Page 1

Nilfi sk GM 80 - GM 80i

Instructions for use

823 0046 000 E (03. 2017)

Page 2

Section I: English

Nilfisk GM 80 & GM 80i

INSTRUCTIONS FOR USE

& PARTS LIST

Table of Contents

Important Safety Instructions

Warranty

Machine Setup

Using the Machine

Emptying

Disposal

Maintenance/Filter Replacement

Troubleshooting

Loss of Power

Loss of Suction

Technical Specifications

Contact Information

2

2

3

4

5

5

5

6

7

7

For Instructions for Use on HEPA/ULPA filter installation, please refer to

the addendum titled, “ABSOLUTE FILTERS – End User Information.”

Page 3

IMPORTANT SAFETY INSTRUCTIONS

PLEASE READ THESE INSTRUCTIONS COMPLETELY BEFORE USING THE

MACHINE. DEPENDING ON LOCAL REGULATIONS AND THE COMPOSITION

OF THE MATERIALS YOU HAVE COLLECTED, THERE MAY BE

REQUIRMENTS FOR SPECIAL HANDLING AND DISPOSAL OF THE

COLLECTED DEBRIS. CONSULT YOUR LOCAL OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION (OSHA) AND ENVIRONMENTAL PROTECTION

AGENCY (EPA) OFFICIALS FOR DETAILS.

CAUTION: This Nilfisk vacuum cleaner or any other vacuum cleaner is not to be used in

explosion-hazardous areas, as serious injury could result.

Under no circumstances may this cleaner safely be used for the collection of hazardous or

toxic materials unless equipped with a special HEPA(High Efficiency Particulate Air)

filter and bag which have been installed according to written instructions from Nilfisk.

ATTENTION EMPLOYER: Please ensure these Instructions for Use are made available

and understood by your employees or any other persons who may use this equipment.

To list all toxic and hazardous materials would be beyond the scope of these Instructions.

It is the Employer's responsibility to identify, for Employees' and others' information,

hazardous or toxic materials which may be collected by this equipment.

Your new Nilfisk industrial vacuum cleaner is a precision-engineered instrument

designed for exceptionally fine filtration. Ordinary vacuum cleaners do not have HEPA

filters, and cannot be safely used for hazardous dust collection. This Nilfisk machine is

safe to use with fine powders or hazardous materials, as long as certain precautions are

taken. Proper care of this cleaner is essential to the maintenance of its ultrafine filtering

capabilities.

BEFORE USE: DO NOT ATTEMPT TO OPERATE THIS CLEANER UNTIL YOU

HAVE INSTALLED ITS VARIOUS COMPONENTS ACCORDING TO THE

FOLLOWING INSTRUCTIONS:

WARRANTY

The Nilfisk companies warrant that Nilfisk equipment will be free of defects in

workmanship or material for a period of two years from the date of delivery. Should any

failure to conform to this warranty appear, the Nilfisk companies shall upon notification

within such time period, correct such non-conformity, at its option, either by repairing

any defective part or parts, or by replacing a part or parts provided that the equipment is

returned to an authorized Nilfisk service facility. In all cases freight both ways will be at

2

Page 4

the expense of the customer. Equipment shall not be returned without advance notice to,

3

and consent of the Nilfisk companies.

EXCEPT AS SPECIFICALLY SET FORTH HEREIN, THE NILFISK COMPANIES

MAKE NO WARRANTIES, EITHER EXPRESSED OR IMPLIED AS TO ANY

MATTER WHATSOEVER, INCLUDING WITHOUT LIMITATION ANY AND ALL

WARRANTIES OF MERCHANTABILITY, FITNESS FOR PURPOSE, OR OTHER

WARRANTIES, ALL OF WHICH ARE EXPRESSLY DISCLAIMED AND

EXCLUDED. NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR

SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES,

INCLUDING BUT NOT LIMITED TO LOSS OF PRODUCTION, LOSS OF TIME,

LOSS OF PROFITS OR OTHER SIMILAR INDIRECT LOSSES WHICH MIGHT

OCCUR AS A RESULT OF DEFECTS, PARTIAL OR TOTAL FAILURE OF THE

PRODUCT TO PERFORM AS SPECIFIED.

Correction of non-conformities or defects in the manner and for the period of time

provided above, shall constitute fulfillment of all liabilities of the Nilfisk companies to

the customer, whether based on contract, negligence or otherwise with respect to, or

arising out of such equipment. The remedies set forth herein are exclusive, and the

liability of the Nilfisk companies with respect to this sale or anything done in connection

therewith, whether in contract, in tort, under any warranty, or otherwise, shall not except

as expressly provided herein, exceed the price of the equipment or part on which such

liability is based.

The warranty does not cover repairs due to normal wear and tear, accident, neglect,

misuse or abuse, incorrect installation or use other than as described in the

instruction booklet. Breaks in hoses and cables are not covered. This warranty is

rendered void if the motor number plate is removed or defaced or if repairs are

made or attempted by persons not authorized by the Nilfisk companies.

MACHINE SET-UP:

Before turning on the motor: Install the microfilter (#616821-Felt,

#017230-AES Polycomposite, #017220-01-Gore-Tex®), the small

felt sock, on the bottom of the motor by sliding the filter over the

Photo 1

Photo 1

Photo 1

Photo 1

motor bottom, and covering as much of the bottom as the depth of

the filter will permit (photo 1). Be sure the filter's elastic collar

holds the filter snugly in place and is as high up on the motor

bottom as possible.

2. Next, mount the HEPA filter (#01710440) according to the

accompanying bulletin. Place the motor back in the cavity in the

top of the cleaner (photo 2). Fasten the motor head in place using

Photo 2

Photo 2

32

Page 5

either the positive twist safety latches or the standard latches,

depending on which option you purchased.

. Installing the Polyliner and Paper Bag: Twist and release the two

positive twist safety latches, or the standard latches, depending on

your machine. They are located on the bod

and back. Lift off the top. Open the polyliner and place in the

bottom of the container with its walls flush against the container

sides and lipped under the container inlet (photo 3). The excess

length of polyliner is draped over the top of the container and

Photo 3

Photo 4

Photo 4

4. The GM 80 and GM 80i offer a package of standard accessories that can be connected

in the following manner. Affix the vacuum hose to the vacuum by inserting it into the

orifice on the lower container. Once it is inserted, rotate the inlet coupler a quarter turn to

lock it into place. Either of the two straight 22 inch wands can be fitted to the other end of

the hose. You can connect the combination floor nozzle or 5 inch upholstery nozzle to the

end of the hose. The rubber crevice nozzle and the 3 inch round brush can be connected

to the end of the straight wand or the curved steel tube of the hose. There is a list of

optional accessories that can be supplied for both models. Please consult your District

Sales Manager or the Customer Service Department at (800) NILFISK for a list of

optional accessories.

down the outside then rolled at the end to permit the container

clips to close.

Install a paper bag inside the polyliner according to the

illustrations printed on the paper bag itself (photo 4). Replace the

top container and fasten the two clips.

y of the container, front

USING THE MACHINE:

Starting and stopping: Press the gray button on the upper

front portion of the vacuum (photo 5).

Photo 5

Correct use of the machine: Thi

collection only. Do not use this vacuum to pick up liquids, or any wet materials.

s machine is not a wet/dry vacuum. It is intended for dry

4

Page 6

EMPTYING:

5

IF THIS VACUUM CLEANER IS USED TO COLLECT HAZARDOUS MATERIAL,

DO NOT ATTEMPT TO OPEN OR EMPTY ITS CONTENTS WITHOUT PERSONAL

PROTECTIVE CLOTHING AND RESPIRATORY PROTECTION.

