Page 1

Instructions/Spare Parts Manual

Nilfisk Model GWD120

Nilfisk Model GWD220

(single motor)

(dual motor)

Wet/Dry Tank Vacuum

CAUTION: This Nilfisk vacuum cleaner is not to be used in explosion-hazardous areas, as

serious injury could result.

Under no circumstances may this vacuum cleaner be used safely for the collection of hazardous or

toxic materials unless equipped with a HEPA filter. Be sure to install the HEPA filter according to

Nilfisk’s written instructions.

Do not use this cleaner for the removal of hazardous substances unless you are licensed and/or

certified for this work by the all authorities having jurisdiction.

EMPTYING: If this vacuum cleaner is used to collect hazardous material, do not attempt to open

or empty its contents without personal protective clothing and respiratory protection. This

procedure must be completed in a contained environment. Contact with the cleaner, filters and all

other accessories used when picking-up hazardous materials must be handled according to federal

(EPA, OSHA), state and local regulations valid for the vacuumed substance.

ATTENTION EMPLOYER: Please ensure these instructions for use are made available and

understood by your employees or any other persons who may use this equipment.

To list all toxic and hazardous materials would be beyond the scope of these instructions. It is the

Employer’s responsibility to identify, for Employee’s and others’ information, hazardous or toxic

materials which may be collected by this equipment. Such information must be communicated to

your Employees and other potential users of this equipment.

Nilfisk-Advance America Inc.

