Page 1

C 100.6, C 110.4, C 110.4 X-TRA,

C 105.6, C 120.6 X-TRA

User Manual

128700022 e (09.2014)

EN-DA-NO-SV-FI-DE-FR-NL-IT-ES-PT-EL-TR-CSHU-PL-HR-SL-SK-LV-LT-ET-RU-ZH

Page 2

EN

User Manual .......................................... 3 - 16

DA

Instruktionsbog ...................................... 17 - 30

NO

Instruksjonsbok...................................... 31 - 44

SV

Instruktionsbok ...................................... 45 - 58

FI

Käyttöohje.............................................. 59 - 72

DE

Betriebsanleitung ................................... 73 - 87

FR

Instructions d’utilisation ......................... 88 - 103

NL

Gebruiksaanwijzing ............................... 104 - 118

IT

Istruzioni sull’uso ................................... 119 - 133

ES

Instrucciones de manejo........................ 134 - 148

PT

Instruções de operação ......................... 149 - 163

EL

Οδηγίες χρήσης ..................................... 164 - 179

TR

Kullanım Kılavuzu .................................. 180 - 194

CS

Návod k obsluze .................................... 195 - 208

HU

Használati útmutató ............................... 209 - 223

PL

Instrukcja użycia .................................... 224 - 238

HR

Priručnik za korisnike............................. 239 - 252

SL

SL Navodila za uporabo ........................ 253 - 266

SK

Návod na používanie ............................. 267 - 281

LV

Lietošanas instrukcijae .......................... 282 - 295

LT

Naudojimosi instrukcija .......................... 296 - 309

ET

Kasutamisjuhend ................................... 310 - 323

RU

Руководство ......................................... 324 - 339

ZH

操作说明 .............................................. 340 - 350

Page 3

EN

T

SHU

U

H

NO

Contents

1 Introduction .................................................................................................. 4

1.1 Symbols used to mark instruction .......................................................................4

2 Safety precautions and working techniques ................................................4

3 Before you start using your high pressure washer ................................ 10

3.1 Mounting of trolley handle and wheels .............................................................10

3.2 Mounting of quick coupling ...............................................................................10

4 Operating your high pressure washer ..................................................... 11

4.1 Connection of high pressure hose ....................................................................11

4.2 Mounting of spray lance and Click&Clean nozzles ...........................................11

4.3 Water Connection .............................................................................................11

4.4 Starting the high pressure washer ....................................................................12

5 After using the pressure washer .............................................................. 12

5.1 Stopping the high pressure washer ..................................................................12

6 Maintenance ............................................................................................... 13

SV

FI

FR

NL

I

L

7 Troubleshooting ......................................................................................... 13

8 Warranty Conditions ................................................................................. 14

9 Main technical Data ................................................................................... 15

10 Declaration of Conformity .........................................................................16

R

C

L

HR

SL

SK

V

R

Z

3Original Instructions

Page 4

T

SHU

U

H

1 Introduction

1.1 Symbols used to mark instruction

EN

All pictograms attached to the high pressure washer and its components are shown and explained in this manual.

Safety instructions marked with this symbol must be observed to prevent personal injury or

serious damage to property.

Caution where there is a risk of damaging the machine or its individual components.

This symbol indicates tips and instructions to simplify work and to ensure a safe operation of

the high pressure washer.

2 Safety precautions and working techniques

Before starting up your machine for the fi rst time, this instruction manual must be read through

carefully. Save the instructions for later use.

WARNING!

• Inhalation of aerosols can be hazardous to health.

Where applicable use a device in order to avoid or re-

NO

SV

FI

FR

NL

I

L

duce aerosols production, e.g., a shield covering the

nozzle. For protection against aerosols use a respiratory mask of class FFP 2 or higher.

• The high water pressure generated by the machine

and the power connection are particular sources of

danger.

• Children should be supervised to ensure that they do

not play with the machine.

• Before starting up your machine please check it carefully for any defects. If you fi nd any, do not start up

your machine, contact your Nilfi sk distributor. The insulation of the electric cable should be faultless and

without any cracks. If the electric cable is damaged,

an authorized Nilfi sk di stributor should replace it.

• The operator and anyone in the immediate vicinity of

the site of cleaning should take action to protect them-

R

C

L

HR

SL

SK

V

selves from being struck by debris dislodged during

operation.

• Always unplug the power plug before cleaning or

maintenance and when replacing parts or converting

R

Z

1Original Instructions

Page 5

EN

T

SHU

U

H

NO

SV

the machine to another function.

• Observe the national safety regulations issued, for

example, by the employers liability insurance association, social security institutions, occupational safety

and health authorities or other organizations.

Accessories and spare parts

FI

FR

NL

I

C

• To ensure the machine safety only use original spare

parts from Nilfi sk or approved by Nilfi sk.

• High pressure hoses, fi ttings and couplings are important for the safety of the machine. Only use hoses, fi ttings and couplings recommended by Nilfi sk.

Physical, sensory or mental conditions

• This machine is not intended for use by persons

(including children) with reduced physical, sensory or mental capabilities or lack of experience and

knowledge.

• Anyone who has consumed alcohol, medicines or

L

drugs affecting their ability to react must not operate

the machine.

R

Applications

This machine has been developed for domestic use

HR

SL

SK

V

R

Z

such as:

• Car, motorbike, boat, caravan, trailer, patio/drive/fl ag-

L

stones, woodwork, brickwork, barbecue, garden furniture, lawn mower.

Any other use is considered as improper use. Nilfi sk

accepts no liability for any damage resulting from such

use. The risk for such use is borne solely by the user.

Proper use also includes proper operation, servicing

and repairs as specifi ed in this instruction.

Clothing and equipment

Always take action to protect yourself when operating

the machine.

