Page 1

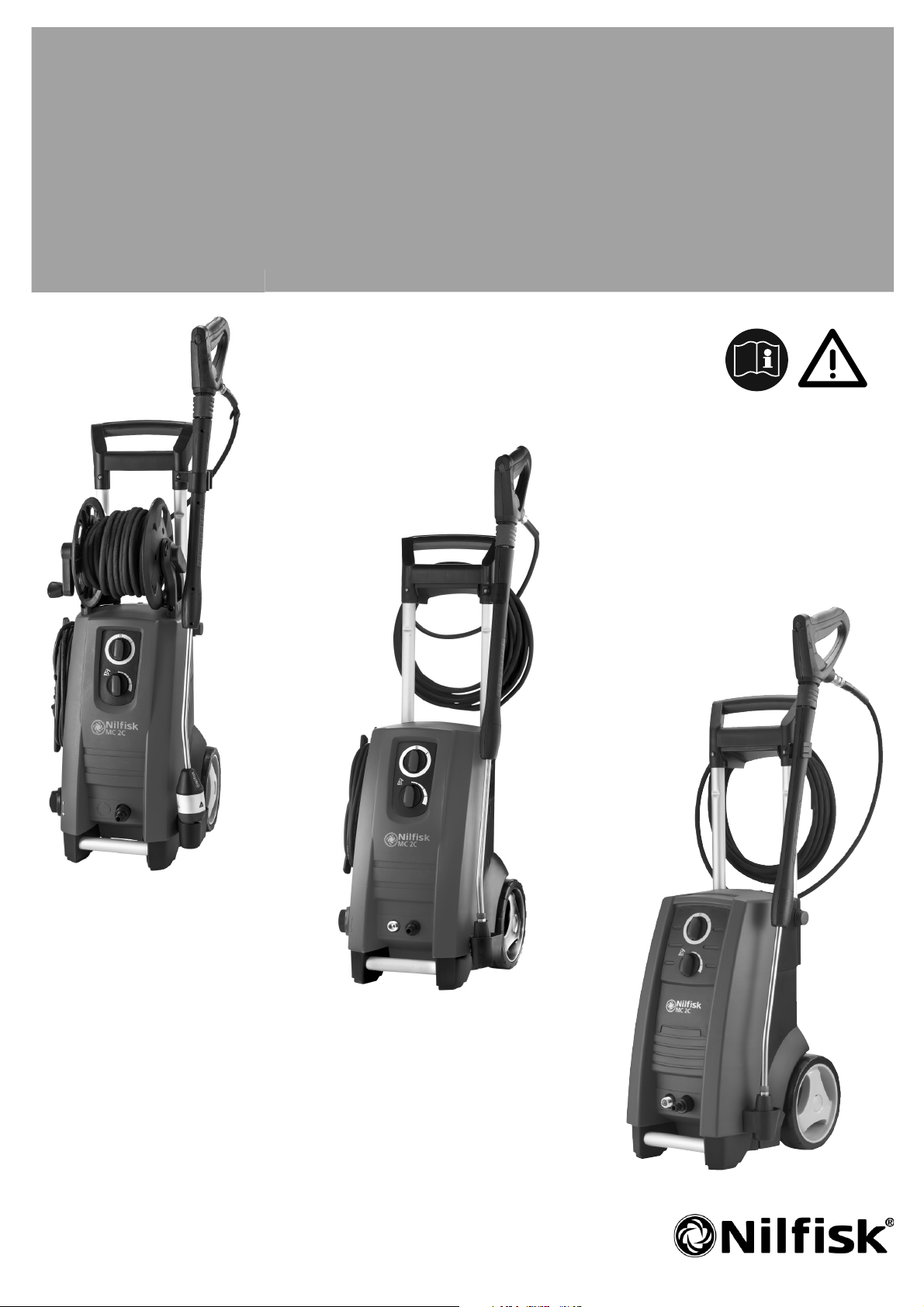

MC 2C -

Instructions for use

128700711 a (10.2017)

EN-DA-NO-SV-FI-DE-FR-NL-IT-ES-PT-EL-TR-CS-HU-PL

Page 2

Instruction manual ........................................................3 - 21

Instruktionsbog ...........................................................22 - 40

Instruksjonsbok ..........................................................41 - 60

Instruktionsbok ...........................................................61 - 80

Käyttöohje ..................................................................81 - 99

Betriebsanleitung ..................................................... 100 - 120

Manuel d'Instructions ............................................... 121 - 142

Gebruikershandleiding ............................................. 143 - 163

Manuale di istruzioni ................................................ 164 - 184

Manual de Instrucciones .......................................... 185 - 205

Manual de Instruções ............................................... 206 - 226

γχειριδιο οδηγιων ..................................................... 227 - 248

Ýþletme kýlavuzu ..................................................... 249 - 270

Návod k obsluze....................................................... 271 - 289

Üzemeltetési útmutató ............................................. 290 - 309

Instrukcja obsługi ..................................................... 310 - 330

Copyright © 2017 Nilfisk A/S

Page 3

Contents

1 Introduction .................................................................................................. 4

1.1 Symbols used to mark instruction .......................................................................4

2 Safety precautions and working techniques ................................................4

3 Description ................................................................................................. 10

3.1 Application ........................................................................................................10

