Page 1

Nilfi sk C 100.4

Nilfi sk C 110.2, C 110.2 X-TRA

User Manual

Page 2

Copyright © 2008 Nilfi sk-AL TO

Page 3

Index

1 Safety precautions and warnings .............................................3

2 Description ...............................................................................5

3 Before you start using your pressure washer ...........................6

4 Operating your pressure washer ..............................................8

5 After using your pressure washer ...........................................10

6 Maintenance ...........................................................................11

7 Trouble shooting .....................................................................13

8 Further information .................................................................14

9 Technical data ........................................................................15

10 Declaration .............................................................................15

1 Safety Precautions and Warnings

Symbols used to mark instructions

Do not let people who have not

been trained in the use of a

high pressure washer nor read

the instruction manual ope rate

the machine.

This appliance is not intended

for use by children or other

persons without assistance or

supervision if their physical,

sensory or mental capabilities prevent them from using it

safely. Children should be supervised to ensure that they do

not play with the appliance.

Before starting up your machine

please check it carefully for any

defects. If you fi nd any, do not

start up your machine and contact your Nilfi sk distributor.

Before starting

up your highpressure washer

for the fi rst time,

this instruction

manual must be

read through carefully. Save the

instructions for later use.

Safety instructions

marked with this

symbol must be

observed to pre-

vent danger to persons.

Especially check:

The insulation of the electric

cable should be faultless

and without any cracks. If the

electric cable is damaged, an

authorized Nilfi sk di stributor

should replace it.

WARNING!

High pressure jets can be

dangerous. Never direct the

water jet at persons, pets,

live electrical equipment or

the machine itself.

Never try to clean clothes or

footwear on yourself or other

persons.

Hold the spray lance fi rmly

with both hands. The spray

lance is affected by a thrust

of up to 16.4 N during ope–

This symbol is

used to mark safety

instructions that

must be ob-

chine and its performance.

simplify work and to ensure a

safe operation.

ration.

The operator and anyone in

the immediate vicinity of the

site of cleaning should take

action to protect themselves

from being struck by debris

dislodged during operation.

Wear goggles and protection

clothes during operation.

This appliance has been de-

signed for use with cleaning

agents supplied or recommended by the manufacturer.

The use of other cleaning

agents or chemicals may

adversely affect the safety of

the appliance.

Disconnect from electrical

power supply before carrying

out user maintenance.

To ensure the appliance

served to prevent

damage to the ma-

This symbol indicates tips and

instructions to

3

Page 4

safety only use original spare

parts from the manufacturer

or approved by the manufacturer.

High pressure hoses, fi ttings

and couplings are important

for the safety of the appliance. Only use hoses, fi ttings

and couplings recommended

by the manufacturer.

Do not use the appliance

if a supply cord or important parts of appliance are

damaged, e.g. safety device ,

high pressure hose and trigger gun.

The appliance is intended to

clean cars and garden etc..

Appropriate ear protection

has to be used.

Never use the machine in

an environment where there

could be a danger of explosion. If any doubt arises,

please contact the local

authorities.

It is not allowed to clean as-

bestos- containing surfaces

with high pressure.

This high pressure washer

must not be used at temperatures below 0°C.

WARNING!

Inadequate extension cables

can be dangerous. Cables on

drums should always be completely unwinded to prevent the

cable from overheating.

If an extension cable is used,

the plug and the socket must be

waterproof and comply with the

below-mentioned requirements

for length and cable dimensions.

1.0 mm² max. 12.5 m

1.5 mm² max. 20 m

2.5 mm² max. 30 m

If the electric cable is

damaged, it must be replaced by the manufacturer

or his service agent or similarly qualifi ed person in order

to avoid a hazard.

Mains power connection

The following should be observed when connecting the

high pressure washer to the

electric installation:

The electric installation shall

be made by a certifi ed electrician and comply with IEC

364.

It is recommended that the

electric supply to this appliance should include either a

residual current device that

will interrupt the supply if the

leakage current to earth exceeds 30 mA for 30 ms.

Water connection

Connection to the public

mains according to regulations.

Inlet hose can be connected

to the water mains with a

max. inlet pressure of 10

bars.

This high pressure washer is

only allowed to be

connected with

the drinking water

mains, when an appropriate

backfl ow preventer has been

installed, Type BA according

to EN 1717. The backfl ow preventer can be ordered under

number 106411177. The length

of the hose between the backfl ow preventer and the high

pressure washer must be at

least 10 metres to absorb possible pressure peaks (min diameter ½ inch).

