Page 1

AquaRide™ SE, AquaRide™ SE AXP

BRX 700 series

Instructions For Use

Instrucciones de uso

Advance MODELS 56314009, 56316515(AXP™)

Nilfi sk MODELS 56314019, 56316516(EDS™)

A-English

B-Español

3/05 revised 3/06 Form Number 56041627

Page 2

A-2 / ENGLISH

TABLE OF CONTENTS

page

Introduction ........................................................................................... A-2

Cautions and Warnings ........................................................................A-3

Consignes de prudence et de sécurité .................................................A-4

Know Your Machine .............................................................................. A-5

Control Panel ........................................................................................ A-6

Prepare the Machine for Use

Description of the Battery Condition Indicators ....................................A-7

Install the Batteries ...............................................................................A-8

Filling the Solution Tank ........................................................................A-9

Pre-Spraying the Carpet ....................................................................... A-9

Plan for Cleaning ..................................................................................A-9

Detergent (AXP

Operating the Machine .......................................................................A-12

Using Attachments .............................................................................. A-12

After Use ............................................................................................. A-13

Maintenance Schedule .......................................................................A-13

Vacuum Shoe Maintenance ................................................................A-13

Spray Nozzle Maintenance ................................................................. A-13

Lubricating the Machine .....................................................................A-13

Cleaning the Vacuum Motor Filters ....................................................A-13

Power Brush Maintenance .................................................................A-13

Removing the Brushes .......................................................................A-14

Removing the Vacuum Shoes ............................................................A-14

Charging the Batteries ........................................................................ A-14

Check the Battery Electrolyte Level .................................................... A-14

Troubleshooting .................................................................................. A-15

Technical Specifi cations ..................................................................... A-16

™

/EDS™) System Preparation & Use ....................A-10-11

INTRODUCTION

This manual will help you get the most from your Nilfi sk-Advance Rider Extractor. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages 5-6.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Nilfi sk-Advance Service Center, who employs factory trained service personnel, and

maintains an inventory of Nilfi sk-Advance original replacement parts and accessories.

Call the NILFISK-ADVANCE DEALER named below for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

(Dealer, affi x service sticker here.)

NAME PLATE

The Model Number and Serial Number of your machine are shown on the Nameplate on the machine. This information is needed when ordering repair parts

for the machine. Use the space below to note the Model Number and Serial Number of your machine for future reference.

MODEL NUMBER _____________________________________________

SERIAL NUMBER _____________________________________________

UNCRATE THE MACHINE

When the machine is delivered, carefully inspect the shipping packaging and the machine for damage. If damage is evident, save the shipping carton (if

applicable) so that it can be inspected. Contact the Nilfi sk-Advance Customer Service Department immediately to fi le a freight damage claim. Refer to the

unpacking instruction sheet included with the machine to remove the machine from the pallet.

A-2 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

revised 3/06

Page 3

ENGLISH / A-3

CAUTIONS AND WARNINGS

SYMBOLS

Nilfi sk-Advance uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and

take the necessary steps to protect personnel and property.

DANGER !

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING !

Is used to call attention to a situation that could cause severe personal injury.

CAUTION !

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

WARNING !

• This machine shall be used only by properly trained and authorized persons.

• While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean

only while ascending (driving up) the ramp.

• Keep sparks, fl ame and smoking materials away from batteries. Explosive gases are vented during normal operation.

• Charging the batteries produces highly explosive hydrogen gas. Charge batteries only in well-ventilated areas, away from

open fl ame. Do not smoke while charging the batteries.

• Remove all jewelry when working near electrical components.

• Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

• Never work under a machine without safety blocks or stands to support the machine.

• Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where

fl ammable liquids exist.

• Do not clean this machine with a pressure washer.

CAUTION !

• This machine is not approved for use on public paths or roads.

• This machine is not suitable for picking up hazardous dust.

• When operating this machine, ensure that third parties, particularly children, are not endangered.

• Before performing any service function, carefully read all instructions pertaining to that function.

• Do not leave the machine unattended without fi rst turning the key switch off (O), removing the key and applying the parking

brake.

• Turn the key switch off (O) before changing the brushes, and before opening any access panels.

• Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

• Use caution when moving this machine in below freezing temperature conditions. Any water in the solution, recovery or

detergent tanks or in the hose lines could freeze, causing damage to valves and fi ttings. Flush with windshield washer fl uid.

• The batteries must be removed from the machine before the machine is scrapped. The disposal of the batteries should be

safely done in accordance with your local environmental regulations.

SAVE THESE INSTRUCTIONS

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - A-3

Page 4

A-4 / ENGLISH

CONSIGNES DE PRUDENCE ET DE SÉCURITÉ

SYMBOLES

Les symboles reproduits ci-dessous sont utilisés pour attirer l’attention de l’opérateur sur des situations dangereuses. Il est

donc conseillé de lire attentivement ces indications et de prendre les mesures adéquates en vue de protéger le personnel et le

matériel.

DANGER !

Ce symbole est utilisé pour mettre l’opérateur en garde contre les risques immédiats pouvant provoquer des dommages

corporels graves, voire entraîner la mort.

ATTENTION !

Ce symbole est utilisé pour attirer l’attention sur une situation susceptible d’entraîner des dommages corporels graves.

PRUDENCE !

Ce symbole est utilisé pour attirer l’attention de l’opérateur sur une situation qui pourrait entraîner des dommages corporels

minimes, ou des dommages à la machine ou à d’autres équipements.

Lire toutes les instructions avant d’utiliser l’appareil.

CONSIGNES GENERALES DE SECURITE

Les consignes spécifi ques de prudence et de sécurité mentionnées ici ont pour but de vous informer de la survenance de tout

risque de dommages matériels ou corporels.

ATTENTION !

• Cette machine ne pourra être utilisée que par du personnel parfaitement entraîné et dûment autorisé.

• Evitez les arrêts subits lorsque la machine est chargée et se trouve sur des rampes ou des plans inclinés. Evitez les virages serrés.

Adoptez une vitesse réduite lorsque la machine est en descente. Ne nettoyez que lorsque la machine monte la pente.

• Eloignez les batteries de toutes fl ammes, étincelles ou substance fumigène. Les gaz explosifs sont ventilés pendant le fonctionnement

normal.

• De plus, du gaz hydrogène explosif s’échappe des batteries lorsqu’elles sont en charge. Ne procédez au chargement des batteries que

dans une zone bien ventilée, loin de toute fl amme. Ne fumez pas à proximité des batteries lorsqu’elles sont en charge.

• Otez tous vos bijoux lorsque vous travaillez à proximité de composants électriques.

• Positionnez la clé de contact sur off (O) et déconnectez les batteries avant de procéder à l’entretien des composants électriques.

• Ne travaillez jamais sous une machine sans y avoir placé, au préalable, des blocs de sécurité ou des étais destinés à soutenir la

machine

• Ne déversez pas d’agents nettoyants infl ammables, ne faites pas fonctionner la machine à proximité de ces agents ou d’autres liquides

infl ammables.

• Ne nettoyez pas cette machine avec un nettoyeur à pression.

PRUDENCE !

• Cette machine n’est pas conçue pour une utilisation sur les chemins ou voies publics.

• Cette machine n’est pas conçue pour le ramassage des poussières dangereuses.

• Lors de l’utilisation de cette machine, assurez-vous que des tiers, et notamment des enfants, ne courent pas le moindre risque.

• Avant de procéder à toute opération d’entretien, veuillez lire attentivement toutes les instructions qui s’y rapportent.

• Ne laissez pas la machine sans surveillance sans avoir, au préalable, coupé le contact, enlevé la clé de contact (O) et tiré le frein à

main.

• Positionnez la clé de contact sur off (O) avant de remplacer la ou les brosses ou d’ouvrir tout panneau d’accès.

• Prenez toutes les mesures nécessaires pour éviter que les cheveux, les bijoux ou les vêtements amples ne soient entraînés dans les

parties mobiles de la machine.

• Faites attention lorsque vous déplacez cette machine dans un endroit où la température peut descendre sous 0°. L’eau contenue dans

les réservoirs de détergent, de récupération ou de solution ou dans les conduites risquerait de geler et par là même d’endommager les

valves et raccords de la machine. Rincez avec un liquide de lave-glace.

• Prenez soin d’enlever les batteries de la machine avant de mettre cette dernière au rebut. Pour ce qui est de l’élimination des batteries,

conformez-vous aux réglementations locales en matière d’environnement.