3.2 Operation elements and model survey .............................................................10

4 Before you start using your pressure washer ........................................ 11

4.1 Mounting of holders for spray lance ..................................................................11

4.2 Mounting of hose hook (only models without hose reel) .............................11

4.3 Mounting of hose reel handle (only models with hose reel) ..............................11

4.4 Mounting of quick coupling ...............................................................................12

4.5 Mounting of high pressure hose .......................................................................12

5 Operating your pressure washer ............................................................. 12

5.1 Connection of high pressure hose ....................................................................12

5.2 Mounting of spray lance ....................................................................................13

5.3 Water connection ..............................................................................................13

5.4 Telescopic handle .............................................................................................13

5.5 Start and stop of the machine (when connected to a water supply) .................14

5.6 Start the machine (when connected to open containers (suction mode)) ........14

5.7 Pressure regulation ...........................................................................................14

5.8 Operation with detergents .............................................................................15

5.9 Regulation of pressure / water volume .............................................................16

6 Fields of application and working methods ........................................... 16

6.1 General .............................................................................................................16

7 After using your pressure washer ........................................................... 17

7.1 Storing the washer ............................................................................................17

7.2 Winding up of electric cable and high pressure hose ......................................17

7.3 Storage of accessories .....................................................................................17

8 Maintenance ............................................................................................... 18

8.1 Cleaning of water inlet fi lter .............................................................................18

8.2 Cleaning of nozzle ............................................................................................18

8.3 Cleaning of machine vents ...............................................................................18

8.4 Greasing of couplings ......................................................................................18

9 Trouble-shooting ....................................................................................... 19

10 Further information ................................................................................... 20

10.1 Warranty conditions ........................................................................................20

11 Main Technical Data ................................................................................... 20

12 EU Declaration of Conformity ................................................................... 21

Original Instructions

3

Page 4

1 Introduction

1.1 Symbols used to mark instruction

All pictograms attached to the high pressure washer and its components are shown and explained in this manual.

Safety instructions marked with this symbol must be observed to prevent personal injury or

serious damage to property.

Caution where there is a risk of damaging the machine or its individual components.

This symbol indicates tips and instructions to simplify work and to ensure a safe operation of

the high pressure washer.

2 Safety precautions and working techniques

Before starting up your machine for the fi rst time, this instruction manual must be read through

carefully. Save the instructions for later use.

WARNING!

• Inhalation of aerosols can be hazardous to health.

Where applicable use a device in order to avoid or reduce aerosols production, e.g., a shield covering the

nozzle. For protection against aerosols use a respiratory mask of class FFP 2 or higher.

• The high water pressure generated by the machine

and the power connection are particular sources of

danger.

• Machines shall not be used by children or untrained

personnel. Children should be supervised to ensure

that they do not play with the machine.

• Do not use the machine within range of persons unless they wear protective clothing.

• Before starting up your machine please check it carefully for any defects. If you fi nd any, do not start up

your machine, contact your Nilfi sk distributor. The insulation of the electric cable should be faultless and

without any cracks. If the electric cable is damaged,

an authorized Nilfi sk di stributor should replace it.

• Always unplug the power plug before cleaning or

maintenance and when replacing parts or converting

4

Original instructions

Page 5

the machine to another function.

• Observe the national safety regulations issued, for

example, by the employers liability insurance association, social security institutions, occupational safety

and health authorities or other organizations.

Accessories and spare parts

• To ensure the machine safety only use original spare

parts from Nilfi sk or approved by Nilfi sk.

• High pressure hoses, fi ttings and couplings are important for the safety of the machine. Only use hoses, fi ttings and couplings recommended by Nilfi sk.

Physical, sensory or mental conditions

Applications

• This machine is not intended for use by persons

(including children) with reduced physical, sensory or mental capabilities or lack of experience and

knowledge. If the machine is used by people with reduced physical, sensory or mental capabilities or lack

of experience and knowledge they shall have been

given supervision or instruction concerning use of the

machine in a safe way and understand the hazards involved.

This machine has been developed for domestic use

such as:

• Car, motorbike, boat, caravan, trailer, patio/drive/fl agstones, woodwork, brickwork, barbecue, garden furniture, lawn mower.

Any other use is considered as improper use. Nilfi sk

accepts no liability for any damage resulting from such

use. The risk for such use is borne solely by the user.

Proper use also includes proper operation, servicing

and repairs as specifi ed in this instruction.

Clothing and equipment

Always take action to protect yourself when operating

the machine.

5Original Instructions

Page 6

• Wear shoes with non-slip soles.

• Wear goggles, ear protection and protective clothes

during operation.

Transporting the high pressure washer

• When transporting the machine in or on a vehicle, it

must be secured, e.g. with straps, so that it cannot slip

or tip over.

• Nilfi sk recommends that the machine is positioned

horizontally on the backside, when transported in or

on a vehicle.

Detergents

• This machine has been designed for use with cleaning agents supplied or recommended by Nilfi sk. The

use of other cleaning agents or chemicals may adversely affect the function of the machine.

