Page 1

en

Service Manual Coffee Machine

EF 748

EF 749

1

01.2004 DOG

Page 2

Contents

Main Components ........................................................ 5

Overview ....................................................................................... 5

Jaw ................................................................................................ 6

Overview of rating plates .............................................................. 7

Water circuit .................................................................................. 8

Technical Data ............................................................................... 9

Operation .................................................................... 10

Preparation .................................................................................. 10

Making coffee ............................................................................... 11

Preparing hot water ..................................................................... 11

Frothing aids ............................................................................... 12

Heating with steam ..................................................................... 12

Frothing ....................................................................................... 12

LED status diagram .................................................................... 13

Troubleshooting ......................................................... 14

Checking the machine - receipt (1) ............................................ 14

Checking the machine - receipt (2) ............................................ 15

Coffee temperature too low ........................................................ 16

Coffee temperature too high ...................................................... 16

No function .................................................................................. 16

No outflow ................................................................................... 17

No steam function or too little steam ......................................... 18

No capsule ejection .................................................................... 18

Jaw does not close ..................................................................... 18

Water on the jaw ......................................................................... 18

Water on side of machine or below machine............................. 19

Pump noisy ................................................................................. 19

Not enough froth when frothing milk ......................................... 19

2

Page 3

Contents

Repair .......................................................................... 20

General disassembly (stage 1) ................................................... 20

General disassembly (stage 2) ................................................... 21

Replacing thermoblock .............................................................. 22

Replacing NTC ............................................................................ 22

Replacing pump .......................................................................... 23

Replacing fine-wire fuse ............................................................. 24

Replacing control board ............................................................. 25

Replacing main switch or steam switch .................................... 26

Replacing LED ............................................................................ 26

Replacing steam pipe ................................................................. 26

Replacing jaw .............................................................................. 27

Complete jaw disassembly ......................................................... 28

Complete jaw disassembly ......................................................... 29

Replacing heating PTC ............................................................... 30

Replacing pyramid plate ............................................................. 31

Replacing capsule cage ............................................................. 31

Electronic mainboard, wiring diagram ....................................... 32

Maintenance................................................................ 33

Descaling .................................................................................... 33

Measuring rate of flow ................................................................ 35

Checking for leaks and pump pressure (1) ................................ 36

Checking for leaks and pump pressure (2) ................................ 37

Checking extraction chamber for leaks ..................................... 38

Measuring coffee temperature ................................................... 39

Measuring closing force ............................................................. 40

Checking reed contact ................................................................ 41

Daily maintenance and final cleaning ........................................ 42

Spare parts ................................................................. 43

3

Page 4

Preface

The purpose of this Service Manual is to provide the service personnel with all necessary

information with regards to correct handling, maintenance and repair of the coffee machine

EF 748 and EF 749.

This manual should be used by the technicians as a valuable aid to guarantee the permanent

readiness for use of the machine. In order to take full advantage of all the functions, it is

absolutely necessary to follow the instructions in this manual.

Please keep this manual together with the corresponding service documentation. This way

you are assured to have the necessary information.

For fast access to information directly from the PC or MAC monitor, this manual is also

available on CD-ROM. The required utility (Adobe Acrobat), also on this CD-ROM, runs on PC

and MAC computers. At the Internet address www.adobe.com you can obtain the utility Adobe

Acrobat for additional platforms, free of charge.

