Nilfisk SCRUBTEC 871, SCRUBTEC 871C, SCRUBTEC 866, SCRUBTEC BOOST 8, SCRUBTEC 886 operators Manual

Page 1

SCRUBTEC 8

SCRUBTEC 866

SCRUBTEC 871

SCRUBTEC 871C

SCRUBTEC 886

Operator’s Manual

and Parts List

Models: 05370F, 05370G, 05390F,

05400F, 05400G, 05410F, 05420F,

56380673

EN

Form No. 71492A 10/08, Rev. 9/10

English (2-27)

Parts List (29-64)

READ THIS MANUAL

Page 2

ENGLISH

EN

READ THIS BOOK

CAUTION: Read the Operator’s Manual before using the appliance.

This book has important information for the use and safe operation of this machine. Failure to read this book prior to operating or attempting any service or maintenance procedure to your Nilfi sk ALTO machine could result in injury to you or to

other personnel; damage to the machine or to other property could occur as well. You must have training in the operation

of this machine before using it. If operator(s) cannot read this manual, have it explained fully before attempting to operate

this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

Table of Contents

Table of Contents

Operator Safety Instructions ....................................................................................................................................................................3

Introduction .............................................................................................................................................................................................4

Machine Specifi cations ............................................................................................................................................................................5

Procedures For Transporting ...................................................................................................................................................................6

Symbols Used On SCRUBTEC ...............................................................................................................................................................7

Machine Control Panel ............................................................................................................................................................................8

Machine Controls and Features ..............................................................................................................................................................10

How To Prepare The Machine For Operation ..........................................................................................................................................10

How To Operate The Machine .................................................................................................................................................................17

Maintenance ............................................................................................................................................................................................21

How To Correct Problems In The Machine ..............................................................................................................................................25

Section II Parts and Service Manual

Solution Tank Assembly ...........................................................................................................................................................................30-31

Recovery Tank Assembly ........................................................................................................................................................................32-33

Handle Assembly (Disc and BOOST Models) .........................................................................................................................................34-35

Handle Assembly (Cylindrical Model) ......................................................................................................................................................36-37

Electrical Box Assembly ..........................................................................................................................................................................38-39

Squeegee Holder Assembly ....................................................................................................................................................................40-41

Squeegee Assembly (32.5”) ....................................................................................................................................................................42-43

Squeegee Assembly (35”) .......................................................................................................................................................................44-45

Squeegee Assembly (41”) .......................................................................................................................................................................46-47

Frame Assembly ......................................................................................................................................................................................48-49

Brush Head Assembly (866) ....................................................................................................................................................................50-51

Brush Head Assembly (871) ....................................................................................................................................................................52-53

Brush Head Assembly (886) ....................................................................................................................................................................54-55

Brush Head Assembly (BOOST 8) ..........................................................................................................................................................56-57

Brush Head Assembly (871C) .................................................................................................................................................................58-59

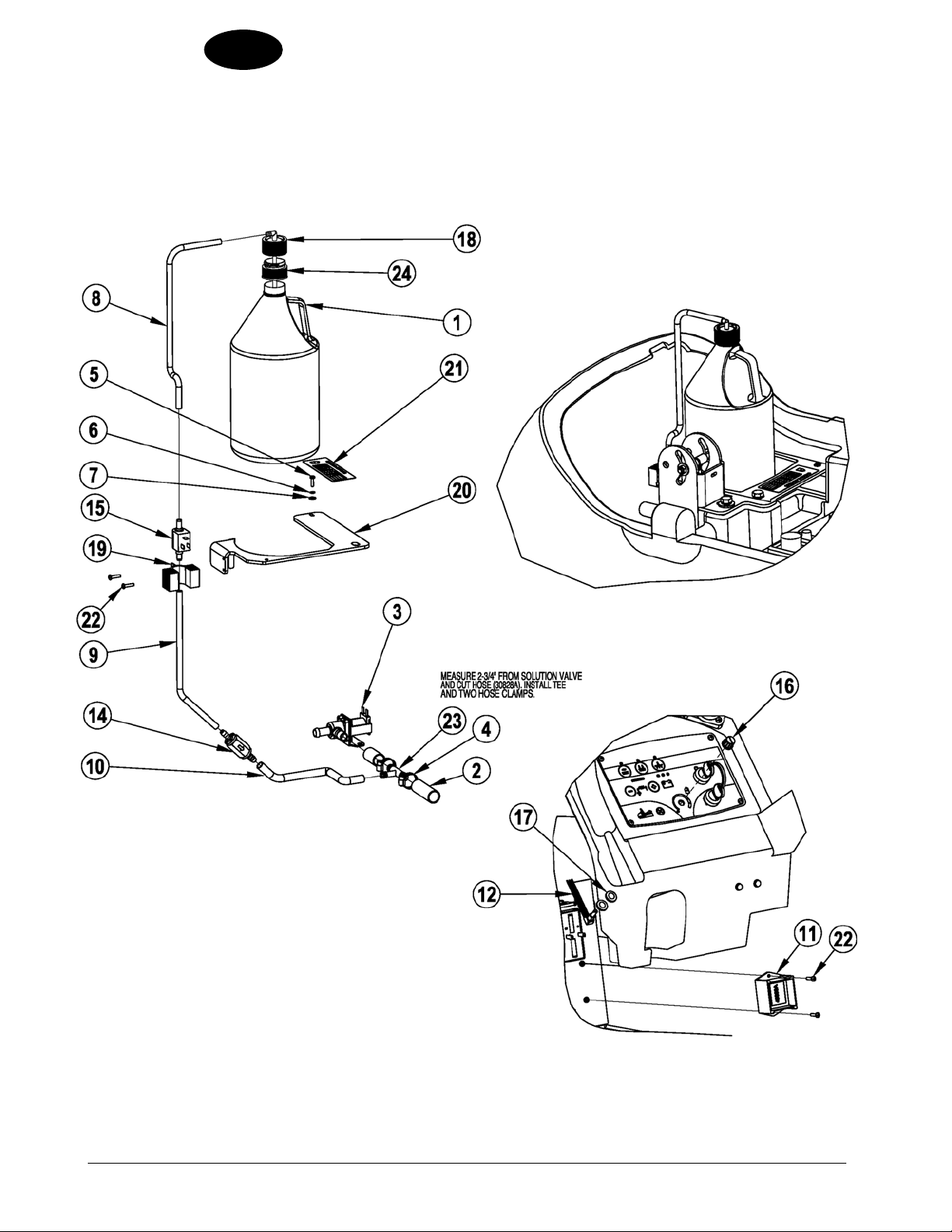

Chemical Mixing Kit .................................................................................................................................................................................60-61

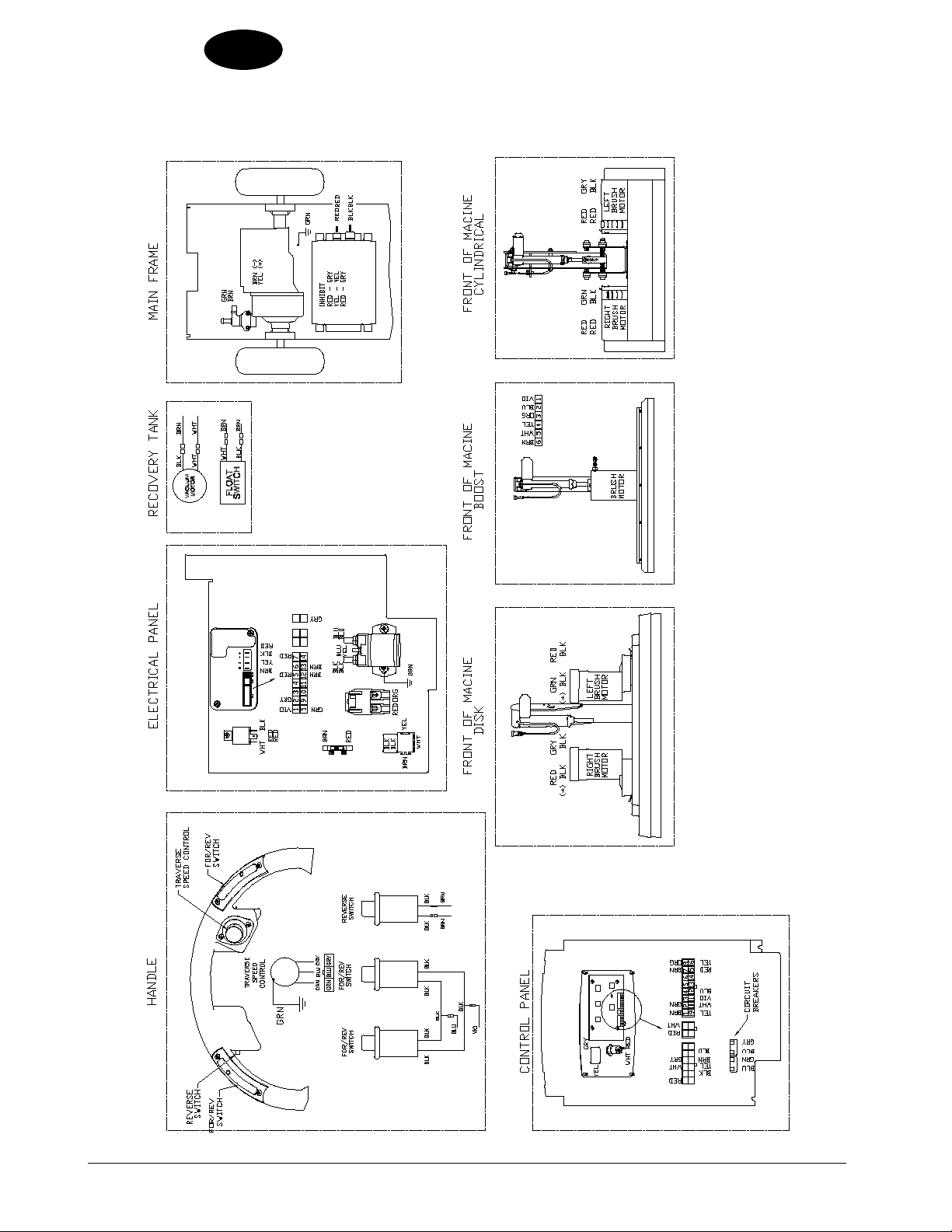

Electrical Schematic ................................................................................................................................................................................62-63

Connection Diagram ................................................................................................................................................................................64

Accessories .............................................................................................................................................................................................65

-2- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

revised 9/10

Page 3

ENGLISH

OPERATOR SAFETY INSTRUCTIONS

DANGER: Failure to read and observe all DANGER statements could result in severe bodily injury

or death. Read and observe all DANGER statements found in your Owner’s Manual and

on your machine.

WARNING: Failure to read and observe all WARNING statements could result in injury to you or to

other personnel; property damage could occur as well. Read and observe all WARNING

statements found in your Owner’s Manual and on your machine.

CAUTION: Failure to read and observe all CAUTION statements could result in damage to the

machine or to other property. Read and observe all CAUTION statements found in your

Owner’s Manual and on your machine.

DANGER: Failure to read the Owner’s Manual prior to operating or attempting any service or maintenance procedure

to your Nilfi sk ALTO machine could result in injury to you or to other personnel; damage to the machine or

to other property could occur as well. You must have training in the operation of this machine before using

it. If your operator(s) cannot read English, have this manual explained fully before attempting to operate this

machine.

EN

DANGER: Operating a machine that is not completely or fully assembled could result in injury or property damage. Do

not operate this machine until it is completely assembled. Inspect the machine carefully before operation.

DANGER: Machines can cause an explosion when operated near fl ammable materials and vapors. Do not use this

machine with or near fuels, grain dust, solvents, thinners, or other fl ammable materials. This machine is not

suitable for picking up hazardous dust.

DANGER: Lead acid batteries generate gases which can cause an explosion. Keep sparks and fl ames away from bat-

teries. Do not smoke around the machine. Charge the batteries only in an area with good ventilation. Make

sure that you unplug the AC charger from the wall outlet before operating the machine.

DANGER: Working with batteries can be dangerous! Always wear eye protection and protective clothing when working

near batteries. Remove all jewelry. Do not put tools or other metal objects across the battery terminals, or the

tops of the batteries.

DANGER: Using a charger with a damaged power cord could result in an electrocution. Do not use the charger if the

power cord is damaged.

WARNING: Operating this machine from anywhere other than the back of the machine could result in injury or damage. Operate

this machine only from the rear.

WARNING: This machine is heavy. Get assistance before attempting to transport or move it. Use two able persons to move the

machine on a ramp or incline. Always move slowly. Do not turn the machine on a ramp. If operating machine on a

gradient over 2%, do not stop, turn or park. Read the “Procedures For Transporting” in this manual before transporting.

WARNING: Machines can topple over if guided over the edges of stairs or loading docks and cause injury or damage. Stop and

leave this machine only on a level surface. When you stop the machine, turn the key “OFF”.

WARNING: Maintenance and repairs performed by unauthorized personnel could result in damage or injury. Maintenance and

repairs must be performed by authorized Nilfi sk ALTO personnel only.

WARNING: Any alterations or modifi cations of this machine could result in damage to the machine or injury to the operator or other

bystanders. Alterations or modifi cations not authorized by the manufacturer voids any and all warranties and liabilities.

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 3 -

Page 4

ENGLISH

WARNING: Electrical components of this machine can “short-out” if exposed to water or moisture. Keep the electrical compo-

WARNING: To reduce the risk of fi re, when replacing fuse, replace only with same type and rating of fuse that comes with ma-

WARNING: Operating a machine without observing all labels and instructional information could result in injury or damage. Read

WARNING: Wet fl oor surfaces can be slippery. Water solutions or cleaning materials used with this type of machine can leave wet

WARNING: Improper discharge of waste water may damage the environment and be illegal. The United States Environmental

CAUTION: Use of this machine to move other objects or to climb on could result in injury or damage. Do not use this machine as

CAUTION: Your machine warranty will be voided if anything other than genuine Nilfi sk ALTO parts are used on your machine.

EN

nents of the machine dry. Wipe the machine down after each use. For storage, keep the machine in a dry building.

chine.

all machine labels before attempting to operate. Make sure all of the labels and instructional information are attached

or fastened to the machine. Get replacement labels and plates from your Nilfi sk ALTO distributor.

areas on the fl oor surface. These areas can cause a dangerous condition for the operator or other persons. Always

put “Caution” signs around/near the area you are cleaning.

Protection Agency has established certain regulations regarding discharge of waste water. Also, city and state regulations regarding this discharge may be in your area. Understand and follow the regulations in your area. Be aware of

the environmental hazards of chemicals that you dispose.

a step or furniture. Do not ride on this machine.

Always use Nilfi sk ALTO parts for replacement.

Introduction :

Scrubtec 866, 871, 886, BOOST 8 and 871C automatic scrubbers are effi cient and superior fl oor cleaning machines. The Scrubtec

886 uses two brushes or pads to scrub a path 86 cm wide. The Scrubtec 871 uses two brushes or pads to scrub a path 71 cm wide.

The Scrubtec 866 uses two brushes or pads to scrub a path 66 cm wide. The Scrubtec BOOST 8 uses one pad or brush to scrub a

path 71 cm wide. The Scrubtec 871C uses two brushes to scrub a path 71 cm wide. A squeegee wipes the fl oor while the vacuum

motor removes the dirty solution from the fl oor in one pass.

Scrubtec 866, 871, 886, BOOST 8 and 871C automatic scrubbers come complete with three battery connector cables, one battery

cable, one battery charger and one operator’s manual.