To empty the container and its contents, first turn off the motor.

To empty the container and its contents, first turn off the motor.

Allow the cleaner to sit undisturbed for at least thirty (30)

Allow the cleaner to sit undisturbed for at least thirty (30)

seconds. Then twist and release the container clips. Once the

seconds. Then twist and release the container clips. Once the

seal is broken, turn on the motor again. This will prevent

seal is broken, turn on the motor again. This will prevent

ultrafine particles which are still suspended in the air inside the

ultrafine particles which are still suspended in the air inside the

container from escaping into the work place. Lift off the

container from escaping into the work place. Lift off the

container top. Remove the polyliner and paper bag within it

container top. Remove the polyliner and paper bag within it

(photo 6). Then seal off the polyliner with the paper bag inside

(photo 6). Then seal off the polyliner with the paper bag inside

and install a new polyliner and paper bag according to step 2,

Machine Setup.

and install a new polyliner and paper bag according to step 2,

Photo 6

DISPOSAL:

Depending on local regulations, and the composition of the material you have collected,

there can be a requirement for special handling and labeling of the filled and sealed

plastic bags. Consult your local Occupational Safety and Health Administration (OSHA)

and Environmental Protection Agency (EPA) official for details.

MAINTENANCE

Routine Maintenance:

To ensure maximum performance of your Nilfisk vacuum cleaner, be sure to check your

main filter regularly. Your filter may need to be shaken out to remove caked dust from

time to time.

Filter Replacement:

To ensure that your Nilfisk vacuum cleaner delivers the years of trouble-free operation

for which it was designed, it is necessary to check and replace filters regularly.

1. Main Filter: The large napped cotton bag which is semipermanently mounted inside the container will not require

frequent replacement. The main filter must be replaced when

the cleaner no longer develops powerful suction, yet bags are

not full and other filter components are not clogged. Extend

main filter service life by frequent changes of disposable

polyliners and paper bags (photo 7).

Photo 7

Page 7

2. Microfilter: This small polyester felt sock, which fits over the motor bottom will

require periodic inspection. Dust will discolor the microfilter. Change the microfilter

as soon as any discoloration is easily noticeable. Do not shake this microfilter since

this can cause liberation of potentially harmful microscopic dust into the air.

Carefully remove and discard with collected debris in the sealable poly bag. If

equipped with a Gore-Tex microfilter, the same rules for periodic inspection and

disposal apply. The Gore-Tex microfilter, which features a clamp that holds it in

place, must be changed when any abrasions, damage or heavy discoloration is noticed

on the surface of the filter (refer to photo 1).

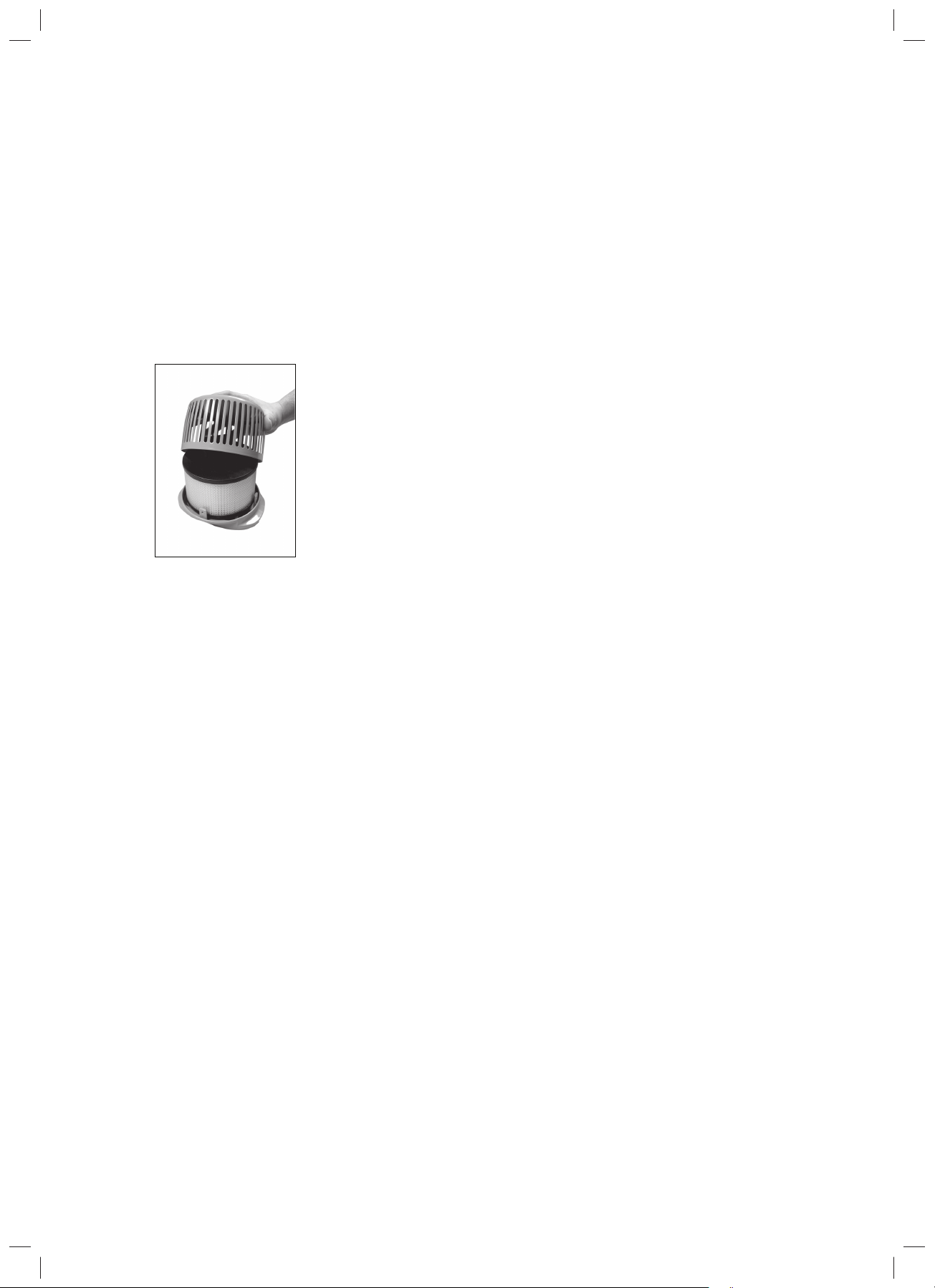

3. HEPA or ULPA Exhaust Filter: This cartridge is mounted on

the top of the motor, outside the container. If the main filter

and microfilter are properly maintained, the glass fiber

element in the exhaust filter should perform satisfactorily for a

minimum of one year. It cannot be renewed or restored. Exact

life will depend upon frequency of use and amount and type

of material collected. Normally four changes of microfilter

equal one change of HEPA/ULPA filters. Remove the

protective metal casing and replace the pleated glass fiber

cartridge according to the accompanying instructions (photo

8). Cartridges must be replaced more frequently if the vacuum

Photo 8

cleaner has had unusually heavy use, or if the various prefilters have been neglected.

CAUTION: Use only genuine Nilfisk replacement filter components. The use of

substitute components could pose a grave risk of personal exposure, and will cause all

equipment warranties to be void.

