Page 1

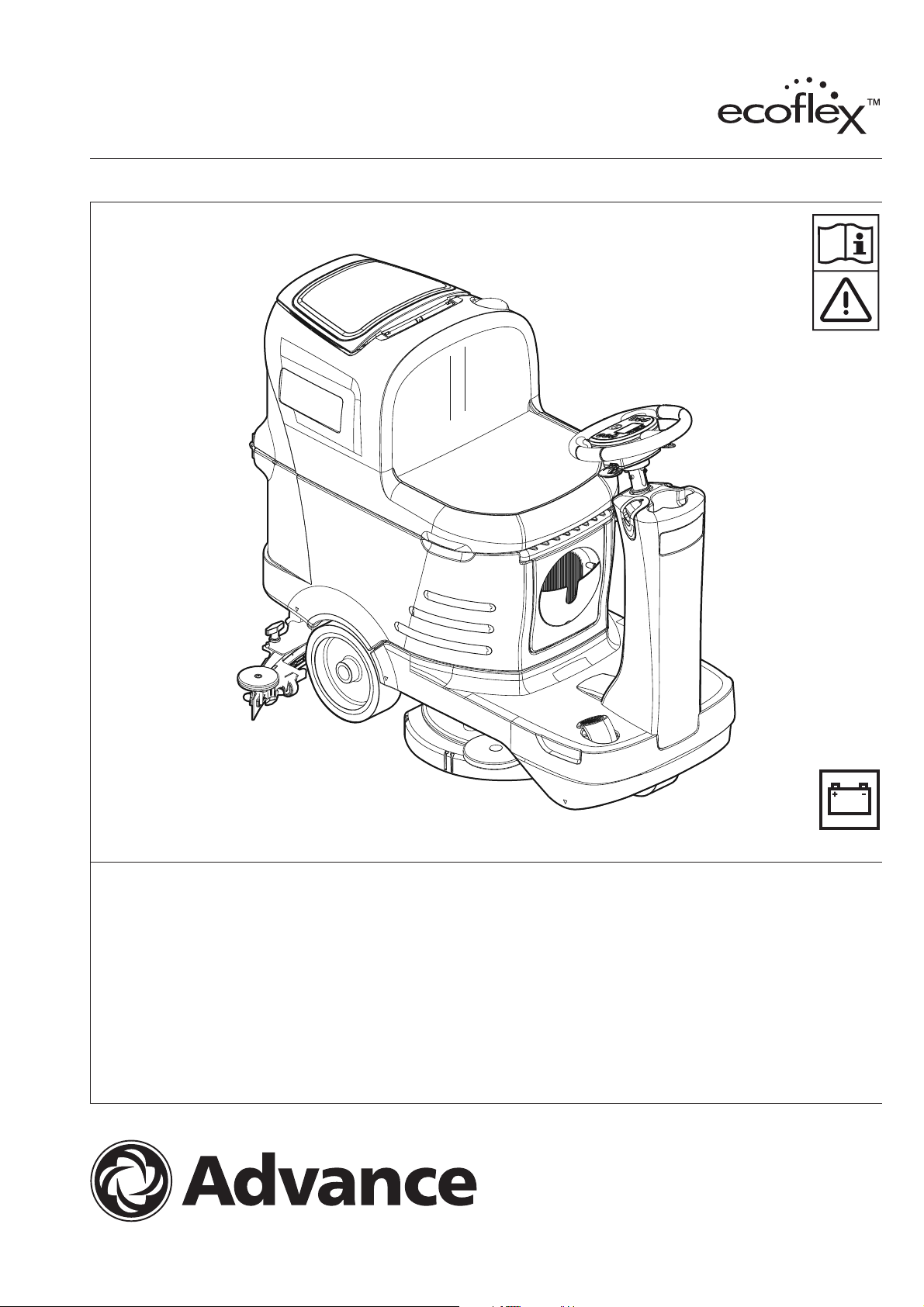

SC2000

Instructions for Use - Original Instructions

Instrucciones de Uso

Instructions d’Utilisation

Instruções de Uso

Model: 9087361020

English

Español

Français

Português

01/2015 (1)

FORM NO. 9100000386

Page 2

Page 3

INSTRUCTIONS FOR USE ENGLISH

TABLE OF CONTENTS

INTRODUCTION .............................................................................................................................................................. 2

MANUAL PURPOSE AND CONTENTS .......................................................................................................................................... 2

TARGET ........................................................................................................................................................................................... 2

HOW TO KEEP THIS MANUAL .......................................................................................................................................................2

IDENTIFICATION DATA ................................................................................................................................................................... 2

OTHER REFERENCE MANUALS ................................................................................................................................................... 2

SPARE PARTS AND MAINTENANCE ............................................................................................................................................. 2

CHANGES AND IMPROVEMENTS ................................................................................................................................................ 2

OPERATION CAPABILITIES ........................................................................................................................................................... 3

CONVENTIONS .............................................................................................................................................................................. 3

UNPACKING/DELIVERY ................................................................................................................................................. 3

SAFETY ........................................................................................................................................................................... 3

VISIBLE SYMBOLS ON THE MACHINE ......................................................................................................................................... 3

SYMBOLS THAT APPEAR ON THIS MANUAL ............................................................................................................................... 4

GENERAL INSTRUCTIONS ............................................................................................................................................................ 4

MACHINE DESCRIPTION ............................................................................................................................................... 6

MACHINE STRUCTURE ................................................................................................................................................................. 6

CONTROL PANEL ........................................................................................................................................................................... 8

ACCESSORIES/OPTIONS .............................................................................................................................................................. 9

TECHNICAL DATA ........................................................................................................................................................................... 9

WIRING DIAGRAM ........................................................................................................................................................................ 10

USE ................................................................................................................................................................................ 11

BATTERY CHECK/SETTING ON A NEW MACHINE .....................................................................................................................11

BATTERY INSTALLATION ..............................................................................................................................................................11

BEFORE MACHINE START-UP .................................................................................................................................................... 12

MACHINE START AND STOP ....................................................................................................................................................... 14

MACHINE OPERATION (SCRUBBING/DRYING) ......................................................................................................................... 14

TANK EMPTYING .......................................................................................................................................................................... 17

AFTER USING THE MACHINE ..................................................................................................................................................... 17

PUSHING/TOWING THE MACHINE ............................................................................................................................................. 17

MACHINE LONG INACTIVITY ...................................................................................................................................................... 17

MAINTENANCE ............................................................................................................................................................. 18

SCHEDULED MAINTENANCE TABLE .........................................................................................................................................18

BATTERY CHARGING .................................................................................................................................................................. 19

SUPER USER KEY (yellow) .......................................................................................................................................................... 20

SQUEEGEE CLEANING ............................................................................................................................................................... 22

SQUEEGEE BLADE CHECK AND REPLACEMENT .................................................................................................................... 22

CLEANING THE BRUSH ............................................................................................................................................................... 23

RECOVERY TANK CLEANING ..................................................................................................................................................... 23

WASHING WATER FILTER CLEANING ........................................................................................................................................ 24

DETERGENT TANK CLEANING ................................................................................................................................................... 24

DRAINING THE ECOFLEX™ SYSTEM ........................................................................................................................................ 25

FUSE CHECK/REPLACEMENT .................................................................................................................................................... 25

SAFETY FUNCTIONS ................................................................................................................................................... 26

EMERGENCY PUSH-BUTTON ..................................................................................................................................................... 26

ANTI-SKID SAFETY SYSTEM ...................................................................................................................................................... 26

DRIVER’S SEAT MICROSWITCH ................................................................................................................................................. 26

ELECTROMAGNETIC BRAKE ...................................................................................................................................................... 26

TROUBLESHOOTING ................................................................................................................................................... 27

SCRAPPING .................................................................................................................................................................. 28

01/2015

9100000386 - SC2000 1

Page 4

ENGLISH INSTRUCTIONS FOR USE

INTRODUCTION

NOTE

The numbers in brackets refer to the components shown in Machine Description chapter.

MANUAL PURPOSE AND CONTENTS

The purpose of this Manual is to provide the operator with all necessary information to use the machine properly, in a safe and

autonomous way. It contains information about technical data, safety, operation, storage, maintenance, spare parts and disposal.

Before performing any procedure on the machine, the operators and qualied technicians must read this Manual carefully. Contact

Advance in case of doubts concerning the interpretation of the instructions and for any further information.

TARGET

This Manual is intended for operators and technicians qualied to perform the machine maintenance.

The operators must not perform procedures reserved for qualied technicians. Advance will not be answerable for damages coming

from the non-observance of this prohibition.

HOW TO KEEP THIS MANUAL

The Instructions for Use Manual must be kept near the machine, inside an adequate case, away from liquids and other substances

that can cause damage to it.

IDENTIFICATION DATA

The machine serial number and model name are marked on the plate (23).

Product number and year of production are marked on the same plate.

This information is useful when requiring machine spare parts. Use the following table to write down the machine identication data.

MACHINE model

PRODUCT code

MACHINE serial number

OTHER REFERENCE MANUALS

– Electronic battery charger Manual, to be considered as integral part of this Manual

– Spare Parts List (supplied with the machine)

– Service Manual (that can be consulted at Advance Service Centers)

SPARE PARTS AND MAINTENANCE

All necessary operating, maintenance and repair procedures must be performed by qualied personnel or by Advance Service

Centers. Only original spare parts and accessories must be used.

Contact Advance for service or to order spare parts and accessories, specifying the machine model, product code and serial

number.

CHANGES AND IMPROVEMENTS

Advance constantly improves its products and reserves the right to make changes and improvements at its discretion without being

obliged to apply such benets to the machines that were previously sold.

Any change and/or addition of accessories must be approved and performed by Advance.

2 SC2000 - 9100000386

01/2015

Page 5

INSTRUCTIONS FOR USE ENGLISH

OPERATION CAPABILITIES

The SC2000 scrubber-dryer is used to clean (scrubbing and drying) smooth and solid oors, in civil or industrial environment, under

safe operation conditions by a qualied operator.

The scrubber-dryer cannot be used for tted carpet and carpet cleaning.

CONVENTIONS

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, that is to say on the driver’s seat

(12).

UNPACKING/DELIVERY

To unpack the machine, carefully follow the instructions on the packing.

To move the machine manually, see the Pushing/Towing The Machine paragraph.

When the machine is delivered, check that the packing and the machine were not damaged during transportation.

In case of visible damages, keep the packing and have it checked by the carrier that delivered it. Call the carrier immediately to ll

in a damage claim.

Please check that the following items have been supplied with the machine:

– Technical documents:

• Scrubber-dryer Instructions for Use Manual

• Scrubber-dryer Spare Parts List

– No. 2 lamellar fuses

– No. 1 splash guard

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments

(such as the State of California, as identied in its Proposition 65 Regulatory Warning Law) to cause cancer,

birth defects or other reproductive harm. In certain locations (including the State of California) purchasers of

these Products that place them in service at an employment job site or a publicly accessible space are required

by regulation to make certain notices, warnings or disclosures regarding the chemicals that are or may be

contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content

of, and to comply with, any laws and regulations relating to the use of these Products in such environments.

The Manufacturer disclaims any responsibility to advise purchasers of any specic requirements that may be

applicable to the use of the Products in such environments.

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take all necessary

precautions to safeguard people and property.

The operator’s cooperation is essential in order to prevent injury. No accident prevention program is effective without the total

cooperation of the person responsible for the machine operation. Most of the accidents that may occur in a factory, while working

or moving around, are caused by failure to comply with the simplest rules for exercising prudence. A careful and prudent operator is

the best guarantee against accidents and is essential for successful completion of any prevention program.

VISIBLE SYMBOLS ON THE MACHINE

WARNING!

Carefully read all the instructions before performing any operation on the machine.

WARNING!

Do not wash the machine with direct or pressurized water jets.

WARNING!

max.2%

Do not use the machine on slopes with a gradient exceeding the specications.

01/2015

9100000386 - SC2000 3

Page 6

ENGLISH INSTRUCTIONS FOR USE

SYMBOLS THAT APPEAR ON THIS MANUAL

DANGER!

It indicates a dangerous situation with risk of death for the operator.

WARNING!

It indicates a potential risk of injury for people.

CAUTION!

It indicates a caution or a remark related to important or useful functions.

Pay careful attention to the paragraphs marked by this symbol.

NOTE

It indicates a remark related to important or useful functions.

CONSULTATION

It indicates the necessity to refer to the Instructions for Use Manual before performing any procedure.

GENERAL INSTRUCTIONS

Specic warnings and cautions to inform about potential damages to people and machine are shown below.

DANGER!

– Before performing any maintenance, repair, cleaning or replacement procedure, remove the ignition key and

disconnect the battery connector.