4

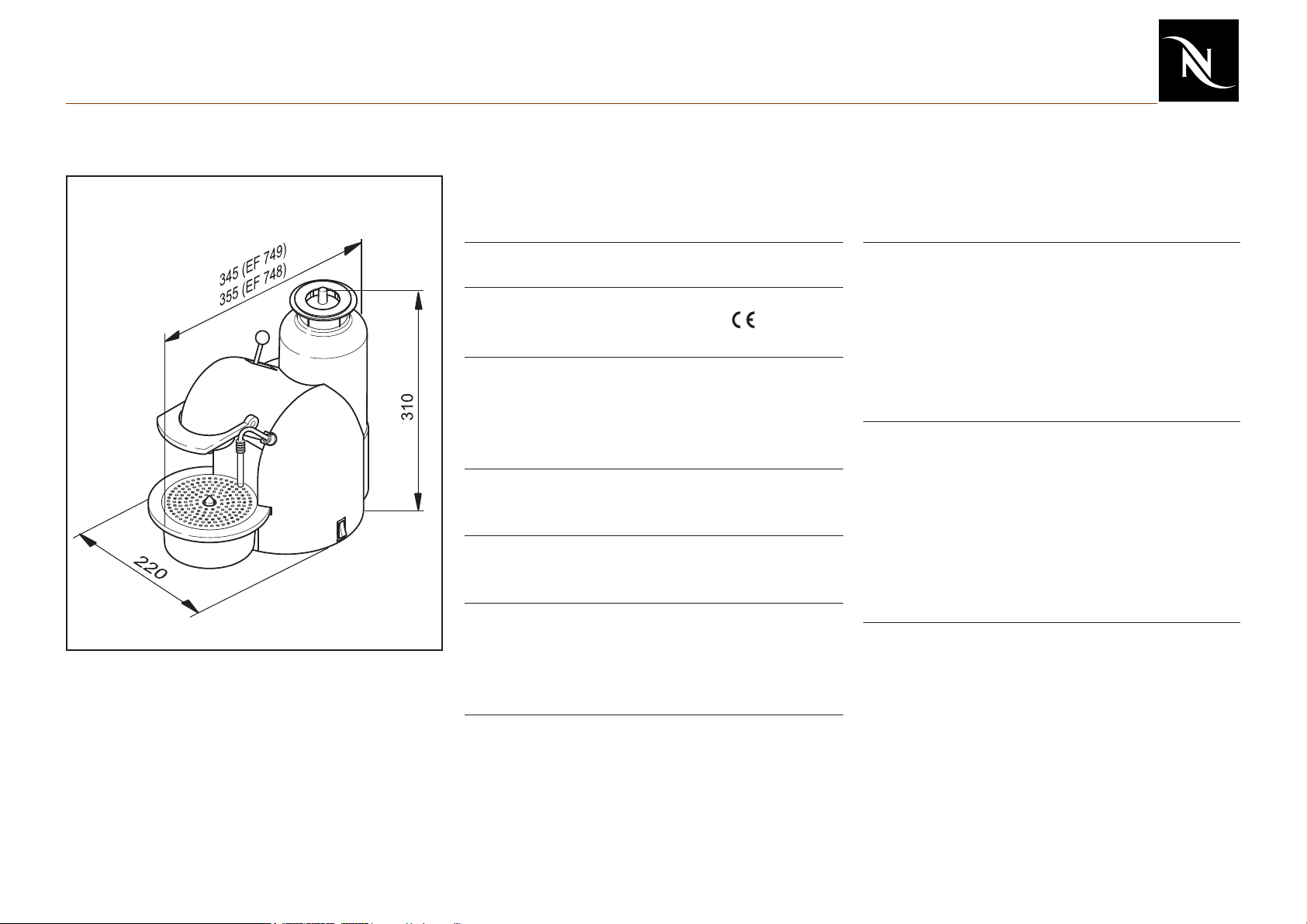

Page 5

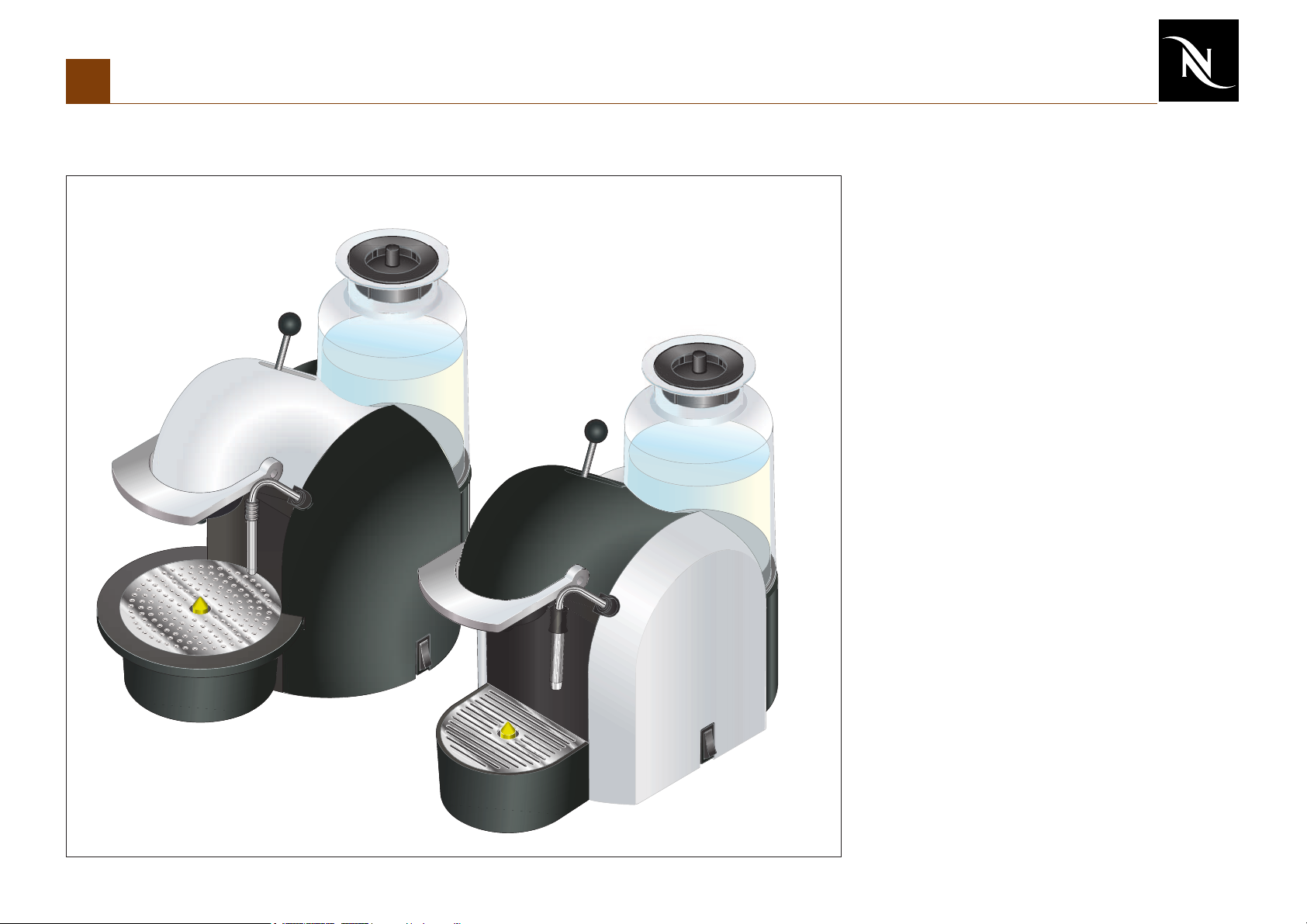

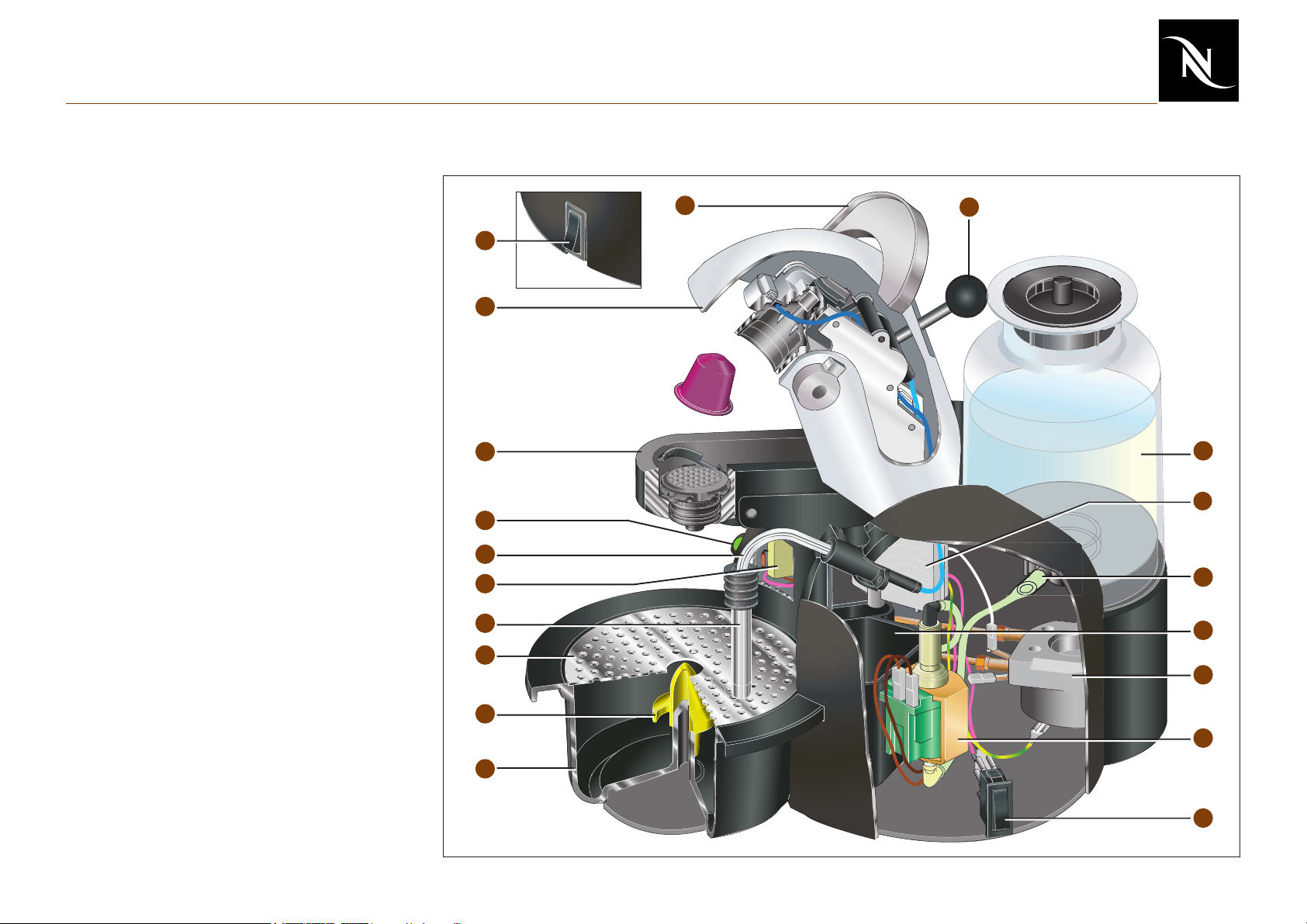

Main Components

Overview

1 Switch On/ Off

2 Switch steam

3 Upper part Jaw

4 Lower part Jaw

5 LED

6 Electronic mainboard

7 Steam pipe

8 Frothing aid

9 Floater

10 Drip tray

11 Drip grid

12 Closing handle

13 Jaw stick coffee / hot water

14 Water tank

15 Water tank connector

16 Condensation room

17 Thermoblock

18 Pump

19 Container for used capsules

12

1

3

4

5

7

6

13

14

16

15

11

10

8

9

19

17

18

2

5

Page 6

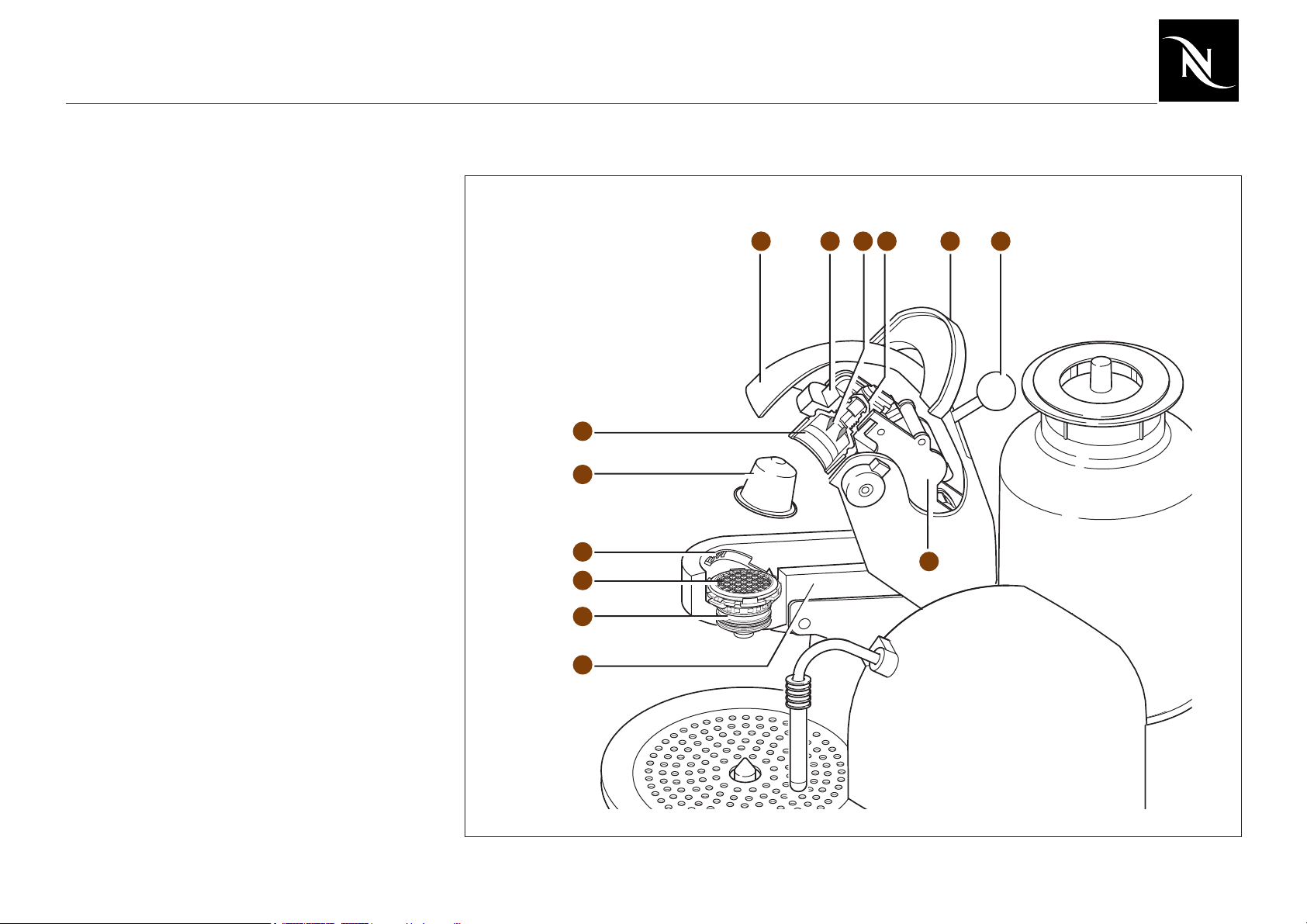

Main Components

Jaw

20 Support for brewing unit

21 Capsule cage

22 Closing handle

23 Jaw stick coffee, hot water/ steam

24 Blades

25 Cover

26 Heating PTC (until Sept. 2003 only)

27 Coffee capsule

28 Ejector

29 Pyramid plate (PPP, plastic)

30 Pyramid plate support

31 Brewing unit with ceramic valve and

reed contact board

32 Capsule cage connection

21

27

26

3225

22 2324

28

29

30

20

31

6

Page 7

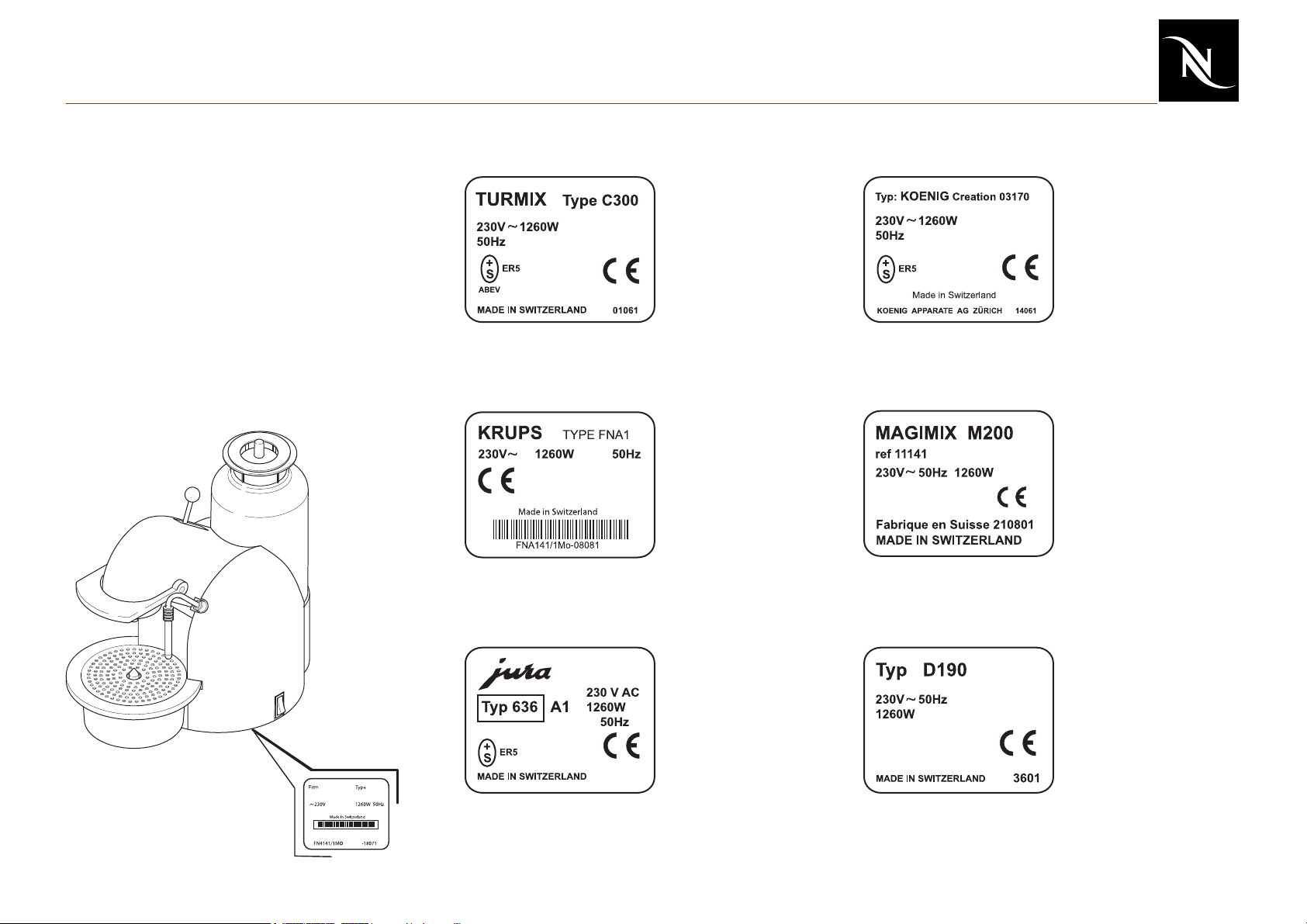

Main Components

Overview of rating plates

Depending on the brand, the rating plate may

