Page 1

SC1500

Service Manual

Advance SC1500 Models: 56104000 (X20D), 56104001 (X20R)

Nilsk SC1500 Models: 56104002 (SC1500-51D)

English

5/13 Form No. 56043166

Page 2

Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Machine Congurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service Manual Purpose and Application . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Other Reference Manuals and Information Sources . . . . . . . . . . . . . . . . . . . . 6

Diagnostic and Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Parts and Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Modications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cautions and Warning Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Prop Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Moving the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Transporting the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

General Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overall Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fastener Torque Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lubrication Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

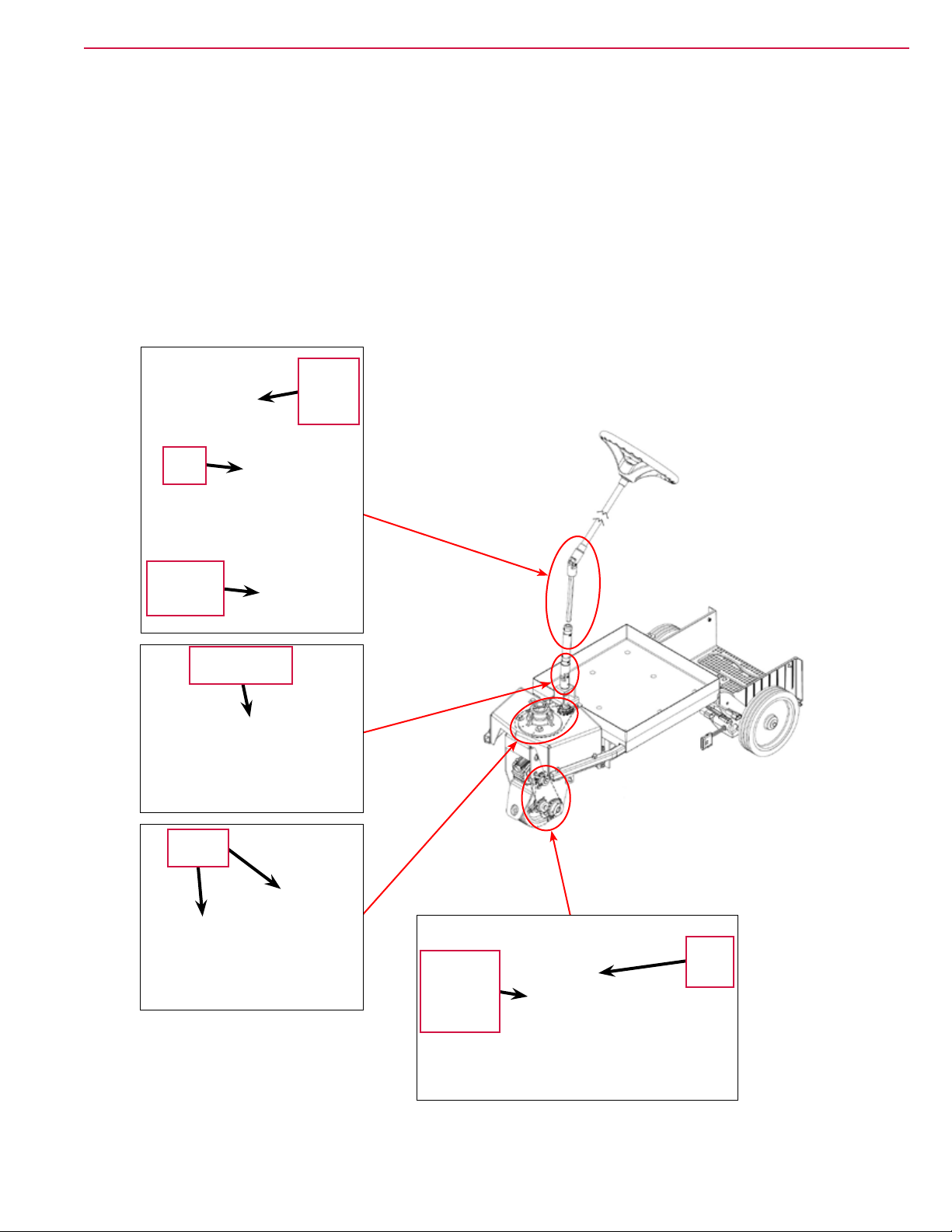

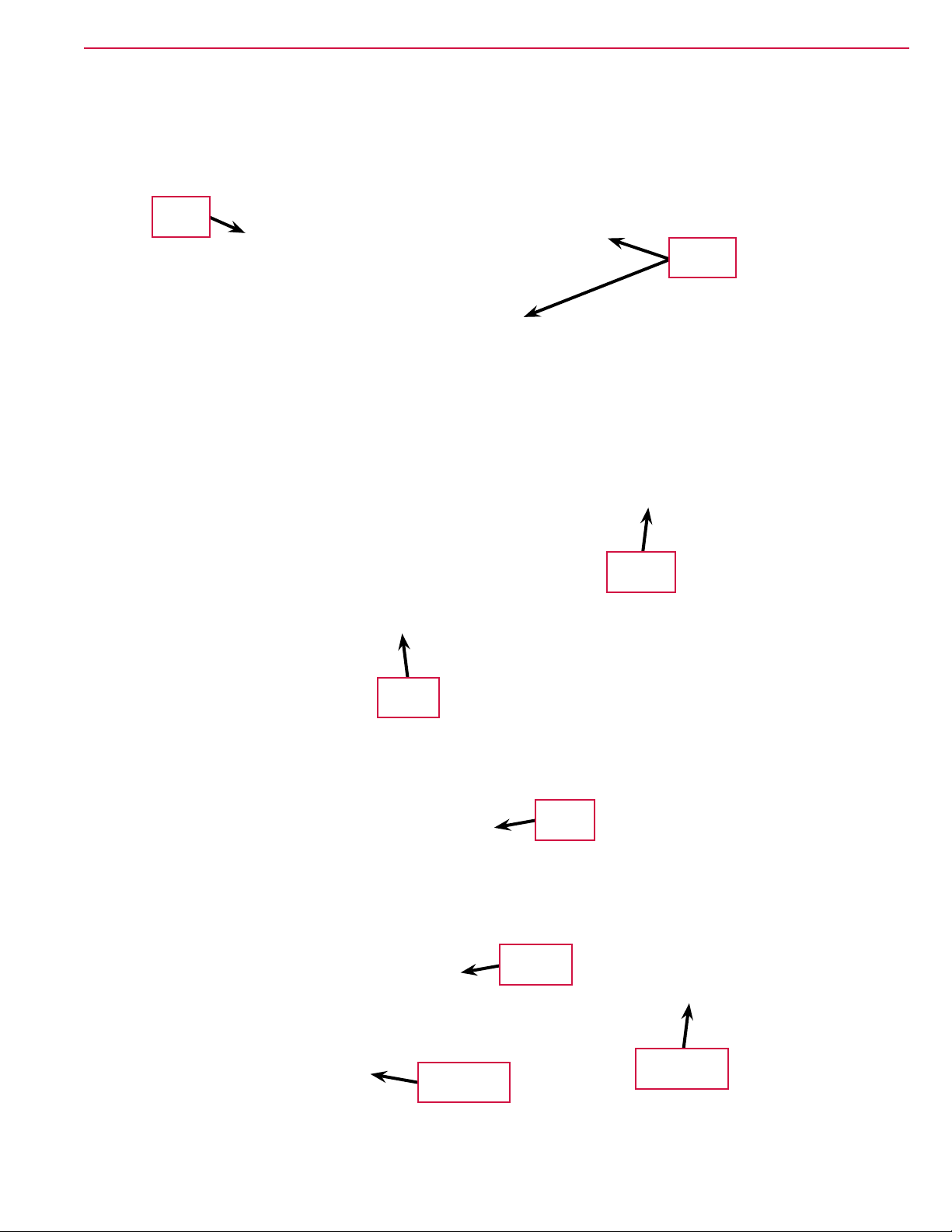

Major Machine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Machine Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

iiService Manual – SC1500

General Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Key Switch, Emergency Stop and Horn Switch . . . . . . . . . . . . . . . . . . . .16

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Speed and Direction Controls and Indicators. . . . . . . . . . . . . . . . . . . . . .18

Scrub Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Solution Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Detergent System Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . .20

Burst of Power Switch and Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Vacuum Power Adjustment Switch and Indicators . . . . . . . . . . . . . . . . . .22

Information Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Battery Status and Charger Screens . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chassis System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Major Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Platform Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Fault Code Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

System Disabled by Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Service Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

To Access the Service Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Service Test Mode Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

To Exit the Service Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Page 3

Programming Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

To Access the Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

To Access a Submenu from the Main Menu . . . . . . . . . . . . . . . . . . . . . . 35

To Change a Programmable Option in a Submenu . . . . . . . . . . . . . . . . . .35

Deck Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Low Battery Voltage Cutout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Burst Of Power Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Detergent (EcoFlex™) Option . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Chemical Rate Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Open Fault Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Display Rev Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Lock Out Brush Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Lock Out Solution Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Backup Alarm Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Forward Alarm Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Horn Volume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Restore Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Fault Recall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Service Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Extra Information on the Graphic Display . . . . . . . . . . . . . . . . . . . . .42

Frozen Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Panel Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Save Scrub Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

A1 Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

E1 Curtis 1210 Speed Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

A1 Control Board Shop Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Contents iiiService Manual – SC1500

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

On-board Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Battery Charger Circuit Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . .54

Battery Charger Not Plugged In . . . . . . . . . . . . . . . . . . . . . . . . . .54

Battery Charger Plugged In. . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Electrical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Wiring Diagram, p/n 56104081, Rev. B, Page 1 . . . . . . . . . . . . . . . . . . . . 58

Wiring Diagram, p/n 56104081, Rev. B, Page 2 . . . . . . . . . . . . . . . . . . . . 59

Wiring Harness Diagram, p/n 56104082, Rev. B . . . . . . . . . . . . . . . . . . . .60

Electrical Connector Pin-out Assignments . . . . . . . . . . . . . . . . . . . . . . . . . 61

To Locate and Identify a Connector . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Connector Pin-out Assignment Tables . . . . . . . . . . . . . . . . . . . . . . . . .62

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Page 4

Recovery System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Circuit Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Vacuum Motor Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Vacuum Motor On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Vacuum Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Scrub System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Scrub Deck and Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

20D Scrub Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

20R REV™ Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Brush Motor Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Deck Actuator Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Circuit Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Scrub Brush Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Scrub Brush Motor Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Scrub Brush Motor On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Deck Actuator Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Scrub Deck Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Scrub Deck in Vacuum-only Position . . . . . . . . . . . . . . . . . . . . . . . .85

Scrub Deck at Normal Scrub Pressure . . . . . . . . . . . . . . . . . . . . . . .86

Scrub Deck at Extra Scrub Pressure . . . . . . . . . . . . . . . . . . . . . . . . 86

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Scrub Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Scrub Deck Actuator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Scrub Deck Actuator Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Contents ivService Manual – SC1500

Solution System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Solution Tank, Water Filter and Valves . . . . . . . . . . . . . . . . . . . . . . . . 97

Solution Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Detergent System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Circuit Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Solution Solenoid Valve Off . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Solution Solenoid Valve On . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Detergent Pump Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Detergent Pump On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Cleaning the Water Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Component Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Nominal Solution Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Page 5

Squeegee System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Steering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Wheel System - Traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Wheel Drive Motor Circuit Descriptions . . . . . . . . . . . . . . . . . . . . . . . 117

Power to the E1 Curtis 1210 Speed Controller. . . . . . . . . . . . . . . . . .117

Speed Control Drive Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Speed Control Communication with the A1 Control Board . . . . . . . . . . . 119

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Speed Control Programming Options . . . . . . . . . . . . . . . . . . . . . . . . . 123

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

General Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

E1 Curtis Speed Controller Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 124

Diagnostics Method A - Graphic Display and Detergent On/Off Indicator . . . 124

Diagnostics Method B - Curtis Programmer . . . . . . . . . . . . . . . . . . . 125

Diagnostic History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Status LED Fault Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Drive Wheel Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Drive Wheel Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Steering Spindle Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Drive Wheel Motor Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Replacing the Motor Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Shop Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

E1 Curtis 1210 Speed Controller – Low Current . . . . . . . . . . . . . . . . 134

E1 Curtis 1210 Speed Controller – Output. . . . . . . . . . . . . . . . . . . .135

General Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Contents vService Manual – SC1500

Page 6

General Information

Machine Congurations

The SC1500 machines are battery-powered commercial oor scrubbing machines suitable for use in hotels,

schools, hospitals, factories, shops, ofces, rental businesses and similar applications.

The SC1500 is available in two scrub system congurations:

• The 20D models have a 20” brush plate assembly to accommodate a variety of disc brushes. The 20D

models can also be used with several grades of pads by using the optional pad holder.

• The 20R models have a 20” REV™ scrub system that uses a pad driver for use with REV™ deck pads only.

The machine is powered by either four 6-volt batteries or two 12-volt batteries, connected in series, to

provide 24 VDC to the motors and controls.

Service Manual Purpose and Application

6Service Manual – SC1500

This Service Manual is a technical resource designed to aid service personnel in maintaining and repairing

the Advance SC1500 Scrubbers to ensure optimum performance and long service life. Please read it

thoroughly before servicing your machine.

Other Reference Manuals and Information Sources

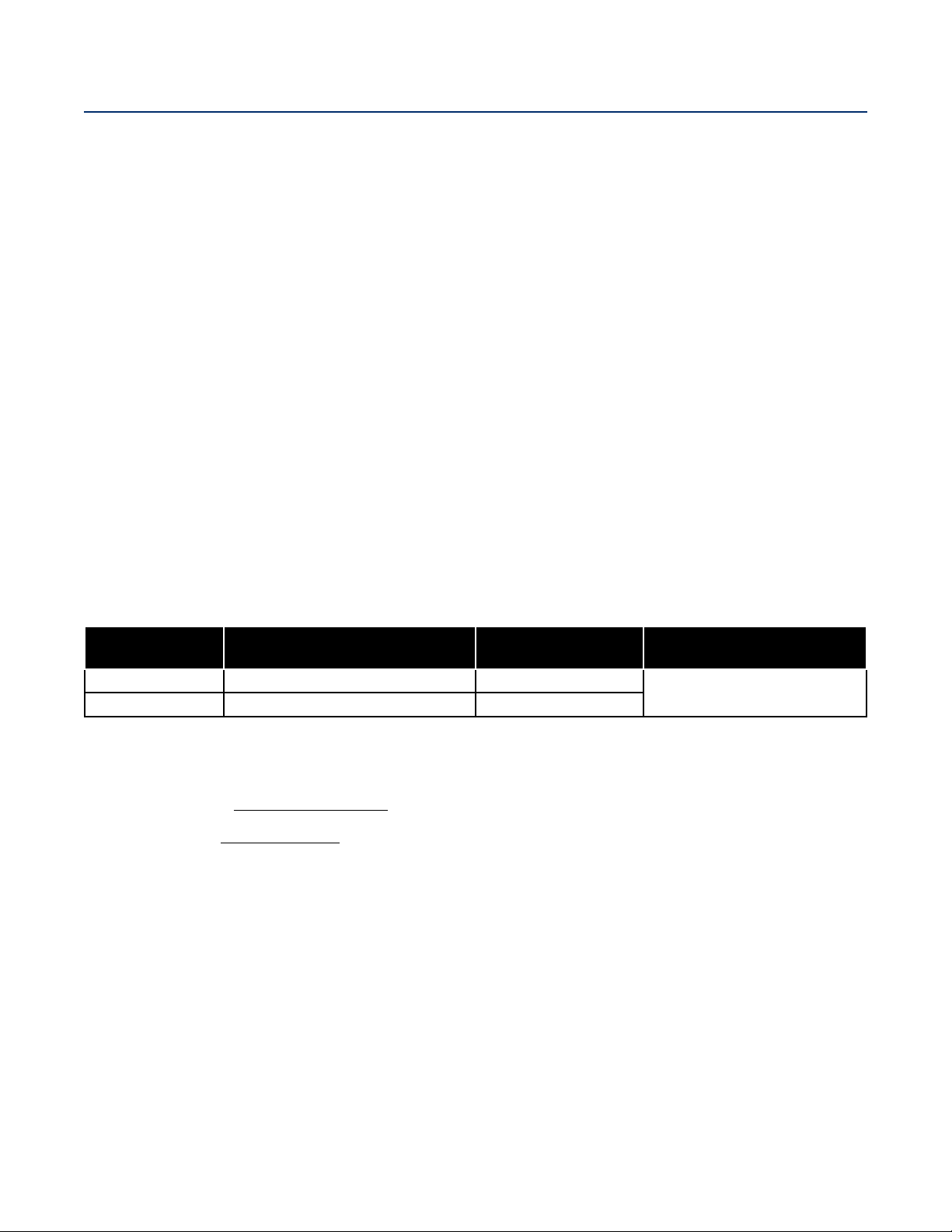

Model Name Model Number

Advance SC1500 56104000, 56104001 56042591

Nilsk SC1500 56104002 (SC1500-51D) 56042592

These manuals can be found on the following Nilsk-Advance’s electronic supported databases:

• Nilsk-Advance Dealer Customer Zone

• Advance website: www.advance-us.com

• Nilsk website: www.nilsk.com

• EzParts service/parts CD-ROM

Parts List

Form Number

Instructions for Use

Form Number

56091047 - English, Español,

Français Português

Diagnostic and Service Tools

In addition to a full set of metric and standard tools, the following items are required in order to successfully

and quickly perform troubleshooting and repair of Advance commercial oor cleaning equipment.

