Page 1

SC400

Service Manual

Advance SC400 9087310020

Nilsk SC400 9087311020

Nilsk SC400 9087318020

English

2012-11 Form No. 9099624000

Page 2

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Machine General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Service Manual Purpose and Field of Application . . . . . . . . . . . . . . . . . . . . . . 4

Other Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Machine Lifting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Machine Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

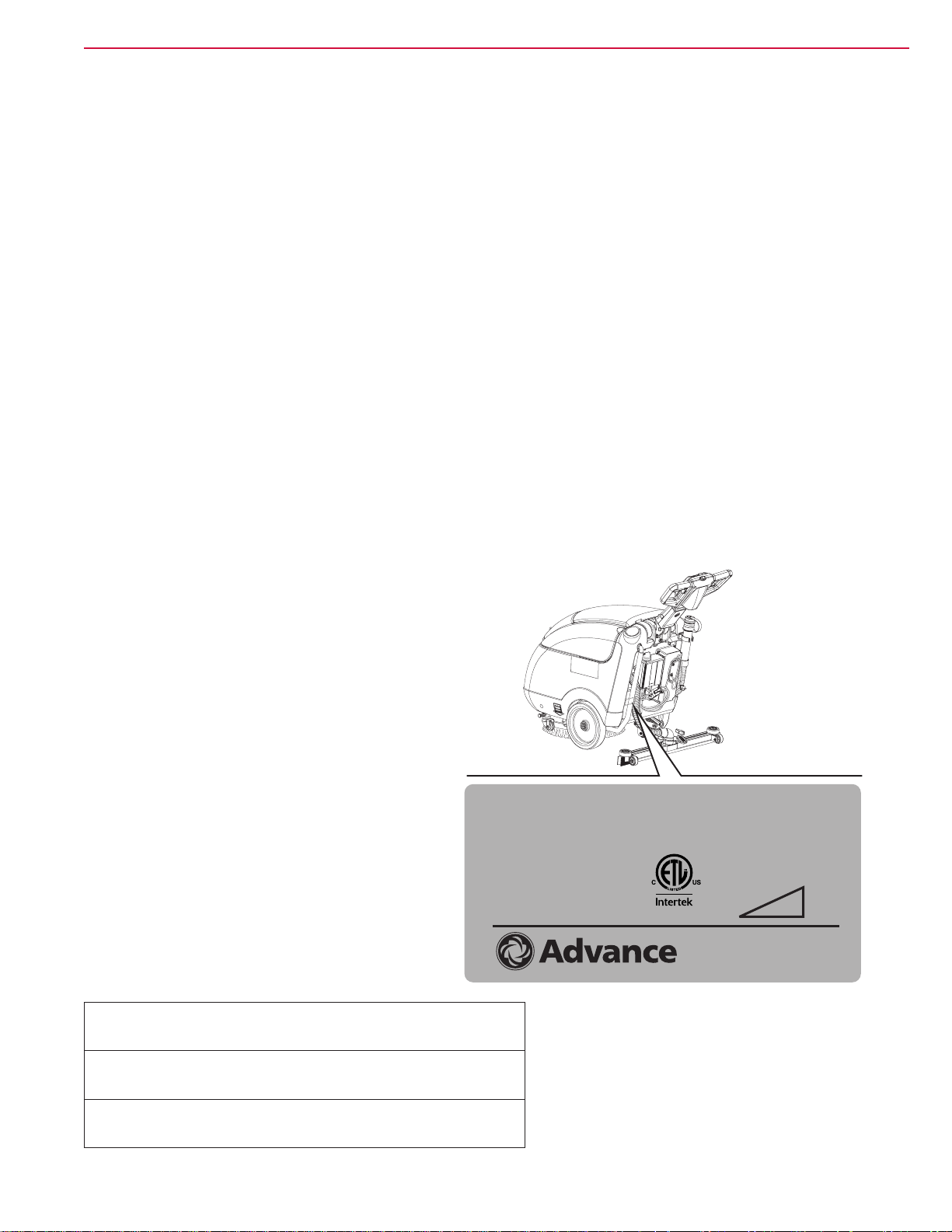

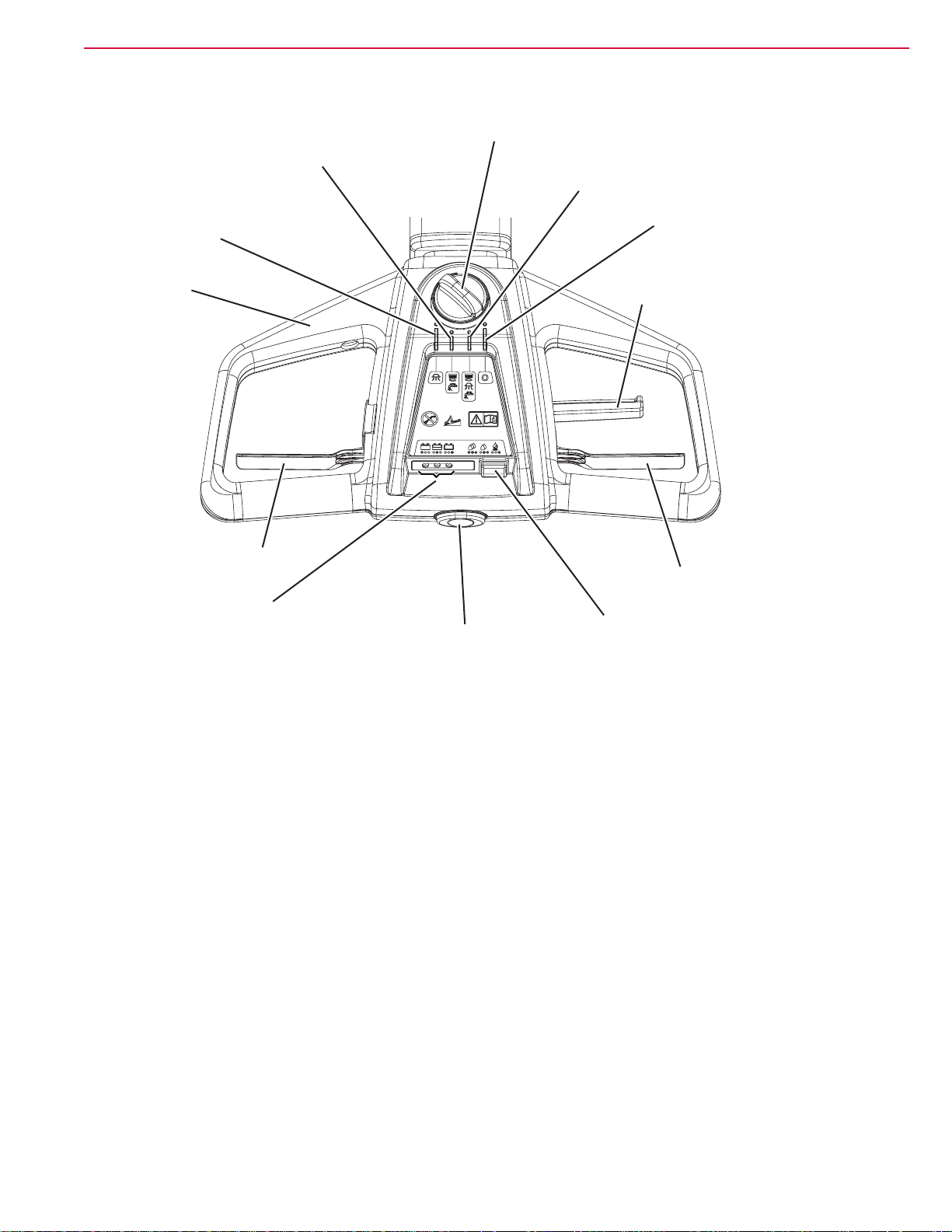

Machine Nomenclature (know your machine) . . . . . . . . . . . . . . . . . . . . . . . . 10

Handlebar with Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Service and Diagnostic Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Scheduled Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Table of Contents 2Service Manual – SC400

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Controls and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Machine Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Recovery System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Page 3

Table of Contents 3Service Manual – SC400

Scrub System, Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Solution System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Squeegee System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Wheel System, Non-Traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Page 4

Service Manual – SC400

General Information

General Information

Machine General Description

The SC400 is a “man-down” industrial machine designed to wash and dry oors, in civil or industrial environments, in one pass. The machine is powered by on-board batteries. The machine is equipped with a single

disc brush, a controlled solution ow dosing system and a rear squeegee with blades, which dries the oor by

vacuuming the dirty water.

Service Manual Purpose and Field of Application

The Service Manual is a technical resource intended to help service technicians when carrying out mainte-

nance and repairs on the SC400, to guarantee the best cleaning performance and a long working life for the

machine.

Please read this manual carefully before performing any maintenance and repair procedure on the machine.

Other Reference Manuals

4

Model Product Code User Manual Spare Parts List

Nilsk SC400 9087311020

Nilsk SC400 9087318020

Advance SC400 9087310020 9099626000 9099627000

These manuals are available at:

− Local Nilsk-Advance Retailer

− Nilsk-Advance website: www.nilsk.com - www.advance-us.com

9099612000 9099613000

Page 5

Service Manual – SC400

General Information

Conventions

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, that is to

say in driving position with the hands on the handlebar.

Service and Spare Parts

Service and repairs must be performed only by authorised personnel or Nilsk Service Centers. The authorised

personnel is trained directly at the manufacturer’s premises and has original spare parts and accessories.

Contact Nilsk Retailer indicated below for service or to order spare parts and accessories, specifying the ma-

chine model and serial number.

(Apply Retailer label here)

5

Serial Number Label

The machine model name and serial number are

marked on the plate (see the example to the side).

Product number and year of production are marked

on the same plate.

This information is useful when requiring machine

spare parts.

Use the following table to write down the machine

identication data.

Model: Scrubber-Dryer SC400 17 B

Prod. Nr: 9087310020

GVW: 136 kg/300 lb

29 A Charg.110-240Vac 50-60 Hz

Type E Scrubber Dryer

Conform to:

UL STD 583

Certified to:

CSA STD C22.2 N.68-92

A Nilfisk-Advance Brand

IPX4

3084826

Serial No: ..................

Date code: .......

LpA = 65 dB(A)

Battery 24 Vdc

2%

“Made in Hungary”

Nilfisk-Advance, Inc.

Plymouth, MN, USA

www.advance-us.com

Model ...............................................................................................................

Product Nr. .......................................................................................................

Serial No.

.........................................................................................................

Page 6

Service Manual – SC400

General Information

Safety

The following symbols indicate potentially dangerous situations. Always read this information carefully and

take all necessary precautions to safeguard people and property.

Symbols

Danger! It indicates a dangerous situation with risk of death for the operator.

Warning! It indicates a potential risk of injury for people or damage to objects.

Caution! It indicates a caution related to important or useful functions.

Note: It indicates a remark related to important or useful functions.

6

General Instructions

Specic warnings and cautions to inform about potential damages to people and machine are shown below.

Warning! Make sure to follow the safety precautions to avoid situations that may lead to

serious injuries.

– Before performing any cleaning, maintenance, repair or replacement procedure, turn the pro-

gram selection knob to “0” and disconnect the battery connector.

– This machine must be used by properly trained operators only.

– Do not wear jewels when working near electrical components.

– Do not work under the lifted machine, if it is not securely xed.

– Do not operate the machine near toxic, dangerous, ammable and/or explosive powders, liquids

or vapors. This machine is not suitable for collecting dangerous powders.

– (For WET batteries only). Keep the battery away from sparks, ames and incandescent material.

During the normal operation explosive gases are released.

– (For WET batteries only). Battery charging produces highly explosive hydrogen gas. Keep the

battery cover open during battery charging and perform this procedure in well-ventilated areas

and away from naked ames.

Page 7

Service Manual – SC400

Caution! Make sure to follow the safety precautions to avoid situations that may lead to

– Carefully read all the instructions before performing any maintenance/repair procedure.

– Before using the battery charger, ensure that frequency and voltage values, indicated on the

machine serial number plate, match the mains voltage.

– Do not pull or carry the machine by the battery charger cable and never use the battery charger

cable as a handle. Do not close a door on the battery charger cable, or pull the battery charger

cable around sharp edges or corners. Do not run the machine on the battery charger cable.

– To reduce the risk of re, electric shock, or injury, do not leave the machine unattended when it

is plugged in.

– Keep the battery charger cable away from heated surfaces.

– Before performing any maintenance procedure, disconnect the battery charger cable from the

electrical mains to avoid any risk of re, electric shock or injuries.

– Do not smoke while charging the batteries.

– Always protect the machine against the sun, rain and bad weather, both under operation and

inactivity condition. Store the machine indoors, in a dry place.

– Before using the machine, close all doors and/or covers.

– This machine is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the machine by a person responsible for they safety.

Children should be supervised to ensure that they do not play with the machine.

– Close attention is necessary when used near children.

– Use only as shown in this Manual. Use only Nilsk’s recommended accessories.

– Check the machine carefully before each use, always check that all the components have been as-

sembled before use. If the machine is not perfectly assembled it can cause damages to people and

properties.

– Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the

machine moving parts.

– Do not use the machine on slopes with a gradient exceeding the specications.

– Do not use the machine on incline.

– Do not tilt the machine more than the angle indicated on the machine itself, in order to prevent

instability.

– Do not use the machine in particularly dusty areas.

– Use the machine only where a proper lighting is provided.

– While using this machine, take care not to cause damage to people or objects.

– Do not bump into shelves or scaffoldings, especially where there is a risk of falling objects.

– Do not lean liquid containers on the machine, use the relevant can holder.

– The machine working temperature must be between 0°C and +40°C.

– The storage temperature must be between 0°C and +40°C.