CONSERVEZ SOIGNEUSEMENT CES INSTRUCTIONS

A-4 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

Page 5

ENGLISH / A-5

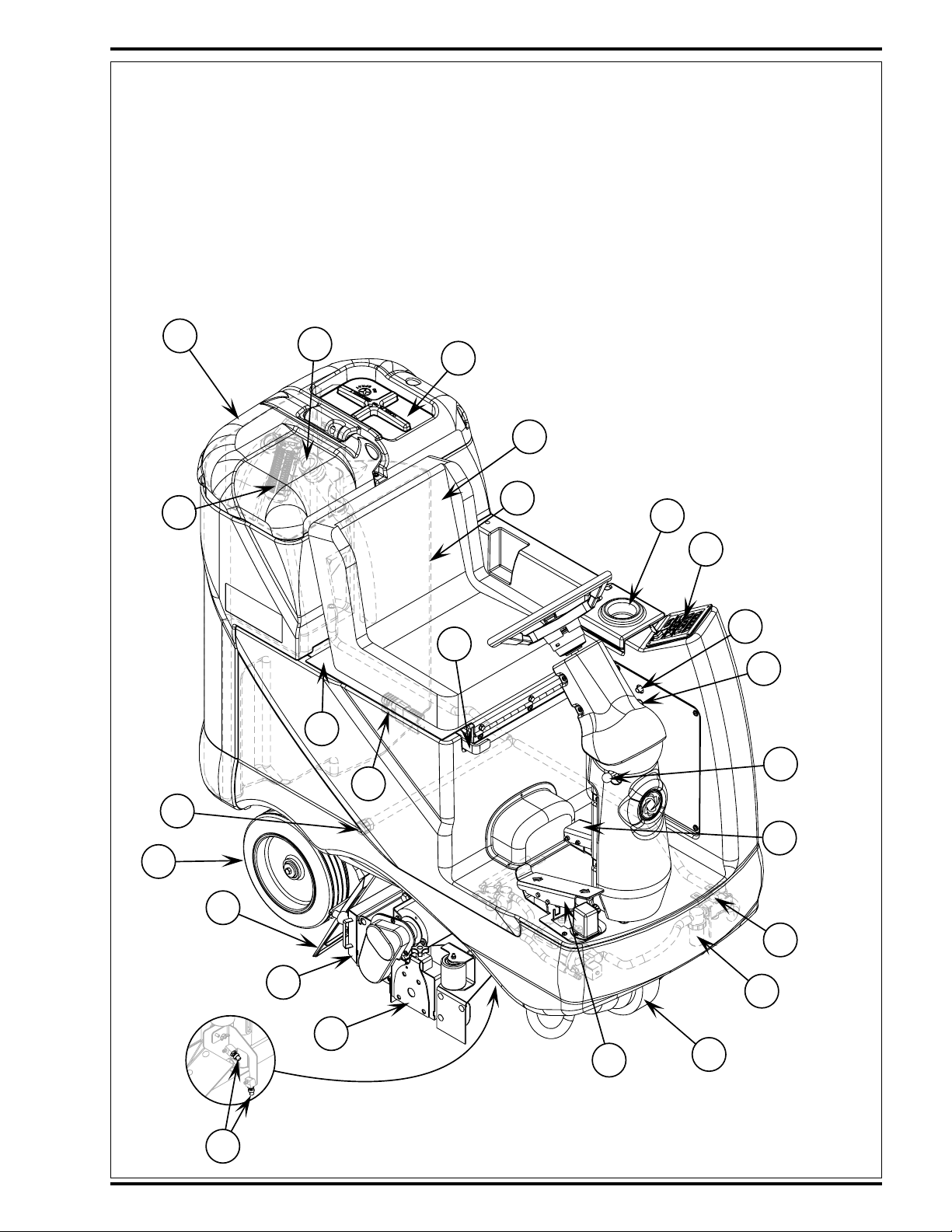

KNOW YOUR MACHINE

1 Recovery Tank Cover

2 Solution Tank Fill Cover

3 Operator’s Seat

4 Solution Tank Drain Hose

5 Steering Wheel Tilt Adjust Knob

6 Brake Pedal / Parking Brake

7 Solution Spray Jets

8 Drive Pedal, Directional/Speed

9 Vacuum Shoes

10 Drive and Steer Wheel

11 Wheel Drive Circuit Breaker

12 Control Circuit Circuit Breaker

1

17

13 Emergency Stop Switch / Battery Disconnect

14 Brush Deck

15 Rear Wheel

16 Battery Compartment (under seat)

17 Recovery Bladder Shutoff Float

18 Vacuum Motor Filter Housing

19 Recovery Bladder

20 Solution Filter

21 Recovery Bladder Drain Hose (rear of machine)

22 Machine Battery Connector

23 Control Panel

24 Debris Hopper

25 Solution Control Valve

21

18

3

19

2

15

23

11

13

12

16

5

22

4

6

9

25

24

20

14

8

10

7

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - A-5

Page 6

A-6 / ENGLISH

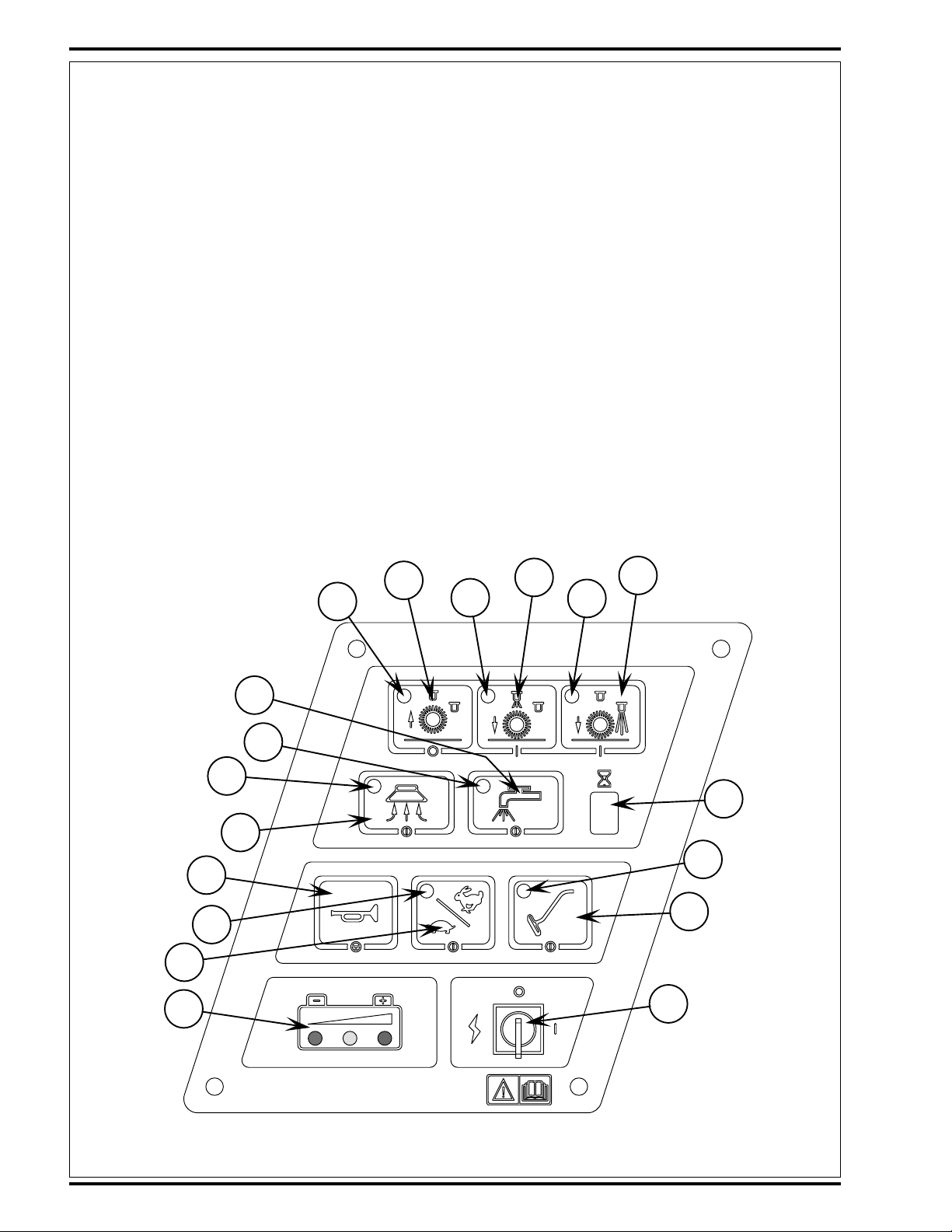

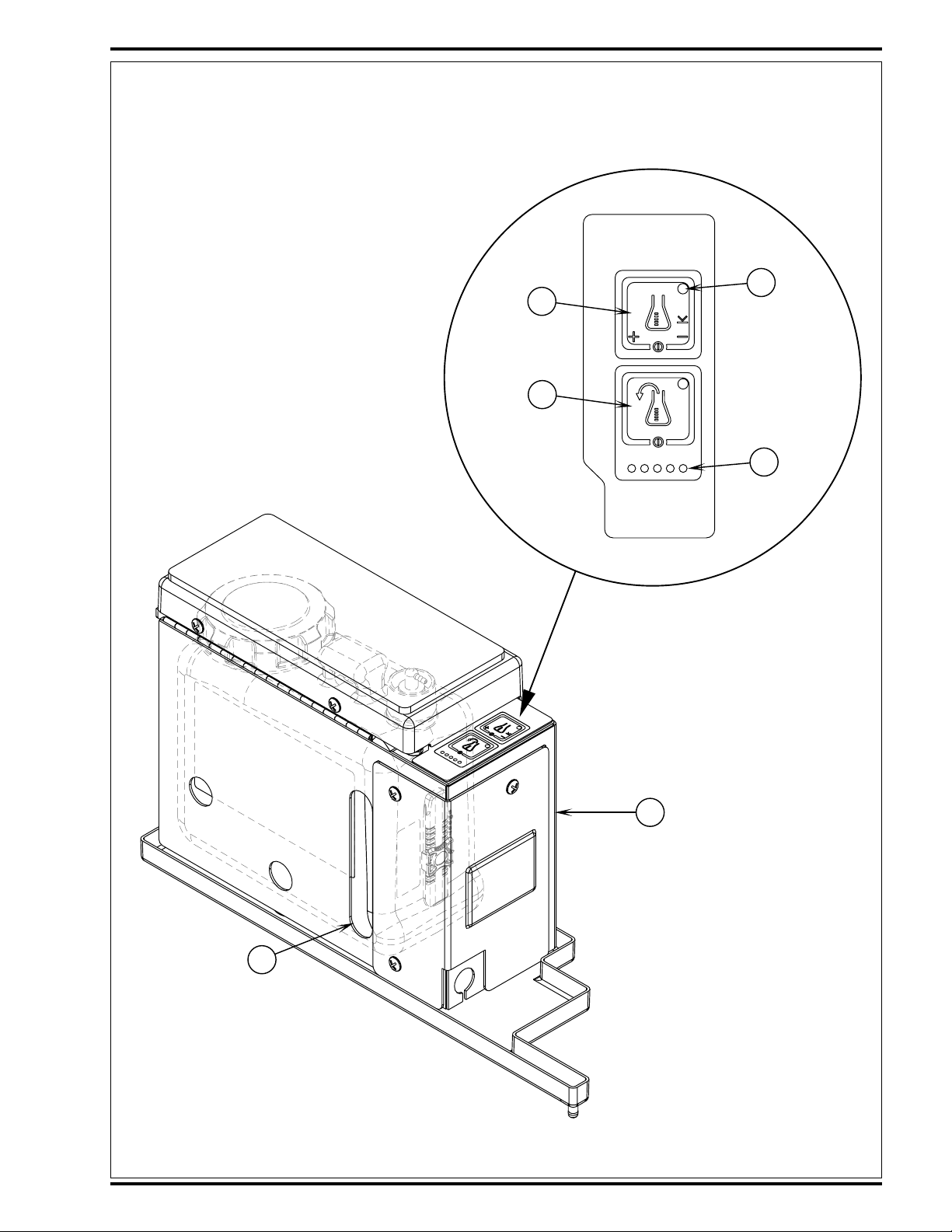

CONTROL PANEL

A Scrub OFF Indicator

B Scrub OFF Switch

C Maintenance Mode Indicator

D Maintenance Mode Switch

E Restoration Mode Indicator

F Restoration Mode Switch

G Hourmeter Display

H Accessory Vacuum Indicator

I Accessory Vacuum ON / OFF Switch

J Key Switch / Main Power

K Battery Condition Indicator

L Speed Select Switch (extract / transport)

M Speed Select Indicator

N Horn Switch

O Vacuum Switch

P Vacuum System Indicator

Q Solution System Indicator

R Solution Switch

L

K

N

M

P

O

R

Q

A

B

C

D

F

E

G

H

I

J

A-6 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

Page 7

ENGLISH / A-7

DESCRIPTION OF THE BATTERY CONDITION INDICATORS

The battery condition indicators give a relative indication of the state of charge of the battery pack. A fully charged battery pack will measure above 37.6 volts

with no load applied (2.09 volts per cell). The AquaRide™ SE / BRX 700 is equipped with a low voltage cutout feature that will turn the scrub system off when

the batteries are discharged to their minimum level. There are two different cutout levels to accommodate different battery types. See the service manual for

details. The voltage levels for the various indications are as follows (the voltages shown represent the voltage under load):

INDICATOR VOLTAGE LEVELS FOR STANDARD CUTOUT LEVEL (AS SHIPPED)

Green indicator = full charge down to 34.00 volts

Green & Yellow indicator 33.99 volts down to 33.00 volts

Yellow indicator = 32.99 volts down to 32.00 volts

Yellow & Red indicator = 31.99 volts down to 31.50 volts

Red indicator = 31.49 volts down to 31.00 volts

Flashing Red indicator = less than 31.00 volts – scrub system will shut down.

