Page 1

Service manual

For installation, operation and service

OEM ISO Reader

VP1006

06 - 2017 / Manual version 2.6

Page 2

Version overview

Manual version 2.0 / January 2008

Manual version 2.1 / September 2009

Chapter 7 : error codes 01 and 02 changed

Appendix E : shielding changed

Appendix F : shielding changed

Manual version 2.2 / 2-2012

Introduction : FCC tekst changed IC added

Appendix A : CE document added

Appendix C : Display changed to last software status

Manual version 2.3 / 4-2012

Neutrodynisation added, available since firmware 2.11.007

Chapter 6.2 : Neutrodynisation added

Appendix C : Display menu option Neutrodynisation added

Appendix I : Neutrodynisation unit between two antennas

Manual version 2.4 / 10-2013

Appendix C : Display menu option ISO protocol added

Manual version 2.5 / 06-2015

Appendix A : Updated product specifications

Manual version 2.6 / 06-2017

Updated FCC_IC Statement

This information is furnished for guidance, and with no guarantee as to its accuracy or completeness; its publication conveys no

license under any patent or other right, nor does the publisher assume liability for any consequence of its use; specifications and

availability of goods mentioned in it are subject to change without notice; it is not to be reproduced in any way, in whole or in

part, without the written consent of the publisher.

© Nedap N.V., Livestock Management P.O. Box 104 NL-7140 AC GROENLO The Netherlands

VP1006-200PM-00 OEM ISO Reader Manual version 2.6

Page 3

VP1006 OEM ISO Reader

Contents

1 Introduction 1

2 Description and functioning 3

3 Safety 3

4 Installation 3

4.1 Mounting 3

4.2 Connections 4

5 Adjustments 5

5.1 Check after power up 5

5.2 Communication bus termination jumper 5

5.3 Address 6

5.4 Antenna 6

5.5 Antenna tuning with EWA antenna transformer 7

5.6 Software setup 7

6 Advanced 8

6.1 Testing inputs and outputs 8

6.2 Advanced antenna adjustment 9

6.3 Identification test options 10

7 Trouble shooting 11

8 Maintenance, cleaning and disposal 11

Appendix A: Specifications / CE 12

Appendix B: Display and push button 14

Appendix C: Overview display menu 15

Appendix D: LED indicator overview 17

Appendix E: RS485 connections with separated wiring 18

Appendix F: RS485 connections with Nedap Velos cable 19

Appendix G: RS232 connections 20

Appendix H: VP1006 connected to a Velos VP8001 (VPU) 21

Appendix I: Neutrodynisation unit between two antennas 22

VP1006-200PM-00 OEM ISO Reader Manual version 2.6

Page 4

VP1006-200PM-00 OEM ISO Reader Manual version 2.6

Page 5

Preface

This manual is part of the service documentation for Nedap Velos. Reference is also made to other

manuals that are part of the Nedap Velos documentation. For an overview of available Nedap Velos

manuals see the manual “Nedap Velos General Description”, or visit the Nedap Agri website

www.nedap-agri.com.

1 Introduction

The Velos VP1006 is used for identification of animals for feeding, weighing, milking, heat detection

etc. The VP1006 must be connected to a computer (controller) and can communicate by a CAN,

RS485 or RS232 protocol. The connected computer must give controlling commands to the VP1006 to

operate inputs, outputs and identification.

The VP1006 has the following main tasks:

- Identification of tags (ISO 134.2 kHz FDX/HDX)

- Controlling outputs - 6 outputs are available to activate e.g. lights, motors, valves, relays

- Reading inputs - 6 inputs available for e.g. sensors, switches

Following antenna types can be used:

- V-sense antennas

- EWA transformer with stainless steel antenna strip

- HDPE antenna with HDPE antenna tuner

The VP1006 must be installed in a housing suitable for farm conditions, for example in a V-box.

Figure : V-box2 with a VP2002 power supply and a VP1006 reader

Reference manuals :

PS0000-200PM-00 Velos general description

VP1002-200PM-00 ISO-Booster

VP6001-200PM-00 V-sense

FCC ID: CGDVELOS2 and IC: 1444A-VELOS2

FCC_IC Statement

This device complies with part 15 of the FCC Rules and with Industry Canada’s licence-exempt RSSs.

Operation is subject to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired operation of the device.

Warning (15.21)

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to

operate the equipment.

Cet appareil se conforme aux normes RSS exemptés de license du Industry Canada. L'opération est soumis aux deux

conditions suivantes:

(1) cet appareil ne doit causer aucune interférence, et

(2) cet appareil doit accepter n'importe quelle interférence, y inclus interférence qui peut causer une opération non pas voulu de

cet appareil.

Les changements ou modifications n’ayant pas été expressément approuvés par la partie responsable de la conformité peuvent

faire perdre à l’utilisateur l’autorisation de faire fonctionner le matériel.

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 1

Page 6

FCC and ISED Radiation Exposure Statement

This equipment complies with FCC (OET Bulletin 65) and Canadian radiation exposure limits set forth in RSS-102 for a

uncontrolled environment. This equipment should be installed and operated with a minimum distance of 20 cm between the

radiator and your body. This transmitter must not be co-located or operating in conjunction with any other antenna or transmitter.