300 Technology Drive

Malvern, PA 19355

Tel: 1.610.647.6420

Fax: 1.610.647.6427

www.pa.nilfisk-advance.com

e-mail: email@nilfisk-advance.com

Page 2

Page 3

Page 4

1

2

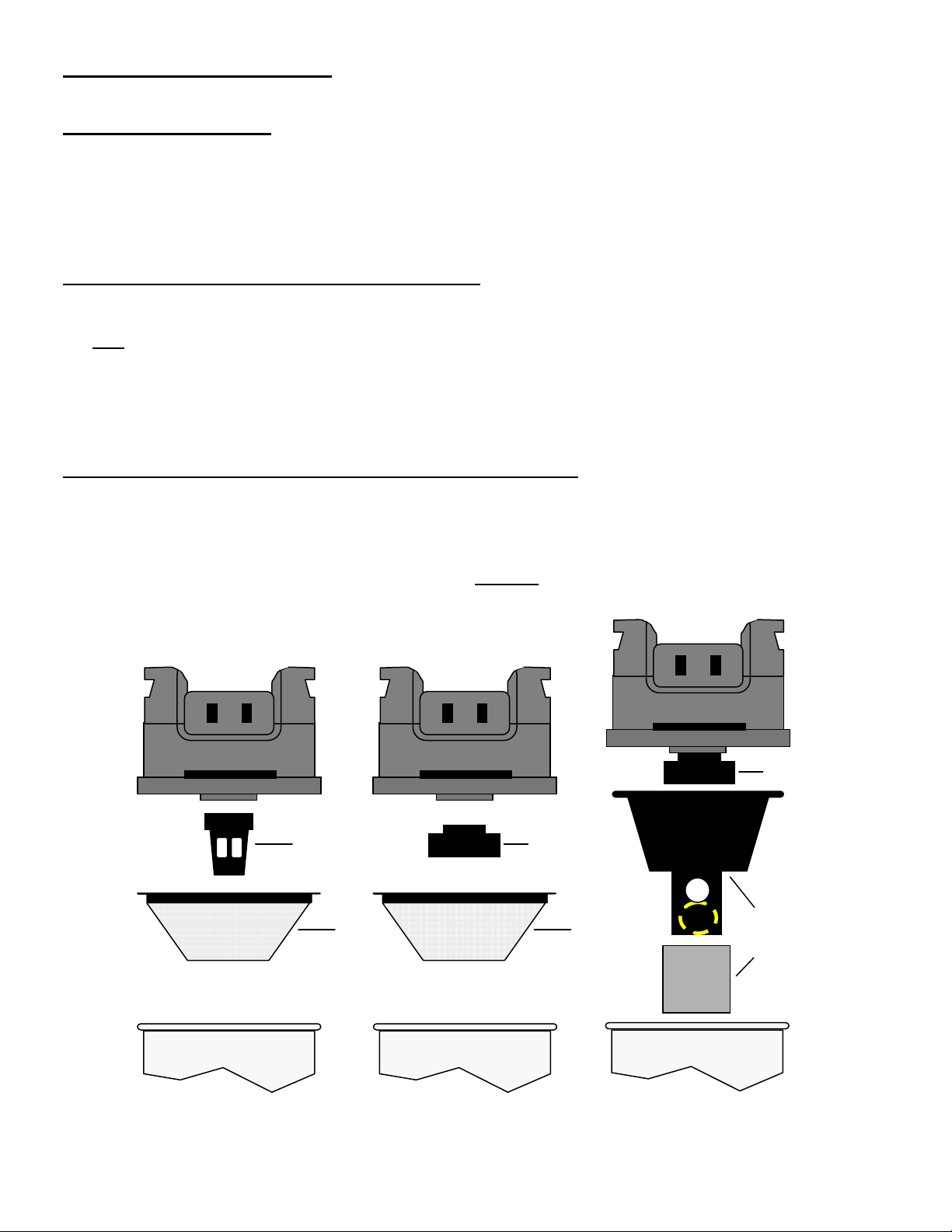

Figure A

3

2

4

5

3

Figure B

Figure C

Machine Configuration

Standard Configuration (Figure A, below)

The GWD120 and 220 model vacuum cleaners are configured for wet/dry collection. The

machines are equipped from the factory with a standard float basket (1) that is designed to shut off

the flow of air when the liquid in the tank reaches the maximum level. The machines are also

equipped with a main filter (2). This filter is washable and does not need to be removed when

collecting wet materials.

Optional HEPA filter/Dust Bag for Dry Use Only (Figure B, below)

If the machines are used for dry collection only, the standard float (1) can be removed and

replaced with an optional, upstream HEPA filter (3) (see HEPA Installation on next page). [NOTE:

Do not use the vacuum cleaner to collect wet materials without the float in place. This would allow

water to enter the motorhead, which could damage the machine.] The main filter (2) should be

used when collecting dry materials. The main filter will protect and prolong the life of the HEPA

filter. Optional dust bags are available for the GWD120 and 220 machines (see parts lists for

optional filters).

Optional HEPA filter/Float Chamber for Wet/Dry Collection (Figure C, below)

If a HEPA filter is required during wet/dry collection, the standard float basket must be replaced

with the optional float chamber assembly (4). The float chamber is a float device with a protective

housing that surrounds the HEPA filter. It is designed to protect the HEPA filter from moisture

during wet collection. A foam filter (5) is included with the float chamber to prevent debris from

entering the float ball cavity. The main filter (2) can not be used with the optional float chamber

and should be removed from the machine.

(std. wet/dry use)

(dry use with HEPA)

(wet/dry use with HEPA)