• Wear shoes with non-slip soles.

• Wear goggles, ear protection and protective clothes

during operation.

2

Original Instructions

Page 6

T

SHU

U

H

Transporting the high pressure washer

• When transporting the machine in or on a vehicle, it

must be secured, e.g. with straps, so that it cannot slip

or tip over.

• Nilfi sk recommends that the machine is positioned

EN

NO

horizontally on the backside, when transported in or

on a vehicle.

Detergents

• This machine has been designed for use with cleaning agents supplied or recommended by Nilfi sk. The

use of other cleaning agents or chemicals may adversely affect the function of the machine.

Before starting the work

Inspecting the machine

• Do not use the machine if a supply cord or important

parts of the machine are damaged, e.g., safety device, high pressure hose, and spray handle and spray

attachments.

• The trigger of the spray handle must move easily and

automatically return to its starting position when re-

SV

FI

FR

NL

I

L

R

leased.

• Always keep high pressure hose and spray attachment in good condition (clean, moving easily) and correctly assembled.

Electrical connection

WARNING!

Minimize the risk for electrical shock:

• Voltage and frequency of the machine (see rating

plate) must match the voltage of and frequency of the

mains supply.

• Only connect the machine to electrical installation

made by a certifi ed electrician and com ply with IEC

60364-1.

• It is recommended that the electrical supply to the

machine should include a residual current device that

C

L

HR

SL

SK

V

R

will interrupt the supply if the leakage current to earth

Z

3Original Instructions

Page 7

EN

T

SHU

U

H

NO

exceeds 30 mA for 30 ms.

• Inadequate extension cables can be dangerous. If an

extension cable is used, it shall be suitable for outdoor

use, and the connection has to be kept dry and off the

ground

SV

FI

FR

NL

I

• Nilfi sk recommends use of an extension cable drum

when cable extension is needed which keeps the

socket at least 60 mm above the ground.

• Cables on extension cable drums should always be

completely unwound to prevent overheating. Extension cables must comply with the below-mentioned requirements for length and cable dimensions:

1.0 mm² Max. 12.5 m

1.5 mm² Max. 20.0 m

2.5 mm² Max. 30.0 m

• If the electric cable is damaged, it must be replaced

by an authorized Nilfi sk distributor or similar qualifi ed

person in order to avoid a hazard.

L

Water connection

• This high pressure washer is only allowed to be con-

R

nected with the drinking water mains, when an appro-

C

HR

SL

SK

V

R

priate backfl ow preventer has been installed, Type BA

according to EN 60335-2-79.

• The backfl ow preventer can be ordered under number

106411177.

L

• As soon as drinking water has fl own through the backfl ow preventer, it is no longer regarded as drinking

water.

• Operation by suction (e.g. a rainwater vessel) is carried out without a backfl ow preventer – see “Connec-

ting to a pressureless water supply”.

IMPORTANT !

• Only use water without any impurities.

• If there is a risk of running sands in the inlet water

(i.e. from your own well), an additional fi lter should be

mounted.

Z

4

Original Instructions

Page 8

T

SHU

U

H

During work

WARNING!

• Never use the machine in an environment where there

could be a danger of explosions. If any doubt arises

EN

NO

contact the local authorities.

• It is not allowed to clean asbestos-containing surfaces

with high pressure.

• Never draw in fl uids containing solvents (e.g., gasoline, heating oil, paint thinner or acetone) These substances damage the materials used in the machine.

Their spray is highly combustible, explosive and poisonous.