be of varying design.

The rating plates carry the following

information:

Turmix

Date code

DDMMY

Krups

FNA141 = type

1M = factory

0 = internal number

08081 = Date code

DDMMY

König

03170 = Item number

with colour code

Date code DDMMY

Magimix

M200 = type code

Item number with colour

and country coding

Date code DDMMYY

Jura

636 = type

A = colour code

1 = Appliance

modification status

7

Saeco

Date code WWYY

Page 8

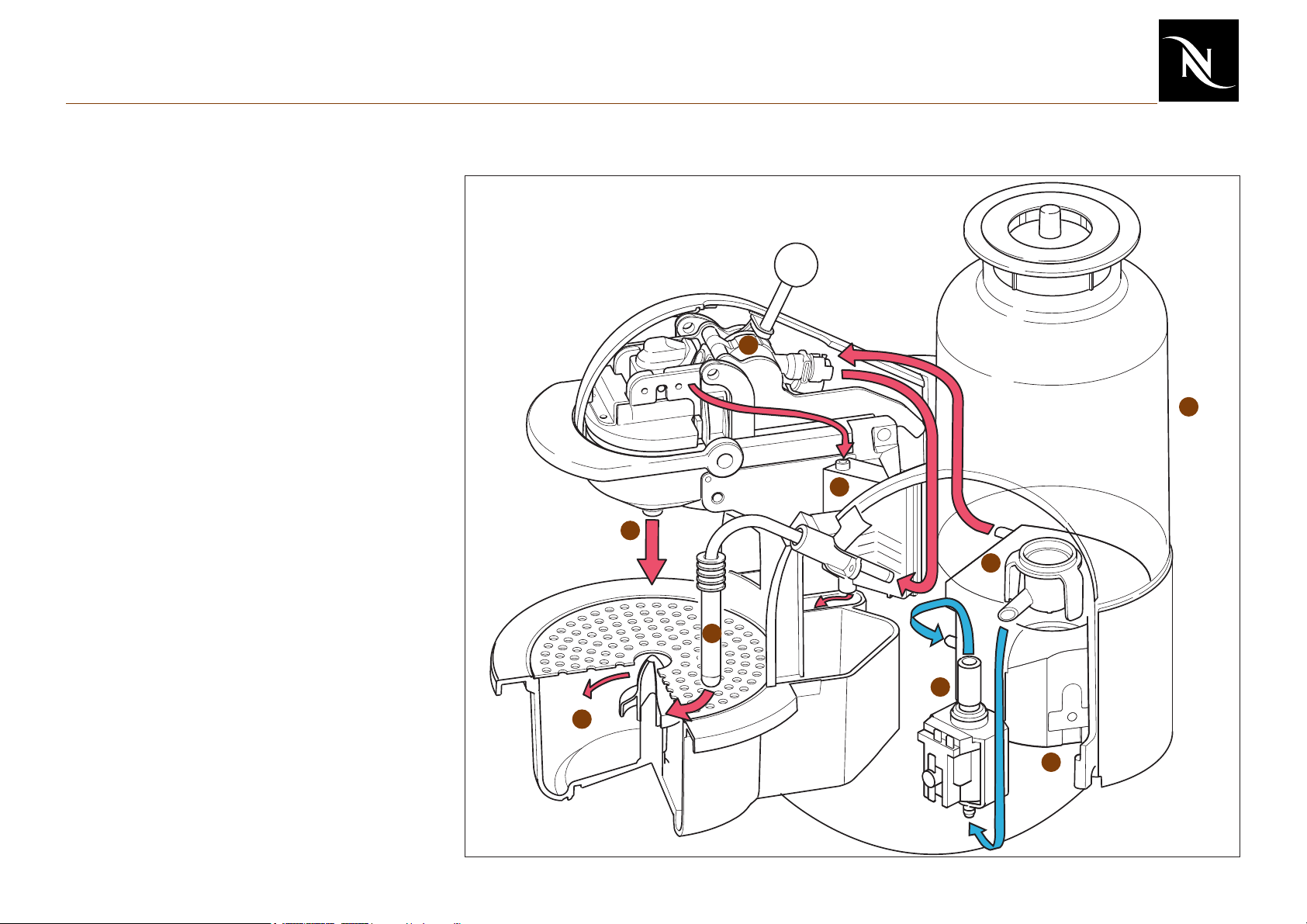

Main Components

Water circuit

1 Water tank

2 Water tank valve

3 Pump

4 Thermoblock

5 Ceramic valve

6 Coffee outlet

7 Steam pipe and frothing aid

8 Condensation room

9 Drip tray

5

1

8

6

2

7

3

9

4

8

Page 9

Main Components

Technical Data

Dimensions in mm

Mains EUR: 230V / 50 Hz

USA /CAN:120 V / 60 Hz

JAP: 110 V / 50-60 Hz

Cable length ~1,5 m

Approvals SEV, CENELEC, - conform

UL, CUL, MITI

Pump pressure:

- max. permissible 17,5 bar ±1,5 bar

- during coffee preparation 9 - 13 bar

(depending on brand of coffee)

Flow performance

100 - 240 ml/min. at 12 bar

Weight of machine 4,8 kg

(without water)

Capacities

Water tank 1.2 l

Drip tray 0.45 l

Capsule container 10-12 pcs.