Cet équipement est conforme a RSS-102 limites énoncées pour un environnement non contrôlé. Cet équipement doit être

installé et utilisé avec une distance minimale de 20 cm entre le radiateur et votre corps.

ISED EMC Declaration

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de Classe B est conforme à la norme Canadienne ICES-003.

FCC Information to the user (15.105(b))

Note: This equipment has been tested and found to comply with the limits for a class B digital devices, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequent energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does not cause

harmful interference to radio or television reception, which can be determine by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver.

• Any changes or modifications not expressly approved by the party responsible for compliance could void the

user's authority to operate the equipment.

• To ensure compliance with FCC regulations, use only the shielded interface cables provided with the

product, or additional specified components or accessories that can be used with the installation of the

product

NOTE:

Antenna VP6041 has the same dimensions as the VP6042.

VP6041 and VP6042 regarding hardware are the same. The VP6041 is adjusted for environments with lots of steel for short distances (pigs). The

VP6042 is adjusted for longer distances (1 m) recognition (Cows).

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 2

Page 7

2 Description and functioning

A VP1006 has 6 inputs used for reading e.g. sensors or switches.

There are also 6 outputs available to activate e.g. lights, motors, valves or relays.

The VP1006 can read tags FDX/HDX 134.2 kHz.

The VP1006 must be connected to a computer and can communicate by a CAN, RS485 or RS232

protocol. The connected computer must give controlling commands to the VP1006 to operate inputs,

outputs and identification.

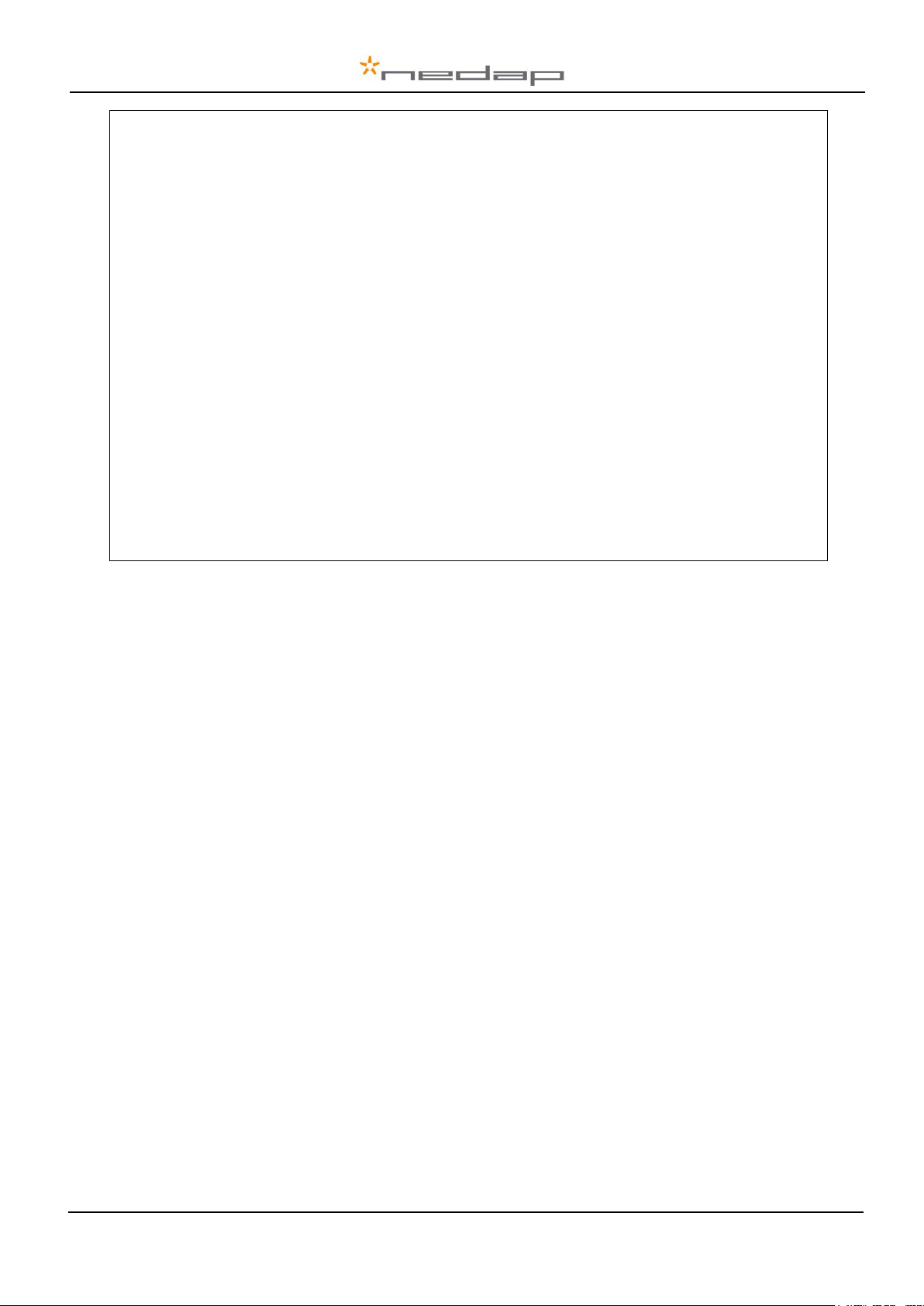

Figure : Sticker on the VP1006 with indication of the connections

Input/output 1 to 4 ( I/O 1 till I/O 4 ) can be used to control feed motors or can be used as normal

input/output. Output/input 5 and 6 ( I/O 5 - I/O 6 ) can only be used as output/input, not for feed motors.