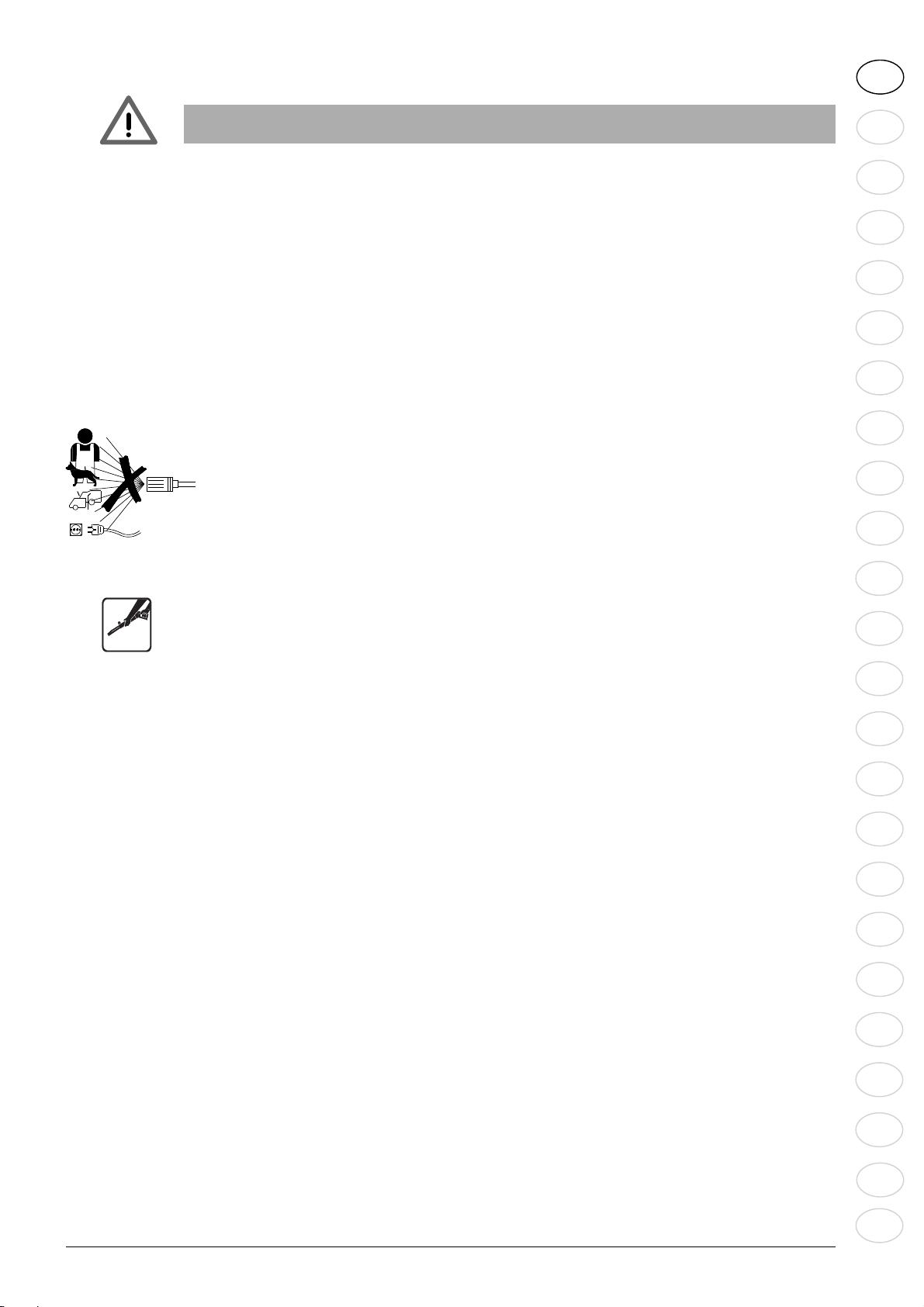

• Never direct the water jet at yourself, other persons,

not even to clean clothing or footwear - risk of injury.

• Never direct the water jet at pets or other animals.

• Never direct the water jet at live electrical equipment

or the machine itself - danger of short-circuiting.

• Hold the spray lance fi rmly with both hands. The spray

lance is affected by a thrust of up to 16.4 N during

operation.

• This high pressure washer machine must not be ope-

SV

FI

FR

NL

I

L

R

rated at temperatures below 0°C.

• Never start up a frozen machine. Frost damages are

not covered by the guarantee!

• Always ensure fi rm and safe footing.

• Keep the machine as far away as possible from the

object being cleaned.

• Always adjust the distance and thus the pressure of

the nozzle to the surface, which is to be cleaned to

avoid any damage to the surface being cleaned.

• The machine shall be operated in an upright position.

• Do not cover the machine or use it in a room without

adequate ventilation.

• If the machine is left or not used for 5 minutes, it must

be switched off on the start/stop switch "O" (1).

C

L

HR

SL

SK

V

R

Z

5Original Instructions

Page 9

EN

T

SHU

U

H

NO

After fi nishing the work

WARNING!

• Always switch off the machine and unplug the power

plug from the socket after work and when leaving the

SV

FI

FR

NL

I

machine unattended.

• Disconnect water inlet hose between machine and

water supply.

• Wind up electrical cable and high pressure hose – to

avoid damage of cable, plug, high pressure hose and

fi ttings.

• Always empty pump, hose and accessories of water

after use of the machine and prior to storing.

Maintenance and repairs

WARNING!

• Always disconnect the electrical plug from the socket

prior to maintenance, cleaning and repair.

L

R

• Any repair should always be made in Nilfi sk

authorized workshop with original Nilfi sk spare parts.

• Do not attempt any maintenance not described in the

C

HR

SL

SK

V

R

instructions.

• If the machine refuses to start, stops, pulsates, pressure fl uctuates, motor busses, fuse blows or no water comes out, check the trouble shooting diagram

L

in these instructions. In case other problems occur,

please contact your local Nilfi sk distributor.

Recycling the high pressure washer

Make the old machine unusable immediately.

• Unplug the machine.

• Cut the electric cable.

Do not discard electrical appliances with household

waste. As specifi ed in WEEE Directive 2012/19/EC on

old electrical and electronic appliances, used electrical

goods must be collected separately and recycled ecologically. Contact your local authorities or your nearest

dealer for further information.

