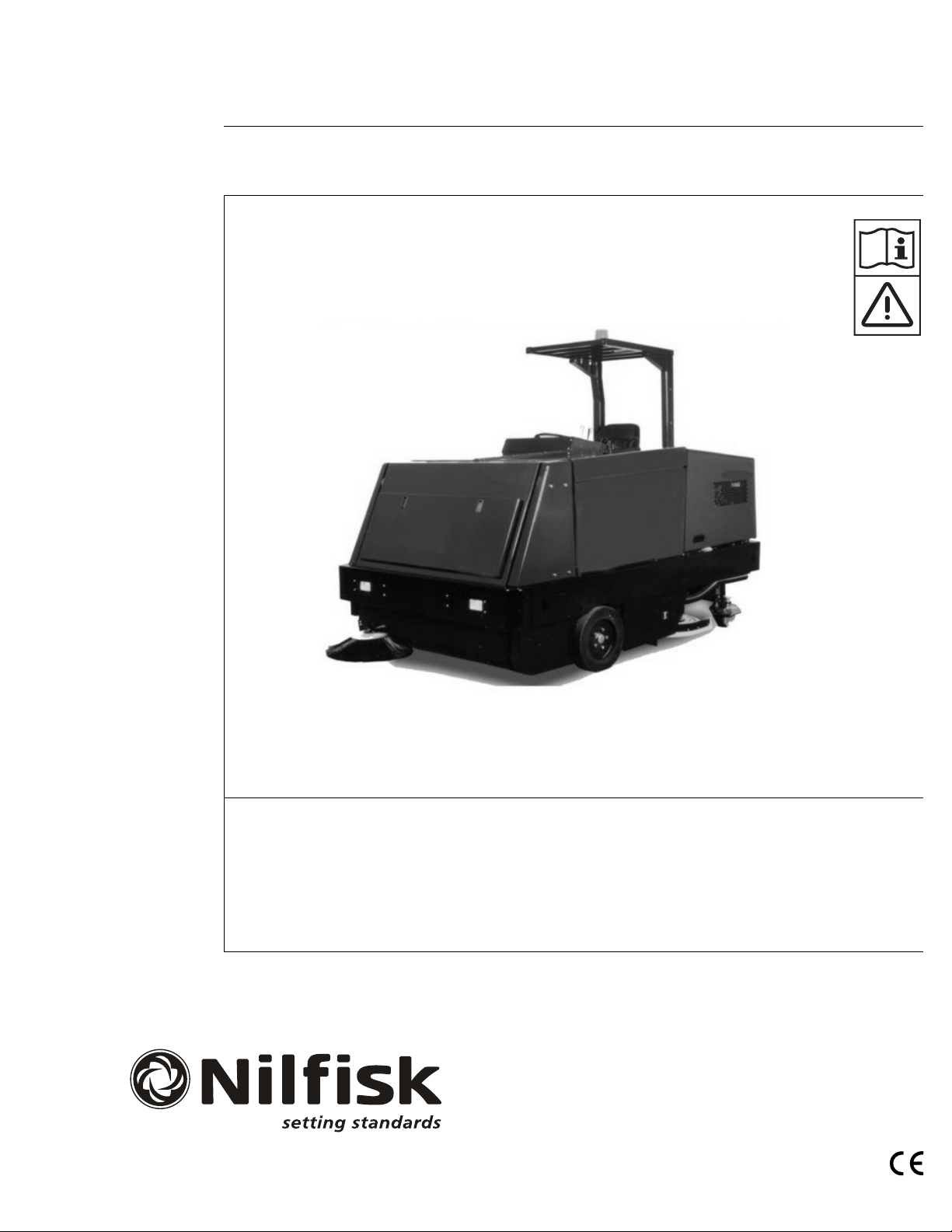

Page 1

CR 1500

Instructions for Use

Kullanım Talimatları

Nilfi sk Models: 56514850 (VD Gas), 56514852 (VD LP), 56514854 (VD Diesel)

A-English

B-Türkçe

3/08 revised 4/08 Form No. 56041719

Page 2

A-2 / ENGLISH

TABLE OF CONTENTS

Page

Table of Contents ................................................................A-2 - A-3

Introduction .................................................................................. A-4

Introduction ...........................................................................A-4

Parts and Service .................................................................A-4

Nameplate ............................................................................A-4

Un-Crating ............................................................................A-4

Machine Operation ...................................................................... A-5

Preparing the Machine for Operation....................................A-5

Cautions and Warnings............................................................... A-6

Consignes De Prudence Et De Securite ....................................A-7

Operation of Controls and Gauges .................................A-8 – A-15

Ignition Switch ......................................................................A-8

Light Switch ..........................................................................A-8

Turn Signal (Option) .............................................................A-9

Glow Plug Switch ..................................................................A-9

Horn Push Button .................................................................A-9

Side Broom Lift .....................................................................A-9

Main Broom Switch .............................................................A-10

Side Broom Switch .............................................................A-10

Dust Control Switch ............................................................A-10

Filter Shaker Switch ............................................................A-10

Water Temperature Gauge .................................................A-11

Hour Meter ..........................................................................A-11

Fuel Gauge .........................................................................A-11

Oil Pressure Gauge ............................................................A-11

Volt Meter ...........................................................................A-11

Scrub Brushes Switch ........................................................A-12

Brush Rotation Switch ........................................................A-12

Brush Pressure Switch .......................................................A-12

Squeegee Blade Switch .....................................................A-12

High Recovery Warning Light .............................................A-12

Low Solution Warning Light ................................................A-12

Hopper Lift ..........................................................................A-13

Hopper Safety Lock Arm .....................................................A-13

Hopper Dump Door.............................................................A-13

Solution Control ..................................................................A-13

Sweeping Broom Lift Control ..............................................A-13

Throttle ...............................................................................A-14

Check Engine Light ............................................................A-14

Parking Brake .....................................................................A-14

Foot Brake ..........................................................................A-14

Accelerator & Directional Control Pedal .............................A-15

Back-Up Alarm Switch ........................................................A-15

Seat Adjustment .................................................................A-15

A-2 - FORM NO. - 56041719 - CR 1500

Page 3

TABLE OF CONTENTS

Page

Scrubbing System Operating Instructions ..................A-16 – A-18

ESP System Operating Instructions ........................................ A-16

ESP Recycling Control Panel .............................................A-16

ESP Recycling System On/Off Switch ................................A-16

Solution High Warning Light ...............................................A-16

Detergent Low Warning Light .............................................A-16

Detergent Flow Knob ..........................................................A-16

The Scrubbing System - How It Works ...............................A-17

Non-Recycling Scrubbing System - How It Works ..............A-17

Recovery or ESP System - How It Works ...........................A-18

Dust Control Operating Instructions ....................................... A-19

The Sweeping & Dust Control System - How It Works .......A-19

Operating Instructions ...................................................A-20 – A-22

Filling the Solution Tank - Non-Recycling (Standard) .........A-20

Filling the Solution Tank - ESP ...........................................A-20

Pre-Start Checklist ..............................................................A-20

Before Starting the Engine .................................................A-20

Starting the Engine .............................................................A-20

Post-Start Checklist ............................................................A-21

Transporting the Machine ...................................................A-21

Beginning the Cleaning Operation ......................................A-21

Helpful Hints for Cleaning Operation ..................................A-22

Post-Operation & Clean-Up Instructions ......................A-23 – A-25

To Stop the Cleaning Operation .........................................A-23

Post-Operation Checklist ....................................................A-23

To Drain the Solution Tank ..................................................A-23

To Clean the Solution Tank .................................................A-23

To Drain the Recovery Tank ................................................A-23

To Clean the Recovery Tank ...............................................A-24

To Empty the Debris Hopper...............................................A-25

Towing Instructions .............................................................A-25

Service Chart ..................................................................A-26 – A-27

General Machine Maintenance ......................................A-28 – A-33

Lubrication ..........................................................................A-28

Engine ................................................................................A-29

Main Broom Removal .........................................................A-29

Main Broom Level Adjustment ............................................A-30

Adjusting Main Broom Wear Pattern ..................................A-30

Side Broom Level Adjustment ............................................A-30

Side Broom Replacement ...................................................A-30

Flaps ...................................................................................A-31

Scrub Brush Replacement ..................................................A-32

Covers and Latches ............................................................A-32

Solution Warning Light ........................................................A-32

Recovery Warning Light .....................................................A-32

Solution Control - Standard ................................................A-32

Solution Control - ESP ........................................................A-32

Recycling Pump ESP System .............................................A-33

ESP System Storage ..........................................................A-33

Rear Squeegee ..................................................................A-33

Squeegee Caster Wheels ...................................................A-33

Adjusting Casters ...............................................................A-33

General Troubleshooting ...............................................A-34 – A-35

Technical Specifi cations ........................................................... A-36

ENGLISH / A-3

FORM NO. - 56041719 - CR 1500 - A-3

Page 4

A-4 / ENGLISH

INTRODUCTION

This manual will help you get the most from your American-Lincoln sweeper / scrubber. Read it thoroughly before operating the machine.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized American-Lincoln™ Service Center, who employs factory trained service

personnel, and maintains an inventory of American-Lincoln™ original replacement parts and accessories.

Call the AMERICAN-LINCOLN INDUSTRIAL DEALER named below for repairs or service. Please specify the Model and Serial Number when

discussing your machine.

(Dealer, affi x service sticker here.)

NAMEPLATE

The Model Number and Serial Number of your machine are shown on the Nameplate, located on the wall of the operator’s compartment. This

information is needed when ordering repair parts for the machine. Use the space below to note the Model Number and Serial Number of your

machine for future reference.

MODEL _______________________________________________

SERIAL NUMBER _______________________________________

Note: Reference the separately supplied engine manufacture’s maintenance and operator manual for more detailed engine specifi cation and

service data.

UNPACKING THE MACHINE

Upon delivery, carefully inspect the shipping crate and the machine for damage. If damage is evident, save all parts of the shipping crate so that

they can be inspected by the trucking company that delivered the machine. Contact the trucking company immediately to fi le a freight damage

claim.

A-4 - FORM NO. - 56041719 - CR 1500

Page 5

MACHINE OPERATION

ENGLISH / A-5

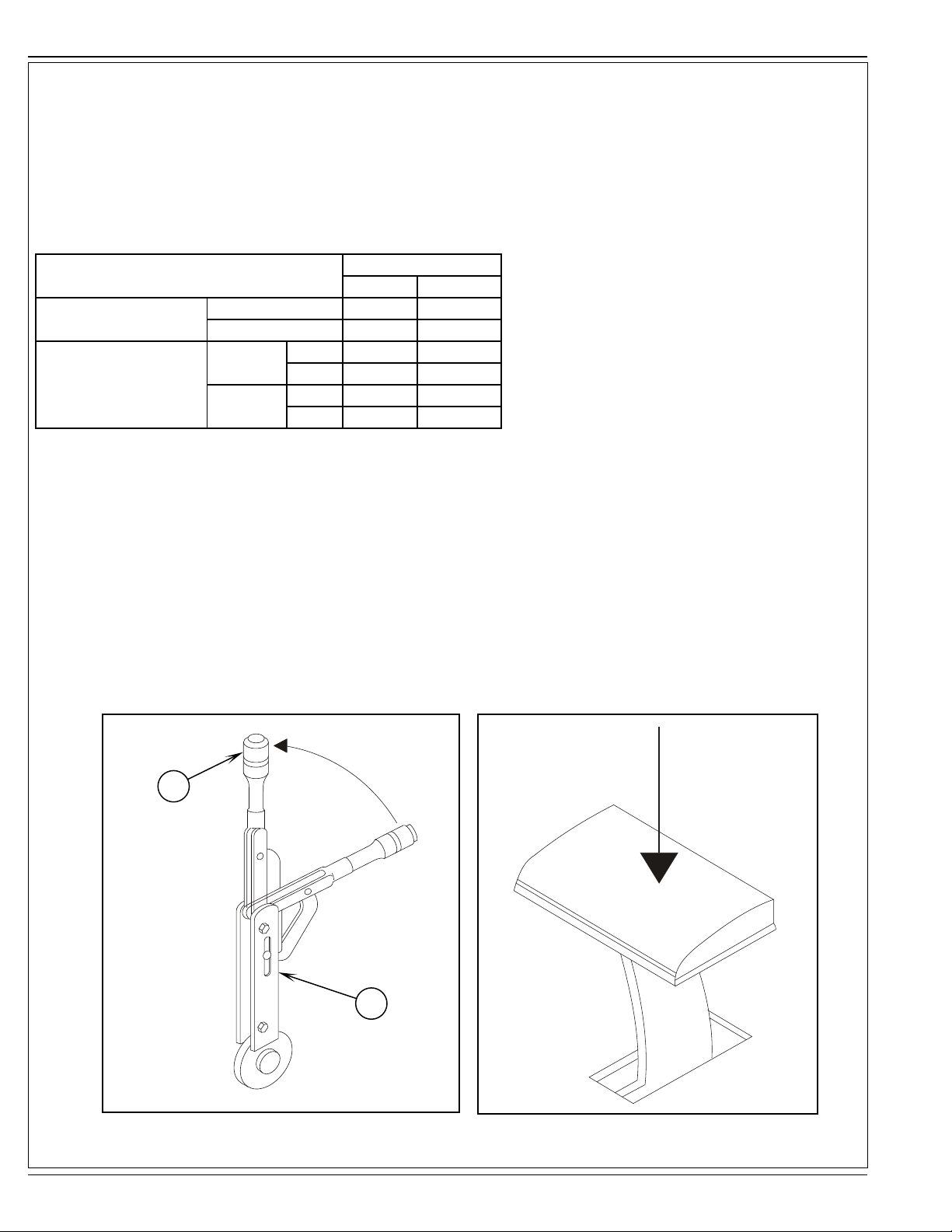

FIGURE 1

YOUR CR 1500 MACHINE HAS BEEN SHIPPED COMPLETE, BUT DO NOT ATTEMPT TO OPERATE WITHOUT FOLLOWING THESE

INSTRUCTIONS.

PREPARING THE MACHINE FOR OPERATION

1. Connect and tighten battery cables.

2. Fill the tank with REGULAR GRADE unleaded gasoline; Diesel fuel if equipped with diesel engine.

WARNING

Never fi ll tank while engine is running. Always be sure fuel container and sweeper are

electrically connected before pouring fuel. This can easily be done by permanently attaching one end of an insulated wire to the

container with battery clip on the opposite end.

3. Check engine crankcase oil level. Although properly lubricated at factory, check before starting engine. No special brand oil is used.

Recommended number of operating hours before the initial oil change is the same as normal. See Maintenance.

4. Check radiator coolant level. Permanent type antifreeze is added at the factory to provide protection to approximately -35° F (37° C). To

retain this protection level, always mix 1 part water to 1 part antifreeze.

5. Check oil level in the hydraulic reservoir located at center of machine beside the engine. Oil fi ll level should be two (2) inches (5 cm.) below

fi ller neck assembly. If oil is required, add HYDRAULIC FLUID ONLY, automatic transmission fl uid FORD type “F”. After the fi rst 50 operating

hours, service must be performed on your engine to insure future high performance and trouble-free operation. See Maintenance.

