MAKERS WARRANTY

Part No: W1980

Version B - 2006

COOKTOP MODEL

T2596NOAU

Installation instructions

User instructions

This cooktop is approved for use with Natural and Propane gases

Leave these instructions with the owner

Contents 3

Introducing your cooktop 4-6

❍ Dear customer

❍ Accessories

❍ Notes on disposal

❍ Gas supply

❍ Electrical supply

❍ What to do if you smell gas

❍ Safety considerations

Installation instructions 7-11

❍ Installer instructions

❍ Statutory requirements

❍ Overall dimensions

❍ Preparing to install

❍ Overhead clearances

❍ Side clearances

❍ Bottom clearance and heat barrier

❍ Bench top specifications

❍ Special considerations for installation over

under bench oven

❍ Installation procedure

❍ Electrical connection

❍ Gas connection

❍ Energy consumption

Gas conversion instructions 12-13

❍ Boiling burners main injector conversion

❍ Boiling burners turn down injector

conversion

❍ Outer wok burner main injector

conversion

❍ Inner wok burner main injector

conversion

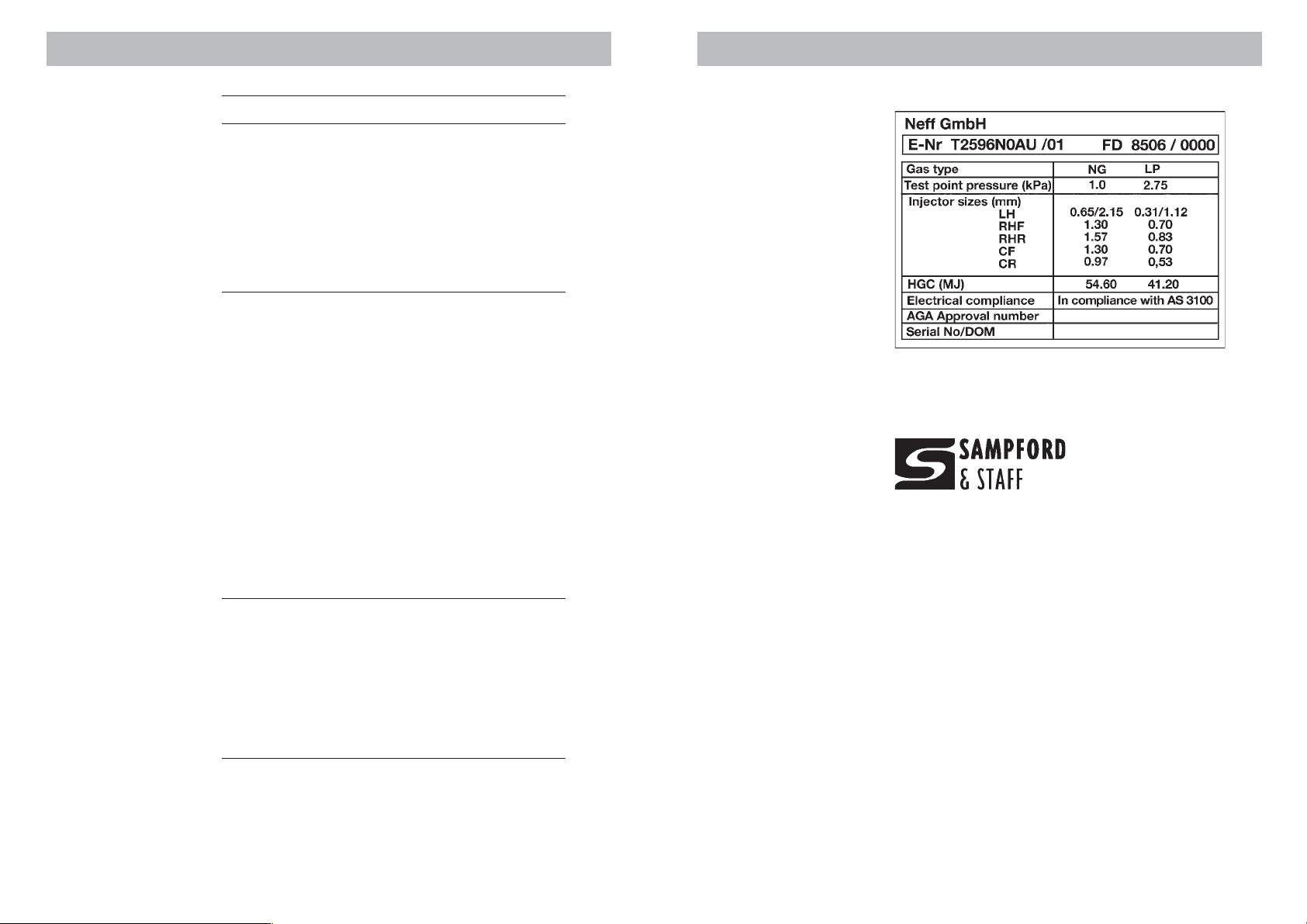

Data plate

This appliance is imported and distributed by:

