Page 1

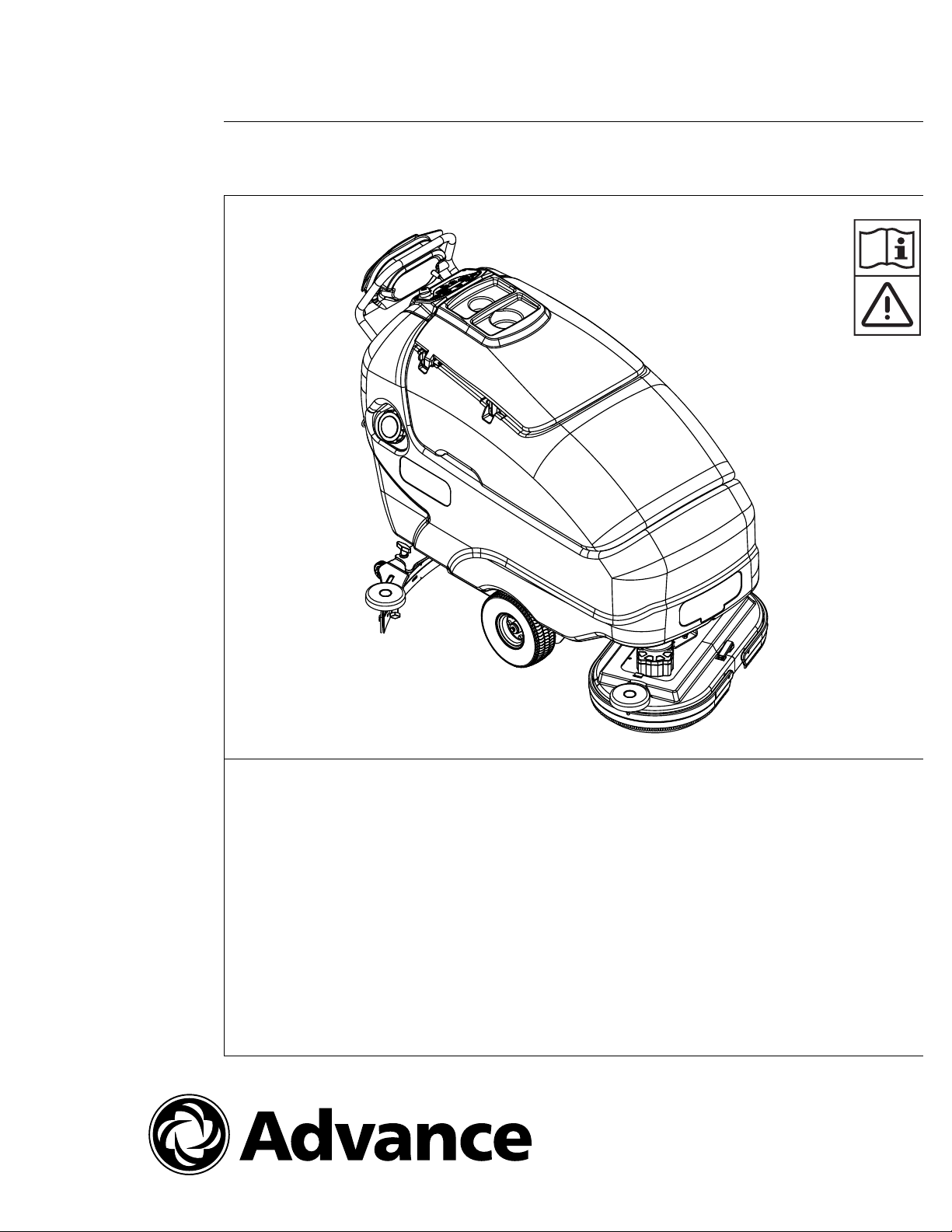

SC750, SC800

SC750 ST, SC800 ST

Instructions for Use - Original Instructions / Instrucciones de uso

Manual de Utilização / Mode d‘ emploi

Advance Models: 56112000(SC750-26D), 56112004(SC750-28D)

56112006(SC750-28C), 56112012(SC750 ST-26D)

56112013(SC750 ST-28C), 56112016(SC800-28D)

56112018(SC800-28C), 56112024(SC800-32C)

56112028(SC800-34D), 56112032(SC800 ST-34D)

56112780(SC750-28R)

A-English

B-Español

C-Português

D-Français

7/10 revised 11/12 Form No. 56041820

Page 2

A-2 / ENGLISH

TABLE OF CONTENTS

Page

Introduction ..............................................................................A-3

Parts and Service ....................................................................A-3

Nameplate ...............................................................................A-3

Unpacking the Machine ...........................................................A-3

Cautions and Warnings ..................................................A-4 - A-5

Know Your Machine ....................................................... A-6 – A-7

Control Panel – SC750, SC800 ...............................................A-8

Control Panel – SC750 ST, SC800 ST ....................................A-9

Preparing the Machine for Use

Batteries ................................................................................A-10

Installing the Brushes and Pads ..................... A-11 – A-12 – A-13

Filling the Solution Tank .........................................................A-15

Squeegee Installation ............................................................A-15

Detergent System (EcoFlex™) .................................. A-16 – A-17

Operating the Machine

Wet Scrubbing ........................................................... A-18 – A-19

Wet Vacuuming .....................................................................A-19

After Using the Machine ........................................................A-20

Maintenance Schedule ..........................................................A-20

Servicing the Vacuum Motor ..................................................A-20

Lubricating the Machine ........................................................A-20

Maintenance

Charging the Batteries (Wet) .................................................A-21

Charging the Batteries (Gel) ..................................................A-21

Servicing the Squeegee ........................................................A-22

Adjusting the Squeegee ........................................................A-22

Troubleshooting .....................................................................A-23

Technical Specifi cations ........................................................A-24

Material Composition .............................................................A-24

A-2 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 3

ENGLISH / A-3

INTRODUCTION

This manual will help you get the most from your Advance™ automatic scrubber/dryer. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages 6-9 unless otherwise noted.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Advance Service Center, who employs factory trained service personnel, and

maintains an inventory of Advance original replacement parts and accessories.

Call Advance for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

MODIFICATIONS

Modifi cations and additions to the cleaning machine which affect capacity and safe operation shall not be performed by the customer or user

without prior written approval from Nilfi sk-Advance Inc. Unapproved modifi cations will void the machine warranty and make the customer liable for

any resulting accidents.

NAMEPLATE

The Model and Serial Number of your machine are shown on the Nameplate in the battery compartment. This information is needed when

ordering repair parts for the machine. Use the space below to note the Model and Serial Number of your machine for future reference.

Model _________________________________________

Serial Number ___________________________________

UNPACKING THE MACHINE

When the machine is delivered, carefully inspect the shipping packaging and the machine for damage. If damage is evident, save the shipping

carton (if applicable) so that it can be inspected. Contact the Advance Customer Service Department immediately to fi le a freight damage claim.

Refer to the unpacking instruction sheet included with the machine to remove the machine from the pallet.

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of California, as

identifi ed in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In certain locations (including

the State of California) purchasers of these Products that place them in service at an employment job site or a publicly accessible space are

required by regulation to make certain notices, warnings or disclosures regarding the chemicals that are or may be contained in the Products at

or about such work sites. It is the purchaser’s responsibility to know the content of, and to comply with, any laws and regulations relating to the

use of these Products in such environments. The Manufacturer disclaims any responsibility to advise purchasers of any specifi c requirements that

may be applicable to the use of the Products in such environments.

revised 7/11

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-3

Page 4

A-4 / ENGLISH

CAUTIONS AND WARNINGS

SYMBOLS

Advance uses the symbols below to signal potentially dangerous conditions. Read this information carefully and take the necessary

steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

This machine is for commercial use, for example in hotels, schools, hospitals, factories, shops and offi ces other than normal

residential housekeeping purposes.

WARNING!

* This machine should only be used by properly trained and authorized persons.

* This machine is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge.

* While on ramps or inclines, avoid sudden stops. Avoid abrupt sharp turns. Use low speed down ramps.

* Observe the Gross Vehicle Weight, GVW, of the machine when loading, driving, lifting or supporting the machine.

* Keep sparks, fl ame and smoking materials away from batteries. Explosive gases are vented during normal operation.

* Charging the batteries produces highly explosive hydrogen gas. Charge batteries only in well-ventilated areas, away from open

fl ame. Do not smoke while charging the batteries.

* Remove all jewelry when working near electrical components.

* Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

* Never work under a machine without safety blocks or stands to support the machine.

* Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where fl ammable

liquids exist.

* Do not clean this machine with a pressure washer.

* Do not operate this machine on ramps or inclines of more than a 2 percent gradient.

* Only use the brushes provided with the appliance or those specifi ed in the instruction manual. The use of other brushes may

impair safety.

* Do not stare into laser. Class 1 Laser Product IEC 60825-1, 2007 AND 21CFR1040.10

A-4 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

revised 11/12

Page 5

ENGLISH / A-5

CAUTION!

* This machine is not approved for use on public paths or roads.

* This machine is not suitable for picking up hazardous dust.

* Use care when using scarifi er discs and grinding stones. Advance will not be held responsible for any damage to fl oor surfaces

caused by scarifi ers or grinding stones.

* When operating this machine, ensure that third parties, particularly children, are not endangered.

* Before performing any service function, carefully read all instructions pertaining to that function.

* Do not leave the machine unattended without fi rst turning the key switch off (O), removing the key and securing the machine.

* Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

* Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

* Use caution when moving this machine in below freezing temperature conditions. Any water in the solution, recovery or

detergent tanks or in the hose lines could freeze, causing damage to valves and fi ttings. Flush with windshield washer fl uid.

* The batteries must be removed from the machine before the machine is scrapped. The disposal of the batteries should be

safely done in accordance with your local environmental regulations.

* Do not use on surfaces having a gradient exceeding that marked on the machine.

* All doors and covers are to be positioned as indicated in the instruction manual before using the machine.

* Refer to the battery charger OEM product manual for additional specifi c battery charger warnings.

* Any use or adjustments of the Laser other than those specifi ed herein may result in hazardous radiation exposure.

SAVE THESE INSTRUCTIONS

revised 11/12

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-5

Page 6

A-6 / ENGLISH

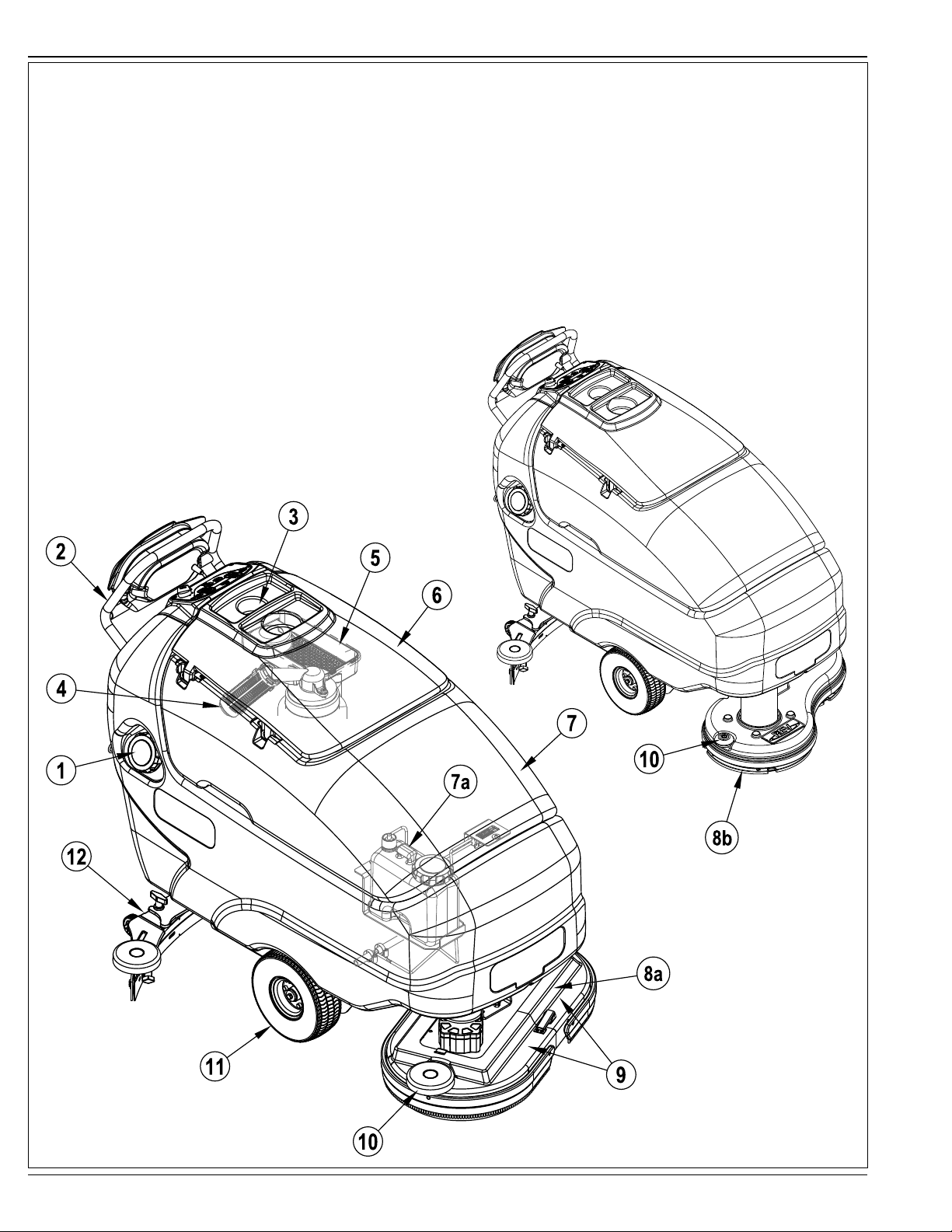

KNOW YOUR MACHINE

As you read this manual, you will occasionally run across a bold number or letter in parentheses - example: (2). These numbers refer to an item

shown on these pages unless otherwise noted. Refer back to these pages whenever necessary to pinpoint the location of an item mentioned in

the text. NOTE: Refer to the service manual for detailed explanations of each item illustrated on the next 4 pages.

