American-Lincoln

Technology

OPERATOR’S

MANUAL

Beginning with Serial Number: 683001

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure

to read this book prior to operating or attempting any service or maintenance procedure to

your machine could result in injury to you or to other personnel. Damage to the machine or to

other property could occur as well. You must have training in the operation of this machine

before using it.

All directions given in this book are as seen from the operator's position at the rear of the machine.

ATS 46/53

SWEEPER/SCRUBBER

A

T

S

4

6

/

5

3

ISO 9001

U

®

L

#

FILE A2287

Part No. 2004 Printed in the

American-Lincoln

®

USA

T ABLE OF CONTENTS

SPECIFICA TIONS ...................................................................................................................................................... 1-6

MACHINE DIMENSIONS ............................................................................................................................................ 1-9

STANDARD HARDW ARE & TORQUE V ALUES ......................................................................................................... 1-10

HYDRAULIC TORQUE REQUIREMENTS ................................................................................................................... 1-11

DECIMAL - METRIC CONVERSION T ABLE ............................................................................................................... 1-12

MACHINE PREPARA TION.......................................................................................................................................... 1-13

PREPARING THE MACHINE FOR OPERA TION .......................................................................................................... 1-13

BATTER Y-POWERED MACHINE PREP ARA TION ....................................................................................................... 1-14

SAFETY INSTRUCTIONS ........................................................................................................................................... 1-15

OPERATION OF CONTROLS AND GAUGES .............................................................................................................. 1-18

LIGHT SWITCH ................................................................................................................................................. 1-18

HORN BUTTON ................................................................................................................................................ 1-18

CHECK ENGINE LIGHT .................................................................................................................................... 1-18

KEY SWITCH ..................................................................................................................................................... 1-19

ENGINE SPEED SWITCH ................................................................................................................................. 1-19

HOUR METER ................................................................................................................................................... 1-19

FUEL GAUGE .................................................................................................................................................... 1-19

SEAT POSITION ADJUSTMENT ........................................................................................................................ 1-19

FILTER SHAKER SWITCH ................................................................................................................................ 1-20

GLOW PLUG SWITCH ...................................................................................................................................... 1-20

SEAT COMP ARTMENT PROP LA TCH............................................................................................................... 1-20

HOPPER SAFETY ARM ..................................................................................................................................... 1-20

SIDE BROOM LEVER........................................................................................................................................ 1-21

SIDE BROOM ADJUSTMENT ............................................................................................................................ 1-21

MAIN BROOM LEVER ........................................................................................................................................ 1-21

MAIN BROOM ADJUSTMENT ............................................................................................................................ 1-21

DUST CONTROL SWITCH ............................................................................................................................... 1-22

SCRUB DECK SWITCH .................................................................................................................................... 1-22

SCRUB DECK HEA VY PRESSURE SWITCH................................................................................................... 1-22

SQUEEGEE SWITCH........................................................................................................................................ 1-22

SOLUTION CONTROL ...................................................................................................................................... 1-23

NON-RECYCLING OR STANDARD SCRUBBING SYSTEM............................................................................. 1-23

RECYCLING OR ESP/AUTOFIL SYSTEM ......................................................................................................... 1-23

DISCONNECT WATER HOSE........................................................................................................................... 1-23

WARNING BA NK ............................................................................................................................................... 1-24

ENGINE TEMPERATURE LIGHT (WARNING LIGHT)....................................................................................... 1-24

ENGINE OIL PRESSURE LIGHT (WARNING LIGHT) ...................................................................................... 1-24

CHARGING SYSTEM LIGHT (WARNING LIGHT) .............................................................................................1-24

CLOGGED FIL TER LIGHT (WARNING LIGHT)................................................................................................. 1-24

HOPPER TEMPERATURE LIGHT (W ARNING LIGHT) ..................................................................................... 1-24

SOLUTION LOW LIGHT (WARNING LIGHT) .................................................................................................... 1-24

RECOVERY HIGH LIGHT (WARNING LIGHT) .................................................................................................. 1-24

FOOT BRAKE .................................................................................................................................................... 1-25

PARKING BRAKE .............................................................................................................................................. 1-25

FWD/REV FOOT PEDAL.................................................................................................................................... 1-25

HOPPER LIFT LEVER ....................................................................................................................................... 1-26

HOPPER DUMP DOOR LEVER ........................................................................................................................ 1-26

TURN SIGNAL ................................................................................................................................................... 1-27

THROTTLE ........................................................................................................................................................ 1-27

BACK-UP ALARM SWITCH ................................................................................................................................ 1-27

BATTERY CONDITION METER ......................................................................................................................... 1-27

FILTER P ANEL LA TCH ...................................................................................................................................... 1-28

HOPPER TEMPERATURE SENSOR ................................................................................................................ 1-28

ENGINE COMPAR TMENT LA TCH..................................................................................................................... 1-28

HYDRAULIC RESERVOIR LEVEL SIGHT GAUGE ........................................................................................... 1-29

MAIN BROOM COMPAR TMENT DOORS .......................................................................................................... 1-29

SEA T COMP ARTMENT COVER......................................................................................................................... 1-29

HOPPER DOOR LEVER ................................................................................................................................... 1-30

HOPPER LIFT LEVER ....................................................................................................................................... 1-30

HOPPER FIL TER COMPAR TMENT COVER ..................................................................................................... 1-30

American-Lincoln 1-1

A TS 46/53

T ABLE OF CONTENTS

ESP SYSTEM OPERA TING INSTRUCTIONS ............................................................................................................. 1-31

ESP RECYCLING CONTROL PANEL ............................................................................................................... 1-31

ESP RECYCLING SYSTEM ON/OFF SWITCH.................................................................................................. 1-31

DETERGENT FLOW KNOB .............................................................................................................................. 1-31

HOPPER SAFETY LOCK ARM........................................................................................................................... 1-31

THE SCRUBBING SYSTEM - HOW IT WORKS ................................................................................................ 1-32

THE NON-RECYCLING OR STANDARD SCRUBBING SYSTEM - HOW IT WORKS....................................... 1-32

RECOVERY OR ESP SYSTEM - HOW IT WORKS............................................................................................ 1-33

THE VARI DUMP SWEEPING & DUST CONTROL SYSTEMS - HOW THEY WORK........................................ 1-33

OPERA TING INSTRUCTIONS .................................................................................................................................... 1-34

DUST CONTROL .............................................................................................................................................. 1-34

BEFORE ST ARTING THE ENGINE ................................................................................................................... 1-34

PRE-STAR T CHECKLIST.................................................................................................................................. 1-34

ST ARTING BATTER Y MACHINES ..................................................................................................................... 1-35

ST AR TING GAS ENGINES ................................................................................................................................ 1-35

STAR TING PROP ANE ENGINES ...................................................................................................................... 1-35

STAR TING DIESEL ENGINES........................................................................................................................... 1-35

EMPTYING THE DEBRIS HOPPER .................................................................................................................. 1-35

POST-OPERATION CHECKLIST....................................................................................................................... 1-36

BA TTERY CHARGING INSTRUCTIONS ........................................................................................................... 1-36

MACHINE STORAGE ................................................................................................................................................. 1-36

GASOLINE-POWERED MACHINES.................................................................................................................. 1-36

BATTER Y -POWERED MACHINES .................................................................................................................... 1-36

HELPFUL HINTS FOR CLEANING OPERA TION ......................................................................................................... 1-37

SERVICE CHART ....................................................................................................................................................... 1-38

SERVICE PRECAUTIONS .......................................................................................................................................... 1-40

SERVICE INSTRUCTIONS ......................................................................................................................................... 1-41

MAIN BROOM .................................................................................................................................................... 1-41

CHECKING THE MAIN BROOM SWEEP P A TTERN.......................................................................................... 1-41

ADJUSTING THE MAIN BROOM HEIGHT ......................................................................................................... 1-41

REPLACING THE MAIN BROOM....................................................................................................................... 1-41

MAIN BROOM LEVEL ADJUSTMENT ................................................................................................................ 1-41

SIDE BROOM .................................................................................................................................................... 1-42

CHECKING THE SIDE BROOM SWEEP P A TTERN.......................................................................................... 1-42

ADJUSTING THE SIDE BROOM HEIGHT ......................................................................................................... 1-42

REPLACING THE SIDE BROOM....................................................................................................................... 1-42

HOPPER SERVICE ........................................................................................................................................... 1-43

HOPPER............................................................................................................................................................ 1-43

CLEANING THE HOPPER ................................................................................................................................ 1-43

CHECKING THE HOPPER SEALS ................................................................................................................... 1-43

DUST CONTROL FILTER ................................................................................................................................. 1-43

CHECKING THE DUST CONTROL FILTER ..................................................................................................... 1-43

CLEANING THE DUST CONTROL FIL TER ...................................................................................................... 1-43

REPLACING THE DUST CONTROL FIL TER.................................................................................................... 1-44

DUST FLAPS ..................................................................................................................................................... 1-44

CHECKING THE DUST FLAPS......................................................................................................................... 1-44

ADJUSTING THE DUST FLAPS ........................................................................................................................ 1-44

BRAKES ............................................................................................................................................................ 1-45

ADJUSTING THE BRAKE PEDAL ..................................................................................................................... 1-45

ADJUSTING THE BRAKES ............................................................................................................................... 1-45

GENERAL MACHINE MAINTENANCE ........................................................................................................................ 1-45

FILLING THE HYDRAULIC RESERVOIR.......................................................................................................... 1-46

CLEANING THE HYDRAULIC SYSTEM ............................................................................................................ 1-46

REPLACING THE RETURN FIL TER ELEMENT ............................................................................................... 1-46

REPLACING THE SCRUB BRUSH .................................................................................................................. 1-47

COVERS AND LATCHES................................................................................................................................... 1-47

SOLUTION LOW WARNING LIGHT .................................................................................................................. 1-47

RECOVERY HIGH WARNING LIGHT................................................................................................................ 1-47

1-2 American-Lincoln

A TS 46/53

T ABLE OF CONTENTS

SOLUTION CONTROL ...................................................................................................................................... 1-47

RECYCLING PUMP ESP SYSTEM.................................................................................................................... 1-48

RECYCLING PUMP STORAGE......................................................................................................................... 1-48

REAR SQUEEGEE ............................................................................................................................................ 1-48

SQUEEGEE CASTER WHEELS ....................................................................................................................... 1-48

ADJUSTING CAS TERS ..................................................................................................................................... 1-48

AIR INTAKE SYSTEM......................................................................................................................................... 1-49

REPLACING THE AIR FIL TER ELEMENT ......................................................................................................... 1-49

AIR FILTER ........................................................................................................................................................ 1-50

COOLING SYSTEM ........................................................................................................................................... 1-51

COOLANT LEVEL.............................................................................................................................................. 1-51

RADIAT OR ......................................................................................................................................................... 1-51

DRIVE BEL TS .................................................................................................................................................... 1-51

BATTER Y ........................................................................................................................................................... 1-52

GAS T ANK .......................................................................................................................................................... 1-52

NEUTRAL ADJUSTMENT .................................................................................................................................. 1-53

LP SYSTEM............................................................................................................................................................... 1-54

LP SAFETY PRECAUTIONS.............................................................................................................................. 1-54