Operation by suction (for example from a rainwater vessel)

is carried out without backfl ow

preventer. Recommended suction set: 126411387.

As soon as water has fl own

through the BA valve, this water

is not considered to be drinking

water any more.

IMPORTANT! Only use water without any impurities. If

there is a risk of running sands

in the inlet water (i.e. from your

own well), an additional fi lter

should be mounted.

Safety devices

The unloader valve can re-

duce pressure if it exceeds

pre-set values.

Locking device on spray gun

(7a) (see illustration at the end

of this manual):

The spray gun features a locking device. When the pawl is

activated, the spray gun cannot

be ope rated.

Thermal sensor:

A thermal sensor protects the

motor against overloading. The

machine will restart after a few

minutes when the thermal sensor has cooled.

4

Page 5

2 Description

2.1 Application

2.2 Operation elements

and model survey

This high-pressure washer has

been developed for domestic

use within:

- Car, motorbike, boat, caravan, trailer, patio/drive/fl agstones, woodwork, brickwork,

barbecue, garden furniture,

lawn mower

See illustration at the end of

this manual.

1 Start/stop switch

2 Water inlet with fi lter (2a)

3 High pressure connection

4 High pressure hose

5 Electric cable

6 Click & Clean spray lance

7 Spray gun with lock (7a)

8 Click & Clean Tornado

nozzle

®

Only use the high-pressure

washer for purposes described

in this manual.

The safety precautions must be

observed to prevent damage

to the machine, the surface to

be cleaned or severe personal

injuries.

9 Click & Clean Powerspeed

nozzle

10 Foam sprayer

11 Nozzle cleaning tool

12 Lance and nozzle holder

13 Model tag

14 Holder for electric cable (not

standard on all models)

Specifi cations: See model tag

(13) of machine.

We reserve the right to alter the

specifi cations.