– This machine must be used by properly trained operators only.

– Do not wear jewels when working near electrical components.

– Do not work under the lifted machine without supporting it with safety stands.

– Do not operate the machine near toxic, dangerous, ammable and/or explosive powders, liquids or vapors.

This machine is not suitable for collecting dangerous powders.

– When using lead (WET) batteries, keep sparks, ames and smoking materials away from the batteries. During

the normal operation explosive gases are released.

– When using lead (WET) batteries, battery charging produces highly explosive hydrogen gas. During battery

charging, lift the recovery tank and perform this procedure in well-ventilated areas and away from naked

ames.

WARNING!

– Carefully read all the instructions before performing any maintenance/repair procedure.

– The machine ignition key has a built-in magnet. Do not place objects having magnetic bands (such as credit

cards, electronic keys, phone cards) near the key. The built-in magnet can damage or erase the data stored

on the magnetic bands.

– Before using the battery charger, ensure that frequency and voltage values, indicated on the machine serial

number plate, match the electrical mains voltage.

– Do not pull or carry the machine by the battery charger cable and never use the battery charger cable as

a handle. Do not close a door on the battery charger cable, or pull the battery charger cable around sharp

edges or corners. Do not run the machine on the battery charger cable.

– Keep the battery charger cable away from heated surfaces.

– Do not charge the batteries if the battery charger cable or the plug are damaged.

– To reduce the risk of re, electric shock, or injury, do not leave the machine unattended when it is plugged

in. Before performing any maintenance procedure, disconnect the battery charger cable from the electrical

mains.

– Do not smoke while charging the batteries.

– To avoid any unauthorized use of the machine, remove the ignition key.

– Do not leave the machine unattended without being sure that it cannot move independently.

4 SC2000 - 9100000386

01/2015

Page 7

INSTRUCTIONS FOR USE ENGLISH

WARNING!

– Always protect the machine against the sun, rain and bad weather, both under operation and inactivity

condition. This machine must be used in dry conditions, it must not be used or kept outdoors in wet

conditions.

– Before using the machine, close all doors and/or covers as shown in the Instructions for Use Manual.

– This machine is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the machine by a person responsible for they safety.

Children should be supervised to ensure that they do not play with the machine.

– Close attention is necessary when used near children. Use only as shown in this Manual. Use only Advance’s

recommended accessories.

– Check the machine carefully before each use, always check that all the components have been properly

assembled before use. If the machine is not perfectly assembled it can cause damages to people and

properties.

– Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the machine

moving parts.

– Do not use the machine on incline.

– Do not tilt the machine more than the angle indicated on the machine itself, in order to prevent instability.

– Do not use the machine in particularly dusty areas.

– Use the machine only where a proper lighting is provided.

– If the machine is to be used where there are other people besides the operator, it is necessary to install the

pivoting light (optional).

– While using this machine, take care not to cause damage to people or objects.

– Do not bump into shelves or scaffoldings, especially where there is a risk of falling objects.

– Do not lean liquid containers on the machine, use the relevant can holder.

– The machine operating temperature must be between +32 °F and 104 °F (0 °C and +40 °C).

– The machine storage temperature must be between +32 °F and 104 °F (0 °C and +40 °C).

– The humidity must be between 30 % and 95 %.

– When using oor cleaning detergents, follow the instructions on the labels of the detergent bottles.

– To handle oor cleaning detergents, wear suitable gloves and protections.

– Do not use the machine as a means of transport.

– Do not allow the brush/pad to operate while the machine is stationary to avoid damaging the oor.

– In case of re, use a powder re extinguisher, not a water one.

– Do not tamper with the machine safety guards and follow the ordinary maintenance instructions

scrupulously.

– Do not allow any object to enter into the openings. Do not use the machine if the openings are clogged.

Always keep the openings free from dust, hairs and any other foreign material which could reduce the air

ow.

– Do not remove or modify the plates afxed to the machine.

– To manually move the machine, the electromagnetic brake must be disengaged. After moving the machine

manually, engage the electromagnetic brake again. Do not use the machine when the electromagnetic brake

handwheel is screwed down.

– When the machine is to be pushed for service reasons (missing or discharged batteries, etc.), the speed

must not exceed 2.5 mi/h (4 km/h).

– This machine cannot be used on roads or public streets.

– Pay attention during machine transportation when temperature is below freezing point. The water in the

recovery tank or in the hoses could freeze and seriously damage the machine.

– Use brushes and pads supplied with the machine or those specied in the Instructions for Use Manual.

Using other brushes or pads could reduce safety.

– In case of machine malfunctions, ensure that these are not due to lack of maintenance. If necessary, request

assistance from the authorised personnel or from an authorised Service Center.

– If parts must be replaced, require ORIGINAL spare parts from an Authorised Dealer or Retailer.

– To ensure machine proper and safe operation, the scheduled maintenance shown in the relevant chapter of

this Manual, must be performed by the authorised personnel or by an authorised Service Center.

– Do not wash the machine with direct or pressurised water jets, or with corrosive substances.

– The machine must be disposed of properly, because of the presence of toxic-harmful materials (batteries,

etc.), which are subject to standards that require disposal in special centres (see Scrapping chapter).

01/2015

9100000386 - SC2000 5

Page 8

ENGLISH INSTRUCTIONS FOR USE

18 11

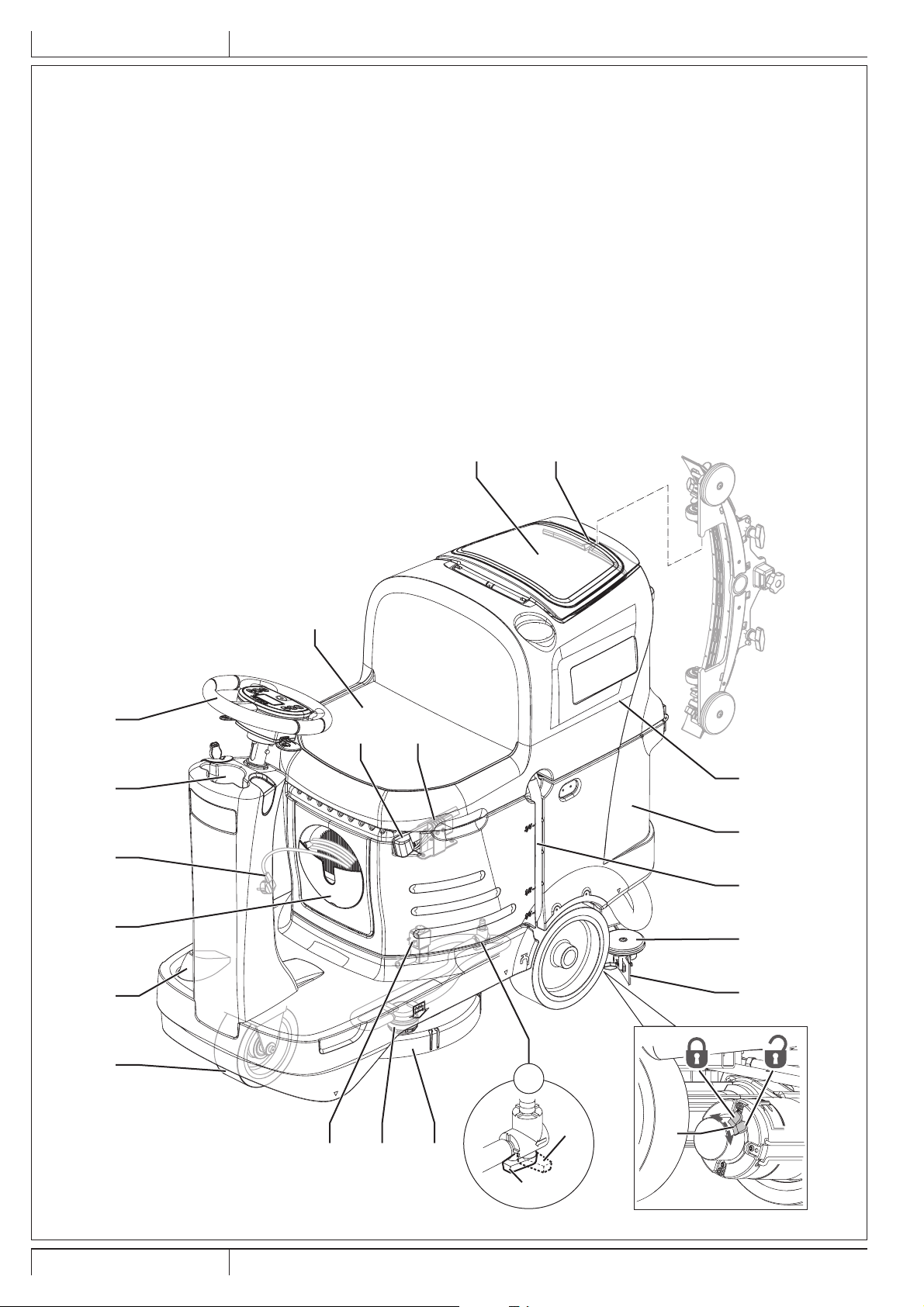

MACHINE DESCRIPTION

MACHINE STRUCTURE

1. Steering wheel with control panel (see the following

paragraph)

