SOLAR BOOSTER D, EH

Instruction manual ..................................... 3 - 32

Betriebsanleitung ...................................... 33 - 62

Manuel d’Instructions ................................ 63 - 92

Gebruikershandleiding .............................. 93 - 122

Manual de instrucciones ........................... 123 - 152

Manuale di istruzioni ................................. 153 - 182

Руководство ............................................. 183 - 211

Üzemeltetési útmutató .............................. 212 - 238

Index

1 Safety precautions and warnings .....................................................................................4

2 Description 2.1 Application ..............................................................................6

2.2 Operation elements ................................................................6

3 Installation 3.1 Temperature conditions ..........................................................6

3.2 Condition of distance ..............................................................7

3.3

3.4 Mounting of handle .................................................................7

3.5 Mounting of spacers ...............................................................7

3.6 Water connection ....................................................................8

3.7 Mains power connection .........................................................8

3.8 High pressure connection .......................................................9

3.9 Venting - D models ..............................................................10

3.10 Venting - EH models ............................................................11

3.11 Connecting to external fuel supply - D-models .....................12

4 Operation 4.1 Connections .........................................................................13

4.1.1 High pressure hose - directly on the machine ...........13

4.1.2 High pressure hose - to outlet point ...........................13

4.1.3 Spray handle - accessories .......................................14

4.1.4 Selection of spray lance .............................................14

4.1.5 Application of detergents (external injector) ..............15

4.1.6 Application of detergents (internal) (optional) ............16

4.2 Running the SOLAR BOOSTER ..........................................16

4.2.1 Starting up .................................................................16

4.2.2 Automatic start/stop ...................................................17

4.2.3 Running with hot water ..............................................17

4.2.4 Double spray lance, pressure regulation ...................18

4.2.5 Stop ...........................................................................18

4.2.6 Automatic system "shut-down" ..................................19

4.2.7 Frost protection ..........................................................19

Mounting of feet and levelling of machine ..............................7

5 Fields of Application 5.1 Fields of application ..............................................................20

and Working Methods 5.2 Working pressure .................................................................20

5.3 Temperature .........................................................................20

5.4 Mechanical impact ................................................................20

5.5 Detergents ............................................................................21

5.6 Working methods .................................................................22

5.7 Typical cleaning tasks ...........................................................23

5.7.1 Agriculture .................................................................23

5.7.2 Vehicles .....................................................................23

5.7.3 Building and equipment .............................................24

6 Maintenance 6.1 Hour counters .......................................................................25

6.2 Oil ...................................................................................25

6.3 Water fi lter ............................................................................25

6.4 Cleaning of high pressure nozzle .........................................26

6.5 Fuel fi lter - D models only .....................................................26

6.6 Disposable waste .................................................................26

7 Trouble Shooting 7.1 General trouble shooting - all SOLAR BOOSTER models ...27

7.2 Error messages, SOLAR BOOSTER EH

(el. heated) models ...............................................................29

7.3 Error mesages, SOLAR BOOSTER D

(diesel heated) models .........................................................30

8 Technical Data .....................................................................................................31

9 Warranty .....................................................................................................32

10 EC Declaration of Conformity ...................................................................................32

3

1 Safety Precautions and Warnings

Before starting up your high

pressure hot water washer for

the fi rst time, this instruction

manual must be read through

carefully. Save the instructions

for later use.

Only let instructed people operate the machine.

General

When using the high pressure

hot water washer all existing

national regulations must be

observed. Beyond the instruction manual and the current

national legal regulations for

prevention of accidents, also

the approved rules for safe

working must be observed.

Any method of use endangering

the safety of persons or equipment is forbidden.

Before use

Before starting up your high

pressure hot water washer

check that it is in a regular

condition. Electric plugs and

couplings must be watertight.

Check the electric cables at

regular intervals for damage

and wear. Only use the high

pressure hot water washer if the

electric cable is all right (damaged electric cables can cause

electric shock!)

Important instructions

Connection to public drinking

water supply must be performed in accordance with the

applicable regulations in your

country.

IMPORTANT: Only use water

without impurities!

Before each use of your high

pressure hot water washer

check the most important visual

parts.

High pressure jets can be

dangerous if misused. Never

direct the water jet towards people, pets, electric wiring, or the

machine itself.

Spray handle and lance are affected by a thrust during operation - therefore always hold the

spray lance fi rmly with both

hands.

Never try to clean clothes or

footwear on yourself or other

persons.

Operator and anyone in immediate vicinity of the site of cleaning should take action to protect

himself from being struck by

debris dislodged during operation.

Check that cleaning will not

result in dangerous substances

(e.g. asbestos, oil) being

washed off the object to be

cleaned and harming the environment.

Do not clean sensitive surfaces

made of rubber, fabrics or the

like with the zero nozzle. With

the fl at jet nozzle keep a distance of at least 15 cm to the

surface to be cleaned.

Never let children operate the

machine.

Do not use the machine if the

electric cable or the high pressure hose are damaged.

Do not cover the machine during operation or use it in a room

without adequate ventilation !

If any of the machines overload protection devices trips

(machine stops unintended),

release the trigger of the spray

handle. Lock the spray handle

with locking device and turn

the start/stop switch to position

„OFF“.

Refer to section "7 Trouble

Shooting".

The machine must be placed in

a room where it is not exposed

to frost.

Never start the cleaner without

water supply. Even a short water defi ciency can damage the

sleeves of the pump.

Operation

Avoid damage to the electric

cables such as squeezing, pulling, knots etc. and keep them

away from sharp or hot objects.

Avoid damage to the high pressure hose such as running over

by vehicles, squeezing, pulling,

knots/kinks etc. and keep it

away from oil and sharp or hot

objects, as such may cause the

hose to burst.

4

The cleaner can be used in

zones classifi ed as ZONE 2.

Important! Never use the

machine in an environment

where there could be a danger of explosion (according to

EN-50014).

Important! When the system

has been in operation and

thereafter stopped, there might

still be a working pressure in

the pipeline and high pressure

hoses. Therefore you should

pay special attention to the following:

• Never dismount the high

pressure hose from the

machine during operation.

Disconnect the machine,

close the shut-off cock and

relieve the high pressure

hose of pressure prior to

dismounting.

• Never dismount the high

pressure hose from the outlet point before it has been

securely closed and the high

pressure hose has been

relieved of pressure.

• Prior to any service interference in the machine it

should be disconnected and

the system relieved of pressure by activating the trigger

of the spray handle.

Repair and Maintenance

Only carry through the maintenance operations described in

the operating instructions. Only

use original Nilfi sk-ALTO spare

parts.

Do NOT make any technical

modifi cations to the high pressure hot water washer.

Warning! High pressure hoses,

nozzles and couplings are

important for the safety when

operating the machine. Only

use the high pressure hoses,

nozzles and couplings pre-

scribed by Nilfi sk-ALTO!

For major repairs, please contact your nearest Nilfi sk-ALTO

service organisation.

Mains power connection

This product is intended for

stationary installation only

and is supplied without a

power cord! Only let an authorized electrician connect

the machine to the mains

supply !

The following points must be

observed:

• Check that the voltage

stated on the data plate

corresponds to your mains

voltage.

• Make sure that the power

cord contains the right

number of wires (including

ground wire) and that each

wire has the right dimensions to carry the load (amperage) stated on the data

plate of the machine.

• Make sure that the installation (cables, connection

points and fuses) is correctly

dimensioned for the load of

the machine - refer to the

data plate of the machine.

If not required by local legislation, we strongly recommend you to connect the

machine to a power source

with a Residual Current Device (RCD) which will disconnect the power supply if the

leakage current exceeds 30

mA for 20 milli seconds !

See section "3.5 Mains power

connection" for further instruc-

tions.

Only let a qualifi ed electrician

maintain the electric installation.

Safety Devices

Safety Valve

The pressure side of the high

pressure pump is fi tted with a

safety valve. This valve leads

the water back to the suction

side of the pump when the

spray handle is closed or if a

nozzle is blocked.

The safety valve is adjusted

and sealed by the producer.

THIS ADJUSTMENT MUST

NOT BE CHANGED !

Machine protection

The machine features an overcurrent protection and built-in

thermal protection of the motor.

In the event of increased power

consumption (maloperation)

and in the event of excessive

motor temperature (obstructed

ventilation etc.), the entire

machine will automatically be

disconnected from the mains

supply.

Short circuit protection

The machine is equipped with

a short-circuit protection. In the

event of short-circuits in the

machine, the protective device

will disconnect the entire machine from the mains supply.

5

2 Description

2.1 Application

2.2 Operation elements

This high pressure hot water

washer has been developed

for stationary installation and

professional use within:

- agriculture

- light industry

- transport

- building and construction

- service

Section 4 describes how to use

the high pressure hot water

washer.

