Nilfisk 118 owners Manual

ELECTRIC EXPLOSION PROOF VACUUM CLEANER MODEL

118EXP

P/N 7 24190 A CONTACT DE MISE À LA TERRE DU FABRICANT

ASPIRATEUR, LES OPERATEURS DOIVENT LIRE ET COMPRENDRE LES

ATENCIÓN: PARA GARANTIZAR LA UTILIZACIÓN SEGURA DE ESTE ASPIRADOR,

LOS OPERADORES DEBEN LEER Y COMPRENDER LAS SIGUIENTES

INSTRUCCIONES ANTES DE INTENTAR PONER LA MÁQUINA EN MARCHA

MISE EN GARDE: AFIN D'ASSURER UNE UTILISATION SECURITAIRE DE CET

OPERATORS MUST READ AND UNDERSTAND THE FOLLOWING

Class II - Group E, F and G Hazardous Locations

For Use in Class I - Group D

INSTRUCTIONS BEFORE ATTEMPTING TO PLACE THE MACHINE IN SERVICE

CAUTION: TO INSURE THE SAFE USE OF THIS VACUUM MACHINE,

Pour utilisation dans les emplacements

dangereux de Classe I - Groupe D, Classe II - Groupes E, F et G

Para la utilización en lugares peligrosos de

INSTRUCTIONS QUI SUIVENT AVANT LA MISE EN MARCHE DE CETTE MACHINE

MODELO DE ASPIRADOR ELÉCTRICO A PRUEBA DE EXPLOSIÓN

ASPIRATEUR ANTI-DÉFLAGRANT ÉLECTRIQUE MODÈLE

(dry use only) (sólo uso en seco) (utilisation sèche seulement)

INSTRUCTIONS FOR USE

INSTRUCCIONES DE USO

INSTRUCTIONS D'UTILISATION

clase I - grupo D, Clase II - grupo E, F y G

Nilfisk-Advance America, Inc., 300 Technology Drive, Malvern, Pa 19355, (610) 647-6420