Pre-heating time approx. ca. 45 s

Safety temperature (thermal cut-off) 184° C

Power consumption

(at all voltages and frequencies):

Heating 1’200 W

Pump 60 W

Heating PTC 15 W

Ratings:

Preheating 15.5 Wh

1 small cup (45ml) 5.5 Wh

1 large cup (110ml) 9 Wh

Stand-by mode (24 hours) 575 Wh

9

Page 10

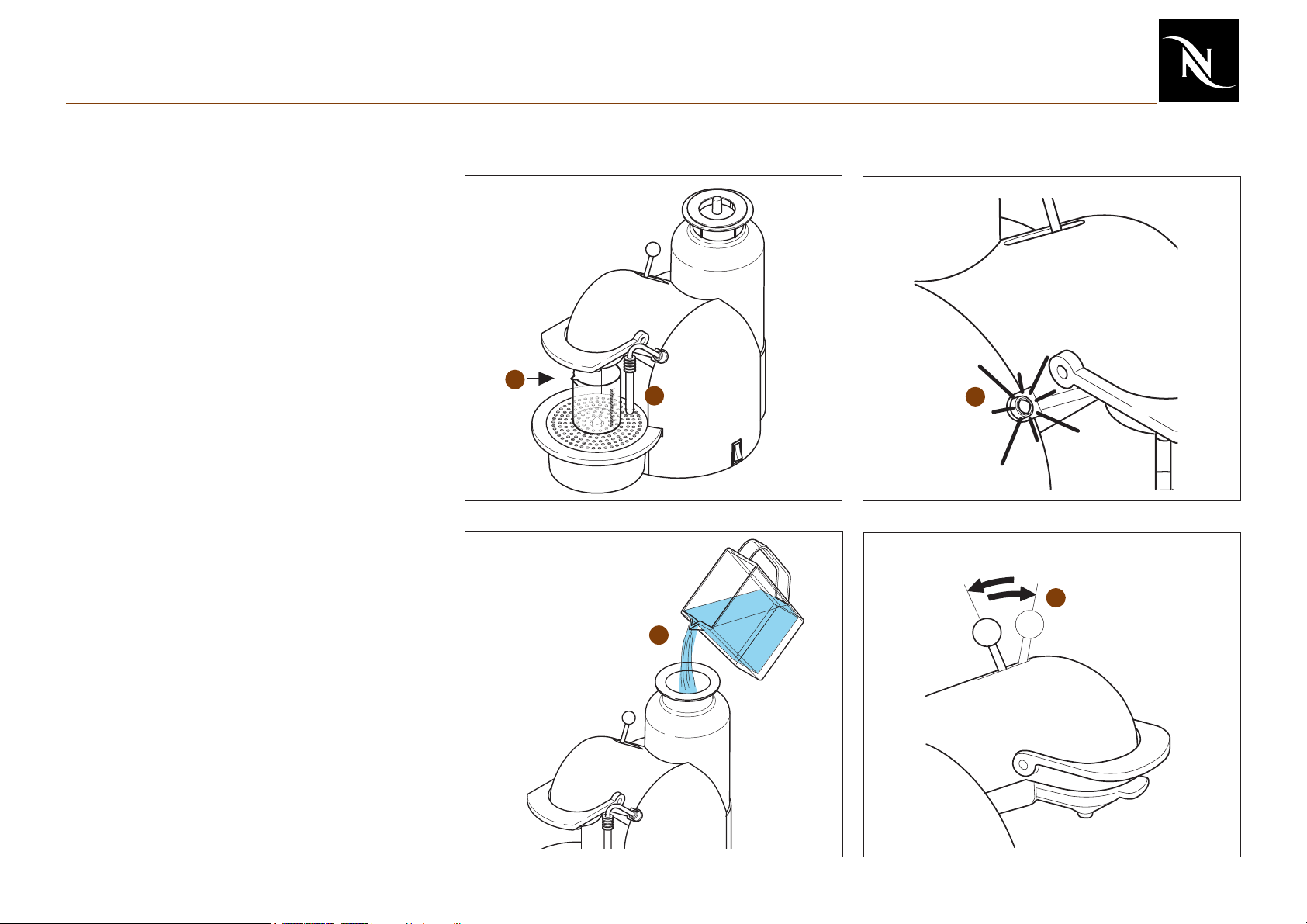

Operation

Preparation

1 Switch on machine

2 Position pot underneath

3 LED flashes green

4 Fill with water

5 Flush JAW

1

2

3

4

10

5

Page 11

Operation

Making coffee

1 Open jaw

2 Insert capsule

3 Close jaw

4 Position cup

5 LED must be green

6 Place jaw stick in the front position,

coffee flows into the cup

7 Once the cup contains the required

amount, return the jaw stick to the

middle position

8 Briefly open jaw and eject capsule into

the capsule container

1

3

2

4

5

67

Preparing hot water

1 Position cup underneath steam pipe

2 LED illuminates green

3 Place jaw stick in the rear position, hot

water flows into the cup

4 Once the cup contains the required

amount, return the jaw stick to the

middle position

4

3

1

2

11

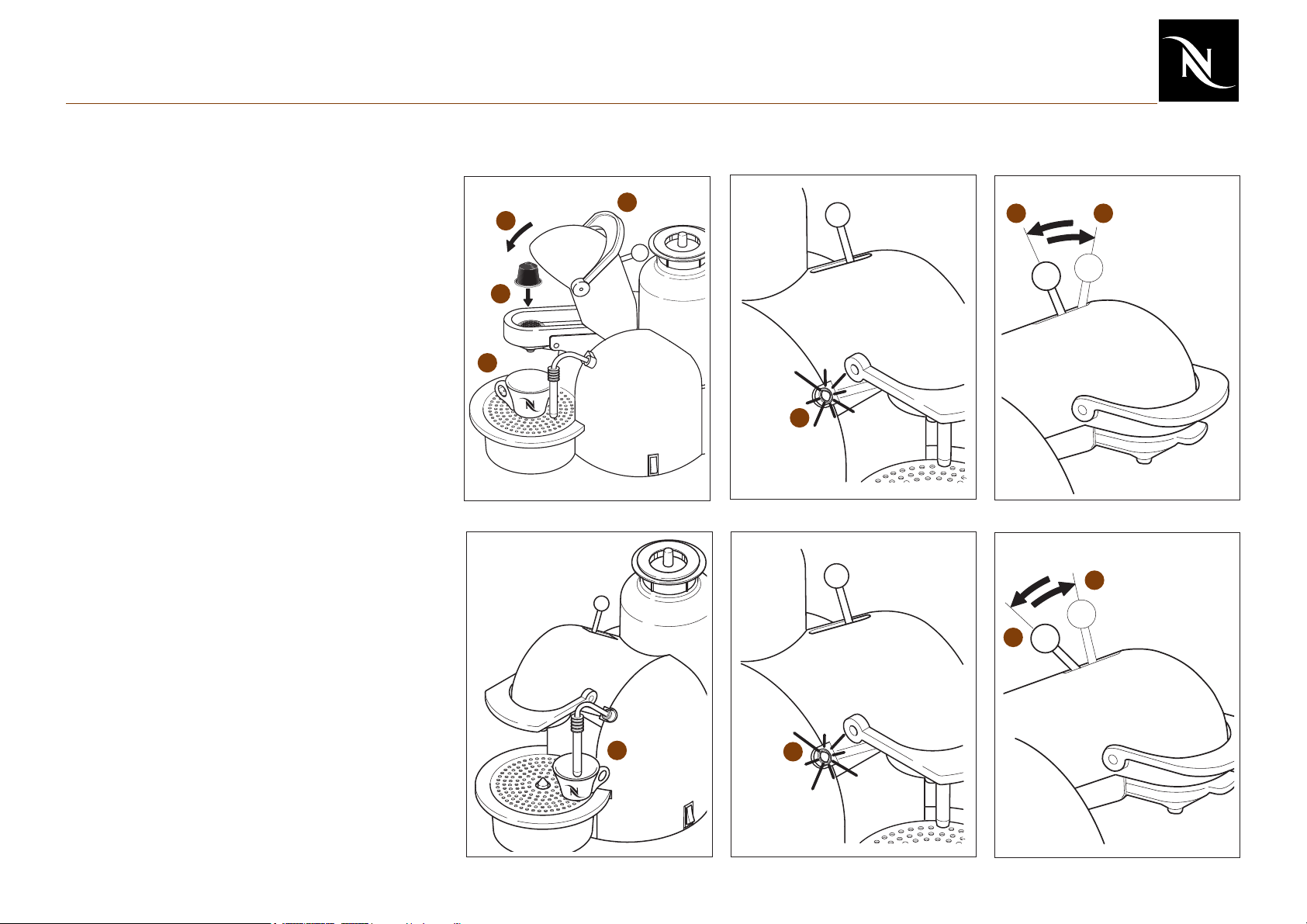

Page 12

Operation

Heating with steam

1 Slide down frothing pipe (only frothing

aid A and B)

2 Press steam switch

3 LED flashes orange, wait until LED

illuminates orange

4 Immerse frothing pipe approx. 1cm

deep in the liquid

5 Place jaw stick in the rear position until

the required temperature is reached

6 Return jaw stick to the middle position

Frothing

6

5

1

4

3

1 Slide down frothing pipe (only frothing

aid A and B)

2 Press steam switch

3 LED flashes orange, wait until LED

illuminates orange

4 Immerse frothing pipe approx. 1cm

deep in the milk

5 Place jaw stick in the rear position until

the required foam is produced

6 Return jaw stick to the middle position

Frothing aids

There are three different types of frothing aid.