FORM NO. - 56041719 - CR 1500 - A-5

Page 6

A-6 / ENGLISH

CAUTIONS AND WARNINGS

SYMBOLS

American-Lincoln™ uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take

the necessary steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

DANGER!

• This machine emits exhaust gases (carbon monoxide) that can cause serious injury or death, always provide adequate

ventilation when using machine.

WARNING!

• This machine shall be used only by properly trained and authorized persons.

• While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only while

ascending (driving up) the ramp.

• To avoid hydraulic oil injection or injury always wear appropriate clothing and eye protection when working with or near hydraulic system.

• Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

• Never work under a machine without safety blocks or stands to support the machine.

• Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where fl ammable liquids exist.

• Do not clean this machine with a pressure washer.

CAUTION!

• This machine is not approved for use on public paths or roads.

• This machine is not suitable for picking up hazardous dust.

• Use care when using scarifi er discs and grinding stones. American-Lincoln

caused by scarifi ers or grinding stones.

• When operating this machine, ensure that third parties, particularly children, are not endangered.

• Before performing any service function, carefully read all instructions pertaining to that function.

• Do not leave the machine unattended without fi rst turning the key switch off (O), removing the key and applying the parking brake.

• Turn the key switch off (O) before changing the brushes, and before opening any access panels.

• Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

• Use caution when moving this machine in below freezing temperature conditions. Any water in the solution or recovery tanks or in the hose

lines could freeze.

• Before use, all doors and hoods should be properly latched.

™

will not be held responsible for any damage to fl oor surfaces

SAVE THESE INSTRUCTIONS

A-6 - FORM NO. - 56041719 - CR 1500

Page 7

ENGLISH / A-7

CONSIGNES DE PRUDENCE ET DE SECURITE

SYMBOLES

American-Lincoln™ utilise les symboles reproduits ci-dessous pour attirer l’attention de l’opérateur sur des situations potentiellement dangereuses.

Il est donc conseillé de lire attentivement ces indications et de prendre les mesures adéquates en vue de protéger le personnel et le matériel.

DANGER !

Ce symbole est utilisé pour mettre l’opérateur en garde contre les risques immédiats pouvant provoquer des dommages corporels graves, voire

entraîner la mort.

ATTENTION !

Ce symbole est utilisé pour attirer l’attention sur une situation susceptible d’entraîner des dommages corporels graves.

PRUDENCE !

Ce symbole est utilisé pour attirer l’attention de l’opérateur sur une situation qui pourrait entraîner des dommages corporels minimes ou des

dommages à la machine ou à d’autres équipements.

Lire toutes les instructions avant d’utiliser l’appareil.

CONSIGNES GENERALES DE SECURITE

Les consignes spécifi ques de prudence et de sécurité mentionnées ici ont pour but de vous informer de la survenance de tout risque de

dommages matériels ou corporels.

DANGER !

• Les gaz d’échappement (monoxyde de carbone) évacués par la machine peuvent entraîner de graves dommages corporels, voire la mort.

Veillez donc toujours à bénéfi cier d’une ventilation suffi sante lorsque vous utilisez la machine.

ATTENTION !

• Cette machine ne pourra être utilisée que par du personnel parfaitement entraîné et dûment autorisé.

• Evitez les arrêts subits lorsque la machine est chargée et se trouve sur des rampes ou des plans inclinés. Evitez les virages serrés. Adoptez une

vitesse réduite lorsque la machine est en descente. Ne nettoyez que lorsque la machine monte la pente.

• Lorsque vous utilisez le système hydraulique ou travaillez à proximité de celui-ci, veillez à porter une tenue appropriée et des lunettes de protection

afi n d’éviter tout risque de blessures ou toute projection d’huile.

• Positionnez la clé de contact sur off (O) et déconnectez les batteries avant de procéder à l’entretien des composants électriques.

• Ne travaillez jamais sous une machine sans y avoir placé, au préalable, des blocs de sécurité ou des étais destinés à soutenir la machine

• Ne déversez pas d’agents nettoyants infl ammables, ne faites pas fonctionner la machine à proximité de ces agents ou d’autres liquides

infl ammables.

• Ne nettoyez pas cette machine avec un nettoyeur à pression.

PRUDENCE !

• Cette machine n’est pas conçue pour une utilisation sur les chemins ou voies publiques.

• Cette machine n’est pas conçue pour le ramassage des poussières dangereuses.

• Faites extrêmement attention lorsque vous utilisez des disques de scarifi cateur et des meules. American-Lincoln™ ne pourra, en aucun cas, être tenu

pour responsable des dommages occasionnés à vos sols par ce type d’équipement.

• Lors de l’utilisation de cette machine, assurez-vous que des tiers, et notamment des enfants, ne courent pas le moindre risque.

• Avant de procéder à toute opération d’entretien, veuillez lire attentivement toutes les instructions qui s’y rapportent.

• Ne laissez pas la machine sans surveillance sans avoir, au préalable, coupé le contact, enlevé la clé de contact (O) et tiré le frein à main.

• Positionnez la clé de contact sur off (O) avant de remplacer les brosses ou d’ouvrir tout panneau d’accès.

• Prenez toutes les mesures nécessaires pour éviter que les cheveux, les bijoux ou les vêtements amples ne soient entraînés dans les parties mobiles

de la machine.

• Faites attention lorsque vous déplacez cette machine dans un endroit où la température peut descendre sous 0°. Car l’eau contenue dans la

solution, dans les réservoirs de récupération ou dans les conduites risquerait de geler.

• Avant utilisation, toutes les portes et capots doivent être correctement fermés.