C309 02/2010

INSTRUCTIONS FOR USE

PAGE 1

English

INSTRUCTIONS FOR USE

PAGE 2

Contents Page

Test For Ground Continuity …………………………………………………………………………. 2

Preparing the Machine for Dry Recovery …………………………………………………………. 3

Making Adjustments to Container Gaskets ……………………………………………………… 3

Using the Vacuum………………………………………………………………………………………. 4

Using the Vacuum/ Turning the Machine On/Off…………………………………………………….. 5

Using the Vacuum/ Cleaning the Main Filter…………………………………………………………. 5

Using the Vacuum/ Emptying the Container…………………………………………………………. 5

Replacing Parts ………………………………………………………………………………………… 6

Replacing Parts/ Replacing the HEPA Filter ……………………………………………………….. 6

Replacing Parts/ Replacing Main filter ……………………………………………………………… 6

Replacing Parts/ Replacing the optional (upstream) HEPA Filter ………………………………… 7

Parts Explosion ………………………………………………………………………………………… 8

Parts Explosion/ Container unit ……………………………………………………………………….. 8

Parts Explosion/ Suction unit …………………………………………………………………………. 9

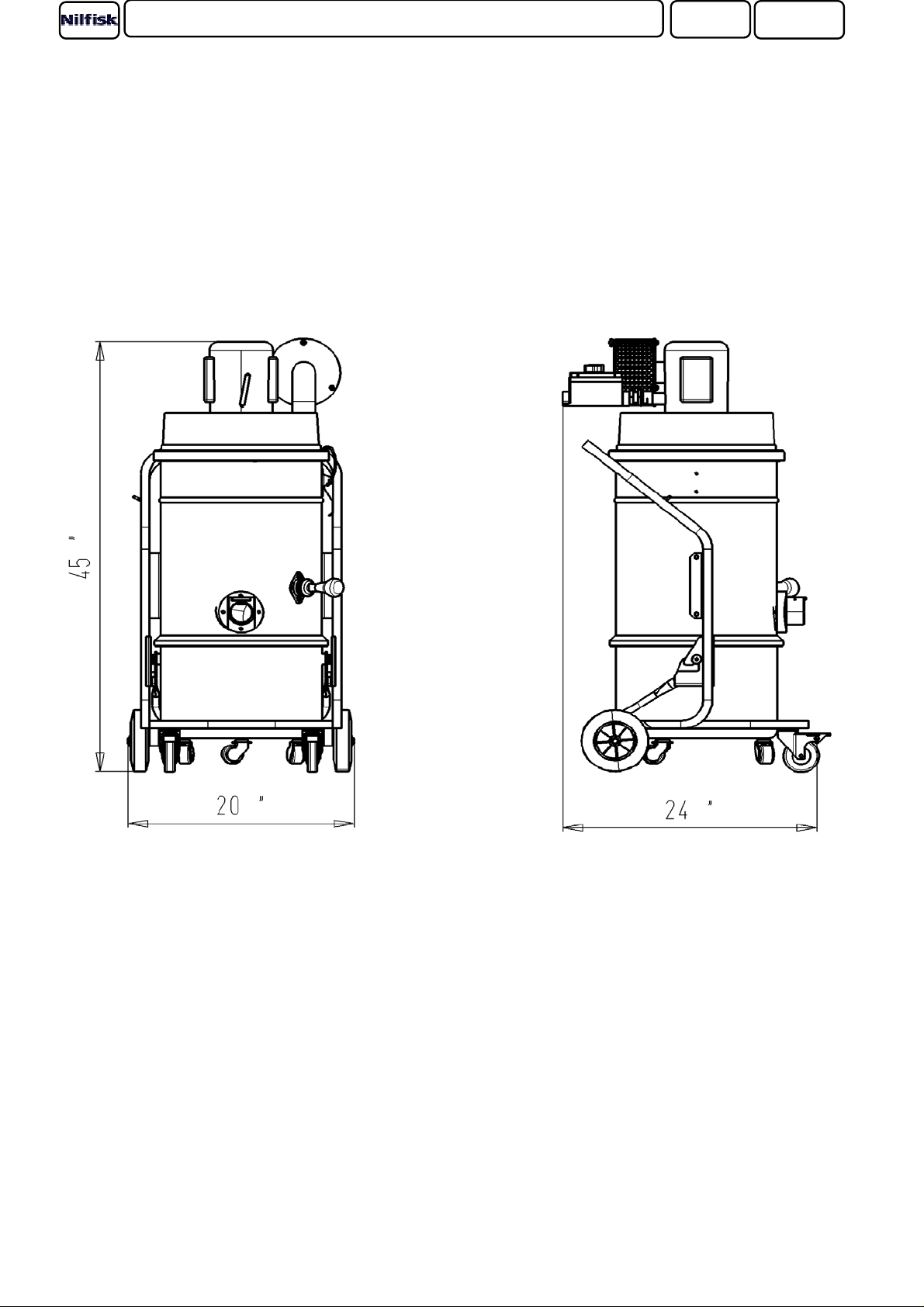

Dimensions ………………………………………………………………………………………………. 10

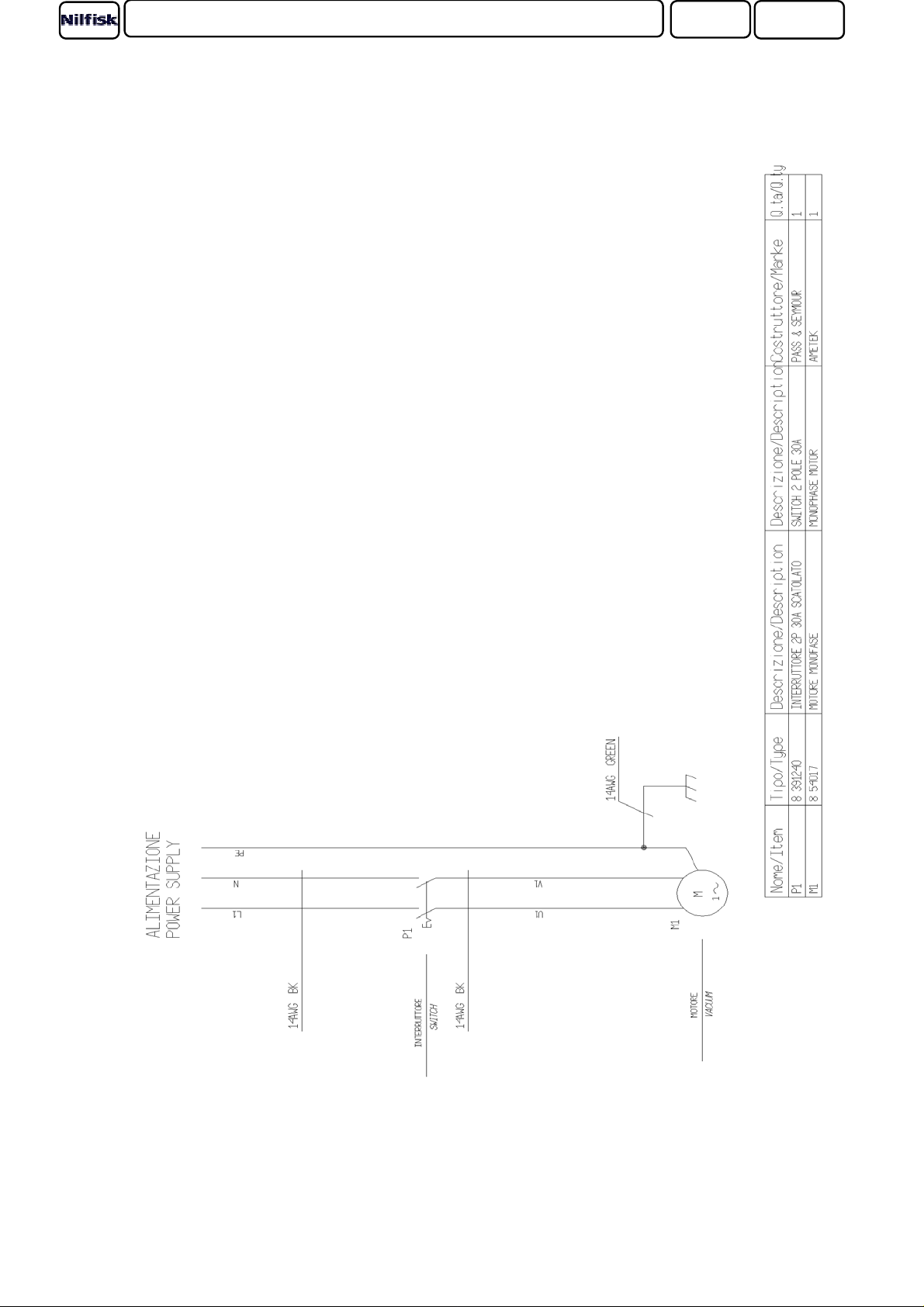

Wirings Diagrams ……………………………………………………………………………………… 11

Applications …………………………………………………………………………………………….. 12

Grounding Instructions ……………………………………………………………………………….. 12

Tools and Attachments ………………………………………………………………………………. 12

Warranty ………………………………………………………………………………………………… 13

