Page 1

HSC 585 MULTI

INFORMATION

&

OPERATING

INSTRUCTIONS

EXTRACTOR

220 - 240V EU

11600205211REVA

CAUTION: DO NOT OPERATE MACHINE

UNTIL YOU HAVE READ ALL SECTIONS

OF THIS INSTRUCTION MANUAL

-1-

26022008

10.22.2007

Page 2

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories,

shops, and offices other than normal residential housekeeping purposes.

When using any electrical appliance, basic precautions should always be followed, including the following:

NOTE: Read all instructions before using this machine.

WARNING!

To reduce the risk of fire, electric shock, or injury:

• Do not leave the machine unattended when it is plugged-in. Unplug the unit from the power outlet

when not in use.

• Unplug the machine from the power outlet before cleaning or servicing.

• Turn off all controls before unplugging.

• To avoid electric shock, do not expose to rain or snow. Store and use indoors.

• Wear hearing protection if desired. The measured sound level of the HSC585 is 75 dB(A)

• Do not allow to be used as a toy. Close attention is necessary when used near children.

• Use only as described in this manual. Use only the manufacturer’s recommended attachments.

• Inspect the power cord regularly for damage, such as cracking, ageing, or damaged insulation. Do

not use with damaged cord or plug. If the cord needs to be replaced, take the machine to an

authorized Nilfisk

• If the cord or prongs become damaged have it replaced by an authorized Nilfisk service technician

or partner.

• Use a defoamer any time you get foam in the recovery tank, to prevent motor damage.

• If foam or liquid comes out of the vacuum motor or exhaust, turn the machine off immediately.

• If the machine is not working as it should, has been dropped, damaged, left outdoors or flooded

with water, return it to a service center.

• Do not pull the machine by the cord, do not use the cord as a handle, close a door on the cord, or

pull the cord around sharp edges or corners. Do not run the machine over the cord. Keep the cord

away from heated surfaces.To unplug, grasp the plug, not the cord.

• Do not handle the plug, the cord, or the machine with wet hands.

• Extension cords must be 12/3 and no longer than 50 feet. Replace the cord or unplug immediately if

the ground prong becomes damaged.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint,

hair, and anything that may reduce air flow.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes, or

any health endangering dusts. Do not use to pick up flammable or combustible liquids such as

gasoline or use in areas where they may be present.

• Use extra care when cleaning on stairs.

• Connect to a properly grounded outlet only.

• Liquid pumped out could be dangerous because of temperature, pressure, or chemical content.

• Do not let the pump run dry. If you run out of water, turn the machine off and refill.

Page 3

INSPECTION:

Carefully unpack and inspect your HSC 585-MULTI for shipping damage. Each machine is tested

and inspected before shipping. Any shipping damage incurred is the responsibility of the carrier.

You should notify the carrier immediately if you notice damage to the box or to the machine or

parts.

CLEANING SOLUTIONS:

Select a proper pre-spray for the surface to be cleaned, and apply the pre-spra y. Use a neutral

pH rinse or detergent (6 to 9 pH) in the HSC 585 to prevent premature wear of the pump, seals

and other components. Powdered chemicals are not recommended.

MAINTENANCE:

For optimum performance, flush the machine with clear water at the end of each working day.

Once a month, minimum, run a flushing compound through the machine to break up any

mineral or chemical build-up that may have formed in the lines, the pumps, or the heater.

The vacuum motor, pump motor, and the pump do not require any scheduled maintenance;

however, the vacuum motors may require replacement brushes after 1000 - 1500 hours, and the

high pressure pump and unloader valve may require rebuild kits after 500 -1000 hours (refer to

machine part list for numbers). Clean the body with an all purpose detergent, and protect it with

an automobile interior polish. Lubricate the wheels, castors, and quick disconnects with an allpurpose silicone spray.

NOTE: to remove the complete reel with hoses from the machine, pull the vacuum hose loose

from the hose barb on the front of the tank, and push the short piece of vacuum hose into the

center of the hose spool. Disconnect the solution hose quick coupling. Grasp the spool from either

side, and lift it off the machine.

NOTE: before servicing any component in the base cabinet, remove the hoses and spool before

opening the tanks.

