Page 1

112, 115, 212, 215, 218

GU 12 SMU, GU 15 SMU

GU 12 DMU, GU 15 DMU,

GU 18 DMU

INSTRUCTIONS FOR USE

MODE D'EMPLOI

INSTRUCCIONES DE USO

EN

ES

FR

English

Español

Français

READ THIS BOOK

LEA ESTE LIBRO

LISEZ CE MANUEL

This book has important information for the use and safe operation of this machine. Failure to read

this book prior to operating or attempting any service or maintenance procedure to your Clarke

machine could result in injury to you or to other personnel; damage to the machine or to other property

could occur as well. You must have training in the operation of this machine before using it. If your

operator(s) cannot read this manual, have it explained fully before attempting to operate this

machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

For new books write to: Clarke®, 2100 Highway 265, Springdale, Arkansas 72764.

Printed in China

823 0102 040

Edition 1 2007-11

Page 2

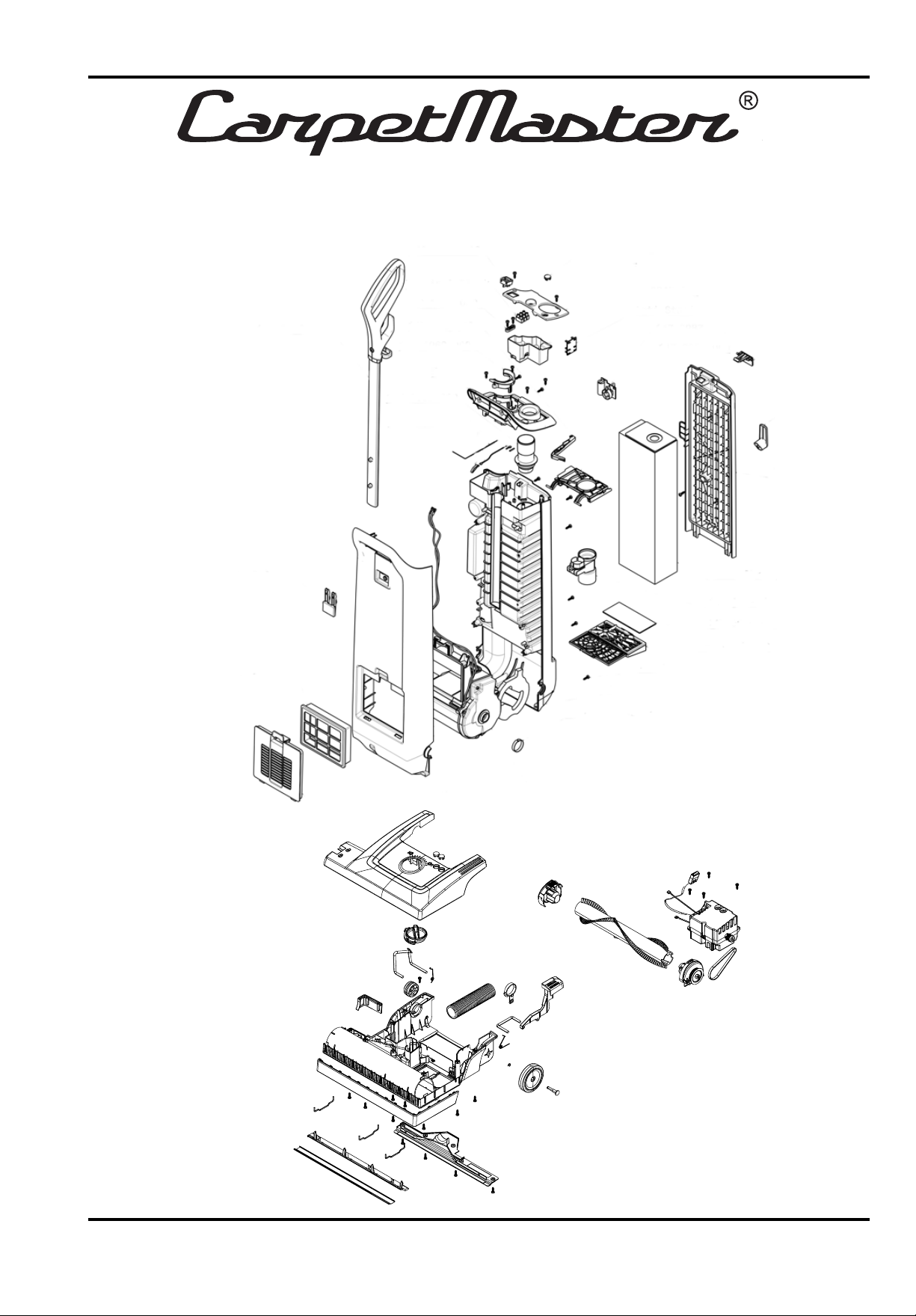

Exploded view - Vue éclatée - Vista detallada

2

Page 3

English 4-13

Français 14-23

Español 24-33

Clarke reserves the right to make changes or improvements to its machine without notice.

Always use genuine Clarke Parts for repair.

2100 Highway 265

Springdale, Arkansas, 72764

3

Page 4

CONTENTS

Important Safety Instructions

Grounding Instructions

Introduction

Parts and Service

Rating plate

Unpacking the Machine

Technical Specifi cations

Know Your Machine

Set-Up and Assembly

Operating the Machine

Using the Wand

Using the Tools

Maintenance

Changing the Paper Dust Bag

Changing the Cloth Dust Bag

Changing the Brush

Changing the HEPA-fi lter

Changing the Exhaust fi lter

Cleaning or changing the Pre-Filter

After Using the Machine

.......................................................................................... 7

........................................................................................... 7

..................................................................................... 10

.......................................................................................10

......................................................................................... 11

.......................................................................... 6

................................................................................. 7

......................................................................... 7

............................................................................... 8

........................................................................... 8

.......................................................................... 9

............................................................................12

................................................................. 5

.........................................................................7

............................................................... 11

................................................................ 11

......................................................................12

...................................................................13

.......................................................................13

......................................................13

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be followed, including the following:

Read all instructions before using this appliance.

This machine is for commercial use, for example in hotels, schools, hospitals, factories, shops and offi ces other than

normal residential housekeeping purposes.

THIS APPLIANCE IS INTENDED FOR DRY USE ONLY!

DO NOT USE FOR WET FLOOR OR CARPET!

WARNING!

To reduce the risk of fi re, electric shock, or injury:

* Do not leave the appliance when it is plugged in. Unplug the unit from the outlet when not in use and before servicing.

WARNING!

To reduce the risk of electric shock, do not use outdoors or on wet surfaces.

* Do not allow to be used as a toy. Close attention is necessary when used by or near children.

* Use only as described in this manual. Use only the manufacturer’s recommended attachments.

* If the appliance is not working as it should be, has been dropped, damaged, left outdoors or dropped into water,

return it to a service center. The machine must not be used if the electrical cord shows any sign of damage.

Regularly inspect the cord for damage, particularly if it has been crushed, shut in a door or run over.

* Do not pull or carry by the cord, use the cord as a handle, or pull the cord around sharp edges or corners.

Keep the cord away from heated surfaces.

* Do not unplug by pulling on the cord. To unplug, grasp the plug, not the cord.

* Do not handle the plug, cord or appliance with wet hands.

* Do not put any object into openings. Do not use with any opening blocked.

* Keep loose clothing, hair, fi ngers, and all parts of body away from openings and moving parts.

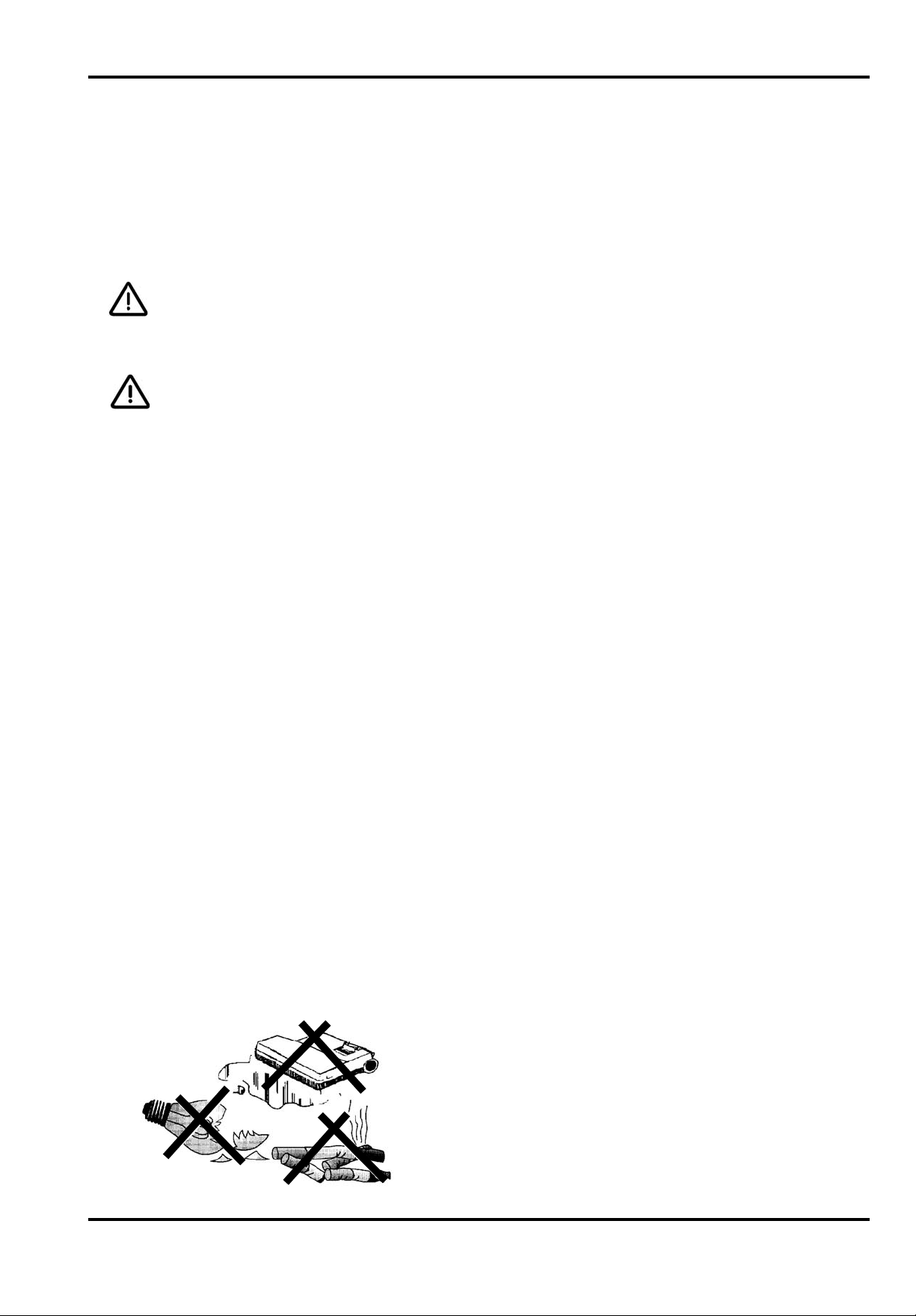

* Do not pick up anything that is burning or smoking, such as cigarettes or matches. Under no circumstances should

the machine be used for picking up hot material. In particular the machine must not be used for cleaning open and

closed fi replaces, ovens or similar that contain warm or glowing ashes.

* Do not use without dust bag and/or fi lters in place.