See illustration at the end of the manual

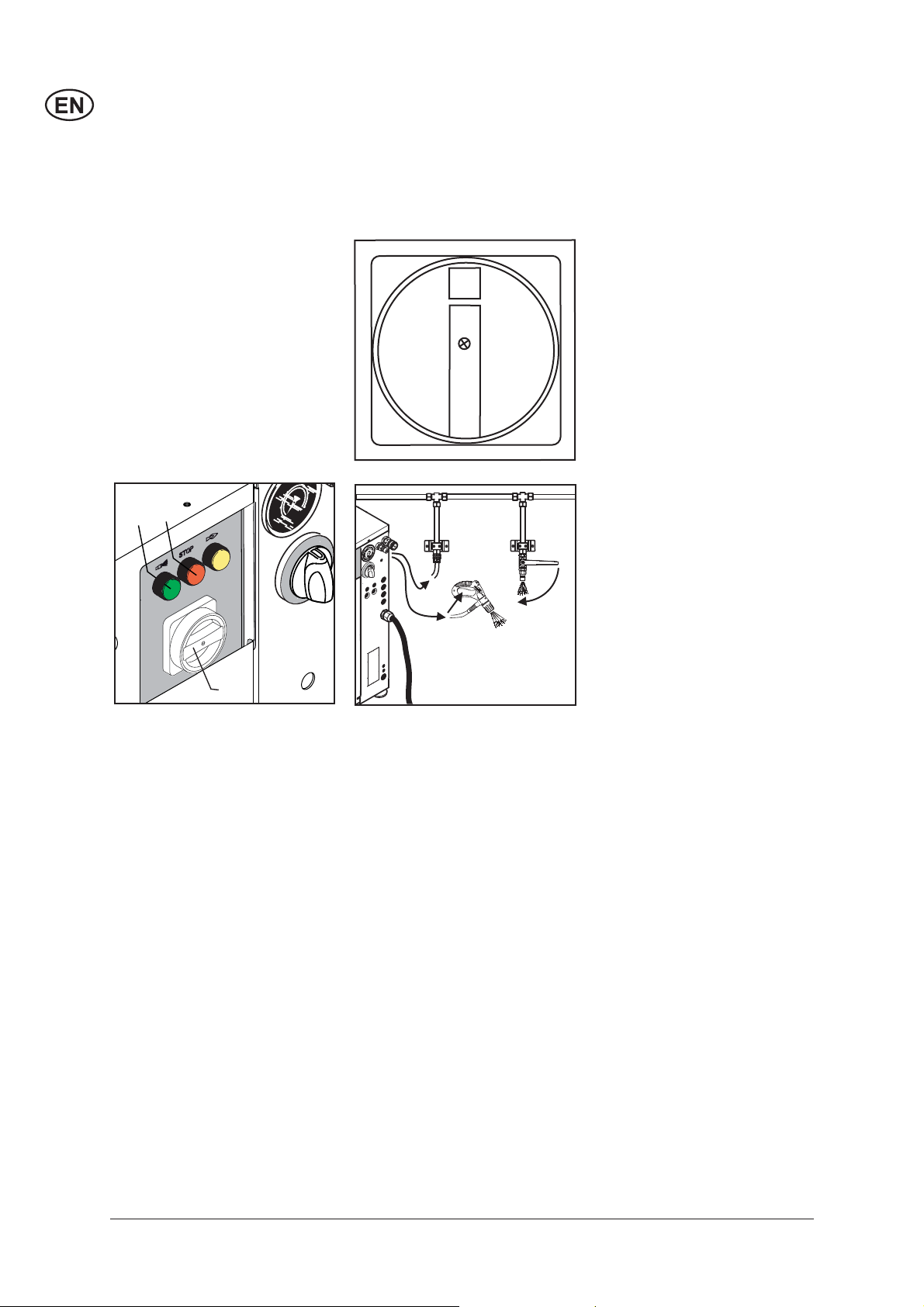

1 High pressure outlet (quick coupling, male)

2 Main switch

3 Start push button (illuminated, green)

4 Stop push button (illuminated, red)

5 Heating ON/OFF push button (illuminated, yellow)

6 Pressure gauge

7 Water inlet (quick coupling, female)

8 Thermostat (temperature adjustment)

9 Electric cable

10 Inspection window (hour counters, error messages)

11 Overheat fuse - resetable

12 Chimney

Only use the high pressure

hot water washer for purposes

described in this manual.

The safety precautions must be

observed to prevent damage

to the machine, the surface to

be cleaned or severe personal

injuries.

3 Installation

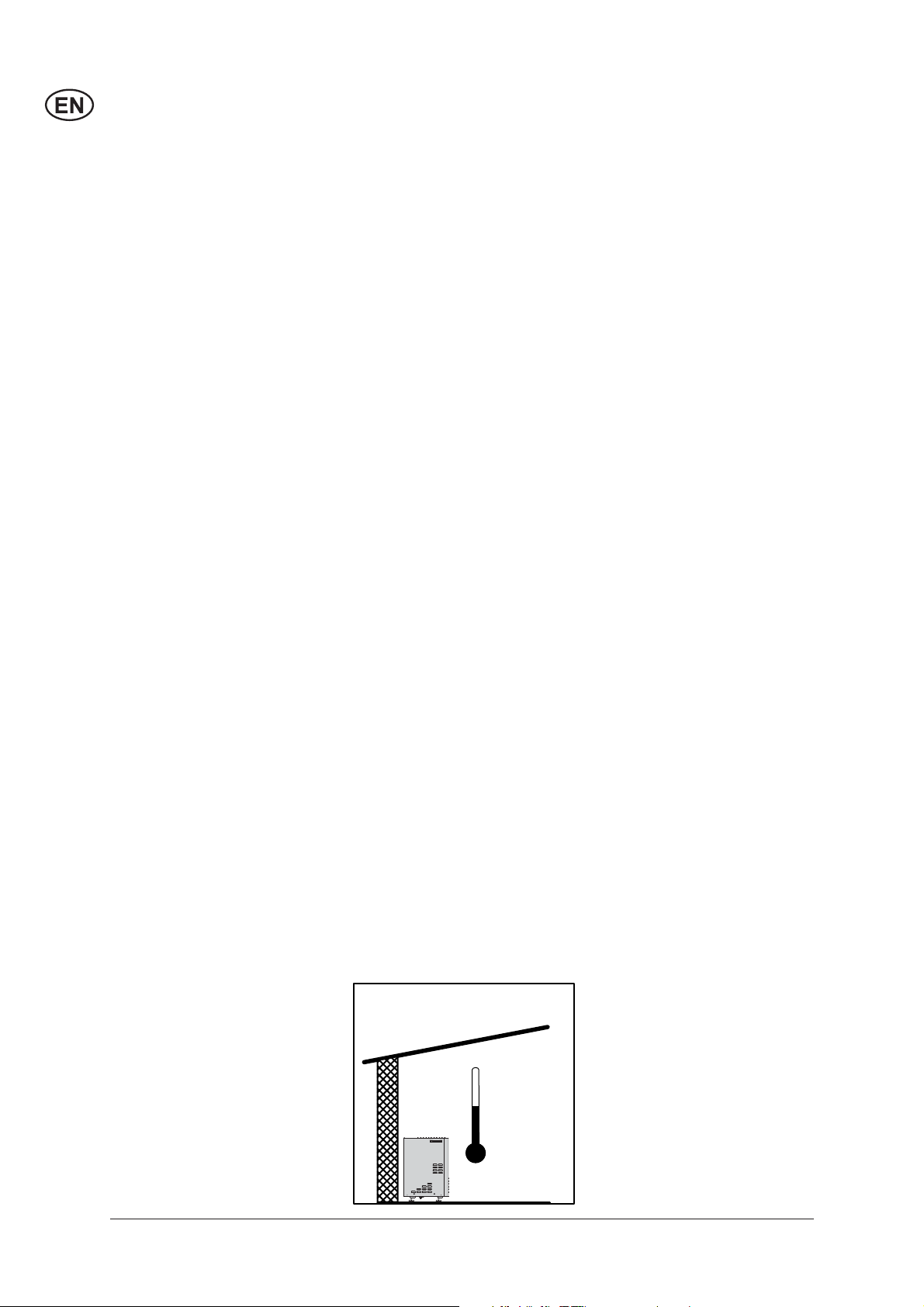

3.1 Temperature conditions

6

Max 40 °C

Min 2 °C

The machine should be installed in a frost-free room.

This applies to pump as well as

pipelines incl. of outlet points.

If connected to outdoor outlet

points it should be possible to

close and emp ty that part of the

line which is exposed to frost.

The maximum ambient temperature for the machine is 40°C.

