SPARE AND REPLACEABLE PARTS

S

Printed 8/09 Printed in U.S.A.

The only ShrimpPro user-replaceable parts are those in

the shrimp cutting area. While the Blade is made from

long-lasting, hardened stainless steel, it will begin to lose

its effectiveness in time and start tearing rather than

cutting shrimp. Do not attempt to sharpen as Blade will

lose its hardness. Replacement Blades may be ordered

from The NEMCO factory. (See phone, fax and address

below.) Having at least one spare on hand, stored in a

secure and accessible place, will avoid downtime.

Generally, the other components in the cutting area will

not require replacement. However, it is possible for the

Feeder Discs to eventually become too smooth to

reliably grasp all sizes of shrimp. Replacements may be

ordered. We can also provide a new part to replace any

component that is lost or damaged.

number and the nature of the problem (the “Claim

Information”).

(2) The Nemco Customer Service Department will

decide on the most appropriate course of action. If

Nemco determines that it must inspect a product,

the following procedure will be followed.

The end user will obtain a Return Goods Authorization

number from Nemco Customer Service to return the

product to Nemco for inspection. Please be sure to use

this number on the box and on paperwork sent with the

unit. Return the unit to Nemco. The Nemco Service

Department will determine if the problem is covered by

the foregoing warranty. If so, Nemco will repair the unit

and return it to the end user. If the unit is determined not

to be covered by the foregoing warranty, the dealer will

be contacted to determine the next course of action.

PRODUCT SERVICE

The ShrimpPro is inherently very reliable and, because

of its rugged construction, should require little or no

service throughout its lifetime. However, if service is ever

needed, it must be performed at the factory or by an

authorized service center. Any attempt to effect repair

without permission or guidance from the manufacturer

may invalidate the warranty and could be dangerous.

ShrimpPro PRODUCT WARRANTY

REGISTRATION

To validate your warranty, it is important that you fill in

and return the Warranty Certificate promptly. When

completed mail to:

NEMCO Food Equipment, Ltd.

301 Meuse Argonne

Hicksville, OH 43526

Nemco has a staffed service department and we

believe prompt service is extremely important to our

customers. Therefore, we request all product service

inquiries be handled in the following manner:

(1) The end user should call Nemco Customer Service

with the company name, address, phone number,

model number, serial number (if applicable), Nemco

Sales Order number or Dealer Purchase Order

ShrimpPro SPECIFICATIONS

Manufactured by NEMCO Food Equipment, Ltd.

Model No.: 55925

Power: 120 V.A.C., 60 Hz, 1 Amp

240 V.A.C., 50Hz, 0.5 Amp

Shipping Weight: 18 lbs.

U.S. and Foreign Pats.

PRODUCT WARRANTY

Except as otherwise provided below, Nemco Food Equipment, Ltd. ("Nemco") warrants, to the original user, its electrical food preparation products (other than

blades and light bulbs) to be free of electrical and mechanical defects in material and workmanship under "normal use" (defined below) for the shorter of the

following periods: (a) one (1) year from the date placed in service by the original user, or (b) 18 months from the date of shipment from its factory. In addition,

Nemco warrants its non-electrical food preparation products (other than blades) to be free of mechanical defects in material and workmanship under normal use

for two (2) years from the date placed in service by the original user. The warranty provided for herein shall be limited to parts and labor. Any determination

that a product is defective or covered by this warranty, shall be made by Nemco, in its sole discretion. The determination of whether to repair or replace a

defective, covered product, or to refund the purchase price for the product, will be at Nemco’s sole discretion. This warranty does not cover products used outside

the United States, or damages caused by accident, misuse, negligence of any person other than Nemco, current or voltage other than stated on the appliance,

fire, flood or other casualty. Any alteration to the product or unauthorized repair voids this warranty. For purposes of this warranty, the phrase, "normal use" shall

mean the use of the product in connection with food in accordance with the product manual accompanying the product.