Page 5

Optional

H

EPA

Filter

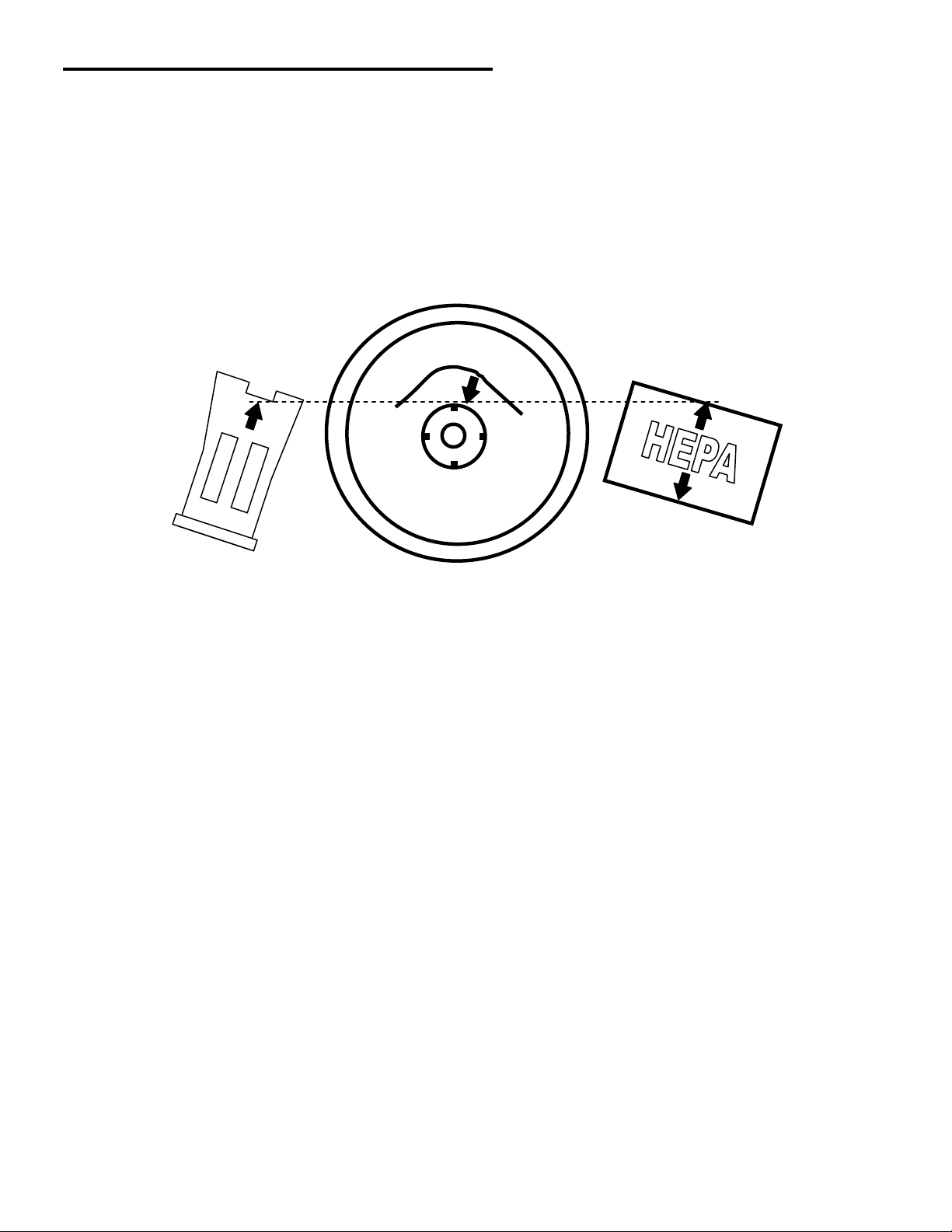

Assembly and Operation of Machine

Float Basket / Optional HEPA Filter

The float basket also serves as the support for the main filter. It will prevent the filter from

collapsing under vacuum pressure. The float basket and the optional HEPA filter are mounted in

the same location under the motor head. If the optional HEPA filter is used, the float basket must

be removed. Once installed, the HEPA filter will serve as the support for the main filter. If the

HEPA filter is removed from the machine, be sure to reinstall the float basket before continuing to

use the main filter.

Installation / Removal of Float Basket

1. To install the float basket, align the arrow on the outside of the basket with the arrow on the

underside of the motor head as shown above. Make sure the float inside is oriented properly with

the open end facing downward. Twist the float basket clockwise until it locks into place.

2. To remove the float basket, twist the support counterclockwise until it unlocks from the motor

head. Remove the float basket and inspect the condition of the foam motor gasket underneath. If

gasket is dirty or damaged, replace it.

Installation / Removal of HEPA Filter

EMPTYING: If this vacuum cleaner is used to collect hazardous material, do not attempt to open

or empty its contents without personal protective clothing and respiratory protection. This

procedure must be completed in a contained environment. Contact with the cleaner, filters and all

other accessories used when picking-up hazardous materials must be handled according to federal

(EPA, OSHA), state and local regulations valid for the vacuumed substance.

1. Before installing the optional HEPA filter, make sure the float basket has been removed from

the underside of the motor head. Align the arrow on the HEPA filter with the arrow on the motor

head as shown above. Twist the HEPA filter clockwise until it locks into place.

2. To remove the HEPA filter, twist the filter counterclockwise until it unlocks from the motor head.

Remove the HEPA filter and inspect the condition of the foam motor gasket underneath. If gasket

is dirty or damaged, replace it.

Float Basket

Underside of motor head

Page 6

Assembly and Operation of Machine (continued)

NOTE: Unplug the machine before servicing, emptying or assembling.

Connect the suction hose to the tank by pushing the hose coupling directly into the machine’s inlet.

The hose should click into place. To remove the hose, press the release button at the top of the

inlet and pull the hose straight out. Slide one of the extension tubes over the hose handle and

slide the other tube over the end of the first tube. Select the appropriate insert for the floor tool and

lock the insert in place using the red sliding tabs on top of the floor tool. Plug the extension tube

into the neck of the floor tool and press the assembly together.

The height of the machine’s handle is adjustable. Loosen the locking screws on each side of the

handle and adjust height to the desired position. Tighten the screws to secure the handle in place.

Make sure the power switch(es) are off (indicated by position “0”) before connecting the machine to

its power source. Plug the power cord into a suitable electrical outlet. Turn the machine ON by

pressing the power switch(es) to the position marked “I”.

Wet Pick up

This machine is equipped with a float that shuts off the airflow through the machine when the

maximum liquid level is reached. A noticeable change in sound level will occur when the float has

actuated. This will be accompanied by a sudden loss of suction power. When this occurs, turn the

machine off.