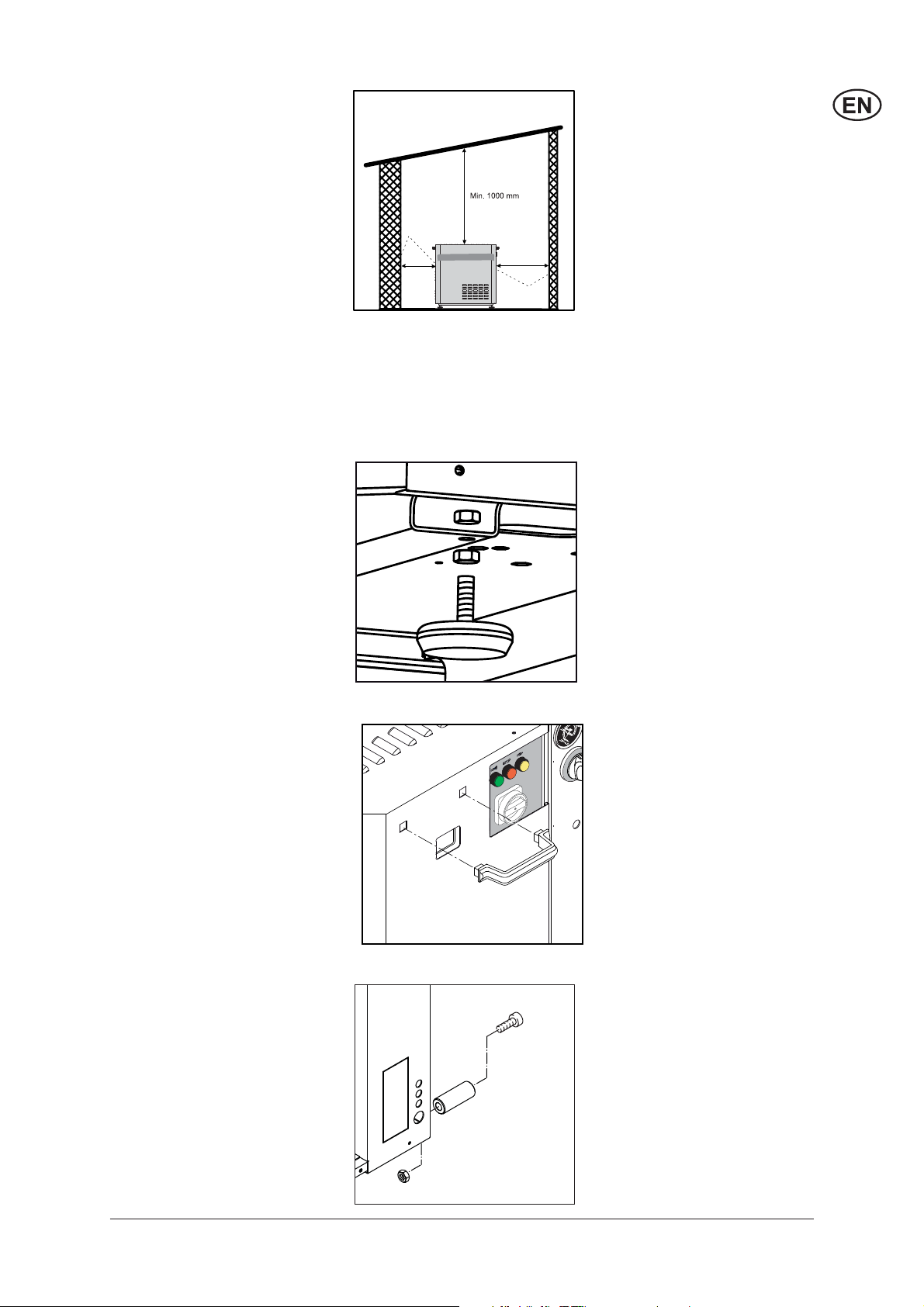

3.2 Condition of distance

Min. 150 mm

Min. 500 mm

In consideration of the cooling

system of the machine and the

accessibility of service, there

must be free wall space on both

sides of the machine. To the

right 500 mm at a min i mum and

to the left 150 mm at a min i mum. To the ceiling there must

be at least 1000 mm and from

the rear point of the machine to

the back wall there must be at

least 100 mm. There must not

be any other objects in this area

either, such as pipes etc.

3.3 Mounting of feet and

levelling of machine

3.4

Mounting of handle

The machine is delivered

without feet mounted. Loosen

the machine from the pallet and

mount the 4 feet by fastening

them to the fl ange underneath

the machine by means of a 19

mm open-end wrench.

Place the machine on a plane

fl oor.

To level the machine, loosen

the lock nut on the appropriate

feet and adjust the height by

screwing the foot up or down.

Next cross-tighten the lock nuts

around the fl ange. It is important that all 4 feet are in contact

with the fl oor.

Mount the enclosed handles on

°

0

the machine by pressing them

°

C

85°

into the suitable openings in the

60°

80°

cabinet.

3.5 Mounting of spacers

Mount the enclosed spacers at

the back of the machine.

7

1

T

3.6 Water connection

that the water supply is within

7

the following specifi cations and

that the water does not contain

particles such as fl oating sand.

Min. water inlet pressure: 1 bar

(at the required fl ow rate of the

°

0

20°

°

C

40°

85°

60°

80°

machine - see data plate.

Max. water pressure: 10 bar

Max. water inlet temp. (EH/GH):

85°C.

Max. water inlet temp. (D/G):

30°C.

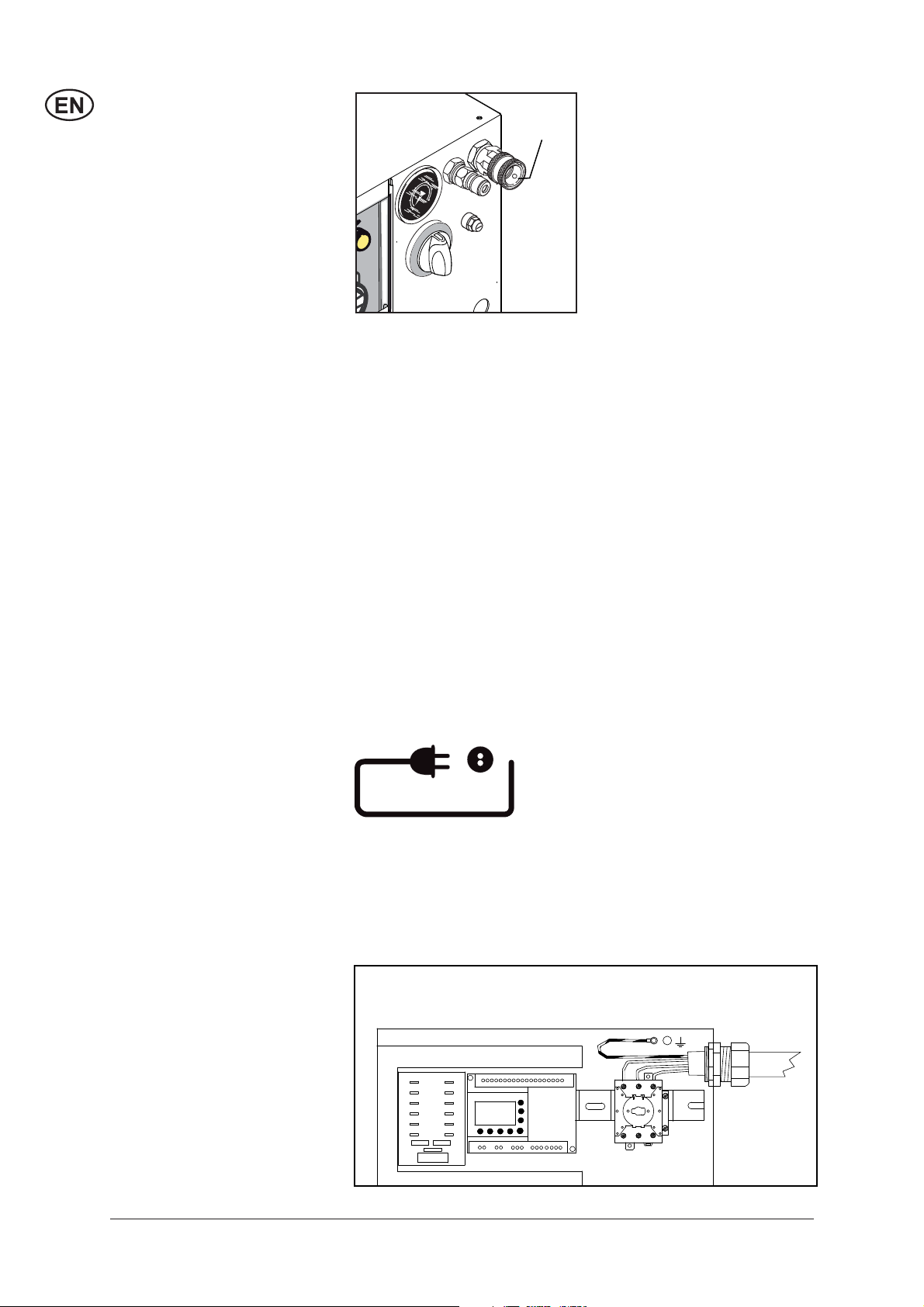

3.7 Mains power

connection

The water connection is made

through a fl exible hose connected to the quick cou pling on the

water inlet (7) of the machine.

Make sure that the supply

hose is suited for the purpose

(temperature and fl ow rate). If

in doubt, contact your Nilfi skALTO representative.

The connection can be made to

a public drinking water supply

network or a private water sup ply. A shut-off cock should be

mounted on the water supply

network in the immediate vicinity of the ma chine. Make sure

All SOLAR BOOSTER feature

a water tank, and no further

protection against back-fl owing

water into the supply network is

required. The machine complies

with EN 1717.

If there is a risk of fl oating sand

or other impurities in the inlet

water, a sand fi lter (50 micron)

should be mounted between the

supply outlet and the internal

fi lter of the machine.

Clean the water inlet fi lter (7)

once a month or in case of

poor throughput (inlet pressure below 1 bar at the fl ow rate

required by the machine).

The following precautions must

be observed:

• Make sure that the supply

cable is of the correct dimen-

CAUTION! An authorized electrician must perform the electrical connection of the machine

to the main power supply. Refer

sion (see voltage and load on

the data plate of the machine)

and is suitable for the specifi c

environment.

to section "1 Safety precau-

tions and warnings".

106420051

12

11

10

9

8

7

F 10

8

6

A

4

3

2

-

B

+

5

4

3

AA1

2

1

F5

15

12

9

7

8

5

14

11

101

13

6

MITSUBISHI

Pump plc

A2

135L1 L2 L3

T

T22T1 4 6T3

3.8 High pressure

connection

• Guide the supply cable

through the strain relief grommet on the frame (9) and

through the strain relief grommet on the electric box into

the electric box.

• Connect the phase cords of

the supply cable to the connection terminals L1(1), L2(3)

and L3(5) of the main switch

of the machine. For single

phase machines use L1(1)

and L2(3) to connect phase

and zero cords.

• Connect protective earth

wire to the terminal marked

and located above the main

switch on the metal chassis

(6). Ensure the connection by

the use of toothed washers.

• Check and measure the

protective earth connection

according to legislation.

• Connect the other end of the

cable to an approved socket

of a correct dimensioned

main supply.

Make sure that the cable is

properly guided and relieved

between the fi xed installation

and the machine and that the

cable is without any damage to

the insulation.

Also see notes in section "1

Safety precautions and warnings"!

The outlet of the machine (1)

can be connected directly to a

1

standard high pressure hose (a)

or to a pipeline with fi xed outlet

points (c).

c

°

0

20°

°

C

40°

85°

°

60

80°

a

a

IMPORTANT: When connecting

to a pipeline always use a fl exible hose connection from the

outlet of the machine (pos. 1).

Contact your Nilfi sk-ALTO distributor for further information

about hose dimension.

It is recommended to let a

service tech ni cian authorized

by Nilfi sk-ALTO prepare the

pipeline.

9

3.9 Venting

2

0°

0

°

C

°

8

5

°

8

0

°

6

0

°

4

0°

(D models)

4

3

2

When the SOLAR BOOSTER

is properly connected to supply water, electrical installation

and a high pressure hose (or

pipeline) the high pressure

pump must be vented before it

is operational.