• Digital voltmeter (DVM) with DC current clamp

• Hydrometer

• Battery load tester for checking batteries

• Set of torque wrenches

Page 7

General Information 7Service Manual – SC1500

These tools are also available from Nilsk-Advance, Inc.:

• Curtis 1311 hand held programmer, p/n 56409441,

• Vacuum water lift gauge, p/n 56205281.

Conventions

All references to right, left, front and rear in this manual are as seen from the Operator’s position.

Parts and Service

Repairs should be performed by an Authorized Advance Service Center that employs factory-trained service

personnel and maintains an inventory of Advance original replacement parts and accessories.

Call the Advance Dealer named below for repair parts or service. Please specify the Model Number (same as

the Part Number) and Serial Number when discussing your machine.

(Dealer, afx service sticker here.)

Modications

Modications and additions to the cleaning machine which affect capacity and safe operation shall not be

performed by the customer or user without prior written approval from Nilsk-Advance Inc. Unapproved

modications will void the machine warranty and make the customer liable for any resulting accidents.

Nameplate

The Model Number and Serial Number of the machine are

shown on the Nameplate located on the inside of the battery

compartment.

This information is needed when ordering repair parts for the

machine.

Page 8

General Information 8Service Manual – SC1500

Cautions and Warning Symbols

Nilsk-Advance uses the symbols below to signal potentially dangerous conditions. Read this information

carefully and take the necessary steps to protect personnel and property.

Danger! Is used to warn of immediate hazards that will cause severe personal injury or death.

Warning! Is used to call attention to a situation that could cause severe personal injury.

Caution! Is used to call attention to a situation that could cause minor personal injury or

damage to the machine or other property.

Read all instructions before using.

General Safety Instructions

Specic Cautions and Warnings are included to warn you of potential danger of machine damage or bodily

harm. This machine is for commercial use, for example in hotels, schools, hospitals, factories, shops and

ofces other than normal residential housekeeping purposes.

Warning! Be sure to follow these safety precautions to avoid situations that could cause

severe personal injury.

• This machine should only be used by properly-trained and authorized personnel.

• This machine is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge.

• Avoid sudden stops when on ramps or inclines. Avoid abrupt sharp turns. Use low speed down

ramps.

• Observe the Gross Vehicle Weight, GVW, of the machine when loading, driving, lifting or

supporting the machine.

• Keep sparks, ame and smoking materials away from batteries. Explosive gases are vented

during normal operation.

• Charging the batteries produces highly-explosive hydrogen gas. Charge the batteries only in

well-ventilated areas away from open ame. Do not smoke while charging the batteries.

• Remove all jewelry when working near electrical components.

• Turn the Key Switch off (O) and disconnect the batteries before servicing electrical components.

• Never work underneath a machine without safety blocks or stands to support the machine.

• Do not dispense ammable cleaning agents, operate the machine on or near these agents, or

operate in areas where ammable liquids exist.

Page 9

General Information 9Service Manual – SC1500

• Only use the brushes provided with the machine or those specied in the Instructions for Use.

The use of other brushes may impair safety.

• Do not clean this machine with a pressure washer.

Caution! Be sure to follow these safety precautions to avoid situations that could cause

personal injury, damage to property or equipment damage.

• This machine is not approved for use on public paths or roads.

• This machine is not suitable for picking up hazardous dust.

• Do not use scarier discs and grinding stones. Advance will not be held responsible for any

damage to oor surfaces caused by scariers or grinding stones (can also cause damage to the

brush drive system).

• When operating this machine, ensure that individuals in close proximity, particularly children,

are not endangered.

• Before performing any service function, carefully read all instructions pertaining to that

function.

• Do not leave the machine unattended without rst turning the Key Switch off (O), removing the

key and applying the parking brake.

• Turn the Key Switch off (O) and remove the key before changing the brushes, and before

opening any access panels.

• Take precautions to prevent hair, jewelry or loose clothing from becoming caught in moving

parts.

• Use caution when moving this machine in below-freezing temperature conditions. Any water in

the solution, recovery or detergent tanks, or in the hose lines could freeze, causing damage to

valves and ttings. Flush with windshield washer uid.

• The batteries must be removed from the machine before the machine is scrapped. The disposal

of the batteries should be safely done in accordance with your local environmental regulations.

• Do not use on surfaces having a gradient exceeding that marked on the machine.

• All doors and covers are to be positioned as indicated in the Instructions for Use before using

the machine.

• This machine should only be used and stored indoors.

Caution! Do not clean this machine with a pressure washer.

Page 10

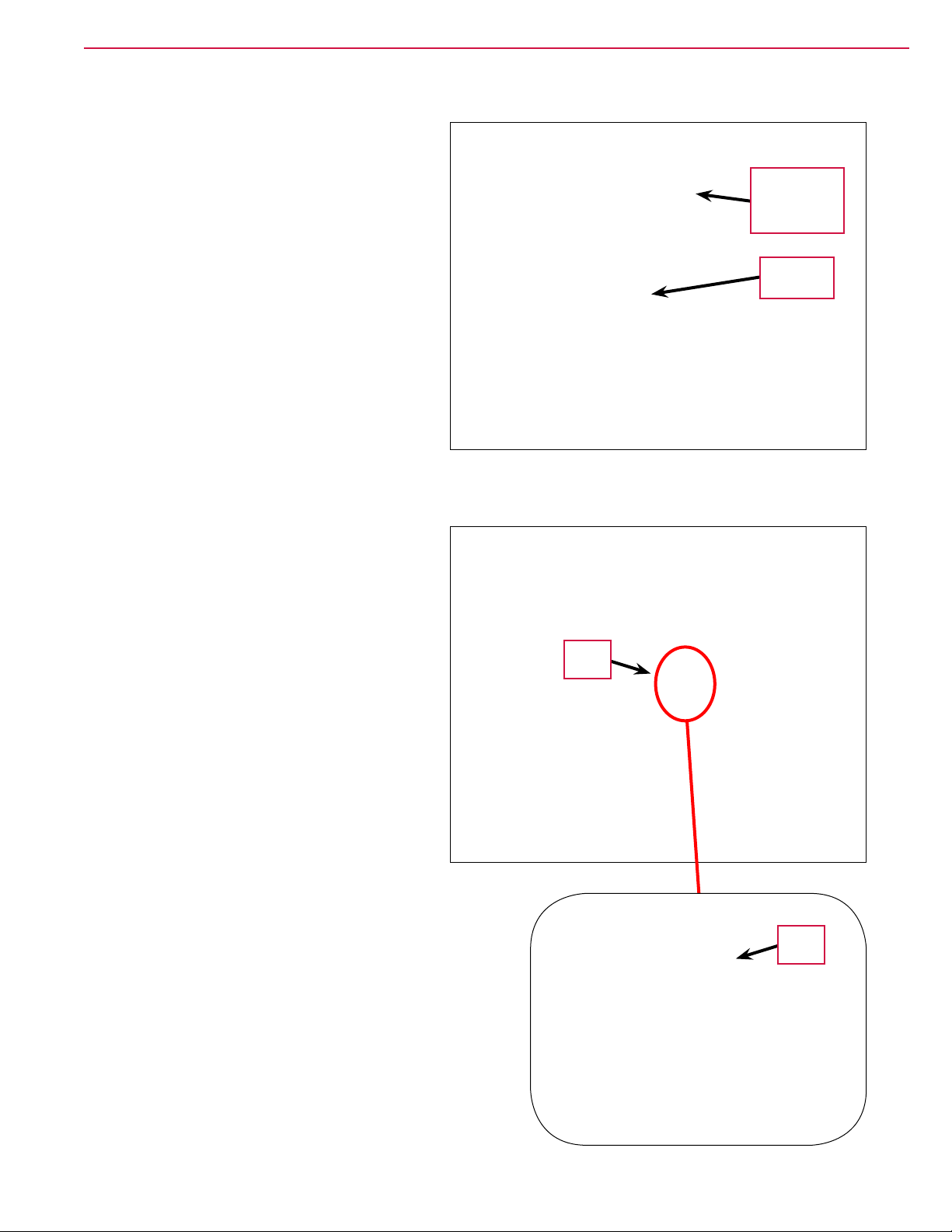

Prop Rod

To prevent the Control Panel Housing / Recovery

Tank Cover

causing injury, always engage the Prop Rod as

shown before working under the Panel Housing

/ Recovery Tank Cover

from dropping unexpectedly and

.

General Information 10Service Manual – SC1500

Control Panel

Housing/

Recovery

Tank Cover

Prop Rod

(engaged)

Moving the Machine

The drive wheel motor has a built-in

electromagnetic brake that engages whenever

the Key Switch is Off or the Go Pedal is

released. You can manually override this

brake if necessary by reaching up around the

back of the front drive wheel and rotating the

Brake Arm up as shown. This should only be

done if you need to push or pull the machine.

Remember to reengage the Brake Arm once you

nish moving the machine.

Note: Turn the drive wheel 45° to

the right for easier access to

the Brake Arm.

Brake

Arm

Brake

Arm

Page 11

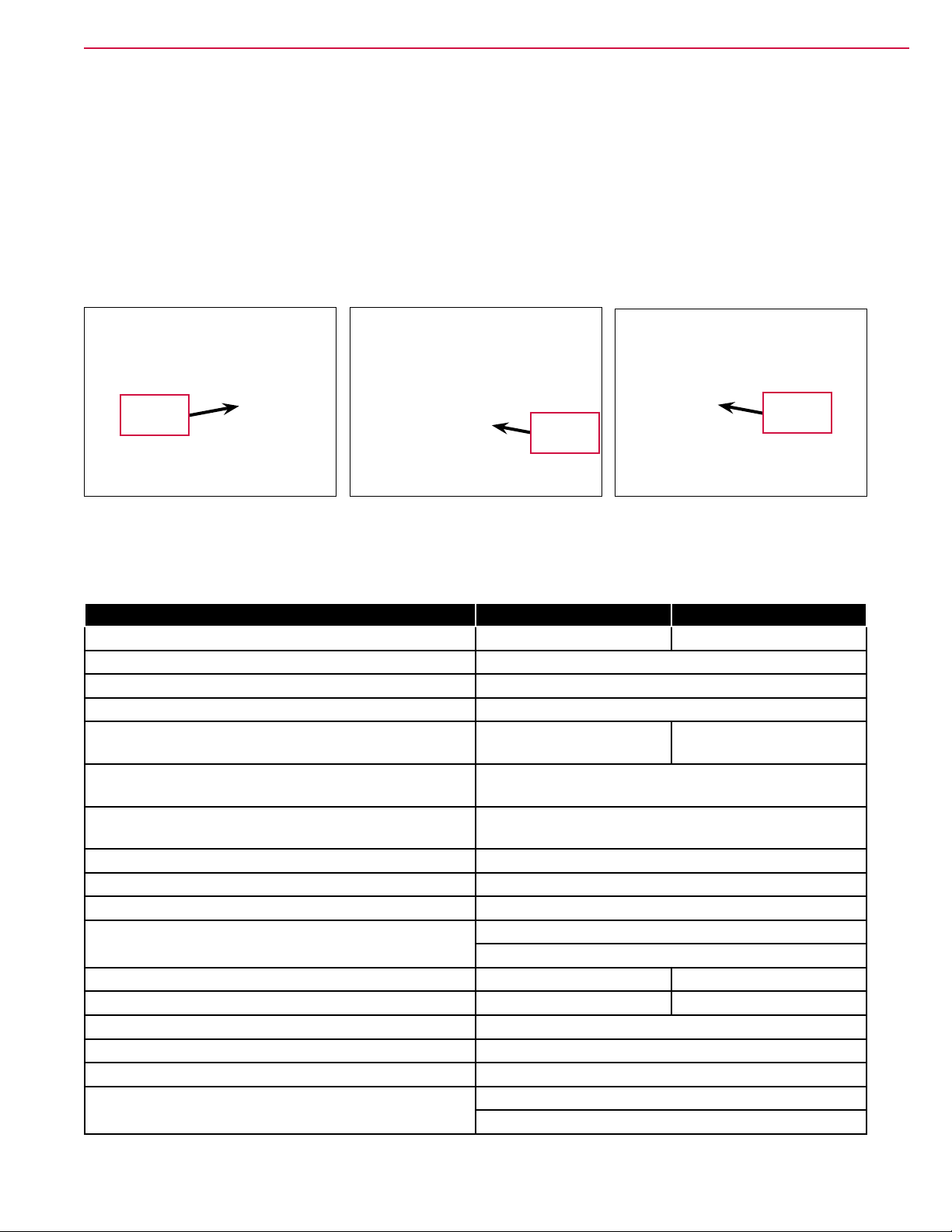

Transporting the Machine

Caution! Before transporting the machine on an open truck or trailer, make sure:

• All tanks are empty.

• The recovery tank cover is latched securely.

• The machine is tied down securely. (Refer to the Tie-down Locations below.

• The machine’s electromagnetic brake is engaged (not manually overridden).

General Information 11Service Manual – SC1500

Left

Tie-down

Front

Tie-down

Right

Tie-down

Specications

General Specications

Model SC1500-X20D SC1500-X20R

Model No. 56104000 56104001

Battery Voltage 24V

Battery Capacity - Amp Hours 260

Protection Grade IPX3

Sound Pressure Level IEC 60335-2-72: 2002 Amend.

