Nikon/PROFILE PROJECTOR

MODEL V-14

------

INSTRUCTIONS

NIPPON KOGAKU KlIK.

CONTENTS

NOMENCLATURE 2

OPTICAL SySTEM 3

§ 1. FUNCTION OF EACH PART

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

~8.

19.

20.

USING

1.

§ 2.

Viewing screen 4

Screen lock 4

Chart clips 4

Hood 4

Turret lens mount 4

Projection lenses 5

Anti·glare shield 5

Stage mount 5

Change·over knob for contour illumination 5

Contour illuminator 6

Surface illuminator 6

Surface illuminator support 6

Focusing wheel 7

Cabinet 7

Power socket 7

Fuse 7

Main switch 8

Contour illuminator switch 8

Surface illuminator switch 8

Dial gage eyelet ' 8

Illumination 9

(1) Contour illumination 9

Detection of the correct position of lamp 9

Changing·over the condenser 10

(2) Surface illumination 10

Oblique illumination 10

Vertical illumination : 10

2. Projection 11

(1) Correct positioning 11

(2) Sharp focusing 11

(3) Centering 12

3. Measurement 13

(1) Placing a scale on the screen 13

(2) Comparing with standard length 14

(3) Comparing with master chart 14

(4) Measuring angle by rotating the screen 15