CONSERVEZ SOIGNEUSEMENT CES INSTRUCTIONS

FORM NO. - 56041719 - CR 1500 - A-7

Page 8

A-8 / ENGLISH

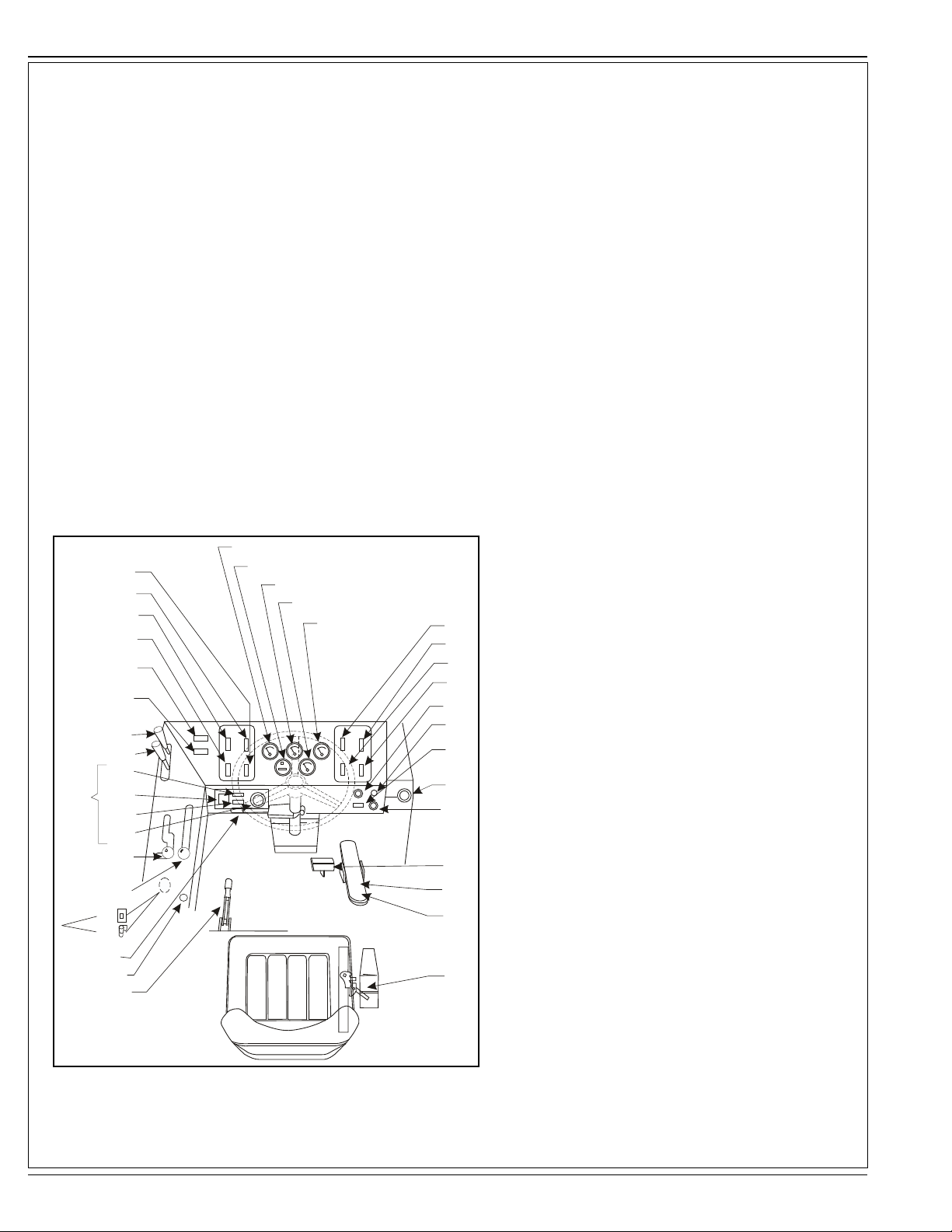

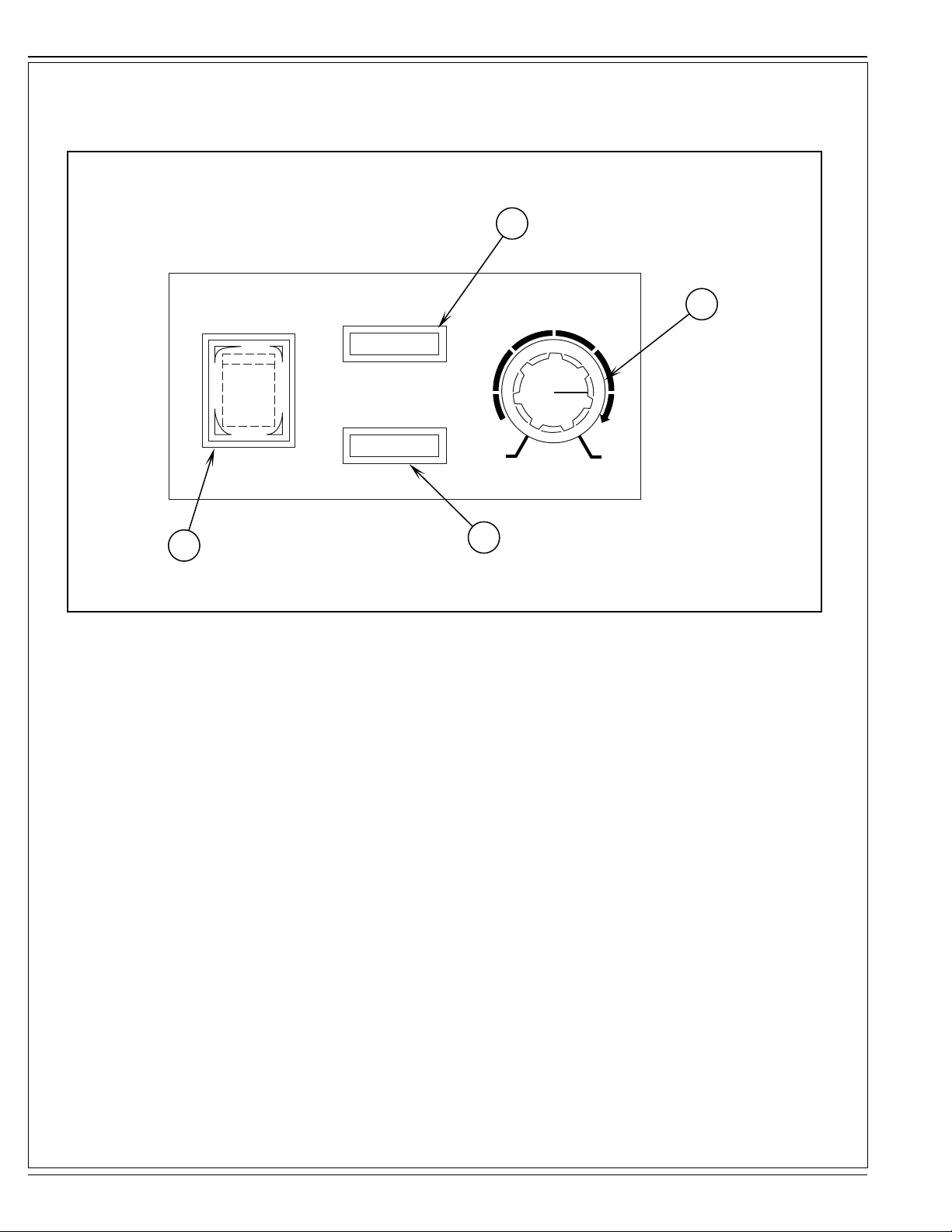

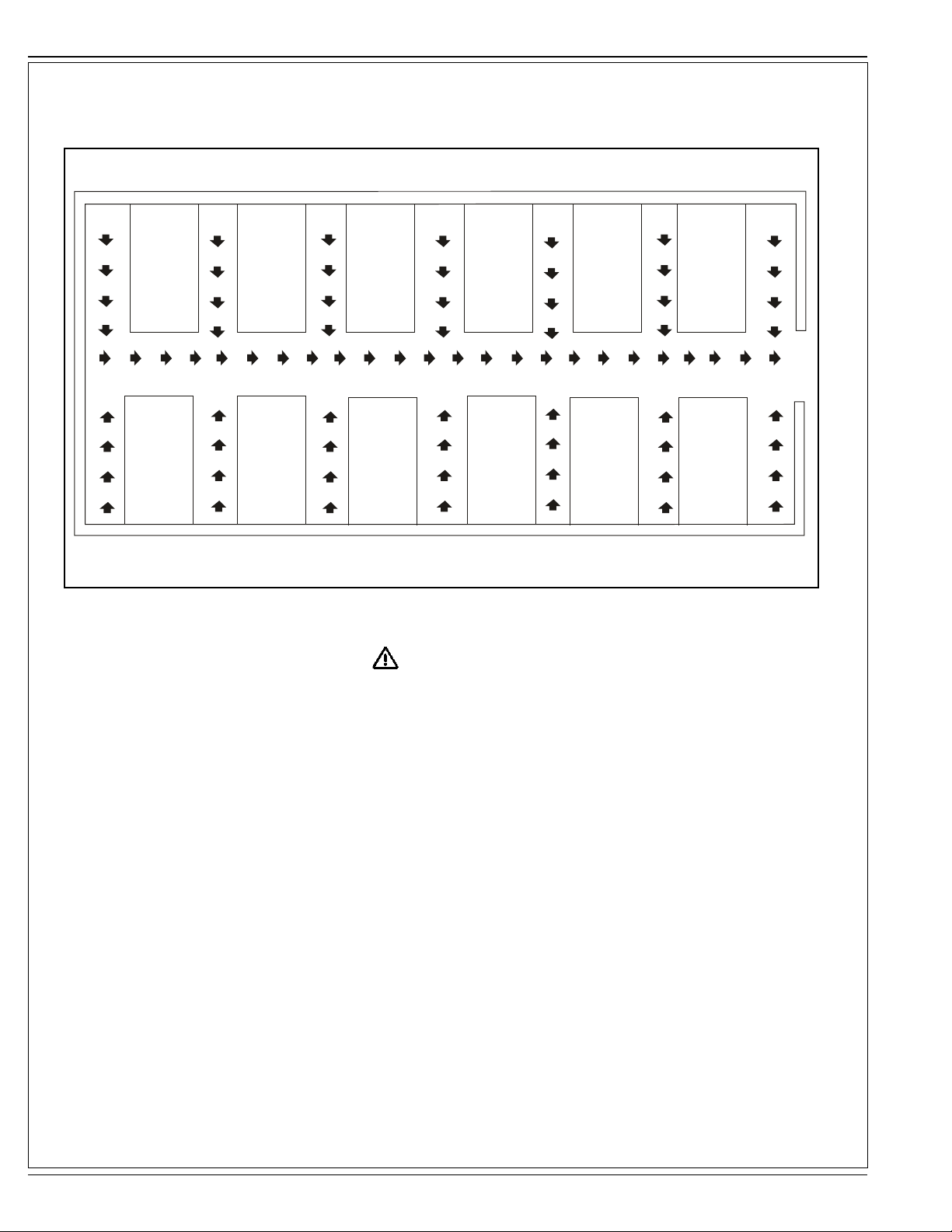

OPERATIONS OF CONTROLS AND GAUGES

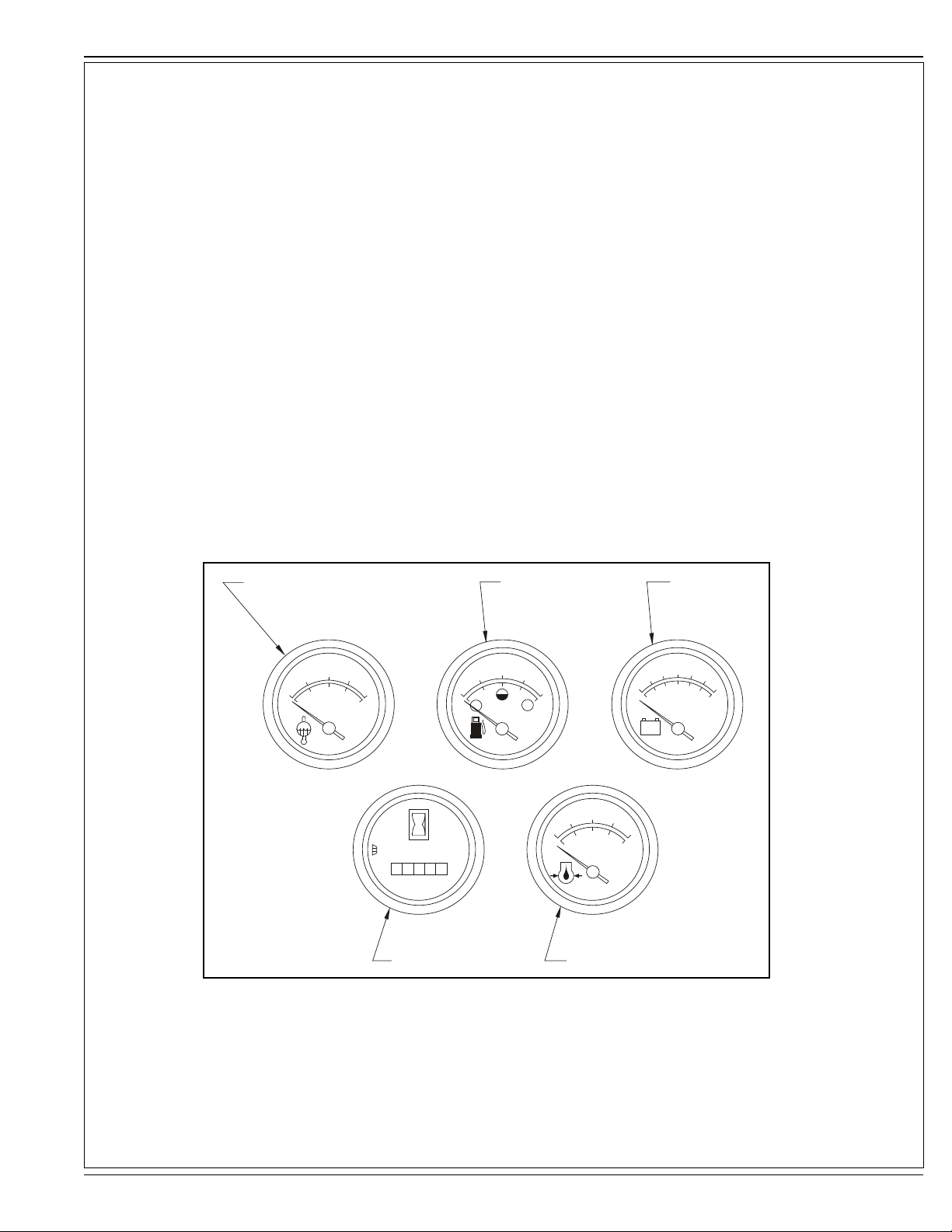

A Water Temperature Gauge

B Hour Meter

C Fuel Gauge

D Oil Pressure Gauge

E Volt Meter

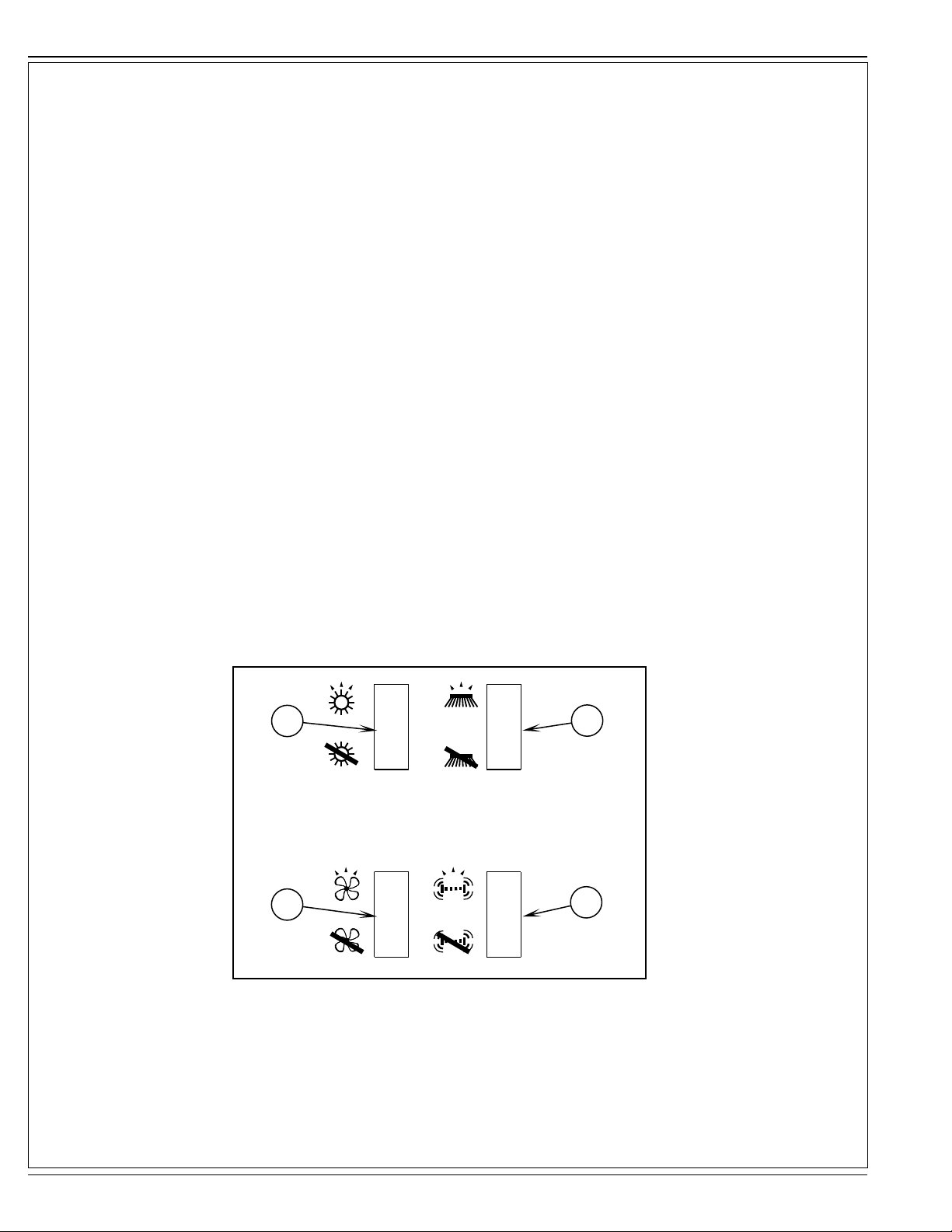

F Main Broom Switch

G Side Broom Switch

H Dust Control Switch

I Filter Shaker Switch

J Ignition Switch

K Light Switch

L Glow Plug Switch (Diesel Only)

M Side Broom Lift

N Horn Push Button

O Foot Brake

P Backup Alarm Switch

Q Accelerator & Directional Control Pedal

R Seat Adjustment

S Parking Brake

A

AM

AL

AK

AJ

AH

AG

AF

AE

AD

AC

Z

AB

AA

Y

X

W

V

U

T

S

B

C

FIGURE 2

T Check Engine Light (Gasoline/LP)

U Turn Signal

V Throttle Diesel

W Throttle Gasoline/LP

X Solution Control

Y Sweeping Broom Lift Control

Z ESP Option

AA Detergent Flow Knob

AB Detergent Low Light

AC Recycling System Switch

AD Solution High Light

AE Hopper Dump door

AF Hopper Lift

AG Low Solution Warning Light

AH High Recovery Warning Light

AJ Brush Pressure Switch

AK Scrub Brush Lift Switch

AL Squeegee Switch

AM Brush Rotation Switch

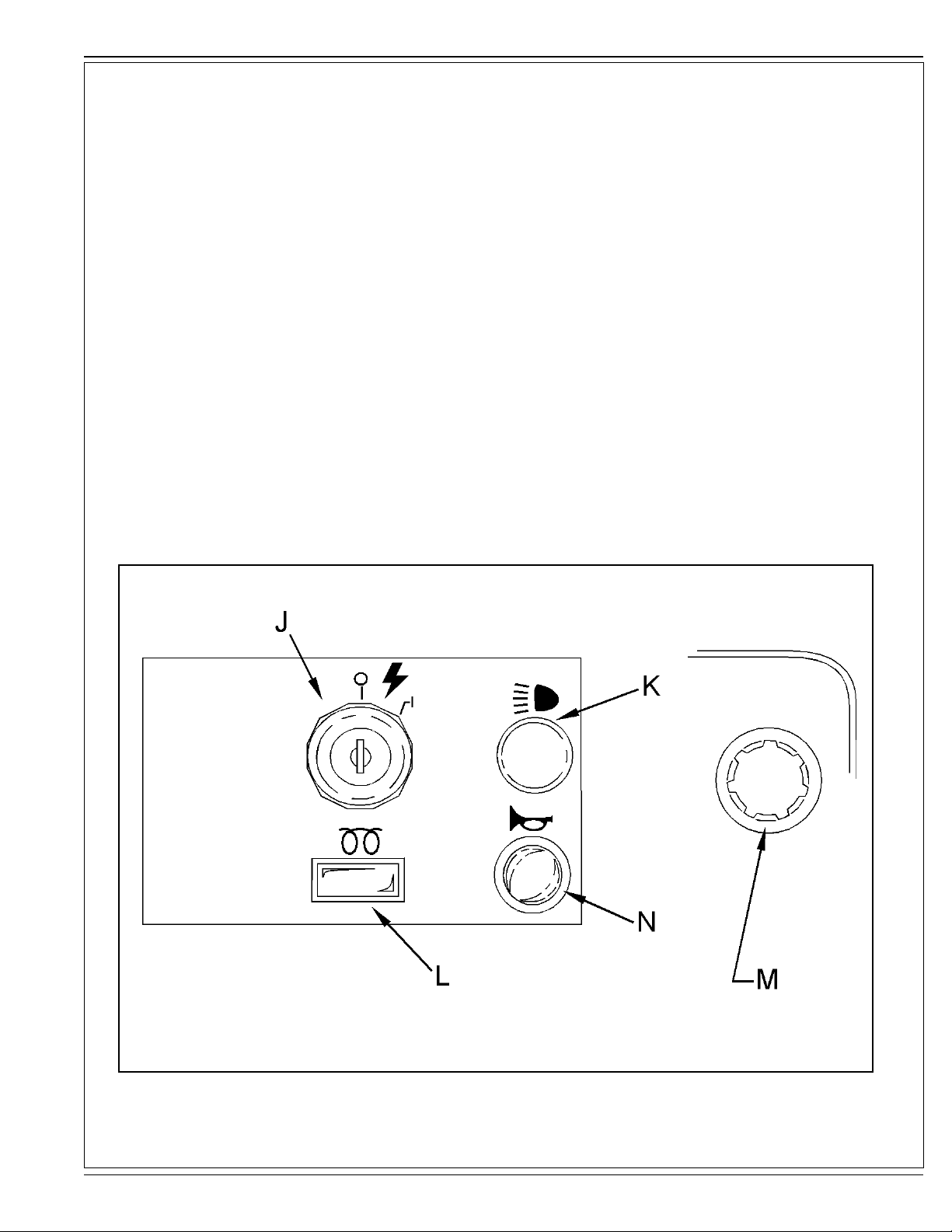

IGNITION SWITCH

The keyed Ignition Switch (J) is located to the right of the steering

column on the front face of the instrument console. It has four

D

E

positions.

F

1. The key turned to the center “OFF” position will shut off

G

the engine. The following items can be activated in the “OFF”

H

position.

I

(a.) Horn

J

(b.) Light Options

K

2. The key turned to the right “IGN/ON” position will allow

L

all the following items to be activated (but will NOT start the

engine):

M

(c.) Horn

N

(d.) Light Options

(e.) Turn Signals

(f.) Instrument Panel Gauges

O

P

3. The key turned to the far right “START” position will start

the engine. This position is a momentary position. The key will

Q

revert to the “IGN/ON” position when it is released.

R

LIGHT SWITCH

The Light Switch (K) is located above the horn button to the right

of the steering wheel. It will work various light options that are

available for this machine, such as:

* HEAD LIGHTS

* TAIL LIGHTS

* INSTRUMENT LIGHTS

All gauges, with the exception of the hour meter, can have an

optional internal instrument light.

A-8 - FORM NO. - 56041719 - CR 1500

Page 9

ENGLISH / A-9

OPERATIONS OF CONTROLS AND GAUGES

4-WAY TURN SIGNAL (OPTION)

The Turn Signal Option (U) is located on the steering column and works as automotive turn signals work, forward on the lever for right and back on

the lever for left. The 4-way fl asher will activate when the turn signal lever is pulled out.