For service to this appliance

Please contact:

Sampford & Staff P/L

52-70 Sparks Avenue

Fairfield, Vic, 3078

Phone: 1300 727 421

Email service@sampford.com.au

User instructions 14-17

❍ Important information

❍ Burner location and control panel

❍ Boiling burners operation and ignition

❍ Wok burner assembly

❍ Wok burner operation

❍ Ventilation requirements

2 23

Contents

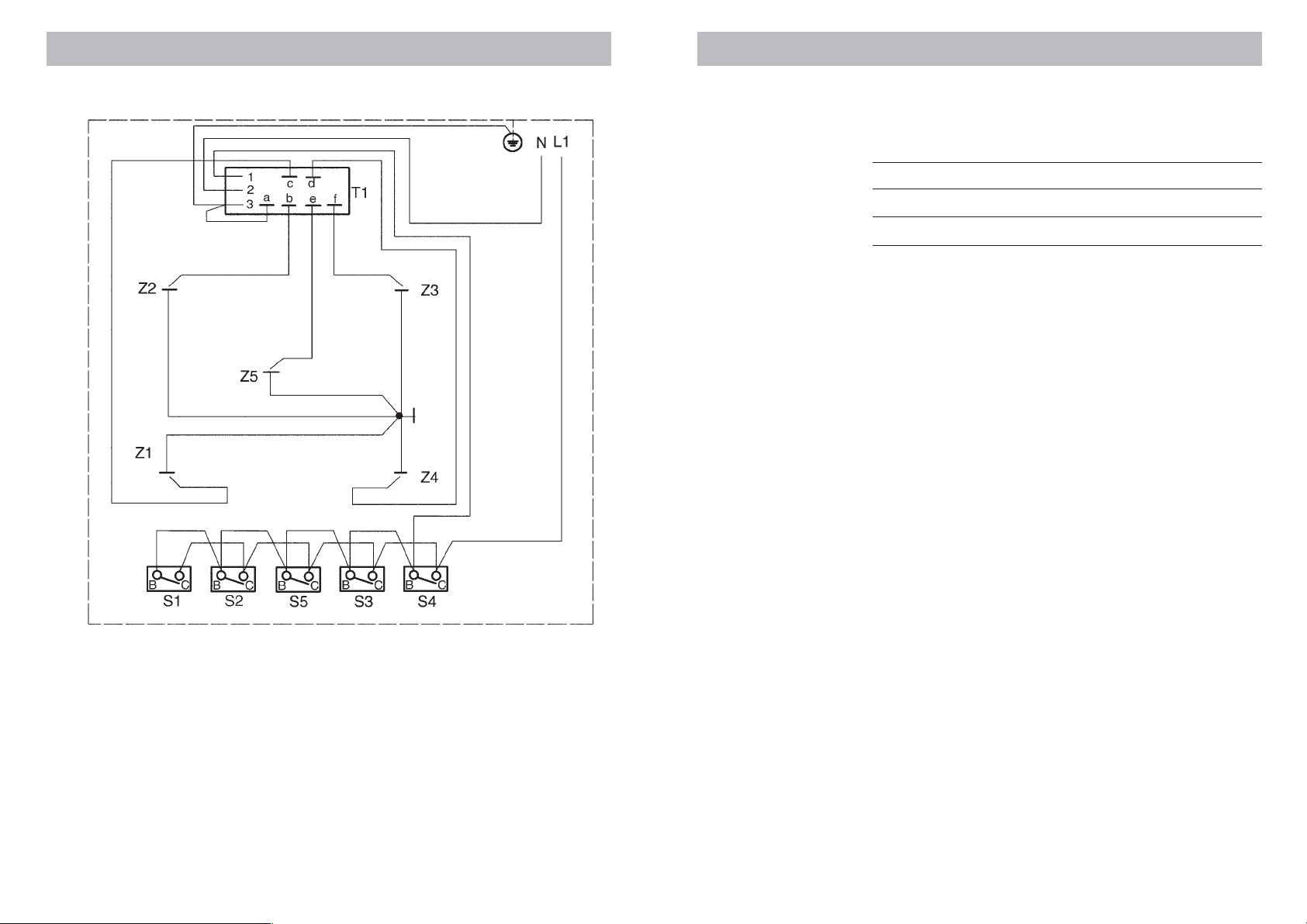

Wiring diagram

❍ Additional pan supports

❍ Recommended pan diameters

❍ Cooking recommendations

Do not & Do 18

Cleaning 19

Maintenance trouble shooting 20

Service 21-23

❍ To remove the hob

❍ To service gas control valves

❍ To replace the thermocouple

❍ To replace the electronic ignition module

❍ To replace internal wiring and the gas

control ignition micro switch

❍ Wiring diagram

❍ Data plate

❍ For service to this appliance

22

3

Introducing your cooktop Service

Dear customer

We thank you and congratulate you on your choice.

This carefully designed product, manufactured with the highest

quality materials, has been carefully tested to satisfy all your cooking

demands.

We therefore request that you read and follow these easy

instructions which will allow you to obtain excellent results right

from the start.

The cooktop is fitted with four boiling burners (one large, two medium and one simmer burner) and a wok burner. All burners are

fitted with electronic spark ignition and flame failure device. The

wok burner is supplied with a supplementary wire pan support for

smaller pans. An additional wire pan support is supplied to fit

over the boiling burner pan supports to support small vessels such

as a coffee pot.

The cooktop’s data plate is accessible even with the cooktop fully

installed. It is positioned on the bottom of the unit. A duplicate

copy is supplied at the back of the instruction booklet. Always

quote the details from it to identify the appliance when ordering

spare parts or requesting a service.

In case of a malfunction, turn off the cooktop’s gas supply

before contacting the service centre for assistance.

Only an authorised person should connect and service

this appliance.

Accessories.

❍ Wok support trivet.

❍ Coffee pot support.

Notes on disposal

❍ Old appliances still have some residual value. An environ-

mentally friendly method of disposal will ensure that valuable

raw materials can be recovered and used again.