(5) Tracing screen images 16

(6) Photographing screen image 16

CAUTION IN HANDLING

1. Screen 17

2. Projection lens 17

3. Mirrors 17

4. Half·reflecting mirror 17

5. Dark image 18

6. Lamp bulb 18

7. Others 18

8. If something wrong or disorder is found 18

TECHNICAL DATA 19

SPECIAL ACCESSORIES 22

-1~

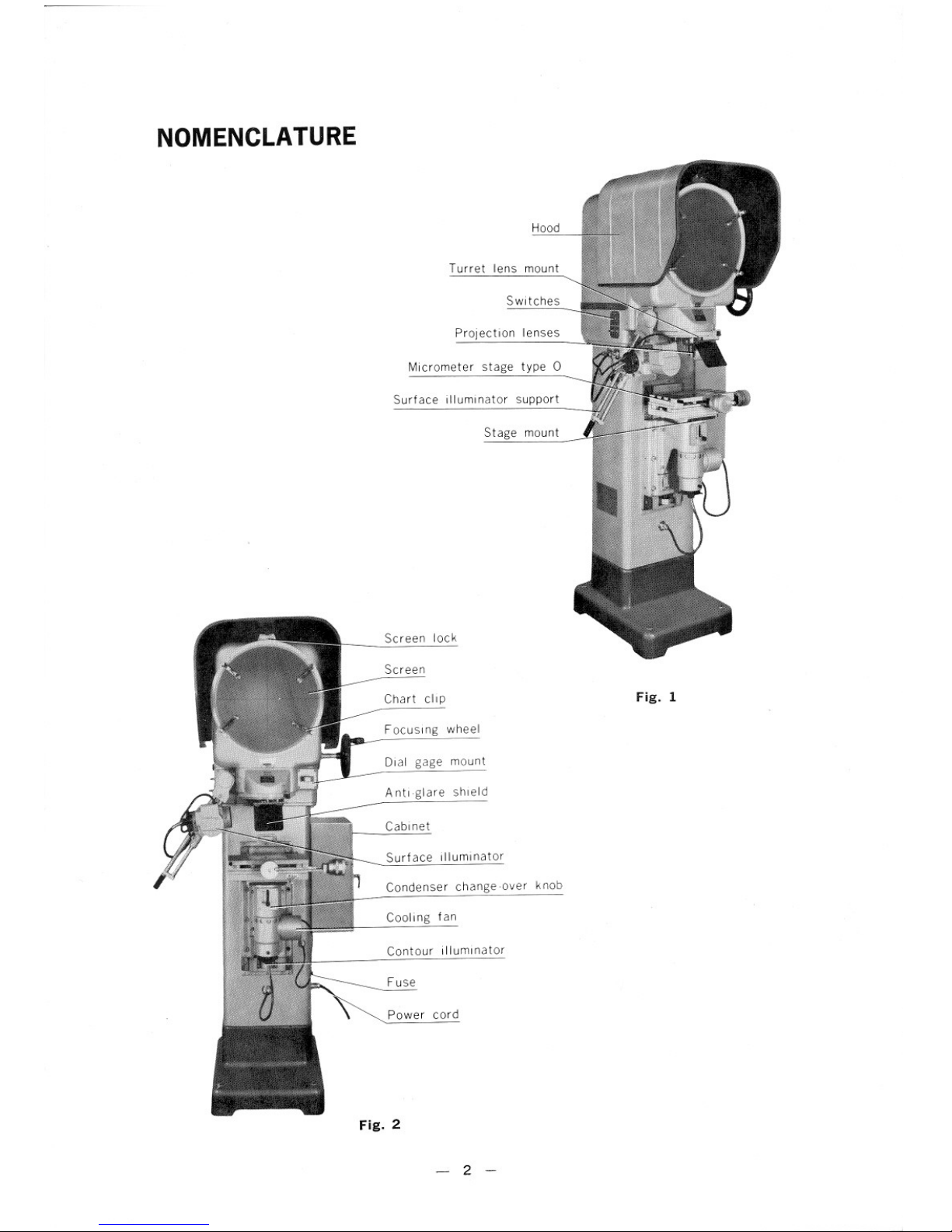

NOMENCLATURE

Turret lens mount

Switches

Projection lenses

MI crometer stage type 0

Surf ace ill umi nator support

Stage mount

Screen lock

Screen

Chart clip

F

OCUSI ng wheel

Dial gage mount

Antiglare shield

Cabi net

Surf ace ill umi nator

Condenser change-over knob

Cooling fan

Contour illuminator

Fuse

Power cord

Fig. 2

2

Fig. 1

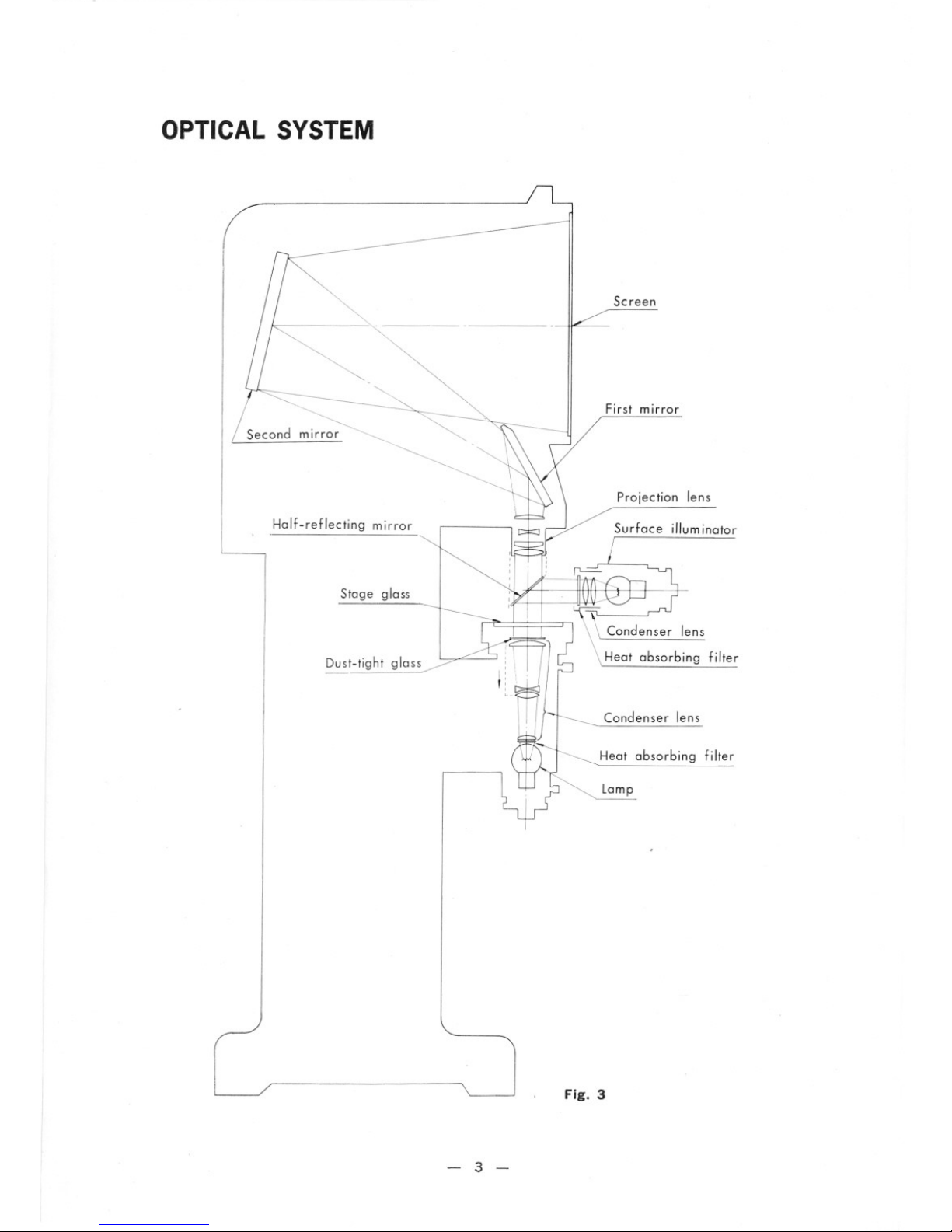

OPTICAL SYSTEM

Half-reflecting mirror

Stage gloss

Dust-tight glass

- 3 -

Screen

Projection lens

Heat absorbing filter

Condenser lens

Heat absorbing filter

lamp

Fig. 3

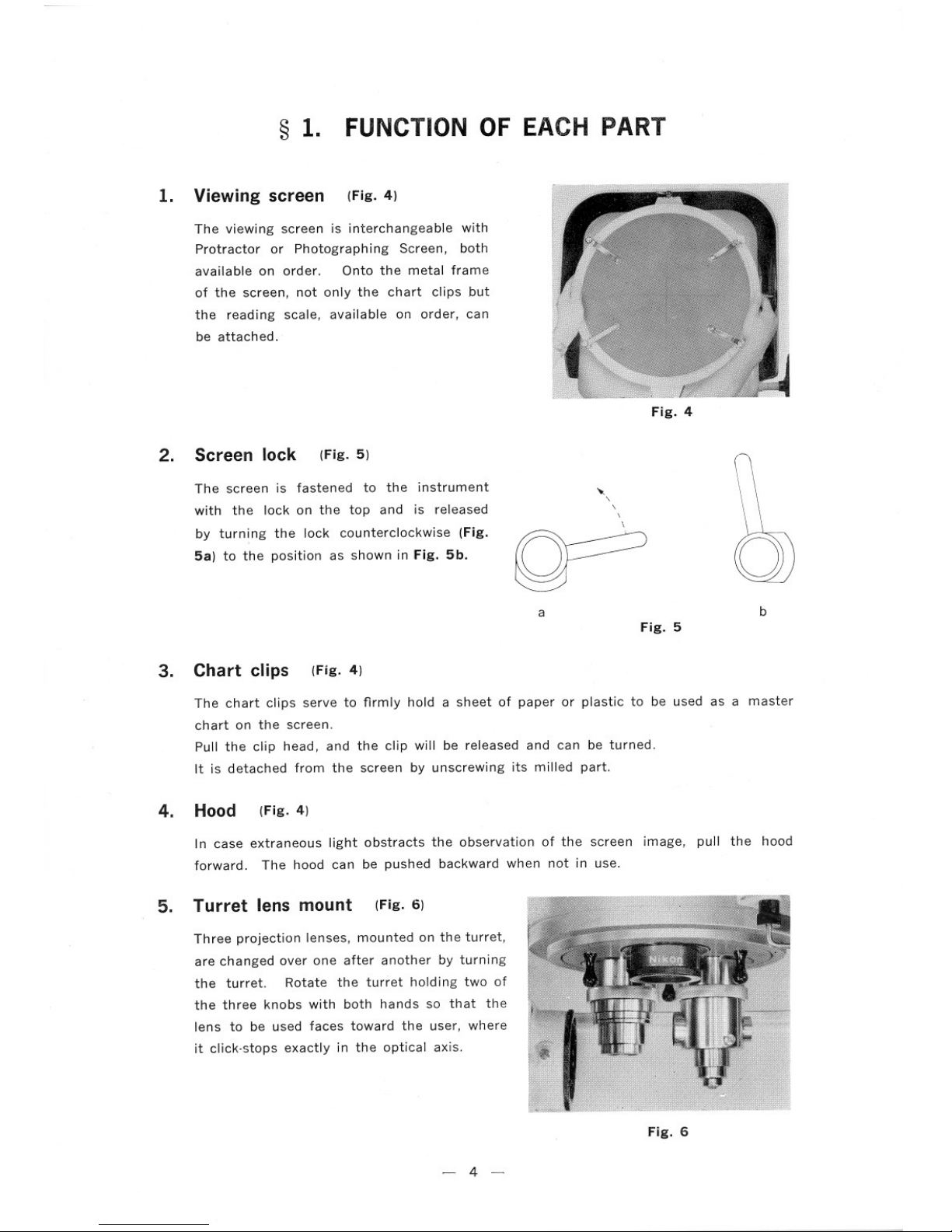

The viewing screen is interchangeable with

Protractor or Photographing Screen, both

available on order. Onto the metal frame

of the screen, not only the chart clips but