1. Turn the main switch, (2) to

position “ON”.

2. Push the “START” button (3),

and the SOLAR BOOSTER

will start.

3. Open the outlet point (spray

handle on high pressure

hose, (d) or outlet on piping

system (e) without having a

spray lance connected.

ON

4. Let the water run until all air

has escaped from the pump

(even water fl ow).

5. In the case of a recently

installed piping sys tem, or if

the pipeline and the pump

have been emptied in any

other way, the system should

be vented by starting the

pump and then letting the

water run at each outlet point

of the pipeline at turns. It is

recommended to begin with

°

0

°

20

°

C

°

40

°

85

°

°

60

80

d

e

the most distant outlet (height

and/or length).

6. When con nect ing the high

pressure hose directly to the

ma chine, starting the pump

and activating the trigger

of the spray handle without

having attached the spray

lance, you should vent the

system.

7. Stop the SOLAR BOOSTER

by pressing the "STOP" push

button (4).

The SOLAR BOOSTER is now

vented.

10

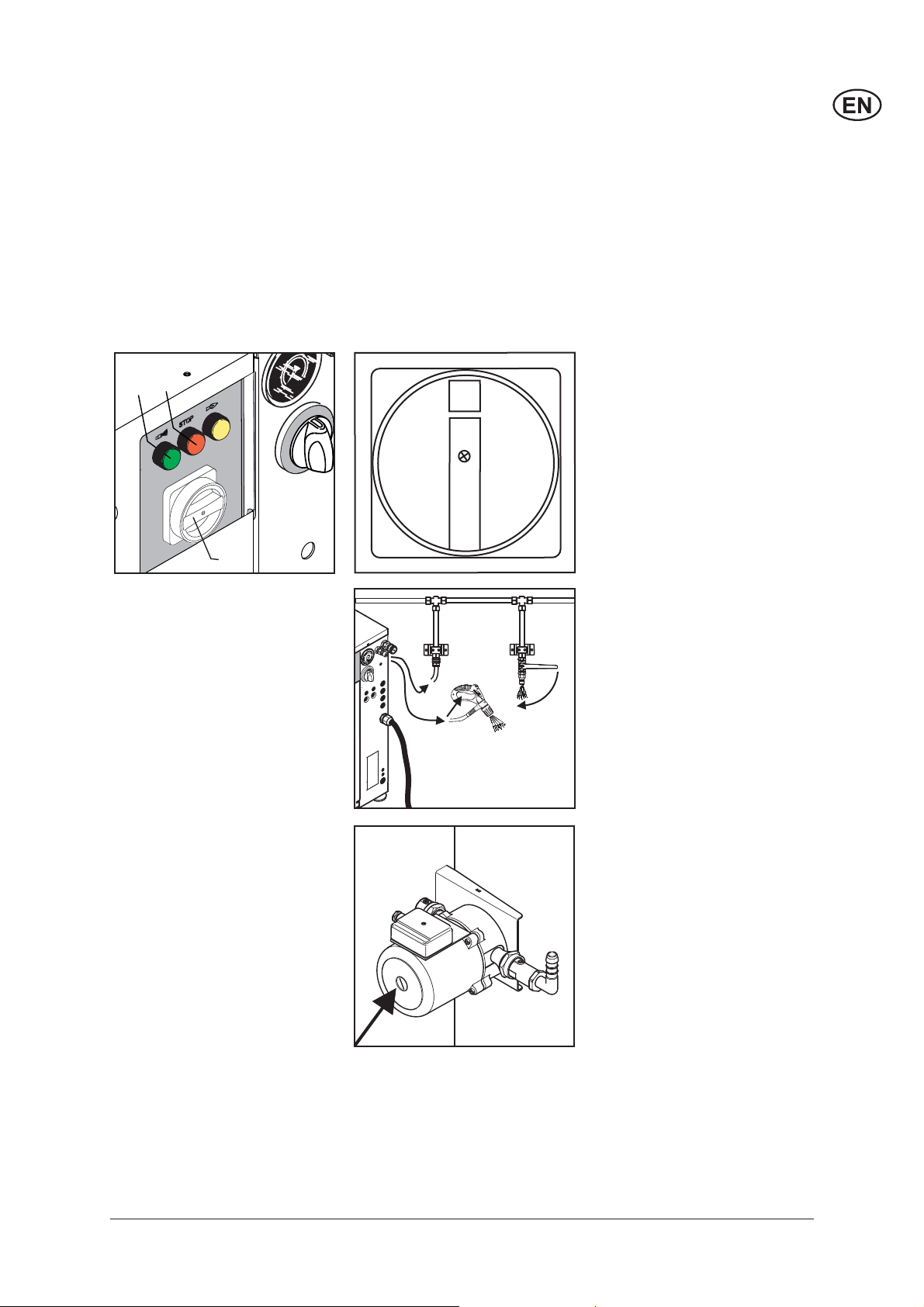

3.10 Venting - SOLAR

2

0°

0

°

C

°

8

5

°

8

0

°

6

0

°

4

0°

BOOSTER EH models

4

3

85

2

When the SOLAR BOOSTER

is properly connected to supply water, electrical installation

and a high pressure hose (or

pipeline) the high pressure

pump must be vented before it

is operational.

3. Otherwise push the “START”

button (3), and the SOLAR

BOOSTER will start.

4. Open the outlet point - spray

handle on high pressure

hose, (d) or outlet on piping

system (e) without having a

spray lance connected.

1. Turn on the water inlet and

wait until the water tank has

been fi lled with water.

2. Turn the main switch (2), to

position "ON".

5. Let the water run until all air

has escaped from the pump

(even water fl ow). If little or no

water fl ows from the system,

it may be necessary to vent

the internal feed pump separately. The Nilfi sk-ALTO service technician should perform

°

ON

0

°

20

°

C

°

40

°

°

°

60

80

this by loosening the centre

screw on the feed pump, see

arrow.

6. In the case of a recently installed piping system, or if the

pipeline and the pump have

been emptied in any other

way, the system should be

vented by starting the pump

and then letting the water run

at each outlet point of the

pipeline at turns. It is recommended to begin with most

e

d

distant outlet (height and/or

length).

7. When connecting the high

pressure hose directly to the

machine, starting the pump

and activating the trigger of

the spray handle without having attached the spray lance

should vent the system.

8. Stop the SOLAR BOOSTER

by pressing the “STOP” push

button (4).

The SOLAR BOOSTER is now

vented.

11

3.11 Connecting to external

fuel supply –

D-models

All SOLAR BOOSTER D- models must be connected to an

external fuel supply (canister or

tank) as no internal

provision is made for storing

fuel.

You can choose between oneand two-string connection,

where "one"-string only has one

supply hose (a) and "two"-string

has an additional return hose

(b) - see illustration.

Please observe that in some

a

b

countries only the "one" string

system is approved.

The fuel hose(s) should be

guided through the rubber

grommet(s) in the chassis of

the SOLAR BOOSTER as

shown in the fi gure and routed

securely to the external fuel

supply.

a = Oil in

b = Oil return (only two-string

connection)

Please observe the following

restrictions to fuel line.

12

4 Operation

4.1 Connections

4.1.1 High pressure hose

- directly on the

machine

The Nilfi sk-ALTO high pressure

hose with imprinted max. wor-

1

king pressure and temperature

should be attached to the outlet

connection of the machine (1)

by the quick coupling (a).

°

0

20°

°

C

40°

85°

°

°

60

80

a

Max.extension hose: 50 m.

Danger of scalding!

Never dismount high pressure

hoses at water temperatures

above 50°C.

IMPORTANT: Prior to dismounting of the high pressure

hose, the machine should be

cooled down. After cooling

down, stop the machine and

close the shut-off cock. Then

activate the trigger of the spray

handle to relieve the high pres sure hose of pressure.

4.1.2 High pressure hose -

to outlet point

In the case of a pipeline with

fi xed outlet points the high pressure hose with imprinted wor-

3

1

king pressure and temperature

should be attached to the nipple

of the high pres sure cock (1)

by the quick coupling (2). Upon

attachment turn the handle of

2

the high pressure cock (3) to

open position.

Danger of scalding!

Never dismount high pressure

hoses at water temperatures

above 50°C.

IMPORTANT: Prior to dis-

mounting of the high pressure

hose or when changing to another outlet point, the machine

should be cooled down. After

cooling down, stop the machine

and close the high pressure

cock care ful ly. Then activate the

trigger of the spray handle to

relieve the high pressure hose

of pressure.

13

4.1.3 Spray handle -

accessories

NOTE!

Clean nipple of any impurities

each time the spray lance has

been dismounted, see illustration.

1. Pull forward the quick coupling trigger (1) of the spray

handle.

2. Insert the nipple of the spray

lance (2) in the quick coupling and release the trigger.

4.1.4 Selection of spray

lance

1

2

You may use a double spray

lance as well as a single spray

lance with the machine.The

recommended nozzle size

of the lance is printed on the

data plate of the machine – i.e.

0530. The working pressure of

the machine can be reduced

by using nozzles with a wider

diameter.

Never use lances with smaller

nozzles (nominal value / diameter) than stated on the data

plate.

3. Pull forward the spray lance

or any other accessory to

ensure correct mounting

before starting the machine.

14

4.1.5 Application of

detergents (external)

If you want to apply detergents

or disinfectants, these can be

dosed to the water through an

external injector. In conjunction

with the injector it may be ad van ta geous to use a wall rack

on which spray lances, 2 pcs.

of 25 l containers as well as 10

m high pressure hose can be

placed.

Refer to your Nilfi sk-ALTO sales

representative for your optimal

solution.

Below you will fi nd various

types of outlet points with

injectors.

Outlet point with detachable

injector

To be attached to the quick coupling of the high pressure cock.

To be used for dosing of lowfoaming detergents or disinfectants.

Dosage 1-8%.

Outlet point with detachable

foam injector

To be attached to the quick coupling of the high pressure cock.

To be used in conjunction with

foam lance for application of

high-foaming de ter gents or

disinfectants.