Nemco shall be responsible only for repairs or replacements of defective parts performed by Nemco’s authorized service personnel. Authorized service agencies

are located in principal cities throughout the continental United States, Alaska and Hawaii.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. NEMCO EXPRESSLY DISCLAIMS ANY

IMPLIED WARRANTY THAT ANY OF ITS PRODUCTS IS MERCHANTABLE, FIT FOR A PARTICULAR PURPOSE, OR DOES NOT INFRINGE ON THE RIGHTS OF

ANY THIRD PARTY. THE FOREGOING WARRANTY SHALL BE NEMCO’S SOLE AND EXCLUSIVE OBLIGATION. ANY PERSON’S (BUYER, USER OR OTHERWISE)

EXCLUSIVE REMEDY AGAINST NEMCO, AND NEMCO’S SOLE OBLIGATION, FOR ANY AND ALL CLAIMS, WHETHER FOR BREACH OF CONTRACT,

WARRANTY, TORT (INCLUDING WITHOUT LIMITATION NEGLIGENCE), OR OTHERWISE, SHALL BE LIMITED TO NEMCO REPAIRING OR REPLACING THE

PRODUCT, OR, AT NEMCO’S OPTION, REFUNDING THE PURCHASE PRICE THEREFOR. IN NO EVENT SHALL NEMCO HAVE ANY LIABILITY FOR DAMAGES

IN AN AMOUNT EXCEEDING THE PURCHASE PRICE OF THE PRODUCT

CONSEQUENTIAL DAMAGES. Any person desiring to make any claim against Nemco must do so within six (6) months after expiration of the applicable warranty

period, or such claim shall be forever barred.

, NOR SHALL NEMCO HAVE ANY LIABILITY FOR INCIDENTAL, SPECIAL OR

NEMCO Food Equipment, Ltd.

301 Meuse Argonne

®

Hicksville, Ohio 43526

Phone (419) 542-7751

Fax (419) 542-6690

Toll Free (800) 782-6761

www.nemcofoodequip.com

Printed 10/08 Printed in U.