* Turn off all controls before unplugging. The plug must always be removed from the socket outlet before starting any

service or repair work of the vacuum cleaner or the cord.

* Avoid vacuuming hard or sharp objects.

* Use extra care when cleaning on stairs.

* The machine must not be used for picking up combustible materials which are health endangering or explosive

materials such as petrol (gasoline), nor should it be used in an explosive atmosphere.

The machine must not be used for picking up water, other liquids or for picking up hazardous - i.e. poisonous dust.

* The machine is not designed for picking up hazardous - i.e. poisonous dust.

* No changes or modifi cations of the mechanical, electrical or thermal safety devices should be made.

* When repairing or replacing the cord, the same type of cord as originally supplied with the machine must be used.

This cord can be supplied by Clarke.

SAVE THESE INSTRUCTIONS

5

Page 6

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should electrically malfunction, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock. This appliance is equipped with a cord having an equipmentgrounding conductor and grounding plug. The plug must be plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

DANGER!

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualifi ed

electrician or service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the appliance.

If it will not fi t the outlet, have a proper outlet installed by a qualifi ed electrician.

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug that looks like the plug illustrated in

Figure 1 below. A temporary adapter illustrated in Figures 2 and 3 may be used to connect this plug to a 2-pole receptacle as shown in Figure 2 if a properly grounded outlet is not available. The temporary adapter should be used only

until a properly grounded outlet (Figure 1) can be installed by a qualifi ed electrician.

The green-colored rigid ear, tab, or the like extending from the adapter must be connected to a permanent ground such

as a properly grounded outlet box cover. Whenever the adapter is used, it must be held in place by a metal screw.

Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or Green/Yellow) wire in the cord is the grounding wire. When replacing a plug, this wire must be attached

to the grounding pin only.

Extension cords connected to this machine should be 12 gauge, three-wire cords with three-prong plugs and outlets.

DO NOT use extension cords more than 50 feet (15 meter) long.

GROUNDED OUTLET

GROUNDING PIN

Figure 1

PLEASE NOTE: FOR NORTH AMERICA ONLY

ADAPTER

METAL

SCREW

GROUNDED

OUTLET BOX

Figure 2

TAB FOR GROUNDING SCREW

Figure 3

6

Page 7

INTRODUCTION

This manual will help you get the most from your Clarke Carpetmaster vacuum cleaner.

Read it thoroughly before operating the machine. This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Clarke Service Center, who employs factory

trained service personnel, and maintains an inventory of Clarke original replacement parts and accessories.

Call the Clarke DEALER named below for repair parts or service.

Please specify the Model and Serial Number when discussing your machine.

(Dealer, affi x service sticker here.)

RATING PLATE

The Model Number and Serial Number of your machine are shown on the rating plate on the machine.

This information is needed when ordering repair parts for the machine. Use the space below to note the Model

Number and Serial Number of your machine for future reference.

MODEL NUMBER____________________________________

SERIAL NUMBER ___________________________________

UNPACKING THE MACHINE

When the machine is delivered, carefully inspect the shipping carton and the machine for damage.

If damage is evident, save the shipping carton so that it can be inspected.

Contact the Clarke Customer Service Department immediately to fi le a freight damage claim.

Visit our web page; www.clarkeus.com

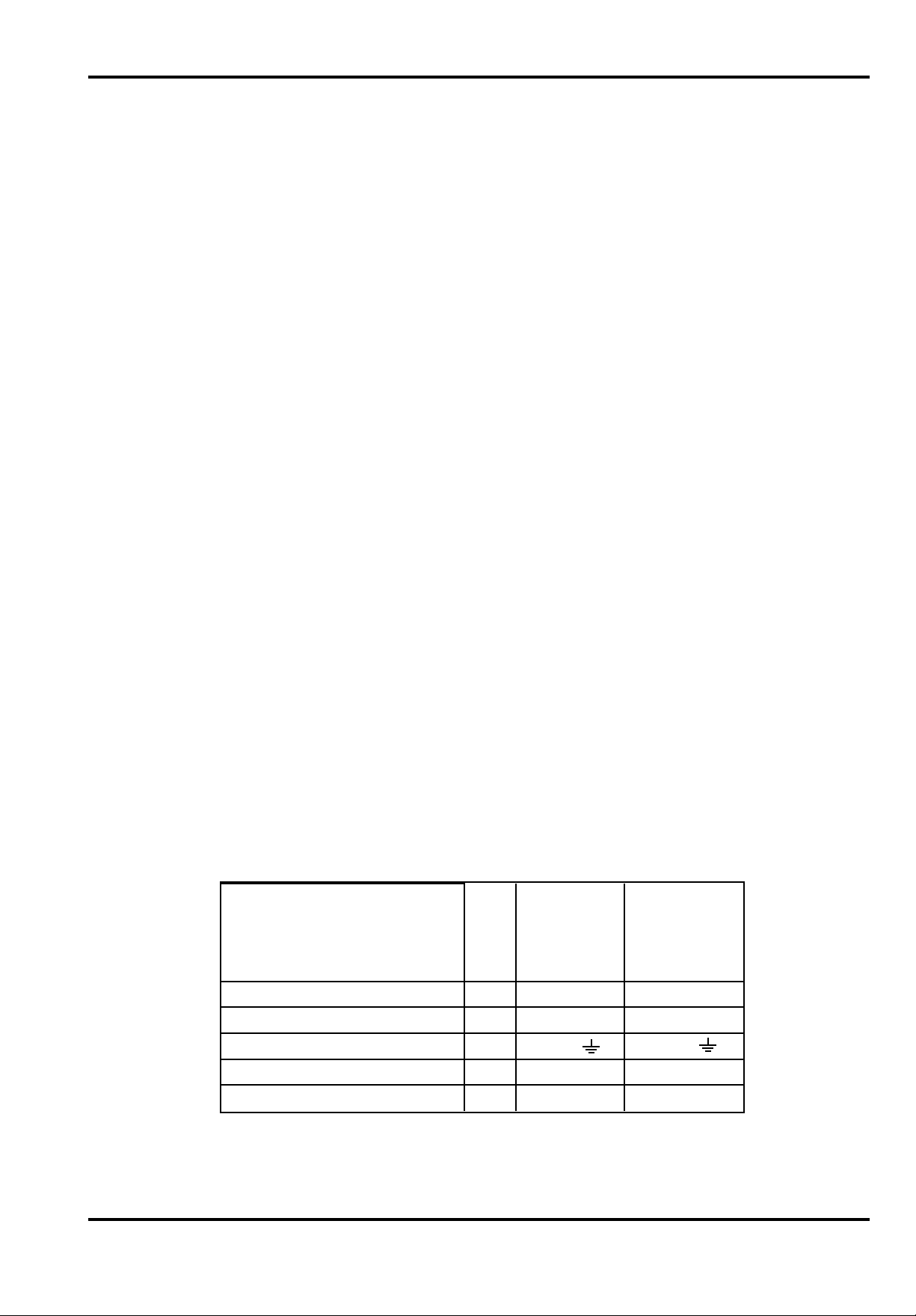

TECHNICAL SPECIFICATION

(as installed and tested on the unit)

Model Single motor

112, 115

GU 12 SMU,

GU 15 SMU

Double motor

212, 215, 218

GU 12 DMU,

GU 15 DMU

GU 18 DMU

Voltage V/Hz 110-120/50-60 110-120/50-60

Rated Power W 1000 1200

Protection class (electrical)

Sound Pressure Level dB(A) 69 69

Total weight lbs/Kg 17/7.7 18.7/8.5

I I

7

Page 8

1

2

As you read this manual, you will occasionally run across

KNOW YOUR MACHINE

a bold number in parentheses - example: (2). These

20

3

6

15

4

16

numbers refer to an item shown on this page. Refer back

to this page whenever necessary, to pinpoint the location

of an item mentioned in the text.

17

13

1 Handle

2 Cord Hook

3 Vacuum Hose

4 Handle Lock Button

5 Dust lid

21

7

18

19

11

5

2

14

7 Light, Green - Only Double Motor Unit

8 Light, Red Only Double Motor Unit

6 Carrying Handle

(212, 215, 218 -versions)

(212, 215, 218 -versions)

9 Brush Housing

10 Brush Height Adjustment Knob

11 Pedal

13 Wand

14 Crevice Tool

10

8

9

15 “Dust Bag Full” Indicator

16 Dust lid button

17 Main Power Switch

18 Exhaust Filter Cover

19 Filter Cover Latch

20 Power Cord Clamp

21 Dusting Brush

2

Insert the handle at the

opening at the top of the

bag housing, until the button

at handle snaps in place.

SET UP AND ASSEMBLY

1. Carefully take out the vacuum cleaner from its carton.

2. Push the Handle (1) into the opening at the top of the Dust

compartment until the button at the rod snaps in place and

secure the handle to the housing.

Never operate the vacuum cleaner without a Dust Bag in

place. Thease machines is equipped with an "no bag" clip.

This means that if a dust bag not is fi tted or fi tted

uncorrect - the dust lid (5) would not be able to close.

IMPORTANT !

Foot pedal must be used

to release base to

operating/non operation

position. Failure to do so

could result in damage to

the release mechanism.

8

Page 9

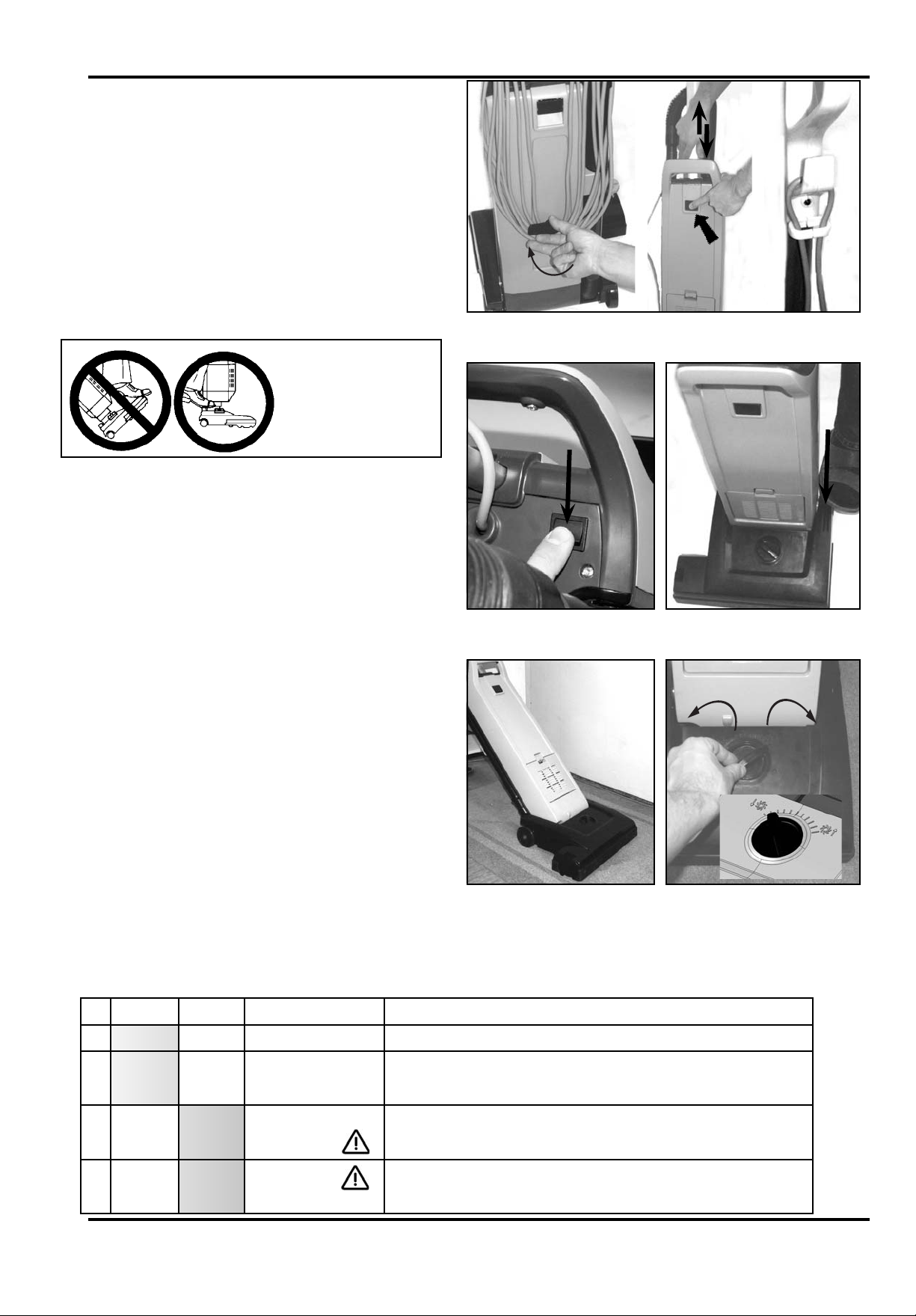

OPERATING THE VACUUM CLEANER

Lower

Higher

On - Off

Release

base

1. Release the power cord from the cord hooks (2) at the backside of

the vacuum cleaner. Turn the lower hook so that the cord is released.