Before starting the work

Electrical connection

Inspecting the machine

• Do not use the machine if a supply cord or important

parts of the machine are damaged, e.g., safety device, high pressure hose, and spray handle and spray

attachments.

• The trigger of the spray handle must move easily and

automatically return to its starting position when released.

• Always keep high pressure hose and spray attachment in good condition (clean, moving easily) and correctly assembled.

WARNING!

Minimize the risk for electrical shock:

• Voltage and frequency of the machine (see rating

plate) must match the voltage of and frequency of the

mains supply.

• Only connect the machine to electrical installation

made by a certifi ed electrician and com ply with IEC

6

Original instructions

Page 7

60364-1.

• It is recommended that the electrical supply to the

machine should include a residual current device that

will interrupt the supply if the leakage current to earth

exceeds 30 mA for 30 ms.

• Due to the high power of the machine - use motor

start / delayed fuses with characteristic D according to

IEC947-2 or corresponding standards outside IEC.

• Inadequate extension cables can be dangerous. If an

extension cable is used, it shall be suitable for outdoor

use, and the connection has to be kept dry and off the

ground.

• Nilfi sk recommends use of an extension cable drum

when cable extension is needed which keeps the

socket at least 60 mm above the ground.

• If the electric cable is damaged, it must be replaced

by an authorized Nilfi sk distributor or similar qualifi ed

person in order to avoid a hazard.

• Connecting the high pressure washer to a supply

system, the max allowed impedance is = 0,4023

(Zmax). Consult with the supply authority that the

equipment is connected only to a supply of that impedance or less.

Water connection

• This high pressure washer is only allowed to be connected with the drinking water mains, when an appropriate backfl ow preventer has been installed, Type BA

according to EN 60335-2-79.

• The backfl ow preventer can be ordered under number

106411177.

• As soon as drinking water has fl own through the backfl ow preventer, it is no longer regarded as drinking

water.

• Operation by suction (e.g. a rainwater vessel) is carried out without a backfl ow preventer – see “Connec-

ting to a pressureless water supply”. The machine

can be connected to water mains with a max. inletpressure of 1 MPa/10 bars and max. 60°C.

7Original Instructions

Page 8

Safety devices

Locking device on spray handle:

• The spray handle features a locking device. When the

pawl is activated, the spray handle cannot be operated.

Thermal sensor:

• A thermal sensor protects the motor against overloading. The machine will restart after a few minutes when

the thermal sensor has cooled.

Pressure safety device:

• An integrated hydraulic safety valve protects the

system from excessive pressure.

During work

WARNING!

• It is not allowed to clean asbestos-containing surfaces

with high pressure.

• Risk of explosion – Do not spray fl ammable liquids.

• Never draw in fl uids containing solvents (e.g., gasoline, heating oil, paint thinner or acetone) These substances damage the materials used in the machine.

Their spray is highly combustible, explosive and poisonous.

• Never direct the water jet at yourself, other persons,

not even to clean clothing or footwear - risk of injury.

• Never direct the water jet at pets or other animals.

• Never direct the water jet at live electrical equipment

or the machine itself - danger of short-circuiting.

• Hold the spray lance fi rmly with both hands. The spray

lance is affected by a thrust of up to 27.4 N and a sudden torque when activating the trigger of the spray

handle during operation.

• Never start up a frozen machine. Frost damages are

not covered by the guarantee!

• Always ensure fi rm and safe footing.

• The machine shall be operated in an upright position.

• If the machine is left or not used for 5 minutes, it must

be switched off on the start/stop switch "O" (1).

8

Original instructions

Page 9

After fi nishing the work

WARNING!

• Always switch off the machine and unplug the power

plug from the socket after work and when leaving the

machine unattended.

• Disconnect water inlet hose between machine and

water supply.

• Always empty pump, hose and accessories of water

after use of the machine and prior to storing.

Maintenance and repairs

WARNING!

• Always disconnect the electrical plug from the socket

prior to maintenance, cleaning and repair.

• Any repair should always be made in Nilfi sk authorized workshop with original Nilfi sk spare parts.

• Do not attempt any maintenance not described in the

instructions.

• If the machine refuses to start, stops, pulsates, pressure fl uctuates, motor busses, fuse blows or no water comes out, check the trouble shooting diagram

in these instructions. In case other problems occur,

please contact your local Nilfi sk distributor.

Recycling the high pressure washer

Make the old machine unusable immediately.

• Unplug the machine.

• Cut the electric cable.

Do not discard electrical appliances with household

waste. As specifi ed in WEEE Directive 2012/19/EC on

old electrical and electronic appliances, used electrical

goods must be collected separately and recycled ecologically. Contact your local authorities or your nearest

dealer for further information.

9Original Instructions

Page 10

3 Description

3.1 Application

3.2 Operation elements and

model survey

This high-pressure washer has

been developed for semiprofessional routine cleaning:

- Professional craftsman jobs,

cleaning of vehicles, boat,

caravan and minor cleaning

jobs within building and construction

Section 6 describes the use of

the high-pressure washer for

various cleaning jobs.

See illustration at the end of

this manual.