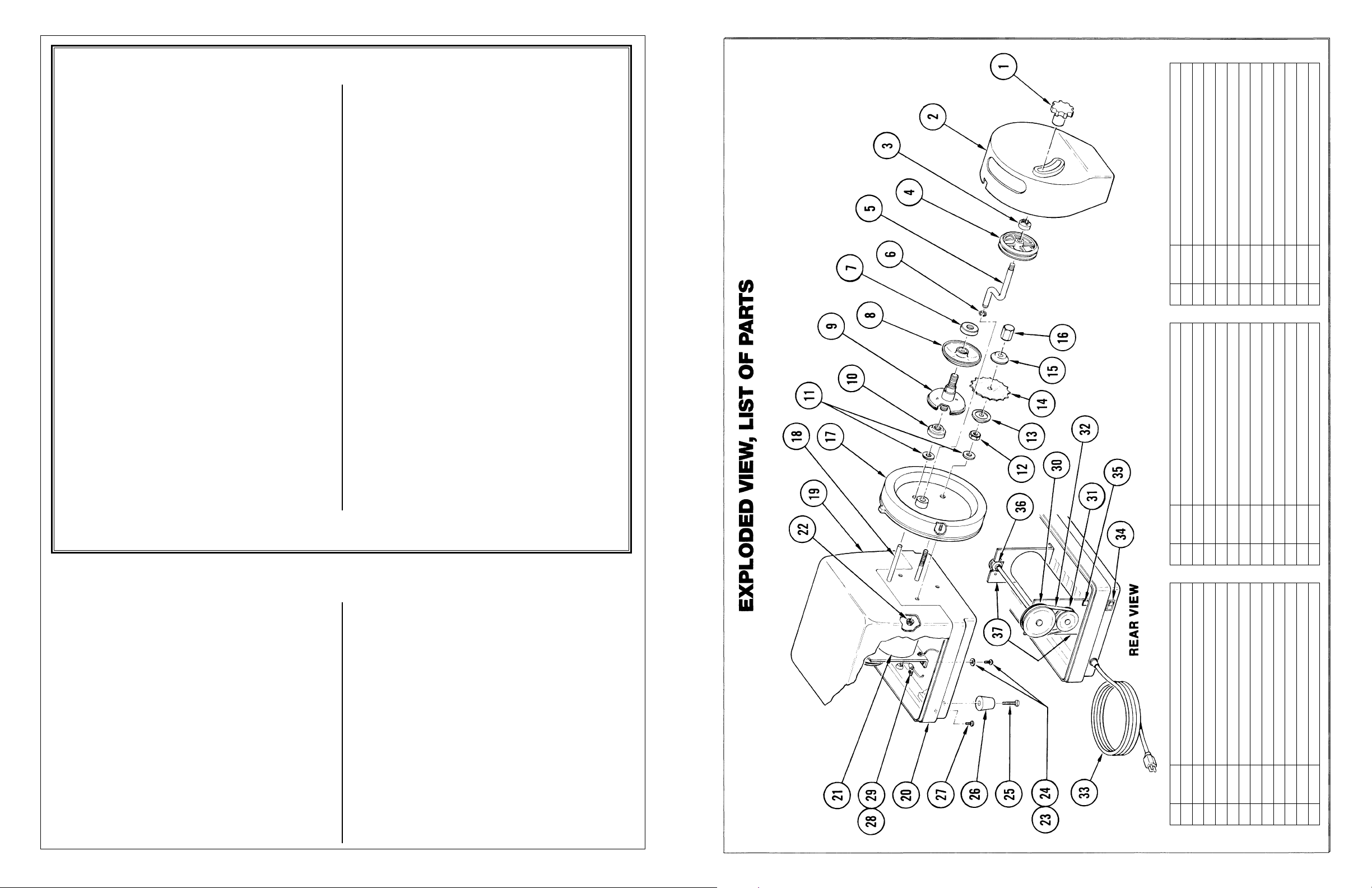

1

IMPORTANT SAFEGUARDS

123

4

56789

10

11

47137

55981

45184

46959

46960

46961

55970

46328

56017

55979

55974

56016

45409

Depth Adjustment Knob

Cutting Guard

Cutting Guard Washer

Depth Cut Roller (Medium)

Depth Cut Roller (Large)

Depth Cut Roller (Small)

Idler Shaft

Retainer Spring

Jam Nut

Female Feeder Disc

Male Feeder Disc

Pipe Thread Nut

Shaft Seal

12131415161718192021222324

45073

55976

55977

55976

56009

55969

55961

55973

55968

47488

46069

46698

45180

Hex Nut, 3/8 - 16

Blade Support Washer

Cutting Blade

Blade Support Washer

Blade Holder Nut

Front Plate

Feeder Disk Shaft

Top Housing

Bottom Housing

Motor

Thread Cutting Nut

Screw, #10 - 32 x 3/8”

Washer, #10 Lock

25262728293031323334353637

46666

46949

46665

46663

46958

46955

46956

46957

47481

47482

55983

46953

55960

Screw, #10 - 16 x 1”

Leg

Screw, #8 x 3/4”

Screw, #10 x 3/8”

Cable Clamp

Drive Pulley (Large)

Drive Pulley (Small)

Drive Belt

Cordset

Power Switch

Rectifier

Bearing

Mounting Bracket

Parts List

• READ ALL INSTRUCTIONS

• NEVER immerse the power unit in water or

other liquid. Severe electrical shock can result.

• CLOSELY SUPERVISE nearby children when

using ShrimpPro.

• DO NOT operate the ShrimpPro outdoors.