A) EF 749

B) EF 748 Turmix and Nespresso

C) EF 748 Krups

A

12

2

B

C

Page 13

Operation

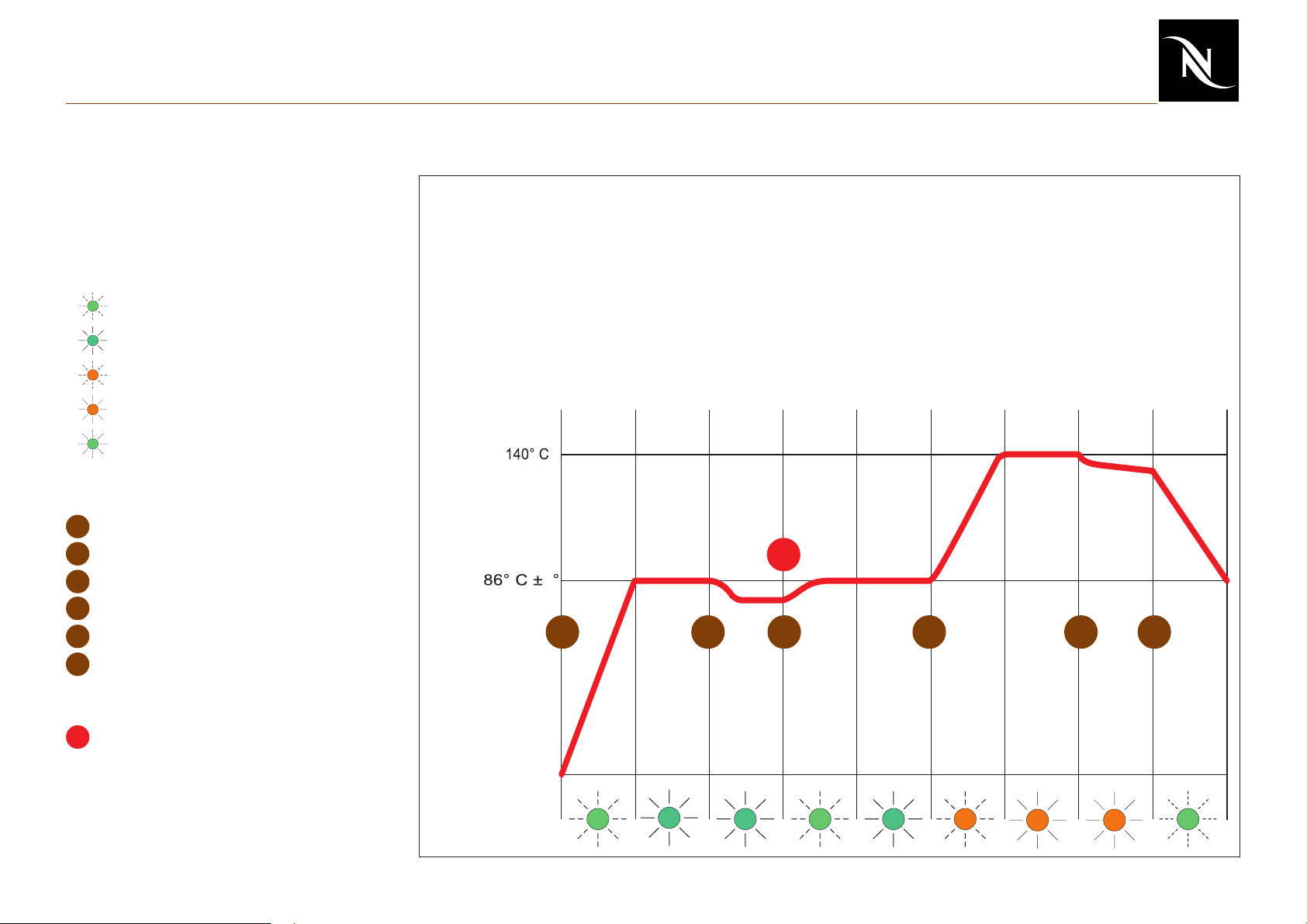

LED status diagram

The LED status diagram shows the

behaviour of the LED depending on

temperature and function.

LED-status

1 LED flashes green slowly

LED illuminates green

2

3 LED flashes orange slowly

4 LED illuminates orange

5 LED flashes green quickly

Operating sequence

A

Switch on main switch

B

Jaw stick forward or back

C

Jaw stick in middle

D

Operate steam switch

Jaw stick back

E

Jaw stick in middle

F

Note

After the preparation of coffee or hot

!

water, the green LED may flash

rapidly for a short time due to overtemperature.

Steam

preparation

Coffee and

hot water

preparation

Heating up

Ready

Coffee / hot water

preparation

Heating up

Ready

Heating up

Steam ready

Steam preparation

Cooling

!

3

A

1

2

CB E F

2

1

D

23

44

5

13

Page 14

Troubleshooting

Checking the machine - receipt (1)

The receipt check enables you to rapidly

locate faults on the machine and to initiate

appropriate repair action.

Keep to the order given in the table.

Repair any faults found and repeat the

repair routine to the end.

• Check appliance for visible damage

• Check mechanical elements

• Switch on

• Fill water tank

• Coffee preparation without capsule

- Parts of housing broken or damaged?

- Mains cable damaged?

- Has the customer opened the machine?

- Does the jaw stick engage?

- Does the closing handle work?

- Is the ejector mechanism in working order?

- LED flashes during heating up

- How long does the machine need for

heating up (typical time approx. 45s)?

- Water tank leaks?

- Does the reed contact work?

- Does the pump work?

- Does hot water escape?

• Hot water preparation

14

- Does the reed contact work?

- Does hot water escape?

Page 15

Troubleshooting

Checking the machine - receipt (2)

• Steam preparation

• De-scale

• Flow rate

• Check for leaks

• Temperature measurement

• Clean

- Does the steam switch work correctly?

LED must flash orange slowly during

heating up and then illuminate continuously.

- Does steam escape?

- See page 33

- See page 34

- See page 35 to 37

- See page 38

- See page 41

• Measure closing force

• Check reed contact

15

- See page 39

- See page 40

Page 16

Troubleshooting

Complaint:

Coffee temperature too low

Coffee temperature too high

No function

Cause?

• Jaw not preheated?

• Machine scaled (low outflow)?

• Faulty NTC temperature sensor?

• Faulty resistor in the thermoblock?

• Faulty heating PTC?

• Faulty NTC temperature sensor or

electronic mainboard?

• Machine not connected to mains?

Remedy!

- Preheat jaw, allow 2 large cups of water to

flow through without capsule

- De-scale machine (see page 33)

- Replace NTC (see page 22)

- Replace thermoblock (see page 22)

- Replace heating PTC (see page 30)

- Replace NTC temperature sensor (see

page 22)

- Replace electronic mainboard (see page 25)

- Check mains voltage and plug into mains

• Intermittent contact in cables?

• Faulty fine-wire fuse?

• Faulty main switch?

• Faulty NTC temperature sensor?

16

- Replace cable

- Replace - determine reason for fault (see

page 24)

- Replace main switch (see page 26)

- Replace NTC temperature sensor (see

page 22)

Page 17

Troubleshooting

Complaint:

No outflow

Cause?

• Water tank empty?

• Water tank fitted incorrectly?

• Top of brewing unit is clogged?

• Pyramid plate is clogged?

• Machine is scaled?

• Pump connected incorrectly, or faulty?

• Electronic mainboard fault?

Remedy!

- Fill

- Insert correctly

- Clean, de-scale or replace (see page 27

and 31)

- Replace (see page 31)

- De-scale (see page 33)

- Check pump connections

- Replace pump (see page 23)

- Replace electronic mainboard (see page 25)

17

Page 18

Troubleshooting

No steam function or too little steam

No capsule ejection

Cause?

• Steam and hot water pipe scaled?

• Steam and hot water pipe clogged?

• Steam switch faulty?

• Pump connected incorrectly?

• Reed contact faulty?

• Electronic mainboard faulty?

• Capsule ejector faulty?

• Capsule cage dirty or damaged?

Remedy!

- De-scale machine (see page 33)

- Clean pipe

- Replace steam switch (see page 26)

- Check electrical connections on pump (see

page 23)

- Check reed contact (see page 40)

- Replace reed contact (see page 29)

- Replace electronic mainboard (see page 25)

- Replace ejector (see page 31)

- Clean or replace capsule cage (see page 31)

Water on the jaw

Water runs out from the side of the jaw

Jaw does not close

• Pyramid plate dirty?

• Jaw poorly closed?

• Brewing unit leaks at the top?

• Not possible to close the jaw?

18

- Clean or replace (see page 31)

- Close jaw correctly

- Replace hose, seal or valve (see page 29)

- Screw capsule cage on fully

Page 19

Troubleshooting

Complaint:

Water on side of machine or below machine

Pump noisy

Cause?

• Thermoblock leaking?

• High pressure connections leaking?

• Silicon hoses torn?

• Valve on the water tank leaking?

• Internal manifold sleeve leaking?

• Water tank empty?

• Water tank not inserted correctly?

Remedy!

- Tighten connections on the thermoblock or

replace (see page 22)

- Replace seals or (and) hoses

- Check for leaks (see page 35)

- Replace silicone hoses

- Replace water tank

- Replace internal manifold sleeve

- Fill

- Insert correctly

Not enough froth when frothing milk

• Steam nozzle dirty or scaled?

• Frothing aid not correctly assembled?

• Milk not at fridge temperature?

• The temperature of the pot is too high?

• Heating element is scaled (temperature

loss)?

19

- Clean or de-scale (see page 33)

- Assemble correctly

- Only use milk at fridge temperature

- Use chrome-steel pot at fridge temperature

- De-scale machine (see page 33)

Page 20

Repair

General disassembly (stage 1)

Tools:

- Special screwdriver (oval)

General information:

The screws are labelled with letters (A, B and

C) in the figures.

These refer to the tightening torques for the

screws.

A = 0,5 to 0,9 Nm

B = 0,8 to 1,4 Nm

C = 1,3 to 1,8 Nm

A and B can be tightened by hand (A =

tighten lightly, B = tighten firmly).