-4- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 5

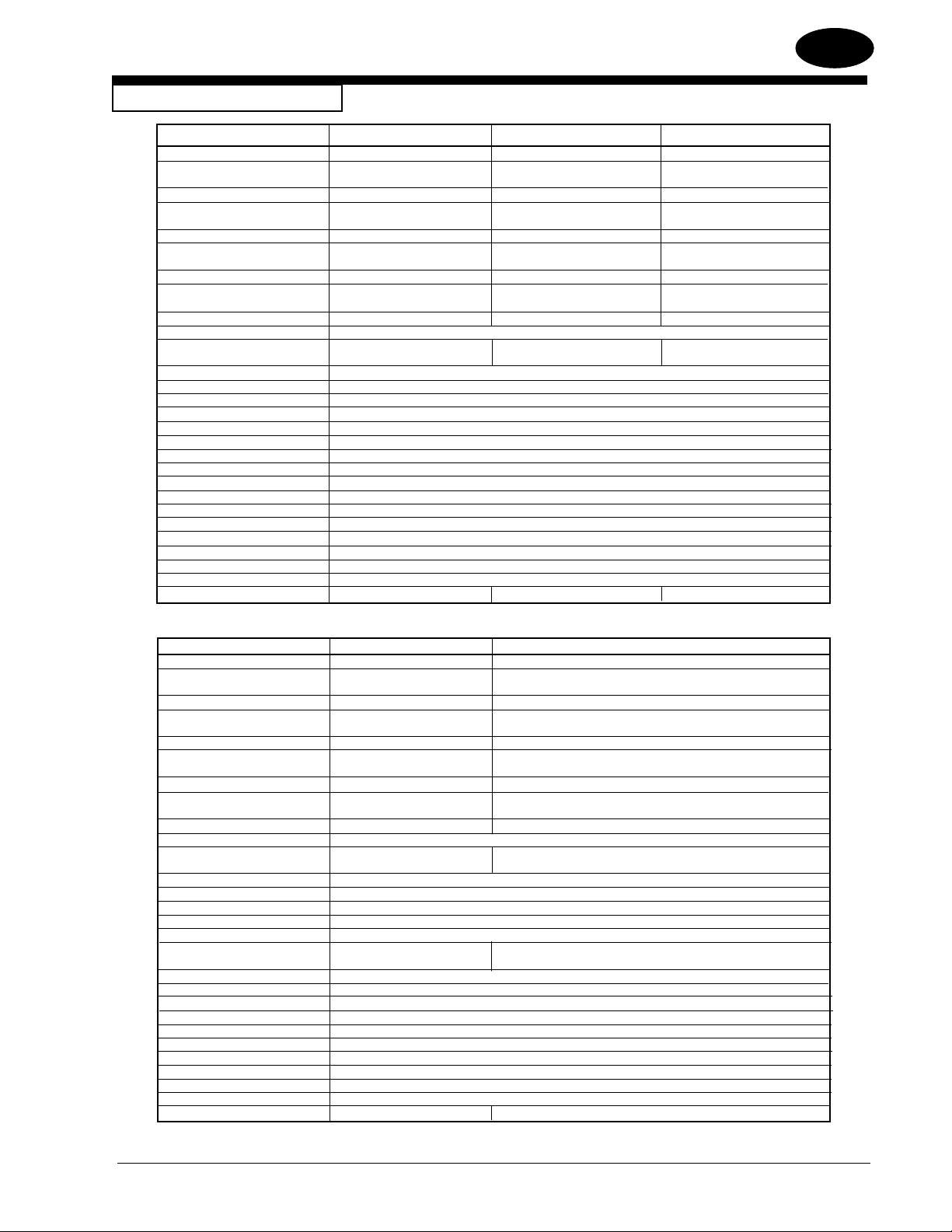

Machine Specifi cations

Model Scrubtec 866 Scrubtec 871 Scrubtec 886

Pad / Brush Size (2) 13” (33 cm) (2) 14” (36 cm) (2) 17” (43 cm)

Brush Motor (s) (2) 3/4 hp (.56 kw) (2) 3/4 hp (.56 kw) (2) 3/4 hp (.56 kw)

200 RPM 200 RPM 200 RPM

Cleaning Width 26” (66 cm) 28” (71 cm) 34” (86.4 cm)

Brush Pressure 1

2nd - 150 lbs. (68 kg) 2nd - 150 lbs. (68 kg) 2nd - 150 lbs. (68 kg)

Brush Retention Gimbal Gimbal Gimbal

Brush Head Steel Deck w/ Bristle Skirt Steel Deck w/ Bristle Skirt Steel Deck w/Bristle Skirt

Water Retention

Squeegee Width 32.5” (81 cm) 35” (89 cm) 41” (107 cm)

Width of Machine 28” (71 cm) Head 30” (76 cm) Head 35.7” (91 cm) Head

23.5” (60 cm) Body 23.5” (60 cm) Body 23.5” (60 cm) Body

Length of Machine 61” (155 cm) 62” (157 cm) 64” (162 cm)

Height of Machine 44” (112 cm)

Weight w/250 Ah batteries 796 lbs. (361.1 kg) 800 lbs. (362.9 kg) 791 lbs. (358.8 kg)

and full solution tank

Power Supply 24 volt, (4 - 6 volt batteries)

Vacuum Motor .75 hp (550W), 3 stage, tangential discharge

Vacuum Motor Protection Electronic Float Shut-Off

Solution Tank 23 gallons (87 liters)

Solution Fill Rear Fill with Bucket or Hose

Solution Flow 0 - 1 gal/min (0 - 3.8 liters/min)

Recovery Tank 23 gallons (87 liters)

Motor Traction .44 hp (.33 kw)

Speed Forward 0 - 260 ft/min (0 - 4.8 km/h)

Speed Reverse 0 - 174 ft/min (0 - 3.2 km/h)

Drive Wheel (2) 10.24” (260 mm) x 3.35” (85 mm) Light Gray, Non-Marking, Foam Filled

Caster (2) 3.94” (10 cm) Polyurethane

Squeegee Material Urethane Front Blade and Rear Blade

Cleaning Grade 2 %

Charger On Board, 24 volt, 25 amp

Vibration @ handle <2.5m/s

Sound test @ operator’s ear 65 dBA 65 dBA 67 dBA

ENGLISH

st

- 80 lbs. (36 kg) 1st - 80 lbs. (36 kg) 1st - 80 lbs. (36 kg)

2

EN

Model Scrubtec 871 C Scrubtec BOOST 8

Pad / Brush Size

Brush Motor (s) (2) .81 hp (.6 kw) 3/4 hp (.56 kw)

613 RPM 2250 RPM

Cleaning Width 28” (71 cm) 28” (71 cm)

Brush Pressure 80 lbs. (36 kg) 1st - 65 lbs. (29.5 kg)

2

Brush Retention N/A Hook & Loop

Brush Head Side Skirts N/A

Water Retention

Squeegee Width 35” (89 cm) 35” (89 cm)

Width of Machine 30.69” (78 cm) Head 28.75” (73 cm) Head

23.5” (60 cm) Body 23.5” (60 cm) Body

Length of Machine 59.5” (151 cm) 60.5” (154 cm)

Height of Machine 44” (112 cm)

Weight w/250 Ah batteries 792 lbs. (359.3 kg) 794 lbs. (360.2 kg)

and full Solution Tank

Power Supply 24 volt, (4 - 6 volt batteries)

Vacuum Motor .75 hp (550W), 3 stage, tangential discharge

Vacuum Motor Protection Electronic Float Shut-Off

Solution Tank 23 gallons (87 liters)

Solution Fill Rear Fill with Bucket or Hose

Solution Flow

Full range .0 - .65 gal/min (0 -2.5 liters/min)

Recovery Tank 23 gallons (87 liters)

Motor Traction .44 hp (.33 kw)

Speed Forward 0 - 260 ft/min (0 - 4.8 km/h)

Speed Reverse 0 - 174 ft/min (0 - 3.2 km/h)

Drive Wheel (2) 10.24” (260 mm) x 3.35” (85 mm) Light Gray, Non-Marking, Foam Filled

Caster (2) 3.94” (10 cm) Polyurethane

Squeegee Material Urethane Front Blade and Rear Blade

Cleaning Grade 2 %

Charger On Board , 24 volt, 25 amp

Vibration @ handle <2.5m/s

Sound test @ operator’s ear 71 dBA 63 dBA

(2) 5.75” x 28” (14.6 x 69cm)

0 - 1 gal/min (0 - 3.8 liters/min)

14” x 28” (35.6 x 71cm)

nd

- 125 lbs. (56.7 kg)

Normal BOOST Scrubbing .12 gal/min (.45 liters/min),

2

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 5 -

Page 6

ENGLISH

PROCEDURES FOR TRANSPORTING

EN

How To Put The Machine In A Van Or Truck

1. Make sure the loading ramp is at least eight (8) feet long, and strong enough to support the machine.

2. Make sure the ramp is clean and dry.

3. Put the ramp in position.

4. Remove squeegee assembly.

5. Remove brush housing, pad drivers or brushes if transporting disc machine.

6. Turn key switch “ON”.

7. Align the machine on a level surface, ten (10) feet in front of the ramp.

8. Put the traverse speed switch in the “HI” position.

9. Press one or both forward switches.

10. Push the machine to the top of the ramp.

11. Turn the key switch “OFF”.

12. Fasten the machine to the vehicle.

WARNING: The machine is heavy. Make sure you use two able persons to assist

the machine in climbing the ramp.

How To Remove The Machine From A Van Or Truck

1. Make sure there are no obstructions in the area.

2. Make sure the unloading ramp is at least eight (8) feet long and strong enough to support the machine.

3. Make sure the ramp is clean and dry.

4. Put the ramp in position.

5. Unfasten the machine.

WARNING: The machine is heavy. Make sure you use two able persons to assist in

moving the machine down the ramp.

6. Turn the key switch “ON”.

7. Carefully and slowly, drive the machine to the top of the ramp by pressing and holding either of the forward switches and the

reverse switch.

8. Put the traverse speed switch in the mid range speed setting. As the machine begins to travel down the ramp, maintain a slow

downward speed by pressing either of the forward switches.

9. Replace squeegee assembly and other removed components, after the machine is unloaded and ready to use.

-6- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 7

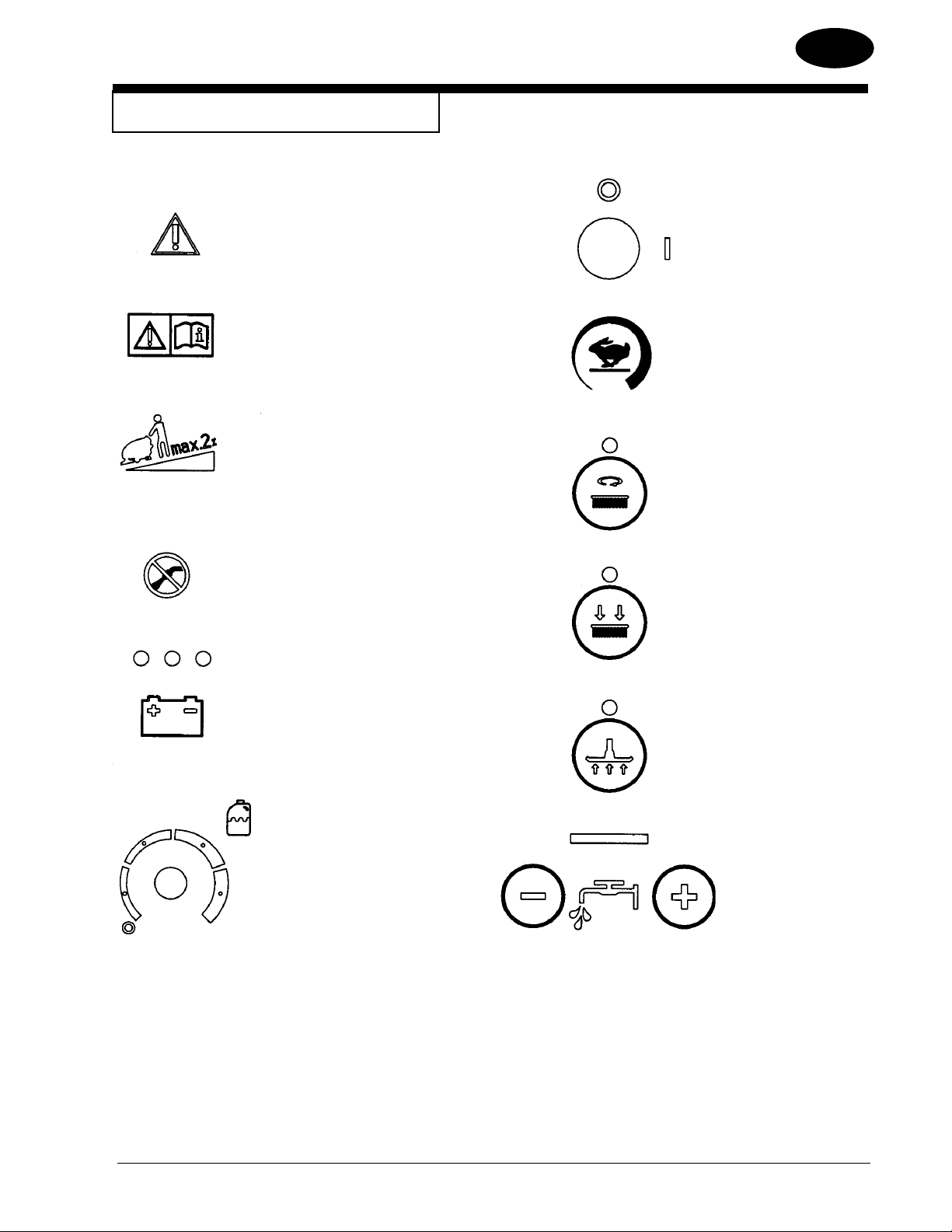

SYMBOLS USED ON SCRUBTEC

ENGLISH

EN

Hazard Alert Symbol

WARNING!

Carefully read all instructions before

performing any procedure.

WARNING!

Do not use the machine on slopes

exceeding the specifi cations.

WARNING!

Do not wash the machine with direct

or pressurized water jets.

On/Off Key Switch

Traverse Speed Control

“One Touch” Control

Additional Brush Pressure

(Not Available on Cylindrical)

Charge/Battery Meter

Chemical Mixing Control

(Optional)

Vacuum On/Off

Solution Control

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 7 -

Page 8

ENGLISH

EN

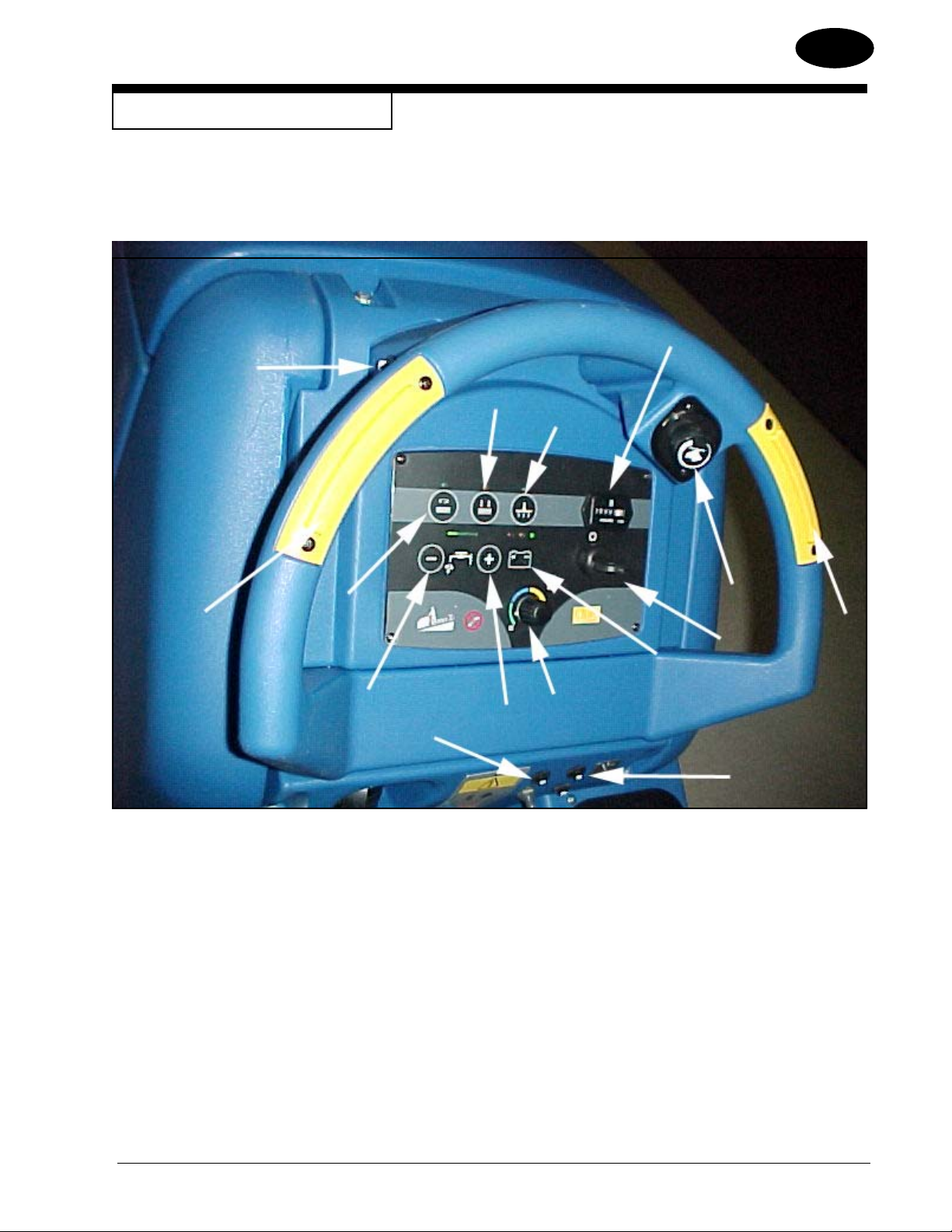

MACHINE CONTROL PANEL

Key Switch (See Figure 1, Item “A”)

The key switch turns “ON” the power to the control panel. “O” is “OFF” and “I” is “ON”.

Traverse Speed Switch (See Figure #1, Item “B”)

The speed control varies from low to high speed. To increase the speed, turn the knob to the right. To decrease the speed, turn the knob to the left.

One Touch Control Button (See Figure 1, Item “C”)

The one touch control button raises and lowers the brush head assembly, starts and stops the vacuum motor automatically. Press the one touch

control button once and the brush head assembly lowers to the fl oor and the vacuum motor turns “ON” (brush head and vacuum LEDs illuminate

green). The brush motors start when the brushes are down and the forward palm button is depressed. Press the one touch control button again and

the brush head assembly raises, the vacuum motor will remain on for 10 seconds and then shut “OFF”.

Increase Brush Pressure Button (See Figure 1, Item D)

This button is used to increase the brush pressure. Increased brush pressure may be required when stripping or cleaning heavily soiled fl oors. T o

increase brush pressure, fi rst lower the brushes by pressing the one touch control button (Item “C”). This will lower the brushes to the normal scrub

position. To increase brush pressure, press the button (Item “D”). The LED above the button will illuminate yellow. Press the button (Item “D”) again

and the brushes will return to normal scrub (yellow LED will turn “OFF”). NOTE: Increase brush pressure is not available on cylindrical machine.

Vacuum Motor Button (See Figure 1, Item “E”)

The vacuum motor button turns the vacuum motor “ON” or “OFF”, regardless of brush head assembly position. The green LED will illuminate when

the vacuum motor is “ON”.

Solution Control Buttons (See Figure 1, Item “F & G”)

The solution control buttons regulate the fl ow of cleaning solution to the fl oor. The normal scrub solution setting is indicated by two green bars on the

meter. On cylindrical machines, with most fl oor conditions, the solution setting should be set one step higher. To increase the fl ow, press the solu-

tion fl ow button “G” (+) until the desired fl ow is reached. To decrease the fl ow, press the solution fl ow button “F” (-) until the desired fl ow is reached.

To shut off the solution, press the solution fl ow button “F” (-) until no indicators are visible on the display. NOTE: No solution will fl ow when the

machine does not traverse.