Unwind the whole power cord .

2. Adjust the height of the handle, by pushing at the handle lock button

(4) and then pull or push at handle to make it comfortable to use.

3. Add the cord to the hook of the handle in order to make an anti strain

function. Then plug-in the power cord into a electrical outlet.

4. Turn the Main Power Switch (17) ON. “l” is ON and “O” is OFF. Now

the vacuum motor will start.

5. Step on the Pedal (11) and then tilt the cleaner backwards. Now the

brush motor will start (Dual-versions only). At Dual-versions the green

light (7) at the brush housing (9) will come on to indicate that the brush

motor is running.

IMPORTANT !

Foot pedal must be used to

release base to

operating/non operation

position. Failure to do so

could result in damage to the

handle release mechanism.

6. Turn the Height Adjustment Knob (10) to adjust the height that the

brush will operate in - depending on the material at the surface to be

vacuumed. For carpets with short textiles the brush should in the lower

position. Turn the knob to the left (when you are placed in front of the

machine) to lower the brush. For carpets with longer textiles the brush

should in a higher position.Turn the knob to the right (when you are

placed in front of the machine) to set the brush at a higher level. If the

red light comes on, slowly turn the knob in the opposite direction until

the light goes off.

If the red light (8) stays on continuously, there may be debris wrapped

around the brush, during operation. At a double motor units this can

cause the overload protector for the brush motor to trip. If this occurs,

turn the Main Switch (17) OFF and unplug the power cord. Remove any

debris from the brush and plug in the power cord, turn the Main Switch

(17) back ON. This will automatically reset the overload protector. If the

overload protector trips repeatedly contact your dealer for service. For

more information of the light indicators at the Dual-versions - see the

table below.

1

1

2

3

Release

base

On - Off

45

Lower

Higher

NOTE! Always disconnect the power cord before performing any

machine maintenance.

Change the bag whenever the “Bag Full” Light (15) comes on.

For details of dust bag replacement see separate instruction in this

manual. If the light comes on before the bag is full, the inside of the bag

may be coated with very fi ne dust (change the bag), or debris may be

built up somewhere between the brush and the bag.

56

LIGHT INDICATION AND FUNCTION FOR THE BRUSH MOTOR

GREEN RED CONDITION FUNCTION

ON OFF

1.

ON -

2.

BLINKING

OFF ON -

3.

OFF ON Brush stalled

4.

OFF

BLINKING

Normal operation In normal operation, the green light is constantly illuminated.

Brush position too high

(low loading)

Brush position too low

(heavy loading)

1. Green light will blink if the brush is not in contact with the carpet.

2. Green light will be constantly illuminated once the brush is in contact with the

carpet or the user adjusts the brush height adjustment to a lower position.

1. If the condition 3, red light blinking, continues for 10 seconds or more, the control

module will cut out the power supply to the brush motor.

2. The red light will still be illuminated until you turn off the switch or unplug the cord.

1. The red light will be constantly illuminated and the control module will instantly cut

the power supply to the brush motor, if the brush was stalled accidentally.

2. The red light will still be illuminated until you turn off the switch or unplug the cord.

- 212, 215, 218 - Double Motor Units only!

9

Page 10

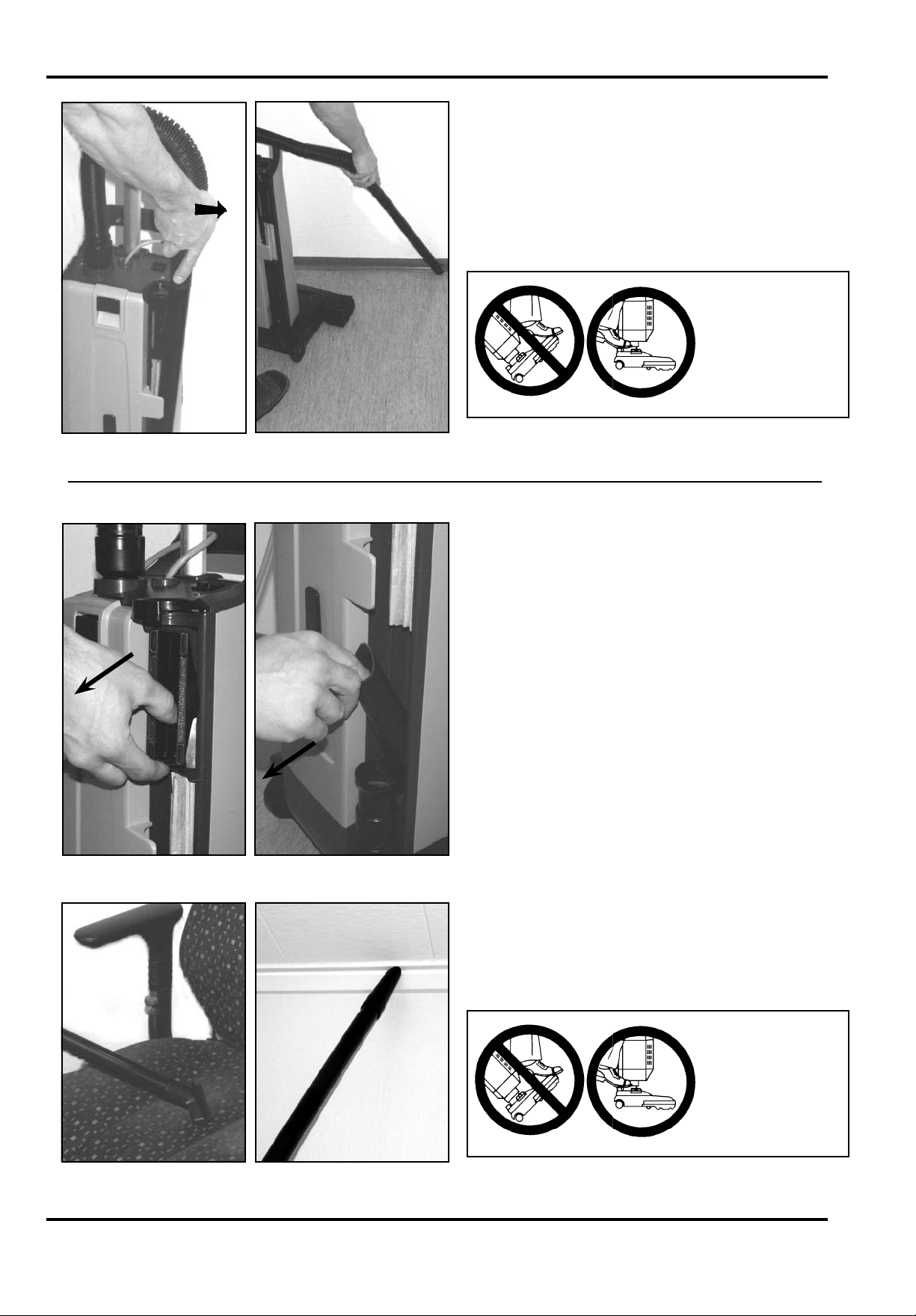

USING THE WAND (OPTIONAL)

The Wand (13) is not supplied as a standard item in all variants of

these machines. Do like this in order to use the wand.

1. Push the machine to upright locked position. The brush motor will

then stop (Dual-version only), and the brush will be lifted up from the

surface at other versions. Then slide the Wand out of its holder.

2. Use the wand for cleaning hard to reach places like fl oor corners,

or furnitures.

IMPORTANT !

Foot pedal must be used

to release base to

operating/non operation

position. Failure to do so

could result in damage to

the handle release

mechanism.

1

2

USING THE TOOLS (OPTIONAL)

These tools are not standard items in all machine variants.

Use these tools for a better cleaning performance at hard to reach

areas. A Crevice Tool (14) and Dusting Brush (21) is placed comfortable at the machine, just behind the wand.

Remove the wand from the vacuum cleaner and you will have free

access to the Tools.

1. The dusting brush is placed in the upper section of the cleaner.

2. The crevice tool is placed in the lower section of the cleaner.

1

2

10

3. Install the Crevice Tool or Dusting Brush on the end of the Wand,

if desired. Now the vacuum cleaner will have an extended coverage

performance and can be used for cleaning hard to reach areas like

roof strips, or furnitures.

IMPORTANT !

Foot pedal must be used

to release base to

operating/non operation

position. Failure to do so

could result in damage to

the handle release

mechanism.