– The humidity must be between 30% and 95%.

– When using oor cleaning detergents, follow the instructions on the labels of the detergent

bottles.

– To handle oor cleaning detergents, wear suitable gloves and protections.

– Do not use the machine as a means of transport; do not push/tow it.

– Do not allow the brush to operate while the machine is stationary to avoid damaging the oor.

– In case of re, use a powder re extinguisher, not a water one.

– Do not tamper with the machine safety guards and follow the ordinary maintenance instructions

scrupulously.

– Do not allow any object to enter into the openings. Do not use the machine if the openings are

clogged. Always keep the openings free from dust, hairs and any other foreign material which

could reduce the air ow.

– Do not remove or modify the plates afxed to the machine.

– This machine cannot be used on roads or public streets.

– Pay attention during machine transportation when temperature is below freezing point. The

water in the recovery tank or in the hoses could freeze and seriously damage the machine.

serious injuries, damages to materials or equipments.

General Information

7

Page 8

Service Manual – SC400

– Use only brushes supplied with the machine or those specied in the User Manual. Using other

brushes could reduce safety.

– If parts must be replaced, require ORIGINAL spare parts from an Authorised Dealer or Retailer.

– Do not wash the machine with direct or pressurised water jets, or with corrosive substances.

– The machine must be disposed of properly, because of the presence of toxic-harmful materials

(batteries, oils, etc.), which are subject to standards that require disposal in special centres (see

the User Manual).

– (For WET batteries only). When lead (WET) batteries are installed on the machine, do not tilt

the machine for more than 30° from the horizontal plane to prevent the highly corrosive acid

from leaking out of the batteries. If the machine must be tilted to perform any maintenance pro-

cedure, remove the batteries.

General Information

8

Page 9

Service Manual – SC400

Machine Lifting

Warning! Donotworkundertheliftedmachine,ifitisnotsecurelyxed.

Machine Transportation

Warning! Before transporting the machine, make sure that:

All covers are closed.

The recovery tank and the detergent tank are empty.

The batteries are disconnected.

The machine is securely fastened to the means of transport.

General Information

9

Page 10

Service Manual – SC400

Solution tank

Machine Nomenclature (know your machine)

Recovery tank

Solution flow opening/closing valve

Solution solenoid valve

Recovery tank cover

Can holder

General Information

Handlebar with control panel

Recovery water drain plug

Recovery water drain hose bracket

Recovery water drain hose

10

Brush deck

Parking wheel

Electrical component box

Battery charger

Solution drain hose with level check marks

Battery charger warning lights

Battery charger cable

Battery connector (red)

Serial number plate/technical data/conformity

certification

Squeegee vacuum hose

Squeegee mounting handwheels

Squeegee blade mounting springs

Squeegee lifting/lowering pedal

Squeegee

Rear squeegee blade

Front squeegee blade

Rear support wheel, when the squeegee is lifted

Solution filter

Central wheels on fixed axle

Brush

Parking wheel positioning pin

P200042

Page 11

Service Manual – SC400

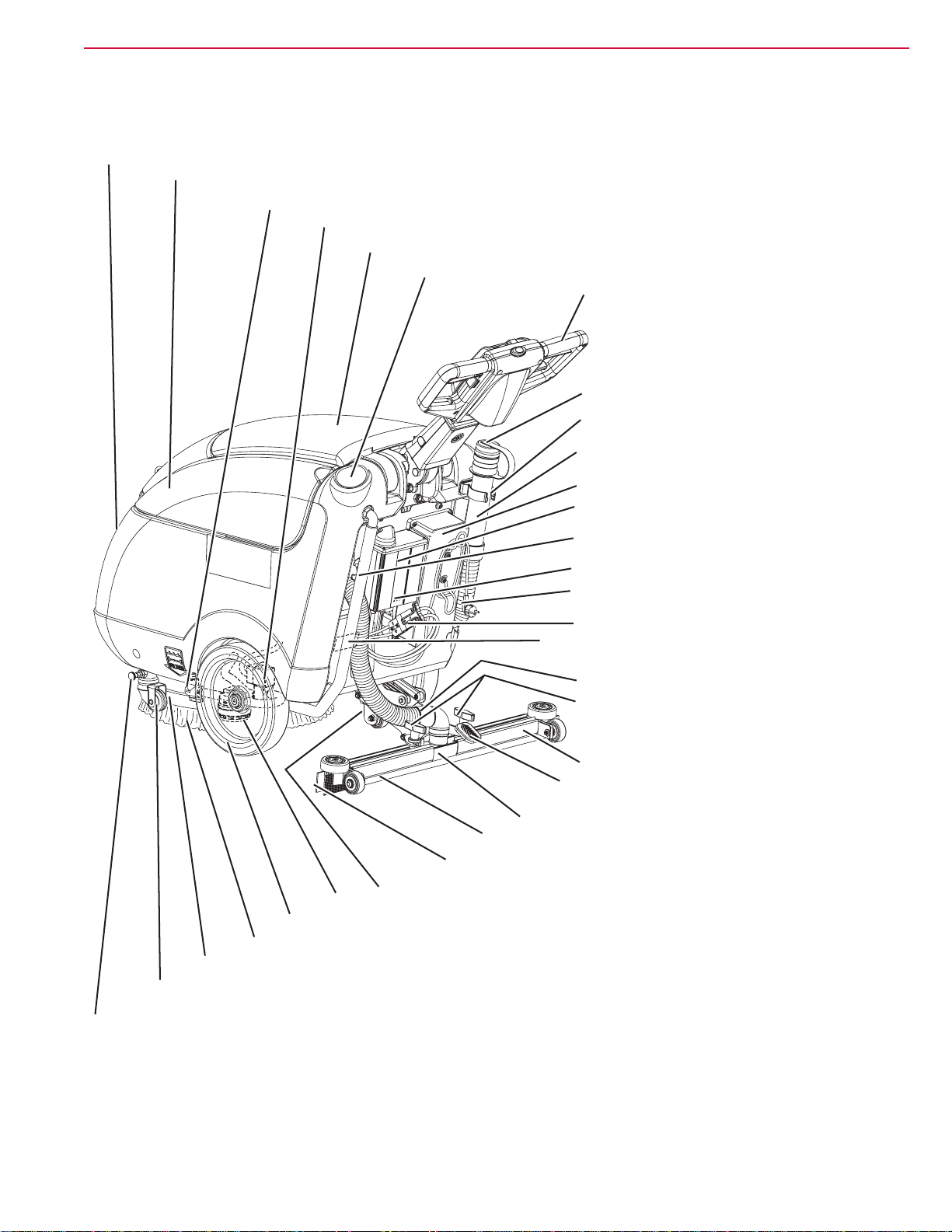

Recovery tank cover (open)

Machine Nomenclature (Continues)