TROUBLESHOOTING

Loss of Power:

1. Make sure the power cord is properly fastened to the motor head, and it’s properly

plugged into the socket.

2. Be sure the electrical circuit has not blown a fuse.

3. If the circuit is functioning properly, but there is still no power, contact the Nilfisk

Customer Service Department at (800) 645-3475, extension 2.

Loss of Suction:

If the GM 80 loses suction power during operation, there may be several reasons,

the most likely of which is a full container. Suction loss is gradual as the container fills

with debris. Check to see if there is any blockage or restriction in the hose.

1) Check the condition of the main filter and microfilter (refer to photos) and determine

whether there is an excessive loading of debris. If there is overloading in the main

filter, you can shake it out. If the problem exists with the microfilter, including if it is

loaded, it needs to be replaced. Call our Customer Service Department at (800) 6453475, extension 2 to order a replacement.

2) If all fails, call our Customer Service Department at (800) 645-3475, extension 2.

6

Page 8

TECHNICAL SPECIFICATIONS

Motor type, grounded GMPJ

Tank capacity 3 1 /4 gallons

Voltage @ 60 Hz. 110-120/220 volt

Paper bag capacity 2 1 /4 gallons

Current draw 9 amps

Filter area** 1477 square inches

Power watts 1100

Dimensions (l x w x h) 14x12x16 inches

Waterlift*, max. 102 inches H2O

Weight without accessories 11 lbs.

Airflow, max.

Cord length

Air performance

87 cfm

30 feet

250 air watts

CONTACT INFORMATION

Nilfisk Industrial Vacuum

740 Hemlock Road, Suite 100

Morgantown

Pennsylvania

19543

Telephone: +1 610-913-5300

www.nilfisk.com

7

Page 9

Section II: Français

Nilfisk GM 80 et GM 80i

MODE D’EMPLOI

ET LISTE DES PIÈCES

Table des matières

Importantes directives de sécurité

Garantie

Installation de l’appareil

Utilisation de l’appareil

Vidage

Élimination

Entretien/remplacement du filtre

Dépannage

Panne d’alimentation

Perte de la succion

Spécifications techniques

oordonnées

C

2

2

3

4

5

5

5

6

8

8

Pour obtenir les directives d’utilisation sur une installation à filtre

HEPA/ULPA, veuillez vous reporter à l’addenda intitulée « FILTRES

ABSOLUS – renseignements pour l’utilisateur final ».

Page 10

IMPORTANTES DIRECTIVES DE SÉCURITÉ

VEUILLEZ LIRE CES DIRECTIVES AU COMPLET AVANT D’UTILISER

L’APPAREIL. SELON LES RÈGLEMENTS LOCAUX ET LA COMPOSITION DES

MATIÈRES QUE VOUS AVEZ RAMASSÉES, IL PEUT Y AVOIR DES EXIGENCES

CONCERNANT LA MANIPULATION ET L’ÉLIMINATION SPÉCIFIQUES DES

DÉBRIS RECUEILLIS. CONSULTEZ VOTRE ORGANISME LOCAL DE SÉCURITÉ

AU TRAVAIL ET LES EMPLOYÉS DE L’AGENCE DE LA PROTECTION DE

L’ENVIRONNEMENT POUR DE PLUS AMPLES RENSEIGNEMENTS.

MISE EN GARDE : cet aspirateur Nilfisk ou tout autre aspirateur ne doivent pas être

utilisés dans des zones où il y a des risques d’explosion puisque des blessures graves

pourraient se produire.

Cet aspirateur ne peut aucunement être utilisé de façon sécuritaire pour la cueillette de

matières dangereuses ou toxiques à moins qu’il ne soit muni d’un filtre et d’un sac

spéciaux HEPA (à particules à haute efficacité) qui ont été installés conformément aux

directives écrites de Nilfisk.

ATTENTION EMPLOYEUR : veuillez vous assurer que ces directives d’utilisation sont

remises à vos employés et comprises par eux ou toute autre personne qui utilisera cet

appareil.

Dresser la liste de toutes les matières toxiques et dangereuses serait au-delà de la portée

de ces directives. L’employeur doit identifier, pour les besoins de ses employés et des

autres, les matières toxiques ou dangereuses qui peuvent être ramassées par cet appareil.

Votre nouvel aspirateur industriel Nilfisk est un instrument de précision conçu pour vous

offrir une filtration exceptionnellement fine. Les aspirateurs ordinaires ne possèdent pas

de filtres HEPA et ne peuvent pas être utilisés de façon sécuritaire pour la cueillette de la

poussière dangereuse. Cet appareil Nilfisk peut être utilisé sans danger avec les poudres

fines ou les matières dangereuses, aussi longtemps que certaines précautions sont prises.

Bien s’occuper de cet appareil est essentiel à la préservation de ses capacités de filtration

ultra fines.

AVANT L'UTILISATION : NE TENTEZ PAS DE FAIRE FONCTIONNER CET

APPAREIL AVANT D’AVOIR INSTALLÉ SES DIVERS COMPOSANTS

CONFORMÉMENT AUX DIRECTIVES SUIVANTES :

GARANTIE

Les entreprises Nilfisk garantissent que l’équipement Nilfisk sera exempt de défauts de

fabrication et de matériau pendant une période de deux ans à compter de la date de

livraison. En cas de non-conformité à cette garantie, les entreprises Nilfisk, après

notification pendant la période susmentionnée, corrigeront cette non-conformité, à sa

discrétion, en réparant toute pièce défectueuse ou en remplaçant la ou les pièces à

condition que l’appareil soit retourné à un centre de service Nilfisk autorisé. Dans tous

2

Page 11

les cas, les frais de transport pour l’envoi et le retour seront payés par le client.

L’équipement ne devra pas être retourné sans avis et le consentement préalables des

entreprises Nilfisk.

À L’EXCEPTION DE CE QUI EST SPÉCIFIQUEMENT PRÉCISÉ AUX

PRÉSENTES, LES ENTREPRISES NI

EXPRESSE OU IMPLICITE DE TOUTE SORTE, Y COMPRIS, SANS TOUTEFOIS

SE LIMITER AUX GARANTIES DE VALEUR MARCHANDE, D’ADAPTATION À

UN USAGE PRÉCIS OU D’AUTRES GARANTIES, EN TOUT OU EN PARTIE, QUI

SONT TOUTES EXPRESSÉMENT RENONCÉES ET EXCLUES. AUCUNE DES

PARTIES NE SERA RESPONSABLE ENVERS L’AUTRE POUR LES DOMMAGES

SPÉCIAUX, INDIRECTS, CONSÉCUTIFS OU CORRÉLATIFS, Y COMPRIS, SANS

TOUTEFOIS SE LIMITER À LA PERTE DE PRODUCTION, DE TEMPS, DE

PROFITS OU AUTRES PERTES INDIRECTES SIMILAIRES QUI POURRAIENT SE

PRODUIRE EN RAISON DE DÉFECTUOSITÉS, DE LA DÉFAILLANCE

PARTIELLE OU TOTALE DU PRODUIT DE FONCTIONNER COMME PRÉVU.

La correction des non-conformités ou des défectuosités de la façon et pendant la période

de temps précisées ci-dessus représente l'exécution de toutes les responsabilités des

entreprises Nilfisk envers le client, qu’elles soient contractuelles, en négligence ou autre

en ce qui concerne ou découlant du produit. Les recours établis aux présentes sont

exclusifs et la responsabilité des entreprises Nilfisk relativement à cette vente ou à tout ce

qui est fait à cet égard, de façon contractuelle, civile, en vertu de toute garantie, ne

dépasseront pas, à l’exception de ce qui est prévu aux présentes, le prix de l’équipement

ou de la pièce sur lesquels une telle responsabilité est fondée.

