Page 1

SC1500

Instructions For Use - Original Instructions

Instrucciones de uso

Mode d’ emploi

Models: 56104000 (X20D), 56104001 (X20R)

This manual is only for machines manufactured after June 2014

A-English

B-Español

C-Français

5/2014 Revised 9/2014 FORM NO. 56091120 REV C

Page 2

INSTRUCTIONS FOR USEA - ENGLISH

TABLE OF CONTENTS

Page

Introduction ........................................................................................... A-3

Cautions and Warnings ................................................................A-4 - A-5

Know Your Machine ......................................................................A-6 - A-7

Control Panel ................................................................................A-8 - A-9

Prepare the Machine for Use

Install the Batteries ............................................................................. A-10

Install the Brush (disc) ........................................................................ A-11

Install the Pad (REV) .......................................................................... A-12

Install the Squeegee ........................................................................... A-13

Fill the Solution Tank ..........................................................................A-13

Detergent System .....................................................................A-14 - A-15

Operating the Machine

Scrubbing .................................................................................A-16 - A-17

After Use .............................................................................................A-18

Maintenance Schedule ....................................................................... A-18

Lubricating the Machine .....................................................................A-19

Electromagnetic Brake .......................................................................A-19

Charging the Batteries (Wet) .............................................................. A-20

Check the Battery Water Level ........................................................... A-20

Charging the Batteries (Gel) ............................................................... A-21

Squeegee Maintenance ......................................................................A-22

Squeegee Adjustment ........................................................................ A-22

Troubleshooting .................................................................................. A-23

Technical Specifi cations .....................................................................A-24

A - 2 SC1500 - 56091120 5/2014

Page 3

ENGLISH - AINSTRUCTIONS FOR USE

INTRODUCTION

This manual will help you get the most from your Advance Scrubber. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages A-6 – A-9.

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops, offi ces and rental businesses. The SC1500 is a

battery powered fl oor cleaning machine.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Advance Service Center, who employs factory trained service personnel, and maintains an

inventory of Advance original replacement parts and accessories.

Call the ADVANCE DEALER named below for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

MODIFICATIONS

Modifi cations and additions to the cleaning machine which affect capacity and safe operation shall not be performed by the customer or user without prior written

approval from Nilfi sk-Advance Inc. Unapproved modifi cations will void the machine warranty and make the customer liable for any resulting accidents.

NAME PLATE

The Model Number and Serial Number of your machine are shown on the Nameplate on the machine. This information is needed when ordering repair parts for

the machine. Use the space below to note the Model Number and Serial Number of your machine for future reference.

MODEL NUMBER ______________________________________________________

SERIAL NUMBER ______________________________________________________

UNCRATE THE MACHINE

When the machine is delivered, carefully inspect the shipping packaging and the machine for damage. If damage is evident, save the shipping carton (if

applicable) so that it can be inspected. Contact the Advance Customer Service Department immediately to fi le a freight damage claim. Refer to the unpacking

instruction sheet included with the machine to remove the machine from the pallet.

TRANSPORTING THE MACHINE

CAUTION!

Before transporting the machine on an open truck or trailer, make sure that . . .

• All tanks are empty.

• Recovery tank cover is latched securely.

• The machine is tied down securely - see Tie Down Locations (6) in Know Your Machine.

• The machine’s electromagnetic brake is engaged (not manually overridden).

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of California, as identifi ed in

its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In certain locations (including the State of California)

purchasers of these Products that place them in service at an employment job site or a publicly accessible space are required by regulation to make certain

notices, warnings or disclosures regarding the chemicals that are or may be contained in the Products at or about such work sites. It is the purchaser’s

responsibility to know the content of, and to comply with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer

disclaims any responsibility to advise purchasers of any specifi c requirements that may be applicable to the use of the Products in such environments.

5/2014 A - 3 56091120 - SC1500

Page 4

INSTRUCTIONS FOR USEA - ENGLISH

CAUTIONS AND WARNINGS

SYMBOLS

Advance uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and

take the necessary steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

This machine is for commercial use, for example in hotels, schools, hospitals, factories, shops and offi ces other than

normal residential housekeeping purposes.

WARNING!

• This machine shall be used only by properly trained and authorized persons.

• This machine is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge.

• While on ramps or inclines, avoid sudden stops. Avoid abrupt sharp turns. Use low speed down ramps.

• Observe the Gross Vehicle Weight, GVW, of the machine when loading, driving, lifting or supporting the machine.

• Keep sparks, fl ame and smoking materials away from batteries. Explosive gases are vented during normal operation.

• Charging the batteries produces highly explosive hydrogen gas. Charge batteries only in well-ventilated areas, away

from open fl ame. Do not smoke while charging the batteries.

• Remove all jewelry when working near electrical components.

• Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

• Never work under a machine without safety blocks or stands to support the machine.

• Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where

fl ammable liquids exist.

• Do not clean this machine with a pressure washer.

• Only use the brushes provided with the appliance or those specifi ed in the instruction manual. The use of other

brushes may impair safety.

A - 4 SC1500 - 56091120 5/2014

Page 5

ENGLISH - AINSTRUCTIONS FOR USE

CAUTIONS AND WARNINGS - CONTINUED

CAUTION!

• This machine is not approved for use on public paths or roads.

• This machine is not suitable for picking up hazardous dust.

• Do not use scarifi er discs and grinding stones. Advance will not be held responsible for any damage to fl oor surfaces

caused by scarifi ers or grinding stones (can also cause damage to the brush drive system).

• When operating this machine, ensure that third parties, particularly children, are not endangered.

• Before performing any service function, carefully read all instructions pertaining to that function.

• Do not leave the machine unattended without fi rst turning the key switch off (O), removing the key and applying the

parking brake.

• Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

• Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

• Use caution when moving this machine in below freezing temperature conditions. Any water in the solution, recovery

or detergent tanks or in the hose lines could freeze, causing damage to valves and fi ttings. Flush with windshield

washer fl uid.

• The batteries must be removed from the machine before the machine is scrapped. The disposal of the batteries

should be safely done in accordance with your local environmental regulations.

• Do not use on surfaces having a gradient exceeding that marked on the machine.

• All doors and covers are to be positioned as indicated in the instruction manual before using the machine.

• This machine should only be used and stored indoors.

SAVE THESE INSTRUCTIONS

5/2014 A - 5 56091120 - SC1500

Page 6

INSTRUCTIONS FOR USEA - ENGLISH

KNOW YOUR MACHINE

As you read this manual, you will occasionally run across a bold number or letter in parentheses - example: (2). These numbers refer to an item shown on these

pages unless otherwise noted. Refer back to these pages whenever necessary to pinpoint the location of an item mentioned in the text. NOTE: Refer to the

service manual for detailed explanations of each item illustrated on the next 4 pages.

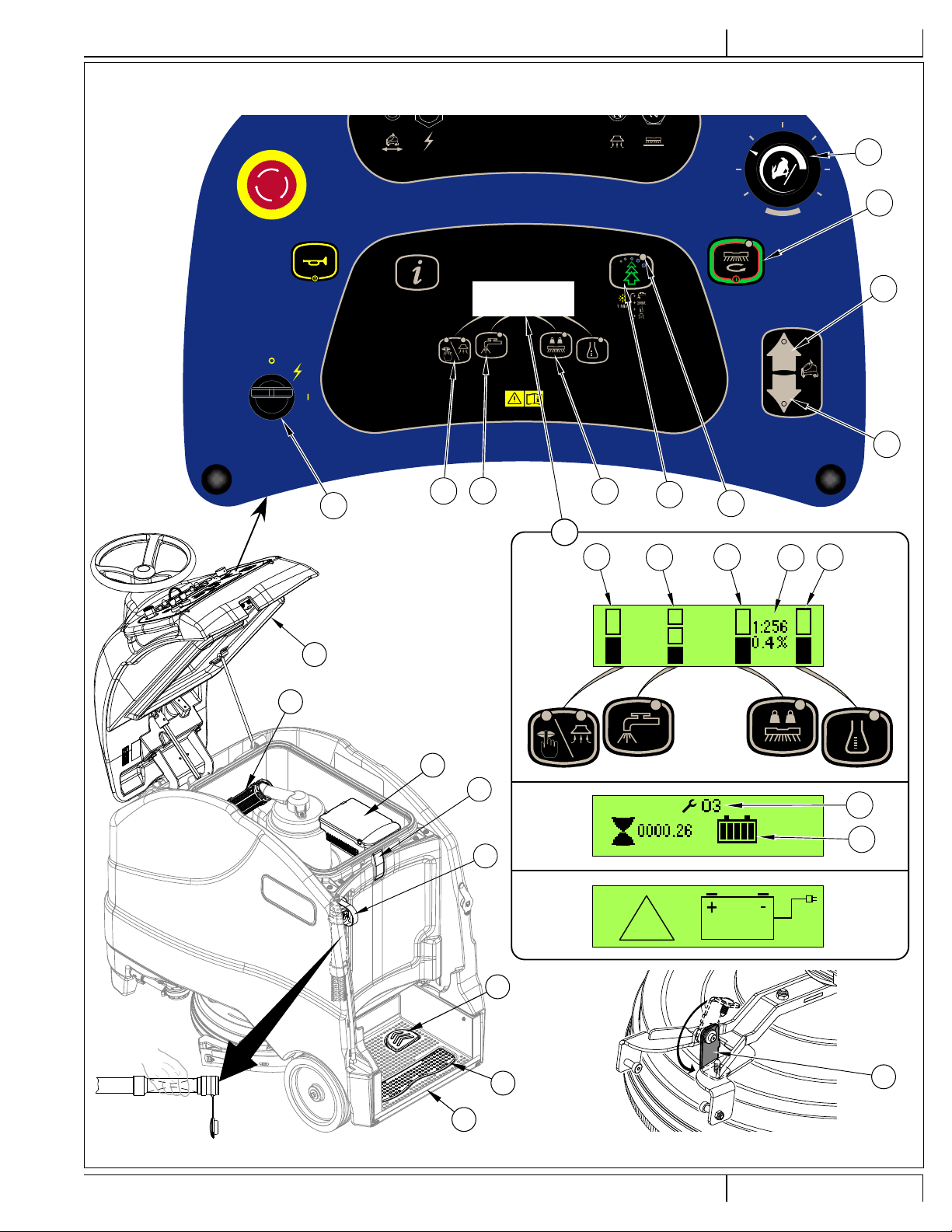

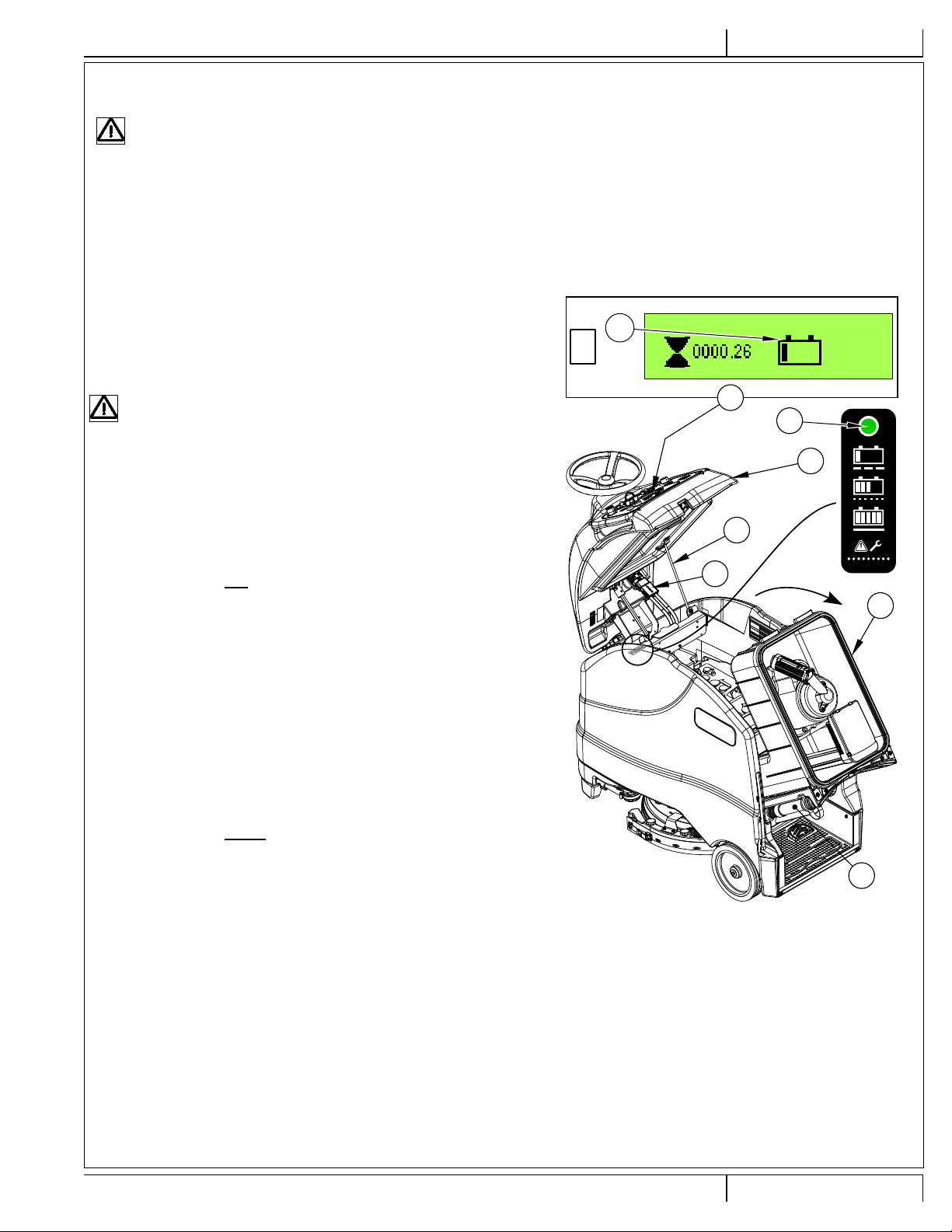

1 Control Panel

2 Steering Wheel

3 Detergent Cartridge

4 Solution Tank

5 Solution Tank Fill Cap

6 Tie Down Locations

7 Drive Wheel

8 Scrub Deck

9 Squeegee Roller

10 Squeegee Assembly

11 Squeegee Cover Knobs (4)

12 On-Board Charger Power Cord

12

1

2

3

4

5

6

11

10

9

8

7

A - 6 SC1500 - 56091120 5/2014

6

Page 7

KNOW YOUR MACHINE

13 Control Panel Housing / Recovery Tank Cover

14 Automatic Vacuum Motor Shutoff Float

15 Recovery Tank

16 Debris Catch Tray

17 Solution Tank Rear Fill Port

18 Go Pedal

19 Operator Presence Pedal

20 Platform

21 Rear Wheel

22 Solution Tank Drain Hose

23 Rear Squeegee Blade Removal Latch

ENGLISH - AINSTRUCTIONS FOR USE

24 Battery Charger

25 Solution Solenoid Valve

26 Solution Filter

27 Solution Shutoff Valve

28 Hand Holds

29 Latch

30 Recovery Tank Drain Hose

31 Solution Tank Level Sight Tube

32 Prop Rod

33 Battery Connector (optional)

34 Solution Drain Valve

35 Battery Charge Status LED

28

28

33

14

13

35

32

15

16

29

30

17

31

18

27

25

26

24

19

23

20

22

34

21

5/2014 A - 7 56091120 - SC1500

Page 8

INSTRUCTIONS FOR USEA - ENGLISH

CONTROL PANEL

A Key Switch

B Emergency Stop

C Horn Switch

D Drive Wheel Circuit Breaker (50 Amp)