Accessories ………………………………………………………………………………………………… 14

PLEASE READ THESE INSTRUCTIONS COMPLETELY BEFORE USING THE MACHINE

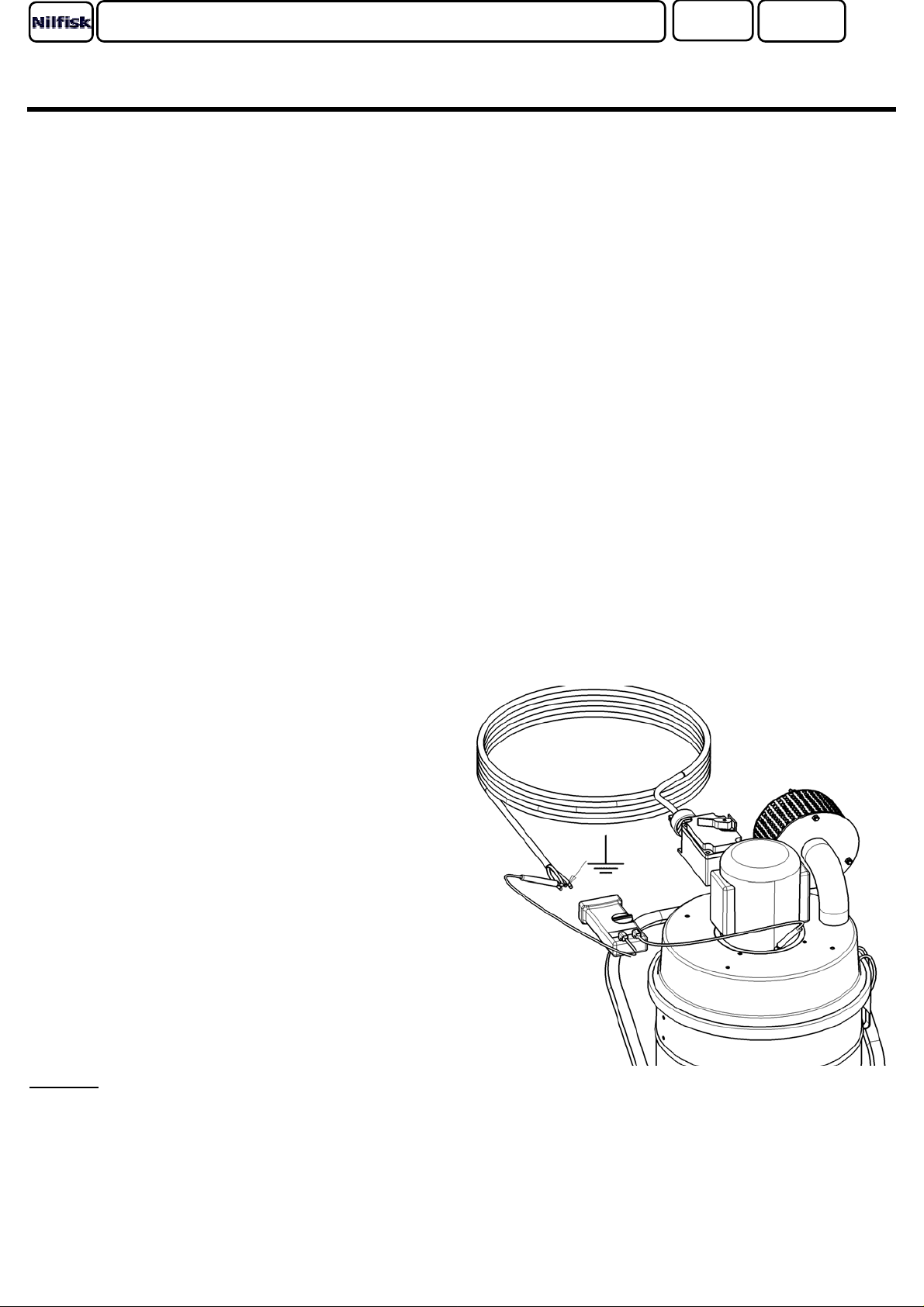

CAUTION: THE OPERATOR SHOULD TEST THE VACUUM MACHINE FOR GROUND

CONTINUITY BEFORE EACH USE

TEST FOR GROUND CONTINUITY (Ul 1213 par. 22)

1. Make sure that the grounding path between the

terminal for connection of the grounding conductor of

the power cord and parts of the Vacuum is assured.

2. Check the ground continuity with an appropriate

continuity tester.

3. The resistance of the grounding continuity path

shall not exceed 0.1 ohm.

WARNING

Using the tester, check for continuity between each connection of the vacuum

cleaner (example: tool to wand, wand to hose, hose to machine, etc) If the problem

can not be corrected refer the unit to an AUTHORIZED SERVICE CENTER ONLY.

: If unacceptable results are recorded, DO NOT OPERATE THE CLEANER.

INSTRUCTIONS FOR USE

PREPARING THE MACHINE FOR DRY RECOVERY

1. Release latches and remove power-head from recovery tank.

2. Insure that the static dissipating, polyester felt filter is properly

mounted in the recovery tank. If not, refer to the instructions for

“Replacing the Main Filter” (page 6).

3. Place the power-head back on the recovery tank and fasten latches.

1

4. Attach the static dissipating hose to the suction

inlet on the recovery tank and attach the desired tool to the hose.