1 Start/stop switch

2 Water inlet (with fi lter)

3 High pressure connection

(only machines without

hose reel)

4 High pressure hose

5 Electric cable

6 Button for regulation of

pressure and water volume

(not standard)

7 Ergo 2000 spray handle

with lock (7a)

8 Flexopower Plus spray

lance (standard models)

9 4-in-1 spray lance (T and

XT models)

Only use the high-pressure

washer for purposes described

in this manual.

The safety precautions must be

observed to prevent damage

to the machine, the surface to

be cleaned or severe personal

injuries.

10 Detachable detergent con-

tainer

11 Nozzle cleaning tool

12 Dosing of detergents

13 Hose reel

14 Hose hook (only machines

without hose reel)

15 Model tag

16 Button for telescopic handle

17 Telescopic handle

18 Turnable cable hook

Specifi cations: See model tag

(15) of machine.

We reserve the right to alter the

specifi cations.

10

Original Instructions

Page 11

4 Before you start using your pressure

washer

4.1 Mounting of holders for

spray lance

Mount the holders for spray

lance on the machine.

4.2 Mounting of hose hook

(only models without

hose reel)

4.3 Mounting of hose reel

handle (only models

with hose reel)

Mount the hose hook (14) on

the handle (2 screws).

Note: the hose hook can be

mounted on the front as well as

on the back. Front position is to

be used if the product is used

together with a special wall

hook for wall storage.

1. Click the hose reel handle

on to the trolley handle (no

screws).

11Original Instructions

Page 12

4.4 Mounting of quick

coupling

1. Screw the quick coupling

tight on to the water inlet (2).

Note: The inlet fi lter must always be fi tted in the water inlet

pipe to fi lter out major impurities as these will damage the

pump valves.

Caution: Failure

to fi t the fi lter will

invalidate the

guarantee.

4.5 Mounting of high

pressure hose

Attach the high pressure hose

(4) to the spray handle (7).

5 Operating your pressure washer

5.1 Connection of high pressure hose

Machines without hose reel: Attach the high pressure hose (4)

to the high pressure connection

of the machine (3).

12

Only max. 7 m additional extension hose can be added.

Machines with hose reel: Unwind the high pressure hose

completely.

Original Instructions

Page 13

5.2 Mounting of spray lance 1. Pull the blue quick-release

A

B

NOTE!

Always remove any dirt from

the nipple before connecting

the spray lance to the spray

handle.

grip (A) of the spray gun

backwards.

2. Insert the nipple of the spray

lance (B) into the quick-release connection and release

it.

3. Pull the spray lance (or other

accessory) forwards to check

that it is securely attached to

the spray gun.

5.3 Water connection An ordinary 1/2" garden hose of

min. 10 m and max. 25 m will

be suitable.

NOTE: Connection to the public

mains according

to regulations.

IMPORTANT! Only use water without any impurities. If

there is a risk of silt, sand or

sediment in the inlet water (i.e.

from your own well), an additional fi lter should be mounted.

1. Let the water run through the

water hose before connecting

it to the machine to prevent

sand and dirt from penetrating the machine.

Note: Check

that the fi lter is

fi tted in the water

inlet pipe and that it is clean

and free from debris.

2. Connect the water hose to

the water supply by means

of the quick connector (inlet

water, max. pressure: 10 bar,

max. temperature: 60°C).

3. Turn on the water.

5.4 Telescopic handle

The machine features a telescopic handle. To raise or lower

the handle, press the button

(16) and move the handle upwards or downwards. When a

click is heard, the handle is in

right position.

13Original Instructions

Page 14

5.5 Start and stop of the machine (when connected

to a water supply)

The spray lance is affected

by a thrust during operation - therefore always hold it

fi rmly with both hands. IMPOR-

TANT: Point the nozzle at the

ground.

to the surface, which is to be

cleaned.

Do not cover the

machine during

operation.

5.6 Start the machine (when

connected to open containers (suction mode))

1. Check that the machine is in

upright position.

NOTE: Do not place the ma-

chine in tall grass!

2. Release the trigger lock.

3. Activate the trigger of the

spray handle and let the water run until all air has escaped from the high pressure

hose.

4. Turn the start/stop switch (1)

to position "I".

5. Activate the trigger of the

spray handle.

Always adjust the distance and

thus the pressure of the nozzle

The washer can take in water

from a rain water tank as an

example. The hose for the water

supply must not be too long,

approx. 5 m.

Make sure that the water tank is

not placed on a lower level than

the machine.

Use an external fi lter if the water contains impurities.

1. Make sure that the water

hose is fi lled completely with

water before connecting to

the machine. Place the entire

hose in a tank or bucket. To

avoid water spillage, crimp

Note: If the machine is left or

not used for 5 minutes, it must

be switched off on the start/stop

switch "O" (1):

1. Turn the start/stop switch to

position "O".

2. Disconnect the electrical plug

from the socket.

3. Shut off the water supply and

activate the trigger to relieve

the machine of pressure.

4. Lock the spray handle.

When releasing the trigger of

the spray handle, the machine

automatically stops. The machine will start again when you

re-activate the spray handle.

the water inlet hose down in

the water and then connect

the hose to the machine with

the quick coupling and fi nally

uncrimp the water inlet hose.