2. Drive pedal

3. Front steering wheel

4. Electromagnetic brake locking/unlocking lever

5. EMERGENCY push-button, to stop immediately all

functions

6. Battery connector

7. Brush deck

8. Washing water lter

9. Washing water valve

A) Open valve

B) Closed valve

10. Solenoid valve

11. Squeegee hook

12. Seat

13. Squeegee

14. Squeegee bumper wheels

15. Washing water tank

16. Washing water level and drain hose

17. Dumping recovery tank assembly

18. Recovery tank cover

19. Can holder

20. Battery charger cable housing and document holder

21. Battery charger cable

1

19

21

20

2

12

5 6

17

15

16

14

13

3

10 8 7

6 SC2000 - 9100000386

A

9

B

4

P100859

01/2015

Page 9

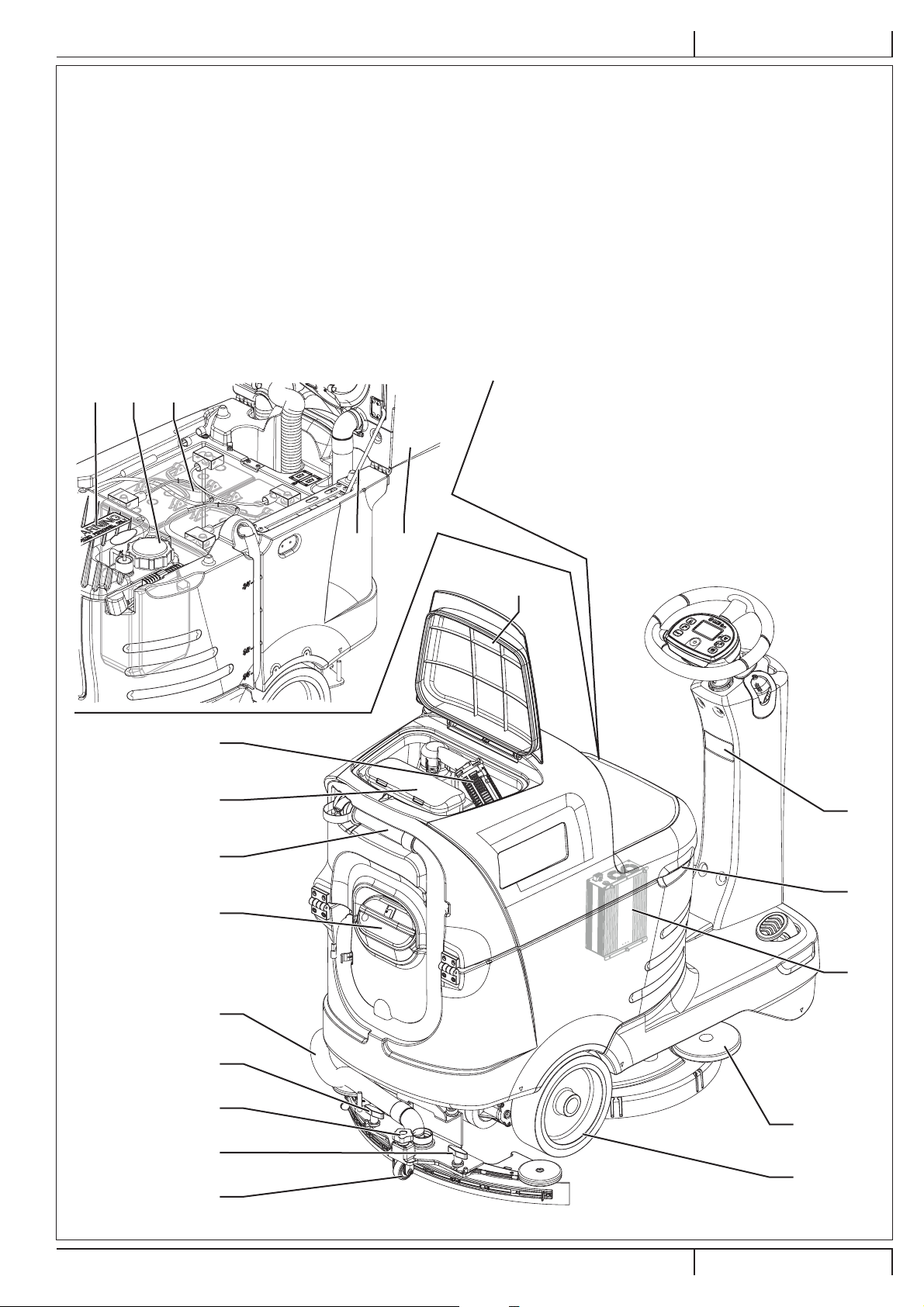

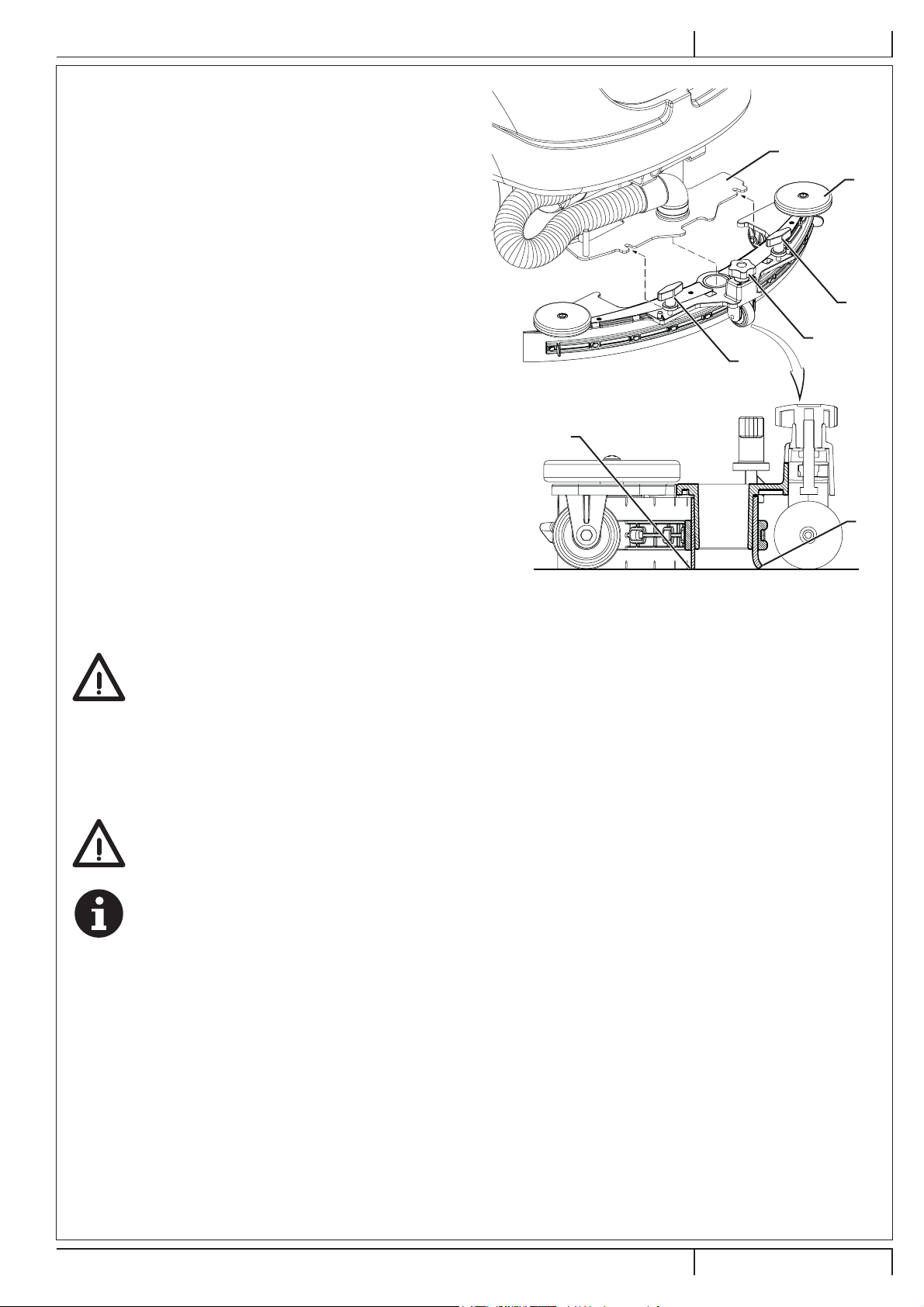

MACHINE STRUCTURE (Continues)

373839

22. Battery charger

23. Serial number plate/technical data/conformity certication

24. Rear driving wheels

25. Washing water tank ller

26. Recovery water drain hose

27. Container with debris collection grid

28. Vacuum grid with automatic shut-off oat

29. Recovery water tank cover (open)

30. Squeegee vacuum hose

INSTRUCTIONS FOR USE ENGLISH

31. Squeegee support wheel

32. Squeegee mounting handwheels

33. Squeegee adjusting knob

34. Brush deck bumper wheel

35. Tank assembly and seat lifting handle

36. Tank assembly and seat support rod

37. Batteries (optional)

38. EcoFlex™ detergent tank

39. Electronic component compartment cover

40. Lifted recovery tank assembly and driver’s seat

28

27

26

25

4036

29

23

35

22

01/2015

30

32

33

34

32

24

31

P100860

9100000386 - SC2000 7

Page 10

ENGLISH INSTRUCTIONS FOR USE

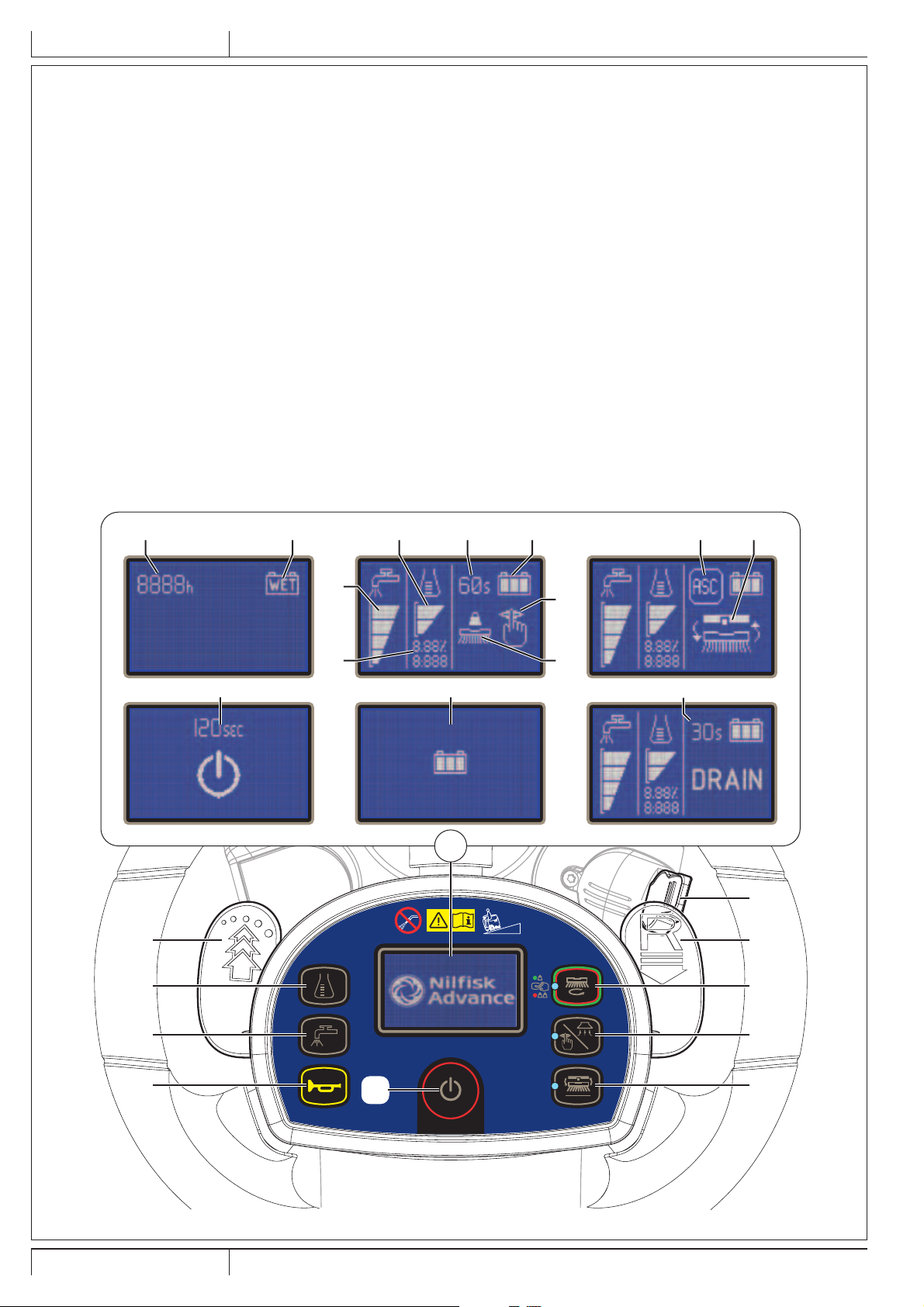

CONTROL PANEL

41. Machine ignition key:

• Operator key (grey)

• Super User key (yellow) (see Maintenance chapter)

42. Machine start/stop push-button

43. One-Touch™ Scrub ON/OFF push-button

• Flashing green LED: Brush deck moving up/down

• Steady green LED: Ready for work

• Steady red LED: Extra pressure active (hold for one

second)

44. Vacuum system adjustment/deactivation push-button:

• LED on - solution ow activated

45. Brush engage/disengage push-button:

• Flashing LED - system activated

46. Detergent percentage adjustment push-button

47. Detergent ow adjustment push-button

48. Horn switch

49. Reverse gear activation/deactivation lever

50. EcoFlex™ activation/deactivation lever

51. Multifunction display

Items displayed:

A) Hours worked

B) Battery type

C) Battery charge level

D) Vacuum mode

E) Brush work mode

F) Detergent solution ow quantity

G) Detergent quantity

H) Percentages of detergent in the washing water

I) EcoFlex™ system override timer

J) Anti-skid control

K) Maximum machine speed setting

L) Auto shut-off timer

M) Battery charging with on-board battery charger

N) EcoFlex™ system drain activation

A B

L

50

H

G

C KI J

F

D

E

M

N

51

41

max.2%

49

46

47

48

8 SC2000 - 9100000386

42

1s

43

44

45

P100861

01/2015

Page 11

INSTRUCTIONS FOR USE ENGLISH

ACCESSORIES/OPTIONS

In addition to the standard components, the machine can be equipped with the following accessories/options, according to the

machine specic use:

– GEL/AGM batteries

– Brushes of different materials

– Pads of different materials

– Squeegee blades of different materials

– Pivoting light

– Mop a trash kit

– TrackClean system

– USB port

– Filling hose

For further information concerning the optional accessories, contact an authorised Retailer.