For tightening screws labelled C it is imperative that a torque wrench is used.

Unplug from the mains before

disassembling machine appliance must be isolated!

Item no. 28087

Procedure:

1. Remove water tank, drip tray, and

capsule container.

2. Place machine on the disassembly jig

(item no. 28087).

3. Remove screws (13) on the underside

and rear of the side pieces.

4. Remove side pieces (2 and 3).

20

Page 21

Repair

General disassembly (stage 2)

Tools

- Torx screwdriver T10, T15

- Special screwdriver (oval)

Procedure

1. General disassembly stage 1.

2. Remove 3 bolts (13) on the cover at the

rear (9) on the underside.

3. Open jaw and remove screws (111) on

the cover.

4. Unscrew ball (80) on the jaw stick.

5. Remove screws (83) and closing lever

(84).

6. Move cover (81) a little to the side and

remove.

7. Remove 2 bolts (12) on the cover at the

rear on the top.

8. Remove cover at the rear (9).

21

Page 22

Repair

Replacing thermoblock

Tools / aids:

- Torx screwdriver T10, T15

- Flat nose pliers

- Open-ended spanner 8/10mm AF

- Pot to collect water

- Torque wrench

Procedure:

1. General disassembly stage 1 and 2 (see

page 20 and 21).

2. Remove bolt (47) on the thermoblock (66).

3. Remove all electrical connectors.

4. Remove fine-wire fuse clip (43).

5. Remove NTC temperature sensor (64).

Replacing NTC

Tools:

- Open-ended spanner 10mm AF

Procedure:

1. Remove connector on the logic board

2. Undo NTC temperature sensor (64)

replace

3. Assemble in reverse sequence. Only

tighten NTC temperature sensor lightly

until the spring washer is flat.

ATTENTION: Keep a pot at hand for

collecting the water left in the

thermoblock.

6. Remove water connections on the

thermoblock.

7. Replace thermoblock (66).

8. Assemble in reverse sequence. Only tighten

NTC temperature sensor lightly until the

spring washer is flat. Tighten bolt (46) to

torque C using torque wrench.

22

Page 23

Repair

Replacing pump

Tools / aids:

- Torx screwdriver T10

- Open-ended spanner 14mm AF

- Long-nose pliers

- Pot to collect water

Procedure:

1. General disassembly stage 1 (see page

20).

2. Remove all electrical connections

3. Remove steam switch (30, 63) on the

underside of the appliance to make it

easier to disassemble the pump (see page

25).

4. Remove clamp (45) and hose (65).

ATTENTION: Keep a pot at hand for

collecting the water left in the pump.

7. Remove seal (51) and angle (37).

8. Replace pump (61).

9. Insert seal (51) and tighten corner

connector (37).

10.Turn corner connector to the correct

position using open-ended spanner on

pump projection.

11.Remaining assembly in reverse sequence.

ATTENTION!

Check cable connection! If the

cables are reversed, it is not possible to

generate any steam.

Red cable

5. Remove angled hose (57).

6. Release pump first from bottom rubber

strap, then from the top rubber strap (54).

23

Page 24

Repair

Replacing fine-wire fuse

Tools:

- Torx screwdriver T15

- Long-nose pliers

- Torque wrench

Procedure:

1. General disassembly stage 1 and 2 (see

page 20 and 21).

2. Remove all connections with red cable.

3. Undo clamp (43).

4. Replace fault fine-wire fuse (998).

5. Assemble in reverse sequence. Tighten

bolt (46) to torque C using torque wrench.

24

Page 25

Repair

Replacing control board

Tools:

- Torx screwdriver T10

- Long-nose pliers

The service engineer must be

earthed using an earthing

strap!

Procedure:

1. General disassembly stage 1 (see page

20).

2. Place earthing strap around the wrist and

connect to the earthing cable on the unplugged machine! In this way a potential

difference is avoided.

3. Remove connections from the board.

4. Undo 2 screws (12) and remove the

control board.

5. Replace control board (59).

6. Assemble in reverse sequence (see wiring

diagram, p.32)

25

Page 26

Repair

Replacing main switch or steam switch

Tools:

- Torx screwdriver T10

- Long-nose pliers

Procedure:

1. General disassembly stage 1 (see page 20).

2. Remove screws (12) on underside of

appliance.

3. Remove connections

4. Replace main switch (62) or steam switch

(63).

5. Assemble in reverse sequence.

Replacing LED

Tools:

- Torx screwdriver T10

Procedure:

1. General disassembly stage 1 (see page 20).

2. Remove connector in the electronic

mainboard.

3. Remove screws (12) and cover (33).

4. Remove screw (48) on the LED board.

5. Replace LED board (58).

6. Assemble in reverse sequence.

Replacing steam pipe

Tools:

- Torx screwdriver T10

- Torque wrench

Procedure:

1. General disassembly stage 1 (see page 20).

2. Remove screws (12).

3. Remove cover (32).

4. Remove steam pipe (40) and replace.

5. Assemble in reverse sequence. Tighten

bolt (12) to torque C using torque wrench.

26

Page 27

Repair

Replacing jaw

Tools:

- Torx screwdriver T10, T15

- Cross-headed screwdriver

- Long-nose pliers

Procedure:

1. General disassembly stage 1 (see page 20).

2. Open jaw and remove screws (111) on the

cover.

3. Unscrew ball (80) on the jaw stick (134).

4. Remove screws (83) and closing lever

(84).

5. Move cover (81) a little to the side and

remove.

6. Disassemble hoses (85, 65) on the

ceramic valve and remove grounding wire

(115) on the support.

- Procedure on disassembly of the jaw when fitted.

7. Pull off hose (132) on the expansion

housing.

8. Unplug heating PTC (110) and reed

contact (86) on the control board.

9. Remove screws (131) on the support

module (126).

10. Remove complete jaw and replace.

27

Page 28

Repair

Complete jaw disassembly

Tools:

- Hammer (plastic head)

- Drift No. 4

- Torx screwdriver T10

- Torque wrench

Procedure:

1. General disassembly stage 1.

2. Disassemble jaw as per page 27.

3. Remove capsule cage (see page 31)

4. Remove cover (112).

5. Remove springs (98).

6. Remove shafts (108 +127).

- Procedure for complete disassembly of the jaw

7. Remove side closing lever (120), locking

lever (119) and shaft (113).

8. Remove screws on the control board.

9. Remove swivelling plate (97) with ejector

lever (94) and spring bearing (99).

28

Page 29

Repair

Complete jaw disassembly

Replacing reed contact

Perform points 1 to 9 (see page 28).

10.Remove screws (87).

11.Remove screws (96) and bearing (109).

12.Remove reed contact (86) and replace.

Attention!

The cover on the ceramic valve must

not be removed.

13.Assemble in reverse sequence.

Replacing connection to capsule cage

Perform points 1 to 9 (see page 28).

10.Remove screws (96) and bearing (109).

Replacing ceramic valve

Perform points 1 to 9 (see page 28).

10.Remove screws (96) and bearing (109).

11.Remove clamp (45) on the ceramic valve.

12.Remove connection (91) and hose (88).

13.Remove screws (87) on the ceramic valve.

14.Replace complete ceramic valve (incl.

reed contact, 86).

15.Assemble in reverse sequence. Fit new

seal (90) and tighten screws (87) to torque

C using torque wrench.

11.Remove clamp (45).

12.Replace connection (91) and fit new

seal (90).

13.Assemble in reverse sequence.

29

Page 30

Repair

Replacing heating PTC

Tools / aids:

- Torx screwdriver T10

Only pertains to machines

produced until sept. 2003.

Procedure:

1. General disassembly stage 1 and 2 (see

page 20 and 21).

2. Disassemble cover (112).

3. Remove connections on the electronic

mainboard.

4. Pull out cable.

5. Remove screws (96) and PTC clamp

(107).

6. Replace heating PTC (110).

7. Assemble in reverse sequence.

30

Page 31

Repair

Replacing pyramid plate

Refer to modification sheet

no. 2003-01.

Procedure:

1. Remove ejector (122).

2. Remove pyramid plate (123) with

receptacle (138).

3. Fit new pyramid plate with receptacle.

Ensure that the pyramid plate is inserted

in the correct position.

4. Fit ejector.

Replacing capsule cage

Tools / aids:

- Assembly tool (106)

Procedure:

1. Rotate capsule cage (137) from the cage

bracket using the assembly tool (106).