1 Solution Tank Fill

2 Operator Control Handle

3 Bottle Holders

4 Recovery Tank Shutoff Float

5 Debris Tray

6 Recovery Tank Lid

7 Recovery Tank (Detergent Cartridge Access Cover)

7a Detergent Cartridge (EcoFlex models only)

8a Scrub Deck (Disc models)

8b Scrub Deck (REV model)

9 Brush Housings (include Bristle Skirt)

10 Scrub Deck Bumper Wheel

11 Drive Wheel

12 Squeegee Assembly

A-6 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 7

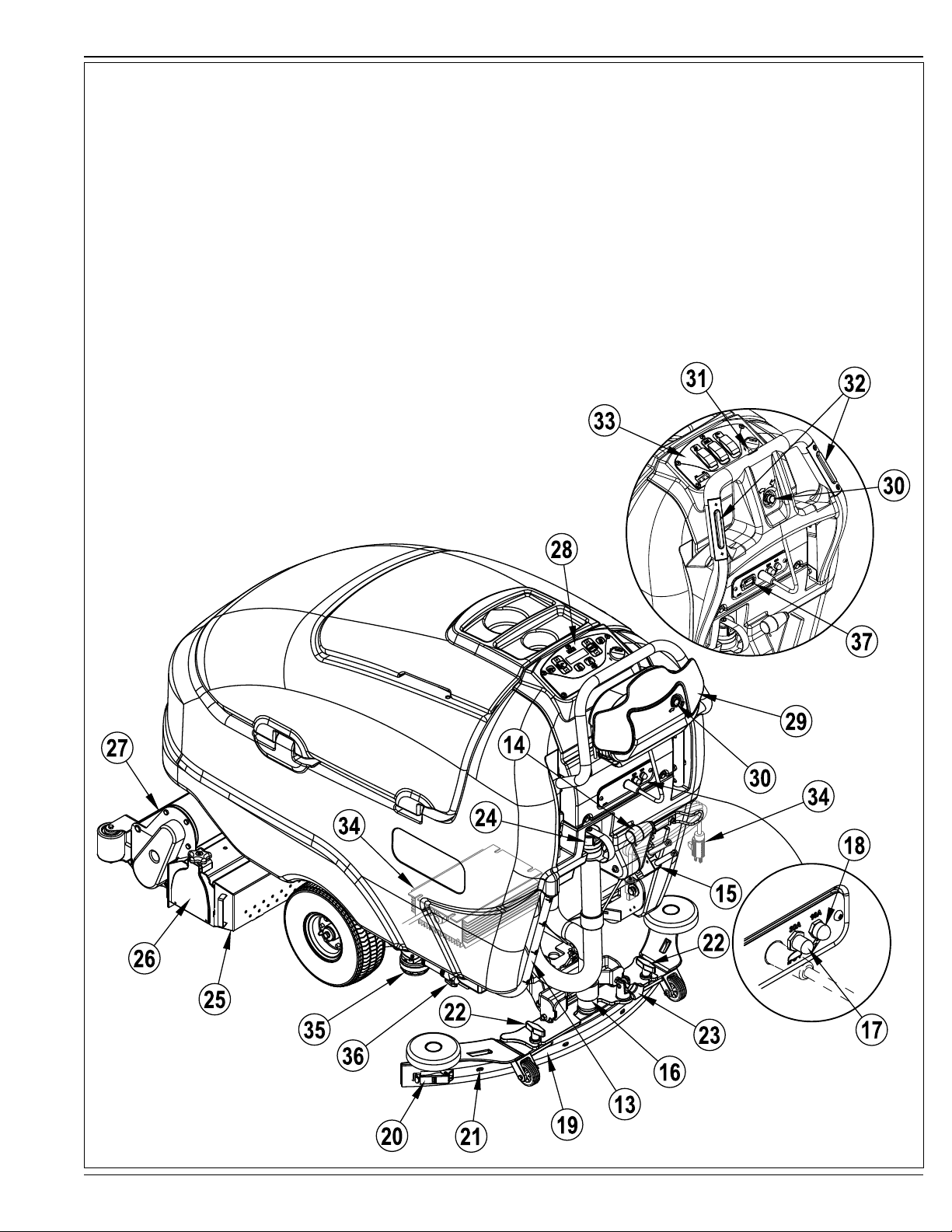

KNOW YOUR MACHINE

ENGLISH / A-7

13 Solution Drain Hose / Level Indicator

14 Squeegee Raise / Lower Lever

15 Battery Pack Connector

16 Recovery Hose

17 Wheel Drive Circuit Breaker (30 Amp)

18 Control Circuit Circuit Breaker (10 Amp)

19 Squeegee Blade Tension Strap

20 Squeegee Blade Latch

21 Squeegee Blade Alignment Pins

22 Squeegee Mount Thumb Nut

23 Squeegee Adjustment Knob

24 Recovery Tank Drain Hose

25 Debris Hopper (Cylindrical Models Only)

26 Idler Assembly (Cylindrical Models Only)

27 Solution Manifold (Cylindrical Models Only)

28 Control Panel (SC750, SC800)

29 Drive Paddle

30 Speed Limit Control Knob

31 Reverse Button (SC750 ST, SC800 ST)

32 Palm Drive Buttons (SC750 ST, SC800 ST)

33 Control Panel (SC750 ST, SC800 ST)

34 Onboard Battery Charger (Not found on all models)

35 Solution Filter

36 Solution Shut-off Valve

37 Hour Meter (Optional on ST Models)

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-7

Page 8

A-8 / ENGLISH

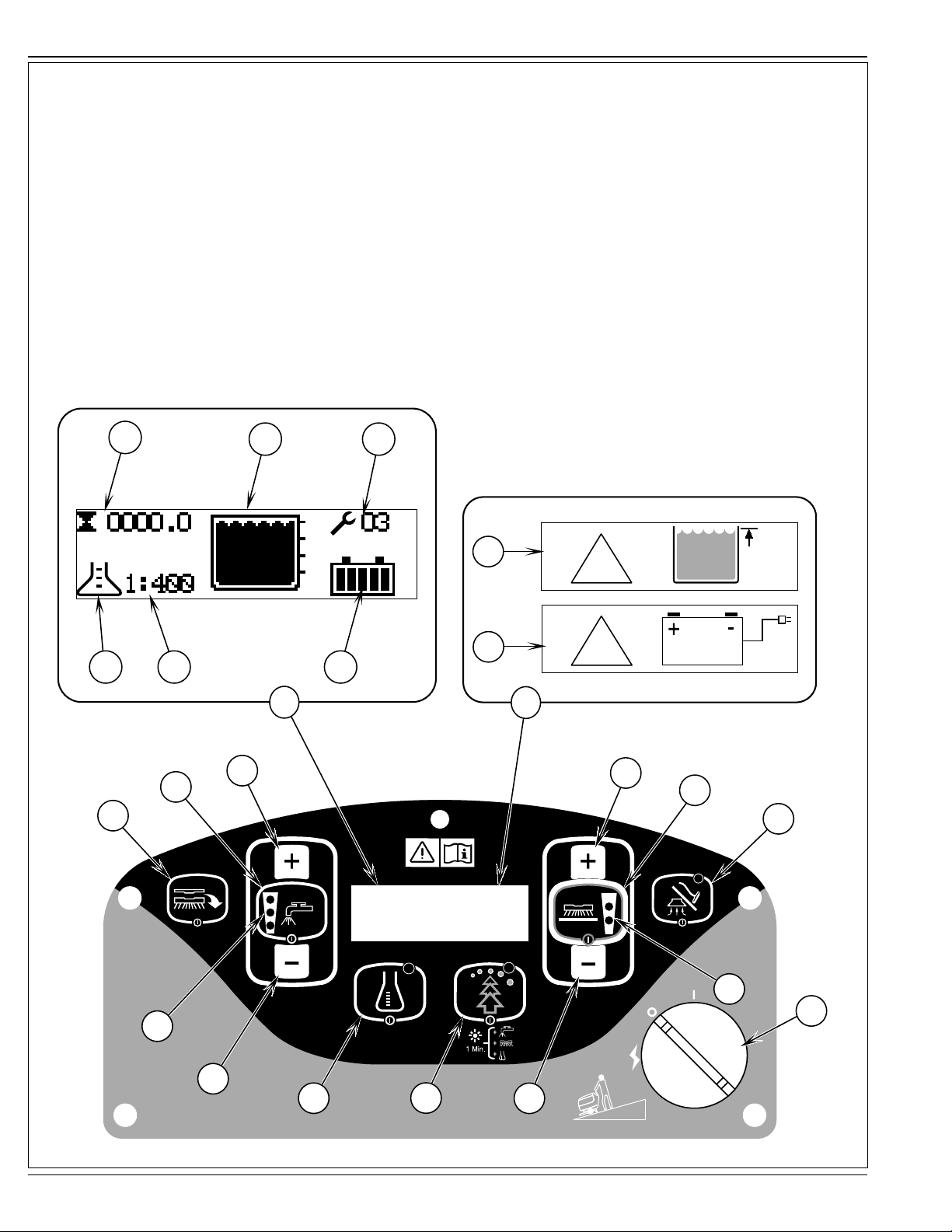

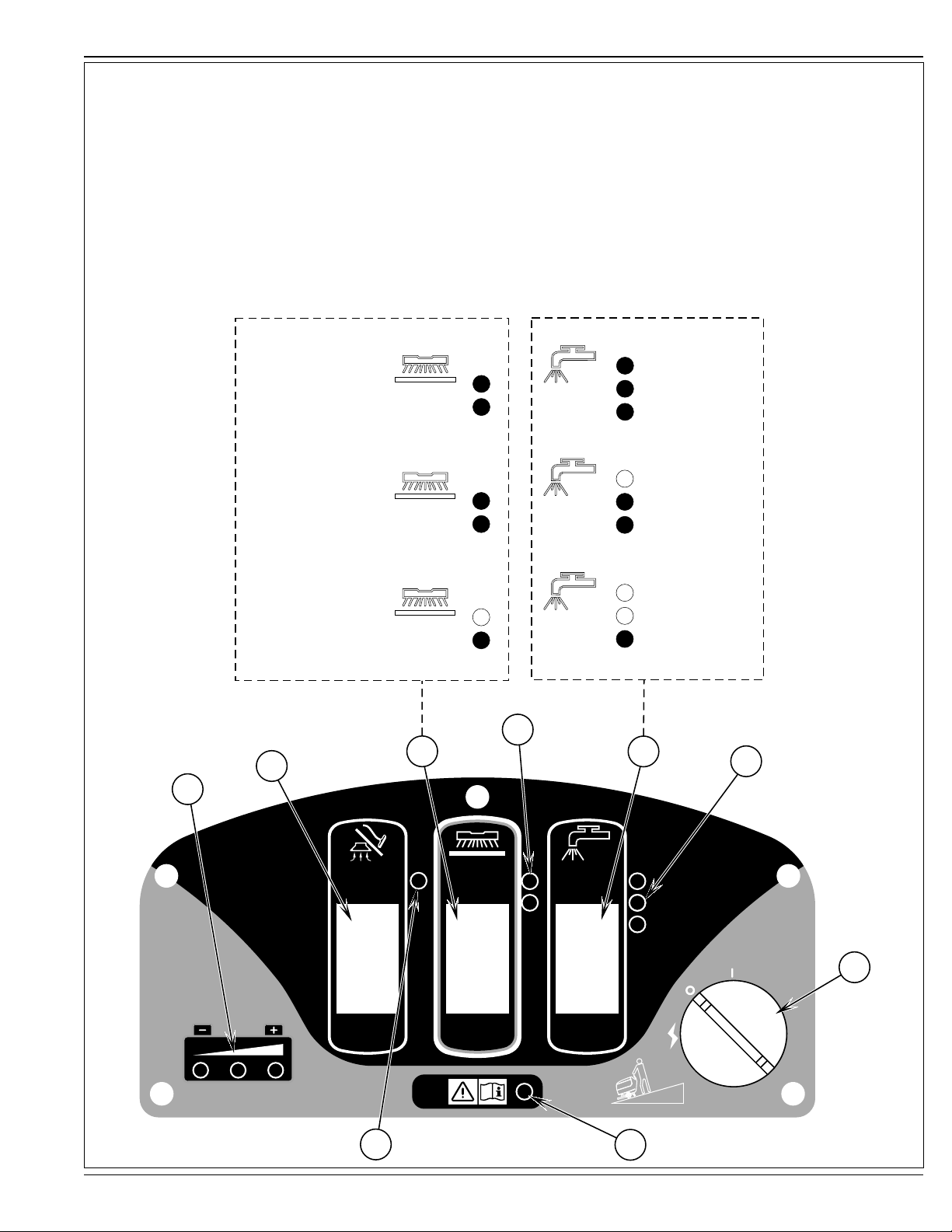

CONTROL PANEL – SC750, SC800

A Key Switch (Main Power)