GLOW PLUG SWITCH (DIESEL)

Under no circumstances should any other unauthorized starting aids be used at the same time as Glow Plugs. The Glow Plug Switch (L) is located

to the right of the steering column on the front face of the instrument console. Use the following procedure to operate:

1. Before operating the starter motor, press the “GLOW PLUG” button for 20 to 30 seconds.

2. With the “GLOW PLUG” button still depressed, engage the starter motor until the engine starts.

3. Continue to press the “GLOW PLUG” button for a few seconds after the engine has started until even running has been obtained.

4. If the engine does not start, disengage the starter motor, but keep the “GLOW PLUG” button depressed for an additional 10 to 15 seconds.

Keep the Glow Plugs energized while starting the engine and for a few seconds after the engine has been running smoothly.

HORN PUSH BUTTON

The Horn Button (N) is located to the right of the steering column on the front face of instrument console. The horn button is always active. Push

the horn button to sound the horn.

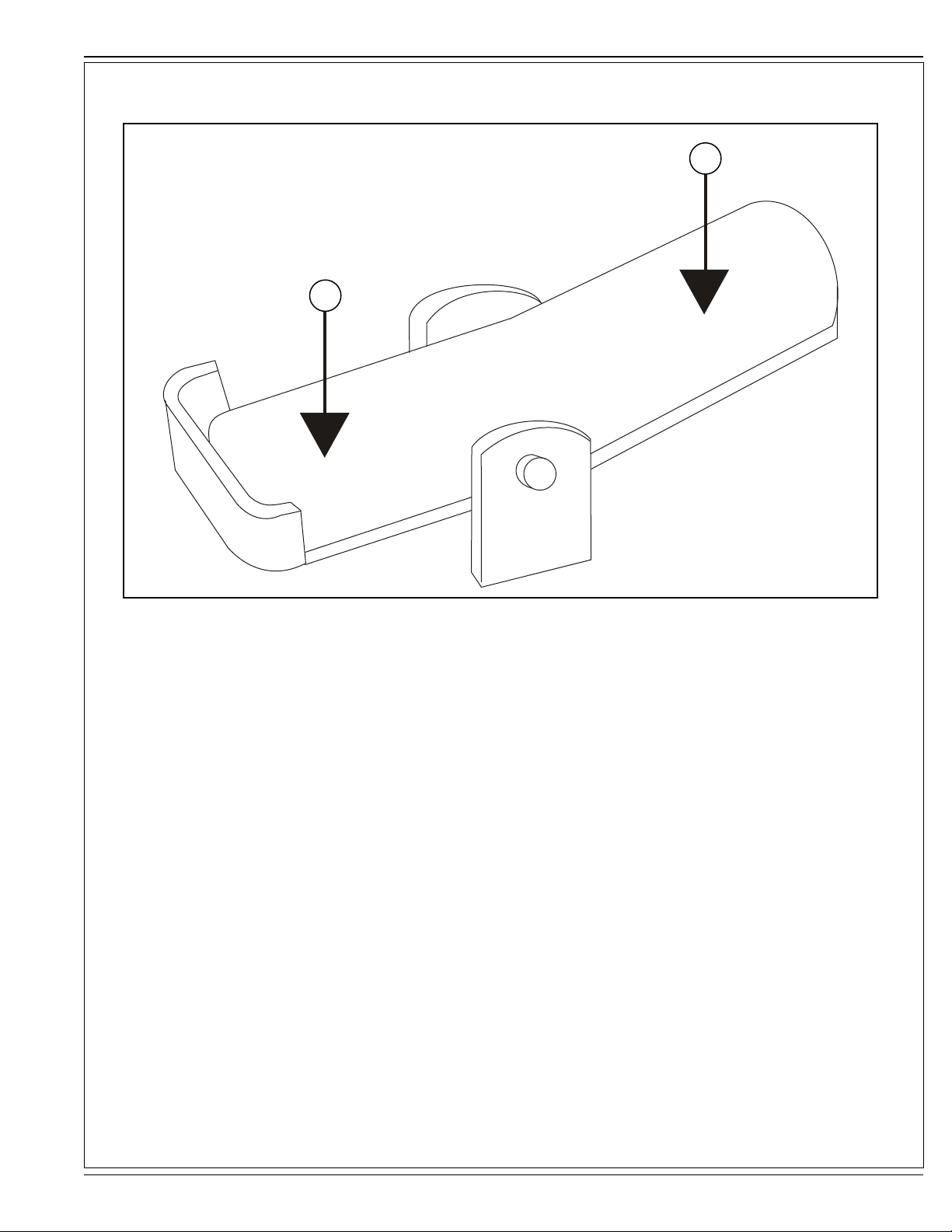

SIDE BROOM LIFT

The Side Broom Lift Lever (M) is located to the right of the instrument console. The handle pulled back and turned to the right will raise the side

broom and lock it into position.

FIGURE 3

FORM NO. - 56041719 - CR 1500 - A-9

Page 10

A-10 / ENGLISH

OPERATIONS OF CONTROLS AND GAUGES

MAIN BROOM SWITCH

The Main Broom Switch (F) is located on the console to the right of the steering wheel in the SWEEPING section. This switch will activate the Main

Broom. This switch has two positions “ON” and “OFF”. See Sweeping Broom Lift Control.

SIDE BROOM SWITCH

The Side Broom Switch (G) is located on the console to the right of the steering wheel in the SWEEPING section. This switch will activate the Side

Broom. This switch has two positions “ON” and “OFF”. See Side Broom Lift Control.

DUST CONTROL SWITCH

The Dust Control Switch (H) is located on the console to the right of the steering wheel in the SWEEPING section. This switch will activate the dust

control system.

FILTER SHAKER SWITCH (VARIABLE DUMP MACHINES ONLY)

The Filter Shaker Switch (I) is located on the console to the right of the steering wheel in the SWEEPING section.

NOTE - (Variable Dump Machines Only)

THE MAIN BROOM SWITCH MUST ALWAYS BE PLACED IN THE OFF POSITION BEFORE SHAKING THE FILTER. FAILURE TO DO SO

WILL RESULT IN DUST REMAINING ON THE SURFACE OF THE FILTER ENVELOPES INSTEAD OF DROPPING INTO THE HOPPER.

The button can be used when the ignition key is in the “ignition” position. The fi lter shaker control button is used during the sweeping cycle and the

hopper unloading cycle. Use the fi lter shaker control switch to remove dust from the fi lter. Use the following procedures to operate the fi lter shaker

control switch:

1. After the machine has made a long sweeping run, turn the broom switch to the “OFF” position.

2. Push the fi lter shaker control switch for 5 to 15 seconds to allow the fi lter to unload.

3. Turn the broom switch to the “ON” position. Repeat this procedure after each long sweeping run.

FIGURE 4

F

G

H

I

NOTE - (Variable Dump Machines Only)

The main broom, side broom, dust control and fi lter shaker turn off automatically when the hopper is dumping and/or the dump door is

in a closed position. SEE HOPPER LIFT and HOPPER DUMP DOOR.

A-10 - FORM NO. - 56041719 - CR 1500

Page 11

ENGLISH / A-11

OPERATIONS OF CONTROLS AND GAUGES

WATER TEMPERATURE GAUGE

The Water Temperature Gauge (A) is located on the console panel above the steering wheel in the gauge cluster. The gauge is mechanical and

activated by a sender in the engine. It displays the engine coolant temperature in Fahrenheit.

HOUR METER

The Hour Meter (B) is located on the console panel above the steering wheel in the gauge cluster. This meter is activated when the engine begins

running. The meter indicates actual “run” time of the machine. The meter can used to determine machine maintenance intervals.

FUEL GAUGE

The Fuel Gauge (C) is located on the console panel above the steering wheel in the gauge cluster. This gauge indicates the level of fuel contained

in the fuel tank.

OIL PRESSURE GAUGE

The Oil Pressure Gauge (D) is located on the console panel above the steering wheel in the gauge cluster. The gauge is mechanical and activated

by a sender in the engine. It displays the engine oil pressure in PSI.

VOLT METER

The Volt Meter (E) is located on the console panel above the steering wheel in the gauge cluster. The gauge indicates the charge level of the

battery.

A

°F

195

100

170

220

280

91

77

104

°C

138

WATER

TEMP

HOURS

0

001

0

1/10

B

C

1/2

1/4

0

FUEL BATTERY

PSI

40

kPa

278

60

553

OIL

PRESS

80

20

0

D

E

14

12

10

+

-

16

FIGURE 5

FORM NO. - 56041719 - CR 1500 - A-11

Page 12

A-12 / ENGLISH

OPERATIONS OF CONTROLS AND GAUGES

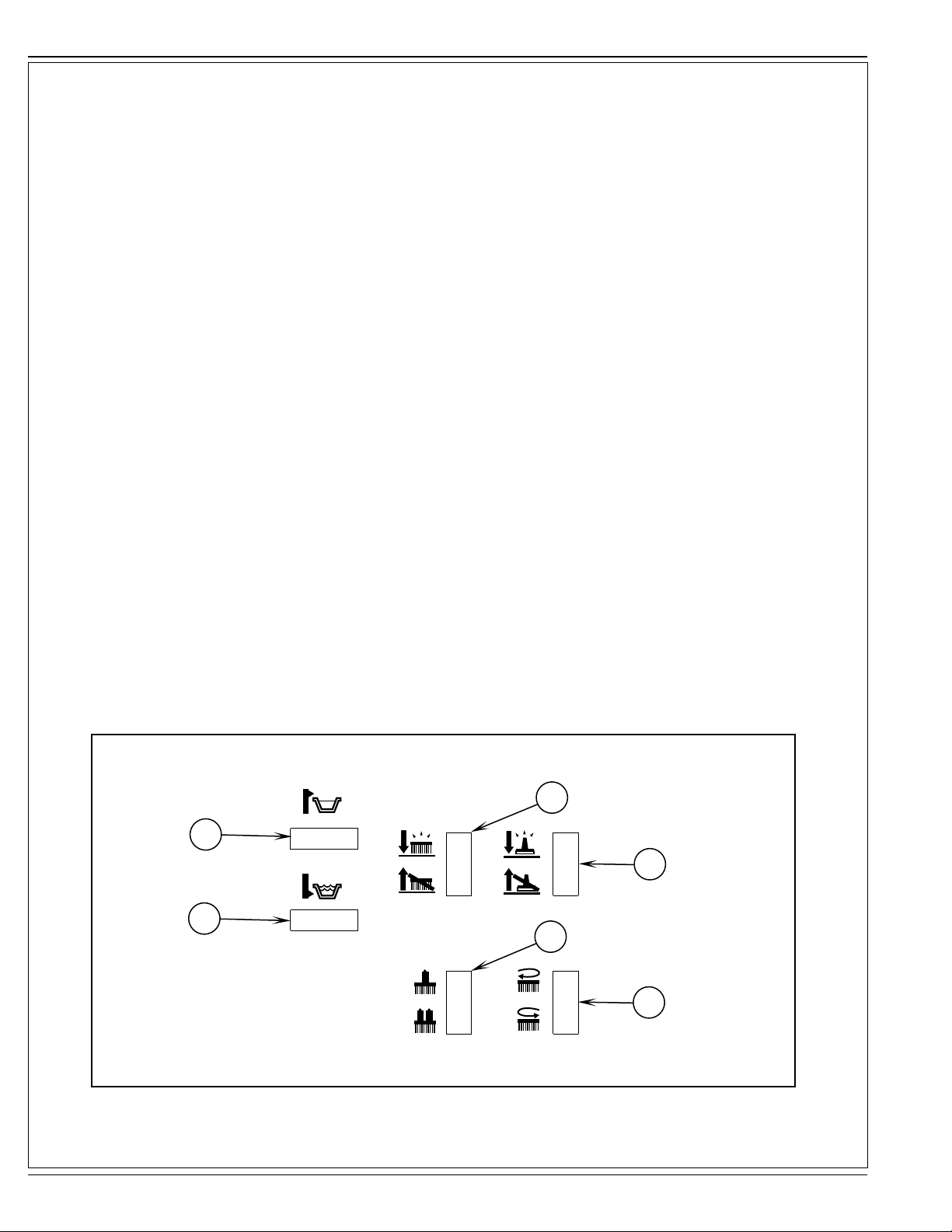

SCRUB BRUSHES SWITCH

The Brushes Switch (AK) is located on the console to the left of the steering wheel in the “SCRUBBING” section. This switch in the position marked

“LOWER” will lower the scrub brush deck and activate the three scrub brushes. The Brush Rotation Switch (AM) and the Brush Pressure Switch

(AJ) can not be activated unless this switch is in the “LOWER” position. This switch in the “RAISE” position will stop the brushes from rotating and

raise the scrub brush deck.

BRUSH ROTATION SWITCH

The Brush Rotation Switch (AM) is located on the console to the left of the steering wheel in the “SCRUBBING” section. This switch reverses the

rotation of the scrub brushes. This switch has two positions, “NORMAL” and “REVERSED”. This switch can not be activated unless the Scrub Brush

Lift Switch is in the “LOWER” position. The switch will light when activated.

BRUSH PRESSURE SWITCH

The Brush Pressure Switch (AJ) is located on the console to the left of the steering wheel in the “SCRUBBING” section. This switch applies additional

downward pressure to the scrub brushes. This switch has two positions, “NORMAL” and “HEAVY”. This switch can not be activated unless the Scrub

Brush Lift Switch is in the “LOWER” position. The switch will light when the switch can be activated.

SQUEEGEE BLADE SWITCH

The Squeegee Blade Switch (AL) is located on the console to the left of the steering wheel in the “SCRUBBING” section. This switch in the position

marked “LOWER” will lower the squeegee and activate the squeegee vacuum. This switch in the “RAISE” position will stop the squeegee vacuum

and raise the squeegee. A switch activated by the forward-reverse foot pedal will automatically raise the squeegee if it is in the lowered position and

the machine is in reverse.

HIGH RECOVERY WARNING LIGHT

The High Recovery Warning Light (AH) is located on the console to the left of the steering wheel beside the “SCRUBBING” section. The recovery

warning light will illuminate approximately 5 minutes before the recovery tank is full, giving ample time to complete the scrubbing cycle before the

mechanical fl oat shuts off the vacuum to the recovery tank.

LOW SOLUTION WARNING LIGHT

The Low Solution Warning Light (AG) is located on the console to the left of the steering wheel beside the “SCRUBBING” section. The Solution

Warning Light will illuminate when the solution tank is empty, marking the end of the scrubbing cycle.