1:2005, ISO 11201 dB(A)

Gross Vehicle Weight (w/full solution tank, empty

recovery tank, heaviest batteries, no Operator

Net Weight ((w/empty solution and recovery tanks, no

batteries or brushes

Maximum Operator/Rider Weight 250 lbs / 113.4 kg

Scrub Deck Width 20 in / 50.8 cm

Squeegee Width 26.5 in / 67.3 cm

Tank Capacities

Static Wheel Loading with 179 lb. rider Front: 362 lbs / 164 kg Rear: 275 lbs / 125 kg

Static Wheel Pressure with 175 lb. rider Front: 116 psi / 8.2 kg/cm

Sound Pressure Level (IEC 60704-1)TR12116 63.33 dB(A)/.029344 µPa

Vibrations at the Hand Controls (ISO 5349-1) <.5 m/s

Vibrations at the Seat (EN 1032) <2.5 m/s2

Gradeability

63 dB LpA, ±3 dB KpA 62 dB LpA, ±3 dB KpA

718 lbs / 326 kg

354 lbs / 161 kg

Solution Tank: 11.7 gal / 44.28 L

Recovery Tank: 13.5 gal / 46.67 L

2

Rear: 139 psi / 9.8 kg/cm

2

Transport: 14.5 percent / 8.2 degrees

Cleaning: 8.0 percent / 4.5 degrees

2

Page 12

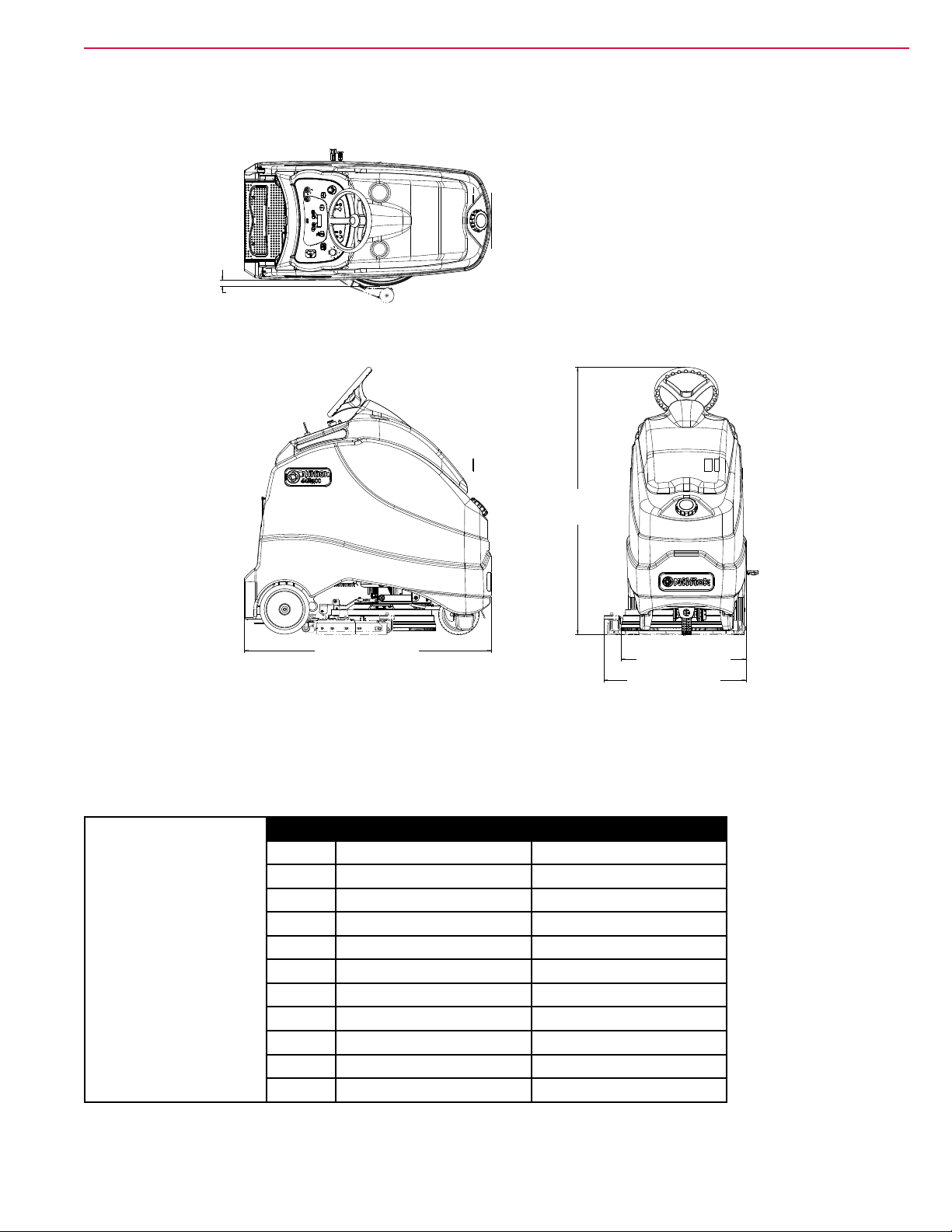

Overall Dimensions

1.13

[28,7]

1.13”

[28,7 mm]

General Information 12Service Manual – SC1500

48.5

48.5” [123,2 cm]

[1232]

Fastener Torque Specications

Size Plated Steel Stainless Steel

#10 42 in.-lb. [4.75 N-m] 28 in.-lb. [3.17 N-m]

1/4“ 100 in.-lb. [11.3 N-m] 67 in.-lb. [7.57 N-m]

5/16” 17 ft.-lb. [23.05 N-m] 11 ft.-lb. [14.91 N-m]

3/8” 31 ft.-lb. [42.03 N-m] 20 ft.-lb. [27.12 N-m]

Standard Torque

Specications (unless

otherwise specied)

1/2” 75 ft.-lb. [101.69 N-m] 50 ft.-lb. [67.79 N-m]

3/4” 270 ft.-lb. [366.07 N-m] 180 ft.-lb. [244.05 N-m]

M5 61 in.-lb. [6.89 N-m] 36 in.-lb. [4.07 N-m]

M6 9 ft.-lb. [12.2 N-m] 62 in.-lb. [7.0 N-m]

M8 22 ft.-lb. [29.83 N-m] 13 ft.-lb. [17.63 N-m]

M10 44 ft.-lb. [59.66 N-m] 25 ft.-lb. [33.9 N-m]

M12 70 ft.-lb. [94.91 N-m] 40 ft.-lb. [54.23 N-m]

52.5”

52.5

[1332]

[133,4 cm]

24.5

24.5” [62,2 cm]

[623]

27.9

27.9” [70,9 cm]

[710]

Page 13

General Information 13Service Manual – SC1500

Maintenance

General Maintenance Information

Keep the machine in top condition by closely following the maintenance schedule. Maintenance intervals

given are for average operating conditions. Machines used in severe environments may require service more

often.

Caution! Do not pressure-wash the machine

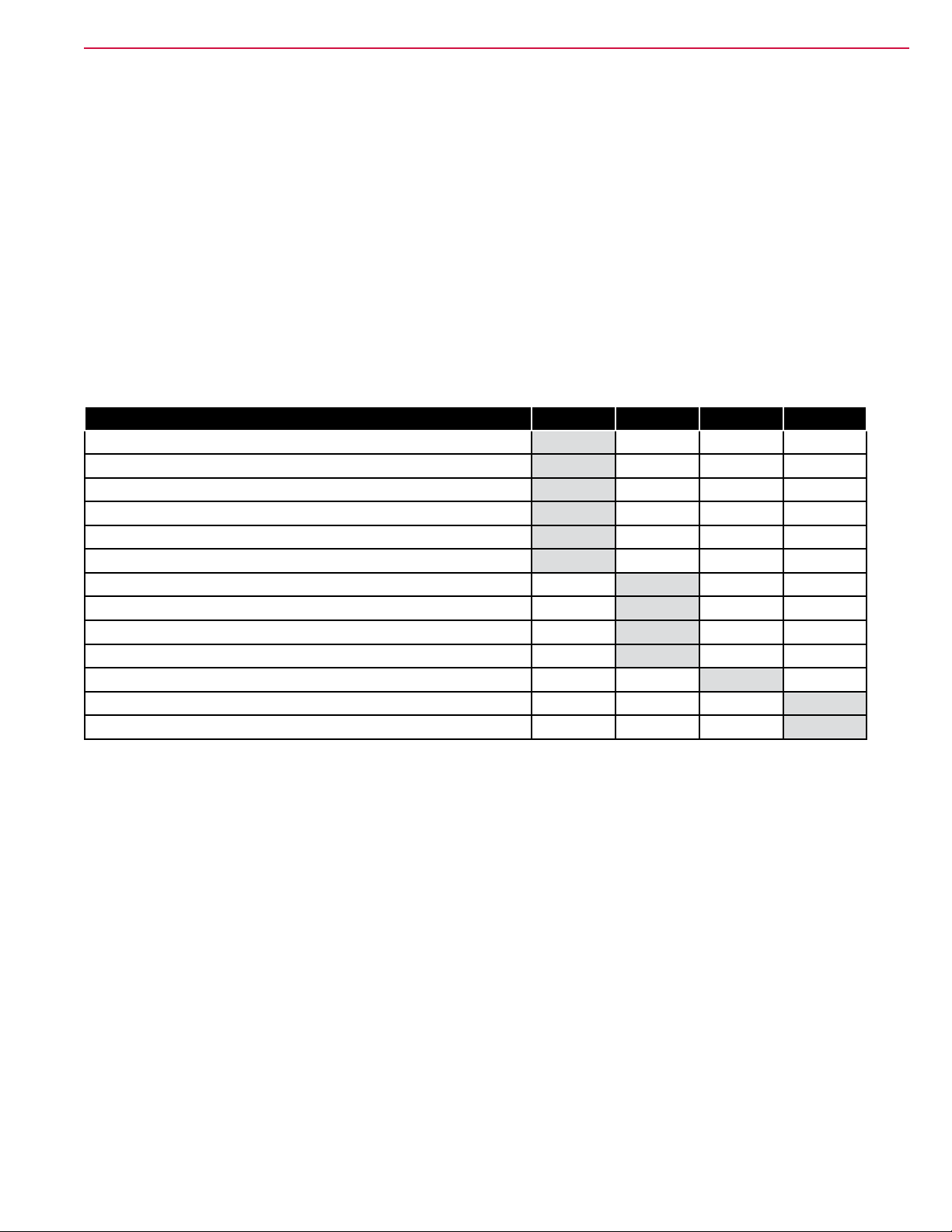

Maintenance Schedule

Maintenance Item Daily Weekly Monthly Yearly

Charge Batteries X

Check/Clean Tanks & Hoses X

Check/Clean the Brushes/Pads X

Check/Clean the Squeegee X

Check/Clean Vacuum Shutoff Float X

Empty/Clean Debris Catch Tray in Recovery Tank X

Check Each Battery Cell(s) Water Level X

Inspect Scrub Housing Skirt X

Inspect and Clean Solution Filter X

Purge Detergent System X

Lubricate Machine X

* Check Carbon Brushes X

** Replace vibration damping isolators (REV model only) X

* Have an Authorized Advance Service Center check the vacuum motor carbon motor brushes once a year or

after 300 operating hours. The brush and drive motor carbon brushes should be checked every 500 hours

or once a year.

** This maintenance procedure must be performed by an authorized Advance Service Center.

Page 14

General Information 14Service Manual – SC1500

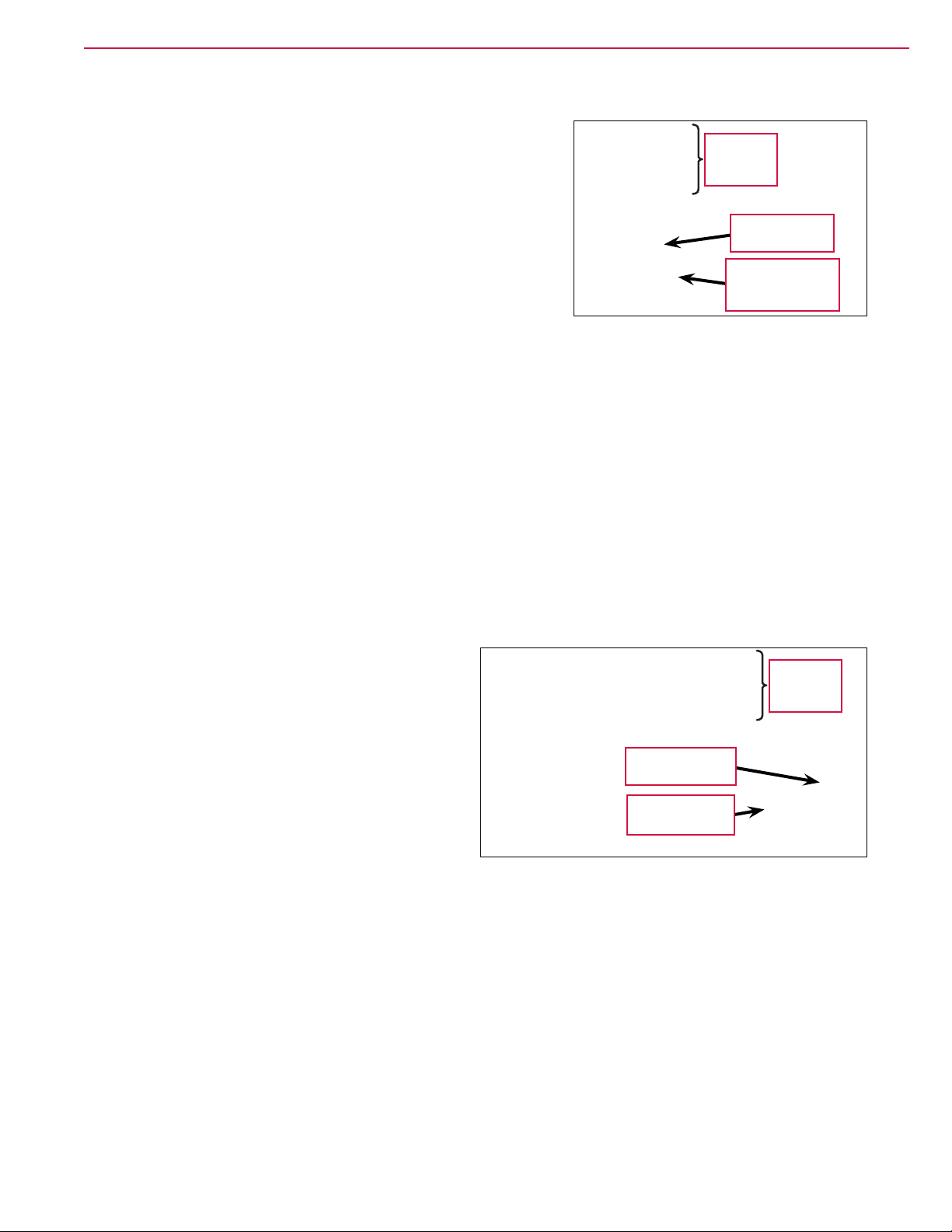

Lubrication Locations

• Once a month apply Lubriplate® 730-2 or equivalent grease to, or grease the tting on, the following

components. Avoid using too much grease.

– Hex Shaft/Steering Tube Assembly

– Drive Wheel Chain

– Drive Chain Idler Sprocket (grease tting)

– Steering Chain

• Once a month apply light machine oil to the Upper and Lower Steering Shaft Universal Joints.

Upper

Steering

Shaft

U-Joint

Hex

Shaft

Steering

Tube

Assembly

Lower Steering

Steering

Chain

Shaft U-Joint

Drive Chain

Idler

Sprocket

(grease

tting)