Emptying the Container

Release the latch on each side of the motorhead and lift the motorhead off of the container.

Remove the main filter and/or float chamber (if equipped). Place one foot behind the rear wheel of

the machine to prevent the machine from moving while emptying. Grasp the handle at the bottom

of the tank and tilt the container backwards to empty. Clean or replace the filters if necessary

before reinstalling. Replace the motorhead onto the container and secure in place using the

latches.

NOTE: Inspect and clean the float system after each use to insure that the float is working

properly. Use a chemical defoaming agent when picking up water containing foaming detergents.

Use only a defoamer recommended by the detergent manufacturer.

Cleaning the Main Filter

The main filter is washable. To clean the filter, remove it from the machine and shake off all excess

debris. Wash the filter gently in water. A mild detergent can be used. Allow the filter to dry

thoroughly before collecting dry materials. To reduce drying time, replace the filter inside the

machine and turn the vacuum on. The air from the vacuum motor will help to dry the filter.

The foam filter on the float chamber is also washable. Shake off any loose debris and wash the

filter gently in water.

The HEPA filter is not washable and no maintenance should be performed on the HEPA filter.

Once the HEPA filter becomes clogged it should be disposed of in accordance with federal (EPA,

OSHA), state and local regulations.

Page 7

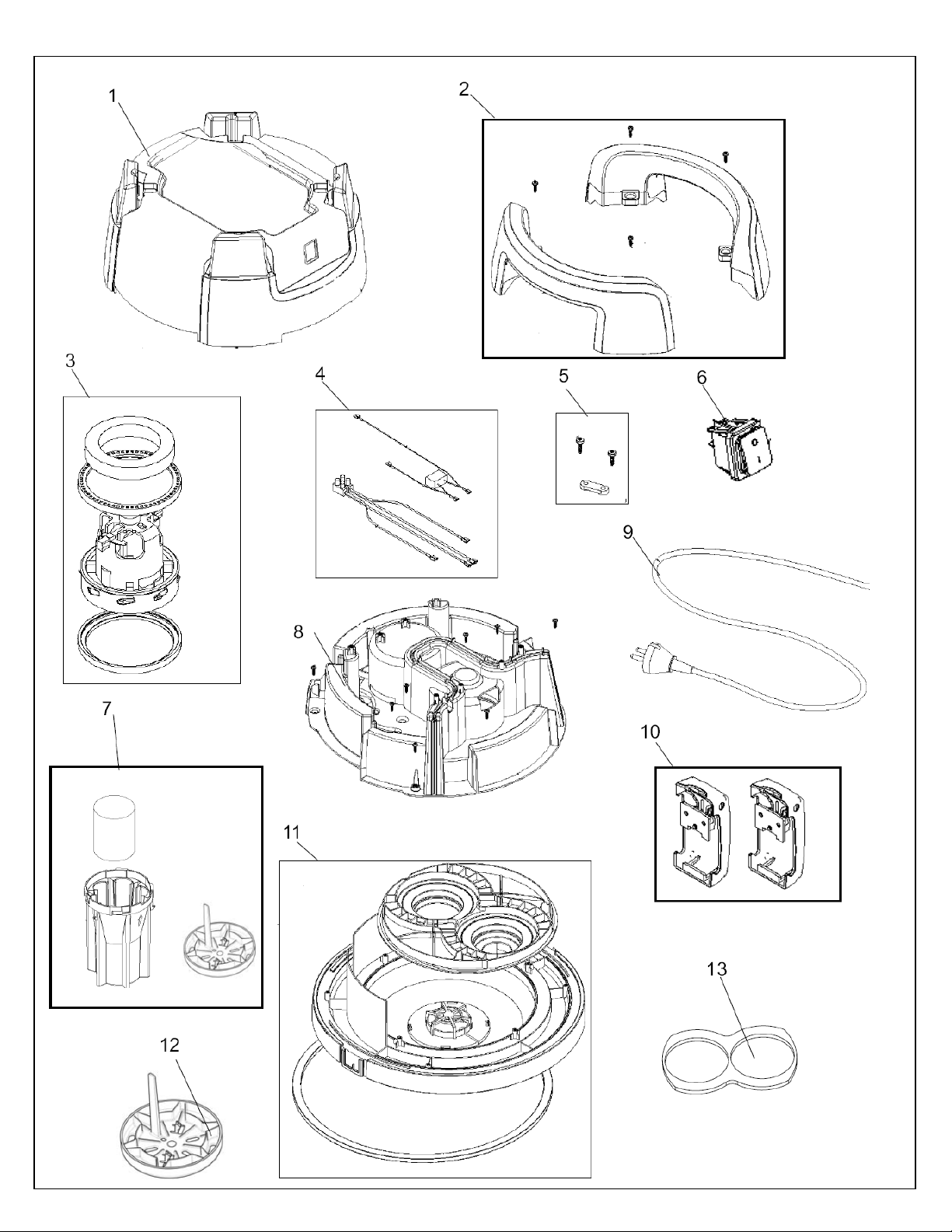

Parts Explosion – GWD120 Motorhead Assembly (single motor)