Before you dispose of your old appliance, make sure that it

has been rendered inoperable.

❍ Your new cooker was protected by suitable packaging while it

was on its way to you. All materials used for this purpose are

environmentally friendly and suitable for recycling. Please make

Warning:

Disconnect power and

gas supply before

servicing the unit.

Service and maintenance must only be carried out by an authorised person.

To replace parts such as injectors, gas control valves and ignition

switches, the ceramic hob, pan support, burner caps and burner

heads must be removed. The boiling burner heads are secured

with 2 fastening and the wok burner with 3 fastening screws.

To remove the hob:

1. Close isolation valve.

2. Remove the control knobs, anti-spillage gaskets, pan supports,

burner caps and burner heads.

3. Using a flat bladed tool lift the

ceramic top and remove. Store

the ceramic top in a safe place.

To service gas control valves

Access to burner compartments is as per ’to remove the hob’. The

gas control valves are secured to the gas manifold by means of a

clamp fixed via two screws.

1. Remove the screws which secure the gas valve to the gas manifold.

2. Replace the defective part.

3. Replace in reverse order and open isolation valve.

To replace the thermocouple

Access to burner compartments is as per ’to remove the hob’.

1. Remove the retaining ring securing the thermocouple.

2. Remove connection from electronic ignition module.

3. Replace defective part.

4. Replace in reverse order.

To replace the electronic ignition module

Access to burner compartments is as per ’to remove the hob’.

1. Remove the metal cover.

2. Disconnect the leads from the thermocouples.

3. Loosen the 2 securing screws.

4. Replace in reverse order.

a contribution to protecting the environment by disposing of

the packaging appropriately.

To replace internal wiring and the gas control ignition

micro switch

Gas supply

Check that the data plate shows the appliance is suitable for the

available gas supply.

Access to burner compartments is as per ’to remove the hob’.

1. Disconnect wiring between ignition module and gas control.

2. Disconnect microswitch from gas control.

3. Replace in reverse order.

4

21

Maintenance trouble shooting

Important

Only authorised personnel from the Service

Agent are qualified to

work on the main gas and

electric systems.