Drive

Wheel

Chain

Page 15

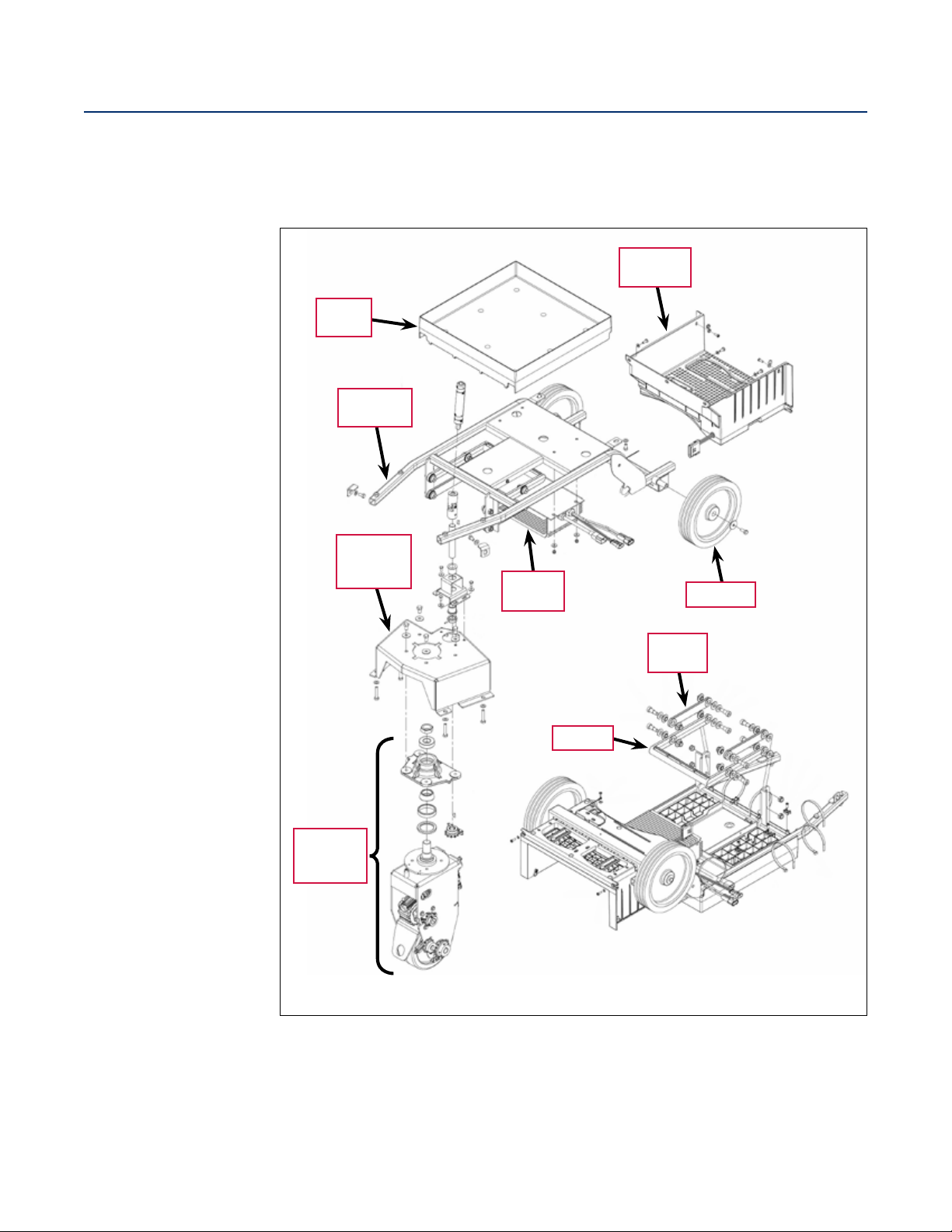

Major Machine Components

Control

System

General Information 15Service Manual – SC1500

Electrical

System

Solution

System

Recovery

System

Chassis

System

Squeegee

Assembly

Scrub

System - 20D

Scrub

System - REV

Page 16

Machine Controls

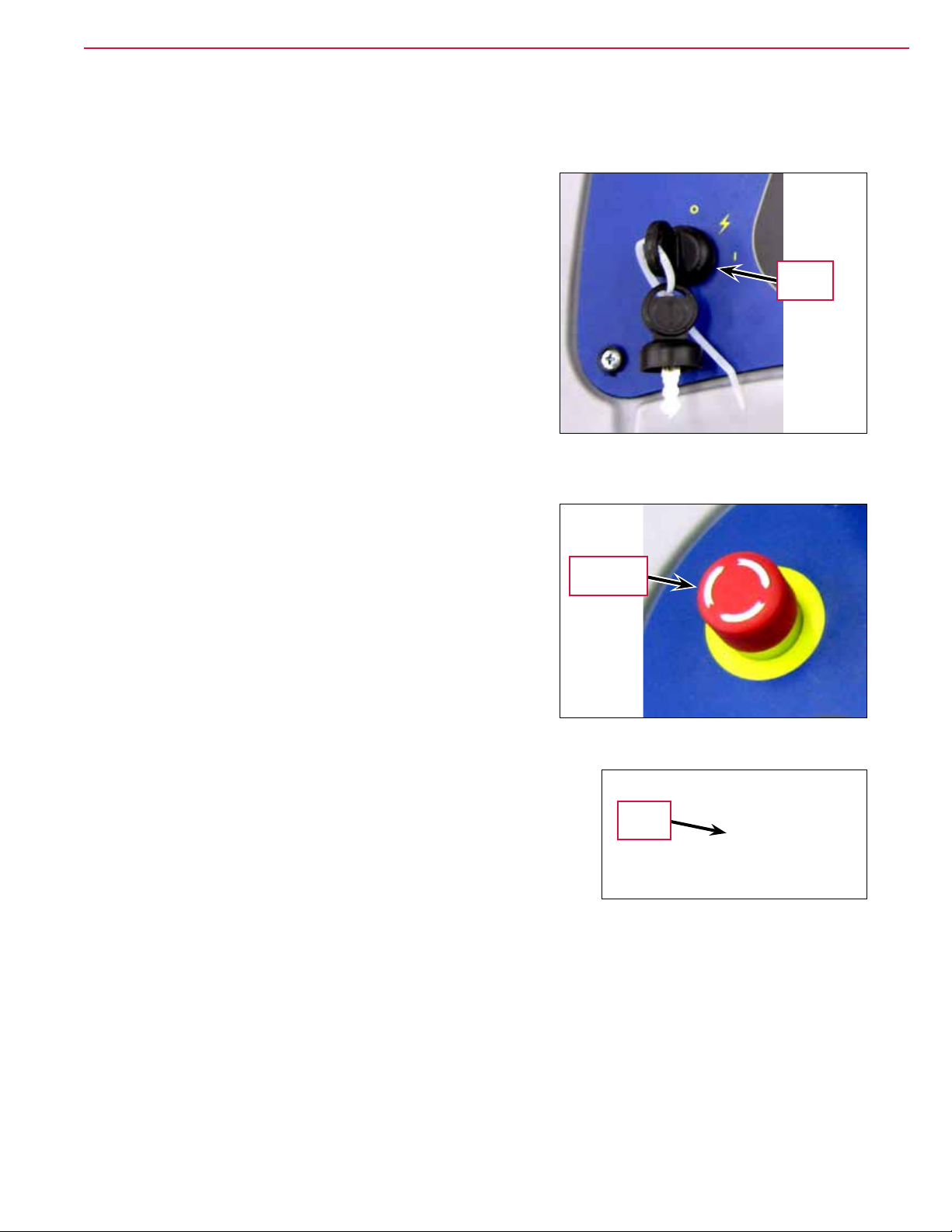

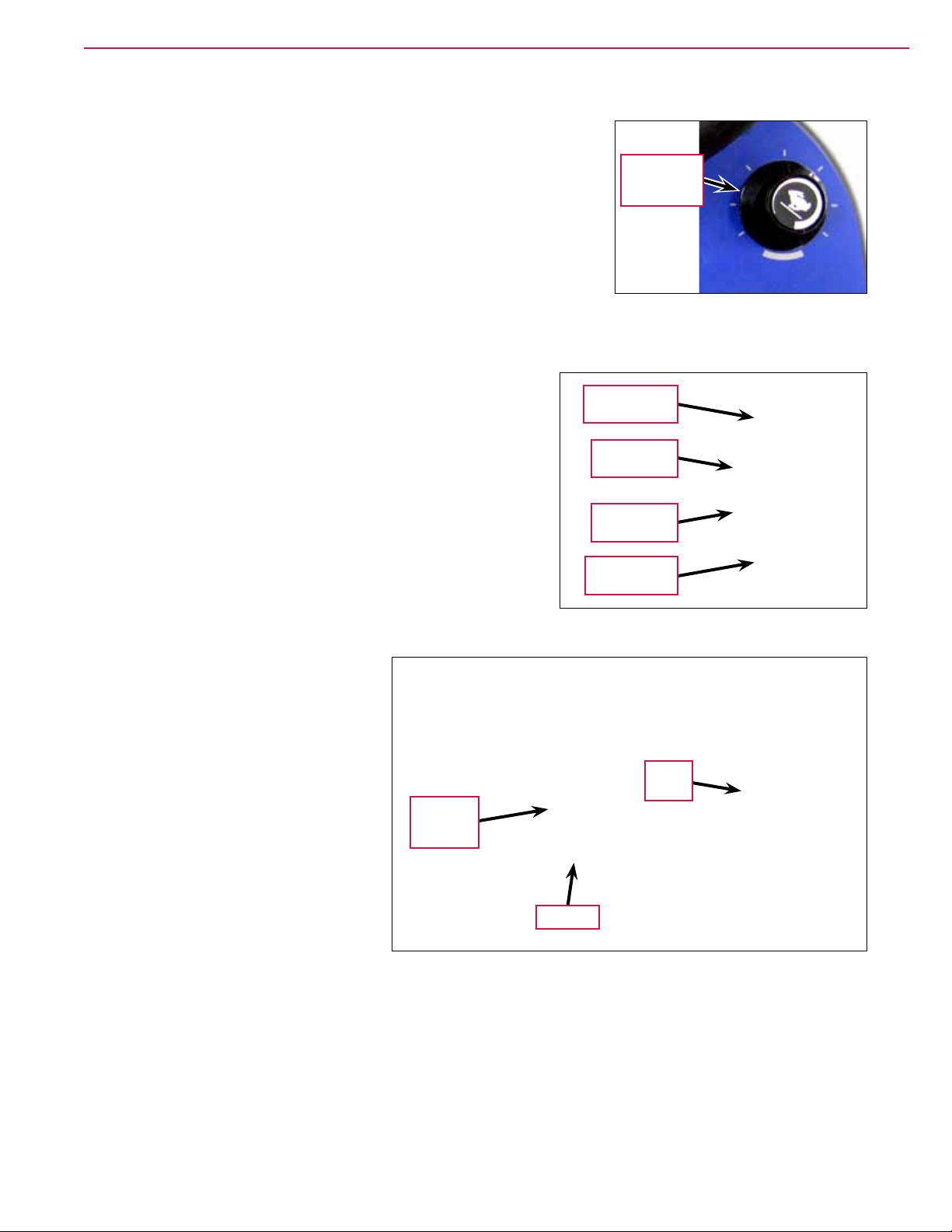

Key Switch, Emergency Stop and Horn Switch

• Key Switch – controls the battery power to the machine.

Note that you must turn the Key Switch to the on (I)

position before stepping onto the machine platform.

General Information 16Service Manual – SC1500

Key

Switch

• Emergency Stop – shuts off all battery power to the

machine when pressed. To reset the Emergency Stop, rotate

the red knob clockwise.

• Horn Switch – sounds the horn when pressed.

Emergency

Stop

Horn

Switch

Page 17

General Information 17Service Manual – SC1500

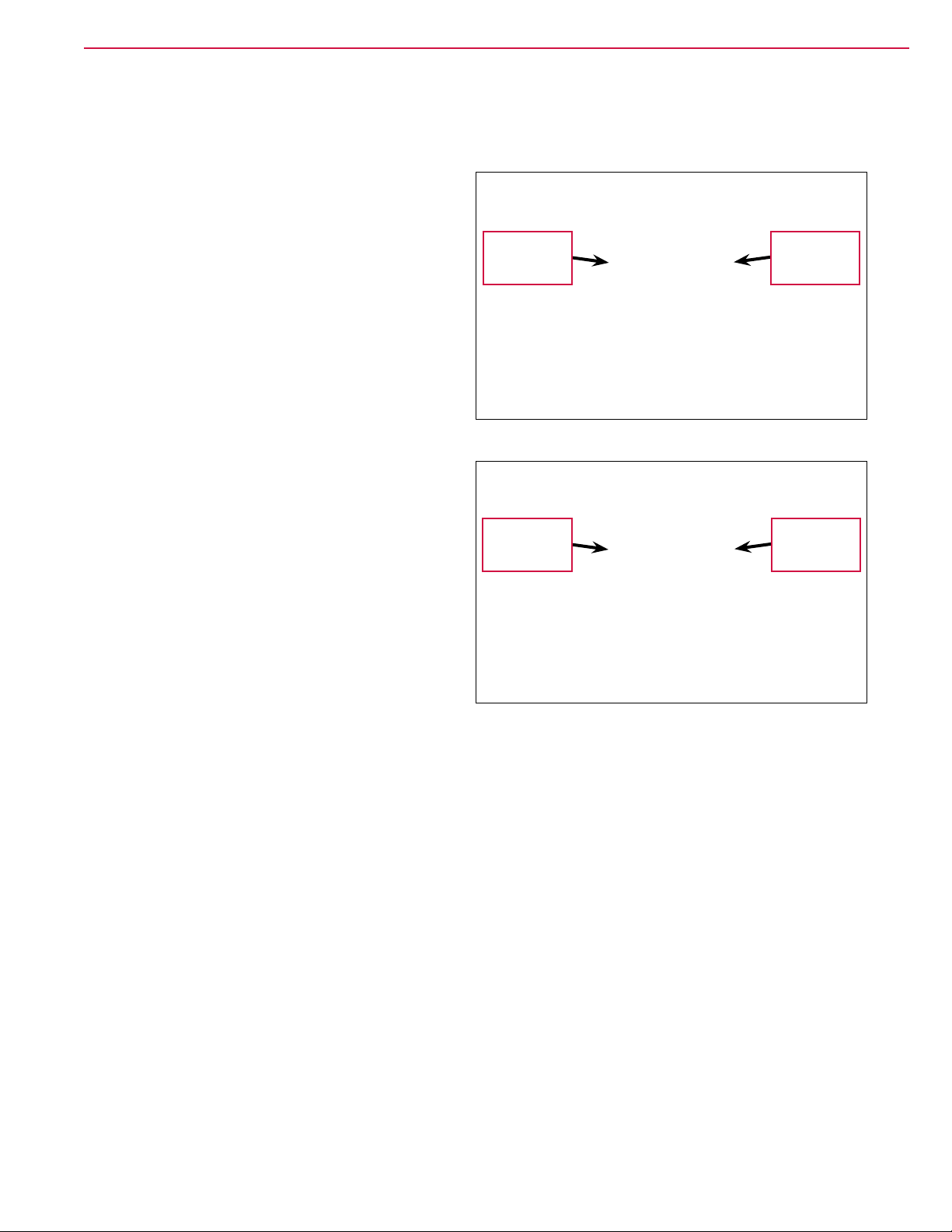

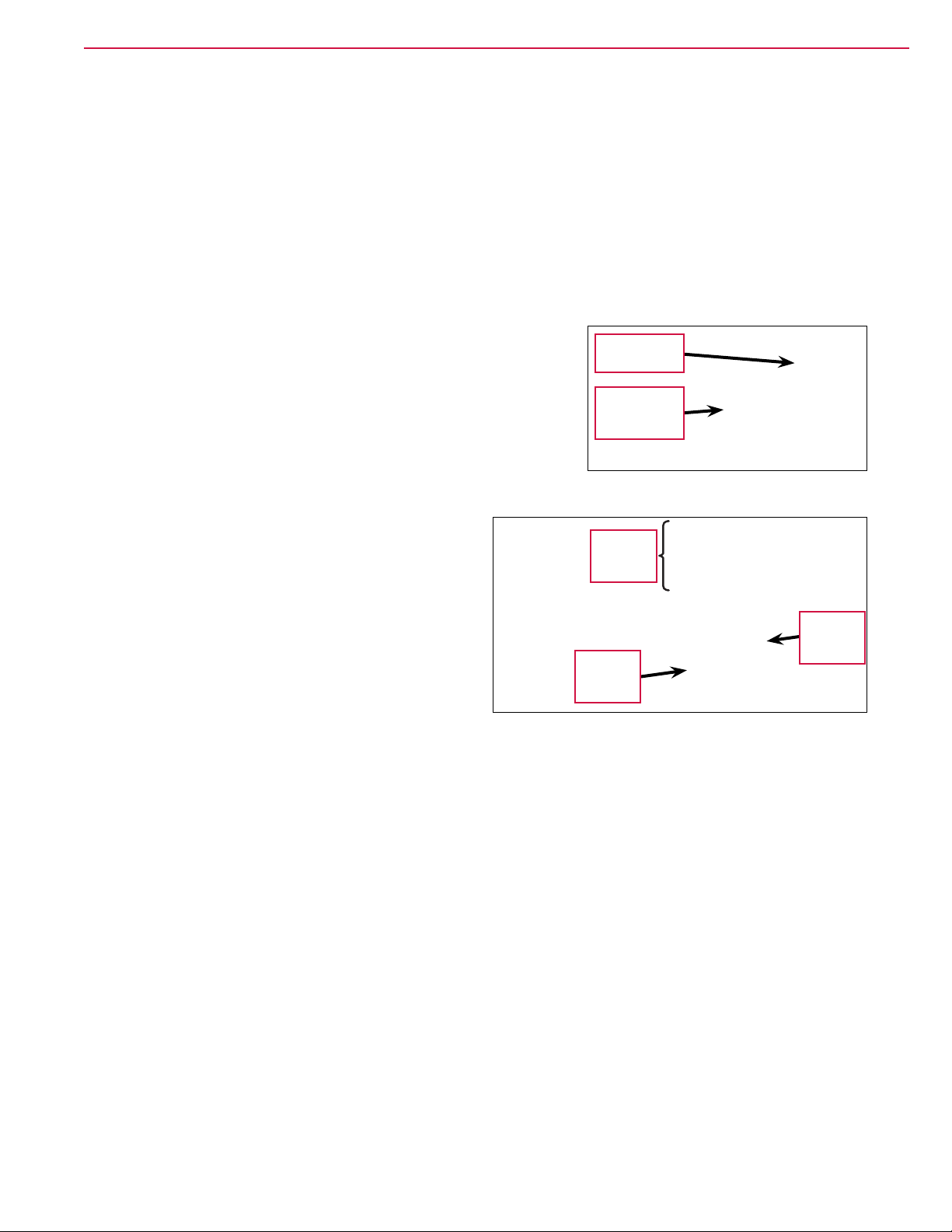

Circuit Breakers

The Circuit Breakers are mounted on the top of the control panel. To reset a Circuit Breaker, press the

corresponding reset button

• 50-amp Circuit Breaker – labeled CB1 in the

Ladder Diagram; controls the positive voltage

to the E1 Curtis 1210 Speed Controller.