INDICATOR VOLTAGE LEVELS FOR ALTERNATE CUTOUT LEVEL

Green indicator = full charge down to 34.50 volts

Green & Yellow indicator 34.49 volts down to 34.00 volts

Yellow indicator = 33.99 volts down to 33.50 volts

Yellow & Red indicator = 33.49 volts down to 33.00 volts

Red indicator = 32.99 volts down to 32.5 volts

Flashing Red indicator = less than 32.5 volts – scrub system will shut down.

NOTE: Refer to service manual for selection of alternate cutout level.

NOTE: Once the low voltage cutout level has been reached (fl ashing red indicator) the batteries must be FULLY recharged (37.6 volts) to reset the battery

condition indicator. The scrub system will not function until the indicator has been reset.

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - A-7

Page 8

A-8 / ENGLISH

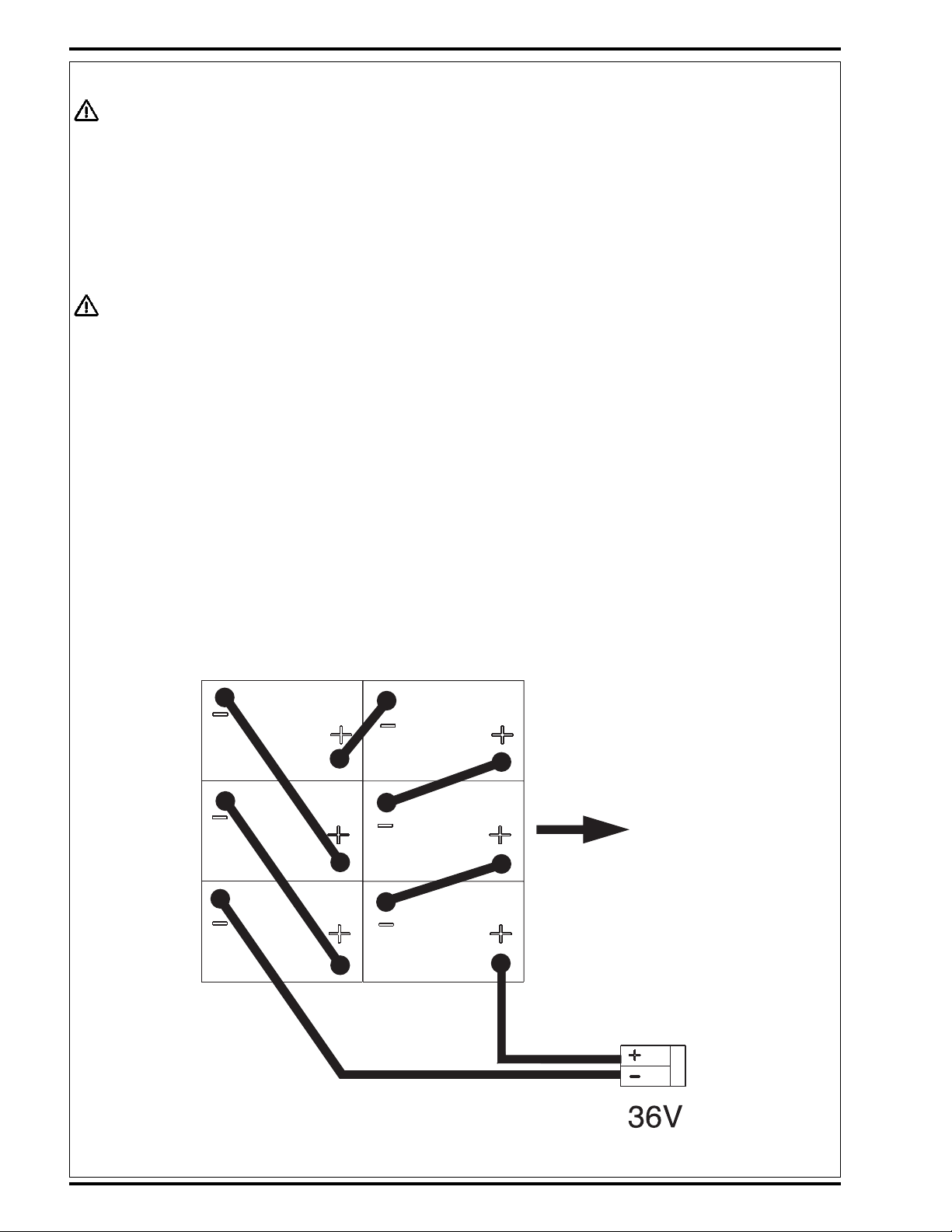

INSTALL THE BATTERIES

WARNING !

Use extreme caution when working with batteries. Sulfuric acid in batteries can cause severe injury if allowed to contact the skin

or eyes. Explosive hydrogen gas is vented from inside the batteries through openings in the battery caps. This gas can be ignited

by any electrical arc, spark or fl ame.

When Servicing Batteries...

* Remove all jewelry.

* Do not smoke.

* Wear safety glasses, a rubber apron and rubber gloves.

* Work in a well-ventilated area.

* Do not allow tools to touch more than one battery terminal at a time.

CAUTION !

Electrical components in this machine can be severely damaged if the batteries are not installed and connected properly.

Batteries should be installed by Nilfi sk-Advance or by a qualifi ed electrician.

1 Turn the Key Switch (J) off (O) and remove the key. Then swing open the Battery Compartment Cover (16).

2 Using (2) people and an appropriate lifting strap, carefully lift the batteries into the compartment tray exactly as shown. Use decal 56015168 battery

cable layout.

3 See Figure 1. Install battery cables as shown and tighten the nuts on the battery terminals.

4 Install the battery boots and secure tightly to the battery cables with the supplied tie straps.

5 Connect the battery pack connector to the machine connector (22) and close the battery compartment cover.

FRONT

FIGURE 1

A-8 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

Page 9

ENGLISH / A-9

FILLING THE SOLUTION TANK

1 Open the Solution Tank Fill Cover (2).

2 Read the dilution instructions on the chemical container. Then fi gure the proper amount of chemical to mix with 40 gallons (151 liters) of water.

3 Pour the proper amount of chemical into the solution tank and fi ll the tank with warm water to 7.62cm (3 inches) from the top of the tank opening.

4 Close the Solution Tank Fill Cover (2).

NOTE: If your machine was factory equipped with a chemical system you DO NOT mix chemical in the solution tank.

CAUTION!

Use low-sudsing, liquid detergents designed for carpet extraction. Water temperature should not exceed 130 degrees Fahrenheit

(54.4 degrees Celsius).

BEFORE USING THE AQUARIDE™ SE / BRX 700

Thorough vacuuming of the carpet to be cleaned is not necessary before using the AquaRide™ SE or BRX 700 automatic extractors, due to the on-board

sweeping broom and debris hopper.

PRE-SPRAYING THE CARPET

Pre-spray spots and heavy traffi c areas before extracting. Use a hand-held bottle sprayer or a pressurized “Hudson” type sprayer. Mix the pre-spray

according to the chemical manufacturer’s directions.

PLAN FOR CLEANING

Before you begin extracting, look at the area to be cleaned and plan your work. Divide the space into sections. Overlap each pass 2 inches (5 cm).

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - A-9

Page 10

A-10 / ENGLISH

DETERGENT (AXP/EDS) SYSTEM PREPARATION AND USE

COMMON INSTRUCTIONS:

The system should be purged of previous detergent when switching to a different

detergent. SERVICE NOTE: Move machine over fl oor drain before purging

because a small amount of detergent will be dispensed in the process.

To Purge When Changing Chemicals:

1 Disconnect and remove the detergent cartridge.

2 Turn the Key Switch (J) ON. Press and hold the Purge Switch (T) down

for at least 3 seconds, then press and hold the Solution Switch (R) (on the

main machine’s control panel) for the duration of the purge cycle. Holding

the solution switch is necessary to open the solution valve and prevent the

purged detergent from fl owing back into the solution tank. NOTE: Once

activated the Purge Indicator (U) will begin to scroll a fl ashing light from left

to right and will automatically shut off after 10 seconds. Normally one purge

cycle is adequate to purge the system.

To Purge Weekly:

1 Disconnect and remove the detergent cartridge. Install and connect a

Cartridge fi lled with clean water.

2 Turn the Key Switch (J) ON. Press and hold the Purge Switch (T) down

for at least 3 seconds, then press and hold the Solution Switch (R) (on the

main machine’s control panel) for the duration of the purge cycle. Holding

the solution switch is necessary to open the solution valve and prevent the

purged detergent from fl owing back into the solution tank. NOTE: Once

activated the Purge Indicator (U) will begin to scroll a fl ashing light from left

to right and will automatically shut off after 10 seconds. Normally one purge

cycle is adequate to purge the system.

The Detergent Box (AA) has a Detergent Level Viewing Slot (BB) for keeping

track of how much detergent is remaining in the cartridge. When the detergent

level is nearing the bottom of this slot it is time to refi ll or replace the cartridge.

General Use:

The detergent injection system is activated when the Key Switch (J) is turned on

but no detergent is dispensed until the scrub system is activated and the Drive

Pedal (8) pushed forward. The solution fl ow rate is determined by the use of

“Maintenance” or “Restoration” mode. The solution fl ow rate can be changed

by pressing the Maintenance Extract Mode Switch (D) for reduced fl ow or the

Restoration Extract Mode Switch (F) for increased fl ow. The detergent fl ow rate

increases or decreases with the solution fl ow rate but the detergent ratio remains

the same. During scrubbing, the detergent system can be turned off at any time

by pressing the Detergent ON/OFF Switch (S) to allow scrubbing with water only.

SERVICE NOTE: Follow the “To Purge Weekly” instructions above if the machine

is going to be stored for an extended period of time or if you plan to discontinue

use of the detergent injection system.