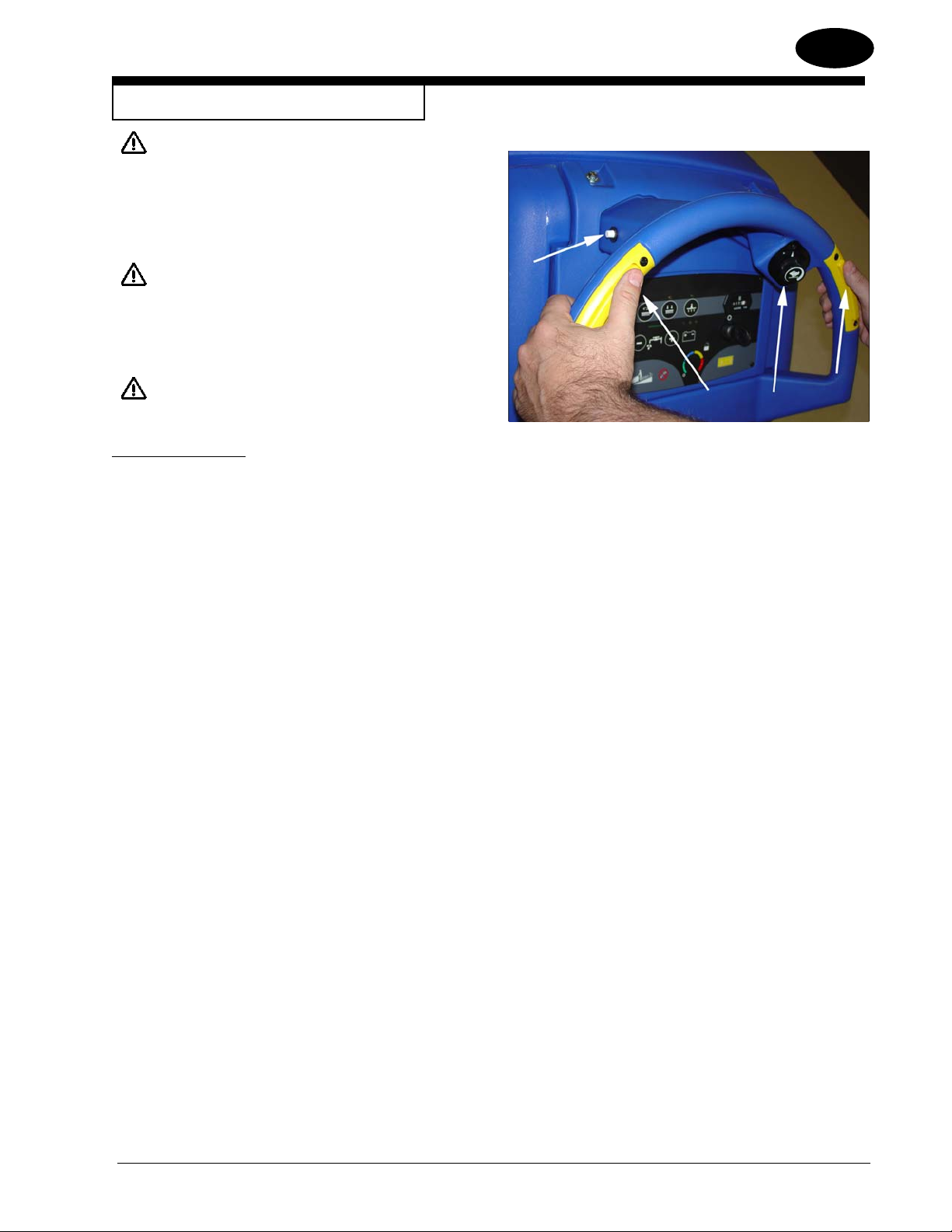

Forward Palm Buttons (See Figure 1, Item “H”)

The forward palm buttons turn the traverse motor “ON” and if the brush motors are in the down position, it also activates the brush motors and solution control module. Either the right or the left palm button can be used.

Reverse Push Button (See Figure 1, Item “I”)

The reverse push button, when used in conjunction with one of the forward palm buttons, causes the machine to reverse direction. The reverse

speed is 67% of the forward speed.

Charge / Battery Meter (See Figure 1, Item “J”)

The charge / battery meter indicates the battery is being charged when the charger is plugged into an AC outlet. It also indicates the amount of

charge that is left in the batteries while the machine is in use. When the charge gets too low the brush/pad motors will shut off.

Circuit Breakers (See Figure 1, Item “K & L”)

The circuit breakers for the brush motors are located on the control panel. If a circuit breaker trips, determine which motor is not operating and turn

the key switch “OFF”. Wait fi ve minutes and push the reset button back in. Turn the key switch “ON”, and try again. An authorized service person

should be contacted if the breaker trips again.

Hour Meter (Optional) (See Figure 1, Item “M”)

The hour meter indicates the number of hours the machine has operated. It runs only when the machine is moving forward or reverse.

Chemical Mixing Control (Optional) (See Figure 1, Item “N”)

The chemical mixing control regulates the amount of concentration of cleaning chemical mixed with the clear water from the solution tank. Turning

the chemical mixing knob clockwise increases the concentration of chemical.

-8- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 9

MACHINE CONTROL PANEL

I

D

E

ENGLISH

M

EN

H

C

F

K

G

Figure 1

N

J

B

A

L

H

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 9 -

Page 10

ENGLISH

MACHINE CONTROLS AND FEATURES

Squeegee Lift Handle (Manual Squeegee Lift) (See fi gure 2)

The squeegee lift handle is located below the control handles in the center. It is

used to raise or lower the squeegee.

Float Shut Off (See Figure 3).

The shut-off switch for the vac motor is located in the recovery tank. It automatically turns off the vac motor when the recovery tank is full.

EN

HOW TO PREPARE THE MACHINE

FOR OPERATION

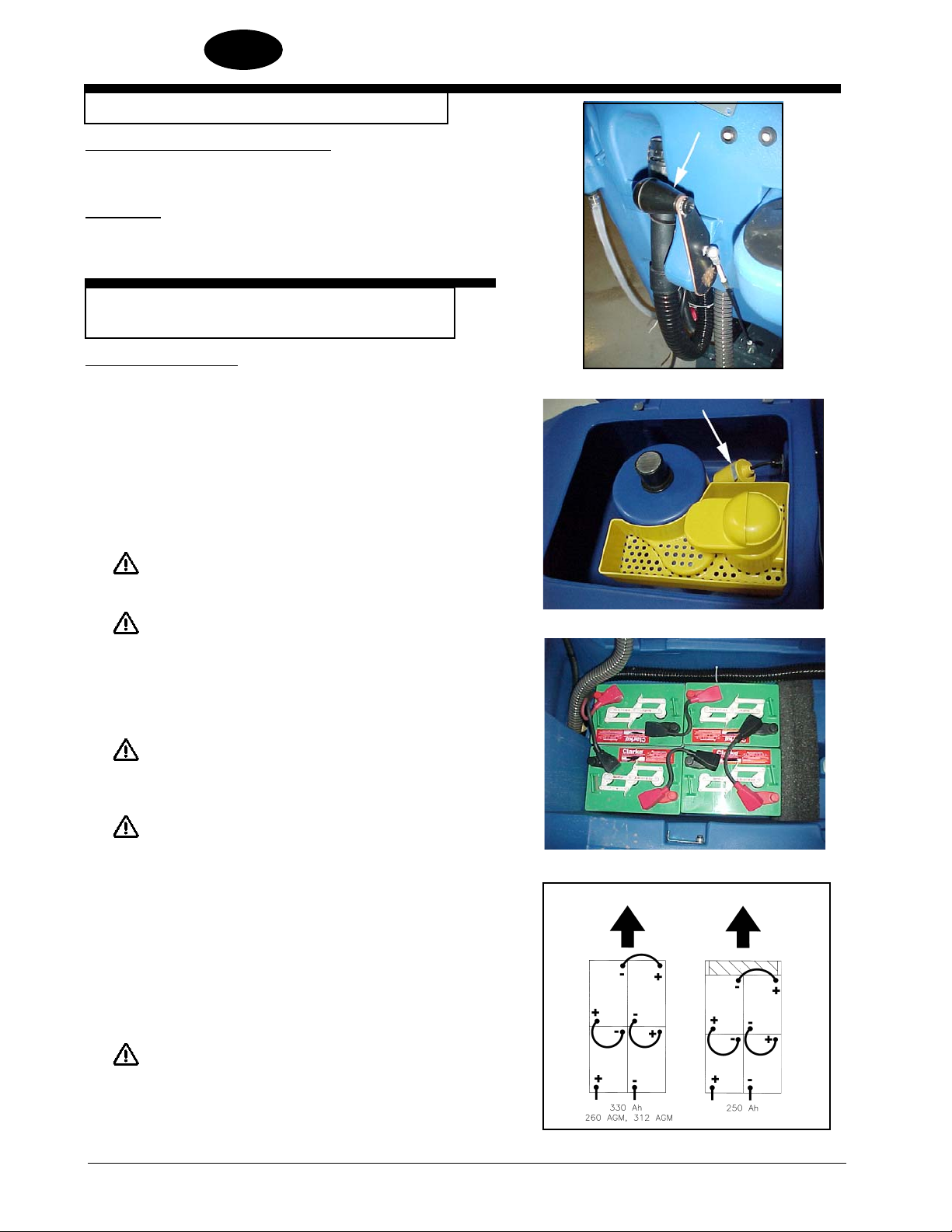

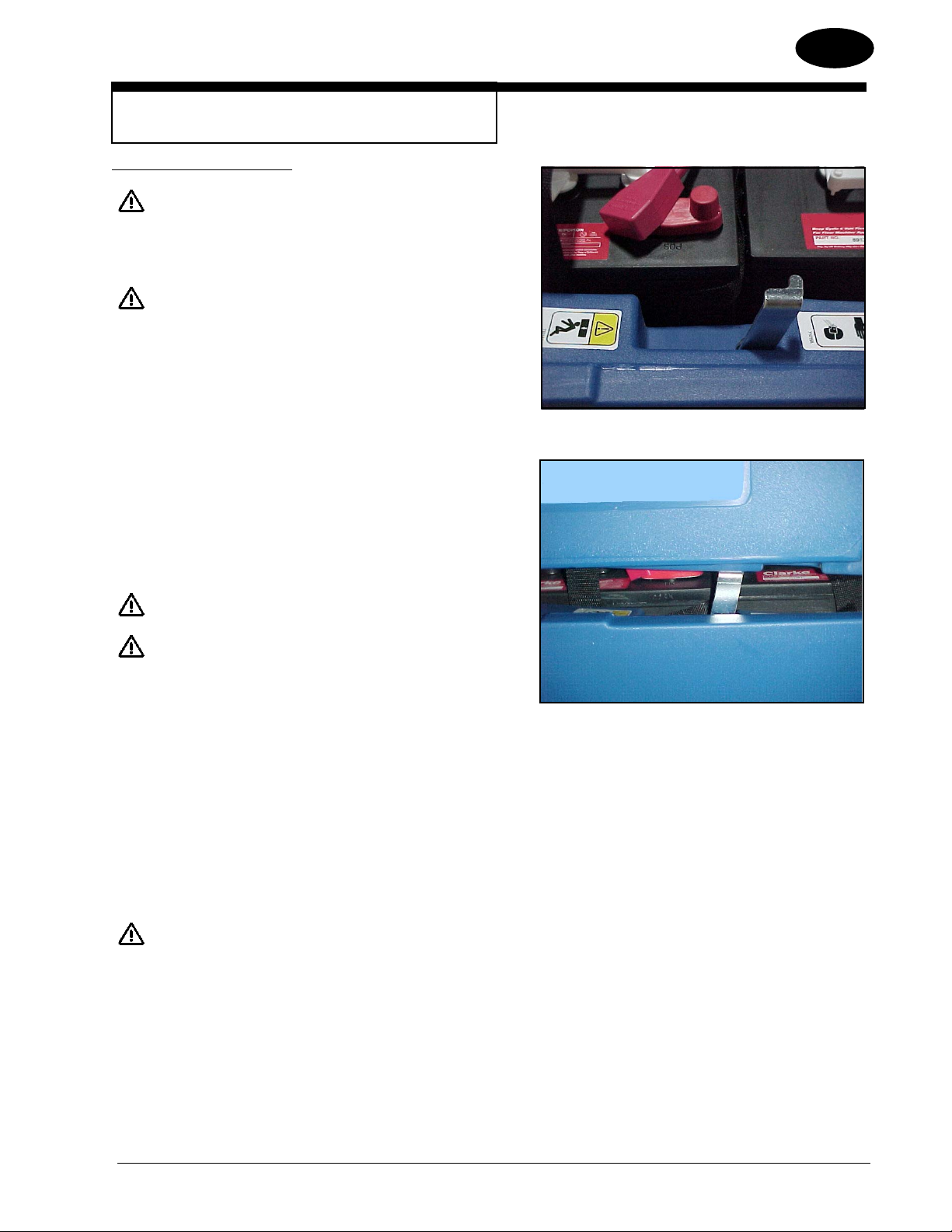

How To Install The Batteries

This machine uses four - 6 volt batteries. The batteries are located in the battery

compartment under the recovery tank.

To install the batteries, follow this procedure:

1. Turn machine off. Set brake (if equipped).

2. Make sure recovery tank is empty.

Figure 2

3. Tip up the recovery tank to it’s full open position. See

fi gure 4.

4. Place the batteries in the tray as shown in Figure 5.

5. Connect the cables between batteries and install battery cable assembly

CAUTION: Before raising the tank, be sure tank is

empty.

WARNING: Do not operate the machine while the

recovery tank is in the open position. The

tank can be accidentally bumped and it may

slam shut.

WARNING: The batteries are heavy. Lifting batteries

without help could result in an injury. Get

help to lift the batteries.

WARNING: Working with batteries can be dangerous.

Always wear eye protection and protective

clothing when working near batteries. NO

SMOKING!

as indicated. See fi gure 5.

Figure 3

Figure 4

FRONT

6. Join the connector from the battery pack to the connector on the control

panel.

7. Close recovery tank by slowly lowering the tank.

WARNING: Never charge any battery with an unsuitable

battery charger. Carefully follow the instructions by the manufacturer of the batteries

and battery charger.

Figure 5

-10- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

revised 9/10

Page 11

HOW TO PREPARE THE MACHINE

FOR OPERATION

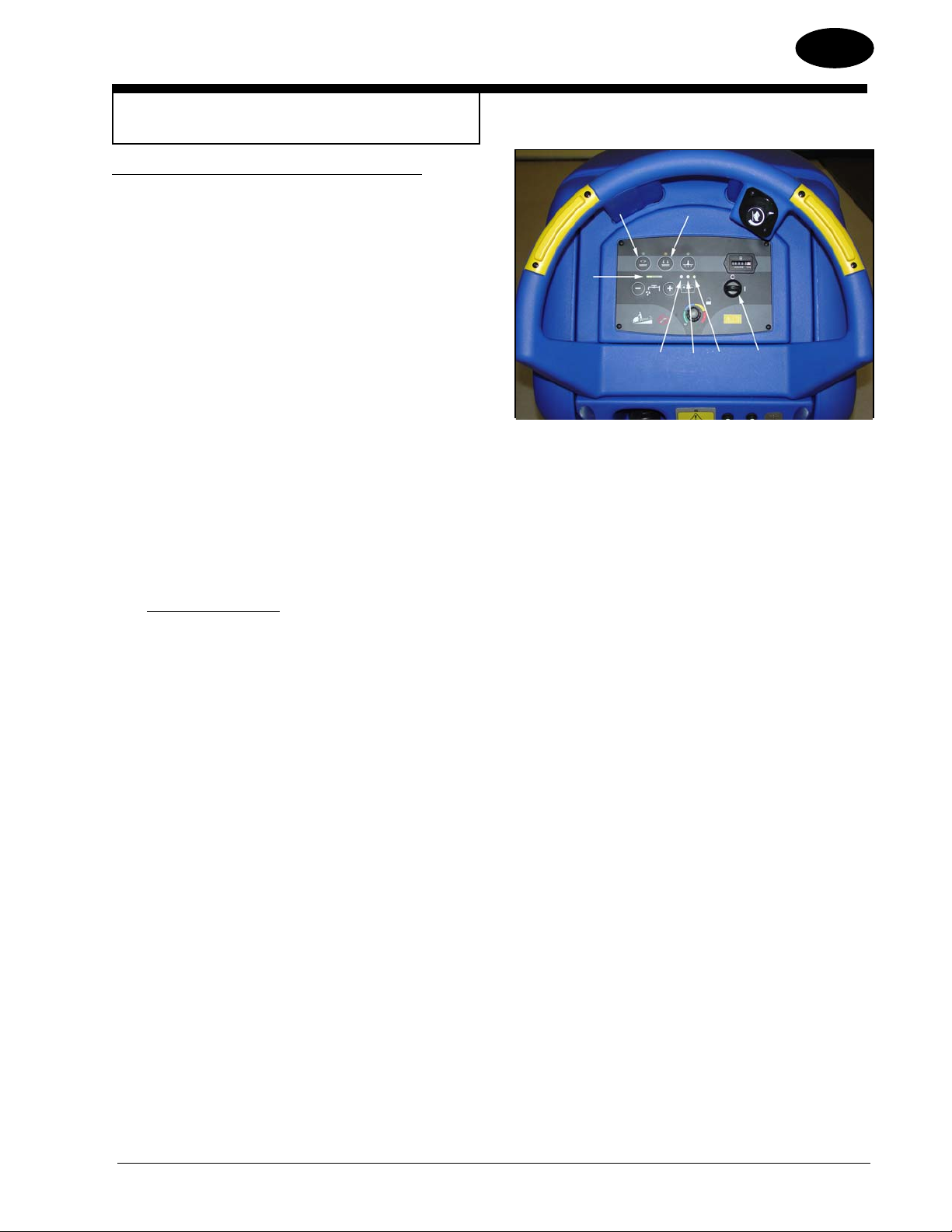

How to program battery charger (WET or AGM batteries):

According to the type of batteries (WET or AGM), set the machine and

electronic board of the battery charger as follows:

Charger Setting

1. Turn the key switch “ON” (see fi gure 5A, item A) and in the very

fi rst seconds of machine operation pay attention to the following:

• If the green warning light (item B) is fl ashing, the charger is

set to AGM.