• 5-amp Circuit Breaker – labeled CB2 in the

Ladder Diagram; controls the positive voltage

to the key switch and to the battery positive

inputs J3-1 and J3-8 on the A1 Control Board.

• 20-amp Circuit Breaker – labeled CB3 in the

Ladder Diagram; controls the positive voltage

to the contacts on solid state relay K1. Relay

K1 controls the positive voltage to the vacuum

motor, M4.

• 25-amp Circuit Breaker – labeled CB4 in the

Ladder Diagram; controls the positive voltage

to the contacts on relay K2. Relay K2 controls

the positive voltage to the brush motor, M5/M6.

50-amp

Circuit

Breaker CB1

20-amp

Circuit

Breaker CB3

5-amp

Circuit

Breaker CB2

25-amp

Circuit

Breaker CB4

Page 18

General Information 18Service Manual – SC1500

Speed and Direction Controls and Indicators

• The Speed Adjustment Knob – labeled R1 in the Ladder Diagram;

100K potentiometer that controls the machine speed in both

forward and reverse.

• The Forward and Reverse Drive Switches select the direction the machine will move when the Go Pedal is

pressed. The corresponding Drive Indicator will light when a Drive Switch is selected.

– Forward Drive Switch – selects the forward direction.

Forward Drive

– Forward Drive Indicator – lights to indicate that the

Forward Drive Switch has been selected. Note that this

indicator is lighted in the adjacent drawing.

– Reverse Drive Switch – selects the reverse direction.

Speed

Adjustment

Knob R1

Indicator

Forward

Drive Switch

– Reverse Drive Indicator – lights to indicate that the

Reverse Drive Switch has been selected.

• Operator Presence Pedal – ensures

that the Operator is standing on

the Platform before the Go Pedal

will drive the machine forward or

reverse.

• Go Pedal – drives the machine in

the direction selected with the

Forward Drive or Reverse Drive

Switches.

Reverse

Drive Switch

Reverse Drive

Indicator

Go

Pedal

Operator

Presence

Pedal

Platform

Page 19

Scrub Controls and Indicators

Note: Thescrubpressure,recoveryvacuumpower,solutionowrateanddetergentstrength

settings that will be in effect when the One-touch™ Scrub On/Off Switch is pressed is

determined by the Save Scrub Settings submenu in the Programming Options.

• IfSAVE SCRUB SETTINGS/YES is selected, the machine will use the scrub settings that

were in use when the key switch was switched off.

• IfSAVE SCRUB SETTINGS/NO is selected, the machine will use the default settings.

(Refer to the Save Scrub Settings subsection in the Control System section.)

General Information 19Service Manual – SC1500

• One-touch

™

Scrub On/Off Switch – lowers the scrub deck and

squeegee to the oor and enables the scrub, vacuum, solution

and detergent systems. The scrub motor, solution system,

detergent pump and vacuum motor will start when you press

the Go Pedal.

• Scrub On/Off Indicator – lights to indicate that the scrub system

is active.

• Extra Pressure Switch – toggles the scrub pressure

between standard pressure (bottom box lled as

shown) and extra pressure (both top and bottom

boxes lled).

• Extra Pressure Indicator – lights to indicate that the

scrub system is active.

• Scrub Brush Pressure Bar Graph – displays the

scrub pressure on the graphic display as follows:

– Bottom box lled – standard scrub pressure (as

shown).

– Top and bottom boxes lled – extra scrub

pressure.

Scrub On/Off

Indicator

One-touch™

Scrub On/Off

Switch

Scrub

Pressure

Bar Graph

Extra

Pressure

Switch

Extra

Pressure

Indicator

Page 20

General Information 20Service Manual – SC1500

Solution Controls and Indicators

• Solution Flow Adjustment Switch – functions as follows:

– When the scrub system is enabled, pressing the Solution

Flow Adjustment Switch

will cycle the solution ow rates

from low (bottom box lled as shown), to medium (bottom

two boxes lled), to high (all three boxes lled), then to off

(no boxes lled).

– When the scrub system is not enabled (machine in

transport mode), pressing and holding the Solution Flow

Adjustment Switch

will dispense solution at the high ow

rate to pre-wet the oor. The solution will continue to

dispense as long as the Solution Flow Adjustment Switch is

pressed.

• Solution On/Off Indicator – lights to indicate that the solution system is active.

• Solution Flow Rate Bar Graph – displays the solution ow rate on the graphic display as follows:

– Bottom box lled – low solution ow rate (as shown).

Solution

Flow Rate

Bar Graph

Solution On/Off

Indicator

Solution

Flow Adjustment

Switch

– Bottom two boxes lled – medium solution ow rate.

– All three boxes lled – high solution ow rate.

– All three boxes empty – solution system off.

Detergent System Controls and Indicators

• Detergent Strength Switch – functions as follows:

– When the scrub system is enabled, pressing

the Detergent Strength Switch will cycle the

detergent ow rate from weak (bottom box

lled as shown), to strong (top and bottom

boxes lled), then to off (no boxes lled).

Detergent On/Off

Indicator

– When the scrub system is not enabled

(machine in transport mode), pressing

and holding the Detergent Strength Switch

Detergent

Strength Switch

and Solution Flow Adjustment Switch

simultaneously will enable the purge mode.

• Detergent On/Off Indicator – indicates that the detergent ow rate is a rate other than zero.

• Detergent Indicator Bar Graph – displays the detergent ow rate, ratio and percentage on the graphic

display as follows:

Detergent

Indicator

Bar Graph

– Bottom box lled – weak detergent ow rate (as shown).

– Top and bottom boxes lled – strong detergent ow rate.

– Both boxes empty – detergent system off.

Page 21

• Detergent Purge Screen – displays the Chemical Purge Icon to

indicate that the detergent purge cycle is active. To start

the purge cycle and display the Detergent Purge Screen, press

and hold the Detergent Strength Switch and the Solution Flow

Adjustment Switch simultaneously for three seconds. The

Detergent On/Off Indicator will ash and the purge cycle will last

for approximately 10 seconds.

Burst of Power Switch and Indicator

General Information 21Service Manual – SC1500

Chemical

Purge

Icon

Detergent Purge Screen

• Burst of Power Switch – temporarily overrides the current machine

settings to increase the machine’s cleaning aggressiveness by

performing the following:

– Increases the scrub pressure from standard pressure to extra

pressure.

Burst of Power

Indicator

Burst of

Power Switch

– Increases the solution ow rate by one level (off to low, low to

medium or medium to high).

– Increases the detergent ow rate to the strong level (off to

weak or weak to strong). Note that this will only happen if the

detergent option is installed.

– Increases the vacuum power from low/quiet to high/standard. Note that the vacuum motor will not

switch from off to low/quiet because of the assumption that if the vacuum is off, the user must be in

double-scrubbing mode and wishes to stay in that mode.

If any one of the functions listed above is already performing at its maximum possible rate, the Burst of

Power Switch

will have no effect on that function but will still affect the other functions. If the detergent

option is not installed, the Burst of Power will not affect detergent ow but will still affect the other

functions.

The Burst of Power mode lasts for a maximum duration of 60 seconds but can be terminated early by

pressing the Information Switch, Burst of Power Switch, Scrub On/Off Switch, Detergent Strength Switch,

Solution Flow Adjustment Switch, Extra Pressure Switch or the Vacuum Power Adjustment Switch.

When the Burst of Power period expires or is terminated, all scrubbing parameters that were changed

return to their original state before the Burst of Power Switch was pressed.

• Burst of Power Indicator – indicates the following:

– The Burst of Power Indicator will be off when the Burst of Power Switch switch is not functional because

it has not been enabled in the Hidden Menu, or because the machine is operating in a mode for which

the Burst of Power option does not apply.

– The Burst of Power Indicator will be solid green when the machine is operating in a reduced/normal

scrubbing mode but the Burst of Power option is available.

– The Burst of Power Indicator will change color from green to yellow and ash for 60 seconds while the

Burst of Power option is active. The Burst of Power Indicator will ash at a rate of 1 Hz for the rst 50

seconds, then at a rate of 2 Hz for the last 10 seconds to indicate that the Burst of Power option is

about to end.

Page 22

Vacuum Power Adjustment Switch and Indicators

• Vacuum Power Adjustment Switch – functions as

follows:

– Pressing the Vacuum Power Adjustment

Switch

while in the scrub mode will cycle

Quiet

Vacuum

Mode

Indicator

the vacuum mode from low/quiet (bottom

box lled as shown), to high/standard (both

top and bottom boxes lled), then to off (no

boxes lled). Note that the vacuum motor

will switch on when the machine is driven

forward. When the machine is driven in

reverse or stops, or if the Vacuum Power

Adjustment Switch

is pressed while the

vacuum motor is running, the vacuum motor

will continue to run for 10 seconds, then

switch off.

Pressing the Vacuum Power Adjustment Switch during this 10-second delay period will shut off the

vacuum motor immediately.

Vacuum

Level Bar

Graph

Standard Vacuum

Mode Indicator

Vacuum Power

Adjustment

Switch

General Information 22Service Manual – SC1500

– When the scrub system is not enabled (machine in transport mode), the Vacuum Power Adjustment

Switch

functions as follows:

◦ Pressing the Vacuum Power Adjustment Switch once will enable the wet vacuuming mode. The

vacuum power will default to the low/quiet mode and the deck actuator will drive the deck to the

“vacuum only” position.

◦ Pressing the Vacuum Power Adjustment Switch a second time will switch the vacuum motor to high/

standard mode.

◦ Pressing the Vacuum Power Adjustment Switch a third time will disable the wet vacuuming mode.

The actuator will immediately raise the deck, and the vacuum motor will turn off after a 10-second

delay.

Note: IftheOne-touch™ Scrub On/Off Switch is pressed while wet vacuuming, the wet vacuuming

mode will be disabled. The scrub deck and vacuum motor control will revert to the standard

scrub mode operation.

• Quiet Vacuum Mode Indicator – indicates that the vacuum motor is in the low/quiet mode.

• Standard Vacuum Mode Indicator – indicates that the vacuum motor is in the high/standard mode.

• Vacuum Level Bar Graph – displays the vacuum motor power mode as follows:

– Bottom box lled – low/quiet mode (as shown).

– Top and bottom boxes lled – high/standard mode.

– Both boxes empty – vacuum motor off.

Page 23

Information Switch

General Information 23Service Manual – SC1500

• Information Switch – displays the Information Screen on the

graphic display. The Information Screen will also be displayed

if a signicant error occurs that results in the shutdown of

some machine system. The graphic display will then display

Hour

Meter

Fault

Codes

the Information screen until next key switch cycle.

The Information Screen shows the Hour Meter, Fault Codes and

the Battery Charge Level Indicator.

• Hour Meter – displays the total number of run hours on the

machine.

• Fault Codes – displays the wrench icon and any active

two-digit fault code. If more than one error exists, the display

will sequence through the error codes at one-second intervals.

(Refer to the Fault Codes subsection in the Control System

Battery

Charge Level

Indicator

Information

Switch

section.)

• Battery Charge Level Indicator – indicates the charge level of the batteries according to the number of lled

“bars” in the battery icon.

– Five solid bars indicates a full battery charge.

– No solid bars (empty battery icon) indicates that the batteries are discharged.

Battery Status and Charger Screens

• Battery Low Voltage Screen – displayed when the battery

voltage drops to approximately 21.75 volts. The graphic

display will alternate between the Battery Status Screen

and the “normal” display at ve-second intervals to alert the

Operator that the batteries need charging and the remaining

battery time is very short.

Note that:

– When the voltage in AGM or Gel batteries drops to 21.75 volts, the A1 Control Board switches off the

scrub motor, solution system and detergent pump, and raises the scrub deck. The vacuum motor can

still remain on.

– When the voltage in AGM or Gel batteries drops to 21.6 volts, the A1 Control Board switches off the

vacuum motor.

– When the voltage in Wet batteries drops to 20.55 volts, the A1 Control Board switches off the scrub

motor, solution system and detergent pump, and raises the scrub deck. The vacuum motor can still

remain on.

– When the voltage in Wet batteries drops to 20.4 volts, the A1 Control Board switches off the vacuum

motor.

Battery Low Voltage Screen

Page 24

• Battery Charger Screen – displayed when AC power is applied

to the onboard charger. Note that this will disable all

machine functions. The Battery Charger Screen displays the

Battery Type and Battery Charge Level Indicator. The Battery

Charge Level Indicator

will display full once the batteries are

done charging.