2. Dismount spray handle,

lance and nozzle.

3. Turn the start/stop switch to

position "I" and let the water

run, until the air has escaped

from the water hose and the

pump.

4. Turn the start/stop switch to

position "O".

5. Mount spray handle and

thereafter lance.

6. Turn the start/stop switch (1)

to position "I".

7. Activate the trigger of the

spray handle.

5.7 Pressure regulation Flexopower Plus spray lance

The pressure can be regulated

on the Flexopower Plus spray

lance.

High pressure

Low pressure / Detergent

14

Original Instructions

Page 15

T and XT models:

4-in-1 spray lance

The pressure can be regulated

on the 4-in-1 spray lance.

Low Pressure / detergent

5.8 Operation with

detergents

20°

65°

Application of detergents is

NOT possible if an extension

hose is applied.

1. Fill the container with a detergent.

2. Mount the Flexopower Plus

spray lance and adjust it to

low pressure. Turn the 4-in-1

nozzle to pos Low Pressure/

Detergent (see section 5.7).

3. Adjust the dosing regulator

(12) to the re quired vol ume

of detergent (0-5%).

Tornado / high pressure

Wide angle / high pressure

Turbohammer / high pressure

4. Apply the detergent from

below and up wards.

5. Let the detergent act for the

time stated on the packing of

the detergent and fl ush with

pure water or use a brush.

External detergent container

1. Remove the cover with suction hose from the detergent

container.

2. Mount the cover with suction

hose on the external detergent container.

The cover has a standard thread

and fi ts common detergent containers. If your container does

not have a standard thread,

detach the fi lter from the suction hose and remove the cover.

Remount the fi lter in the suction

hose.

Extra detergent hose can be

pulled out of the machine.

15Original Instructions

Page 16

5.9 Regulation of pressure

/ water volume (only

models with button for

regulation of pressure

and water volume)

Working pressure and water

volume can be regulated on the

machine by turning the button

for regulation of pressure / water volume (6).

6 Fields of application and working

methods

6.1 General Effi cient high pressure cleaning is achieved by following a few

guidelines, combined with your own personal experience of specifi c

cleaning tasks. Accessories and detergents, when correctly chosen, can increase the effi ciency of your pressure washer. Here is

some basic information about cleaning.

6.1.1 Detergent and foam Foam or detergent should be applied onto dry surfaces so that the

chemical product is in direct contact with the dirt. Detergents are

applied from bottom to top, for example on a car bodywork, in order

to avoid "super clean" areas, where the detergent collects in higher

concentration and streams downwards. Let the detergent work for

several minutes before rinsing but never let it dry on the surface being cleaned. Note: It is important that the detergents do not dry up.

Otherwise the surfac that has to be cleaned can be da maged.

6.1.2 Mechanical effect In order to break down tough layers of dirt, additional mechanical

effect may be required. Special wash brushes offer this supplementary effect that removes stubborn dirt, traffi c fi lm or the like.

16

Original Instructions

Page 17

7 After using your pressure washer

7.1 Storing the washer The machine should be sto-

red in a frost-free room!

Pump, hose and accessories

should always be emptied of

water prior to storing as follows:

7.2 Winding up of electric

cable and high pressure

hose

1. Stop the machine (turn the

start/stop switch (1) to position “O” and detach water

hose and accessory.

2. Restart the machine and

activate the trigger. Let the

machine run until no more

water runs through the spray

handle.

3. Stop the machine and unplug. Wind the electric cable

round the hooks placed on

the side of the machine.

4. Separate spray handle and

spray lance.

To avoid accidents, the electric

cable and the high pressure

hose should always be wound

5. Machines without hose reel:

Detach high pres sure hose,

coil it up and place it on the

hose storage.

Machines with hose reel: Coil

the high pressure hose up on

the hose reel.

6. Place spray handle, nozzles

and other ac ces so ries in the

holders of the machine.

Should the machine by mistake

be frozen, let it thaw and check

it for damage.

NEVER START-UP A FROZEN

MACHINE.

Frost damages are not

covered by the guarantee!

up carefully.

1. Wind up the electric cable on

the dedicated hooks. Built-in

clip for good holding.

The lower hook can be

turned to release the electric

cable.

2. The high pressure washer

comes in two models: A) with

hook for storage of high pressure hose (14) - B) with a

hose reel (13).

7.3 Storage of accessories The standard accessories

(spray handle, spray lance

(A) and nozzle cleaning tool)

can be stored on the pressure

A

washer.

17Original Instructions

Page 18

8 Maintenance

8.1 Cleaning of water inlet

fi lter

WARNING! Always disconnect

the electrical plug from the

socket prior to maintenance or

cleaning.

To ensure a long and problem

free working life, please take

the following advice:

Wash off water hose, high

pressure hose, spray lance

and accessories before

mounting.

Clean the connectors of dust

and sand.

Clean the nozzles.

Any repair should always be

made in an authorized workshop with original spare parts.

Clean the water inlet fi lter regularly once a month or more frequently according to use. Carefully loosen the fi lter with a pair

of pliers and clean it. Check that

it is intact before re-mounting it.

The inlet fi lter must always be

fi tted inside the water inlet pipe

to fi lter out various impurities,

as they will damage the pump

valves.