• If the yellow warning light (item C) is fl ashing, the charger is

set to GEL EXIDE.

• If the red warning light (item D) is fl ashing, the charger is set

to WET.

G

E

ENGLISH

F

DCB

EN

A

2. If the setting is to be changed, perform the following procedure:

a. Turn the key switch “OFF”.

b. Press and hold the buttons (items E and F) at the same time,

then turn the key switch (item A) “ON”.

c. Continue to hold the buttons (items E and F) until the battery

meter LED light turns “ON” and “OFF” and then release both

buttons.

d. Within 3 seconds, toggle the button (item F) to advance the

green bar (item G) to the desired charger setting (see green

bar position for charger settings below):

Green bar setting (item G)

• 1st green bar - WET @ 25 amps, 250 & 330 ah batteries

(4 RED blinks).

• 2nd green bar - GEL/AGM @ 25 amps, 260 & 312 AGM (4

GREEN blinks).

• 3rd green bar - GEL EXIDE @ 25 amps (4 YELLOW

blinks).

• 4th green bar - WET @ 15 amps (2 RED blinks).

• 5th green bar - GEL/AGM @ 15 amps (2 GREEN blinks).

• 6th green bar - GEL EXIDE @ 15 amps (2 YELLOW

blinks).

e. Once proper battery charger profi le is selected, wait until bat-

tery LED light quits fl ashing and stays on before turning key

switch “OFF”.

f. Repeat step 1 to verify that proper charger profi le was pro-

grammed for battery type (WET or GEL).

Figure 5A

NOTE: Charge the batteries before using the

machine.

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 11 -

Page 12

ENGLISH

EN

HOW TO PREPARE THE MACHINE

FOR OPERATION

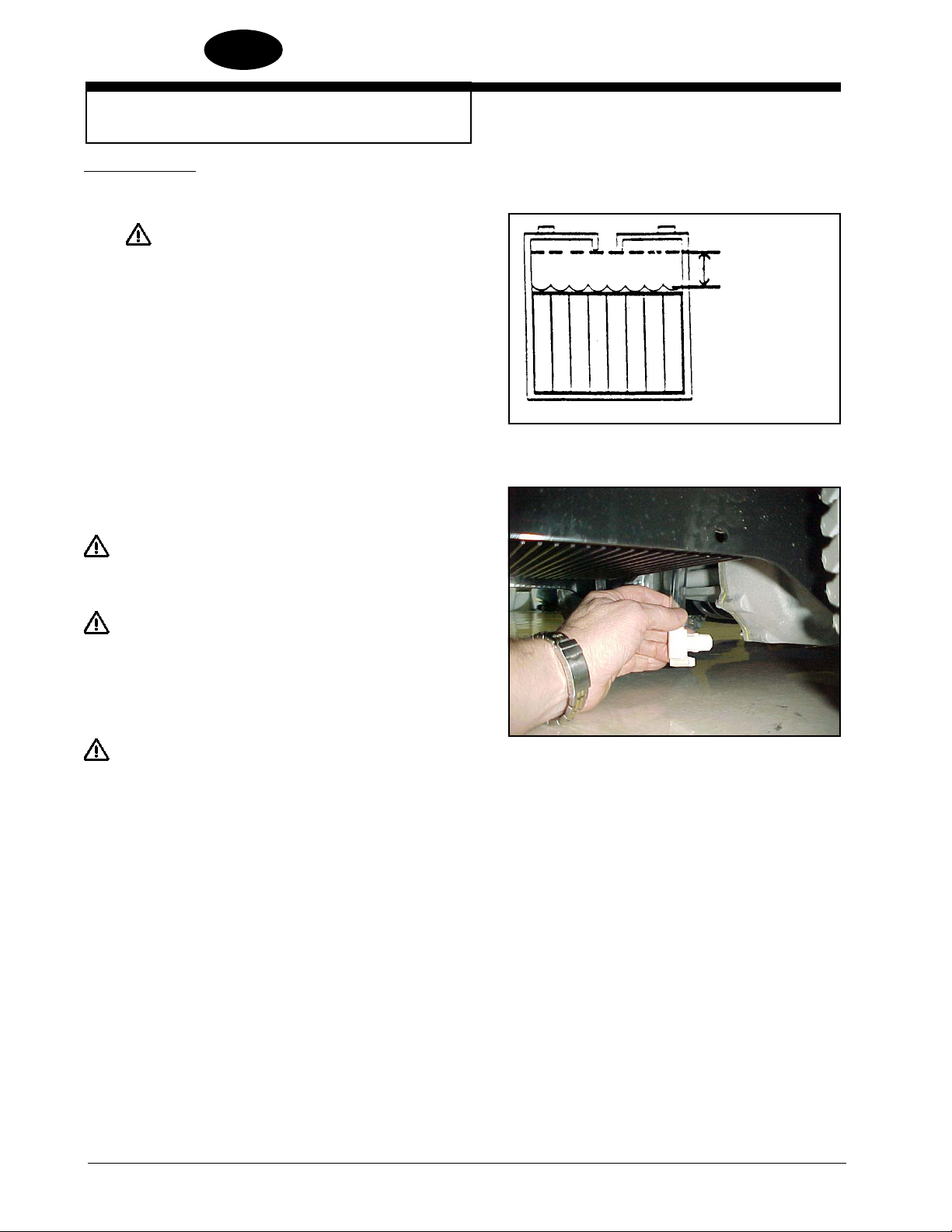

Battery Maintenance

The electrical power to operate the machine comes from the storage batteries.

Storage batteries need preventative maintenance.

WARNING: Working with batteries can be dangerous.

Always wear eye protection and protective

clothing when working near batteries. NO

SMOKING!

To maintain the batteries in good condition, follow these instructions:

1. Keep the electrolyte at the correct level. The correct level is between 1/4”

(1/2 cm) below the bottom of the tube in each cell and above the tops of

the plates. Check the level of the electrolyte each time you charge the

batteries. See fi gure 6.

Correct Level

NOTE: Check the level of electrolyte prior to charging the batteries. Be sure the

plates in each cell are covered with electrolyte before charging. Do not top off

the cells prior to charging the battery. Electrolyte expands during charging. As a

result, the electrolyte could overfl ow from the cells. Always top off the cells with

distilled water after charging.

CAUTION: Irreversible damage will occur to the batteries if

electrolyte does not cover the plates. Keep the

electrolyte at the correct level.

CAUTION: Machine damage and discharge across the tops of

the batteries can occur if the batteries are over fi lled.

Do not fi ll the batteries up to the bottom of the tube

in each cell. Wipe any acid from the machine or the

tops of the batteries. Never add acid to a battery after

installation.

CAUTION: Batteries must be refi lled with distilled water only. Do

not use tap water as it may contain contaminants that

will damage batteries.

2. Keep the tops of the batteries clean and dry. Keep the terminals and

connectors clean. To clean the top of the batteries, use a damp cloth with

a weak solution of ammonia or bicarbonate of soda solution. To clean the

terminals and connectors, use a terminal and connector cleaning tool. Do

not allow ammonia or bicarbonate of soda to get into batteries.

Figure 6

Figure 7

3. Keep the batteries charged.

4. To drain battery compartment: (See fi gure 7)

a. Always wear protective eye protection and protective clothing.

b. Add a weak solution of ammonia or bicarbonate of soda solution to

battery compartment to neutralize any spilled acid.

c. Locate drain hose behind the transaxle.

d. Place hand behind fl ange and open valve.

e. When empty, close valve.

f. Neutralize any acid spills with ammonia or bicarbonate of soda.

-12- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 13

HOW TO PREPARE THE MACHINE

FOR OPERATION

How To Charge The Batteries

WARNING: Charging the batteries in an area without ade-

quate ventilation could result in an explosion.

To prevent an explosion, charge the batteries

only in an area with good ventilation.

WARNING: Lead acid batteries generate gases which

could explode. Keep sparks and fl ames away

from batteries. NO SMOKING!

To charge the batteries, follow this procedure:

ENGLISH

EN

1. Make sure the key switch is in the “OFF” position.

2. Before charging the batteries, the battery compartment needs to

be vented. To vent compartment, tip up the recovery tank and

rotate the tank support bracket, located in the solution tank (see

fi gure 8). Slowly lower the recovery tank and let it rest on the support bracket (see fi gure 9). To close the tank, lift up on the recovery

tank, rotate the support bracket down, then slowly lower the tank to

the closed position.

CAUTION: Before raising tank, be sure tank is empty.

W ARNING: Do not operate the machine while the recovery

tank is in the open position. The tank can be

accidentally bumped and it may slam shut.

3. Connect the battery charger AC cord located at the rear of the machine to an appropriate wall receptacle.

4. Observe indicator lights on the charger/battery meter to ensure the

charging process has started. Red, yellow and green lights indicate state of charge. Steady on green light indicates the batteries

are fully charged.

Figure 8

Figure 9

NOTE: Make sure you plug into a circuit that is not loaded by other equipment. Wall breakers may be tripped and no charge will occur.

WARNING: Never charge any battery with an unsuitable

battery charger. Carefully follow the instructions given by the manufacturer of the batteries and battery charger.

NOTE: To prevent permanent damage to the batteries, avoid their complete discharge. Never leave the batteries completely discharged, even if

the machine is not being used. When recharging the batteries, keep the

recovery tank open. Check the level of the electrolyte and if necessary

top off with distilled water.

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 13 -

revised 9/10

Page 14

ENGLISH

EN

HOW TO PREPARE THE MACHINE

FOR OPERATION

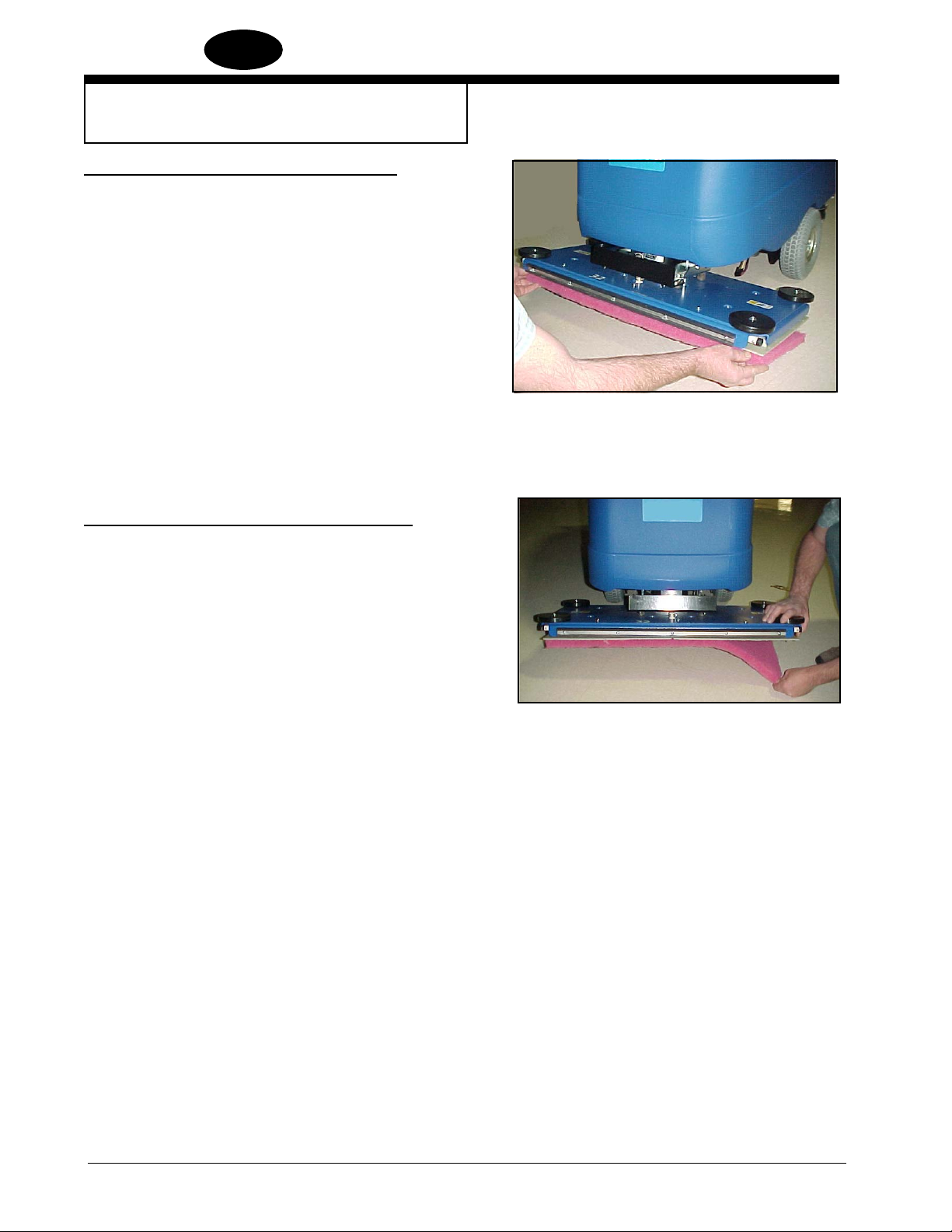

How To Install The Brush Or Pad (BOOST Machine)

To install the brush or pad on the machine, follow this

procedure:

1. Turn the key switch “ON”.

2. Put the brush head assembly in the “Up” position.

3. Turn the key switch “OFF”.

4. Go to the front of the machine.

5. Press on a brush or pad, under the fl ex plates.

See fi gure 10.

NOTE: When using a black pad, position pad on head. Lower head

and operate momentarily to affi x pad to pad driver (if you have

diffi culty, position pad on fl oor and lower head then operate.)

How To Remove The Brush Or Pad (BOOST Machine)

To remove the brush or pad from the machine, follow this procedure:

1. Turn the key switch “ON”.

2. Put the brush head assembly in the “Up” position.

3. Turn the key switch “OFF”.

4. Go to the front of the machine and pull downward on the brush or

pad until it releases from the fl ex plates. See fi gure 11.

Figure 10

Figure 11

-14- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 15

HOW TO PREPARE THE MACHINE

FOR OPERATION

How To Install The Brushes Or Pad Drivers

On The Disc Machine

To install the brushes or pad drivers on the machine,

follow this procedure:

1. Turn the key switch “ON”.

2. Put the brush head assembly in the “UP” position.

3. Turn the key switch “OFF”.

4. Unlatch right and left brush housings and remove them. See

fi gure 12.

5. Put a brush or pad driver under the brush motor plate. See

fi gure 13.

6. Align the lugs on the motor gimbal with the slots in the brush

gimbal.

ENGLISH

Figure 12

EN

7. Pull the brush up until the gimbal locks.

8. Repeat steps 5, 6 and 7 to install the second brush or pad driver.

9. Reinstall right and left brush housings and latch front cover.

DANGER: Operating a machine that is not completely

or fully assembled could result in injury or

property damage. Do not operate this machine unless it is completely assembled.

Inspect the machine carefully before operation.

How To Remove The Brushes Or Pad Drivers

On the Disc Machine

To remove the brushes or pad drivers from the machine, follow this

procedure:

1. Turn the key switch “ON”.

2. Put the brush head assembly in the “UP” position.

3. Turn the key switch “OFF”.

Figure 13

4. Unlatch right and left brush housings and remove them. See

fi gure 12.

5. Push down on two sides of the brush or pad driver until the gimbals release.

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 15 -

Page 16

ENGLISH

EN

HOW TO PREPARE THE MACHINE

FOR OPERATION

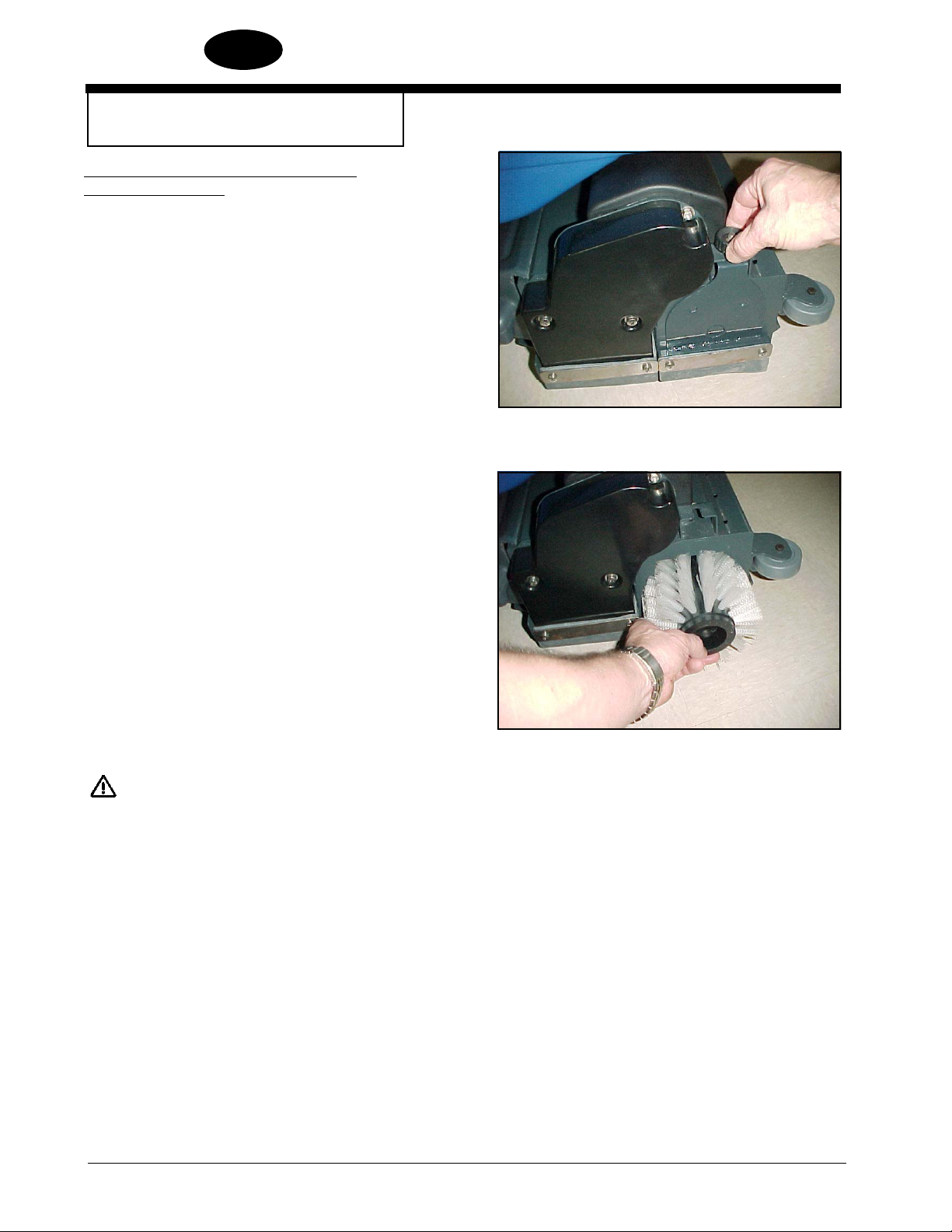

How To Change Or Reverse Bristle Direction

On Cylindrical Machine

To install or reverse bristle direction on the machine, follow this

procedure:

1. Turn the key switch “ON”.

2. Put the brush head assembly in the “UP” position.

3. Turn the key switch “OFF”.

4. Go to the front of the machine and loosen thumb screw on

brush door. See fi gure 14.