TECHNICAL DATA

Model SC2000 53 B

Washing water tank capacity 18.5 US gal (70 liters)

Recovery tank capacity 18.5 US gal (70 liters)

Machine length 50 in (1,270 mm)

Machine width with squeegee 28.3 in (720 mm)

Machine width without squeegee 21.6 in (550 mm)

Machine height 40.1 in (1,020 mm)

Turning space for U-turns 71 in (1,800 mm)

Cleaning width 21 in (530 mm)

Rear driving wheel diameter 10 in (254 mm)

Rear driving wheel specic pressure on the oor 145 psi (1.0 N/mm2)

Front steering wheel diameter 7.9 in (200 mm)

Front wheel specic pressure on the oor 188 psi (1.3 N/mm2)

Brush/pad diameter 21 in (530 / 508 mm)

Brush pressure with extra-pressure function turned off 33 lb (15 kg)

Brush pressure with extra-pressure function turned on 66 lb (30 kg)

Solution ow values 0.75 cl/m / 1.5 cl/m / 3.0 cl/m / (2.8 l/min, if enabled)

EcoFlex™ system detergent percentage 0.25 % - 3 %

Sound pressure level at workstation (ISO 11201, ISO 4871, EN 60335-2-72) (LpA) 68 ± 3 dB(A)

Sound pressure level at workstation in silent mode (LpA) 62 ± 3 dB(A)

Machine sound power level (ISO 3744, ISO 4871, EN 60335-2-72) (LwA) 84 dB(A)

Vibration level at the operator’s arms (ISO 5349-1, EN 60335-2-72) 130 in/s2 (3.3 m/s2)

Vibration level at the operator’s body (ISO 5349-1, EN 60335-2-72) 35.4 in/s2 (0.9 m/s2)

Maximum gradient when working 2 %

Drive system motor power 0.53 hp (400 W)

Drive speed (variable) 0 - 3.7 mi/h (0 - 6 km/h)

Vacuum system motor power 0.4 hp (310 W)

Vacuum system circuit capacity 39 in H2O (1,000 mm H2O)

Brush motor power 0.6 hp (450 W)

Brush motor speed 155 rpm

Total absorbed power (*) 26 A (620 W)

IP protection class X4

Protection class (electric) III (I for the battery charger)

Battery compartment size 13.8x14.2x11 in (350x360x280 mm)

System voltage 24V

Standard batteries (2) Discover 12V-105Ah

Battery charger 100-240Vac 50-60Hz, 24Vdc 13A

Operating time (standard batteries) (*) 2.5 hour

Weight without batteries and with empty tanks 267 lb (121 kg)

Gross vehicle weight (GVW) 754 lb (342 kg)

Shipping weight 342 lb (155 kg)

(*) Values reect standard operating conditions (EN 60335-2-72)

01/2015

9100000386 - SC2000 9

Page 12

ENGLISH INSTRUCTIONS FOR USE

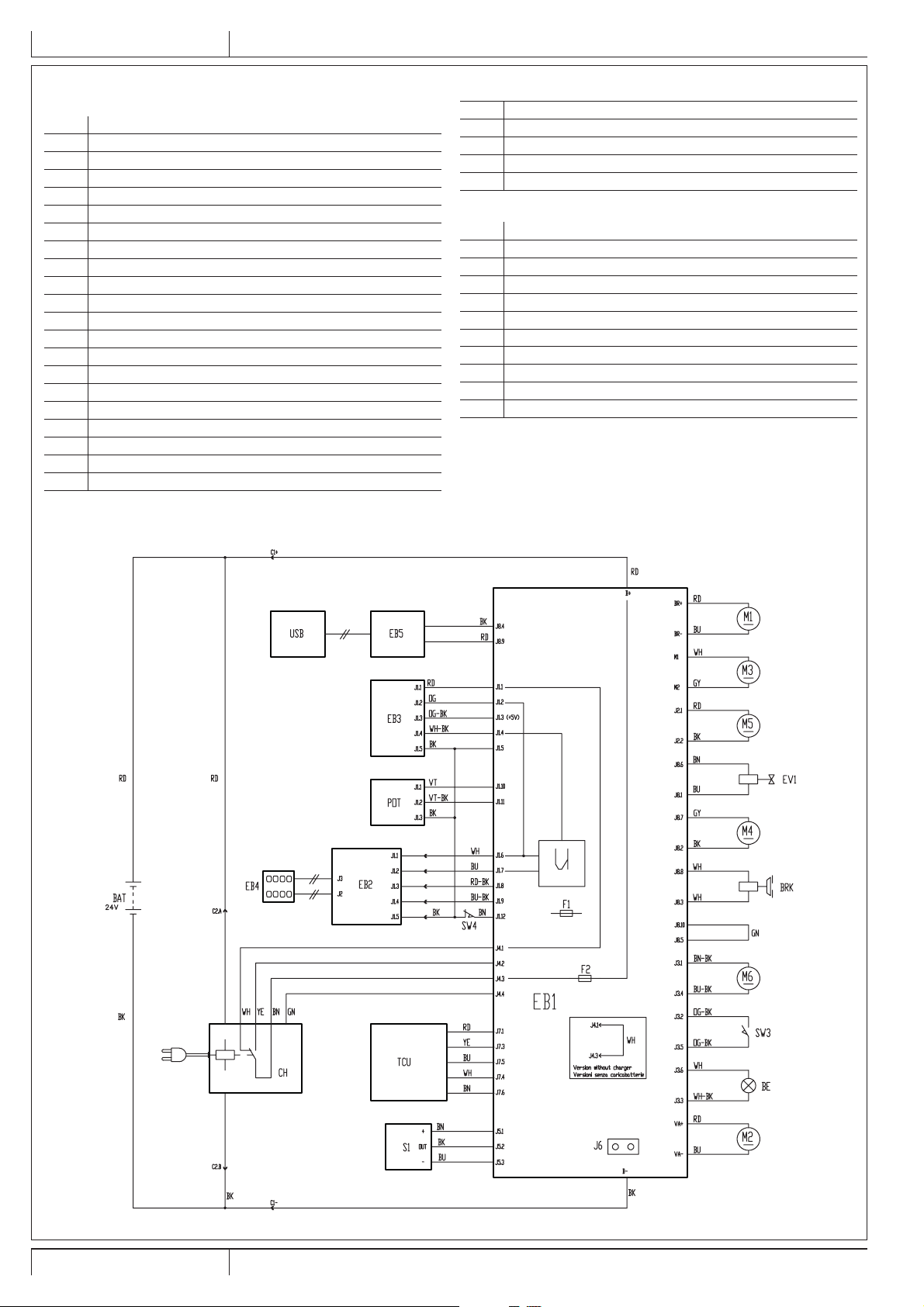

WIRING DIAGRAM

Key

BAT 24V batteries

BE Pivoting light (optional)

BRK Electromagnetic brake

C1 Battery connector

C2 Battery charger connector

CH Battery charger

EB1 Function electronic board

EB2 Display electronic board

EB3 Key electronic board

EB4 Dashboard instrument electronic board

EB5 5V power unit (optional)

EV1 Solenoid valve

F1 Main electronic board fuse

F2 Signal circuit fuse

M1 Brush motor

M2 Vacuum system motor

M3 Drive system motor

M4 EcoFlex™ pump

M5 Brush deck actuator motor

M6 Squeegee actuator motor

POT Drive pedal potentiometer

S1 Washing water level sensor

SW3 Seat microswitch

SW4 Anti-skid control sensor

TCU TrackClean™ (optional)

USB USB port (optional)

Color codes

BK Black

BU Blue

BN Brown

GN Green

GY Grey

OG Orange

PK Pink

RD Red

VT Violet

WH White

YE Yellow

10 SC2000 - 9100000386

P100862

01/2015

Page 13

INSTRUCTIONS FOR USE ENGLISH

USE

WARNING!

On some points of the machine there are some adhesive plates indicating:

– DANGER

– WARNING

– CAUTION

– CONSULTATION

While reading this Manual, the operator must pay particular attention to the symbols shown on the plates (see Visible Symbols On

The Machine paragraph).

Do not cover these plates for any reason and immediately replace them if damaged.

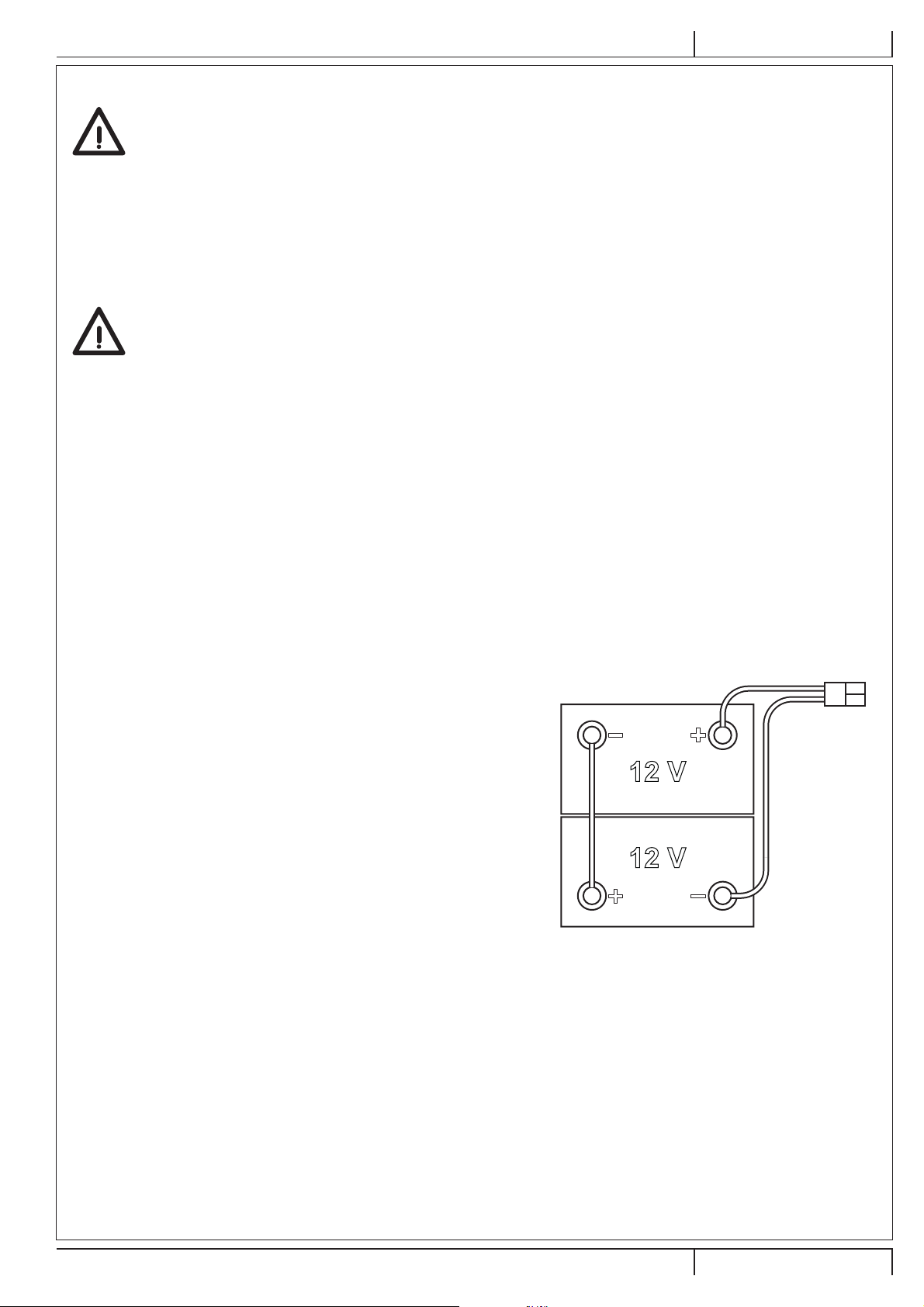

BATTERY CHECK/SETTING ON A NEW MACHINE

WARNING!

The electric components of the machine can be seriously damaged if the batteries are either improperly installed

or connected. The batteries must be installed by qualied personnel only.

Set the machine according to the type of batteries used.

Check the batteries for damage before installation.

Disconnect the battery connector and the battery charger plug.

Handle the batteries with great care.

Install the battery terminal protection caps supplied with the machine.

The machine requires 2 12V batteries, connected according to the diagram shown in Figure 1.

The machine can be supplied in one of the following modes:

Batteries already installed on the machine

1. Ensure that the battery connector (6) is connected.

2. When rst using the machine with new batteries, perform a full charging cycle (see the procedure in Maintenance chapter).

Without batteries

1. Buy appropriate batteries (see “Technical Data” paragraph). For battery choice and installation, apply to qualied battery

Retailers.

2. Set the machine according to the type of batteries installed as shown in the Super User key section of the Maintenance

chapter.

BATTERY INSTALLATION

Battery Installation

1. Remove the operator key (41).

2. Disconnect the battery connector by pressing the

emergency push-button (5).

3. Lift the cover (18) and check that the recovery tank (17) is

empty, otherwise empty it with the drain hose (26).

4. Close the cover (18).

5. Grasp the handle (35) and carefully lift the recovery tank

assembly (17).

6. The machine is supplied with cables suitable to install 2

12V batteries.

7. Carefully lift the batteries until the relevant compartment,

then place them properly.

8. Route and install the battery cable as shown in Figure 1,

then carefully tighten the nut on each battery terminal.

9. Place the protection cap on each terminal, then connect

the battery connector (6).

10. Disengage the support rod (36), then grasp the handle (35)

and carefully lower the recovery tank assembly (17).

BACK

Figure 1

FRONT

P100863

Battery Charging

11. Fully charge the batteries (see the procedure in

Maintenance chapter).