What’s wrong Possible cause Solution

It is not always necessary to call the Service Agent. In some cases,

you may be able to solve the problem yourself. This table contains

some useful information.

If any of the fault finding procedures below do not rectify the

problem call Sampford & Staff. For contact details refer back page

of this booklet.

...If none of the electrical ❍ Power turned off. ❍ Turn power on.

systems work. ❍ Faulty fuse. ❍ Check the fuse in the main

fuse box and replace if faulty.

❍ The automatic safety ❍ Check the main fuse box to see

switch has been tripped whether the automatic trip

or a fuse has blown. switch or a differential switch

has tripped.

...If the electronic ignition ❍ There may be food or ❍ The gap between the spark

system does not work. cleaning product plug and the burner needs to

particles between the be cleaned carefully.

spark plugs and the

burners.

❍ The burners are wet. ❍ Dry the burner caps carefully.

❍ The burner covers are ❍ Make sure that the burner caps

not located correctly. are correctly located.

...If the flame on the ❍ The burner components ❍ Put the components in their

burners is not evenly have not been correct positions.

distributed. assembled properly.

❍ The gas ports on the ❍ Clean the gas ports on the

burners are dirty. burners.

...If the gas flow does not ❍ The isolation valve is ❍ Open the isolation valve.

seem normal or there closed.

is no gas flow at all. ❍ If the gas is supplied ❍ Replace the gas bottle with a

from a gas bottle, it full one.

may be empty.

...If the kitchen smells ❍ One of the valves has ❍ Check to see if a valve has

of gas. been left open. been left open.

❍ Possible leak on the ❍ Check that the coupling on

gas bottle coupling. the gas bottle is in order.

...If the safety shut off ❍ The control knob was ❍ Once the burner is lit, hold the

device on different not held down long control knob down a few

burners doesn’t work. enough. seconds longer.

❍ The burner ports are ❍ Clean the burner ports.

dirty.

Flames are normally blue and sharply defined. If flames are ever yellowish or noisy or if the gas

does not ignite within the period specified under ‘boiling burner operation’ abnormal operation

is indicated. Call your local Service Agent.

20

Never pour water on

burning fat or oil. Cover

with a damp cloth to

extinguish the fire and

disconnect the cooking

appliance.

Electrical supply

This appliance requires connection to a 10 Amp wall socket.

What to do if you smell gas

❍ Do not try to light the appliance.

❍ Do not touch any electrical switch; do not use a phone in your

building.

❍ Immediately call your gas supplier from a neighbour’s phone.

Follow the gas suppliers’s instructions.

❍ If you cannot reach your gas supplier, call the fire department.

Safety considerations

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury

or death.

❍ Never leave the appliance unattended when cooking with fat

or oil. It could ignite if overheated.

❍ In case of a defect, switch electric power off at the mains.

❍ Never use an appliance that is not working correctly.

❍ Do not allow the flame to extend beyond the edge of the cook-

ing utensil. This instruction is based on safety considerations.

❍ Do not forget that the unit becomes hot when in use. Common

sense is important. Just because the flame is out, does not mean

parts cannot still be hot.

❍ Be sure to disconnect the electrical supply before disassembly

of the appliance.

❍ Keep the appliance area clear and free from combustible ma-

terials, gasoline and other flammable vapours and liquids.

❍ Note: To avoid jeopardising the electrical safety of the appli-

ance, it is forbidden to use high-pressure or steam jet cleaning

devices.

❍ Cabinets installed above the gas cooktop must have a mini-

mum clearance of 650 mm (24”).

❍ Important

When using a very large pot, leave a gap of at least 50 mm

(2”) to avoid damaging any parts in bench top wood, plastic

or other non-heat resistant materials. Never leave oil or hot fat

unattended.

❍ Never place unstable pans or containers on the cooking hob

or burners, as they may accidentally tip over.

❍ Never cover up the slots at the rear of the appliance.

5

Cleaning

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS

APPLIANCE WHILE IT IS OPERATION.

WHERE THIS APPLIANCE IS INSTALLED IN A MARINE CRAFT OR

IN CARAVANS, FOR SAFETY REASONS IT SHALL NOT BE USED

AS A SPACE HEATER.

THIS APPLIANCE IS NOT INTENDED FOR THE USE BY YOUNG

CHILDREN OR INFIRM PERSONS WITHOUT SUPERVISION.