LP V APORIZER - REGULA T OR QUICK CHECK............................................................................................... 1-55

LP V APOR WITHDRAW AL SYSTEM.................................................................................................................. 1-55

LP CHECKLIST ................................................................................................................................................. 1-55

LP FUEL TANKS ................................................................................................................................................ 1-56

USE AND CARE OF LP T ANKS ......................................................................................................................... 1-57

CHANGING THE LP T ANKS .............................................................................................................................. 1-57

STORING LP FUEL TANKS............................................................................................................................... 1-57

PARTS LIST LEGEND................................................................................................................................................ 1-58

GENERAL TROUBLESHOOTING ............................................................................................................................... 1-59

CHECK ENGINE LIGHT CODES ................................................................................................................................. 1-61

ORDERING P ARTS .................................................................................................................................................... 1-64

CHAPTER 2 PARTS................................................................................................................................................... 2-4

MAIN BROOM LEVER ........................................................................................................................................ 2-4

SIDE BROOM - BATTERY .................................................................................................................................. 2-6

SIDE BROOM .................................................................................................................................................... 2-7

SIDE BROOM PULLEY...................................................................................................................................... 2-8

SIDE BROOM LEVER........................................................................................................................................ 2-10

SIDE BROOM LIFT SYSTEM-BA TTERY ............................................................................................................ 2-12

SIDE BROOM LIFT SYSTEM-GAS ..................................................................................................................... 2-14

BROOM CHAMBER FLAPS & SEALS ............................................................................................................... 2-16

LOWER DOOR .................................................................................................................................................. 2-18

HOPPER (VARIABLE DUMP) ............................................................................................................................ 2-20

HOPPER LID/COVER (VARIABLE DUMP) ........................................................................................................ 2-24

HOPPER DUMP DOOR .................................................................................................................................... 2-25

HOPPER DOOR CYLINDER-GAS .................................................................................................................... 2-26

HOPPER DOOR CYLINDER-BATTERY ............................................................................................................ 2-27

HOPPER CONTROL VAL VE - BATTERY (VARIABLE DUMP) ........................................................................... 2-28

HOPPER CONTROL VAL VE - GAS (VARIABLE DUMP).................................................................................... 2-29

SCRUB DECK (46”) - BATTER Y....................................................................................................................... 2-30

SCRUB DECK (46”) - GAS ............................................................................................................................... 2-33

SCRUB DECK & SQUEEGEE (53”) - BA TTERY ...............................................................................................2-36

SCRUB DECK & SQUEEGEE (53”) - GAS........................................................................................................ 2-44

SIDE SQUEEGEES (46”) .................................................................................................................................. 2-48

REAR SQUEEGEES (46”) ................................................................................................................................. 2-49

SQUEEGEE LIFT - BATTERY ............................................................................................................................ 2-50

SQUEEGEE LIFT - GAS .................................................................................................................................... 2-52

SWING SQUEEGEE SUPPORT........................................................................................................................ 2-54

SOLUTION TANK .............................................................................................................................................. 2-56

SOLUTION FEED .............................................................................................................................................. 2-58

RECOVERY TANK ............................................................................................................................................. 2-60

RECOVERY DRAIN SYSTEM ............................................................................................................................ 2-62

FRONT BUMPER .............................................................................................................................................. 2-63

American-Lincoln 1-3

A TS 46/53

T ABLE OF CONTENTS

FRONT WHEEL ..............................................................................................................................................2-64

WHEEL WELL FLAP ..................................................................................................................................... 2-65

REAR WHEEL ASSEMBLY........................................................................................................................... 2-66

BRAKE PEDAL .............................................................................................................................................. 2-68

FORWARD/REVERSE CONTROL - BATTERY............................................................................................ 2-70

FORWARD/REVERSE CONTROL - GAS/LP/DIESEL ................................................................................. 2-72

FRAME ........................................................................................................................................................... 2-74

SAFETY ARM ................................................................................................................................................. 2-75

STEERING COLUMN ..................................................................................................................................... 2-76

VAC FAN - BATTERY .................................................................................................................................... 2-78

VAC FAN - GAS/LP/DIESEL......................................................................................................................... 2-79

VAC MOTOR MANIFOLD (BATTERY) .......................................................................................................... 2-80

VAC MOTOR MANIFOLD (GAS.LP/DIESEL) ...............................................................................................2-82

FILTER SHAKER ............................................................................................................................................2-84

SEAT & FLOOR ASSEMBLY ....................................................................................................................... 2-86

PUMP ASSEMBLY, WHEEL DRIVE - BATTERY ......................................................................................... 2-88

HYDRAULIC TUBES ................................................................................................................ ...................... 2-92

HYDRAULICS MAIN BROOM ........................................................................................................................ 2-93

HYDRAULIC HOSE DIAGRAM - GAS/LP/DIESEL .....................................................................................2-94

HYDRAULIC SCHEMATIC (GAS/LP/DIESEL) .............................................................................................. 2-95

HYDRAULIC SCHEMATIC (BATTERY).......................................................................................................... 2-95A

HYDRAULIC HOSE DIAGRAM - BATTERY.................................................................................................2-96

SIDE BROOM HYDRAULICS ........................................................................................................................ 2-98

HOPPER LIFT HYDRAULICS ........................................................................................................................ 2-99

HOPPER DUMP DOOR HYDRAULICS ........................................................................................................ 2-100

HOPPER CONTROL CHECK VALVE HYDRAULICS - GAS/LP/DIESEL .................................................... 2-101

SCRUB DECK HYDRAULICS ........................................................................................................................ 2-102

SCRUB DECK LIFT HYDRAULICS - BATTERY............................................................................................ 2-103

SCRUB DECK LIFT HYDRAULICS - GAS/LP/DIESEL ................................................................................ 2-104

SQUEEGEE LIFT HYDRAULICS ................................................................................................................... 2-105

HYDRAULIC RESERVOIR - BATTERY ......................................................................................................... 2-106

HYDRAULIC RESERVOIR (PISTON PUMP) ................................................................................................ 2-108

DRIVE WHEEL HYDRAULICS ..................................................................................................................... 2-110

HYDRAULIC PUMP - GAS/LP/DIESEL ........................................................................................................ 2-112

HYDRAULIC MAIN CONTROL VALVE - GAS/LP/DIESEL ........................................................................... 2-114

HYDRAULIC CYLINDER CONTROL VALVE - GAS/LP/DIESEL .................................................................. 2-116

HYDRAULIC RETURN BLOCK ...................................................................................................................... 2-118

VAC FAN HOPPER HYDRAULICS ............................................................................................................... 2-120

STEERING 90º - 90º HYDRAULICS .............................................................................................................. 2-121

ENGINE COVERS - BATTERY...................................................................................................................... 2-122

ENGINE COVERS - GAS/LP/DIESEL .......................................................................................................... 2-124

FORD 416EFI GAS ENGINE - HARDWARE ................................................................................................ 2-126

FORD 416EFI GAS ENGINE - AIR INTAKE, EXHAUST ............................................................................... 2-128

FORD 416EFI GAS ENGINE - FUEL SYTEM ............................................................................................... 2-130

FUEL TANK - GAS ......................................................................................................................................... 2-132

FORD 416EFI ENGINE (GAS & LP) - RADIATOR & HOSES ...................................................................... 2-134

FORD 416EFI ENGINE (GAS & LP) - FUEL COMPUTER & OIL FILTER.................................................... 2-136

FORD 416EFI LP ENGINE - FUEL SYTEM .................................................................................................. 2-138

FUEL TANK - LP ............................................................................................................................................ 2-140

FORD 416EFI LP ENGINE - AIR INTAKE, EXHAUST................................................................................... 2-144

FORD 416EFI LP ENGINE - HARDWARE .................................................................................................... 2-146

MITSUBISHI S4L2 DIESEL ENGINE - HARDWARE .................................................................................... 2-148

MITSUBISHI S4L2 DIESEL ENGINE - FUEL SYSTEM................................................................................ 2-150

MITSUBISHI S4L2 DIESEL ENGINE - THROTTLE ASSY............................................................................. 2-152

FUEL TANK - DIESEL .................................................................................................................................... 2-154

MITSUBISHI S4L2 DIESEL ENGINE - RADIATOR, FAN .............................................................................. 2-156

MITSUBISHI S4L2 DIESEL ENGINE - AIR CLEANER .................................................................................. 2-158

MITSUBISHI S4L2 DIESEL ENGINE - EXHAUST SYSTEM ........................................................................2-159

ELECTRICAL ASSEMBLY - BATTERY ......................................................................................................... 2-160

1-4 American-Lincoln

A TS 46/53

T ABLE OF CONTENTS

BATTERY ELECTRICAL ASSEMBLY - GAS/LP ........................................................................................... 2-162

BATTERY ELECTRICAL ASSEMBLY - DIESEL ........................................................................................... 2-163

DECALS ......................................................................................................................................................... 2-164

CONSOLE ASSEMBLY ................................................................................................................................. 2-167

INSTRUMENT PANEL CONNECTION DRAWING - BATTERY .................................................................... 2-168

INSTRUMENT PANEL CONNECTION DRAWING - GAS/LP/DIESEL ......................................................... 2-169

ELECTRICAL SCHEMATIC - BATTERY ........................................................................................................ 2-170

ELECTRICAL SCHEMATIC - GAS/LP/DIESEL ............................................................................................. 2-171

MACHINE CONNECTION DIAGRAM BATTERY ...........................................................................................2-172

HARNESS ROUTING - BATTERY ................................................................................................................. 2-173

MACHINE CONNECTION DIAGRAM GAS/LP/DIESEL................................................................................2-174

HARNESS ROUTING - GAS/LP/DIESEL ...................................................................................................... 2-175

FORD 416EFI ENGINE HARNESS ............................................................................................................... 2-176

MITSUBISHI S4L2 DIESEL ENGINE HARNESS .......................................................................................... 2-177

FLOOR PANEL CONNECTION DIAGRAM - GAS/LP/DIESEL .................................................................... 2-178

FLOOR PANEL CONNECTION DIAGRAM - BATTERY................................................................................2-179

POWER PANEL CONNECTION DIAGRAM - BATTERY.............................................................................. 2-180

CHAPTER 3 OPTIONS .................................................................................................................................. 3-3

ROLL-OUT BATTERY (800 AH OPTION).......................................................................................................3-3

BRUSHES OPTION ........................................................................................................................................ 3-4

HOPPER THERMO-SENSOR SHUTDOWN OPTION .................................................................................. 3-6

BACK-UP ALARM OPTION ...........................................................................................................................3-8

REAR WORK LIGHT OPTION ....................................................................................................................... 3-10

OVERHEAD GUARD OPTION ....................................................................................................................... 3-11

AMBER SAFETY LIGHT OPTION WITH OVERHEAD GUARD ................................................................... 3-12

AMBER SAFETY LIGHT OPTION WITHOUT OVERHEAD GUARD............................................................ 3-13

ESP/AUTOFIL OPTION .................................................................................................................................. 3-14

ESP/AUTOFIL WIRING - BATTERY .............................................................................................................. 3-20

ESP/ AUTOFIL WIRING - GAS...................................................................................................................... 3-22

FIRE EXTINGUISHER ....................................................................................................................................3-24

CLOGGED FILTER OPTION .......................................................................................................................... 3-26