Z

6

Original Instructions

Page 10

EN

T

SHU

U

H

NO

SV

FI

FR

NL

I

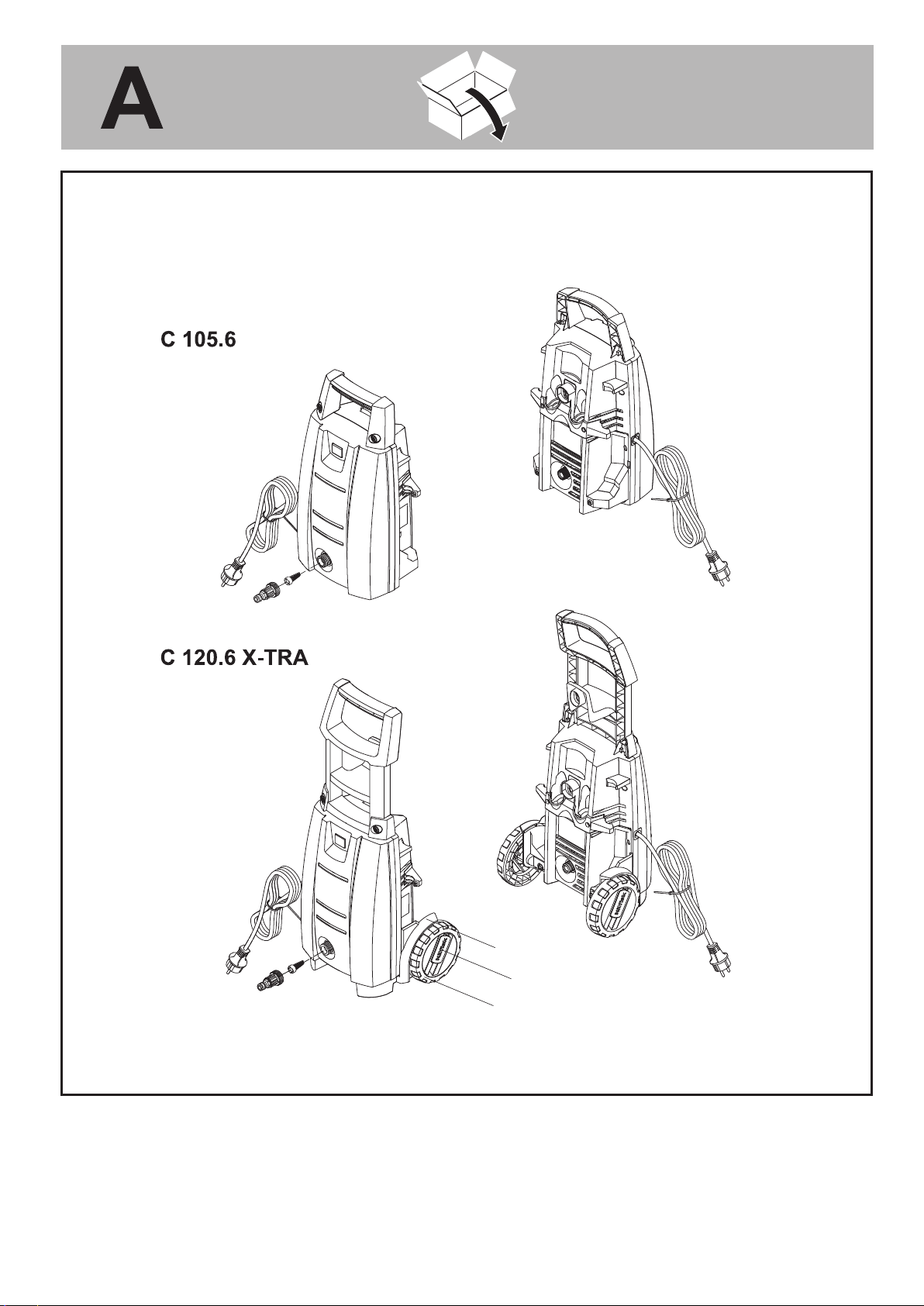

3 Before you start using your high pressure washer

See the pictorial quick reference guide – unpacking.

A

Operation elements

Illustration shows the operation elements and how to prepare your machine for use.

1. Start/stop switch

2. Water inlet with fi lter (2a)

3. High pressure connection

4. High pressure hose

5. Electric cable

6. Click&Clean spray lance

7. Spray handle with lock (7a)

8. Click&Clean Tornado nozzle (C 100.6, C 105.6 and C 110.4)

9. Click&Clean Tornado PR nozzle (C 120.6)

10. Click&Clean Powerspeed nozzle

11. Foam sprayer

12. Nozzle cleaning tool

13. Accessory storage

14. Model tag

15. Trolley handle

16. Holder for hose/electric cable (C 100.6-6, C 110.4 and C 120.6)

17. Hexagon key for handle and bracket mounting

18. Wheel brackets

19. Wheels

20. Wheel caps

R

C

HR

SL

SK

V

L

3.1 Mounting of trolley handle and wheels

Mounting of trolley handle

Only applicable for models with trolley handle and wheels (C 100.6-6, C 110.4, C 110.4 X-TRA

and C 120.6 X-TRA)

A1 Place the trolley handle (15) on the machine.

A2 Secure the handle by mounting the 2 screws using the enclosed hexagon key (17).

Mounting of wheel brackets

A3 Place the wheel brackets (18) on the machine.

L

A4 Secure the wheel brackets by mounting the 2 screws, using the enclosed hexagon key.

A5 Place the wheels (19) on the wheel axel – push into position – you should hear a click

when the wheels are in correct position.

A6 Secure the wheels by mounting the wheel caps (20) – you should hear a click when the

wheel caps are in correct position and the wheel is secured.

3.2 Mounting of quick coupling

A7 When mounting the quick coupling for the fi rst time, check that the factory fi tted fi lter (2a)

is positioned in the water inlet pipe.

A8 Screw the quick coupling tight on to the water inlet (2).

IMPORTANT!

The inlet fi lter must always be fi tted in the water inlet pipe to fi lter out sand, lime stone and

R

Z

10

other impurities as these will damage the pump valves. The fi lter is factory fi tted.

If the fi lter is removed this will invalidate the guarantee.

Original Instructions

Page 11

T

SHU

U

H

4 Operating your high pressure washer

EN

B

See the pictorial quick reference guide – operating your high pressure washer.

4.1 Connection of high pressure hose

B1 Attach the high pressure hose (4) to the spray handle (7). Detach the high pressure hose

by pressing the pawl (A).

B2 Mount the high pressure hose on the outlet (3).

4.2 Mounting of spray lance and Click&Clean nozzles

B3 Push the spray lance (6) into the spray handle and screw it on.

NOTE!

The spray lance has a built-in low pressure nozzle that can be used for fl ushing away

dirt.

B4 When attaching the nozzles (8, 9, 10), press the nozzles into the spray lance.

IMPORTANT!

When attaching the click & Clean nozzles, the pawl on the side of the spray lance should come

out again. The nozzle should stay in position when pulling it.

B5 Push the foam sprayer (11) into the spray lance.

NO

SV

FI

FR

NL

I

NOTE!

The foam sprayer features a swivel lock, which must be positioned in the hole in the Click &

Clean spray lance. Press the pawl to detach the Click & clean nozzles and the foam sprayer.

IMPORTANT!