LFISK N’OFFRENT AUCUNE GARANTIE,

La garantie ne couvre pas les réparations requises après un usage normal, un

accident, de la négligence, une mauvaise utilisation ou de l’abus, une mauvaise

installation ou utilisation autre que ce qui est décrit dans le livret d’utilisation. Les

bris de tuyaux et de câbles ne sont pas couverts. Cette garantie est annulée si la

plaque numérique du moteur est enlevée ou défigurée ou si des réparations sont

faites ou tentées par des personnes non autorisées par les entreprises Nilfisk.

INSTALLATION DE L’APPAREIL :

Avant de m

(n° 616821-Felt, n° 017230-AES Polycomposite, n° 017220-01Gore-TexMC), le petit bas en feutre dans le fond du moteur en

glissant le filtre sur le fond du moteur et en couvrant le fond autant

que la profondeur du filtre le permettra (photo 1). Assurez-vous

que le collet élastique du filtre tient le filtre fermement en place et

qu’il se trouve au niveau le plus élevé possible sur le fond du

moteur.

Photo 1

2. Ensuite, installez le filtre HEPA (n° 01710440) conformément

au bulletin s'y rattachant. Replacez le moteur dans la cavité dans la

partie supérieure de l’aspirateur (photo 2). Fixez la tête du moteur

en place au moyen des loquets de sécurité à torsion positive ou des

loquets standard, selon l’option que vous avez achetée.

ettre le moteur en marche : installez le microfiltre

Photo 2

3

Page 12

Installation du sac en papier et de la doublure en polyéthylène :

tournez et relâchez les deux loquets à torsion positive ou les

loquets standard, selon votre appareil. Ils sont situés sur le corps

du contenant, à l’avant et à l’arrière. Soulevez le couvercle.

Ouvrez la doublure en polyéthylène et placez-la dans le fond du

contenant en gardant ses parois affleurées contre les côtés du

Photo 3

Photo 4

4. Les appareils GM 80 et GM 80i offrent un jeu d’accessoires standards qui peuvent être

reliés de la façon suivante. Fixez le tuyau d’aspiration à l’aspirateur en l’insérant dans

l’orifice du contenant inférieur. Une fois inséré, faites tourner le raccord d’admission

d’un quart de tour pour le verrouiller en place. L’un ou l’autre des deux tubes-rallonges

droits de 56 cm peuvent être ajustés à l’autre extrémité du tuyau. Vous pouvez relier

l’embout à plancher à jet réglable ou le suceur à meubles de 13 cm à l’extrémité du tuyau.

Le suceur plat en caoutchouc et la brosse ronde de 7,6 cm peuvent être reliés à l'extrémité

du tube-rallonge droit ou du tube courbé en acier du tuyau. Il y a une liste d’accessoires

en option qui peut vous être fournie sur demande pour les deux modèles. Veuillez

consulter votre directeur régional des ventes ou le service à la clientèle au (800) NILFISK

pour obtenir une liste des accessoires en option.

contenant et en saillie sous l’admission du contenant (photo 3).

L’excédent de la doublure en polyéthylène est replié sur la partie

supérieure du contenant et vers le bas à l’extérieur, puis roulé à

l’extrémité pour permettre aux pinces du contenant de se fermer.

Installez un sac en papier à l’intérieur de la doublure en

polyéthylène conformément aux illustrations imprimées sur le sac

en papier lui-même (photo 4). Replacez le couvercle du contenant

et attachez les deux pinces.

UTILISATION DE L’APPAREIL :

Démarrage et arrêt : appuyez sur le bouton gris situé sur la

partie supérieure avant de l’aspirateur (photo 5).

Photo 5

Photo 5

Utilisation appropriée de l’appareil : cet appareil n’est pas un aspirateur pour déchets

solides et humides. Il est conçu pour la collecte de déchets secs seulement. N’utilisez pas

cet aspirateur pour ramasser des liquides ou toutes matières humides.

4

Page 13

VIDAGE :

SI CET ASPIRATEUR EST UTILISÉ POUR RAMASSER DES MATIÈRES

DANGEREUSES, NE TENTEZ PAS D’OUVRIR OU DE VIDER SON CONTENU

SANS PORTER DES VÊTEMENTS PROTECTEURS ET UNE PROTECTION DES

VOIES RESPIRATOIRES.

Pour vider le contenant et son contenu, arrêtez d’abord le

moteur. Laissez l’aspirateur se reposer pendant au moins trente

To empty the container and its contents, first turn off the motor.

(30) secondes. Tournez et relâchez ensuite les pinces du

Allow the cleaner to sit undisturbed for at least thirty (30)

contenant. Une fois le seau brisé, remettez le moteur en marche.

seconds. Then twist and release the container clips. Once the

Cela empêchera les particules ultrafines qui sont suspendues

seal is broken, turn on the motor again. This will prevent

dans l’air à l’intérieur du contenant de s’échapper dans le lieu

ultrafine particles which are still suspended in the air inside the

de travail. Soulevez le couvercle du contenant. Retirez la

container from escaping into the work place. Lift off the

doublure en polyéthylène et le sac en papier (photo 6). Scellez

container top. Remove the polyliner and paper bag within it

la doublure en polyéthylène avec le sac en papier à l'intérieur et

(photo 6). Then seal off the polyliner with the paper bag inside

installez une doublure neuve en polyéthylène et un sac en papier

Photo 6

ÉLIMINATION :

Selon les règlements locaux et la composition de la matière que vous avez ramassée, il

peut y avoir des exigences concernant la manipulation et l’étiquetage spécifiques des sacs

en plastique remplis et scellés. Consultez votre organisme local de sécurité au travail et

les employés de l’agence de la protection de l’environnement pour de plus amples

renseignements.

neuf conformément à l’étape 2, Installation de l’appareil.

ENTRETIEN

Entretien régulier :

Pour assurer la performance maximale de votre aspirateur Nilfisk, assurez-vous de

vérifier votre filtre principal régulièrement. Votre filtre peut avoir besoin d’être secoué de

temps à autre pour éliminer la poussière durcie.

Remplacement du filtre :

Pour s’assurer que votre aspirateur Nilfisk vous fournisse les années de fonctionnement

sans tracas pour lesquelles il a été conçu, il est nécessaire de vérifier et de remplacer les

filtres régulièrement.

1. Filtre principal : le grand sac en coton gratté qui est installé de

façon semipermanente à l’intérieur du contenant n’a pas besoin

d’être remplacé souvent. Le filtre principal doit être remplacé

lorsque l’aspirateur ne fournit plus de succion puissante, sans

que les sacs soient pleins et les autres composants du filtre,

obstrués. Prolongez la durée utile du filtre principal en

remplaçant souvent les doublures en polyéthylène et les sacs en

papier jetables (photo 7).

Photo 7

5

Page 14

2. Microfiltre : ce petit bas en polyester de feutre, qui couvre le fond du moteur, devra

être examiné périodiquement. La poussière modifiera la couleur du microfiltre.

