diverter valve (WST 100 DV only)

3 Drain valve

Emptying the liquid container (WSS 100) Figure 1

• When the tank is full, the oat (11-gure 1) stops the

vacuuming operation; nevertheless, the vacuum motors

(5-gure 1) remain activated.

• Switch off the vacuum units by pushing the switches (3).

• Open the drain valve (9) to drain the container.

• After emptying, close the drain valve (9).

Emptying the liquid container with the diverter

valve (WST 100 DV) Figure 7

• When the tank is full, the oat stops the vacuuming

operation; nevertheless, the vacuum motrs remain

activated.

• Switch off the vacuum motors by pushing the switches

(1).

Note: Drain any excess liquid from inside the suction hose

back into the container before activating the diverter valve.

• Make sure the discharge hose (4-gure 7) is properly

attached to the drain valve (3-gure 7) and the valve on

the handle is closed.

• Open the drain valve (3)

09/2009

6

Page 8

WSS100 - WST100 DV

Emptying the chip basket

Figure 8

1 Chip basket

2 Container closing band

3 Motorhead (WST 100 DV)

4 Motorhead (WSS 100)

WARNING!

Before proceeding with these operations, turn off the

vacuum cleaner and remove the plug from the power

socket.

Lift the container with a suitable lifting device.

• Open the container closing band (2) and lift off/tilt back

the vacuum cleaner motor head.

• Remove the chip basket.

• Empty the basket and clean it (see “Cleaning the

containers” paragraph).

• Place the chip basket back in position, making sure it is

correctly positioned.

At the end of a cleaning session

• Turn off the vacuum cleaner and remove the plug from

the socket.

• Wind up the power cord.

• Empty the container as described in the “Emptying

the containers” paragraph. Clean the vacuum cleaner

as described in the “Maintenance, cleaning and

decontamination” paragraph.

• Store the vacuum cleaner in a dry place, out of reach of

unauthorized personnel.

Maintenance, cleaning and

decontamination

WARNING!

The precautions described below must be taken during

all the maintenance operations, including cleaning and

replacing of the safety lters.

• To allow the user to carry out the maintenance

operations, the vacuum cleaner must be

disassembled, cleaned and overhauled as far as

is reasonably possible, without causing hazards

for the maintenance staff or others. The suitable

precautions include decontamination before

disassembling the vacuum cleaner, adequate

ltered ventilation of the exhaust air from the

room in which it is disassembled, cleaning of

the maintenance area and suitable personal

protection.

Compartments that are not dust-tight must be opened

with suitable tools (screwdrivers, wrenches, etc.) and

thoroughly cleaned.

• Carry out a technical inspection at least once a

year, for example: check the lters to nd out

whether the seal of the vacuum cleaner has

been impaired in any way and make sure that

the electric control panel operates correctly.

This inspection must be carried out by the

manufacturer or by a qualied technician.

WARNING!

Use only genuine spare parts supplied and authorized

by the manufacturer.

7

09/2009

Page 9

WSS100 - WST100 DV

Cleaning the containers

WARNING!

Before proceeding with these operations, turn off the

vacuum cleaner and remove the plug from the power

socket.

Chip Basket

• Clean the container after each emptying (see “Emptying

the chip basket” paragraph).

• Check that the holes are free of dirt; clean them if

necessary.

Liquid container

Figure 9

1 Float ball and support plate

2 Chip basket

3 Container closing band

4 Drain valve

• Empty the liquid container (see “Emptying the containers”

paragraph).

• Open the liquid container closing band (3).

• Lift the motor head.

• Remove the oat, its support (1) and the chip basket (2)

• Wash the container with water to remove deposits.

• Open the valve (4) to empty the container.

• Close the drain valve (4).

• Place the oat drain, its support and the chip basket back

into position.

• Lock the motor head by using the liquid container closing

band (3).

Cleaning or replacement of the safety

lters

Figure 10

1 Safety lters

2 Separator

3 Filter cover

• Open the container closing band (3 g 9).

• Lift off the motor head

• Remove the lter cover (3) and the separator (2) after

removing the screws.

• Clean the lters (1) with water or replace them if

necessary.

• Install the lter cover (3), the separator (2) and the lters

(1) by replacing the xing screws.

• Reinstall the motor head and close the container with the

appropriate closing band.

Seal inspection

Figure 11

1 Vacuum hose

2 Sight level hose

• Hoses check

Make sure that the suction connecting hose (1) and the

sight level hose (2) are in a good condition and correctly

xed.

If the hose is damaged or broken, it must be replaced.

Figure 12

1 Gasket

2 Liquid container

3 Motor head

Replace the seal (1) between the container (2) and the

motor head (3) if it is torn, cut, etc.

09/2009

8

Page 10

WSS100 - WST100 DV

Vacuum cleaner disposal

Dispose of the vacuum cleaner in compliance with the laws in

force.

The symbol (gure 13), which is present on the product or

in its documentation, indicates that the product cannot be

disposed of together with other domestic waste at the end of

its life cycle.

To prevent damages to the environment or the health caused

by improper waste disposal, please separate this product from

other waste and recycle it responsibly in order to support the

sustainable reuse of material resources.

Domestic users should contact the retailer or the local ofce

providing information on separate collection and recycling of

this product.

Companies should contact the supplier and check the

purchase contract terms and conditions.

This product can not be disposed of together with other

coinercial waste.

Wiring diagrams

Wiring diagram list - g. 14

Reference

number

1 Armature

2 Coil

3 Terminal strip

4 Condenser

5 Bipolar switch

6 Thermal protection

7 Grounding cable

Internal wires 18 AWG

Power Cable 14 AWG

Part

9

09/2009

Page 11

WSS100 - WST100 DV

Troubleshooting

Problem Cause Remedy

The vacuum cleaner suddenly stops. Activation of the level monitoring

system.

Intervention of thermal protection

devices.

The vacuum cleaner performance has

decreased.

Electrostatic current on the vacuum

cleaner.

The vacuum cleaner does not start

after emptying the container.

Clogged lters. Replace them.

Clogged vacuum hose. Check the vacuum hose and clean it.

Non existent or inefcient grounding. Check all grounding, particularly the union to

The vacuum hose is not free from

debris.

The shaving container is full. Empty the shaving container and check the

Emptying of the liquid container.

Push the switches to stop the vacuum

cleaner, wait until the motors cool down,

then start it again.

the inlet.

Make sure that the oat does not close the

hose and/or the hose is not clogged.

seals.

09/2009

10

Page 12

1

WSS100 - WST100 DV

1

7

3

6

4

2

8

9

2 3

C

11

5

BB

A

5

10

4

C

A

B

WSS100 WST100 WST100 - WSS100

1

2

09/2009

11

Page 13

WSS100 - WST100 DV

1

1

2

2

WST100 WSS100

5

7

6

1

6

3

8

5

1

B

A

2

4

3

3

4

12

09/2009

Page 14

WSS100 - WST100 DV

1

3

2

9

11

10

1

2

1

3

1

12

2

13

09/2009

13

Page 15

WSS100 - WST100 DV

1

2 2

6

3

4

5

7

5

4

3

6

2

2

1

14

14

09/2009

Loading...

Loading...