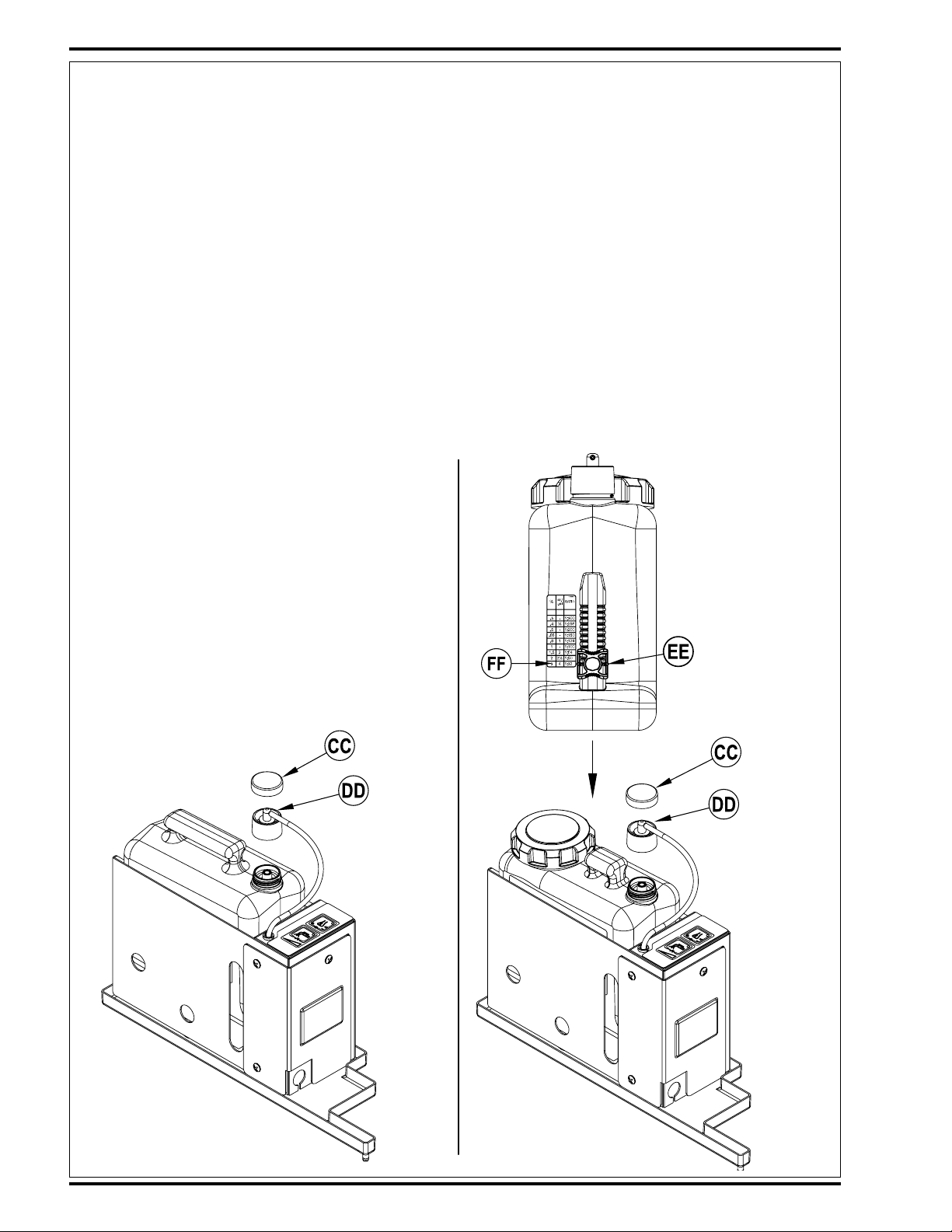

DISPOSABLE CARTRIDGE SPECIFIC INSTRUCTIONS:

Remove the Cap (CC) and place the cartridge in the detergent box. Install the Dry

Break Cap (DD) as shown.

NON-DISPOSABLE CARTRIDGE SPECIFIC INSTRUCTIONS:

Fill the detergent cartridge with a maximum of 1.25 gallons (4.73 Liters) of detergent.

SERVICE NOTE: Remove the detergent cartridge from the detergent box prior to fi lling to

avoid spilling detergent on the machine.

It is recommended that a separate cartridge be used for each detergent you plan to use.

The detergent cartridges have a white decal on them so you can write the detergent name

on each cartridge to avoid mixing them up. The detergent cartridge has a Magnetic Slider

(EE) on one end that needs to be set to the proper dilution ratio according to the dilution

instructions on the manufacturer’s bottle. Slide the Magnet Slider (EE) to the appropriate

location on Detergent Dilution Ratio Decal (FF). When installing a new cartridge, remove

the Cap (CC) and place the cartridge in the detergent box. Install the Dry Break Cap (DD)

as shown.

A-10 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

revised 3/06

Page 11

DETERGENT (AXP/EDS) SYSTEM PREPARATION AND USE

S

T

ENGLISH / A-11

V

U

revised 3/06

AA

BB

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - A-11

Page 12

A-12 / ENGLISH

OPERATING THE MACHINE

WARNING!

Be sure you understand the operator controls and their functions.

While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only

while ascending (driving up) the ramp.

To Extract...

Follow the instructions in preparing the machine for use section of this manual.

1 While seated on the machine, adjust the steering wheel to a comfortable operating position using the adjustment knob (5).

2 Turn the Master Key Switch (J) ON (I). This will display the control panel indicator lights, reference the Battery Condition Indicator (K) and Hour Meter

(G).

3 Release the Parking Brake (6). To transport the machine to the work area, apply even pressure with your foot on the front of the Drive Pedal (8) to go

forward or the rear of the pedal for reverse. Vary the pressure on the foot pedal to obtain the desired speed.

4 Press either the Maintenance Mode Switch (D) or the Restoration Mode Switch (F) to activate the scrub system. Note: refer to the “Functional

Description of Control Switches” section for a more detailed explanation of these and other control panel functions.

NOTE (AXP/EDS Models): The Detergent system is activated by default when the Key Switch (J) is turned ON (I). The Detergent ON/OFF Indicator

(V) is lit when the detergent system is activated. The Detergent system can be turned OFF by pressing the Detergent ON/OFF Switch (S). When the

system is activated detergent fl ows whenever solution fl ows.

5 When either the Maintenance Mode Switch (D) or the Restoration Mode Switch (F) is selected, the brush deck and vacuum shoes are automatically

lowered to the fl oor. The machine’s scrub brush rotation and solution system fl ow starts when the Drive Pedal (8) is activated. NOTE: When operating

the machine in reverse, solution will not be dispensed. The brush deck can be programmed to raise in reverse, have a qualifi ed service technician refer

to the service manual to perform this function.

6 Begin cleaning by driving the machine forward in a straight line at a normal walking speed and overlap each path by 2-3 inches (50-75 mm). Turn the

Solution Switch (R) OFF prior to turns to ensure complete extraction of solution from carpet. Adjust when necessary the machine speed according to

the condition of the carpet.

If there is little or no fl uid entering the recovery bladder, the solution tank may be empty. Refi ll the solution tank with water and the proper ratio of

cleaning chemical.

7 The recovery bladder has an automatic fl oat shut-off to prevent solution from entering the vacuum system when the recovery bladder is full. When the

fl oat shut-off is activated, the control system will shut down the scrub, vacuum, solution and detergent (AXP/EDS models) systems. The Hourmeter

Display (G) will display “FULL”. To clear the display, press the Scrub OFF Switch (B), Maintenance Mode Switch (D) or the Restoration Mode Switch

(F). When the fl oat closes, the recovery bladder must be emptied. The machine will not pick up water with the fl oat closed. NOTE: If the control

repeatedly gives a full indication when the tank is not full, the automatic shut-off feature can be disabled, have a qualifi ed service technician refer to the

service manual to perform this function.

8 When the operator wants to stop cleaning or the recovery bladder is full, press the Scrub OFF Switch (B). This will automatically stop the scrub

brushes and solution fl

to allow any remaining water in the pick up hose to be brought into the recovery bladder.

9 Drive the machine to a designated waste water “DISPOSAL SITE” and empty the recovery bladder. To empty, pull the Drain Hose (21) from its rear

storage area, then remove the plug (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). Refi ll

the solution tank and continue cleaning.

ow and the brush deck will raise to the up position. NOTE: The vacuum system will be turned off after a 10 second delay this is

USING ATTACHMENTS

Steps to follow in fi tting the machine with optional attachments for detail or upholstery cleaning.

1 Disconnect the recovery hose connection at the Y-fi tting, which goes to the vacuum shoes. Connect the coupler and hose from suitable wet pick-up

tools to the recovery hose.

2 Attach the solution connection to the accessory port, located at the rear of the machine on the chassis. (An optional Wand Caddy Kit is available from

Nilfi sk-Advance).

3 Turn the Master Key Switch (J) ON, next press the Accessory Vacuum Switch (I). The vacuum motor will run continuously until the switch is pressed

again to turn it OFF. NOTE: If the control repeatedly gives a full indication when the tank is not full, the automatic shut-off feature can be disabled, have

a qualifi ed service technician perform this function.

A-12 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

revised 3/06

Page 13

ENGLISH / A-13

AFTER USE

1 When fi nished cleaning, press the Scrub Off Switch (B), this will automatically raise, retract and stop all the machine systems (brush, vacuum &

solution). Then drive the machine to a service area for daily maintenance and review of other needed service up-keep.

2 To empty the solution tank, remove the Solution Drain Hose (4) from its storage clamp. Direct the hose to a designated “DISPOSAL SITE” and remove

the plug. Rinse the tank with clean water.

3 To empty the recovery bladder, pull the Recovery Bladder Drain Hose (21) from its storage area. Direct the hose to a designated “DISPOSAL SITE”

and remove the plug (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). Rinse the Waste

water Bladder (19) with clean water.

4 Remove the Brushes, rinse with warm water and remove any built-up string, hair or carpet fi bers.

5 Disconnect the Recovery Hose from the Recovery Tank and fl ush with warm water to wash any debris out of the Recovery Hose / Vacuum Shoe

Assembly.

6 Remove the debris hopper and clean thoroughly. Remove from left or right side of machine by lifting hopper up and tilting it forward then pull out.

7 Check the maintenance schedule below and perform any required maintenance before storage.

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Monthly Yearly

Charge Batteries •

Check/Clean Tanks & Hoses •

Check/Clean/ Power Brushes •

Check/Clean Vacuum Shoes •

Check/Clean Vacuum Shut-Off Float •

Check/Clean the vacuum motor foam fi lter(s) •

Empty Debris Hopper •

Clean Spray Nozzles •

Check Each Battery Cell(s) Water Level •

Inspect Brush Deck Skirts •

Inspect and clean Solution Filter •

Check Foot/ Parking Brake for Wear & Adjustment •

Purge the Detergent Injection System (AXP/EDS models only) •

Lubrication - Grease Fittings •

* Check Carbon Brushes •

* Have Nilfi sk-Advance check the vacuum motor carbon motor brushes once a year or after 300 operating hours. The brush and drive motor carbon brushes

check every 350 hours or once a year.

NOTE: Refer to the Service Manual for more detail on maintenance and service repairs.

8 Store the machine indoors in a clean dry place. Keep from freezing. Leave the tanks open to air them out.

9 Turn the Master Key Switch (J) OFF (O) and remove the key.

VACUUM SHOE MAINTENANCE

Check the vacuum shoes daily, they can be removed to aid in cleaning, see “Removing the Vacuum Shoes”. Remove any built-up string, hair or carpet

fi bers.