Operation of the VP1006

Antenna : for reading tags, normally on

Inputs : read continuously with status change sent to the controller

Outputs : switched on or off by commands from the controller

LEDs : switched on or off by the VP1006 according to the status

Error : errors are sent to the controller

All inputs and outputs can be tested by the use of the push button and display. For operation of the

push button and display see appendix B.

3 Safety

Installation and service only by trained personnel.

Always turn off the main power when working on the electrical installation.

4 Installation

Installation consits of the following steps:

1. Mounting

2. Installation of all wiring (connections)

3. Power up

4. Set address (when more then one VP1006)

5. Set communication protocol

6. Antenna adjustment (green LED on)

7. Checking the connected equipment like lamps, motors, sensors etc.

8. Configuration in the PC

Follow this manual to complete the steps.

4.1 Mounting

See the relevant equipment manual relating to where the VP1006 is to be installed.

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 3

Page 8

4.2 Connections

See the relevant equipment manual relating to where the VP1006 is to be installed. See also appendix

E, F and G for the different connection possibilities.

Figure : I/O of the VP1006. The feed motor, input and output connections are shown above as an

example.

Details VP1006 inputs and outputs

Vin + Power

- Minus

RS232 / 485

RxD / B-

Data receive

TxD / A+

Data send

Shield of RS232 / 485

SYNC

~

Synchronisation for HDX, AC (no plus or minus, cable must be twisted pair)

~ See above

I/O 1 .. 4

M

Motor output or normal output max 3A

M-

Minus for motor output or normal output

I Input of motor or normal input

- Minus for motor input or normal input

I/O 5 .. 6

O

Output max 250mA

- Minus for output (O) and minus input (I)

I Input

ANTENNA

+

Antenna with external adjustment

Antenna with no adjustment

- Antenna minus (shield of coax cable)

F SYNC

Frequency synchronisation (not used yet)

IMPORTANT : Use power supply with a fused output such as Velos VP2001, VP2002.

Details Velos cable

M

orange

blue white

blue

black

red

orange white

green

red

white

brown

Velos cable

Switch

Light

Feed motor

Red (+)

Black (-)

Blue (Ch)

Blue/white (Cl)

Shield

Orange (Sync)

Orange/white (Sync)

Shield

Power

1,5 mm2

Communication

0,34 mm2

Twisted pair shielded

HF Synchronisation

0,34 mm2

Twisted pair shielded

Part No. 7705310

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 4

Page 9

5 Adjustments

Before starting with adjustments first install all components and wiring. Follow the sequence as

indicated in this chapter.

5.1 Check after power up

Check if the VP1006 has power after power up. This means 3 green LED’s are on, see figure below.

For more details about the LED indicators see Appendix D.

If LED’s are green, continue with address settings

5.2 Communication bus termination jumper

Termination is only used in case of RS485 communication.

When using RS485: at the last VP1006 in the communication

line (bus) the jumper must be set to the other position. Also at

the beginning of the line (computer) termination is required.

For RS232 and CAN always use default jumper position

Check LED “COM” to evaluate the connection to the computer.

Default

Jumper

position

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 5

Page 10

5.3 Address

Each VP1006 requires a unique address on the communication bus. Use the display and push button

to set the address. How to use the display and push button is shown in appendix B. See appendix C

for the complete overview of the display menu.

The display will indicate the actual address at startup (01 for a new unit). If an address is accepted by

the communication bus the display goes blank. If there is no communication with the controller also the

address is shown. If the address is not accepted, the display will show the address.

How to change an address (for example set address to 12)

1. Short press on the button. Ad will appear.

2. Now hold the button till the display starts blinking. dA will appear.

3. Short press on the button. SA will appear.

4. Now hold the button until the display starts blinking. 0- will appear.

5. Short press on the button. The 0- is now changed into 1-.

6. Hold the button until the display starts blinking. 10 will appear.

7. Short press on the button. The 10 is now changed into 11.

8. Short press on the button again. The 11 is now changed into 12.

9. Hold now the button until the display starts blinking. The 12 is now stored in the memory.

10. There will now be 12 blinking on the display now. If the address is accepted by the process

unit the display goes blank.

How to check the address

1. Short press the button. Ad will appear.

2. Now hold the button until the display starts blinking. dA will appear.

3. Hold the button again until the display starts blinking. The actual address will be shown.

4. Leave the menu by pressing the button until the display goes blank.

If the display does not go blank (address remains on the display), the address in not accepted.

When the address setting is ok continue with the antenna adjustment.

5.4 Antenna

In the event Velos V-sense antenna’s are used.