E Control Circuit Circuit Breaker (5 Amp)

F Graphic Display (see Control Panel-Continued))

G Vacuum Motor Circuit Breaker (20 Amp)

H Brush Motor Circuit Breaker (25 Amp)

I One-Touch

J Scrub ON/OFF Indicator

K Speed Adjustment Knob

L Forward Drive Switch

M Forward Drive Indicator

N Reverse Drive Switch

O Reverse Drive Indicator

™

Scrub ON/OFF Switch

P Burst of Power Switch

Q Burst of Power Indicator

R Detergent Strength Switch

S Detergent ON/OFF Indicator

T Extra Pressure Switch

U Extra Pressure Indicator

V Read All Instructions Before Using Symbol

W Solution Flow Adjustment Switch

X Solution ON/OFF Indicator

Y Vacuum Power Adjustment Switch

YA Quiet Vacuum Mode Indicator

YB Standard Vacuum Mode Indicator

Z Information Switch

F

D

E

C

G

H

I

J

K

B

50A 5A 20A 25A

M

L

A

N

X

W

Y

YA

YB

Z

T

U

R

S

V

P

Q

A - 8 SC1500 - 56091120 5/2014

O

Page 9

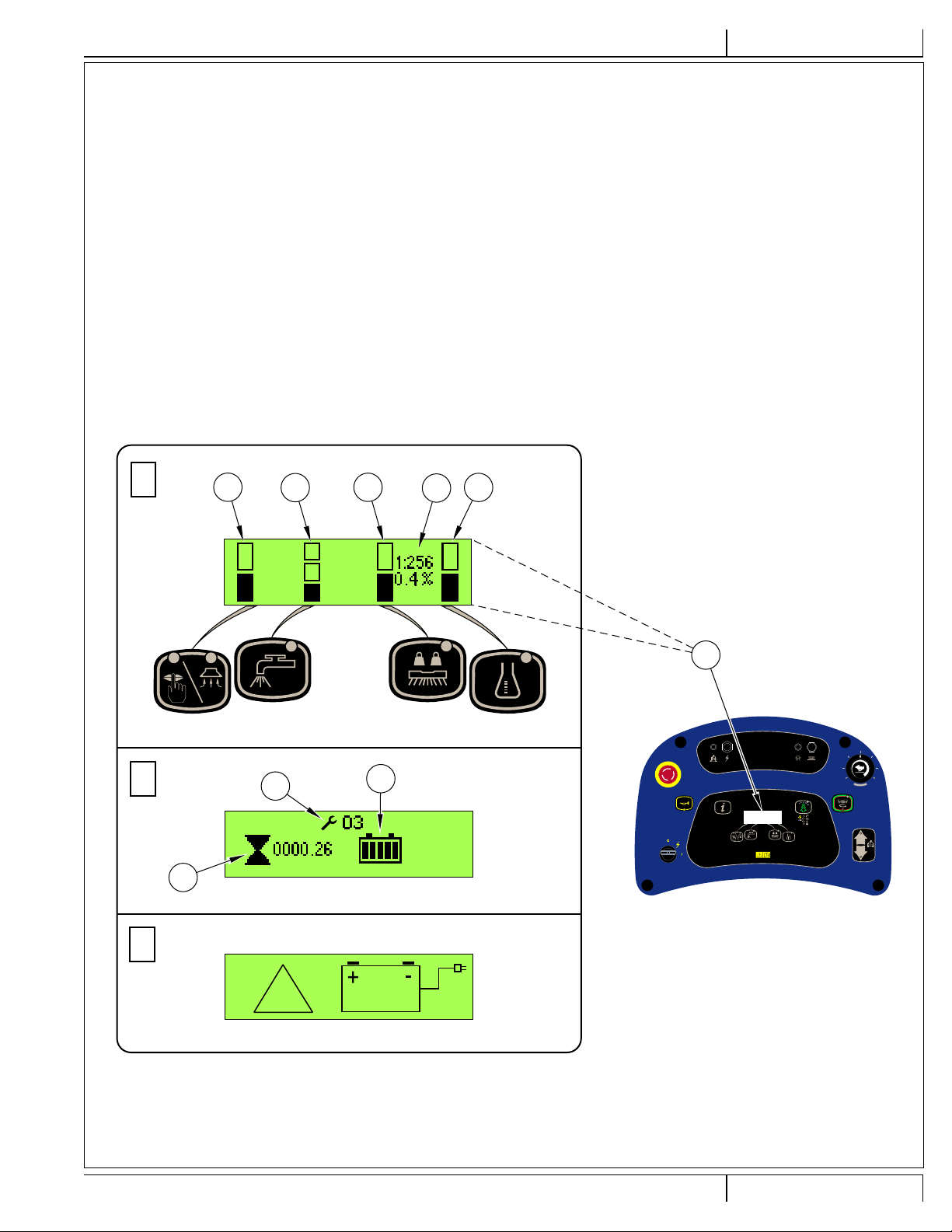

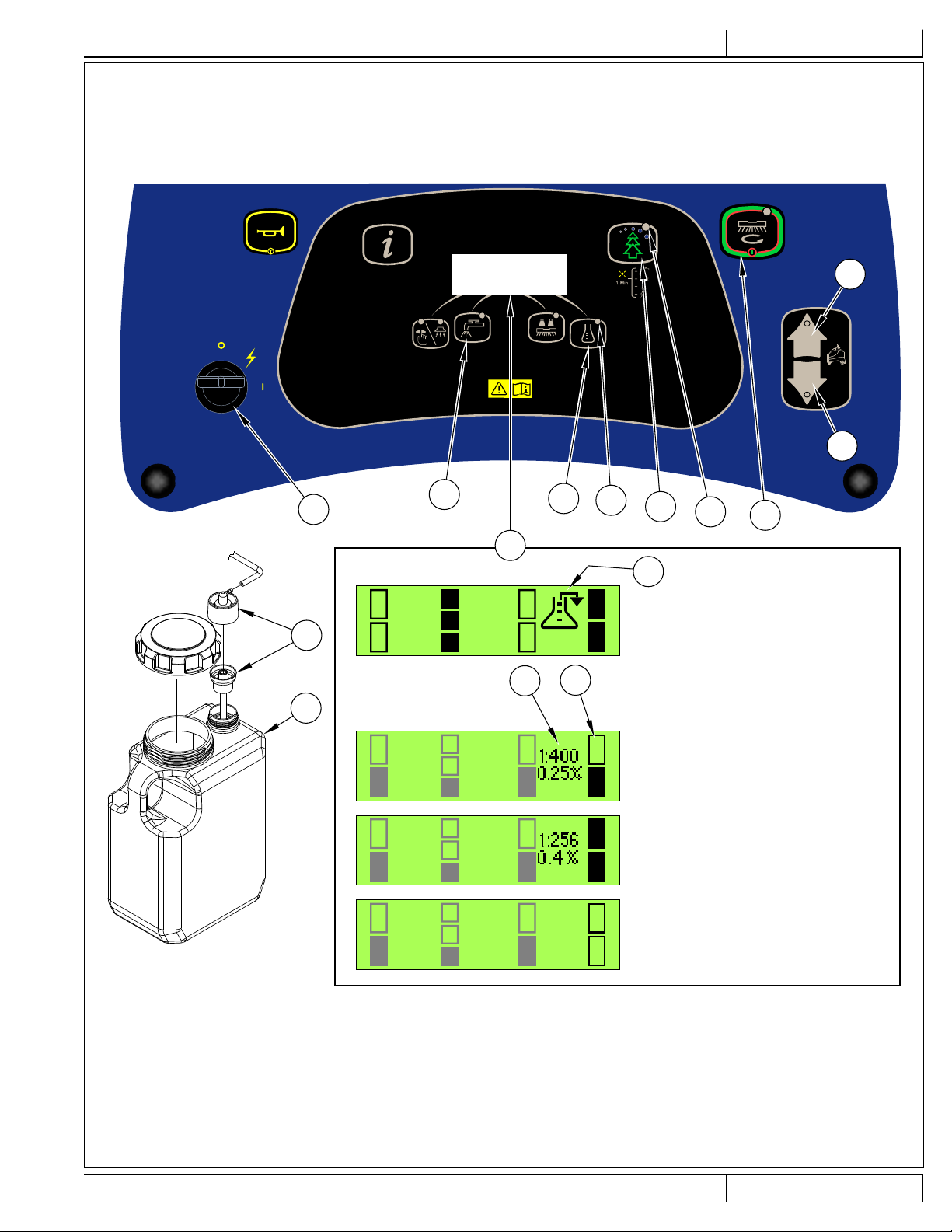

CONTROL PANEL - CONTINUED

1 Scrubbing Screen

2 Information Screen

3 Battery Low Voltage Screen

F Graphic Display

F1 Vacuum Level Bar Graph

TOP = High

BOTTOM = Low

NONE = Off

F2 Solution Flow Rate Bar Graph

TOP = High

MIDDLE = Medium

BOTTOM = Low

NONE = Off

ENGLISH - AINSTRUCTIONS FOR USE

F3 Scrub Brush Pressure Bar Graph

TOP = Extra Pressure

BOTTOM = Standard Pressure

F4 Detergent Ratio/Percentage Indicator

F5 Detergent Indicator Bar Graph

TOP = Strong Detergent

BOTTOM = Weak Detergent

NONE = Off

F6 Fault Codes

F7 Hour Meter

F8 Battery Charge Level Indicator

1

F1

F2

F3

F4

F5

F

2

F6

F8

F7

3

!

5/2014 A - 9 56091120 - SC1500

Page 10

INSTRUCTIONS FOR USEA - ENGLISH

BATTERIES

If your machine shipped with batteries installed do the following:

Check that the batteries are connected to the machine.•

Turn ON the Key Switch • (A) and check the Battery Indicator (F8). If the gauge is completely fi lled the batteries are ready for use. If the gauge is less than full

the batteries should be charged before use. See the “Charging The Batteries” section.

IMPORTANT!:• IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE OEM PRODUCT MANUAL FOR INSTRUCTIONS

REGARDING SETTING THE CHARGER FOR BATTERY TYPE.

If your machine shipped without batteries installed do the following:

Consult your Authorized Advance dealer for recommended batteries.•

Install the batteries by following the instructions below.•

IMPORTANT!:• IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE OEM PRODUCT MANUAL FOR INSTRUCTIONS

REGARDING SETTING THE CHARGER FOR BATTERY TYPE.

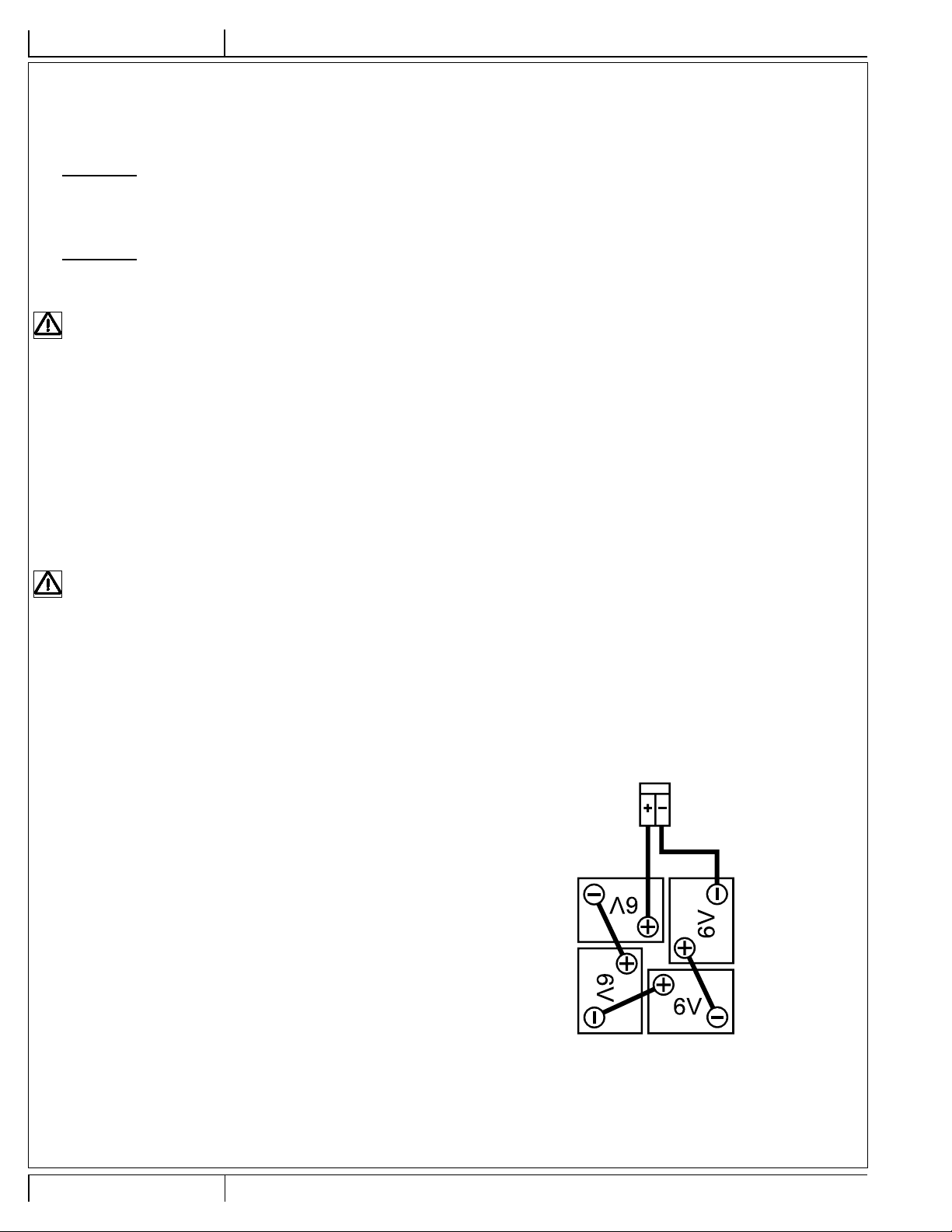

INSTALL THE BATTERIES

WARNING !