SPRAY NOZZLE MAINTENANCE

Remove the spray nozzles once a week. Soak the nozzles overnight in a vinegar and water solution to remove chemical deposits.

LUBRICATING THE MACHINE

Once a month, pump a small amount of grease into each grease fi tting on the machine until grease seeps out around the bearings.

Grease fi tting locations are:

• Steering Wheel Shaft Universal joint

Once a month, apply light machine oil to lubricate the:

• Steering Chain

• General Pivot Points For the Brush Deck Linkage

CLEANING THE VACUUM MOTOR FILTERS

Clean the vacuum motor fi lters daily with compressed air. For extremely dirty fi lters, wash with warm, soapy water and rinse thoroughly with clean water.

Allow the fi lters to dry completely before re-installing in the machine. MAINTENANCE NOTE: Keep a second set of fi lters on hand to use while fi rst set is

drying.

POWER BRUSH MAINTENANCE

Check the brushes daily. Remove any built-up string, hair or carpet fi bers. Check the bristle length. Have a service technician change the brushes when the

brush bristles are worn to 1/2 inch (12.7 mm).

revised 3/06

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - A-13

Page 14

A-14 / ENGLISH

REMOVING THE BRUSHES

1 Turn the Master Key Switch (J) OFF.

2 Loosen the Black Knob (A) on top of the idler assembly and remove the idler assembly. Slide the brush out of the brush deck housing.

3 To reinstall, slide the brush into the housing, lift slightly, push and turn until it seats. NOTE: Make sure Slots (B) in end of Brush line up with and seat

fi rmly on Lugs (C) on the Drive End Assembly. Re-install the idler assembly and tighten Black Knob (A).

C

B

A

Right Side of Machine

End View of Brush

End View of Drive End Assembly

REMOVING THE VACUUM SHOES

1 Turn the Master Key Switch (J) OFF.

2 Loosen the Black Knob (D) on the back of the scrub deck. Lift the

Bar (E) up and remove. Slide the vac shoe out of the shoe support

weldment (F). Procedure is the same for both vac shoes.

3 Reinstallation is reverse of removal.

F

CHARGING THE BATTERIES

Charge the batteries each time the machine is used, or whenever the

Battery Condition Meter (K) is showing a yellow, red or fl ashing red

indicator light(s).

To Charge the Batteries...

1 Depress the Battery Disconnect (13).

2 Open the Battery Compartment Cover (16) to provide proper

ventilation.

3 Push the connector from the charger into the Battery Connector (22).

4 Follow the instructions on the battery charger.

5 Check the fl uid level in all battery cells after charging the batteries. Add distilled water, if necessary, to bring the fl uid level up to the bottom of the fi ller

tubes.

View from left rear of machine

D

E

WARNING !

Do not fi ll the batteries before charging.

Only charge batteries in a well-ventilated area.

Do not smoke while servicing the batteries.

CAUTION !

To avoid damage to fl oor surfaces, always wipe water and acid from the top of the batteries after charging.

CHECKING THE BATTERY ELECTROLYTE LEVEL

Check the electrolyte level of the batteries at least once a week.

After charging the batteries, remove the vent caps and check the electrolyte level in each battery cell. Use distilled water to fi ll the batteries to the bottom of

the fi ller tube.

Do not over-fi ll the batteries!

CAUTION !

Acid can spill onto the fl oor if the batteries are overfi lled.

Tighten the vent caps. If there is acid on the batteries, wash the tops of the batteries with a solution of baking soda and water (2 tablespoons of baking soda

to 1 quart of water).

A-14 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

Page 15

ENGLISH / A-15

GENERAL MACHINE TROUBLESHOOTING

Problem Possible Cause Remedy

Poor water pick-up Recovery bladder full Empty recovery bladder

Recovery bladder drain hose leak Secure drain hose cap or replace

Recovery tank cover gasket leak Replace gasket / Seat cover properly

Debris caught in vacuum shoes Clean vacuum shoes

Vacuum hose clogged Remove debris

Foam fi lter cover not seated Seat cover properly

Poor extracting performance Worn brushes Rotate or replace brushes

Wrong cleaning chemical Consult Nilfi sk-Advance

Moving machine too fast Slow down

Inadequate solution fl ow Solution tank empty Fill solution tank

or no solution

Solution lines, valves, fi lter, or spray jets clogged Flush lines and clean solution fi lter & spray jets

Solution control valve is in closed position Place control valve handle in open position

Solution solenoid valves Clean or replace valves

Machine does not run Emergency stop switch tripped Reconnect battery connectors

Operator seat safety switch Check for open circuit and replace

Main system controller Check for error fault codes

(see service manual)

Tripped 10 Amp circuit breaker Check for electrical short circuit & reset

No FWD/REV wheel drive Drive system speed controller Check for error fault codes

(see service manual)

Tripped 45 Amp circuit breaker Check for drive motor overload

Emergency stop switch tripped Reconnect battery connectors

Vacuum shuts off and display Plugged vacuum hose(s) Clear debris

shows “FULL” when

recovery bladder is not full Vacuuming large amounts of water Slow down or disable auto shut-off feature

at a high travel speed (see service manual)

Poor Sweeping Performance Debris Hopper Full Empty and clean hopper

Brushes worn Replace brushes

Bristles have taken a set Rotate brushes

No Detergent Flow Empty detergent cartridge Fill detergent cartridge

(AXP/EDS models only)

Plugged or kinked detergent fl ow line Purge system, straighten lines to remove any kinks

Dry seal cap on detergent cartridge not sealed Reseat dry seal cap

Detergent ratio slider magnet missing Replace slider

Detergent pump wiring disconnected Connect or reconnect wiring

or backwards

revised 3/06

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - A-15

Page 16

A-16 / ENGLISH

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model AquaRide™SE, AquaRide™SE AXP, BRX 700, BRX 700 EDS

Model No. 56314009, 56316515, 56314019, 56316516

Current A 65

Voltage, Batteries V 36V

Battery Capacity Ah 238

Protection Grade IPX3

Sound Pressure Level (IEC 60704-1) dB(A)/20μPa 73

Gross Weight lbs / kg 1570 / 712

Vibrations at the Hand Controls (ISO 5349-1) m/s

Vibrations at the Seat (EN 1032) m/s

Gradeability

Transport 14% (8°)

Cleaning 10% (6°)

2

<2.5m/s

2

<0.5m/s

2

2

A-16 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

revised 3/06

Page 17

Page 18

B-2 / ESPAÑOL

ÍNDICE

página

Introducción .......................................................................................... B-2

Precauciones y advertencias ................................................................ B-3

Conozca su máquina ............................................................................ B-4

Panel de control .................................................................................... B-5

Preparación de la máquina para el uso

Descripción de los indicadores de ESTADO de las baterías ................B-6

Instalación de las baterías .................................................................... B-6

Llenado del depósito de solución .........................................................B-7

Pulverización previa de la moqueta ...................................................... B-7

Planifi cación de limpieza ......................................................................B-7

Sistema de detergente (AXP

Funcionamiento de la máquina ..........................................................B-10

Utilización de accesorios ....................................................................B-10

Después de la utilización .................................................................... B-11

Programa de mantenimiento .............................................................. B-11

Mantenimiento de las zapatas de la aspiradora ................................. B-11

Mantenimiento de la boquilla pulverizadora ....................................... B-11

Lubricación de la máquina .................................................................. B-11

Limpieza de los fi ltros del motor de aspiración ................................... B-11

Mantenimiento del cepillo eléctrico ..................................................... B-11

Desmontaje de cepillo(s) ....................................................................B-12

Desmontaje de las zapatas de la aspiradora .....................................B-12

Recarga de las baterías .....................................................................B-12

Comprobación del nivel de electrolito de las baterías ........................B-12

Localización de averías ......................................................................B-13

Especifi caciones técnicas ................................................................... B-14

™

/EDS™) ............................................... B-8-9

INTRODUCCIÓN

Este manual le ayudará a sacarle el máximo rendimiento a su Nilfi sk-Advance AquaRide™ SE / BRX 700. Léalo con detenimiento antes de hacer funcionar

la máquina.

Nota: Los números en negrita y entre paréntesis indican un elemento que se ilustra en las páginas B-4-B-5.

Este producto está destinado exclusivamente a uso comercial.

COMPONENTES Y SERVICIO

Las reparaciones, cuando sean necesarias, debe realizarlas su Centro Autorizado de Servicio Nilfi sk-Advance que emplea personal de servicio formado en

fábrica y lleva un inventario de piezas de repuesto y accesorios Nilfi sk-Advance originales.

Llame al DISTRIBUIDOR NILFISK-ADVANCE que se indica a continuación para lo referente a piezas de repuesto y servicio. Por favor, especifi que el

Modelo y Número de Serie cuando hable de su máquina.

(Distribuidor, coloque aquí la pegatina de su servicio.)

PLACA DE IDENTIFICACIÓN

El Número de modelo y Número de serie de la máquina se indican en la placa de identifi cación instalada en ella. Esta información es necesaria a la hora de

solicitar repuestos para la máquina. Utilice el espacio situado más abajo para anotar el Modelo y Número de serie de la máquina para futuras consultas.

NÚMERO DE MODELO

NÚMERO DE SERIE

DESEMBALAJE DE LA MÁQUINA

Cuando reciba la máquina, examine con atención el embalaje y la máquina, con el fi n de comprobar si existe algún daño. Si observa algún daño, guarde la

caja de embalaje (si procede) para que se pueda inspeccionar. Póngase en contacto inmediatamente con el Departamento de Servicio al Cliente de Nilfi sk-

Advance para presentar una reclamación por daños en transporte. Consulte la hoja de instrucciones de desembalaje incluida con la máquina para sacar la

máquina del palet.

B-2 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

revised 3/06

Page 19

ESPAÑOL / B-3

PRECAUCIONES Y ADVERTENCIAS

SÍMBOLOS

Nilfi sk-Advance utiliza los símbolos que aparecen a continuación para indicar situaciones potencialmente peligrosas. Lea

siempre con atención esta información y tome las medidas necesarias para la protección del personal y los objetos.

¡PELIGRO!

Se utiliza para advertir de peligros inmediatos que pueden producir graves daños personales o la muerte.

¡ADVERTENCIA!

Se utiliza para llamar la atención sobre una situación que puede causar graves daños personales.

¡PRECAUCIÓN!

Se utiliza para llamar la atención sobre una situación que puede causar daños personales leves o daños a la máquina u otros

objetos.

Lea todas y cada una de las instrucciones antes de utilizar el apa

rato.

INSTRUCCIONES GENERALES DE SEGURIDAD

Se incluyen Precauciones y Advertencias específi cas que le advierten de los posibles riesgos de daño a la máquina o daño

corporal.

¡ADVERTENCIA!

• Sólo deben utilizar esta máquina las personas autorizadas y con la formación adecuada.

• Si se encuentra sobre una rampa o inclinación, evite las paradas bruscas cuando lleve carga. No tome las curvas

bruscamente. Utilice una velocidad lenta si va cuesta abajo. Limpie sólo yendo cuesta arriba.