the reading scale, available on order, can

be attached.

§ 1.

1. Viewing screen

FUNCTION OF EACH PART

(Fig. 4)

Fig. 4

The screen is fastened to the instrument

with the lock on the top and is released

by turning the lock counterclockwise (Fig.

5a) to the position as shown in Fig. 5b.

2. Screen lock

3. Chart clips

(Fig. 5)

(Fig. 4)

"

,

\

\

\

~

a

Fig. 5

b

The chart clips serve to firmly hold a sheet of paper or plastic to be used as a master

chart on the screen.

Pull the clip head, and the clip will be released and can be turned.

It is detached from the screen by unscrewing its milled part.

4. Hood

(Fig. 4)

In case extraneous light obstracts the observation of the screen image, pull the hood

forward. The hood can be pushed backward when not in use.

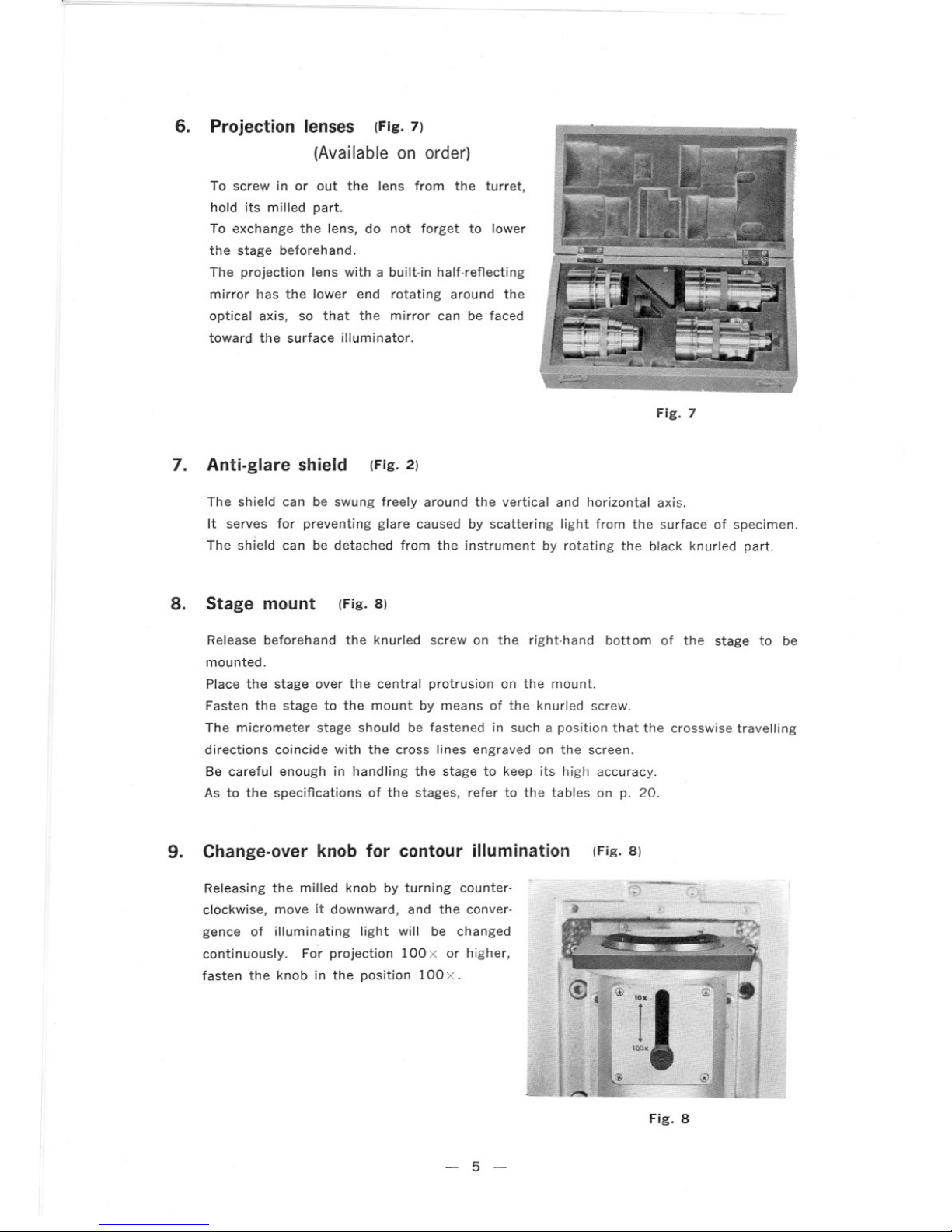

Three projection lenses, mounted on the turret,

are changed over one after another by turning

the turret. Rotate the turret holding two of

the three knobs with both hands so that the

lens to be used faces toward the user, where

it click-stops exactly in the optical axis.