• DO NOT attempt to operate the ShrimpPro if

the unit has been dropped or if power cord or

power plug have been damaged. Return it for

repair. (See SERVICE.) There are no user

serviceable parts.

• DO NOT operate when wearing loose clothing

or accessories (bracelet, neck chain, necktie,

scarf, etc.). These could be caught by the

rotating Discs and cause injury. Loose hair

should be pulled back and secured.

• MAKE SURE that the power cord is unplugged

before removing Cutting Guard.

• AVOID touching the moving Discs. They could

grab your fingers and draw them into the cutter.

• THE SHRIMPPRO is equipped with a power

cord with a three-blade plug. Plug this ONLY

into a matching 120 volt A.C. three-blade outlet.

DO NOT cut off the third blade or attempt to

use with a two-blade extension cord. If you are

too far from the outlet, use a three-wire

extension cord of adequate power rating (see

specifications), obtainable at almost any

hardware store.

• UNPLUG the machine when not in use, before

attempting to clean, when changing Blades or

when making any adjustments to the Discs.

Pull only on the plug, never on the cord.

• MAKE SURE that the power switch is in the

‘OFF’ position before plugging-in or unplugging

the power cord.

• DO NOT attempt to use with unauthorized

attachments or for any application other than

that for which the unit was designed. Such

use could create a hazardous situation or

cause personal injury to the user.

• DO NOT operate on or near hot surfaces or

appliances used for cooking.

• DO NOT let power cord hang over edge of

table or counter.

• WHEN NOT IN USE, store the unit in a safe

place where it will not be a hazard to

passers-by.

• ALWAYS store with Cutting Guard securely

attached so that the blade is covered for safety.

• NEVER attempt to lift ShrimpPro by its Cutting

Guard. Always lift from under the base.

SAVE THESE INSTRUCTIONS

INSTRUCTIONS FOR USE & CARE

UNPACKING

When you open the shipping container, you will find

that the ShrimpPro is fully assembled and ready to

cut medium-sized shrimp (16/20 to 36/40). In the

carton, you will also find two Depth Cut Rollers,

differing in width. If you wish to cut small or large

shrimp, you must replace the already mounted

medium Roller (Item number 4 in the exploded view

drawing of Page 7) with the appropriate alternate

(the wider Roller for larger shrimp and the narrow

one for small shrimp). The procedure for

replacement is given on page 3.

Two 9/16” open end wrenches, used for Cutting

Blade replacement or cleaning, and a bottle

of lubricant with a dropper top are also packed with

the ShrimpPro. This is a food-grade lubricant which

is approved for incidental contact with food.

Examine the ShrimpPro for possible shipping

damage. Remove the Cutting Guard and inspect

cutting area components (see exploded view

drawing). The Cutting Guard (Item number 2)

may be removed by first unscrewing the Depth

Adjustment Knob (Item 1) and then pulling the

Guard away from and off of the machine.

When removing the Guard, make sure that the

Adjustment Knob Washer (Item 3) remains on

the Guard (Item 2). If any damage is noted,

immediately notify both the shipping company

and the manufacturer.

2

7

PRE-OPERATING CHECKS

AND ADJUSTMENTS

Before replacing the Cutting Guard, perform the

following checks:

Note: These steps presume that you will be

processing medium-sized shrimp. If you will be

working small or large shrimp, the Depth Cut Roller

must be changed and the Feeder Discs will need

readjustment. The steps needed to do each of

these are covered later in this booklet.

CAUTION: USE CARE WHEN WORKING NEAR

THE EXPOSED BLADE. IT IS SHARP AND CAN CUT

FINGERS, USE CUT PROTECTIVE GLOVES!

1. Cutting Blade

Make sure that the Round Cutting Blade is secure

on its shaft and cannot slip. Hold the Inner Blade

Nut (closest to the motor - Item 12) with one of the

included wrenches. With the other wrench, turn the

Outer Cap Nut (Item 16) clockwise until it is tight

(See Figure A). Do not overtighten.