General Information 24Service Manual – SC1500

Battery

Type

Battery Charge

Level Indicator

Battery Charger Screen

Page 25

Chassis System

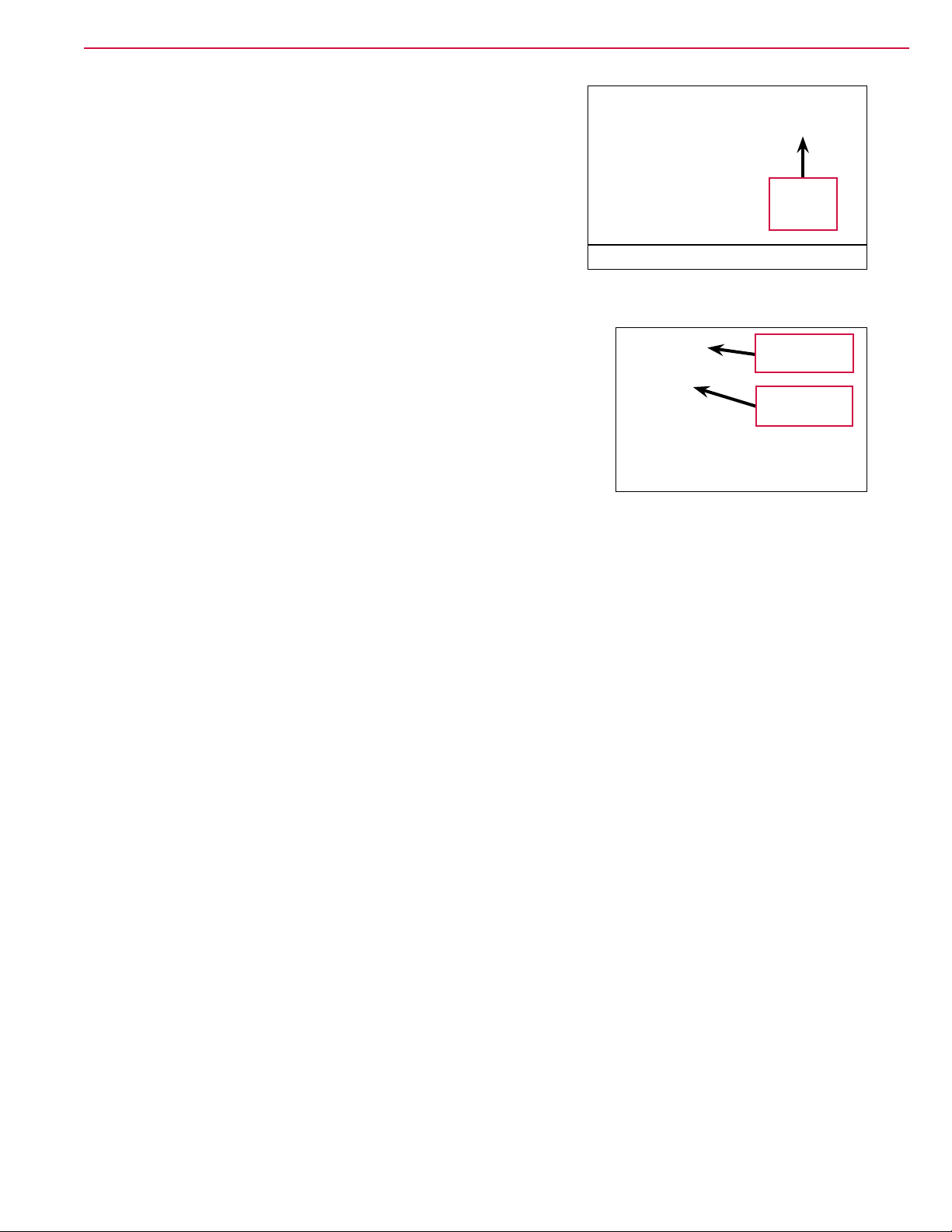

Major Chassis Components

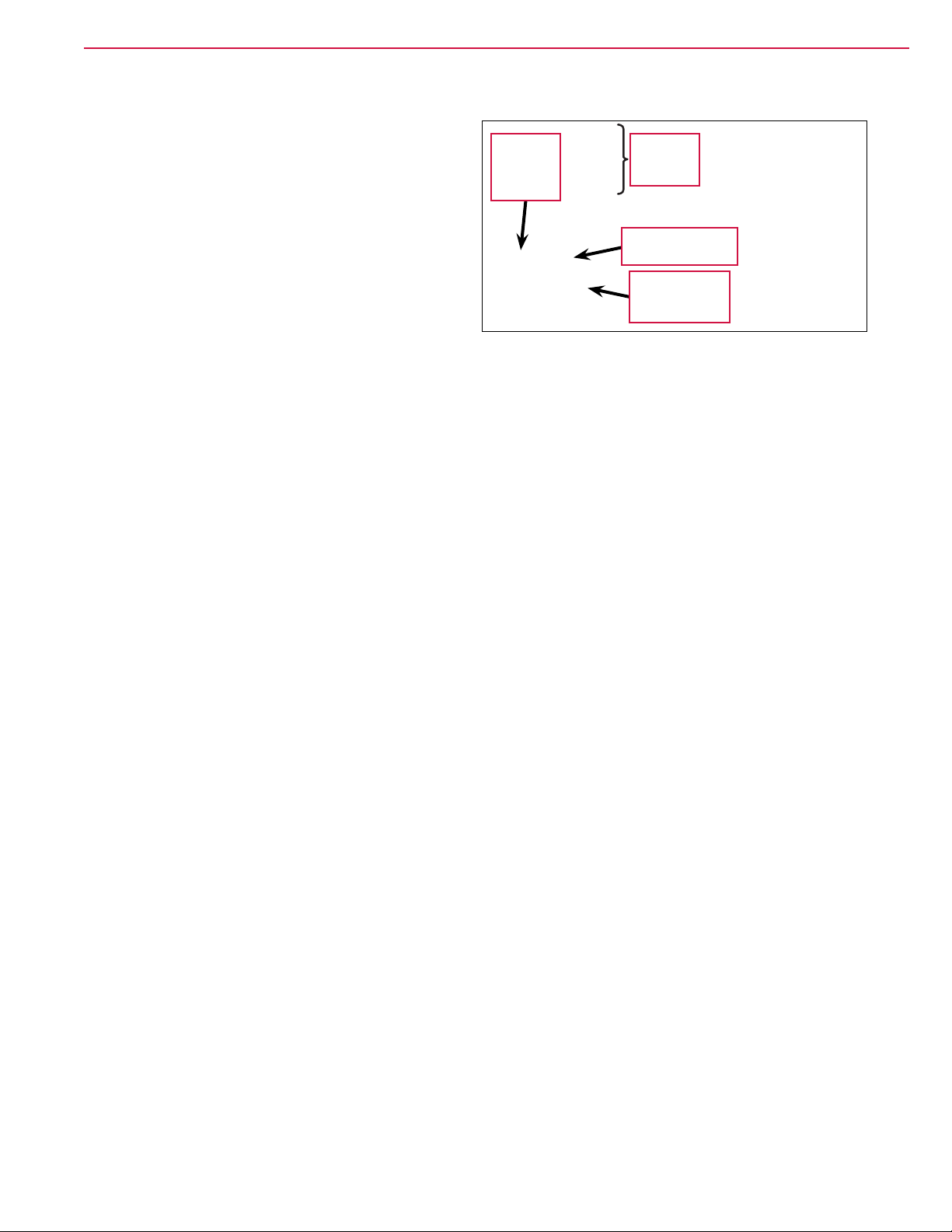

The Chassis System provides the framework on which the machine components are mounted.

The Battery Tray

contains the batteries

and connectors and is

mounted to the top of

the Chassis Weldment.

The Platform Assembly

provides a place for the

Operator to stand and

houses the Operator

Presence Pedal and Go

Pedal.

The Battery Charger

is mounted to the

bottom of the Chassis

Weldment

.

The non-traction

Wheels are held by at

washers and M8 x 20

screws that thread into

the axle in the Chassis

Weldment

.

The Drive Wheel

Assembly

is fastened

to the Spindle Mount

Weldment

which

bolts to the Chassis

Weldment

.

Battery

Tray

Chassis

Weldment

Spindle

Mount

Weldment

Battery

Charger

Link Bar

Platform

Assembly

Wheel (2)

Linkage

Bar (2)

25Service Manual – SC1500

The Link Bar and the

two Linkage Bars are

bolted to vertical

plates on the bottom of

the Chassis Weldment

and support the Scrub

Deck.

Drive

Wheel

Assembly

Page 26

Chassis System 26Service Manual – SC1500

Platform Switches

The Operator Presence Pedal and Go Pedal are mounted on the top of the Platform.

• When the Operator stands on the Platform, he/she presses the Operator Presence Pedal which actuates the

Operator Presence Switch (called the “Deadman Switch S2” in the Wiring Diagram). The Operator Presence

Switch

must be actuated before the Go Pedal will drive the machine forward or reverse.

• When the Operator presses the Go Pedal it actuates the Go Switch to drive the machine in the direction

selected with the Forward Drive or Reverse Drive Switches.

Go Switch

Go Pedal

Operator

Presence

Switch

Platform

Operator

Presence

Pedal

Page 27

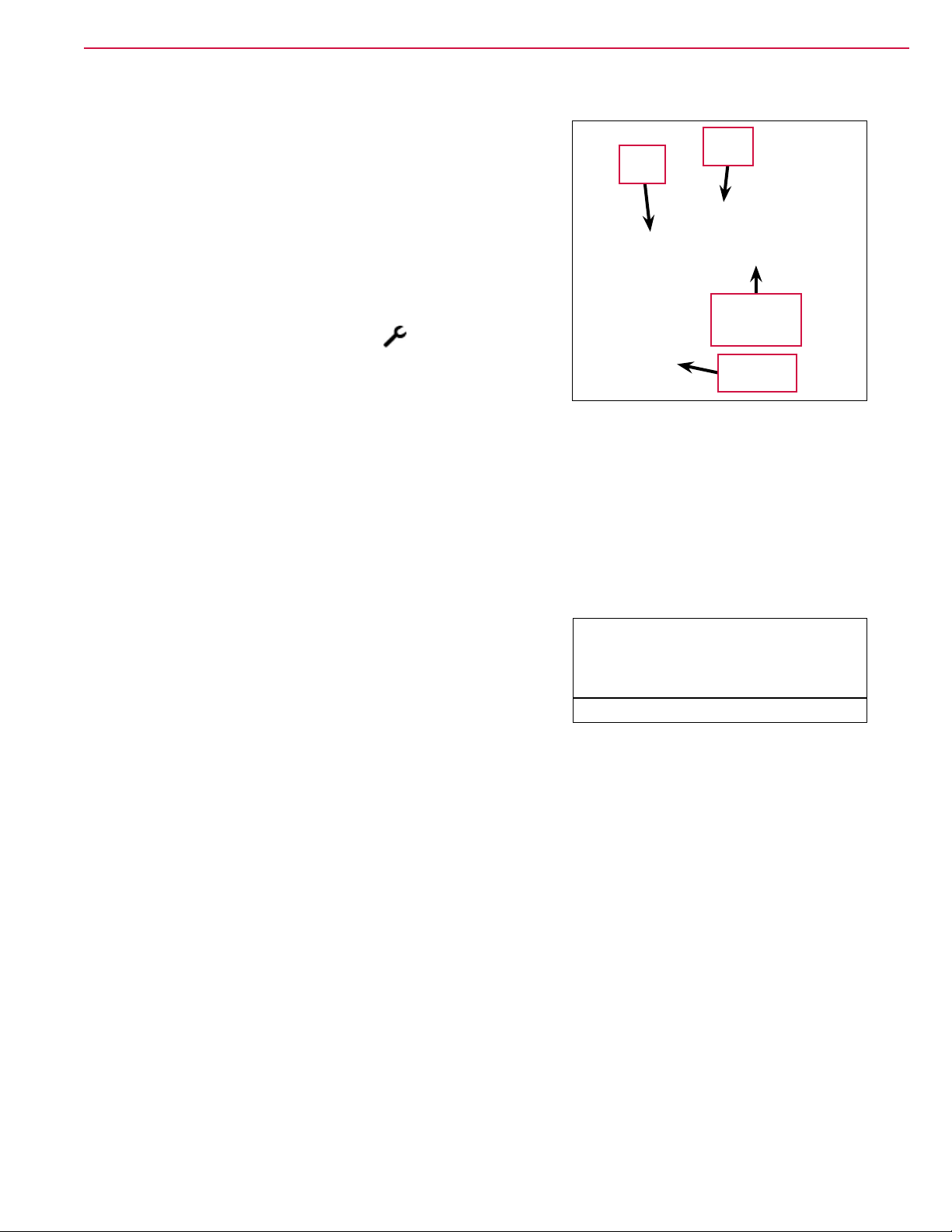

Control System

Functional Description

The Control System consists of the A1 Control Board (Main Machine Controller) and the E1 Curtis 1210

Speed Controller.

The A1 Control Board controls the scrubbing and wastewater recovery functions based on Operator requests,

and motion and direction inputs from the E1 Curtis 1210 Speed Controller. The A1 Control Board can store

and display a variety of fault codes to inform the Operator of any machine fault conditions. The A1 Control

Board also supports special modes of operation called the “Programming Mode” and the “Service Test Mode”.

The Programming Mode is used primarily for “telling” the A1 Control Board how the machine is equipped so

that it can operate accordingly. The Service Test Mode allows you to operate various machine components

regardless of current inputs.

The E1 Curtis 1210 Speed Controller controls the drive motor that propels the machine based on Operator

requests. (Refer to the Wheel System, Traction section for more information.)

27Service Manual – SC1500

Page 28

Component Locations

The following components are included in

this section:

• A1 Control Board

• E1 Curtis 1210 Speed Controller

The A1 Control Board is mounted to the

rear of the Interface Panel Assembly.

The E1 Curtis 1210 Speed Controller is

mounted inside of the Control Panel.

Interface

Panel

Assembly

A1 Control

Board

Control System 28Service Manual – SC1500

E1 Curtis

1210 Speed

Controller

Control

Panel

Troubleshooting

Fault Codes

The graphic display will show any error codes detected by

the A1 Control Board on the Information Screen as they

occur. The display will show the wrench icon and the

two-digit fault code number. The example shown here, 03,

is a speed control fault.

If more than one fault exists, the display will sequence through the fault codes at one-second intervals.

If the error is signicant and results in a machine system shutdown, the graphic display will show the

Information Screen until next key switch cycle. Otherwise the Information Screen will be active only when

the Information Switch is pressed.