• Mantenga las chispas, llamas y materiales de fumadores alejados de las baterías. Durante el funcionamiento normal se

desprenden gases explosivos.

• Al recargar las baterías se produce gas de hidrógeno altamente explosivo. Recargue las baterías exclusivamente en zonas

bien ventiladas, lejos de llamas directas. No fume mientras recarga las baterías.

• Quítese todas las joyas cuando trabaje cerca de componentes eléctricos.

• Ponga el interruptor de llave en posición de apagado (O) y desconecte las baterías antes de revisar los componentes

eléctricos.

• No trabaje nunca debajo de la máquina sin colocar antes bloques o soportes de seguridad en los que apoyar la máquina.

• No aplique sustancias limpiadoras infl amables ni utilice la máquina sobre estas sustancias, cerca de ellas, ni en zonas en

las que haya líquidos infl amables.

• No lave la máquina con una limpiadora a presión.

¡PRECAUCIÓN!

• Esta máquina no ha sido aprobada para su uso en vías públicas.

• Esta máquina no es apta para la recogida de polvo peligroso.

• Cuando utilice la máquina, asegúrese de que no existe peligro para terceras personas, especialmente niños.

• Antes de proceder a cualquier función de servicio, lea con atención todas las instrucciones relativas a dicha función.

• No abandone la máquina sin antes apagar el interruptor de llave (O), retirar la llave y echar el freno de estacionamiento.

• Apague el interruptor de llave (O) antes de cambiar el cepillo o cepillos y antes de abrir cualquiera de los paneles de

acceso.

• Tome las debidas precauciones para evitar que el pelo, las joyas o las prendas sueltas queden atrapados entre los

componentes móviles.

• Tome las precauciones adecuadas cuando esté moviendo esta máquina mientras hiela. El agua de la solución, los

depósitos de recuperación y de las tuberías puede congelarse, causando daños a las válvulas y accesorios. Limpie con

líquido limpiaparabrisas.

• Quite las baterías de la máquina antes de su desguace. Las baterías deben desecharse de forma segura, de acuerdo con

la reglamentación medioambiental local.

GUARDE ESTAS INSTRUCCIONES

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - B-3

Page 20

B-4 / ESPAÑOL

CONOZCA SU MÁQUINA

1 Tapa del depósito de recuperación

2 Tapa de llenado del depósito de solución

3 Asiento del operador

4 Tubería de drenaje del depósito de solución

5 Botón de ajuste de la inclinación del volante

6 Pedal del freno / freno de estacionamiento

7 Surtidores pulverizadores de solución

8 Pedal de tracción, dirección / velocidad

9 Zapatas de la aspiradora

10 Rueda de tracción y de dirección

11 Disyuntor del motor de tracción de la rueda

12 Disyuntor del circuito de control

13 Conmutador de parada de emergencia / desconexión de la batería

14 Portacepillos

15 Rueda trasera

16 Compartimento de las baterías (debajo del asiento)

17 Flotador del cierre automático de la cámara de recuperación

18 Alojamiento de los fi ltros de los motores de aspiración

19 Cámara de recuperación

20 Filtro de la solución

21 Tubería de drenaje de la cámara de recuperación (parte trasera

de la máquina)

22 Conector de las baterías de la máquina

23 Panel de control

24 Tolva de residuos

25 Válvula de control de la solución

1

17

21

18

3

19

2

23

11

13

12

16

5

22

4

15

9

24

14

7

B-4 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

6

25

20

8

10

Page 21

PANEL DE CONTROL

A Indicador de apagado del fregado

B Interruptor de apagado del fregado

C Indicador de modo de mantenimiento

D Interruptor de modo de mantenimiento

E Indicador de modo de restauración

F Interruptor de modo de restauración

G Pantalla del cronómetro

H Indicador de aspiración con accesorio

I Interruptor de encendido / apagado de la aspiración con accesorio

J Interruptor de llave / Alimentación principal

K Indicador de estado de las baterías

L Interruptor de selección de velocidad (extracción / transporte)

M Indicador de selección de velocidad

N Interruptor del claxon

O Interruptor de aspiración

P Indicador del sistema de aspiración

Q Indicador del sistema de solución

R Interruptor de solución

ESPAÑOL / B-5

L

K

N

M

P

O

R

Q

A

B

C

D

F

E

G

H

I

J

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - B-5

Page 22

B-6 / ESPAÑOL

DESCRIPCIÓN DE LOS INDICADORES DE ESTADO DE LAS BATERÍAS

Los indicadores de estado de las baterías indican relativamente el estado de carga del grupo de baterías. Un grupo de baterías totalmente recargado dará

una medición de 37,6 voltios sin aplicarse carga alguna (2,09 voltios por célula). AquaRide™ SE / BRX 700 dispone de una función de corte por baja tensión

que apagará el sistema de fregado cuando las baterías estén al mínimo. Para cubrir los distintos tipos de baterías hay dos niveles de corte diferentes.

Consulte el manual de servicio para tener más detalles. Los niveles de tensión de los distintos indicadores son los siguientes (las tensiones indicadas

representan la tensión con carga):

NIVELES DE TENSIÓN DE LOS INDICADORES PARA NIVEL DE CORTE ESTÁNDAR (COMO SE ENVÍA)

Indicador verde = carga total hasta 34,00 voltios

Indicador verde y amarillo = de 33,99 voltios hasta 33,00 voltios

Indicador amarillo = de 32,99 voltios hasta 32,00 voltios

Indicador amarillo y rojo = de 31,99 voltios hasta 31,50 voltios

Indicador rojo = de 31,49 voltios hasta 31,00 voltios

Indicador intermitente rojo = menos de 31,00 voltios; el sistema de fregado se apagará.

NIVELES DE TENSIÓN DE LOS INDICADORES PARA NIVEL DE CORTE ALTERNATIVO

Indicador verde = carga total hasta 34,50 voltios

Indicador verde y amarillo = de 34,49 voltios hasta 34,00 voltios

Indicador amarillo = de 33,99 voltios hasta 33,50 voltios

Indicador amarillo y rojo = de 33,49 voltios hasta 33,00 voltios

Indicador rojo = de 32,99 voltios hasta 32,5 voltios

Indicador intermitente rojo = menos de 32,5 voltios; el sistema de fregado se apagará.

NOTA: Consulte el manual de servicio para la selección del nivel de corte alternativo.

NOTA: Una vez alcanzado el nivel de corte por baja tensión (indicador rojo intermitente), deben recargarse las baterías al MÁXIMO (37,6 voltios) para que

se restablezca el indicador de estado de las baterías. El sistema de fregado no funcionará hasta que el indicador esté restablecido.

INSTALACIÓN DE LAS BATERÍAS

¡ADVERTENCIA!

Tome las máximas precauciones cuando trabaje con las baterías. El ácido sulfúrico de las baterías puede causar daños graves

si entra en contacto con la piel o con los ojos. Desde el interior de las baterías se libera gas explosivo de hidrógeno por las

aberturas de los tapones de las baterías. Este gas puede incendiarse con cualquier arco eléctrico, chispa o llama.

Cuando revise las baterías...

* Quítese todas las joyas.

* No fume.

* Lleve gafas de seguridad, un delantal de goma y guantes de goma.

* Trabaje en una zona bien ventilada.

* No permita que las herramientas toquen simultáneamente más de un terminal de batería.

¡PRECAUCIÓN!

Los componentes eléctricos de esta máquina pueden dañarse seriamente si las baterías no están instaladas o conectadas

correctamente. Las baterías deben ser instaladas por Nilfi sk-Advance o por un electricista cualifi cado.

1 Apague (O) el Interruptor de llave (J) y quite la llave. A

continuación abra la Tapa del compartimento de baterías

(16).

2 Con (2) personas y una correa de levantamiento

apropiada, levante con cuidado las baterías hasta la

bandeja del compartimento, exactamente tal y como se

indica. Utilice la disposición de cables de batería de la

pegatina 56015168.

3 Ver la Figura 1. Instale los cables de batería tal y como

se muestra y apriete las tuercas de los terminales de las

baterías.

4 Instale los manguitos de las baterías y apriételos bien

a los cables de las baterías con las correas de sujeción

provistas.

5 Enchufe el conector del grupo de baterías al conector

de la máquina (22) y cierre la tapa del compartimento de

baterías.

FIGURA 1

Parte delantera

Frente

Parte anteriore

B-6 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

Page 23

ESPAÑOL / B-7

LLENADO DEL DEPÓSITO DE SOLUCIÓN

1 Abra la tapa de llenado del depósito de solución (2).

2 Lea las instrucciones para la dilución que aparecen en la etiqueta del envase del producto químico. A continuación, calcule la cantidad adecuada de

producto químico que se ha de mezclarse con 151 litros (40 galones) de agua.

3 Eche la cantidad adecuada de producto químico en el depósito de solución y rellene el depósito con agua templada hasta 7,62 cm (3 pulgadas) por la

abertura superior del depósito.

4 Cierre la tapa de llenado del depósito de solución (2).

NOTA: Las máquinas AXP/EDS pueden utilizarse normalmente con detergente mezclado en el depósito o con el sistema de aplicación de detergente AXP/

EDS. Al utilizar el sistema de aplicación de detergente AXP/EDS, no mezcle detergente en el depósito; utilice agua.

¡PRECAUCIÓN!

Utilice detergentes líquidos poco espumosos aptos para la extracción de moquetas. La temperatura del agua no deberá

superar los 130 grados Fahrenheit (54,4 grados Celsius).

ANTES DE USAR AQUARIDE™ SE / BRX 700

Los extractores automáticos AquaRide™ SE y BRX 700 no necesitan que se pase la aspiradora antes de limpiar la moqueta gracias a su cepillo de barrido y

a la tolva de residuos incorporados.

PULVERIZACIÓN PREVIA DE LA MOQUETA

Antes de extraer la moqueta, pulverice previamente las manchas y las zonas por donde se pase a menudo. Utilice un pulverizador de botella o un

pulverizador presurizado tipo “Hudson”. Mezcle la solución para pulverización previa según las instrucciones del fabricante del producto químico.

PLANIFICACIÓN DE LIMPIEZA

Antes de empezar la extracción, observe el área que vaya a limpiarse y haga una planifi cación del trabajo. Divida el espacio en secciones. Cada pasada

debe coincidir con la anterior en una banda de 5 cm (2 pulgadas).

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - B-7

Page 24

B-8 / ESPAÑOL

REPARACIÓN Y USO DEL SISTEMA DE DETERGENTE (AXP/EDS)

INSTRUCCIONES COMUNES:

Elimine del sistema el detergente anteriormente utilizado antes de cambiar a un detergente

diferente. NOTA DE SERVICIO: Desplace la máquina sobre un punto de drenaje en

el suelo antes de eliminar el detergente porque saldrá una pequeña cantidad durante el

proceso.