®

5

Page 6

3 Before you start using your

pressure washer

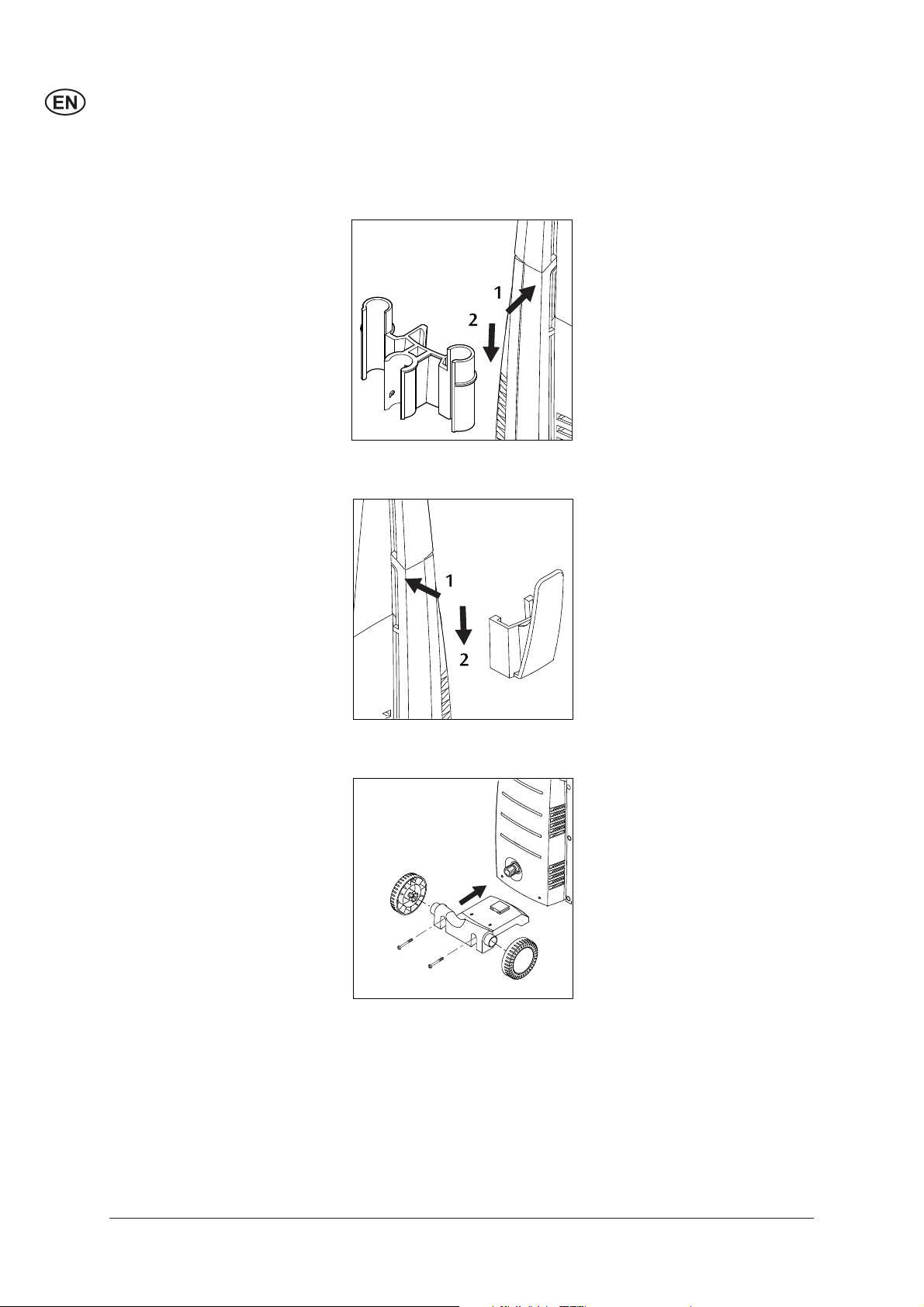

3.1 Mounting of lance and

nozzle holder

3.2 Mounting of holder for

electric cable

1. Press the lance and nozzle

holder (12) on to the machine.

1. Press the holder for electric

cable (14) on to the machine.

The holder is not standard on

all models.

3.3 Mounting of wheels (only

models including wheels)

6

1. Mount the wheel bracket

by pressing it into the guide

at the bottom of the machine and mounting the two

screws.

2. Mount the wheels by pressing them into the bracket.

Page 7

3.4 Mounting of trolley

handle (models with trolley handle)

1. Place the trolley handle on

the machine.

2. Secure the handle by mounting the 2 screws.

3.5 Mounting of quick

coupling

3.6 Mounting of high pressure hose on spray gun

1. Screw the quick coupling

tight on to the water inlet (2).

Note: The inlet fi lter (2a) must

always be fi tted in the water

inlet pipe to fi lter out sand, limestone and other impurities as

these will damage the pump

valves.

Caution: Failure

to fi t the fi lter will

invalidate the

1. Attach the high pressure

hose (4) to the spray gun (7).

Detach the high pressure

hose by pressing the pawl

(A).

guarantee.

7

Page 8

4 Operating your pressure washer

4.1 Connection of high pressure hose

4.2 Mounting of spray

lance and Click & Clean

nozzles

1. Mount the high pressure

hose on the outlet (3).

1. Push the spray lance (6) into

the spray gun (7) and screw

it on.

Note: The spray

lance (6) has a

built-in low pressure nozzle that can be used

for fl ushing away dirt.

2. Attach the nozzle.

Warning: When

attaching the Click

& Clean nozzles,

the pawl on the

lance (6) should come out

again.

Note: The foam sprayer (10)

features a swivel lock, which

must be positioned in the hole

in the Click & Clean spray lance

(6).

Press the pawl to detach the

Click & Clean nozzle.

side of the spray

8

Page 9

4.3 Water connection An ordinary 1/2" garden hose of

min. 10 m and max. 25 m will

be suitable.

NOTE: Connection to the public

mains according to regulations.

IMPORTANT! Only use water without any impurities. If

there is a risk of running sands

in the inlet water (i.e. from

your own well), an additional

fi lter (106411231) should be

mounted.

1. Let the water run through the

water hose before connecting

it to the machine to prevent

sand and dirt from penetrating the machine.

Note: Check that the fi lter is

fi tted in the water inlet pipe

and that it is not clogged up.

2. Connect the water hose to

the water supply by means

of the quick connector (inlet

water, max. pressure: 10 bar,

max. temperature: 40°C).

3. Turn on the water.

4.4 Start and stop of the

machine

The spray lance is affected

by a thrust during operation

- therefore always hold it fi rmly

with both hands. IMPORTANT:

Point the nozzle at the

ground.

1. Check that the machine is in

uprigth position.

NOTE: Do not place the ma-

chine in high grass!

2. Release the trigger lock (7a).

3. Activate the trigger of the

spray gun and let the water

run until all air has escaped

from the water hose.

4. Press the Start/stop switch

"I" (1).

5. Activate the trigger of the

spray gun.

Always adjust the distance and

thus the pressure of the nozzle

to the surface, which is to be

cleaned.

Do not cover the machine

during operation or use it in a

room without adequate ventilation !