5. Lower door approximately 1/2 inch and remove brush door.

6. Remove brush. See fi gure 15.

Figure 14

7. Inspect brush condition. If damaged or worn, replace it. Otherwise, turn brush end for end periodically to reverse bristle

direction for better life.

8. Slide brush onto driver or opposite side and rotate slowly until drive lugs are lined up with brush slots. Push brush all the

way in.

9. Install brush door assembly into brush.

10. Raise door and tighten thumb screw.

11 Repeat for the other brush.

DANGER: Operating a machine that is not com-

pletely or fully assembled could result

in injury or property damage. Do not

operate this machine unless it is completely assembled. Inspect the machine

carefully before operation.

Figure 15

-16- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 17

HOW TO OPERATE THE MACHINE

How To Operate the Squeegee

The squeegee wipes the fl oor while the vacuum motor removes the

dirty solution from the fl oor. Use your hand to lower or raise the

squeegee handle. To operate the squeegee, follow this procedure:

1. To lower the squeegee rotate the squeegee lever down. See

fi gure 16.

2. To raise the squeegee, rotate the squeegee lever up. See

fi gure 16.

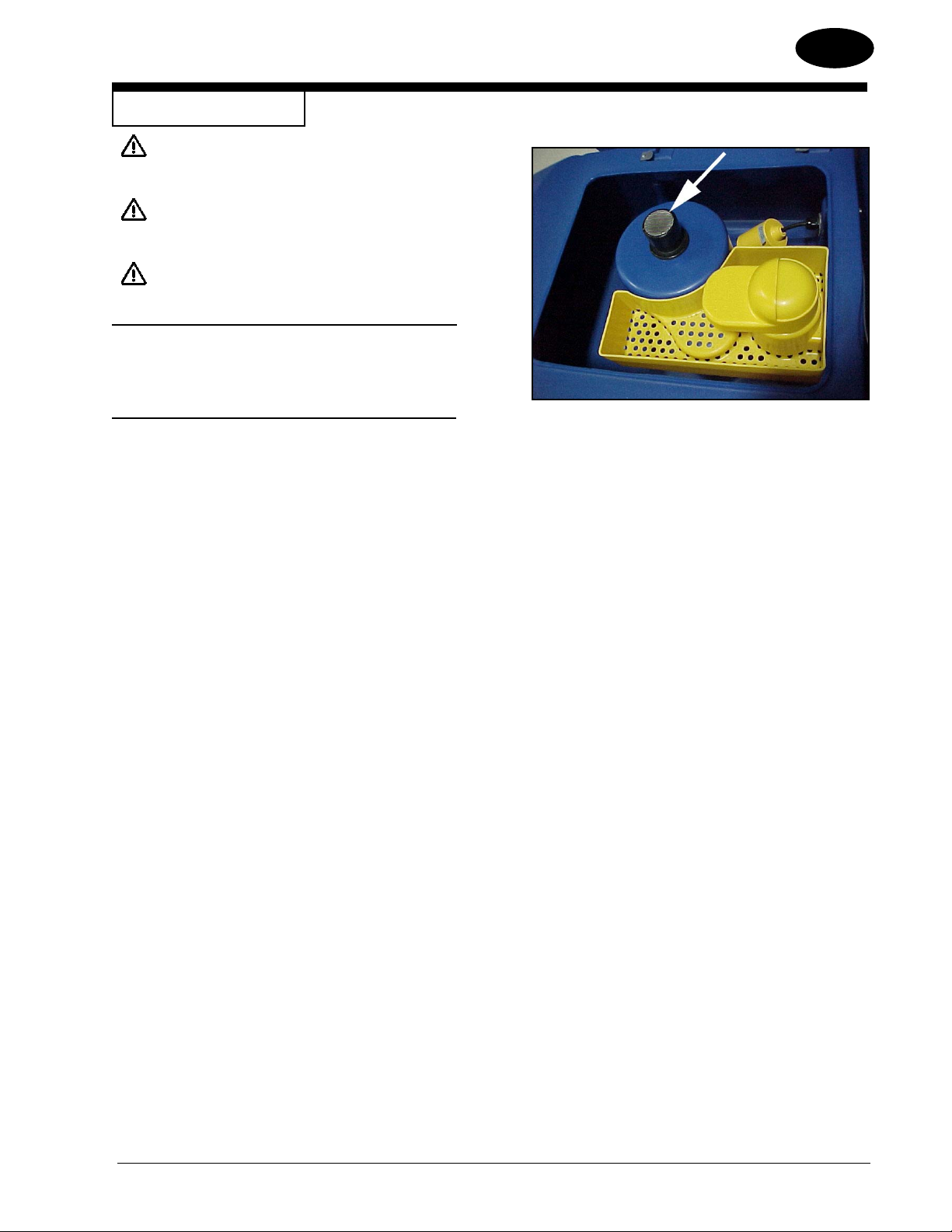

How to Fill The Solution Tank

1. Remove the solution tank lid. See fi gure 17.

2. If the machine does not have the Chemical Mixing System,

add a cleaning chemical to the solution tank. For the correct amount of chemical, follow the directions shown on the

container.

ENGLISH

EN

3. Fill the solution tank with water.

4. Replace solution tank lid.

WARNING: Water solutions or cleaning materials used

with this type of machine can leave wet areas on the fl oor surface. These areas can

cause a dangerous condition for the operator or other persons. Always put CAUTION

signs near the area you are cleaning.

WARNING: Machines can ignite fl ammable materi-

als and vapors. Do not use with or near

fl ammables such as gasoline, grain dust,

solvents, and thinners. Only use a cleaning concentration recommended by the

chemical manufacturer.

WARNING: Nilfi sk ALTO recommends a maximum

water temperature of 120°F(49°C)

Figure 16

Figure 17

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 17 -

Page 18

ENGLISH

EN

HOW TO OPERATE THE MACHINE

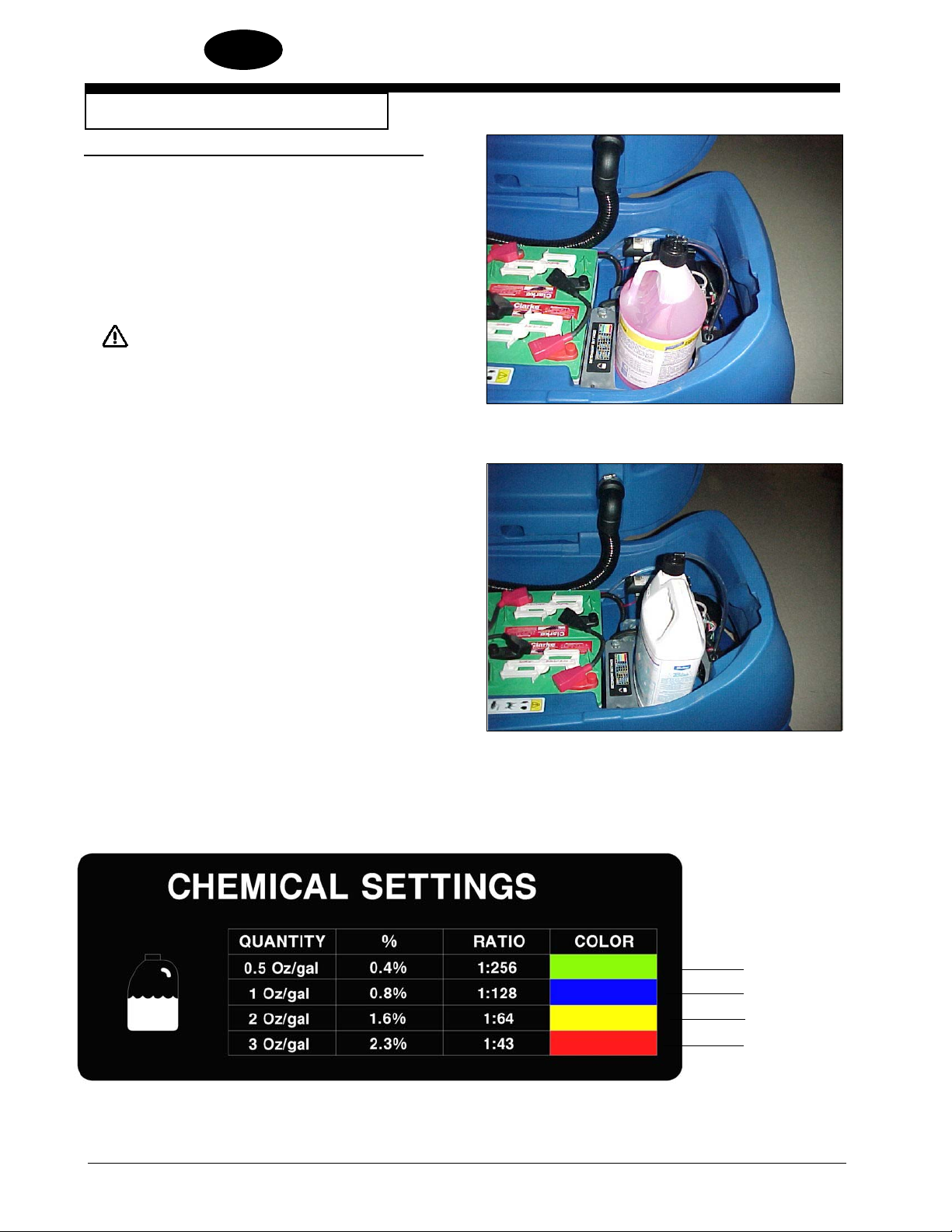

How To Operate The Chemical Mixing System (Optional)

The chemical mixing system is designed to automatically mix the

cleaning chemical directly from the manufacturer’s chemical container into the clear water coming from the solution tank. The chemical

control knob on the control panel is used to select the desired ratio

according to the recommendation of the chemical manufacturer and

the application requirements. The ratio settings are shown in fi gure

19.

CAUTION: Do not operate the chemical pump dry.

If the chemical container is empty, make

sure the chemical control is in the off

position.

To operate the chemical mixing system, follow this procedure:

1. Select the proper cleaning chemical for scrubbing application.

Figure 18A

2. Set the chemical knob to the recommended setting per the

chemical manufacturer.

3. Make sure the recovery tank is empty and then open the

recovery tank.

4. Position the manufacturer’s chemical container into the

bracket located at the front right side of the solution tank.

See fi gure 18A & 18B

5. Remove container cap and insert bottle adapter and

tighten cap.

6. Slowly close the recovery tank.

NOTE: With the knob turned fully counterclockwise, only

water will be delivered to the fl oor.

Figure 18B

GREEN

BLUE

YELLOW

RED

Figure 19

-18- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 19

HOW TO OPERATE THE MACHINE

WARNING: Water solutions or cleaning materials used with

this type of machine can leave wet areas on the

fl oor surface. These areas can cause a dangerous condition for the operator or other persons.

Always put CAUTION signs near the area you

are cleaning.

WARNING: Machines can ignite fl ammable materials and

vapors. Do not use with or near fl ammables

such as gasoline, grain dust, solvents and

thinners. Only use a cleaning concentration

recommended by the chemical manufacturer.

B

ENGLISH

EN

WARNING: Nilfi sk ALTO recommends a maximum water

temperature of 120oF (49oC).

Operating The Machine

NOTE: Put the machine in the lowest traverse speed setting. Use the

machine in an area that has no furniture or objects until you can do the

following:

1. Move the machine in a straight direction, forward and backward.

2. Stop the machine safely.

3. Turn the machine both left and right and return to a straight direction.

To move the machine, follow this procedure:

1. Release the parking brake (if equipped with machine).

2. Turn the key switch to the “ON” position

3. Raise the brush.

4. Raise the squeegee.

Figure 20

A

A

C

5. When either the left or right forward palm buttons (fi gure 20, item A)

are pushed in, the machine will go forward.

6. Control the speed of traverse by using the traverse speed control

knob (fi gure 20, item C).

7. To stop, release the forward palm buttons.

8. To reverse the machine, push in the white reverse switch (fi gure 20

item B) and either the right or left forward palm buttons (fi gure 20

item A) at the same time.

9. To stop, release the forward palm buttons.

10. To turn the machine, push the rear of the machine to the side.

11. When you stop the machine, turn the key switch “OFF”, remove the

key and set the parking brake (if equipped).

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 19 -

Page 20

ENGLISH

EN

HOW TO OPERATE THE MACHINE

How To Clean A Floor

WARNING: Water solutions or cleaning materials used with

this type of machine can leave wet areas on the

fl oor surfaces. These areas can cause a dangerous

condition for the operator or other persons. Always

put CAUTION signs near the area you are cleaning.

To clean a fl oor, follow this procedure:

1. Set the parking brake (if equipped with machine.)

2. Put the water and a cleaning chemical in the clean solution tank.

3. Release the parking brake (if equipped with machine.)

4. Turn the key switch “ON”.

5. Lower the squeegee.

6. Press the one touch control button to lower the brush head assembly

and start vacuum motor.

7. Adjust the fl ow of clean solution to the fl ow desired.

8. Move the machine across the fl oor in the forward direction.

9. Make a 180° turn.

NOTE: When you make more passes across the fl oor, let the brush clean

approximately 2 inches (5 cm) of the area already cleaned by the brush.

NOTE: During most cleaning procedures, apply and remove the solution in

one operation.

How To Clean A Very Dirty Floor

To clean a very dirty fl oor, follow this procedure:

1. Apply solution to the fl oor.

2. Do not lower the squeegee. Shut vacuum motor “OFF”.

3. Lower the brush or pad and scrub the fl oor.

4. Scrub the fl oor again with additional solution and lower the squeegee

and turn vacuum motor “ON”.

5. Pick up all the solution with the squeegee.

-20- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 21

MAINTENANCE

WARNING: Maintenance and repairs must be done by au-

thorized personnel only.

WARNING: Always empty the solution tank and recovery

tank before doing any maintenance.

WARNING: Keep all fasteners tight.

These Maintenance Procedures Must Be Done Every Day

Keep the machine clean, it will need fewer repairs and have longer

life.

ENGLISH

EN

Do These Procedures When You Begin Your Work Period

1. Turn off key switch.

2. Disconnect AC power from battery charger (follow charger instructions).

3. Make sure the screen fi lter over the vacuum motor is clean and

in position (see fi gure 21.

4. Make sure the valve on the recovery drain hose is clean. Tightly

close the valve.

5. Make sure the brushes are in position and installed correctly

6. Check the installation of the squeegee and squeegee hose.

7. Make sure the solution drain/level indicator hose is secure on

upper fi tting.

Figure 21

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 21 -

Page 22

ENGLISH

EN

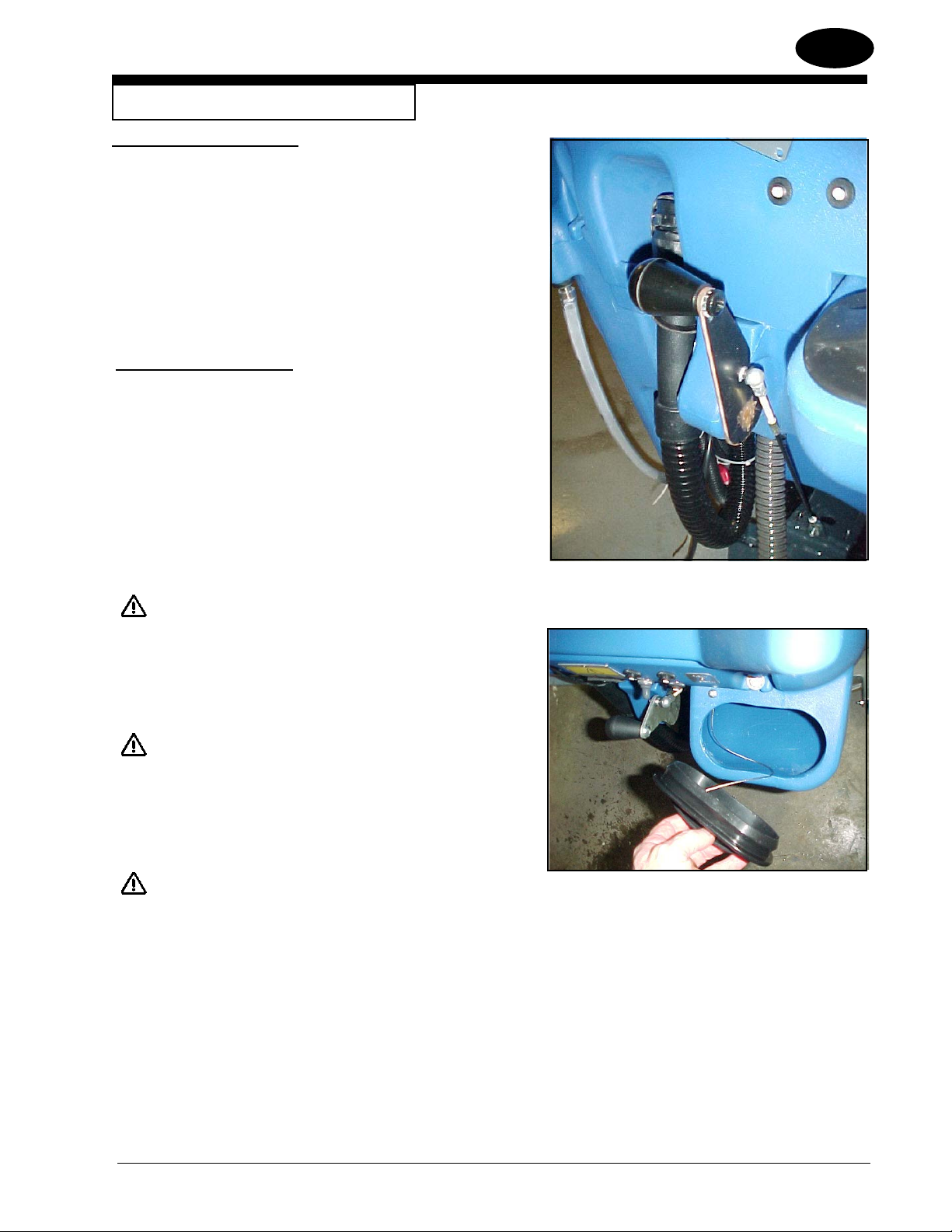

MAINTENANCE

Do These Procedures When You End Your Work

1. Drain the solution tank (if necessary) (Figure 22) and the recovery

tank (Figure 23). To drain the tanks, follow this procedure:

a. Turn the key switch “OFF”.

b. Remove the drain hose from the back of the machine.

c. Put the end of the hose over a drain or bucket.

d. Recovery Tank:

Turn the drain cap counterclockwise to open.