Recovery tank cover gasket

General Information

11

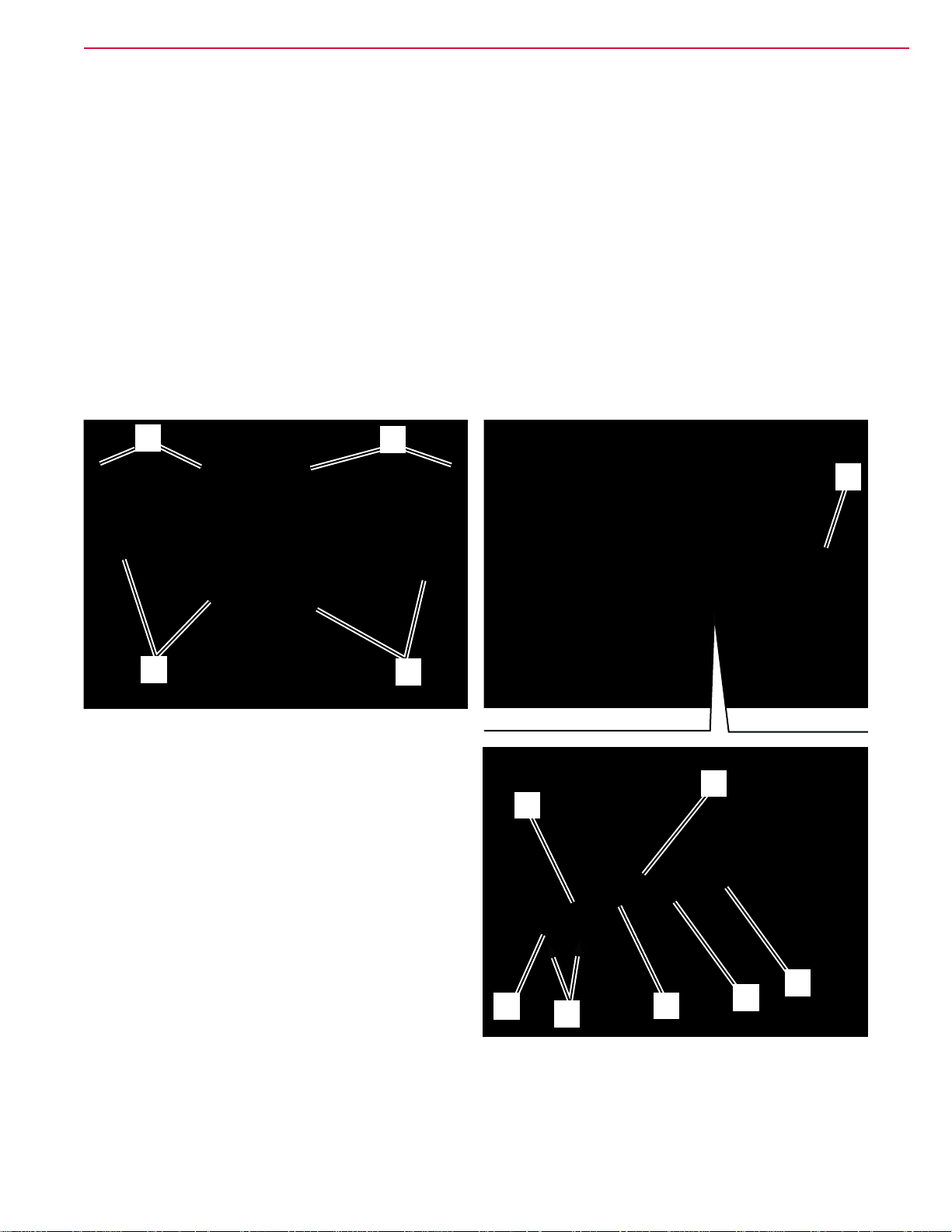

Battery

connection

diagram

FRON T OF

MACH INE

12V 12V

BACK OF

MACH INE

Batteries

Lifted

squeegee

Machine forward

speed adjusting handwheel

PANEL

PANEL

Brush

Vacuum grid with automatic shut-off float

Recovery tank compartment

Detergent removable filler hose

Solution tank filler neck

Front brush support

Vacuum system motor

Brush motor

Machine straight forward

movement adjusting handwheel

Pad-holder

Pad

Brush rotation direction

P200003

Page 12

Service Manual – SC400

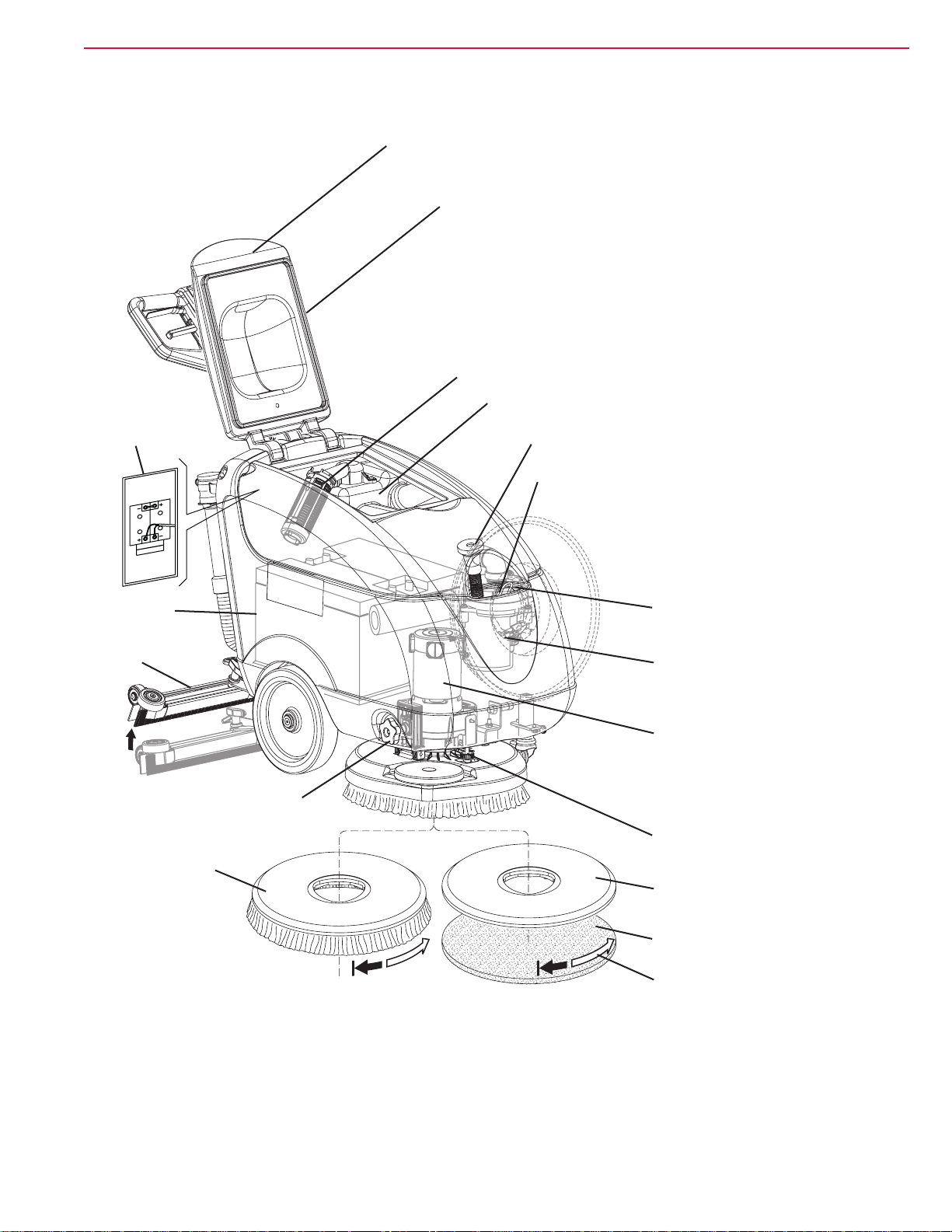

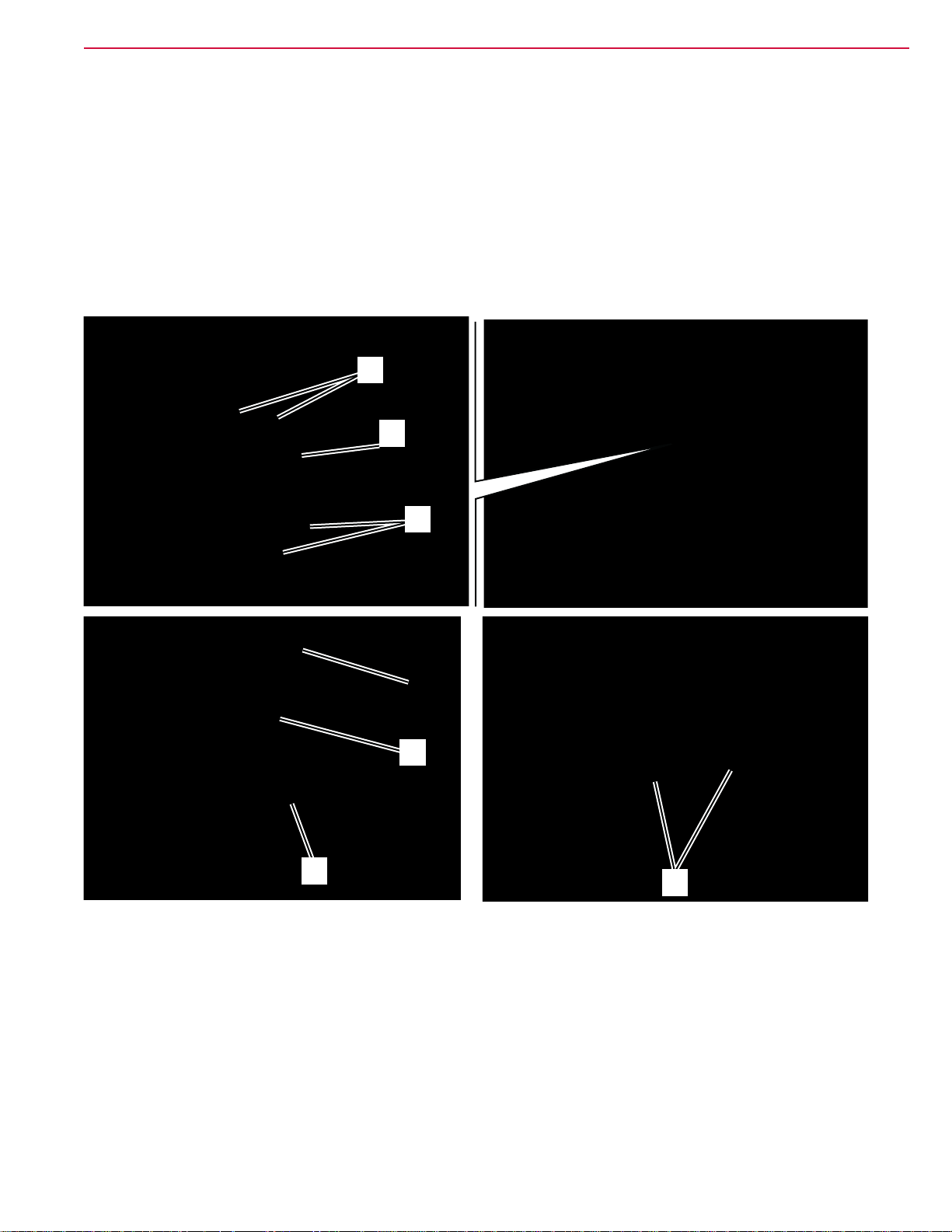

Program selection knob / rotary switch

Handlebar with Control Panel

Program: brush - solution

flow activation

Program: vacuum

system activation

General Information

Program: brush - vacuum system solution flow activation

Machine switching off “0”

12

Handlebar

Handlebar inclination

adjusting lever

Brush lever(*)

Brush lever(*)

LED indicators for:

- solution quantity

- battery charge

Machine start-up enabling

push-button(*)

Solution flow push-button

(*) The brush levers operate only after pushing the machine start-up enabling push-button

P200044

Page 13

Service Manual – SC400

General Information

Service and Diagnostic Equipment

Besides a complete set of standard meters, the following instruments are necessary to perform fast checks,

maintenance and repairs on Nilsk-Advance machines:

Besides a complete set of standard meters, the following instruments are necessary to perform fast checks and

repairs on Nilsk-Advance machines:

• Laptop computer charged with the current version of EzParts, Adobe Reader and (if possible) Internet

connection

• Digital Volt Meter (DVM)

• Amp clamp with possibility of making DC measurements

• Hydrometer

• Battery charge tester to check 12V batteries

• Static control wrist strap

• Dynamometric wrench set

• A copy of the User Manual and Spare Parts List of the machine to be serviced (provided with the machine

or available at www.advance-us.com or other Nilsk-Advance websites).

The following equipment is also available at Nilsk-Advance Centers:

• Vacuum water lift gauge, P/N 56205281

13

Page 14

Service Manual – SC400

Technical Data

General Information

14

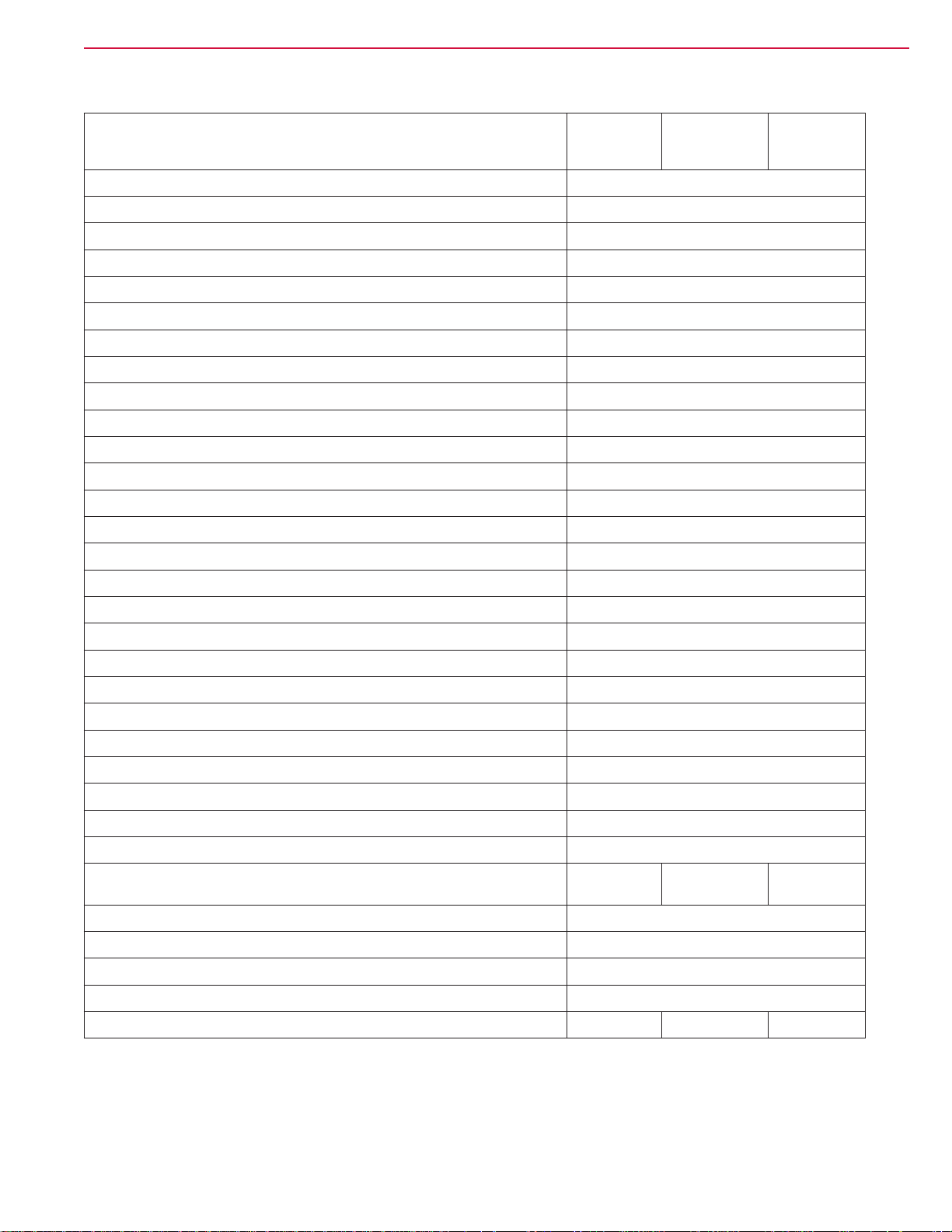

General

Advance

SC400 17 B

Nilsk

SC400 43 B

FULL PKG

SC400 43 B

Solution tank capacity 6.0 US gal (23 liters)

Recovery tank capacity 5.5 US gal (21 liters)

Machine length 48.4 in (1,230 mm)

Machine width with squeegee 28.3 in (720 mm)

Machine width without squeegee 22.4 in (570 mm)

Min/max machine height with adjustable handlebar 28.5 - 43.9 in (725 - 1,115 mm)

Minimum turning radius 29.5 in (750 mm)

Cleaning width 17 in (430 mm)

Diameter of wheels on xed axle 9.8 in (250 mm)

Wheel pressure on the oor 290 psi (2 N/mm

2

)

Brush/pad diameter 17 in (430 - 432 mm)

Brush pressure with full tank and lowered squeegee 77 lb (35 kg)

Min/max solution ow 01 / 042 gpm (0.4 / 1.6 liters/min)

Sound pressure level at workstation (ISO 11201, ISO 4871, EN 60335-2-72) (LpA) 65 dB(A) ± 3 dB(A)

Machine sound pressure level (ISO 3744, ISO 4871, EN 60335-2-72) (LwA) 89 dB(A)

Vibration level at the operator’s arms (ISO 5349-1, EN 60335-2-72) < 98.4 in/s

2

(< 2.5 m/s2)

Nilsk

Maximum gradient when working 2%

IP protection class X4

Protection class (electric) III

Vacuum system motor power 0.4 hp (300 W)

Vacuum water lift (blocked) 47.2 inH

O (1,200 mmH2O)

2

Brush motor power 0.6 hp (450 W)

Brush motor speed 155 rpm

Total absorbed power 29 A (0.75 kW)

Battery compartment size 13.7x17.7x10.2 in (350x350x260 mm)

Battery voltage 24V

Standard batteries (2) -

12V - 50 Ah C5

(AGM) Spiracell

-

Battery charger 100-240 VAC

Work autonomy (standard batteries) 1.5 hour

Weight without batteries and with empty tanks 130 lb (59 kg)

Gross vehicle weight (GVW) 300 lb (136 kg)