After the first time power up the antenna tuning must be checked. Check the TUNING LED, green is

OK and means the antenna is correctly tuned. When the green LED is not ON the antenna must be

tuned.

Antenna tuning

1. Turn the trimmer on the antenna until the green LED is ON

See also the manual of the antenna being used for information about tuning

Green on

Antenna tuning ok

Red on

Antenna out of range, turn the trimmer to the right until green LED is on

Red on

Antenna out of range, turn the trimmer to the left until green LED is on

Red blinking

No antenna connected or low antenna signal

All off

Antenna switch off by the software

If there is no antenna LED on, the software has set the antenna field off. For tuning set the antenna in

ID test mode by using the display/push button (see also appendix C).

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 6

Page 11

5.5 Antenna tuning with EWA antenna transformer

In case a stainless steel loop antenna is used.

Jumper position in the EWA

Measure the circumference of the antenna-loop. Set jumpers to the combination as described in the

table on Antenna-Transformer PCB. Note that the highest possible number should be chosen.

EWA connection to the VP1006

9 : 1 11 : 1 13 : 1 15 : 1

Use connection 9 :1 to start

Tuning

Use a plastic screw driver to tune. Tune the coil inside the EWA until the green LED of the antenna

tuning is on. When green the antenna tuning is ok. See also instructions on previous page.

When it is not possible to get a green LED use another connection and try again.

5.6 Software setup

The software in the connected controller determines how the inputs and outputs on the VP1006 are

controlled. See manual with the relevant settings to configure the software for this VP1006.

When the software setup is done the VP1006 is ready for use.

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 7

Page 12

6 Advanced

Tests and adjustments described in this chapter are not used for a standard startup and configuration

of the VP1006.

6.1 Testing inputs and outputs

There are two types of output tests. An output test to switch the output on and off, and an output test

especially for Nedap feed motors. There is also available an input test for checking connected

equipment like switches and sensors.

Use the display and push button for testing, see appendix B how to use it.

Feed motor test

Use the motor test o1, o2, o3 or o4 to test a feed motor.

This is a combination of an input and output test. When the test is finished the test results are shown

as code on the display (blinking). Test all outputs ”0A” will test all outputs one by one.

Code on the display

Description motor test results

00

Motor run ok

01

Output already in use

02

No motor current measured

03

No input signal seen

04

-

05

-

06

Motor current too high for too long

07

-

08

Current still measured after test has stopped

09

Output voltage is stopped due to motor safeguard function

10

Output already in use

11

-

12

Motor current too low while running

Example of a feed motor test (connected to output 1)

1. Short press on the button until “It” appears.

2. Now hold the button until the display starts blinking. “dE” will appear.

3. Short press on the button 2 times. “o1” will appear.

4. Now hold the button until the display starts blinking. Output 1 will be switched on. When ready

the test result are shown on the display.

Output test

Use the test L1, L2, .. L6 to test the connected equipment e.g. lights, valves or relays. This test will

switch on the selected output. The test is stopped by a short press on the button.

Example of a light test (connected to output 6)

1. Short press on the button until “It” appears.

2. Now hold the button until the display starts blinking. “dE” will appear.

3. Short press on the button until “L6” appears.

4. Now hold the button until the display starts blinking. Output 6 will be switched on. To switch off,

a short press on the button.

Input test

Use the test i1, i2, .. i6 to test the connected equipment e.g. switches and sensors. This test will read

the selected input. The results are indicated with a “0” or “1”. Open or closed depends on the settings

from the behavior component. The test is stopped by a short press on the button.

Example of a switch test (connected to output 5)

1. Short press on the button until “It” appears.

2. Now hold the button till the display starts blinking. “dE” will appear.

3. Short press on the button until “i5” appears.

4. Now hold the button until the display starts blinking. Input 5 will be read.

5. Activate the switch on and off. If ok, the display value will show zero and one

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 8

Page 13

6.2 Advanced antenna adjustment

Antenna power

The antenna power default is set to maximum (99) and needs no adjustments.

Lowering the antenna power will reduce the reading distance of the antenna.

Check the antenna power

The antenna power level is shown on the display in the service menu at HF option AP (Adjust Power)

1. Select menu option AP (Adjust Power) on the display by using the push button

2. Push the button until the display starts to blink, a value will appear on the display

3. The value on the display is the actual power setting. 99 is the default factory setting.

4. To leave the menu without modifying the settings press the button until the display goes blank

(press about 4 seconds)

Modify the antenna power

1. Select the actual antenna power on the display (see above antenna power check)

2. Short press on the button and the first digit of the value will change

3. Continue to press until the desired value, then hold the button until blinking

4. The second digit can be changed in the same way

5. When the desired value is on the display, press until the display blinks

6. The next menu item AS is now indicated.

7. To leave the service menu and return to normal operation, press the button until the display

goes blank (press about 4 seconds)

Antenna squelch

Antenna squelch is a possibility to set a threshold for the ID level of a tag. It means the antenna power

is still the same, but the software will not transfer weak received tag numbers.

The antenna squelch default is set to minimum (-0). This means no threshold. Maximum is -9.