Page 8

Parts Explosion – GWD120 Motorhead Assembly (single motor)

Page 9

Parts Explosion – GWD220 Motorhead Assembly (dual motor)

Page 10

Parts Explosion – GWD220 Motorhead Assembly (dual motor)

520

Page 11

Parts Explosion – GWD120/220 Container Assembly

Page 12

Parts Explosion – GWD120/220 Container Assembly

Page 13

Parts Explosion – GWD120/220 Trolley Assembly

Page 14

Parts Explosion – GWD120/220 Trolley Assembly

Page 15

Parts Explosion – GWD120/220 Hose and Accessories

Page 16

Parts Explosion – GWD120/220 Hose and Accessories

Page 17

(Optional)

Parts Explosion – GWD120/220 Standard and Optional Filters

(Optional)

(Optional)

4

(Optional)

3

5

(Standard)

6

(Standard)

Page 18

Parts Explosion – GWD120/220 Standard and Optional Filters

1 147 0746 010 1 Dust Bag (3/pack) Optional

2 M90041 1 Float Chamber Assembly Optional - Required

w/ Foam Impact Filter when using HEPA

for wet collection

3 01786000 1 Foam Impact Filter Optional

4 140 8678 500 1 HEPA filter Optional

5 140 9512 500 1 Main Filter Standard

6 140 8682 500 1 Motor Filter Standard

Page 19

Parts Explosion – GWD120/220 Optional Fixed Front Nozzle

Page 20

Parts Explosion – GWD120/220 Optional Fixed Front Nozzle

Page 21

Warranty

The Nilfisk companies warrant that Nilfisk equipment will be free of defects in workmanship or material for a period of

two years from the date of delivery. Should any failure to conform to this warranty appear, the Nilfisk companies

shall upon notification within such time period, correct such non-conformity, at its option, either by repairing any

defective part or parts, or by replacing a part or parts provided that the equipment is returned to an authorized Nilfisk

service facility. In all cases freight both ways will be at the expense of the customer. Equipment shall not be

returned without advance notice to, and consent of the Nilfisk companies.

EXCEPT AS SPECIFICALLY SET FORTH HEREIN, THE NILFISK COMPANIES MAKE NO WARRANTIES, EITHER

EXPRESSED OR IMPLIED AS TO ANY MATTER WHATSOEVER, INCLUDING WITHOUT LIMITATION ANY AND

ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR PURPOSE, OR OTHER WARRANTIES, ALL OF WHICH

ARE EXPRESSLY DISCLAIMED AND EXCLUDED. NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LOSS

OF PRODUCTION, LOSS OF TIME, LOSS OF PROFITS OR OTHER SIMILAR INDIRECT LOSSES WHICH MIGHT

OCCUR AS A RESULT OF DEFECTS, PARTIAL OR TOTAL FAILURE OF THE PRODUCT TO PERFORM AS

SPECIFIED.

Correction of non-conformities or defects in the manner and for the period of time provided above, shall constitute

fulfillment of all liabilities of the Nilfisk companies to the customer, whether based on contract, negligence or

otherwise with respect to, or arising out of such equipment. The remedies set forth herein are exclusive, and the

liability of the Nilfisk companies with respect to this sale or anything done in connection therewith, whether in

contract, in tort, under any warranty, or otherwise, shall not except as expressly provided herein, exceed the price of

the equipment or part on which such liability is based.

The warranty does not cover repairs due to normal wear and tear, accident, neglect, misuse or abuse,

incorrect installation or use other than as described in the instruction booklet. Breaks in hoses and cables

are not covered. This warranty is rendered void if the motor number plate is removed or defaced or if repairs

are made or attempted by persons not authorized by the Nilfisk companies.

Nilfisk-Advance America Inc.

300 Technology Drive

Malvern, PA 19355

Tel: 1.610.647.6420

Fax: 1.610.647.6427

www.pa.nilfisk-advance.com

e-mail: email@nilfisk-advance.com

Loading...

Loading...