Remplacez le microfiltre dès que vous remarquez tout changement de couleur. Ne

secouez pas le microfiltre puisque cela peut causer le dégagement de poussières

microscopiques possiblement nocives dans l’air. Retirez-le soigneusement et jetez-le

avec les débris ramassés dans le sac en polyéthylène scellable. Si l’appareil est muni

d’un microfiltre Gore-Tex, les mêmes règles s’appliquent pour l’inspection

périodique et l’élimination. Le microfiltre Gore-Tex, qui comprend une pince qui le

tient en place, doit être remplacé lorsque vous remarquez toutes abrasions, tous

dommages ou toute décoloration importante sur la surface du filtre (reportez-vous à la

photo 1).

3. Filtre d’évacuation HEPA ou ULPA : cette cartouche est

installée sur la partie supérieure du moteur, à l’extérieur du

contenant. Si le filtre principal et le microfiltre sont

correctement entretenus, l'élément en fibre de verre dans le

filtre d'évacuation devrait fonctionner de façon satisfaisante

pendant au moins un an. Il ne peut pas être renouvelé ou

restauré. La durée utile exacte dépend de la fréquence

d’utilisation et de la quantité et du type de matières ramassées.

Normalement, quatre remplacements du microfiltre équivalent

à un remplacement des filtres HEPA/ULPA. Retirez le boîtier

métallique protecteur et remplacez la cartouche plissée en

Photo 8

fibre de verre conformément aux directives s'y rattachant

(photo 8). Les cartouches doivent être remplacées plus

souvent si l’aspirateur a été utilisé fréquemment ou si les

divers préfiltres ont été négligés.

MISE EN GARDE : utilisez seulement les composants de filtre de rechange Nilfisk

d’origine. L’utilisation de composants substituts pourrait entraîner un risque important

d’exposition personnelle et annulera toutes les garanties de l’équipement.

DÉPANNAGE

Panne d’alimentation :

1. Assurez-vous que le cordon d’alimentation est bien fixé à la tête du moteur et qu’il

est bien branché dans la prise.

2. Assurez-vous que le fusible du circuit électrique n’est pas grillé.

3. Si le circuit fonctionne correctement, mais qu’il n’y a toujours pas d'alimentation,

communiquez avec le service à la clientèle de Nilfisk au 800-645-3475, poste 2.

Perte de la succion :

Si le GM 80 perd de la succion pendant le fonctionnement, il peut y avoir de nombreuses

raisons, la plus probable étant que le contenant est plein. La perte de succion est graduelle

tandis que le contenant se remplit de débris. Assurez-vous qu’il n'y a pas de blocage ou

de restriction dans le tuyau.

6

Page 15

1) Vérifiez l’état du filtre principal et du microfiltre (reportez-vous aux photos) et

déterminez s’il y a une charge excessive de débris. Si le filtre principal est surchargé,

vous pouvez le secouer. Si le problème persiste avec le microfiltre, y compris si ce

dernier est trop chargé, vous devrez alors le remplacer. Communiquez avec notre

service à la clientèle au 800-845-3475, poste 2 pour commander un remplacement.

2) Si ces mesures ne corrigent le problème, communiquez avec le service à la clientèle

au 800-645-3475, poste 2.

7

Page 16

SPÉCIFICATIONS TECHNIQUES

Type de moteur, mis à la terre GMPJ

Capacité du réservoir 12,3 litres

Tension à 60 Hz 110-120/220 volts

Capacité du sac en papier 8,5 litres

Appel de courant 9 ampères

Zone de filtration** 0,9 mètre carré

Puissance en watts 1 100

Dimensions (long. x larg. x haut.) 35,6 x 30,5 x 40,6 cm

Élévation d’eau*, max. 259 cm H2O

Poids sans accessoires 5 kg

Débit d’air, max. 2,4 m /min

Longueur du cordon 9 mètres

Performance de l'air 250 watts d’air

COORDONNÉES

Nilfisk Industrial Vacuum

740 Hemlock Road, Suite 100

Morgantown

Pennsylvania

19543

Telephone: +1 610-913-5300

www.nilfisk.com

8

Page 17

Section III: Español

Nilfisk GM 80 y GM 80i

INSTRUCCIONES DE USO

Y LISTA DE PIEZAS

Contenido

Instrucciones importantes de seguridad

Garantía

Montaje de la máquina

Uso de la máquina

Vaciado

Eliminación de desechos

Mantenimiento y reemplazo del filtro

Resolución de problemas

Pérdida de potencia

Pérdida de succión

Especificaciones técn

I

nformación de contacto

icas

2

2

3

4

5

5

5

6

8

8

Para obtener instrucciones sobre la instalación de los filtros HEPA y ULPA,

consulte el anexo titulado “FILTROS ABSOLUTOS – Información para el

usuario final”.

Page 18

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

LEA LAS INSTRUCCIONES COMPLETAS ANTES DE USAR LA MÁQUINA.

DEPENDIENDO DE LAS NORMAS LOCALES Y LA COMPOSICIÓN DE LOS

MATERIALES QUE HAYA RECOLECTADO, ES POSIBLE QUE EXISTAN

REQUISITOS ESPECIALES PARA LA MANIPULACIÓN Y ELIMINACIÓN DE

ESTOS DESECHOS. CONSULTE CON LOS REPRESENTANTES LOCALES DE LA

ADMINISTRACIÓN DE SEGURIDAD Y SALUD OCUPACIONAL (OSHA) Y LA

AGENCIA DE PROTECCIÓN AMBIENTAL (EPA).

PRECAUCIÓN: esta aspiradora Nilfisk, al igual que cualquier otra aspiradora, no debe

utilizarse en áreas donde existe peligro de explosión, ya que podría sufrir lesiones graves.

Bajo ninguna circunstancia se debe utilizar esta aspiradora para la recolección de

materiales tóxicos o peligrosos, a menos que esté equipada con una bolsa y filtro HEPA

(filtro de aire de alta eficiencia para partículas) especiales instalados de acuerdo con las

instrucciones escritas por Nilfisk.

ATENCIÓN EMPLEADOR: asegúrese de que sus empleados o cualquier otra persona

que utilice este equipo comprendan estas instrucciones de uso y las tengan a la mano.

La lista de todos los materiales que pueden ser tóxicos y peligrosos supera el alcance de

estas instrucciones. Es responsabilidad del empleador identificar los materiales tóxicos o

peligrosos que pueden recolectarse con este equipo para informar a sus empleados o a

otras personas.

Su nueva aspiradora industrial Nilfisk, es un instrumento con ingeniería de precisión,

diseñada para un filtrado excepcionalmente fino. Las aspiradoras comunes no cuentan

con filtros HEPA y no se pueden utilizar de manera segura para la recolección de polvo

peligroso. Esta máquina Nilfisk se puede utilizar en forma segura con polvos finos o

materiales peligrosos, siempre que se tomen ciertas precauciones. El cuidado adecuado

de esta aspiradora es fundamental para el mantenimiento de su capacidad de filtrado ultra

fino.

ANTES DE USAR: NO INTENTE HACER FUNCIONAR ESTA ASPIRADORA

HASTA QUE HAYA INSTALADO TODOS LOS COMPONENTES DE ACUERDO

CON LAS SIGUIENTES INSTRUCCIONES:

GARANTÍA

Las empresas Nilfisk garantizan la inexistencia de defectos de fabricación o en los

materiales de los equipos Nilfisk durante un período de dos años a partir de la fecha de

entrega. En caso de presentarse una falla, las empresas Nilfisk, previa notificación dentro

del período de vigencia de la garantía, corregirán esta falta de cumplimiento de calidad,

2

Page 19

según su criterio, ya sea reparando la pieza o piezas defectuosas o reemplazando las

mismas siempre que el cliente devuelva el equipo a un centro autorizado Nilfisk. En

todos los casos los gastos de flete correrán por cuenta del cliente. El cliente no devolverá

el equipo sin aviso previo y consentimiento de las empresas Nilfisk.