3

3

Page 11

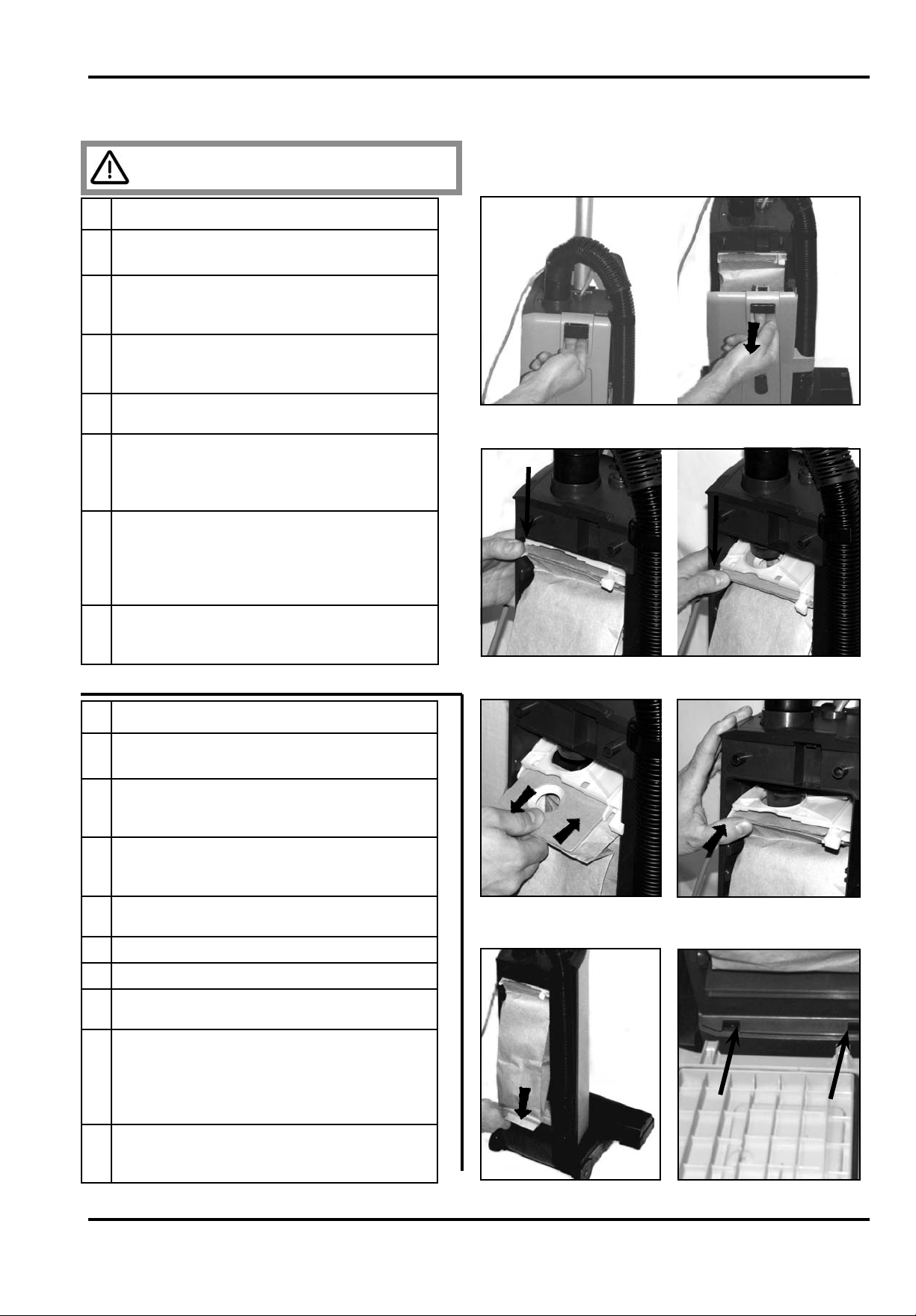

MAINTENANCE

3

4

Always disconnect the power cord before

performing any machine maintenance.

CHANGING THE PAPER DUST BAG

Change the bag whenever the “Bag Full” (15) indicator comes on. To replace the Paper Dust Bag:

Disconnect the power cord from the electrical outlet. Pull

1.

the Dust lid button (16) and remove the Dust lid outwards

to remove it from the cleaner.

Push downwards at the edge to the left of the plastic

2.

holder, so that the bag inlet loosens from the vacuum inlet

of the machine.

Grasp at the cardboard piece of the bag and gently pull

3.

the full bag outwards - away from cleaner.

Insert a new paper dust bag into the slot of the bag holder

4.

and push the bag in place. Check so that the paper dust

bag not is jammed in the holder.Only the cardboard piece

of the bag should be attached to the bag holder.

Push the bag holder with the new bag upwards, so that

5.

the bag inlet fasten to the inlet of the machine. Make

sure that the bag is unfold and will fi t in place at the bag

housing. Also check that the ”no bag” clip is placed to the

left so that the lid will be able to close.

Fit the two notches of the back cover to the two slots at

6.

the lower part of the bag housing, and push the back

cover back in place at the housing.

NOTE!

Photos belows shows changing of the paper dust bag!

Never operate the machine without a Dust Bag in place.

1

2

1

2

EMPTYING THE CLOTH DUST BAG

Empty the Bag whenever the “Bag Full” Light (15)

comes on. To empty or to replace:

Disconnect the power cord from the electrical outlet. Pull

1.

the Dust lid button (16) and drag the Dust lid outwards to

remove it from the cleaner.

Push downwards at the edge to the left of the plastic

2.

holder, so that the bag inlet loosens from the vacuum inlet

of the machine.

Grasp at the plastic fl ange of the bag and gently pull the

3.

bag outwards - away from cleaner.

Remove bag clip and shake out bag contents.

4.

Put the bag clip back on the bag.

5.

Insert the cleaned/new cloth bag into the slot of the bag

6.

holder and push the bag in place so that bag is secured.

Push the bag holder with the new bag upwards, so that

7.

the bag inlet fasten to the inlet of the machine. Make

sure that the bag is unfold and will fi t in place at the bag

housing. Also check that the ”no bag” clip is placed to the

left so that the lid will be able to close.

Fit the two notches of the back cover to the two slots at

8.

the lower part of the bag housing, and push the back

cover back in place at the housing.

3

4

3, 4

56

5

11

Page 12

CHANGING OR CLEANING OF THE BRUSH

Unplug the power cord from the electrical outlet.

1.

Release the brush roller by unlocking the bearing

2.

block. Push the button backwards left towards the

unlocking symbol at the brush housing.

Grasp at the bearing block and pull it out from the

3.

brush housing.

Remove the used brush.

2

3

4.

Replace the used brush roller with a new one, or

5.

clean and remove all debris at the present brush.

Slide back the brush into the the fi xed bearing block

6.

in the brush house.

Push the bearing block in its position. Lock it by

7.

turning clockwise.

4

7

6

Always disconnect the power cord before

performing any machine maintenance.

FILTERS - type of fi lter may vary from different models

At these machines there are two different fi lters; one pre-fi lter before the vacuum motor and one exhaust fi lter.

There are two different types of exhaust fi lters available to these machines, HEPA-fi lter and a standard exhaust fi lter. The HEPA-fi lter

(High Effi ciency Particulate Air filter) offers better fi ltration capacity then the standard exhaust fi lter. The exhaust fi lters catches any

dirt that may escape from the dust bag, or motor pre fi lter. Replace the fi lter every fourth time that the dust bag is changed (more

often in very dusty applications). The exhaust fi lters is located at the front side of the machine just above the brush house.

The HEPA fi lter can not be cleaned or washed clean. When the HEPA-fi lter is clogged it must be replaced.

CHANGING THE HEPA-FILTER

1. Disconnect the power cord from the electrical outlet.

Push the Filter Cover Latch (19) downwards so that the

cover (18) is released. Remove the fi lter cover from cleaner.

2. Grasp at the fi lter frame and remove the used and dirty

HEPA-fi lter

3. Grasp at the fi lter frame and then insert the new HEPA fi lter

to the cleaner by pushing it in place. (Do never touch the fi lter

media at a HEPA-fi lter! Doing so may cause a loss of

1

2

performance of the HEPA-fi lter).

4. Snap the Filter Cover back in place at the cleaner.

12

IMPORTANT!

Never operate the cleaner without the HEPA-Filter in place at the

machine. Note! These machines are not designed for picking

up hazardous - i.e. poisonous dust!

3

4

Page 13

CHANGING THE EXHAUST FILTER

1. Disconnect the power cord from the electrical outlet.

Push the Filter Cover Latch

Cover

2. Remove the cover with the fi lter, from the cleaner.

3. Remove the used and dirty exhaust fi lter.

4. Insert a new exhaust fi lter to the fi lter cover.

5. Snap the Filter Cover back in place at the cleaner.

(18) is released.

(19) downwards so that the Filter

IMPORTANT !

Never operate the machine without the Exhaust Filter in

place at the machine.

CLEANING OR CHANGING THE PRE FILTER

The pre fi lter catches any dirt spilled from the bag, before it can enter

the vacuum motor. The fi lter is located below the bag.

Clean the fi lter every third time that the bag is changed (more often in

very dusty applications).

To clean/replace the Pre Filter.

1. Disconnect the power cord from the electrical outlet. Then

push the Dust lid button (16) in and remove the dust lid (5).

2. Grasp at the fi lter holder and pull the holder out from the

Dust compartment.

3. Remove the dirty fi lter and replace with a new pre fi lter.

The pre fi lter may also be washed. Wash it in warm

water. Let the fi lter dry completely before putting it back into

the fi lter holder.

4. This machine is also equipped with a deodorizer function (an anti

smell). It´s a located in the pre fi lter holder.

Replace it to a new deodorizer when the function begins to

fade.

5. Put back the new/washed fi lter into the holder. Then put back the

holder with fi lter in place at the bag housing.

6. Fit the two notches of the back cover to the two slots at the lower

part of the bag housing, and push the back cover back

in place at the housing.

IMPORTANT !

Never operate the machine without the pre-fi lter in place.

1

1

3

2

2

5

AFTER USING THE MACHINE

Unplug the Power Cord from the electrical outlet.

1.

2. If the Dust Bag Full” Indicator (15) not has been lightened

during operation - the dust bag still have fi lling capacity. Open

the dust housing cover to ensure that the dust bag not is

full, replace if necessary. See also separate instructions for

replacing the dust bag. Clean the bag housing, if necessary.

Wind up the cord (starting from the machine inlet side).

3.

Store the cord at the hook at the Dust lid cover and the hook

4.

at the handle.

Check the brush house. Remove any built-up carpet fi bers or

5.

debris from the brush and the brush housing.

6. Store the machine indoors in a clean, dry place.

3

4

13

Page 14

SOMMAIRE

Consignes de sécurité importantes

Consignes de mise à la masse

Introduction

Pièces et entretien

Plaque signalétique

Déballage de l’appareil

Spécifi cations techniques

Il est indispensable de bien connaître l’appareil

Installation et montage

Utilisation de l’appareil

Utilisation du tube

Utilisation des accessoires

Maintenance

Remplacement du sac à poussière en papier

Remplacement du sac à poussière en tissu

Remplacement de la brosse

Remplacement du fi ltre HEPA

Remplacement du fi ltre d’évacuation

Nettoyage ou remplacement du préfi ltre

Après utilisation

.................................................................................................17

..................................................................................... 17

........................................................................................ 17

.............................................................................. 17

...........................................................................17

.............................................................................. 18

...............................................................................19

...................................................................................... 20

.........................................................................20

.............................................................................................. 21

......................................................................22

..........................................................................................23

........................................................... 15

...................................................................16

........................................... 21

.............................................. 21

....................................................................22

.........................................................23

.....................................................23

........................................ 18

14

Page 15

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

Toujours suivre certaines précautions élémentaires lors de l’utilisation d’un appareil électrique.

Lire toutes les instructions avant d’utiliser la machine.

Cette machine est adaptée à l’usage commercial, par exemple dans les hôtels, les écoles, les hôpitaux, les

usines, les magasins et les bureaux.

CET APPAREIL NE DOIT ETRE UTILISE QU’A SEC!

NE PAS UTILISER SUR UNE SURFACE HUMIDE!

AVERTISSEMENT !

Pour réduire les risques d’incendie, de décharge électrique ou de blessures:

* Ne pas abandonner l’appareil s’il est branché. Débrancher l’alimentation secteur quand l’appareil n’est pas

utilisé ou avant l’entretien.

AVERTISSEMENT !

Pour réduire les risques de décharges électriques, ne pas utiliser l’appareil en extérieur ou sur des surfaces

humides.

* Cet appareil n’est pas un jouet. Rester attentif quand il est utilisé par ou près des enfants.

* Utiliser l’appareil conformément aux instructions de la notice. Utiliser seulement les accessoires préconisés

par le fabricant.

* Ne pas utiliser l’appareil si le cable d’alimentation ou la prise est endommagé. Retourner l’appareil au centre

de service aprèsvente s’il ne fonctionne pas correctement, s’il est tombé, s’il a été endommagé, s’il a été

laissé à l’extérieur ou s’il est tombé dans l’eau.