Record the serial number and model of your new extractor here:

Model:

Purchase Date:

Write the name and phone number of your distributor:

_____________________________________

_____________________________________

HSC 585-Multi_ Serial Number: __________________

_____________

11600205211REVA

-3-

Page 4

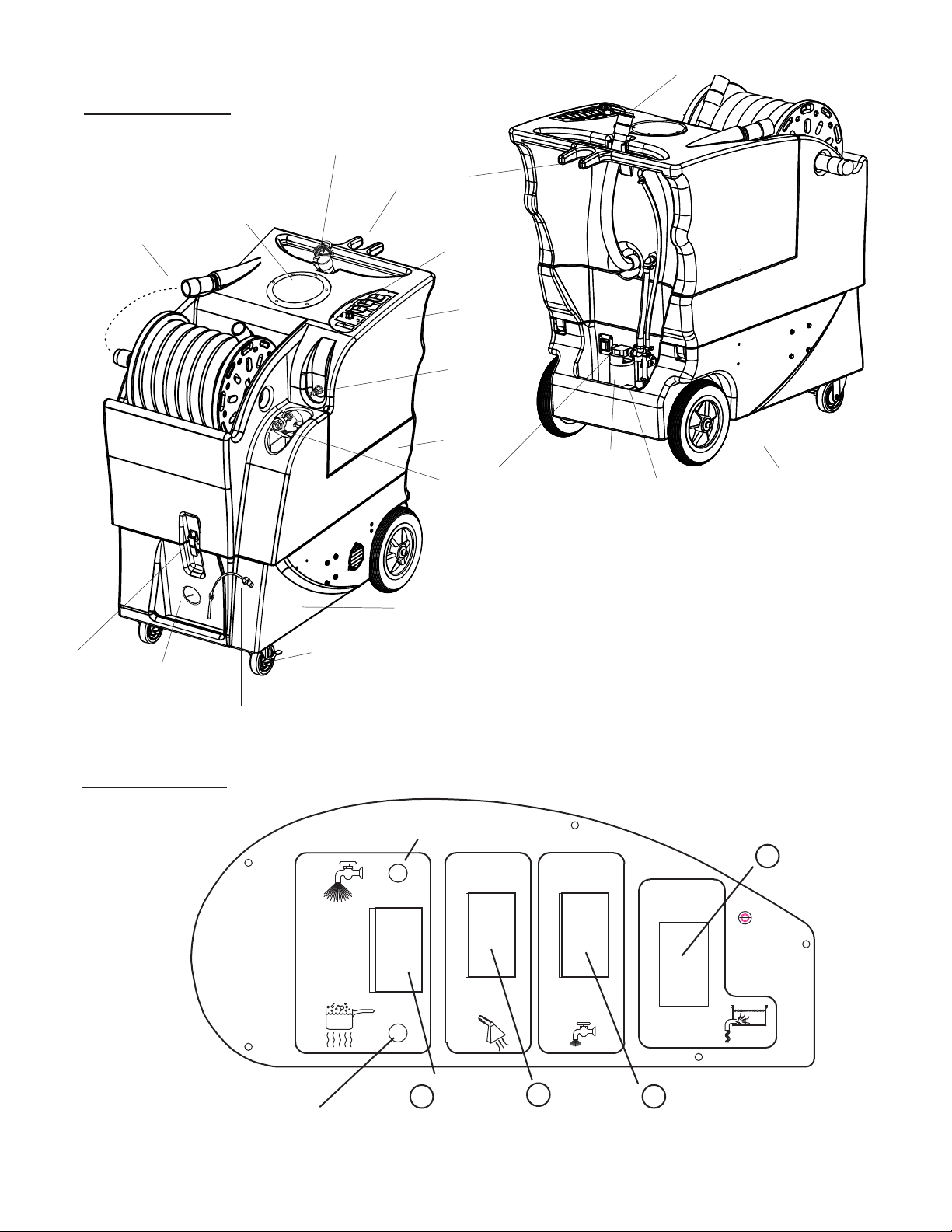

KNOW YOUR MACHINE

HSC 585 MULTI

Drain Hose

Drain Hose

Cap

Vacuum Hose

Connection

Hoses

Latch

Pressure

Gauge

SWITCH PLATE

Vacumm

T ank Lid

7 Bar

Quick Disconnect

Castor

with Brake

Wand Holder

Switches

Solution

Tank

Garden Hose

Connector

Wheel

Base

Compartment

HIGH

PRESSURE

PUMP

LIGHT

(NO HEAT)