Shipping weight 179 lb / 81 kg 267 lb / 121 kg 179 lb / 81 kg

Page 15

Service Manual – SC400

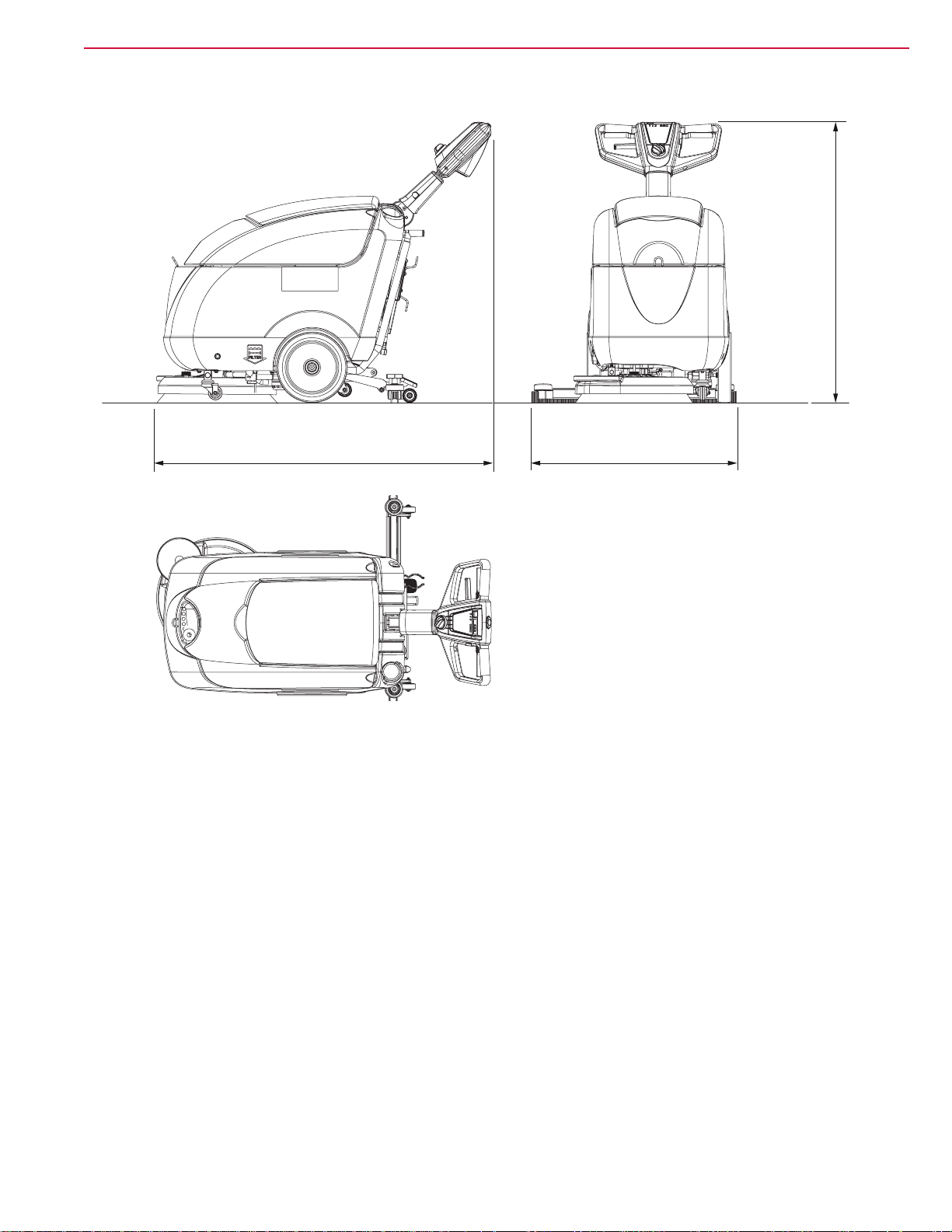

Dimensions

General Information

15

725 ÷ 1115 mm (28.5 ÷ 43.9 in)

720 mm (28.3 in)1230 mm (48.4 in)

P200074

Page 16

Service Manual – SC400

General Information

Maintenance

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

Warning! Read carefully the instructions in the Safety chapter before performing any

maintenance procedure.

The following table provides the scheduled maintenance. The intervals shown may vary according to particu-

lar working conditions, which are to be dened by the person in charge of the maintenance.

For instructions on maintenance procedures, see the following paragraphs.

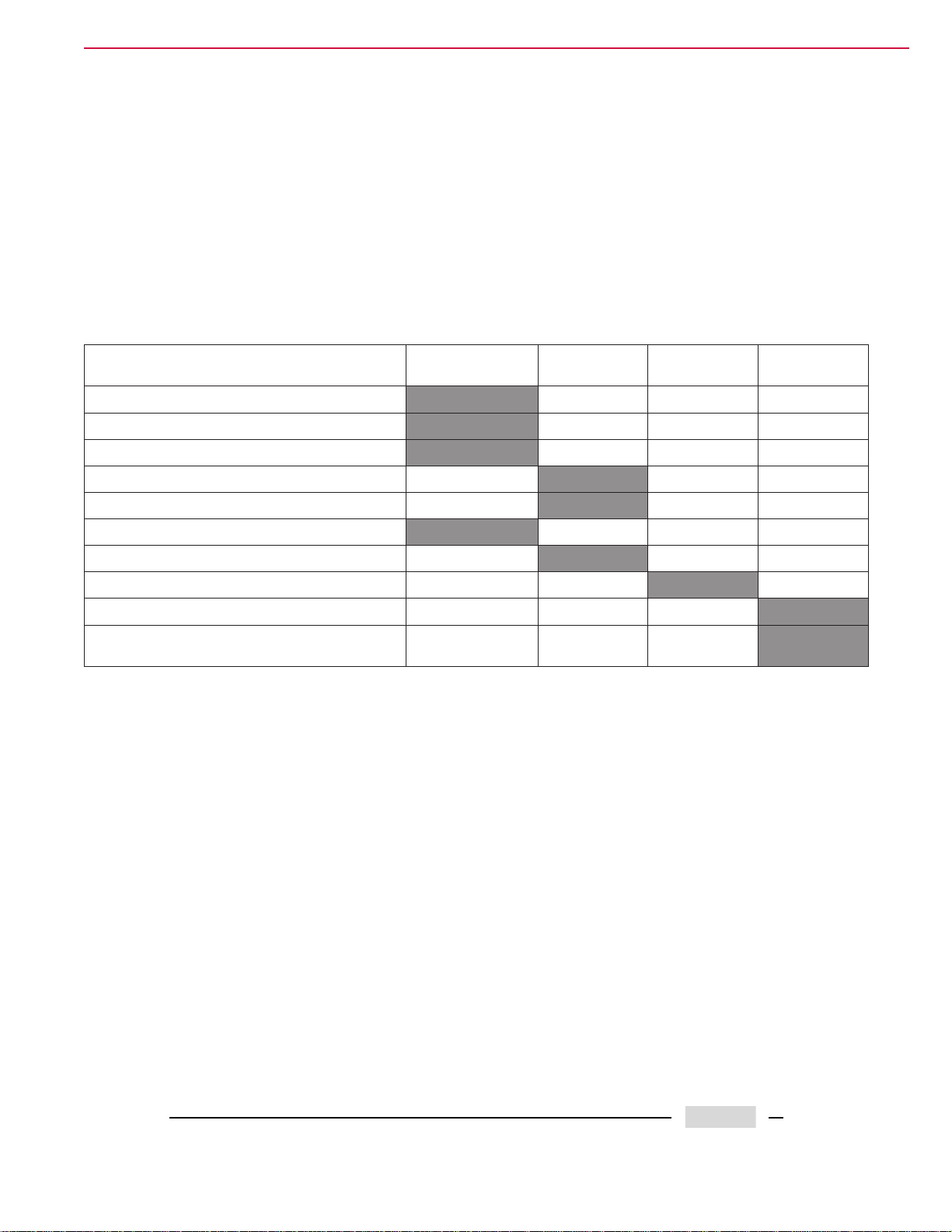

Scheduled Maintenance Table

16

Procedure

Squeegee Cleaning

Brush Cleaning

Tank and Vacuum Grid Cleaning

Squeegee Blade Check and Replacement

Solution Filter Cleaning

Battery Charging

WET battery uid level check

Screw and nut tightening check (1)

Brush motor carbon brush check and replacement

Vacuum system motor carbon brush check and

replacement

Daily, after using the

machine

Weekly

Every six

months

(1) And after the rst 8 working hours.

Yearly

Page 17

Control System

Functional Description

Control System 17Service Manual – SC400

The function control is performed with the program

selection knob/rotary switch (SW1), the machine

start-up enabling push button (SW2) (which can be

used simultaneously with the brush levers) and the

solution ow push-button (SW3).

The switch outputs are read by the function electron-

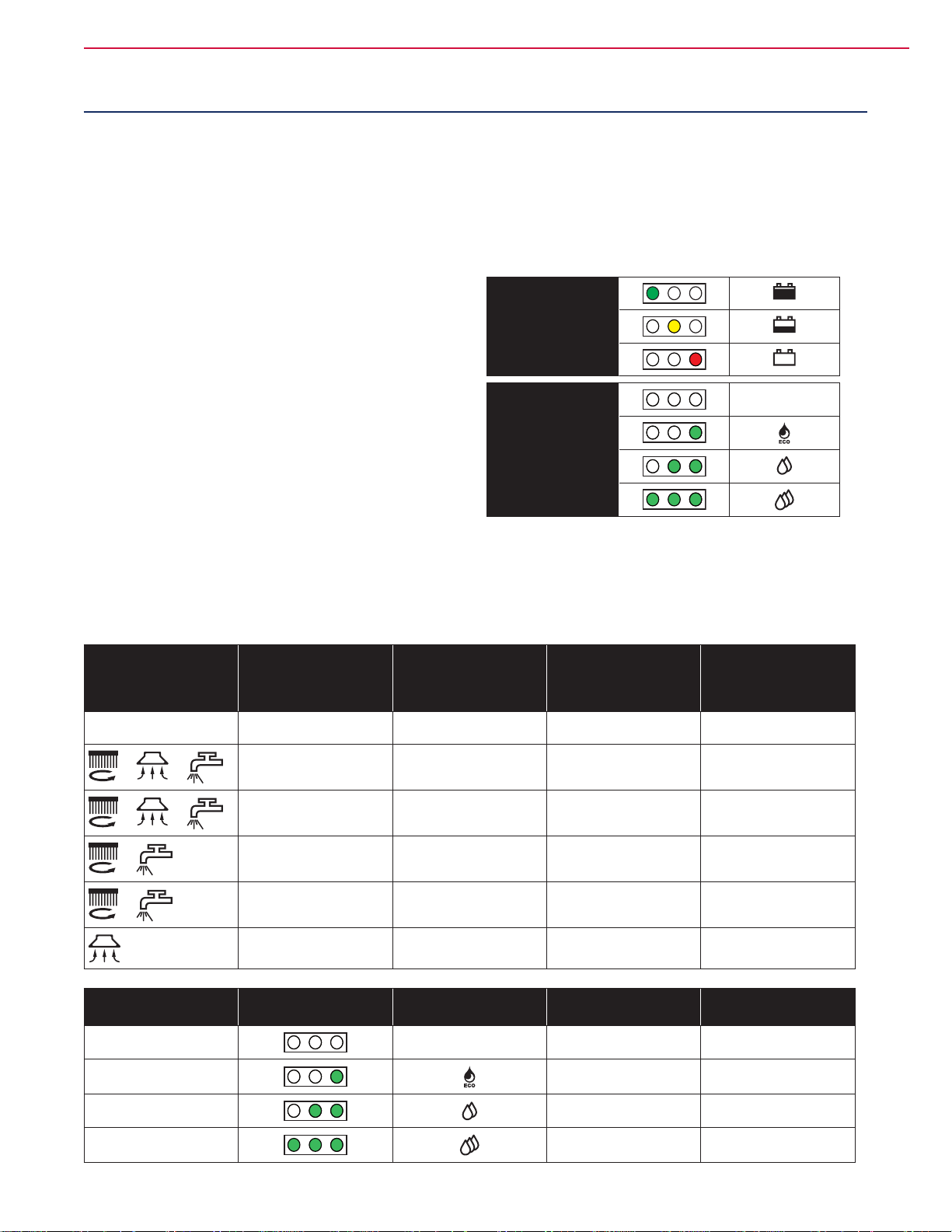

The LED electronic board (EBLED) has a set of 3

two-color LEDs. The set of 3 LEDs is used to indicate

either battery charge level or water ow level depending on the current mode of operation:

LEDs to display the

battery charge level

ic board (EB1) which consequently controls the relevant outputs: electromagnetic switch (K1) for brush

motor, relay (K2) for vacuum system motor, while the

solenoid valve (EV1) is activated directly form the

electronic board.

The control circuits are protected by the fuse (F3) on

LEDs to set water

ow level

the function electronic board (EB1).

The LED electronic board (EBLED) is driven by the

function electronic board (EB1).

Diagram of Output Activation according to the Position of the Switches (SW1), (SW2)

and (SW3)

Program selection knob

/rotary switch (SW1)

settings

Machine start-up

enabling push button

(SW2) settings (with

brush levers)

Function electronic

board (EB1) + LED

electronic board

(EBLED)

Brush motor (M1) +

solenoid valve (EV1)

Vacuum system motor

(M2)

O

Solution ow push-

button setting (SW3)

0

1

2

3

Pressed/released Off Off Off

Released On Off On

Pressed On On On

Released On Off Off

Pressed On On Off

Pressed/released On Off On

LED display Symbols Solenoid valve ON time

(EV1)

- Always OFF

1 sec 5 sec

3 sec 3 sec

Always ON -

Solenoid valve OFF time

(EV1)