SPRAY WAND OPTION ................................................................................................................................3-28

WET SWEEP BYPASS/THERMO SENSOR OPTION.................................................................................3-32

RETRACTABLE SEATBELT OPTION ............................................................................................................ 3-36

RETRACTABLE SEATBELT OPTION (LP ONLY) ......................................................................................... 3-37

SUSPENSION SEAT OPTION ....................................................................................................................... 3-38

SEAT SWITCH KIT ......................................................................................................................................... 3-39

PAD DRIVER OPTION (16") .......................................................................................................................... 3-40

PAD DRIVER OPTION (18") .......................................................................................................................... 3-41

OIL COOLER OPTION ................................................................................................................................... 3-42

VACUUM WAND OPTION ............................................................................................................................. 3-43

VAC HOSE SERVICE KIT ............................................................................................................................. 3-44

SPARE PARTS LIST - SC7750 MACHINE .................................................................................................... 3-45

SPARE PARTS LIST - SC7750 MACHINE .................................................................................................... 3-46

SPARE PARTS LIST - SC7750 BATTERY MACHINE .................................................................................. 3-47

SPARE PARTS LIST - SC7750 BATTERY MACHINE .................................................................................. 3-48

SPARE PARTS LIST - GAS/LP/DIESEL MACHINE ..................................................................................... 3-49

WARRANTY ................................................................................................................................................... 3-50

American-Lincoln 1-5

A TS 46/53

SPECIFICATIONS

CLEANING P ATH

Scrubbing 46 Inches (1 16.84 cm) or 53” (134.62cm)

Sweeping 60 Inches (152.40 cm) V ariable Dump

Edge Cleaning 6 Inches (15.24 cm) Right Side 53 Inches

(134.62 cm) Only

TRAVEL SPEED 0-6 MPH

STEERING Rack & Pinion 90°-90° Hydraulic Power

Steering

Adjustable S teering Column

TURNING RADIUS

Left 74.5 Inches (189.23 cm)

Right 74.5 Inches (189.23 cm)

Aisle “U” Turn 1 10.0 Inches (279.40 cm)

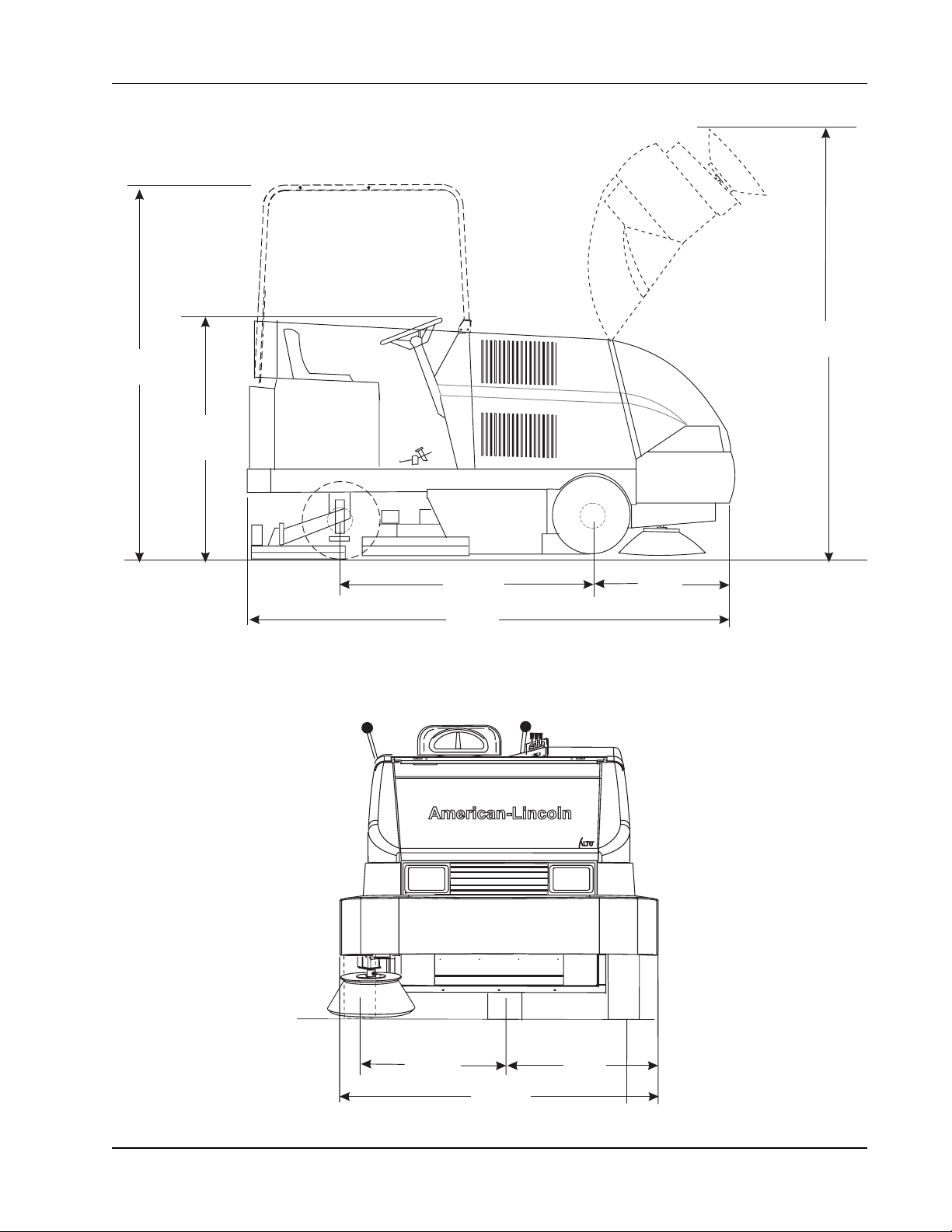

DIMENSIONS

Length 102.5 Inches (265.43 cm)

Width 55.0 Inches (132.08 cm)

Height 55.5 Inches (140.97 cm)

Height w/ Overhead Guard 78.75 Inches (197.49 cm)

Wheel Base 50.8 Inches (128.90 cm)

WEIGHT

Standard Machine (Gas) 2900 lbs. (1305.0 Kg)

Standard Machine (Battery) 2600 lbs. (1 170.0 Kg) Less Battery

TIRES

Type, Gas Solid Rubber (Front & Rear)

Front, Battery (Urethane) Two (2) 16” (41cm) x 3.75” (8.26 cm)

Rear One (1) 16” (41 cm) x 4.00” (10.16 cm)

RAMP CLIMBING

Sweeping 6 Degrees (Gas, LP , Diesel); 3 Degrees (Batt.)

Transporting 8 Degrees (Gas, LP, Diesel); 6 Degrees (Batt.)

ENGINE DAT A

Ford TSG416 EFI Engine

Bore and S troke 3.23” x 2.97” (82.1 mm x 75.5 mm)

Oil Capacity 4.4 quarts (4.2 liters)

Displacement 4 cylinders, 1.6 liters (97.5 CID)

Fuel 87 A.K.I. (S tandard unleaded)

ASI grade HD-5 for LP versions

Mitsubishi S4L2 Diesel

Bore and S troke 3.07” x 3.62” (78 x 92 mm)

Oil Capacity 5.6 quarts (5.4 liters) - w/standard oil pan

Displacement 4 cylinders, 1.8 liters (107.3 cu. in.)

Fuel ASTM No. 2-D

1-6 American-Lincoln

A TS 46/53

SPECIFICATIONS

MAIN BROOM

One-piece plastic core disposable type. Broom position can be set to “restricted down” or

“free floating.”

Length 45 Inches (1 14 cm)

Diameter 14 Inches (35.6 cm)

Bristle Length 3.25 Inches (8.26 cm)

Optional Bristle T ype Nylo n (H erringbone) Proex and Wire

High Density Nylon Poly and Wire

Main Broom Lift Hard Linkage

Main Broom Arms Patented (No-T ool Broom Change)

SIDE BROOM

Side Broom Size 21 Inch (53.34 cm) Diameter

Side Broom Bracket Swing Away Shock Mount

Side Broom Lift Cable

INSTRUMENTS AND CONTROLS

Fuel Gauge Main Broom Lever (Activates Immediately when lowered)

Key Switch Rectangular Hour Meter

Headlight/Taillight Switch Side Broom Lever (Activates Immediately when lowered)

2-Position Throttle Switch Engine Oil Pressure Light

Squeegee Switch Recovery High Light

Scrub Deck Switch Clogged Filter Light (OPTION)

Scrub Deck Heavy Load Switch (Gas, Diesel) Horn Button

Hopper T emperature Light (OPTION) Glow Plug (Diesel)

Solution Low Light Solution Control

Coolant T emperature Light Hopper Up/Down

Charging System Light (Gas, Diesel) Dump Door Open/Closed

Check Engine Light (Gas, LP) Filter Shaker Switch

Dust Control Switch (Battery)

SCRUBBING SYSTEM

Brush Size-46” Three (3) 16” (40.64 cm) Diameter Brushes

Brush Size-53” Three (3) 17.88” (45.42 cm)

Diameter Brushes

Brush Drive Hydraulic Motors, Off in Neutral

(after 2 second delay)

Brush Drive Lift Hydraulic Cylinder

Ground Clearance

Scrub Load 250 lbs. (1 12.50 Kg) or 400 lbs. (180.0 Kg)

SQUEEGEE

V acuum/Squeegee 55.5 Inch (140.97 cm) Wide Swing,

Gum Rubber Outer Blade

Side Squeegees (2) Patented Configuration

Squeegee Lift Cylinder and Cable, Auto Lift in Reverse

Squeegee Hose 2 Inch (5.08 cm) Diameter

T ANKS

Solution T ank 70 Gallon (264.96 Liters) Polyethylene

Recovery T ank 70 Gallon (264.96 Liters) Polyethylene

Solution Metering V ariable to 3.0 GPM

American-Lincoln 1-7

A TS 46/53

SPECIFICATIONS

HOPPER

Capacity 10 Cubic Feet (.2832 Cubic Meters),

700 lbs. (315 Kg)

Dump and Lift Variable Dump with Dump Door

Filter 78 Sq. Ft. (72,464 Sq. Cm)

Dump Height 60-Inch (152.40 cm) V ariable Dump;

Reach Into Dumpster 1 1 Inches (27.94 cm)

SYSTEM FLUID CAP ACITIES

Fuel T ank 10.0 Gallons (37.95 Liters)

Hydraulic System(Gas, LP , Diesel) 9.0 Gallons (34.07 Liters)

Swing Out for Service (Gas, LP , Diesel)

Hydraulic System (Battery) 4.0 Gallons (15.16 Liters)

OPTIONAL EQUIPMENT

Seat Belt Back Up Alarm

Wet Sweep Bypass/Thermo-Sensor Push-Pull Light Switch (Work Light/V ariable Dump Only)

Amber Safety Light Headlight/T aillight Switch

ESP & Autofil Recycling System Overhead Guard

Pad Drivers Non-Marking Tires

Oil Cooler (Gas Only) Scrub Brushes

46” Scrub Option (Field-Installed) (Gas ) 53” Scrub Option (Field-Installed) (Gas)

Spray W and Option V acuum Wand Option

Fire Extinguisher Clogged Filter

Roll-Out Battery (Battery Only)

WARRANTY

Our general conditions of business are applicable with regard to the guarantee. Subject to change as a

result of technical advances. The guarantee is invalidated if the machine is not operated in accordance

with these instructions or otherwise abused. The guarantee is invalidated if the machine is not serviced as

described.