5. Turret lens mount

(Fig. 6)

Fig. 6

- 4 -

6. Projection lenses (Fig. 7)

(Available on order')

To screw in or out the lens from the turret,

hold its milled part.

To exchange the lens, do not forget to lower

the stage beforehand.

The projection lens with a built-in half-reflecting

mirror has the lower end rotating around the

optical axis, so that the mirror can be faced

toward the surface illuminator.

Fig. 7

7. Anti.glare shield

(Fig. 2)

The shield can be swung freely around the vertical and horizontal axis.

It serves for preventing glare caused by scattering light from the surface of specimen.

The shield can be detached from the instrument by rotating the black knurled part.

8. Stage mount

(Fig. 8)

Release beforehand the knurled screw on the right-hand bottom of the stage to be

mounted.

Place the stage over the central protrusion on the mount.

Fasten the stage to the mount by means of the knurled screw.

The micrometer stage should be fastened in such a position that the crosswise travelling

directions coincide with the cross lines engraved on the screen.

Be careful enough in handling the stage to keep its high accuracy.

As to the specifications of the stages, refer to the tables on p. 20.

9. Change·over knob for contour illumination

(Fig. 8)

Releasing the milled knob by turning counter-

clockwise, move it downward, and the conver-

gence of illuminating light will be changed

continuously. For projection 100x or higher,

fasten the knob in the position 100 x .

- 5 -

Fig. 8

10. Contour illuminator (Fig. 9)

To take out the lamp house, slightly release

the fastening sCrew, turning clockwise (viewed

from above) the knurled part, pull out the lamp

house downward.

For replacement, insert the lamp house with

the top end of the groove faced toward the

side opposite to the fastening screw. Push in

the house by turning counterclockwise. Lock

it in position with the fastening screw.

Three screws are provided for centering the

lamp. These screws being released, the lamp

can be rotated by turning the base of the

lamp socket.

11. Surface illuminator (Fig. 10)

After the knurled screw at the right is released,

the condenser can be drawn in and out to

change the convergence of illuminating light.

To take out the lamp, release the lamp and

the screw at the left.

The three screws around the lamp socket are

used for centering the lamp.

Release these screws, and the lamp can be

rotated by turning the base of the lamp socket.

To set the surface illuminator in proper posi-

tion, move the surface illuminator vertically

along the supporting rod after the lock screw

is released. It can also be tilted for itself.

Lubricate the fan motor at its bearings with

machine oil once or twice a month.

12. Surface illuminator support (Fig. 10)

Fig. 9

Fig. 10

Release the black knurled grip at the bottom of the supporting rod by turning counter-

clockwise. Then, the supporting rod can be swung laterally.

Lock it in the desired position by fastening the grip.