Use extreme caution when working with batteries. Sulfuric acid in batteries can cause severe injury if allowed to contact the skin or

eyes. Explosive hydrogen gas is vented from inside the batteries through openings in the battery caps. This gas can be ignited by

any electrical arc, spark or fl ame. If battery acid makes contact with your skin, fl ush the affected area with water for 5 minutes and

seek medical attention.

When Servicing Batteries...

• Remove all jewelry.

• Do not smoke.

• Wear safety glasses, a rubber apron and rubber gloves.

• Work in a well-ventilated area.

• Do not allow tools to touch more than one battery terminal at a time.

• ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

• ALWAYS connect the negative cable last when installing batteries.

CAUTION !

Electrical components in this machine can be severely damaged

if the batteries are not installed and connected properly. Batteries

should be installed by Advance or by a qualifi ed electrician.

1 Empty the Recovery Tank (15) using the Recovery Tank Drain Hose (30).

2 Turn the Key Switch (A) off (O) and remove the key. Unlatch (29) then swing

open the Recovery Tank Cover (13) and set the Prop Rod (32).

3 Tip the Recovery Tank (15) back towards the operator’s platform to expose

the battery compartment.

4 Using (2) people and an appropriate lifting strap, carefully lift the batteries

into the compartment tray exactly as shown. Refer to the molded diagram

on the underside of the Recovery Tank Cover.

5 See Figure 1. Install battery cables as shown and tighten the nuts on the

battery terminals.

6 Install the battery boots and secure tightly to the battery cables with the

supplied tie straps.

7 Connect the machine’s main power cables to the batteries or if so equipped

plug together the battery connector (33). Close the recovery tank cover.

When changing batteries or the charger, please contact your local

authorized service center for correct battery, charger and machine

settings to prevent battery damage.

FIGURE 1

24V

260A/H-20HR-RATE

A - 10 SC1500 - 56091120 5/2014

Page 11

ENGLISH - AINSTRUCTIONS FOR USE

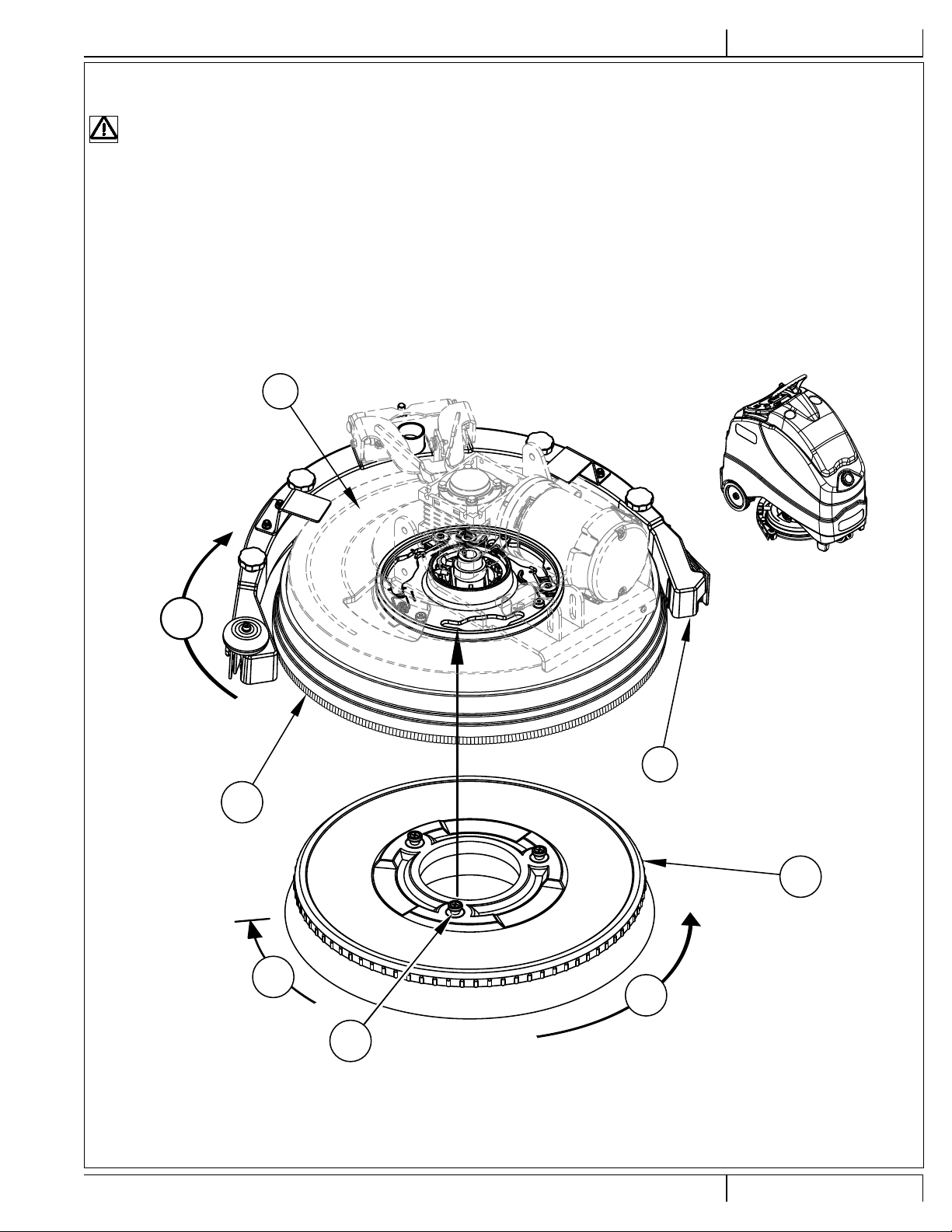

INSTALL THE BRUSH (DISC SYSTEM)

1 Make sure the Scrub Deck (8) is in the RAISED position. Make sure the Key Switch (A) is off (O).

CAUTION !

Turn the key switch off (O) and remove the key, before changing the brush.

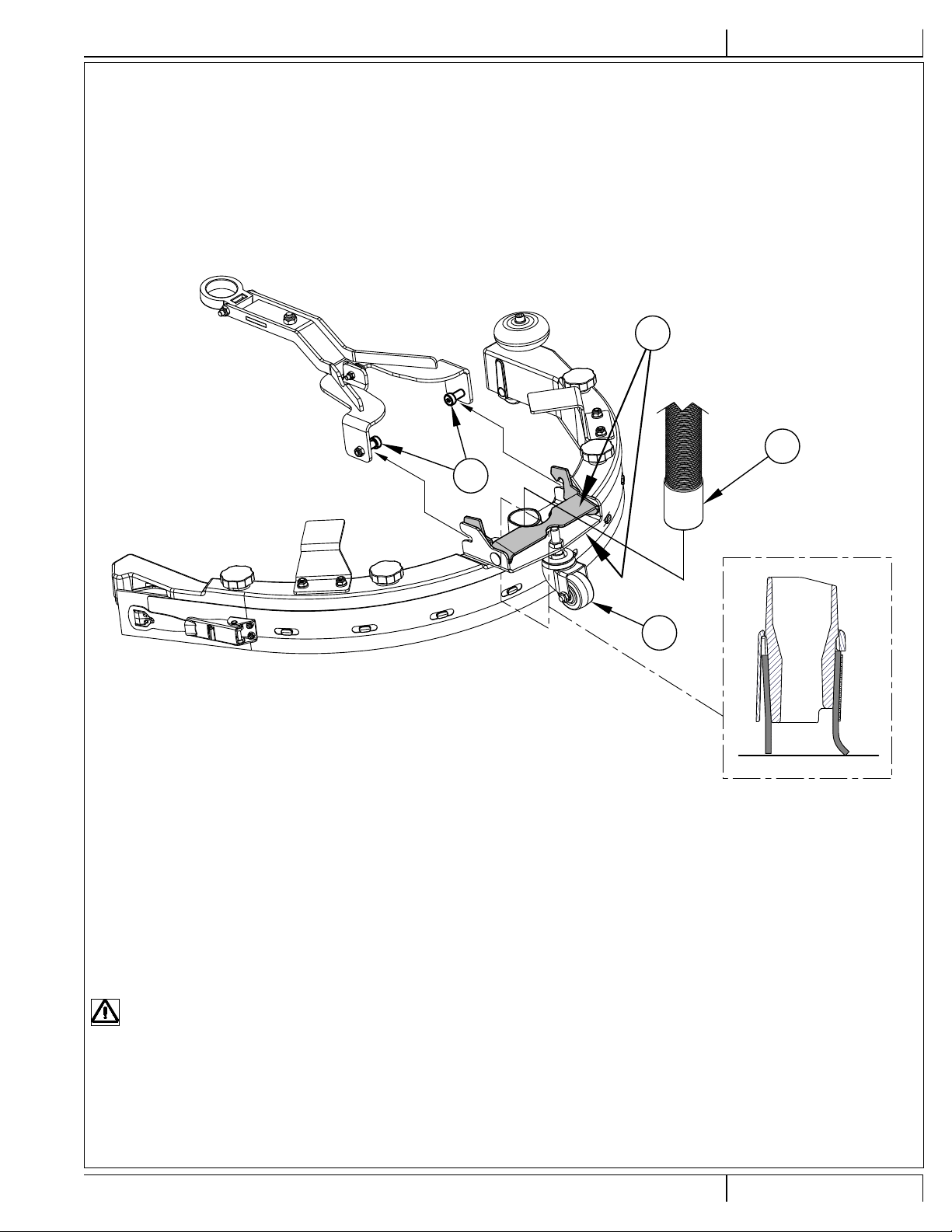

2 See Figure 2. Rotate the Squeegee Assembly (10) away from your side of the machine to create better access to the brush, (AA).

3 Lift the Scrub Deck Skirt (AB) up and slide the brush under the scrub deck.

4 If using a pad, install the pad on the pad holder.

5 To mount the Brush (AC) (or pad holder) lift the brush and align the Lugs (AD) on the brush with the holes on the mounting plate then turn to lock in place

(from the right side of the machine, turn the outside edge of brush towards the rear of machine as shown (AE)). NOTE: During operation the brush should

rotate in direction (AF).