MACHINE DAT A

R

MACHINE NAME

MODEL

WEIGHT

IP X3

L

DATE / SERIAL NUMBER

RATED POWER

MAX OPERATING SLOPE

WA

B

1-8 American-Lincoln

A TS 46/53

78.75“

200.025 cm

52“

143.5 cm

SC7750

American-Lincoln®

MACHINE DIMENSIONS

85.5“

217.17 cm

50.8“

129.03 cm

102.5“

260.35 cm

27.0“

68.60 cm

C1694d/0402

25.75“

65.41 cm

55.5“

140.97 cm

25.75“

65.41 cm

American-Lincoln 1-9

A TS 46/53

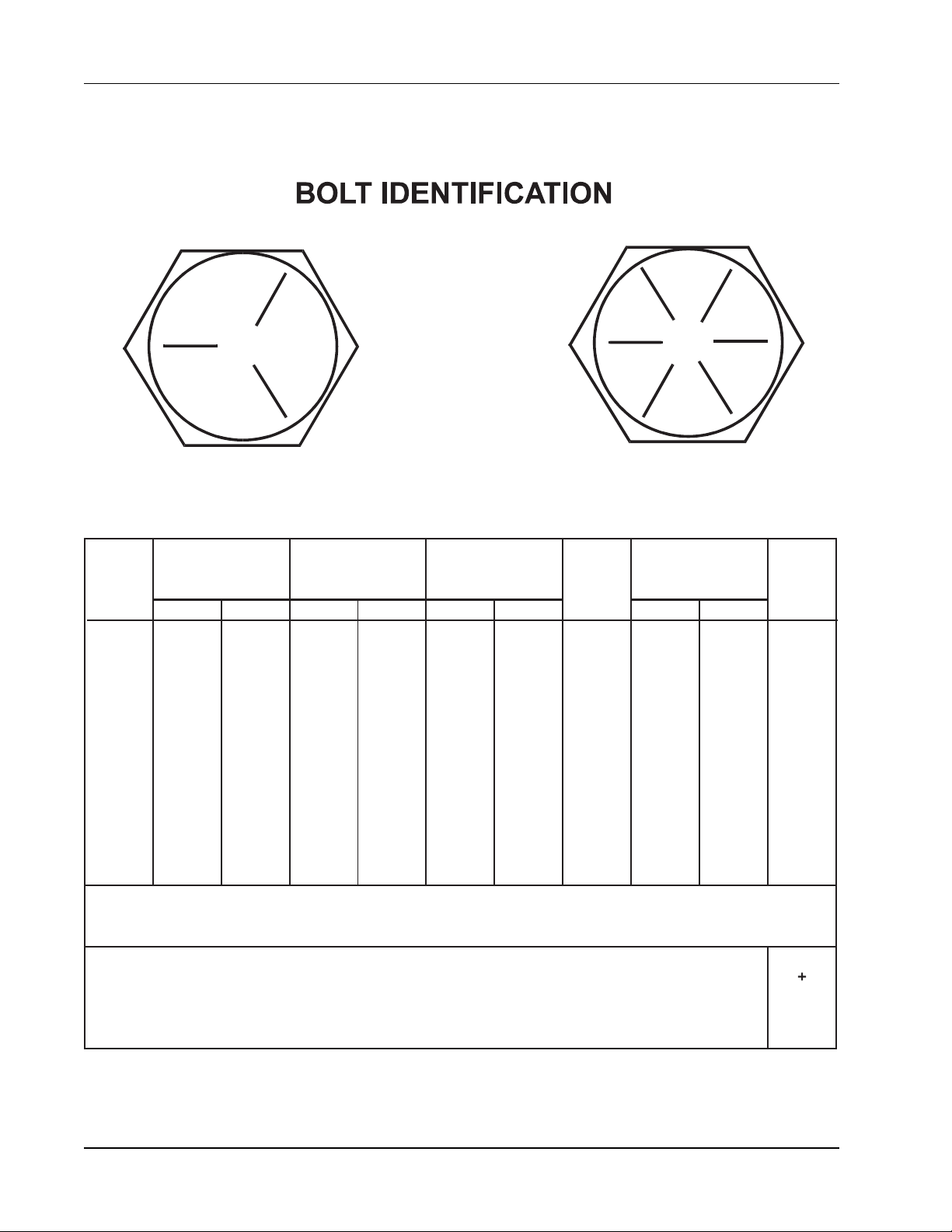

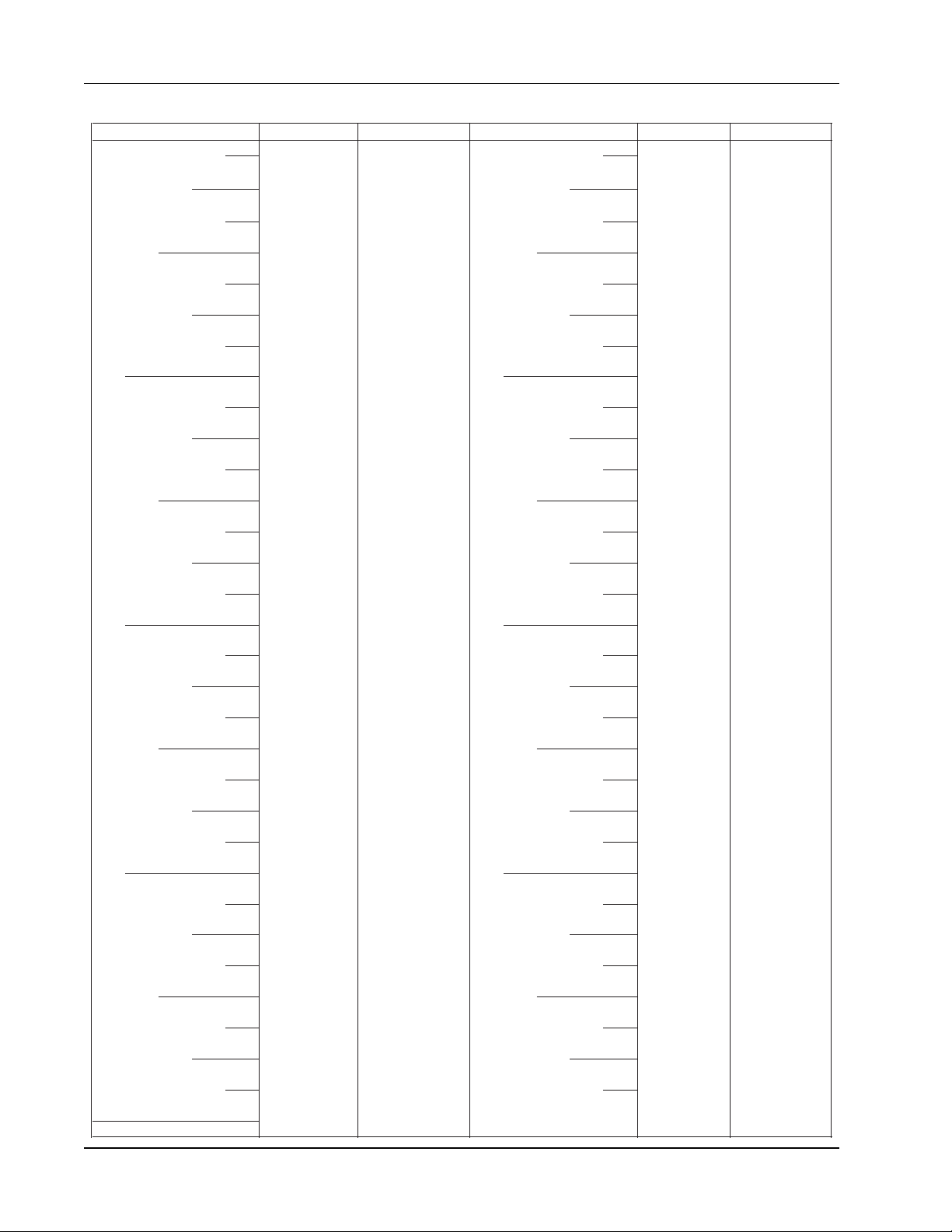

ST ANDARD HARDWARE & TORQUE VALUES

SAE - Grade 5

C

14

27

39

86

15

28

44

68

98

135

239

387

579

Grade

5

Plated

Grade

8

Plated

FFF

15

28

43

108

17

31

49

76

110

153

267

-

-

C

-

-

-

130

22

40

63

95

138

191

338

545

818

-

-

-

151

24

44

70

108

155

216

378

-

-

410H

Stainless

C

18

33

47

114

19

34

55

85

-

-

-

-

-

20

35

54

132

22

39

62

95

-

-

-

-

-

Screw

Size

*6

*8

*10

*1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

C = Coarse Thread

F = Fine Thread

* = Torque values for #6 through 1/4 are lb./in. All others are lb./ft.

Brass

5

9

13

32

6

10

16

-

-

-

-

-

-

SAE - Grade 8

Type

F&T

&BT

C

20

37

49

120

-

-

-

-

-

-

-

-

-

F

23

41

64

156

-

-

-

-

-

-

-

-

-

Type

B, AB

21

34

49

120

-

-

-

-

-

-

-

-

-

NOTE

Decrease the torque by 20% when using thread lubricant

The torque tolerance is ± on torque values.