Solution Tank:

When hose is lowered to water level, water will fl ow.

2. Flush the tanks. To fl ush the tanks, put clean water in the tank

through the opening on top of the tank.

Figure 22

3. If a tank or drain hose has an obstruction, use a water hose to fl ush

the tank or hose. Put the water hose into the drain hose.

4. Leave the tanks and the recovery drain valve open to dry in the air.

5. Check the squeegee blade. Use a cloth to clean the squeegee

blade. If the squeegee blade is damaged or worn, turn or replace

the blade.

6. Check and clean the solution lid gasket. Use a mild cleaning solu-

tion and rinse the parts in clean water.

Check the batteries and if necessary add distilled water after charging.

The correct level is within 1/4 inch (1/2 cm) of the bottom of the tube

in each cell.

CAUTION: Tap water may contain contaminants that

will damage batteries. Batteries must be

refi lled with DISTILLED WATER ONLY.

WARNING: Lead acid batteries generate gases which

can cause an explosion. NO SMOKING.

Always wear eye protection and protective clothing when working near batteries.

Figure 23

Use a clean cloth and wipe the surface of the machine.

Charge the batteries. See the instruction in the section of this book

called “How To Charge The Batteries”.

-22- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 23

MAINTENANCE

These Maintenance Procedures Must Be Done Every Week:

WARNING: Maintenance and repairs must be done by authorized

personnel only. Always empty the solution tank and

the recovery tank before doing any maintenance.

Keep all fasteners tight.

WARNING: Always wear eye protection and protective clothing

when working near batteries. Do not put tools or other

metal objects across the battery terminals or the tops

of the batteries.

CAUTION: To prevent damage to the machine, and discharge

across the tops of the batteries, do not fi ll the batteries

above the bottom of the tube in each cell. Wipe any

acid from the machine or the tops of the batteries. Do

not add acid to battery after installation.

NOTE: Always turn off key switch before servicing the machine.

ENGLISH

Figure 24

EN

WARNING: Always wear eye protection and protective clothing

when working near batteries. NO SMOKING!

1. To inspect batteries, tip up recovery tank to its full open position. See fi gure

24. To close the tank, slowly lower the tank to the closed position.

CAUTION: Before raising the tank, be sure tank is empty.

WARNING: Do not operate the machine while the recovery tank

is in the open position. The tank can be accidentally

bumped and it may slam shut.

2. Disconnect the batteries. Use a cloth and a solution of ammonia or bicarbonate of soda to wipe the top of the batteries. Clean the battery terminals.

Reconnect the batteries.

3. Check the hoses for leaks, obstructions and other damage.

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 23 -

Page 24

ENGLISH

EN

MAINTENANCE

Maintenance For The Squeegee

To remove the squeegee, follow this procedure:

1. Remove the squeegee assembly by loosening the two knobs that attach

the squeegee to the machine. Pull the squeegee assembly off. See

fi gure 25.

2. Inspect the squeegee blades.

3. If the blades are worn, unclamp bands and turn the blade so that a new

edge is in the wiping position (see fi gures 25A and 25B).

4. Reinstall squeegee assembly on the machine.

Adjusting Squeegee Tilt

The tilt of the squeegee causes the rear blade to raise up in the center or

on the ends, depending on which direction the tilt is changed. Turn

the adjusting screw clockwise or counterclockwise (see fi gure 26), to

achieve uniform squeegee blade fl are.

WARNING: Maintenance and repairs must be done by au-

thorized personnel only.

WARNING: Electrical repairs must be done by authorized

personnel only.

Maintenance Procedures Must Be Done :

Contact a Nilfi sk ALTO Authorized Service Center

to perform these procedures.

Every 500 hrs (heavy) 1000 hrs (normal)

Figure 25

Figure 25A

1. Check the carbon brushes in the electric motors.

2. Clean the battery terminals and connectors. Make sure all of the battery connections are tightened correctly.

Figure 25B

3. Check all of the switches, controls, valves, hoses and gaskets.

4. Check and remove debris from the transaxle hubs.

Every 500 hrs (BOOST Only)

1. Replace the rubber isolators (see Brush Head Assembly Parts List section). The rubber isolators are considered wear items and must be replaced between 500 hrs (heavy) and 1000 hrs (normal).

Figure 26

-24- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

revised 9/10

Page 25

PROBLEM CAUSE ACTION

The machine does not remove all the

water from the fl oor.

HOW TO CORRECT PROBLEMS IN THE MACHINE

The squeegee is up

The vacuum tank is full.

Lower the squeegee.

Drain the tank.

ENGLISH

EN

The batteries do not give the normal

running time.

The cleaning is not even.

The screen fi lter is dirty.

There is an obstruction or damage in the

squeegee, squeegee hose or standpipe.

The vacuum motor is not running.

The squeegee hose is disconnected.

The squeegee blade is damaged, worn, or in-

correctly installed.

The gasket on the cover of the recovery tank

is damaged.

The recovery drain hose valve is not

closed.

The battery terminals are dirty or damaged.

The electrolyte level is too low.

The batteries are not fully charged.

The charger is damaged.

The battery is defective.

The batteries are disconnected.

The scrub brushes or pads are worn.

There is damage to the brush assembly, cast-

ers or the solution valve.

Clean the screen fi lter.

Remove the obstruction or repair the damage.

Check for blown fuse. Have an authorized service person make repairs.

Connect the hose.

Turn or replace the squeegee blade.

Correctly install the squeegee blade.

Replace the gasket.

Close valve.

Clean the terminals and connectors. Replace

the damaged cables. Charge the batteries.

Add distilled water to each cell and charge the batteries.

Charge the batteries for a full 16 hour charge.

Have an authorized service person repair the charger.

Have an authorized service person check voltage of

each cell while discharging.

Connect the batteries.

Replace the scrub brushes or pads.

Have an authorized service person make the needed

repairs.

The machine does not run.

One or both brush motors are not running

The solution level is low.

The machine loses power.

Check for tripped breaker, reset. Check for loose

connections.

Fill the solution tank.

NOTE: If the motors continue to stop consult an autho-

rized service person.

Reset the circuit breaker.

Check wire connection to traverse motor.

Replace the fuses.

Check the batteries connections.

Release parking brake (if installed)

NOTE: If the motors continue to stop, consult an au-

thorized service person.

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 25 -

Page 26

ENGLISH

EN

-26- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 27

ENGLISH

EN

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 27 -

Page 28

ENGLISH

EN

NOTES

-28- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 29

ENGLISH

EN

SCRUBTEC 8

SCRUBTEC 866

SCRUBTEC 871

SCRUBTEC 871C

SCRUBTEC 886

Section II

Parts and Service Manual

(71492A)