Page 29

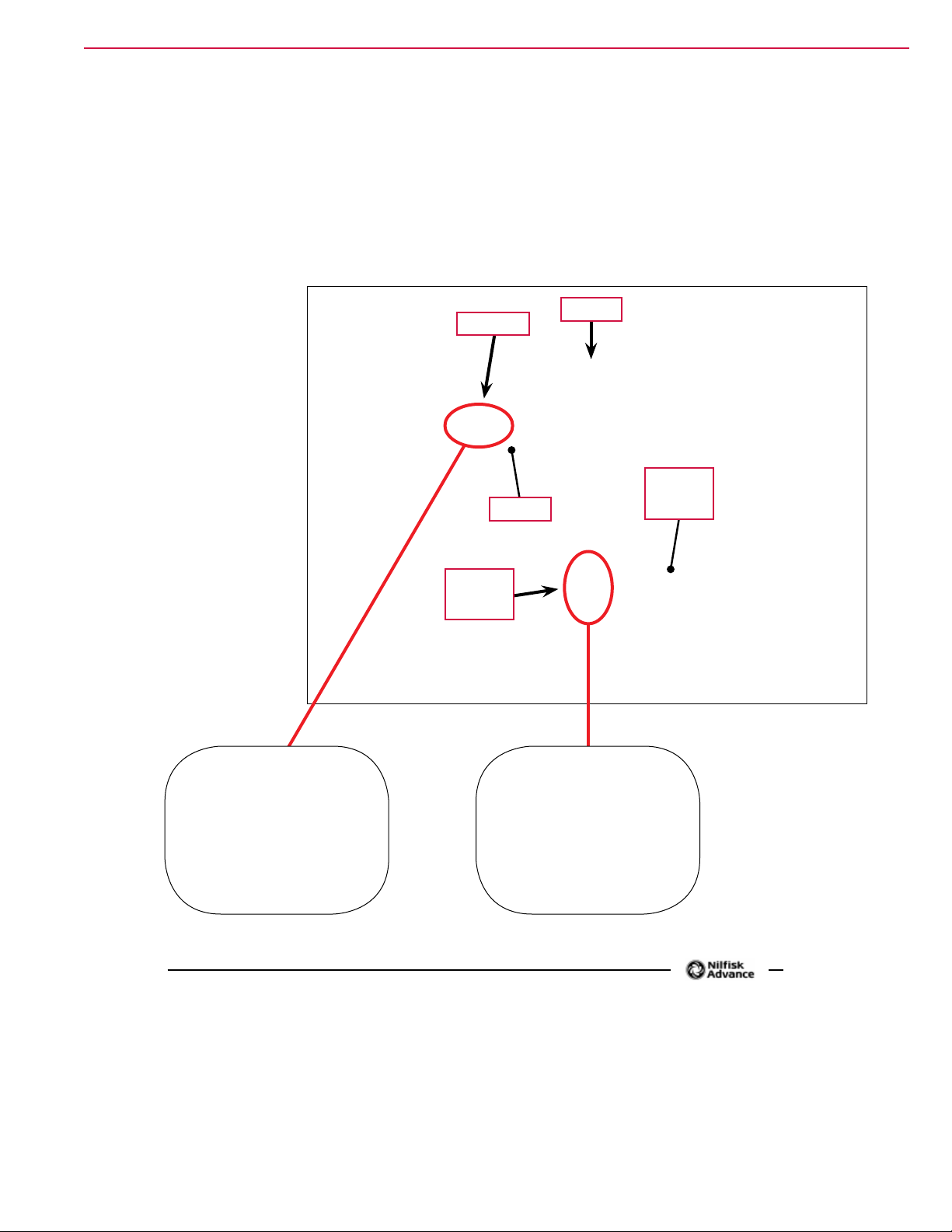

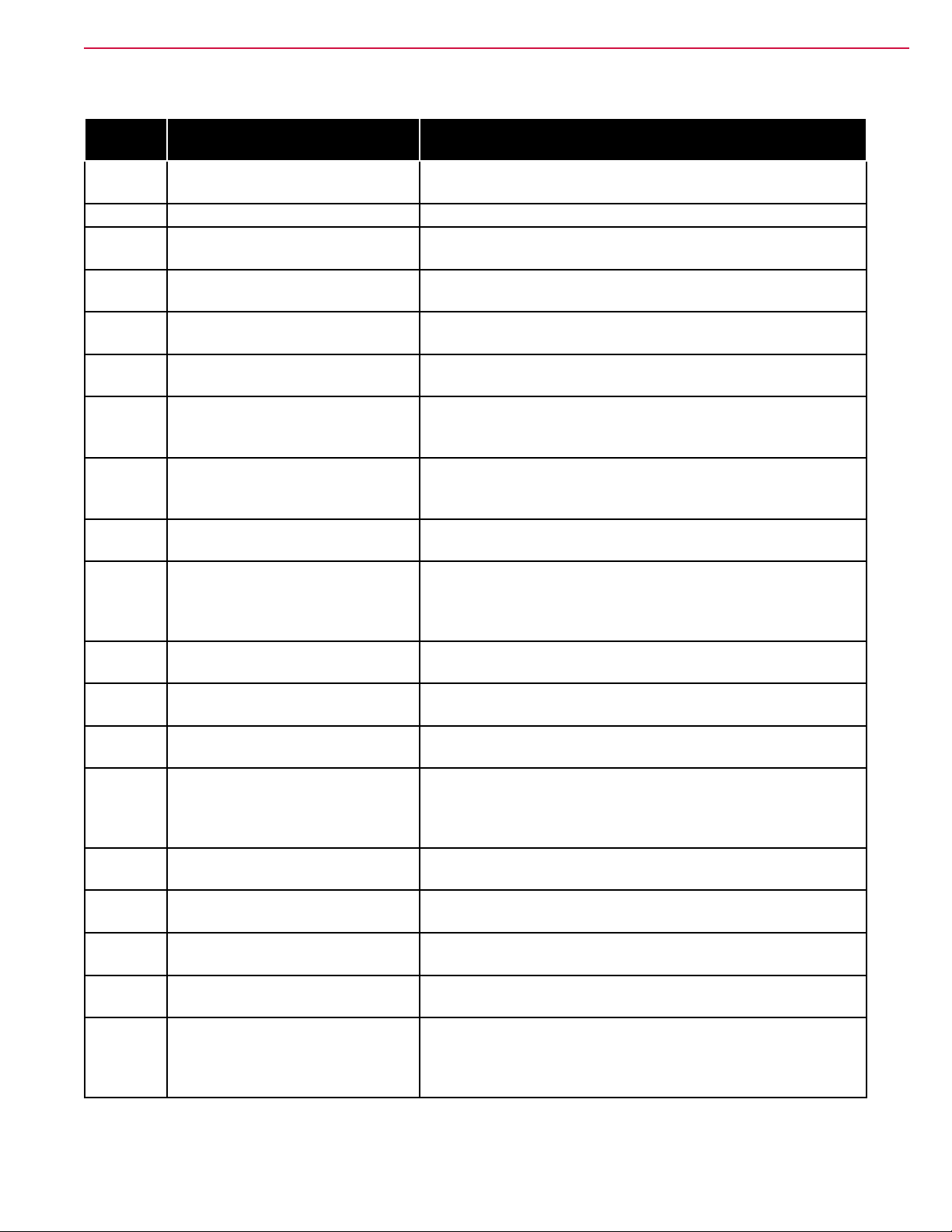

Fault Code Table

Control System 29Service Manual – SC1500

Display

Code

03 Speed Control fault

04 Scrub Deck Actuator overload The Scrub Deck Actuator has drawn more than 4.5 amps.

08 Solution Solenoid overload

09

10

11 Detergent Pump overload

21 Detergent Pump driver fault

24 Deck Actuator driver fault

30 Solution Solenoid open

32 Scrub Deck Actuator open

35 Brush Contactor (K2) coil open

36

37 Detergent Pump open

52

62 Solution Solenoid driver on

63

64

65 Detergent Pump driver stuck on

70 On-board Battery charger fault

Fault Description Conditions Needed to Set the Fault Code

The E1 Curtis Speed Controller is communicating a problem

to the A1 Control Board.

The Solution Solenoid Valve has drawn more than

approximately 1 amp.

Vacuum Contactor (SSR1) coil

overload

Brush Contactor (K2) coil

overload

Vacuum Contactor (SSR1) coil

open

Scrub Deck Actuator position

fault

Brush Contactor (K2) driver

stuck on

Vacuum Contactor (SSR1) driver

stuck on

The Vacuum Contactor has drawn more than approximately

1 amp.

The Brush Contactor has drawn more than approximately 1

amp.

The Detergent Pump has drawn more than approximately 1

amp.

The driver IC for the Detergent Pump is reporting a fault;

current limiting or shutdown is in effect due to either a

detected over-current or over-temperature condition.

The driver IC for the Deck Actuator is reporting a fault;

current limiting or shutdown is in effect due to either a

detected over-current or over-temperature condition

The measured current was below the minimum value while

the Solution Solenoid should have been on.

The measured current never exceeded the minimum

threshold while moving from one deck position to another

(only valid when the target position and the starting position

switch states should be different).

The measured current was below the minimum value while

the Brush Contactor should have been on.

The measured current was below the minimum value while

the Vacuum Contactor should have been on.

The measured current was below the minimum value while

the Detergent Pump should have been on.

The measured current was greater than or equal to the

minimum threshold value while the deck was moving, but the

software timed out looking for the new position (never saw

the actuator switch states read the target values).

The measured current was above the minimum value while

the Solution Solenoid driver should have been off.

The measured current was above the minimum value while

the Brush Contactor driver should have been off.

The measured current was above the minimum value while

the Vacuum Contactor driver should have been off.

The measured current was above the minimum value while

the Detergent Pump driver should have been off.

An error has been generated via the serial communications

between the charger and the A1 Control Board due to an

incorrect charging prole code being repeatedly sent by the

charger, or the bit timing being severely out of spec.

Page 30

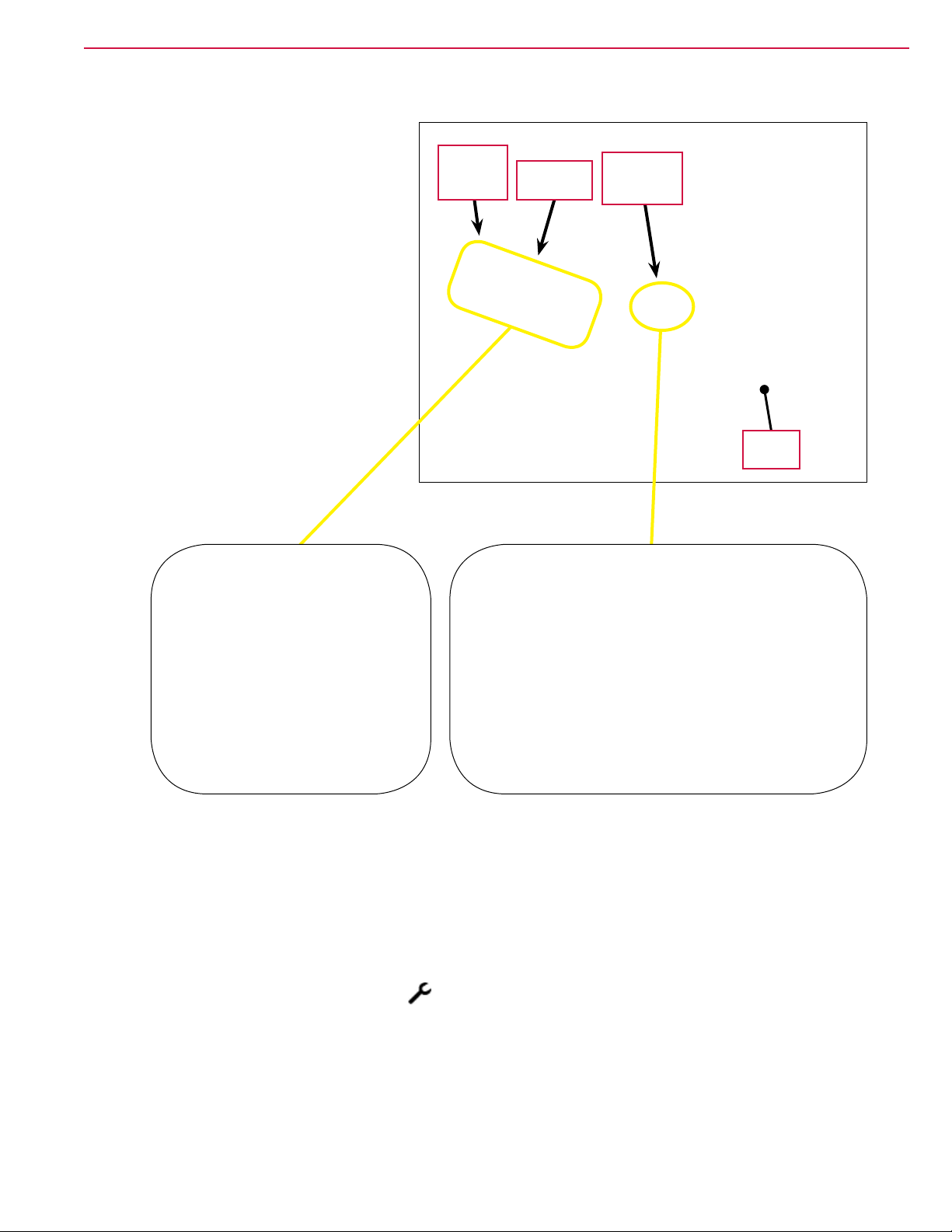

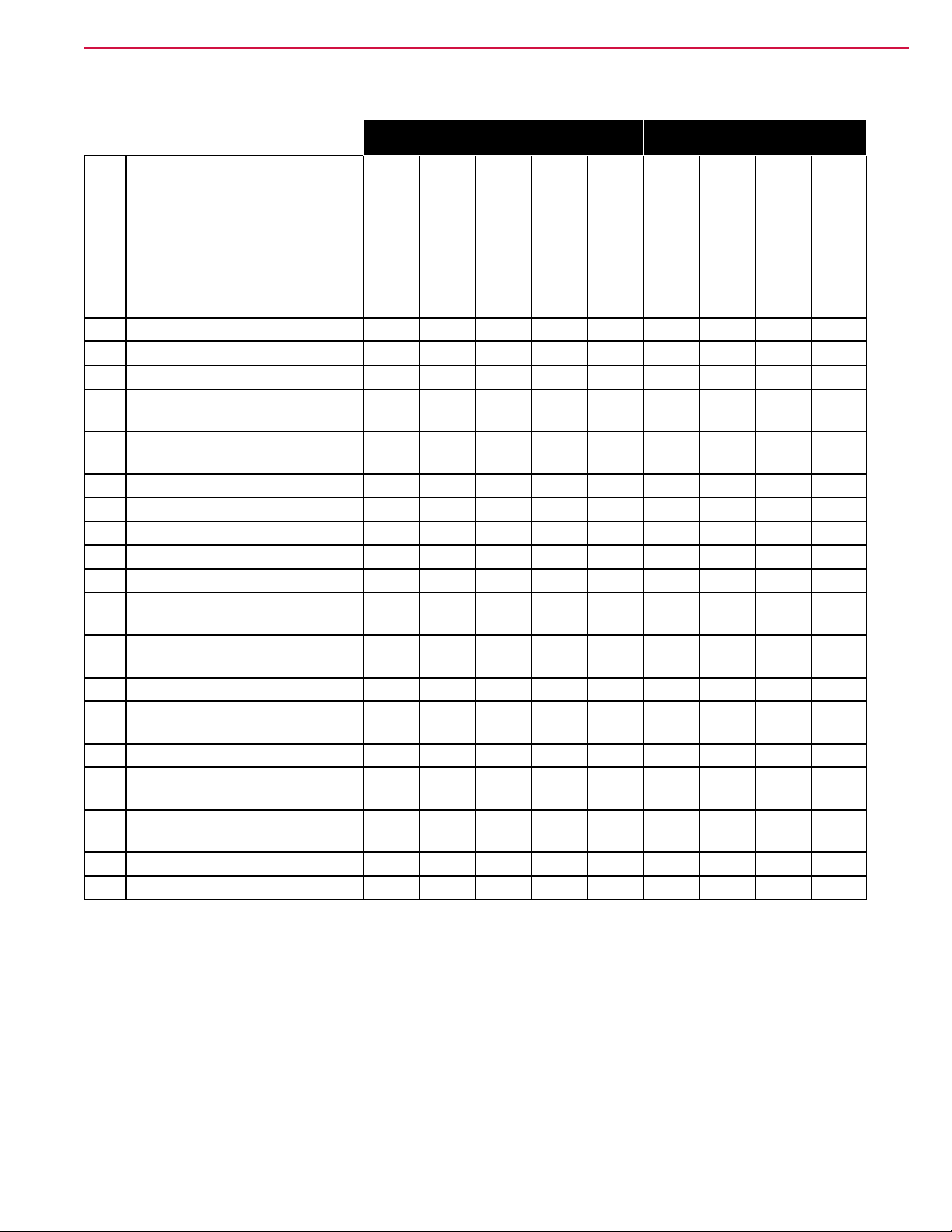

System Disabled by Fault Codes

Control System 30Service Manual – SC1500

Disable System Flash Indicator

Motor

Display Code

Fault Description

03 Speed Control fault x

04 Scrub Deck Actuator overload x x x x x

08 Solution Solenoid overload x x x

09 Vacuum Contactor (SSR1) coil

overload

10 Brush Contactor (K2) coil

overload

11 Detergent Pump overload x x

21 Detergent Pump driver fault x x

24 Deck Actuator driver fault x x x x

30 Solution Solenoid open x x x

32 Scrub Deck Actuator open x x x x

35 Brush Contactor (K2) coil

open

36 Vacuum Contactor (SSR1) coil

open

37 Detergent Pump open x x

52 Scrub Deck Actuator position

fault

62 Solution Solenoid stuck closed x

63 Brush Contactor (K2) coil

stuck closed

64 Vacuum Contactor (SSR1) coil

stuck closed

65 Detergent Pump stuck closed x

70 On-board Battery charger fault

Disable Detergent

x x x x x x

x x x x x

x x x x x

x x x x x x

x x x x

x x x x x

Disable Solution

Disable Brush

Disable Recovery

Scrub Deck

Vacuum Motor

Actuator Disable

x

Detergent Indicator

Indicator

Brush Motor

Solution Indicator

Vacuum Indicator

Page 31

Control System 31Service Manual – SC1500

Service Test Mode

The Service Test Mode allows you to switch the individual electrical system components on and off

independent of the normal Operator inputs. This serves as a “shortcut” when troubleshooting the machine

systems.

Note: Once you’ve selected the Service Test Mode from the Hidden Menu,

the only way to exit the Service Test Mode is to press the Scrub On/

Off Switch six times or turn the key switch off.

To Access the Service Test Mode

1. Display the main menu. (Refer to the Programming Options/To Access the Main Menu subsection.)

2. Press the Forward (up) or Reverse (down) Drive Switches to scroll

through the PROGRAMMING OPTIONS menu until the display shows

PROGRAMMING OPTIONS / 16. SERVICE TEST MODE.

3. Press the Burst Of Power Switch to enter the Service Test Mode.

The display will show the Service Test Mode submenu.

PROGRAM OPTIONS

16. SERVICE TEST MODE

SPD: N 26.5 BRU: OFF

REV: OFF VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

Page 32

Control System 32Service Manual – SC1500

Service Test Mode Functions

The control panel switches are used to control various A1 Control Board output functions. The table below

lists the control panel switches, and their corresponding Service Test Mode functions and displays:

Control Panel Switch Service Test Mode Function Graphic Display Descriptions

Forward

Drive

Switch

The Forward Drive Switch enables the machine

to drive forward. The blue LED indicator will be

lit when the Switch is active. For the machine

to move forward, the Emergency Stop must be

reset, the Operator Presence Pedal must be

pressed and the Go Pedal must be pressed.

Note that the Inhibit (

INH) output must be off

(via the Information Switch – see below).

SPD: F 26.5 BRU: OFF

REV: OFF VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

• SPD: – indicates the drive

controller state. In this

case it would display F for

forward.

• The three digits display the

battery voltage (26.5 volts in

this example).

Reverse

Drive

Switch

The Reverse Drive Switch enables the

machine to drive in reverse. The blue LED

indicator will be lit when the Switch is active.

For the machine to move backward, the

Emergency Stop must be reset, the Operator

Presence Pedal must be pressed and the Go

Pedal must be pressed. Note that the Inhibit

(

INH) output must be off (via the Information

Switch – see below).

SPD: R 26.5 BRU: OFF

REV: ON VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

• SPD: – indicates the drive

controller state. In this

case it would display R for

reverse.

• The three digits display the

battery voltage (26.5 volts in

this example).

• REV: – indicates that the

reverse output is ON.

Information

Switch

Pressing the Information Switch toggles the

Inhibit output (

INH) from the A1 Control Board

to the E1 Curtis Speed Controller ON and OFF.

Note that INH must be OFF in order to test the

forward and reverse drive in the Service Test

Mode.

SPD: R 26.5 BRU: OFF

REV: ON VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

• INH: – indicates the state

of the inhibit signal. In this

case the inhibit signal is ON.

• E(NN) – displays any active

fault codes.