C2000/9905

1-10 American-Lincoln

A TS 46/53

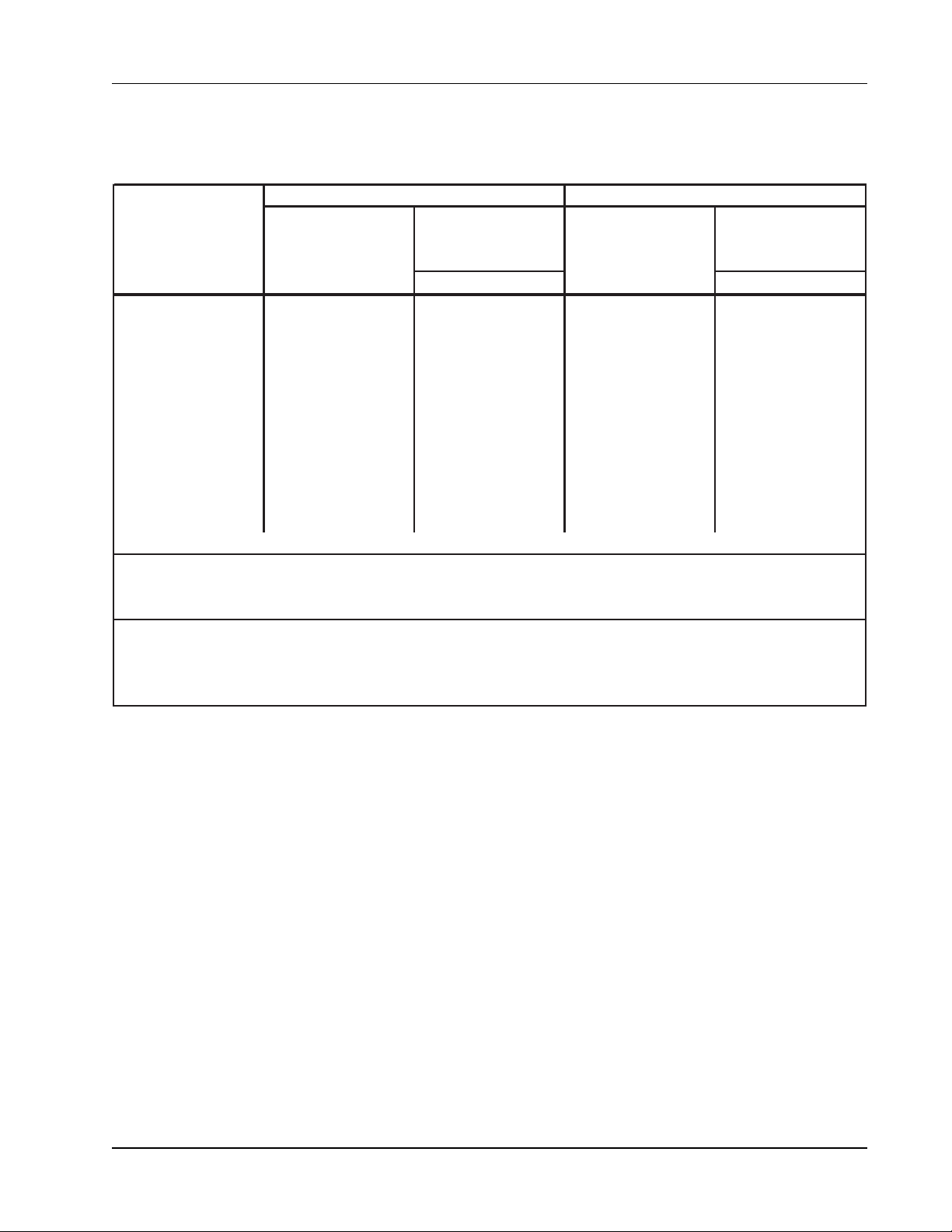

HYDRAULIC TORQUE REQUIREMENTS

HYDRAULIC TORQUE REQUIREMENTS

Refer to the following chart for torque values on all hydraulic hoses and fittings.

Nominal O-Ring Face Seal End SAE O-Ring Boss End

SAE Thread Swivel Thread Str. Fitting

Dash Size Nut Size or Locknut

Size Inch Torque Inch Torque

LB-FT LB-FT

-3 * * 3/8-24 8-10

-4 9/16-18 10-12 7-16-20 14-16

-5 * * 1/2-20 18-20

-6 11/16-16 18-20 9/16-18 24-25

-8 13/16-16 32-35 3/4-16 50-60

-10 1-14 46-50 7/8-14 72-80

-12 1 3/16-12 65-70 1 1/16-12 125-135

-14 1 3/16-12 65-70 1 3/16-12 160-180

-16 1 7-16-12 92-100 1 5/16-12 200-220

-20 1 11/16-12 125-140 1 5/8-12 210-280

-24 2-12 150-165 1 7/8-12 270-360

* O-Ring face seal type end not defined for this tube size.

NOTE

Parts must be lightly oiled with hydraulic fluid.

C-2002

American-Lincoln 1-11

A TS 46/53

DECIMAL-METRIC CONVERSION T ABLE

DECIMAL-METRIC CONVERSION TABLE

Fraction Decimal Millimeter Fraction Decimal Millimeter

1 0.015625 0.3969 33 0.515625 13.0969

64 64

1 0.03125 0.7938 17 0.53125 13.4938

32 32

3 0.046875 1.1906 35 0.546875 13.8906

1 0.0625 1.5875 9 0.5625 14.2875

16 16

1 0.125 3.1750 5 0.625 15.8750

8 8

3 0.1875 4.7625 11 0.6875 17.4625

16 16

1 0.25 6.3500 3 0.75 19.0500

4 4

5 0.3125 7.9375 13 0.8125 20.6375

16 16

3 0.375 9.5250 7 0.875 22.2250

8 8

7 0.4375 11.1125 15 0.9375 23.8125

16 16

1 0.5 12.7000 1 1.0000 25.4000

2

C-2001

1-12 American-Lincoln

64 64

5 0.078125 1.9844 37 0.578125 14.6844

64 64

3 0.09375 2.3813 19 0.59375 15.0813

32 32

7 0.109375 2.7781 39 0.609375 15.4781

64 64

9 0.140625 3.5719 41 0.640625 16.2719

64 64

5 0.15625 3.9688 21 0.65625 16.6688

32 32

11 0.171875 4.3656 43 0.671875 17.0656

64 64

13 0.203125 5.1594 45 0.703125 17.8594

64 64

7 0.21875 5.5563 23 0.71875 18.2563

32 32

15 0.234375 5.9531 47 0.734375 18.6531

64 64

17 0.265625 6.7469 49 0.765625 19.4469

64 64

9 0.28125 7.1438 25 0.78125 19.8438

32 32

19 0.296875 7.5406 51 0.796875 20.2406

64 64

21 0.328125 8.3344 53 0.828125 21.0344

64 64

11 0.34375 8.7313 27 0.84375 21.4313

32 32

23 0.359375 9.1281 55 0.859375 21.8281

64 64

25 0.390625 9.9219 57 0.890625 22.6219

64 64

13 0.40625 10.3188 29 0.90625 23.0188

32 32

27 0.421875 10.7156 59 0.921875 23.4156

64 64

29 0.453125 11.5094 61 0.953125 24.2094

64 64

15 0.46875 11.9063 31 0.96875 24.6063

32 32

31 0.484375 12.3031 63 0.984375 25.0031

64 64

A TS 46/53

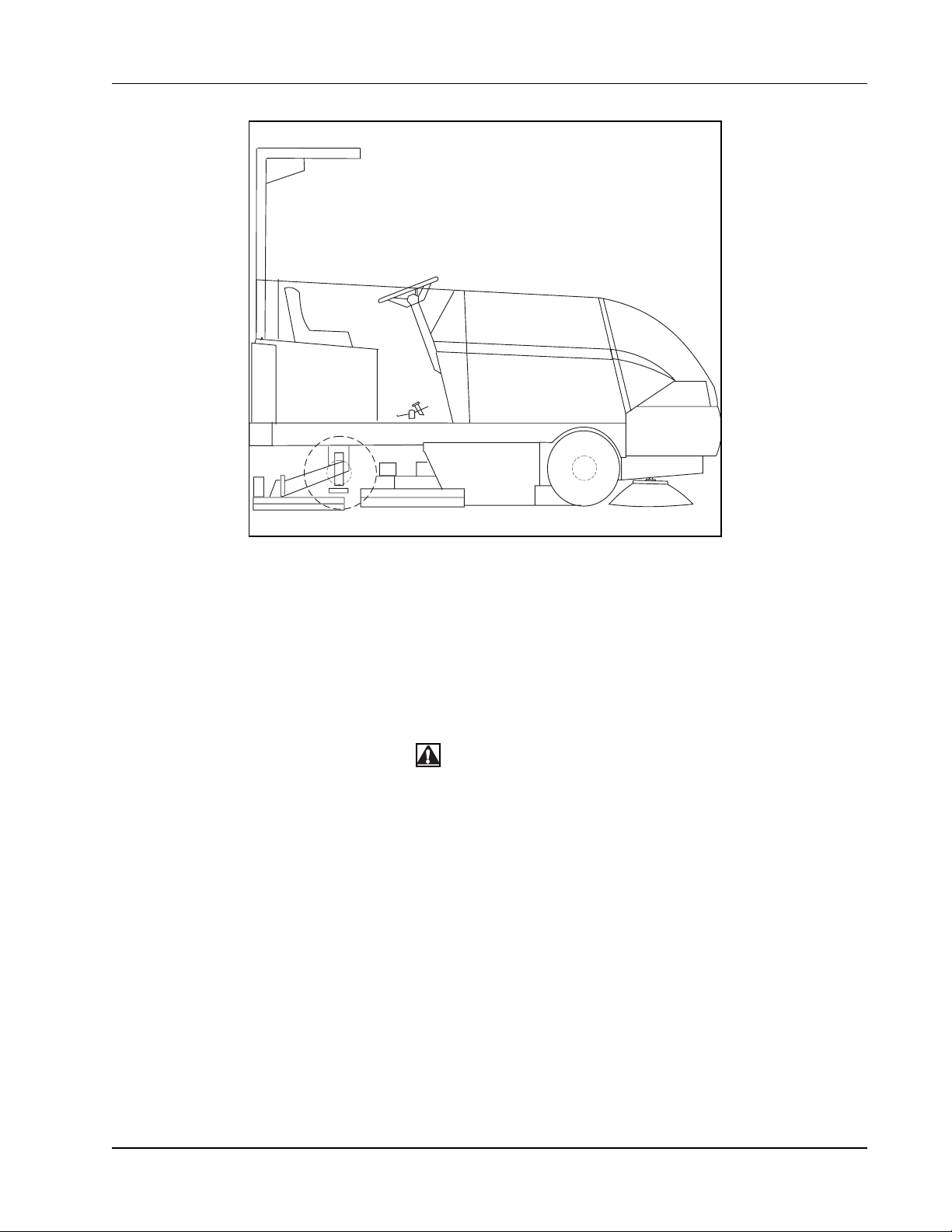

MACHINE PREP ARA TION

SC7750

American-Lincoln

®

C1694c FIGURE 1

YOUR ATS 46/53 MACHINE HAS BEEN SHIPPED COMPLETE, BUT DO NOT A TTEMPT TO OPERA TE

WITHOUT FOLLOWING THESE INSTRUCTIONS.

PREP ARING THE MACHINE FOR OPERA TION (IC Engine Powered)

1. Connect and tighten battery cables.

2. Fill the tank with REGULAR GRADE gasoline. (Diesel fuel if equipped with diesel engine.)

WARNING

Never fill the tank while the engine is running. Always be sure the gasoline container and sweeper are electri-

cally connected before pouring gasoline. This can easily be done by providing an insulated wire (permanently

attached to container) with a battery clip on the other end.

3. Check engine crankcase oil level. Although properly lubricated at the factory, check before starting the

engine. No special break in oil is used and recommended number of operating hours before the initial oil

change is the same as normal. See Maintenance.

4. Check radiator coolant level. Permanent type antifreeze is added at the factory to provide protection to

approximately -35°F (37°C). To retain this protection level, always add ½ part water to ½ part antifreeze.

5. Check oil level in the hydraulic reservoir located at the center of the machine beside the engine. The oil

fill level should be halfway on sight glass. If oil is needed, add HYDRAULIC FLUID ONL Y, automatic

transmission fluid FORD type “F.” After the first 50 operating hours, service must be performed on your

engine to ensure future high performance and trouble free operation. See Maintenance.

NOTE

After the first 50 operating hours, service must be performed on your engine to ensure

future high performance and trouble free operation. See Maintenance.

American-Lincoln 1-13

A TS 46/53

MACHINE PREP ARATION - BATTER Y

BA TTERY -POWERED MACHINES

*Uncrate the machine and carefully remove from skid to prevent damage.

*The A TS 46/53 machines that are shipped without batteries have the (+) positive drive motor lead discon

nected.