Before starting the cleaning job, check that the machine is in an upright position and placed on

an even surface. Do not place the machine in high grass!

4.3 Water Connection

IMPORTANT!

Connecting to pressurized water supply

The inlet water max. pressure is 1 MPa/10 bar and the max. temperature is 40°C – see rating

plate. An ordinary ½” garden hose of min. 10 m and max. 25 m will be suitable.

B6 Check that the fi lter is fi tted in the water inlet pipe and that it is not clogged up.

B7 Connect the water hose to the water supply by means of the quick connector. Turn on the

water.

Connection to the drinking water mains according to national and local regulations.

Let the water run through the water hose before connecting it to the machine to prevent sand

and dirt from penetrating the machine.

B8 Turn off the water and connect the water hose by means of the quick coupling to the wa-

ter inlet.

L

R

C

L

HR

SL

SK

V

Connecting to pressure less water supply

The machine can also operate in suction mode, meaning that you can connect the machine to

e.g. rainwater vessels, rivers, lakes and cisterns etc. When taking in water from non drinking

water mains the backfl ow preventer is not needed.

11Original Instructions

R

Z

Page 12

EN

T

SHU

U

H

NO

SV

FI

FR

NL

When connecting the machine to operate from pressure less water supplies – always use additional fi ltering to secure that impurities are not sucked in. Hose length should be max. 3 meter

4.4 Starting the high pressure washer

and of minimum ½".

To meet these requirements, Nilfi sk recommends that you use the original Nilfi sk suction hose

kit.

The Machine is designed for suction up to 50 cm above water surface.

• Position the machine at max. 0.5 meter above water surface. Detach the high pressure hose

from the outlet.

• Ensure that the inlet fi lter is in position and attach the suction hose kit, secure tight connection to the inlet.

• Turn on the machine, pressing the start/stop switch (1) into position "I".

• Wait until a steady jet exits the outlet.

• Switch off the machine and attach high pressure hose (4), spray handle, lance and nozzle.

• Start the machine again and activate the spray handle.

IMPORTANT!

I

R

C

HR

SL

Connecting to mains power supply

The voltage and frequency of the machine (see model tag (14)) must match the voltage and

frequency of the power supply.

B9 Insert the power plug into power supply socket.

B10 Turn on the water.

B11 Release the trigger lock (7a). Remember to unplug, turn off the high pressure washer and

L

lock the trigger, when leaving the high pressure washer unattended

B12 Activate the trigger of the spray handle and let the water run until all air has escaped from

the water hose.

B13 Turn on the machine, pressing the start/stop switch into position “I”.

B14 Activate the trigger of the spray handle. When releasing the trigger of the spray handle,

the machine automatically stops. The machine will start again when you reactivate the

trigger of the spray handle.

5 After using the pressure washer

L

C

See the pictorial quick reference guide – storing the high pressure washer.

The high pressure washer should be stored in a frost free room! Should the machine by a mistake be frozen, it will be necessary to check it for damages.

SK

R

Z

5.1 Stopping the high pressure washer

V

12

C1 Shut off the water supply and activate the trigger of the spray handle and let the machine

run until no more water runs out of the nozzle. This will wash out water hose, high pressure hose, spray lance and nozzles.

C2 Stop the machine, pressing the start/stop switch into position “0”.

C3 Unplug the machine from the power supply socket and wind up the electrical cable (5)

and place it on the holder (16).

C4 Rinse the spray lance, nozzles and the foam sprayer after use.

C5 Place spray handle, lance, nozzles, foam sprayer and other accessories in the holders on

the high pressure washer.

Original Instructions

Page 13

T

SHU

U

H

6 Maintenance

EN

D

Cleaning of the water inlet fi lter

Cleaning of nozzle

Cleaning of machine vents

See the pictorial quick reference guide - maintenance.

To ensure a long and problem free working life of the high pressure washer, please take the

following advices:

• Wash out water hose, high pressure hose, spray lance and accessory before mounting

• Clean the connectors of dust and sand

• Rinse the detergent bottle and the detergent nozzle

• Clean the nozzle

• Keep the water inlet fi lter clean and unclogged

D1 Clean the water inlet fi lter regularly once a month or more frequently according to use.

Carefully loosen the fi lter with a screwdriver and clean it. Check that it is intact before remounting it.

A clogging up in the nozzle causes a pump pressure which is too high, why cleaning is required immediately.

IMPORTANT!

The nozzle cleaning tool (12) should only be used when the nozzle is detached and the machine is stopped!

D2 Stop the machine and disconnect the nozzle. Clean the nozzle.

D3 Flush the nozzle backwards with water.

D4 The machine should be kept clean so as to let cooling air pass freely through the ma-

chine vents.

NO

SV

FI

FR

NL

I

L

R

Greasing of O-rings

D5 To ensure an easy connection and that O-rings do not dry up the couplings should be

greased regularly.

7 Troubleshooting

To avoid unnecessary disappointments, you should check the following before contacting the Nilfi sk service

organization.

Symptom Cause Recommended action

Machine refuses to

star

Fluctuating pressure Pump sucking

Machine not plugged in

Defective socket

Fuse has blown

Defective extension cable

Valves dirty, worn out or stuck

Pump seals worn out

Plug in machine

Try another socket.

Replace fuse. Switch off other machines.

Try without the extension cable.

Check that hoses and connections are airtight.

Clean and replace or refer to local Nilfi sk distributor.

Clean and replace or refer to local Nilfi skdistributor.