Extra

Pressure

and Horn

Switches

Pressing the Extra Pressure Switch scrolls

the

DEK: eld through the four available deck

positions:

• UP – raised (transport) position

• VAC – vacuum-only (wet vacuuming) position

• LOW – standard scrub pressure position

SPD: R 26.5 BRU: OFF

REV: ON VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

DEK: – indicates the scrub

deck position. In this case

the deck would be in the UP

(transport) position.

• HI – extra scrub pressure position

Pressing the Horn Switch will move the deck

to the selected position. Note that the Extra

Pressure Switch is locked out while the deck is

moving. The DEK: line will be highlighted and

inverted.

Page 33

Control System 33Service Manual – SC1500

Control Panel Switch Service Test Mode Function Graphic Display Descriptions

Scrub

On/Off

Switch

Pressing the Scrub On/Off Switch toggles the

brush motor contactor and scrub deck motor

ON and OFF.

SPD: R 26.5 BRU: OFF

REV: ON VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

BRU: – indicates the state of

the brush motor. In this case

the motor would be OFF.

Vacuum

Power

Adjustment

Switch

Pressing the Vacuum Power Adjustment Switch

scrolls the Solid State Relay (SSR1) and

Vacuum Motor among the three states:

OFF

(0V), LOW (16.8V) and HI (battery voltage).

SPD: R 26.5 BRU: OFF

REV: ON VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

VAC: – indicates the state of

the vacuum motor. In this case

the motor would be OFF.

Solution

Flow

Adjustment

Switch

Pressing the Solution Flow Adjustment Switch

toggles the solution solenoid

ON and OFF.

When the solenoid is ON it will operate at 50%

duty cycle (1 cycle = 3 seconds ON, 3 seconds

OFF).

SPD: R 26.5 BRU: OFF

REV: ON VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

SOL: – indicates the state of

the solution solenoid. In this

case the solenoid would be

OFF.

Detergent

Strength

Switch

Pressing the Detergent Strength Switch toggles

the Detergent Pump

ON and OFF. When the

Detergent Pump is ON, the Pump will be driven

at a rate equivalent to 1:128 (0.8%).

SPD: R 26.5 BRU: OFF

REV: ON VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

CP: – indicates the state of the

detergent (chemical) pump. In

this case the pump would be

OFF.

To Exit the Service Test Mode

To exit the Service Test mode, press the Scrub On/Off Switch six times or turn the key switch off.

Programming Options

The SC1500 graphic display has two “layers” of hidden menus that allow you to view and change the various

programmable machine congurations, system settings and parameters. The top “layer” is the main menu

from which you can navigate to the 20 submenus. The second “layer” is the submenus that display the

programmable options. These submenus are the screens on which you can change the congurations and

settings.

Page 34

Control System 34Service Manual – SC1500

To Access the Main Menu

1. Turn the key switch to the Off position. (If the optional on-board battery charger is installed, it must be

unplugged from the AC power).

2. Press and hold in the Solution Flow Adjustment Switch and Extra Pressure

Switch simultaneously.

3. While holding both switches, turn the key switch to the On position.

4. Continue to hold both switches for at least two seconds until the

display shows PROGRAMMING OPTIONS / 1. DECK TYPE in the main

PROGRAM OPTIONS

1. DECK TYPE

menu.

5. Release both switches.

6. Press the Forward (up) or Reverse (down) Drive Switches to scroll through the links in

the main menu.

The main menu contains the following links to the corresponding programming option

submenus:

1. DECK TYPE

2. LOW VOLTAGE CUTOUT

3. BATTERY CHARGER

4. BURST OF POWER

5. DETERGENT OPTION

6. DETERGENT RATE BIAS

7. OPEN FAULT DETECT

8. DISPLAY REV LEVEL

9. LOCKOUT BRUSH

10. LOCKOUT SOLUTION

11. BACKUP ALARM VOL

12. FWD ALARM VOL

13. HORN VOL

14. RESTORE DEFAULTS

15. FAULT RECALL

16. SERVICE TEST MODE

17. XTRA INFO ON DISPLAY

18. FROZEN PARAMETERS

19. PANEL TEST

20. SAVE SCRUB SETTINGS

Service Note: The A1 Control Board will automatically display the main menu upon machine

power-up if no scrub deck has been selected and saved in the DECK TYPE submenu.

This will occur when a new Control Board is installed into a machine, or the

RESTORE DEFAULTS has been performed. The purpose of this is to prompt the

Operator to select the appropriate deck type before using the Control Board in

the machine. Once the deck type has been selected, the controller will no longer

automatically display the main menu at machine power-up.

Page 35

To Access a Submenu from the Main Menu

1. Press the Forward (up) or Reverse (down) Drive Switches to scroll through the links in

the main menu.

2. To display the selected submenu(s) for the displayed main menu link, press the Burst of

Power Switch.

To Change a Programmable Option in a Submenu

1. Press the Forward (up) or Reverse (down) Drive Switches to scroll through the available

programming options in the submenu(s).

Control System 35Service Manual – SC1500

2. When the desired programming option submenu is displayed, press the Scrub On/Off

Switch. This will enter the displayed programming option and return to the main menu

link.

Deck Type

The SC1500 can be equipped with two different deck options. The 1. DECK

TYPE

submenus allow you to specify the type of deck installed in your

machine. Note that the type of deck selected congures the solution ow

rate settings corresponding to the deck type.

PROGRAM OPTIONS

1. DECK TYPE

PROGRAM OPTIONS

DECK TYPE

20 INCH / 51 CM DISC

PROGRAM OPTIONS

DECK TYPE

20 INCH / 51 CM REV

Page 36

Low Battery Voltage Cutout

Control System 36Service Manual – SC1500

The purpose of the low battery voltage cutout is to help prolong battery

life. The A1 Control Board will raise the deck, and switch off the brush

and vacuum motors, solution solenoid valve and detergent pump

automatically when the batteries discharge to the selected cutout level.

The 2. LOW VOLT CUTOUT submenus allow you to select the voltage cutout

level for the type of battery installed in your machine:

• The standard cutout setting for wet cell/lead acid batteries is 20.55

volts (80% discharged or 20% charge remaining).

• The alternate cutout setting for gel/maintenance free batteries is 21.75

volts (70% discharged or 30% charge remaining).

The default setting is WET BATTERY 80% / LVC=20.55V.

Battery Charger

The 3. BATTERY CHARGER submenus allow you to specify the battery type

in your machine so the on-board charger will use the charging algorithm

that is compatible with the battery type. If your machine is not equipped

with an onboard charger, select NONE (the default setting).

PROGRAM OPTIONS

2. LOW VOLT CUTOUT

PROGRAM OPTIONS

LOW VOLT CUTOUT

WET BATTERY 80%

LVC=20.55V

PROGRAM OPTIONS

LOW VOLT CUTOUT

MAIN FREE BATTERY 70%

LVC=21.75V

PROGRAM OPTIONS

3. BATTERY CHARGER

PROGRAM OPTIONS

BATTERY CHARGER

NONE

PROGRAM OPTIONS

BATTERY CHARGER

WET 25A

PROGRAM OPTIONS

BATTERY CHARGER

AGM DISCOVER 25A

PROGRAM OPTIONS

BATTERY CHARGER

GEL EXIDE 25A

PROGRAM OPTIONS

BATTERY CHARGER

GEL-AGM 25A

PROGRAM OPTIONS

BATTERY CHARGER

WET 15A

PROGRAM OPTIONS

BATTERY CHARGER

AGM FULLRIVER 25A

Page 37

Burst Of Power Operation

Control System 37Service Manual – SC1500

The 4. BURST OF POWER submenus allow you to enable or disable the

burst-of-power function. When the burst-of-power function is enabled

(YES), pressing the Burst Of Power Switch while scrubbing will attempt

to make a temporary increase in the solution ow rate, brush pressure,

vacuum level and detergent ow rate.

The default setting is NO.

Detergent (EcoFlex™) Option

The 5. ECOFLEX INSTALLED submenus allow you to enable or disable the

detergent system.

• If the menu setting is YES, the controller will expect a Detergent

Pump to be installed. If no Detergent Pump is installed, eventually the

Control Board could generate an error code.

• If the menu setting is NO, the Detergent Strength Switch has no

effect on machine operation, and the graphic display will not show

the Detergent Indicator Bar Graph. Note that if the machine has a

detergent system installed, it will not work when the menu setting NO

is selected.

PROGRAM OPTIONS

4. BURST OF POWER

PROGRAM OPTIONS

BURST OF POWER

NO

PROGRAM OPTIONS

BURST OF POWER

YES

PROGRAM OPTIONS

5. ECOFLEX INSTALLED

PROGRAM OPTIONS

ECOFLEX INSTALLED

NO

PROGRAM OPTIONS

ECOFLEX INSTALLED

YES

The default setting is NO.

Chemical Rate Bias

The 6. CHEMICAL RATE BIAS submenus allow you to increase or decrease

the detergent/chemical mix rate by 10 percent to achieve a higher or

lower mix concentration than the selected programmed ratio.

• The -10% LESS CHEMICAL

setting will increase

the wait time

between Detergent Pump delivery pulses 10 percent to decrease

detergent ow.

• The +10% MORE CHEMICAL

setting will decrease

the wait time

between Detergent Pump delivery pulses 10 percent to increase

detergent ow.

Note that the 6. CHEMICAL RATE BIAS submenus only have an effect if the

ECOFLEX INSTALLED / YES option is selected (see above).

The default setting is NONE.

PROGRAM OPTIONS

6. CHEMICAL RATE BIAS

PROGRAM OPTIONS

CHEMICAL RATE BIAS

NONE

PROGRAM OPTIONS

CHEMICAL RATE BIAS

-10% LESS CHEMICAL

PROGRAM OPTIONS

CHEMICAL RATE BIAS

+10% MORE CHEMICAL

Page 38

Open Fault Detect

Control System 38Service Manual – SC1500

Normally, the A1 Control Board will perform checks of the electrical

system during operation. If a fault occurs in a particular system,

that system (and possibly others) will be shut down. This can make

troubleshooting the system difcult. The 7. OPEN FAULT DETECT

submenus allow service personnel to disable all of the open circuit faults

to facilitate troubleshooting. Note that selecting OPEN FAULT DETECT /

OFF

will not disable the over-current protection on any of the systems.

The default setting is OFF.

Display Rev Level

The 8. DISPLAY REV LEVEL submenu displays the revision level of the

software in the A1 Control Board. This revision level is a parameter hardcoded in the software.

PROGRAM OPTIONS

7. OPEN FAULT DETECT

PROGRAM OPTIONS

OPEN FAULT DETECT

OFF

PROGRAM OPTIONS

OPEN FAULT DETECT

ON

PROGRAM OPTIONS

8. DISPLAY REV LEVEL

PROGRAM OPTIONS

DISPLAY REV LEVEL

REV A

Lock Out Brush Pressure

The 9. LOCKOUT BRUSH submenus allow you to lock out the low or high

scrub pressure settings. The Operator will not be able to select a scrub

pressure setting that is locked out.

The default setting is NONE.

PROGRAM OPTIONS

9. LOCKOUT BRUSH

PROGRAM OPTIONS

LOCKOUT BRUSH

NONE

PROGRAM OPTIONS

LOCKOUT BRUSH

LOW

PROGRAM OPTIONS

LOCKOUT BRUSH

HIGH

Page 39

Lock Out Solution Flow Rate

Control System 39Service Manual – SC1500

The 10. LOCKOUT SOLUTION submenus allow you to lock out single or

multiple solution ow rate settings. The Operator will not be able to

select ow rate(s) that are locked out during normal operation.

The default setting is NONE.

PROGRAM OPTIONS

10. LOCKOUT SOLUTION

PROGRAM OPTIONS

LOCKOUT SOLUTION

NONE

PROGRAM OPTIONS

LOCKOUT SOLUTION

LOW

PROGRAM OPTIONS

LOCKOUT SOLUTION

MEDIUM

PROGRAM OPTIONS

LOCKOUT SOLUTION

HIGH

PROGRAM OPTIONS

LOCKOUT SOLUTION

LOW & MEDIUM

PROGRAM OPTIONS

LOCKOUT SOLUTION

LOW & HIGH

Backup Alarm Volume

The 11. BACKUP ALARM VOL (volume) submenus allow you to set the

backup alarm volume.

The default setting is MEDIUM.

PROGRAM OPTIONS

LOCKOUT SOLUTION

MEDIUM & HIGH

PROGRAM OPTIONS

11. BACKUP ALARM VOL

PROGRAM OPTIONS

BACKUP ALARM VOL

OFF

PROGRAM OPTIONS

BACKUP ALARM VOL

LOW

PROGRAM OPTIONS

BACKUP ALARM VOL

MEDIUM

PROGRAM OPTIONS

BACKUP ALARM VOL

HIGH

Page 40

Forward Alarm Volume

Control System 40Service Manual – SC1500

The 12. FWD (forward) ALARM VOL (volume) submenus allow you to set

the forward alarm volume.

The default setting is OFF.

Horn Volume

PROGRAM OPTIONS

12. FWD ALARM VOL

PROGRAM OPTIONS

FWD ALARM VOL

OFF

PROGRAM OPTIONS

FWD ALARM VOL

LOW

PROGRAM OPTIONS

FWD ALARM VOL

MEDIUM

PROGRAM OPTIONS

FWD ALARM VOL

HIGH

The HORN VOLUME submenus allow you to set the horn volume.

The default setting is HIGH.

PROGRAM OPTIONS

13. HORN VOLUME

PROGRAM OPTIONS

HORN VOLUME

OFF

PROGRAM OPTIONS

HORN VOLUME

LOW

PROGRAM OPTIONS

HORN VOLUME

MEDIUM

PROGRAM OPTIONS

HORN VOLUME

HIGH

Page 41

Restore Defaults

Control System 41Service Manual – SC1500

The 14. RESTORE DEFAULTS submenus allow you to reset the programmed

options/parameters stored in the A1 Control Board EEPROM to their

factory default values. Note that selecting RESTORE DEFAULTS / YES will

not reset the hour meter.

The default setting is NO.

Note: IfyouselectYES to restore the defaults, it will be like

installinganew“outofthebox”controller.Therst

time you turn on the key switch, the graphic display will

automatically bring you to the programming options

menu. Also any “user preferences” like brush pressure

lockoutorsolutionowratelockoutwillbelost.

Fault Recall

Whenever the A1 Control Board detects an electrical system fault, one or

more error codes are displayed and stored in the Board EEPROM. The

15. FAULT RECALL submenu allows you to recall any error code(s) that

had been logged from previous machine operation. This can be useful for

troubleshooting the machine.

• Any logged fault codes will be shown on the display. (Fault codes 3, 32

and 52 are shown here in this example.)

PROGRAM OPTIONS

14. RESTORE DEFAULTS

PROGRAM OPTIONS

RESTORE DEFAULTS

NO

PROGRAM OPTIONS

RESTORE DEFAULTS

YES

PROGRAM OPTIONS

15. FAULT RECALL

PROGRAM OPTIONS

FAULT RECALL

3 32 52

• If no fault code is present, the display will show a “-“

Pressing the Burst Of Power Switch with the FAULT RECALL submenu

PROGRAM OPTIONS

FAULT RECALL

-

displayed will erase the fault history and the entire Frozen Parameters

memory. (Refer to the Frozen Parameters subsection.)

Note that there may be a slight delay after pressing the Burst Of Power Switch before the “-“ symbol

appears to conrm that the memory has been cleared. This is normal and is due to the large amount of

Frozen Parameter data that is being erased.

Service Test Mode

Pressing the Burst Of Power Switch with the 16. SERVICE TEST MODE

main menu link displayed will put the machine into the Service Test

PROGRAM OPTIONS

16. SERVICE TEST MODE

Mode and display the Service Test Mode submenu.

Refer to the Troubleshooting/Service Test Mode subsection for

information regarding the Service Test Mode functions.

SPD: N 26.5 BRU: OFF

REV: OFF VAC: OFF

INH: ON E00 SOL: OFF

DEK: UP CP: OFF

Page 42

Extra Information on the Graphic Display

Control System 42Service Manual – SC1500

The 17. EXTRA INFO ON LCD submenus allow you to display additional

information on the graphic display. This additional information is

displayed in real time on both the Scrubbing and Information screens and

can aid in troubleshooting the machine in normal operation.

The extra information is displayed in a two-letter or three-letter code that