01/2015

9100000386 - SC2000 11

Page 14

ENGLISH INSTRUCTIONS FOR USE

BEFORE MACHINE START-UP

WARNING!

When starting the machine, or before operating the One-Touch™ push-button (43), make sure that there is

no foreign material between the deck and the tank assembly which could obstruct the deck movement. If the

machine has been turned off without lifting the deck, the deck would lift automatically at next machine start-up.

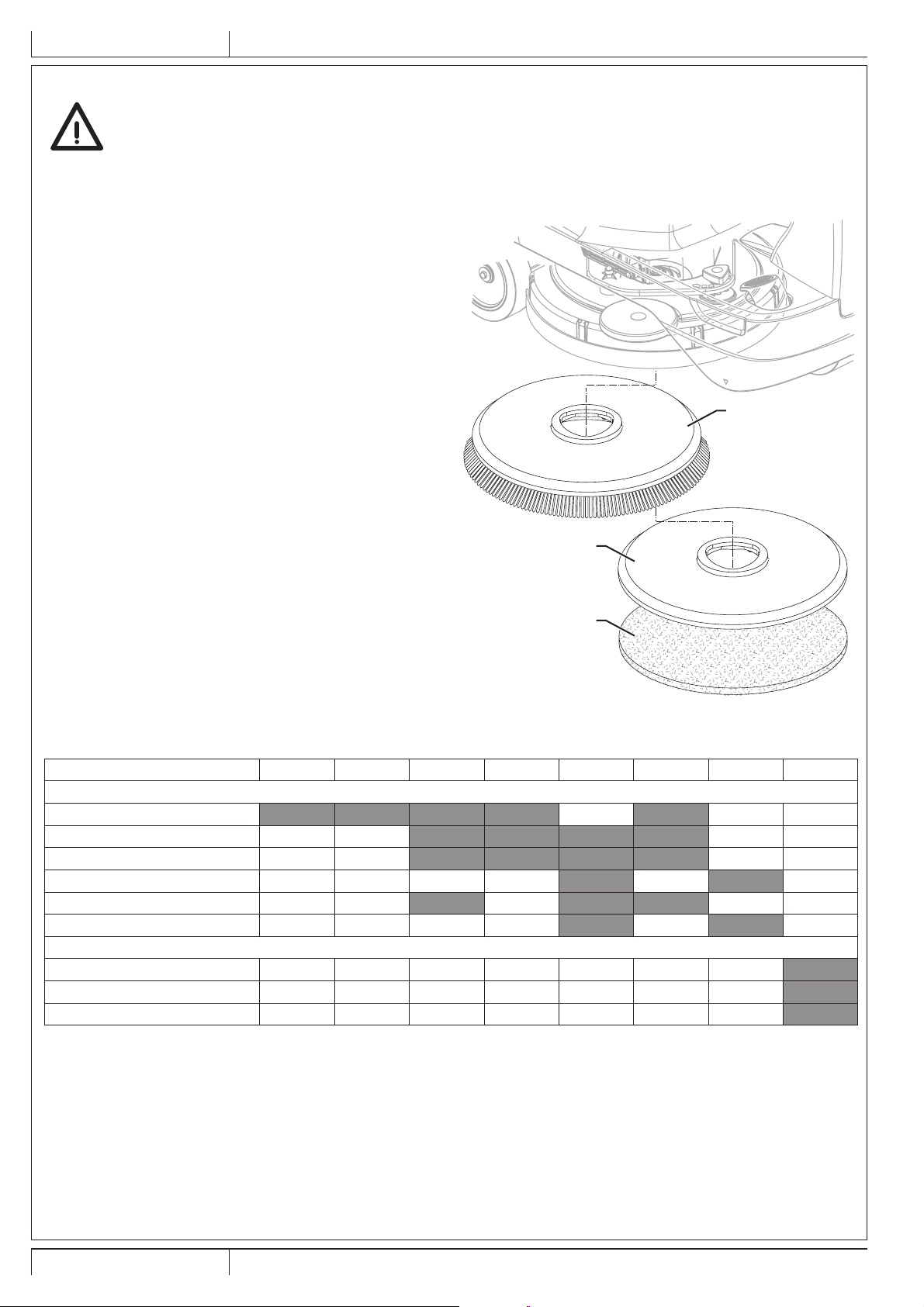

Brush or pad-holder removal/installation

1. According to the kind of cleaning to be performed, the

machine can be equipped either with the brush (A, Fig.

2) or the pad-holder (B) with pad (C) together with the

appropriate deck.

2. Place the brush (A) or the pad-holder (B) under the deck

(7).

3. Insert the operator key (41) in its slot.

4. Press the push-button (43) to lower the deck on the brush.

5. Press the switch (45) to engage the brush.

6. To remove the brush, the deck must be lifted by pressing

the push-button (43), then press the release push-button

(45).

7. When the display shows the icon (51-K), wait for the brush

to fall on the oor.

A

B

C

Figure 2

P100864

Available brushes and their relevant application guides (suggestions only)

Models 46 GRIT 80 GRIT 180 GRIT 240 GRIT 500 GRIT PROLENE PROLITE UNION MIX

General cleaning:

Concrete

Terrazzo oor

Ceramic tiles/quarrystones

Marble

Vinyl tiles

Rubber tiles

Polishing:

Rubber tiles

Marble

Vinyl tiles

12 SC2000 - 9100000386

01/2015

Page 15

Squeegee installation

1. Install the squeegee (A, Fig. 3) and fasten it to the bracket

(C) with the handwheels (B).

2. If necessary, adjust the squeegee with the knob (D) so that

the rear blade (E) and front blade (F) touch the oor as

shown in the gure.

Washing water tank lling

1. Ensure that the washing water valve (9) is open (9-A).

2. To ll the washing water tank (15) remove the ller neck

plug (25).

3. Fill the tank (15) with clean water. If equipped, use the

water ller hose (optional) located in the ller neck (25).

Do not ll the tank completely, leave a few inches from the

edge. Use the level hose (16) as reference.

The water temperature must not exceed 40 °C.

INSTRUCTIONS FOR USE ENGLISH

C

A

B

D

B

F

Figure 3

EcoFlex™ detergent tank lling

WARNING!

When using oor cleaning detergents, follow the instructions on the labels of the detergent bottles.

To handle oor cleaning detergents, wear suitable gloves and protections.

4. Lift the cover (18) and check that the recovery tank (17) is empty, otherwise empty it with the drain hose (26).

5. Close the cover (18).

6. Grasp the handle (35) and carefully lift the recovery tank assembly (17).

7. Fill the tank (38) with a detergent suitable for the work to be performed (highly concentrated detergent).

Do not ll the detergent tank completely, leave a few inches from the edge.

CAUTION!

Use only low-foam and non-ammable detergents, intended for automatic scrubber applications.

NOTE

To accelerate lling of the hoses and system operation (with a new system, if the system has been emptied for cleaning,

etc.), it is a good idea to drain the EcoFlex™ system once or several times (see the procedure in the Maintenance

chapter).

E

P100865

01/2015

9100000386 - SC2000 13

Page 16

ENGLISH INSTRUCTIONS FOR USE

MACHINE START AND STOP

Starting the machine

1. Prepare the machine as shown in the previous paragraph.

2. To turn on the machine, insert the operator key (41); if the key is already inserted, press the push-button (42).

3. In the rst 2 seconds after machine start-up, the multifunction display (51) indicates the machine working hours (51-A) and the

type of batteries installed (51-B).

NOTE

Check the battery charge level.

When the multifunction display shows at least one segment of the battery symbol (51-C) which is on but not ashing, the

machine is ready for use.

When the battery symbol (51-C) shows just one segment ashing, the batteries have to be charged (see the procedure in

Maintenance chapter).

4. Drive the machine to the working place, by starting it with both hands on the steering wheel (1) and by pressing the drive pedal

(2).

The drive speed can be adjusted from zero to maximum speed according to the pressure on the drive pedal (2).

5. The forward/reverse gear is selected with the relevant lever (49) which is at the right of the steering wheel.

NOTE

The driver’s seat (12) is equipped with a safety sensor, which allows the machine to be driven by pressing the pedal (2)

only when the operator is on the driver’s seat.

NOTE

The machine is equipped with an anti-skid safety system (display icon (51-J)) that reduces the speed when turning and

when the machine tilts laterally, irrespectively of the pressure on the pedal.

In this case, the reduction of speed is not a malfunction but a characteristic that improves the machine stability and

safety in every condition.

Stopping the machine

6. Stop the machine by releasing the drive paddle (2). It is not necessary to lock the machine during stopping or parking, because

the electromagnetic brake on the wheels turn on automatically when the drive pedal is not pressed.

7. Turn off the machine by removing the operator key (41), or by pressing the push-button (42).

NOTE

If the machine is on but not working, it automatically turns off after 2 minutes.

CAUTION!

In the event of an emergency, to stop all machine functions immediately, press the push-button (5).

To reset the machine functions, connect the connector (6) again.

MACHINE OPERATION (SCRUBBING/DRYING)

1. Start the machine as shown in the previous paragraph.

2. Press the One-Touch™ button (43) to lower the brush deck (7) and the squeegee (13) and start scrubbing and drying.

3. Start scrubbing, by starting it with both hands on the steering wheel (1) and by pressing the drive pedal (2) as necessary.

4. If necessary, to reduce the noise, turn on the vacuum system mute function by pressing the push-button (44).

NOTE

The machine is equipped with a safety system that turns on the brush and vacuum system only when the machine is

moving.

14 SC2000 - 9100000386

01/2015

Page 17

INSTRUCTIONS FOR USE ENGLISH

5. Adjust the solution ow by pressing the push-button (47) as necessary, depending on the type of cleaning to be performed.

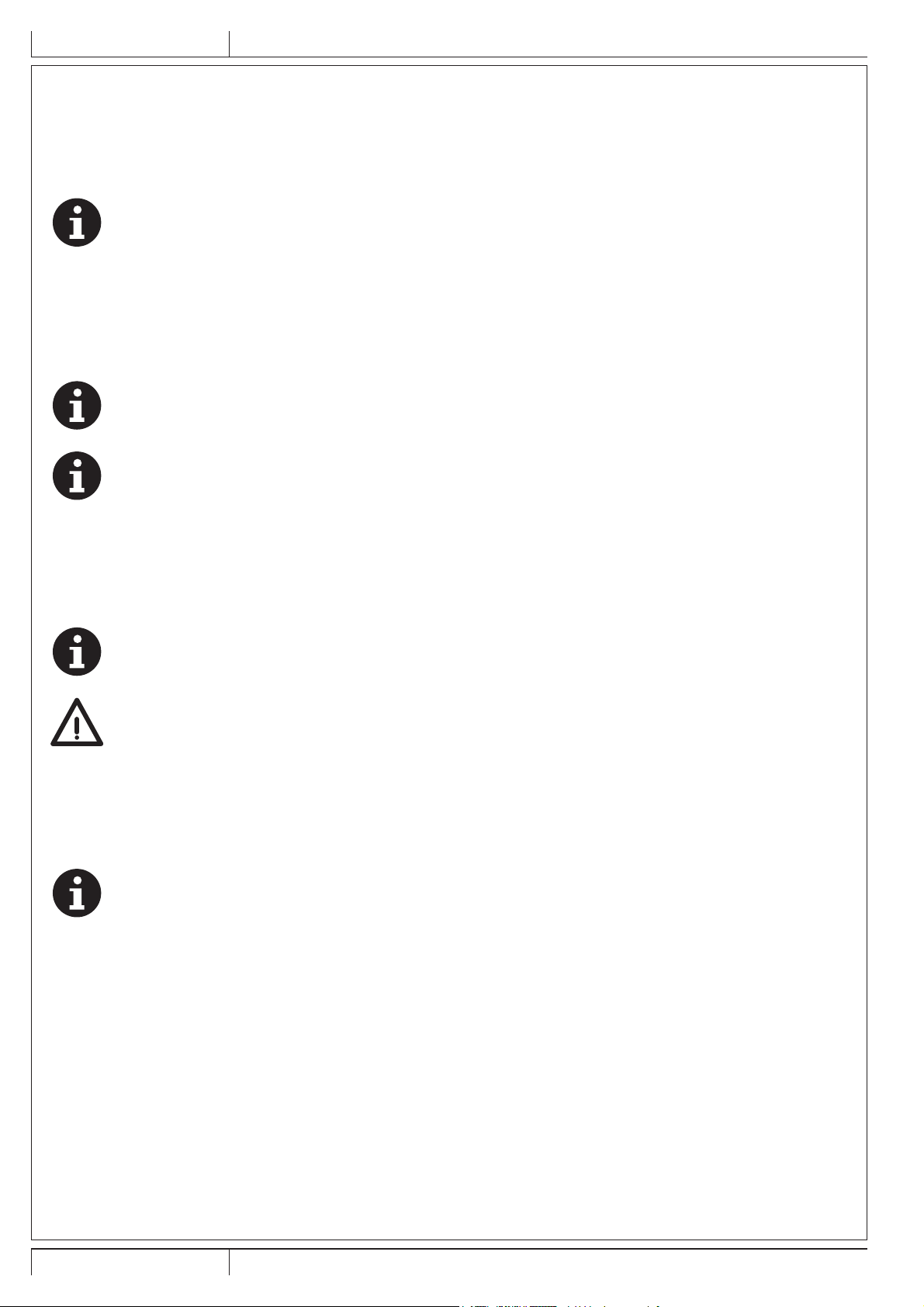

NOTE

For the rst 3 ow levels (Fig. 4), the amount of solution dispensed is automatically adjusted according to the machine

speed, in order to obtain a constant amount of solution per linear meter of cleaning.