CON E

EMPRESAS NILFISK NO OTORGAN NINGUNA GARANTÍA EXPLÍCITA O

IMPLÍCITA CUALQUIERA SEA EL MOTIVO, INCLUIDAS A TÍTULO

EJEMPLIFICATIVO, TODA GARANTÍA DE COMERCIABILIDAD, APTITUD

PARA EL USO U OTRAS GARANTÍAS, LAS CUALES QUEDAN

EXPRESAMENTE DENEGADAS Y EXCLUIDAS. NINGUNA DE LAS PARTES

SERÁ RESPONSABLE ANTE LA OTRA POR DAÑOS ESPECIALES, INDIRECTOS,

INCIDENTALES O DERIVADOS, INCLUIDOS A MODO EJEMPLIFICATIVO, LA

PÉRDIDA DE PRODUCCIÓN, PÉRDIDA DE TIEMPO, PÉRDIDA DE GANANCIAS

O CUALQUIER OTRA PÉRDIDA INDIRECTA SIMILAR QUE PUEDA

OCASIONARSE POR DEFECTOS Y/O FALLA TOTAL O PARCIAL DEL

PRODUCTO EN CUANTO A SU FUNCIONAMIENTO ESPECÍFICO.

La corrección de cualquier problema de calidad o defecto, del modo y dentro del período

de tiempo mencionado anteriormente, constituye el cumplimiento de toda responsabilidad

de las empresas Nilfisk hacia el cliente, ya sea por contrato, negligencia o de otro modo

con respecto a dicho equipo. Las reparaciones que aquí se establecen son exclusivas y la

responsabilidad de las empresas Nilfisk con respecto a esta venta o a cualquier acto

relacionado con la misma, ya sea por contrato, extracontractualmente, bajo cualquier

garantía o de otro modo no deberá exceder el precio del equipo o de la pieza en que se

basa tal responsabilidad, excepto como se establece expresamente aquí.

XCEPCIÓN DE LO QUE AQUÍ SE ESTABLECE ESPECÍFICAMENTE, LAS

La garantía no cubre reparaciones ocasionadas por el desgaste normal, accidentes,

negligencia, mal uso, abuso, instalación incorrecta o por un uso distinto del que se

describe en el manual de instrucciones. No quedan cubiertas las roturas en cables y

mangueras. Esta garantía se invalida si se borra o altera el número de identificación

del motor o si personas no autorizadas por las empresas Nilfisk realizan o intentan

realizar reparaciones.

MONTAJE DE LA MÁQUINA:

Foto 1

Antes de en

Fieltro, No. 017230-Policompuesto AES, No. 017220-01-GoreTex®), el filtro pequeño de fieltro, en la parte inferior del motor

deslizándolo sobre la parte inferior de éste, cubriéndola tanto como

lo permita la profundidad del filtro (foto 1). Asegúrese de que el

cuello elástico del filtro mantenga al mismo en forma ajustada en

posición, lo más elevado posible desde la parte inferior del motor.

2. Luego, monte el filtro HEPA (No. 01710440) de acuerdo al

boletín adjunto. Vuelva a colocar el motor dentro de la cavidad que

cender el motor: instale el microfiltro (No. 616821-

Foto 2

3

Page 20

se encuentra en la parte superior de la aspiradora (foto 2). Fije la

cabeza del motor con los sujetadores de seguridad de giro positivo

o con los sujetadores estándar, según el modelo que haya adquirido.

Instalación de la bolsa Polyliner y de papel: gire y libere los dos

sujetadores de seguridad de giro positivo o los sujetadores

estándar, según el modelo de su máquina. Estos se encuentran en

el cuerpo del recipiente, en la parte delantera y trasera. Levante la

parte superior. Abra la bolsa Polyliner y colóquela en la parte

inferior del recipiente, pegada a los costados del mismo y con los

Foto 3

Foto 4

4. Los modelos GM 80 y GM 80i ofrecen un paquete de accesorios estándar que se

pueden conectar de la siguiente manera: conecte la manguera a la aspiradora insertándola

en el orificio que se encuentra en el recipiente inferior. Una vez insertada, gire el

acoplador de entrada un cuarto de giro para bloquearla en esa posición. Se puede acoplar

al otro extremo de la manguera cualquiera de los dos tubos rectos de 56 cm (22 pulg.).

Puede conectar en el extremo de la manguera la boquilla de combinación para piso o la

boquilla de 13 cm (5 pulg.) para tapizados. La boquilla de hule para esquinas y el cepillo

circular de 7.6 cm (3 pulg.) se pueden conectar en el extremo recto de la manguera o en el

tubo de acero curvo de la manguera. Existe una lista de accesorios opcionales para ambos

modelos. Consulte al Gerente de ventas del distrito o al Departamento de atención al

cliente al (800) NILFISK para obtener la lista de accesorios opcionales.

bordes en la entrada del recipiente (foto 3). La longitud sobrante

de la bolsa Polyliner se pliega por encima de la parte superior del

recipiente, se dobla hacia fuera y se enrolla para poder cerrar los

broches del recipiente.

Instale una bolsa de papel dentro de la bolsa Polyliner de acuerdo

a las ilustraciones impresas en la bolsa de papel (foto 4). Vuelva a

colocar la parte superior del recipiente y ajuste ambos broches.

USO DE LA MÁQUINA:

Encendido y apagado: Presione el botón gris que se

encuentra en la parte superior delantera de la aspiradora

Foto 5

Uso correcto de la máquina: esta máquina no es una aspiradora para sólidos y líquidos.

Sólo sirve para la recolección de sólidos. No utilice esta aspiradora para recoger líquidos

ni materiales húmedos.

4

(foto 5).

Page 21

VACIADO:

SI UTILIZA ESTA ASPIRADORA PARA RECOLECTAR MATERIALES

PELIGROSOS, NO INTENTE ABRIRLA NI VACIAR SU CONTENIDO SIN

UTILIZAR MASCARILLA Y VESTIMENTA DE PROTECCIÓN.

Para vaciar el contenido del recipiente, apague el motor. Deje la

aspiradora en reposo al menos durante treinta (30) segundos.

To empty the container and its contents, first turn off the motor.

Luego, gire y libere los broches del recipiente. Una vez roto el

Allow the cleaner to sit undisturbed for at least thirty (30)

sello, vuelva a encender el motor. Esto evitará que las partículas

seconds. Then twist and release the container clips. Once the

ultrafinas que se encuentren suspendidas en el aire dentro del

seal is broken, turn on the motor again. This will prevent

recipiente se liberen en el lugar de trabajo. Levante la cubierta del

ultrafine particles which are still suspended in the air inside the

recipiente. Extraiga la bolsa Polyliner y de papel del interior (foto

container from escaping into the work place. Lift off the

6). Luego, selle la bolsa Polyliner con la bolsa de papel en su

container top. Remove the polyliner and paper bag within it

interior e instale una nueva bolsa Polyliner y de papel según el

(photo 6). Then seal off the polyliner with the paper bag inside

paso 2 en Montaje de la máquina.

and install a new polyliner and paper bag according to step 2,

Foto 6

ELIMINACIÓN DE DESECHOS:

Dependiendo de las normas locales y de la composición de los materiales que haya

recolectado, es posible que existan requisitos especiales para la manipulación y

etiquetado de las bolsas de plástico utilizadas. Consulte con los representantes locales de

la Administración de seguridad y salud ocupacional (OSHA) y la Agencia de protección

ambiental (EPA) para obtener más detalles.