3. Feeder Disc

Assembly

Positioning

Look down

over the

Feeder Discs.

Make sure that

the Cutting

Blade is cen-

tered between

the two Discs

and that the

groove in the

Depth Cut Roller is centered over the Blade. If it

is incorrectly positioned, unscrew the Feeder

Shaft inner plastic nut (Item 10) by hand until

the entire Feeder Disc assembly will slide on

its shaft. The nut is unscrewed by turning it clockwise. See Figure C. Align the Disc Assembly so

that the blade is properly centered and hand

tighten the plastic nut.

4. Lubrication

Remove the cap from the dropper tip of the food

2. Depth Cut Roller

lubricant bottle. Puncture the top of the dropper tip

The Depth Cut Roller should be centered between

the two Feeder Discs (See Figure B). If it is not

correctly positioned, unscrew and remove the outer

plastic Jam Nut (Item 7) from the Feeder shaft and

remove the Outer Feeder Disc (Item 8). Slide the

Depth Cut Roller along its shaft until it just touches

the Inner Disc (Item 9). Replace the Outer Disc.

When remounting this Disc, make sure that the

two raised keys on the Inner Disc fit into the two

keyways in the center of the Outer Disk that are

marked ‘M’ (for medium sized shrimp). It may be

necessary to lift the Depth Cut Roller in order to

mate the Discs. Replace the outer Jam Nut and

screw down until finger tight.

6

3

with a pin or small nail. Place several drops of

lubricant on the Depth Adjustment Shaft on both

sides of the Roller at its center hole. Lift the bent

Roller Shaft and slide the Roller back and forth on

it, over the lubricant, until lubricant is worked

under the Roller. To ensure smooth and quiet

operation, the Roller should be lubricated in this

manner before each use.

5. Cutting Guard Replacement

Make sure that the power switch is in the

‘OFF’ position before proceeding. Make sure

that the notch in the top of the Cutting Guard

mates with the projection at the top of the front

plate and that the Guard snaps into place on

both sides. The threaded end of the Depth

Adjusting Shaft fits through the plastic washer

in the open arc in the front of the Guard. Replace

the Adjusting Knob.

PICKING A WORK

LOCATION

Choose a work location with adequate space so that

you can work freely, that is well lighted, and is close

to a standard 120 volt A.C. (240 volt for export

model) three blade wall outlet (the line cord is about

six feet long). Arrange to drape the line cord (and

the extension cord, if one is used) where it will not

interfere with your working freedom of movement

and where it will not trip passersby.

The ShrimpPro should be placed on a flat, nonporous surface with the exit chute over the counter

edge above a sing or catch tray. DO NOT select

a location which can be flooded with water.

The user must always work on the right side of the

machine with the Feed Slot in the Cutting Guard

facing him (Figure D).

CUTTING AND DEVEINING SHRIMP

To be cleanly cut, shrimp must be raw, fully thawed

and firm. The cutting procedure is as follows:

1. After making sure that power switch is in the

‘OFF’ position, plug the line cord into the wall outlet.

2. Place a container, tray or 1/2 size steam table pan

containing thawed, uncooked shrimp on top of

the machine.

3. Loosen Depth Adjustment Knob and slide it to the

shallowest cut position (top of arc, away from

‘Deeper Cut’ arrow as shown in Figure E.) Tighten

Knob.

4. Turn the ShrimpPro ‘ON’.

5. Pick up on shrimp at the tail end. Turn it so the

back of the shrimp is away from you and lower it

into the Feeder opening on the top of the Cutting

Guard (see Figure F). The shrimp should be

inserted so that it falls between the Feeder Discs

and the Depth Cut Roller. The cut shrimp will be

deposited in your sink or catch tray.