FIGURE 2

8

AA

10

AB

AC

AE

AF

AD

5/2014 A - 11 56091120 - SC1500

Page 12

INSTRUCTIONS FOR USEA - ENGLISH

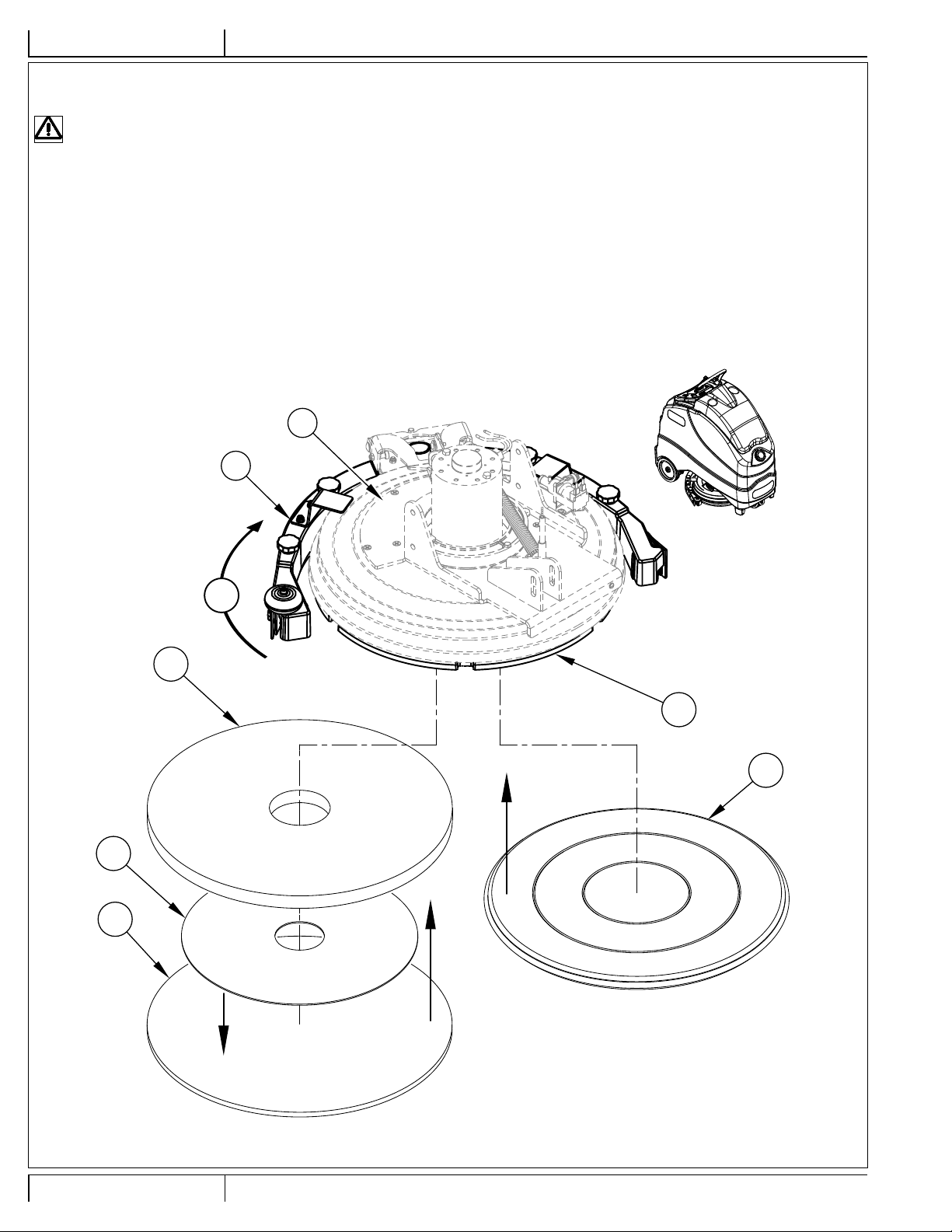

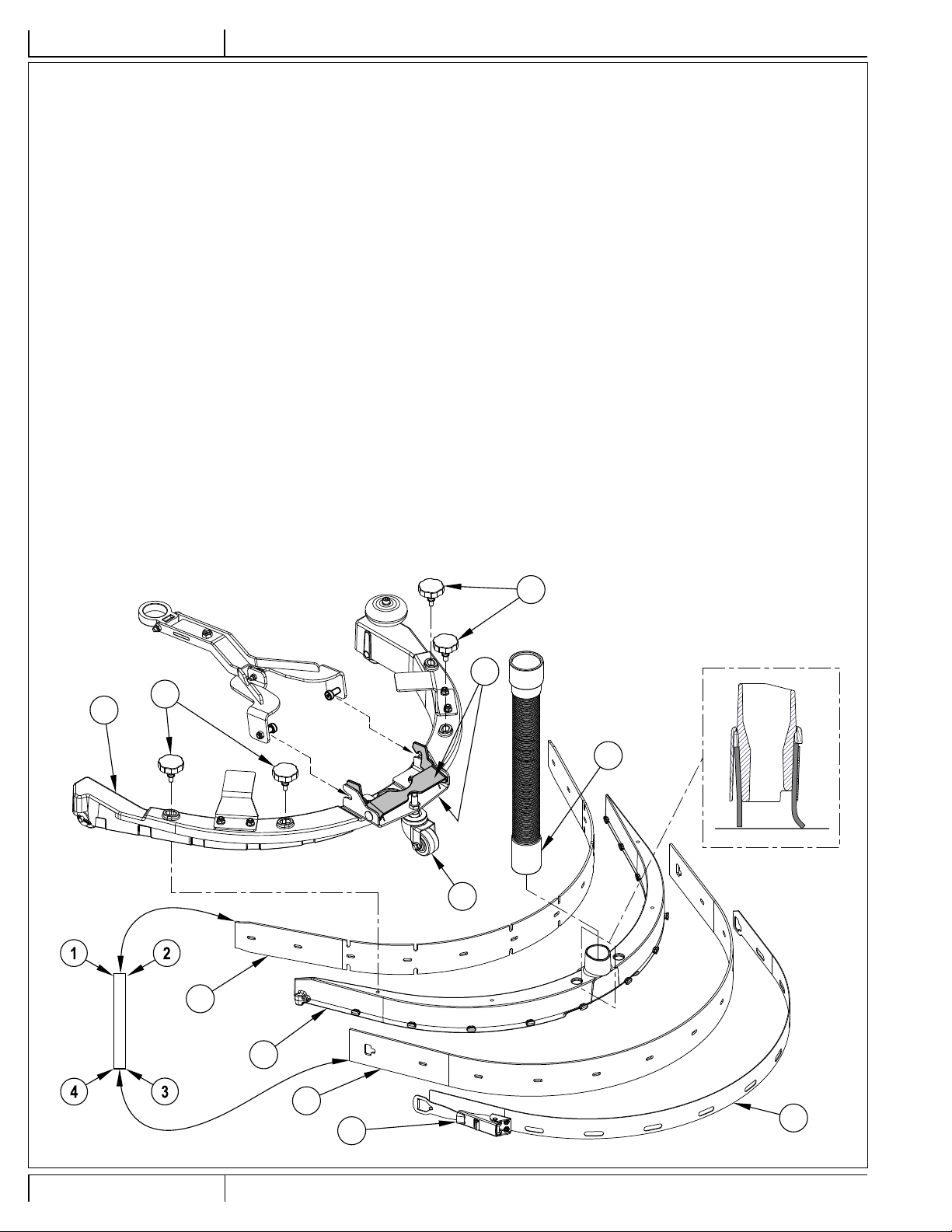

INSTALL THE PAD (REV SYSTEM)

1 Make sure the Scrub Deck is in the RAISED position. Make sure the Key Switch (A) is off (O).

CAUTION !

Turn the key switch off (O) and remove the key, before changing the pad

2 See Figure 3. Rotate the Squeegee Assembly (10) away from your side of the machine to create better access to the pad, (AA).

3 Daily Scrubbing: Slide a daily scrubbing pad (AE) or Microfi ber Pad (AB) under the pad driver, center it on the fi xed pad driver (AC) and lift it upwards and

press it onto the harpoon face of the pad driver.

4 Floor Finish Removal: Install a new red pad (AE) to the pad driver (AC) as described in step 3 above. If using the optional double sided Velcro (AF), attach

it to the center of maroon SPP pad (AD) and slide this assembly under the red pad and center it and then press upwards to attach this assembly to the red

pad. If the optional double sided Velcro is not used, install a new red as described in step 3 above and place a new maroon SPP pad on the fl oor centered

on the red pad. Lower the deck to the fl oor on top of the maroon SPP pad and check that it is centered.

NOTE: Never attach a maroon SPP pad directly to the pad driver, damage to the pad driver will result causing replacement.

FIGURE 3

8

10

AF

AD

AA

AE

AC

AB

A - 12 SC1500 - 56091120 5/2014

Page 13

ENGLISH - AINSTRUCTIONS FOR USE

INSTALL THE SQUEEGEE

1 See Figure 4. Squeeze the back of the Squeegee Mount Bracket (AA) to open and release the bracket once it’s in place over the deck arm Pins (AB).

2 Connect the Recovery Hose (AC) to the squeegee inlet.

3 Lower the scrub deck and squeegee, move the machine ahead slightly. If necessary adjust the rear squeegee height using the Rear Caster Wheel (AD) so

that the rear squeegee blade touches the fl oor evenly across its entire width and is bent over slightly as shown in the squeegee cross section (AE).

FIGURE 4

AA

AC

AB

AE

AD

FILL THE SOLUTION TANK

Read the cleaning chemical label and calculate the proper amount of chemical to mix for a tank that holds 12 US gallons (45 liters).

Open the Solution Tank Fill Cap (5) or the Solution Tank Rear Fill Port (17), then fi ll the tank 1/3 full of water, add the cleaning chemical, then fi ll up the tank the

remainder of the way. The amount of solution in the tank can be observed by looking at the Solution Tank Level Sight Tube (31).

CAUTION!

Use only low-foaming, non-fl ammable liquid detergents intended for automatic scrubber machine applications. Water temperature

should not exceed 130 degrees Fahrenheit (55 degrees Celsius).

5/2014 A - 13 56091120 - SC1500

Page 14

INSTRUCTIONS FOR USEA - ENGLISH

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX)

COMMON INSTRUCTIONS:

The Detergent Cartridge (3) is located under the Control Panel Housing (13). Fill the detergent cartridge with a maximum of 1 gallon (4 Liters) of

detergent. SERVICE NOTE: Remove the detergent cartridge from the machine prior to fi lling to avoid spilling detergent on the machine.

It is recommended that a separate cartridge be used for each detergent you plan to use. The detergent cartridges have a white decal on them so you can

write the detergent name on each cartridge to avoid mixing them up. When installing a new cartridge, remove the factory cap and place the cartridge in

the machine. Install the Dry Break Cap (AA) as shown in Figure 5.

The system should be purged of previous detergent when switching to a different detergent. SERVICE NOTE: Move machine over fl oor drain before

purging because a small amount of detergent will be dispensed in the process.

To Purge When Changing Detergent (SCRUB AND SOLUTION SYSTEMS MUST BE OFF):

1 Disconnect and remove the detergent cartridge.

2 Turn the key switch (A) to the ON (I) position. Wait a few seconds for the start-up sequence to fi nish.

3 Press and hold the Detergent Switch (R) and the Solution Switch (W) for 3 seconds. Release the switches when the chemical purge icon (F10) appears on

the display and the Detergent Indicator (S) starts fl ashing. NOTE: Once activated the purge process takes at least 10 seconds. See illustration on next page

for Detergent System indicators. Normally one purge cycle is adequate to purge the system.

To Purge Weekly (SCRUB AND SOLUTION SYSTEMS MUST BE OFF):

1 Disconnect and remove the detergent cartridge. Install and connect a Cartridge fi lled with clean warm water.

2 Follow steps 2 and 3 from “To Purge When Changing Detergent”.

When the detergent level is nearing the bottom of the cartridge it is time to refi ll or replace the cartridge.

SERVICE NOTE: Follow the “To Purge Weekly” instructions above if the machine is going to be stored for an extended period of time.

Detergent Ratio (SCRUB AND SOLUTION SYSTEM MUST BE ON):

No detergent is dispensed until the scrub and detergent systems are activated, direction is selected (L) or (N) and the Go Pedal (18) is pushed.

The Detergent Ratio/Percentage Indicator (F4) will always be displayed when the detergent system is on.

There are 4 modes of EcoFlex operation:

1. Chemical Free Cleaning Mode – During scrubbing, the detergent system can be turned off at any time to allow scrubbing with water only.

Press the Detergent Switch (R) until the Detergent Indicator (S) is OFF and Detergent Indicator Bar Graph (F5) displays both top and bottom

boxes empty.

2. Weak Detergent Mode – Detergent Indicator (S) ON, Detergent Indicator Bar Graph (F5) displays bottom box fi lled and top box empty.

Pressing the Detergent Switch (R) will cycle from weak to strong to OFF and back to weak in a repeating sequence. See below the steps “To

program the Weak Detergent Ratio/Percentage”.

3. Strong Detergent Mode – Detergent Indicator (S) ON, Detergent Indicator Bar Graph (F5) displays both top and bottom boxes fi lled. Pressing

the Detergent Switch (R) will cycle from weak to strong to OFF and back to weak in a repeating sequence. See below the steps “To program

the Strong Detergent Ratio/Percentage”. Do not use a detergent level exceeding the detergent manufacturer’s recommendation.

4. Burst of Power Cleaning Mode – Press the Burst of Power Switch (P) to temporarily (1 minute) engage the strong detergent strength, extra

scrub pressure, full vacuum power and increase the solution fl ow rate to the next available level. The Burst of Power Indicator (Q) will blink

during this 1 minute interval, after which all scrub parameters will return to their previous state.

To program the Strong Detergent Ratio/Percentage (set this fi rst)

Press the OneTouch™ Scrub Switch 1. (I) to activate the scrub system.

Press the Detergent Switch 2. (R) until the Bar Graph (F5) displays Strong detergent (both top and bottom boxes fi lled).

Press and hold the Detergent Switch 3. (R) again for 3 seconds to enter the programming mode. Once you have entered the strong detergent adjustment

mode the top box of (F5) will fl ash. Also the detergent ratio/percentage (F4) and indicator (S) will begin to fl ash.

While the indicators are fl ashing, pressing and releasing the detergent switch 4. (R) will cycle through the options. The ratio and it’s corresponding

percentage are displayed together.

Ratio = 1:32, 1:50, 1:64, 1:100, 1:128, 1:150, 1:200, 1:256, 1:300, 1:400.

Percentage = 3%, 2%, 1.5%, 1%, 0.8%, 0.66%, 0.5%, 0.4%, 0.3%, 0.25%.

Once the desired ratio/percentage is displayed on the screen 5. (F4), stop and it will save the setting after 3 seconds.

If the weak setting is currently set to a higher value than the new strong programmed setting, the software will automatically adjust the weak setting to 6.

be one value weaker than the strong setting.

To program the Weak Detergent Ratio/Percentage

Press the OneTouch™ Scrub Switch 1. (I) to activate the scrub system.

Press the Detergent Switch 2. (R) until the Bar Graph (F5) displays Weak detergent (bottom box fi lled and top box empty).

Press and hold the Detergent Switch 3. (R) again for 3 seconds to enter the programming mode. Once you have entered the weak detergent adjustment

mode the bottom box of (F5) will fl ash. Also the detergent ratio/percentage (F4) and indicator (S) will begin to fl ash.

While the indicators are fl ashing, pressing and releasing the detergent switch 4. (R) will cycle through the available options. The weak setting must be a

value weaker than or equal to the strong setting, so only the values that fall within that range will be displayed as you cycle through them.

Once the desired ratio/percentage is displayed on the screen 5. (F4), stop and it will save the setting after 3 seconds.

A - 14 SC1500 - 56091120 5/2014

Page 15

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX)

FIGURE 5

ENGLISH - AINSTRUCTIONS FOR USE

L

N

AA

3

A

W

R

S

P

Q

I

F

F10

Purge

Press and hold (R) & (W)

for 3 seconds to purge

F4

F5

Weak detergent

Strong detergent

Detergent OFF

5/2014 A - 15 56091120 - SC1500

Page 16

INSTRUCTIONS FOR USEA - ENGLISH

OPERATING THE MACHINE

WARNING!

Be sure you understand the operator controls and their functions.

While on ramps or inclines, avoid sudden stops. Avoid abrupt sharp turns. Use low speed down ramps.

To Scrub...

Follow the instructions in “Preparing the Machine for Use” section of this manual.

1 See Figure 6. Step onto the Platform (20) compressing Operator’s Presence Pedal (19). NOTE: Do not press the Go Pedal (18) until you are ready to move the

machine.

2 Turn the Key Switch (A) ON (I). Wait a few seconds for the start-up sequence to fi nish. The graphic display (F) will show the information screen [2]. Reference the

Battery Charge Level Indicator (F8) before proceeding.

3 To transport the machine to the work area, fi rst push the Forward Drive Switch (L) or Reverse Drive Switch (N) to select the direction of travel and then apply pressure

with your foot on the Go Pedal (18). Safety Feature: If you press and hold the Go Pedal (18) prior to pressing either Forward (L) or Reverse (N) an “error 03” (F6) will

appear on the screen preventing the machine from moving. If this occurs cycle the key switch OFF and ON in order to operate the machine.

An audible alert from the horn will sound in reverse. Adjust machine speed by rotating the Speed Adjustment Knob (K) clockwise to go faster or counterclockwise to go

slower.

4 Press and hold the Solution Switch (W) to pre-wet the fl oor, solution will be dispensed at the HIGH rate while the switch is held. NOTE: This will help prevent scarring

of the fl oor surface when starting to scrub with dry brushes. This can only be done prior to pressing the One-Touch Scrub Switch (I).

5 Press the One-Touch Scrub Switch (I). The graphic display (F) will change to the scrubbing screen [1]. The scrub deck and squeegee will be lowered to the fl oor. The

scrub, vacuum, solution and detergent systems are enabled and will all start when the Go Pedal (18) is activated. The scrub parameters are saved after each use.