Dosage 1-5%.

Outlet point with cleaning

trolley and foam injector

To be attached to the quick coupling of the high pressure cock.

To be used in the same way as

“Outlet point with detachable

foam injector”.

Makes it possible to place 4

spray lances, 2 pcs. of 25 l

containers as well as 20 m high

pressure hose.

15

4.1.6 Application of

detergents (internal)

If your SOLAR BOOSTER is

equipped with an optional,

internally mounted chemical

system – dosing the chemical

to the inlet of the high pressure

pump, please refer to the separate “Operating instructions,

Chemical dosing” on this option.

4.2 Operation

4.2.1 Starting up

The shut-off cock on the water

6

4

3

inlet should be open, and the

spray handle on the high pressure hose should be closed.

°

0

20°

C°

°

85

°

60°

80

1. Turn the main switch (2) to

40°

position - ON -.

2. Push the green "START"

push button (3).

2

Check on the pressure gauge

(6) that a pressure is being built

up in the system and that the

motor of the SOLAR BOOSTER

stops within appr. 20 seconds

ON

with the green “START” push

button (3) lit. The SOLAR

BOOSTER is now in “Stand-by”

mode waiting for the operator to

activate the spray handle.

If a pressure is not being built

up, vent the machine as de scribed in sections 3.7 - 3.8

Venting.

16

If the motor of the SOLAR

BOOSTER does not start or

stops unintendedly with the red

“STOP” push button (4) fl ashing, an error is present. Read

the error message through the

"Inspection window" and refer

to section "7 Troubleshooting".

1

4.2.2 Automatic start/stop

Always hold the spray lance

with both hands!

The SOLAR BOOSTER will

automatically start when the

trigger (1) of the spray handle is

activated and will automatically

stop and enter standby mode

when the trigger is released. If

the handle has not been activated within 20 seconds, the

machine will enter stand-by

mode.

When the machine is not in

use, the trigger should be

locked with locking device (see

arrow).

4.2.3 Running with hot

water

The SOLAR BOOSTER is

equipped with a heating source

the water can be read on the

display. The control unit of the

(electrical, or diesel driven) to

heat the water.

The heating source can be

switched on or off at convenience by pushing the yellow

“Heating” push button (5). Pushing the button once will turn

on the lamp in the button and

switch ON the heating source.

SET TEMP.

70 C

CURRENT TEMP

40 C

ESC

+

-

OK

Pushing the button again will

turn out the lamp in the button

and switch OFF the heating

source. SOLAR BOOSTER will moni-

tor the water temperature and

5

4

3

°

0

°

C

85°

°

°

60

80

regulate the heating source to

provide the preset temperature.

On EH-models, with heating

°

20

tanks on the suction side of the

°

40

high pressure pump, heating

will be performed independently of the spraying operation

- “Working mode” as well as

“Standby mode”. The tempera-

8

ture is controlled by a temperature sensor in the water tank.

Thus the water will always be

On the D-model the temperature can be adjusted within the

limits stated on the “Thermo-

preheated to the desired value

– ready for use when the spray

handle is activated.

stat” (8), by turning the knob

to the desired value. When the

heating source is ON (push button (5) alight), the preset and

the actual outlet temperature of

On D-models heating is performed by a burner in a pressurized boiler. Heating is control-

led by a thermostat on the

outlet of the boiler when water

17

is fl owing out of the SOLAR

BOOSTER – “Working mode”.

As the hot water does not

have to pass through the high

pressure pump the maximum

temperature can be as high as

99°C.

If an error occurs to the heating

system of the SOLAR BOOSTER, the machine stops and the

red “STOP” push button (4) will

start fl ashing and the heating

source will be shut off. Press

the red button to re-set the

machine. By pushi

"START" push button (3), the

SOLAR BOOSTER will continue to be functional with non

heated water.

In this case please refer to section "7 Troubleshooting".

ng the green

4.2.4 Double spray lance,

pressure regulation

1

min. max.

The spray lance features 2

nozzles, a high pressure nozzle

and a low pressure nozz le.

High pressure mode

When the pressure reducing

valve (1) is completely closed

(turned clockwise - B), only the

high pressure nozzle is used -

high pressure mode.

Low pressure mode

When the reducing valve (1)

is completely opened (turned

counterclockwise - A), both

spray lances are used - low

pressure mode / possibility of

dosing detergents.

The pres sure may be reg u lat ed

between these positions.

4.2.5 Stop

18

Danger of scalding!

Never detach high pressure

hoses at a water temperature

above 50°C.

Prior to dismounting of the high

pressure hose, the machine

should be cooled down. After

cooling down, stop the machine

and close the shut-off cock.

Never detach the high pressure

hose while the machine is in

operation.

OFF

1. To stop the machine push

4

0°

20°

°

C

°

40

°

85

°

°

60

80

the red "STOP" button (4).

The red light will come on.

To disconnect the SOLAR

BOOSTER completely from

mains, turn the main switch

(2) to position - OFF -.

2. Close the shut-off cock of

the water inlet and activate

2

the spray lance or open the

high pressure cock to relieve

the pipeline / high pressure

hose of pressure.

4.2.6 Automatic "system

shut-down"

4.2.7 Frost protection

Your SOLAR BOOSTER features a function called "system

shut-down".

If this function is activated the

SOLAR BOOSTER will automatically shut down if it has not

been used in a period preset by

the user (1 sec. - 9 hours).

On the SOLAR BOOSTER

EH-model it will be possible to

automatically stop the heating

of the water in the water tank if

Max 40 °C

Min 2 °C

the SOLAR BOOSTER has not

been used in a period preset by

the user (1 sec. - 9 hours).

The functions system shutdown and switching off the

heating work together but may

have different switch-off delays.

The functions are disabled on

delivery - please contact your

Nilfi sk-ALTO service representative if you would like the

function(s) to be enabled.

The machine should be installed in a frost-free room.

This applies to pump as well as

pipelines incl. of outlet points.

Concerning outdoor outlet

points it should be possible to

empty that part of the line which

is exposed to frost.

IMPORTANT: For safety reasons, hoses, spray lances

and other accessories should

always be thawed prior to use.

19

5 Fields of Application and

Working Methods

5.1 Fields of application

5.2 Working pressure

5.3 Temperature

The most important fi elds of application for this product are:

Agriculture Cleaning of machinery, agricultural implements, stalls,

Transport Cleaning of trucks, buses, cars etc.

Building & Cleaning of vehicles, equipment, buildings etc.

Construction

Light industry Degreasing and cleaning of machines, workpieces, and

Service Cleaning of vehicles, public baths, institutions etc.

The high pressure system may be used with high or low pressure

at your own option:

Low pressure Is fi rst and foremost used for the application of detergents

High pressure Is used during the actual cleaning.

Intermediate As an example it may be used for the cleaning of surfaces

pressure which cannot stand a too powerful jet, i.e. soft surfaces.

Hot water signifi cantly increases the effi ciency of the cleaning

process – especially grease,

oils and fats can be broken

down more easily at higher

temperatures.

Temperatures up to 60°C

should clean off proteins, such

as blood substances.

equipment and buildings.

vehicles.

and for fl ushing.

Oil and traffi c fi lm should be

exposed to app. 70°C, whereas

grease and fat is easiest to

remove with temperatures of 80

to 85°C.

Several detergents become

more effi cient when acting with

hot water – please refer to

manufacturers recommendations.

5.4 Mechanical impact

20

In order to break down tough

layers of dirt, additional mechanical impact may be required. Special lances with

special nozzles (pulsating jet /

concentrated “0” jet) are available for such purposes as are

rotating brushes plus soft &

sand blasting equipment.

Please ask your Nilfi sk-ALTO

representative.

5.5 Detergents

As standard the system is

delivered without a detergent

injector and the optional, factory

mounted, internal chemical

system.

If you want to use detergents

or disinfectants these should

be dosed through an external

injector (see section 4.1.5) or

through the pump (see section

4.1.6).

The most effi cient cleaning is

reached with detergents in conjunction with the high pressure

cleaning. For that purpose Nilfi sk-ALTO can offer you a series

of products specially developed

for high pressure cleaning,

among other fi elds within:

• Cleaning of vehicles, machines, stalls etc.

• Disinfection

• Degreasing of workpieces

• Descaling

The products are water-based,

without phosphates, and the

applied tensides (surface active

substances) comply with the

present requirements for easy

biodegradability.

Contact your Nilfi sk-ALTO

distributor for directions as to

which product(s) will fulfi l your

requirements.

The method of application and

the dosage of the individual

products appear from the product labels or the data sheet.

Low-foaming detergents are

applied through an injector and

under low pressure. A change

to cleaning under high pressure

is effected by regulating from

»low pressure mode« to »high

pressure mode« on the double

spray lance or by attaching a

high pressure spray lance.

For foam cleaning you will have

to attach a special foam equipment. Insert the suction hose

of the injector into the foam

detergent.

Attach the foam lance on the

spray handle and now you are

ready for foam application.

Upon the application open the

by-pass cock of the foam injector and replace the foam lance

by a spray lance, and you are

ready for cleaning.

General rules for addition of

detergents

Nilfi sk-ALTO cleaning equipment can be used for all detergents and disinfectants, which

are suitable for high pressure

cleaning according to the

prescriptions of the supplier. (If

using external injector, section

4.1.5, the pH-value should be

between 4 and 14. If using addition of chemicals through the

high-pressure pump, section

4.1.6, the pH-value MUST be

between 5.5 and 8.5). Acid and

lye should not be applied in a

concentrated form.

Carefully observe the prescriptions and guidelines of the

supplier, also the rules concerning safety clothing and drainage

facilities.

Detergents, which are not exactly

prescribed for use in conjunction with high pressure cleaning,

must only be used upon a previous approbation from Nilfi skALTO and the supplier.

The use of Nilfi sk-ALTO detergents ensures that machines,

accessories and detergents

match, which is the condition of

an optimal solution of a cleaning

task.