Purgar al cambiar productos químicos:

1 Desconecte y retire el cartucho de detergente.

2 Encienda el conmutador de llave principal (J). Pulse y mantenga pulsado el

interruptor de purga (T) al menos 3 segundos; a continuación, pulse y mantenga

pulsado el conmutador de la solución (R) (en el panel de control de la máquina

principal) durante el ciclo de purga. Mantener pulsado el conmutador de la solución

es necesario para abrir la válvula de la solución y evitar que el detergente purgado

vuelva al depósito de la solución. NOTA: Una vez activado, el indicador de purga

(U) comenzará a mostrar una luz intermitente de izquierda a derecha y se apagará

automáticamente después de 10 segundos. Por lo general, un ciclo de purga es

adecuado para purgar el sistema.

Purgar semanalmente:

1 Desconecte y retire el cartucho de detergente. Instale y conecte un cartucho lleno

de agua limpia.

2 Encienda el conmutador de llave principal (J). Pulse y mantenga pulsado el

interruptor de purga (T) al menos 3 segundos; a continuación, pulse y mantenga

pulsado el conmutador de la solución (R) (en el panel de control de la máquina

principal) durante el ciclo de purga. Mantener pulsado el conmutador de la solución

es necesario para abrir la válvula de la solución y evitar que el detergente purgado

vuelva al depósito de la solución. NOTA: Una vez activado, el indicador de purga

(U) comenzará a mostrar una luz intermitente de izquierda a derecha y se apagará

automáticamente después de 10 segundos. Por lo general, un ciclo de purga es

adecuado para purgar el sistema.

La caja de detergente (AA) tiene una ranura de visualización del nivel de detergente (BB)

para saber cuánto detergente queda en el cartucho. Cuando el nivel de detergente se

acerque a la parte inferior de la ranura, rellene o sustituya el cartucho.

Uso general:

El sistema de inyección de detergente se activa cuando el interruptor de llave (J)

se enciende pero no sale detergente hasta que se activa el sistema de fregado y se

empuja el pedal de tracción (8). El fl ujo de solución se determina por el uso del modo

“Mantenimiento” o “Restauración”. El fl ujo de la solución puede cargarse pulsando el

interruptor de modo de extracción de mantenimiento (D) para un fl ujo menor o el interruptor

de modo de extracción de restauración (F) para un fl ujo mayor. El fl ujo del detergente

aumenta o disminuye con el fl ujo de la solución pero índice del detergente no varía.

Durante el fregado, el sistema de detergente puede apagarse en cualquier momento

pulsando el conmutador de detergente (S) para permitir el fregado sólo con agua.

NOTA DE SERVICIO: Siga las instrucciones “Purgar semanalmente” indicadas más arriba

si la máquina va a almacenarse durante un periodo de tiempo prolongado o si prevé un

uso discontinuo del sistema de inyección de detergente. Las sustancias químicas de alta

viscosidad pueden infl uir el la precisión de la dosifi cación.

INSTRUCCIONES ESPECÍFICAS DEL CARTUCHO DESECHABLE:

Retire la tapa (CC) y coloque el cartucho en la caja de detergente. Instale la tapa sellada

(DD) como se muestra.

INSTRUCCIONES ESPECÍFICAS DEL CARTUCHO NO DESECHABLE:

Llene el cartucho de detergente con 1,25 galones (4,73 litros) como máximo.

NOTA DE SERVICIO: Retire el cartucho de la caja de detergente antes de

llenarlo para no derramar detergente en la máquina.

Se recomienda utilizar un cartucho individual por cada detergente que prevea

usar. Los cartuchos de detergente tienen una pegatina blanca de modo que

puede escribir el nombre del detergente en cada cartucho para no mezclarlos.

El cartucho de detergente tiene un deslizador magnético (EE) en un extremo

el cual debe ajustarse a la cantidad de mezcla adecuada de acuerdo con las

instrucciones descritas en la botella del fabricante. Coloque el deslizador

magnético (EE) en la posición adecuada en la pegatina de cantidad de mezcla

de detergente (FF). Al instalar un nuevo cartucho, retire la tapa (CC) y coloque el

cartucho en la caja de detergente. Instale la tapa sellada (DD) como se muestra.

B-8 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

revised 3/06

Page 25

SISTEMA DE DETERGENTE (AXP/EDS)

ESPAÑOL / B-9

V

S

T

U

revised 3/06

AA

BB

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - B-9

Page 26

B-10 / ESPAÑOL

MANEJO DE LA MÁQUINA

¡ADVERTENCIA!

Asegúrese de que comprende los controles del operador y sus funciones.

Si se encuentra sobre una rampa o inclinación, evite las paradas bruscas cuando lleve carga. No tome las curvas bruscamente.

Utilice una velocidad lenta si va cuesta abajo. Limpie sólo yendo cuesta arriba.

Para extraer...

Siga las instrucciones de la sección “Preparación de la máquina para el uso” de este manual.

1 Sentado en la máquina, use el botón de ajuste (5) para colocar el volante en una posición de funcionamiento cómoda.

2 Encienda (I) el conmutador principal de llave (J). Se encenderán las luces indicadoras del panel de control, el indicador de estado de las baterías (K) y

el cronómetro (G).

3 Libere el freno de estacionamiento (6). Para llevar la máquina a la zona de trabajo, aplique con el pie una presión uniforme en la parte delantera del

pedal de tracción (8) para ir hacia delante o en la parte trasera para ir marcha atrás. Cambie la presión que hace en el pedal con el pie para obtener la

velocidad deseada.

4 Pulse el Interruptor de modo de mantenimiento (D) o el Interruptor de modo de restauración (F) para activar el sistema de fregado. Nota: consulte la

sección “Descripción funcional de los interruptores de control” si desea una explicación más detallada sobre ésta y otras funciones del panel de control.

NOTA (modelos AXP/EDS): El sistema de detergente se activa por defecto cuando se enciende (I) el interruptor de llave (J). El indicador de

encendido/apagado de detergente (V) está encendido cuando el sistema de detergente está activado. El sistema de detergente puede apagarse

pulsando el interruptor de encendido/apagado de detergente (S). Cuando el sistema está activado el detergente fl uye cada vez que fl uya la solución.

5 Cuando se selecciona o bien el Interruptor de modo de mantenimiento (D) o bien el Interruptor de modo de restauración (F), el portacepillos y las

zapatas de la aspiradora se bajan automáticamente al suelo. La rotación de los cepillos de fregado y el fl ujo del sistema de solución de la máquina

empiezan cuando se activa el pedal de tracción (8). NOTA: Cuando la máquina funcione marcha atrás no saldrá solución. Puede programarse el

portacepillos para que se levante si se va marcha atrás, cosa que debe hacer un técnico cualifi cado tras consultar el manual de servicio.

6 Empiece a limpiar conduciendo la máquina marcha adelante en línea recta a una velocidad de paseo normal, solapando las pasadas unos 50-75 mm

(2-3 pulgadas). Apague el interruptor de la solución (R) antes de dar la vuelta para garantizar la extracción completa de la solución de la moqueta. En

función del estado de la moqueta, regule la velocidad de la máquina cuando sea necesario.

Si entra muy poco líquido, o no entra nada, en la cámara de recuperación, es posible que el depósito de solución esté vacío. Rellene el depósito de

solución con agua y la proporción correcta de limpiador químico.

7 El depósito de recogida tiene un fl otador de cierre automático para evitar que la solución entre en el sistema de aspiración cuando está lleno el

depósito de recogida. Cuando se activa el fl otador de cierre, el sistema de control apaga los sistemas de fregado, aspiración, solución y detergente

(modelos AXP/EDS). La pantalla de cronómetro (G) indicará “FULL” (Lleno). Para borrar la pantalla, pulse el interruptor de apagado de fregado (B),

el interruptor de modo de mantenimiento (D) o el interruptor de modo de restauración (F). Hay que vaciar el depósito de recogida cuando el fl otador

lo cierra. La máquina no recogerá el agua si el fl otador está cerrado. NOTA: Si el control indica constantemente que el depósito está lleno cuando

no lo está, se puede desactivar la opción de cierre automático. Esto debe hacerlo un técnico de mantenimiento cualifi cado consultando el manual de

servicio.

8 Cuando quiera dejar de limpiar o la cámara de recuperación esté llena, pulse el Interruptor de apagado del fregado (B). Esto parará automáticamente

los cepillos de fregado y el fl

Esto se hace para dejar que el agua que queda en la manguera de recogida llegue a la cámara de recuperación.

9 Conduzca la máquina a un lugar establecido para la eliminación de aguas residuales y vacíe la cámara de recuperación. Para vaciar, tire de la tubería

de drenaje (21) para sacarla de su zona de almacenamiento en la parte trasera y, a continuación, quite el tapón (sostenga el extremo de la tubería por

encima del nivel de agua para evitar el fl ujo súbito e incontrolado de agua residual). Rellene el depósito de solución y siga limpiando.

ujo de solución y se levantará el portacepillos. NOTA: El sistema de aspiración se apagará transcurridos 10 segundos.

UTILIZACIÓN DE ACCESORIOS

Pasos a seguir para añadir a la máquina accesorios opcionales para la limpieza detallada o de tapizados.

1 Desenganche la conexión de la tubería de recuperación del racor en Y que llega hasta las zapatas de la aspiradora. Conecte el acoplamiento y la

manguera entre las herramientas de recogida adecuadas y la tubería de recuperación.

2 Enganche la conexión de la solución al puerto del accesorio, situado en la parte trasera de la máquina, sobre el chasis. (Nilfi sk-Advance tiene a su

disposición un Kit opcional de transporte para varas.)

3 Encienda el conmutador principal de llave (J) y luego pulse el Interruptor de aspiración con accesorio (I). El motor de aspiración estará encendido

hasta que se vuelva a pulsar el interruptor para apagarlo. NOTA: Si el control indica constantemente que el depósito está lleno cuando no lo está, se

puede deshabilitar la opción de cierre automático, cosa que debe hacer un técnico de mantenimiento cualifi cado.

B-10 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

revised 3/06

Page 27

ESPAÑOL / B-11

DESPUÉS DE LA UTILIZACIÓN

1 Cuando termine de limpiar, pulse el interruptor de apagado del fregado (B). Esto parará, levantará y recogerá automáticamente todos los sistemas de

la máquina (fregado, aspiración y solución). A continuación conduzca la máquina a la zona de mantenimiento para el mantenimiento diario y la revisión

de otros servicios necesarios.

2 Para vaciar el depósito de solución, retire la tubería de drenaje de la solución (4) de su pinza de almacenamiento. Oriente la tubería al lugar

establecido para la eliminación de residuos y quite el tapón. Enjuague el depósito con agua limpia.

3 Para vaciar la cámara de recuperación, retire la tubería de drenaje de la cámara de recuperación (21) de su zona de almacenamiento. Oriente la

tubería al lugar establecido para la eliminación de aguas residuales y quite el tapón (sostenga el extremo de la tubería por encima del nivel de agua

para evitar el fl ujo súbito e incontrolado de agua residual). Enjuague la cámara de agua residual (19) con agua limpia.