2. Fit new capsule cage.

31

Page 32

Repair

Electronic mainboard, wiring diagram

1) Reed contact

2) NTC temperature sensor

3) Board fastening

4) LED board

5) Steam switch (violet)

6) Steam switch (violet)

7) Pump (black)

8) Thermoblock (white)

9) Mains cable (blue)

10) Heating PTC (white)

11) Heating PTC (blue)

12) Fine-wire fuse and thermoblock (red)

1

2

4

3

5

6

3

7

9

8

10

11

12

32

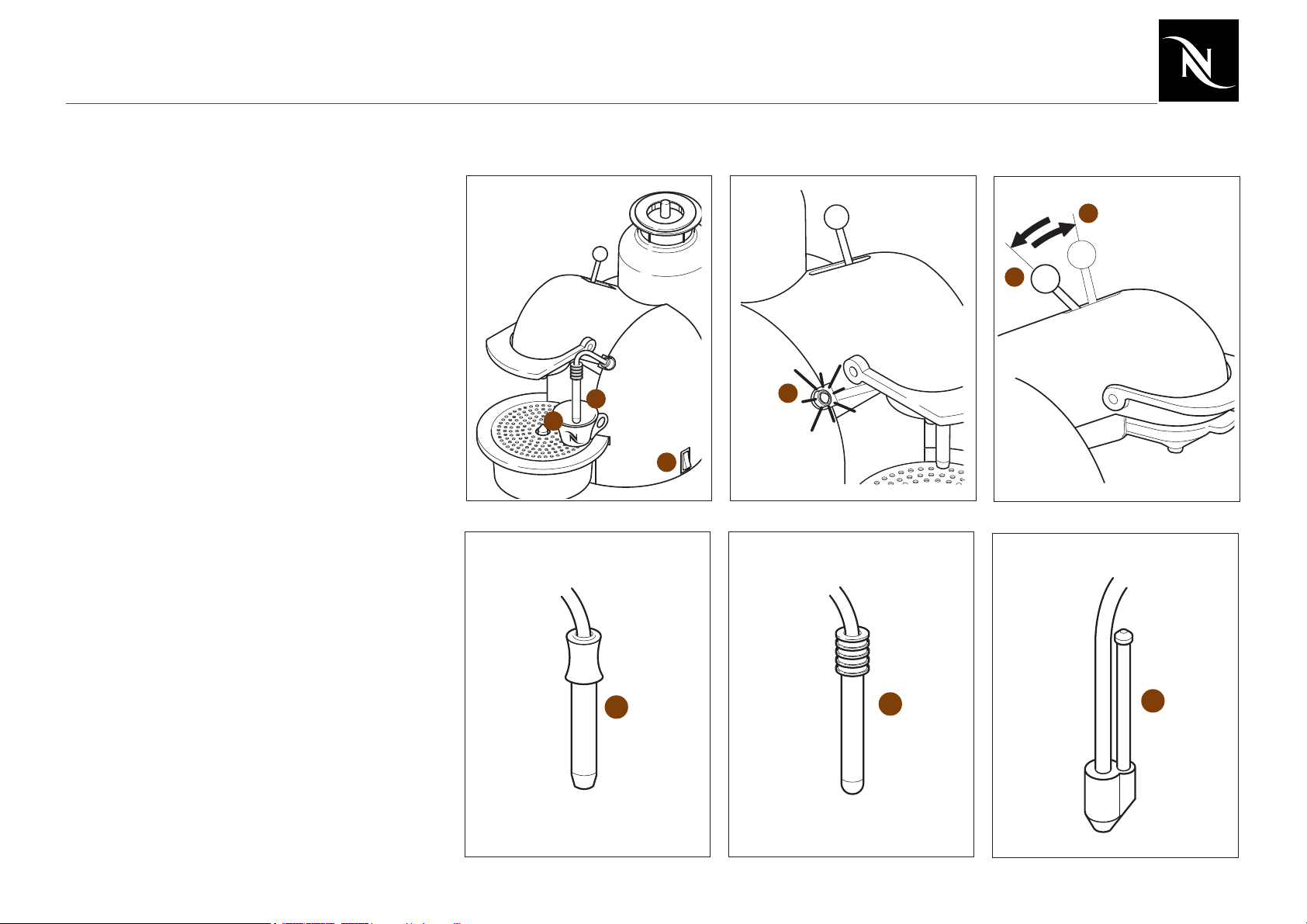

Page 33

Maintenance

Descaling

Never use vinegar.

Decalcifier is aggressive to the

surface of the casing.

Preparation

1. Eject capsule, close jaw and place jaw

stick to middle position.

1

4

2. Remove steam nozzle and frothing pipe

and put them into a pot (min. 0.6 l capacity).

3. Remove drip grid and place pot on drip

tray.

Read safety instructions on side

of descaling sachet.

4. Fill water tank with 0.1 l descaling fluid

and 0.5 l water.

5. Switch on machine.

6. Wait till green indicator lights up.

Descaling

7. Place jaw stick in hot water position.

8. Let entire descaling solution pass through

steam pipe.

9. Place jaw stick to middle position.

2

3

Item no. 24361

9

7

10

6

8

10. Fill water tank again with descaling

solution from pot.

33

Page 34

Maintenance

Descaling

11. Place pot with steam nozzle and frothing

pipe on drip tray.

12. Place jaw stick in coffee position and let

pass the entire descaling solution through

coffee outlet.

13. Place jaw stick to middle position.

Rinsing

14. Empty pot. Rinse steam nozzle and

frothing pipe.

15. Flush water tank thoroughly and fill it with

fresh water.

16. Place pot on drip tray.

17. Place jaw stick in hot water position. Let

half a tank of water run through steam pipe.

18. Place jaw stick in coffee position and let

remaining water run through coffee outlet.

17

13

19

18

12

11

14

15

19. Place jaw stick to middle position.

20. Switch machine off – decalcification is

completed.

21. Mount steam nozzle and frothing pipe.

22. Insert drip grid.

23. Clean machine.

16

34

22

23

21

Page 35

Maintenance

Measuring rate of flow

1. Remove ejector

2. Remove pyramid plate support

3. Fit pressure gauge

4. Close jaw

5. Position measuring beaker underneath

6. Switch on machine

7. Open valve fully

8. Place jaw stick in the front position

9. Close valve until 12 bar are indicated

10. Perform measurement for approx.

30 sec.

11. There must be at least 60-120ml in the

measuring beaker

If the manometer indicates large

fluctuations during the

measurement (12 +/- 4 bar), this is an

indication that the pump is faulty.

Keep a watch for leaks!

12 bar

1

4

2

3

7

9

10

8

The manometer must be

observed continuously and the

pressure regulated using the valve if

necessary. With increasing temperature

the pressure also increases, if necessary

readjust the pressure to 12 bar.

60...120 ml

35

5

30 s

Page 36

Maintenance

Checking for leaks and pump pressure (1)

1) Preparation of the machine

1. General disassembly stage 1 (see

page 20).

2. Open jaw and remove screws (111) on

the cover.

84

83

134

3. Unscrew ball (80) on the jaw stick

(134).

4. Remove screws (83) and closing lever

(84).

5. Move cover (81) a little to the side and

remove.

6. Refit closing lever.

7. Fit pressure gauge.

8. Close jaw.

9. Position pot underneath.

81

111 (A)

36

Page 37

Maintenance

Checking for leaks and pump pressure (2)

The following components are checked for

leaks:

- Capsule cage

- Connections

- Thermoblock

- Pump

2) Check

1. Perform points 1 to 9 on page 35.

2. Jaw stick to the front (the valve on the

pressure gauge must be opened).

3. Switch on machine.

4. Leave water to run out for approx. 10 s.

5. Fully close valve. The pressure will

rise rapidly initially and stabilise

between 16-19 bar (pump pressure

check). The pressure will rise slowly

due to the temperature increase.

8. The needle on the display must not

drop below 12bar in 60 s.

9. Open valve, open jaw (pressure

gauge empties).

The residual pressure must be

released after the test by

opening the valve!

The pump is permitted to be in

operation for max. 50 sec.

without an outlet.

6. Visual and acoustic check on all

pressurised connections. The pump

must not be in operation for longer

than 50 s.

7. Switch off machine using the On-Off

switch (jaw stick remains in the front

position).

System: no leak leak

37

Page 38

Maintenance

Checking extraction chamber for leaks

1. Switch on machine.

2. Remove ejector.

3. Remove pyramid plate support.

4. Insert special pyramid plate support.

5. Insert capsule and close jaw.

6. Jaw stick to the front.

7. Check outflow. The coffee should flow out

evenly and without splashing to the side.

8. If the jet is not correct, replace capsule

cage.

Preparation of the special pyramid plate

support

Saw off the lower part of the pyramid plate

support such that the inner cone is not

damaged.

6

5

2

3

4

7

38

Page 39

Maintenance

Measuring coffee temperature

1. Switch on machine.

2. After warming up, leave 150ml of water to

flow through to heat the jaw.

3. Insert capsule (Cosi is the most suitable).

4. Close jaw.

5. Position a pot underneath.

6. Place jaw stick in front position.

7. Measure the temperature approx.

5 - 10 mm below the outlet opening.

8. Temperature should be approx.

86 °C ± 3 °C (187 °F ± 5.4 °F).

39

Page 40

Maintenance

Measuring closing force

1. Switch on machine

2. After warming up, leave 150ml of water to

flow through to heat up the jaw.

3. Insert capsule.

4. Attach spring balance to the middle of the

closing lever.

5. Press down closing lever with the aid of

the spring balance until the closing lever

is closed. Ensure that the spring action

of closing is not taken into account.

6. Read off value. Repeat measurement

several times as necessary.

Closing force for new appliance: 25N +/-5N

If the closing force is less than 10N,

replace capsule cage, pyramid plate and

support.

Art. Nr. 80005

Art. Nr. 4.004

Ordering information:

Spring balance (80005) and compression

force measuring tool (4.004) can be ordered

from the following address:

PESOLA AG

Rebmattli 19

CH-6340 Baar

Switzerland

Tel. +41 (0) 41 769 60 40

Fax +41 (0) 41 769 60 42

e-mail info@pesola.ch

www.pesola.ch

www.pesola.com

40

Page 41

Maintenance

Checking reed contact

1. Press the test button on the reed contact

tester - both LEDs must illuminate. If

necessary, replace battery.

2. General disassembly stage 1 (see page

20, only remove the side piece covering

electronic components).

3. Remove connection from reed contact to

the electronic mainboard and connect to

the reed contact tester.

4

5

4. Place the jaw stick at the front. The

“coffee” LED illuminates, otherwise the

reed contact is faulty.

5. Place the jaw stick at the rear: The

“steam” LED illuminates, otherwise the

reed contact is faulty.

During the test the machine

must be switched off and

unplugged from the mains!