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 29 -

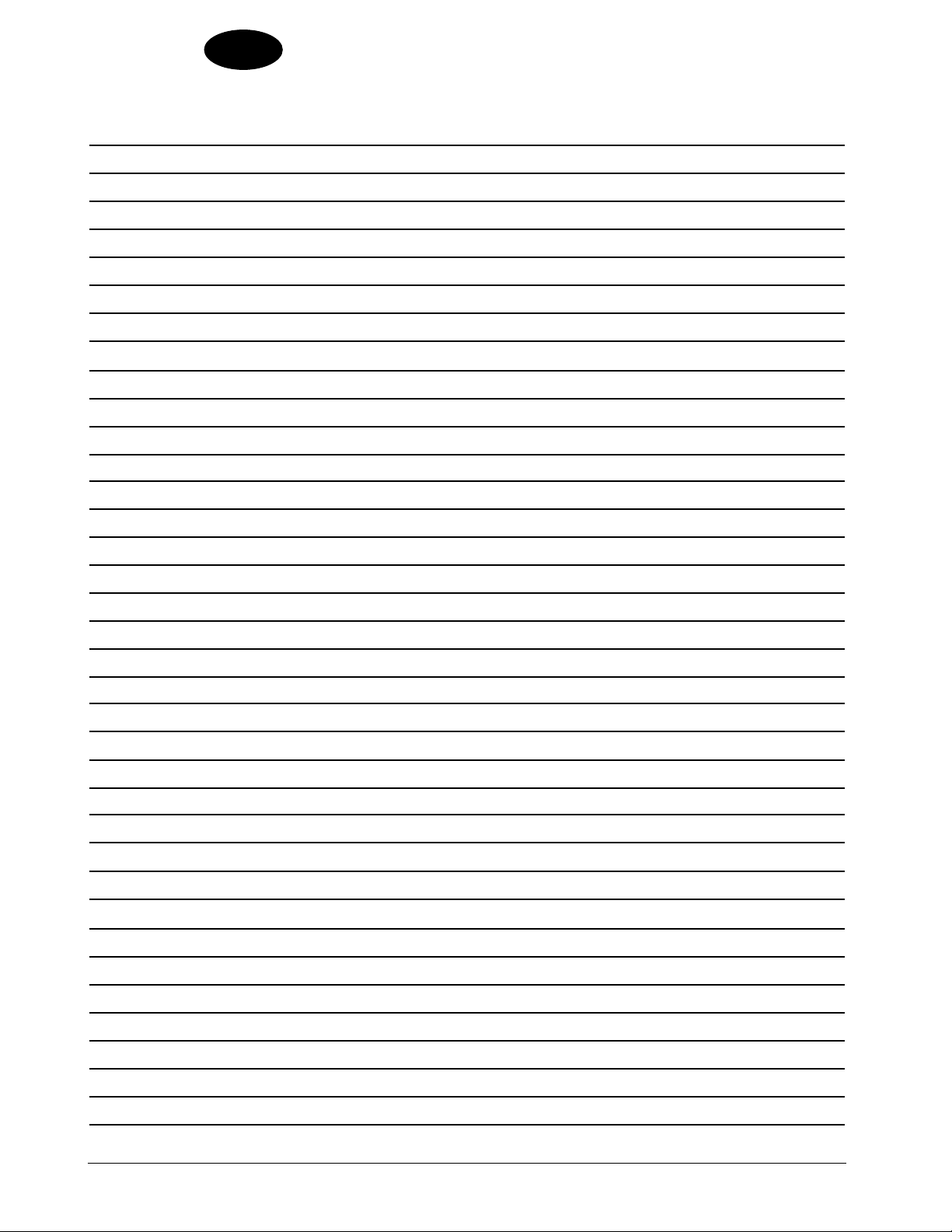

Page 30

ENGLISH

27

26

EN

Nilfi sk ALT O

Scrubtec 866, 871, 886, BOOST 8, and 871C

Solution Tank Assembly

26

25

1

2

4

3

5

26

7

6

9

8

24

23

28

22

28

21

-30- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

20

19

18

17

10

11

12

8

13

14

14

15

16

Page 31

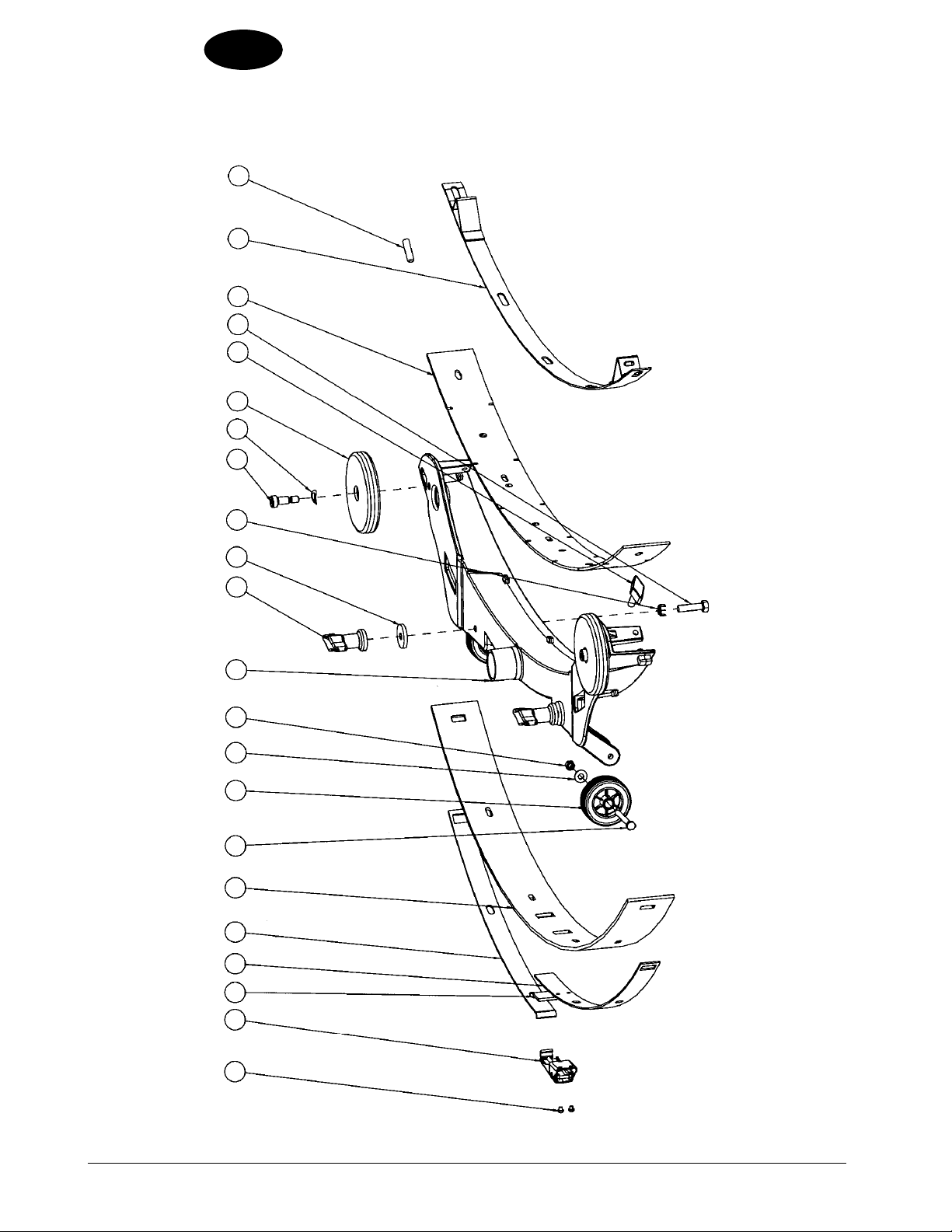

Nilfi sk ALTO

Scrubtec 866, 871, 886, BOOST 8, and 871C

Solution Tank Assembly Parts List 12/08

Ref # Part No. Description Qty

1 39887A Gasket Handle 3

2 61930A Rod, Recovery Tank Prop 1

3 170860 Washer, Flat 5/16 2

4 80317A Washer, Bowed .455 ID x .740 OD 1

5 88630A Bolt, M6-1 x 8 x 10MM SHSB 1

6 30796A Tank, Solution 1

7 71496A Label, Nilfi sk ALTO 1

8 80196A Nut, M5-.8 Nylock SS 2

9 80205A Screw, M5 x 0.8 x 20MM Pan Head 1

10 80176A Screw, M5 x 12 PHSS 1

11 54773A Lanyard 1

12 30804A Lid, Solution Rear Fill 1

13 30792A Hose, Level/Drain 1

14 980643 Washer, 7/16 OD x .036 THK 4

15 964004 Screw, M5-.8 x 16MM PN ST PH 2

16 9095149000 Cord Wrap 1

17 722030 Clamp, Hose 1

18 32100A Connector, Straight 2

19 31242A Bushing 2

20 9097028000 Valve, Solution 1

21 59614A Valve, Battery Drain 1

22 34704A Hose, Clear Vinyl 1

23 820207 Adapter, Solution Hose 1

24 9095286000 Gasket, Valve Solution 1

26 40172A Cable, Series (Ring Style) 3

41206A Cable, Series (Taper Style) 3

27 41060A Cable, Battery (Ring Style) 1

41080A Cable, Battery (Taper Style) 1

28 50248A Clamp, Hose 2

ENGLISH

EN

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 31 -

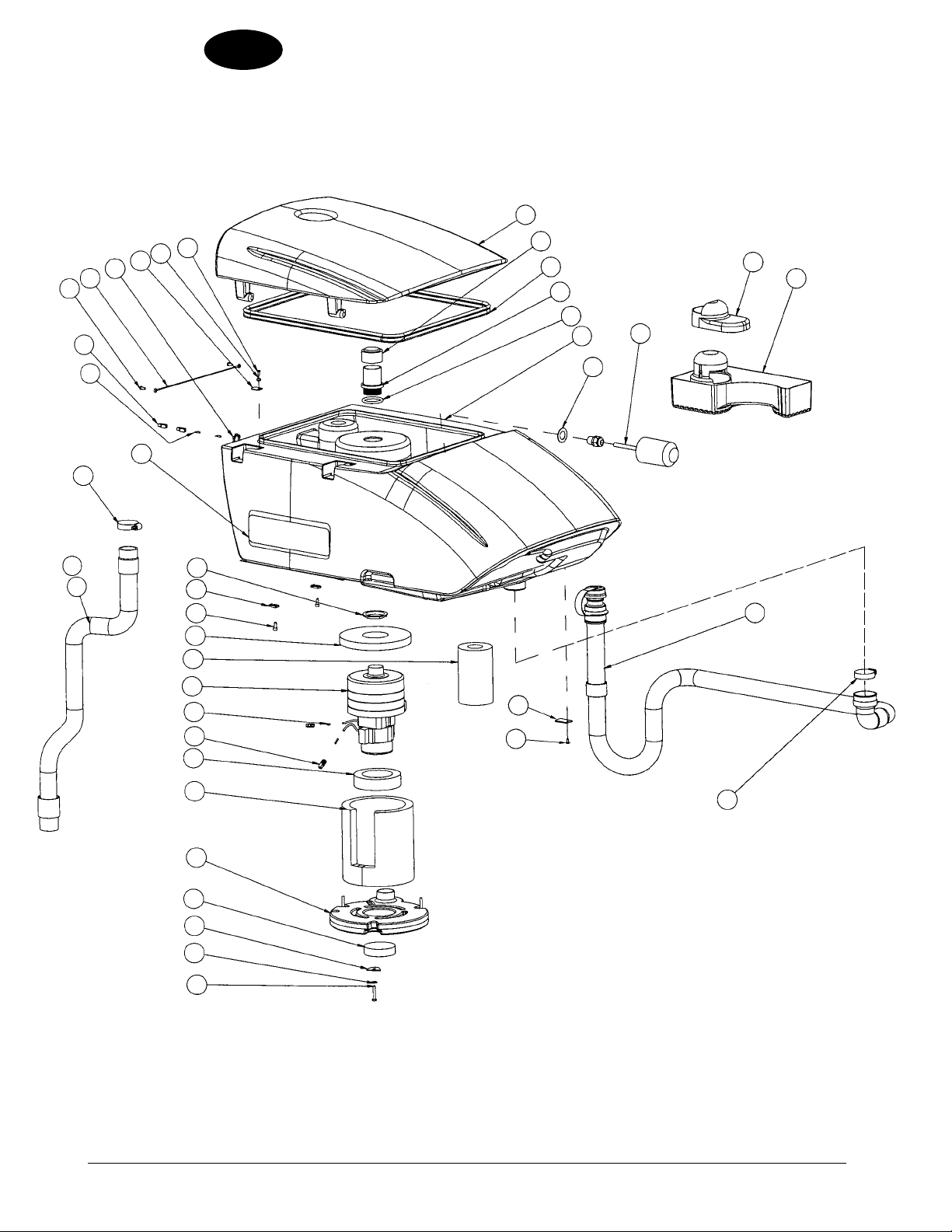

Page 32

ENGLISH

33

21

32

31

30

12

34

28

35

36

EN

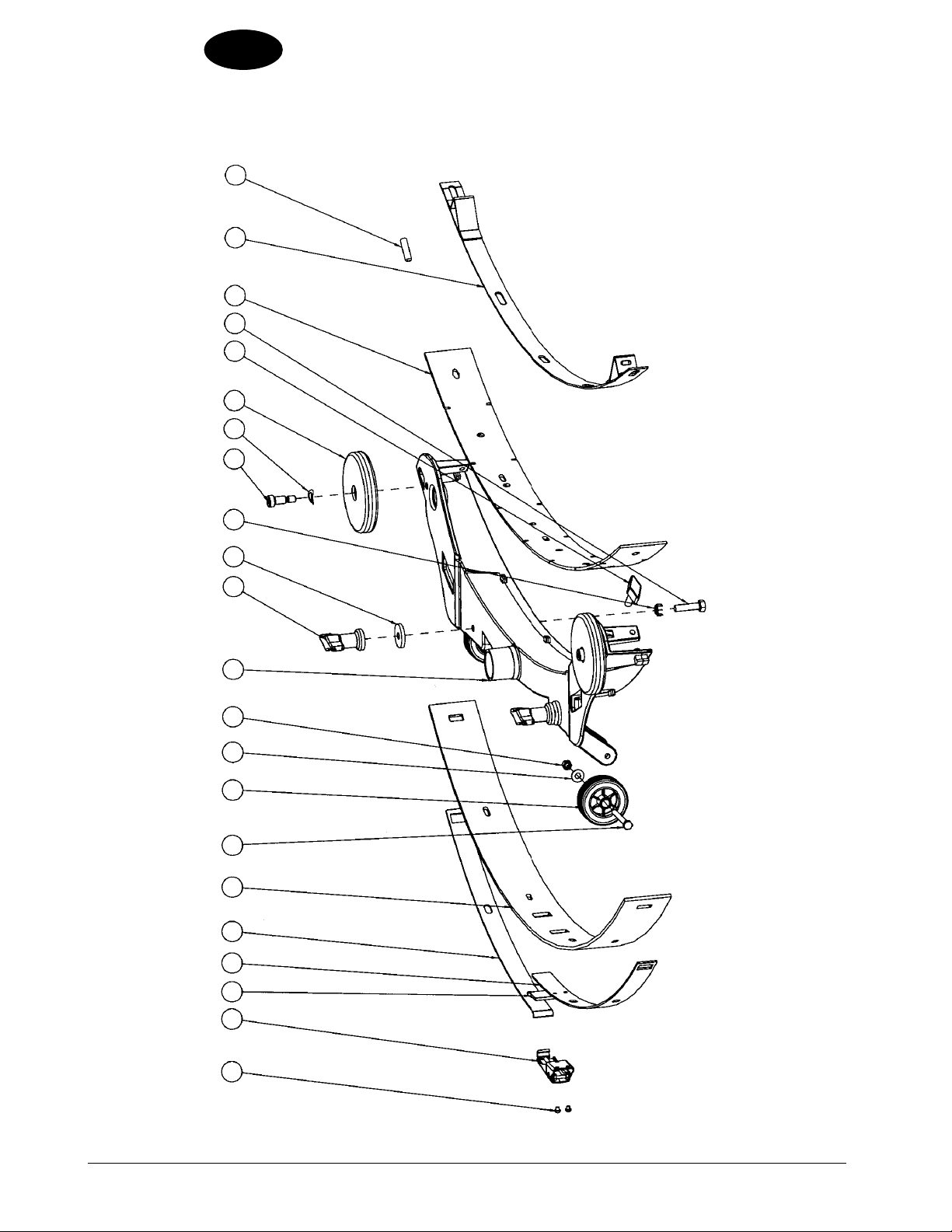

Nilfi sk ALT O

Scrubtec 866, 871, 886, BOOST 8, and 871C

Recovery Tank Assembly Drawing 12/08

1

2

3

4

5

6

9

10

8

7

37

29

23

22

19

21

20

18

16

15

14

26

25

24

17

13

27

11

38

36

12

-32- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 33

Nilfi sk ALTO

Scrubtec 866, 871, 886, BOOST 8, and 871C

Recovery Tank Assembly Parts List 12/08

Ref # Part No. Description Qty

1 30798A Lid, Recovery Tank 1

2 58069A Screen, Vac Filter 1

3 39718A Gasket, Recovery Lid 1

4 30805A Tube, Stand 1

5 837304 O-Ring 1

6 30797A Tank, Recovery 1

7 87612A Seal, Washer 1

8 40002A Switch, Float Electrical 1

9 30827A Lid, Tray Debris 1

10 30791A Tray, Debris 1

11 30799A Hose, Drain 1

12 54774A Clamp, Hose 2

13 80410A Screw, 6MM x 1.00 x 35MM Lg Hex 3

14 87026A Washer, 1/4 Flat SS 3

15 9096638000 Plate Cover 3

16 9096672000 Filter 1

17 9096051000 Cover, Vac 1

18 9096491000 Panel, Acoustic Insulation 1

19 9096490000 Gasket, Vac 1

20 43401A Housing, Connector 2

21 41809A Contact, Housing Connector 4

22 9097367000 Motor, Vacuum 1

23 9096442000 Pipe, Acoustic Insulation 1

24 30823A Gasket, Vac Motor 1

25 80179A Screw, M6 x 15 2

26 52548A Tab, 1/4” Screw 2

27 920797 Nut, Drain Valve 1

28 71451A Label, Scrubtec BOOST 8 2

71447A Label, Scrubtec 866 2

71448A Label, Scrubtec 871 2

71450A Label, Scrubtec 886 2

71449A Label, Scrubtec 871C 2

29 30832A Hose, Squeegee 1

30 43402A Housing, Connector 2

31 80363A Screw, M5 x 12 BT 2

32 9096634000 Cable 2

33 82100A Locknut, 1/2” Conduit 1

34 9096643000 Plate 2

35 9096679000 Spacer 1

36 80057A Screw, M4-.7 x 10 4

37 53371A Clamp, Hose (“P” Trap) 2

38 60367A Plate, Retainer 2

ENGLISH

EN

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 33 -

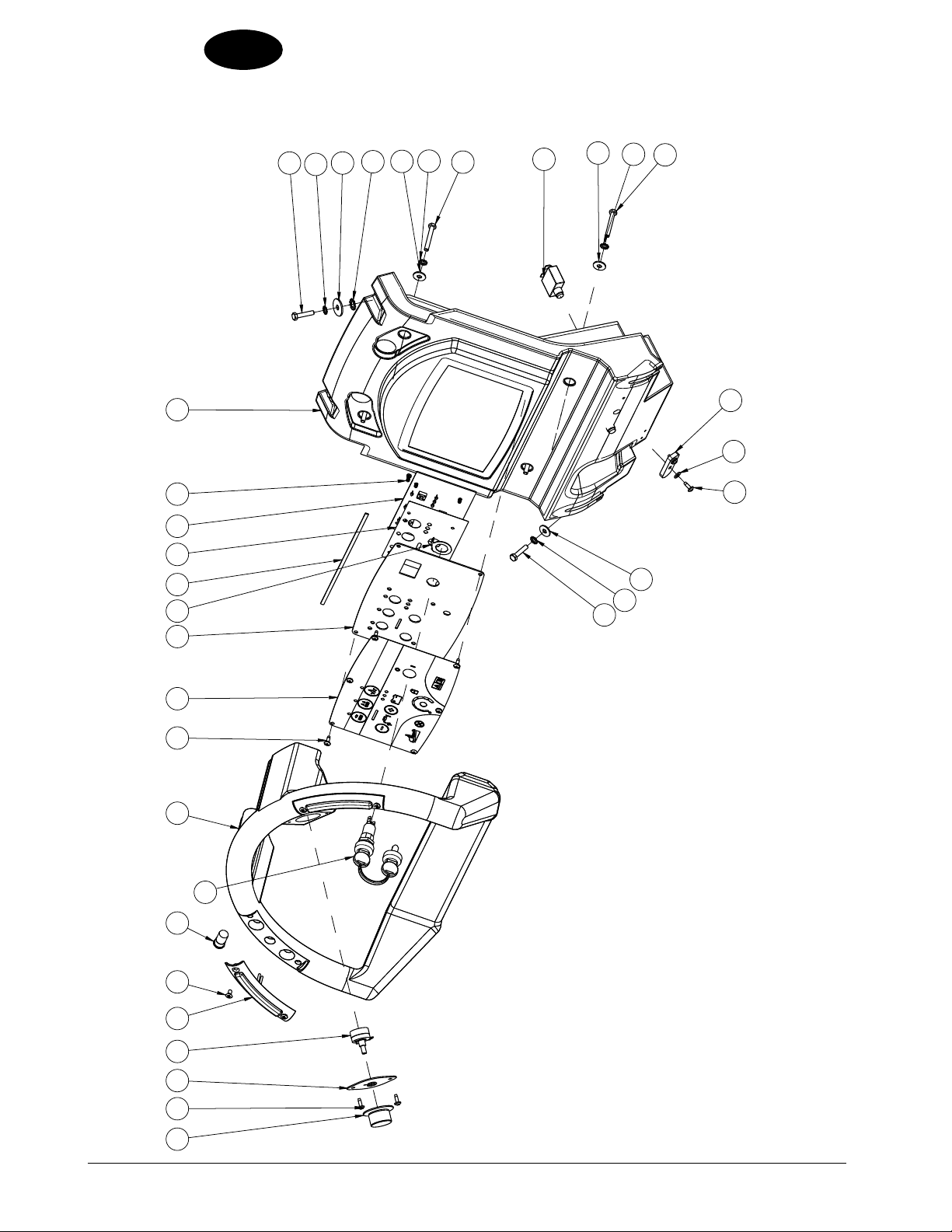

Page 34

ENGLISH

EN

16

Nilfi sk ALT O

Scrubtec 866, 871, 886 and BOOST 8

Handle Assembly Drawing 9/10

17

25

26

18

17

19

20

18

17

19

1510

14

13

23

24 12

11

2

9

21

22

2

18

17

16

8

7

56

2341

-34- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

revised 9/10

Page 35

Nilfi sk ALTO

Scrubtec 866, 871, 886 and BOOST 8

Handle Assembly Parts List 9/10

Ref # Part No. Description Qty

1 50962A Knob, Speed Control 1

2# 962957 Screw, 10-16 x 1/2 Self Tap 10

3 61922A Retainer, 5K Potentiometer 1

4 41078A Harness, Potentiometer Asm. 1

5 11131A Switch, Control Handle Asm. 2

6 80192A Screw, M5-0.8 x 10MM Oval Phil. 4

7 52556A Switch, Push Button 1

8 1462888000 Switch, Key 1

9 30785A Handle, Control 1

10 71425A Label, Control Panel 1

11 61929A Panel, Control 1

12 39886A Gasket, Console 9.50 1

13 41067A Board, Function 1

14 50267A Screw, 8-32 x .375 4

15 30784A Housing, Control 1

16 87902A Screw, 6MM x 1.00 x 30MM LG Hex 4

17 980614 Washer, 1/4” Starlock, External 8

18 87007A Washer Control Shaft 6

19 88628A Screw, 6MM x 1.00 x 45MM LG Hex 4

20 41431B Breaker, 35A Circuit 2

21 39888A Retainer, Drain Hose 1

22 980643 Washer, 7/16 OD x .036 THK 2

23 30831A Insulator, Mylar 1

24 61948A Washer, Tab Ground 1

25 980205 Washer, .31 I.D. x 1.06 O.D. 2

26 980666 Washer, 3/8 Starlock 2

NI 41063A Harness, Key Switch 1

ENGLISH

EN

# = Revised or new since last update

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 35 -

revised 9/10

Page 36

ENGLISH

EN

16

Nilfi sk ALT O

Scrubtec 871C

Handle Assembly Drawing 9/10

17

25

26

18

17

19

20

18

17

19

2

9

1510

14

13

23

24 12

11

21

22

2

18

17

16

8

7

56

2341

-36- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

revised 9/10

Page 37

Nilfi sk ALTO

Scrubtec 871 C

Handle Assembly Parts List 9/10

Ref # Part No. Description Qty

1 50962A Knob, Speed Control 1

2# 962957 Screw, 10-16 x 1/2 Self Tap 10

3 61922A Retainer, 5K Potentiometer 1

4 41078A Harness, Potentiometer Asm. 1

5 11131A Switch, Control Handle Asm. 2

6 80192A Screw, M5-0.8 x 10MM Oval Phil. 4

7 52556A Switch, Push Button 1

8 1462888000 Switch, Key 1

9 30785A Handle, Control 1

10 71484A Label, Control Panel Cyl. 1

11 61929A Panel, Control 1

12 39886A Gasket, Console 9.50 1

13 41067A Board, Function 1

14 50267A Screw, 8-32 x .375 4

15 30784A Housing, Control 1

16 87902A Screw, 6MM x 1.00 x 30MM LG Hex 4

17 980614 Washer, 1/4” Starlock, External 8

18 87007A Washer Control Shaft 6

19 88628A Screw, 6MM x 1.00 x 45MM LG Hex 4

20 41422B Breaker, 25A Circuit, Traverse 2

21 39888A Retainer, Drain Hose 1

22 980643 Washer, 7/16 OD x .036 THK 2

23 30831A Insulator, Mylar 1

24 61948A Washer, Tab Ground 1

25 980205 Washer, .31 I.D. x 1.06 O.D. 2

26 980666 Washer, 3/8 Starlock 2

NI 41063A Harness, Key Switch 1

ENGLISH

EN

# = Revised or new since last update

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 37 -

revised 9/10

Page 38

ENGLISH

EN

Nilfi sk ALT O

Scrubtec 866, 871, 886, BOOST 8, and 871C

Electrical Box Assembly Drawing 10/08

20

19

18

16

17

12

34 5

6

7

8

9

15

14

13

12

10

11

3

-38- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 39

Nilfi sk ALTO

Scrubtec 866, 871, 886, BOOST 8, and 871C

Electrical Box Assembly Drawing 12/08

Ref # Part No. Description Qty

1 80249A Screw, M5-.8 x 12MM Hex 3

2 980643 Washer, 7/16 OD x .036 THK 3

3 962027 Screw, 8-32 x 1/2 P.H. 3

4 61933A Plate, Electrical 1

5 41068B Controller, I-Drive 24V Traverse 1

6 80380A Screw, 8-32 x 1 1/4” P.H. 2

7 41810A Contactor, Brush 24V 1

8 980614 Washer, 1/4” Starlock External 2

9 85391A Screw, 1/4-20 x .625 Pan Hd. 2

10 Ref. Relay Holder

11 54764A Insert, Hex 1/4-20 UNC 2

12 41075A Relay 1

13 Ref. Fuse Holder

14 41073A Fuse, 30A (see WARNING below) 1

15 962979 Screw, 6-32 x 1/2 PN ST PH 2

16 920056 Nut, 6-32 E.S.N.A. Nylock 2

17 Ref. Fuse Holder

18 41074A Fuse, 60A (see WARNING below) 1

19 41069B Relay, i-Drive 24V Traverse 1

20 54763A Insert, Hex #8-32 UNC 7

NI 41065B Harness, Traverse 1

NI 41061A Harness, Machine 1

(included in 41061A Harness)

(included in 41061A Harness)

(included in 41061A Harness)

1

1

1

ENGLISH

EN

WARNING: To reduce the risk of fi re, when replacing

fuse, replace only with same type and rating

of fuse that comes with machine.