C

L

HR

SL

SK

V

R

Z

13Original Instructions

Page 14

EN

T

SHU

U

H

Symptom Cause Recommended action

NO

SV

FI

FR

NL

I

Machine stops Fuse has blown

Incorrect mains voltage

Thermal sensor activated

Nozzle partially blocked

Fuse blows Fuse too small Change to an installation higher than the

Machine pulsating Air in inlet hose/pump

Inadequate supply of mains

water

Nozzle partially blocke

Water fi lter blocked

Hose kinked

Machine often starts

and stops by itself

Machine starts, but no

water comes out

L

Pump/spray handle is leaking Contact your nearest Nilfi sk Service Centre.

Pump/hoses or accessory

frozen

No water supply

Water fi lter blocked

Nozzle blocked

Replace fuse. Switch off other machines.

Check that the mains voltage corresponds

to specifi cation on the model tag.

Leave the washer for 5 minutes to cool

down.

Clean the nozzle (see section 6.2)

amp. consumption of the machine.

You may try without the extension cable.

Allow machine to run with open trigger until

regular working pressure resumes.

Check that the water supply corresponds to

specifi cations required (see model tag)

NB! Avoid using long, thin hoses (min. 1/2")

Clean the nozzle (see section 6.2)

Clean the fi lter (see section 6.1)

Straighten out hose.

Wait for pump/hoses or accessory to thaw.

Connect inlet water.

Clean the fi lter (see section 6.1)

Clean the nozzle (see section 6.2)

R

C

HR

SL

SK

V

In case problems other than the above occur, please contact your local Nilfi sk distributor. Local Nilfi sk distributors are listed on the back cover of this instruction.

Customer Service at Penrith – 01768 868995

8 Warranty Conditions

L

Nilfi sk guarantees high pressure washers for domestic use for 2 years. If your high pressure washer or ac ces so ries are handed in for repair, a copy of the receipt must be enclosed.

Guarantee repairs are being made on the following con dit ions:

• that defects are attributable to fl aws or defects in materials or workmanship. (wear and tear

as well as misuse are not covered by the gu a ran tee).

• that the directions of this instruction manual have been thoroughly observed.

• that repair has not been carried out or attempted by other than Nilfi sk-trained service staff.

• that only original accessories have been applied.

• that the product has not been exposed to abuse such as knocks, bumps or frost.

• that only water without any impurities has been used.

• that the high pressure washer has not been used for rental nor used com mer cial ly in any

other way.

Repairs under this guarantee include replacement of defective parts, exclusive of packing and postage/carriage. Besides, we refer to your national law of sale.

The machine should be forwarded to one of the service centres of the Nilfi sk organisation with description/

spe ci fi ca ti on of the fault.

R

Z

Repairs not covered by the guarantee conditions will be invoiced. (I.e. malfunctions due to Causes men ti o ned in section Troubleshooting Chart of the instruction manual).