* Ne pas tirer ou porter l’appareil par le cable d’alimentation, ou coincer le cable dans une porte ou tirer le cable sur des angles vifs ou des coins. Ne pas faire passer l’appareil sur le cable. Eloigner le cable des surfaces

chaudes.

* Ne pas débrancher l’appareil en tirant sur le cable d’alimentation, mais en saisissant la prise.

* Ne pas manipuler la prise, le cable d’alimentation ou l’appareil avec les mains humides.

* Ne rien introduire dans les ouvertures de l’appareil. Ne pas utiliser l’appareil si l’une des ouvertures est

obstruée; éliminer la poussière, les peluches, les cheveux et tout corps étranger pouvant gêner le fl ux d’air.

* Eloigner les vêtements amples, cheveux, doigts et toute autre partie du corps des pièces en mouvement et

des ouvertures.

* Ne pas aspirer d’objets qui brûlent ou dégagent de la fumée, comme des cigarettes, des allumettes ou des

cendres chaudes, ni de poussières dangereuses pour la santé. Ne pas aspirer d’eau ou des liquides.

* Ne pas utiliser sans sac à poussière et/ou fi ltre en place.

* Placer toutes les commandes en position d’arrêt avant de débrancher l’appareil.

* Eviter d’aspirer des corps durs ou pointus.

* Etre particulièrement prudent en nettoyant les escaliers.

* Ne pas aspirer de liquides infl ammables ou combustibles, telle l’essence, et ne pas utiliser à proximité.

* Eviter d’aspirer des objets durs ou pointus.

* Ne pas modifi er les systèmes électriques, mécaniques ou thermiques.

* Remplacer le cable far un cable identique fourni far Clarke.

CONSERVER CES INSTRUCTIONS

15

Page 16

INSTRUCTIONS VISANT LA MISE À LA TERRE

Cet appareil doit être mis à la terre. En cas de défaillance ou de panne éventuelles, la mise a la terre fournit

au courant un chemin de moindre résistance qui réduit le risque de choc électrique. Cet appareil est pourvu

d’un cordon muni d’un conducteur de terre et d’une fi che avec broche de terre. La fi che doit être branchée

dans une prise appropriee correctement installée et mise à la terre conformément aux règlements et ordonnances municipaux.

AVERTISSEMENT !

Un conducteur de terre mal raccordé peut entraîner un risque de choc électrique. Consulter un électricien ou

un technicien d’entretien qualifi é si vous n’êtes pas certain que la prise est correctement mise à la terre. Ne

pas modifi er la fi che fournie avec l’appareil - si elle ne peut être insérée dans la prise, faire installer une prise

adéquate par un électricien qualifi é.

Cet appareil est destiné à un circuit de 120 V et est muni d’une fi che de terre semblable à celle illustrée par le

croquis 1. Un adaptateur temporaire semblable à celui illustré par le croquis 2 et C peut être utilisé pour brancher cette fi che à une prise bipolaire comme l’illustre le croquis 2 si une prise avec mise à la terre n’est pas

disponible. L’adaptateur temporaire devrait etre utilisé seulement jusqu’à ce qu’une prise avec mise à la terre

soit installée par un électricien qualifi é. L’oreille rigide ou le crochet ou autre dispositif semblable, de couleur

verte, prolongeant l’adaptateur doit Iêtre raccordé à un élément correctement mis à la terre comme le couvercle d’une boîte de sortie mise à la terre. L’adaptateur doit être fi xé par une vis métallique. Note: Au Canada,

I’utilisation d’un adaptateur temporaire n’est pas autorisée par le Code canadien de l’électricité.

Remplacez la prise si la prise de terre est abîmée ou cassée.

Le fi l Vert (ou Vert/Jaune) dans la ganse est le fi l de terre. Lors du remplacement d´une prise, ce fi l doit être

raccordé à la prise de terre uniquement. Les ralonges connectées à cette machine doivent avoir 12 mesures,

trois ganses de fi l ayant trois fi ches masculines féminines tree-prong plugs

and outlets. N´UTILISEZ PAS de ralonge de plus de 15 m (50 pieds) de long.

VEUILLEZ NOTER: CES INSTRUCTIONS CONCERNENT UNIQUEMENT L’AMÉRIQUE DU NORD

PRISE MISE À LA TERRE

Figure 1

BROCHE DE MISE À LA TERRE

SORTIES

GROUPÉES

MISES À LA TERRE

Figure 2

ADAPTATEUR

VIS EN

MÉTAL

Figure 3

ONGLET POUR VIS DE MISE À LA TERRE

16

Page 17

INTRODUCTION

Ce manuel est destiné à vous aider à tirer le meilleur parti de votre aspirateur.

Lisez-le attentivement avant d’utiliser l’appareil. Ce produit est destiné à un usage professionnel.

PIÈCES ET ENTRETIEN

Les réparations, le cas échéant, doivent être réalisées par votre Centre d’entretien agréé, dont le personnel est formé en usine et qui utilise exclusivement des accessoires et pièces de rechange d’origine.

Dans tous les cas, n’oubliez pas de préciser le modèle et le numéro de série de votre appareil.

PLAQUE SIGNALÉTIQUE

Le modèle et le numéro de série de votre appareil fi gurent sur sa plaque signalétique.

Ces informations sont indispensables lors de la commande des pièces de rechange. Utilisez l’espace

ci-dessous pour noter le modèle et le numéro de série de votre appareil pour référence.

MODÈLE____________________________________

NUMÉRO DE SÉRIE ___________________________________

DÉBALLAGE DE L’APPAREIL

À la livraison de l’appareil, vérifi ez soigneusement que le carton d’emballage et l’appareil n’ont pas été

endommagés dans le transport.

S’il est évident qu’ils ont subi des dommages, conservez le carton d’emballage en vue d’une inspection

future.

Contactez immédiatement le Service clientèle Advance en cas de dommages consécutifs au transport

de l’appareil.

Pour en savoir plus, rendez-vous sur notre site Web à l’adresse suivante :

www.clarkeus.com

SPÉCIFICATION TECHNIQUE

(telle qu’installée et testée sur l’unité)

Modèle

Tension V/Hz 120/50-60 120/50-60

112, 115

GU 12 SMU,

GU 15 SMU

212, 215, 218

GU 12 DMU,

GU 15 DMU

GU 18 DMU

Puissance nominale W 1000 1200

Classe de protection (électricité) I I

Niveau de pression sonore dB(A) 69 69

Poids total lbs/kg 17.0 / 7.7 17.0 / 7.7

17

Page 18

IL EST INDISPENSABLE DE BIEN

1

2

20

3

6

15

4

16

17

Lors de la lecture de ce manuel, vous rencontrerez

parfois des chiffres en gras entre parenthèses, par

exemple : (2). Ces chiffres font référence à un élément

illustré sur cette page. Reportez-vous à la page men-

tionnée en référence chaque fois que nécessaire. Cela

vous permettra de situer où se trouve l’élément dont il

13

21

7

18

19

11

5

2

14

8

10

9

16 Bouton d’ouverture du couvercle du compartiment

CONNAITRE L’APPAREIL

est question dans le texte.

1 Poignée

2 Crochet porte cordon

3 Flexible d’aspiration

4 Bouton de verrouillage de la poignée

5 Couvercle du sac à poussière

6 Poignée de transport

7 Témoin lumineux vert

(uniquement sur les modèles DMU)

8 Témoin lumineux rouge

(uniquement sur le modèles DMU)

9 Boîtier de la brosse

10 Bouton de réglage de la hauteur de brosse

11 Pédale

13 Tube

14 Suceur plat

15 Témoin de sac plein

du sac à poussière

17 Interrupteur d’alimentation

18 Capot du fi ltre d’aspiration

19 Loquet du capot de fi ltre

20 Pince de fi xation du cordon d’alimentation

21 Brosse ronde

2

Insérez la poignée dans

l’ouverture au-dessus du

compartiment du sac à

poussière, jusqu’à ce que

le bouton sur la poignée se

mette en place.

INSTALLATION ET MONTAGE

1. Sortez délicatement l’aspirateur de son carton d’em-

ballage.

2. Insérez la poignée (1) dans l’ouverture située audessus du compartiment du sac à poussière jusqu’à ce

que l’ergot soit en position et que la poignée soit fi xée

dans le boîtier.

N’utilisez jamais l’aspirateur sans sac à poussière.

Ces appareils sont dotés d’un clip d’absence de

sac. Autrement dit, si aucun sac n’est inséré ou s’il

n’est pas correctement mis en place, le couvercle du

compartiment du sac à poussière (5) ne peut pas se

fermer.

IMPORTANT !

Utilisez la pédale pour

mettre la base en position de fonctionnement/

repos. Le non-respect

de cette procédure peut

endommager le mécanisme de libération.

18

Page 19

Position

inférieure

Position

supérieure

Marche

- Arrêt

Libération

de la base

UTILISATION DE l’ASPIRATEUR

1. Retirez le cordon d’alimentation des crochets porte-cordon (2) situés à

l’arrière de l’aspirateur. Faites pivoter le crochet inférieur afi n de libérer le

cordon. Déroulez tout le cordon d’alimentation.

2. Réglez la hauteur de la poignée en poussant le bouton de verrouillage

de la poignée (4), puis tirez ou poussez la poignée jusqu’à atteindre une

position d’utilisation confortable.

3. Placez le cordon sur le crochet de la poignée afi n d’éviter tout frottement.

Branchez ensuite le cordon d’alimentation dans la prise électrique.

4. Mettez l’interrupteur d’alimentation (17) en position Marche. « l »

correspond à la position Marche et « O » à la position Arrêt. Le moteur de

l’aspirateur démarre.

5. Appuyez sur la pédale (11), puis inclinez l’aspirateur vers l’arrière. Le

moteur de la brosse démarre (modèles DMU uniquement). Sur les modèles

DMU, le voyant vert (7) situé sur le boîtier de la brosse (9) s’allume pour

indiquer que le moteur de la brosse est opérationnel.

IMPORTANT !

Utilisez la pédale pour

mettre la base en position

de fonctionnement/repos.

Le non-respect de cette

procédure peut endommager le mécanisme de

libération.

6. Tournez le bouton de réglage de la hauteur de brosse(10) afi n de régler

la hauteur de la brosse en fonction de la surface à aspirer. Pour les tapis à

poils ras, la brosse doit être en position la plus basse. Tournez le bouton

vers la gauche (lorsque vous êtes face à l’appareil) pour abaisser la brosse.

Pour les tapis à poils longs, la brosse doit être en position la plus haute.

Tournez le bouton vers la droite (lorsque vous êtes face à l’appareil) pour

régler la brosse à son niveau supérieur. Si le voyant rouge s’allume, tournez

lentement le bouton dans le sens opposé jusqu’à ce qu’il s’éteigne.

Si le voyant rouge (8) reste allumé, il se peut que des débris se soient enroulés autour de la brosse pendant l’opération. Sur les modèles bi-moteurs

(DMU), cela peut déclencher le protecteur de surcharge du moteur de la

brosse. Si tel est le cas, mettez l’interrupteur principal (17) en position Arrêt

et débranchez le cordon d’alimentation. Retirez les débris de la brosse,

branchez à nouveau le cordon d’alimentation, mettez l’interrupteur principal

(17) sur Marche. Le protecteur de surcharge est automatiquement réinitialisé. Si le protecteur de surcharge se déclenche constamment, contactez

votre revendeur. Pour plus d’informations sur les témoins lumineux des

modèles DMU, reportez-vous au tableau ci-dessous.