*Open the battery compartment and connect the (+) positive motor lead to the top terminal post (the wire

“P” is also attached to it). T ighten the terminal nut.

*Install the scrub brushes.

*Check the oil level in the hydraulic reservoir

*Install batteries as follows (if not included):

1. Turn the key to the “OFF” position.

2. Raise the Solution Cover to the open position.

3. Use a battery lifting device with a 2500 lbs. (1 150 Kg) cap acity hoist to lift the battery.

4. Using the lifting device, lower the 36 volt battery into the battery compartment directly in front of the

driver’s compartment. Orient the cables & plug them in as required.

5. Plug the polarized connector from the battery into the 36 volt plug provided.

WARNING

Hydrogen gas is formed during the charging operation and is explosive! Only charge batteries in a well-venti-

lated area with the lid open. Avoid any open flame or electrical sparks. Pulling out the charger plug with the timer

on will cause an arc and must be avoided.

1-14 American-Lincoln

A TS 46/53

SAFETY INSTRUCTIONS

THE FOLLOWING ST A TEMENTS ARE USED THROUGHOUT THIS MANUAL AS INIDICA TED IN THEIR

DESCRIPTIONS:

DANGER

To warn of immediate hazards which will result in severe personal injury or death.

WARNING

To warn of hazards or unsafe practices which could result in severe personal injury or death.

CAUTION

T o warn of hazards or unsafe practices which could result in minor personal injury .

A TTENTION

T o warn of unsafe practices which could result in extensive equipment damage.

NOTE

To give important information or to warn of unsafe practices which could result in equipment damage.

WARNING

THE FOLLOWING INFORMATION SIGNALS POTENTIALLY DANGEROUS CONDITIONS TO THE OPERATOR OR

EQUIPMENT. READ THIS MANUAL CAREFULLY. KNOW WHEN THESE CONDITIONS CAN EXIST. THEN, T AKE

NECESSARY STEPS T O TRAIN MACHINE OPERATING PERSONNEL. FOR THE SAFE OPERATION OF THIS

MACHINE, READ AND UNDERST AND ALL WARNINGS, CAUTIONS AND NOTES.

WARNING

Machines can ignite flammable materials and vapors. Do not use with or near flammables such as gasoline,

grain dust, solvents, and thinners.

WARNING

Heavy machinery. Improper use can cause personal injury.

WARNING

Operate only when lids, doors, and access panels are securely closed.

WARNING

Use care when reversing machine in confined area.

WARNING

When servicing the machine, disconnect the batteries first to prevent possible injury.

WARNING

When working on the machine, empty hopper, remove batteries, clear area of people and obstructions, use

additional people and proper procedures when lifting the machine.

WARNING

Always empty the hopper and disconnect the battery before doing maintenance.

WARNING

You must have training in the operation of this machine before using it.

READ THE INSTRUCTION BOOK.

WARNING

Do not operate this machine unless it is completely assembled.

WARNING

Do not use this machine as a step or furniture.

American-Lincoln 1-15

A TS 46/53

SAFETY INSTRUCTIONS

WARNING

Stop and leave this machine on a level surface. When you stop the machine, put the power switch in the “OFF”

position and engage the Wheel Lock.

WARNING

To prevent injury and damage to the machine, do not lif t the machine or move it to an edge of a st air or loading

dock.

WARNING

Lead acid batteries generate gases, which can cause an explosion. Keep sparks and flames away from batteries.

NO SMOKING . Charge batteries only in areas with good ventilation.

WARNING

Always wear eye protection and protective clothing when working near batteries. Remove all jewelry . Do not put

tools or other metal objects across the battery terminals or across the tops of batteries.

WARNING

Authorized personnel must do maintenance and repairs only. Tighten all fasteners. Maintain adjustments

according to the specifications given in the service manual for the machine. Keep the electrical parts of the

machine dry. For storage, keep the machine in a building.

WARNING

Make sure all labels, decals, warnings, cautions and instructions are fastened to the machine. Purchase new

labels and decals from American-Lincoln.

WARNING

The operator must exhibit extreme caution when negotiating, turning, and traveling across grades or ramps.

Start, stop, change direction, travel and brake smoothly. Slow down when turning.

WARNING

Avoid uneven surfaces and loose materials. Watch for obstructions, especially overhead.

WARNING

Operate only from the designated operator’s position. Stay inside the body of the machine. Keep hands and feet

on the designated controls. Always operate in well-lighted areas.

WARNING

Do not carry passengers on the machine. Set the Wheel Lock when leaving the machine. Chock (block) the

wheels if the machine is parked on a grade (ramp), or is being prepared for maintenance.

WARNING

Never leave the operator’s compartment when the engine is running.

WARNING

Report damage or faulty operation immediately. Do not operate the machine until repairs have been completed.

Authorized personnel must do maintenance and repairs only.

WARNING

To maintain the stability of this machine in normal operation, the overhead guard, counterweights, rear bumper

guard, or any similar equipment installed by the manufacturer, as original equipment should never be removed.

If it becomes necessary to remove such equipment for repair or maintenance, this equipment must be reinstalled

before the machine is placed back into operation.

1-16 American-Lincoln

A TS 46/53

SAFETY INSTRUCTIONS

WARNING

Electrical hazard. Shocks can cause serious personal injury. Unplug the battery before cleaning or servicing. To

avoid possible injury or property damage, read the Operator’s Manual before servicing the machine. Authorized

personnel must do maintenance and repairs.

WARNING

Disconnecting the battery connector with the key switch in the “I” position will cause sparks that could ignite

explosive hydrogen gas generated by the batteries. To prevent serious injury or possible property damage, turn

Key Switch to “O” position before disconnecting the battery cable from the machine for charging or service.

FOR SAFETY, OBSERVE THE FOLLOWING W ARNINGS. FAILURE TO COMPLY MAY CREATE A SERIOUS RISK OF INJURY T O YOU AND OTHERS. THIS MACHINE SHOULD NOT BE USED IN HAZARDOUS

LOCA TIONS INCLUDING AREAS OF VOLA TILE DUST OR V APOR CONCENTRA TIONS.

Operators must be trained and qualified to operate this machine. They must also understand the

operator’s manual before starting.

Use caution when mounting or dismounting the machine particularly on wet slippery surfaces.

Do not dump the hopper over an open pit or dock. Do not dump the hopper when positioned on a grade

(ramp). The machine must be level (horizontal).

American-Lincoln 1-17

A TS 46/53

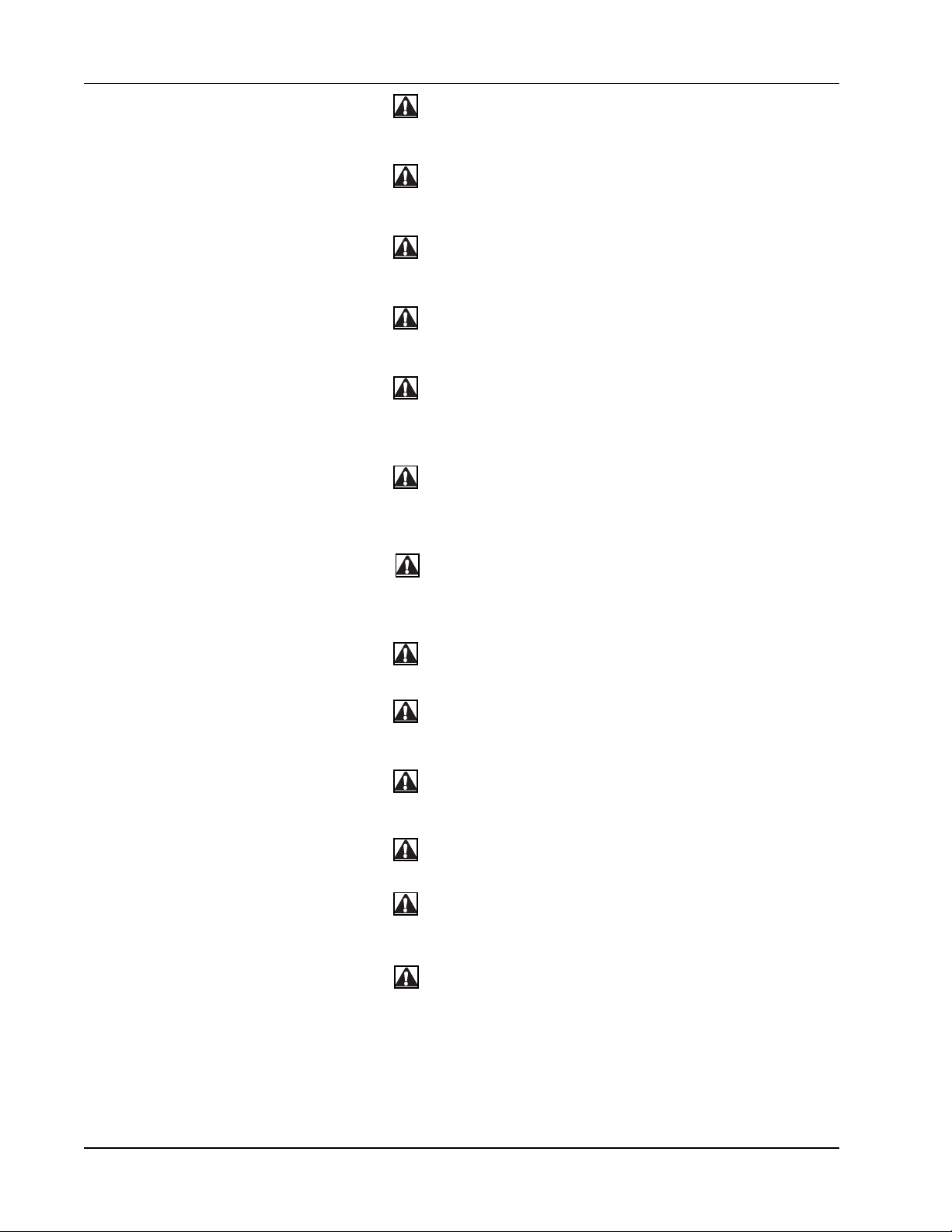

OPERA TION OF CONTROLS AND GAUGES

WET SWEEP

WARNING

BANK

MAIN

BROOM

LEVER

SCRUB DECK

HEAVY PRESSURE

SCRUB DECK

SWITCH

SQUEEGEE

SWITCH

HOPPER

LEVER

HOPPER

DOOR

LEVER

CHECK ENGINE

LIGHT(Gas/LP)

HORN BUTTON

SOLUTION

CONTROL

LEVER

MAIN

BROOM

ADJUSTMENT

THROTTLE

LEVER

(Diesel)

FUEL

GAUGE

HOUR

METER

LIGHT

SWITCH

CIRCUTBREAKERS

American-Lincoln

1/2

4/4

0

FUEL

BYPASS

(Option)

FILTER

SHAKER

SWITCH

WORK

LIGHT

(Option)

KEY

SWITCH

GLOW

PLUG

SWITCH

(Diesel Only)

SIDE

BROOM

LEVER

ENGINE

SPEED

SWITCH

(Gas/LP)

SIDE

BROOM

ADJUSTMENT

CIRCUIT

BREAKERS

(Gas/Diesel/LP)

FWD/REV

FOOT

PEDAL

FOOT

BRAKE

SEAT

ADJUSTMENT

PARKING

BRAKE

LEVER

P5034b-1ecp FIGURE 2

LIGHT SWITCH (See Figure 2)

The light switch is located above the horn button to the right of the steering wheel. It will work various light

options that are available for this machine, such as:

* HEAD LIGHTS

* TAIL LIGHTS

* INSTRUMENT LIGHTS

HORN BUTTON (See Figure 2)

The horn button is located on the left side console. Push the button with your finger to sound the horn. The

horn button is always active.