When the key is turned ON and the One-Touch scrub button is pressed the scrub parameters (vacuum power, solution fl ow rate, scrub pressure setting and detergent

strength) will all be remembered from previous use.

Scrub: Each press of the Brush Pressure Switch (T) will change between STANDARD pressure ((F3) bottom box fi lled top box empty) and EXTRA pressure ((F3)

both bottom and top boxes fi lled). The scrub system can only be turned OFF by pressing the One-Touch Scrub Switch (I).

Solution: The solution fl ow rate can be changed independently of the scrub pressure by pressing the Solution Switch (W). Each press of the switch will cycle

between LOW, MEDIUM, HIGH, OFF and back to LOW. LOW is indicated when (F2) displays bottom box fi lled, MEDIUM is indicated when (F2) displays bottom and

middle boxes fi lled, HIGH is indicated when (F2) displays all three boxes fi lled, and OFF is indicated when (F2) displays all three boxes empty.

Vacuum: The vacuum level can be changed independently. Each press of the Vacuum Switch (Y) will cycle between LOW, HIGH, OFF and back to LOW. LOW is

indicated when Vacuum Level Bar Graph (F1) displays bottom box fi lled, HIGH is indicated when (F1) displays both bottom and top boxes fi lled. OFF is indicated

when (F1) displays both bottom and top boxes empty. NOTE: To pick up solution without scrubbing, press the Vacuum Switch (Y) while in transport mode. This will

cause the squeegee to lower and the vac motor to turn ON at the LOW level.

Detergent: See “Detergent System Preparation and Use (EcoFlex)” for more detailed information regarding the adjustment and use of the detergent system.

6 Daily Scrub: Begin scrubbing by driving the machine forward in a straight line at a safe speed and overlap each path by 2-3 inches (50-75 mm). Adjust the machine

speed, scrub pressure, solution fl ow and detergent level when necessary according to the condition of the fl oor. NOTE: The machine speed can be adjusted by

rotating the Speed Adjustment Knob (K) clockwise to go faster or counterclockwise to go slower.

Floor Finish Removal (REV model only): Ensure there is a red pad attached directly to the fi xed pad driver and that the maroon SPP pad is not attached to the fi xed

pad driver. Adjust the scrub parameters as follows: Adjust the machine speed potentiometer to a slow scrub speed approximated by that shown in Figure 6 (K). Adjust

the solution fl ow rate to low, the scrub pressure to high and turn detergent off. The vacuum power setting can be set to either low or high.

7 Press the Burst of Power Switch (P) to temporarily (1 minute) engage the strong detergent strength, extra scrub pressure, full vacuum power and increase the solution

fl ow rate to the next available level. The Burst of Power Indicator (Q) will blink during this 1 minute interval, after which all scrub parameters will return to their previous

state.

CAUTION!

To avoid damaging the fl oor, only start and stop the scrubbing function while the machine is in motion.

8 When scrubbing, check behind the machine occasionally to see that all of the waste water is being picked up. If there is water trailing the machine, you may be

dispensing too much solution, the recovery tank may be full, or the squeegee tool may require adjustment.

9 For extremely dirty fl oors, a one-pass scrubbing operation may not be satisfactory and a “double-scrub” operation may be required. This operation is the same as

a one-pass scrubbing except on the fi rst pass the squeegee is in the up position. Lift up the squeegee assembly and rotate the double scrub bracket (AA) down, to

hold the squeegee off the fl oor. This allows the cleaning solution to remain on the fl oor to work longer. The fi nal pass is made over the same area, with the squeegee

lowered to pick up the accumulated solution.

10 The recovery tank has a shut-off fl oat (14) that causes a change in pitch in the vac motor. When this fl oat is activated, the recovery tank must be emptied. The machine

will not pick up water with the fl oat activated.

11 When the operator wants to stop scrubbing:

Press the One-Touch Scrub Switch (I) once. This will automatically stop the scrub brushes and solution fl ow and the scrub deck will raise up. The squeegee will raise

up after a brief delay with the scrub deck and the vacuum will stop after a brief time delay (this is to allow any remaining water to be picked up without turning the

vacuum back on) if the vacuum switch is pressed during this time delay the vacuum will turn off.

12 Drive the machine to a designated waste water “DISPOSAL SITE” and empty the recovery tank. To empty, pull the Recovery Tank Drain Hose (30) from its rear

storage area, then unscrew the cap (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). The drain hose can

be squeezed to regulate the fl ow. Unlatch (29) and lift open the Recovery Tank Cover (13) to inspect and empty the Debris Catch Tray (16) in the recovery tank. Refi ll

the solution tank and continue scrubbing.

NOTE: Make sure the Recovery Tank Cover (13) and the Recovery Tank Drain Hose (30) cap are properly seated or the machine will not pick-up water correctly.

When the batteries require recharging the Battery Low Voltage Screen [3] will come on. Then the scrub brushes and solution fl ow will stop and the scrub deck will raise up.

Once the battery voltage drops below a second cutoff level the squeegee will raise up and the vacuum will stop after a brief delay. Transport the machine to a service area

and recharge the batteries according to the instructions in the Battery section of this manual.

A - 16 SC1500 - 56091120 5/2014

Page 17

FIGURE 6

ENGLISH - AINSTRUCTIONS FOR USE

50A 5A 20A 25A

K

I

L

N

W

A

Y

T

P

Q

F

[1]

F1

F2

F3

F4

F5

14

13

16

29

30

18

19

[2]

[3]

F6

F8

!

AA

20

5/2014 A - 17 56091120 - SC1500

Page 18

INSTRUCTIONS FOR USEA - ENGLISH

revised 8/2014

AFTER USE

1 When fi nished scrubbing, press the One-Touch Scrub Switch (I), this will automatically raise, retract and stop all the machine systems (brush, squeegee,

vacuum, solution and detergent. Then drive the machine to a service area for daily maintenance and review of other needed service upkeep.

2 To empty the solution tank:

Direct the Solution Tank Drain Hose (22) toward a designated “DISPOSAL SITE” and open the Solution Drain Valve (34). Also the tank can be drained by

closing the Solution Shutoff Valve (27) and removing the cap from the Solution Filter (26), then open the Solution Shutoff Valve to drain the solution out

through the fi lter. Rinse the tank with clean water.

3 To empty the recovery tank, pull the Recovery Tank Drain Hose (30) from its storage area. Direct the hose to a designated “DISPOSAL SITE” and unscrew

the cap (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). Unlatch (29) and lift open the

Recovery Tank Cover (13) set the prop rod (32). Inspect and empty the Debris Catch Tray (16) in the recovery tank. Rinse the tank with clean water.

4 Remove the brush or pad holder. Rinse the brush or pad in warm water and hang up to dry.

5 Remove the squeegee, rinse it with warm water and hang it up to dry.

6 Check the maintenance schedule below and perform any required maintenance before storage.

7 Store the machine indoors in a clean dry place. Keep from freezing. Leave the tanks open to air them out.

8 Turn the Key Switch (A) OFF (O) and remove the key.

9 Batteries are the most expensive replacement item on this machine. To protect your investment and to get as many cycles from the batteries as possible,

remember the following:

When installing batteries make certain the machine and charger are programed for the correct battery type.

Batteries will last longer if they are kept fully charged.

Batteries will prematurely fail if stored in a discharged state.

Battery chargers will not over or undercharge the batteries.

Every day after use, the battery charger must be plugged in and the charger must be allowed to run through a full charging sequence to fully charge the

batteries. This may take 8-12 hours depending on the battery status.

Always have the charger plugged into an AC outlet if the machine will not be used for a longer period of time to keep the battery(s) charged.

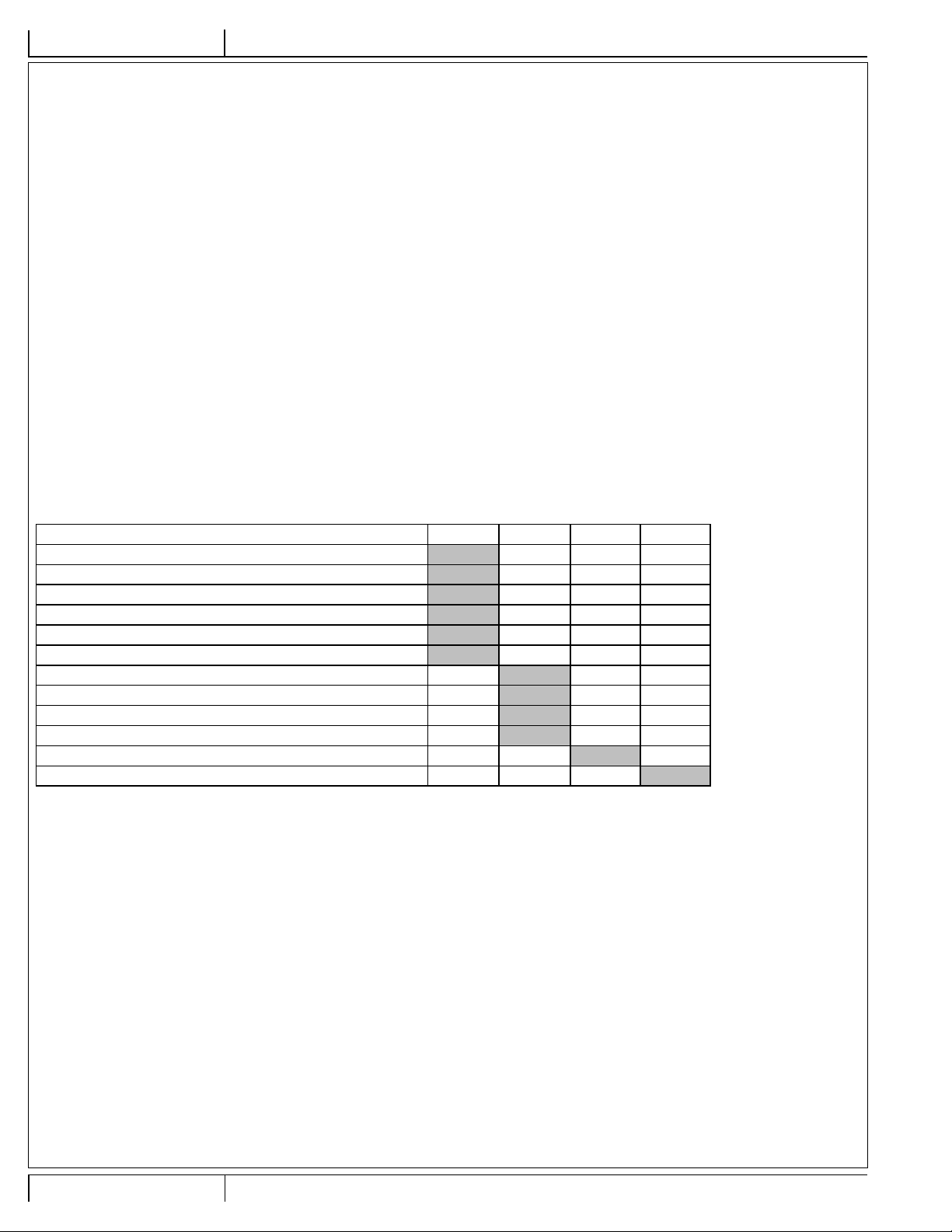

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Monthly Yearly

Charge Batteries X

Check/Clean Tanks & Hoses X

Check/Clean the Brushes/Pads X

Check/Clean the Squeegee X

Check/Clean Vacuum Shut-Off Float X

Empty/Clean Debris Catch Tray in Recovery Tank X

Check Each Battery Cell(s) Water Level X

Inspect Scrub Housing Skirt X

Inspect and clean Solution Filter X

Purge Detergent System X

Lubrication of Machine X

* Check Carbon Brushes X

* Have an Authorized Advance Service Center check the vacuum motor carbon motor brushes once a year or after 300 operating hours. The brush and drive

motor carbon brushes should be checked every 500 hours or once a year.

A - 18 SC1500 - 56091120 5/2014

Page 19

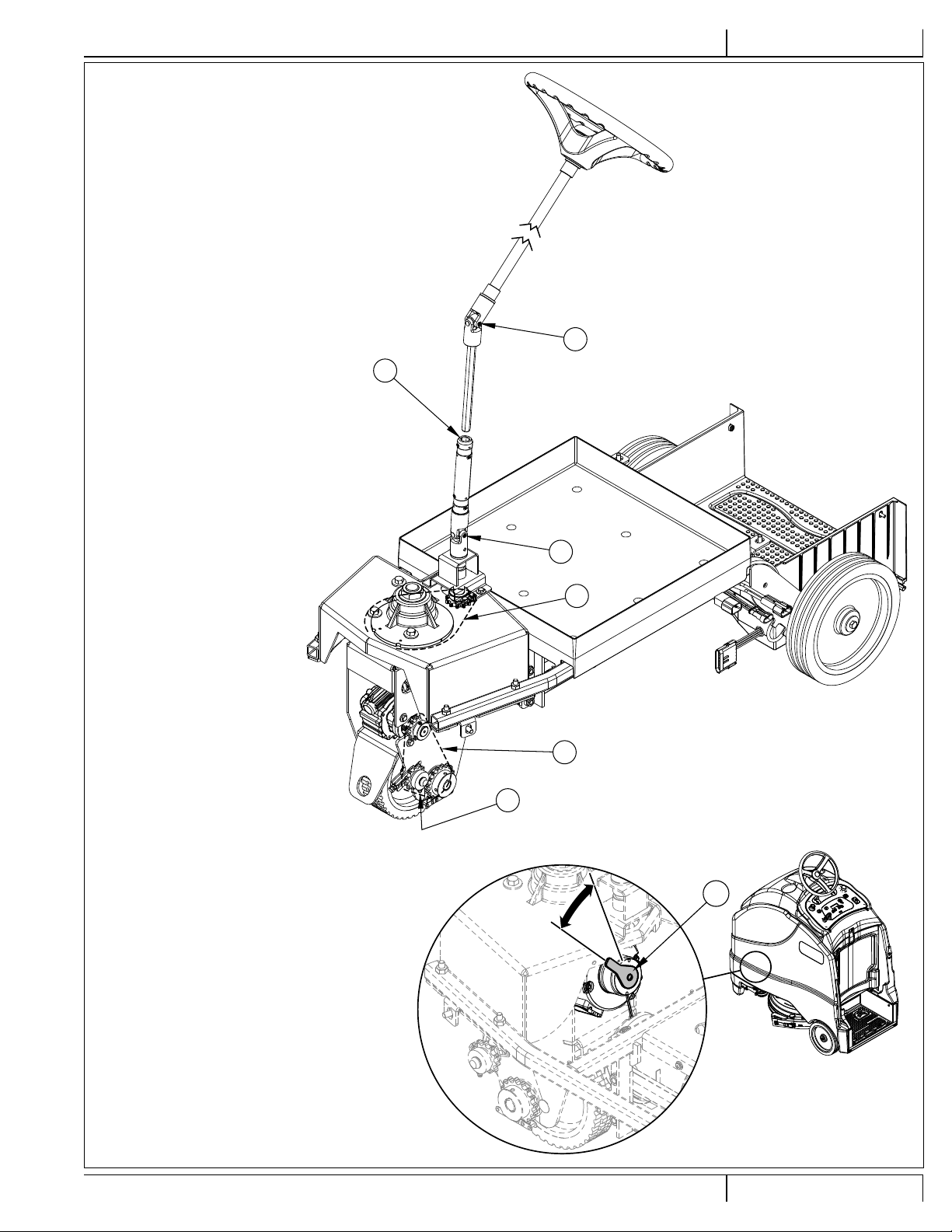

LUBRICATING THE MACHINE

Apply grease to (or grease fi tting locations) (AA):