Nilfi sk-ALTO can offer you a

wide range of effi cient agents

for cleaning and disinfection.

The products are composed

of substances which combine

effi ciency and environmental

considerations at one and the

same time.

21

5.6 Working methods

Your high pressure hot water

washer has been developed for

cleaning according to the socalled »2-step method«.

In connection with the working

process the optimum cleaning

will be reached by following

these 3 pieces of advice:

However, your high pressure

hot water washer must be

equipped with an external

detergent injector.

STEP 1

Application of detergent -soaking.

STEP 2

High pressure cleaning.

In practice the working process

is laid down in accordance with

the actual job, but as a starting

point the following working method can be described for a job:

1. Apply detergent under low

pressure. The dosage is

chosen according to the

job which is to be carried

through, and the adjustment

is made on the dosing unit.

2. Await acting time. Let the

detergent act on the dirt/surface for a short time prior to

pressure cleaning - usually a

few minutes.

3. High pressure cleaning. Clean all surfaces under high

pressure.

4. Rinse afterwards, if necessary. To make sure that residual impurities are removed

from the surface.

Advice no. 1

When using a detergent, usually always apply it on a dry surface. If the surface is rinsed with

water at fi rst, it may be diffi cult

for it to absorb the detergent,

and the result is a reduced

effect of the detergent.

Advice no. 2

When applying a detergent

on large vertical surfaces (i.e.

the sides of a truck) work from

below and upwards. Thus you

will avoid the detergent running

off the surface through grooves

and dark streaks appearing on

the surface whilst cleaning.

Advice no. 3

During the high pressure cleaning you should work so that

the high pressure water does

not run over the surface which

has not been cleaned yet. This

is to ensure that there is suffi cient detergent on the surface

when the high pressure water

hits the surface.

22

5.7 Typical cleaning tasks

5.7.1 Agriculture

Task Accessories Method

Stables

Pig pens, sties

Cleaning of walls,

fl oors and equipment

Disinfectant

Machinery

Tractors

Ploughs etc.

5.7.2 Vehicle

Task Accessories Method

Chemical foam injectors

Foam lance

Powerspeed lance

Floor cleaner

Detergents

Universal

Alkafoam

Disinfectant

DES 3000

Detergent injection

Powerspeed lances

Curved lances and underchassis washers

Brushes

1. Soaking - apply foam to all surfaces (bottom to

top) and wait for approx. 30 minutes.

2. Remove the dirt from surface with the high pressure lance or chosen accessory. Again, clean from

bottom to top on vertical surfaces.

3. To fl ush away large quantities of dirt, change to

low pressure mode and use the higher fl ow to

push away the dirt.

4. Use recommended disinfectant products and

methods to ensure hygiene. Apply DES 3000

disinfectant once the surfaces are perfectly clean.

1. Apply detergent to vehicle or equipment surfaces

in order to soften up dirt and grime. Apply from

bottom to top.

2. Proceed with cleaning using the high pressure

lance. Clean again from bottom to top. Use accessories to clean in diffi cult to reach places.

3. Clean fragile areas such as motors, rubber at

lower pressure levels to avoid damage.

Vehicle bodywork

Standard lance

Detergent injection

Curved lances and underchassis washers

Brushes

Detergents

Active Shampoo

Active Foam

Sapphire

Super Plus

Aktive Wax

Allosil

RimTop

1. Apply detergent to vehicle or equipment surfaces

in order to soften up dirt and grime. Apply from

bottom to top. In cases of particularly dirty vehicles, pre-spray with a product such as Allosil in

order to remove traces of insects etc, then rinse

at low pressure and apply normal car cleaning

detergent. Let detergents settle for 5 minutes before cleaning off. Metallic surfaces can be cleaned

using RimTop.

2. Proceed with cleaning using the high pressure

lance. Clean again from bottom to top. Use accessories to clean in diffi cult to reach places. Use

brushes in order to add a mechanical cleaning

effect. Short lances can help for cleaning of motors and wheel arches. Curved lances or undercarriage washers can be valuable for the cleaning

of car under-chassis and wheel arches.

3. Clean fragile areas such as motors, rubber at

lower pressure levels to avoid damage.

4. Apply a liquid wax using the pressure washer in

order to protect the bodywork from pollution.

23

5.7.3 Building and equipment

Task Accessories Method

General surfaces

Metallic equipment

Rusted or damaged surfaces

prior to treatment

Foam injectors

Standard lance

Curved lances

Tank cleaning head

Detergents

Intensive

J25 Multi

Combi Aktive

Alkafoam

Disinfectant

DES 3000

Wet sand blasting equipment

1. Apply thick foam over the surfaces to be cleaned.

Apply on dry surfaces. Apply from top to bottom

on vertical surfaces. Let the foam act for up to 30

minutes for the optimal effect.

2. Proceed with cleaning using the high pressure

lance. Use applicable accessories. Use high pressure to dislodge large amounts of incrusted dirt or

grime. Use lower pressure and high water volume

in order to rapidly fl ush away loose dirt and rinse

surfaces.

3. Apply DES 3000 disinfectant once the surfaces

are perfectly clean.

Areas covered by amounts of loose dirt, such as animal remains in slaughterhouses, can be removed by

using high water fl ow to fl ush away the dirt to evacuation pits or drains.

Tank cleaning heads can be used to clean barrels,

vats, mixing tanks etc. Cleaning heads may be hydraulically or electrically powered and give the possibility for automatic cleaning without a constant user.

1. Connect the sand blasting lance to the pressure

washer and place the suction tube in the sand.

2. Always wear protective equipment during sand

blasting.

3. Spray the surfaces to be treated with the mix of

water and sand. Rust, paint etc will be stripped

off.

These are merely several examples of cleaning tasks that can be solved by a pressure washer in

association with accessories and detergents. Each cleaning task is different. Please consult your local

dealer or Nilfi sk-ALTO representative in order to discuss the best solution for your own cleaning tasks.

6 Maintenance

To ensure the most optimal

maintenance of your SOLAR

BOOSTER, you should consider making a “Service Contract”

with Nilfi sk-ALTO. In this way

your SOLAR BOOSTER will

always be ahead of potential

problems.

Though paying attention to a

few things will ensure a prolonged and reliable operation of

your Solar Booster. Therefore

it will be a good idea to make a

habit of the following:

Prior to attaching the water

hose and the high pressure

hose, the quick couplings

should be cleaned of dust and

sand. Flush if necessary. This

will prevent premature clogging

of fi lters.

Prior to attaching the spray

lance or other accessories to

the spray handle, the machine

should be started and the quick

coupling cleaned of dust and

sand.

24

6.1 Hour counters

HOUR PUMP

0250

HOUR HEATER

0100

Your SOLAR BOOSTER features built-in hour counters that

keep track of the number of

ESC

+

-

OK

working hours on your machine.

By depressing the red "STOP"

button (4) and keeping it depressed, you will be able to see

the number of working hours

on the pump and the heating

system through the inspection

window (10).

Letting go of the "STOP" button

will switch off the hour counter

display again.

6.2 Oil

PROTECT THE

ENVIRONMENT

ESC

PUMP OIL LEVEL

+

-

OK

Waste oil and oil sludge must

be removed as laid down in the

instructions.

Your SOLAR BOOSTER is

equipped with an electronic

“oil sensor”, which monitors

the level of lubricant oil in the

high pressure pump. If the oil

level (by malfunction or excessive wear) should drop to a low

level, your SOLAR BOOSTER

will stop (or not be able to start)

with an error indication “PUMP

OIL LEVEL” in the inspection

window.

Topping up the oil cup will be

possible with the cabinet removed, but you should send for

a Nilfi sk-ALTO service technician as soon as possible to disclose the cause of the oil loss.

6.3 Water fi lter

To avoid debris entering the

high pressure pump, a water

fi lter (fi ne) is fi tted at the wa ter

7

inlet. Dependent on the purity of

the water, this fi l ter will have to

be cleaned at regular in ter vals.

The fi lter can be removed when

the quick coupling (7) has been

un screwed.

25

6.4 Cleaning of high

pressure nozzle

A clogging up in the nozzle will

cause the pump pressure to increase above normal operating

pressure, and cleaning of the

nozzle is required immediately.

1. Stop the cleaner and detach

the spray lance.

2. Clean the nozzle with the

cleaning tool.

IMPORTANT: ONLY use the

cleaning tool when the spray

lance is detached.

3. Flush the spray lance backwards with water.

4. If the pressure is still too

high, repeat items 1-3.

6.5 Fuel fi lter D-models only

6.6 Disposable waste

This high pressure hot water

washer consists of parts which

can affect the environment

when thrown away. Parts that

can pollute are as follows:

Oil, painted/zinc-coated parts,

plastics/plastic-coated parts.

Therefore, it is important to

follow the laws concerning the

removal of polluting and dangerous materials when replacing spare parts or disposing of

high pressure hot water washer.

It is recommended that you

Remove the cabinet to gain access to the fuel pump.

1. Clean fi lter:

Unscrew fi lter cap (1).

2. Clean/replace fuel fi lter (2).

3. Dispose of cleaning solution/damaged fi lter in accordance with the disposal

regulations.

bring the rejected parts to

waste disposal areas or recycling plants that are approved

for the destruction of these

types of materials.

26

7 Trouble Shooting

You have chosen the best quality and therefore deserve the best service. All SOLAR BOOSTER

feature an “Error detection system” that will stop the SOLAR BOOSTER in case of a severe error that

needs immediate attention. The red light of the STOP button will fl ash, and the display in the inspection

window will indicate the nature of the error. Please refer to the specifi c section (7.2 to 7.3) that represents your machine.

Though the user can correct some of these errors, you should note the error and contact the nearest

Nilfi sk-ALTO service organisation. To avoid unnecessary dis ap point ments, you should check section

"7.1 General trouble shooting" before contacting the nearest Nilfi sk-ALTO service organisation.

Should other malfunctions occur than those mentioned in sections 7.1 to 7.3, please contact your

nearest Nilfi sk-ALTO service organisation.