CHECK ENGINE LIGHT (Gas, LP Only) (See Figure 2)

The check engine light is located on the left side console. If the light comes on, it indicates a problem with the

engine. Flip the switch located on/near the air cleaner bracket in the engine compartment, count the number of

times the panel light flashes, then go to “Engine Check Light Codes” at the end of this chapter to determine the

problem.

1-18 American-Lincoln

A TS 46/53

OPERA TION OF CONTROLS AND GAUGES

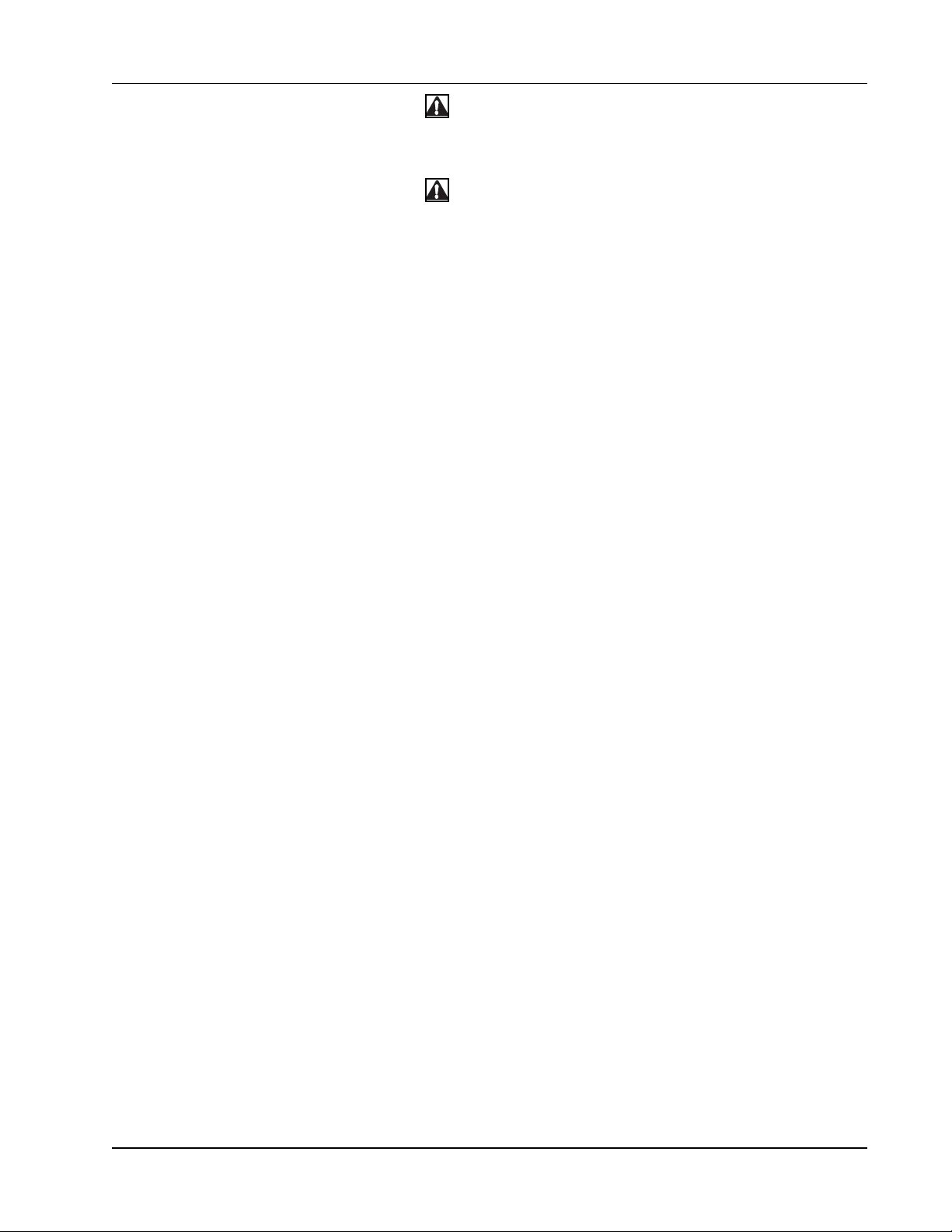

KEY

SWITCH

C1631A FIGURE 3

American-Lincoln

1/2

4/4

0

FUEL

ENGINE

SPEED

SWITCH

FUEL

GAUGE

KEY SWITCH (See Figure 3)

The keyed ignition switch is located on the instrument

panel to the left of the side broom lever . The key switch is

a two-position switch that controls power to the machine

systems and accessories.

The “OFF” position (O position) will shut off the engine.

The IGN/ON position (I position) provides power to all

machine systems and accessories.

The “START” position (one position clockwise of I position)

is momentary and provides power to the starter motor .

NOTE

To re-engage, the starter key must be returned to the “OFF”

position.

ENGINE SPEED SWITCH (Gas, LP) (See Figure 3)

A two-position switch controls the engine, which is located

on the instrument panel to the left of the side broom lever.

The switch position determines the governed operating

speed of the engine.

Place the speed switch in the “IDLE” position to start the

machine.

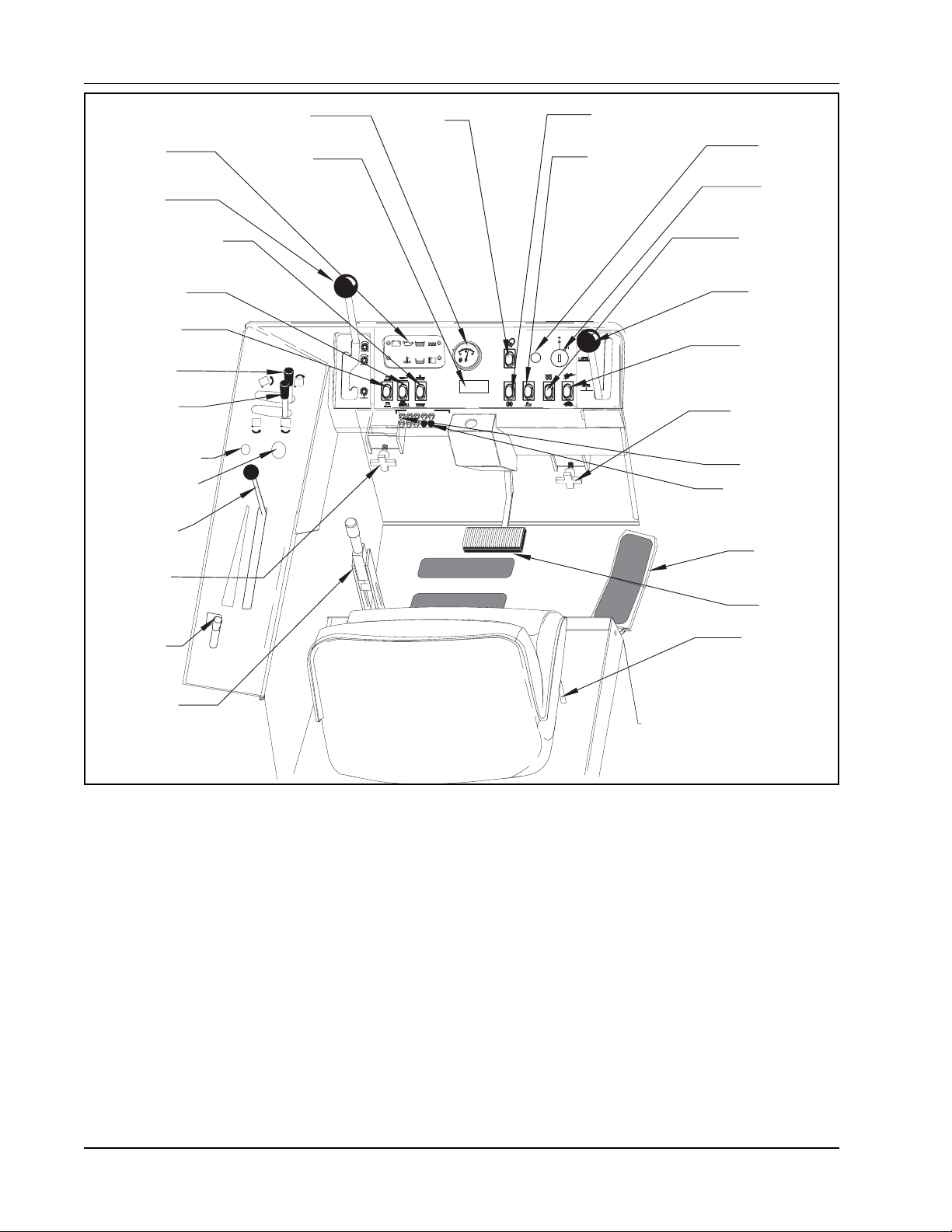

C1633 FIGURE 4

SEAT

POSITION

ADJUSTMENT

LEVER

C-0508a

TO

LOCK

TO ADJUST

C0508A-2 FIGURE 5

HOUR

METER

Place the speed switch in the “FAST” position for transport

and when normal sweeping action is desired.

HOUR METER (See Figure 4)

The hour meter is located on the instrument panel above

the engine speed switch. The meter is activated when the

engine begins running. The meter indicates the actual “run”

time of the machine. The meter can be used to determine

when maintenance should be done on the machine.

FUEL GAUGE (See Figure 4)

The fuel gauge is located on the instrument panel to the

right of the main broom lever and indicates the level of fuel

in the tank. The key switch powers the fuel gauge. The

key switch must be in the “ON” position for the fuel gauge

to work. The fuel gauge is not included on machines that

use Liquid Propane fuel.

SEA T POSITION ADJUSTMENT (See Figure 5)

The seat position adjustment lever is located on the right

side of the seat base. The lever is spring loaded to the

“LOCK” position.

T o adjust the seat, push “FORW ARD” on the lever and

move the seat to the desired position. Then release the

lever to “LOCK” the seat into place.