Page 18

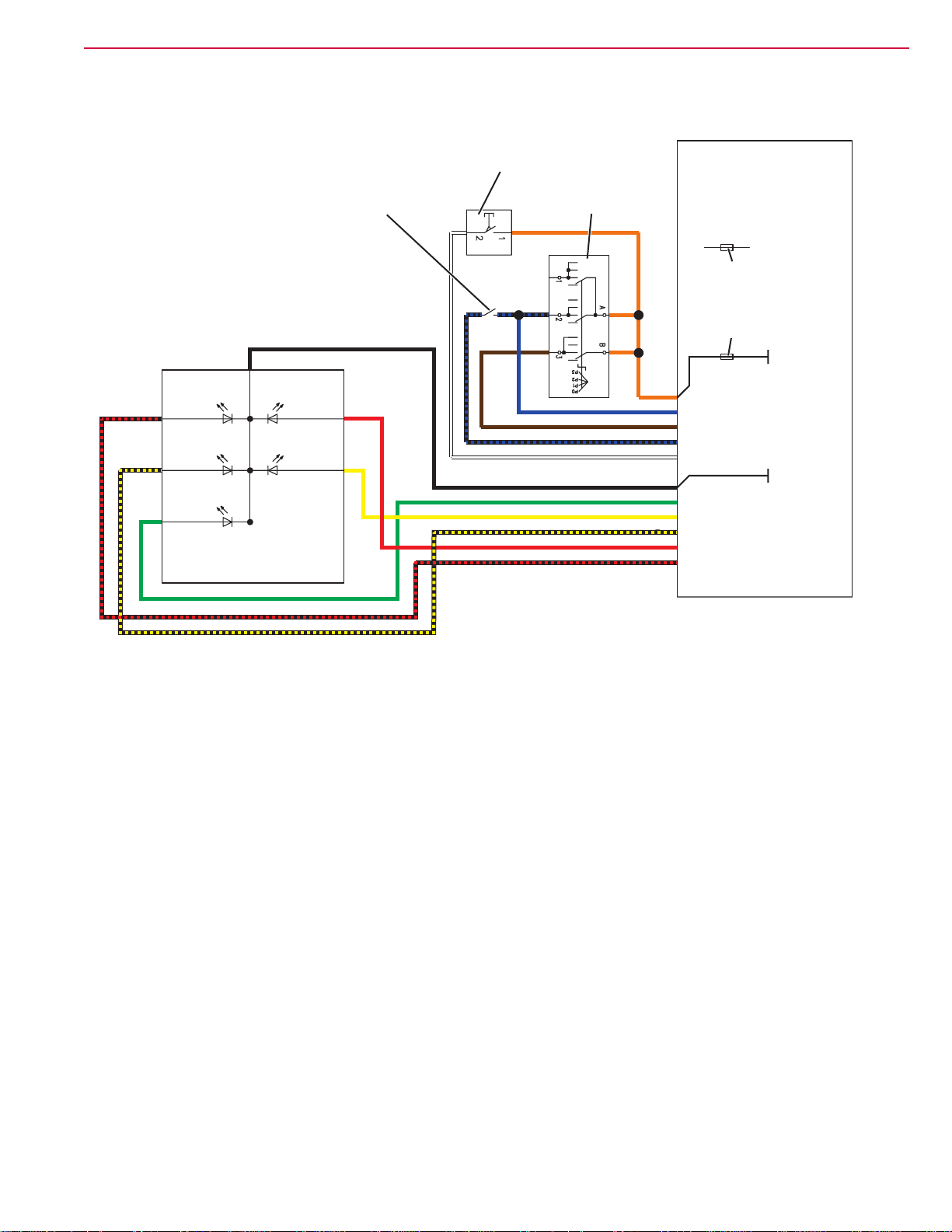

Wiring Diagram

Control System 18Service Manual – SC400

DETERGENT FLOW

PUSH-BUTTON (SW3)

JA.6 - LDC-Green anode

LED power supply

JA.4 - LDB-Green anode

LED power supply

JA.2 – LDA-Green anode

LED power supply

LED ELECTRONIC

BOARD (EBLED)

BRUSH ENABLING

PUSH-BUTTON (SW2)

JA.1 - Common cathode

LED power supply

JA.5 – LDC-Red anode

LED power supply

JA.3 – LDB-Yellow anode

LED power supply

ROTARY SWITCH (SW1)

FUNCTION ELECTRONIC

BOARD (EB1)

BRUSH RELEASE

FUSE (F4)

SIGNAL CIRCUIT

FUSE (F3)

+ 24V

J3.1 - Control power supply

J3.2 - Brush function return

J3.3 - Vacuum system function return

J3.4 - Brush rotation enabling

J3.5 - Water push-button return

J3.7 - Common cathode LED power supply

J3.8 - LDA-G anode LED power supply

J3.9 - LDB-Y anode LED power supply

J3.10 - LDB-G anode LED power supply

J3.11 - LDC-R anode LED power supply

J3.12 - LDC-G anode LED power supply

B -

P200075

Page 19

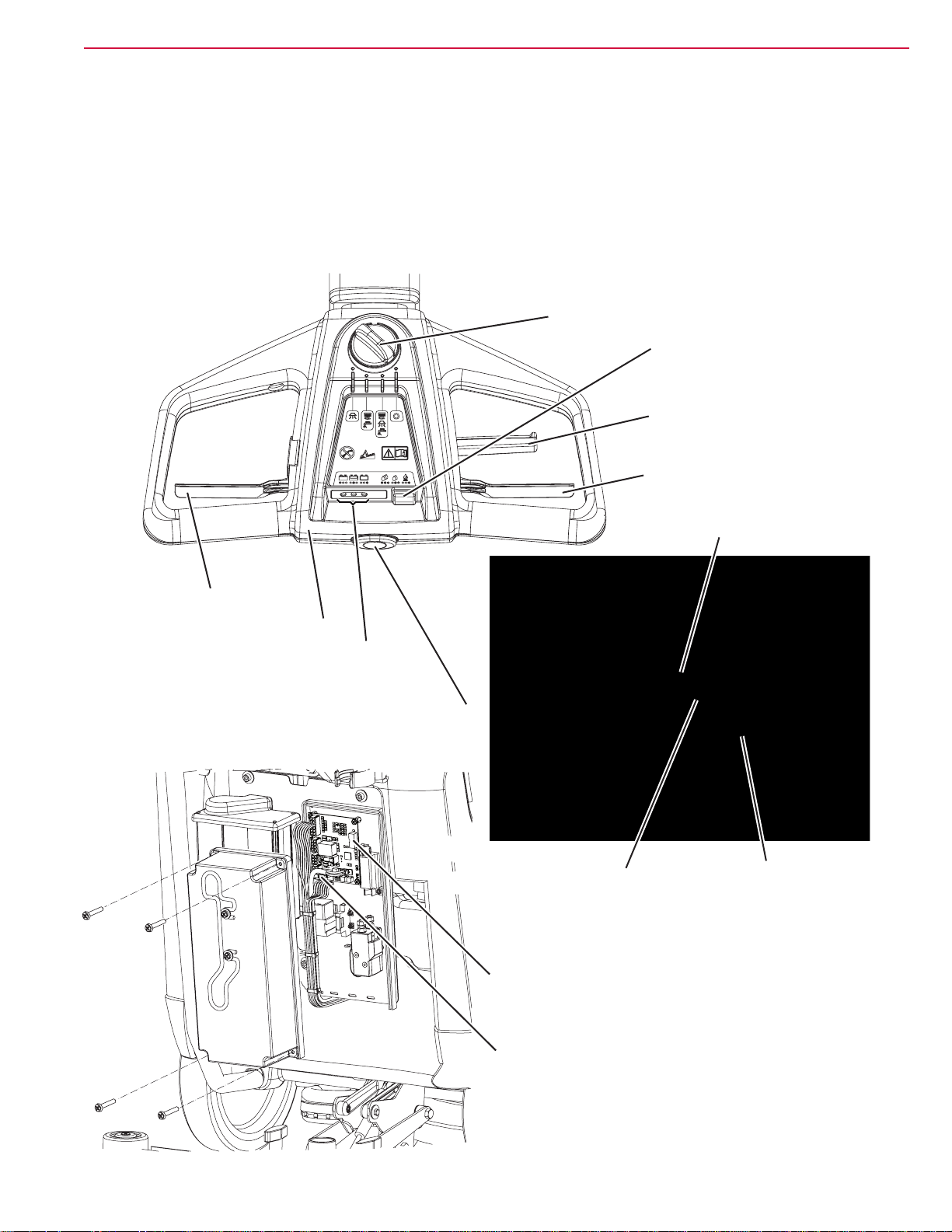

Component Locations

Control System 19Service Manual – SC400

• Handlebar with control panel

• Program selection knob / rotary switch (SW1)

• LED indicators for:

– solution quantity

– battery charge

• Rotary switch (SW1)

• Brush levers

• Machine start-up enabling push button (SW2)

• Solution ow push-button (SW3)

• Function electronic board (EB1)

• LED electronic board (EBLED)

• Low consumption circuit fuse (F3)

• Wiring harness

• Handlebar inclination adjusting lever

Program selection knob/

rotary switch (SW1)

Solution flow

push-button (SW3)

Handlebar inclination

adjusting lever

Brush lever

Rotary switch (SW1)

Brush lever

Handlebar with control panel

LED indicators for:

- solution quantity

- battery charge

enabling push button (SW2)

Machine start-up

Wiring harness

Function electronic board (EB1)

LED electronic board

(EBLED)

Low consumption circuit fuse (F3)

P200045

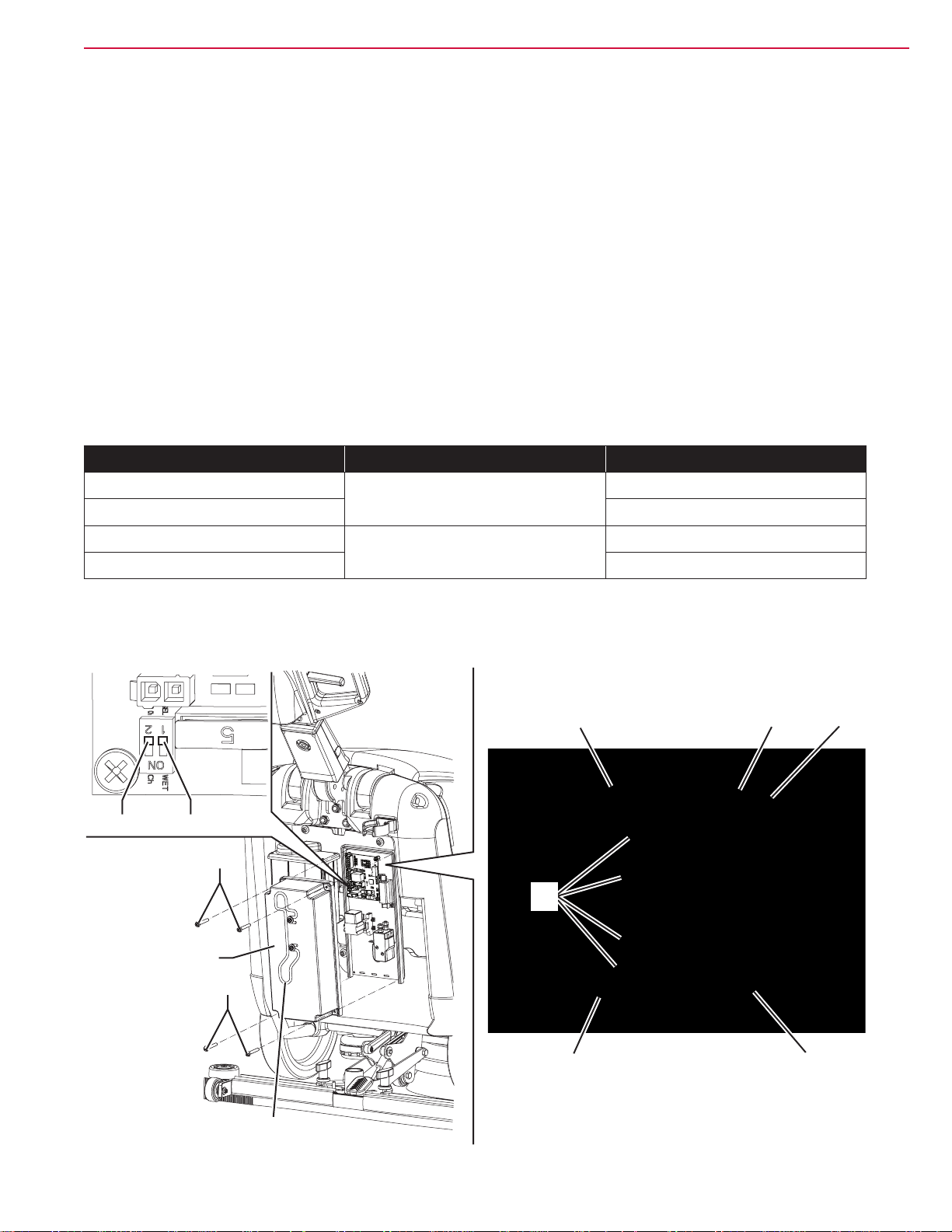

Page 20

Removal and Installation

Function Electronic Board (EB1) Disassembly/Assembly

Disassembly

Control System 20Service Manual – SC400

1. Drive the machine on a level oor. Make sure

that the machine cannot move independently.

2. Turn the machine program selection knob to “0”.

3. Disconnect the battery connector (red).

4. Disconnect the battery charger cable from the

holder (A).

5. Remove the screws (B) and remove the cover (C).

Fitting DIP-switch DIP-switch position

WET batteries

GEL-AGM batteries GEL (OFF)

Battery charger installed (standard)

Battery charger not installed NO CH (ON)

Note: The battery charger is installed on the machine as a standard component; the dip-

switch must be turned to OFF (CH position)

6. Disconnect the connectors (D) of the function

electronic board (E).

7. Remove the screws (F) and remove the function

electronic board (E).

Assembly

8. Assemble the components in the reverse order of

disassembly, and note the following:

• Set the DIP-switches (G) according to the

machine tting as shown below.

WET (ON)

DIP 1

CH (OFF)

DIP 2

G

G

C

B

B

A

D

F

E

F

F

F

P200046

Page 21

Control System 21Service Manual – SC400

LED Electronic Board (EBLED) Disassembly/Assembly

Disassembly

1. Drive the machine on a level oor. Make sure that the machine cannot move independently.

2. Turn the machine program selection knob to “0”.

3. Disconnect the battery connector (red).

4. On the lower side of the handlebar with the control panel, unscrew the screws (A).

5. Lower the upper side (B) of the handlebar with the control panel.

6. Disconnect the connector (C) of the LED electronic board (D). Remove the screws (E) and remove the

LED electronic board (D).

7. If necessary, disconnect the connector (F) and remove the solution ow push-button (G) by disengaging

the inner tabs (H).

A

A

A

B

A

C

F

G

H

E

D

E

P200047

Page 22

Control System 22Service Manual – SC400

LED Electronic Board (EBLED) Disassembly/Assembly (Continues)

8. If necessary, remove the selector assembly (N) of the machine program selection knob (I), as shown

below:

• Disconnect the connectors (J)

• On the outer side, turn the knob (I) on the position (K) (vacuum system activation).

• Loosen the set screw inside the housing (L), then remove the knob (I) from the housing.