B Solution Increase Switch

C Solution ON/OFF Switch

C1 Solution Flow Indicators (Normal, Heavy & Extreme)

D Solution Decrease Switch

E Detergent ON/OFF Switch

F Display Panel

F1 Hour Meter

F2 Solution Tank Level Indicator

F3 Fault Codes

F4 Detergent Indicator (if so equipped)

F5 Detergent Ratio Indicator

F6 Battery Indicator

F7 Recovery Tank FULL Indicator

F8 Battery Low Indicator

F1

F2 F3

G Scrub Pressure Increase Switch

H Scrub ON/OFF Switch

(Disc System - Regular & Heavy)

(Cylindrical System - 1 Pressure Sensing)

H1 Scrub Pressure Indicator

I Scrub Pressure Decrease Switch

J EcoFlex Switch

K Brush Remove Switch (Disc Decks Only)

(Brush Remove Switch is disabled on REV model)

L Vacuum/Wand Switch

F7

!

F4 F5 F6

F

B

C

K

C1

D

E

F8

!

F

G

H

L

H1

A

J

I

max.2%

A-8 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 9

CONTROL PANEL – SC750 ST, SC800 ST

A Key Switch (Main Power)

B Solution ON/OFF Switch (Low, Medium & High)

B1 Solution Flow Indicator

C Vacuum/Wand Switch

C1 Vacuum Motor Disabled Indicator

D Scrub ON/OFF Switch

(Disc System - Regular & Heavy)

(Cylindrical System - 1 Pressure Sensing)

D1 Scrub Pressure Indicator

E Battery Indicator

F Fault Code Indicator

ENGLISH / A-9

Cylindrical Scrub

Pressure

(press once)

Heavy Disc Scrub

Pressure

(press twice)

Regular Disc Scrub

Pressure

(press once)

High

Solution

Flow

(press three times)

Medium

Solution

Flow

(press twice)

Low

Solution

Flow

(press once)

D1

C

D

B

B1

E

C1

A

x.2%

ma

F

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-9

Page 10

A-10 / ENGLISH

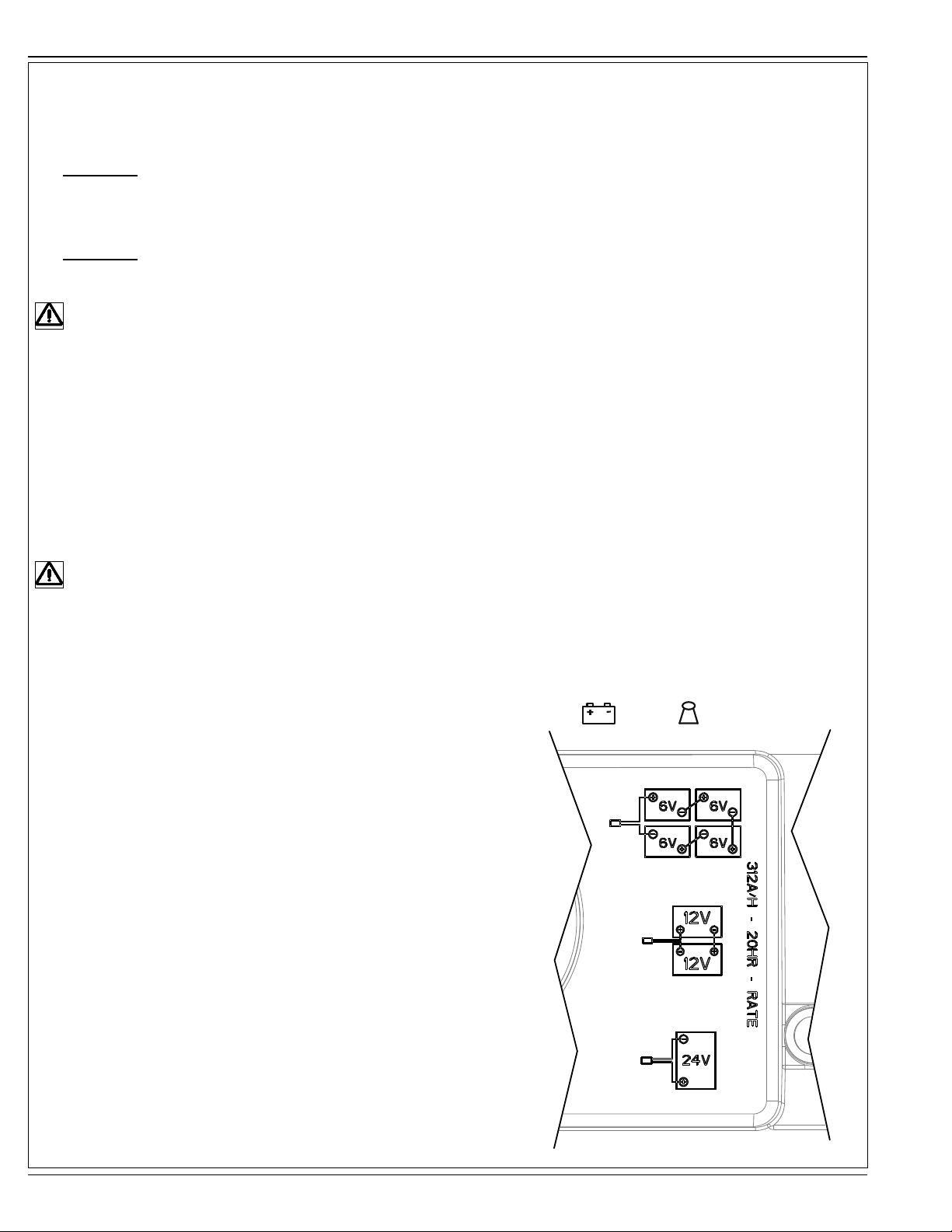

BATTERIES

If your machine shipped with batteries installed do the following:

Check that the batteries are connected to the machine (15).

Turn ON the Key Switch (A) and check the Battery Indicator (F6 or E). If the gauge is completely fi lled or the green light is ON, the batteries are ready for

use. If the gauge is less than full or the green light is OFF, the batteries should be charged before use. See the “Charging The Batteries” section.

IMPORTANT!: IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE OEM PRODUCT MANUAL FOR INSTRUCTIONS

REGARDING SETTING THE CHARGER FOR BATTERY TYPE.

If your machine shipped without batteries installed do the following:

Consult your Authorized Advance dealer for recommended batteries.

Install the batteries by following the instructions below.

IMPORTANT!: IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE OEM PRODUCT MANUAL FOR INSTRUCTIONS

REGARDING SETTING THE CHARGER FOR BATTERY TYPE.

WARNING!

Use extreme caution when working with batteries. Sulfuric acid in batteries can cause severe injury if allowed to contact the skin

or eyes. Explosive hydrogen gas is vented from the batteries through openings in the battery caps. This gas can be ignited by

any electrical arc, spark or fl ame. Do not install any lead-acid battery in a sealed container or enclosure. Hydrogen gas from

overcharging must be allowed to escape.

When Servicing Batteries...

• Remove all jewelry

• Do not smoke

• Wear safety glasses, rubber gloves and a rubber apron

• Work in a well-ventilated area

• Do not allow tools to touch more than one battery terminal at a time

• ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

• ALWAYS connect the negative cable last when installing batteries.

CAUTION!

Electrical components in this machine can be severely damaged if the

batteries are not installed and connected properly. Advance, a qualifi ed

electrician, or the battery manufacturer should install batteries.

1 Remove the batteries from their shipping crate and carefully inspect them for cracks or

other damage. If damage is evident, contact the carrier that delivered them or the battery

manufacturer to fi le a damage claim.

2 Turn the Master Key Switch (A) OFF and remove the key.

3 Disconnect the Battery Pack Connector (15)

4 Tip the recovery tank to the side, locked position. Remove the battery cables from inside

the battery compartment.

5 Your machine comes from the factory with enough battery cables to install four 6 volt

batteries. Carefully lift the batteries into the battery compartment and arrange them

exactly as shown in FIGURE 1. Secure the batteries as close to the back of the machine

as possible.

6 Install the battery cables as shown. Position the cables so the battery caps can be easily

removed for battery service.

7 Carefully tighten the nut in each battery terminal until the terminal will not turn. Do not

over-tighten the terminals, or they will be very diffi cult to remove for future service.

8 Coat the terminals with spray-on battery terminal coating (available at most auto parts

stores).

9 Put one of the black rubber boots over each of the terminals and connect the Battery

Pack Connector (15).

When changing batteries or the charger, please contact your local authorized

service center for correct battery, charger and machine settings to prevent

battery damage.

FIGURE 1

312 AH @ 20 HR RATE

(4) MAX 158KG/348LB

A-10 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

revised 11/12

Page 11

ENGLISH / A-11

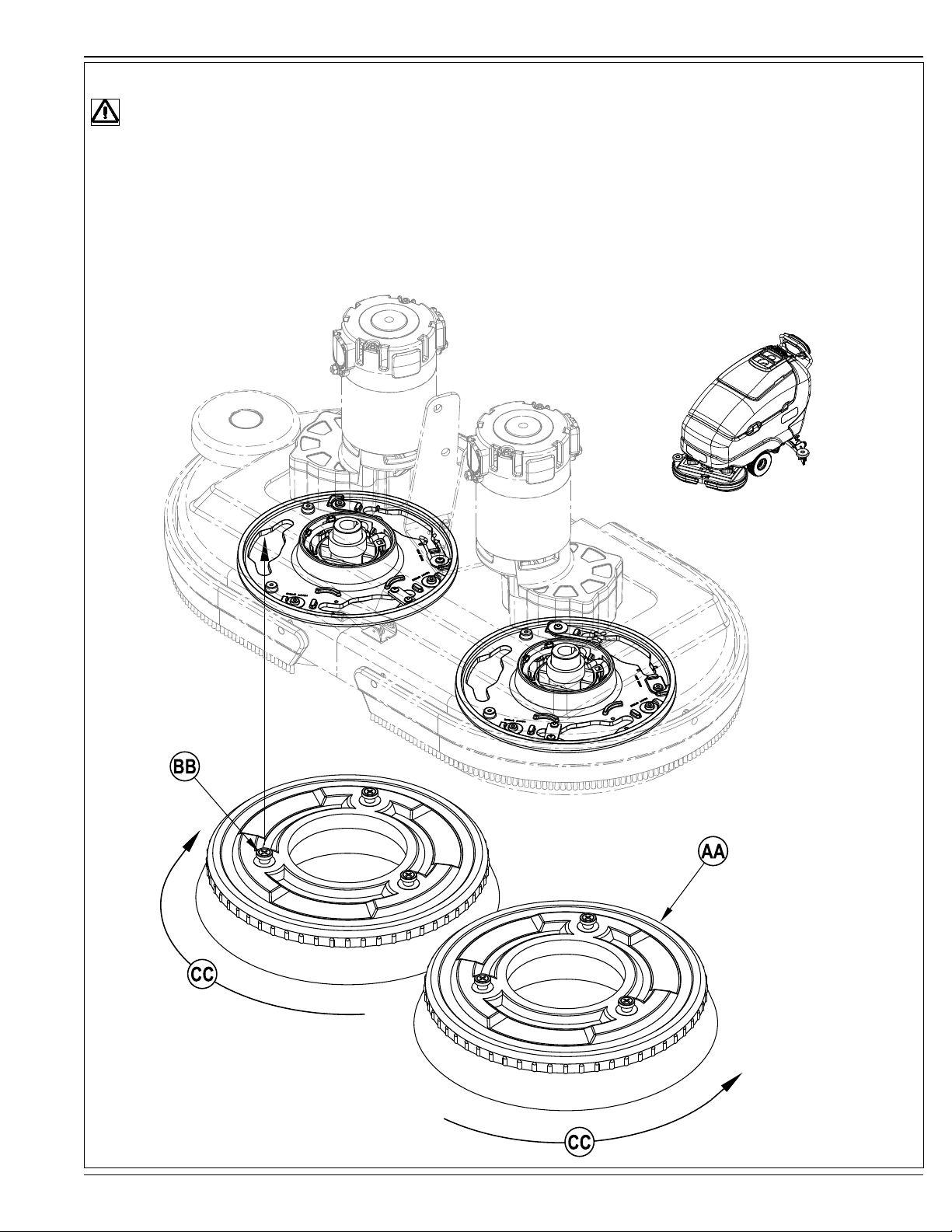

INSTALLING THE BRUSHES (DISC SYSTEM)

CAUTION!

Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

1 Make sure the Scrub Deck (8a) is in the RAISED position. Make sure the Key Switch (A) is off (O).

2 If using pads, install the pads on the pad holders.

3 See Figure 2. To mount the Brushes (AA) (or pad holders) align the Lugs (BB) on the brush with the holes on the mounting plate and turn to

lock in place (turn the outside edge of brush towards the rear of machine as shown (CC)).

FIGURE 2

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-11

Page 12

A-12 / ENGLISH

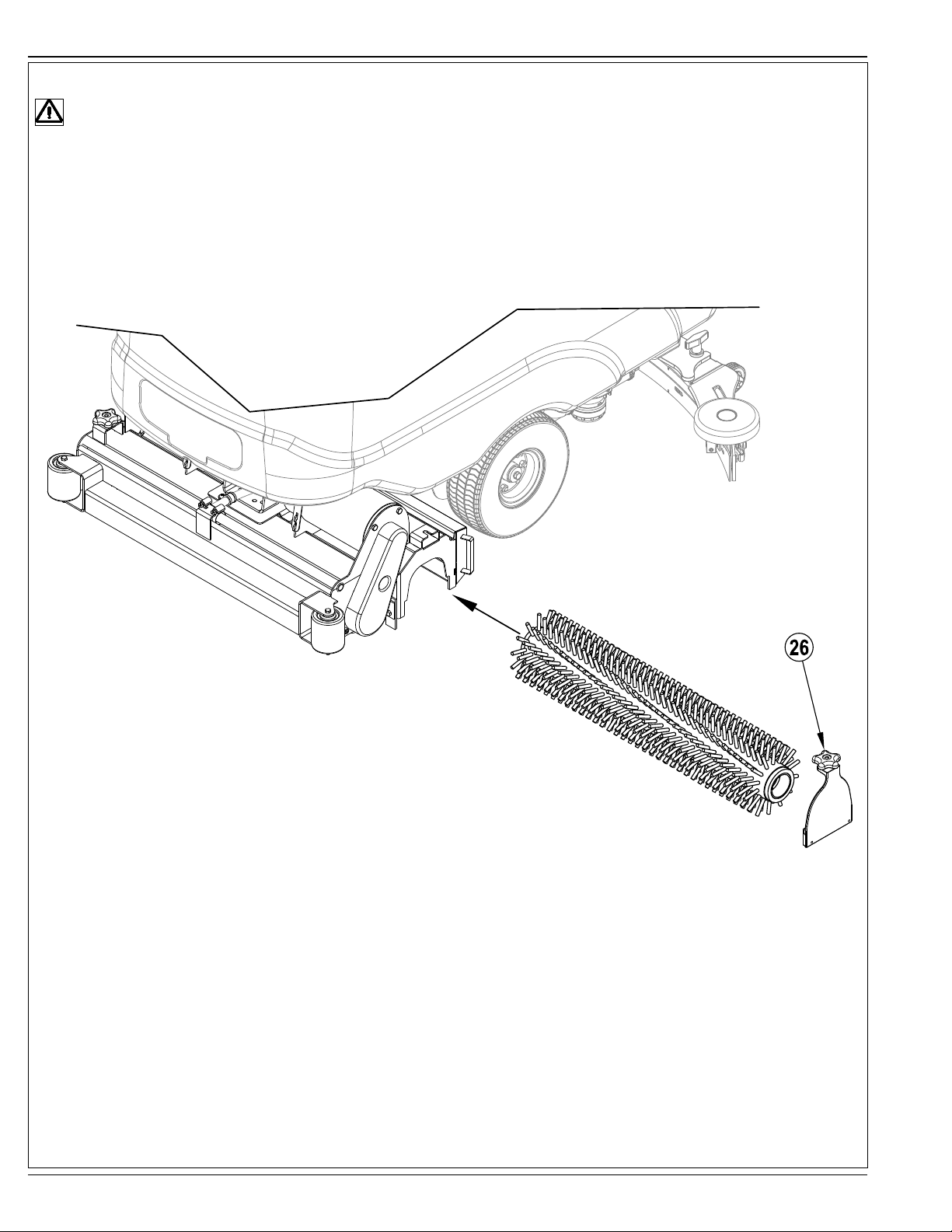

INSTALL THE BRUSHES (CYLINDRICAL SYSTEM)

CAUTION!

Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

1 Make sure the Brush Deck is in the RAISED position. Make sure the Key Switch (A) is off (O).

2 See Figure 3. To access the brushes loosen the black knobs (one on each side) on top of the idler assemblies (26) and remove the idler

assemblies. Slide the brush into the housing, lift slightly, push and turn until it seats. Re-install the idler assemblies.

FIGURE 3

A-12 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 13

ENGLISH / A-13

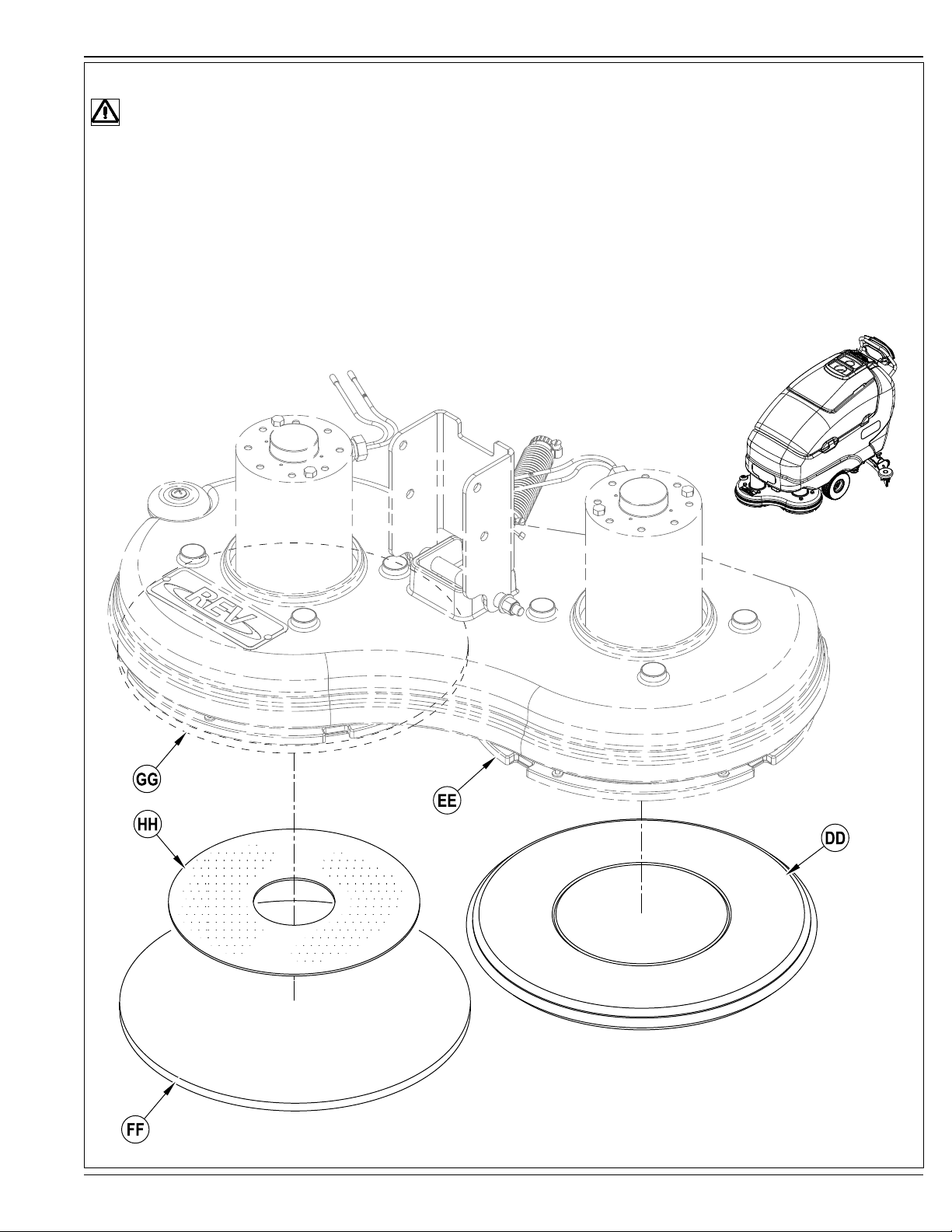

INSTALLING THE PADS (REV SYSTEM)

CAUTION!

Turn the key switch off (O) and remove the key, before changing the pads, and before opening any access panels.

1 Make sure the Scrub Deck (8b) is in the RAISED position. Make sure the Key Switch (A) is off (O).

2 See Figure 4. If using the Microfi ber Pad (DD), install directly to the Pad Driver Assembly (EE).

3 If using the Maroon Pad (FF), install the standard Red Pad (GG) to the Pad Driver Assembly (EE) fi rst and use the 2 Sided Velcro (HH)

between the red pad and maroon pad to hold it in place.

NOTE: If the Maroon SPP pad is not installed as defi ned above, damage to the pad driver will result!

FIGURE 4

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-13

Page 14

A-14 / ENGLISH

A-14 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 15

ENGLISH / A-15

FILLING THE SOLUTION TANK

Fill the solution tank with a maximum of 21 gallons (79.5 Liters) for SC750/SC750 ST models and 25 gallons (94.6 Liters) for SC800/SC800 ST

models of cleaning solution. Do not fi ll the solution tank above 7.5 cm (3 inches) from the bottom of the Solution Fill (1). The solution should be

a mixture of water and the proper cleaning chemical for the job. Always follow the dilution instructions on the chemical container label. NOTE:

EcoFlex machines can either be used conventionally with detergent mixed in the tank or the detergent dispensing system can be used. When

using the detergent dispensing do not mix detergent in the tank, plain water should be used.

CAUTION!

Use only low-foaming, non-fl ammable liquid detergents intended for machine application. Water temperature should not exceed 130

degrees Fahrenheit (54.4 degrees Celsius)

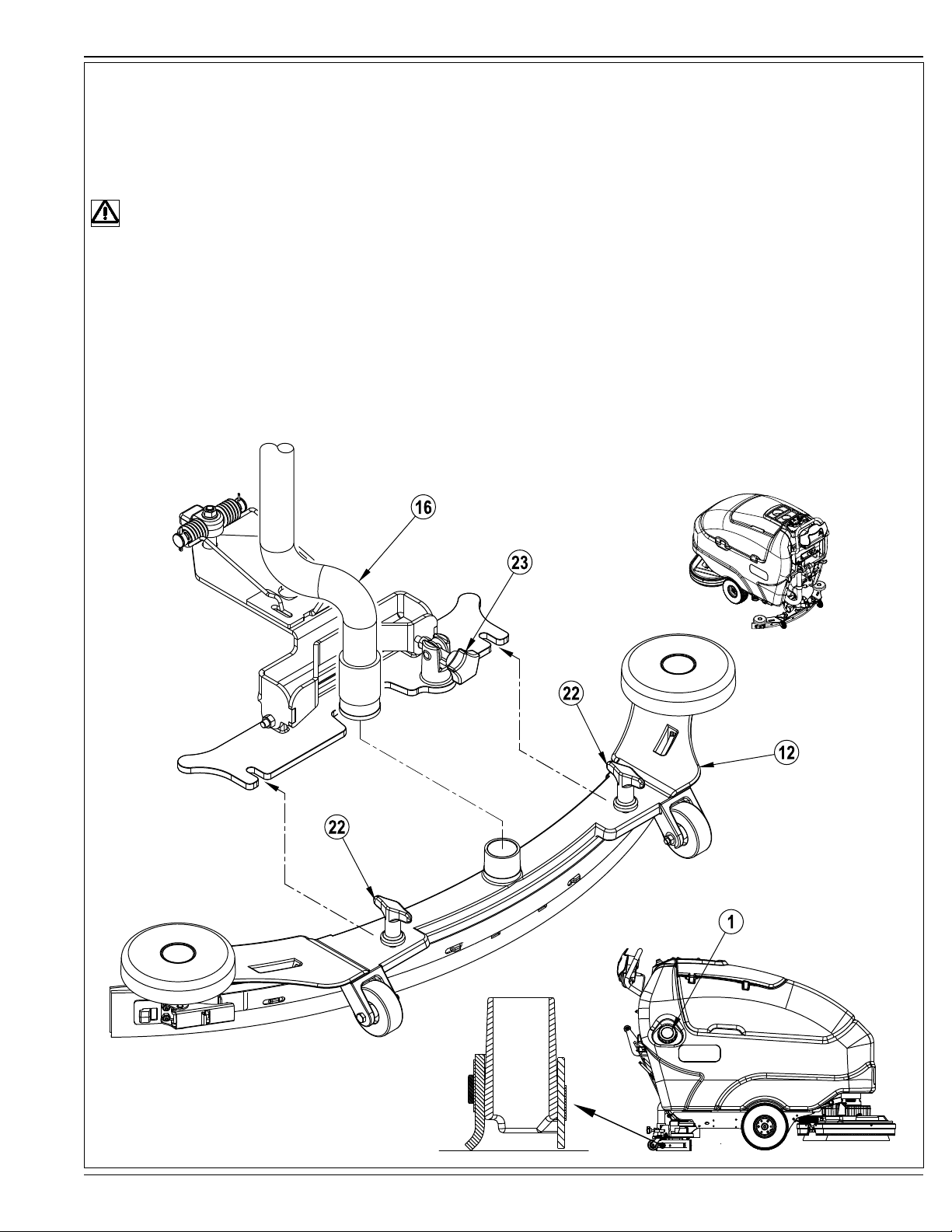

SQUEEGEE INSTALLATION

1 See Figure 5. Slide the Squeegee Assembly (12) onto the squeegee mount bracket and tighten the Squeegee Mount Thumb Nuts (22).