REMARQUE ! Débranchez toujours le cordon d’alimentation avant

toute opération de maintenance sur l’appareil.

Remplacez le sac lorsque le témoin de sac plein(15) s’allume.

Pour en savoir plus sur le remplacement du sac à poussière, reportez-vos

aux consignes appropriées dans ce manuel. Si le témoin s’allume avant que

le sac soit plein, l’intérieur du sac peut être recouvert de poussière très fi ne

(remplacez le sac), ou des débris peuvent s’être amassés entre la brosse et

le sac.

1

1

2

3

Libération

de la base

Marche

- Arrêt

45

Position

inférieure

Position

supérieure

56

TÉMOINS LUMINEUX ET FONCTION POUR LE MOTEUR DE LA BROSSE

(modèles DMU uniquement)

VERT ROUGE ÉTAT FONCTION

Allumé Éteint Fonctionnement

1.

Allumé -

2.

Clignotant

Éteint Allumé -

3.

Éteint Allumé Brosse bloquée 1. Le voyant rouge reste allumé et le module de commande coupe instantanément

4.

Éteint Position de la brosse

Clignotant

normal

trop haute

(surface d’aspiration

plane)

Position de la brosse

trop basse (surface

d’aspiration

dense)

En fonctionnement normal, le voyant vert reste allumé.

1. Le voyant vert clignote si la brosse n’est pas en contact avec la surface à aspirer.

2. Le voyant vert reste allumé une fois la brosse en contact avec la surface à aspirer

ou lorsque l’utilisateur abaisse la hauteur de la brosse.

1. Si la condition 3 (voyant rouge clignotant) persiste pendant 10 secondes ou plus,

le module de commande coupera l’alimentation du moteur de la brosse.

2. Le voyant rouge reste allumé jusqu’à ce que vous éteignez l’aspirateur ou que

vous débranchiez le cordon d’alimentation.

l’alimentation du moteur de la brosse si la brosse est bloquée accidentellement.

2. Le voyant rouge reste allumé jusqu’à ce que vous éteignez l’aspirateur ou que

vous débranchiez le cordon d’alimentation.

19

Page 20

UTILISATION DU TUBE (EN OPTION)

Le tube (13) n’est pas fourni en série sur tous les modè-

les. Pour utiliser le tube, procédez comme suit.

1. Poussez l’appareil en position verrouillée verticale. Le

moteur de la brosse s’arrête (modèle DMU uniquement).

Sur tous les autres modèles, la brosse se relève et n’est

plus en contact avec la surface à aspirer. Retirez ensuite

le tube de son support.

2. Utilisez le tube pour nettoyer les surfaces diffi ciles

d’accès telles que les coins ou le mobilier.

IMPORTANT !

Utilisez la pédale pour

mettre la base en position de fonctionnement/

repos. Le non-respect

de cette procédure peut

endommager le mécanisme de libération de

1

2

UTILISATION DES OUTILS (EN OPTION)

Ces accessoires ne sont pas fournis en standard sur

tous les modèles.

Ils facilitent et améliorent le nettoyage des surfaces

diffi ciles d’accès. Un suceur plat (14) et une brosse

ronde (21) se trouvent derrière le tube, pour un accès

pratique.

de la poignée.

Retirez le tube de l’aspirateur pour accéder aux accessoires.

1. La brosse ronde se situe dans la partie supérieure

de l’aspirateur.

2. Le suceur plat se trouve dans la partie inférieure de

l’aspirateur

1

2

3. Installez le suceur plat ou la brosse ronde à l’extrémité du tube, selon le cas. L’aspirateur dispose ainsi

d’une capacité de couverture supplémentaire et peut

être utilisé pour le nettoyage de surfaces diffi ciles d’accès comme les plafonds ou le mobilier.

IMPORTANT !

Utilisez la pédale pour

mettre la base en position de fonctionnement/

repos. Le non-respect

de cette procédure peut

endommager le mécanisme de libération de

de la poignée.

20

3

3

Page 21

MAINTENANCE

3

4

Débranchez toujours le cordon d’alimentation avant toute opération de maintenance

sur l’appareil.

REMPLACEMENT DU SAC À

POUSSIÈRE EN PAPIER

Remplacez le sac lorsque le témoin de sac plein (15) s’allume. Pour remplacer le sac à poussière :

Débranchez le cordon d’alimentation de la prise électrique.

1.

Tirez le bouton du couvercle du compartiment du sac à poussière (16) et retirez le couvercle de l’aspirateur.

Appuyez sur le bord gauche du support en plastique de

2.

sorte à libérer le sac de la prise d’aspiration de l’appareil.

Saisissez la partie cartonnée du sac et tirez doucement

3.

dessus afi n de libérer le sac.

Insérez un nouveau sac à poussière dans la fente du porte-

4.

sac et appuyez sur le sac pour le mettre en place. Vérifi ez

que le sac à poussière est correctement inséré dans le

porte-sac. Seule la partie cartonnée du sac doit être fi xée

sur le porte-sac.

Appuyez sur le porte-sac avec le nouveau sac tourné vers

5.

le haut de sorte que l’ouverture du sac se fi xe sur la prise

d’aspiration de l’appareil. Assurez-vous que le sac est déplié

et épousera la forme du compartiment du sac. Vérifi ez également que le clip d’absence de sac se trouve à gauche afi n de

permettre la fermeture du couvercle.

Insérez les deux encoches du panneau arrière dans les deux

6.

fentes situées sur la partie inférieure du compartiment du sac

et appuyez sur le couvercle pour le remettre en place.

REMARQUE !

Les photos présentées ici montrent le remplacement d’un sac à poussière en papier. N’utilisez

jamais l’aspirateur sans sac à poussière.

1

2

1

2

VIDAGE DU SAC À POUSSIÈRE

EN TISSU

Videz le sac dès que le témoin de sac plein (15) s’allume.

Pour vider ou remplacer le sac :

Débranchez le cordon d’alimentation de la prise électrique.

1.

Tirez sur le bouton du couvercle du compartiment du sac à

poussière (16) et retirez le couvercle de l’aspirateur.

Appuyez sur le bord gauche du support en plastique de sorte

2.

à libérer le sac de la prise d’aspiration de l’appareil.

Saisissez la bride en plastique du sac et tirez doucement

3.

dessus afi n de libérer le sac.

Retirez la pince du sac et videz son contenu.

4.

Replacez la pince sur le sac.

5.

Insérez le sac vide/nouveau sac dans la fente du porte-sac

6.

et appuyez sur le sac pour le mettre en place.

Appuyez sur le porte-sac avec le nouveau sac tourné vers

7.

le haut de sorte que l’ouverture du sac se fi xe sur la prise

d’aspiration de l’appareil. Assurez-vous que le sac est déplié

et épousera la forme du compartiment du sac. Vérifi ez également que le clip d’absence de sac se trouve à gauche afi n de

permettre la fermeture du couvercle.

Insérez les deux encoches du panneau arrière dans les deux

8.

fentes situées sur la partie inférieure du compartiment du sac

et appuyez sur le couvercle pour le remettre en place.

3, 4

3

4

5

56

21

Page 22

REMPLACEMENT OU NETTOYAGE DE LA BROSSE

Débranchez le cordon d’alimentation de la

1.

prise électrique.

Libérez la brosse en déverrouillant le bloc d’ap-

2.

pui. Faites coulisser le bouton vers la gauche

et le symbole de déverrouillage situé sur le

boîtier de la brosse.

Saisissez le bloc d’appui et retirez-le du boîtier.

2

4

3

6

3.

Retirez la brosse usagée.

4.

Remplacez la brosse usagée par une nouvelle

5.

brosse, ou nettoyez-la et retirez les débris

collés sur la brosse.

Réintroduisez la brosse dans lebloc d’appui

6.

fi xe dans le boîtier de la brosse.

Appuyez sur le bloc d’appui pour le remettre

7.

en place. Faites-le pivoter vers la droite pour le

verrouiller.

Débranchez toujours le cordon d’alimentation avant

toute opération de maintenance sur l’appareil.

7

FILTRES - le type de fi ltre peut varier en fonction des modèles

Ces appareils sont équipés de deux fi ltres : un premier fi ltre placé devant le moteur d’aspiration, un deuxième au niveau

de l’évacuation.

Deux types de fi ltres d’évacuation sont disponibles sur ces appareils : un fi ltre HEPA et un fi ltre d’évacuation standard. Le fi ltre HEPA

(fi ltre à haute effi cacité pour les particules de l’air) garantit de meilleures performances de fi ltration que le fi ltre d’évacuation standard.

Ce dernier capture la poussière pouvant s’échapper du sac à poussière ou du préfi ltre moteur Remplacez le fi ltre tous les quatre

changements de sac à poussière (plus souvent dans les applications très poussiéreuses).

Le fi ltre d’évacuation se trouve à l’avant de l’appareil, directement sous le boîtier de la brosse.

Le fi ltre HEPA ne peut pas être nettoyé ou lavé. Remplacez le fi ltre HEPA lorsqu’il est encrassé.

REMPLACEMENT DU FILTRE HEPA

1. Débranchez le cordon d’alimentation de la prise électrique.

Appuyez sur le loquet de fermeture du capot de fi ltre (19)

afi n de libérer le capot (18). Retirez le capot de fi ltre de

l’aspirateur.

2. Saisissez le fi ltre HEPA sale par le cadre et retirez-le de

l’aspirateur

3. Insérez le nouveau fi ltre HEPA dans l’aspirateur en le

tenant par le cadre, puis appuyez dessus pour le mettre en

place. (Ne touchez jamais le matériau fi ltrant du fi ltre HEPA

1

2

sous peine de réduire ses capacités fi ltrantes.)

4. Refermez le capot de fi ltre.

22

IMPORTANT !

N’utilisez jamais l’aspirateur sans son fi ltre HEPA.

Remarque ! Ces appareils ne sont pas conçus pour

ramasser des poussières toxiques

3

4

Page 23

REMPLACEMENT DU FILTRE D’ÉVACUATION

1. Débranchez le cordon d’alimentation de la prise électrique.

Appuyez sur le loquet de fermeture du capot de fi ltre (19)

afi n de libérer le capot (18).

2. Retirez le capot avec le fi ltre de l’aspirateur.

3. Retirez le fi ltre d’évacuation usagé et sale.

4. Insérez un nouveau fi ltre d’évacuation dans le capot de

fi ltre.

5. Refermez le capot de fi ltre.

NETTOYAGE OU REMPLACEMENT DU PRÉFILTRE

Le préfi ltre capture la poussière qui s’échappe du sac, avant

qu’elle ne pénètre dans le moteur de l’aspirateur. Ce fi ltre se situe

sous le sac.

Nettoyez le fi ltre tous les trois changements de sac (plus souvent

dans les applications très poussiéreuses).

Pour nettoyer/remplacer le préfi ltre.

1. Débranchez le cordon d’alimentation de la prise électrique.

Appuyez ensuite sur le bouton du compartiment du sac à poussière (16) et retirez le couvercle (5).

2. Saisissez le porte-fi ltre et retirez-le du compartiment du sac à

poussière.

3. Retirez le fi ltre souillé et remplacez-le par un nouveau préfi ltre.

Vous pouvez également laver le préfi ltre dans de l’eau chaude.

Laissez-le entièrement sécher avant de le replacer dans le

porte-fi ltre.

4. Cet appareil est également équipé d’une fonction désodorisante

(anti-odeur). Celle-ci se trouve dans le support du préfi ltre.