YOUNG CHILDREN SHOULD BE SUPERVISED TO ENSURE THEY

DO NOT PLAY WITH THIS APPLIANCE.

WARNING - THE UNDERSIDE OF THIS HOB MAY EXCEED 95˚C.

FIT A TIMBER BARRIER TO THE ENCLOSURE, REFER TO THE INSTALLATION INSTRUCTIONS.

Make sure you keep these instructions for use and assembly in

a safe place, so that you can hand them on with the appliance

if it ever changes owner

Important

Always allow the burner

caps to cool down before

cleaning then.

Clean vinegar, lemon or

tomato juice as soon as

posssible after spillage.

Please clean cooktop thoroughly before first use. Operate boiling burners and wok burners on HIGH for a few minutes to eliminate the ‘new’ smell.

Never use abrasive or caustic cleaners,

oven cleaning sprays or scourers that might

scratch the glass.

Never use sharp objects such as metal

scourers or knives to remove the hardened

remains of food from the ceramic surface

or burner.

Wipe grains of sand and other debree that

may drop from cleaning vegetables and

fruits. These particles will scratch the ceramic surface.

Clean the ceramic cooktop with a sponge

and a mild detergent or soapy water (or

specialist cleaning product) when cooktop

has cooled down completely.

Use a glass scraper for stubborn dirt and

always place it flat to the glass, taking special care not to get it too near to the trim

on the burners.

To keep the burners and pan supports

clean, you must clean them periodically by

washing them in soapy water and brushing them with a non-metallic brush to ensure that the port holes and grooves are

perfectly clean and can provide a perfect

flame. Always dry the burner caps and the

pan supports if they have become wet.

From time to time clean the thermocouple

and the spark igniter with a soft toothbrush.

6

19

Do not Do

Installation instructions

18

Do not use small pans on

large burners. The flames

should never come up the

side of the pan.

Never cook without a lid

or with the lid half off;

you are wasting energy.

Do not use pans with uneven bottoms, as they

make the food take longer

to cook and waste energy.

Do not place a pan on

one side of a burner, as it

could tip over.

Never place pans directly

on top of the burners.

Do not use large pots or

heavy weights which can

bend the pan support or

deflect the flame onto the

hotplate.

Avoid using griddles and

earthen ware pots etc. at

maximum heat for a long

time.

Do not remove the wok

pan support and enclose

the burner with a wok

stand as this will concentrate and deflect heat onto

the hotplate.

Do not place anything,

e.g. flame tamer, asbestos mat, between the pan

and the pan support as

serious damage to the

cooktop may result.

Use only wok support supplied or recommended by

the manufacturer of the

cooktop.

Always use pans that are

suitable for each burner,

so as avoid wasting gas

and discolouring the

pans.

Always place the lid on

the pan. Use pans, frying

pans and casserole dishes

with thick flat bottoms.

Always place the pan

centrally over the burner,

not to one side.

Place the pan on the pan

support. Ensure that the

burner’s pan support and

covers are properly in

place before use.

Handle pans with care

when they are on the

cooking hotplate.

Only use one burner per

pan. For concave vessels

use the supplementary

pan support on the large

wok burner.

Be careful handling the

supplementary pan supports. They are HOT after

use.

Installer instructions

❍ This appliance must be installed in a position with the proper

level of ventilation. Do not obstruct the flow of combustion and

ventilation air.

❍ The gas pressure regulator supplied with the appliance must

be installed in line with the gas pipe. (N.G. only)

❍ Before commencing any work, make sure that the power point

switches are turned off and the three in plug is removed.

❍ If the appliance cannot be adjusted to perform correctly con-

tact Sampford & Staff or the local gas utility. For service contact telephone number refer back page.

❍ Instruct the user in the operation of the appliance before leav-

ing.

❍ For pressure testing in excess of 3.5 kPa (1/2” psig) the appli-

ance and its individual shut-off valve must be disconnected

from the gas supply piping system. For pressure testing of the

gas piping system at test pressures equal to or less than 3.5

kPa (1/2”psig) the appliance must be isolated from the gas

supply system by closing its individual shut off valve during

any pressure testing.

❍ The data plate is attached to the bottom of the unit. A duplicate

copy is supplied at the back of the instruction booklet.

❍ This appliance should not be connected to a combustion prod-

uct evacuation device.

❍ Before installing your new cooktop make sure that the meas-

urements are all correct.