Level 4 (when enabled) supplies the maximum possible quantity of detergent solution, regardless of the machine speed

(to enable or disable this, see the Super User key section in the Maintenance chapter).

The level 0 closes the solution ow completely.

Lev.

4

Lev.Lev.

Lev.

2

Lev.

3

1 0

0,75 cl/m OFF1,5 cl/m 3,0 cl/m 2,8 l/min

Figure 4

P100866

NOTE

For correct scrubbing/drying of oors at the sides of the walls, Advance suggests to go near the walls with the right side

of the machine as shown in gure 5.

A

B

Figure 5

6. To stop scrubbing/drying, press the push-button (43) and wait for the brush deck (7) to lift. After 10 seconds, the vacuum

system turns off too and the squeegee (13) lifts.

P100867

01/2015

9100000386 - SC2000 15

Page 18

ENGLISH INSTRUCTIONS FOR USE

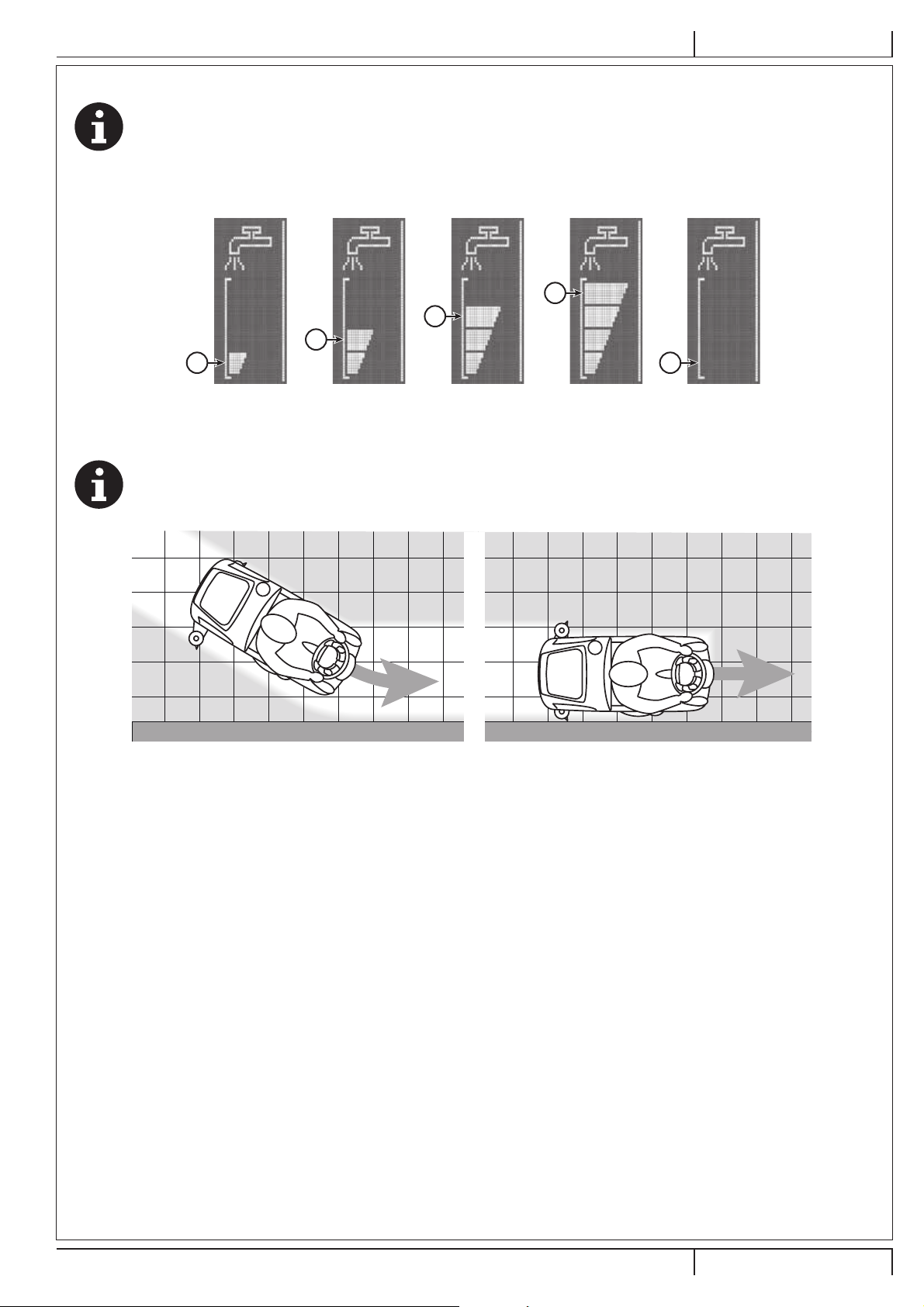

Adjusting of detergent concentration in the washing

water

(For machines with EcoFlex™ system)

The system for mixing the detergent in the washing water is

automatically activated when the brush is running.

The percentage of detergent added to the washing water is set

to level 1 (Fig. 6).

By pressing the push-button (46), it is possible to set the

percentage level to 2, or reset it to level 0.

The set percentages are shown on the multifunction display

(51-G).

1

Lev.

2

Lev.Lev.

0

OFF

Figure 6

P100868

EcoFlex™ system

Use the EcoFlex™ lever (50) when a temporary stronger washing power is needed.

With the EcoFlex ™ system activated, increased solution ow, activation of the extra pressure of the brush and an increase in the

solution detergent concentration (level 2 if the level was set to 1 - level 1 if the level was set to 0) is obtained.

By using the EcoFlex™ lever (50) again, the original settings (LED on) are restored.

NOTE

If the lever (D) is not used once again, the original settings are restored automatically after 60 seconds.

NOTE

All of the above solution ow and detergent concentration values are factory settings.

To change these settings, see the Super User key section in the Maintenance chapter.

Working with brush extra pressure function turned on

If the oor proves to be particularly difcult to clean, it is possible to turn on the brush extra pressure function, according to the

following procedure:

1. Press the push-button (43) to lower the brush deck as shown in “Starting The Machine” paragraph.

2. Press and hold the push-button (43) for more than 1 second. The extra pressure function activation is shown by LED which

turns from green to red, and by the icon on the display (51).

3. To return to normal pressure, press and hold the push-button (43) for more than 1 second.

4. To lift the brush deck without returning to the normal pressure, press the push-button (43) and release it immediately.

CAUTION!

In case of brush motor overload, due to foreign bodies which prevent them from turning, or to excessively

aggressive oors/brushes, the safety system stops the brush after about one minute of continuous overload.

If the overload takes place when the extra pressure function is on, the system automatically turns the extra

pressure function off.

If the overload persists, the brush stops.

To start scrubbing again after a brush stop due to overload, turn off and then on the machine with the pushbutton (42).

Battery discharge during operation

When there is only one segment turned on and ashing on the battery symbol (51-C), it is advisable to charge the batteries,

because the residual autonomy will last for a few minutes (depending on battery characteristics and work to be performed).

When the battery symbol (51-C) is ashing and no segment is turned on, the battery autonomy is over. After a few seconds, the

brush is automatically tuned off, while the vacuum system and the drive system stay on, to nish drying the oor and drive the

machine to the appointed recharging area.

CAUTION!

Do not use the machine with discharged batteries, to avoid damaging the batteries and reducing the battery life.

NOTE

In case the machine drive system cannot be used in order to move the machine, see Pushing/Towing The Machine

paragraph.

16 SC2000 - 9100000386

01/2015

Page 19

INSTRUCTIONS FOR USE ENGLISH

TANK EMPTYING

An automatic oat shut-off system (28) turns off the vacuum system when the recovery tank (17) is full.

The vacuum system deactivation is signalled by a sudden increase in the vacuum system motor noise, and the oor is not dried.

CAUTION!

If the vacuum system turns off accidentally (for example, when the oat is activated because of a sudden

machine movement), to resume the operation: turn off the vacuum system by pressing the push-button (44),

then open the cover (18) and check that the oat inside the grid (28) has gone down. Then close the cover (18)

and turn on the vacuum system by pressing the push-button (44).

When the recovery tank (17) is full, empty it according to the following procedure.

Recovery tank emptying

1. Lift the brush deck and the squeegee by pressing the push-button (43).

2. Drive the machine to the appointed disposal area.

3. Turn off the machine with the push-button (42) and remove the operator key (41).

4. Empty the recovery tank (17) with the drain hose (26). Then, rinse the tank with clean water.

Washing water tank emptying

5. Perform steps 1 to 3.

6. Empty the washing water tank (15) using the level hose (16). Then, rinse the tank with clean water.

AFTER USING THE MACHINE

After working, before leaving the machine:

1. Remove the brush as shown in the relevant paragraph.

2. Remove the operator key (41).

3. Empty the tanks (17 and 15) as shown in the previous paragraph.

4. Remove the squeegee (13) and clean it with hot water. Open the recovery tank cover (18) and hang the squeegee on the tank

hook (11).

5. Perform the daily maintenance procedures (see the Maintenance chapter).

6. Store the machine in a clean and dry place, with the brush and the squeegee lifted or removed.

PUSHING/TOWING THE MACHINE

To push/tow the machine easily when the drive system cannot be used (for example in case of missing batteries, discharged

batteries, etc.), disengage the electromagnetic brake with the lever (4).

When pushing/towing procedure is over, turn the lever (4) to the original position, to engage the electromagnetic brake again.

WARNING!

If the lever (4) is not repositioned after pushing/towing the machine, the electromagnetic brake is disengaged.

WARNING!

Do not start the machine when the electromagnetic brake is disengaged.

For safety reasons, it is recommended to disengage the electromagnetic brake only for the time necessary to

manually move the machine.

MACHINE LONG INACTIVITY

If the machine is not going to be used for more than 30 days, proceed as follows:

1. Perform the procedures shown in After using the machine paragraph.

2. For versions with EcoFlex™ system, empty the detergent tank (38) and clean the system with a draining cycle (see the

procedure in Maintenance chapter).

3. Close the washing water valve (9-B).

4. Press the emergency push-button (5) to disconnect the battery connector (6).

01/2015

9100000386 - SC2000 17

Page 20

ENGLISH INSTRUCTIONS FOR USE

MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

The following table provides the scheduled maintenance. The intervals shown may vary according to particular working conditions,

which are to be dened by the person in charge of the maintenance.

WARNING!

The procedures must be performed with the machine off and the battery disconnected.

Moreover, read carefully the instructions in the Safety chapter before performing any maintenance procedure.

All scheduled or extraordinary maintenance procedures must be performed by qualied personnel, or by an authorised Service

Center.

CAUTION!

When the Service icon appears on the display (51), contact an authorised Advance Service Centre for

scheduled maintenance.

This Manual describes only the simplest and most common maintenance procedures.

For other maintenance procedures shown in the Scheduled Maintenance Table, refer to the Service Manual that can be consulted

at any Service Center.

SCHEDULED MAINTENANCE TABLE

Procedure

Battery Charging

Squeegee Cleaning

Brush/pad cleaning

Recovery tank and debris tray cleaning, and cover gasket check

EcoFlex™ system cleaning and draining

Squeegee blade check

Washing water lter cleaning

Battery (WET) uid level check

Squeegee blade replacement

Electromagnetic brake efciency check (1)

Brush/pad-holder motor carbon brush check or replacement (1)

Drive system motor carbon brush check or replacement (1)

Daily, after using

the machine

Weekly

Every six

months

Yearly

(1) This maintenance procedure must be performed by an authorised Advance Service Center.