Check the antenna squelch level

The antenna squelch level is shown on the display in the service menu at HF, option AS (Adjust

Squelch)

1. Select menu option AS (Adjust Squelch) on the display by using the push button

2. Push the button until the display starts to blink, a value will appear on the display

3. The value on the display is the actual setting. -0 is the default factory setting.

4. To leave the menu without modifying the settings press the button until the display goes blank

(press about 4 seconds)

Modify the antenna squelch level

1. Select the actual antenna squelch level on the display (see above squelch level check)

2. Short press on the button and the value will change

3. Continue to press until the desired value, then hold the button until blinking

4. The next menu item “df” is now indicated.

5. Hold a tag in the antenna and determine the maximum reading distance

6. If reading distance is ok leave the menu. If not ok try another level.

7. To leave the service menu and return to normal operation, press the button until the display

goes blank (press about 4 seconds)

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 9

Page 14

Antenna tuning with option “AA”

With HF menu option “Adjust Antenna (AA)”, it is possible to see the antenna tuning on the display.

The highest display value is the optimum adjustment.

How to tune

1. Select option “AA” on the display and press the button until the display starts to blink. A value

will now appear on the display.

2. Now turn the antenna trimmer slowly (on the antenna). The display value will change. If the

value is going down, turn the other way. Turn till the maximum display value is found.

Neutrodynisation between two antennas

Two large antennas can have coupling with antenna fields. Result : tag is identified in both antennas. A

solution is to install a neutrodynisation unit to reduce cross talk caused by antenna coupling.

How to tune

1. Set reader A in neutro transmit mode (HF menu option nc - nt).

2. Set reader B in neutro receive mode

(HF menu option nc - nr)

3. Turn the wheels apart to the highest display value at reader B

The display value and wheel distance apart can vary. Low display value means usually low coupling.

Always use a sync cable between the readers. It is used during normal operation and also used for the

tuning to switch of transmitter of the receive unit. If one unit is set to neutro transmit, it will switch off all

other readers connected to the same sync cable.

Antenna tuning visible by a light

With HF menu option “Adjust Antenna (AA)” output 6 is also switched on. By connecting a light to

output 6 the status during tuning can be monitored. When the light is blinking it is indicating the

optimum adjustment point and is corresponding with the highest display value.

6.3 Identification test options

Identification test with option “id”

When a tag is in the antenna field, the green LED used for the antenna tuning will be blinking. There is

also a test in the internal test menu called “id”. This test will also show the green LED blinking but also

shows the last two digits of the tag number on the display.

Signal level indication option “SF” and “SH”

There is a test available to give an indication about the signal received on the reader of the VP1006.

This test is separated in a FDX (SF) and HDX (SH) noise indication test. This test is mainly used for

HDX because at HDX there is a greater risk of external influence on the antenna field.

How to use the signal level test

1. Select option “SH” on the display and press the button until the display starts to blink. A value

will appear on the display.

2. Now move a HDX tag slowly into the antenna field. The display value will normally increase

when getting closer to the antenna. If there is negligible or little increase in display value this is

an indication something external is causing noise.

The possible cause of noise can be frequency controlled electric motors or a transmitter operating on

or close to 134.2 kHz

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 10

Page 15

Errors / malfunctioning is indicated by the indicator LED’s or the display.

Error by indicator LED

Indicator LED’s are normally green or switched off. A red or orange indicator LED means normally

there is something not ok. See Appendix D for the explanation of the different colors.

Errors indicated at menu option “dE”

In menu option “dE” it is possible to see actual error codes. When entering the display menu option

“dE” the errors code will be shown and the error will be cleared. If the error is not cleared it means

there is still an error. There can be more than one error. Further errors are displayed one after another

with a short delay between each code.

“dE” code on the display

Description

00

No errors

01

Max time for motor exceeded

02

Max motor current error

03

-

04

-

05

Outputs switched off due to high motor current

06

Software switched off due to current and time

07

Output switched off due to current, time and also output active

08

Input of motor output seen X times while motor is not active

09

Motor 1 error

10

Motor 2 error 11

Motor 3 error 12

Motor 4 error

13

Vout overload

14

Output 5 shut off due to overload

15

Output 6 shut off due to overload

16

Software switched off due to max current and time

17

CAN–bus over voltage

18

Voltage to next module switched off

Identification performance and disturbance

Identification performance can be reduced by disturbance caused by variable-frequency drives used

for ventilation, milk pumps, vacuum pumps, etc. Also ballasts used for fluorescent tube lighting may

interfere. If there is interference one can locate the source by switching off all the equipment on a farm

and then switch them on again one by one. Most of the time when a variable-frequency drive is

causing a problem it is due to bad installation or without the mandatory main filters.

Maintenance

No regular maintenance required.

Software update

A VP1006 is equipped with software to activate inputs and outputs, display / push button and a motor

safeguard. This software is called firmware. During manufacturing the firmware is programmed and

ready for use. In case of an update it is possible to download new firmware thru the CAN-bus. In the

Velos system the web browser interface of the VPU (VP8001) is used to handle this. For more details

about downloading new firmware see also the manual of the VPU (VP8001).