CAUTION: Failure to fi t the fi lter

will invalidate the guarantee.

8.2 Cleaning of nozzle A clogging up in the nozzle

causes a pump pressure which

is too high. This is why cleaning

is required immediately.

1. Stop the machine and dis-

connect the nozzle.

2. Clean the nozzle. IMPOR-

TANT: The cleaning tool (11)

should only be used when

the nozzle is detached!

3. Flush the nozzle backwards

with water.

8.3 Cleaning of machine

vents

8.4 Greasing of couplings To ensure easy connection and

The machine should be kept

clean so as to let cooling air

that o-rings do not dry up, the

pass freely through the machine vents.

couplings should be greased

regularly.

18

Original Instructions

Page 19

9 Trouble-shooting

Please ensure that you check the following before contacting the Nilfi sk service organization:

Symptom Cause Recommended action

Machine refuses to start Machine not plugged in Plug in machine.

Defective socket Try another socket.

Fuse has blown Replace fuse. Switch off other machines.

Defective extension cable Try without the extension cable.

Fluctuating pressure Pump sucking air Check that hoses and connections are air-

tight.

Valves dirty, worn out Clean and replace or refer to local Nilfi sk-

or stuck distributor

Pump seals worn out Clean and replace or refer to local Nilfi sk-

distributor.

Motor busses Low voltage or Activate the trigger of the spray handle.

low temperature

Machine stops Fuse has blown Replace fuse. Switch off other machines.

Incorrect mains voltage Check that the mains voltage corresponds

to specifi cation on the model tag.

Thermal sensor activated Leave the washer for 5 minutes to cool

down.

Nozzle partially blocked Clean the nozzle (see section 7.2)

Fuse blows Fuse too small Change to an installation higher than the

amp. consumption of the machine.

You may try without the extension cable.

Machine pulsating Air in inlet hose/pump Allow machine to run with open trigger until

regular working pressure resumes.

Inadequate supply of Check that the water supply corresponds to

mains water specifi cations required (see model tag)

NB! Avoid using long, thin hoses (min. 1/2")

Nozzle partially blocked Clean the nozzle (see section 7.2)

Water fi lter blocked Clean the fi lter (see section 7.1)

Hose kinked Straighten out hose.

Machine often starts Contact your nearest Nilfi sk Service

and stops by itself Centre.

Spray handle is leaking Replace seat/ball/O-ring in the valve of the

spray handle.

Machine starts, but Pump/hoses or accessory Wait for pump/hoses or accessory to thaw.

no water comes out frozen

No water supply Connect inlet water.

Water fi lter blocked Clean the fi lter (see section 7.1)

Nozzle blocked Clean the nozzle (see section 7.2)

Pump pressure drops Button for regulation of Adjust the button to correct working pres-

pressure / water volume not sure.

correctly adjusted

In case problems other than the above occur, please contact your local Nilfi sk distributor.

19Original Instructions

Page 20

10 Further information

10.1 Service and Mainte-

nance

In case of need for service and

maintenance, please contact

your dealer.

11 Main Technical Data

Type

Rated pressure

Cleaning impact

Water flow

Voltage/phase/

frequency/current

Max. water temp.

bar/MPa

kg/force

Qmax/

QIEC

l/min

V/-/Hz/A

°C

MC 2C-

60/380

69/6.9

-/2.4

gallon

115/1/

60/15

60

2

MC 2C-

80/520 T

80/8.0

2

8.7/8.2

115-127/

60/15

60

MC 2C-

120/520 T

120/12 120/12 140/14 140/14 150/16 150/15 150/15

2.2 2.2 2.5 2.5 2.9 2.9 2.9

8.6/7.8 8.6/7.8 10.2/9.0 10.2/9.0 10.2/9.5 10.2/9.5 10.2/9.5

1/

230/1/

50/10

MC 2C-

120/520 XT

230/1/

50/10

60 60 60 60 60 60 60

MC 2C-

140/610 XT

230/1/

50/12.6

MC 2C-

140/610 P

230/1/

50/12.6

MC 2C150/650

230/1/

50/14.5

MC 2C-

150/650 (KR)

230/1/

60/14.5

MC 2C-

150/650 XT

230/1/

50/14.5

Cable m 5

Pump Rev./min 3400

Nozzle size

Sound pressure

level

Guaranteed

sound power

level

Vibration according to ISO 5349-1

Weight kg 28.1

1/8"

dB(A)

dB(A)

m/s

0.475

77.4

92

2

< 2.5

5

3400

0.475

77.4

92

< 2.5

27.3

5555555

2800 2800 2800 2800 2800 3400 2800

0.350 0.350 0.370 0.370 0.370 0.370 0.370

76.1 76.1 77.4 77.4 73.5 79.7 79.7

91 91 92 92 88 94 94

< 2.5 < 2.5 < 2.5 < 2.5 < 2.5 < 2.5 < 2.5

27.1 27.1 28.1 28.1 28.1 26.3 28.1

20

Original Instructions

Page 21

12 EU Declaration of Conformity

We,

Nilfi sk A/S

Kornmarksvej 1

DK-2605 Broendby

DENMARK

Hereby solely declare, that the

Product: HPW - Consumer

Description: 220-240V, 50 Hz, IPX5

Type: MC 2C

Is in compliance with the following standards:

EN 60335-1:2012+A11:2014

EN 60335-2-79:2012

EN 55014-1:2006+A1:2009+A2:2011

EN 55014-2: 2015

Compliance to harmonic current emissions is documented in TCF_42331_01

EN 61000-3-11:2000

EN 50581:2012

Following the provisions of:

2006/42/EC

2014/30/EC

2011/65/EC

2000/14/EC – Conformity assessment procedure according to Annex V

- Measured sound power level: 73-80 dB(A); Guaranteed sound power level: 88-94 dB(A)

Hadsund, 13-10-2017

Esben Graff

VP Portfolio Management, Consumer

21Original Instructions

Page 22

Page 23

HEAD QUARTER

DENMARK

Nilfi sk A/S

Kornmarksvej 1

DK-2605 Broendby

Tel.: (+45) 4323 8100

Website: www.nilfi sk.com

SALES COMPANIES

ARGENTINA

Nilfi sk Argentina

Herrera 1855 Piso 4° B Ofi c 405

Ciudad de Buenos Aires

Tel.: (+54) 11 6091 1576

Website: www.consumer.nilfi sk.com.ar

AUSTRALIA

Nilfi sk Pty Ltd

Unit 1/13 Bessemer Street

Blacktown NSW 2148

Tel.: (+61) 2 98348100

Website: www.consumer.nilfi sk.com.au

AUSTRIA

Nilfi sk GmbH

Metzgerstrasse 68

5101 Bergheim bei Salzburg

Tel.: (+43) (0)662/45 6400-90

Website: www.nilfi sk.at

BELGIUM

Nilfi sk n.v-s.a.

Riverside Business Park

Boulevard Internationalelaan 55

Bâtiment C3/C4 Gebouw

Bruxelles 1070

Tel.: (+32) 2 467 60 50

Website: www.consumer.nilfi sk.be

BRAZIL

Nilfi sk Equipamentos de Limpeza Ltda.

Rua Professor Aff onso José Fioravante,

110 - City Jaraguá São Paulo SP 02998-010 Brasil

Tel.: (+11) 3959-0300

Website: www.nilfi sk.com.br

CANADA

Nilfi sk Canada

240 Superior Boulevard

Mississauga, Ontario L5T 2L2

Tel.: (+1) 800-668-8400

Website: www.nilfi sk.ca

CHILE

Nilfi sk S.A.

Salar de Llamara 822, Pudahuel

Centro Empresaial Enea (Fase 2)

8320000 Santiago

Tel.: (+56) 2684 5000

Website: www.nilfi sk.cl

CHINA

Nilfi sk

4189 Yindu Road

Xinzhuang Industrial Park

201108 Shanghai

Tel.: (+86) 21 3323 2000

Website: www.nilfi sk.cn

CZECH REPUBLIC

Nilfi sk s.r.o.

VGP Park Horní Počernice

Do Čertous 1/2658

193 00 Praha 9

Tel.: (+420) 244 090 912

Website: www.consumer.nilfi sk.cz

DENMARK

Nilfi sk Danmark A/S

Industrivej 1

Hadsund, DK-9560

Tel.: 72 18 21 20

Website: www.consumer.nilfi sk.dk

FINLAND

Nilfi sk Oy

Kovuhaankuja 1

01510 Vantaa

Tel.: (+358) 207 890 600

Website: www.consumer.nilfi sk.fi

FRANCE

Nilfi sk SAS

26 Avenue de la Baltique

Villebon sur Yvette

91978 Courtaboeuf Cedex

Tel.: (+33) 169 59 87 24

Website: www.consumer.nilfi sk.fr

GERMANY

Nilfi sk GmbH

Guido-Oberdorfer-Straße 2-10

89287 Bellenberg

Tel.: (+49) (0)7306/72-444

Website: www.consumer.nilfi sk.de

GREECE

Nilfi sk A.E.

Αναπαύσεως 29

Κορωπί Τ.Κ. 194 00

Tel.: (30) 210 911 9600

Website: www.consumer.nilfi sk.gr

HOLLAND

Nilfi sk B.V.

Versterkerstraat 5

1322 AN Almere

Tel.: (+31) 36 5460760

Website: www.consumer.nilfi sk.nl

HUNGARY

Nilfi sk Kft.

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklós-Lakihegy

Tel.: +24/507-450

Website: www.nilfi sk.hu

INDIA

Nilfi sk India Limited

Pramukh Plaza, ‘B’ Wing, 4th fl oor, Unit No. 403

Cardinal Gracious Road, Chakala

Andheri (East) Mumbai 400 099

Tel.: (+91) 22 6118 8188

Website: www.nilfi sk.in

IRELAND

Nilfi sk Limited

1 Stokes Place

St. Stephen’s Green

Dublin 2

Tel.: (+353( (0)1 294 3838

Website: www.nilfi sk.ie

ITALY

Nilfi sk SpA

Strada Comunale della Braglia, 18

26862 Guardamiglio (LO)

Tel.: (+39) (0) 377 414021

Website: www.nilfi sk.it

JAPAN

Nilfi sk Inc.