- 6 -

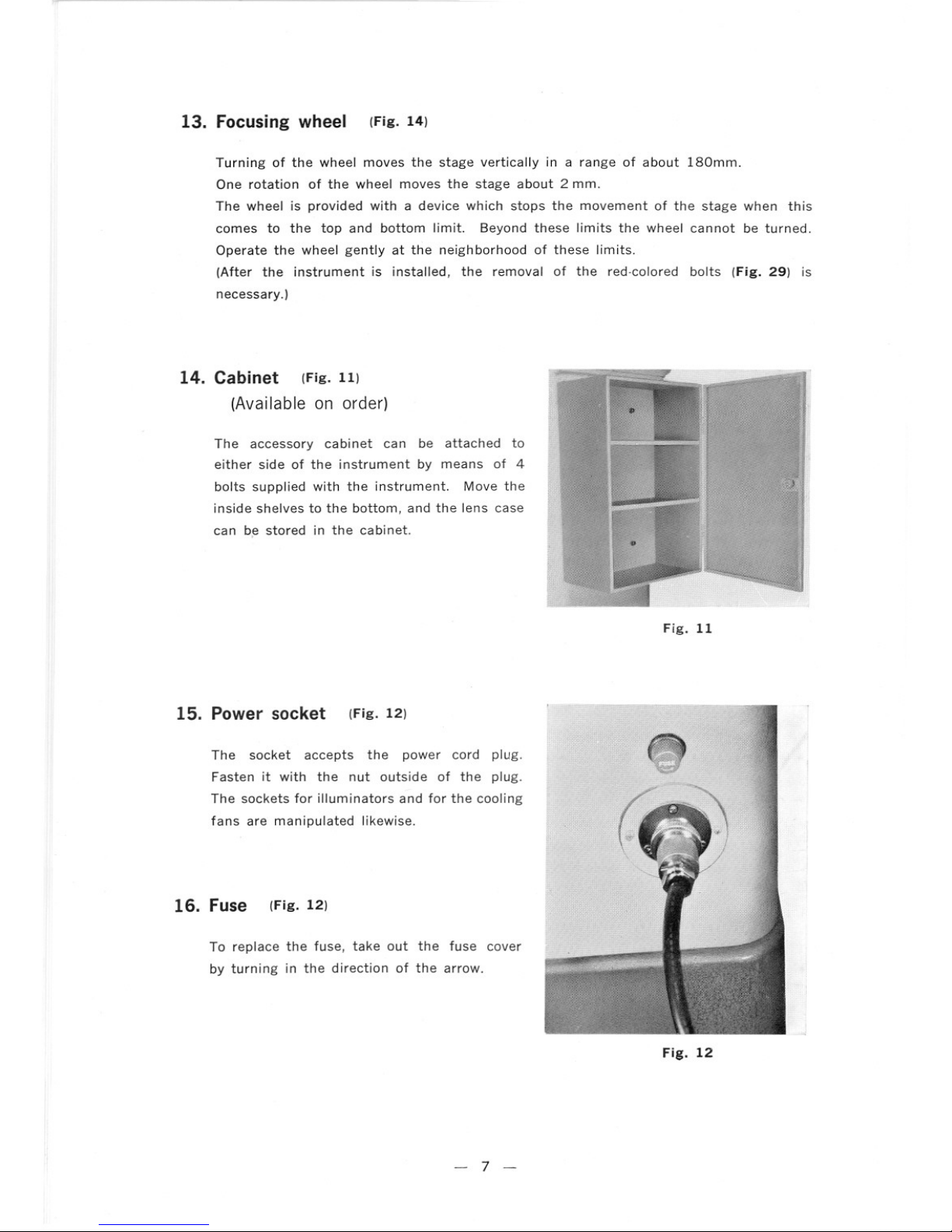

13. Focusing wheel

(Fig. 14)

Turning of the wheel moves the stage vertically in a range of about 180mm.

One rotation of the wheel moves the stage about 2 mm.

The wheel is provided with a device which stops the movement of the stage when this

comes to the top and bottom limit. Beyond these limits the wheel cannot be turned.

Operate the wheel gently at the neighborhood of these limits.

(After the instrument is installed, the removal of the red·colored bolts (Fig. 29) is

necessary.)

14. Cabinet (Fig. 11)

(Available on order)

The accessory cabinet can be attached to

either side of the instrument by means of 4

bolts supplied with the instrument. Move the

inside shelves to the bottom, and the lens case

can be stored in the cabinet.

Fig. 11

16. Fuse (Fig. 12)

To replace the fuse, take out the fuse cover

by turning in the direction of the arrow.

The socket accepts the power cord plug.

Fasten it with the nut outside of the plug.

The sockets for illuminators and for the cooling

fans are manipulated likewise.

(Fig. 12)

15. Power socket

Fig. 12

- 7 -

18. Contour .illuminator switch (Fig. 13)

Switch on the" MAIN switch", and the electric

current will flow to the primary circuit of the

built-in transformer. After using the projector,

never forget to switch off.

Turning" CONTOUR" switch to H or L, lights

the lamp for Contour illuminator and at the

same time the cooling fan starts running.

In the H position the brightness will be increas-

ed and in the L position it will be decreased,

the life of the lamp bulb being elongated about

three times by using at this position.

Fig. 13

(Fig. 13)17. Main switch

19. Surface illuminator switch

(Fig. 13)

The left-hand "SURFACE" switch is manipulated in the same way as the right-hand

"CONTOUR ".

The larger socket below the switch panel is for power supply for the surface illuminator

and the smaller one for the cooling fan.

20. Dial gage eyelet

(Fig. 14)

A dial gage attached to the eyelet on the

projector body, using the supporting rod which

is available on order, permits height or depth

measurement.

Move the projector stage vertically to take

reading of the dial gage at each sharply

focused position. The inner diameter of the

dial gage mounting hole is 6.5mm with coun-

terbore diameter 18mm.

In place of the dial gage eyelet, the right-

hand surface illuminator can be attached for

both-side oblique illuminations along with the

left-hand illuminator. For power supply to the

right-hand illuminator and for its cooling fan,

use the power socket and cooling fan socket

for the" Contour Illuminator" respectively.

Fig. 14

- 8 -

§ 2.

USING

The use of the Profile Projector Model V-14 consists of the following three procedures:

Illumination of the specimen

Projection of the enlarged image

Observation or measurement

1. Illumination

The projector permits two different illuminations, contour and surface, independently or

simultaneously. The contour illumination is used for projecting magnified profile images

of specimens and the surface illumination for projecting magnified surface images of

opaque specimens.

(1) Contour illumination

The lamp for contour illumination is turned on by manipulating the main switch

and then the "CONTOUR" switch. (See § 1-18)

Detection of the correct position of lamp (Fig. 9)

For minimizing the magnification error accompanied by out of focus of the screen

image, the illumination should be so-called telecentric. This telecentric illumi·

nation is obtained by the correct alignment of the lamp bulb to the optical axis

and by keeping the prescribed distance of the bulb from the condenser lens.

To detect the exact position of the lamp bulb for telecentric illumination, pro-

ceed as follows:

Mount the" Detect" lens on the lens turret in place of one of the projection

lenses. Set the change-over knob for condenser lens at 10

x.

A sharp image of the lamp flIament obtained at the center of the screen indio

cates that the correct telecentric illumination is attained.

If the filament image is not sharp or not located at the center, adjust the posi·

tion of the lamp as below:

a) Slightly releasing the fastening screw, move the lamp house vertically by

rotating the milled part until the image of the flIament is sharp on the screen.

Fasten the screw in this position.

bl Then, releasing the three centering screws, rotate the base of the lamp

socket until the axis of the flIament image on the screen becomes hori·

zontal.

- 9 -

c) Then, manipulate the three centering screws so that the filament image

comes to the center of the screen.

The above adjustment once exactly established, holds good for other projec-

tion lenses and will not be necessary so long as the lamp bulb is not

replaced.

Detach the" Detect" lens from the turret and replace it with another pro-

jection lens.

Changing-over the condenser (Fig. 8)

With the change-over knob positioned at the top, the largest illuminated field

will be obtained. As it is lowered, the illuminated area will be smaller.

Fasten the knob in the position where uniform brightness throughout the entire

area of the screen is attained for each magnification.

(2) Surface illumination

Two surface illuminations, oblique and

vertical, are possible.

To turn on the surface illuminator lamp,

switch on the "MAl N " and then "SU R-

FACE" (See ~

1-19). As to the mani-

pulation of the surface illuminator and

its support. (See ~

1-12)

Fig. 15

Oblique illumination (Fig. 15)

For this illumination, throw the light of

the surface illuminator from above slant-

wise onto the specimen surface being

observed. Unevenness of the surface will

be seen in relief, so that the illumination

is suitable for inspecting scratches on a

smooth surface, for examining patterns,

cloth, paper, etc.