Statutory requirements

This appliance shall be installed in accordance with the manufacturer’s installation instructions, local gas fitting regulations, municipal building codes, electrical wiring regulations, the Installation Code for gas burning appliances, AS 5601 and any other

statutory regulations. Refer to the AGA Installation Code for piping size details.

Overall dimensions

7

Preparing to install

Only an authorised person should connect the appliance.

This built-in cooktop is intended to be inserted in a benchtop cut-

out. For cutout dimension refer figure below.

The small pot trivet is provided as an

additional support for pan diameters

less than 12cm.

Recommended pan diameters

Burner Min Ø of pan Max Ø of pan

Wok burner ≥ 22cm

Large boiling burner 22 cm 26 cm

Medium boiling burners 14 cm 20 cm

Simmer burner 12 cm 14 cm

Cooking recommendations

Very high /High Medium Low

Wok burner Boiling, grilling, Reheating and keeping

browning, and Asian things hot, cooked and

food (wok). pre-cooked dishes.

Large boiling Steaks, omelettes, Rice, white Steaming,

burner frying. sauce and and

ragout. vegetables.

Medium Steaming potatoes, Reheating, keeping

boiling fresh vegetables, things hot and making

burner stews and pasta. tasty casseroles.

Overhead clearances

A range hood fitted above the top must be installed according to

the installation instructions for the range hood. A minimum distance of 650 mm is required for a range hood and 750 mm for an

exhaust fan. Minimum clearance to an overhead cupboard is

600mm.

Side clearances

Simmer Casseroles, rice Defrosting Melting:

burner pudding and and slow butter,

caramels. cooking: chocolate

vegetables and jelly.

fruits and

frozen

products.

If the distance measured from the periphery of the nearest burner

to any vertical surface is less than 200 mm, the surface shall be

protected in accordance with clauses 5.12.1.1 & 5.12.1.2 of AS

5601.

Bottom clearance and heat barrier

Leave a space of at least 10mm between any drawer partition that

is installed underneath the cooktop.

8

17

Wok burner assembly

To assemble the wok burner and pan support place the burner

body onto the burner skirt and the burner head onto the burner

body so the anti-twisting lip fits into the notch in each case.

It is important that these parts are assembled in the correct

position. The cooktop may otherwise not function correctly or

might be damaged.

Wok burner operation

The wok control has 4 settings.

Largest flame = The outer and inner burners are both

operating on high flame.

Large flame = The outer burner burns low and the

inner burner burns high.

Small flame = Only the inner burner burns high.

Smallest flame = Only the inner burner burns low.

For ongoing cooking a variable setting between the flame sizes

can be used.

Ventilation requirements

The use of a cooktop produces heat and moisture in the kitchen.

For this reason make sure that the room is properly ventilated.

Keep natural ventilation openings, such as windows, open or

provide a mechanical ventilation device (e.g. a range hood or

overhead exhaust fan).

Additional pan supports

The wok burner is supplied with an additional pan support for pans larger than

26mm diameter, i.e. roasting dishes, earthenware pots and woks, etc.

Benchtop specification

This cooktop can be fitted to a benchtop of 18 - 30mm thickness.

Special considerations for installation over under bench

oven

If installing the cooktop over an under bench oven and connecting

the cooktop via a hose assembly, ensure that the hose assembly is

retained from accidental contact with the flue outlet of the under

bench oven.

Installation procedure

Before connecting the unit, check whether the local connection

conditions (type of gas) are compatible with the unit’s settings. The

model number, type of appliance, gas pressure, gas type, injector

size and total hourly gas consumption are noted on the data plate

attached to the underside of the cooktop base. A duplicate of this

data plate is at the rear of this booklet.

Observe any special conditions imposed by local suppliers (utilities).

1. For cutout dimensions and clearances refer drawing on previous page. Observe the minimum insertion gap. DANGER! combustion may be affected.

2. Slightly loosen the retaining

screws of the 4 clamping brackets positioned at the bottom of

the cooktop.

3. Insert the cooktop into the bench

cutout.

4. After insertion, from below, swivel the clamp brackets 90° and

tighten them against the bottom of the benchtop.

Electrical connection

An electrical 10 amp socket needs to be within 1 m of the hotplate

to allow electrical connection. The socket must remain accessible

after installation of the appliance.