Use grease type Lubriplate® 730-2 or equivalent

• Steering Chain

• Drive Wheel Chain

• Drive Chain Idler Sprocket (grease fi tting)

• Steering Shaft (steering assembly tube)

Once a month, apply light machine oil to lubricate the (AB):

• Steering shaft universal joints

AA

ENGLISH - AINSTRUCTIONS FOR USE

FIGURE 7

AB

ELECTROMAGNETIC BRAKE

See Figure 8. The drive wheel motor has a built in

electromagnetic brake that is engaged whenever the Key

Switch (A) is OFF or the Go Pedal (18) is not being pressed,

machine in neutral. This brake can be manually overridden if

necessary by reaching up around the back of the front drive

wheel and rotating the Brake Arm (AC) up as shown. This

should only be done in the event you need to push or pull the

unit. Remember to re-engage the brake arm once you fi nish

moving the machine. NOTE: Turn the drive wheel 45° to the

right for easier access to the brake arm.

AB

AA

AA

AA

FIGURE 8

AC

5/2014 A - 19 56091120 - SC1500

Page 20

INSTRUCTIONS FOR USEA - ENGLISH

CHARGING WET BATTERIES

Charge the batteries each time the machine is used or when the Battery Charge Level Indicator (F8) is reading less than full.

WARNING!

Do not top off the batteries before charging. Check to ensure the plates are covered only.

Charge batteries in a well-ventilated area. If battery acid makes contact with your skin, fl ush the affected area with water for 5

minutes and seek medical attention.

Do not smoke while servicing the batteries.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries

to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

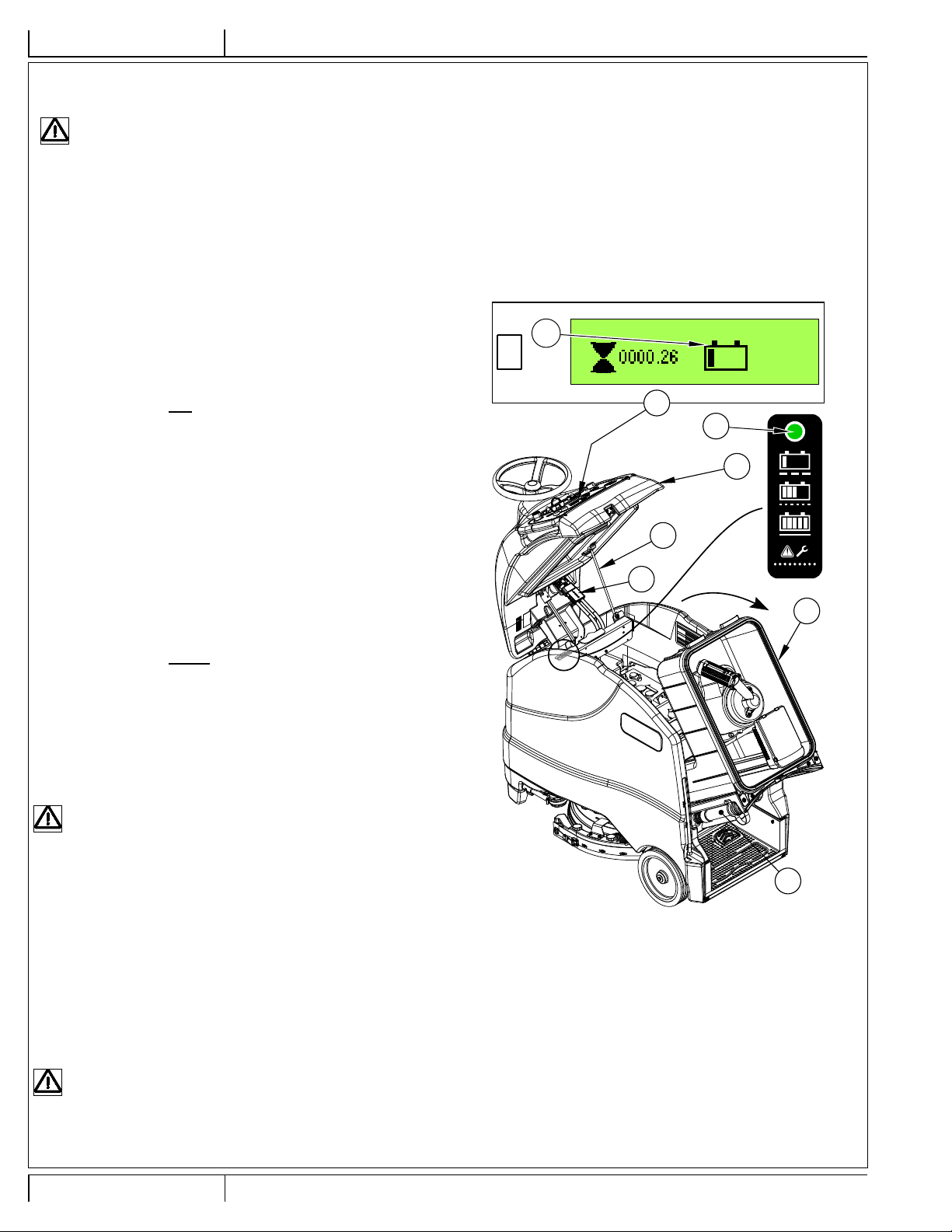

If your machine shipped with an onboard battery charger do the following:

1 Turn the Key Switch (A) OFF.

2 See Figure 9. Open the Control Panel Housing (13) set the Prop Rod (32).

3 Empty the Recovery Tank (15) using the Recovery Tank Drain Hose (30). Tip

the Recovery Tank (15) back for proper ventilation.

4 Unwind the electrical cord for the onboard charger near the front of the machine

and plug it into a properly grounded outlet. Refer to the OEM product manual

for more detailed operating instructions. While AC power is applied to the

onboard charger all machine functions are disabled.

5 The Battery Charge Status LED (35) will begin fl ashing green. This indicates

that the charging cycle has begun. As the charging cycle continues, the fl ashing

of the LED will become more rapid.

6 When the Battery Charge Status LED (35) is steady on, the charging process

has completed. This may take several hours depending upon the condition of

the batteries before charging.

If your machine shipped without an onboard battery charger do the following:

1 Turn the Key Switch (A) OFF.

2 See Figure 9. Open the Control Panel Housing (13) set the Prop Rod (32).

3 Empty the Recovery Tank (15) using the Recovery Tank Drain Hose (30). Tip

the Recovery Tank (15) back for proper ventilation.

4 Disconnect the batteries from the machine and push the connector from the

charger into the Machine Battery Connector (33). Follow the instructions on the

battery charger. SERVICE NOTE: Make sure you plug the battery charger into

the connector that attaches to the batteries.

FIGURE 9

F8

2

F

35

13

32

33

15

CAUTION!

To avoid damage to fl oor surfaces, wipe water and acid from the top

of the batteries after charging. Under or overcharging will shorten

battery life and limit performance. Be sure to FOLLOW PROPER

30

CHARGING INSTRUCTIONS!

CHECKING THE BATTERY WATER LEVEL

Check the water level of the batteries at least once a week.

Remove the vent caps and check the water level in each battery cell. Use distilled or demineralized water in a battery fi lling dispenser (available at most auto parts

stores) to fi ll each cell to the level indicator (or to .39 inches / 10 mm over the top of the separators). DO NOT over-fi ll the batteries!

CAUTION!

Acid can spill onto the fl oor if the batteries are overfi lled.

Tighten the vent caps. Wash the tops of the batteries with a solution of baking soda and water (2 tablespoons of baking soda to 1 liter of water).

A - 20 SC1500 - 56091120 5/2014

Page 21

ENGLISH - AINSTRUCTIONS FOR USE

CHARGING GEL/AGM (VRLA) BATTERIES

Charge the batteries each time the machine is used or when the Battery Charge Level Indicator (F8) is reading less than full.

WARNING!

Charge batteries in a well-ventilated area. If battery acid makes contact with your skin, fl ush the affected area with water for 5

minutes and seek medical attention.

Do not smoke while servicing the batteries.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to

prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

CAUTION!

Your voltage regulated lead acid (VRLA) battery will deliver superior

performance and life ONLY IF IT IS RECHARGED PROPERLY! Under

or overcharging will shorten battery life and limit performance. Be

sure to FOLLOW PROPER CHARGING INSTRUCTIONS! DO NOT

ATTEMPT TO OPEN THIS BATTERY! If a VRLA battery is opened, it

loses its pressure and the plates become oxygen contaminated. THE

WARRANTY WILL BE VOIDED IF THE BATTERY IS OPENED.

If your machine shipped with an onboard battery charger do the following:

1 Turn the Key Switch (A) OFF.

2 See Figure 9. Open the Control Panel Housing (13) set the Prop Rod (32).

3 Empty the Recovery Tank (15) using the Recovery Tank Drain Hose (30). Tip the

Recovery Tank (15) back for proper ventilation.

4 Unwind the electrical cord for the onboard charger near the front of the machine

and plug it into a properly grounded outlet. Refer to the OEM product manual for

more detailed operating instructions. While AC power is applied to the onboard

charger all machine functions are disabled.

5 The Battery Charge Status LED (35) will begin fl ashing green. This indicates that

the charging cycle has begun. As the charging cycle continues, the fl ashing of the

LED will become more rapid.

6 When the Battery Charge Status LED (35) is steady on, the charging process

has completed. This may take several hours depending upon the condition of the

batteries before charging.

If your machine shipped without an onboard battery charger do the following:

1 Turn the Key Switch (A) OFF.

2 See Figure 9. Open the Control Panel Housing (13) set the Prop Rod (32).

3 Empty the Recovery Tank (15) using the Recovery Tank Drain Hose (30). Tip the

Recovery Tank (15) back for proper ventilation.

4 Disconnect the batteries from the machine and push the connector from the

charger into the Machine Battery Connector (33). Follow the instructions on the

battery charger. SERVICE NOTE: Make sure you plug the battery charger into the

connector that attaches to the batteries.

IMPORTANT: Make sure you have an appropriate charger for use on Gel cell

batteries. Use only “voltage-regulated” or “voltage-limited” chargers. Standard

constant current or taper current chargers MUST NOT be used. A temperaturesensing charger is recommended, as manual adjustments are never accurate and

will damage any VRLA battery.

FIGURE 9

F8

2

F

35

13

32

33

15

30

5/2014 A - 21 56091120 - SC1500

Page 22

INSTRUCTIONS FOR USEA - ENGLISH

SQUEEGEE MAINTENANCE

If the squeegee leaves narrow streaks or water, the blades may be dirty or damaged. Remove the squeegee, rinse it under warm water and inspect the blades.

Reverse or replace the blades if they are cut, torn, wavy or worn.

To Reverse or Replace the Rear Squeegee Wiping Blade...

1 See Figure 10. Raise the deck and squeegee assembly off the fl oor, then unsnap the Rear Squeegee Blade Removal Latch (23).

2 Remove the Tension Strap (AA).

3 Slip the rear blade (AB) off the alignment pins.

4 The squeegee blade has 4 working edges. Turn the blade so a clean, undamaged edge points toward the front of the machine. Replace the blade if all 4

edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee tilt if necessary.

To Reverse or Replace the Front Squeegee Blade...

1 Raise the squeegee off the fl oor, then rotate the squeegee towards the outside of the machine to access. Disconnect the squeegee hose (AD) from the

squeegee. Squeeze the back of the Squeegee Mount Bracket (AE) to open the bracket and pull the squeegee assembly off the machine.

2 Loosen the four Squeegee Cover Knobs (11). Then lift the Squeegee Cover (AF) off of the Squeegee Casting (AG).

3 Slip the front blade (AH) off the alignment pins.

4 The squeegee blade has 4 working edges. Turn the blade so a clean, undamaged edge points toward the front of the machine. Replace the blade if all 4

edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee tilt if necessary.

SQUEEGEE ADJUSTMENT

There is only one squeegee assembly adjustment possible, tilt.

Adjust the squeegee tilt if the squeegee is not wiping the fl oor dry.

1 Park the machine on a fl at, even surface and lower the squeegee. Then drive the machine forward enough to have the squeegee blades fold over to the

rear.

2 Adjust the squeegee tilt using the Rear Caster Wheel (AC) so that the rear squeegee blade touches the fl oor evenly across its entire width and is bent over

slightly as shown in the squeegee cross section (AI).