Cleaning

A VP1006 must be installed in a suitable housing (V-box) so cleaning of the VP1006 is not required.

Disposal

Discard according to the regulations prevailing at the time of disposal

7 Trouble shooting

8 Maintenance, cleaning and disposal

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 11

Page 16

Appendix A: Specifications / CE

Specifications VP 1006

Dimensions

143 x 120 x 68 mm LxWxH (excluding mounting rail) Weight: ± 360 gr

CAN

CAN-bus communication 125 kBit

Power

Input voltage 25 VDC, +20% -20%

Min power consumption 300 mA with antenna switched on

Maximum power consumption 2,5 A

Protected against reverse connection power supply

Software

Downloadable by the CAN network

Inputs

Reading inputs, analog (0-40V) and digital. Suitable for NPN and PNP sensors.

Outputs

Max. 2.5 Amp by current limiter, short-circuiting protected Motor safe-guard (after 25

sec)

Antennas

800 µH. Different types possible.

Detection distance

Varies per antenna

Synchronisation

Synchronisation according to ISO 11785

Environment

Temperature: Operating: -10 – 50 °C, Storage: -25 – 70 °C

Relative humidity: 10 – 93% non condensing

Maximum noise level: 10 dBµA/m quasi peak, according CISPR 16-1-1

Conducted noise: according EN55022

IP class

IP 30. When installed in V-box IP 65 (cover and cables installed correctly !)

Always use a NEDAP power supply. The Nedap guarantee-regulations are only valid when is installed as

indicated in this manual. Install data cables at a safe distance from (high) powered cables

For more detailed information contact your local Nedap supplier or check the internet site.

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 12

Page 17

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 13

Page 18

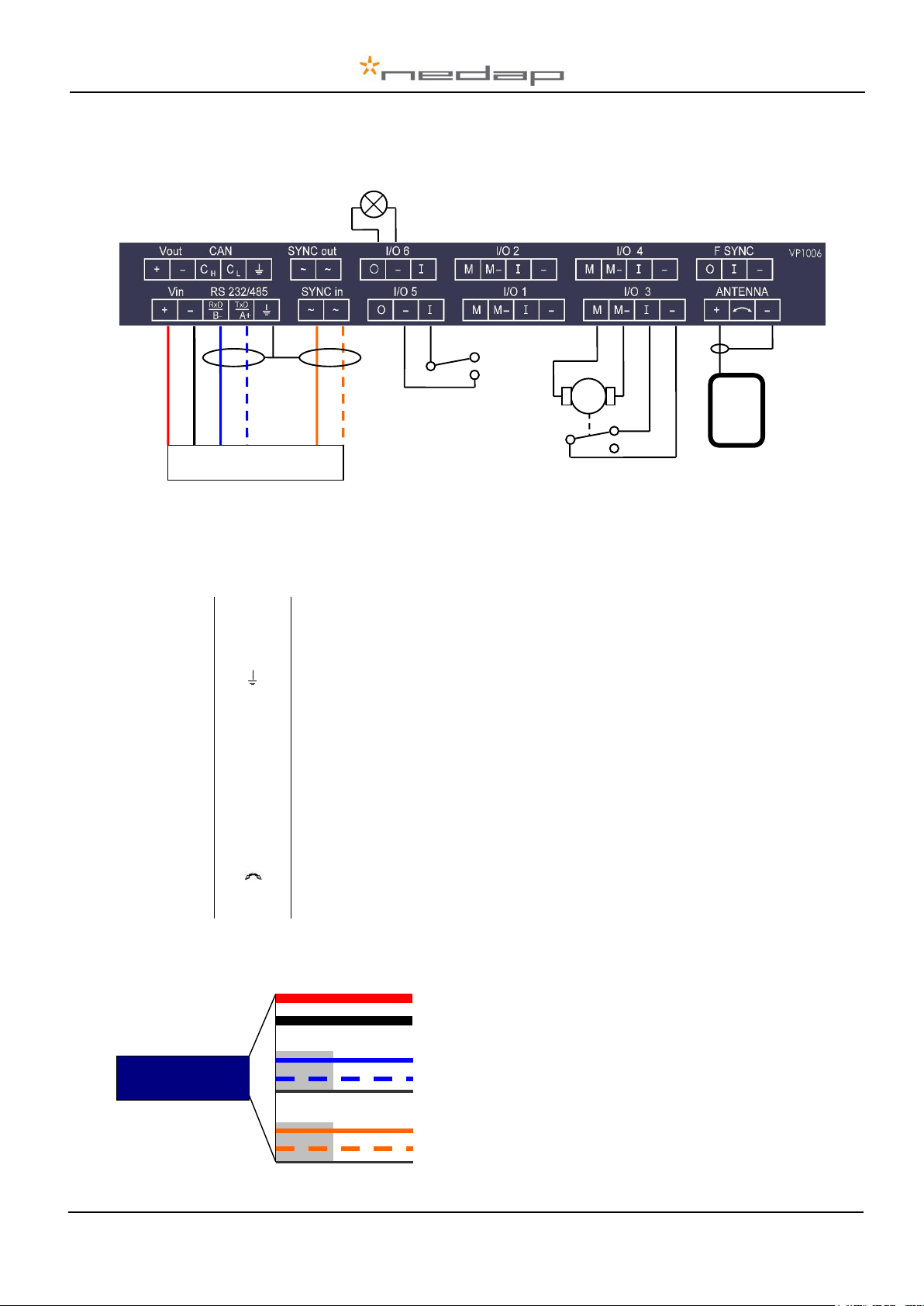

Appendix B: Display and push button

DISPLAY ADDRESS

Shows the actual address

SET ADDRESS

Change the address

ADJUST ANTENNA

ANTENNA POWER

Press button until blinking

Short press on button

To leave menu:

Press button until display goes blank

How to use the display and push button

Normally the display is off. If there is no connection to the VPU the address is shown. It is also possible

some program states of a behavior component are shown during operation.