7.1 General trouble shooting - all SOLAR BOOSTER models

Symptom Reason Action

Machine will not start > A fuse has blown • Change the fuse.

(NO ERROR indication)

> Power disconnected • Connect power.

Fuses blow > Installation does not • Change to an installation.

correspond to the ampere corresponding to the ampere

consumption of the machine consumption of the machine

at a minimum.

Change the fuse.

Working pressure too low > Nozzle worn • Replace the nozzle.

> Wrong spray lance • Replace the spray lance

(see section 4.1.4).

> Reduction valve of spray • Turn reduction valve com-

lance not adjusted to max. pletely counter-clockwise

pressure. (see section 4.1.4).

> Nozzle partly clogged up • Clean the nozzle

(see section 6.4).

Working pressure fl uctuating > Insuffi cient water supply • Dismount the cabinet and

check that the water tank is

not drained of water during

operation of the machine. If it

is, clean the water inlet fi lter

of the machine. If that does

not solve the problem, the

water supply for the machine

is insuffi cient.

NB! Avoid long, thin hoses

(min. 3/4").

> High pressure hoses too long • Dismount high pressure

extension hoses and retry.

Extension hose max. 50 m.

27

Symptom Reason Action

NB! Avoid long extension

hoses with many couplings.

> Air in the system • Vent the system

(see section 3.7).

> Detergent container empty • Refi ll or close dosing valve.

> Water inlet fi lter clogged up • Clean fi lter (see sect. 6.3).

No working pressure > Nozzle clogged up • Clean nozzle (see sect. 6.4).

> No inlet water • Check that the shut off cock

of the water inlet is open.

Check that the water supply

meets the requirements

(see section 1.2).

> High pressure cock of outlet • Close all high pressure

point open cocks not in use.

Machine starts and > Leaky hose/ • Repair leak.

stops pipeline/spray handle

28

7.2 Errors messages, SOLAR BOOSTER ExxH (electrical heated) models

If heating cannot be switched on or is switched off without any error messages, it is likely that the

overheat protection (pos. 11 on fold out page) has tripped. Unscrew the dust cap, and push the rod to

reset the overheat protection switch. If this error re-occurs, call Nilfi sk-ALTO service.

Error Message

(red STOP light fl ashing) Reason Action

Pump oil level low > Level of lubricant oil of HP • Remove cabinet and top up

pump is at a low level oil if no leakage is present.

• Call Nilfi sk-ALTO service if

oil is leaking or if water is

mixed in the oil (creamy

white or transparent)

Overload cut out > Overload or short circuit of • Call Nilfi sk-ALTO service.

SOLAR BOOSTER.

E3

E2

> Missing phase in your instal. • Call authorized electrician.

Water shortage > Lack of water in heating tank • See section “3.8 Venting”

• Check your water supply

– open?, suffi cient pressure?

• Check and clean inlet fi lter,

section 6.3.

Motor cut out > Motor is not running • Motor overheated – let

the SOLAR BOOSTER cool

down and retry. Check

pressure and check nozzle

size and clean nozzle if

necessary.

• Cooling of motor disturbed

– call Nilfi sk-ALTO service.

• Other motor problems – call

Nilfi sk-ALTO service.

E1

E10

29

7.3 Error messages, SOLAR BOOSTER D (diesel heated) models

If your SOLAR BOOSTER Diesel model does not heat the water although the yellow “Heating” push

button (5) has been activated, the “overheat melting fuse” has blown. This fuse is located within the

machine and MUST ONLY be exchanged by a Nilfi sk-ALTO service technician.

Error Message

(red STOP light fl ashing) Reason Action

Pump oil level low > Level of lubricant oil of HP • Remove cabinet and top up

pump is at a low level oil if no leakage is present.

• Call Nilfi sk-ALTO service if

oil is leaking or if water is

mixed in the oil (creamy

white or transparent)

Overload cut out > Overload or short circuit of • Call Nilfi sk-ALTO service.

SOLAR BOOSTER.

> If Option “Low water security” • Check your water supply

mounted – lack of inlet – open?, suffi cient pressure?

pressure can be the reason

Water Shortage > Lack of water • Check your water supply

– open?, suffi cient pressure?

• Check and clean inlet fi lter,

section 6.3.

or

> Defective or mal-adjusted • Call Nilfi sk-ALTO service.

fl ow sensor / pressure switch

Flow failure > Defective or mal-adjusted • Call Nilfi sk-ALTO service.

fl ow sensor

No fl ame detected > No fl ame is detected when it • Check your fuel supply,

should be present and refi ll is necessary.

E3

E2

E1

E4

> Fuel fi lter clogged • Call Nilfi sk-ALTO service.

> Flame sensor soothed or • Call Nilfi sk-ALTO service.

defective

Illegal fl ame detected > Flame detected when it should • Flame sensor not mounted

NOT be present in place. Mount sensor.

> Flame sensor defective • Call Nilfi sk-ALTO service

E5

E6

30

8 Technical Data

8-103D

SOLAR BOOSTER

7-58D

SOLAR BOOSTER

7-58D

SOLAR BOOSTER

5-52D

SOLAR BOOSTER

5-45D

SOLAR BOOSTER

7-58E36H

SOLAR BOOSTER

7-58E36H

SOLAR BOOSTER

7-58E18H

SOLAR BOOSTER

7-38E18H

SOLAR BOOSTER

135 170 170 170 150 165 170 160 180

530 680 680 680 550 600 680 700 1100

400 400 400 400 400 400 400 230 400

Water tank Water tank Water tank Water tank EcoPower 5 EcoPower 5 EcoPower 7 EcoPower 7 EcoPower 7

zzzzzzzzz

zzzzzzzzz

zzzzzzzzz

zzzzzzzzz

zzzzzzzzz

zzzzzzzzz

zzzzzzzzz

zzzzzzzzz

zzzzzzzzz

zzzz

zzzzzzzzz

zzzzzzzzz

SOLAR BOOSTER PROGRAM

Item Nr. 107370260 107370270 107370274 107370276 107370050 107370055 107370070 107370075 107370080

Qiec [l/h] 810 1110 1110 1110 900 1000 1110 1110 1900

Cleaning Impact [kg-force] 3.8 5.8 5.8 5.8 4.5 5.2 5.8 5.8 10.3

Δ temp - (Full fl ow) [ºC] 19 14 28 42 73 65 76 74 49

Performance data :

Pump pressure [bar]

Heating power [kW] 18 18 36 54 80 80 115 115 115

Effi ciiency [%] 99 99 99 99 92 92 92 92 94

Weight (empty) [kg] 150 155 156 157 184 189 212 212 232

Max. sound power level [dB(A)] 93 93 93 93 92 92 93 93 93

Motor / Pump :

Nozzle type

Qmax [l/h] 875 1200 1200 1200 1020 1100 1200 1200 2000

Pump type C3 C3 C3 C3 NA5 NA5 C3 C3 AR

Motor output power [kW] 5.6 6.5 6.5 6.5 5.5 6.7 6.5 6.5 11.0

Motor / pump [rpm] 1450 1450 1450 1450 1450 1450 1450 1450 1450

Pump drive Direct Direct Direct Direct Direct Direct Direct Direct Direct

Connection requirements :

Voltage [V]

Current - Max. consumption [amp] 35,9/~3 39,4/~3 65,3/~3 91,2/~3 14/~3 15/~3 15/~3 25/~3 24/~3

Power consump. (heating+motor) [kW] 18 + 5.8 18 + 7.5 36 + 7.5 54 + 7.5 1.4 + 6.1 1.4 + 6.9 1.4 + 7.5 1.4 + 7.1 1.4 + 12.7

Frequency [Hz] 50 50 50 50 50 50 50 50 50

Min. inlet water pressure (full fl ow) [bar] 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

Heating :

Boiler type

Max. inlet temperature [ºC] 85 85 85 85 30 30 30 30 30

Max. outlet temperature [ºC] 85 85 85 85 99 99 99 99 99

Burner fuel type Electricity Electricity Electricity Electricity Diesel Diesel Diesel Diesel Diesel

Fuel consumption @ΔT=40°C [kg/h] - - - - 4.3 4.8 4.9 4.9 4.9

Available options :

Stainless steel cabinet

Manual detergent

Remote control

1 x detergent

2 x detergent

Mechanical coin box

Mechanical coin box with detergent

Low water security

No-Scale

Cold/warm selector switch

Pressure relief

Multiple machine connection box

31

9 Warranty

Your Nilfi sk-ALTO product is

guaranteed for 12 months from

date of purchase (purchase

receipt must be presented) on

the following conditions:

• that defects are attributable

to fl aws or defects in materi-

• that only original accessories have been applied.

• that the product has not

been exposed to abuse such

as knocks, bumps or frost.

• that the instructions in the

manual have been carefully

observed.

Any illegitimate guarantee

repair will be invoiced. (I.e. malfunctions due to causes mentioned in section “7.0 Trouble

shooting” of the instruction

manual).

als or workmanship. (Usual

wear and tear as well as

misuse is not covered by the

guarantee).

• that repairs have not been

carried out or attempted

by other than Nilfi sk-ALTO-

A warranty repair comprises the

replacement of defective parts,

but it does not cover freight and

packaging charges. Besides we

refer to national Sale of Goods

Act.

trained service staff.