I

Vac Tank

85 Bar

Quick

Disconnect

I

Auto

Dump

Pump

I

Power

Prime

Pedal

I

Wheel

Power

Cord

DUMP PUMP

5

ON/OFF

SWITCH

HEAT

SELECTED

LIGHT

I

2

PUMP/HEAT

SELECTOR

SWITCH

O

VACUUM

3

ON/OFF

SWITCH

O

4

100 PSI

PUMP

ON/OFF

SWITCH

O

Page 5

OPERATION

REFER TO THE DIAGRAMS ON THE PREVIOUS PAGE

CAUTION

: Never leave the 85 bar pump running if you are not actively using it

CAUTION: IF FOAM OR WATER COMES OUT THE VACUUM EXHAUST,

TURN THE MACHINE OFF IMMEDIATELY

HIGH PRESSURE WASHER

1 Before each use, inspect the machine, hoses, and cleaning tools for cleanliness and completeness. Make

sure hoses are in good condition and the spray nozzle(s) is tight.

REFER TO THE AUTO-FILL AND AUTO-DUMP INSTRUCTIONS ON THE FOLLOWING PAGES.

2. If you choose to use the automatic pump-out feature, connect the dump hose to the brass hose fitting

on the back of the machine, and place the open end of the hose in a drain. Make sure the drain hose

on the back of the vacuum tank is closed, and the lid is tight on the recovery tank. NOTE: never turn

ON the automatic pump-out switch unless you have removed the brass cap from the hose connector on

the rear of the machine. This pump will run continuously if it is turned on, and if the water can not be

pumped out (cap still screwed on) damage may occur to the pump.

If you choose not to use the auto pump-out option, just make sure the brass cap is on the hose

connector on the rear of the machine. CAUTION: do not turn the pump-out switch on if the cap is still

on the hose connector on the back of the machine.

3 . If you choose to use the auto-fill feature, connect the fill-hose to the auto-fill valve (located over the

solution tank fill hole). Turn on the water source. NOTE: do not turn the water on full power. The water

flowing into the auto-fill system does not need a lot of pressure behind it. Allow the tank to fill with

solution. When you use the auto-fill system, the auto-fill valve will automatically turn on and turn off as

the tank empties and then fills. NOTE: If you are not going to use the auto-fill system, just fill the

tank with water and cleaning chemical. Follow chemical directions regarding dilution and mixing. Do not

use harsh chemicals; they may damage seals in pumps and valves, and cause the pump to wear

prematurely. NOTE: Never put water in the tank with a temerature exceeding 54

°

C/130 °F.

4 . Pre-spray the area to be cleaned with a pump-up sprayer. Follow chemical directions.

5 . Plug in the power cord. Turn on the high pressure pump by placing the HIGH PRESSURE/HEAT selection

switch (2) in the UP position, to select the High Pressure Pump. NOTE: The high pressure pump and

the heat can not operate at the same time. NOTE: this switch is off when it is set to the middle

position and neither the high pressure pump nor the heater is selected.

6 . The 85 bar pump is not self-priming; you will need to prime the high pressure pump using the ‘power

prime’ system: turn on both the pump and the vacuum, cover the hole in the hose barb with your

hand, then depress the Power Prime Pedal. This will pull trapped air out of the pump and into the

recovery tank

, priming the pump. You will notice a ‘tone’ change in the pump (smoother, with less of a

rattle), and the water being pulled into the recovery tank will change from a white, full of air stream of

continue on next page

Page 6

HIGH PRESSURE continued

water to a clear, solid stream. Priming may take 20 - 60 seconds, or even longer sometimes, and it will

require a

pump and the vacuum. Then press the Power Prime Pedal once again, for a moment,

full solution tank. When the pump is primed, let off the Power Prime Pedal, and turn off the

to release the line

pressure; you will hear a ‘swoosh’ of air as the back pressure in the lines is released. The pump will need

to be primed anytime air gets into it -- try not to let the pump run dry. Proceed to the next step.