• Remove the screws (M) and, from the inside, remove the selector assembly (N) of the knob (I).

Assembly

9. Assemble the components in the reverse order of disassembly.

J

N

J

K

I

L

M

P20048

Page 23

Machine Start-up Enabling Push-Button Disassembly/Assembly (SW2)

Disassembly

Control System 23Service Manual – SC400

1. Drive the machine on a level oor. Make sure

that the machine cannot move independently.

2. Turn the machine program selection knob to “0”.

3. Disconnect the battery connector (red).

4. On the lower side of the handlebar with the

control panel, unscrew the screws (A).

5. Move the upper side (B) of the handlebar with

the control panel.

6. Remove the screws (C) and move the lower side

(D) of the handlebar from the frame (E).

A

A

7. Disconnect the connectors (F) of the brush

enabling push-button (G).

8. Remove the screws (H) and remove the switch

(G).

9. If necessary, remove from the housing the

enabling push-button (I) of the switch (G).

10. If necessary, remove the brush levers (J) from

the housing.

Assembly

11. Assemble the components in the reverse order of

disassembly.

B

D

A

A

CC

E

J

I

H

J

F

F

G

P200049

Page 24

Specications

FunctionElectronicBoard(EB1)Specications

FUSES

Control System 24Service Manual – SC400

F4

F3

Code Description Type Size

F3 Low consumption circuit fuse LITTELFUSE ATOFUSE 5A

F4 Brush release circuit fuse OMEGA CT520320 20A

DIP-SWITCHES

GEL

Ch

12

ON

WET

NO Ch

Code Description

DIP1 WET/GEL selector

DIP2 Battery charger enabling

Page 25

Function Electronic Board (EB1) Connectors

J1: MOLEX MINIFIT type, 6-ways vertical

Control System 25Service Manual – SC400

J1

456

123

PIN Description

1 Electronic board power supply + in 24V 5A BAT

2 Solenoid valve power supply + out 24V 1A EV1

3 Solenoid valve power supply - out 0V 1A EV1

4 Not used

5 Not used

6 Not used

Electronic board

in/out

V ref. I max. Connected to

Page 26

Function Electronic Board (EB1) Connectors (Continues)

J2: MOLEX MINIFIT type, 8-ways vertical

J2

Control System 26Service Manual – SC400

5678

1234

PIN Description Electronic board

1 Brush fuse voltage drop reading + in 0V <1A F1

2 Brush fuse voltage drop reading - in 0V <1A F1

3 Brush electromagnetic switch power supply

-

4 Vacuum system relay power supply - out 0V 1A ES2

5 Electromagnetic switch/relay power supply

+

6 Brush motor braking circuit in 24V 100A imp. 0A cont. ES1.NC

7 Electronic board power supply - in 0V 5A BAT

8 Not used

in/out

out 0V 1A ES1

out 24V 2A ES1-ES2

V ref. I max. Connected to

Page 27

Function Electronic Board (EB1) Connectors (Continues)

J3: MOLEX MINIFIT type, 12-ways vertical

J3

Control System 27Service Manual – SC400

789101112

123456

PIN Description Electronic board

in/out

1 Control power supply out 24V <1A SW1 - 2 - 3

2 Brush function return in 24V <1A SW1

3 Vacuum system function return in 24V <1A SW1

4 Brush rotation enabling in 24V <1A SW2

5 Water push-button return in 24V <1A SW3

6 Not used

7 Common cathode LED power supply out 0V <1A JA.1

8 LDA-G anode LED power supply out 0.7V <1A JA.2

9 LDB-Y anode LED power supply out 0.7V <1A JA.3

10 LDB-G anode LED power supply out 0.7V <1A JA.4

11 LDC-R anode LED power supply out 0.7V <1A JA.5

12 LDC-G anode LED power supply out 0.7V <1A JA.6

V ref. I max. Connected to

Page 28

Function Electronic Board (EB1) Connectors (Continues)

J4: MOLEX MINIFIT type, 2-ways vertical

Control System 28Service Manual – SC400

J4

2

1

PIN Description Electronic board

in/out

1 Battery charger enabling power supply out 24V 5A CH.1

2 Battery charger enabling return in 24V 5A CH.2

V ref. I max. Connected to

LED ELECTRONIC BOARD CONNECTOR (EBLED B side)

JA: MOLEX MINIFIT type, 6-ways vertical

456

123

PIN Description Electronic board

in/out

1 Common cathode LED power supply in 0V <1A J3.7

2 LDA-Green anode LED power supply in 0.7V <1A J3.8

3 LDB-Yellow anode LED power supply in 0.7V <1A J3.9

4 LDB-Green anode LED power supply in 0.7V <1A J3.10

5 LDC-Red anode LED power supply in 0.7V <1A J3.11

V ref. I max. Connected to

6 LDC-Green anode LED power supply in 0.7V <1A J3.12

LEDElectronicBoard(EBLED)Specications

Code Description

LDA GREEN / RED two-color Ø5mm LED

LDB GREEN / YELLOW two-color Ø5mm LED

LDC GREEN / RED two-color Ø5mm LED

Page 29

Control System 29Service Manual – SC400

Controls and Functions

a. Low consumption circuit fuse (F3): directly downstream of J1.1, it protects all the inner and outer

circuits supplied by the electronic board.

b. Battery charger enabling circuit power supply (J4.1): directly downstream of F3.

c. BATTERY CHARGER enabling (J4.2): if the dip-switch DIP2 is turned to 0 (CH position), the

electronic board functions are activated only when the on-board battery charger is NOT connected to

the electrical mains; if DIP2 is turned to 1 (NO CH position), the electronic board functions are active

whether or not the battery charger is on board.

THE BATTERY CHARGER IS INSTALLED ON THE MACHINE AS A STANDARD

COMPONENT; the dip-switch MUST BE turned to 0 (CH position).

d. BRUSH function: is activated when J3.2 is at 24V with a 1 sec.-delay at switching off.

The BRUSH function includes activation of J2.3 (BRUSH ELECTROMAGNETIC SWITCH) and

J1.2,3 (SOLENOID VALVE) outputs, which are subjected to the presence of the signal on J3.4 with a

1 sec.-delay to switching on. The output on J1.2,3 (SOLENOID VALVE) is controlled by the WATER

FLOW CONTROL function (see step f).

The BRUSH function is subjected to the BATTERY PROTECTION function (see step g) and to the

BRUSH MOTOR PROTECTION function (see step j).

e. VACUUM SYSTEM function: is activated when J3.3 is at 24V with a 1 sec.-delay at switching on and

a 1 sec.-delay at switching off.

The VACUUM SYSTEM function includes the activation of J2.4 (VACUUM SYSTEM RELAY)

output.

The VACUUM SYSTEM function is subjected to the BATTERY PROTECTION function (see step g).

f. WATER FLOW CONTROL function: J1.2,3 (SOLENOID VALVE) output, when activated (see step

d), is modulated by ON/OFF cycles according to the following table; the current status is shown by

the LEDs (see step h):

Solution ow push-button

setting (SW3)

0

1

2

3

LED display Solenoid valve ON time (EV1) Solenoid valve OFF time (EV1)

- Always OFF

1 sec 5 sec

3 sec 3 sec

Always ON -

The default setting for the solution ow push-button (SW3) is 1.

The next detergent percentage setting is NOT stored into memory when the machine is turned off.

Page 30

Control System 30Service Manual – SC400

Controls and Functions (Continues)

g. BATTERY PROTECTION function: battery charge status is shown by the 3 LEDs depending on the

type of battery (WET/GEL, see step j) according to the following diagram:

Transition threshold (V, tolerance ±0.1) WET GEL

1 Green (x) <=> yellow (x) 22.0 22.2

2 Yellow (x) => red (ashing 1Hz) 20.4 21.6

3 Safety threshold 19.4 20.6

The transition is ltered with a time constant of 3 sec. as to the supply voltage reading.

When threshold 2 is reached, the J2.3 (BRUSH ELECTROMAGNETIC SWITCH) and J1.2,3

(SOLENOID VALVE) outputs are automatically cut off after a 5 sec.-delay.

In chase threshold 3 is reached, also J2.4 (VACUUM SYSTEM) output is automatically deactivated

(without delays) and the BRUSH MOTOR BRAKING function (see step k) is disabled.

Irrespective of the voltage reading, when transition 2 is performed, it is not possible to go back to

YELLOW or GREEN condition.

The system reset happens when the machine is turned off by turning the rotary switch (SW1) to 0.

h. WATER FLOW SETTING function: When the battery charge status is above threshold 1, the 3 LEDs

show the charge status only during the rst 5 sec. after BRUSH or VACUUM SYSTEM function has

been activated, then they switch to the display of water ow setting (see step f). If during the rst 5

sec. the push-button SW3 is pressed, the display immediately switches to the water ow setting.

When the water ow setting is displayed, each time the push-button SW3 is pressed, the setting of

the water ow increases by 1 in sequence (from 3 to 0).

When the battery charge status is below threshold 1, the display shows the battery charge status.

The LEDs switches from battery charge status to water ow setting display, only when the pushbutton SW3 is pressed. This display last 5 sec., before switching again. If during the 5 sec. the pushbutton SW3 is pressed, the setting of the water ow increases by 1 in sequence (from x=3 to x=0). If

the push-button SW3 is not pressed for more than 5 sec., the display switches again to the battery

charge status.

i. Battery type selection (WET/GEL): each time the electronic board is switched on, the current

condition is shown for 2 sec. by LEDs according to the following diagram:

WET RED LED ashing

GEL GREEN LED ashing

After the rst 2 sec., the LEDs show the battery charge status or the water ow level (see step h).

WET/GEL setting depends from dip-switch DIP1 position, according to the silk-screen printed “WET”

and “GEL” marks beside the dip-switch.

Page 31

Control System 31Service Manual – SC400

Controls and Functions (Continues)

j. BRUSH MOTOR PROTECTION function: through the differential input (J2.1 - J2.2), the voltage

drop is read on the BRUSH MOTOR fuse: if the voltage drop exceeds the alarm threshold for more

than 30 sec., the J2.3 (BRUSH ELECTROMAGNETIC SWITCH) and J1.2,3 (SOLENOID VALVE)

outputs are switched off until their reset by switching off the electronic board.

When the threshold is exceeded (without delays), the GREEN, YELLOW and RED LEDs ash

simultaneously (freq. 1Hz).

The alarm threshold is 40±2mV, which correspond to about 40±5 Ampere in the motor.

If the protection activates (automatic switching off of J2.3 and J1.2,3 outputs), the GREEN, YELLOW

and RED LEDs continue to ash until their reset by switching off the machine.

k. BRUSH REMOVAL SYSTEM: When the BRUSH function is active and the push-button SW2 is NOT

PRESSED for at least 3 sec., if the push-button SW2 is pressed and released 3 times in 2 sec., the

following cycle is performed:

1) Alternating ashing of RED AND GREEN LEDs for 2 sec. to conrm brush remove mode.

2) Closing (by a TIANBO HJR-3FF-S-Z relay contact) of J2.6 output on J1.1 positive power supply

through F4 fuse, for 2 sec. shunt B+ to both states of motor to cause abrupt stop.

3) Activation after 0,2 sec. of J2.3 (BRUSH ELECTROMAGNETIC SWITCH) output for 1 sec..

The BRUSH REMOVAL SYSTEM is subjected to the BATTERY PROTECTION function (see step g).

During this cycle (which lasts 4 sec.) the SW2 push-button is disabled.

Page 32

Electrical System

Functional Description

Electrical System 32Service Manual – SC400

Basically the electrical system consists of a function

electronic board (EB1) which determines the brush

motor, vacuum system motor and solenoid valve activation by means of the relevant controls (rotary switch

(SW1) and brush activation push-button (SW2)), disabling them when the battery voltage drops below the

battery safety threshold value.

The batteries are connected to the system by means of

the ANDERSON POWER connector (C1).

Fuses

The brush motor circuit is protected from short-circuits by the 40A fuse (F1). The motor is protected

from overloads by means of the electronic protection

system described in the Function Electronic Board

Specications chapter.

The vacuum system motor circuit is protected by the

30A fuse (F2).

The solenoid valve (EV1) and the function electronic

board (EB1) control circuits are protected by the 5A

fuse (F3) on the function electronic board (EB1).

The battery charger (CH) is connected to the batteries

(BAT) directly on the – and + terminals and it supplies the enabling signal to activate the machine functions only when it is disconnected from the electrical

mains with the J4 2-way connector. When the battery

charger is connected to the electrical mains, the battery charger inner relay opens the contact and stops

the enabling signal on the J4 connector.

For further details, see the descriptions of individual

sub-systems.

The brush release circuit is protected by the 20A fuse

(F4) on the function electronic board (EB1).

(Only for 9087311020 - 9087318020 models). The

125A battery fuse (F0) is assembled directly on the

+ terminal of the battery and jump connected to the

negative terminal of the other. This fuse operates only

in case of short circuits on the machine power wiring

harness, to prevent re or battery explosion.