4 Desmonte el cepillo o cepillos, enjuague con agua limpia y elimine las fi bras, hilachas y cabellos acumulados.

5 Desconecte la tubería de recuperación del depósito de recuperación y lave con agua templada para eliminar cualquier residuo que pueda haber en el

conjunto de zapatas de la aspiradora / tubería de recuperación.

6 Desmonte la tolva de residuos del AquaRide

inclinándola hacia delante, luego tire de ella.

7 Compruebe el programa de mantenimiento que viene a continuación y realice cualquier operación de mantenimiento necesaria antes de guardar la

máquina.

PROGRAMA DE MANTENIMIENTO

OPERACIÓN DE MANTENIMIENTO Diaria Semanal Mensual Anual

Recargar baterías •

Limpiar e inspeccionar depósitos y tuberías •

Comprobar y limpiar cepillo(s) eléctrico(s) •

Comprobar y limpiar zapatas de la aspiradora •

Comprobar y limpiar el fl otador de cierre de la aspiración •

Comprobar y limpiar fi ltro(s) de espuma del motor de aspiración •

Vaciar la tolva de residuos (modelos para barrer) •

Limpiar las boquillas pulverizadoras •

Comprobar el nivel de agua de todas las células de las baterías •

Inspeccionar las faldillas del portacepillos •

Inspeccionar y limpiar el fi ltro de la solución •

Purgar el sistema de detergente (sólo modelos AXP/EDS) •

Comprobar el desgaste y el ajuste de los frenos de pie y de Estacionamiento •

Lubricación - engrasadores •

* Comprobar los cepillos de carbono •

* Haga que Nilfi sk-Advance compruebe los cepillos de carbono del motor de aspiración una vez al año o después de 300 horas de funcionamiento.

Compruebe los cepillos de carbono de los motores de tracción y fregado cada 350 horas o una vez al año.

NOTA: Para más información sobre reparaciones de mantenimiento y servicio, consulte el Manual de Servicio.

8 Almacene la máquina bajo techo, en un lugar limpio y seco. Protéjala de la congelación. Deje los depósitos abiertos para airearlos.

9 Apague (O) el conmutador de llave principal (J) y retire la llave.

™

SE / BRX 700 y límpiela a fondo. Desmonte la tolva desde el lado izquierdo o derecho, levantándola e

MANTENIMIENTO DE LAS ZAPATAS DE LA ASPIRADORA

Compruebe las zapatas de la aspiradora a diario, que pueden desmontarse para facilitar la limpieza, véase “Desmontaje de las zapatas de la aspiradora”.

Elimine las fi bras, hilachas y cabellos acumulados.

MANTENIMIENTO DE LAS BOQUILLAS PULVERIZADORAS

Desmonte las boquillas pulverizadoras una vez a la semana. Tenga las boquillas toda la noche en una solución de agua y vinagre para eliminar los

depósitos químicos.

LUBRICACIÓN DE LA MÁQUINA

Ponga una vez al mes una pequeña cantidad de grasa en todos los engrasadores de la máquina hasta que salga grasa por los cojinetes.

Los lugares donde se encuentran los engrasadores son:

• Junta universal de la barra del volante

Una vez al mes, aplique aceite ligero de máquina para lubricar lo siguiente:

• Cadena de dirección

• Puntos de giro en general de las articulaciones del portacepillos

LIMPIEZA DE LOS FILTROS DEL MOTOR DE ASPIRACIÓN

Limpie los fi ltros del motor de aspiración a diario con aire comprimido. Si los fi ltros están muy sucios, lávelos con agua templada con jabón y aclare a fondo

con agua limpia. Deje que los fi ltros se sequen por completo antes de volver a montarlos en la máquina. NOTA DE MANTENIMIENTO: Tenga a mano un

segundo juego de fi ltros para usarlo hasta que se sequen los primeros.

MANTENIMIENTO DEL CEPILLO ELÉCTRICO

Compruebe el cepillo o cepillos a diario. Elimine las fi bras, hilachas y cabellos acumulados. Compruebe la longitud de las cerdas. Cuando las cerdas estén

desgastadas y tengan 12,7 mm (1/2 pulgada), pida a un técnico de mantenimiento que sustituya el (los) cepillo(s).

revised 3/06

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - B-11

Page 28

B-12 / ESPAÑOL

DESMONTAJE DE CEPILLO(S)

1 Apague el conmutador de llave principal (J).

2 Afl oje el botón negro (A) de la parte superior del conjunto en vacío y desmonte dicho conjunto. Deslice el cepillo para sacarlo del alojamiento del

portacepillos.

3 Para volver a montarlo, deslice el cepillo para introducirlo en el alojamiento, levante ligeramente, empuje y gire hasta que quede acoplado. NOTA:

Asegúrese de que las Ranuras (B) del extremo del cepillo quedan alineadas y que se acoplan fi rmemente a las lengüetas (C) del Conjunto del extremo

de tracción. Vuelva a montar el conjunto en vacío y apriete el botón negro (A).

+

*

)

Lado derecho de la máquina

Lado direito da máquina

Lato destro della macchina

Vista de frente del cepillo

Vista posterior da escova

Vista della parte terminale della spazzola

Vista de frente del conjunto del

extremo de tracción

Vista posterior do extremo da

transmissão

Vista della parte terminale del gruppo

terminale di azionamento

DESMONTAJE DE LAS ZAPATAS DE LA

ASPIRADORA

1 Apague el conmutador de llave principal (J).

2 Afl oje el botón negro (D) de la parte trasera del portacepillos. Levante la

barra (E) y desmóntela. Deslice la zapata fuera de su soporte soldado (F).

El procedimiento es igual para las dos zapatas.

3 Para montar siga el mismo procedimiento pero en orden inverso.

RECARGA DE BATERÍAS

Recargue las baterías cada vez que se use la máquina o cuando el indicador

de estado de las baterías (K) muestre una luz indicadora amarilla, roja o roja

intermitente.

Para cargar las baterías...

1 Presione la desconexión de las baterías (13).

2 Abra la tapa del compartimento de las baterías (16) para que la ventilación

sea adecuada.

3 Introduzca el conector del cargador en el Conector de las baterías (22).

4 Siga las instrucciones que aparecen en el cargador de las baterías.

5 Compruebe el nivel del fl uido en todas las células de las baterías después de recargar las baterías. Si es necesario, añada agua destilada para que el

nivel de fl uido llegue hasta el fondo de los tubos de llenado.

Vista desde la parte trasera izquierda de la máquina

Vista do lado esquerdo da traseira da máquina

Vista dalla parte posteriore sinistra della macchina

.

,

-

¡ADVERTENCIA!

No rellene las baterías antes de recargarlas.

Recargue las baterías exclusivamente en una zona bien ventilada.

No fume mientras maneja las baterías.

¡PRECAUCIÓN!

Para evitar daños a la superfi cie del suelo, después de la recarga limpie siempre el agua y el ácido de la parte superior de las

baterías.

COMPROBACIÓN DEL NIVEL DE ELECTROLITO DE LAS BATERÍAS

Compruebe el nivel de electrolito de las baterías al menos una vez a la semana.

Después de cargar las baterías, retire los tapones de ventilación y compruebe el nivel de electrolito de todas células de las baterías. Utilice agua destilada

para rellenar las baterías hasta el fondo del tubo de llenado.

¡No rellene demasiado las baterías!

¡PRECAUCIÓN!

Si las baterías están demasiado llenas, puede salpicar ácido al suelo.

Apriete los tapones de ventilación. Si hay ácido en las baterías, limpie la parte superior con una solución de levadura química y agua (2 cucharadas de

levadura química en 1 cuarto de agua [aprox. 1 litro]).

B-12 - FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series

Page 29

ESPAÑOL / B-13

SOLUCIÓN DE PROBLEMAS GENERALES DE LA MÁQUINA

Problema Causa probable Solución

Recogida escasa del agua Cámara de recuperación llena Vacíe la cámara de recuperación

Fuga en la tubería de drenaje de la Sujete la tapa de la tubería de drenaje o sustitúyala

cámara de recuperación

Fuga en la junta de la tapa del depósito Sustituya la junta / Asiente correctamente la tapa

de recuperación

Suciedad recogida en las zapatas de la Limpie las zapatas

Aspiradora

Manguera de aspiración obstruida Retire los residuos

Tapa del fi ltro de espuma mal puesta Ponga la tapa correctamente

Extracción defi ciente Cepillo(s) desgastado(s) Invierta o sustituya los cepillos

Limpiador químico incorrecto Consulte a Nilfi sk-Advance

Movimiento demasiado rápido de Reduzca la velocidad

la máquina

Flujo de solución inadecuado Depósito de solución vacío Llene el depósito de solución

o falta de solución

Tuberías, válvulas, fi ltro o surtidores de Lave las tuberías y limpie los surtidores y el fi ltro

la solución obstruidos

Válvula de control de la solución en Ponga la manilla de la válvula de control en posición

posición cerrada abierta

Válvulas de solenoide de la solución Limpie o sustituya las válvulas

La máquina no funciona Interruptor de parada de emergencia Vuelva a enchufar los conectores de las baterías

disparado

Interruptor de seguridad del asiento Compruebe si hay algún circuito abierto y sustitúyalo

del operador

Controlador principal del sistema Compruebe los códigos de error

(véase el manual de servicio)

Disyuntor de 10 amp.desconectado Compruebe si hay algún cortocircuito eléctrico y

reinicie

Ausencia de tracción de las Controlador de velocidad del sistema Compruebe los códigos de error

ruedas en marcha adelante/ de tracción (véase el manual de servicio)

atrás

Disyuntor de 45 amp. desconectado Compruebe si se ha producido una sobrecarga del

motor de tracción

Interruptor de parade de emergencia Vuelva a enchufar los conectores de las baterías

disparado

La aspiración se apaga y la Manguera(s) de aspiración obstruidas Elimine los residuos

Pantalla indica “FULL” y la

cámara de recuperación no Aspiración de grandes cantidades de Reduzca la velocidad o desactive la función de

está llena agua a alta velocidad de desplazamiento apagado automático

(véase el manual de servicio)

Barrido poco efi caz Tolva de residuos llena Vacíe y limpie la tolva

Cepillos gastados Sustituya los cepillos

Las cerdas han adquirido una forma Invierta los cepillos

No hay fl ujo de detergente Cartucho de detergente vacío Llenar cartucho de detergente

(Sólo modelos AXP/EDS) Línea de fl ujo de detergente obstruida o torcida Purgar el sistema, enderezar las líneas para

eliminar pliegues

Tapa de junta seca en cartucho de detergente Sellar tapa de junta seca

sin sellar

Falta imán en el deslizador de mezcla Sustituir deslizador

de detergente

Cableado de la bomba de detergente Conectar o reconectar cableado

desconectado o hacia atrás

revised 3/06

FORM NO. 56041627 - AquaRide™ SE, AquaRide™ SE AXP / BRX 700 series - B-13

Page 30

B-14 / ESPAÑOL