7. Add defoamer to the recovery tank.

8 . Attach the solution spray hose to the solution quick disconnect. Attach the vacuum hose to the hose

barb on the front of the recovery tank. Pull the hoses out from the reel. Attach the other ends of the

hoses to the cleaning tool.

9. If you choose to use the automatic pump-out feature, MAKE SURE THE CAP IS REMOVED FROM THE

HOSE CONNECTION ON THE BACK OF THE MACHINE BEFORE YOU TURN THE SWITCH ON. This

pump will run continuously once you turn it on, and if it tries to pump out water, but the cap is still on the

hose fitting, the pump may be damaged.

10. Turn on the vacuum (3) and turn on the dump pump (if you chose to use this feature) (5). Begin

spraying. If you are not using the auto-fill or auto-dump features, turn off the pump and vacuum when

the solution tank gets low; fill the solution tank, and empty and clean the recovery tank. If you use the

auto-fill and/or auto-dump features, you will not need to stop working to fill and/or empty your tanks.

11 . When the job is finished, turn off the automatic pump-out pump turn and turn off the water source, if

they were employed. Use the vacuum hose to suck the remaining solution from the holding tank into the

recovery tank.

13 . Run a few gallons of clean water through the system. Completely empty the recovery tank by placing the

drain hose over a floor drain, toilet, or tub, and removing the cap. You can clean the tank at this time with

clean water. When the tank is empty, cap the drain hose and place it back in the hook and loop holder.

Disconnect the hoses from the cleaning tool, and reel them up onto the hose spool.

14 . Unplug the power cord. Clean the machine and the tool.

LOW PRESSURE AND HEAT

CAUTION: if foam or water comes out the vacuum exhaust, turn

the machine off immediately

1 Before each use, inspect the machine, hoses, and cleaning tools for cleanliness and completeness. Make

sure hoses are in good condition and the spray nozzle(s) is tight.

REFER TO THE AUTO-FILL AND AUTO-DUMP INSTRUCTIONS ON THE FOLLOWING PAGE

2. If you choose to use the automatic pump-out feature, connect the dump hose to brass hose fitting on

the back of the machine, and place the open end of the hose in a drain. NOTE: NEVER TURN ON THE

PUMP OUT PUMP UNTIL YOU HAVE REMOVED THE CAP FROM THE HOSE CONNECTOR ON THE REAR

OF THE MACHINE. Make sure the drain hose on the back of the vacuum tank is closed and the lid is tight

on the recovery tank. If you are not going to use the auto pump-out option, just make sure the brass

cap is on the hose connector on the rear of the machine.

continue on next page

Page 7

LOW PRESSURE AND HEAT continued

3 . If you choose to use the auto-fill feature, connect the fill-hose to the hose connection over the solution

tank fill hole. Turn on the water source, and allow the tank to fill with solution. NOTE: do not turn the

water on to full pressure; water flowing into the auto-fill system does not need a lot of pressure behind it.

If you choose not to use the auto-fill system, just fill the tank with water and cleaning chemical. Follow

chemical directions regarding dilution and mixing. Do not use harsh chemicals as they may damage seals

in pumps and valves, and cause the pump to wear prematurely. NOTE: using warm water in the tank

may improve the efficiency of the heat exchanger when cleaning with heat, but never use water with a

temperature exceeding 54

°

C/130 °F.

4. Select ‘HEAT” by moving the HEAT/HIGH PRESSURE switch towards the thermometer symbol. NOTE:

this switch is off when it is set to the middle position and neither the high-pressure pump nor the heater is

selected. When set to the bottom position, the heat is selected; the red light will come on and stay on.

The heater and the high-pressure pump can not operate at the same time.

5 . Plug in the power cord.

6 . Press the ‘power prime’ pedal (located on the rear, lower left of the machine) for a moment to release

any back pressure in the pump lines.

7. Connect the solution hose to the quick disconnect on the short hose from the 7 bar pump on the front

of the base, and connect the vacuum hose to the hose barb on the top, left of the recovery tank.