AK

AH

AL

AG

AJ

A-12 - FORM NO. - 56041719 - CR 1500

AM

FIGURE 6

Page 13

ENGLISH / A-13

OPERATIONS OF CONTROLS AND GAUGES

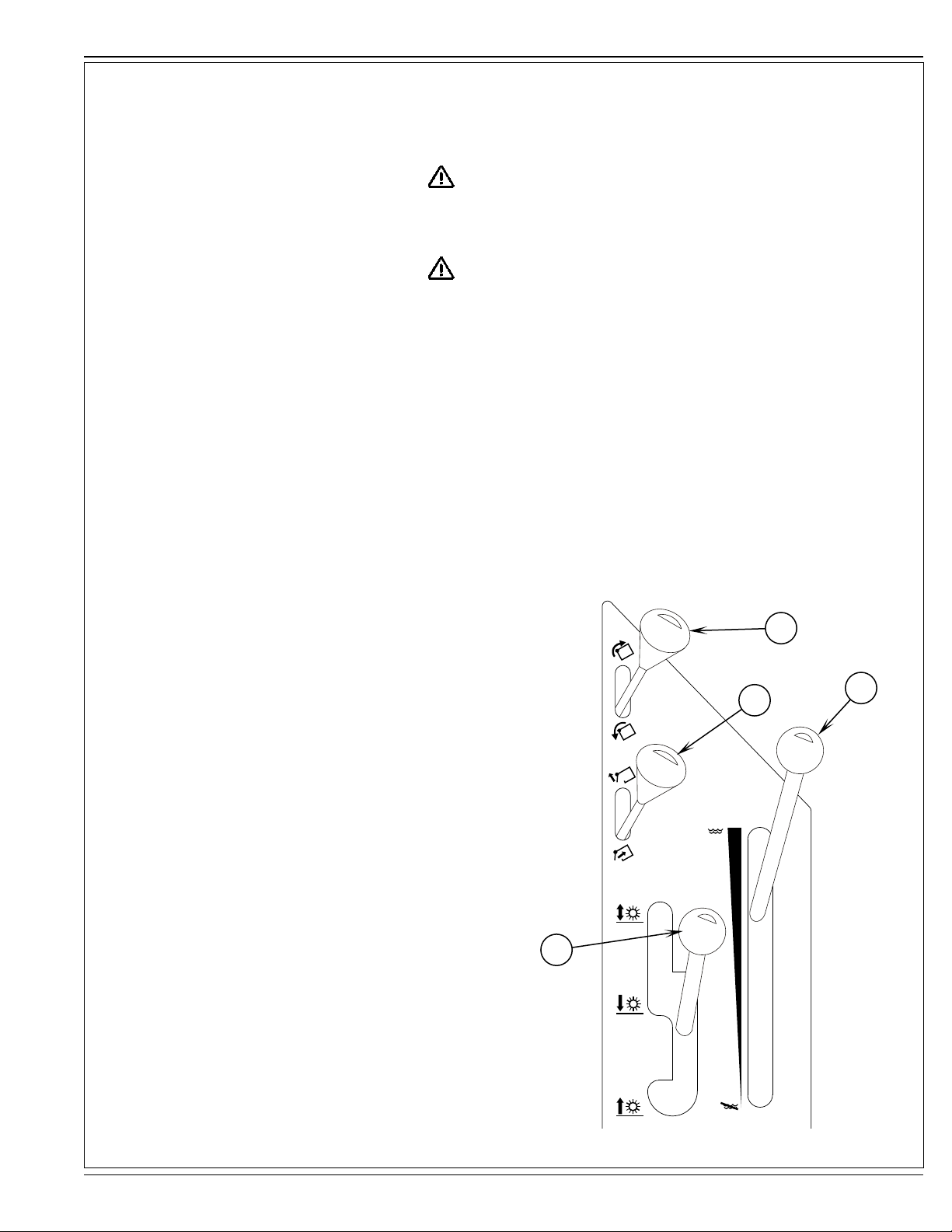

HOPPER LIFT - (VARIABLE MACHINES ONLY)

The Hopper Lift Lever (AF) is located to the left of the steering wheel on the left side of the driver compartment. This lever, which is marked

“HOPPER”, raises and lowers the debris hopper to ease unloading.

WARNING

The hopper may drop unexpectedly and cause injury, always engage the safety arm before working under the hopper.

HOPPER SAFETY LOCK ARM (VARIABLE DUMP ONLY)

WARNING

When the hopper is raised the safety arm must be engaged before any work is done under the hopper

The Hopper Safety Lock Arm is located under the hopper assembly. After the work is complete, the safety arm must be disengaged.

HOPPER DUMP DOOR - (VARIABLE DUMP MACHINES ONLY)

The Hopper Dump Door Lever (AE) is located to the left of the steering wheel on the left of the driver compartment. This lever opens and closes the

hopper door. This lever is located below the Hopper Lift Door and is marked “DUMP DOOR”.

SOLUTION CONTROL

To apply solution to the scrubbing brushes, push the Solution Control Lever (X) forward until the desired setting is reached. The solution rate is

continuously variable from off to approximately 1-3/4 GPM at low and 3-1/2 GPM at high. To stop application of solution, pull back on the lever until

it stops at the “off” position. The solution warning light will illuminate when the solution tank is empty, marking the end of the scrubbing cycle.

NOTE

For best results, discontinue application of solution 10 feet

before stopping or making a 90° or 180° turn.

SWEEPING BROOM LIFT CONTROL

The Main Broom Lift Control (Y) is located to the left of the driver

seat. To lower the main broom, grasp the lever and pull back to

clear the locking notch. Move the lever forward to the fi rst or second

notch in the elongated slot. The fi rst notch, “SWEEP”, is for normal

sweeping (2 to 3 inch [5 to 8 cm.] broom pattern). The second

notch, “FLOAT”, is for heavy sweeping (4 to 5 inch [10 to 13 cm.]

broom pattern).

To raise the main broom, pull the lever back and slide into the locking

notch. You may operate the main broom in either the “SWEEP” or

“FLOAT” position. However, the “SWEEP” position should be used

for normal sweeping and will result in increased broom life. The

“FLOAT” position should be used only when sweeping extremely

uneven areas.

NOTE - (Variable Dump Machines Only)

A switch triggered by the hopper and dump door position

controls the sweeping functions, main broom, side broom,

dust control, and fi lter shaker. The hopper must be down and

the dump door open before these functions will work.

FIGURE 7

AF

AE

X

Y

FORM NO. - 56041719 - CR 1500 - A-13

Page 14

A-14 / ENGLISH

OPERATIONS OF CONTROLS AND GAUGES

THROTTLE CONTROL

See Figure 2. The Throttle Control (V or W) is located on the left side console. Gas and LP equipment have a Throttle Switch (W). Diesel

versions have a Lever (V). To operate the diesel: For full throttle, grasp the lever and push up and right to the locking notch. To reduce to idle,

grasp the lever and push it up and to the left (away from the locking notch). Let the lever lower until it rests at the bottom of the slot. “Load”

(brooms and/or brushes and/or dust control operating) and “No Load” (brooms, brushes & dust control off) RPMs are the same for gas and

LP equipment. There will be a slight drop between “Load” and “No Load” RPMs with diesels. Always return the throttle switch/lever to the idle

position before turning off the key to stop the engine.

MACHINE

SWEEPER / SCRUBBER

(1 speed)

SWEEPER

(2 speed levels)

Gas/LP 950 2050

Diesel 950 2150

Gas/LP

Diesel

1st 950 2050

2nd 950 2450

1st 950 2150

2nd 950 2550

RPM’s

IDLE “NO LOAD”

CHECK ENGINE LIGHT (MIL) - GAS, LP ONLY

The Check Engine Light “MIL” (T) is located on the left side console. If the light comes on, it indicates a problem with the engine. Go to the GM

Engine Service Manual, Section 7, for directions on how to diagnose the problem.

PARKING BRAKE

The Parking Brake Lever (S) is located in the left side of the driver compartment fl oor. See Figure 8. This lever, when raised to the upright position

(a), will “lock” the foot brake pedal in the down position.

FOOT BRAKE

See Figure 2. The Foot Brake Pedal (O) is located to the right of the steering column on the fl oor of the driver compartment. See Figure 9. The foot

brake on the front wheels is a mechanical system actuated by the brake pedal.

a

FIGURE 8

A-14 - FORM NO. - 56041719 - CR 1500

S

FIGURE 9

Page 15

OPERATIONS OF CONTROLS AND GAUGES

c

ENGLISH / A-15

b

FIGURE 10

ACCELERATOR & DIRECTIONAL CONTROL PEDAL

See Figure 2. The Accelerator and Directional Control Pedal (Q) is located on the fl oor of the driver compartment, to the right of the brake pedal.

The accelerator and directional control pedal controls machine direction and travel speed.

1. Put foot pressure on the upper portion of the pedal (b). The machine will move forward.

2. Increase the foot pressure on the upper portion of the pedal to increase the forward speed.

3. Put foot pressure on the lower portion of the pedal (c). The machine will move in reverse.

4. Increase the foot pressure on the lower portion of the pedal to increase the reverse speed.

5. To stop the machine, put light foot pressure on the opposite end of the accelerator and directional control pedal. If the machine is moving

forward put light foot pressure on the lower portion of the pedal. If the machine is moving in reverse put light foot pressure on the upper

portion of the pedal.

BACKUP ALARM SWITCH

See Figure 2. The Backup Alarm Switch (P) is located under the lower section of the accelerator and directional control pedal and operates the

backup alarm. The alarm makes a loud audible noise when the machine is being driven in reverse.

SEAT ADJUSTMENT

See Figure 2. The Seat Adjustment Lever (R) is located on the right of the seat. This lever allows the seat to be adjusted forward or back when the

lever is moved.

FORM NO. - 56041719 - CR 1500 - A-15

Page 16

A-16 / ENGLISH

SCRUBBING SYSTEM OPERATING INSTRUCTIONS

THE ESP RECYCLING CONTROL PANEL

B

RECYCLING

SYSTEM

ON

OFF

A

HIGH

SOLUTION

LOW

DETERGENT

FIGURE 11

DETERGENT FLOW

OFF

MAX

C

THE ESP RECYCLING SYSTEM ON/OFF SWITCH

See Figure 11. The ESP Recycling System ON/OFF Switch (A) turns the ESP recycling system on and off.

D

SOLUTION HIGH WARNING LIGHT

The Solution High Warning Light (B) will come on if the solution tank is too full of water from the recycling system.

DETERGENT LOW WARNING LIGHT

The Detergent Low Warning Light (C) will illuminate when the detergent tank is low, warning the operator to add detergent.

DETERGENT FLOW KNOB

The rotary Detergent Flow Knob (D) controls the detergent fl ow into the scrubbing solution. The operator may choose from any detergent setting, for

light to heavy cleaning applications. The detergent light will illuminate when the detergent tank is low, warning the operator to add detergent.

