Nelson Heat Trace VH1-500, VH1-1000, VH2-500, VH2-1000, VH2-2000 Installation Guide

NELSON™ HEAT TRACING SYSTEMS

TANK HEATING PANELS

INSTALLATION

INSTRUCTIONS

GENERAL

Nelson Heat Tracing System's VH Series Silicone Tank Heating Panels are constructed with high

temperature resistance elements, vulcanized between two thin layers of fiberglass reinforced silicone rubber.

The panel is protected by a rugged corrosion resistant, stainless steel ground shield. This unique construction

provides a rugged water and chemical resistance with flexibility down to -57°C (-70°F). This flexible panel is

attached to the tank using aluminum foil tape, proving a low cost, simple installation.

A. Receiving Inspection

1. Inspect each unit upon receipt

2. Visually inspect for physical damage

3. Megohm insulation test with 500V meager between power wires and ground

B. Panel Location

1. Locate units as low as practical on the tank. Preferably.

2. Locate power connection brackets to facilitate routing of flexible conduit between panels

3. Locate panels a minimum of 305mm (12") apart.

C. Preparation

1. Remove dirt, loose scale, and rust from tank surface where aluminum tape will be attached.

2. Install on smooth surface. DO NOT INSTALL OVER RIDGES, BUMPS, OR EDGES THAT COULD

RUB AGAINST THE PANEL AND CAUSE PRE-MATURE FAILURE.

D. Attachment

1. Hold panel in place, metal shield and bracket facing outward.

2. Apply aluminum foil tape (AT-50) to the edge of panel, extending it 203 - 356mm (8-14") beyond the

panel edges.

3. Stretch panel smoothly across tank wall and tape the opposite edge, again extending 203 - 356mm (814") beyond the panel edges.

4. Repeat taping for other edges of the panel.

5. Tape added strips across the panel, around the circumference at approximately 203mm (8") spacing.

Extend the tape 203 - 356mm (8-14") beyond the edges of the panel.

6. Panel may be pre-formed to put a permanent set in the stainless shield on the panel. This will allow the

panel to be easily held in place on small diameter tanks.

7. If it becomes necessary to band the panel to the tank, use fiberglass tape (GT-6 or GT-60). Put two

wraps of tape around the tank circumference at 305mm (12") intervals.

8. After installation, meager panel again between the power wiring and the ground. Insulation resistance

should be at least 50 megohm with a 500V meager.

E. Electrical Connection

1. 13mm (0.5") conduit nipple, 76mm (3") long exist panel wiring through tank thermal insulation.

2. Electrical connection fittings are connected with flexible, watertight conduit. DO NOT CONNECT RIGID

CONDUIT DIRECTLY TO ANY OF THE HEATER PANEL'S ELECTRICAL CONNECTION FITTINGS.

P.O. BOX 726 TULSA, OK 74101 TEL 918-627-5530 FAX 918-641-7336 www.nelsonheaters.com