5. Conduct a ground continuity check before operating (Figure 1).

6. Operate this machine only on properly grounded electrical outlets.

PAGE 3

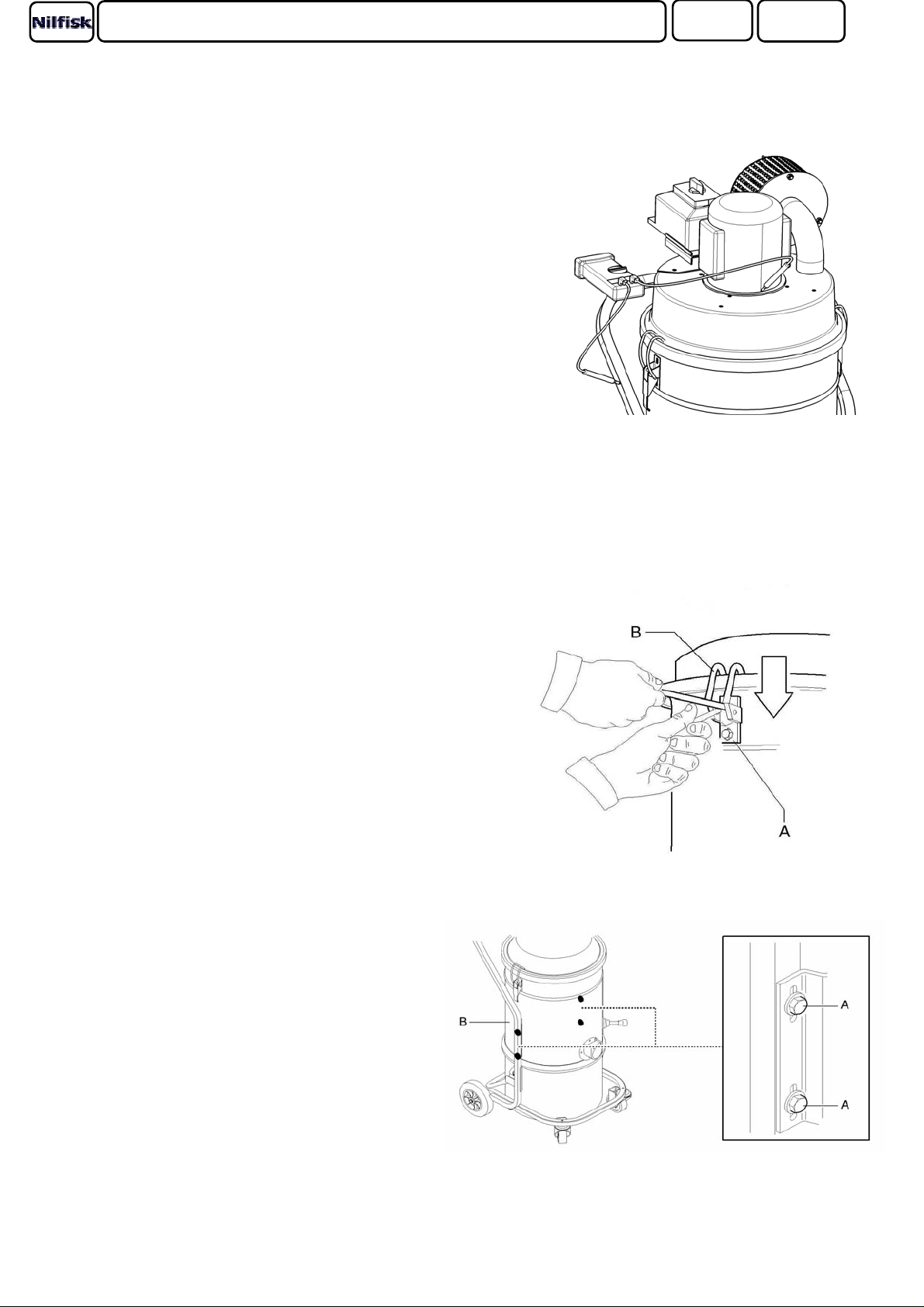

MAKING ADJUSTMENTS TO CONTAINER GASKETS

If you suspect the gasket between the motor head and the filter

chamber is not sealing properly:

1. Loosen latch screws "A" and slide latch downward.

2. Tighten latch screws.

3. Turn on the unit and inspect the seal between the motor

head and filter chamber.

4. Replace the gasket if the seal continues to leak.

If you suspect the gasket between the filter chamber and the

collection can is not sealing properly:

1. Loosen the screws "A" that lock filter chamber "B" against

the vacuum structure.

2. Lower filter chamber "B" slightly and retighten screws "A".

3. Turn on the unit and inspect the seal between the filter

chamber and the collection can.

4. Replace the gasket if the seal continues to leak.

USING THE VACUUM

.

.

.

INSTRUCTIONS FOR USE

PAGE 4

CAUTION:

FOR GROUND CONTINUITY BEFORE EACH USE

WARNING

WHILE WORKING WITH HAZARDOUS MATERIAL

FAILURE TO DO SO WILL EXPOSE PEOPLE IN THE WORK

AREA AND OTHERS TO HAZARDOUS MATERIALS WHICH

IS A SERIOUS HEALTH RISK

EMPTYING: IF THIS VACUUM CLEANER IS USED TO COLLECT HAZARDOUS

MATERIALS, DO NOT ATTEMPT TO OPEN OR EMPTY ITS CONTENTS

WITHOUT PERSONAL PROTECTIVE CLOTHING AND RESPIRATORY

PROTECTION. ALL DISPOSED FILTERS, BAGS, DEBRIS SHOULD

BE TREATED AS A HAZARDOUS SUBSTANCE AND MUST BE

DISPOSED OF IN ACCORDANCE WITH ALL FEDERAL, STATE

AND LOCAL REGULATIONS

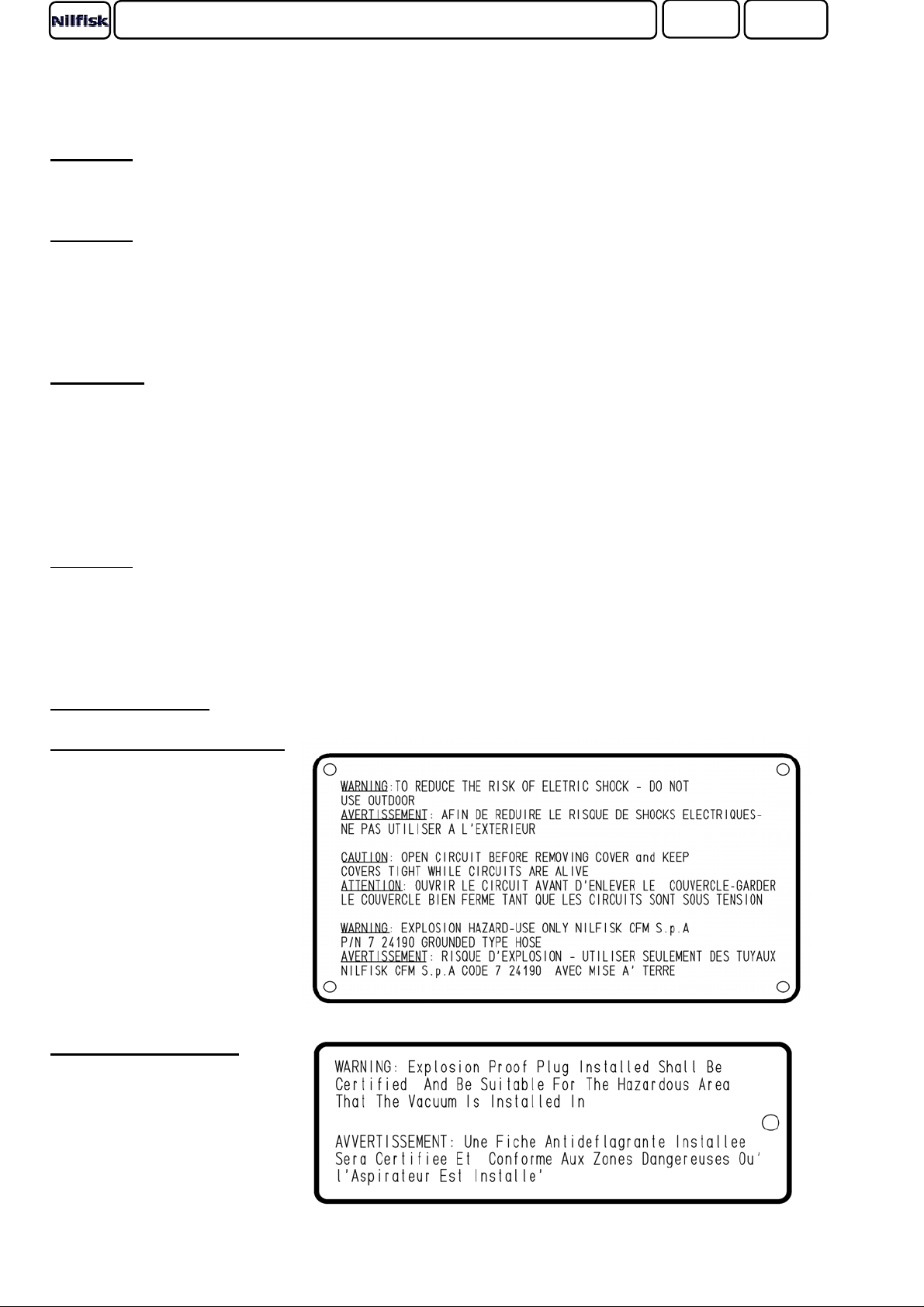

WARNING: EXPLOSION HAZARD - USE ONLY NILFISK CFM P/N 7 24190

GROUNDED TYPE HOSE.