A-16 - FORM NO. - 56041719 - CR 1500

Page 17

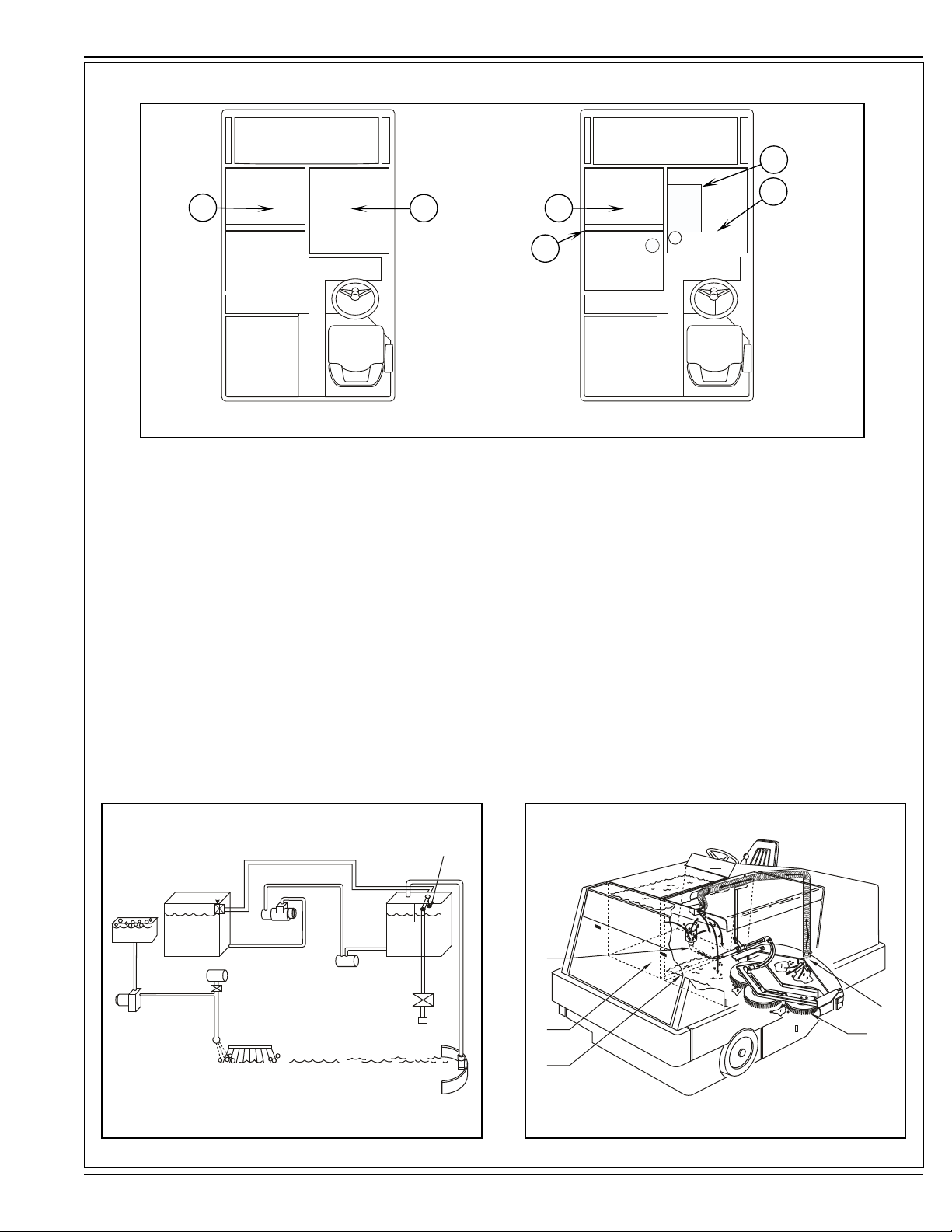

SCRUBBING SYSTEM OPERATING INSTRUCTIONS

A

B

A

C

NON-RECYCLING RECYCLING

FIGURE 12

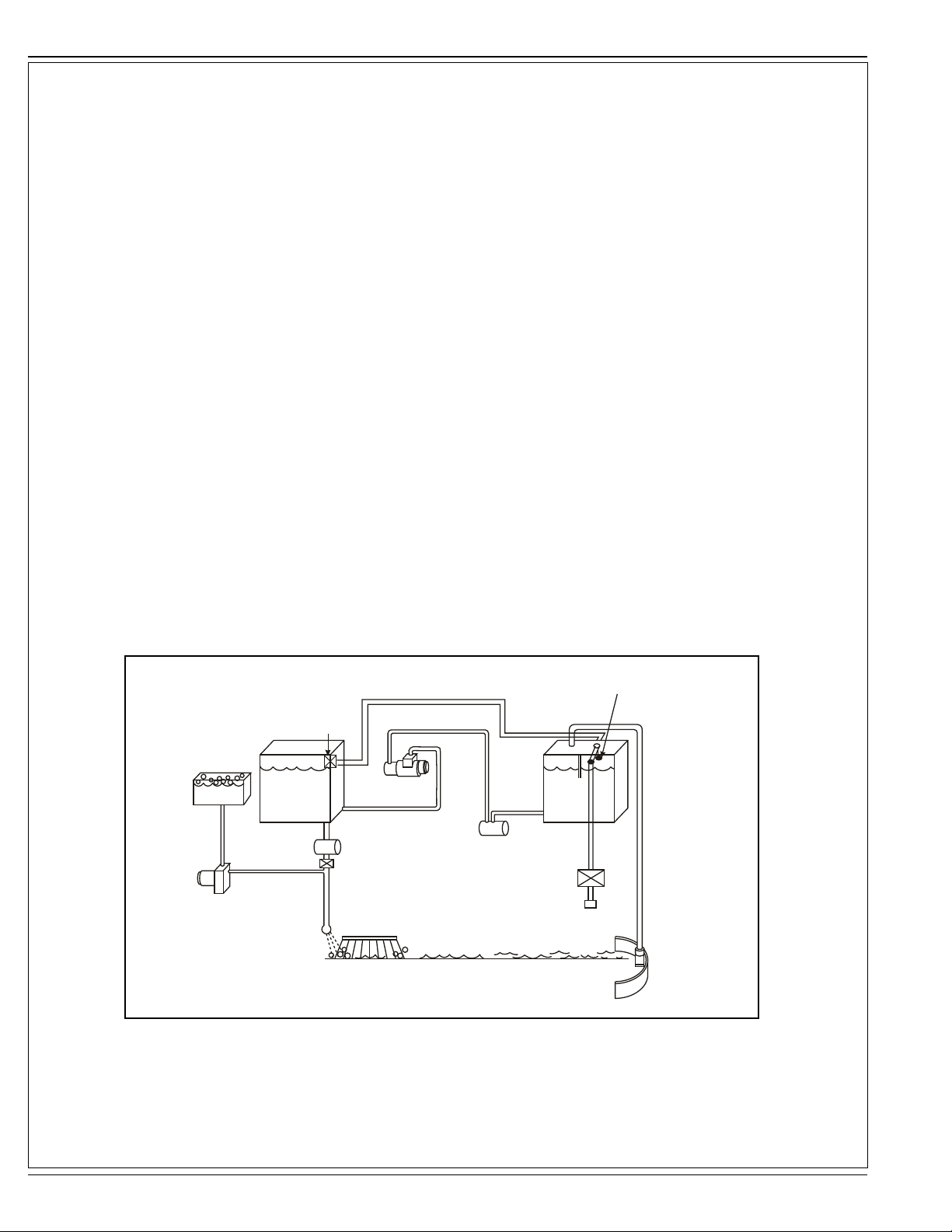

THE SCRUBBING SYSTEM - HOW IT WORKS

There are two scrubbing systems available for the CR 1500 machine, the non-recycling

or standard scrubbing system and the recycling or ESP scrubbing system.

THE NON-RECYCLING OR STANDARD SCRUBBING

SYSTEM - HOW IT WORKS

During the scrubbing process (shown in Figure 13), detergent solution water from the

solution tank is fed to the solution line. There it is fed to the fl oor where three disc

scrubbing brushes work to dislodge soil.

After scrubbing, the dirty solution is vacuumed from the fl oor and discharged into the

containment chamber in the forward portion of the recovery tank, where a system of

baffl es helps to clarify the solution. Sensors in each tank will indicate by lights on the

control panel when the water in the solution tank is too low or when the water in the

recovery tank is too high.

ENGLISH / A-17

D

B

A Recovery Tank

B Solution Tank

C Baffl e

D Detergent Tank

E Check Valve

F Solution Pump

G Orifi ce

H Filter

I Flow Valve

J Autofi l Valve

K Detergent Pump

L Scrub Brushes

M Fill Coupling

N Squeegee

O Floor Contact

P Solution Line

Q Vacuum

G

E

D

B

F

A

P

H

I

K

L

O

FIGURE 13

H

J

M

N

B

Q

C

A

FIGURE 14

FORM NO. - 56041719 - CR 1500 - A-17

Page 18

A-18 / ENGLISH

SCRUBBING SYSTEM OPERATING INSTRUCTIONS

THE RECOVERY OR ESP SCRUBBING SYSTEM - HOW IT WORKS

During the scrubbing process (shown in Figure 15), fi ltered water from the solution tank is fed to the solution line, where it combines with detergent

from the metering pump. This mixture is then fed to the fl oor where three disc scrubbing brushes work to dislodge soil.

After scrubbing, the dirty solution is vacuumed from the fl oor and discharged into the containment chamber in the forward portion of the recovery

tank, where a system of baffl es helps to clarify the solution on its way to the pumping chamber in the rear of the recovery tank. At intervals, a system

of sensors activates the recycling pump, which sends fi ltered solution from the pumping chamber on its way to the solution tank. Here, it is ready to

be mixed with fresh, metered detergent and repeat the cycle.

A Recovery Tank

B Solution Tank

C Baffl e

D Detergent Tank

E Check Valve

F Solution Pump

G Orifi ce

H Filter

I Flow Valve

J Autofi l Valve

K Detergent Pump

L Scrub Brushes

M Fill Coupling

N Squeegee

O Floor Contact

P Solution Line

Q Vacuum

D

K

B

E

G

F

H

H

I

A

J

M

L

N

O

FIGURE 15

A-18 - FORM NO. - 56041719 - CR 1500

Page 19

ENGLISH / A-19

DUST CONTROL OPERATING INSTRUCTIONS

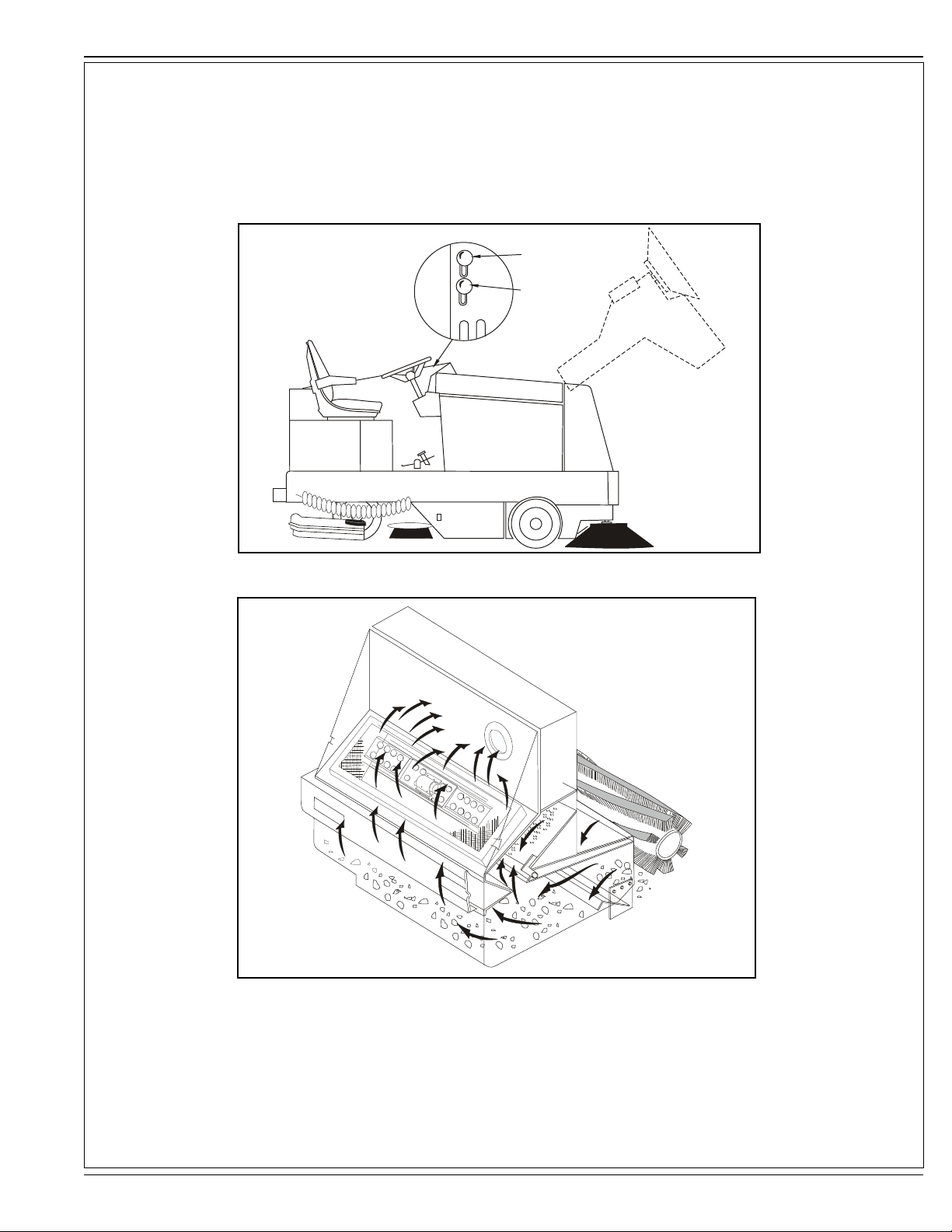

THE VARIABLE DUMP SWEEPING AND DUST CONTROL SYSTEMS - HOW THEY WORK

Variable Dump CR 1500 machines are equipped with a sweeping and dust control system. Figure 16 shows the highest position for the variable

dump.

AE Hopper Door Lever

AF Hopper Lift Lever

AF

AE

FIGURE 16

FIGURE 17

The debris from sweeping is thrown into the hopper (Figure 17). The baffl e system that is built into the variable dump debris hopper is designed to

minimize dust in the air while the machine is sweeping. The impeller vacuum fan pulls the lighter dust up and through a baffl e system. The Pre-

Clean Flap separates the heavier dust particles to an area below the fi lters. The dust fi lters capture the lighter dust particles. This allows the dust

fi lters to remain cleaner and need less shaking to remove dust. When the dust fi lters become clogged the fi lter shaker switch should be pushed to

start the dust shaker cycle. This will extend the life of the fi lters.

NOTE

TURN MAIN BROOM OFF FIRST

FORM NO. - 56041719 - CR 1500 - A-19

Page 20

A-20 / ENGLISH

OPERATING INSTRUCTIONS

FILLING THE SOLUTION TANK

NON-RECYCLING OR STANDARD SCRUBBING SYSTEM

1. Make sure the solution control lever is in the “Off” (rear) position.

2. Open the solution tank cover (right hand side).

3. Fill the tank with 100 gallons (378 L) of water and the correct mixture of American-Lincoln #100 Industrial Cleaner for the job.

4. Close the solution tank cover.

RECYCLING OR ESP SYSTEM

1. Make sure the solution control lever is in the “Off” (rear) position.

2. Open the solution tank cover (right hand side).

3. Fill the solution tank as outlined above with 100 gallons (378 L) of pure water.

4. Fill the detergent tank with 5 gallons (19 L) of American-Lincoln #100 Industrial Cleaner.

5. Close the solution tank cover.

NOTE

Fill recovery tank halfway with water for the ESP system

WARNING

To prevent over-sudsing and machine damage,

use only AMERICAN-LINCOLN Industrial Cleaning Solution #100.

WARNING

DO NOT put gasoline, combustible or other fl ammable material

in the solution, recovery or detergent tanks.

NOTE

Before starting the engine, perform the pre-start checklist.

PRE-START CHECKLIST

1. Clean engine air fi lter element if needed

2. Check engine oil level

3. Check radiator coolant level

4. Check hydraulic fl uid level

5. Check fuel level

6. Check all systems for leaks

7. Check brakes and controls for proper operation

BEFORE STARTING ENGINE

1. Set parking brake

2. Make sure all controls are in the “Off” position

TO START ENGINE

1. Be sure accelerator and directional control pedal is in neutral.

2. Turn key to “On” position and hold it until the engine starts.

3. If engine fails to start after following the above procedures, refer to Engine Manual.

WARNING

The manufacturer does not advise storing the machine in below-freezing temperatures unless all fl uids have been drained from the

detergent, solution and recovery tanks and associated systems. When machine has been stored in below-freezing temperatures, run

engine at lowest possible settings and let machine sit 5-10 minutes to warm engine and hydraulic oil.

A-20 - FORM NO. - 56041719 - CR 1500

Page 21

ENGLISH / A-21

OPERATING INSTRUCTIONS

POST-START CHECKLIST (ENGINE RUNNING)

1. Check main and side brooms to make sure they are free of debris which will inhibit rotation & pick-up.

NOTE: Always wear hand protection when cleaning debris from brooms and/or brushes.

2. Check squeegees to make sure there is no damage and they meet the fl oor.

TO TRANSPORT MACHINE (NO SCRUBBING OR SWEEPING)

1. Be sure the brooms, brushes (scrub deck) and squeegee are in the “Up” position with all other controls in the “Off” position.

2. Release parking brake.

3. Push throttle control up.

4. Push forward on the directional control pedal to place the machine in motion.

5. Vary your foot pressure on the directional control pedal to obtain desired travel speed.

6. To stop, allow directional control pedal to return to neutral (centered) position. (Pedal will automatically return to neutral when foot pressure is

released). FOR NORMAL OPERATION, DEPRESS DIRECTIONAL CONTROL PEDAL WITH HEEL INTO NEUTRAL.

7. Push engine throttle down. Turn key to “Off”.

8. Set parking brake.

TO BEGIN THE CLEANING OPERATION

1. Choose the mode of operation (recycling ESP or non-recycling STANDARD) as dictated by the machine fi ll or machine type.

2. Bring engine to full RPM.

3. Lower the main broom.

4. Lower the side broom.

5. Turn on the main and side brooms.

6. Sweep for the length of the machine.

7. Move recovery switch to the “On” position.

8. Lower the scrub brushes.

9. Lower squeegee to the “Lower” position.

10. Move solution control lever to the desired setting.

11. Turn on the Recovery Switch for the ESP Recycling system, if applicable.

12. Begin scrubbing operation.

Single sweep and scrub the average fl oor with light to medium soil. In this operation the cleaning is accomplished in one pass with simultaneous

solution feed, sweeping, scrubbing and dirty water pick-up. The rate of solution feed and the speed of travel required will vary with fl oor condition.

This knowledge will come with operator experience.

FORM NO. - 56041719 - CR 1500 - A-21

Page 22

A-22 / ENGLISH

OPERATING INSTRUCTIONS

HELPFUL HINTS FOR CLEANING OPERATION

SIDE AISLES

MAIN AISLE

SIDE AISLES

FIGURE 18

WARNING

Do not turn the steering wheel sharply when the machine is in motion. The sweeper is very

responsive to movement of the steering wheel. Do not make sudden turns.

Scrub in straight paths. Do not bump posts. Do not scrape the sides of the machine.

When the machine is in motion, do not push the directional/speed control pedal all the way forward. This is the

same as starting in “High” and will put a strain on the motor and drive system.

1. Plan your sweeping and scrubbing in advance. Try to arrange long runs with minimum stopping and starting.

Sweep debris from narrow aisles out into main aisle ahead of time. Do an entire fl oor, or section at one time.

2. Pick up oversize debris before sweeping.

3. Allow a few inches overlap of sweep and scrub paths. This will eliminate leaving dirty patches.

4. Don’t turn steering wheel too sharply when machine is in motion. The machine is very responsive to movement of the steering wheel - so

avoid sudden turns.