FIGURE 10

AF

11

AH

AC

AE

11

AI

AD

AG

AB

AA

23

A - 22 SC1500 - 56091120 5/2014

Page 23

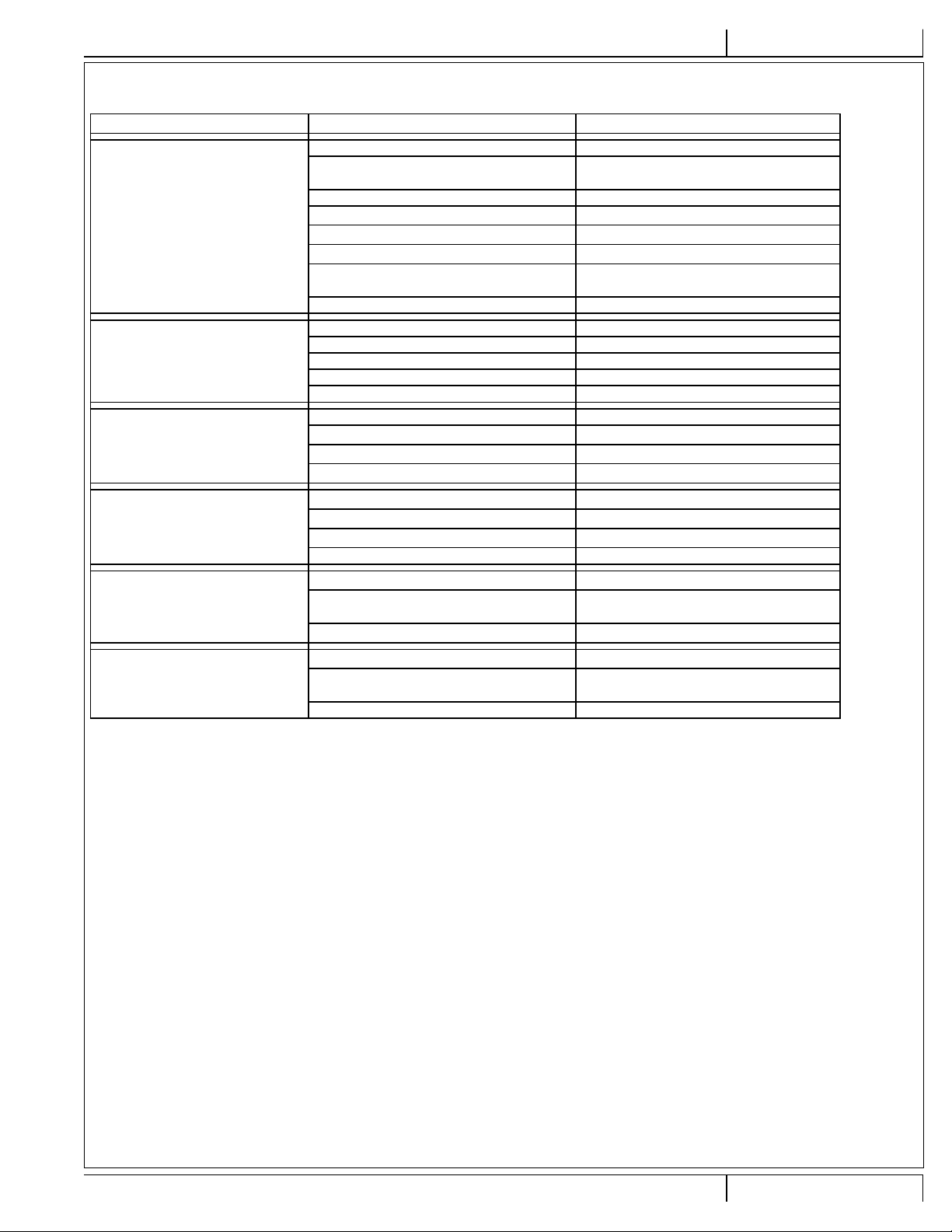

GENERAL MACHINE TROUBLESHOOTING

Problem Possible Cause Remedy

Worn or torn squeegee blades Reverse or replace

Adjust so blades touch fl oor evenly

across entire width

Secure drain hose cap or replace

Replace gasket / Seat cover properly

Clean squeegee assembly

Remove debris

Flush lines and clean solution fi lter

Open solution shutoff valve

Clean or replace valve

Reconnect battery connectors

Check for electrical short circuit & reset

Reset the Emergency Stop Switch

Check error fault codes

(contact Advance Authorized Service Center)

Check for drive motor overload

Fill detergent container

Purge system, straighten lines to

remove any kinks

Poor water pick-up

Poor scrubbing performance

Inadequate or no solution fl ow

Machine does not power ON

No FWD/REV wheel drive

No Detergent Flow

Squeegee out of adjustment

Recovery tank full Empty recovery tank

Recovery Tank Drain Hose (30) leak

Recovery Tank Cover (13) gasket leak

Debris caught in Squeegee (10)

Recovery Hose between squeegee and recovery

tank clogged

Vacuum set to quiet mode Set vacuum to high

Worn brush or pad Replace brush or pad

Wrong brush or pad type Consult Advance

Wrong cleaning chemical Consult Advance

Moving machine too fast Slow down

Not using enough solution Increase solution fl ow

Solution tank empty Fill solution tank

Solution lines, valves or fi lter (26) clogged

Solution Shutoff Valve (27) closed

Solution Solenoid Valve (25)

Machine Battery Connector (33) disconnected

Tripped 5 Amp circuit breaker (E)

Key Switch (A) failure (contact Advance Authorized Service Center)

Charger Interlock engaged Unplug Charger

Emergency Stop Switch (B) tripped

Drive system speed controller

Tripped 50 Amp circuit breaker (D)

Empty Detergent Container (3)

Plugged or kinked detergent fl ow line

Detergent pump Check pump, wiring and lines

ENGLISH - AINSTRUCTIONS FOR USE

5/2014 A - 23 56091120 - SC1500

Page 24

INSTRUCTIONS FOR USEA - ENGLISH

ACCESSORIES / OPTIONS

In addition to the standard components, the machine can be equipped with the following accessories/options, according to the machine specifi c use:

• Brushes with harder or softer bristles

• Pads with more or less abrasiveness

• Shelf Charger

• Battery Full Indicator

For further information about the above-mentioned accessories, contact an authorized Retailer.

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model SC1500-X20D SC1500-X20R

Model No. 56104000 56104001

Voltage, Batteries V 24V 24V

Battery Capacity Ah 260 260

Protection Grade IPX3 IPX3

Sound Pressure Level

IEC 60335-2-72: 2002 Amend. 1:2005, ISO 11201

Gross Vehicle Weight / Transport Weight lbs / kg 897 / 407 897 / 407

Empty Weight lbs / kg 620 / 281 620 / 281

Maximum Wheel Floor Loading (center front) psi / N/mm

Maximum Wheel Floor Loading (right rear) psi / N/mm

Maximum Wheel Floor Loading (left rear) psi / N/mm

Vibrations at the Hand Controls (ISO 5349-1) m/s

Vibrations for the Whole Body (ISO 2631-1) m/s

Gradeability Transport 14% (7.1°) 14% (7.1°)

Gradeability Cleaning 8.3% (4.75°) 8.3% (4.75°)

dB(A) 63 dB LpA, ±3 dB KpA 62 dB LpA, ±3 dB KpA

2

2

2

2

2

160 / 1.10 160 / 1.10

139 / 0.96 139 / 0.96

135 / 0.93 135 / 0.93

0.17 0.82

0.01 0.13

revised 9/2014

Material Composition and Recyclability

Type % of machine weight % recyclable

Aluminum 2% 100%

Electrical / motors / engines - misc. 14% 38%

Ferrous metals 41% 100%

Harnesses / cables 6% 83%

Liquids 0% 0%

Plastic - non-recyclable 4% 0%

Plastic - recyclable 5% 100%

Polyethylene 27% 90%

Rubber 1% 33%

A - 24 SC1500 - 56091120 5/2014

Page 25

Page 26

INSTRUCCIONES DE USOB - ESPAÑOL

ÍNDICE

Página

Introducción .......................................................................................... B-3

Precauciones y advertencias ....................................................... B-4 - B-5

Conozca su máquina ................................................................... B-6 - B-7

Panel de control ........................................................................... B-8 - B-9

Preparación de la máquina para su uso

Instalación de las baterías .................................................................. B-10

Instalación del cepillo (disco) .............................................................. B-11

Instalación de la bayeta (REV) ........................................................... B-12

Instalación de la rasqueta ................................................................... B-13

Llenado del depósito de solución .......................................................B-13

Sistema de detergente ............................................................ B-14 - B-15

Manejo de la máquina

Fregado ................................................................................... B-16 - B-17

Después de la utilización .................................................................... B-18

Programa de mantenimiento ..............................................................B-18

Lubricación de la máquina .................................................................. B-19

Freno electromagnético ...................................................................... B-19

Recarga de las baterías (líquido) .......................................................B-20

Comprobación del nivel de agua de las baterías ...............................B-20

Recarga de las baterías (gel) .............................................................B-21

Mantenimiento de la rasqueta ............................................................B-22

Ajuste de la rasqueta .......................................................................... B-22

Resolución de problemas ................................................................... B-23

Especifi caciones técnicas ................................................................... B-24

B - 2 SC1500 - 56091120 5/2014

Page 27

ESPAÑOL - BINSTRUCCIONES DE USO

INTRODUCCIÓN

Este manual le ayudará a sacar el máximo rendimiento a su fregadora Advance. Léalo con atención antes de utilizar la máquina.

Nota: Los números que aparecen en negrita entre paréntesis indican elementos ilustrados en las páginas B-6 – B-9.

Esta máquina sólo es adecuada para el uso comercial, por ejemplo en hoteles, colegios, hospitales, fábricas, tiendas, ofi cinas y negocios de alquiler. La SC1500

es una máquina de limpieza de pisos a batería.

COMPONENTES Y SERVICIO

Las reparaciones, cuando sean necesarias, deben ser realizadas por su Centro Autorizado de Servicio Advance, que utiliza personal de servicio formado en

fábrica y lleva un inventario de las piezas de repuesto y accesorios Advance originales.

Llame al DISTRIBUIDOR ADVANCE que se indica a continuación para lo referente a piezas de repuesto y servicio. Por favor, especifi que el modelo y el número

de serie cuando hable de su máquina.

MODIFICACIONES

Las modifi caciones y los agregados a la máquina de limpieza que afecten su capacidad y su funcionamiento seguro no serán realizados por el cliente o el usuario

sin la autorización previa y por escrito de Nilfi sk-Advance Inc. Las modifi caciones que no cuenten con la aprobación correspondiente anularán la garantía de la

máquina y harán que el cliente sea responsable de cualquier accidente resultante.

PLACA DE IDENTIFICACIÓN

El Número de modelo y Número de serie de la máquina se indican en la placa de identifi cación instalada en la misma. Esta información es necesaria a la hora

de solicitar repuestos para la máquina. Utilice el espacio situado más adelante para anotar el número de modelo y el número de serie de la máquina para futuras

consultas.

NÚMERO DE MODELO __________________________________________________

NÚMERO DE SERIE ____________________________________________________

DESEMBALAJE DE LA MÁQUINA

Cuando reciba la máquina, examine con atención la caja del embalaje y la máquina, con el fi n de comprobar si existe algún daño. Si observa algún daño, guarde

la caja de embalaje (si procede) para que se pueda inspeccionar. Póngase en contacto inmediatamente con el Departamento de Servicio al Cliente de Advance

para presentar una reclamación por daños en transporte. Consulte la hoja de instrucciones de desembalaje incluida con la máquina para sacar la máquina del

palet.

TRANSPORTE DE LA MÁQUINA

¡PRECAUCIÓN!

Antes de transportar la máquina sobre un camión o remolque abierto, asegúrese de. . .

• Que todos los depósitos estén vacíos.

• Que la tapa del depósito de recuperación esté bien cerrada.

• Que la máquina esté fi rmemente sujetada – véase Puntos de Sujeción (6) en Conozca su máquina.

• El freno electromagnético de la máquina esté activo (no desactivado manualmente).

ADVERTENCIA:

Los Productos a la venta en este Manual contienen, o pueden contener, productos químicos reconocidos por algunos gobiernos (como el Estado

de California, según lo indica en su Proposición 65, Ley de Advertencia Regulatoria) como causantes de cáncer, defectos de nacimiento u

otros daños reproductivos. En algunas jurisdicciones (incluido el Estado de California), los compradores de estos Productos que los coloquen

en servicio en un emplazamiento laboral o en un espacio de acceso público tienen la obligación regulatoria de realizar determinados avisos,

advertencias o divulgaciones respecto de los productos químicos contenidos o posiblemente contenidos en los Productos utilizados en tal lugar.

Es la responsabilidad del comprador conocer y cumplir con todas las leyes y reglamentaciones relacionadas con el uso de estos Productos en

tales entornos. El Fabricante niega toda responsabilidad de informar a los compradores sobre requisitos específi cos que pueden regir el uso de

los Productos en tales entornos.

5/2014 B - 3 56091120 - SC1500

Page 28

INSTRUCCIONES DE USOB - ESPAÑOL

PRECAUCIONES Y ADVERTENCIAS

SÍMBOLOS

Advance utiliza los símbolos que se indican más abajo para señalar situaciones potencialmente peligrosas. Lea siempre

con atención esta información y tome las medidas necesarias para la protección de las personas y la propiedad.

¡PELIGRO!

Se utiliza para advertir de riesgos inmediatos que producirán lesiones personales graves o incluso fatales.

¡ADVERTENCIA!

Se utiliza para llamar la atención sobre una situación que podría producir lesiones personales graves.

¡PRECAUCIÓN!

Se utiliza para llamar la atención sobre una situación que podría provocar lesiones personales leves o daños en la

máquina u otros objetos.

Lea todas las instrucciones antes de utilizar la máquina.

INSTRUCCIONES GENERALES DE SEGURIDAD

Se incluyen precauciones y advertencias específi cas que advierten de los peligros potenciales de daños a la máquina o

lesiones personales.

Esta máquina es para uso comercial, por ejemplo en hoteles, colegios, hospitales, fábricas, tiendas y ofi cinas, y no para

usos relacionados con el mantenimiento doméstico.

¡ADVERTENCIA!

• Esta máquina únicamente deben utilizarla personas autorizadas y con la debida formación.

• Esta máquina no debe ser utilizada por personas (incluidos niños) con capacidades físicas, sensoriales o mentales

reducidas, o con falta de experiencia y conocimientos.

• Al circular sobre rampas o pendientes, evite las paradas bruscas. Evite las curvas muy cerradas. Circule lentamente

al bajar rampas.

• Preste atención al peso bruto del vehículo de la máquina al cargarla, transportarla, elevarla o apoyarla.

• Mantenga las chispas, llamas y materiales de fumadores alejados de las baterías. Durante el funcionamiento normal

se desprenden gases explosivos.

• Al recargar las baterías se produce gas de hidrógeno altamente explosivo. Recargue las baterías exclusivamente en

zonas bien ventiladas, lejos de llamas sin proteger. No fume mientras recarga las baterías.

• Quítese todas las joyas cuando trabaje cerca de componentes eléctricos.

• Apague el interruptor de llave (O) y desconecte las baterías antes de realizar mantenimiento o reparaciones en los

componentes eléctricos.