Connect the other ends of both hoses to the cleaning tool.

8 . Turn on the 7 bar “demand” pump (4). NOTE: the ‘demand’ pump will not run until pressure is

released.

9 . Spray for a few seconds to fill the lines with solution. Wait two minutes to allow the heater to reach

temperature.

10. Begin cleaning. It may take several cycles to heat the lines and the cleaning tool.

11 .If you are not using the auto-fill or auto-dump features, turn off the pump and the vacuum when the

solution tank gets low. Fill the solution tank, and empty and clean the recovery tank. If you are using

the automatic features, your machine will empty and fill itself -- no need for you to stop working.

12 . When finished with the job, turn off the water source, if using the auto-fill feature. Remove the auto-fill

hose from the hose connection on the machine. Vacuum the remaining solution from the solution holding

tank into the recovery tank. Run a few gallons of clean water through the system. Drain the

recovery tank by placing the drain hose over a floor drain, toilet, or tub and removing the cap. You can

clean the tank at this time with clean water. When the tank is empty, cap the drain hose and place it

back in the hook and loop holder. Disconnect the hoses from the cleaning tool, and reel them up onto the

hose spool.

13 .Unplug the power cords. Clean and dry the machine and the tool.

DANGER: always unplug the machine from the electrical outlet(s) before

cleaning or maintaining.

NOTE: before servicing any component in the base cabinet, remove the hoses and spool

before opening the tanks. Refer to the instruction on page 3.

Page 8

USING THE AUTOMATIC-FILL AND/OR AUTOMATIC-DUMP

AUTOMATIC-FILL INSTRUCTIONS

Operation:

1. Attach a garden hose to the auto-fill hose connection above the holding tank fill hole, and connect the

other end of the hose to your water source.

2. Make sure the float that hangs into the solution tank from the auto-fill valve is free of obstruction and

can move freely.

3. Turn on the water supply. Do NOT turn the water on full pressure. This system does not require a

high presssure water source. Just turn the water on.

4. The float for the automatic fill will shut-off the flow of incoming water when the tank is nearly full, and

it will allow the valve to open again once the water level has dropped to a predetermined level.

AUTOMATIC-FILL

High

Pressure

Outlet

Water Hose

Connection

Page 9

AUTOMATIC-DUMP INSTRUCTIONS

Operation:

1. Before each use: if necessary, unscrew the stainless steel filter inside the recovery tank and clean it.

Also make sure the float in the recovery tank is clean.

2. Attach a garden hose to the automatic pump-out fitting on the back of the base of the machine (refer

toillustration below).

3. Run the other end of the hose into a drain.

4. Turn on the switch for the automatic pump-out (switch is located on the switch panel on the top of the

machine).

NOTE: the pump out pump is ‘self-priming.’ When there is water in the recovery tank, it will automatically

pump out.

After each job, run clear water though the automatic pump-out to wash out any chemical residue.

Remove and clean the stainless steel filter in the back of the tank. Reinstall the filter once it is clean.

Empty and clean the recovery tank. Disconnect and roll up the dump hose. Clean and dry the

machine and accessories.

DANGER: DO NOT USE SOLVENTS, OR ANY CHEMICALS THAT MAY BE FLAMMABLE,

EXPLOSIVE, OR COMBUSTIBLE.

CAUTION: always use a defoamer in the recovery tank to prevent water or foam from

entering the vacuum motor.