WARNING: NEVER, UNDER ANY CIRCUMSTANCES,

ALLOWYOUR FINGERS TO ENTER THE FEEDER

SLOT, A FINGER CAN BE DRAWN INTO THE

MACHINE BY THE FEEDER DISCS AND BE

SEVERELY INJURED.

Also, do not allow foreign objects to enter the slot.

They could cause the ShrimpPro to jam and create

serious damage. Should shrimp not feed properly,

turn the machine off before attempting to correct

the problem.

6. Inspect the cut shrimp. If greater depth of cut is

desired, loosen the Depth Cut Knob and slide it

down to a deeper cut position, then tighten the

Knob.

7. Pass the same cut shrimp through the machine

again and again, adjusting the depth of cut each

time until you get the cut depth that you want.

Depending upon the adjustment, shrimp can be

lightly cut and deveined, butterflied or split, (knob

in the full down position) or cut in any desired

depth from light to full split.

SETTING UP FOR DIFFERENT

SIZE SHRIMP

At delivery, the ShrimpPro has been set up for

shrimp in the medium size range. If you want to cut

shrimp of a different size, you must change the

Depth Cut Roller and readjust the Feeder Disc

spacing. ShrimpPro is shipped with two additional

Rollers; one for small shrimp and one for large

shrimp. The chart below shows which Roller is

designed for each shrimp size group and what

Feeder Disc spacing setting goes with each. Due to

shrimp size and packing variations, your experience

may differ somewhat. Use what works best for you.

Shrimp Size Disc

Range Setting Roller

70/80-41/50 S thinnest (S)

1. Make sure that the ShrimpPro power switch is in

the ‘OFF’ position and unplug the line cord.

NOTE: ALWAYS UNPLUG THE MACHINE BEFORE

REMOVING THE CUTTING GUARD.

2. Remove the Cutting Guard by unscrewing the

Depth Adjustment Knob.

3. Unscrew and remove the Feeder Shaft outer plastic nut, then remove the Outer (female) Feeder Disc.

4. Remove the Depth Cut Roller from the bent shaft.

5. Select the new Depth Cut Roller from the chart

above and slide it onto the Roller shaft until it just

touches the Inner Feeder Disc.

6. Remount the Outer Feeder Disc, making sure that

it always engages the correct keys around the

inner diameter of the Inner Disc as listed in the

chart. Screw the outer plastic nut back on the shaft,

making it hand tight.

7. Loosen the inner Feeder Shaft Nut and slide the

Disc assembly along the shaft until the Cutting

Blade is centered over the groove in the selected

Roller. Hand tighten the inner nut.

A REMINDER — USE CAUTION WHEN WORKING

NEAR THE CUTTING BLADE! IT IS ALWAYS BEST TO

USE CUT PROTECTIVE GLOVES.

8. Replace the Cutting Guard and Depth Adjustment

Knob, making sure that Depth Shaft goes through

the plastic Guide Washer in Guard arc opening.

Set adjustment for shallowest cut.

9. Check power switch. It should be in the ‘OFF’

position. Plug the line cord in.

10. Turn machine on and begin to cut shrimp.

Adjust for depth of cut as described earlier.

36/40-U/15 M medium (M)

U/12-U/8 L thickest (L)

The steps you must take to set the machine up to

cut different size shrimp are similar to those covered

in the earlier Section of PRE-OPERATING CHECKS

AND ADJUSTMENTS. Refer back to that Section’s

text and illustrations if you require clarification of the

instructions below.

4

CLEANING

ShrimpPro should be thoroughly cleaned after each

days use.

CAUTION: DO NOT IMMERSE THE UNIT IN WATER.

THIS COULD CAUSE DAMAGE TO THE MACHINE

AND CREATE THE POSSIBILITY OF OPERATOR

ELECTRICAL SHOCK THE NEXT TIME IT IS USED.

5

Loading...