THIS EQUIPMENT IS CERTIFIED FOR EXPLOSION-PROOF

OPERATION,ONLY IF USED WITH SUPPLIED OR RECOMMENDED

HOSE AND TOOLS. ANY ALTERATION TO THIS EQUIPMENT BY

A THIRD PARTY WILL NULLIFY ITS CERTIFICATION.

OPERATORS SHOULD TEST THE VACUUM MACHINE

: A HEPA FILTER MUST BE INSTALLED IN THE VACUUM MACHINE

WARNING LABELS

-ON THE VACUUM CLEANER

-ON THE POWERCORD

:

INSTRUCTIONS FOR USE

USING THE VACUUM

TURNING THE MACHINE ON/OFF 1

1. Plug the vacuum cleaner into an approved power source.

2. Turn on the vacuum cleaner by rotating the main switch

to the “ON” position (Figure 1).

3. Turn off the vacuum cleaner by rotating the main switch

back to the “OFF” position (Figure 1).

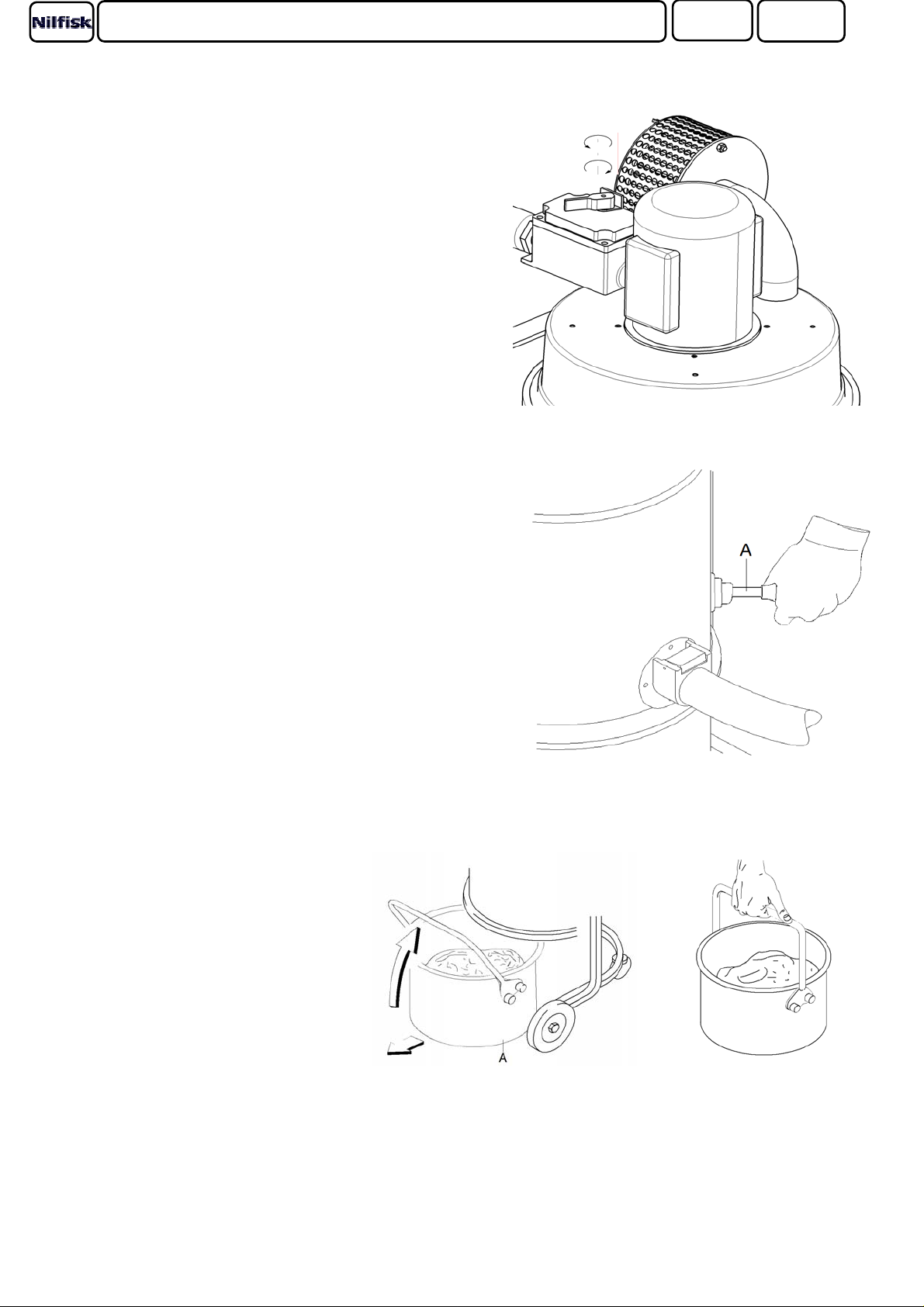

CLEANING THE MAIN FILTER

PAGE 5

If the performance of the vacuum cleaner decreases during

use, it may be necessary to clean the primary filter:

1. Turn off the vacuum and disconnect the vacuum from

its power source.

2. Actuate the filter shaker "A" (Figure 2) by raising

and lowering the lever.

3. Repeat this several times to shake the dirt from the

primary filter.

4. Wait a few minutes for the dust to settle at the bottom

of the container.

5. Empty the container

2

EMPTYING THE CONTAINER

1. Turn off the vacuum and disconnect the

vacuum from its power source. 3 4

2. Detach container "A" (Figure 3) by lifting

the handle.

3. Slide the container out from the machine

and carry the container by the handle (figure 4).

p

INSTRUCTIONS FOR USE

REPLACING PARTS

REPLACING THE HEPA FILTER

1

1. Remove the wing nuts that secure the HEPA screen (Figure 1).

2. Pull off the screen surrounding the three posts.

3. Remove old HEPA cartridge by carefully pulling cartridge through the posts.

4. Remove the old foam gasket from around the exhaust port.

5. Place a new foam gasket around the exhaust port (Figure 2).

2

6. Carefully install new HEPA cartridge against the foam

gasket with the label facing out.