MANTENIMIENTO

Mantenimiento de rutina:

Para garantizar el máximo rendimiento de su aspiradora Nilfisk, asegúrese de comprobar

regularmente el filtro principal. Es posible que deba sacudir el filtro de vez en cuando

para quitar el polvo acumulado.

Reemplazo del filtro:

Para garantizar el funcionamiento sin problemas de su aspiradora Nilfisk durante el

tiempo correcto, es necesario comprobar y reemplazar los filtros regularmente.

1. Filtro principal: la bolsa grande, de algodón aterciopelado, que

se encuentra montada en forma semipermanente dentro del

recipiente no requiere un reemplazo frecuente. Se debe

reemplazar el filtro principal cuando la aspiradora ya no realice

una succión potente, aunque las bolsas no estén llenas ni estén

obstruidos otros componentes del filtro. Prolongue la vida útil

Foto 7

del filtro principal cambiando frecuentemente las bolsas

Polyliner y de papel desechables (foto 7).

5

Page 22

2. Microfiltro: se debe inspeccionar en forma periódica el pequeño filtro de fieltro con

poliéster, colocado sobre la parte inferior del motor. El polvo decolora el microfiltro.

Cambie el microfiltro en cuanto perciba la decoloración. No sacuda el microfiltro, ya

que podría liberar partículas microscópicas de polvo potencialmente peligrosas en la

atmósfera. Extráigalo cuidadosamente y deséchelo junto con los residuos recolectados

dentro de la bolsa Polyliner sellada. Si la aspiradora está equipada con un microfiltro

Gore-Tex, se deben observar las mismas reglas con respecto a la inspección periódica

y la eliminación de desechos. El microfiltro Gore-Tex, que cuenta con una abrazadera

que lo mantiene en posición, se debe cambiar en cuanto se observen señales de

abrasión, daños o decoloración severa en la superficie del mismo (consulte la foto 1).

3. Filtro de escape HEPA o ULPA: este cartucho está montado

en la parte superior del motor, fuera del recipiente. Si se

realiza un mantenimiento adecuado del filtro principal y del

microfiltro, el elemento de fibra de vidrio del filtro de escape

debe actuar satisfactoriamente durante un plazo mínimo de un

año. El elemento no se puede renovar ni restaurar. La vida útil

depende de la frecuencia de uso, y de la cantidad y tipo de

material recolectado. Normalmente, cuatro cambios del

microfiltro equivalen a un cambio de los filtros HEPA o

ULPA. Quite la cubierta protectora metálica y reemplace el

cartucho ranurado de fibra de vidrio de acuerdo con las

Photo 8

instrucciones adjuntas (foto 8). Se deben reemplazar los

cartuchos con mayor frecuencia si se utiliza la aspiradora en

forma inusual para trabajo pesado o si se han descuidado los

prefiltros.

PRECAUCIÓN: utilice solamente componentes originales de repuesto para filtros Nilfisk.

El uso de componentes sustitutos puede representar un grave riesgo de exposición

personal y anula la garantía del equipo.

RESOLUCIÓN DE PROBLEMAS

Pérdida de potencia:

1. Asegúrese de que el cable de alimentación de corriente se encuentre correctamente

conectado a la cabeza del motor y que esté enchufado correctamente en la toma de

corriente.

2. Asegúrese de que no se haya quemado algún fusible del circuito eléctrico.

3. Si el circuito eléctrico funciona correctamente y sin embargo no hay alimentación de

corriente, comuníquese con el Departamento de atención al cliente de Nilfisk al (800)

645-3475, extensión 2.

Pérdida de succión:

En el modelo GM 80, la pérdida de succión durante el funcionamiento puede tener varios

motivos, pero el más común es que el recipiente está lleno. La pérdida de succión es

gradual y aumenta según se vaya llenando el recipiente. Verifique la existencia de

bloqueos u obstrucciones en la manguera.

6

Page 23

1) Verifique el estado del filtro principal y del microfiltro (consulte las fotos) y

determine si la acumulación de desechos es excesiva. Si hay una sobrecarga en el

filtro principal, puede sacarlo y sacudirlo. Si el problema es el microfiltro, incluido

que el mismo esté cargado, será necesario reemplazarlo. Para solicitar un repuesto,

comuníquese con el Departamento de atención al cliente de Nilfisk al (800) 645-3475,

extensión 2.

2) Si no puede solucionar el problema, comuníquese con el Departamento de atención al

cliente de Nilfisk al (800) 645-3475, extensión 2.

7

Page 24

ESPECIFICACIONES TÉCNICAS

Tipo de motor, conectado a tierra GMPJ

Capacidad del depósito 12.3 litros (3.25 gal.)

Voltaje a 60 Hz. 110-120/220 voltios

Capacidad de la bolsa de papel 8.5 litros (2.25 gal.)

Consumo de energía 9 amperios

Superficie del filtro** 9529 cm2 (1477 pulg.2)

Potencia (en vatios) 1100

Dimensiones (largo x ancho x altura) 35.3 x 30.4 x 40.6 cm (14 x 12 x 16 pulg.)

Elevación de agua*, máx. 102 pulg. H2O

Peso sin accesorios 5 Kg (11lb)

Flujo de aire, máx. 0.246 m3/min (87 pies3/min)

Longitud del cable 9.14 m (30 pies)

Eficiencia de succión 250 vatios de aire

INFORMACIÓN DE CONTACTO

Nilfisk Industrial Vacuum

740 Hemlock Road, Suite 100

Morgantown

Pennsylvania

19543

Telephone: +1 610-913-5300

www.nilfisk.com

8

Page 25

Page 26

Page 27

Page 28

HEAD QUARTER

DENMARK

Nilfi sk A/S

Kornmarksvej 1

DK-2605 Broendby

Tel.: (+45) 4323 8100

www.nilfi sk.com

SALES COMPANIES

ARGENTINA

Nilfi sk srl.

Edifi cio Central Park

Herrera 1855, 6th fl oor/604

Ciudad de Buenos Aires

Tel.: (+54) 11 6091 1571

www.nilfi sk.com.ar

AUSTRALIA

Nilfi sk Pty Ltd

Unit 1/13 Bessemer Street

Blacktown NSW 2148

Tel.: (+61) 2 98348100

www.nilfi sk.com.au

AUSTRIA

Nilfi sk GmbH

Metzgerstrasse 68

5101 Bergheim bei Salzburg

Tel.: (+43) 662 456 400 90

www.nilfi sk.at

BELGIUM

Nilfi sk n.v-s.a.

Riverside Business Park

Boulevard Internationalelaan 55

Bâtiment C3/C4 Gebouw

Bruxelles 1070

Tel.: (+32) 14 67 60 50

www.nilfi sk.be

BRAZIL

Nilfi sk do Brasil

Av. Eng. Luis Carlos Berrini, 550

40 Andar, Sala 03

SP - 04571-000 Sao Paulo

Tel.: (+11) 3959-0300 / 3945-4744

www.nilfi sk.com.br

CANADA

Nilfi sk Canada Company

240 Superior Boulevard

Mississauga, Ontario L5T 2L2

Tel.: (+1) 800-668-8400

www.nilfi sk.ca

CHILE

Nilfi sk S.A. (Comercial KCS Ltda)

Salar de Llamara 822

8320000 Santiago

Tel.: (+56) 2684 5000

www.nilfi sk.cl

CHINA

Nilfi sk

4189 Yindu Road

Xinzhuang Industrial Park

201108 Shanghai

Tel.: (+86) 21 3323 2000

www.nilfi sk.cn

CZECH REPUBLIC

Nilfi sk s.r.o.