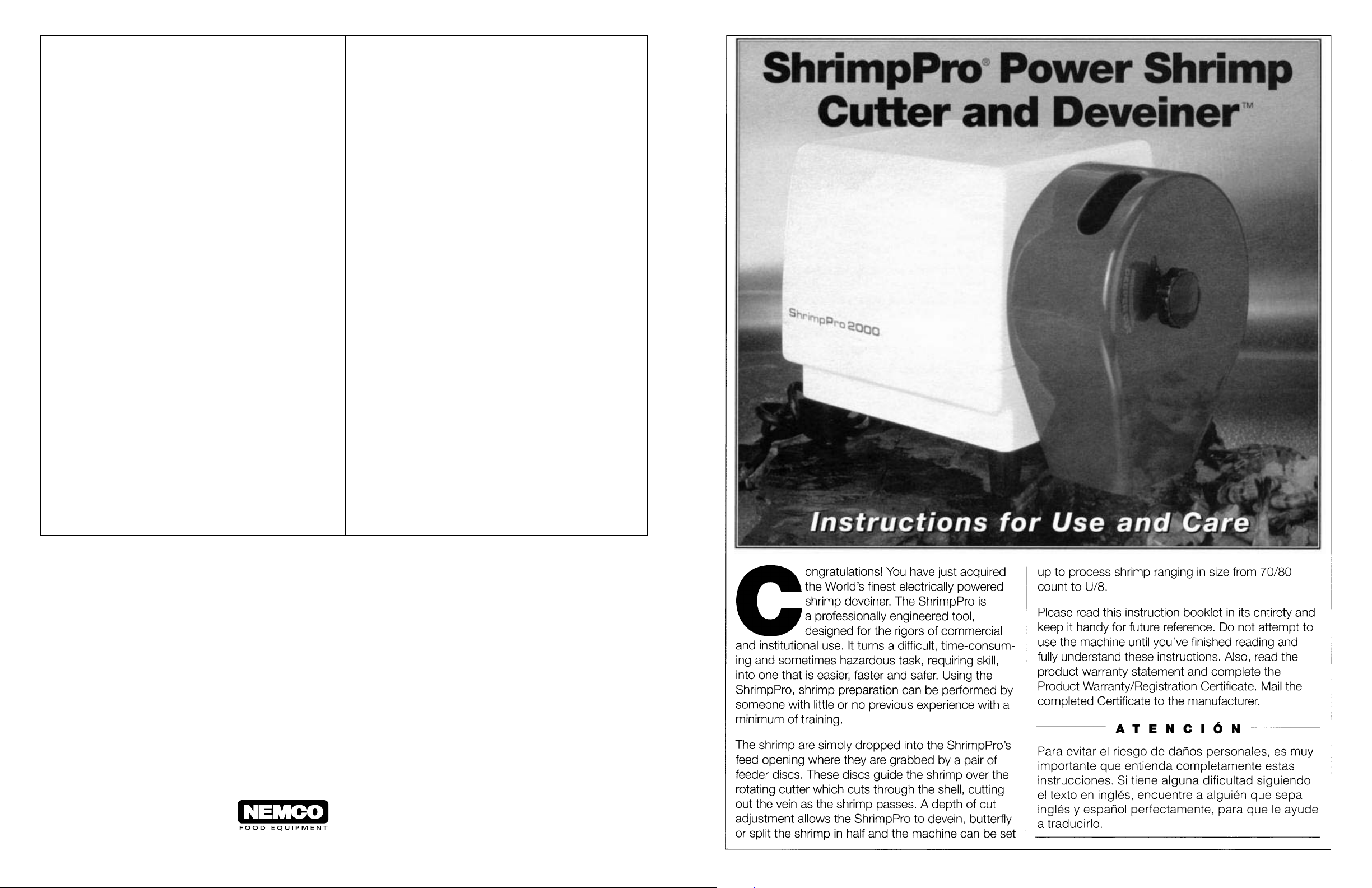

Loading...