• Nunca trabaje debajo de una máquina sin colocar antes bloques o soportes de seguridad que sostengan la misma.

• No aplique sustancias limpiadoras infl amables ni utilice la máquina sobre estas sustancias o cerca de ellas, ni

tampoco en zonas en las que haya líquidos infl amables.

• No limpie esta máquina con una limpiadora a presión.

• Use solamente los cepillos suministrados junto con el aparato o aquellos especifi cados en el manual de instrucciones.

El uso de otros cepillos puede afectar negativamente a la seguridad.

B - 4 SC1500 - 56091120 5/2014

Page 29

ESPAÑOL - BINSTRUCCIONES DE USO

PRECAUCIONES Y ADVERTENCIAS - CONTINUACIÓN

¡PRECAUCIÓN!

• Esta máquina no ha sido aprobada para su uso en vías públicas.

• Esta máquina no es adecuada para limpiar polvos peligrosos.

• No utilizar discos de escarifi cación ni piedras abrasivas. No se podrá responsabilizar a Advance de daño alguno

a las superfi cies de los suelos causado por escarifi cadores o piedras abrasivas (también puede causar daños al

sistema de tracción del cepillo).

• Cuando utilice la máquina, asegúrese de que no existe peligro para terceras personas, especialmente niños.

• Antes de realizar cualquier función de mantenimiento o reparación, lea con atención todas las instrucciones relativas

a la misma.

• No abandone la máquina sin antes apagar el interruptor de llave (O), retirar la llave y aplicar el freno de

estacionamiento.

• Apague el interruptor de contacto (O) y quite la llave antes de cambiar los cepillos y antes de abrir cualquiera de los

paneles de acceso.

• Tome las debidas precauciones para evitar que pelo, joyas o prendas amplias queden atrapados entre elementos en

movimiento.

• Sea cauto al mover esta máquina con temperaturas bajo cero. El agua de la solución, los depósitos de recuperación

o detergente y de las tuberías puede congelarse, causando daños a las válvulas y accesorios. Limpie con

limpiaparabrisas.

• Retire las baterías de la máquina antes de su desguace. Las baterías deben desecharse de forma segura, de

acuerdo con la reglamentación medioambiental local.

• No utilice la máquina en superfi cies con pendientes superiores a las indicadas en la máquina.

• Antes de utilizar la máquina, todas las puertas y cubiertas deberían estar colocadas como se indica en el manual de

instrucciones.

• Esta máquina sólo debe utilizarse y almacenarse bajo techo.

GUARDE ESTAS INSTRUCCIONES

5/2014 B - 5 56091120 - SC1500

Page 30

INSTRUCCIONES DE USOB - ESPAÑOL

CONOZCA SU MÁQUINA

A lo largo de este manual encontrará números o letras en negrita entre paréntesis – por ejemplo: (2). Estos números se refi eren a una pieza o componente que se

muestra en estas páginas, a menos que se indique lo contrario. Consulte estas páginas siempre que lo necesite para localizar alguna pieza o componente citado

en el texto. NOTA: Consulte el manual de servicio para obtener explicaciones más detalladas de cada objeto ilustrado en las siguientes 4 páginas.

1 Panel de control

2 Volante

3 Cartucho de detergente

4 Depósito de solución

5 Tapón de llenado del depósito de solución

6 Puntos de sujeción

7 Rueda motriz

8 Plataforma de limpieza

9 Rodillo de la rasqueta

10 Conjunto de la rasqueta

11 Perillas de cubierta de rasqueta (4)

12 Cable de alimentación del cargador a bordo

12

1

2

3

4

5

6

11

10

9

8

7

B - 6 SC1500 - 56091120 5/2014

6

Page 31

CONOZCA SU MÁQUINA

13 Tapa del depósito de recuperación / alojamiento del panel de control

14 Flotador de apagado del motor de aspiración automático

15 Depósito de recuperación

16 Bandeja de residuos

17 Puerto de llenado trasero del depósito de solución

18 Pedal de avance

19 Pedal de presencia del operador

20 Plataforma

21 Rueda trasera

22 Tubo de vaciado del depósito de solución

23 Pestillo de retirada de la hoja de la rasqueta trasera

ESPAÑOL - BINSTRUCCIONES DE USO

24 Cargador de la batería

25 Válvula de solenoide de la solución

26 Filtro de la solución

27 Válvula de cierre de la solución

28 Manijas

29 Pestillo

30 Tubo de vaciado del depósito de recuperación

31 Tubo de indicación visual de nivel del tanque de solución

32 Varilla de apoyo

33 Conector de la batería (opcional)

34 Válvula de drenaje de la solución

35 Indicador LED del Estado de carga de la Batería

28

28

33

14

13

35

32

15

16

29

30

17

31

18

27

25

26

24

19

23

20

22

34

21

5/2014 B - 7 56091120 - SC1500

Page 32

INSTRUCCIONES DE USOB - ESPAÑOL

PANEL DE CONTROL

A Interruptor de contacto

B Parada de emergencia

C Interruptor de claxon

D Disyuntor de la rueda de tracción (50 A)

E Disyuntor del circuito de control (5 A)

F Pantalla gráfi ca (ver Panel de control – continuación)

G Disyuntor del motor de aspiración (20 A)

H Disyuntor del motor del cepillo (25 A)

I Interruptor de encendido/apagado de fregado One-Touch

J Indicador de encendido/apagado de fregado

K Botón de ajuste de velocidad

L Interruptor de avance

M Indicador de avance

N Interruptor de marcha atrás

O Indicador de marcha atrás

P Interruptor de aumento de potencia

Q Indicador de aumento de potencia

R Interruptor de nivel de detergente

S Indicador de encendido/apagado de detergente

T Interruptor de presión extra

U Indicador de presión extra

V Símbolo de Lea todas las instrucciones antes de utilizar

™

W Interruptor de ajuste de cantidad de solución

X Indicador de encendido/apagado de solución

Y Interruptor de ajuste de potencia de aspiración

YA Indicador de modo silencioso de aspiración

YB Indicador de modo estándar de aspiración

Z Interruptor de información

F

D

E

C

G

H

I

J

K

B

50A 5A 20A 25A

M

L

A

N

X

W

Y

YA

YB

Z

T

U

R

S

V

P

Q

B - 8 SC1500 - 56091120 5/2014

O

Page 33

PANEL DE CONTROL - CONTINUACIÓN

1 Pantalla de fregado

2 Pantalla de información

3 Pantalla de bajo voltaje de baterías

F Pantalla gráfi ca

F1 Gráfi co de barras del nivel de aspiración

SUPERIOR = Alto

INFERIOR = Bajo

NINGUNO = Apagado

F2 Gráfi co de barras de fl ujo de la solución

SUPERIOR = Alto

MEDIO = Medio

INFERIOR = Bajo

NINGUNO = Apagado

ESPAÑOL - BINSTRUCCIONES DE USO

F3 Gráfi co de barras de presión del cepillo de fregado

SUPERIOR = Presión extra

INFERIOR = Presión estándar

F4 Indicador de mezcla/porcentaje de detergente

F5 Gráfi co de barras indicador de detergente

SUPERIOR = Detergente fuerte

INFERIOR = Detergente suave

NINGUNO = Apagado

F6 Códigos de error

F7 Contador horario

F8 Indicador de nivel de carga de las baterías

1

F1

F2

F3

F4

F5

F

2

F6

F8

F7

3

!

5/2014 B - 9 56091120 - SC1500

Page 34

INSTRUCCIONES DE USOB - ESPAÑOL

BATERÍAS

Si su máquina se entrega con baterías instaladas, realice lo siguiente:

Compruebe que las baterías estén conectadas a la máquina.•

Encienda el conmutador de llave • (A) y compruebe el indicador de batería (F8). Si el indicador está completamente lleno, las baterías están listas para el

uso. Si el indicador no está lleno, las baterías deberían cargarse antes de la utilización. Consulte la sección “Recarga de las baterías”.

¡IMPORTANTE!:• SI SU MÁQUINA ESTÁ EQUIPADA CON UN CARGADOR DE BATERÍA A BORDO, CONSULTE EL MANUAL DEL PRODUCTO OEM

PARA OBTENER INSTRUCCIONES SOBRE EL AJUSTE DEL CARGADOR PARA EL TIPO DE BATERÍA.

Si su máquina se entrega sin baterías instaladas, realice lo siguiente:

Consulte con su distribuidor autorizado de Advance en cuanto a las baterías recomendadas.•

Instale las baterías siguiendo las instrucciones indicadas a continuación.•

¡IMPORTANTE!:• SI SU MÁQUINA ESTÁ EQUIPADA CON UN CARGADOR DE BATERÍA A BORDO, CONSULTE EL MANUAL DEL PRODUCTO OEM

PARA OBTENER INSTRUCCIONES SOBRE EL AJUSTE DEL CARGADOR PARA EL TIPO DE BATERÍA.

INSTALACIÓN DE LAS BATERÍAS

¡ADVERTENCIA!

Tome las máximas precauciones cuando trabaje con las baterías. El ácido sulfúrico de las baterías puede causar daños graves si

entra en contacto con la piel o con los ojos. Desde el interior de las baterías se libera, a través de unas aperturas en las tapas de las

baterías, gas explosivo de hidrógeno. Este gas puede incendiarse con cualquier arco eléctrico, chispa o llama. Si el ácido de batería

entra en contacto con su piel, enjuague la zona afectada con agua durante 5 minutos y consulte a un médico.

Cuando maneja las baterías...

• Sáquese todas las joyas.

• No fume.

• Lleve gafas de seguridad, un delantal de goma y guantes de goma.

• Trabaje en una zona bien ventilada.

• No permita que las herramientas toquen simultáneamente más de un borne de la batería.

• Al sustituir las baterías, desconecte SIEMPRE en primer lugar el cable (de tierra) negativo para evitar chispas.

• Al instalar las baterías, conecte SIEMPRE el cable negativo al fi nal.

¡PRECAUCIÓN!

Los componentes eléctricos de esta máquina pueden dañarse

seriamente si las baterías no están instaladas o conectadas

correctamente. Las baterías deben ser instaladas por Advance o

por un electricista cualifi cado.

1 Vacíe el depósito de recuperación (15) con el tubo de drenaje del depósito

de recuperación (30).

2 Apague (O) el interruptor de llave (A) y quite la llave. Desenganche (29) y

luego abra la tapa del depósito de recuperación (13) y ajuste la varilla de

apoyo (32).

3 Incline hacia atrás el depósito de recuperación (15) hacia la plataforma del

operador para exponer el compartimiento de las baterías.

4 Con (2) personas y una correa de elevación apropiada, levante con cuidado

las baterías hasta la bandeja del compartimento, exactamente tal y como se

muestra. Consulte el diagrama moldeado en la parte inferior de la tapa del

depósito de recuperación.

5 Ver la Figura 1. Instale los cables de batería tal y como se muestra y apriete

las tuercas de los bornes de las baterías.

6 Instale los manguitos de las baterías y apriételos bien a los cables de las

baterías con las correas de sujeción provistas.

7 Conecte los cables de alimentación principal de la máquina a las baterías,

o si existe, enchufe el conector de las baterías (33). Cierre la tapa del

depósito de recuperación.

Cuando cambie las baterías o el cargador, consulte con su centro

local de servicios autorizado los valores correctos para la batería,

el cargador y la máquina, a fi n de evitar daños a la batería.

FIGURA 1

24V

260A/H-20HR-RATE

B - 10 SC1500 - 56091120 5/2014

Page 35

ESPAÑOL - BINSTRUCCIONES DE USO

INSTALACIÓN DEL CEPILLO (SISTEMA DE DISCO)

1 Asegúrese de que la plataforma de limpieza (8) se encuentre en posición ELEVADA. Asegúrese de que el interruptor de contacto (A) está apagado (O).

¡PRECAUCIÓN!

Apague el interruptor de contacto (O) y quite la llave antes de cambiar el cepillo.

2 Ver la Figura 2. Gire el conjunto de la rasqueta (10) para alejarlo de su lado de la máquina y mejorar el acceso al cepillo, (AA).

3 Levante la faldilla de la plataforma de limpieza (AB) y deslice el cepillo bajo la plataforma de limpieza.

4 Si utiliza una bayeta, instale la bayeta en el portabayetas.

5 Para montar el cepillo (AC) (o el portabayetas), eleve el cepillo y alinee las lengüetas (AD) del cepillo con las ranuras de la placa de montaje y gire para que

se bloquee en su sitio (desde el lado derecho de la máquina, gire el borde exterior del cepillo hacia la parte posterior de la máquina como se muestra (AE)).

NOTA: Durante la operación, el cepillo debe girar en la dirección (AF).

FIGURA 2

8

AA

10

AB

AC

AE

AF

AD

5/2014 B - 11 56091120 - SC1500

Page 36

INSTRUCCIONES DE USOB - ESPAÑOL

INSTALACIÓN DE LA BAYETA (SISTEMA REV)

1 Asegúrese de que la plataforma de limpieza se encuentre en la posición ELEVADA. Asegúrese de que el interruptor de contacto (A) está apagado (O).

¡PRECAUCIÓN!

Apague el interruptor de contacto (O) y quite la llave antes de cambiar la bayeta.

2 Ver la Figura 3. Gire el conjunto de la rasqueta (10) para alejarlo de su lado de la máquina y mejorar el acceso a la bayeta, (AA).

3 Fregado diario: Deslice una bayeta de fregado diario (AE) o bayeta de microfi bra (AB) bajo el motor de bayeta, céntrela en el motor de bayeta fi jo (AC) y

levántela y presiónela dentro de la superfi cie con forma de arpón del motor de bayeta.

4 Desaparición del acabado del suelo: Instale una nueva bayeta roja (AE) en el motor de bayeta (AC) como se describe arriba en el paso 3. Si usa el

velcro de dos caras opcional (AF), colóquelo en el centro de la bayeta SPP marrón (AD), y deslice este conjunto bajo la bayeta roja y céntrelo y luego

presione hacia arriba para acoplar este conjunto a la bayeta roja. Si no usa el velcro de dos caras opcional, coloque una nueva bayeta roja como se

describe arriba en el paso 3 y coloque una nueva bayeta SPP marrón en el piso centrada en la bayeta roja. Baje la plataforma al piso sobre la bayeta SPP

marrón y verifi que que esté centrada.

NOTA: Nunca coloque una bayeta SPP marrón en el motor de bayeta, dado que se dañará el motor de bayeta y se deberá reemplazar.

FIGURA 3

8

10

AF

AD