Remplacez le désodorisant lorsqu’il perd en effi cacité.

5. Replacez le fi ltre neuf/lavé dans le porte-fi ltre. Remettez ensuite

en place le fi ltre et son support dans le compartiment du sac à

poussière.

6. Insérez les deux encoches du panneau arrière dans les deux

fentes situées sur la partie inférieure du compartiment du sac et

appuyez sur le couvercle pour le remettre en place.

IMPORTANT !

N’utilisez jamais l’aspirateur sans préfi ltre.

1

1

3

2

2

5

APRÈS UTILISATION

Débranchez le cordon d’alimentation de la prise électrique.

1.

Si le témoin de sac plein (15) ne s’est pas allumé pen-

2.

dant l’utilisation de l’appareil, cela signifi e que le sac

n’est pas plein. Ouvrez le capot du compartiment du sac

à poussière afi n de vérifi er que le sac n’est pas plein.

Remplacez-le si nécessaire. Consultez également les

consignes de remplacement du sac à poussière. Nettoyez le compartiment du sac à poussière si nécessaire.

Essuyez le cordon (de l’aspirateur vers l’extérieur).

3.

Rangez le cordon sur le crochet situé sur le couvercle

4.

du sac à poussière et le crochet sur la poignée.

Vérifi ez le boîtier de la brosse. Retirez les fi bres de tapis

5.

et les débris collés sur la brosse et le boîtier.

Rangez l’appareil à l’intérieur, dans un lieu propre et sec.

6.

3

4

23

Page 24

ÍNDICE

Importantes precauciones de seguridad

Instrucciones para hacer la toma a tierra

Introducción

Piezas y servicio

Placa de identifi cación

Desembalado de la máquina

Especifi caciones técnicas

Conozca la máquina

Montaje

Manejo de la máquina

Utilización del tubo prolongador

Utilización de las herramientas

Mantenimiento

Cambio de la bolsa de polvo de papel

Cambio de la bolsa de polvo de tela

Cambio del cepillo

Cambio de fi ltro HEPA

Cambio de fi ltro de salida

Limpieza o cambio del prefi ltro

Después del uso

................................................................... 27

............................................................ 27

.................................................. 27

......................................... 27

...............................................27

...................................................... 28

.......................................................................... 28

................................................... 29

................................... 30

.....................................30

............................................................. 31

......................... 31

............................ 31

........................................................32

..................................................32

.............................................33

.....................................33

...........................................................33

....................... 25

...................... 26

24

Page 25

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Deben aplicarse ciertas precauciones básicas siempre que se utilice un aparato eléctrico, incluyendo las siguientes:

Lea todas las instrucciones antes de utilizar la máquina.

Esta máquina también es adecuada para el uso profesional, por ejemplo, en hóteles, colegios, hospitales, fábricas, tiendas

y ofi cinas,

que no sean los usos domésticos normales.

¡ESTE APARATO HA SIDO DISEÑADO ÚNICAMENTE PARA SU USO EN SECO!

¡NO UTILICE LA MÁQUINA EN SUELOS O MOQUETAS HÚMEDOS!

¡AVISO !

Para reducir el riesgo de incendio, descarga eléctrica o lesión:

* No deje la máquina conectada a la red. Desenchufe la máquina cuando no se está utilizando y antes de efectuar una

revisión.

¡AVISO !

Para reducir el riesgo de una descarga eléctrica, no utilice la máquina al aire libre, ni en superfi cies húmedas o mojadas.

* No deje que se utilice la máquina como juguete. Debe prestarse una atención especial cuando la maneja o se utiliza

cerca de os niños.

* Siga escrupulosamente las indicaciones de este manual. Utilice únicamente piezas recomendadas por el fabricante.

* No utilice la máquina con el cable o clavija en estado defectuoso. Si el aparato no funciona correctamente, si ha sufrido

una caída o daños, si se ha dejado a la intemperie, o si ha sufrido una inmersión en agua, devuélvalo a un Centro de

Servicio. No utilice la máquina si el cable eléctrico muestra cualquier signo de daño. Inspeccione regularmente el cable por

si presente algún daño, especialmente cuando haya sido aplastado, cogido por una puerta o pisado por un objeto pesado.

* No arrastre o transporte la máquina por el cable. No utilice el cable para dirigir la máquina. Mantenga el cable alejado de

bordes y esquinas que lo podrían dañar. Así mismo, mantenga el cable alejado de fuentes de calor.

* No desenchufe la máquina tirando del cable. Para desenchufar, tire de la clavija, no del cable.

* No toque la clavija, el cable o la máquina con las manos húmedas o mojadas.

* No inserte ningún objeto en las aberturas. No utilice la máquina con ninguna abertura obstruida.

* Mantenga alejado de las aberturas y piezas en movimiento las prendas sueltas, el pelo, los dedos y todas las demás

partes del cuerpo.

* No aspire ningún tipo de objeto que esté ardiendo o que desprenda humo, como cigarrillos o cerillas. Bajo ninguna

circunstancia la máquina podrá ser usada para aspirar materiales calientes. En particular no utilice la máquina para limpiar

chimeneas, hornos o similares con cenizas calientes o incandescentes.

* No utilice la máquina sin tener colocados los fi ltros y/o la bolsa del polvo.

* Apague todos los controles antes de desenchufar la máquina. La clavija siempre debe ser desenchufada de la red eléctrica antes de revisar o reparar la máquina o el cable de conexión eléctrica.

* No aspire objetos duros o afi lados.

* Tenga un cuidado especial cuando aspirar las escaleras.

* No utilice la máquina para recoger combustible, materiales nocivos para la salud o materiales explosivos como la gasolina, tampoco debe utilizarse en atmósferas explosivas. No utilice la máquina para aspirar agua u otros líquidos o para

aspirar polvo peligroso, contaminante o tóxico.

* No realice ningún tipo de intervención o modifi cación en los dispositivos mecánicos, eléctricos o de seguridad térmica de

la máquina.

* Cuando repare o sustituya el cable de conexión eléctrica, utilice el mismo tipo de cable suministrado originalmente con la

máquina. Este cable le puede ser suministrado por Clarke.

NO PIERDA ESTAS INSTRUCCIONES

25

Page 26

INTRUCCIONES PARA HACER LA TOMA A TIERRA

Este aparato deberá ser conectado a tierra. En caso de malfuncionamiento o de desperfectos, la toma a tierra

proporciona una vía de menor resistencia de la corriente eléctrica para reducir el riesgo de choques eléctricos.

Esta unidad viene equipada con un cordón con conductores para toma a tierra y con un enchufe con toma a

tierra. Ese enchufe deberá ser enchufado a un receptáculo en buen estado con instalación a tierra según

los códigos y ordenanzas de la zona.

¡PELIGRO !

Si el conductor a tierra no está instalado correctamente pueden producirse riegos de choques eléctricos. En

caso de duda, consulte con un electricista o personal de servicio autorizados. No modifi que el cordón provisto

con el aparato. Si no calza en el receptáculo, llame a un electricista califi cado para que coloque un receptáculo

adecuado.

Este aparato se usa con un circuito de 120-voltios nominales, y tiene un enchufe con toma a tierra tal como se

muestra en la fi gura 1, a continuación.

Se puede usar un adaptador provisorio tal como se ve en las fi guras 2 y 3 en caso de disponerse de un receptáculo sin toma a tierra como en la fi gura 2. Dicho adaptador provisorio se usará solamente hasta que un

electricista califi cado instale un receptáculo con la toma a tierra correspondondiente (fi gura 1). La lengüeta de

conexión de color verde que sale del adaptador deberá ser conectada a una toma a tierra permanente

como, por ejemplo, la caja del receptáculo con toma a tierra. Siempre que se use el adaptador, hay que sostenerlo en su lugar con un tornillo de metal.

Sustituya el enchufe si la patilla de tierra está dañada o rota.

El hilo verde (o verde/amarillo) del cordón es el hilo de tierra. Cuando sustituya el enchufe, este hilo sólo debe

ir conectado a la patilla de tierra.

Los cables alargadores conectados a esta máquina deben ser del calibre 12, trifi lares, con tres patillas y tomas

de pared adecuadas. NO UTILICE cables alargadores de más de 15 m.

ATENCIÓN : PARA AMÉRICA DE NORTE SOLAMENTE.

SALIDA DE TIERRA

CLAVIJA DE TIERRA

Figura 1

CAJA DE SALIDA A

TIERRA

Figura 2

ADAPTADOR

TORNILLO

METÁLICO

Figura 3

APÉNDICE PARA TORNILLO DE

TIERRA

26

Page 27

INTRODUCCIÓN

Este manual le ayudará a obtener la máxima utilidad de su aspirador Clakre.

Lea en su totalidad el manual antes de utilizar el aparato. Este producto ha sido diseñado únicamente

para uso comercial.

PIEZAS Y SERVICIO

Las reparaciones, en caso de ser necesarias, han de ser realizadas por el centro de servicio autorizado que dispone de personal formado en fábrica así como de piezas y accesorios originales Clarke.

Llame al Clarke DEALER mencionado abajo para las piezas de reparación o servicio.

En toda comunicación relativa a la máquina le rogamos indique el modelo y el número de serie.

(Concesionario, fi jar aquí la etiqueta de servicio.)

PLACA DE IDENTIFICACIÓN

Los números de modelo y serie de su máquina aparecen en la placa de identifi cación que hay en la

misma.

Esta información es necesaria al solicitar piezas de repuesto. Utilice los espacios que siguen a continuación para anotar los números de modelo

y de serie de su máquina, como referencia para el futuro.

NÚMERO DE MODELO____________________________________

NÚMERO DE SERIE___________________________________

DESEMBALADO DE LA MÁQUINA

Una vez haya recibido la máquina, examine atentamente el embalaje y la máquina a fi n de detectar

posibles daños.

Si estos son evidentes, guarde el embalaje para que pueda ser examinado.

Contacte al departamento de servicio Clarke Customer inmediatamente para registrar cualquier reclamación de daños de transporte.

Para más información visite nuestra página web: www.clarkeus.com

ESPECIFICACIÓN TÉCNICA

(según instalación y pruebas efectuadas en el aparato)

Modelo

Tensión V/Hz 120/50-60 120/50-60

112, 115

GU 12 SMU,

GU 15 SMU

212, 215, 218

GU 12 DMU,

GU 15 DMU

GU 18 DMU

Potencia nominal W 1000 1200

Clase de protección (eléctrica) II

Nivel de presión acústica dB(A) 69 69

Peso total lbs/Kg 17.0 / 7.7 17.0 / 7.0

27

Page 28

CONOZCA LA MÁQUINA

1

2

20

3

6

15

4

7

18

16

5

19

17

11

8

10

9

Durante la lectura de este manual, encontrará a

veces números entre paréntesis, p. ej.: (2). Estos

números se refi eren a un objeto que aparece en

esta página. Vuelva a esta página siempre que

tenga que situar cualquiera de las piezas que se

mencionan en el cuerpo del texto.

1 Mango

2 Soporte para cable

13

3 Manguera de aspiración

4 Botón fi ador del mango

5 Tapa del alojamiento de la bolsa de polvo

21

6 Mango de transporte

7 Luz verde - Sólo unidades motor doble

2

(versiones Dual)

8 Luz roja Sólo unidades motor doble

14

(versiones Dual)

9 Alojamiento del cepillo

10 Botón para el ajuste de la altura del cepillo

11 Pedal

13 Tubo

14 Boquilla biselada

15 Indicador de “Bolsa llena”

16 Cierre del alojamiento de la bolsa de polvo

17 Interruptor principal de corriente

18 Tapa del fi ltro de salida

19 Cierre de la tapa del fi ltro

20 Abrazadera del cable de alimentación

21 Cepillo de polvo

2

Introduzca el mango en

la abertura de la parte

superior del alojamiento

de la bolsa hasta que el

botón entre en su sitio.