AUTOMATIC-DUMP

Hose

Connection

Dump

Pump

Power

Prime

Valve

Power

Prime

Pedal

11600205211REVA

-9-

Page 10

23

1

2

5

3

4

6

14

7

34

12

11

13

9

8

10

24

17

21

16

15

30

31

18

HSC 585 Multi

REV A 3.8.08

28

20

32

19

20A

37

25

26

21A

29

27

22

23

Page 11

HSC 585 MULTI

PAR T LIST

220 - 240V

ITEM QTY PART No. DESCRIPTION

1 1 600758501 Reel with hoses, complete

2 1 600758502 Lid kit

3 1 600758503 Vacuum air inlet kit

4 1 600758504 Switch plate kit

5 1 600758505 Switch and light kit

6 1 600758506 Auto-fill kit

7 1 600758516 Vacuum tank

8 1 600758508 Heater outlet kit

9 2 600758509 Cord wrap kit

10 1 600758510 Solution tank

11 1 600758511 Fuse kit

12 1 600758512 Water inlet filter kit

13 1 600758513 Power prime kit

14 1 600758514 Drain hose kit

15 1 600758515 Power cord kit, EU

1 600758536 Power cord kit, UK

16 1 600758531 Auto-dump pump kit

17 1 600758517 Vacuum motor kit

18 1 600758518 Pump kit, 7 bar

19 1 600758519 Pump and motor, complete, 85 bar

20 1 600758520 Pump complete, 85 bar, no motor

20A 1 600758544 Pressure regulator, unloader valve

21 1 600758541 Relay kit, vacuum motor

21A 1 600758542 Relay kit, pump motor

22 1 600758522 Base

23 1 600758523 Pressure gauge kit

24 1 600758524 Glide kit, for reel

25 1 600758525 Heat exchanger replacement kit

26 1 600758526 Heat repair kit

27 1 600758527 Low pressure pump outlet kit

28 1 600758528 Castor kit (2)

29 1 600758529 Louver kit

30 1 600758530 Wheel kit (2)

31 1 600758538 RFI filter kit

32 1 600758532 Latch kit

33 1 600758537 Motor, no pump (85 bar)

34 1 600758545 Internal water hoses, kit

MISCELLANEOUS PARTS AND KITS

1 600758521 Pump rebuild kit

1 600758533 Vacuum hose kit, for reel

1 600758534 Solution hose kit, for reel

1 600758535 Label kit

1 600758540 Water inlet filter bag (4 in kit)

ALWAYS USE ONLY ORIGINAL NILFISK PARTS ON YOUR HSC 585 MULTI

Page 12

ACCESSORIES

HFT-40

TURBO HARD SURFACE

TOOL

600305899

• Use on all types of hard flooring

2

• Cleaning capacity is up to 93 m

• Lightweight, but robust

• Brush ring attachment

• No wheels to restrict 360° travel

• Water temperature up to 110 °C / 230 °F

• Patented automatic vacuum compensator

leaves the floor dryer

• In line filter keeps spray jets clean

or 1000 ft2/Hr

HFT-45

HARD SURFACE

COMBO TOOL

60070045

• Designed for edging hard surfaces

• Hose is rated to 172 bar / 500 -2500 psi

• Use water up to 110 °C / 230°F

• Heads lay flat for cleaning under fixtures

• Ergonomic design

EVOLUTION CARPET WAND

600203099

• Use it with the 7 bar/100 psi pump on carpets

• Its light weight is less fatiguing

• It recovers more water from the carpet than

heavier wands

• Use with heated water up to 100 °C / 215°F

HFT-43

MINI TURBO HARD

SURFACE TOOL

60070043

• Great fo getting in those small areas

• 35 to 172 bar / 500 -2500 psi

• Use it on floors or walls

• Lightweight but sturdy

• No wheels to restrict 360° travel

• Water temperature up to 110 °C / 230 °F

IN-LINE FILTER

600709908

• Connect the filter to the water inlet of most

tools

• Prevents plugged spray jets

• Comes apart for cleaning

STAINLESS STEEL HAND TOOL

600203099

• Use it with up to 27 bar / 400 psi

• Durable

• Reliable valve

• Optional in-line filter available

HOOK AND LOOP STRAP

600709906

• Connect the filter to the water inlet of most

tools

• Prevents plugged spray jets

• Comes apart for cleaning

Page 13

SPECIFICATIONS:

MX 585 MULTI

Vacuum at Nozzle:

NOTES:

Vacuum:

Rated Power:

Pump:

Suction Power:

Heat:

Suction Width:

Weight:

Dimensions:

3-stage

2950 W maximum

Positive displacement, 83 bar & Demand,7 bar

372 W

30.4 KPA

to 100

ºC

38 mm

89.5 KG

39”H x 21”W x 36” L

11600205211REVA

11-600205211REVA

-13-

Loading...

Loading...