2 Connect the Recovery Hose (16) to the squeegee inlet.

3 Lower the squeegee, move the machine ahead slightly and adjust the squeegee tilt using the Squeegee Adjustment Knob (23) so that the

rear squeegee blade touches the fl oor evenly across its entire width and is bent over slightly as shown.

FIGURE 5

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-15

Page 16

A-16 / ENGLISH

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX MODELS ONLY)

COMMON INSTRUCTIONS:

Pressing and releasing the Detergent Switch (E) while the solution system is active will cause the detergent system to alternately turn on and off.

The system should be purged of previous detergent when switching to a different detergent. SERVICE NOTE: Move machine over fl oor drain

before purging because a small amount of detergent will be dispensed in the process.

To Purge When Changing Chemicals:

1 Disconnect and remove the detergent cartridge.

2 Turn the Key Switch (A) ON. Press and hold the Solution Switch (C) and the Detergent Switch (E) down for 3 seconds. NOTE: Once

activated the purge process takes 10 seconds. See illustration on next page for Detergent System indicators. Normally one purge cycle is

adequate to purge the system.

To Purge Weekly:

1 Disconnect and remove the detergent cartridge. Install and connect a Cartridge fi lled with clean water

2 Turn the Key Switch (A) ON. Press and hold the Solution Switch (C) and the Detergent Switch (E) down for 3 seconds. NOTE: Once

activated the purge process takes 10 seconds. See illustration on next page for Detergent System indicators. Normally one purge cycle is

adequate to purge the system.

When the Detergent Cartridge is almost empty a Display Panel (F) indicator will come on. This “Low Detergent” indicator will remain on until you

reset the system. Once this indicator comes on you should be able to simply pour an entire gallon bottle of detergent into the Cartridge to refi ll

without worrying about measuring. NOTE: Only reset the system when the cartridge is full. When switching cartridges, the “Low Detergent”

indicator is only accurate if the replacement cartridge is at the same level as the cartridge being replaced.

To Reset:

1 Turn the Key Switch (A) ON. Press and hold together the Solution Increase Switch (B) and the Solution Decrease Switch (D) down for 3

seconds. See illustration on next page for Detergent System indicators.

Detergent Ratio:

The detergent ratio is locked at 1:400, except while overriding the EcoFlex cleaning mode. The pre-programmed ratio that is used during 1

EcoFlex override can be adjusted. With the detergent system OFF, press and hold the Detergent ON/OFF Switch (E) for 2 seconds. The

detergent indicator will fl ash and each press of the switch will cycle through the available ratios (1:32, 1:50, 1:64, 1:100, 1:128, 1:150, 1:200,

1:256, 1:300, 1:400). Once the desired ratio is displayed on the screen (F5), stop and it will lock in after 5 seconds.

2 With EcoFlex in the OFF/disabled state (LED off) the detergent ratio is adjustable. With the detergent system OFF, press and hold the

Detergent ON/OFF Switch (E) for 2 seconds. The detergent indicator will fl ash and each press of the switch will cycle through the available

ratios (see above). Once the desired ratio is displayed on the screen (F5), stop and it will lock in after 5 seconds.

CARTRIDGE SPECIFIC INSTRUCTIONS:

Fill the detergent cartridge with a maximum of 1.25 gallons (4.73 Liters) of detergent. SERVICE NOTE: Remove the detergent cartridge from the

detergent box prior to fi lling to avoid spilling detergent on the machine.

It is recommended that a separate cartridge be used for each detergent you plan to use. The detergent cartridges have a white decal on them so

you can write the detergent name on each cartridge to avoid mixing them up. When installing a new cartridge, remove the Cap (AA) and place the

cartridge in the detergent box. Install the Dry Break Cap (BB) as shown.

A-16 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 17

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX MODELS ONLY)

ENGLISH / A-17

DETERGENT ENABLED

DETERGENT DISABLED

FULL (RESET)

DETERGENT LOW

PURGE

Press and hold (C) & (E)

for 3 seconds to purge.

D

C

B

E

Press and hold (B) & (D) for 3

seconds to reset.

F

Detergent system is ON

when indicator is ON.

A

%

2

max.

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-17

Page 18

A-18 / ENGLISH

WET SCRUBBING

WARNING!

Be sure you understand the operator controls and their functions. While on ramps or inclines, avoid sudden stops when loaded.

Avoid abrupt sharp turns. Use low speed down hills. Clean only while ascending (driving up) the ramp.

To Scrub…

1 Follow the instructions in the “Preparing the Machine for Use” section of this manual.

2a SC750, SC800 models: Turn the Master Key Switch (A) ON (I). This will display the control panel indicator lights, reference the Battery Condition Indicator (F6) and Hour Meter

(F1) before proceeding.

3a To transport the machine to the work area, push the Drive Paddle (29) forward to go forward or pull the Drive Paddle (29) backward to move the machine in reverse. Vary the

pressure on the Drive Paddle (29) to obtain the desired speed.

NOTE: Speed Control Knob (30) is used to control the maximum speed in either forward or reverse.

4a Press and hold the Solution Switch (C) for 5 seconds to pre-wet the fl oor. NOTE: This must be done prior to pressing the Scrub ON/OFF Switch (H).

5a Press the Scrub ON/OFF Switch (H), the scrub pressure will default to Normal (one scrub pressure indicator lit). Use the Scrub Pressure Increase Switch (G) and Scrub

Pressure Decrease Switch (I) to change between Regular and Heavy Scrub modes. Only one pressure sensing is available for cylindrical machines.The solution fl ow rate will

automatically adjust to coincide with the scrub pressure.

NOTE: The solution fl ow rate can be changed independently of the scrub pressure by pressing the Solution Increase Switch (B) or Solution Decrease Switch (D). Any

subsequent scrub pressure adjustments will reset the solution fl ow rate to correspond with the scrub pressure.

NOTE: The scrub, solution, vacuum and detergent (EcoFlex models) systems are automatically enabled when the Scrub ON/OFF Switch (H) is pressed. Any individual system

can be turned OFF or back ON by simply pressing its switch at any time during scrubbing. No further action is required other than lowering the squeegee (12).

6a Lower the squeegee with the Squeegee Raise / Lower Lever (14).

7a When the Drive Paddle (29) is in the neutral position, the scrub, vacuum, solution and detergent (EcoFlex models) systems are activated but not running. Grip the Operator

Control Handle (2) and push the Drive Paddle (29) forward to start the scrub, vacuum, solution and detergent (EcoFlex models), and to move the machine forward. For best

results, move the machine at a slow walking speed. Press the Solution Switch (C) once to turn OFF while making sharp turns. Pull the Drive Paddle (29) backward to move the

machine in reverse. The brushes will run while moving the machine in reverse, but solution and chemical will not be dispensed.

2b ST models: Turn the Master Key Switch (A) ON (I). This will display the control panel indicator lights, reference the Battery Indicator (E) before proceeding.

3b To transport the machine to the work area, push either of the Palm Buttons (32) to go forward or press either Palm Button (32) and the Reverse Button (31) to move the machine

in reverse.

NOTE: Speed Control Knob (30) is used to control the maximum speed in either forward or reverse.

4b Press and hold the Solution Switch (B) for 5 seconds to pre-wet the fl oor. NOTE: This must be done prior to pressing the Scrub ON Switch (D).

5b Press the Scrub ON Switch (D) once for Regular Scrub Pressure (one scrub pressure indicator lit) or twice for Heavy Scrub Pressure (two scrub pressure indicators lit). Only one

pressure sensing is available for cylindrical machines. Once the scrub system is activated, pressing the Solution Switch (B) will toggle between solution off, low, medium and

high solution fl ow rates.

NOTE: The solution and vacuum systems are automatically activated when the Scrub ON Switch (D) is pressed. No further action is required other than lowering the squeegee

(12). Any individual system can be turned OFF or back ON by simply pressing its switch at any time during scrubbing.

6b Lower the squeegee with the Squeegee Raise / Lower Lever (14).

7b When the Palm Buttons (32) are not being pressed (machine stationary), the scrub, vacuum and solution systems are activated but not running. Grip the Operator Control

Handle (2) and press either of the Palm Buttons (32) to start the scrub, vacuum, solution, and to move the machine forward. For best results, move the machine at a slow

walking speed. Press either palm button plus the reverse button to move the machine in reverse. The brushes will run while moving the machine in reverse, but solution will not

be dispensed.

CAUTION!

To avoid damaging the fl oor, keep the machine moving while the brushes are turning.

8 When scrubbing, check behind the machine occasionally to see that all of the waste water is being picked up. If there is water trailing the machine, you may be dispensing too

much solution, the recovery tank may be full, or the squeegee tool may require adjustment.

9 EcoFlex models only: The machine defaults to the EcoFlex cleaning mode (EcoFlex Switch Indicator is lit GREEN) conserving solution and detergent. Press the EcoFlex

Switch (J) to override the EcoFlex cleaning mode and temporarily increase scrub pressure, solution fl ow and the detergent ratio. This will cause the indicator to fl ash (YELLOW)

for one minute, solution fl ow rate will increase to the next level, scrub pressure will increase to the next level and the detergent ratio will increase to the pre-programmed ratio.

The pre-programmed ratio that is used during EcoFlex override can be adjusted. With the detergent system OFF, press and hold the Detergent ON/OFF Switch (E) for 2

seconds. The detergent indicator will fl ash and each press of the switch will cycle through the available ratios (1:32, 1:50, 1:64, 1:100, 1:128, 1:150, 1:200, 1:256, 1:300,

1:400). Once the desired ratio is displayed on the screen (F5), stop and it will lock in after 5 seconds.

NOTE: Pressing and holding the EcoFlex Switch (J) for 2 seconds disables the EcoFlex system. The only way to re-enable is to push the EcoFlex Switch (J) again. Cycling the

Key Switch (A) does not re-enable the system. The EcoFlex system will only function if the Scrub System (H) has been enabled.

10 For extremely dirty fl oors, a one-pass scrubbing operation may not be satisfactory and a “double-scrub” operation may be required. This operation is the same as a one-pass

scrubbing except on the fi rst pass the squeegee is in the up position. This allows the cleaning solution to remain on the fl oor to work longer. The fi nal pass is made over the

same area, with the squeegee lowered to pick up the accumulated solution.

11a SC750, SC800 models: The recovery tank has a shut-off fl oat (4) that causes ALL systems to turn OFF except the drive system when the recovery tank is full. When this fl oat is

activated, the recovery tank must be emptied. The machine will not pick up water or scrub with the fl oat activated.

NOTE: All other indicators vanish and a “Recovery Tank FULL” Indicator (F7) turns on in the Display Panel when the switch is activated on “EcoFlex” models.

11b SC750 ST, SC800 ST models: The recovery tank has a shut-off fl oat (4) that causes ALL systems to turn OFF except the drive system when the recovery tank is full. When this

fl oat is activated, the recovery tank must be emptied. The machine will not pick up water or scrub with the fl oat activated.

12 When the operator wants to stop scrubbing or the recovery tank is full;

SC750, SC800 models: Press the Scrub ON/OFF Switch (H) once. This will automatically stop the scrub motors and the solution fl ow and the deck will raise to its upper limit.

NOTE: The vacuum will stop after a 10 second delay. This is to allow any remaining water to be picked up without turning the vacuum back on.

SC750 ST, SC800 ST models: Press the Scrub ON/OFF Switch (D) once to the down position when it is in the regular scrub mode. This will automatically stop the scrub motors

and the solution fl ow and the deck will raise to its upper limit. NOTE: The vacuum will stop after a 10 second delay. This is to allow any remaining water to be picked up without

turning the vacuum back on.