American-Lincoln 1-19

A TS 46/53

OPERA TION OF CONTROLS AND GAUGES

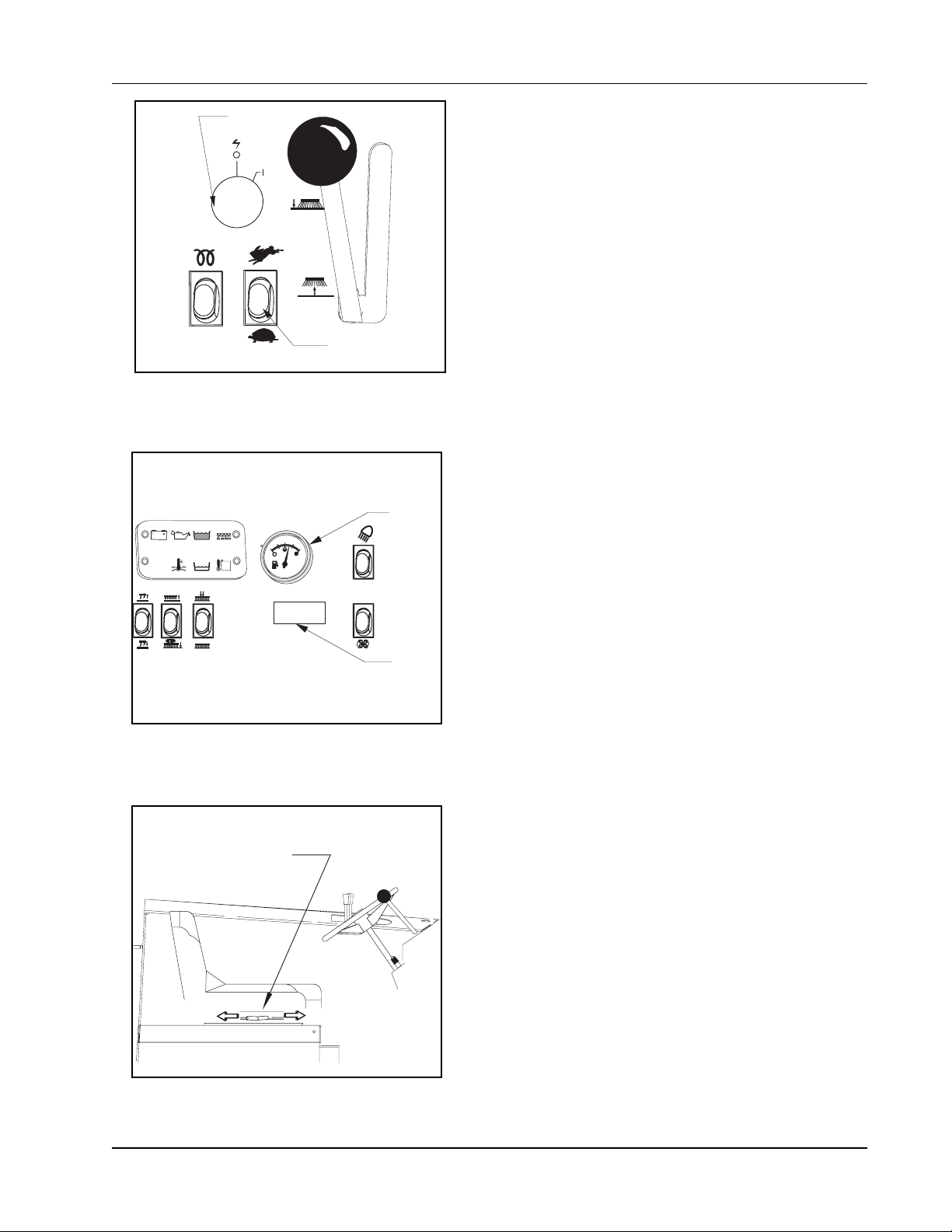

FIL TER SHAKER SWITCH (V ariable Dump Machines

Only) (See Figure 6)

The filter shaker switch is located on the instrument panel

below the ignition switch. This is a momentary switch that

will activate the filter shaker motors for 20 to 30 seconds to

clear the dust control filter. The Impeller fan will stop when

the filter shaker has been activated. The filter shaker will

only operate with the hopper in the “DOWN” position.

Use the filter shaker to clear the filter when the dust control

light comes on (warning bank) and just before dumping the

FILTER

SHAKER

SWITCH

C1640-2 FIGURE 6

GLOW

PLUG

SWITCH

hopper.

GLOW PLUG SWITCH (Diesel) (See Figure 6)

Under no circumstances should any other unauthorized

starting aids be used at the same time as Glow Plugs.

The Glow Plug Switch is located to the right of the steering

column on the front face of the instrument console. Use the

following procedure to operate.

1. Before operating the starter motor , press the “GLOW

2. With the “GLOW PLUG” switch still depressed, engage

3. Continue to press the “GLOW PLUG” switch for a few

4. If the engine does not start, disengage the starter motor ,

PLUG” switch for 20 to 30 seconds.

the starter motor until the engine starts.

seconds after the engine has started until even running

has been obtained.

but keepthe “GLOW PLUG” switch depressed for a

further 10 to15 seconds, when a further attempt should

be made to start the engine, keeping the Glow Plugs

energized while starting and for a few seconds after the

engine has fired until it is running smoothly .

SEA T COMP ARTMENT PROP LA TCH (See Figure 7)

C1699 FIGURE 7

The seat compartment latch is located under the seat

compartment cover and is used to hold the cover open.

T o hold the seat compartment cover open, lif t the cover and

rotate the latch.

HOPPER

SAFETY ARM

HOPPER SAFETY ARM (See Figure 8)

The hopper safety arm is located near the right front wheel

well. The safety arm will prevent the hopper from dropping

unexpectedly during service/maintenance.

WARNING

TO ENGAGE THE SAFETY ARM:

MODELNO. SERIALNO.

3

TO

ENGAGE

1. Empty hopper

2. Set the parking brake.

3. Raise the hopper.

4. Lift safety arm to engage the slot on the hopper frame.

C1700

5. When work has been completed, replace the safey arm

to the stowed position.

C1700 FIGURE 8

1-20 American-Lincoln

A TS 46/53

SIDE

BROOM

LEVER

SIDE

BROOM

ADJUSTMENT

OPERA TION OF CONTROLS AND GAUGES

SIDE BROOM LEVER (See Figure 9)

The Side Broom Lever is located to the right of the instrument console. The handle pulled back and turned to the

left, will raise the side broom and lock it into position.

T o raise the side broom pull the lever back into the “UP”

position.

T o lower the side broom, move the lever out of the “UP”

position and move it forward to the “DOWN” position.

NOTE

IF THE MAIN BROOM IS ENGAGED, THE SIDE BROOM WILL

AUTOMA TICALLY ENGAGE WHEN LOWERED.

SIDE BROOM ADJUSTMENT (See figure 9)

The side broom lever has an adjustment for changing the

sweep height to compensate for broom wear. The side

broom adjustment is located under the right side of the

instrument panel.

C1641 FIGURE 9

MAIN

BROOM

LEVER

CIRCUT BREAKERS

C1642-1 FIGURE 10

MAIN

BROOM

ADJUSTMENT

MAIN BROOM LEVER (See figure 10)

The main broom lever is located on the left side of the

instrument panel. The main broom lever has three positions and controls the main broom sweep height.

To lower the main broom, grasp the lever and move it to

the left out of the “UP” position, and place it in the

“SWEEP” or “FLOA T” position.

The “SWEEP” position is used for normal sweeping and

should be used under most sweeping conditions (approximately 2” broom pattern).

The “FLOA T” position is used for sweeping very uneven

surfaces only . Using the float position will cause premature

wear on the main broom if used under normal operating

conditions for extended periods of time (approximately 4”

broom pattern).

NOTE

The Main Broom will automatically engage when lowered to

the sweep position or the float position. The hopper must be

completely closed.

MAIN BROOM ADJUSTMENT (See Figure 10)

The main broom lever has an adjustment for changing the

sweep height to compensate for broom wear. The main

broom adjustment is located under the left side of the

instrument panel.

American-Lincoln 1-21

A TS 46/53

OPERA TION OF CONTROLS AND GAUGES

)

DUST CONTROL SWITCH (Wet Sweep Bypass Option Option for All Machines) (See Figure 11)

The Dust Control Switch is a two position switch located on

the instrument panel next to the filter shaker switch. The

switch controls the vacuum fan in the dust control system.

(Optional on I.C. Engine: St andard on Batt. Power)

T o turn on the dust control system for “NORMAL” sweeping,

press on the top portion of the switch. To turn off the dust

DUST

CONTROL

SWITCH

(Wet Sweep

Bypass

C1640-1 FIGURE 1 1

SCRUB DECK

SWITCH

control system for sweeping in wet conditions, press the

lower portion of the switch. This will prevent the filter from

being damaged by water pickup while sweeping.

SCRUB DECK SWITCH (See Figure 12)

The brushes switch is located on the console to the left of

the steering wheel in the “SCRUBBING” section. This switch

in the position marked “LOWER” will lower the scrub brush

deck and activate the three scrub brushes. The heavy

pressure switch cannot be activated unless this switch is in

the ”LOWER” position. This switch in the “RAISE” position

will stop the brushes from rotating and raise the scrub brush

deck

CIRCUT BREAKERS

C1642A FIGURE 12

SQUEEGEE

SWITCH

CIRCUT BREAKERS

SCRUB DECK

HEAVY

PRESSURE

NOTE

Lowering the scrub deck will not start the brushes rotating

the foot pedal must be moved to engage the scrub brushes. If

the machine stops moving for 2 seconds or more the

brushes will automatically stop rotating until the machine

starts moving again.

SCRUB DECK HEA VY PRESSURE SWITCH

(See Figure 12) (I.C. Machines Only)

The scrub deck heavy pressure switch is located on the

console to the left of the steering wheel in the “SCRUBBING” section. This switch applies additional downward

pressure to the scrub brushes. This switch has two positions down “NORMAL” and up ”HEA VY”. This switch cannot

be activated unless the scrub deck switch is in the

“LOWER” position, the switch will light when it can be

activated.

SQUEEGEE SWITCH (See Figure 13)

The squeegee blade switch is located on the console to the

left of the steering wheel in the “SCRUBBING” section. This

switch in the position marked “LOWER” will lower the

squeegee and activate the squeegee vacuum. This switch in

the “RAISE” position will stop the squeegee vacuum and

raise the squeegee. A switch activated by the forward-

reverse foot pedal will automatically raise the squeegee if it

is in the lowered position and the machine is in reverse.

The switch has a center position to raise the squeegee with

the vacuum in to allow vacuuming the water left on the

C1642B FIGURE 13

squeegee recovery hose. This prevents water from dripping

on the floor with the squeegee “UP .”

1-22 American-Lincoln

A TS 46/53

CIRCUTBREAKERS

0

1/2

4/4

FUEL

SOLUTION

CONTROL

C1716ecp

OPERA TION OF CONTROLS AND GAUGES

C1716ecp FIGURE 14

SOLUTION CONTROL (See Figure 14)

T o apply solution to the scrub brushes, pull the solution control lever back until the desired setting is reached.

The solution rate is continuously variable from off to approximately 1-3/4 GPM at low and 3 GPM at high. To

stop application of solution push forward on the lever until it stops at the “off” position. The solution warning light

will illuminate when the solution tank is low, marking the end of the scrubbing cycle.

NOTE

For best results, discontinue application of solution 10 feet before stopping or making a 90° or 180° turn.

NON-RECYCLING OR ST ANDARD SCRUBBING SYSTEM

1. Make sure the solution control lever is in the “off” (FORW ARD) position.

2. Open the solution tank cover (V acuum Assembly)

3. Fill the tank with 70 gallons of water and the correct mixture of American-Lincoln #100 Industrial

Cleaner for the job on hand.

4. Close the solution tank cover (V acuum Assembly).

RECYCLING OR ESP & AUT OFIL SYSTEM

1. Make sure the solution control lever is in the “off” position.

2. Connect hose to autofil coupling.