1-6-6 Kita-shinyokohama, Kouhoku-ku

Yokohama, 223-0059

Tel.: (+81) 45548 2571

Website: www.nilfi sk.com

MALAYSIA

Nilfi sk Sdn Bhd

Sd 33, Jalan KIP 10

Taman Perindustrian KIP

Sri Damansara

52200 Kuala Lumpur

Tel.: +603 6275 3120

Website: www.nilfi sk.com

MÉXICO

Nilfi sk de México S. de R.L. de C.V.

Pirineos 515, Int. 60-70

Zona Industrial Benito Juárez

Queretaro, QRO, CP 76120

Tel.: (+52) (442) 427 77 91

Website: www.nilfi sk.com

NEW ZEALAND

Nilfi sk Limited

Suite F, Building E

42 Tawa Drive

0632 Albany Auckland

Tel.: (+64) 9 414 1996

Website: www.nilfi sk.com

NORWAY

Nilfi sk AS

Bjørnerudveien 24

1266 Oslo

Tel.: (+47) 22 75 17 80

Website: www.consumer.nilfi sk.no

PERU

Nilfi sk S.A.C.

Calle Boulevard 162, Of. 703, Lima 33- Perú

Lima

Tel.: (511) 435-6840

Website: www.nilfi sk.com

POLAND

Nilfi sk Sp. Z.O.O.

Millenium Logistic Park

ul. 3 Maja 8, Bud. B4

05-800 Pruszków

Tel.: (+48) 22 738 3750

Website: www.consumer.nilfi sk.pl

PORTUGAL

Nilfi sk Lda.

Sintra Business Park

Zona Industrial Da Abrunheira

Edifi cio 1, 1° A

P2710-089 Sintra

Tel.: (+351) 21 911 2670

Website: www.nilfi sk.pt

RUSSIA

Nilfi sk LLC

Vyatskaya str. 27, bld. 7/1st

127015 Moscow

Tel.: (+7) 495 783 9602

Website: www.consumer.nilfi sk.ru

SINGAPORE

Den-Sin

22 Tuas Avenue 2

639453 Singapore

Tel.: (+65) 6268 1006

Website: www.densin.com

SLOVAKIA

Nilfi sk s.r.o.

Bancíkovej 1/A

SK-821 03 Bratislava

Tel.: (+421) 910 222 928

Website: www.consumer.nilfi sk.sk

SOUTH AFRICA

Nilfi sk (Pty) Ltd

Kimbult Offi ce Park, 9 Zeiss Road

Laser Park, Honeydew

Johannesburg

Tel.: (+27) 118014600

Website: www.nilfi sk.co.za

SOUTH KOREA

Nilfi sk Korea

#204 2F Seoulsup Kolon Digital Tower

25 Seongsuil-ro 4-gil,

Seongdong-gu, Seoul

Tel.: (+82) 2 3474 4141

Website: www.nilfi sk.co.kr

SPAIN

Nilfi sk S.A.U

Paseu del Rengle, 5 Planta. 9-10

08302 Mataró

Tel.: (34) 93 741 2400

Website: www.consumer.nilfi sk.es

SWEDEN

Nilfi sk AB

Taljegårdsgatan 4

431 53 Mölndal

Tel.: (+46) 31 706 73 00

Website: www.consumer.nilfi sk.se

SWITZERLAND

Nilfi sk AG

Ringstrasse 19

Kircheberg/Industri Stelz

9500 Wil

Tel.: (+41) 71 92 38 444

Website: www.consumer.nilfi sk.ch

TAIWAN

Nilfi sk Ltd

Taiwan Branch (H.K)

No. 5, Wan Fang Road

Taipei

Tel.: (+88) 6227 00 22 68

Website: www.nilfi sk.tw

THAILAND

Nilfi sk Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Ladyao, Jatuchak, Bangkok 10900

Tel.: (+66) 2275 5630

Website: www.nilfi sk.co.th

TURKEY

Nilfi sk A.S.

Serifali Mh. Bayraktar Bulv. Sehit Sk. No:7

Ümraniye, 34775 Istanbul

Tel.: +90 216 466 94 94

Website: www.consumer.nilfi sk.com.tr

UNITED ARAB EMIRATES

Nilfi sk Middle East Branch

SAIF-Zone

P.O. Box 122298

Sharjah

Tel.: (+971) (0) 655-78813

Website: www.nilfi sk.com

UNITED KINGDOM

Nilfi sk Ltd.

Nilfi sk House, Bowerbank Way

Gilwilly Industrial Estate, Penrith

Cumbria CA11 9BQ

Tel: (+44) (0) 1768 868995

Website: www.consumer.nilfi sk.co.uk

UNITED STATES

Nilfi sk Inc.

14600 21st Avenue North

Plymouth, MN-55447

Tel.: (+1) 800-989-2235

Website: www.nilfi sk.com

VIETNAM

Nilfi sk Vietnam

No. 51 Doc Ngu Str.

P. Vinh Phúc, Q.Ba Dinh

Hanoi

Tel.: (+84) 761 5642

Website: www.nilfi sk.com

Loading...

Loading...