The best result will be attained when the

brightest image is obtained by adjusting

the position and inclination of the surface

illuminator and the convergence of light.

In this type of illumination, light supplied

by the surface illuminator is thrown from

above vertically down to the surface to

be observed.

- 10 -

,

Fig. 16

Fig. 17

For this purpose, the use of a half-reflecting mirror is necessary on the projection

lens. Such an illumination is suited for inspecting smooth shiny surfaces, engraved

graduation, pattern, etc.

Slip on the half-reflecting mirror to the projection lens 10 X or 20 X. When using

the projection lens 50X or 100x, bring the built-in half-reflecting mirror to an angle

of 45 degrees by turning the small outside knob counterclockwise as far as it will go,

For the other types of illuminations, turn the knob in the reverse direction to bring

the mirror away out of the light path.

Important points for the correct surface illumination are as follows:

1. Face the half-reflecting mirror correctly toward the surface illuminator, other-

wise the brightness on the projected image will not be obtained equal at the

top and the bottom.

2. Throw the light exactly toward the center of the window glass, or the image

will show a brightness difference at the right and the left.

3. Supply the light to a full extent to avoid darkness or brightness difference at

the center and at the periphery of the screen.

Depending upon whether the oblique or vertical illumination is used, the position

and inclination of the surface illuminator and the convergence of the light should be

differently adjusted. Even in the same type of illumination, the most suitable lighting

conditions are not the same according to the magnification chosen. Therefore, it is

necessary, every time the type of illumination or magnification is changed, to adjust

the conditions so that the best illuminating effect, that is, the most and uniform

brightness is attained throughout the entire area of the screen.

(1) Correct positioning

In projecting the image, the procedures are

to be taken in the following order:

Fig. 18

(Fig. 18)

The surface or section of specimen to be

projected should be placed at a right angle

to the optical axis of the projection lens.

In case the specimen has a flat top surface

parallel to its flat bottom, it only needs to

place the specimen on the stage without

any flxture, because the surface of the

stage is exactly at a right angle

to the optical axis of the lens.

However, for specimens of cylin-

drical form, such as pin, shaft,

screw, etc., it is necessary to

employ a fixture, such as V-block

and center support (Fig. 19),

which holds them in position.

(2) Sharp focusing

Focusing is performed by rais-

2. Projection

Fig. 19

- 11 -

ing and lowering the stage by means of the focusing wheel. If sharpness is not

obtained over the entire screen image, make the surface or section of the specimen

to be. projected exactly at a right angle to the optical axis of lens. Insufficient

focusing will result in magnification error. This error may come out more serious

in the reflecting illumination.

Be careful in focusing not to thrust the specimen against the lens or the half-refiecting

mirror while viewing the screen image.

To avoid this, raise the stage so far that the clearance between specimen and lens

front be slightly less than the free working distance (see below) of the lens being

used. Then, looking the image on the screen, lower the stage slowly until the image

becomes plainly sharp.

Free Working Distances of Projection Lenses

(mm)

Magnifi-

Dia. of

A

B

D1D2

object field

m

35.67628268180

17.838810080

20X

17.86617210150

11.324245850

--- Nikonl

11.34343116100

r"""'"

7.115154233

~ ~'Ji---r

50X

7.14444135118

5.611112722

0, J\~---LA

3.5771613

100X

3.514143028

-t 0' '=f:-1-

200X

1.7882019

_/~,. _ B

300X

1.1882121

400X

0.8661212

500 X

0.7661212

Fig. 20

0.3551111

In this table, the free working distance of each lens means a clearance between

the focal plane and the lens front (A) or the bottom end of half-refiecting mirror

(Bl. when the lens is critically focused to the specimen surface.

D1: Maximum diameter of a cylindrical specimen, the generatrix of which is pro-

jected at the center of the screen.

D2: Maximum diameter of a cylindrical specimen, the generatrix of which is pro-

jected at the edge of the screen.

* Long working distance type

(3) Centering

At lower magnifications, the portion of the image to be examined can easily be

brought to the center by moving the specimen by hand.

At a highe~ magnification, the use of the micrometer stage (Fig. 21), available on

order, in place of the regular stage will be convenient in positioning the specimen

exactly in the center.

It is a general principle in

higher magnifications to

bring the image to the

center, first using a lower

magnification lens and

then changing over to a

higher magnification lens.

Fig. 21

- 12-

3. Measurement

The Profile Projector permits the user not only to conveniently examine or inspect minute

details of the specimen by its enlarged image projected on the screen, but also to easily

and accurately determine or measure the dimensions of the specimen, because the instru·

ment has been designed to give the projected image with a high accuracy of magnifi·

cation throughout the entire screen area.

It is also noteworthy that from the nature of its measuring method, the Profile Projector

has great advantages in measuring the following types of specimen:

1. Too minute or small to be held in the end·to·end length measuring apparatus

2. Liable to deformation or damage under the measuring pressure

3. Such an irregular shape that the measurement is difficult or troublesome by means

of other instruments

The measuring methods with the Profile Projector should be various according to the

measured, accuracy of measurement required, etc. Several basic methods will be described

below:

(1) Placing a scale on the screen (Fig. 22)

Dimensions of the screen image can be measured using a scale on the screen sur·

face.

In this case, for reading of the scale, a magnifying glass may be used.

However, the use of a high power magnifying glass is not advisable, because diffi·

culty in determining the image contour will occur, due to the ground glass grains

of the screen coming in sight, and eye strain may not be avoided in prolonged work.

It is recommended to use a glass scale available on order (one type with one

division: 0.5 mm and the other: 0.1 mm), since the graduation viewed through the

glass can be brought into direct with the image on the screen, so that any measuring

error caused by parallax is avoided.

the

Fig. 22

- 13-

(2) Comparing with standard length

When inspection is to be repeated for a lot of specimens, it is convenient to draw

two fiducial lines on the screen glass with the interval corresponding to the standard

as shown in (Fig. 23), for example.