5. Try to follow as straight a path as possible. Avoid bumping into posts or scraping the sides of the machine.

6. When placing the machine in motion, avoid slamming the directional control pedal all the way forward quickly. This is equivalent to starting out

in “HIGH” and puts needless strain on the engine and drive system.

7. Always allow the machine to warm up before operating in cold temperatures.

8. Periodically turn sweeping (main) broom end for end to prevent the bristles from “setting” in one direction.

NOTE

Replace sweeping broom when bristles are worn to 3-inch (8-cm.) length. Replace disc brushes when bristles

are reduced to 1/2 inch (1.3 cm) in length. Replace squeegee blades when all usable edges have become

rounded with wear, impairing the wiping action.

A-22 - FORM NO. - 56041719 - CR 1500

Page 23

ENGLISH / A-23

POST-OPERATION & CLEAN-UP INSTRUCTIONS

TO STOP THE CLEANING OPERATION

Discontinue the cleaning operation whenever a solution or recovery warning or stop light is illuminated.

The solution light will illuminate when the solution tank is empty. At this time, discontinue the scrubbing cycle, put all controls in position for transport

and drive to the drain area. See instructions on how to drain and clean the recovery and solution tanks, and empty the debris hopper.

The recovery warning light will illuminate approximately 5 minutes before loss of vacuum to the recovery tank. This warning period should give

ample time to complete the scrubbing cycle and transport or scrub to the drain area.

NOTE

After stopping the engine, perform this post-operation checklist.

POST-OPERATION CHECKLIST

1. Clean debris hopper.

2. Check sweeping broom for wear or damage.

3. Check all fl aps for wear, damage and adjustment.

4. Drain and clean solution tank (ESP system)

5. Clean solution fi lter screen (ESP system)

6. Drain and clean recovery tank.

7. Clean recovery tank screens and fl oats.

TO DRAIN SOLUTION TANK (RECYCLING OPERATION) (ESP SYSTEM)

Draining the solution tank is accomplished by a 4-foot (92 cm.) long drain hose located under the frame channel. To drain the tank, lower the hose,

remove the plug and drain. When the draining operation is completed, clean the solution tank as outlined below.

8. Check manifold and vacuum hoses for debris or obstructions,

backfl ush if necessary.

9. Check scrub brushes for wear or damage.

10. Check rear and side squeegees for wear, damage and adjustment.

11. Fill fuel tank.

12. Check all systems for leaks.

FIGURE 19

TO CLEAN SOLUTION TANK (RECYCLING OPERATION) (ESP SYSTEM)

Cleaning the solution tank is simplifi ed by the large access cover. Flush all deposits from the tank, also fl ush all probes and the solution line strainer

to remove any deposits - remove strainer if necessary. When the cleaning operation is completed, plug and replace the hose. Close and secure

covers.

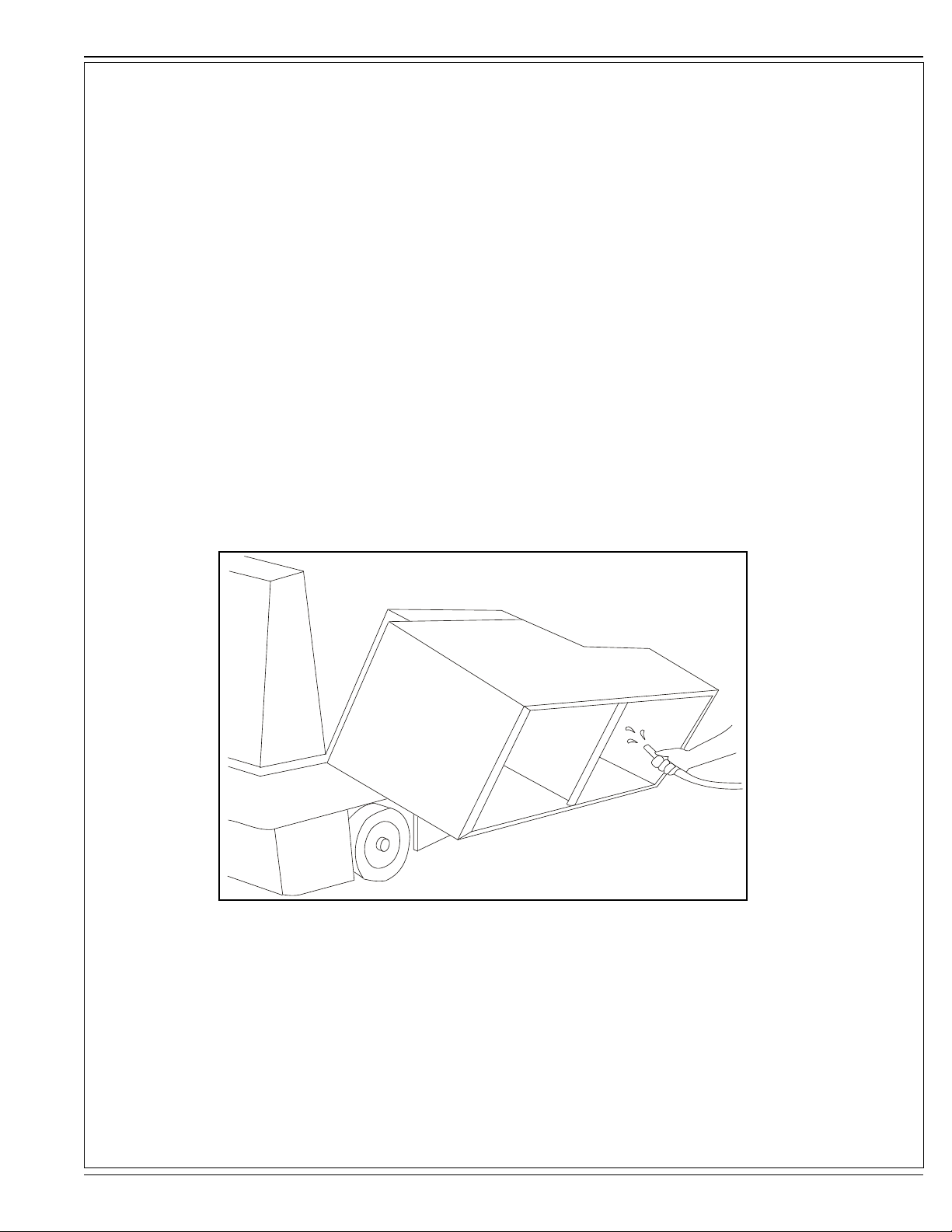

TO DRAIN RECOVERY TANK

A 4-foot long drain hose for the recovery tank is located under the frame channel. To drain the tank, lower the hose, remove the plug and drain.

Open the recovery tank and remove the drain plug. When the draining operation is completed, fl ush and clean the recovery tank as outlined on the

next page.

FORM NO. - 56041719 - CR 1500 - A-23

Page 24

A-24 / ENGLISH

POST-OPERATION & CLEAN-UP INSTRUCTIONS

TO CLEAN RECOVERY TANK

The large access cover on the recovery tank simplifi es the cleaning process. Once the recovery tank lid is opened, tip out the tank. With the

recovery tank in the tipped out position (Figure 19), fl ush all sand, sludge, debris, etc. out of the tank with a water hose, then replace the tank and

fl ush the manifold, ball fl oat screen and level switch to remove any deposits. The tank lid should be removed and cleaned approximately every 50

running hours.

WARNING

Do not attempt to fl ush large amounts of tank debris through the drain hose - This will cause clogging and hamper future drainage.

Always fl ush the recovery tank with clean water at the end of each cleaning cycle. Never let debris accumulate, settle and harden in the

tank, tank lid, or on associated hardware.

AE Hopper Door Lever

AF Hopper Lift Lever

AN Tow Control Shaft

AF

AE

FIGURE 20

AN

FIGURE 21

A-24 - FORM NO. - 56041719 - CR 1500

Page 25

ENGLISH / A-25

POST-OPERATION & CLEAN-UP INSTRUCTIONS

TO EMPTY DEBRIS HOPPER

1. Transport or sweep and scrub to the dump site.

2. Close the hopper dump door with the hopper dump lever.

3. Raise the hopper with the hopper lift lever to the desired level.

4. Move the machine forward, over the dumpster, if necessary.

5. Open the hopper dump door with the hopper dump lever.

6. Lower the hopper with the hopper lift lever to the normal operation position.

NOTE (Variable Dump Only)

The sweep functions - main broom, side broom, dust fan, and fi lter shakers - only work when the hopper is down and the dump door is

open.

TOWING INSTRUCTIONS (SEE FIGURE 21)

1. Locate Tow Control shaft Extension (AN) as shown in Figure 21. (See arrow)

2. To open hydraulic circuit to wheel drive motor, turn shaft 90° so that the fl ats on the shaft are parallel to the front axle.

3. After towing, turn shaft 90° so that the fl ats on the shaft are parallel to the pump centerline.

FORM NO. - 56041719 - CR 1500 - A-25

Page 26

A-26 / ENGLISH

SERVICE CHART

For service assistance, consult the yellow pages under power sweepers and scrubbers. For best performance, replace worn parts with genuine American-Lincoln

parts.

EVERY 8 HOURS or DAILY operation check and clean/adjust if necessary:

1. Inspect panel fi lters for damage and clean.

2. Check engine oil level.

3. Check hydraulic fl uid level.

4. Check radiator core for blockage.

5. Check all fl aps for wear or damage.

6. Check brooms for wear or damage, adjust as required.

7. Check panel fi lters (clean side) for leakage.

8. Check brake pedal and parking brake.

9. Check for LP/Diesel odor at connections.

10. Check water separator (Diesel).

11. Check engine air cleaner.

12. Check hydraulic oil fi lter.

13. Check coolant level.

50 HOUR (WEEKLY) MAINTENANCE CHECKLIST

14. Solution tank (recycling or ESP system).

15. Solution fi lter screen (recycling or ESP system).

16. Recovery tank. (Include cleaning of tank lid.)

17. Recovery tank screens and fi lters.

18. Scrub brushes for wear or damage.

19. Rear and side squeegees for wear or damage.

20. Check tension on all belts.

21. Check battery electrolyte level. (Unless Maintenance-Free Battery)

22. Check all hydraulic hoses for wear or cuts.

23. Rotate main broom (end-to-end).

24. Clean or replace panel fi lters.

Perform recommended engine maintenance (see engine manual if applicable).

100 HOUR MAINTENANCE CHECKLIST

25. Change crankcase oil.

26. Change engine oil fi lter.

27. Lubricate drive wheel, l swivel wheel bearings, and steering rack guide (engine side above rear wheel).

MAKE SURE TO GREASE ZERK LOCATED ABOVE PINION RACK (See Rear Wheel Assy., Parts List)

28. Lubricate front wheel bearings.

29. Lubricate all moving joints.

30. Check brake pads for wear and adjust accordingly.

31. Lubricate all 6 (Diesel)/4 (Gas/LP) DANHOUSER Bushings with NAPA #765-1363 or equivalent anti-seize lubricant. The bushings are located on the

steering, scrub deck lift, squeegee lift, main broom lift, both threaded ends of the throttle cable and variable dump door cylinders.

Perform recommended engine maintenance (see engine manual if applicable).

250 HOUR MAINTENANCE CHECKLIST

32. Lubricate squeegee casters.

33. Clean solution tank and fi lter screen.

34. Replace engine air fi lter element.

35. Flush radiator coolant system.

36. Remove spark plug - clean or replace (Gas/LP).

37. Check distributor and points - service or replace (Gas/LP).

38. Clean and lubricate governor linkage (Diesel).

39. Replace fuel fi lter.

40. Replace hydraulic fi lter element.

Perform recommended engine maintenance (see engine manual if applicable).

400 HOUR MAINTENANCE CHECKLIST

41. Clean hydraulic reservoir.

42. Clean hydraulic intake strainer.

43. Change hydraulic fl uid.

Perform recommended engine maintenance (see engine manual if applicable).

A-26 - FORM NO. - 56041719 - CR 1500

Page 27

SERVICE CHART

ENGLISH / A-27

4

13, 35

38

26

21

9

31

41, 42, 43

20

2, 25

8 15, 33 14

39 36, 37

11, 34 17

3

29

16

31

1, 7, 24

12, 40

31

27

32

19

18

28, 30

29 5 31 6, 23

FIGURE 22

FORM NO. - 56041719 - CR 1500 - A-27

Page 28

A-28 / ENGLISH

GENERAL MACHINE MAINTENANCE

LUBRICATION

4

1

5

6

3

4

FIGURE 23

3

4

2

100 Hour Lubrication

1. Lubricate drive wheel swivel, wheel bearings and steering rack guide.

2. Lubricate front wheel bearings.

3. Lubricate all moving joints.

4. Lubricate all 6 (Diesel)/4 (Gas/LP) DANHOUSER Bushings with NAPA #765-1363 or equivalent anti-seize lubricant. The bushings are located

on the steering, scrub deck lift, squeegee lift, main broom lift, both threaded ends of the throttle cable and the variable dump door cylinders.

250 Hour Lubrication

5. Lubricate squeegee casters.

6. Lubricate governor linkage (Diesel).

Use good grade multipurpose grease. Avoid using too much grease.

A-28 - FORM NO. - 56041719 - CR 1500

Page 29

ENGLISH / A-29

GENERAL MACHINE MAINTENANCE

ENGINE

Read and follow all the instructions in the Engine Manual Section. Due to the nature of work being done by the machine, extra care must be taken

to protect the engine from these elements. Check the oil each day before starting operations. Be sure to check the air fi lter cap’s dust collector and

empty as necessary. Also check the air cleaner and replace as conditions demand. Do not let the engine become coated with dust and dirt.

A

D

E

C

B

FIGURE 24

TO REMOVE MAIN SWEEPING BROOM

1. Open the Right Broom Chamber Door (A).

2. Put the main broom control in the “SWEEP” position.

3. Remove the Retaining Bolt (B).

4. Remove the Idler Arm Assembly (C).

5. Remove the Main Broom (D) and discard.

6. Put a new main broom in the broom chamber.

7. Rotate the new broom to the right on the Drive Hub (E) until it engages the drive hub broom tabs.

8. Put the Idler Arm Assembly (C) in place.

9. Put the Retaining Bolt (B) in place and tighten.

10. Close the Broom Chamber Door (A).

11. Start the engine.

12. Put the broom lever in the “SWEEP” position.

13. Let the broom sweep in place for 30 seconds.

14. Put the broom lever in the “UP” position.

15. Back the machine off the test spot.

16. Inspect the polished area where the broom swept, for broom bristle contact with the fl oor. The area of broom bristle contact with the fl oor

should be 2 to 3 inches (5 to 8 cm.) wide.

FORM NO. - 56041719 - CR 1500 - A-29

Page 30

A-30 / ENGLISH

GENERAL MACHINE MAINTENANCE

MAIN BROOM LEVEL ADJUSTMENT

The main broom level is factory set and shouldn’t need adjustment, if the level gets out of adjustment and the broom bristle

contact pattern is not an even 2” to 3” (5 to 8 cm.) wide. Adjust the broom arm lift frame. The frame is supported by two

fl ange bearings. These bearings are located inside the broom doors. The carriage bolts on the two end fl anges must be

loosened. The frame can then be leveled and the bolts tightened.