Wiring Diagram

BATTERY

CONNECTOR (C1-)

24V BATTERY (BAT)

FUNCTION ELECTRONIC

BOARD (EB1)

J4.1 - Battery charger enabling power supply

J4.2 - Battery charger enabling return

BATTERY CHARGER (CH)

BATTERY FUSE (F0)

+ 24V

BATTERY

CONNECTOR (C1+)

P200076

Page 33

Component Locations

Brush motor

Brush release

• Battery charger (CH)

• Batteries (BAT)

• Battery connection connector (C1)

• Battery wiring harness

• Machine wiring harness

• Electrical component box

Electrical System 33Service Manual – SC400

• Battery fuse (F0) (only for 9087311020 –

9087318020 models)

• Brush motor fuse (F1)

• Vacuum system motor fuse (F2)

• Solenoid valve and electronic board fuse (F3)

• Brush release fuse (F4)

Battery charger (CH)

Solenoid valve and

electronic board fuse (F3)

Electrical

component

box

Battery connection

connector (C1)

fuse (F4)

fuse (F1)

Machine wiring harness

Batteries (BAT)

Battery wiring harness

Vacuum system motor fuse (F2)

Battery fuse (F0)

(only for 9087311020 – 9087318020 models)

P200050

Page 34

Electrical System 34Service Manual – SC400

Maintenance and Adjustments

Battery Installation And Battery Type Setting (WET or GEL/AGM)

Set the electronic board of the machine and the battery charger according to the type of batteries to be in-

stalled (WET or GEL/AGM) as shown below.

Machine Setting

1. Disconnect the battery connector (red).

2. Remove the screws (A), then carefully remove the electrical component box cover (B).

3. On the electronic board, turn the microswitch (C) to WET or GEL/AGM, according to the type of

batteries to be installed.

Warning! Do not move/set the adjacent switch (D).

4. Reinstall the electric component box cover (B) and tighten the screws (A).

D

C

A

B

A

P200051

Page 35

Electrical System 35Service Manual – SC400

P

Battery Installation And Battery Type Setting (WET or GEL/AGM) (Continues)

Battery charger setting

5. To set the battery charger, refer to the relevant Manual supplied with the machine.

Battery Installation

6. Disconnect the vacuum hose (E) from the squeegee (F).

7. Disconnect the recovery water drain hose (G) from the bracket (H).

8. Open the cover (I).

9. Grasp the recovery tank (J) in the area (K) and slightly raise it.

10. Disconnect the vacuum hose (L) from the tank, then remove the tank (J) with the hoses (M) and (N).

11. Install the batteries on the machine according to the diagram (P).

12. Perform steps 6 to 10 in the reverse order.

13. Connect the battery connector (red).

14. Charge the batteries (see the procedure in Battery Charging paragraph).

FRON T OF

MACH INE

12V 12V

I

H

PANEL

PANEL

BACK OF

MACH INE

G

E

KJ

L

N

M

F

P200081

Page 36

Battery Charging

Note: Charge the batteries when the yellow or red LED turns on, or at the end of each working

Caution! When the batteries are discharged, charge them as soon as possible, as that

Caution! Whenusinglead(WET)batteries,batterychargingproduceshighlyexplosive

Caution! Pay careful attention when charging lead batteries (WET) as there may be battery

Electrical System 36Service Manual – SC400

cycle. Keeping the batteries charged make their life last longer.

condition makes their life shorter. Check for battery charge at least once a week.

hydrogen gas. Charge the batteries in well-ventilated areas and away from naked

ames.

Do not smoke while charging the batteries.

Do not reinstall the recovery tank until the battery charging cycle is over.

uidleakages.Thebatteryuidiscorrosive.Ifitcomesincontactwithskinoreyes,

rinse thoroughly with water and consult a physician.

1. Drive the machine to the appointed recharging area.

2. Turn the machine program selection knob to “0”.

3. For WET batteries only:

• Tip up the recovery tank.

• Check the level of electrolyte inside the batteries; if necessary, top up through the caps.

• Leave all the battery caps open for next charging.

• If necessary, clean the upper surface of the batteries.

4. Connect the battery charger cable to the electrical mains (the electrical mains voltage and frequency

must be compatible with the battery charger values shown on the machine serial number plate).

Note: When the battery charger is connected to the electrical mains, all machine functions are

automatically cut off.

The battery charger red or yellow LED turned on, indicates that the batteries are

charging.

5. When the battery charger green LED stays on, the battery charging cycle is over.

6. When the battery charging is completed, disconnect the battery charger cable from the electrical mains

and wind it round its housing.

7. For WET batteries only:

• Close all the battery caps.

• Tip down the recovery tank.

8. Now the machine is ready to be used.

Note: For further information about the operation of the battery charger, see the Battery

Charger Manual.

Page 37

Electrical System 37Service Manual – SC400

Fuse Check and Replacement

Fusesintheelectriccomponentbox

1. Drive the machine on a level oor. Make sure that the machine cannot move independently.

2. Disconnect the battery connector (red).

3. Remove the screws (A), then remove the electrical component box cover (B).

4. Check the following fuses for integrity:

• (C): F1 (40 A) circuit breaker, brush motor (open cover).

• (D): F2 (30 A) blade fuse, vacuum system motor.

• (E): F3 (5 A) blade fuse, solenoid valve and electronic board.

• (F): F4 (20 A) glass fuse, brush release system.

5. Replace the open fuse, when the component that caused deactivation has fully cooled down.

6. Place the cover (B) and tighten screws.

7. Connect the battery connector (red).

Battery Fuse (only for 9087311020 – 9087318020 models)

1. Drive the machine on a level oor. Make sure that the machine cannot move independently.

2. Disconnect the battery connector (red).

3. Remove the recovery tank.

4. On the battery cable (G) check/replace the following fuse:

• (H): F0 (125 A) battery fuse.

5. Assemble the recovery tank.

6. Connect the battery connector (red).

G

A

F

C

B

E

D

H

A

P200052

Page 38

Troubleshooting

Trouble Possible Causes Remedy

The machine is not working The battery connector (C1) is not connected or broken Connect or replace it

Electrical System 38Service Manual – SC400

The batteries (BAT) are discharged or its connections are

not efcient

The batteries (BAT) are broken Check the battery no-load voltage

The battery charger (CH) is broken Replace

The fuses (F0, F3) are open Replace

The wiring harness is cut or pressed or short circuited Repair

The rotary switch (SW1) of the program selection knob is

not working

The function electronic board (EB1) is broken Replace

The DIP-switch 2 is turned to NO CH (ON) when the

battery charger is installed

Charge the batteries or clean/repair the

connections

Replace

Turn the DIP-switch 2 to CH (OFF)

Page 39

Machine Wiring Diagram

VACUUM SYSTEM

BRUSH

Electrical System 39Manuale di Assistenza – SC400

MOTOR (M2)

MOTOR (M1)

DETERGENT SOLENOID

VALVE (EV1)

FUNCTION ELECTRONIC BOARD (EB1)

SIGNAL CIRCUIT FUSE (F3) BRUSH RELEASE FUSE (F4)

BATTERY CONNECTOR (C1+)

24V BATTERY (BAT)

BRUSH ELECTROMAGNETIC

SWITCH (K1)

VACUUM SYSTEM

MOTOR FUSE (F2)

BRUSH MOTOR

FUSE (F1)

VACUUM SYSTEM

RELAY (K2)

VACUUM SYSTEM

BRUSH

RELAY (K2)

ELECTROMAGNETIC

SWITCH (K1)

ROTARY SWITCH (SW1)

BRUSH ENABLING PUSH-BUTTON (SW2)

DETERGENT FLOW PUSH-BUTTON (SW3)

LED ELECTRONIC

BOARD (EBLED)

BATTERY CHARGER (CH)

BATTERY CONNECTOR (C1-)

BATTERY FUSE (F0)

P200077

Page 40

Electrical System 40Service Manual – SC400

Specications

General Values

Total absorbed power 29 A (0.75 kW)

Battery compartment size 13.7x17.7x10.2 in (350x350x260 mm)

Battery voltage 24 V

Standard batteries (2) 12 V - 50 Ah C5 (AGM) Spiracell

Battery charger 100-240 VAC

Work autonomy (standard batteries) 1.5 hour

Page 41

Recovery System

B - B +

Functional Description

Recovery System 41Service Manual – SC400

The water recovery system removes the dirty water

from the oor and pipes it to a recovery tank. When

the machine is running, the dirty water on the oor is

collected by the squeegee blades and collected through

the slots in the same, piped through the vacuum hose

and into the tank by the airow created by vacuum

motor (M2). The dirty water is piped into the recovery

tank, while the airow continues to the vacuum fan.

The vacuum system motor (M2) is supplied by the

relay (K2) which is driven by the function electronic

board (EB1) when the rotary switch (SW1) is turned

to 1 or 3. The circuit is protected by the fuse (F2).

The automatic oat in the vacuum grid stops vacuum

system motor (M2) from collecting any liquids.

Wiring Diagram

VACUUM SYSTEM

MOTOR FUSE (F2)

VACUUM

SYSTEM RELAY (K2)

When the automatic oat closes and shuts down the

vacuum system, the vacuum system motor noise will

increase and the oor will not be dried.

When the recovery tank is full it can be emptied

through the drain hose.

VACUUM SYSTEM

MOTOR (M2)

ROTARY

SWITCH

(SW1)

J2.4 - Vacuum system relay power supply –

B -

+ 24V

J2.5 - Electromagnetic switch / relay power supply +

FUNCTION ELECTRONIC

BOARD (EB1)

SIGNAL CIRCUIT

FUSE (F3)

+ 24V

J3.1 - Control power supply

J3.3 - Vacuum system function return

P200078

Page 42

Component Locations

• Recovery tank

• Vacuum grid with automatic shut-off oat

• Recovery tank cover

• Cover gasket

• Recovery water drain hose

• Squeegee vacuum hose

Coperchio serbatoio acqua di recupero

Recovery tank cover

Guarnizione del coperchio

Cover gasket

Griglia di aspirazione con

Vacuum grid with

chiusura automatica

automatic shut-off float

a galleggiante

• Vacuum system motor (M2)

• Electrical component box

• Vacuum system motor fuse (F2)

• Vacuum system relay (K2)

Recovery water

Tubo di scarico

drain hose

acqua di recupero

Recovery System 42Service Manual – SC400

Serbatoio acqua di recupero

Recovery tank

Motore impianto

Vacuum system

di aspirazione (M2)

motor (M2)

Vacuum system relay (K2)

Vacuum system motor fuse (F2)

Vano Componenti elettrici

Electrical component box

Relè (K2)

Fusibile (F2)

Tubo di aspirazione tergitore

Squeegee vacuum hose

P200053

Page 43

Recovery System 43Service Manual – SC400

A

Maintenance and Adjustments

Tank and Vacuum Grid Cleaning

1. Drive the machine to the appointed disposal area.

2. Turn the machine program selection knob to “0”.

3. Open the recovery tank cover (A), then clean and wash the cover, the tank (B) and the vacuum grid (C)

with clean water.

If necessary, release the fasteners (D) and open the grid (C), remove the oat (E), clean all the

components and then reinstall them.

If necessary, clean also the solution tank.

Drain the water from the tanks with the relevant drain hoses.

4. Check the recovery tank cover gasket (F) for integrity.

The gasket (F) must be efcient, because it creates vacuum in the tank that is necessary for vacuuming

the recovery water.

If necessary replace the gasket (F) by removing it from its housing (G). When assembling the new

gasket, install its junction (H) in the central rear area as shown in the gure.

5. The gasket (F) must be in good shape, as it is necessary for the recovery tank stay sealed.

6. Close the recovery tank cover (A).

F

D

C

E

H

I

D

G

C

B

P200054

Page 44

Troubleshooting

Trouble Possible Causes Remedy

Recovery System 44Service Manual – SC400

The vacuum system motor (M2) does not

turn on

The recovery water vacuuming is

insufcient or there is no vacuuming

The vacuum system motor carbon brushes are worn Replace

The rotary switch (SW1) is broken Replace

The vacuum system motor is faulty Check the amperage.

Check the carbon brushes.

Replace.

The fuse (F2) is open Replace

The relay (K2) is broken Replace

The vacuum grid with automatic shut-off oat is activated

because the recovery tank is full

The vacuum grid is dirty Clean

The tank cover is not correctly positioned Adjust

The tank cover gasket is not efcient Clean/replace

The vacuum system motor lter is dirty Clean

The vacuum gaskets are damaged or do not match

perfectly

The squeegee vacuum hose is broken Replace

The recovery tank vacuum hose is broken Replace

Drain the recovery tank

Repair or replace

Page 45

Removal and Installation

A

A

B

E

D

C

Vacuum System Motor Amperage Check

Warning! This procedure must be

performedbyqualied

personnel only.

1. Check that the squeegee and the vacuum hose

are clean and that there is no dirt in their inner

parts.

2. Keep the squeegee lifted.

3. Remove the screws (A), then remove the

electrical component box cover (B).

Warning! Do not touch uncovered

electrical components while

performing the following

steps.

4. Apply the Amp clamp (C) on the electrical cable

(D) of the vacuum system motor on the relay

output (E).

Recovery System 45Service Manual – SC400

Remove the Amp clamp (C).

If the amperage is higher, perform the following

procedures to detect and correct the abnormal

input:

• Check that the vacuum system motor fuse

(F2) is properly tightened.

• Check the condition of the vacuum system

motor carbon brushes.

• Remove the vacuum system motor (see the

procedure in the Vacuum System Motor

Disassembly/Assembly paragraph), and check

the condition of all its components.

If the above-mentioned procedures do

not produce the correct readings for the

vacuum system motor amperage, the motor

must be replaced (see the procedure in the

Vacuum System Motor Disassembly/Assembly

paragraph).

Reassembly

5. Turn on the vacuum system and check that the

vacuum system motor amperage is between 13

and 17 A at 24V.

Stop the vacuum system.

Turn the machine program selection knob to “0”.

6. Assemble the components in the reverse order of

disassembly.

P200055

Page 46

Vacuum System Motor Carbon Brush Check/Replacement

Recovery System 46Service Manual – SC400

Disassembly/Check

1. Remove the vacuum system motor (see the

procedure in the Vacuum System Motor

Disassembly/Assembly paragraph).

2. At the workbench, remove the vacuum system

motor guard (A) by disengaging its inner

fasteners (B).