3

1

41

Page 42

Maintenance

Daily maintenance and final cleaning

1. Clean water tank and fill with fresh water

2. Empty drip tray and clean

3. Empty capsule container

4. Flush jaw (min. 150 ml)

1

2

4

42

3

Page 43

Spare parts

Pos. EFR item Description

001 0025391 Support black

002A Side piece 748 right black

003A Side piece 748 left black

002B Side piece 748 right yellow

003B Side piece 748 left yellow

002C Side piece 748 right blue

003C Side piece 748 left blue

002D Side piece 749 right silver

003D Side piece 749 left silver

002E Side piece 749 right white

003E Side piece 749 left white

002F Side piece 749 right red

003F Side piece 749 left red

004A 0025394 Drip tray 748 black

004B 0026377 Drip tray 749 black

005 0025395 Capsule container black

006A 0025396 Cover 748

006B 0026378 Cover 749 black

007 0025427 Water tank cover black

008A 0027295 Float yellow

008B 0027120 Moulded plug black

009 0025404 Cover rear black

010 0026373 Centring ring water tank black

43

Page 44

Spare parts

Pos. EFR item Description

011 0023908 Valve flange 420 black to water tank

012 0016052 Cross panhead screw KST/PT 3.0x12 zinc plated blue Torx-10

013 0024863 Cross panhead screw locking washer zinc plated blue oval

KST/Remf.3.0x12

014 0010585 Locking washer 770 Inox

015 0010586 Grid 770 rust-free

016A 0025446 Drip plate 748

016B 0026374 Drip plate 749

017 0011933 IInternal manifold sleeve (M3) 22.22/15.87x4.76 black

018 0015890 Elastic stop 15.9 x 4.75mm black SJ-6115

019 0025463 Water tank transp. compl. welded/assembled

020 0025451 Base plate

44

Page 45

Spare parts

Pos. EFR item Description

030 0025417 Switch panel black

031 0025409 Receptacle steam pipe black

032 0025419 Panel steam pipe black

033 0025418 Panel LED black

035 0027429 Expansion housing cpl. welded, bare

036 0006517 Cap top D=16x10.6mm for heater cartridge

037 0005466 Connection angle black 770 (pump)

038 0001053 Strain relief transparent screwed

039 0001442 Sheet bracket 946 EX100/964

040 0025751 Steam pipe long, chrome-plated

041A 0001349 Steam nozzle 925 Ms chrome-plated M6x0.5 for screw fitting

041B 0012050 Protective rubber Turmix Nespresso

042A 0011970 Frothing aid Turmix Nespresso

042B 0002630 Frothing aid Krups 72mm compl. incl. brass pipe, body, cap

042C 0014622 Frothing aid 749 AE compl. with grill AE Ks nozzle, pipe, O-ring

043 0021542 Fine-wire fuse TB2001 0.5x10.0x21.0mm

044 0005245 Lock washer M5 zinc-plated blue

045 0005470 Clamp 770 pressure hose

046 0019799 Screw GF/Tapt.M4.0x 8 zinc plated panhead with lock ring Torx-20

047 0018121 Screw GF/Tapt.M4.0x40 zinc plated blue panhead Torx-20 waxed

048 0020151 Screw sheet 2.9x 9.5 zinc-plate black panhead Torx-10 point

049 0025452 Support TB2001

050 0008242 Washer 04.3x12.0x1.5 zinc plated blue M4

45

Page 46

Spare parts

Pos. EFR item Description

051 0024374 O-ring 003.40x1.90 silicone 70 Shore red, 2-comp. silicon

052 0001565 O-ring 005,28x1.78 EPDM 70 Shore black

053 0010629 O-ring 005.70x1.90 EPDM 70 Shore black

054 0025450 Pump supports AE grey 60 Shore 3 fastening holes 6.5mm

055 0009212 Hose silicon 05.0x2.00x090 75 Shore, transparent

056 0012440 Hose silicon 08.0x1.75x260 55 Shore white, cut

057 0005454 Angle hose 770 silicon

058 0025298 El.LED 748

059 0025299 El. control board 748 230-240V 50-60Hz

060A 0025449 Mains cable black HO5VVF-3G075 1,50 S1: Cebec S2: 140/90/40

060B 0025554 Mains cable black H05VVF-3G075 1.50 S1:GB S2:140/90/40

060C 0025555 Mains cable black H05VVF-3G075 1.50m S1: SEV/ S2: 140/90/40

061 0018526 Pump CP4/SP(CP2) 230V/50Hz without thermost./

without strap/with th. recept.

062 0004561 Switch B111C1121000 16A/250V black, making 0/I white

063 0025447 Switch B1A4C112K000 16A/250 black white

marking steam symbol

064 0015448 Temperature sensor with wires 230mm

065 0027345 Hose PFA D4.0/2.50x280mm

with 1 clamping ring/1 Sertokl’ ring/2 tubular rivets assembled

066 0026677 Replacement thermobl.2001 230V compl. with Serto fitting

and flange connector

46

Page 47

Spare parts

Pos. EFR item Description

080 0024394 Ball handle black for jaw stick

081A 0027886 Cover 748 silver painted symbols black

081B 0025401 Cover 749 black symbols silver

081C 0027884 Cover 748 yellow symbols black

081D 0027885 Cover 748 blue symbols black

082 0025432 Panel valve lever Inox

083 0024537 Cross cyl. head screw KST/PT 4.0x 8 Inox Torx-15

084 0025293 Closing lever chrome-plated cast zinc

085 0025278 Hose FEP D4.0/2.50x220mm with 2 clamping rings

with tubular rivets assembled

086 0024397 El. reed contact board

087 0022504 Screw KST/PT 3.5x16 zinc-plated blue panhead Torx-10

088 0025280 Hose FEP D4.0/2.50x 35mm

089 0024314 Support ring black profile seal

090 0024379 Seal black for capsule cage connection

091 0024301 Connection to capsule cage black

093 0005255 Washer 03.2x09.0x0.8 zinc-plated blue M3 DIN 9021/ISO 7093

094A 0024296 Ejector lever black first version

094B 0028218 Ejector lever 748/2 black

095 0027339 Spring (torsion spring) Inox D=1.0x12.0;Nt4.25

096 0020740 Cross panhead screw GF/Tapt.M3.0x 8 Torx-10, waxed

zinc-plated blue

097 0024288 Swivelling plate Inox to brewing unit

098 0024377 Spring for brewing unit D=0.70x6.0x29.4mm Inox

099 0024304 Spring bearing plain

102 0024387 O-ring 010.00x2.00 black

104 0024317 Plate Inox

105 0024318 Banjo bolt Inox

106 0024361 Assembly tool black for capsule cage

107 0024307 PTC clamp until Sept. 2003 only

47

Page 48

Spare parts

Pos. EFR item Description

108 0024298 Shaft for module support rear, Inox hardened

109 0024302 Bearing capsule cage aluminium

110 0024396 Heating PTC type 83/112/20/17,5 32-I, for brewing unit 748

111 0018904 Cross panhead screw KST/PT 3.0x16 zinc plated blue Torx-10

112 0024360 Cover swivelling piece black

113 0024300 Shaft for closing lever steel hardened

115 0025455 Si wire EU yellow-gr.480mm 0.75 1xFHL4.8- Ni/1xRKS4.3-Ni

116 0010997 Panhead screw M4.0x 8 zinc-plated black Torx-15

117 0024390 Connecting piece black for closing lever

118 0024388 Recessed disc size 6, for shafts / with slot, type KL, dacrometised

119 0024395 Closing lever plate Inox

120 0024291 Sealing plate Inox

121 0024295 Shaft sealing system for brewing unit Inox hardened

122 0024311 Ejector black

123 0036692 Plate pyramide Polymer black PPP

124A 0025676 Outlet compl. welded for brewing unit, black first version

124B 0029385 Outlet 748/2 compl. welding black

125 0011020 Seal black (OCS) for outlet

126A 0024312 Support module, black first version

126B 0028220 Support 748/2 module, black Brewing unit

127 0024299 Shaft for module support steel hardened

128 0024297 Supporting plate Inox

129 0025678 Cover spring

130 0025398 Panel brewing head black

131 0019504 Cross panhead screw KST/PT 3.0x20 zinc-plate blue Torx-10

132 0025287 Hose silicon 05.0x2.00x200 70 Shore black, cut

133 0026392 Hose silicon 08.0x1.75x190 55 Shore white, cut

48

Page 49

Spare parts

135 0026650 Replacement ceramic valve pre-assembled

Pos. EFR item Description

136 0026797 Replacement support ring with seal fitted

137 0026651 Replacement capsule cage fitted

138A 0026799 Replacement outlet with seal fitted first version

138B 0037590 Spare-Outlet 737 compl. with gasket assemb.

139 0026798 Replacement brewing unit without support assembled

140 0026801 Replacement brewing unit with support assembled

998A 0025461 EF wire EU 216°C (1xG4) brown 130/120/120/250mm

998B 0025456 Si wire EU black 310mm 0.75 1xFHL4.8- Ni/1xFLH6.3-Ni

998C 0025460 Si wire EU violet 260mm 0.75 1xFHL4.8-Ni/1xFHW4.8-Sn

49

Page 50

Spare parts

0027918

0028087

0027917

0024361

998D 0001219 Si wire EU white 130mm 0.75 2xFHL4.8-Ni

Pos. EFR item Pesola item Description

0027917 Pressure gauge

0027918 Reed contact tester

0028087 Machine assembly/disassembly

0024361 Assembly tool

0004872 Special (oval) screwdriver with Bit

0004878 Bit oval for screwdriver

80005 Spring balance 5kg. Pesola AG, Switzerland

4.004 Spring balance accessory

(compression force measuring tool) Pesola AG, Switzerland

80005

4.004

0004878

0004872

50

Loading...

Loading...