Important note:

This appliance is connected to the mains (240 VAC) by means of

the connecting lead which must be fixed to the kitchen unit to prevent it from coming into contact with hot parts of the hob (or an

oven installed underneath) and remain accessible after installation of the cooktop.

16

9

10

When connecting the cooktop ensure that the earth wire is connected first and that all wires are connected to the correct terminals.

Gas connection:

The cooktop is adjusted to operate on the gas type specified on

the gas type label located on the

bottom of the unit. If in doubt as to

type of gas available contact the

network operator or gas supplier for

confirmation of gas type.

The cooktop must be connected to

the gas supply with upstream connection of an isolation valve in accordance with the respectively valid regulations. We recommend

that the isolation valve be fitted prior to the cooktop to enable

isolation of cooktop from gas supply. The valve must be easily

accessible at all times.

This appliance may be connected with a hose assembly, class B or

class D. If connected with a hose assembly ensure that the supply

connection point is accessible with the appliance installed.

The position of the inlet connection is measured from bottom RH

rear of unit, 45mm centre line from rear and 27mm centre line for

RH side.

1. Remove plastic cap from gas supply line prior to installation.

2. Fit regulator (N.G.) or Propane fitting (Propane) directly to the

R1/2” connection. Direction of gas flow is indicated on the

rear of the regulator.

Natural gas connection Propane gas connection

Burner location and control panel

The cooktop consists of a ceramic top fitted with four boiling burners and one wok burner. All burners are fitted with electronic ignition and safety shut off device.

1. Wok burner 4. Medium boiling burner

2. Small boiling burner 5. Medium boiling burner

3. Large boiling burner 6. 5 control knobs

Boiling burners operation and ignition

The boiling burners have two heat settings.

Large flame = highest setting

Small flame = lowest (simmer) setting

The highest flame setting is used for initial

boiling. For ongoing cooking a variable

setting between high and low flame can

be made.

To activate the burner depress the control

knob and turn to ‘high flame’ position.

Keep knob depressed for approx. 6-7 seconds to allow the safety

shut off to activate. The flame will extinguish if the knob is released

too soon.

If ignition fails depress knob and try again. If flame is not established in 15 seconds release the control knob and open a door and

wait 1 minute before attempting a new ignition procedure.

If the burner flames are extinguished - for whatever reason - turn

OFF the control knob and wait at least one minute before retrying

to ignite the burner.

Ensure that the flames do not extinguish when you reduce to low

flame quickly.

To turn off the gas supply to a burner return the control knob to the

‘OFF’ position.

15

User instructions

In the event of a fault

disconnect the electrical

power to the cooktop

and shut off the gas

supply.

Contact your local gas

supplier or service

agent. The service

agent contact details

are at the rear of this

booklet.

14

Important information

The top plate of the cooktop consists of a very resistant ceramic

and with proper handling will stand up to all household stresses.

Before using the cooktop for the first time, please read the following practical tips.

❍ This appliance is intended for domestic use only

❍ Do not use the ceramic top as a work surface or storage space.

❍ Do not let pans with rough or textured bottom surfaces rest on

the ceramic top. They can cause scratching when moved around

on the top.

❍ Do not drop hard or sharp objects onto the top. This may dam-

age it.

❍ Never use two burners to heat one single receptacle.

❍ The cooktop must be switched off immediately if the ceramic

top develops any cracks, splits or fractures. If this should happen, switch off the power and gas supply.

❍ Do not use the cooktop to heat a room.

❍ Never prepare food in aluminium foil or plastic containers on

the hob. The material melts on.

❍ Melted-on sugar or food containing sugar should be cleaned

off immediately using a glass scraper, otherwise they could

cause damage to the ceramic surface.

❍ The surfaces of the cooktop, trivets and burners will become

hot during operation. Small children must be kept at a safe

distance from the appliance.

❍ Do not use large-diameter pans on the burners nearest to the

control knobs, as the flames might reach them, making them so

hot that they could cause injury.

❍ Grease and oils are flammable if overheated. Always stay near

the oven when preparing food using grease and oil, e.g. french

fries.

❍ Never cover the ventilation openings at the rear of the cooktop,

e.g. with a tea towel.

❍ Only ignite the gas burners when all the burner components

are correctly assembled.

❍ Never flambe dishes while using a range hood or extractor

fan. The flames could set the range hood or extractor fan on

fire.

❍ Leads from electrical appliances must not touch the cooktop.

They will melt on and the cable insulation will be damaged.