GA-1591 Rev. 3

Sheet 1 of 4

September 2005

NELSON™ HEAT TRACING SYSTEMS

TANK HEATING PANELS

INSTALLATION

INSTRUCTIONS

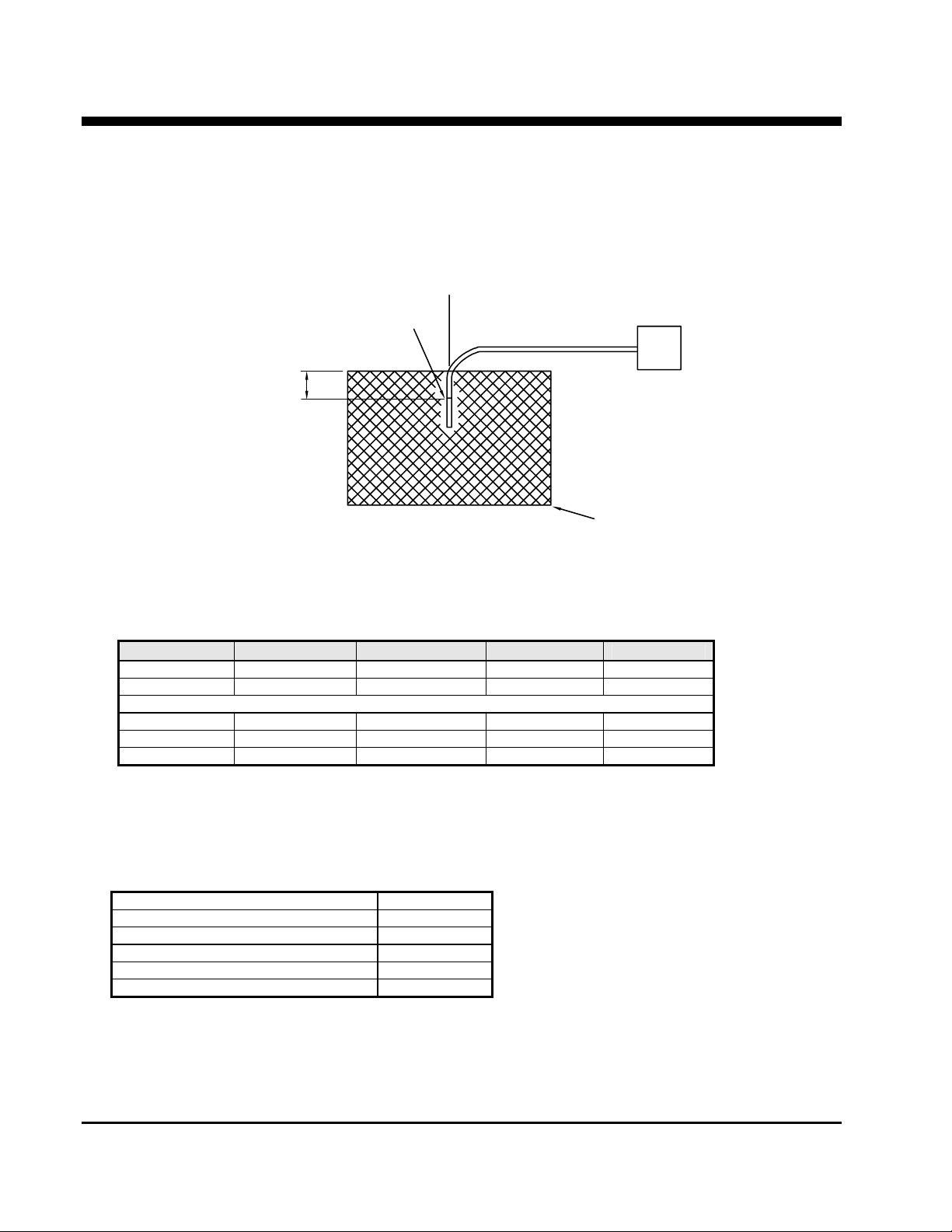

F. Thermostat Bulb Location & Mounting

1. Locate the primary thermostats sensing bulb. As low as possible on the tank, as far away from heating

panel as practical. Secure to vessel wall with aluminum tape.

2. Install the hi-temperature cut-out sensing bulb directly on the heater panel secure bulb to heating panel

with aluminum foil tape. Hi-temp sensing bulb must be located on the highest mounted heating panel

on the vessel. Locate hi-temp sensing bulb 152mm (6”) from the highest edge and centered. See

Figure 1 below.

C

Sensing Bulb

152mm (6")

L

HI-TEMP

CUT-OUT

T-STAT

Figure 1

G. Performance and Rating Data

Tank Heater Size (inches) Watts @100°F Voltage VAC Load Amps

VH1-500 12 x 22 500 120 4.17

VH1-1000 29 x 28 1000 120 8.33

VH2-500 12 x 22 500 240 2.08

VH2-1000 18 x 28 1000 240 4.17

VH2-2000 24 x 42 2000 240 8.33

Note: For 208V - multiply VH2 wattage by 0.75

H. Heater Specifications

Maximum operating temperature: 260°C (500°F)

Maximum temperature (UL recognition): 220°C (428°F)

Minimum ambient temperature: -57°C (-70°F)

Thickness: 15mm (.60”)

Lead Length: 305mm (12”)

Weight: 12 oz / 2 ft

Heating Panel

P.O. BOX 726 TULSA, OK 74101 TEL 918-627-5530 FAX 918-641-7336 www.nelsonheaters.com

GA-1591 Rev. 3

Sheet 2 of 4

September 2005

Loading...

Loading...