10 Declaration of Conformity

Declaration of Conformity

The undersigned, representing the following manufacturer,

Nilfi sk-ALTO, Division of Nilfi sk-Advance A/S, Industrivej 1, DK-9560 Hadsund

declares that the product:

• • • High Pressure Washer • • •

type : SOLAR BOOSTER D, EH

is in conformity with the provisions of the following EC directives, with subsequent

amendments:

2006/42/EC, 2006/95/EC, 2004/108/EC

and furthermore declares that the following harmonised standards have been applied:

EN 60335-2-79 (2006), EN 55014-1 (2006), EN 55014-2 (2001), EN 61000-3-2 (2006)

The following (parts/clauses of) national technical standards and spec i fi ca tions have

been used:

DS EN 60335-2-79

Hadsund, 2008-10-01

Anton Sørensen

V.P. Technical Operations Europe

32

20

°

0

°

C

°

85

°

80

°

60

°

40

°

SOLAR BOOSTER EH

SOLAR BOOSTER D

°

0

°

0

2

°

C

°

40

°

85

°

0

°

6

80

°

0

°

0

2

°

C

°

40

°

85

°

°

60

80

940

(only EH)

http://www.nilfi sk-alto.com

HEAD QUARTER

DENMARK

Nilfi sk-Advance Group

Sognevej 25

DK-2605 Brøndby

Tel.: (+45) 4323 8100

Fax: (+45) 4343 7700

E-mail: mail.com@nilfi sk-advance.com

SALES COMPANIES

ARGENTINA

Nilfi sk-Advance srl.

Edifi cio Central Park

Herrera 1855, Offi ce 604

Ciudad Autónoma de Buenos Aires

Tel.: (+54) 11 6091 1571

Fax:(+54) 11 6091 1575

AUSTRALIA

Nilfi sk-ALTO

48 Egerton St.

P.O. Box 6046

Silverwater, N.S.W. 2128

Tel.: +61 2 8748 5966

Fax: +61 2 8748 5960

E-mail: info@nilfi skalto.com.au

AUSTRIA

Nilfi sk-Advance GmbH

Metzgerstrasse 68

5101 Bergheim bei Salzburg

Tel.: 0662 456 400-0

Fax: 0662 456 400-34

E-mail: info.at@nilfi sk-advance.com

BELGIUM

Nilfi sk-ALTO a division of Nilfi sk-Advance n.v-s.a.

Riverside Business Park

Boulevard Internationalelaan 55

Bâtiment C3/C4 Gebouw

Bruxelles 1070 Brussel

Tel.: (+32) 2 467 60 40

Fax: (+32) 02 466 61 50

E-mail: info.be@nilfi sk-alto.com

CANADA

Clarke Canada

Part of the Nilfi sk-Advance Group

4080-B Sladeview Crescent, Unit 1

Mississauga, Ontario L5L 5Y5

Tel.: (+1) 905 569 0266

Fax: (+1) 905 569 8586

CHINA

Nilfi sk-Advance (Shenzhen) Ltd.

Blok 3, Unit 130 1001 Honghua Road

Int. Commercial & Trade Center

Fuitian Free Trade Zone

518038 Shenzhen

Tel.: (+86) 755 8359 7937

Fax: (+86) 755 8359 1063

CZECH REPUBLIC

ALTO Ceská Republika s.r.o.

Do Čertous 2658/1

193 00 Praha 9

Tel.: (+420) 24 14 08 419

Fax: (+420) 24 14 08 439

E-mail: info@alto-cz.com

DENMARK

Nilfi sk-Advance A/S

Industrivej 1

9560 Hadsund

Tel.: +45 7218 2100

Fax: +45 7218 2105

E-mail: salg.dk@nilfi sk-alto.com

Nilfi sk-ALTO Food division

Division of Nilfi sk-Advance A/S

Blytækkervej 2

9000 Aalborg

Tel.: +45 7218 2100

Fax: +45 7218 2099

E-mail: food.division@nilfi sk-alto.dk

107319182 (10.2008)

FINLAND

Nilfi sk-Advance Oy Ab

Piispantilankuja 4

02240 Espoo

Tel.: +358 207 890 600

Fax: +358 207 890 601

E-mail: asiakaspalvelu.fi @nilfi sk.com

FRANCE

Nilfi sk-ALTO

ALTO France SAS

Aéroparc 1

19 rue Icare

67960 Entzheim

Tel.: (+33) 3 88 28 84 00

Fax: (+33) 3 88 30 05 00

E-mail: info.fr@nilfi sk-alto.com

GERMANY

Nilfi sk-ALTO

Division of Nilfi sk Advance

Guido-Oberdorfer-Str. 10

89287 Bellenberg

Tel.: (+49) (0) 180 5 37 37 37

E-mail: info.de@nilfi sk-alto.com

GREECE

Nilfi sk-Advance SA

8, Thoukididou str.

164 52 Argiroupolis

Tel.: +30 210 96 33443

Fax: +30 210 96 52187

E-mail: nilfi sk-advance@clean.gr

HOLLAND

Nilfi sk-ALTO

Division of Nilfi sk-Advance BV

Camerastraat 9

3322 BB Almere

Tel.: (+31) 36 5460 760

Fax: (+31) 36 5460 761

E-mail: info.nl@nilfi sk-alto.com

HONG KONG

Nilfi sk-Advance Ltd.

2001 HK Worsted Mills Ind’l Bldg.

31-39 Wo Tong Tsui St.

Kwai Chung

Tel.: (+852) 2427 5951

Fax: (+852) 2487 5828

HUNGARY

Nilfi sk-Advance Kereskedelmi Kft.

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklos-Lakihegy

Tel: (+36) 24475 550

Fax: (+36) 24475 551

E-mail: info@nilfi sk-advance.hu

INDIA

Nilfi sk-Advance India Limited

349, Business Point,

No 201,2nd fl oor, above Popular Car World,

Western Express Highway, Andheri ( East),

Mumbai - 400 069

Tel: (+91) 22 321 74592

ITALY

Nilfi sk-ALTO

Divisione di Nilfi sk-Advance A/S

Località Novella Terza

26862 Guardamiglio (LO)

E-mail: d.puglia@nilfi sk-advance.it

JAPAN

Nilfi sk-Advance Inc.

1-6-6 Kita-shinyokohama, Kouhoku-ku

Yokohama, 223-0059

Tel.: (+81) 45 548 2571

Fax: (+81) 45 548 2541

MALAYSIA

Nillfi sk-Advance Sdn Bhd

Sd 14, Jalan KIP 11

Taman Perindustrian KIP

Sri Damansara

52200 Kuala Lumpur

Tel.: (+60) 3 603 6275 3120

Fax: (+60) 3 603 6274 6318

MEXICO

Nilfi sk-Advance de Mexico, S. de R.L. de C.V.

Prol. Paseo de la Reforma 61, 6-A2

Col. Paseo de las Lomas

01330 Mexico, D.F.

Tel: +52 55 2591 1002 (switchboard)

Fax: +52 55 2591 1002 ext. 229

E-mail: info@advance-mx.com

NORWAY

Nilfi sk-Advance AS

Bjørnerudveien 24

1266 Oslo

Tel.: (+47) 22 75 17 70

Fax: (+47) 22 75 17 71

E-mail: info.no@nilfi sk-alto.com

POLAND

Nilfi sk-Advance Sp. Z.O.O.

05-800 Pruszków

ul. 3-go MAJA 8

Tel.: +48 22 738 37 50

Fax: +48 22 738 37 51

E-mail: info@nilfi sk-alto.pl

PORTUGAL

Nilfi sk-ALTO

Division of Nilfi sk-Advance Lda.

Sintra Business Park

Zona Industrial Da Abrunheira

Edifi cio 1, 1° A

P2710-089 Sintra

Tel.: +35 808 200 537

Fax: +35 121 911 2679

E-mail: mkt@nilfi sk-advance.es

RUSSIA

Нилфиск-Эдванс

127015 Москва

Вятская ул. 27, стр. 7

Россия

Tel.: (+7) 495 783 96 02

Fax: (+7) 495 783 96 03

E-mail: info@nilfi sk.ru

SINGAPORE

Nilfi sk-Advance Pte. Ltd.

Nilfi sk-ALTO Division

40 Loyang Drive

Singapore 508961

Tel.: (+65) 6 759 9100

Fax: (+65) 6 759 9133

E-mail: sales@nilfi sk-advance.com.sg

SPAIN

Nilfi sk-ALTO

Division of Nilfi sk-Advance S.A.

Torre D’Ara

Paseo del Rengle, 5 Pl. 10

08302 Mataró

Tel.: (+3) 4 902 200 201

Fax: (+3) 4 93 757 8020

E-mail: mkt.es@nilfi sk-alto.com

SWEDEN

ALTO Sverige AB

Member of Nilfi sk-Advance Group

Aminogatan 18, Box 4029

431 04 Mölndal

Tel.: (+46) 31 706 73 00

Fax: (+46) 31 706 73 40

E-mail: info.se@nilfi sk-alto.com

TAIWAN

Nilfi sk-Advance Taiwan Branch

No. 5, Wan Fang Road

Taipei

Tel.: (+886) 227 002 268

Fax: (+886) 227 840 843

THAILAND

Nilfi sk-Advance Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Ladyao, Jatuchak, Bangkok 10900

Tel.: (+66) 2 275 5630

Fax: (+66) 2 691 4079

TURKEY

Nilfi sk-Advance Profesional Temizlik

Ekipmanlari Tic. A/S.

Necla Cad. NI.: 48

Yenisahra / Kadiköy

Istanbul

Tel.: (+90) 216 470 08 - 60

E-mail: info.tr@nilfi sk-advance.com

UNITED KINGDOM

Nilfi sk-ALTO

Division of Nilfi sk-Advance Ltd.

Bowerbank Way

Gilwilly Industrial Estate, Penrith

Cumbria CA11 9BQ

Tel.: (+44) 1 768 86 89 95

Fax: (+44) 1 768 86 47 13

E-mail: sales.uk@nilfi sk-alto.com

USA

Nilfi sk-Advance Inc.

14600 21st Avenue North

Plymouth, MN 55447-3408

Tel.: (+1) 763 745 3500

Fax: (+1) 763 745 3718

E-mail: info@advance-us.com

VIETNAM

Nilfi sk-Advance Representative Offi ce

No. 51 Doc Ngu Str.

Ba Dinh Dist.

Hanoi

Tel.: (+84) 4 761 5642

Fax: (+84) 4 761 5643

E-mail: nilfi sk@vnn.vn

Loading...

Loading...