❍ Always watch pressure cookers until they reach the correct pres-

sure. You should first set the burner to highest level and reduce

the heat when the required pressure has been reached.

3. Check for gas soundness at connections. NEVER use a naked

flame to check for leaks.

4. Check correct operation of each burner individually and in

combination. Burner flames should be clear blue, with no yellow tipping. If the burners show any abnormality check that

burner heads are correctly located and refer to the ‘maintenance trouble shooting’ chart on page 20. If satisfactory performance can not be obtained, contact Sampford & Staff or

the local gas utility. For service contact number refer back page

of this booklet.

Note: These burners have no aeration adjustment.

It should be expressly noted that we cannot accept any liability for

direct or indirect damage caused by wrong connection or improper

installation. When being repaired, the appliance must always be

disconnected from the main gas and electricity supply; if required,

notify our customer service.

Energy consumption

Natural Gas (1kPa)

Burner Main Turndown Hourly gas

injector size injector size consumption

(mm) (mm) (MJ/hr)

Left Front 1.30 0.68 8.10

Left Rear 0.97 0.98 4.80

Right Front 1.30 0.68 8.10

Right Rear 1.57 0.85 11.60

Wok- outer ring burner 2.15 1.30 22.00

Wok - inner burner spud size 0.65 1.70

Propane Gas (2.75 kPa)

Burner Main Turndown Hourly gas

injector size injector size consumption

(mm) (mm) (MJ/hr)

Left Front 0.70 0.68 6.00

Left Rear 0.53 0.98 3.50

Right Front 0.70 0.68 6.00

Right Rear 0.83 0.85 8.50

Wok- outer ring burner 1.12 1.30 17.20

Wok - inner burner spud size 0.31 1.10

11

Gas conversion instructions

Converting the cooktop from Natural Gas to Propane Gas can

only be carried out by an authorised person.

Boiling burners main injector conversion

Request change-over injectors from our customer service department (refer injector charts on previous page for sizes).

Before conversion the cooktop must be disconnected from the electricity and gas valves must be turned to the OFF position.

1 Remove the pan supports, 5 control knobs and anti-spillage

gaskets, burner caps and burner heads.

2. Conversion of main and turndown injectors requires the removal of the ceramic top. Use a flat bladed tool to lift the ceramic frame and remove. Store ceramic top in a safe position.

3 Change the injectors using a 7-mm socket wrench and be sure

to tighten them down properly so that they are fully airtight.

NOTE: it is not necessary to adjust the primary air control on these

burners.

Boiling burners turndown injector conversion

1. Undo burner burner heads fastening screws and remove boiling burner heads.

2. Disassemble wok pan supports and burner head. Undo the

three fastening screws and remove wok burner body.

.

3 Remove ceramic cooktop.

4 The turndown injector is incorporated in the gas tap as indi-

cated in figure above. Use a small screw driver to rotate anticlockwise to closed position.

5. Reassemble parts in reverse order. For replacement of wok

burner refer to adjacent figure.

Outer wok burner main injector conversion

1. Disassemble the wok burner pan supports and wok burner as

indicated in figure at left

2. Undo 3 wok burner head fastening screws and remove burner

head.

3. Unscrew and remove boiling burner heads.

4. Remove ceramic top. Refer previous page.

5. The main injector block is fixed to the throat of the mixing

tube. Use a size 10 spanner to unscrew the injector. At the

same time hold the injector block with a

size 13 spanner to anchor the connection

against movement.

6. Replace with relevant injector according

to the injector chart.

7. To adjust aeration release the locking screw

and shift the aeration sleeve 11mm for

Natural Gas or 12mm for Propane Gas.

(Refer ‘X’ dimension in figure).

Inner wok burner main injector conversion

1. Using a size 8 spanner unscrew fitting 3 from injector block 2

as indicated in figure below. At the same time hold the injector

block with a size 12 spanner to anchor the connection against

movement.

2. Remove the injector spud (4) and replace with relevant sized

spud according to the injector chart.

3. Aeration is provided by 2 circular holes (6). Leave in the fully

open position

4. Tighten all parts and check for

gas soundness before replacing

the ceramic top. Reassemble the

cooktop in reverse order.

5. Adhere the data plate for the

replacement injectors on top of

the previously valid data plate.

6. Check for flame stability by

turning the control knobs a few

times from large to small flame

whilst the burners are ignited.

The flames should not extinguish.

12

13

Loading...

Loading...