3. With a proper tool, remove the tin soldering spot

(C) between both lead-in wires (D).

4. Disconnect the lead-in wires (D).

5. Remove the screws (E) and remove the carbon

brushes (F).

A

6. Check the carbon brushes (F) for wear. The

carbon brushes are worn when:

• The contact with the motor armature is insuf-

cient

• The contact surface is not integral

• The stroke is less than 0.12 in (3 mm)

• The spring is broken

In this cases, replace both motor carbon brushes.

Assembly

7. Assemble the components in the reverse order of

disassembly, and note the following:

• after connecting the lead-in wires (D) fasten

them with a tin soldering spot (C).

E

E

F

B

F

D

D

A

C

D

P200056

Page 47

Recovery System 47Service Manual – SC400

CD

Vacuum System Motor Disassembly/Assembly

Disassembly

1. Remove the recovery tank.

2. Loosen the band (A) and disconnect the hose (B) from the vacuum system motor below.

3. Remove the guard (C).

4. Disconnect the connector (D) of the vacuum system motor (E).

5. Remove the screws (F), then lift them from the housing and remove the vacuum system motor (E).

6. If necessary, remove the sound-proof panels (G) and (H) from the motor.

Assembly

7. Assemble the components in the reverse order of disassembly.

B

F

A

E

F

F

G

E

H

P200057

Page 48

Recovery System 48Service Manual – SC400

Specications

General Values

Recovery tank capacity 5.5 US gal (21 liters)

Vacuum system motor power 0.4 hp (300 W)

Vacuum water lift (blocked) 47.2 inH

O (1,200 mmH2O)

2

Page 49

Scrub System, Disc

B - B +

Functional Description

Scrub System, Disc 49Service Manual – SC400

The disc brush system can be started by the operator.

The disc brush rotates counter-clockwise.

The brush system, when turning, cleans/washes the

oor surface and assists machine forward movement.

The deck, where brushes suitable for cleaning the

particular type of oor are installed, is the main part

of the scrub system. The brush deck is xed and inte-

grated in the machine with a support bracket. The ad-

justing systems adjusts the forward speed, while the

handwheel on the deck adjusts the machine straightforward drive.

The brush working pressure is functional to the machine designed balance.

The brush motor (M1) is supplied by the electromagnetic switch (K1) which is driven by the function electronic board (EB1) when the rotary switch (SW1) is

turned to 1 or 2, and the brush enabling push-button

(SW2) is pressed. The circuit is protected by the fuse

(F1) and by the electronic protection system described

in the Function Electronic Board Specications chapter.

The system, once activated, uses the solution coming

form the solution system, to wash the oor.

In case of brush motor overload, a safety system stops

the brushes after about one minute of continuous

overload. The overload is shown by the three battery

warning LEDs ashing simultaneously.

The overload is detected by monitoring the current

ow sum on the motor. The current is measured by

checking the voltage drop through the fuse (F1). If the

voltage drop is higher than 40 mV, the 3 battery LEDs

ash simultaneously and, if the overload persists, the

motor stops after a variable delay, depending on the

overload amount.

To start scrubbing again after a brush stop due to

overload, cycle the rotary switch (SW1) off and then

back on.

To work properly, the brush motor needs the following:

• Rotary switch (SW1) turned to 1 or 2

• Brush enabling push-button (SW2) pressed

• Charged batteries (the red LED must not be

ashing).

BRUSH RELEASE SYSTEM:

In order to release the brush from its hub, the brush

motor starts running, then it is stopped quickly.

Therefore the brush due to its inertia is disengaged

from the hub. The system works better if the brush

deck is lifted from the oor during this operation.

Wiring Diagram

BRUSH ENABLING

PUSH-BUTTON (SW2)

BRUSH

ELECTROMAGNETIC

SWITCH (K1)

BRUSH MOTOR

FUSE (F1)

BRUSH

ELECTROMAGNETIC

SWITCH (K1)

ROTARY SWITCH

(SW1)

BRUSH

MOTOR (M1)

J2.1 - Brush fuse voltage drop reading +

J2.2 - Brush fuse voltage drop reading –

J2.3 - Brush electromagnetic switch power supply –

J2.5 - Electromagnetic switch/relay power supply +

BRUSH RELEASE

FUSE (F4)

J2.6 - Brush motor braking circuit

SIGNAL CIRCUIT

FUSE (F3)

J3.1 - Control power supply

J3.2 - Brush function return

J3.4 - Brush rotation enabling

B -

+ 24V

+ 24V

FUNCTION ELECTRONIC

BOARD (EB1)

P200079

Page 50

Component Locations

• Disc brush deck

• Brush motor (M1)

• Drive hub

• Electromagnetic switch (K1)

• Brush motor fuse (F1)

Brush release fuse (F4)

Brush motor fuse (F1)

Scrub System, Disc 50Service Manual – SC400

• Brush release fuse (F4)

• Machine forward speed adjusting handwheel

• Machine straight forward movement adjusting

handwheel

Electromagnetic switch (K1)

Brush motor (M1)

Drive hub

Disc brush deck

Machine straight forward movement

adjusting handwheel

Machine forward speed

adjusting handwheel

P200058

Page 51

Maintenance and Adjustments

Brush Cleaning

Warning! It is advisable to wear protective gloves when cleaning the brush because there may

be sharp debris.

1. Remove the brush (as shown in the User Manual).

2. Insert the positioning pin (A) and disengage the machine parking device (B).

3. Clean the brush with water and detergent.

4. Check the brush bristles for integrity and wear; if necessary, replace the brush.

5. Install the brush (as shown in the User Manual).

Scrub System, Disc 51Service Manual – SC400

A

B

P200059

Page 52

Scrub System, Disc 52Service Manual – SC400

Machine Forward Movement Adjustment

Note: Themachinespeedandforwardmovementvaryaccordingtothetypeofoortobe

cleaned and the choice of using the brush or the pad.

If necessary, perform the following procedure.

1. Adjust the machine speed with the handwheel (A) according to the following procedure:

• Turn it counter-clockwise to increase the machine speed.

• Turn it clockwise to decrease the machine speed.

2. If it is difcult to keep the machine moving straight-forwardly because it deviates to the left or to the

right, adjust the knob (B) by turning it clockwise or counter-clockwise.

3. With the machine ready to operate, perform hands-on tests of the machine speed; if necessary, perform

step 2 again.

B

A

P200060

Page 53

Scrub System, Disc 53Service Manual – SC400

Troubleshooting

Open Circuit

• The fuse (F1) determines an open in the supply circuit of the brush deck motor. This system allows to

prevent the circuits from being damaged under overload conditions.

• The open in the fuse can be caused by the following:

• Short circuit in the brush motor wiring harness; fault in the motor.

Trouble Possible Causes Remedy

The brush does not clean properly The brush is excessively worn Replace

The brush does not turn Activation of motor overload Restart the machine as shown in

The motor carbon brushes are worn Replace

The motor is faulty Check the motor amperage/replace

There are ropes or debris restraining the brush rotation Remove and clean

The fuse (F1) is open Replace

The motor electromagnetic switch (K1) is damaged Replace

The brush motor electromagnetic switch wiring harness is

damaged

The wiring harness between function electronic board

(EB1) and brush motor electromagnetic switch (K1) is

damaged

The levers or the enabling push-button are broken Replace

The brush release system does not work The fuse (F4) is open Replace.

The electromagnetic switch (K1) is broken Replace

the User Manual

Repair

Repair

Page 54

Removal and Installation

Brush Motor Amperage Check

Scrub System, Disc 54Service Manual – SC400

Warning! This procedure must be

performedbyqualied

personnel only.

1. Remove the brush.

2. Remove the screws (A), then remove the

electrical component box cover (B).

Warning! Do not touch uncovered

electrical components while

performing the following

steps.

3. Apply the Amp clamp (C) on the electrical cable

(D) of the brush motor on the electromagnetic

switch output (E).

4. Turn on the brush (as shown in the User

Manual) and check that the brush motor

amperage is between 3 and 4 A at 24 V.

Stop the brush rotation.

Turn the machine program selection knob to “0”.

Remove the Amp clamp (C).

If the amperage is higher, perform the following

procedures to detect and correct the abnormal

amperage:

• Check that the brush hub is free from foreign

materials (ropes, dirt, ...) preventing it from

turning.

• Check that the brush motor fuse (F1) is properly tightened.

• Check the condition of the brush motor carbon brushes

• Remove the brush motor (see the procedure

in the Brush Motor Disassembly/Assembly

paragraph), and check the condition of all its

components.

If the above-mentioned procedures do not

produce the correct readings for the brush motor

amperage, the motor must be replaced (see the

procedure in the Brush Motor Disassembly/

Assembly paragraph).

Reassembly

5. Assemble the components in the reverse order of

disassembly.

A

D

B

A

E

C

P200061

Page 55

Brush Motor Carbon Brush Check/Replacement

Scrub System, Disc 55Service Manual – SC400

Disassembly/Check

1. Remove the recovery tank (as shown in User

Manual).

2. Loosen the band (A) and disconnect the hose (B)

from the vacuum system motor below.

3. Remove the guard (C).

4. On the brush motor (D), if necessary, remove

dirt form the area of the four carbon brush

covers (E).

5. Turn and remove the four covers (E) (bayonet

joint).

6. Remove the carbon brush nuts (F) with the leadin wires.

7. Disengage the tabs (G) and remove the carbon

brushes (H).

B

8. Check the carbon brushes (H) for wear. The

carbon brushes are worn when:

• The contact with the motor armature is insuf-

cient

• The contact surface is not integral

• The stroke is less than 0.12 in (3 mm)

• The spring is broken

In this cases, replace all motor carbon brushes.

Assembly

9. Assemble the components in the reverse order of

disassembly.

E

E

E

A

D

E

E

C

D

H

G

F

E

G

P200062

Page 56

Brush Deck Disassembly/Assembly

Note: Thegureshowsthe520Watt-motor;the450Watt-motorissimilar.

Disassembly

1. Remove the recovery tank and the solution tank (as shown in User Manual).

2. Remove the brush (as shown in the User Manual).

3. If possible, place the machine on a hoisting system.

Make sure that the machine cannot move independently.

4. Turn the machine program selection knob to “0”.

5. Disconnect the battery connector (red).

6. On the machine front left side, remove the screw inside the hole (A).

7. With the wheel (B), fully unscrew the threaded pin (C) from the upper nut screw.

8. Turn the handwheel (D) clockwise until the end of the stroke (brush lowering).

Scrub System, Disc 56Service Manual – SC400

9. Unscrew the nut (E) and remove the screw (F) thus letting the brush deck (G) lowering down.

10. Lift the machine front side (P) and keep it lifted.

11. Loosen the clamp (H) and disconnect the hose (I).

A

D

F

E

P

C

B

G

H

I

P200063

Page 57

Scrub System, Disc 57Service Manual – SC400

Brush Deck Disassembly/Assembly (Continues)

13. Remove the brush deck (J) by turning it as shown in the gure, then lay it on a at surface.

14. Cut the clamp (K).

15. Remove the four protecting caps (L) of the four electrical connections (M) of the brush motor (N).

16. Mark the position of each of the four electrical connections (M) to make subsequent assembly easier.

Remove the nuts and disconnect the four electrical connections (M) from the motor.

17. Retrieve the brush deck (J).

Assembly

18. Assemble the components in the reverse order of disassembly.

L

M

K

N

J

M

L

P200064

Page 58

Scrub System, Disc 58Service Manual – SC400

Brush Motor Disassembly/Assembly

Disassembly

1. Remove the brush deck (see the procedure in the Brush Deck Disassembly/Assembly paragraph).

2. On the lower side of the deck, remove the centre screw (A).

3. Remove the ange (B).

4. Remove the spacer (C) and the key (D) from the hub (E).

5. Remove the screws (F) and remove the brush case (G).

6. Retrieve the brush motor (H).

Assembly

7. Assemble the components in the reverse order of disassembly.

A

H

B

F

D

C

E

F

G

P200065

Page 59

Scrub System, Disc 59Service Manual – SC400

Brush Deck Adjuster Disassembly/Assembly

Disassembly

1. Remove the brush deck (see the procedure in the Brush Deck Disassembly/Assembly paragraph).

2. On the front right side of the machine, remove the screw (A) and the handwheel (B).

3. Remove the nut (C) and, form inside the wall, remove the deck adjuster (D).

Assembly

4. Assemble the components in the reverse order of disassembly.

G

A

B

C

D

P200066

Page 60

Scrub System, Disc 60Service Manual – SC400

Specications

General Values

Brush/pad diameter 17 in (430 - 432 mm)

Brush pressure with full tank and lowered squeegee 77 lb (35 kg)

Brush motor power 0.6 hp (450 W)

Brush motor speed 155 rpm

Brush motor amps 3 - 4 A, No load

Page 61

Solution System

DETERGENT SOLENOID

Functional Description

Solution System 61Service Manual – SC400

The solution system supplies the detergent to the

brush when cleaning the oor. The solution tank is

also the main machine body. There is a manual valve

on the left side of the tank to close the water supply

whenever maintenance must be performed on the machine.

The detergent quantity is adjusted by the operator

with the push-button (SW3). The solution ows from

the tank to the tap, through the lter and solenoid

valve (EV1) and then to the brush deck.

The solenoid valve (EV1) is supplied by the function

electronic board (EB1) when the rotary switch (SW1)

Solution ow push-button

setting (SW3)

0

1

2

3

LED display Solenoid valve ON time (EV1) Solenoid valve OFF time (EV1)

is turned to 1 or 2, the brush activation push-button

(SW2) is pressed and the push-button (SW3) setting is

different from 0 (3 LEDs off).

The circuit is protected by the fuse (F3) on the function electronic board (EB1).