Note: If the machine is left or not

used for 5 minutes, it must be switched off on

the start/stop switch "O" (1):

1. Press the start/stop switch

"O".

2. Disconnect the electrical plug

from the socket.

3. Shut off the water supply and

activate the trigger to relieve

the machine of pressure.

4. Lock the spray gun (7a).

When releasing the trigger of

the spray gun, the machine

automatically stops. The machine will start again when you

re- activate the spray gun.

9

Page 10

5 After using your pressure washer

5.1 Storing the washer The machine should be sto-

red in a frost-free room!

Pump, hose and accessories

should always be emptied of

water prior to storing as follows:

5.2 Winding up of electric

cable and high pressure

hose

1. Stop the machine (press the

start/stop switch “O” (1) and

detach water hose and accessory.

2. Restart the machine and

activate the trigger. Let the

machine run until no more

water runs through the spray

gun.

3. Stop the machine, unplug

and wind up hose and cable.

4. Place spray handle, nozzles

and other accessories in the

holders of the machine.

Should the machine by mistake

be frozen, it will be necessary

to check it for damage.

NEVER START-UP A FROZEN

MACHINE.

Frost damages are not

covered by the guarantee!

To avoid accidents, the electric

cable and the high pressure

hose should always be winded

carefully up around the handle.

C 110.2 X-TRA: Wind up the

cable on the appropriate hook.

5.3 Storage of accessories The spray handle, lance and

nozzles can be stored on the

pressure washer.

10

Page 11

6 Maintenance

6.1 Cleaning of water inlet

fi lter

WARNING! Always discon-

nect the electrical plug from the

socket prior to maintenance or

cleaning.

To ensure a long and problem

free working life, please take

the following advice:

Wash out water hose, high

pressure hose, spray lance

and accessories before

mounting.

Clean the connectors of dust

and sand.

Rinse the detergent spraying

attachment after use.

Clean the nozzles.

Any repair should always be

made in an authorized workshop

with original spare parts.

Clean the water inlet fi lter

regularly once a month or more

frequently according to use.

Carefully loosen the fi lter with a

screwdriver and clean it. Check

that it is intact before re-mounting it.

The inlet fi lter must always be

fi tted inside the water inlet pipe

to fi lter out sand, limestone and

other impurities, as they will

damage the pump valves.

CAUTION: Failure to fi t the fi lter

will invalidate the guarantee.

6.2 Cleaning of nozzle A clogging up in the nozzle

causes a pump pressure which

is too high. This is why cleaning

is required immediately.

1. Stop the machine and disconnect the nozzle.

2. Clean the nozzle. IMPOR-

TANT: The cleaning tool (11)

should only be used when

the nozzle is detached!

3. Flush the nozzle backwards

with water.

11

Page 12

6.3 Cleaning of machine

vents

The machine should be kept

clean so as to let cooling air

pass freely through the machine vents.

6.4 Greasing of couplings

To ensure an easy connection and that o-rings do not dry

up, the couplings should be

greased regularly.

12

Page 13

7 Trouble-shooting

To avoid unnecessary disappointments, you should check the following before contacting the Nilfi sk

service organization:

Symptom Cause Recommended action

Machine refuses to start Machine not plugged in Plug in machine.

Defective socket Try another socket.

Fuse has blown Replace fuse. Switch off other machines.

Defective extension cable Try without the extension cable.

Fluctuating pressure Pump sucking air Check that hoses and connections are air-

tight.

Valves dirty, worn out Clean and replace or refer to local Nilfi sk

or stuck distributor

Pump seals worn out Clean and replace or refer to local Nilfi sk-

distributor.

Machine stops Fuse has blown Replace fuse. Switch off other machines.

Incorrect mains voltage Check that the mains voltage corresponds

to specifi cation on the model tag.

Thermal sensor activated Leave the washer for 5 minutes to cool

down.

Nozzle partially blocked Clean the nozzle (see section 6.2)

Fuse blows Fuse too small Change to an installation higher than the

amp. consumption of the machine.

You may try without the extension cable.

Machine pulsating Air in inlet hose/pump Allow machine to run with open trigger until

regular working pressure resumes.

Inadequate supply of Check that the water supply corresponds to

mains water specifi cations required (see model tag)

NB! Avoid using long, thin hoses (min. 1/2")

Nozzle partially blocked Clean the nozzle (see section 6.2)

Water fi lter blocked Clean the fi lter (see section 6.1)

Hose kinked Straighten out hose.

Machine often starts Pump/spray gun is Contact your nearest Nilfi sk Service

and stops by itself leaking Centre.