13 Raise the squeegee with the Squeegee Raise / Lower Lever (14). and drive the machine to a designated wastewater “DISPOSAL SITE” and empty the recovery tank. To empty,

pull the Recovery Tank Drain Hose (24) from its hanger and open the cap (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste

water). The Recovery Tank Drain Hose (24) can be squeezed to regulate the fl ow. Refi ll the solution tank and continue scrubbing.

A-18 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 19

ENGLISH / A-19

WET SCRUBBING

NOTE: Make sure the Recovery Tank Lid (6) and the Recovery Tank Drain Hose (24) cap are properly seated or the machine will not pick-up water correctly. When

the batteries require recharging the Battery LOW Indicator (F8) will come on (SC750, SC800 models) or the Battery Indicator (E) will fl ash red (Standard models)

and the vacuum motor will shut off after 30 seconds. Transport the machine to a service area and recharge the batteries according to the instructions in the Battery

section of this manual.

WET VACUUMING

Fit the machine with optional attachments for wet vacuuming.

1 Disconnect the Recovery Hose (16) from the Squeegee (12).

2 Attach suitable wet pick-up tools to the hose (Available from Advance).

3 Turn the Master Key Switch (A) ON.

4 Press the Vacuum/Wand Switch (L) (SC750, SC800 models)

or (C) (SC750 ST, SC800 ST models) once to turn ON the vacuum motor.

The vacuum motor will run continuously until the switch

is pressed again to turn it OFF.

NOTE: The “Recovery Tank FULL” indicator is disabled

when the wand mode is activated.

The fl oat will stop the fl ow into the recovery tank.

F7

F8

F1

!

!

F5

F

F6

H

G

B

H1

C

L

I

D

A

J

6

4

SERVICE NOTE: Refer to the service manual

for detailed functional descriptions of all

controls and optional programmability.

29

30

2

24

14

12

16

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-19

Page 20

A-20 / ENGLISH

AFTER USE

1 Raise the brushes (or pads) and raise the squeegee. Move the machine to a service area.

2 Turn the Master Key Switch (A) OFF and remove the key.

3 To empty the solution tank, pull the Solution Drain Hose (13) off the upper connector. Direct the hose to a fl oor drain or bucket. Rinse the tank with clean

water. Inspect the solution hoses; replace if kinked or damaged.

4 To empty the recovery tank, remove the Recovery Tank Drain Hose (24) from its hanger and remove the cap (hold the end of the hose above the water level

in the tank to avoid sudden, uncontrolled fl ow of waste water). The Recovery Tank Drain Hose (24) can be squeezed to regulate the fl ow. Rinse the recovery

tank and shut-off fl oat (4) with clean water. Inspect the recovery and vacuum hoses; replace if kinked or damaged.

5 Remove the brushes or pad holders. Rinse the brushes or pads with warm water and hang up to dry. Allow buffi ng pads to dry completely before using again.

NOTE: You can either remove the brushes manually or automatically by pressing the Brush Remove Switch (K) (SC750, SC800 disk models only).

6 Remove the squeegee, rinse it with warm water and hang it up to dry.

7 Check the maintenance schedule below and perform any required maintenance before storage.

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Monthly Yearly

Charge Batteries X

Check/Clean Tanks & Hoses X

Check/Clean/Rotate the Brushes/Pads X

Check/Clean the Squeegee X

Check/Clean Vacuum Shut-Off Float X

Empty/Clean Debris Tray In Recovery Tank X

Clean Hopper on Cylindrical System X

Check Each Battery Cell(s) Water Level (does not apply to gel cell batteries) X

Inspect Scrub Housing Skirts X

Inspect and clean Solution Filter X

Clean Solution Manifolds on Cylindrical System X

Purge Detergent System (EcoFlex only) X

Lubricate the Machine X

* Check Carbon Brushes X

* Have Advance check the vacuum motor carbon motor brushes once a year or after 300 operating hours. The brush and drive motor carbon brushes check every

500 hours or once a year.

NOTE: Refer to the Service Manual for more detail on maintenance and service repairs.

8 Store the machine in a clean, dry place.

9 Turn the Master Key Switch (A) OFF (O) and remove the key.

SERVICING THE VACUUM MOTOR

Have your Advance Dealer check the carbon motor brushes

once a year or after 300 operating hours.

IMPORTANT!

Motor damage resulting from failure to service the

carbon brushes is not covered under warranty.

See the Limited Warranty Statement.

LUBRICATING THE MACHINE

Once a month, apply light machine oil to lubricate the:

• General Pivot Points For the Squeegee Linkage (A).

• Squeegee mount angle adjustment knob threads (B).

• Squeegee Tool end wheels (C).

• General Pivot Points For the Brush Linkage (D).

• Pivot points on REV Deck (G).

• Scrub deck bumper wheels (F).

Once per quarter, Grease the following

• Rear Caster Wheel Swivels (E).

C

D

G

F

A

B

C

E

A-20 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

revised 11/12

Page 21

ENGLISH / A-21

CHARGING WET BATTERIES

SC750, SC800 - Charge the batteries each time the machine is used or when the Battery Indicator (F6) is reading less than full.

SC750 ST, SC800 ST - Charge the batteries each time the machine is used or when the Battery Indicator (E) is fl ashing RED.

WARNING!

Do not fi ll the batteries before charging.

Charge batteries in a well-ventilated area.

Do not smoke while servicing the batteries.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

If your machine shipped with an onboard battery charger do the following:

Turn the Key Switch (A) OFF. Unwind the electrical cord from the side of the onboard charger and plug it into a properly grounded outlet. Refer to the OEM product manual for more

detailed operating instructions.

If your machine shipped without an onboard battery charger do the following:

Disconnect the batteries from the machine and push the connector from the charger into the Battery Pack Connector (15). Follow the instructions on the battery charger.

CAUTION!

To avoid damage to fl oor surfaces, wipe water and acid from the top of the batteries after charging.

CHECKING THE BATTERY WATER LEVEL

Check the water level of the batteries at least once a week.

After charging the batteries, remove the vent caps and check the water level in each battery cell. Use distilled or demineralized water in a battery

fi lling dispenser (available at most auto parts stores) to fi ll each cell to the level indicator (or to 10 mm over the top of the separators). DO NOT

over-fi ll the batteries!

CAUTION!

Acid can spill onto the fl oor if the batteries are overfi lled.

Tighten the vent caps. Wash the tops of the batteries with a solution of baking soda and water (2 tablespoons of baking soda to 1 liter of water).

CHARGING GEL (VRLA) BATTERIES

SC750, SC800 - Charge the batteries each time the machine is used or when the Battery Indicator (F6) is reading less than full.

SC750 ST, SC800 ST - Charge the batteries each time the machine is used or when the Battery Indicator (E) is fl ashing RED.

WARNING!

Charge batteries in a well-ventilated area.

Do not smoke while servicing the batteries.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

CAUTION!

Your voltage regulated lead acid (VRLA) battery will deliver superior performance and life ONLY IF IT RECHARGED PROPERLY! Under or

overcharging will shorten battery life and limit performance. Be sure to FOLLOW PROPER CHARGING INSTRUCTIONS! DO NOT ATTEMPT

TO OPEN THIS BATTERY! If a VRLA battery is opened, it loses its pressure and the plates become oxygen contaminated. THE WARRANTY

WILL BE VOIDED IF THE BATTERY IS OPENED.

If your machine shipped with an onboard battery charger do the following:

Turn the Key Switch (A) OFF. Unwind the electrical cord from the side of the onboard charger and plug it into a properly grounded outlet. Refer to the OEM product manual for more

detailed operating instructions.

If your machine shipped without an onboard battery charger do the following:

Disconnect the batteries from the machine and push the connector from the charger into the Battery Pack Connector (15). Follow the instructions on the battery charger. SERVICE

NOTE: Make sure you plug the battery charger into the connector with the handle attached to it.

IMPORTANT: Make sure you have an appropriate charger for use on Gel cell batteries. Use only “voltage-regulated” or “voltage-limited” chargers. Standard constant

current or taper current chargers MUST NOT be used. A temperature-sensing charger is recommended, as manual adjustments are never accurate and will damage any

VRLA battery.

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-21

Page 22

A-22 / ENGLISH

SERVICING THE SQUEEGEE

If the squeegee leaves narrow streaks or water, the blades may be dirty or damaged. Remove the squeegee, rinse it under warm water and

inspect the blades. Reverse or replace the blades if they are cut, torn, wavy or worn.

To Reverse or Replace the Rear Squeegee Wiping Blade...

1 See Figure 6. Raise the squeegee tool off the fl oor, and then unsnap the Rear Squeegee Blade Removal Latch (20) on the squeegee tool.

2 Remove the Tension Strap (19).

3 Slip the rear blade off the Alignment Pins (21).

4 The squeegee blade has 4 working edges. Turn the blade so a clean, undamaged edge points toward the front of the machine. Replace the

blade if all 4 edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee tilt.

To Reverse or Replace the Front Squeegee Blade...

1 Raise the squeegee tool off the fl oor, then loosen the (2) Thumb Nuts (22) on top of the squeegee tool. Disconnect the Recovery Hose (16)

and remove the squeegee tool (12) from the mount.

2 Loosen the Front Squeegee Blade Removal Knob (AA), then remove Tension Strap (AB) and blade..

3 The squeegee blade has 4 working edges. Turn the blade so a clean, undamaged edge points toward the front of the machine. Replace the

blade if all 4 edges are nicked, torn or worn to a large radius.

4 Install the blade, following the steps in reverse order and adjust the squeegee tilt.

ADJUSTING THE SQUEEGEE

Adjust the squeegee angle whenever a blade is reversed or replaced, or if the squeegee is not wiping the fl oor dry.

To Adjust the Squeegee Angle...

1 Park the machine on a fl at, even surface and lower the squeegee.

2 While moving the machine forward slowly, turn the Squeegee Adjustment Knob (23) until the rear squeegee blade folds over evenly across

the entire width of the squeegee as shown below.

FIGURE 6

A-22 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 23

GENERAL MACHINE TROUBLESHOOTING

Problem Possible Cause Remedy

Worn or torn squeegee blades Reverse or replace

Squeegee out of adjustment Adjust so blades touch fl oor evenly

across entire width

Recovery tank full Empty recovery tank

Poor water pick-up

Poor scrubbing performance

Inadequate solution fl ow

or no solution

Recovery tank drain hose leak Secure drain hose cap or replace

Recovery tank cover gasket leak Replace gasket / Seat cover properly

Debris caught in squeegee Clean squeegee tool

Vacuum hose clogged Remove debris

Using too much solution Adjust solution fl ow at control panel

Foam fi lter cover not seated Seat cover properly

Worn brush or pad Rotate or replace brushes

Wrong brush or pad type Consult Advance

Wrong cleaning chemical Consult Advance

Moving machine too fast Slow down

Not using enough solution Increase solution fl ow at control panel

Solution tank empty Fill solution tank

Solution lines, valves, fi lter or trough

clogged

Solution shutoff valve closed Open solution shutoff valve

Solution solenoid valve Clean or replace valve

Flush lines, trough and clean solution fi lter

ENGLISH / A-23

Machine does not run

No FWD/REV wheel drive

Vacuum shuts off and display shows

“Recovery Tank FULL indicator” when

recovery tank is not full

Poor Sweeping Performance

(Cylindrical System)

No Detergent Flow (EcoFlex models only)

Battery connector disconnected Reconnect battery connectors

Main system controller Check error fault codes

(see service manual)

Tripped 10 Amp circuit breaker Check for electrical short circuit & reset

Drive system speed controller Check error fault codes

(see service manual)

Tripped 30 Amp circuit breaker

Emergency stop switch tripped Reset the Emergency Stop Switch

Plugged squeegee hose Clear debris

Vacuuming large amounts of water

at a high travel speed

Hopper Full Empty and clean hopper

Brushes worn Replace brushes

Bristles have taken a set Rotate brushes

Empty detergent cartridge Fill detergent cartridge

Plugged or kinked detergent fl ow line Purge system, straighten lines to

Dry seal cap on detergent cartridge not

sealed

Detergent pump wiring

disconnected or backwards

Check for drive motor overload

Slow down or disable auto shut-off feature

(see service manual)

remove any kinks

Reseat dry seal cap

Connect or reconnect wiring

Variability of the Pad Rotation

(REV System)

Pad changes rotation speed at various

times

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - A-23

Dependant on fl oor substrate,

Pad type and down pressure setting

Page 24

A-24 / ENGLISH

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model SC750-26D

SC750 ST-26D SC750-28D

SC750-28C SC750 ST-28D SC750-28R

Model No. 56112000

56112012 56112004

56112006 56112013 56112780

Voltage, Batteries V 24V 24V 24V 24V

Battery Capacity Ah 312 312 312 312

Protection Grade IPX4 IPX4 IPX4 N/A

Sound Pressure Level

(IEC 60704-1)

Sound Pressure Level

(IEC 60704-1) Uncertainty

Gross Weight lbs / kg 942/427.3 942/427.3 942/427.3 969/439.5

Transport Weight lbs / kg 932/422.7 932/422.7 932/422.7 959/435.0

Maximum Wheel Floor Loading (right front) psi N/mm

Maximum Wheel Floor Loading (left front) psi N/mm

Maximum Wheel Floor Loading (center rear) psi N/mm

Vibrations at the Hand Controls

(ISO 5349-1)

Vibrations at the Hand Controls

(ISO 5349-1) Uncertainty

Gradeability Transport 2% (1.15º) 2% (1.15º) 2% (1.15º) 2% (1.15º)

Gradeability Cleaning 2% (1.15º) 2% (1.15º) 2% (1.15º) 2% (1.15º)

Model

Model No.