14

Original Instructions

Page 15

T

SHU

U

H

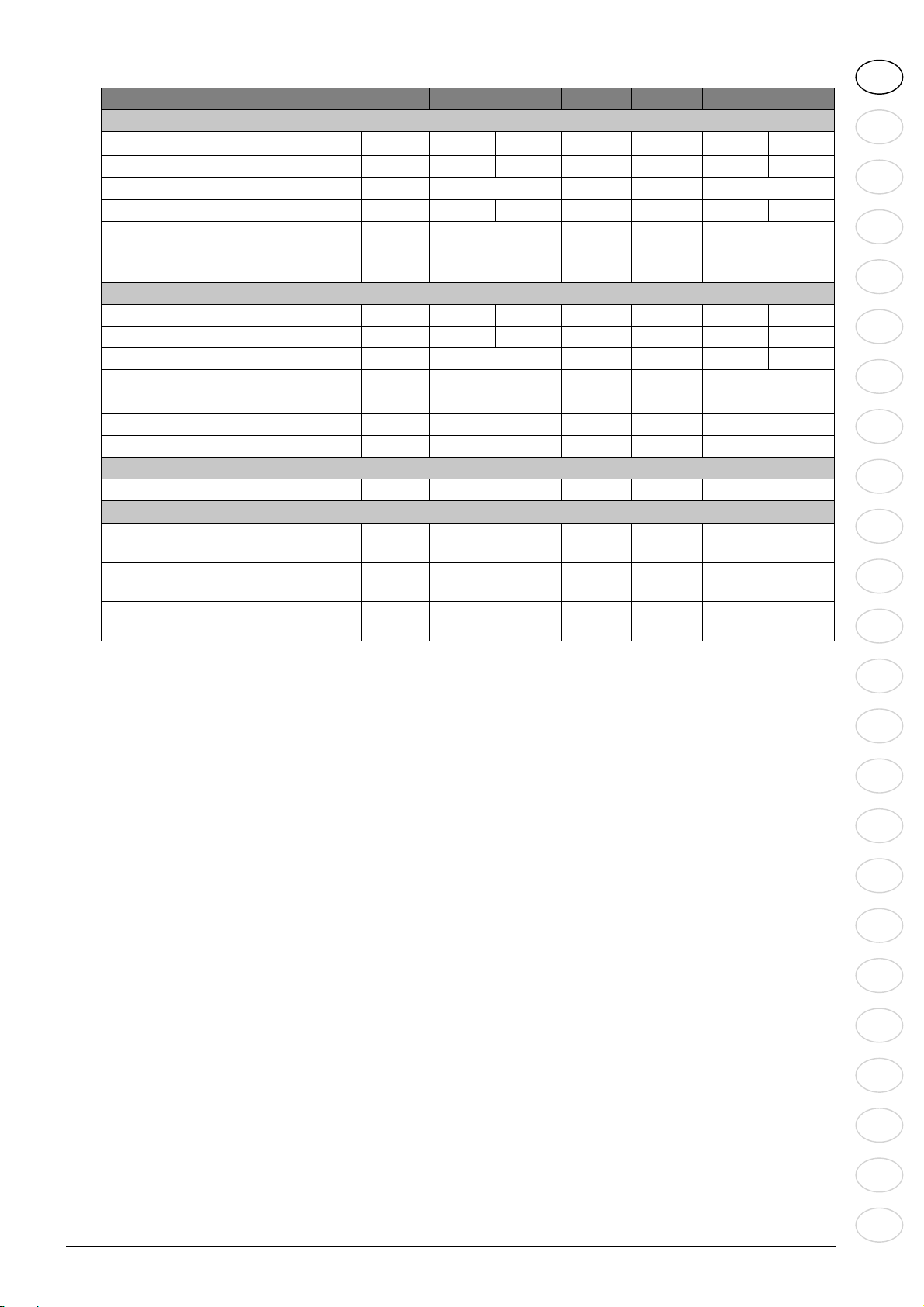

9 Main technical Data

Type

Electric specifications

Rated voltage V 220-240 120 220-240 220-240 220-240 120

Rated frequency Hz 50/60 60 50/60 50/60 50/60 60

Rated power consumption kW 1.3 1.4 1.4 1.4

Current A 5.7 11 6.1 6.1 6.1 12

Protection class

Protection degree IP xx IPX5 IPX5 IPX5 IPX5

Hydraulic specifications

Rated pressure MPa/bar 7/70 7/70 7.5/75 8/80 8.5/85 8/80

Max. pressure MPa/bar 10/100 9/90 10.5/105 10/110 12/120 10/100

Rated water flow l/min/l/h 5.3/320 5.2/310 5.2/310 5.2/310 5.3/320

Max. water flow l/min/l/h 7.3/440 7.3/440 7.3/440 7.3/440

Max. water inlet pressure Mpa/bar 1/10 1/10 1/10 1/10

Max. water inlet temperature °C 40 40 40 40

Max. water inlet temp. suction mode °C 20 20 20 20

Class I/

Class II

C 100.6 C 105.6 C 110.4 C 120.6

Class II Class II Class II Class II

EN

NO

SV

FI

FR

NL

Weight kg 5.1 (6.1)* 5.5 6.1(6.5)** 6.7

Hand-arm vibration according to

ISO 5349-1: Standard nozzle

Sound pressure level L

ance with ISO 3744

Guaranteed sound power level L

in accordance with 2000/14/EC

We reserve the right to make alterations.

* C 100.6-6, ** C 110.4 X-TRA

in accord-

pA

WA

2

m/s

dB(A) 74 ±3 74 ±3 74 ±3 74 ±3

dB(A) 90 90 90 90

< 2.5 ±1 < 2.5 ±1 < 2.5 ±1 < 2.5 ±1

I

L

R

C

L

HR

SL

SK

V

R

Z

15Original Instructions

Page 16

EN

T

SHU

U

H

10 Declaration of Conformity

We,

NO

SV

FI

FR

NL

I

Nilfi sk-Advance A/S

Sognevej 1

DK-2605 Broendby

DENMARK

Hereby solely declare, that the product:

Product Description Type

HPW - Consumer 220 - 240 V 1~, 50/60 Hz –

IP X5

Is in compliance with the following standards:

Nilfi sk C 100.6 / C 105.6 / C 110.4 /

C 120.6

and accessory variants of abovementioned types

Id and Version Title

EN 60335-1:2012 Household and similar electrical appliances - Safety - Part 1: General

requirements

EN 60335-2-79:2012 Household and similar electrical appliances - Safety - Part 2-79:

Particular requirements for high pressure cleaners and steam cleaners

R

C

HR

SL

SK

V

L

L

EN 55014-1:2006+

A1:2009+A2:2011

EN 55014-2:1997+A1:2001

+A2:2008

EN 61000-3-2:2006+A1:2009

+A2:2009

EN 61000-3-3:2008 Electromagnetic compatibility (EMC) - Part 3-3: Limits - Limitation of

Following the provisions of:

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

RoHS Directive 2011/65/EC

Noise Emission Directive 2000/14/EC – Conformity assessment procedure according to Annex V.

Measured noise level: 74 dB; Guaranteed noise level: 90 dB

Ecodesign requirements for standby and off mode 1275/2008/EC

Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus - Part 1: Emission

Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus - Part 2: Immunity - Product family

standard

Electromagnetic compatibility (EMC) - Part 3-2: Limits - Limits for harmonic current emissions (equipment input current < = 16 A per phase)

voltage changes, voltage fl uctuations and fl icker in public low-voltage

supply systems, for equipment with rated current < = 16 A per phase

and not subject to conditional connection

Hadsund 01-01-2013 Anton Sørensen

GM – Technical Operations & Hadsund

Place Date Name, Title Signature

R

Z

16

Original Instructions

Page 17

14

2a

2

3

O

I

A1

A2

A3

A4

A5

A6

A7

A8

Page 18

19

18

20

Page 19

B1

B2

B3

B4

B5

B6

B10

Max. 40°C

B7

B11

B12

Max. 40°C

B8

B13

O

I

B 9

B14

C3

C2C1 C1

C3

C5C5C4

Page 20

D1

D5

D2

D3

D4

Page 21

http://www.nilsk.com

HEAD QUARTER

DENMARK

Nilsk-Advance Group

Sognevej 25

DK-2605 Brøndby

Tel.: (+45) 4323 8100

E-mail: mail.com@nilsk-advance.com

SALES COMPANIES

AUSTRALIA

Nilsk-Advance

48 Egerton St.

P.O. Box 6046

Silverwater, N.S.W. 2128

Website: www.nilsk.com.au

AUSTRIA

Nilsk-Advance GmbH

Metzgerstrasse 68

5101 Bergheim bei Salzburg

Website: www.nilsk.at

BELGIUM

Nilsk-Advance n.v-s.a.