Machine starts, but Pump/hoses or accessory Wait for pump/hoses or accessory to thaw.

no water comes out frozen

No water supply Connect inlet water.

Water fi lter blocked Clean the fi lter (see section 6.1)

Nozzle blocked Clean the nozzle (see section 6.2)

In case problems other than the above occur, please contact your local Nilfi sk distributor.

13

Page 14

8 Further information

8.1 Recycling the washer Make the old cleaner unusable

immediately.

1. Unplug the cleaner and cut

the electric cable.

Do not discard electrical appliances with household waste.

8.2 Warranty conditions Nilfi sk guarantees high pres-

sure washers for domestic use

for 2 years. If your high pressure washer or ac ces so ries are

handed in for repair, a copy of

the receipt must be enclosed.

Guarantee repairs are being

made on the following con dit ions:

that defects are attributable

to fl aws or defects in materials or workmanship. (wear

and tear as well as misuse

are not covered by the

gu a ran tee).

that the directions of this

instruction manual have been

thoroughly observed.

that repair has not been

carried out or attempted by

other than Nilfi sk-trained

service staff.

that only original accessories

have been applied.

that the product has not been

exposed to abuse such as

knocks, bumps or frost.

that only water without any

impurities has been used.

As specifi ed in European Directive 2002/96/EC on old electrical and electronic appliances,

used electrical goods must

be collected separately and

recycled ecologically.

Contact your local authorities or

your nearest dealer for further

information.

that the high pressure

washer has not been used

for rental nor used com mer cial ly in any other way.

Repairs under this guarantee

include replacement of defective parts, exclusive of packing

and postage/carriage. Besides,

we refer to your national law of

sale.

The machine should be forwarded to one of the service

centres of the Nilfi sk organisation with description/spe ci fi ca ti on of the fault.

Repairs not covered by the

guarantee conditions will be

invoiced. (I.e. malfunctions due

to Causes men ti o ned in section

Troubleshooting Chart of the

instruction manual).

In order that Nilfi sk can render

you optimum service, you

should register your product on

our web site www.nilfi sk-alto.

com under “PRODUCT REGISTRATION”.

14

Page 15

9 Main Technical Data

Type C 100.4-5 C 110.2-5 C 110.2-5 X-TRA

Rated pressure bar/MPa 65/6.5 70/7.0 70/7.0

Permissible pressure bar/MPa max. 100/10.0 max. 110/11.0 max. 110/11.0

Rated flow l/min 5.3 5.0 5.2

Rated input kW 1.3 1.4 1.4

Rated voltage V 230-240 230-240 230-240

Max. water temperature °C 40 40 40

Inlet pressure bar/MPa 0.15-10/0.015/1.0 0.15-10/0.015/1.0 0.15-10/0.015/1.0

Sound pressure level dB(A) 78 78 78

Guaranteed sound power level dB(A) 92 92 92

Vibration according to ISO 5349 m/s

2

max. 2.5 max. 2.5 max. 2.5

10 Declaration

Manufacturer's name and address or his

authorized representative in the Community

Name of the person responsible for the

technical documentation

Description of the equipment:

Equipment name

Model

Dimension

Rated output voltage

Rated frequency

Rated input power

Measured sound pressure level

Guaranteed sound power level

Declaration

Declaration

Nilfi sk-Advance AG

Nilfi sk Business Unit

Guido-Oberdorfer-Str. 10

89287 Bellenberg

GERMANY

Wolfgang Nieuwkamp

High pressure washer

Nilfi sk

C 100.4-5 / C 110.2-5 / C 110.2-5 X-TRA

255 x 240 x 630 mm

AC 230-240 V

50 Hz

1.3 - 1.4 kW

90 dB(A)

92 dB(A)

The equipment refer in this document fulfi ls all the requirements of the Directive :

Machine Directive 98/37/EC

Low-voltage Directive 73/23/EEC

EN 60335-2-79: 2004

EN 60335-1/A1: 2004

EN 50366: 2003

EMC Directive 89/336/EEC

EN 55014-1/A2: 2002

EN 55014-2/A1: 2001

EN 61000-3-2/A2: 2005

EN 61000-3-3/A1: 2001

Outdoor Noise Directive 2000/14/EC

Place and date of the declaration

Signature

Bellenberg, November 10, 2005

15

Page 16

Page 17

C 110.2-5

Page 18

Nilfi sk-ALTO, Division of Nilfi sk-Advance A/S, Industrivej 1, DK - 9560 Hadsund, tel.: (+45) 7218 2100

128303200 (01.2008)

Loading...

Loading...