PAGE 6

7. Reinstall the screen around the posts.

8. Tighten the wing nuts.

REPLACING THE MAIN FILTER

1. Release the latches "A" and remove the Motor Head "B" (Figure 3). 3

2. Raise one side of the filter and reach down under the filter

with one hand to remove s

the filter shaker lever "E" from the filter ring "F" (Figure 5).

3. Lift up of the filter and cut the ties (G) that attach the filter

to the ring "F"(Figure 5).

4. Unscrew clamp "H" and remove the upper ring "I" (Figure 4).

5. Mount the upper ring "I" onto the new filter and secure

the ring in place with clamp "H" (Figure 4).

6. Secure the Filter "C" to the ring "F" using the ties "G"

supplied in the new filter kit (Figure 5).

lit pin "D". This will release

4

7. Place the new filter assembly inside the filter chamber and

reconnect the assembly using the split pin "D" (Figure 5).

8. Mount the motor head "B" onto the machine and secure 5

in place with the latches "A" (Figure 3).

9. Dispose of the old filter in accordance with all federal,

state and local regulations.

INSTRUCTION FOR USE

REPLACING PARTS

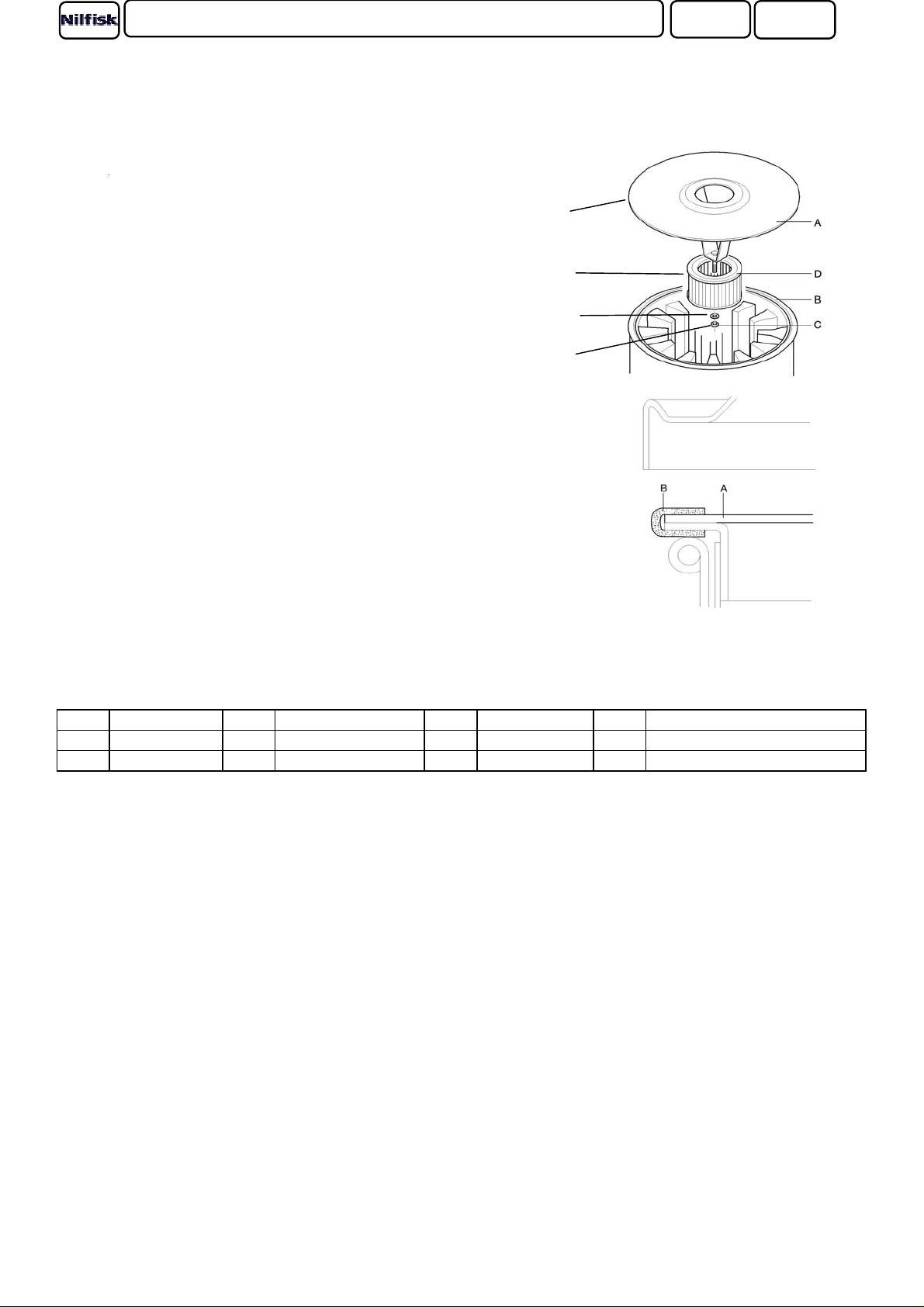

REPLACING THE OPTIONAL (UPSTREAM) HEPA FILTER

1. Release the latches and remove the motor head.

2. Separate disc "A" from gasket "B" and remove

disc/filter assembly from the vacuum machine.

3. Loosen nut "C" and remove the HEPA filter "D".

4. Fit a new HEPA Filter onto Disc"A" and tighten

in place.

5. Slide the disc with new filter into gasket "B".

6. Replace the motor head onto the vacuum machine.

PAGE 7

7. Dispose of the old filter in accordance with all

federal, state and local regulations.