Voltage, Batteries V

Battery Capacity Ah

Protection Grade

Sound Pressure Level

(IEC 60704-1)

Sound Pressure Level

(IEC 60704-1) Uncertainty

Gross Weight lbs / kg 994/450.9 994/450.9 994/450.9

Transport Weight lbs / kg 984/446.3 984/446.3 984/446.3

Maximum Wheel Floor Loading (right front) psi N/mm

Maximum Wheel Floor Loading (left front) psi N/mm

Maximum Wheel Floor Loading (center rear) psi N/mm

Vibrations at the Hand Controls

(ISO 5349-1)

Vibrations at the Hand Controls

(ISO 5349-1) Uncertainty

Gradeability Transport 2% (1.15º) 2% (1.15º) 2% (1.15º)

Gradeability Cleaning 2% (1.15º) 2% (1.15º) 2% (1.15º)

dB(A) 61 61 61 64

dB(A) 3.0 3.0 3.0 3.0

m/s

m/s

2

2

2

2

2

59.08/0.407 59.08/0.407 59.08/0.407 56.88/0.392

60.10/0.414 60.10/0.414 60.10/0.414 69.61/0.480

287.56/1.983 287.56/1.983 287.56/1.983 268.39/1.85

Less than 2.5 Less than 2.5 Less than 2.5 Less than 2.5

.02 .02 .02 .02

SC800-28D SC800-32C

SC800-28C SC800-34D SC800 ST-34D

56112016 56112024

56112018 56112028 56112032

24V 24V 24V

312 312 312

IPX4 IPX4 IPX4

dB(A) 61 61 61

dB(A) 3.0 3.0 3.0

m/s

m/s

2

2

2

2

2

71.0/.490 71.0/.490 71.0/.490

66.6/.459 66.6/.459 66.6/.459

287.6/1.983 287.6/1.983 287.6/1.983

.09 .09 .09

.02 .02 .02

MATERIAL COMPOSITION

LBS KG

Aluminum 13.58 6.16

Rubber 15.888 7.21

Plastic 23.037 10.45

Polyethylene 116.4 52.79

Ferrous Metal & Copper

Transaxle 23 10.43

Brush Motor 17.25 7.82

Vac Motor 6 2.72

Other Electric 19.41 8.80

A-24 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 25

Page 26

B-2 / ESPAÑOL

ÍNDICE

Página

Introducción ........................................................................................ B-3

Componentes y servicio .....................................................................B-3

Placa de identifi cación ........................................................................ B-3

Desembalaje de la máquina ...............................................................B-3

Precauciones y advertencias .................................................... B-4 – B-5

Conozca su máquina ................................................................ B-6 – B-7

Panel de control – SC750, SC800 ...................................................... B-8

Panel de control – SC750 ST, SC800 ST ...........................................B-9

Preparación de la máquina para su utilización

Baterías ............................................................................................ B-10

Instalación de los cepillos y las bayetas ................................B-11 – B-13

Llenado del depósito de solución .....................................................B-15

Instalación de la boquilla ..................................................................B-15

Sistema de detergente (EcoFlex™) .................................... B-16 – B-17

Manejo de la máquina

Fregado en húmedo ............................................................. B-18 – B-19

Aspiración en húmedo ......................................................................B-19

Después de la utilización de la máquina ..........................................B-20

Programa de mantenimiento ............................................................B-20

Mantenimiento del motor de aspiración ............................................ B-20

Lubricación de la máquina ................................................................ B-20

Mantenimiento

Recarga de las baterías (líquido) .....................................................B-21

Recarga de las baterías (gel) ...........................................................B-21

Mantenimiento de la boquilla ............................................................B-22

Ajuste de la boquilla .........................................................................B-22

Resolución de problemas .................................................................B-23

Especifi caciones técnicas ................................................................. B-24

Composición Del Material ................................................................. B-24

B-2 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

revised 7/11

Page 27

ESPAÑOL / B-3

INTRODUCCIÓN

Este manual le ayudará a obtener el máximo rendimiento de su limpiadora/secadora automática Advance™. Léalo con atención antes de utilizar la máquina.

Nota: Los números que aparecen en negrita entre paréntesis indican elementos ilustrados en las páginas 5-8, a menos que se indique lo contrario.

Este producto está destinado exclusivamente a uso comercial.

COMPONENTES Y SERVICIO

Las reparaciones, cuando sean necesarias, deben ser realizadas por su Centro Autorizado de Servicio Advance que utiliza personal de servicio formado en

fábrica y lleva un inventario de piezas de repuesto y accesorios Advance originales.

Llame a Advance para lo referente a piezas de repuesto y servicio. Por favor, especifi que el Modelo y Número de Serie cuando hable de su máquina.

MODIFICACIONES

Las modifi caciones y los agregados a la máquina de limpieza que afecten su capacidad y su funcionamiento seguro no serán realizados por el cliente o el usuario

sin la autorización previa y por escrito de Nilfi sk-Advance Inc. Las modifi caciones que no cuenten con la aprobación correspondiente anularán la garantía de la

máquina y harán que el cliente sea responsable de cualquier accidente resultante.

PLACA DE IDENTIFICACIÓN

El Número de Modelo y de Serie de la máquina se indican en la placa de identifi cación instalada en el compartimento de las baterías.

Esta información es necesaria a la hora de solicitar repuestos para la máquina. Utilice el siguiente espacio para anotar el Modelo y el Número de Serie de su

máquina para futuras consultas.

Modelo _____________________________________________

Número de Serie _____________________________________

DESEMBALAJE DE LA MÁQUINA

Cuando reciba la máquina, examine con atención el embalaje y la máquina, con el fi n de comprobar si existe algún daño. Si observa algún daño, guarde la caja

de embalaje (si procede) para que se pueda inspeccionar. Póngase en contacto inmediatamente con el Departamento de Servicio al Cliente de Advance para

presentar una reclamación por daños en transporte. Consulte la hoja de instrucciones de desembalaje incluida con la máquina para sacar la máquina del palet.

ADVERTENCIA:

Los Productos a la venta en este Manual contienen, o pueden contener, productos químicos reconocidos por algunos gobiernos (como el Estado

de California, según lo indica en su Proposición 65, Ley de Advertencia Regulatoria) como causantes de cáncer, defectos de nacimiento u

otros daños reproductivos. En algunas jurisdicciones (incluido el Estado de California), los compradores de estos Productos que los coloquen

en servicio en un emplazamiento laboral o en un espacio de acceso público tienen la obligación regulatoria de realizar determinados avisos,

advertencias o divulgaciones respecto de los productos químicos contenidos o posiblemente contenidos en los Productos utilizados en tal lugar.

Es la responsabilidad del comprador conocer y cumplir con todas las leyes y reglamentaciones relacionadas con el uso de estos Productos en

tales entornos. El Fabricante niega toda responsabilidad de informar a los compradores sobre requisitos específi cos que pueden regir el uso de

los Productos en tales entornos.

revised 7/11

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - B-3

Page 28

B-4 / ESPAÑOL

PRECAUCIONES Y ADVERTENCIAS

SÍMBOLOS

Advance utiliza los símbolos que aparecen a continuación para indicar situaciones potencialmente peligrosas. Lea cuidadosamente

esta información y emprenda las acciones que resulten necesarias para proteger a personas y objetos.

¡PELIGRO!

Se utiliza para advertir de peligros inmediatos que pueden producir graves daños personales o la muerte.

¡ADVERTENCIA!

Se utiliza para llamar la atención sobre una situación que puede causar graves daños personales.

¡PRECAUCIÓN!

Se utiliza para llamar la atención sobre una situación que puede causar daños personales leves o daños a la máquina u otros

objetos.

Lea todas y cada una de las instrucciones antes de utilizar el aparato.

INSTRUCCIONES GENERALES DE SEGURIDAD

Se incluyen Precauciones y Advertencias específi cas que le advierten de los posibles riesgos de daño a la máquina o daño corporal.

Esta máquina es para uso comercial, por ejemplo en hoteles, colegios, hospitales, fábricas, tiendas y ofi cinas, y no para usos

relacionados con el mantenimiento doméstico.

¡ADVERTENCIA!

* Sólo deben utilizar esta máquina las personas autorizadas y con la formación adecuada.

* Esta máquina no debe ser utilizada por personas (incluidos niños) con capacidades físicas, sensoriales o mentales reducidas, o con falta de experiencia y

conocimientos.

* Al circular sobre rampas o pendientes, evite las paradas bruscas. Evite las curvas muy cerradas. Circule lentamente al bajar rampas.

* Observe el peso bruto del vehículo (GVW) de la máquina cuando cargue, maneje, eleve o sostenga la máquina.

* Mantenga las chispas, llamas y materiales de fumadores alejados de las baterías. Durante el funcionamiento normal se desprenden gases explosivos.

* Al recargar las baterías se produce gas de hidrógeno altamente explosivo. Recargue las baterías exclusivamente en zonas bien ventiladas, lejos de llamas

sin proteger. No fume mientras recarga las baterías.

* Quítese todas las joyas cuando trabaje cerca de componentes eléctricos.

* Ponga el conmutador en posición de apagado (O) y desconecte las baterías antes de revisar los componentes eléctricos.

* No trabaje nunca debajo de la máquina sin colocar antes bloques o soportes de seguridad en los que apoyar la máquina.

* No aplique sustancias limpiadoras infl amables ni utilice la máquina sobre estas sustancias, cerca de ellas, ni en zonas en las que haya líquidos infl amables.

* No lave la máquina con una limpiadora a presión.

* No haga funcionar esta máquina en rampas o en pendientes superiores al 2 por ciento.

* Use solamente los cepillos suministrados junto con el aparato o aquellos especifi cados en el manual de instrucciones. El uso de otros cepillos puede afectar

a la seguridad.

* No mire directamente al láser. Producto Láser Clase 1 IEC 60825-1, 2007 Y 21CFR1040.10.

B-4 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

revised 11/12

Page 29

ESPAÑOL / B-5

¡PRECAUCIÓN!

* Esta máquina no ha sido aprobada para su uso en vías públicas.

* Esta máquina no es apta para la recogida de polvo peligroso.

* Tenga cuidado cuando utilice discos de escarifi cación y piedras abrasivas. No se podrá responsabilizar a Advance de daño alguno a las superfi cies de los

suelos causado por escarifi cadores o piedras abrasivas.

* Cuando utilice la máquina, asegúrese de que no existe peligro para terceras personas, especialmente niños.

* Antes de proceder a cualquier función de servicio, lea con atención todas las instrucciones relativas a dicha función.

* No deje la máquina sin vigilancia sin antes haber puesto el conmutador en posición de apagado (O), haber quitado la llave y haber aplicado el freno de

estacionamiento.

* Apague el conmutador de llave (O) y quite la llave antes de cambiar los cepillos y antes de abrir cualquiera de los paneles de acceso.

* Tome las debidas precauciones para evitar que el pelo, las joyas o las prendas sueltas queden atrapados entre los componentes móviles.

* Tome las precauciones adecuadas cuando esté moviendo esta máquina mientras hiela. El agua de la solución, los depósitos de recuperación o detergente

y de las tuberías puede congelarse, causando daños a las válvulas y accesorios. Limpie con limpiaparabrisas.

* Retire las baterías de la máquina antes de su desguace. Las baterías deben desecharse de forma segura, de acuerdo con la reglamentación

medioambiental local.

* No utilice la máquina en superfi cies con pendientes superiores a las indicadas en la máquina.

* Antes de utilizar la máquina, todas las puertas y cubiertas deberían estar colocadas como se indica en el manual de instrucciones.

* Consulte el manual del producto OEM del cargador de batería para obtener advertencias adicionales sobre el cargador de batería específi co.

* Cualquier uso o ajustes del láser distinto a los especifi cados aquí pueden resultar en exposición riesgosa a la radiación.

GUARDE ESTAS INSTRUCCIONES

revised 11/12

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - B-5

Page 30

B-6 / ESPAÑOL

CONOZCA SU MÁQUINA

A lo largo de este manual encontrará números o letras en negrita entre paréntesis – por ejemplo: (2). Estos números se refi eren a un objeto que se muestra

en dicha página, a menos que se indique lo contrario. Consulte estas páginas siempre que lo necesite para localizar los elementos citados en el texto.

NOTA: Consulte el manual de servicio para obtener explicaciones más detalladas de cada objeto ilustrado en las siguientes 4 páginas.