Measure a difference of the image from the standard using a scale, or more simply,

a screw micrometer equipped on the micrometer stage available on order, where the

difference is obtained not in the magnified but in the actual value directly.

Fiducial lines

Difference

Fig. 23

(3) Comparing with master chart

Inspection of a specimen of complicated shape as shown in (Fig. 24) can easily and

accurately be made by superposing the projected image on the master chart.

Needless to say that the chart should be drawn exactly at a prescribed magnification

and be held firmly on the screen adhesive.

When the line or figure representing the tolerance is given on the master chart

along with the fiducial one, it facilitates rapid inspection.

Fig. 24

- 14-

For master charts, translucent paper or plastic sheet will be used. However, if more

accurate work is required, paper adhered to transparent glass plate is recommended,

which can be brought into close contact with the screen surface only by using the

chart clips.

Plastic sheet can be handled more conveniently than glass, because of its light

weight and unbreakable property. But it is more liable to be scratched and has

greater thermal expansion and undergoes some dimensional change by age.

(4) Measuring angle by rotating the screen (Fig. 25,26)

The angle can be measured also by rotating the protractor screen available on

order.

First, bring one of the cross lines engraved on the screen into coincidence with

a side of the angle to be measured, the apex being in contact with the center of

the cross lines, and take reading of the angle on the protractor. Then, by rotating

the screen, bring the same line up to the other side of the angle and read the

protractor.

The difference between the two readings will give the angle to be measured.

Fig. 25

Fig. 26

In measuring a fairly large angle, it may be efficient to take the difference from the

right angle of the cross lines.

More rapid and convenient angle measurement will be performed by using the micro-

meter stage, in which it need not make the center of the cross lines coincide with

the apex of the angle to be measured.

It is noteworthy that, in bringing a side of the angle to the cross lines, a better

result will be obtained, if a slight clearance is made therebetween, by which the

coincidence error may be avoided.

- 15 -

(5) Tracing screen images

Comparison of two similarly shaped specimens is conveniently parformed byoverlay-

ing the screen image of one specimen traced on translucent paper upon the pro-

jected image of the other on the screen, or by placing both traced images of speci-

mens upon the other. If necessary, the traced images on the paper can be kept

for later use.

As paper is breakable and liable to expansion and contraction, it is not suitable for

accurate work and for use after a long period.

Sheet of plastic in place of paper may be better, though more expensive.

Plastic sheet with a mat surface on which fiducial lines or figures can be drawn

directly is available and also used as a master chart as described previously.

Fig. 27

focusing glass and a plate holder in which

When using the photographing screen, no

To take photograph, make the room

dark, hold a sheet of photosensitive

plate, film, paper, etc. on the screen

and give an appropriate exposure by

switching on and off the illuminator of

the projector.

There is a photographing screen,

available on order which is mounted

on the instrument in place of the

normal screen. It is provided with a

plate, film or paper is put beforehand.

dark room will be necessary.

No correct exposure time can be given here, because they vary with the surface of

specimen, type of illumination, magnification, voltage of the lamp being used, etc.

The surest way to determine the correct exposure is to expose a test plate in steps

of time and giving the best result. If the exposure time is too short to be controlled

in such a case where a high sensitive material is used, it will be better to decrease

the intensity of the lamp, or it will be convenient also to put in and out a piece of

cardboard underneath the projection 'lens, instead of switching on and off the lamp.

For accurate measurement, photographic plate is preferably used to paper as the

former is less liable to expansion or shrinkage.

The photograph of projected image

taken as a permanent record has an

advantage that it permits examination

and measurement at a later time.

(6) Photographing screen image (Fig. 27)

- 16 -

CAUTION IN HANDLING

The Profile Projector, being a high precision instrument, should be handled carefully enough

to maintain its accuracy. The place for setting up the instrument should be free as far as

possible from vibration, dirt, high temperature and moisture.

1. Screen

Grease or finger marks on the screen which will make the image undiscernible can be

washed out, using warm water with soap. For washing, do not detach the glass sepa-

rately, but with its metal frame, to avoid damage. Dry and then attach it to the

instrument.

2. Projection lens

Never attempt to disassemble the lens. Avoid rough handling and touching the lens sur-

faces with fingers or other things to prevent their anti-refiection coat from being

scratched.

3. Mirrors

Do not touch the mirrors built in the instrument to avoid changing of the position and

inclination which causes inaccurate magnification.

They have aluminium-plated surfaces which are liable to be scratched if touched or

rubbed. If need arises to take dirt or cloudiness off their surfaces, contact the maker

or his agent.

4. Half-reflecting mirror

The half-reflecting mirror built-in or to be attached to the projection lens for vertical

illumination is coated with an extremely thin metallic layer which is also liable to

be scratched. Take the same caution as for the mirrors above mentioned. Little dust

or dirt left on their surfaces will not affect the image quality. To take dirt off their

surfaces, use a soft feather. If not sufficient, use a wad of cotton soaked with ether

and sweep over them carefully to wash off the dirt or dust. Do not rub them.

- 17-

5. Dark image

7. Others

Should the lamp fail, check the lamp fila-

ment and the fuse.

Insufficient contact of the cord plug or of

the socket may cause failing of the lamp.

To detach the lamp bulb from the socket,

turn the bulb counterclockwise while depress-

ing. For attaching, reverse this procedure.

Be careful of the two differently sized notches

on the bayonet.

The vertical movement of the stage is locked

by two red-colored bolts.

Therefore, before manipulating the focusing

wheel, remove the bolts using a hexagonal

wrench. (Fig. 29)

For transportation, move the instrument

gently to avoid vibration and shock al5 far as

possible.

For installation, set up the stage surface

horizontal.

Fig. 28

(Fig. 28)

If the screen image is too dark, check the

lamp bulb after taking out.

If the glass surface of the bulb becomes

blackened, change the bulb with spare. Dust

on the surface also may c;:ausedarkness.