VGP Park Horní Počernice

Do Čertous 1/2658

193 00 Praha 9

Tel.: (+420) 244 090 912

www.nilfi sk.cz

DENMARK

Nilfi sk Danmark A/S

Industrivej 1

Hadsund, DK-9560

Tel.: 72 18 21 20

www.nilfi sk.dk

FINLAND

Nilfi sk Oy Ab

Koskelontie 23 E

02920 Espoo

Tel.: (+358) 207 890 600

www.nilfi sk.fi

FRANCE

Nilfi sk SAS

26 Avenue de la Baltique

Villebon sur Yvette

91978 Courtabouef Cedex

Tel.: (+33) 169 59 87 00

www.nilfi sk.fr

GERMANY

Nilfi sk GmbH

Guido-Oberdorfer-Straße 2-10

89287 Bellenberg

Tel.: (+49) (0)7306/72-444

www.nilfi sk.de

GREECE

Nilfi sk A.E.

Αναπαύσεως 29

Κορωπί Τ.Κ. 194 00

Tel.: (30) 210 9119 600

www.nilfi sk.gr

HOLLAND

Nilfi sk B.V.

Versterkerstraat 5

1322 AN Almere

Tel.: (+31) 036 5460760

www.nilfi sk.nl

HONG KONG

Nilfi sk Ltd.

2001 HK Worsted Mills

Industrial Building

31-39, Wo Tong Tsui St.

Kwai Chung, N.T.

Tel.: (+852) 2427 5951

www.nilfi sk.com

HUNGARY

Nilfi sk Kft.

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklós-Lakihegy

Tel.: (+36) 24 475 550

www.nilfi sk.hu

INDIA

Nilfi sk India Limited

Pramukh Plaza, ‘B’ Wing, 4th fl oor, Unit

No. 403

Cardinal Gracious Road, Chakala

Andheri (East) Mumbai 400 099

Tel.: (+91) 22 6118 8188

www.nilfi sk.in

IRELAND

Nilfi sk

1 Stokes Place

St. Stephen’s Green

Dublin 2

Tel.: (+35) 3 12 94 38 38

www.nilfi sk.ie

ITALY

Nilfi sk SpA

Strada Comunale della Braglia, 18

26862 Guardamiglio (LO)

Tel.: (+39) (0) 377 414021

www.nilfi sk.it

JAPAN

Nilfi sk Inc.

1-6-6 Kita-shinyokohama, Kouhoku-ku

Yokohama, 223-0059

Tel.: (+81) 45548 2571

www.nilfi sk.com

MALAYSIA

Nilfi sk Sdn Bhd

Sd 33, Jalan KIP 10

Taman Perindustrian KIP

Sri Damansara

52200 Kuala Lumpur

Tel.: (60) 3603 627 43 120

www.nilfi sk.com

MEXICO

Nilfi sk de Mexico, S. de R.L. de C.V.

Pirineos #515 Int.

60-70 Microparque

Industrial WSantiago

76120 Queretaro

Tel.: (+52) (442) 427 77 00

www.nilfi sk.com

NEW ZEALAND

Nilfi sk Limited

Suite F, Building E

42 Tawa Drive

0632 Albany Auckland

Tel.: (+64) 9 414 1996

Website: www.nilfi sk.com

NORWAY

Nilfi sk AS

Bjørnerudveien 24

1266 Oslo

Tel.: (+47) 22 75 17 80

www.nilfi sk.no

PERU

Nilfi sk S.A.C.

Calle Boulevard 162, Of. 703, Lima 33Perú

Lima

Tel.: (511) 435-6840

www.nilfi sk.com

POLAND

Nilfi sk Sp. Z.O.O.

Millenium Logistic Park

ul. 3 Maja 8, Bud. B4

05-800 Pruszków

Tel.: (+48) 22 738 3750

www.nilfi sk.pl

PORTUGAL

Nilfi sk Lda.

Sintra Business Park

Zona Industrial Da Abrunheira

Edifi cio 1, 1° A

P2710-089 Sintra

Tel.: (+351) 21 911 2670

www.nilfi sk.pt

RUSSIA

Nilfi sk LLC

Vyatskaya str. 27, bld. 7/1st

127015 Moscow

Tel.: (+7) 495 783 9602

www.nilfi sk.ru

SINGAPORE

Den-Sin

22 Tuas Avenue 2

639453 Singapore

Tel.: (+65) 6268 1006

www.densin.com

SLOVAKIA

Nilfi sk s.r.o.

Bancíkovej 1/A

SK-821 03 Bratislava

Tel.: (+421) 910 222 928

www.nilfi sk.sk

SOUTH AFRICA

WAP South Africa

12 Newton Street

Spartan 1630

Tel.: (+27) 11 975 7060

www.wap.com.za

SOUTH KOREA

Nilfi sk Korea

3F Duksoo B/D, 317-15

Sungsoo-Dong 2Ga

Sungdong-Gu, Seoul

Tel.: (+82) 2497 8636

www.nilfi sk.co.kr

SPAIN

Nilfi sk S.A.

Torre d’Ara,

Passeig del Rengle, 5 Plta. 10

08302 Mataró

Tel.: (34) 93 741 2400

www.nilfi sk.es

SWEDEN

Nilfi sk AB

Taljegårdsgatan 4

431 53 Mölndal

Tel.: (+46) 31 706 73 00

www.nilfi sk.se

SWITZERLAND

Nilfi sk AG

Ringstrasse 19

Kircheberg/Industri Stelz

9500 Wil

Tel.: (+41) 71 92 38 444

www.nilfi sk.ch

TAIWAN

Nilfi sk Ltd

Taiwan Branch (H.K)

No. 5, Wan Fang Road

Taipei

Tel.: (+88) 6227 00 22 68

www.nilfi sk.tw

THAILAND

Nilfi sk Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Ladyao, Jatuchak, Bangkok 10900

Tel.: (+66) 2275 5630

www.nilfi sk.co.th

a

TURKEY

Nilfi sk A.S.

Serifali Mh. Bayraktar Bulv. Sehit Sk. No:7

Ümraniye, 34775 Istanbul

Tel.: +90 216 466 94 94

www.nilfi sk.com.tr

UNITED ARAB EMIRATES

Nilfi sk Middle East Branch

SAIF-Zone

P.O. Box 122298

Sharjah

Tel.: (+971) (0) 655-78813

www.nilfi sk.com

UNITED KINGDOM

Nilfi sk Ltd.

Nilfi sk House, Bowerbank Way

Gilwilly Industrial Estate, Penrith

Cumbria CA11 9BQ

Tel: (+44) (0) 1768 868995

www.nilfi sk.co.uk

UNITED STATES

Nilfi sk, Inc.

9435 Winnetka Ave N,

Brooklyn Park

MN- 55445

www.nilfi sk.com

VIETNAM

Nilfi sk Vietnam

No. 51 Doc Ngu Str.

P. Vinh Phúc, Q.Ba Dinh

Hanoi

Tel.: (+84) 761 5642

www.nilfi sk.com

Loading...

Loading...