18 SC2000 - 9100000386

01/2015

Page 21

INSTRUCTIONS FOR USE ENGLISH

BATTERY CHARGING

NOTE

Charge the batteries when there is only one ashing segment displayed in the battery symbol (51-C), or at the end of the

shift.

Keeping the batteries charged make their life last longer.

CAUTION!

When the batteries are discharged, charge them as soon as possible, as that condition makes their life shorter.

Check for battery charge at least once a week.

WARNING!

When using lead (WET) batteries, battery charging produces highly explosive hydrogen gas. Charge the

batteries in well-ventilated areas and away from naked ames.

Do not smoke while charging the batteries.

Keep the recovery tank raised until the battery charging cycle is over.

WARNING!

Pay close attention when charging WET CELL batteries, as there may be battery uid leakages. The battery uid

is corrosive. If it comes in contact with skin or eyes, rinse thoroughly with water and consult a physician.

1. Drive the machine to the appointed recharging area.

2. Ensure that the machine is off and the operator key (41) has been removed.

3. Lift the cover (29) and check that the recovery tank (17) is empty; if not, empty it using the drain hose (26).

4. Close the cover (18).

5. Grasp the handle (35) and carefully lift the recovery tank assembly (17).

6. (For WET CELL batteries only) Check the level of electrolyte inside the batteries. If necessary, unscrew the caps and top up.

When the correct level is restored, close the caps and clean the tops of the batteries.

7. Plug the battery charger cable (21) into the electrical mains (the mains voltage and frequency must be compatible with the

battery charger values shown on the machine serial number plate).

NOTE

When the battery charger is connected to the electrical mains, all machine functions are automatically cut off.

When the rst or second segment from the left in the battery symbol (51-M) is ashing, this means that the battery charger is

charging the batteries.

When the third segment from the left in the battery symbol (51-M) is ashing, this means that the battery charger is nishing

the battery charging cycle.

8. When all segments of the battery symbol (51-M) are steadily lit, the battery charging cycle is complete.

9. Disconnect the battery charger cable plug (21) from the mains and place it in its holder (20).

10. Disengage the support rod (36), then grasp the handle (35) and carefully lower the recovery tank assembly (17).

11. Now the machine is ready to be used.

NOTE

For further information about the operation of the battery charger (22), see the relevant Manual.

01/2015

9100000386 - SC2000 19

Page 22

ENGLISH INSTRUCTIONS FOR USE

E

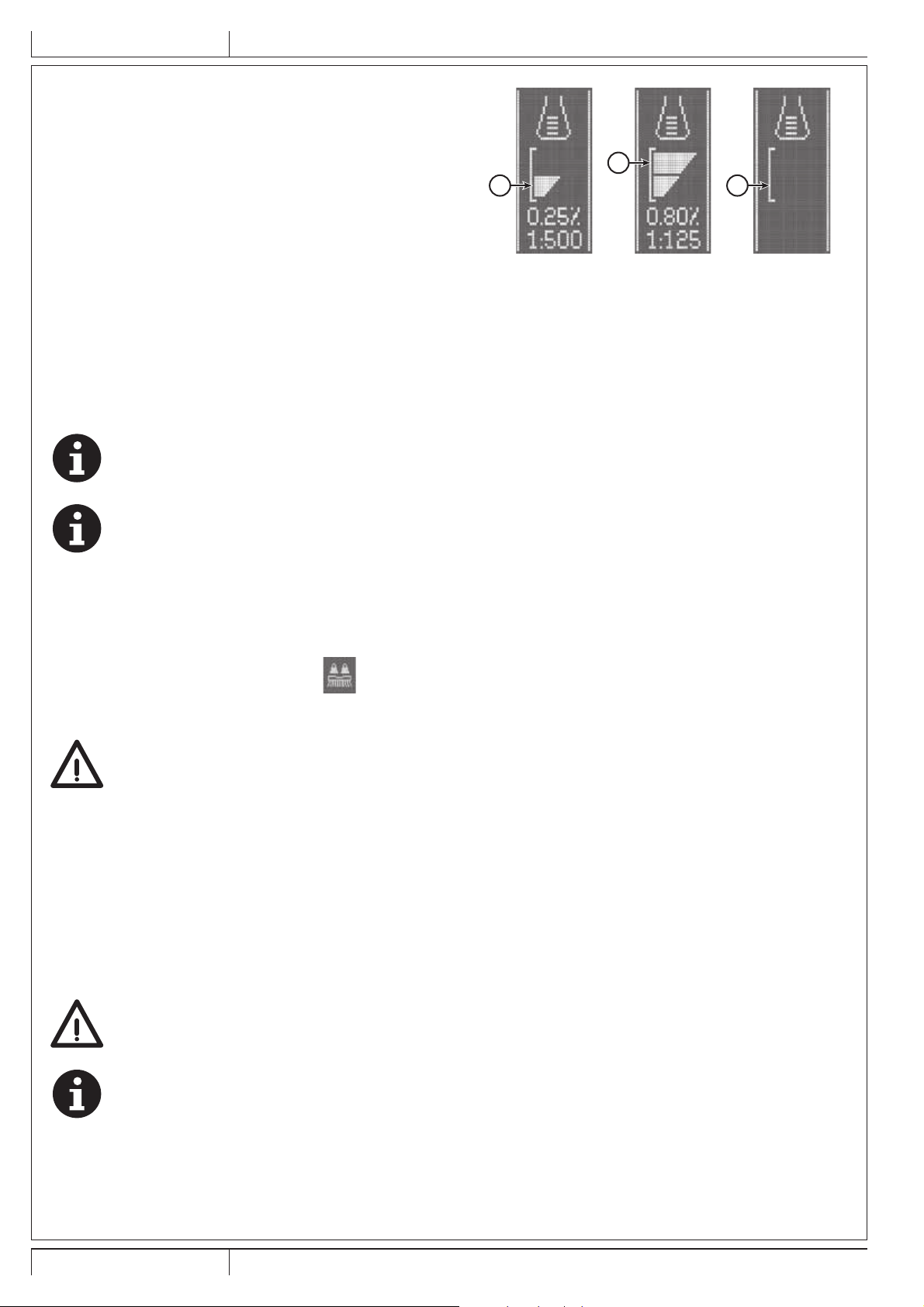

SUPER USER KEY (yellow)

The Super User (yellow) key allows you to check some additional information on some machine operating parameters and to adjust

others to your specic requirements.

Main Screen (E, Fig. 7)

1. Insert the Super User (yellow) key in place of the operator

(grey) key to access the main screen of the multifunction

display (51).

2. Press push-button (A) to change the machine settings (see

Machine Settings Screen section).

3. Press push-button (B) to check for any stored machine

alarms (see Alarms Log Screen section).

4. Press push-button (C) to check the machine’s hours of

operation (see Operating Time Counter Screen section).

5. Press push-button (D) to exit service mode and return to

operator mode.

Machine Settings Screen (F, Fig. 7)

This function allows you to customise some parameters

described in the following table of modiable parameters.

1. Press push-button (B) to increase the value of the current

parameter.

Press push-button (C) to decrease the value of the current

parameter.

2. Press push-button (A) to move to the next parameter.

3. To return to the main screen, press and hold the pushbutton (A) for more than 1 second.

F

A

B

C

D

Figure 7

TABLE OF MODIFIABLE PARAMETERS Values

Code Description Minimum Factory Setting Maximum

CHM1 Detergent concentration level 1 0.25 % (1:500) 0.25 % (1:500) 3 % (1:33)

CHM2 Detergent concentration level 2 0.25 % (1:500) 0.80 % (1:125) 3 % (1:33)

P1/P3 Level 1 solution ow rate in relation to level 3

P2/P3 Level 2 solution ow rate in relation to level 3

P3 Level 3 solution ow rate (ow rate as function of speed) 1.0 cl/m 3.0 cl/m 5.0 cl/m

P4 Enablement of level 4 (2.8 l/min regardless of speed) OFF OFF ON

SPT EcoFlex™ function timer 0 (disabled) 60 sec. 300 sec.

XPRES Brush deck extra pressure enablement OFF ON ON

FVMAX Maximum forward speed 10 % 100 % 100 %

RVMAX Maximum reverse speed 10 % 40 % 50 %

WSMIN Minimum working speed 10 % 25 % 100 %

WSMAX Maximum working speed 10 % 100 % 100 %

BRK Electromagnetic brake activation delay 0 sec. 3 sec. 5 sec.

BAT (**) Installed battery type (see table) 0 1 5

TOFF Automatic shut-off time 0 (disabled) 300 sec. 600 sec.

BRGH Display contrast 5 20 50

VRID Silent mode setting 1 1 5

RPM (*) Reduced brush rpm activation threshold 5 9 20

RESET Restore factory settings for all parameters OFF OFF ON

(ow rate as function of speed)

(ow rate as function of speed)

0 % 25 % 100 %

0 % 50 % 100 %

(*) Increase the value of this parameter to reduce the brush motor speed in a wider range of applications and vice versa.

P100869

20 SC2000 - 9100000386

01/2015

Page 23

INSTRUCTIONS FOR USE ENGLISH

G

H

(**) As described in the Use chapter, set the machine and the on-board battery charger on the basis of the type of battery to be

installed by modifying the BAT parameter from the table below:

Installed battery type Value

WET Wet cell batteries 0

GEL / AGM Generic GEL or AGM batteries 1

GEL EXIDE GEL batteries or EXIDE®/SONNENSHINE brand 2

GEL OPTIMA GEL batteries or OPTIMA™ brand 3

GEL DISCOVER GEL batteries or DISCOVER® brand 4

GEL FULLRIVER GEL batteries or FULLRIVER® brand 5

Alarms log screen (G, Fig. 8)

This function allows you to check for any stored alarms on the

machine.

Use this function only with support from a Advance Service

Centre to solve any operating problems.

To return to the main screen (E, Fig. 7), press push-button (A)

repeatedly.

A

Operating Time Counter Screen (H, Fig. 9)

This function allows you to check the total accumulated hours of

work for each machine subsystem:

– TOTAL counter (machine running time)

– DRIVE counter (drive system usage time)

– BRUSH counter (brush rotation system usage time)

– VACUUM counter (vacuum system usage time)

To return to the main screen (E, Fig. 7), press push-button (A).

Figure 8

P100870

A

Figure 9

P100871

01/2015

9100000386 - SC2000 21

Page 24

ENGLISH INSTRUCTIONS FOR USE

SQUEEGEE CLEANING

NOTE

The squeegee must be clean and its blades must be in good conditions in order to get a good drying.

CAUTION!

It is advisable to wear protective gloves when cleaning the squeegee because there may be sharp debris.

1. Drive the machine on a level oor.

2. Ensure that the machine is off and the operator key (41) has been removed.

3. Loosen the handwheels (32) and remove the squeegee (13).

4. Wash and clean the squeegee. In particular, clean the compartments (A, Fig. 10) and the vacuum hole (B). Check the

condition of the front (C) and rear (D) blades, ensuring there are no cuts and tears; if necessary, replace them as shown below.

5. Install the squeegee in the reverse order of removal.

SQUEEGEE BLADE CHECK AND REPLACEMENT

1. Clean the squeegee as shown in the previous paragraph.

2. Check the condition of the front (C, Fig. 10) and rear (D) blades, ensuring there are no cuts and tears; if necessary, replace

them as shown below. Check that the front corner (E) of the rear blade is not worn; otherwise, turn the blade to replace the

worn corner with one of the three remaining intact corners. If the other corners are worn too, replace the blade according to the

following procedure:

• Using the tab (F), release and remove the elastic strap (G) from the fasteners (H), then turn or replace the rear blade (D).

• Install the blade in the reverse order of removal.

• Unscrew the handwheels (I) and remove the strap (J), then turn or replace the front blade (C).

• Install the blade in the reverse order of removal.

3. Install the squeegee (13) and screw down the handwheels (32).

4. Lower the squeegee to the oor to check the height of the blades, proceeding as follows:

• Check that the lip (K) of the front blade (C) and the lip (L) of the rear blade (D) are resting as shown in the gure.

• Use the knob (33) to make adjustments.

C

J

KEL

D

G

I

J

A

B

A

D

C

I

G

F

F

H

Figure 10

P100872

22 SC2000 - 9100000386

01/2015

Page 25

INSTRUCTIONS FOR USE ENGLISH

CLEANING THE BRUSH

CAUTION!

It is advisable to wear protective gloves when cleaning the brush because there may be sharp debris.

1. Remove the brush as shown in Use chapter.

2. Clean the brush with water and detergent.

3. Check the condition of the brush bristles, ensuring they are not excessively worn; if necessary, replace the brush.

RECOVERY TANK CLEANING

1. Drive the machine to the appointed disposal area.

2. Ensure that the machine is off and the operator key (41) has been removed.

3. Raise the cover (18).

4. Wash the inside of the tank (17) and the cover with clean water.

5. Drain the water in the tank through the hose (26).

6. Clean the vacuum grid (28), release the fasteners (A, Fig. 11), open the grid (B) and recover the oat (C) then clean it carefully

and reinstall it.