If darkness arises in the contour illumination,

check the stage glass and window glass

below.

Darkness in the surface illumination may be

caused by dirt on the glass elements in the

surface illuminator. Wipe off the dust with

a soft feather and linen soaked with alcohol.

6. Lamp bulb

Fig. 29

8. If something wrong or disorder is found

Contact the agent or the maker immediately without disassembling the instrument in

any way. For any other difficulties or troubles, we are always ready to furnish infor-

mation.

- 18-

TECHNICAL DATA

Screens

Effective diameter of screen: 356mm

Provided with cross lines engraved on fine grain ground glass

Equipped with 4 detachable chart clips

Glass scale, available on order, can be attached

Interchangeable with Protractor or Photographing Screen

Projection lenses (Available on order)

Magnification

Diameter of

Remarks

lOx

35.6mm

Half·reflecting mirror attached

l7.8mm

II

II

II

11.3mm

Half-reflecting mirror built-in

II

II

7.lmm

II

II

II

5.6mm

II

3.5mm

II

II

II

1.7mm II

l.lmm

II

O.8mm

II

O.7mm II

O.3mm

II

The lenses with" L" are specially designed types with longer free ·distances.

The above lenses are used commonly for contour and surface illumination including

vertical and oblique.

Turret lens mount

Accepts three lenses (screw mount)

Provided with 2 dust-tight caps

- 19 -

Stages

Normal stage (Available on order)

Type

Surface area

Throat clearance

Remarks

L

200x160mm

0-153 mm

With T groove

/I

35 -193mm

/I

Micrometer stages (Available on order)

I Cross travel I Minimum

I Throat

Remarks

Surface area

(lat. x longi.) reading

clearance

With 2' reading revolving stage.

0-148mm

With T groove.

(50x25mm)

(O.OOlmm)Range of zero·resetting: 0.1"

With block gages.

With 21 reading revolving stage.

With T groove.

I 150mm in dia.

(25x25mm)

/I

/I

Range of zero·resetti ng: 0.1"

I I With dovetail groove.

'(lat.) (Iongi.) 4"x2'I'

/I

/I

Range of zero-resetting: 0.1'1

I

With block gages.

For A2 and a block gage are available on order.

Dial gage mount

Permits mounting of a dial gage for measuring height or depth of specimen

Supporting bar is available on order

Interchangeable with right-hand surface illuminator

Light source

Incandescent lamp: 15V, 150W with specified filament.

Same type bulb is used for contour and surface illuminator.

Changed over to 2 brightness

10 spare bulbs are supplied.

Electrical requirement

Power cord: 2m long, with AC. plug

Built-in transformer

Primary current: AC. 100V, 115V, 220V or 240V (Please specify)

Single phase 50-60 cycles

Capacity: 300 V. A.

- 20 -

Accuracy of magnification

Within ± 0.1% of nominal value of each lens except 200x-1000x

Within

± 0.15% when used with half-reflecting mirror

These accuracies are guaranteed for projection lenses delivered with instrument body

Dimensions

Height:

Width:

Depth:

Floor area:

Approx.

Approx.

Approx.

Approx.

172cm

120cm (door opened)

86cm

42cm wide X 55cm deep

* Height up to the center of screen can be decreased 100mm on order.

Weight

Instrument: Approx. 120kg

Lens cabinet: Approx. 4kg (4 lenses 10 x -100 x included)

Illumination

Contour illuminator

Permits telecentric illumination (with detecting lens)

Zooming condenser for 10x-100x

Heat-absorbing fllter, cooling fan and centering device

Surface illuminator

Permits vertical illumination using half-reflecting mirror, and oblique illumination

directly.

With vertical, lateral and inclination adjustment

Heat-absorbing fllter, cooling fan and centering device

Attachable anti-glare shield glass provided

* Right-hand surface illuminator is available on order.

Cabinet (Available on order)

Accepts accessories, hexagonal wrench, lamp bulbs, etc

With door and 2 detachable shelves

Can be attached to either side of the instrument

- 21 -

SPECIAL ACCESSORIES

Protractor screen

Effective diameter: 356mm

Minimum angular reading: I'

With coarse and fine motion and locking device

Photographing screen

Provided with focusing glass and 2 both-side plate-holders

Accepting plate or paper: 12cm x 16.5cm

Glass scale

Graduation: 0-200mm

One division: 0.5mm

Accuracy: (15+ 2~0)fl

Attachable to projector screen

Set of glass scales

Reading scale

Standard scale

range: 0-300mm

range: 0- 50mm

One division: O.lmm

One division: 1mm

Accuracy: (6 + ~O )fl

Accu racy: (3 + 1~~O )fl

6 x magnifying glass with eyesight adjustment

Tilting center fixture

T groove type: For micrometer stage A2 or E2.

Tilting angle:

± 10', one division: 10

Dovetail slot type: For micrometer stage 0

Tilting angle: ± 15', one division: 10

V groove fixture

For general use and dovetail groove stage

Maximum diameter of specimen held: 25mm

Maximum height of axis of specimen: Approx. 47mm (for 25mm diameter)

Dial gage supporting rod

Rotating table

Attachable on top of micrometer stage type 0

Surface area 160mm in diameter

With T groove for attaching fixture

Angular graduation:

3600, one division: 2'

Height: 18mm

Mercury lamp illuminator

For contour and surface illuminations

Provided with high pressure mercury lamp 200W

- 22-

(Nikon)

NIPPON KOGAKU K. K.

Nishikawa Bldg., 1-7, Nihonbashi-dori, Chuo-ku, Tokyo 103, Japan

NIPPON KOGAKU (U. S.A.) INC.

623 Stewart Avenue, Garden City, New York, 11530, U. S. A.

NIKON EUROPEN. V.

Entrepotgebouw Schiphol-Centrum, Amsterdam, The Netherlands

NIKON AG.

Kirchenweg 5, 8008 Zurich, Switzerland

Printed in Japan (70.10.c) A-4

Loading...

Loading...