HOW TO ADJUST MAIN BROOM WEAR PATTERN

When the bristles of the broom begin to wear out the following adjustments may be made to keep a 2-inch (5-cm.)

broom pattern.

1. Loosen the nut located in the engine compartment.

2. Set the broom lever to the “Sweep” position and adjust the lock nut to obtain a 2-inch (5 cm) broom pattern. The

lock nut will move the adjusting rod that adjusts the sweeping pattern of the broom for wear.

Raise or

Lower for

Wear Adjustment

Floor

Contact

Area

3

Forward

A

FIGURE 25

SIDE BROOM LEVEL ADJUSTMENT

As the Side Broom (A) wears, loosen the two wear adjusting bolts and slide the broom-motor assembly into a position so that the broom contacts

the fl oor at a 3 degree angle when lowered as shown in Figure 25.

SIDE BROOM REPLACEMENT

Put the side broom lift control in the “UP” position. Remove the retaining screw in the bottom middle of the side broom. Remove the side broom.

Transfer the side broom fl ange spacer and screws to the replacement side broom. Put the replacement side broom on the shaft. Put the retaining

screw in position and tighten.

A-30 - FORM NO. - 56041719 - CR 1500

Page 31

GENERAL MACHINE MAINTENANCE

1/16"

(1.6 mm)

ENGLISH / A-31

A

FIGURE 26

FLAPS

The urethane and rubber fl aps are susceptible to damage and should be inspected regularly and maintained in good

condition. The side fl aps are adjustable and should be maintained at approximately 1/16” (1.6 mm.) above the fl oor. Set

fl ap even with the fl oor (A). The front and rear fl aps have no provision for adjustment.

All fl aps should be replaced when worn or damaged to such an extent that they couldn’t perform their function.

FORM NO. - 56041719 - CR 1500 - A-31

Page 32

A-32 / ENGLISH

GENERAL MACHINE MAINTENANCE

A

FIGURE 27

SCRUB BRUSH REPLACEMENT

1. Raise the scrub brush deck by pressing the “Scrub Brush” Switch on the instrument panel.

2. Press the Brush Latches (A) in to release the scrub brush.

3. Remove old scrub brush.

4. Snap new brush into place.

COVERS AND LATCHES

The covers have been designed to allow access, either by hinge or removal, to all areas of the machine. No maintenance

is required. For lubrication of latches see Lubrication Section.

SOLUTION WARNING LIGHT

The solution warning light will illuminate when the solution tank is empty. This part of the level control system requires no

maintenance. If the system fails to operate, consult the Electrical Troubleshooting Guide.

RECOVERY WARNING LIGHT

The recovery warning will illuminate approximately 5 minutes before loss of vacuum to the recovery tank. This part of

the level control system requires no maintenance, except for daily cleaning of the tank level switch. If the system fails to

operate, consult the Electrical Troubleshooting Guide.

SOLUTION CONTROL (NON-RECYCLING OR STANDARD)

The solution control lever controls the amount of solution applied to the scrubbing brushes. Except for a few drops of oil

applied to the lever pivot every 100 hours, the system should require no major maintenance.

The solution control should shut off completely with the lever in the (rear) “off” position. If complete shut off does not occur,

the control cable should be adjusted.

SOLUTION CONTROL (RECYCLING OR ESP SYSTEM)

In the recycling mode, the solution control lever is also used to activate the detergent pump. If the detergent pump fails

to operate (engine running) when the solution control lever is moved into the low to high range, fi rst check the circuit by

manually activating the switch. If the detergent pump does not operate at this time, a further electrical or mechanical

check is indicated. (See Electrical Troubleshooting Guide or Detergent Pump Troubleshooting).

A-32 - FORM NO. - 56041719 - CR 1500

Page 33

ENGLISH / A-33

GENERAL MACHINE MAINTENANCE

RECYCLING PUMP ESP SYSTEM

The recycling pump is located directly behind and under the recovery tank. The pump is electric and except for daily

cleaning of the pump intake screens, it requires no regular maintenance.

NOTE

Do not run pump dry. The unit depends on the liquid pumped for lubrication.

RECYCLING (ESP) PUMP STORAGE

Always drain pump for extended storage, especially when freezing temperatures may be encountered.

REAR SQUEEGEE

The squeegee will require service when the inner edges of the blades become round with wear, impairing the wiping

action or water pickup. To service the rear squeegee use the following steps:

1. Loosen the four aluminum knobs item 10, (these hold the squeegee tool to the squeegee support).

2. Remove the squeegee tool and turn upside down to service the blades or caster wheels. The squeegee blades are

designed to fl ip over and use another unworn edge (items 5 & 6).

TO SERVICE THE BLADES:

1. Loosen the clamp bolts, which clamp items 8 & 9 together.

2. Loosen far enough to slip the end clamp brackets off the squeegee tool. This will allow fl ipping the blades or

installing new blades.

3. Install blades so that outer blade is 3/16” (4.7 mm) longer than inner blades, this is achieved by assembling the top

edge of the blade against the squeegee tool weldment.

4. Reinstall squeegee clamp band and tighten clamp bolt tight.

10

5

6

8

9

FIGURE 28

SQUEEGEE CASTER WHEELS

Grease caster wheel zerks (2) on each caster should be greased each time the blades are serviced for a total of 3 caster

wheels.

ADJUSTING CASTERS

Lower squeegee on a fl at surface, making sure the rear squeegee blade is perpendicular to the surface. Adjust caster

3/16” above the fl at surface, Lock jam nuts.

FORM NO. - 56041719 - CR 1500 - A-33

Page 34

A-34 / ENGLISH

GENERAL TROUBLESHOOTING

PROBLEM PROBABLE CAUSE REMEDY

Sweeping does not

function

Poor water pick up at

squeegee

Water spill from squeegee 1. Side squeegee blades, poor contact with

1. Dump door closed

2. Hopper is raised

3. Hopper switch out of adjustment

1. Side or rear squeegee are worn or damaged

2. Clogging in water pick up

3. Air leaks in suction hose and connection

4. Air leaks at recovery tank cover and/or

manifold gaskets

5. Poor vacuum

6. Drain hose or drain plug leakage or not

closed properly.

fl oor.

1. Open dump door

2. Lower hopper

3. Adjust hopper switch

1. Examine squeegee rubber blade for cuts

or worn spots.

2. Repair or replace hose and connection

3. Repair or replace gaskets

4. Check seal on recovery tank

5. Check vacuum motor

6. Close, repair or replace drain plug in

recovery tank.

1. Readjust blades for proper contact

2. Squeegee blades worn or damages

3. Too much solution being applied before

making turns.

4. Brushes rotating opposite direction

Lack of suction at rear 1. Clogged suction hose or pick up tool

2. Loose connections between suction

hose and squeegee or between hoses or

manifold inlet.

3. Vacuum motor not operating

4. Vacuum fl oat cage clogged

5. Vacuum fl oat shut off

2. Replace or adjust

3. Shut off solution fl ow 5’ to 10’

4. Check position of switches.

1. Disconnect suction hose from squeegee;

fl ush squeegee & hoses.

2. Check all hose connections for

looseness or damage.

3. Check hydraulic motor in recovery

4. Clean perforated metal thoroughly

5. Excessive solution in recovery drain

tank. Excessive foam build up, change

cleaning chemical mixture. Use

American-Lincoln approved materials.

A-34 - FORM NO. - 56041719 - CR 1500

Page 35

GENERAL TROUBLESHOOTING

PROBLEM PROBABLE CAUSE REMEDY

ENGLISH / A-35

Poor scrubbing 1. Worn scrubbing brushes

2. Incorrect method of operation

3. Wrong cleaning agent or mixture

4. Poor solution distribution

Engine runs, but machine

will not move on level

ground

1. Foot pedal and/or linkage jammed or not

adjusted

2. Front wheels jammed or brakes locked

3. Hydraulic pump trouble

1. Inspect brushes. If worn to ½” (1.3cm)

or less, replace all 3 brushes

2. Check scrubbing procedures, brush

pressure, type of brush, solution fl ow, &

cleaning chemical used. For extreme

conditions double scrubbing may be

necessary.

3. Use Nilfi sk recommended materials

4. Clean out distribution tube & metering

holes to brushes. Check feed hose &

clean if necessary. Check valve & cable

control system.

1. Check pedal linkage

2. Check wheels and brakes

3. Check & repair pump, check tow valve.

See CESSNA information.

4. Rear wheel hydraulic motor, broken shaft

key, broken shaft, etc.

Machine moves slowly 1. Low hydraulic oil level

2. Brake dragging

3. Hydraulic oil temp, too high

4. Worn hydraulic pump or drive wheel motor

Hydraulic pump making

excessive noise

1. Clogged inlet strainer or suction line

2. Air bubbles in hydraulic fl uid

3. Hydraulic pump is worn or damaged

4. Check & repair. See Char-Lynn

information

1. Add oil to reservoir

2. Check brakes

3. Check oil level, add SAE 5 (FORD Type

F) ATF, if required

4. See hydraulic CESSNA

1. Clean inlet strainer. Drain & fl ush

reservoir, if oil is dirty. Refi ll with clean

SAE 5 (FORD Type F) ATF.

2. Check for low hydraulic fl uid level,

leaking fi ttings or hoses

3. See CESSNA Pump Section

FORM NO. - 56041719 - CR 1500 - A-35

Page 36

A-36 / ENGLISH

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model CR 1500 Petrol (Variable Dump) CR 1500 LPG (Variable Dump)

Model No. 56514850 56514852

Sound Pressure Level (ISO 11201 dB (A) 87 87

Sound Power Level (ISO 3744) dB (A) Lwa 109.0 Lwa 109.0

Total Weight lbs/kg 4,350 / 1973 4,350 / 1973

Vibrations at the Hand Controls (ISO 5349-1) m/s2 0.70 m/s

Vibrations at the Seat (EN 1032) m/s2 0.20 m/s

2

2

0.70 m/s

0.20 m/s

Gradeability

Transport 14.1% (8°) 14.1% (8°)

Cleaning 10.5% (6°) 10.5% (6°)

Model CR 1500 Diesel (Variable Dump)

Model No. 56514854

Sound Pressure Level (ISO 11201 dB (A) 87

Sound Power Level (ISO 3744) dB (A) Lwa 109.0

Total Weight lbs/kg 4,350 / 1973

Vibrations at the Hand Controls (ISO 5349-1) m/s2 0.70 m/s

Vibrations at the Seat (EN 1032) m/s2 0.20 m/s

2

2

Gradeability

Transport 14.1% (8°)

Cleaning 10.5% (6°)

2

2

A-36 - FORM NO. - 56041719 - CR 1500

Page 37

Page 38

B-2 / TÜRKÇE

İÇİNDEKİLER

Sayfa

İçindekiler ............................................................................ B-2 - B-3

Giriş ............................................................................................. B-4

Giriş ......................................................................................B-4

Yedek Parça ve Servis ..........................................................B-4

Tanıtma Levhası ...................................................................B-4

Sandığı Açma .......................................................................B-4

Makineyi Çalıştırma ..................................................................... B-5

Makineyi Çalıştırmaya Hazırlama ......................................... B-5

Önlemler ve Uyarılar .................................................................... B-6

Kontroller ve Göstergelerin Kullanımı ............................B-8 – B-15

Kontak Anahtarı ....................................................................B-8

Işık Anahtarı .......................................................................... B-8

Dönüş Sinyali (Opsiyonel) ....................................................B-9

Buji Anahtarı .........................................................................B-9

Korna Düğmesi ..................................................................... B-9

Yan Süpürge Kaldırma ..........................................................B-9

Ana Süpürge Anahtarı ........................................................B-10

Yan Süpürge Anahtarı .........................................................B-10

Toz Kontrol Anahtarı ...........................................................B-10

Filtre Çalkalama Anahtarı ...................................................B-10

Su Sıcaklık Göstergesi .......................................................B-11

Saat Ölçer ...........................................................................B-11

Yakıt Göstergesi .................................................................B-11

Yağ Basıncı Göstergesi ......................................................B-11

Voltmetre ............................................................................B-11

Ovma Fırçaları Anahtarı .....................................................B-12

Fırça Dönüş Anahtar

Fırça Basınç Anahtarı ......................................................... B-12

Silecek Lastiği Anahtarı ......................................................B-12

Yüksek Geri Alma Uyarı Işığı ..............................................B-12

Düşük Çözelti Uyarı Işığı ....................................................B-12

Huni Kaldırma ..................................................................... B-13

Huni Güvenlik Kilit Kolu ......................................................B-13

Huni Boşaltma Kapısı ......................................................... B-13

Çözelti Kontrolü ..................................................................B-13

Süpürge Kaldırma Kontrolü ................................................B-13

Gaz .....................................................................................B-14

Motor Işığı Kontrolü ............................................................B-14

Park Freni ...........................................................................B-14

Ayak Freni ...........................................................................B-14

Gaz Pedalı ve Yön Kontrol Pedalı ......................................B-15

Yedek Alarm Anahtarı .........................................................B-15

Koltuk Ayarı .........................................................................B-15

ı ..........................................................B-12

B-2 - FORM NO. - 56041719 - CR 1500

Page 39

İÇİNDEKİLER

Sayfa

Ovma Sistemi Kullanım Talimatları ...............................B-16 – B-18

ESP Sistemi Kullanım Talimatları ............................................. B-16

ESP Geri Alma Kontrol Paneli ............................................B-16

ESP Geri Alma Sistemi Açma/Kapama Anahtarı ................B-16

Çözelti Yüksek Uyarı Işığı ...................................................B-16

Deterjan Düşük Uyarı Işığı..................................................B-16

Deterjan Akışı Düğmesi ......................................................B-16

Ovma Sistemi - Nasıl Çalışır...............................................B-17

Geri Almasız Ovma Sistemi - Nasıl Çalışır .........................B-17

Geri Alma veya ESP Sistemi - Nasıl Çalışır ........................B-18

Toz Kontrolü Kullanım Talimatları ............................................ B-19

Süpürme ve Toz Kontrol Sistemi - Nasıl Çalışır ..................B-19

İşletim Talimatları ...........................................................B-20 – B-22

Çözelti Deposunu Doldurma – Geri Almasız (Standart) .....B-20

Çözelti Deposunu Doldurma - ESP ....................................B-20

Çalıştırma Öncesi Kontrol Listesi........................................B-20

Motoru Çalıştırmadan Önce................................................B-20

Motoru Çalıştırma ............................................................... B-20

Çalı

Makineyi Taşıma .................................................................B-21

Temizleme İşlemine Başlama .............................................B-21

Temizleme İşlemi için Faydalı İpuçları ................................B-22

Kullanım Sonrası ve Temizleme Talimatları .................B-23 – B-25

Temizleme İşlemini Durdurma ............................................B-23

Kullanım Sonrası Kontrol Listesi .........................................B-23

Çözelti Deposunu Boşaltma ...............................................B-23

Çözelti Deposunu Temizleme .............................................B-23

Geri Alma Deposunu Boşaltma...........................................B-23

Geri Alma Deposunu Temizleme ........................................B-24

Çöp Hunisini Boşaltma .......................................................B-25

Çekme Talimatları ...............................................................B-25

Servis Şeması .................................................................B-26 – B-27