POS. N^CODE Q DESCRIPTION POS. N^CODE Q DESCRIPTION

1 8 33323G 1 DISC 3

2 8 17262 1 HEPA FILTER 4

BR010X

BN10X

1 WASHER

1 NUT

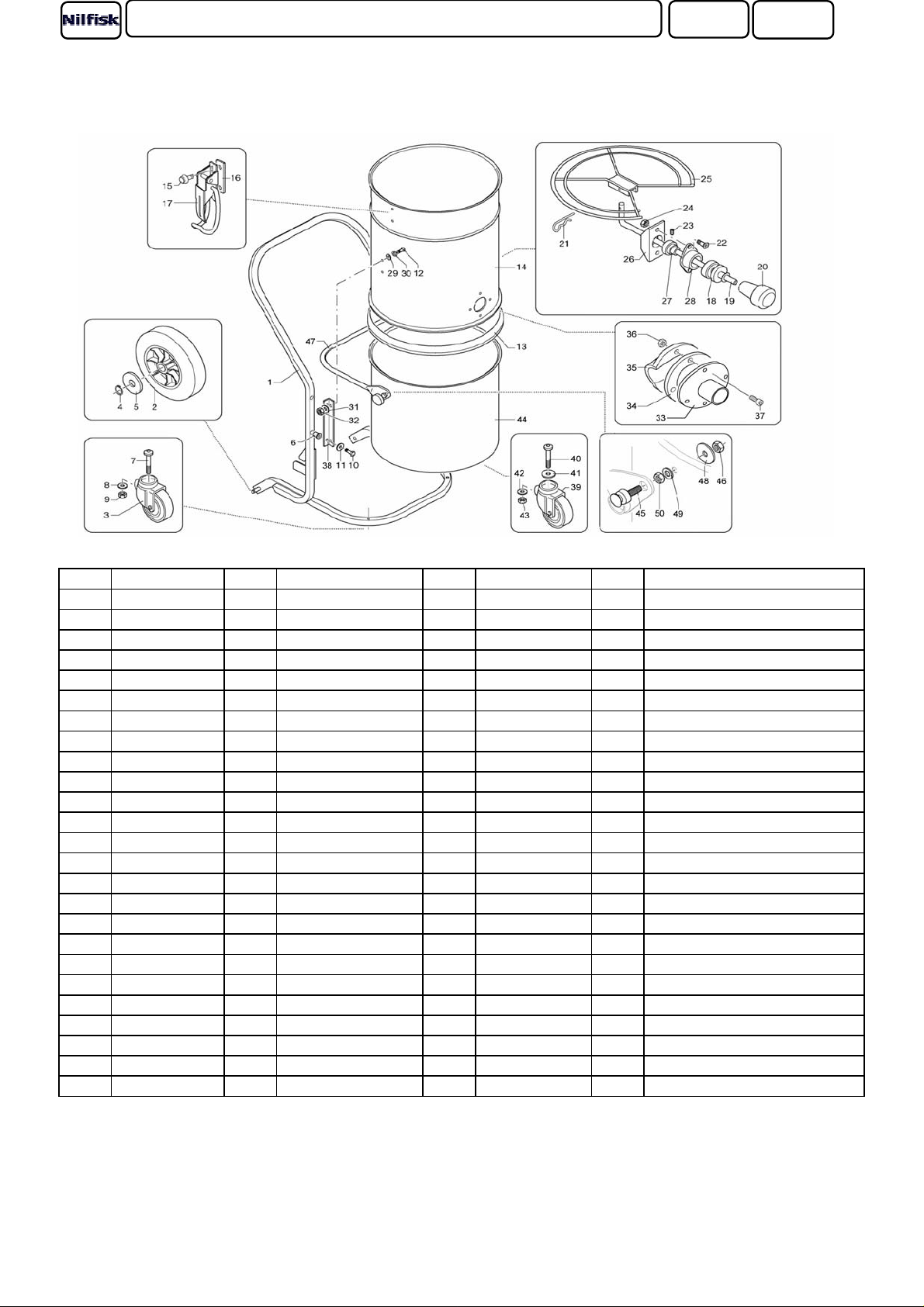

PARTS EXPLOSION

CONTAINER UNIT

INSTRUCTION FOR USE

PAGE 8

CT DE N^CODE Q DESCRIPTION POS. N^CODE Q DESCRIPTION

1 8 36359 1 CAR 26 8 15130 1 SUPPORT

2 8 40261 2 WHEEL 27 8 38047 1 ARTICULATION

3 8 40910 2 WHEEL 28 8 15131 1 BELOWS HOLDER

4 BSEE15G 2 CLIP 29 BR00824X 4 WASHER

5

6 8 38059 4 RIVET

7 BVTBCE0840ZB 2 SCREW 32 BDNO8X 4 NUT

8 BRO08ZB 2 WASHER 33 8 32086 1 FILLER

9 BDABO8ZB 2 NUT 34 8 17005 1 SEAL

10 BVTEO62OZB 4 SCREW 35 8 32314 1 DEFLECTOR

11 BROO618ZB 4 WASHER 36 BDNO5X 4 NUT

12 BVTBCEO816X 4 SCREW 37 BVTBCEO525X 4 SCREW

13 8 17226 1 SILICON SEAL 38 8 18970 2 BRACKET

14 8 11110 1 CHAMBER 39 8 40402 3 WHEEL

15 BVTEZO6O8X 4 SCREW 40 BVTBCEO82OX 3 SCREW

16 8 18010 2 PLAQUE 41 BR00832X 3 WASHER

17 8 36030 2 LOCK 42 BROO8ZB 3 WASHER

18 8 40393 1 BELLOWS 43 BDAO8ZB 3 NUT

19 8 33221 1 ROD-INOX 44 8 30337 1 CONTAINER

20 8 40373 1 HANDGRIP 45 8 14579 2 PIN

21 8 38018 1 COTTER PIN 46 BDAO8X 2 NUT

22 BVTBCO616X 1 SCREW 47 8 18971 1 HANDLE

23 BVSTCECO4O6X 1 DOWEL 48 BR00832X 2 WASHER

24 BDAO6X 1 NUT 49 BROO8X 2 WASHER

25 8 33174 1 RING 50 BDNO8X 2 NUT

BRO15ZB 1 WASHER 30 BRODO8X 4 WASHER

31

BROO8X 4 WASHER

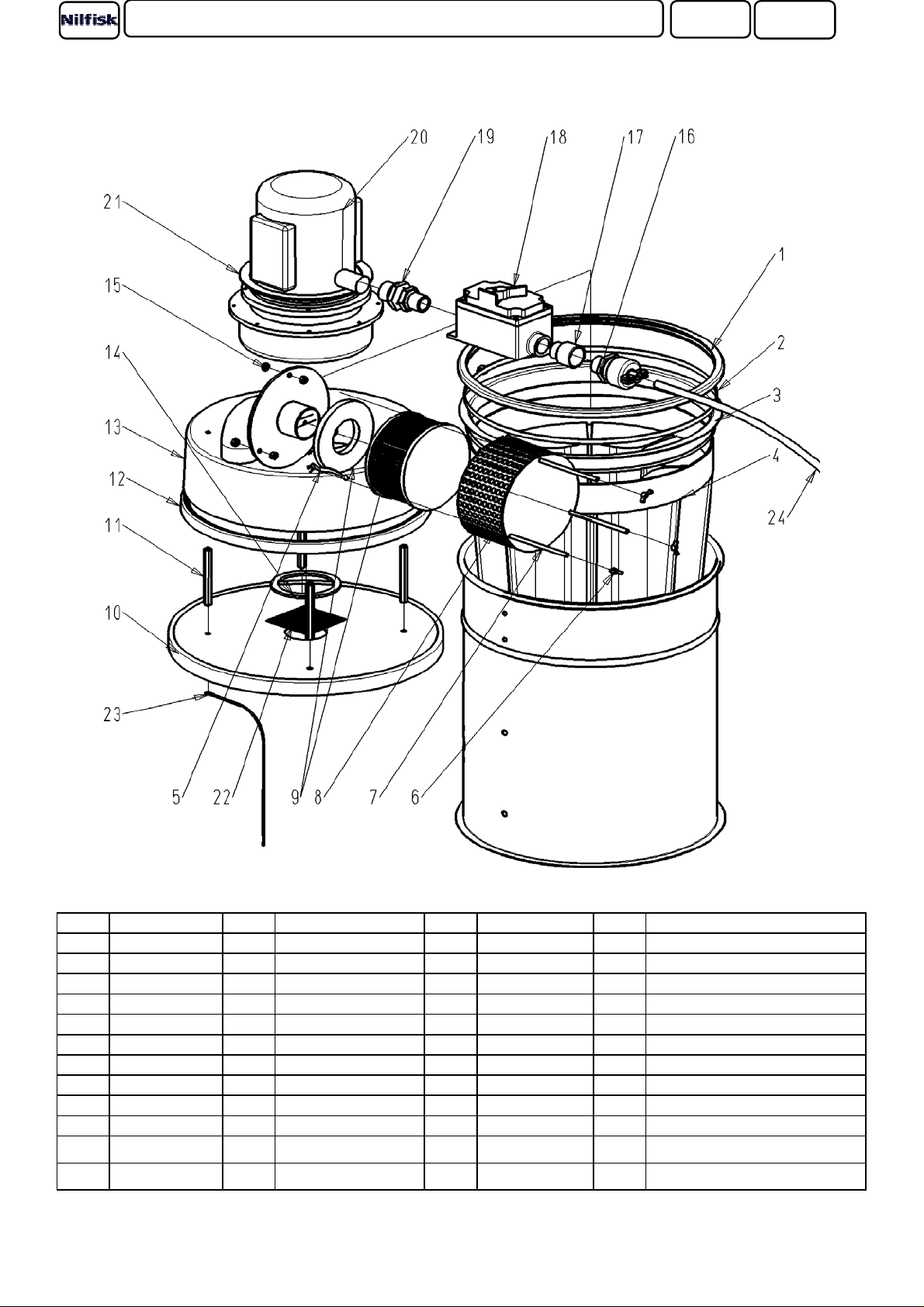

PARTS EXPLOSION

SUCTION UNIT

INSTRUCTION FOR USE

PAGE 9

POS. N^CODE Q DESCRIPTION POS. N^CODE Q DESCRIPTION

1 8 17125 1 GASKET 13 8 12403 1 CAP

2 8 18078 1 STOP 14 8 17006 3 GASKET

3 8 15009 1 RING

4 8 17140 1 FILTER 16 8 391241 1 CABLE-PRESS

5

6 8 38073 3 WING NUTS 18 8 391240 1 SWITCH

7 8 38072 3 POSTS 19 8 391243 1 CONNECTOR

8 8 31698 1 SCREEN 20 8 54017 1 MOTOR

9 01727631 1 HEPA FILTER 21 8 17804 1 GASKET

10 8 35130 1 MOTOR FIXING DEVICE 22 8 13066 1 MESH

11 8 14623 4 STUD 23 8 39669 1 EARTH CABLE

12 8 17124 1 GASKET 24 8 391244 1 CABLE

8 18980 2 GROUNDING TAB 17 8 391242 1 CONNECTOR

15

BDN06X 8 NUT

DIMENSIONS

INSTRUCTION FOR USE

PAGE 10

P/N 7 24190 A CONTACT DE MISE À LA TERRE DU FABRICANT

WIRING DIAGRAMS

INSTRUCTION FOR USE

PAGE 11