MONTAJE

1. Retire cuidadosamente la máquina del embalaje.

2. Inserte a presión el mango (1) en la abertura de

la parte superior del alojamiento de la bolsa hasta

que quede fi rmemente sujeto.

No opere nunca la máquina sin una bolsa de

polvo instalada. Estas máquinas están provistas

con un clip de ”no bolsa”, lo que signifi ca que

si no hay bolsa de polvo o está incorrectamente

montada, no podrá cerrarse la tapa (5).

¡IMPORTANTE!

Para soltar la base de la

máquina en la posición

operativa/no operativa

hay que utilizar el pedal.

De no hacerse así pueden producirse daños

en el mecanismo de

liberación.

28

Page 29

FUNCIONAMIENTO DE LA MÁQUINA

Descender

Elevar

Encendido

- Apagado

Soltar la

base

1. Suelte el cable de corriente de sus soportes (2) en la parte posterior del

aparato. Gire el soporte inferior para soltar el cable. Desenrolle completamente el cable.

2. Ajuste la altura del mango pulsando el botón (4) y tirando del mismo o

empujándolo hasta la posición más cómoda de uso.

3. Haga pasar el cable a través del soporte y fíjelo al mango. De esta manera el cable queda descargado. Enchufe después el cable en una toma

de corriente adecuada.

4. Apriete el interruptor (17) para poner en marcha el motor. La letra “l”

signifi ca encender y la “O” apagar.

5. Apriete el pedal (11) para soltar el mango e inclinar después la máquina

hacia atrás. Arrancará entonces el motor del cepillo (sólo versiones Dual).

En las versiones Dual se encenderá la luz verde (7) del alojamiento del

cepillo (9) para indicar que está en marcha el motor del cepillo.

1

¡IMPORTANTE!

Para soltar la base de la

máquina en la posición

operativa/no operativa

hay que utilizar el pedal.

De no hacerse así pueden

producirse daños en el

mecanismo de liberación.

6. Gire el botón (10) para ajustar la altura del cepillo que puede variar

según la superfi cie del material que ha de limpiarse. Para moquetas y alfombras con materiales textiles cortos, el cepillo ha de descender. Gire el

botón de ajuste de altura hacia la izquierda (si el usuario se halla delante

de la máquina) para descender el cepillo. Para alfombras con materiales textiles largos hay que levantar el cepillo.Gire el botón de ajuste de

altura hacia la derecha (si el usuario se halla delante de la máquina) para

levantar el cepillo. Si se enciende la luz roja, gire con cuidado el botón de

ajuste de la altura en el sentido opuesto hasta que se apague la luz roja.

Si la luz roja (8) está encendida constantemente puede ser indicación

de que suciedad o hilos se han arrollado alrededor del cepillo. En las

unidades de motor doble puede ocurrir que se active la protección contra

sobrecalentamiento del motor. De producirse esto, corte la corriente a la

máquina con el interruptor (17) y extraiga después el cable del enchufe.

Quite los hilos o demás obstáculos que se hayan adherido al mismo.

Vuelva a enchufar el cable y active el interruptor (17). Con ello se repon-

drá automáticamente la protección contra sobrecalentamientos del motor.

Si vuelve a activarse la protección contra sobrecalentamientos, diríjase al

vendedor para que efectúe el servicio de la máquina. Para más información

sobre los indicadores en las versiones Dual, véase el cuadro de más abajo.

NOTA: Antes de proceder al cualquier intervención de servicio en la

máquina hay que desenchufarla.

Cuando se enciende el indicador de “Bolsa llena”(15) hay que cambiar lo

antes posible la bolsa.

Para información sobre el cambio de bolsa, véanse las instrucciones que

aparecen en este manual algo más adelante. Si la luz permanece encendida pese a que la bolsa no está llena, puede ser debido a que un polvo

fi no ha obturado la bolsa (cambiarla también en este caso) o a haberse

acumulado polvo entre el cepillo y la bolsa.

1

2

3

Soltar la

base

Encendido

- Apagado

45

Descender

Elevar

INDICACINES LUMINOSAS PARA EL MOTOR DEL CEPILLO

(Sólo en las variantes de dos motores - DUAL)

VERDE ROJA ACLARACIÓN FUNCIÓN

Encen-

1.

dida

Encendi-

2.

da Parpadea

Apagada Encendi-

3.

Apagada Encen-

4.

Apagada Funcionamiento

normal

Apagada La posición del cepillo

es demasiado alta

(baja carga)

La posición del

da Parpadea

dida

cepillo es demasiado

baja (carga

pesada)

Cepillo sobrecar-

gado

En funcionamiento normal la luz verde permanece encendida con luz fi ja.

1. La luz verde parpadea si los cepillos no están en contacto con la moqueta.

2. Ajuste la altura de los cepillos a una posición más baja y volverá a encenderse

con luz fi ja la luz verde.

1. Si la luz roja parpadea durante más de 10 segundos, se corta la corriente al

motor para protegerlo contra sobrecargas.

2. La luz roja se enciende con luz fi ja hasta que se apaga el interruptor y se desenchufa el cable.

1. La luz roja se enciende con brillo fi jo y se corta la corriente al motor si éste se

sobrecarga.

2. La luz roja se enciende con luz fi ja hasta que se apaga el interruptor y se desenchufa el cable.

56

29

Page 30

UTILIZACIÓN DEL TUBO PROLONGADOR

(EQUIPO OPCIONAL)

El tubo de prolongación (13) no es equipo estándar en todas

las variantes. Para utilizarlo proceda de la manera siguiente.

1. Ponga la máquina en posición vertical bloqueada. Se para

entonces automáticamente el motor del cepillo (sólo variantes

Dual), y en otras variantes el cepillo se levantará de la superfi cie. Quite luego el tubo prolongador de su soporte.

2. Utilice después el tubo para aumentar el alcance del aparato y poder llegar a lugares de acceso difícil, por ejemplo,

listones del suelo, etc.

¡IMPORTANTE!

Para soltar la base de

la máquina en la posición operativa/no operativa hay que utilizar

el pedal. De no hacerse

así pueden producirse

daños en el mecanis-

1

2

mo de liberación.

UTILIZACIÓN DE ACCESORIOS

(EQUIPO OPCIONAL)

Estos útiles no son equipo estándar en todas las variantes.

Utilícelos para incrementar la utilidad de la máquina en lugares de acceso difícil. La boquilla biselada (14) y el cepillo de

polvo (21) se hallan cómodamente colocados en la máquina,

inmediatamente detrás del tubo de prolongación.

Extraiga el tubo del aspirador para poder utilizar los accesorios.

1. El cepillo de polvo está colocado en la parte superior de la

máquina.

2. La boquilla biselada está colocada en la parte inferior de

la máquina.

1

2

3. Monte la boquilla o el cepillo en el tubo de prolongación.

Se habrá prolongado así el alcance del aspirador pudiendo

ser utilizado para acceder a lugares difíciles como listones

del techo o muebles.

¡IMPORTANTE!

Para soltar la base de

la máquina en la posición operativa/no operativa hay que utilizar

el pedal. De no hacerse

así pueden producirse

daños en el mecanismo de liberación.

3

3

30

Page 31

MANTENIMIENTO

3

4

Antes de cualquier intervención de mantenimiento en la máquina hay que desenchufarla.

CAMBIO DE LA BOLSA DE POLVO

Cuando se enciende el indicador de “Bolsa llena”(15) hay

que cambiar lo antes posible la bolsa. Proceda de la manguera siguiente:

Desenchufe el cable de la toma de corriente. Tire del cierre

1.

(16) para abrir el alojamiento de la bolsa. Quite la tapa del

alojamiento de la bolsa.

Retire la bolsa de tela de su soporte; presione hacia aden-

2.

tro/hacia abajo el cierre de manera que se desprenda de la

entrada en la máquina la boca de entrada de la bolsa.

Agarre el trozo de cartón de la bolsa y tire con cuidado de

3.

ésta para sacarla de su soporte.

Introduzca una bolsa de papel nueva en la ranura del so-

4.

porte introduciendo en éste la bolsa. Controle que la bolsa

de papel esté bien colocada en el soporte. Sólo la pieza de

cartón de la bolsa ha de adherirse al soporte.

Empuje el soporte con la bolsa hacia arriba hasta que

5.

el soporte quede fi jado a la pieza correspondiente en la

máquina. Controle después que la bolsa está desplegada y

se adapta a su alojamiento. Compruebe que la función ”no

clip” está a la izquierda de manera que pueda cerrarse la

tapa del alojamiento de la bolsa.

Vuelva a montar la tapa del alojamiento de la bolsa colo-

6.

cando las dos ranuras de la tapa en las guías correspondientes de la máquina. Empuje después la tapa hacia dentro

hasta que quede correctamente encajada.

NOTA:

Las fotos de abajo muestran el cambio de la bolsa de polvo

de papel.

No opere nunca la máquina sin una bolsa de polvo instalada.

11

VACIADO DE LA BOLSA DE POLVO

DE TELA

Cuando se enciende el indicador de “Bolsa llena”(15) hay

que limpiar lo antes posible la bolsa. Para cambiar la bolsa

proceda de la manera siguiente:

Desenchufe el cable de la toma de corriente. Tire del cierre

1.

(16) para abrir el alojamiento de la bolsa. Quite la tapa del

alojamiento de la bolsa.

Retire la bolsa de tela de su soporte; presione hacia aden-

2.

tro/hacia abajo el cierre de manera que se desprenda de la

entrada en la máquina la boca de entrada de la bolsa.

Agarre la arandela de la bolsa de tela y tire con cuidado

3.

hacia afuera para extraer la bolsa de su soporte.

Quite el clip que cierra la bolsa y extraiga su contenido

4.

sacudiendo la bolsa.

Vuelva a montar el clip para cerrar la bolsa.

5.

Vuelva a colocar la bolsa nueva o la que se ha vaciado.

6.

7.

8.

Monte la arandela en el soporte y la bolsa en éste.

Empuje el soporte con la bolsa hacia arriba hasta que

el soporte quede fi jado a la pieza correspondiente en la

máquina. Controle después que la bolsa está desplegada y

se adapta a su alojamiento. Compruebe que la función ”no

clip” está a la izquierda de manera que pueda cerrarse la

tapa del alojamiento de la bolsa.

Vuelva a montar la tapa del alojamiento de la bolsa

colocando las dos ranuras de la tapa en las guías correspondientes de la máquina. Empuje después la tapa hacia

dentro hasta que quede correctamente encajada.

2

2

3

4

3, 4

56

5

31

Page 32

CAMBIO DEL CEPILLO

Desenchufe el cable de la toma de corriente.

1.

Desacople el cepillo de rodillo abriendo el so-

2.

porte de cojinete. Empuje el botón hacia atrás

y a la izquierda en la dirección del símbolo de

apertura en el alojamiento del cepillo.

Extraiga el soporte del cojinete para sacarlo del

3.

2

4

3

6

alojamiento del cepillo.

Desmonte el cepillo gastado.

4.

Limpie el cepillo o sustitúyalo por otro nuevo.

5.

Vuelva a montar el cepillo en el soporte del

6.

cojinete en el alojamiento del cepillo.

Ponga el soporte del cojinete en su posición y

7.