7. Remove the debris collection tank (D) and open its cover, then clean it carefully and reinstall it on the vacuum hose.

8. Check the condition of the tank cover gasket (E).

NOTE

The gasket (E) allows the creation of a vacuum in the tank, which is necessary to suck up the recovery water.

If necessary, replace the gasket (E) by removing it from its housing (F). When tting the new gasket, position the joint (G) in

the lower area, as shown in the gure.

9. Check that the seating surface (H) of the gasket (E) is in good condition, clean and suitable to form a seal with the gasket

itself.

10. Close the cover (18).

D

H

E

E

G

F

A

A

B

C

Figure 11

P100873

01/2015

9100000386 - SC2000 23

Page 26

ENGLISH INSTRUCTIONS FOR USE

WASHING WATER FILTER CLEANING

1. Drive the machine on a level oor.

2. Ensure that the machine is off and the operator key (41) has been removed.

3. Close the washing water valve (9). The valve is closed when it is in position (9-B) and it is open when it is in position (9-A).

4. Remove the transparent cover (A, Fig. 12), retrieve the gasket (B), then remove the lter strainer (C). Wash and rinse them

with clean water, then ret them carefully onto the lter support (D).

5. Open the valve (9-A).

D

B

C

A

Figure 12

P100874

DETERGENT TANK CLEANING

(For machines with EcoFlex™ system)

Clean the detergent tank (38) as follows.

1. Drive the machine to the appointed disposal area.

2. Ensure that the machine is off and the operator key (41) has been removed.

3. Lift the cover (29) and check that the recovery tank (17) is empty; if not, empty it using the drain hose (26).

4. Close the cover (18).

5. Grasp the handle (35) and carefully lift the recovery tank assembly (17).

6. Unscrew the cap (A, Fig. 13) from the detergent tank (B).

7. Remove the tank.

8. Rinse and wash out the tank with clean water in the appointed disposal area.

9. Replace the detergent tank (B) as shown in the gure, then ret the cap (A).

10. When the detergent tank has been drained, it may be necessary to drain the EcoFlex™ system too (see procedure in following

section).

A

B

24 SC2000 - 9100000386

Figure 13

P100875

01/2015

Page 27

INSTRUCTIONS FOR USE ENGLISH

DRAINING THE ECOFLEX™ SYSTEM

(For machines with EcoFlex™ system)

Clean the detergent tank following the procedure in the previous section.

To remove residual detergent from the detergent hoses and pump, proceed as follows.

1. To turn on the machine, insert the operator key (41) in its slot on the control panel (3); if the key is already inserted, press the

push-button (42).

2. Press the push-button (43). Check that the detergent quantity indicator (50-G) on the display has at least one segment lit.

3. Press and hold buttons (46) and (47) at the same time until screen (50-N) appears on the display (after approximately 5

seconds).

4. Release buttons (46) and (47) and wait for the countdown timer on the display to nish and the vacuum system to be activated.

5. Collect the detergent remained on the oor.

6. Remove the operator key (41).

7. Lift the recovery tank assembly (17), then check that the detergent tank hose (38) is empty, otherwise perform steps 3 to 7

again.

NOTE

The draining cycle lasts about 30 seconds, then the vacuum function automatically turns on, which allows to remove the

detergent remained.

The draining cycle can also be performed with the detergent tank (38) full of water, thus cleaning the system thoroughly.

It is advisable to perform this type of draining to clean the EcoFlex™ system from dirt and deposits if the machine has

not been used/cleaned for a long time.

The draining cycle can also be performed to quickly ll the detergent supply hose when the tank (38) is full but the

system is still empty.

If necessary, the draining cycle can be performed several times in succession.

FUSE CHECK/REPLACEMENT

NOTE

All machine electrical circuits are protected by auto-resettable electronic devices. The safety fuses activates only in case

of serious damage.

It is recommended to have the fuses replaced by qualied personnel only.

Refer to the Service Manual available at any Advance Retailer.

01/2015

9100000386 - SC2000 25

Page 28

ENGLISH INSTRUCTIONS FOR USE

SAFETY FUNCTIONS

The machine is equipped with the following safety functions.

EMERGENCY PUSH-BUTTON

The emergency push-button (5) is located in an easily accessible position. Press it rmly in case of immediate necessity to stop all

machine functions.

To reset the machine operation, lift the recovery tank assembly (17) and reconnect the battery connector (6).

ANTI-SKID SAFETY SYSTEM

This system reduces the speed when turning and when the machine tilts laterally to avoid sudden skids, this increasing the machine

stability in any condition. The system activation is shown by the icon (51-J) on the display.

DRIVER’S SEAT MICROSWITCH

It is located inside the driver’s seat (12) and it does not allow the machine drive system to operate if the operator is not seated on

the driver’s seat.

ELECTROMAGNETIC BRAKE

It is built-in the rear driving wheels (24) and keeps the machine braked when the machine is off or stopped.

26 SC2000 - 9100000386

01/2015

Page 29

INSTRUCTIONS FOR USE ENGLISH

TROUBLESHOOTING

TROUBLE POSSIBLE CAUSE REMEDY

The motors are not operating; the display (51) and

button LEDs do not turn on.

The machine does not move and the display (51)

shows the alarm:

WARNING ALARM T3

At machine start-up, the button (43) LED ashes

and the brushes do not work.

The brush does not operate; the battery symbol

(51-C) border ashes and the display shows the

alarm message:

WARNING ALARM G4

When working, the display shows the alarm

message: WARNING ALARM F2

The display (51) shows the alarm message:

WARNING ALARM T2

While recharging the batteries with the on-board

battery charger, the display (51) shows the alarm

message:

WARNING ALARM C4 or C5

The display (51) shows an alarm message of the

following type:

WARNING ALARM XX

Where “XX” is a code other than those listed

above.

The dirty water vacuuming is insufcient. The recovery tank is full. Empty the tank.

The solution ow is insufcient. The washing water tank is empty. Rell.

The squeegee leaves marks on the oor. There is debris under the squeegee blades. Remove the debris.

The battery connector is disconnected. Connect.

The batteries are completely discharged. Charge the batteries.

Machine turned on with pedal pressed. Release the drive pedal.

Machine switched off without rst raising the

brush deck.

The batteries are discharged. Charge the batteries.

Brush motor overload. Use a different/less aggressive brush and/or

There are foreign materials (tangled threads,

etc.) preventing the brush from rotating.

Drive motor overload. Turn off the machine and then turn it on again.

Battery charger not able to correctly recharge

the batteries within the maximum time.

The machine electronic control system is in

alarm condition.

The vacuum grid is clogged or the oat is

stuck closed.

Debris collection lter container clogged. Clean.

The hose is disconnected from the squeegee. Connect.

The squeegee is dirty or the squeegee blades

are worn or damaged.

The tank cover is not properly closed, or the

gasket is damaged.

The washing water lter is dirty. Clean the lter.

The EcoFlex™ system tank is dirty/encrusted. Clean with the drain cycle.

The squeegee blades are worn, chipped or

torn.

The squeegee has not been balanced with the

handwheel.

If the problem persists, contact an authorised

Service Center.

Wait for the deck to raise before turning the

brushes on again by pressing the switch.

If the problem persists, replace the batteries.

avoid working with extra pressure turned on.

Clean the brush hub.

Avoid using the machine on slopes greater

than those indicated or going over excessively

tall obstacles.

Run the battery charging cycle again.

If the problem persists, replace the batteries.

Turn off the machine and then turn it on again.

If the problem persists, contact an authorised

Service Center.

Clean the vacuum grid.

Clean the squeegee or overturn/replace the

blades.

Correctly close the cover or clean/replace the

gasket.

Overturn or replace the blades.

Adjust the squeegee.

NOTE

The machine is inoperative without the battery charger.

In case of battery charger malfunction, contact an authorised Service Center.

For any further information, contact Advance Service Centres.

01/2015

9100000386 - SC2000 27

Page 30

ENGLISH INSTRUCTIONS FOR USE

SCRAPPING

Have the machine scrapped by a qualied scrapper.

Before scrapping the machine, remove and separate the following materials, which must be disposed of properly according to the

Law in force:

– Batteries

– Brushes

– Plastic hoses and components

– Electrical and electronic components (*)

(*) Refer to the nearest Advance Center especially when scrapping electrical and electronic components.

Machine material composition and recyclability

Type Recyclable

percentage

Aluminium 100 % 3 %

Electric motors - various 29 % 32 %

Ferrous materials 100 % 23 %

Wiring harness 80 % 7 %

Liquids 100 % 0 %

Plastic - non-recyclable material 0 % 3 %

Plastic - recyclable material 100 % 3 %

Polyethylene 92 % 26 %

Rubber 20 % 2 %

SC2000 weight percentage

28 SC2000 - 9100000386

01/2015

Page 31

INSTRUCCIONES DE USO ESPAÑOL

ÍNDICE

INTRODUCCIÓN .............................................................................................................................................................. 2

FINALIDAD Y OBJETO DE ESTE MANUAL ................................................................................................................................... 2

DESTINATARIOS ............................................................................................................................................................................2

CONSERVACIÓN DEL MANUAL .................................................................................................................................................... 2

DATOS DE IDENTIFICACIÓN ......................................................................................................................................................... 2

OTROS MANUALES DE REFERENCIA .........................................................................................................................................2

PIEZAS DE REPUESTO Y MANTENIMIENTO ............................................................................................................................... 2

MODIFICACIONES Y MEJORAS .................................................................................................................................................... 2

CARACTERÍSTICAS DE FUNCIONAMIENTO ............................................................................................................................... 3

CONVENCIONES ............................................................................................................................................................................ 3

DESEMBALAJE/ENTREGA ............................................................................................................................................ 3

SEGURIDAD .................................................................................................................................................................... 3

SÍMBOLOS VISIBLES EN LA MÁQUINA ........................................................................................................................................ 3

SÍMBOLOS QUE APARECEN EN EL MANUAL .............................................................................................................................. 4

INSTRUCCIONES GENERALES .................................................................................................................................................... 4

DESCRIPCIÓN DE LA MÁQUINA ................................................................................................................................... 6

ESTRUCTURA DE LA MÁQUINA .................................................................................................................................................... 6

PANEL DE CONTROL ..................................................................................................................................................................... 8

ACCESORIOS/OPCIONES ............................................................................................................................................................. 9

DATOS TÉCNICOS ......................................................................................................................................................................... 9

ESQUEMA ELÉCTRICO ...............................................................................................................................................................10

USO ................................................................................................................................................................................ 11

CONTROL/PREPARACIÓN DE LAS BATERÍAS EN LA MÁQUINA NUEVA .................................................................................11

INSTALACIÓN DE LAS BATERÍAS ................................................................................................................................................11

ANTES DE LA PUESTA EN MARCHA DE LA MÁQUINA.............................................................................................................. 12

PUESTA EN MARCHA Y PARADA DE LA MÁQUINA ................................................................................................................... 14

MÁQUINA EN FUNCIÓN (LAVADO/SECAMIENTO) ..................................................................................................................... 14

VACIADO DE LOS DEPÓSITOS ................................................................................................................................................... 17

DESPUÉS DEL USO DE LA MÁQUINA ........................................................................................................................................ 17

DESPLAZAMIENTO DE LA MÁQUINA MEDIANTE EMPUJE/REMOLQUE................................................................................. 17

PERIODO DE LARGA INACTIVIDAD DE LA MÁQUINA ............................................................................................................... 17

MANTENIMIENTO ......................................................................................................................................................... 18

ESQUEMA DE MANTENIMIENTO PROGRAMADO ..................................................................................................................... 18

CARGA DE LAS BATERÍAS .......................................................................................................................................................... 19

LLAVE DE SERVICIO (amarilla) .................................................................................................................................................... 20

LIMPIEZA DE LA BOQUILLA ......................................................................................................................................................... 22

CONTROL Y SUSTITUCIÓN DE LOS CAUCHOS DE LA BOQUILLA.......................................................................................... 22

LIMPIEZA DEL CEPILLO ............................................................................................................................................................... 23

LIMPIEZA DEL DEPÓSITO DEL AGUA DE RECUPERACIÓN ..................................................................................................... 23

LIMPIEZA DEL FILTRO DEL AGUA DE LAVADO.......................................................................................................................... 24

LIMPIEZA DEL DEPÓSITO DEL DETERGENTE .......................................................................................................................... 24