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 39 -

Page 40

ENGLISH

EN

Nilfi sk ALT O

Scrubtec 866, 871, 886, BOOST 8, and 871C

Squeegee Holder Assembly Drawing 12/08

10

26

25

24

23

22

30

28

27

1

3

2

4

29

5

6

7

8

9

10

11

12

13

14

15

9

9

17

17

13

18

19

21

20

-40- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

16

Page 41

Nilfi sk ALTO

Scrubtec 866, 871, 886, BOOST 8, and 871C

Squeegee Holder Assembly Parts List 12/08

Ref # Part No. Description Qty

1 52557A Knob, Lift 1

2 980666 Washer, 3/8 Starlock External 1

3 85389A Screw, 3/8-16 x 5/8 1

4 V17027 Joint, Ball 1

5 9097366000 Cable, Lift 1

6 9096537000 Spring, Squeegee Left 1

7 80199A Nut, M6-1.00 Nylock S.S. 1

8 925044 Pin, Cotter .094 x 1.00 2

9 80198A Nut, M8-1.25 Nylock S.S. 4

10 980651 Washer, 5/16 Flat 4

11 9096052000 Support, Spring 1

12 9096538000 Spring, Squeegee Right 1

13 87613A Washer, Flat .22 x .64 x .10 Nylon 2

14 61953A Plate, Squeegee Support 1

15 9096497000 Pin, Squeegee Mounting 1

16 80163A Nut, M8-1 Hex 1

17 38708A Spacer 2

18 80223A Nut, M10-1.5 Nylock 1

19 L08602422 Spacer 1

20 L08601509 Pin 1

21 54699A Knob, M8 x 55 1

22 9096045000 Bracket, Squeegee 1

23 964054 Screw, M6-1 x 25MM Hex 1

24 87007A Washer 2

25 1462258000 Spacer 1

26 9096495000 Screw, Socket Head 2

27 61952A Lever, Squeegee Lift 1

28 80179A Screw, M6 x 15 Pan 1

29 80171A Nut, M6 Hex 1

30 88640A Nut, M6-1 Acorn 1

ENGLISH

EN

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 41 -

Page 42

ENGLISH

EN

Nilfi sk ALT O

Scrubtec 866, 871, 886, BOOST 8, and 871C

Squeegee Assembly Drawing 10/08

18 19 20

13

1415

17

16

21

10 11 12

9

8

7

6

34 5

22

12

-42- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 43

Nilfi sk ALTO

Scrubtec 866, 871, 886, BOOST 8, and 871C

Squeegee Assembly Parts List 1/10

For Models with Squeegee Size 32.5”

Ref # Part No. Description Qty

1 83009A Rivet, Pop 5/32 Dia., .126-.187 G 2

2 9098321000 Latch Squeegee 1

3 9097356000 Support, Squeegee 1

4 9097357000 Strap, Wldmt., Squeegee 1

5 30816U Blade, 32.5” Rear Urethane 1

6 88629A Screw, M6-1 x 55MM Hex 2

7 9096505000 Wheel, Squeegee 2

8 87026A Washer, 1/4 Flat S.S. 2

9 80199A Nut, M6 x 1.00 Nylock S.S. 2

10 29927A Frame, 32.5” Squeegee 1

11 9098257000 Nut Thumb 2

12 9096682000 Washer, Rubber 2

13 962157 Screw, 5/16-18 x 1.25 Hex 2

14 54647A Knob, M8 x 30 1

15 88609A Screw, 5/16 x 3/8 x 5/8 SHSS 2

16 80317A Washer, Bowed .455 ID x 7.40 OD 2

17 30048A Guide, Wheel 2

18 30817U Blade, 32.5” Front Urethane 1

19 60465A Strap, Wldmt., Squeegee 1

20 88632A Screw, Set M8-1.25 x 30MM 1

21 60564A Shim, Screw 2

22 39717A Pad, Squeegee 1

ENGLISH

EN

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 43 -

revised 1/10

Page 44

ENGLISH

EN

Nilfi sk ALT O

Scrubtec 866, 871, 886, BOOST 8, and 871C

Squeegee Assembly Drawing 10/08

18 19 20

13

1415

17

16

21

10 11 12

9

8

7

6

34 5

22

12

-44- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 45

Nilfi sk ALTO

Scrubtec 866, 871, 886, BOOST 8, and 871C

Squeegee Assembly Parts List 1/10

For Models with Squeegee Size 35”

Ref # Part No. Description Qty

1 83009A Rivet, Pop 5/32 Dia., .126-.187 G 2

2 9098321000 Latch Squeegee 1

3 9097361000 Support, Squeegee 1

4 9097362000 Strap, Wldmt., Squeegee 1

5 30815U Blade, 35” Rear Urethane 1

6 88629A Screw, M6-1 x 55MM Hex 2

7 9096505000 Wheel, Squeegee 2

8 87026A Washer, 1/4 Flat S.S. 2

9 80199A Nut, M6 x 1.00 Nylock S.S. 2

10 29928A Frame, 35” Squeegee 1

11 9098257000 Nut Thumb 2

12 9096682000 Washer, Rubber 2

13 962157 Screw, 5/16-18 x 1.25 Hex 2

14 54647A Knob, M8 x 30 1

15 88609A Screw, 5/16 x 3/8 x 5/8 SHSS 2

16 80317A Washer, Bowed .455 ID x 7.40 OD 2

17 30048A Guide, Wheel 2

18 30818U Blade, 35” Front Urethane 1

19 60466A Strap, Wldmt., Squeegee 1

20 88632A Screw, Set M8-1.25 x 30MM 1

21 60564A Shim, Screw 2

22 39717A Pad, Squeegee 1

ENGLISH

EN

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 45 -

revised 1/10

Page 46

ENGLISH

EN

Nilfi sk ALT O

Scrubtec 866, 871, 886, BOOST 8, and 871C

Squeegee Assembly Drawing 10/08

18 19 20

13

1415

17

16

21

10 11 12

9

8

7

6

34 5

22

12

-46- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 47

Nilfi sk ALTO

Scrubtec 866, 871, 886, BOOST 8, and 871C

Squeegee Assembly Parts List

For Models with Squeegee Size 41”

Ref # Part No. Description Qty

1 83009A Rivet, Pop 5/32 Dia., .126-.187 G 2

2 9098321000 Latch Squeegee 1

3 9097375000 Support, Squeegee 1

4 9097376000 Support, Squeegee 1

5 30814U Blade-Squeegee 42in 1

6 88629A Screw, M6-1 x 55MM Hex 2

7 9096505000 Wheel, Squeegee 2

8 87026A Washer, 1/4 Flat S.S. 2

9 80199A Nut, M6 x 1.00 Nylock S.S. 2

10 29929A Frame, 42” Squeegee 1

11 9098257000 Nut Thumb 2

12 9096682000 Washer, Rubber 2

13 962157 Screw, 5/16-18 x 1.25 Hex 2

14 54647A Knob, M8 x 30 1

15 88609A Screw, 5/16 x 3/8 x 5/8 SHSS 2

16 80317A Washer, Bowed .455 ID x 7.40 OD 2

17 30048A Guide, Wheel 2

18 30819U Blade, 42” Front Urethane 1

19 60546A Strap, Wldmt., Squeegee 1

20 88632A Screw, Set M8-1.25 x 30MM 1

21 60564A Shim, Screw 2

22 39717A Pad, Squeegee 1

ENGLISH

EN

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 47 -

revised 6/10

Page 48

ENGLISH

EN

Nilfi sk ALT O

Scrubtec 866, 871, 886, BOOST 8, and 871C

Frame Assembly

-48- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

revised 6/10

Page 49

Nilfi sk ALTO

Scrubtec 866, 871, 886, BOOST 8, and 871C

Frame Assembly Parts List 9/10

ENGLISH

EN

Ref # Part No. Description Qty

1 88633A Screw, M8 x 85 Hex Head 2

2 170860 Washer, Flat 5/16 4

3 61937A Spacer, .590 OD x .328 ID 2

4 88620A Screw, M12 x 90M Hex 1

5 9097456000 Lever 1

6 88635A Screw, M8 x 75 Hex Head 1

7 9096112000 Spacer 2

8 9097402000 Actuator (for all models except BOOST) 1

40280A Actuator (for BOOST 28/32 models only) 1

9 80198A Nut, M8-1.25 Nylock S.S. 3

10 88618A Nut, M12 Nylon Insert 1

11 88626A Screw, M6-1 x 40MM Hex 1

12 87026A Washer, 1/4 Flat S.S. 6

13 1462258000 Spacer 2

14 80199A Nut, M6-1.00 Nylock S.S. 8

15 9097368000 Support, Jack Motor 1

16 88616A Screw, M10 x 75M Hex 1

17 87054A Washer Fender .375 5

18 80214A Screw, M6 x 1 x 12 2

19 59789A Valve, Solution 1

20 30828A Hose, Clear x 25.00 Long 1

21 88624A Screw, M5 x 12MM Hex Self Tap 4

22 61932A Bracket, Solution Valve 1

23 88623A Nut, M4-.7 Nylock Insert 2

24 9097370000 Bracket, Filter 1

25 9097404000 Filter, Water 1

26 722030 Clamp, Hose 4

27 80057A Screw, M4-.7 x 10 2

28 30829A Hose, Clear x 3.00 Long 1

29 57994A Screw, M6-1 x 20 9

Ref # Part No. Description Qty

30 980614 Washer, 1/4” Starlock External 3

31 980205 Washer, .31 ID x 1.06 OD 2

32 69639A Strap, Static 1

33 88612A Washer, Lock M10 10

34 88614A Screw, M10-1.5 x 20MM 6

35 61949A Bracket, Ground Strap 1

36 41081A Cord, Charger NEMA NOTE 1 1

37# 56380160 Transaxle TSBCL2010-25, TSBCL2009-02 1

[ ] 40628A Carbon Brushes, Transaxle (Set) 1

40 88611A Washer, Flat M10 6

41 88613A Screw, M10-1.5 x 16MM Hex 4

42 9095202000 Caster, Rear 1

43 80196A Nut, M5-.8 Nylock SS 4

44 61934A Bracket, Brake 1

45 54772A Clamp, Toggle Straight Line 1

46 80249A Screw, M5-.8 x 12MM Hex 4

47 920160 Nut, 5/16 Jam Hex 1

48 962157 Screw, 5/16-18 x 1.25 Hex Hd 1

49 60580A Wheel, 10” Foam Filled 2

50 980652 Washer, 5/16 Lock 8

51 80183A Bolt, M8-1.25 x 20, Hex 8

52 980657 Washer, Lock 1/4 4

53

# 41077A Charger, Battery NOTE 1 TSBCL2009-04 1

54 61931A Chassis, Wldmt 1

55 80223A Nut, M10-1.5 Nylock 1

56 9096113000 Spacer 2

57 54689A Gas Spring 500N 1

58 71017A Label, Moving Parts 1

[ ] 41062A Harness Chrg Jumper NOTE 2 1

[ ] 40512B Charger Battery 25 Amp NOTE 2 1

[ ] 40297A Cable Charger Adapter1 NOTE 2 1

# = Revised or new since last update

[ ] = Not Shown

#NOTE 1: Only used on models with on-board charger.

#NOTE 2: Only used on models without on-board charger.

Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C FORM NO. 71492A - 49 -

revised 9/10

Page 50

ENGLISH

EN

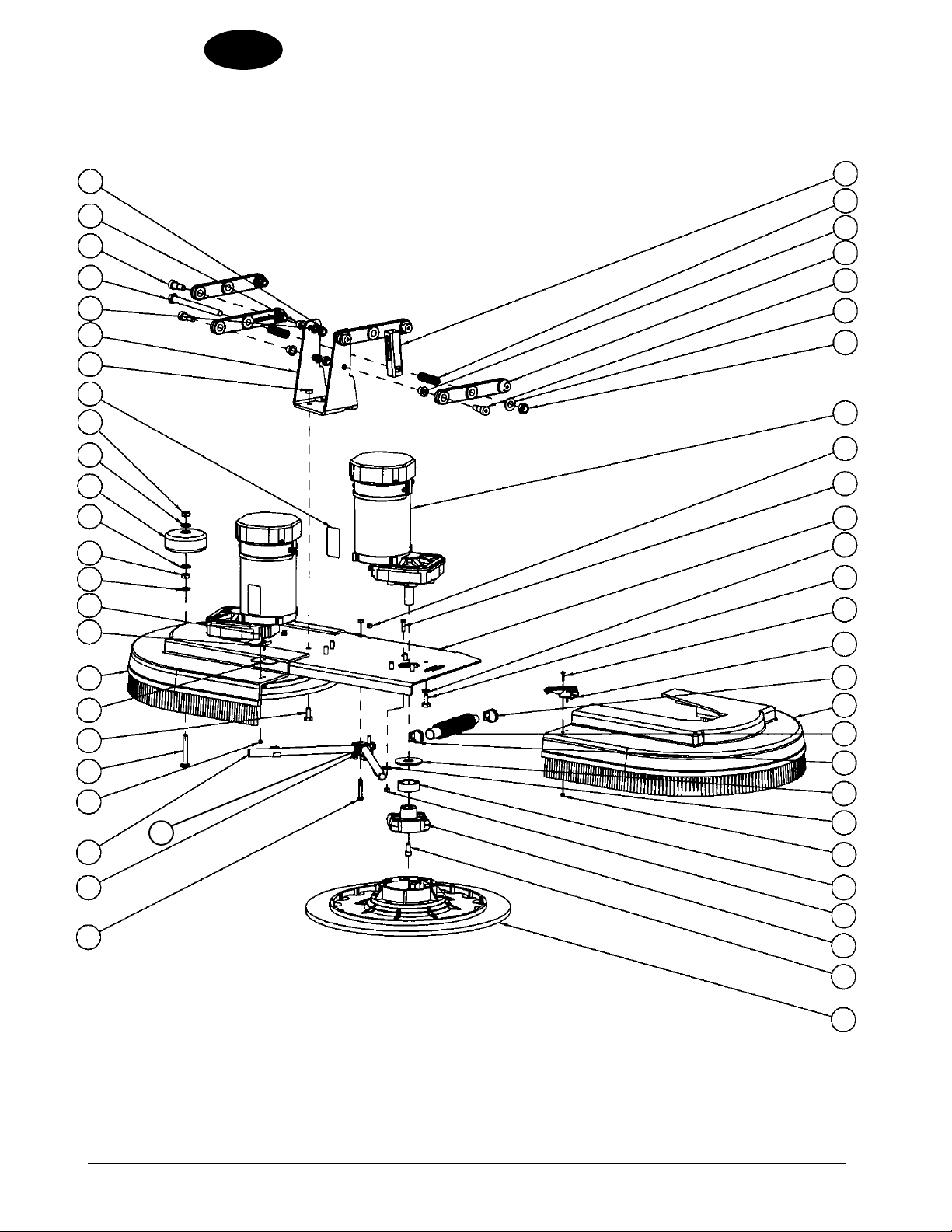

Nilfi sk ALT O

Scrubtec 866

Brush Head Assembly Drawing 12/08

41

40

39

38

37

34

35

36

35

34

12

42

14

33

1

3

5

2

3

4

5

6

7

8

9

10

11

12

13

14

15

31

32

30

28

29

44

27

26

16

17

18

43

19

21

20

22

9

23

24

25

-50- FORM NO. 71492A Nilfi sk ALTO Operator’s Manual (EN) - SCRUBTEC 866, 871, 866, Boost 8 and 871C

Page 51

Nilfi sk ALTO

Scrubtec 866

Brush Head Assembly Parts List 1/10

Ref # Part No. Description Qty

1 56109717 Tube Jack Motor 1

2 E04016 Spring 2

3 88647A Bushing, Flanged 8

4 9097197000 Lever, Bushing Head Lift 4

5 88617A Screw, M10 x M12 x 16MM SBSH 8

6 980648 Washer, 17/32 x 1 1/16 Plain 1

7 88618A Nut, M12 Nylon Insert 1

8 44809B Motor, Brush 2

NI 40826A Carbon Brushes, Motor (set) 1

9 80199A Nut, M6-1.00 Nylock SS 4

10 57994A Screw, M6-1 x 20 2

11 61925A Plate, 26” Brush Wldmt 1

12 980638 Washer, 3/8 Lock 9

13 962244 Screw, 3/8-16 x .75 Hex 8

14 964002 Screw, M4-.7 x 16MM PH 4

15 55721A Latch 1

16 722030 Clamp, Hose 1

17 30661A Brush Housing L.H. 1

18 30412A Hose, Solution 1

19 59856A Washer, Rubber 2

20 88623A Nut, M4-.7 Nylock Insert 4

21 782002 Clamp, Manifold 2

22 61658A Collar, Brush Driver 2

23 34400B Gimbal, Motor 2

24 962714 Screw, Gimbal Mount 2

25 38035A Driver, Pad 13” Gimbal 2

26 88627A Screw, M6-1 x 40MM PH 2

27 38014A Splitter, Solution 1

28 34705A Hose, Solution 6.00” Lg. 2

29 85610A Screw, 3/8-16 x 2.5” PH 1