1 Llenado del depósito de solución

2 Manilla de control del operario

3 Portabotellas

4 Flotador de cierre del depósito de recuperación

5 Cesta del fi ltro

6 Tapa del depósito de recuperación

7 Cubierta de acceso al cartucho de detergente (EcoFlex)

7a Cartucho (sólo modelos EcoFlex) de detergente (EcoFlex)

8a Plataforma de limpieza (modelos de disco)

8b Plataforma de limpieza (modelo REV)

9 Zócalo de la plataforma de limpieza

10 Parachoques de la plataforma de limpieza

11 Rueda motriz

12 Conjunto de boquilla

B-6 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 31

CONOZCA SU MÁQUINA

ESPAÑOL / B-7

13 Tubería de drenaje de la solución / Indicador de nivel

14 Palanca de elevación/descenso de la boquilla

15 Conector del conjunto de baterías

16 Tubería de recuperación

17 Disyuntor del motor de la tracción de rueda (30 A)

18 Disyuntor del circuito de control (10 A)

19 Correa de tensión de la cuchilla de la boquilla

20 Pestillo de la cuchilla de la boquilla

21 Pasadores de alineación de la cuchilla de la boquilla

22 Tuerca de palomilla de montaje de la boquilla

23 Botón de ajuste de la boquilla

24 Tubería de drenaje del depósito de recuperación

25 Tolva de residuos (sólo modelos cilíndricos)

26 Conjunto en vacío (sólo modelos cilíndricos)

27 Colector de la solución (sólo modelos cilíndricos)

28 Panel de control (SC750, SC800)

29 Paleta de tracción

30 Botón de control del límite de velocidad

31 Botón marcha atrás (SC750 ST, SC800 ST)

32 Botones de transmisión de palma (SC750 ST, SC800 ST)

33 Panel de control (SC750 ST, SC800 ST)

34 Cargador de batería a bordo (no se encuentra en todos los modelos)

35 Filtro de la solución

36 Válvula de cierre de la solución

37 Cronómetro (opcional en modelos ST)

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - B-7

Page 32

B-8 / ESPAÑOL

PANEL DE CONTROL – SC750, SC800

A Interruptor de contacto (principal)

B Interruptor de aumento de la solución

C Interruptor de encendido/apagado de la solución

C1 Indicadores de fl ujo de la solución (normal, duro y extremo)

D Interruptor de reducción de la solución

E Interruptor de encendido/apagado de detergente

F Pantalla

F1 Medidor de horas de funcionamiento

F2 Indicador de nivel del depósito de solución

F3 Códigos de error

F4 Indicador detergente (si está instalado)

F5 Indicador de mezcla de detergente

F6 Indicador de batería

F7 Indicador de depósito de recuperación lleno

F8 Indicador de batería baja

F1

F2 F3

G Interruptor de aumento de la presión de fregado

H Interruptor de encendido/apagado de fregado

(Sistema de discos – normal y duro)

(Sistema cilíndrico – 1 Detector de presión)

H1 Indicadores de presión de fregado

I Interruptor de reducción de la presión de fregado

J Interruptor EcoFlex

K Interruptor de extracción de cepillo (plataformas de disco únicamente)

(El interruptor de extracción de cepillo está

desactivado en el modelo REV)

L Interruptor de aspiración/varilla

™

F7

!

F4 F5 F6

F

B

C

K

C1

D

E

F8

!

F

G

H

L

H1

A

.2%

J

I

max

B-8 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 33

PANEL DE CONTROL – SC750 ST, SC800 ST

A Interruptor de contacto (principal)

B Interruptor de encendido/apagado de la solución (Bajo, mediano y alto)

B1 Indicadores de fl ujo de la solución

C Interruptor de aspiración/varilla

C1 Indicador de desactivación de motor de aspiración

D Interruptor de encendido/apagado de fregado

(Sistema de discos – normal y duro)

(Sistema cilíndrico – 1 Detector de presión)

D1 Indicadores de presión de fregado

E Indicador de batería

F Indicador de errores

ESPAÑOL / B-9

Presión

de fregado cilíndrico

(pulse una vez)

Presión

de fregado de disco

duro

(pulse dos veces)

Presión

de fregado de disco

normal

(pulse una vez)

Flujo de

solución

alto

(pulse 3 veces)

Flujo de

solución

medio

(pulse dos veces)

Flujo de

solución

bajo

(pulse una vez)

D1

C

D

B

B1

E

C1

A

max.2%

F

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - B-9

Page 34

B-10 / ESPAÑOL

BATERÍAS

Si su máquina se entrega con baterías instaladas, realice lo siguiente:

Compruebe que las baterías estén conectadas a la máquina (15).

Encienda el conmutador de llave (A) y compruebe el indicador de batería (F6 o E). Si el indicador está completamente lleno o la luz verde está encendida,

las baterías están listas para el uso. Si el indicador no está completamente lleno o la luz verde está apagada, las baterías deberían recargarse antes del

uso. Consulte la sección “Recarga de las baterías”.

¡IMPORTANTE!: SI SU MÁQUINA ESTÁ EQUIPADA CON UN CARGADOR DE BATERÍA A BORDO, CONSULTE EL MANUAL DEL PRODUCTO OEM

PARA OBTENER INSTRUCCIONES SOBRE EL AJUSTE DEL CARGADOR PARA EL TIPO DE BATERÍA.

Si su máquina se entrega sin baterías instaladas, realice lo siguiente:

Consulte con su distribuidor autorizado Advance en cuanto a las baterías recomendadas.

Instale las baterías siguiendo las instrucciones indicadas a continuación.

NO instale 3 baterías de 12 voltios en su máquina. Esto afectará a la estabilidad de la máquina.

¡IMPORTANTE!: SI SU MÁQUINA ESTÁ EQUIPADA CON UN CARGADOR DE BATERÍA A BORDO, CONSULTE EL MANUAL DEL PRODUCTO OEM

PARA OBTENER INSTRUCCIONES SOBRE EL AJUSTE DEL CARGADOR PARA EL TIPO DE BATERÍA.

¡ADVERTENCIA!

Tome las máximas precauciones cuando trabaje con las baterías. El ácido sulfúrico de las baterías puede causar daños graves si

entra en contacto con la piel o con los ojos. Desde el interior de las baterías se libera gas explosivo de hidrógeno a través de unas

aperturas en las tapas de las baterías. Este gas puede incendiarse con cualquier arco eléctrico, chispa o llama. No instale baterías

de plomo-ácido en un contenedor cerrado. El gas de hidrógeno debido a la sobrecarga debe poder liberarse.

Cuando revise las baterías...

* Quítese todas las joyas

* No fume

* Lleve gafas de seguridad, un delantal de goma y guantes de goma

* Trabaje en una zona bien ventilada

* No permita que las herramientas toquen simultáneamente más de un terminal de batería

* Al sustituir las baterías, desconecte SIEMPRE en primer lugar el cable (de tierra) negativo para evitar chispas.

* Al instalar las baterías, conecte SIEMPRE el cable negativo al fi nal.

¡PRECAUCIÓN!

Los componentes eléctricos de esta máquina pueden dañarse seriamente si las

baterías no están instaladas o conectadas correctamente. Las baterías deben

ser instaladas por Advance, un electricista cualifi cado o el fabricante de las

baterías.

1 Retire las baterías de su caja de embalaje e inspecciónelas para ver si existen grietas u

otros daños. Si los daños son evidentes, póngase en contacto inmediatamente con el

transportista que se las entregó para presentar una reclamación por daños en transporte.

2 Apague el conmutador principal de llave (A) y quite la llave.

3 Desconectar el conector del paquete de baterías (15).

4 Incline el depósito de recuperación hacia la posición lateral cerrada. Retire los cables de la

batería del interior del compartimento de las baterías.

5 Su máquina viene de fábrica con sufi cientes cables para instalar 4 baterías de 6 voltios.

Levante las baterías con cuidado para meterlas en el compartimento de las baterías y

colóquelas exactamente como se muestra en la FIGURA 1. Ponga las baterías tan cerca

de la parte trasera de la máquina como pueda.

6 Instale los cables de las baterías como se muestra. Ponga los cables de forma que las

cubiertas de las baterías puedan retirarse fácilmente para el mantenimiento de las baterías.

7 Apriete con cuidado las tuercas de los terminales de las baterías hasta que el terminal

no gire. No apriete demasiado los terminales; de lo contrario será muy difícil retirarlos en

futuras operaciones de mantenimiento.

8 Bañe los terminales con revestimiento para terminales de baterías en pulverizador

(disponible en la mayoría de las tiendas de material para coches).

9 Ponga un manguito de goma negro encima de cada terminal y conecte el conector del

conjunto de las baterías (15).

FIGURA 1

312 AH @ 20 HR RATE

(4) MAX 158KG/348LB

Cuando cambie las baterías o el cargador, consulte con su centro local de

servicios autorizado los valores correctos para la batería, el cargador y la

máquina, a fi n de evitar daños a la batería.

B-10 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

revised 11/12

Page 35

ESPAÑOL / B-11

INSTALACIÓN DE LOS CEPILLOS (SISTEMA DE DISCO)

¡PRECAUCIÓN!

Apague el conmutador de llave (O) y quite la llave antes de cambiar los cepillos y antes de abrir cualquiera de los paneles de

acceso.

1 Asegúrese de que el portacepillos (8a) se encuentre en la posición ELEVADA. Asegúrese de que está apagado (O) el conmutador de llave (A).

2 Si utiliza bayetas, instale las bayetas en los portabayetas

3 Ver la Figura 2. Para montar los cepillos (AA) (o los portabayetas), alinee las lengüetas (BB) del cepillo con las ranuras de la bandeja de montaje y gire

para que se bloquee en su posición (gire el borde exterior del cepillo hacia la parte trasera de la máquina como se muestra (CC)).

FIGURA 2

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - B-11

Page 36

B-12 / ESPAÑOL

INSTALACIÓN DE LOS CEPILLOS (SISTEMA CILÍNDRICO)

¡PRECAUCIÓN!

Apague el conmutador de llave (O) y quite la llave antes de cambiar los cepillos y antes de abrir cualquiera de los paneles de

acceso.

1 Asegúrese de que el portacepillos se encuentre en la posición ELEVADA. Asegúrese de que está apagado (O) el conmutador de llave (A).

2 Ver la Figura 3. -Para acceder a los cepillos, afl oje los botones negros (uno a cada lado) que están en la parte superior de los conjuntos en vacío (26) y

retire los conjuntos. Deslice el cepillo en el contenedor, levante ligeramente, empuje y gire hasta que se asiente. Vuelva a instalar los conjuntos en vacío.

FIGURA 3

B-12 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 37

ESPAÑOL / B-13

INSTALACIÓN DE LAS BAYETAS (SISTEMA REV)

¡PRECAUCIÓN!

Apague el interruptor de contacto (O) y quite la llave antes de cambiar las bayetas y antes de abrir cualquiera de los paneles de

acceso.

1 Asegúrese de que la plataforma de limpieza (8b) se encuentre en la posición ELEVADA. Asegúrese de que está apagado (O) el conmutador de llave (A).

2 Consulte la fi gura 4. Si usa la bayeta de microfi bra (DD), instálela directamente en el conjunto del portabayetas (EE).

3 Si usa la bayeta marrón (FF), instale la bayeta roja estándar (GG) en el conjunto del portabayetas (EE) primero y luego use el velcro de dos caras (HH)

entre la bayeta roja y la marrón, para sostenerla en su lugar.

NOTA: Si la bayeta SPP marrón no se instala como se indica más arriba, se dañará el portabayetas.

FIGURA 4

FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST - B-13

Page 38

B-14 / ESPAÑOL

B-14 - FORM NO. - 56041820 - SC750, SC800, SC750 ST, SC800 ST

Page 39

ESPAÑOL / B-15

LLENADO DEL DEPÓSITO DE SOLUCIÓN

Llenar el depósito de solución con un máximo de 21 galones (79,5 litros) para los modelos SC750/SC750 ST y 25 galones (94,6 litros) para los modelos SC800/

SC800 ST con la solución de limpieza. No llene el depósito de solución por encima de 7,5 cm (3 pulgadas) de la parte inferior del depósito (1). La solución debe

ser una mezcla de agua y el limpiador químico apropiado para la aplicación. Siga siempre las instrucciones que aparecen en la etiqueta del envase del producto

químico. NOTA: Las máquinas EcoFlex pueden utilizarse normalmente con detergente mezclado en el depósito o con el sistema de aplicación de detergente

EcoFlex. Al utilizar el sistema de aplicación de detergente EcoFlex, no mezcle detergente en el depósito; utilice agua.

¡PRECAUCIÓN!

Utilice únicamente detergentes líquidos no infl amables de bajo poder espumante que estén diseñados para aplicaciones de fregado

automático. La temperatura del agua no deberá superar los 130 grados Fahrenheit (54,4 grados Celsius)

INSTALACIÓN DE LA BOQUILLA