Riverside Business Park

Boulevard Internationalelaan 55

Bâtiment C3/C4 Gebouw

Bruxelles 1070

Website: www.nilsk.com

CHILE

Nilsk-Advance de Chile

San Alfonso 1462

Santiago

Website: www.nilsk.com

CHINA

Nilsk-Advance (Suzhou)

Building 18, Suchun Industrial Estate

Suzhou Industrial Park

215021 Suzhou

Website: www.nilsk-cs.com

CZECH REPUBLIC

Nilsk-Advance

VGP Park Horní Počernice

Do Čertous 1/2658

193 00 Praha 9

Website: www.nilsk.com

DENMARK

Nilsk-Advance NORDIC A/S

Sognevej 25

2605 Brøndby

Tel.: (+45) 4323 4050

E-mail: kundeservice.dk@nilsk.com

FINLAND

Nilsk-Advance Oy Ab

Koskelontie 23 E

02920 Espoo

Website: www.nilsk.

FRANCE

Nilsk-Advance

26 Avenue de la Baltique

Villebon sur Yvette

91978 Courtabouef Cedex

Website: www.nilsk.fr

GERMANY

Nilsk-ALTO

eine Marke der Nilsk-Advance GmbH

Guido-Oberdorfer-Straße 2-10

89287 Bellenberg

Website: www.nilsk.de

GREECE

Nilsk-Advance A.E.

Αναπαύσεως 29

Κορωπί Τ.Κ. 194 00

Website: www.nilsk.gr

HOLLAND

Nilsk-Advance

Versterkerstraat 5

1322 AN Almere

Website: www.nilsk.nl

HUNGARY

Nilsk-Advance Kereskedelmi Kft.

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklos-Lakihegy

Website: www.nilsk.hu

INDIA

Nilsk-Advance India Limited

Pramukh Plaza, ‘B’ Wing, 4th oor, Unit No. 403

Cardinal Gracious Road, Chakala

Andheri (East) Mumbai 400 099

Website: www.nilsk.com

IRELAND

Nilsk-Advance

1 Stokes Place

St. Stephen’s Green

Dublin 2

Website: www.nilsk.com

ITALY

Nilsk-Advance SpA

Strada Comunale della Braglia, 18

26862 Guardamiglio (LO)

Website: www.nilsk.it

JAPAN

Nilsk-Advance Inc.

1-6-6 Kita-shinyokohama, Kouhoku-ku

Yokohama, 223-0059

Website: www.nilsk.com

MALAYSIA

Nilsk-Advance Sdn Bhd

Sd 14, Jalan KIP 11

Taman Perindustrian KIP

Sri Damansara

52200 Kuala Lumpur

Website: www.nilsk.com

MEXICO

Nilsk-Advance de Mexico, S. de R.L. de C.V.

Agustín M. Chavez No. 1, PB ocina 004

Col. Centro de Ciudad Santa Fe

01210 Mexico, D.F.

Website: www.nilsk.com

NEW ZEALAND

Nilsk-Advance

Danish House

6 Rockridge Avenue

Penrose, Auckland 1135

Website: www.nilsk.com

NORWAY

Nilsk-Advance AS

Bjørnerudveien 24

1266 Oslo

Tel.: (+47) 22 75 17 70

E-mail: info.no@nilsk.com

POLAND

Nilsk-Advance Sp. Z.O.O.

ul. 3 Maja 8

05-800 Pruszków

Website: www.nilsk.pl

PORTUGAL

Nilsk-Advance

Sintra Business Park

Zona Industrial Da Abrunheira

Edicio 1, 1° A

P2710-089 Sintra

Website: www.nilsk.pt

RUSSIA

Нилфиск-Эдванс

127015 Москва

Вятская ул. 27, стр. 7

Россия

Website: www.nilsk.ru

SOUTH AFRICA

WAP South Africa

12 Newton Street

Spartan 1630

Website: www.nilsk.com

SOUTH KOREA

Nilsk-Advance Korea

3F Duksoo B/D, 317-15

Sungsoo-Dong 2Ga, Sungdong-Gu

Seoul

Website: www.nilsk.com

SPAIN

Nilsk-Advance S.A.

Torre d’Ara, Planta 9

08302 Mataró

Barcelona

Website: www.nilsk.es

SWEDEN

Nilsk-Advance AB

Taljegårdsgatan 4

431 53 Mölndal

Website: www.nilsk-alto.se

SWITZERLAND

Nilsk-Advance

Ringstrasse 19

Kircheberg/Industri Stelzl

9500 Wil

Website: www.nilsk-alto.ch

TAIWAN

Nilsk-Advance Taiwan Branch

1F, No. 193, sec. 2, Xing Long Rd.

Taipei

Tel.: (+88) 6227 002 268

Website: www.nilsk-alto.tw

THAILAND

Nilsk-Advance Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Ladyao, Jatuchak, Bangkok 10900

Website: www.nilsk-thailand.com

TURKEY

Nilsk-Advance A.S.

Serifali Mh. Bayraktar Bulv. Sehit Sk. No:7

Ümraniye

Istanbul

Website: www.nilsk.com

UNITED KINGDOM

Nilsk (A Division of Nilsk-Advance Ltd.)

Bowerbank Way

Gilwilly Industrial Estate, Penrith

Cumbria CA11 9BQ

Tel: 01768 868995

Website: www.nilsk.co.uk

UNITED ARAB EMIRATES

Nilsk-Advance Middle East Branch

SAIF-Zone

P.O. Box 122298

Sharjah

Website: www.nilsk.com

VIETNAM

Nilsk-Advance Representative Ofce

No. 51 Doc Ngu Str.

Ba Dinh Dist.

Hanoi

Website: www.nilsk.com

Loading...

Loading...