INSTRUCTION FOR USE

DANGER

WARNING: EXPLOSION HAZARD - USE ONLY NILFISK CFM P/N 7 24190 GROUNDED TYPE HOSE.

INSTRUCTION FOR USE

INSTRUCTION FOR USE

PAGE 12

PAGE 12

PAGE 12

APPLICATIONS

The electric motors used in the Nilfisk Explosion Proof vacuum Cleaner model 118EXP have been listed by

Underwriters Laboratories Inc. in guide PTDR file E25653, for use in the following hazardous locations classifications:

Class l/Group D Atmospheres containing: gasoline, petroleum, naphtha, benzine, butalie, propane, alcohol,

acetone, benzol, lacquer solvent vapors or natural gas.

Warning: Do not use this or any other Nilfisk CFM vacuum for the purposes of cleaning or extracting

fuel residues from airplanes or ships.

Class ll/Group E

Class ll/Group F

Class ll/Group G

NOTE: The motors used in this vacuum cleaner are designed for use in commercial and industrial vacuum

equipment which employs filters to remove dirt from the airstream before reaching the motor’s vacuum fans.

Do not operate the vacuum cleaner without the proper filter system installed.

Atmospheres containing: metal dust

Atmospheres containing: carbon, black coal or coke dust.

Atmospheres containing: flour, starch or grain dust.

GROUNDING INSTRUCTIONS

This vacuum cleaner must be connected to an earth ground source. Cord plug installed by customer,shall be

suitable for the hazardous locations area that vacuum is installed in. If the vacuum cleaner should malfunction or

break down, grounding provides a path of least resistance for electric current to reduce the risk of electrical shock.

This vacuum cleaner must be properly installed and grounded in accordance with all local codes and ordinances.

: Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service person if you are in doubt as to whether the outlet is properly grounded.

Use only with certified explosion-proof plugs and outlets.

TOOLS AND ATTACHMENTS

This equipment is only certified for explosion-proof operation if it is equipped with the proper

conductive hose and tools. Any alteration to this equipment by a third party will nullify its certification.

Loading...

Loading...