Activate the menu short press on the button, the display menu is shown

Scroll down short press on the button

Select press button until blinking

Change and store select item to change, open item by pressing button until blinking, change by

short press on button, store by pressing button until blinking

Check a setting select the item to check, press button until blinking, first value shown is actual

setting

The display is normally automatically switched off after 30 minutes.

Display Push button

Figure: a section of a display menu

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 14

Page 19

Appendix C: Overview display menu

DISPLAY ADDRESS

Shows the actual address

SET ADDRESS

Change the address

ADJUST ANTENNA

Antenna tuning will be shown by output 6 (lamp)

ANTENNA POWER

Min/max 10 / 99. Normally set to 99. Possible to set a lower value.

ANTENNA SENSITIVITY SQUELCH

Min/max 9 / 0. Normally set to 0. Possible to set a lower value.

Neutrodynisation adjustment

Nt = Neutro transmit Nr = neutro receive

DISPLAY ERROR – CLEAR ERROR

Shows error code and error clearing after showing.

TEST ALL OUTPUTS

All outputs are switched on one by one. Test results are shown on the display

TEST MOTOR OUTPUT

o1 … o4

TEST OUTPUT

L1 … L6

TEST INPUT

I1 … i6

SIGNAL LEVEL FDX

Shows signal level measured by the FDX receiver

SIGNAL LEVEL HDX

Shows signal level measured by the HDX receiver

TEST IDENTIFICATION

Shows last 2 digits of a tag number

COMMUNICATION CHANNEL

Enter a number to set the right settings (see table next page)

COMMUNICATION PROTOCOL

Enter a number to set the right settings (see table next page)

Press button until blinking

Short press on button

To leave menu:

Press button until display goes blank

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 15

Page 20

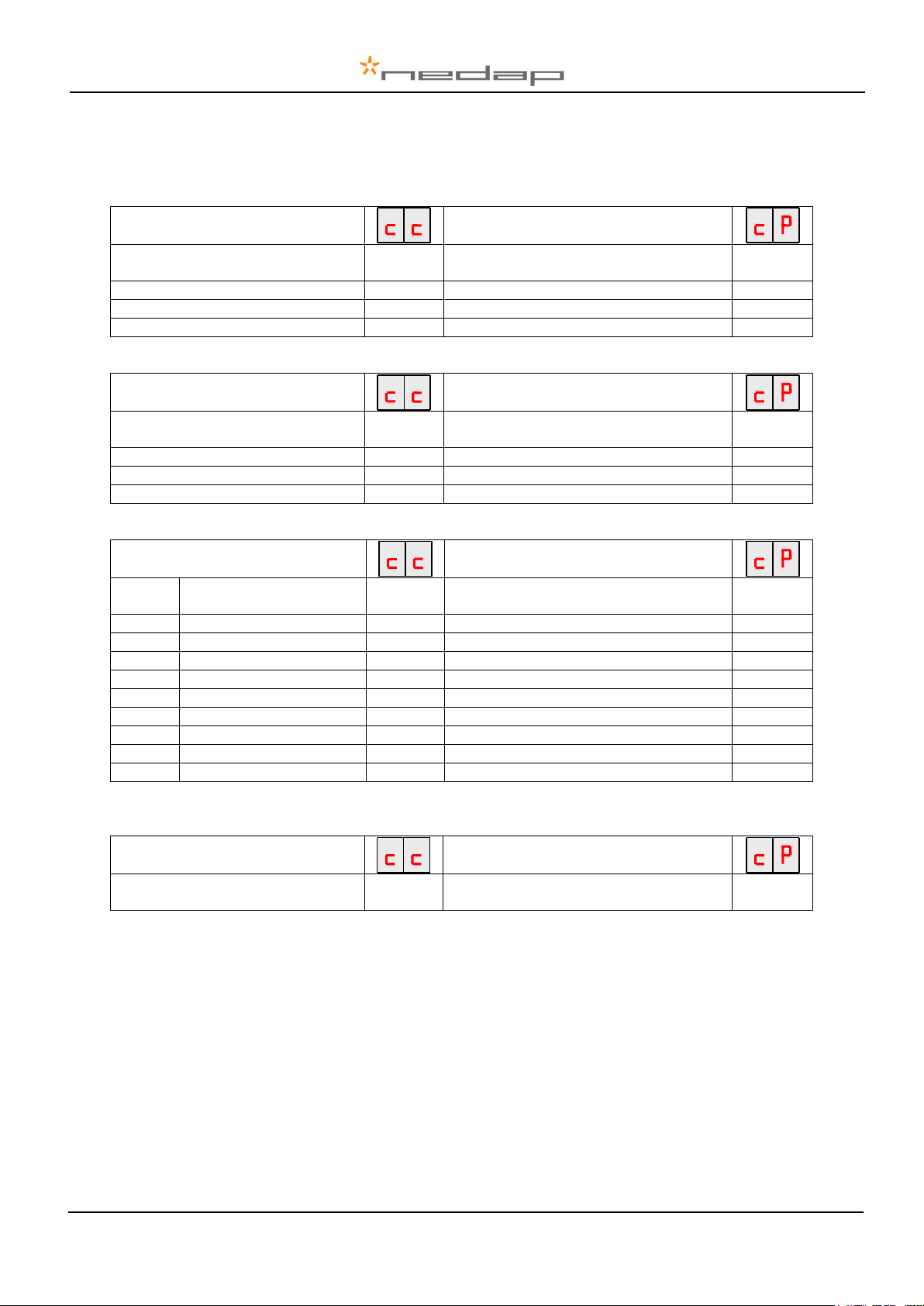

CP-menu communication possibilities

RS232 20

Nedap extended protocol 2400 Baud

21

Nedap extended protocol 9600 Baud

22

Nedap extended protocol 19200 Baud

23

Nedap extended protocol 38400 Baud

24

RS232 20

ISO protocol 2400 Baud

31

ISO protocol 9600 Baud

32

ISO protocol 19200 Baud

33

ISO protocol 38400 Baud

34

RS485

Bias off - no. of breaks 0

40

Nedap extended protocol 2400 Baud

21

RS485

Bias on - no. of breaks 0

41

Nedap extended protocol 9600 Baud

22

RS485

Bias off - no. of breaks 2

42

Nedap extended protocol 19200 Baud

23

RS485

Bias on - no. of breaks 2

43

Nedap extended protocol 38400 Baud

24

RS485

Bias off - no. of breaks 4

44

RS485

Bias on - no. of breaks 4

45

RS485

Bias off - no. of breaks 6

46

RS485

Bias on - no. of breaks 6

47

RS485

Bias off - no. of breaks 8

48

RS485

Bias on - no. of breaks 8

49

RS232 20

Texas Instruments protocol

10

RS232 with Nedap extended protocol

ISO

RS485 with Nedap extened protocol

RS232 with Texas Instruments protocol*

*Serie 2000 reader systems ASCII protocol, 9600 baud, 8 databits, no parity, 1 stopbit

Default factory settings: RS232, nedap extended protocol 9600 baud (CC=20 and CP=22)

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 16

Page 21

Appendix D: LED indicator overview

POWER

Green on

Power on

off

No power

STATUS

Blue

Slow blinking

Fast blinking

1 short flash

2 short flashes

3 short flashes

Operating ok

Downloading or error during download

V-pack not coupled

Firmware present but not active

No firmware present

Display

on

Address indicated

No communication

off Communication status ok

V in

Green on

Input power applied

off

No power

Orange

Low power, less than 20V

Orange blinking

Wrong CAN-bus connection, Vin and Vout swapped

Red

Error, plus and minus swapped

V out

Green on

Output power

off

No power

Orange blinking

Low power

Red blinking

Error, plus and minus swapped

COM

Green on

V-pack is last one on the bus

off

V-pack is not last one on the bus

Orange blinking

CAN-bus error and last V-pack on the bus

Red

CAN-bus error

Red blinking

CAN-bus warning / connected wrong

+24V

Green on

24V output switched on

off

Output switched off

M1 .. M4

Green on

Output on

off

Output off

Red blinking

Output error

I1 .. I4

Green on

Input contact open

off

Input contact closed

TUNING /ID

Green on

Green blinking

Antenna ok

Antenna ok and tag identified

Red on

Antenna not tuned correctly

Red on

Antenna not tuned correctly

Red blinking

Antenna error / not connected

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 17

Page 22

Appendix E: RS485 connections with separated wiring

VP1006 (1)

RS485 cable

A

B

(2)

(n)

orange

orange/white

shield

orange

orange/white

orange

orange/white

shield

orange

orange/white

To RS485

of computer

Last VP1006 : Jumper

up !!

RS485 cable specifications

(PC to first VP1006)

:

32 (incl computer)

Velos cable

Power

Shield not connected

Shield not connected

to last VP1006

Max. number of VP1006

twisted pair shielded

2

Wires : min. 0.34 mm

Max length between PC and last VP1006 1200m

interface

80 meter from power supply

gth Velos cable

Velos cable Max len

-

)

Supply

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 18

VP2002

(VP2001

Page 23

Appendix F: RS485 connections with Nedap Velos cable

IMPORTANT : avoid short circuit of shields, install protection around the end of the shields.

orange

orange/white

orange

orange/white

orange

orange/white

blue

blue/white

shield

orange

orange/white

B

A

To RS485

shield

B

A

shield

shield

B

A

RS485 cable specifications

(PC to first VP1006)

:

32 (incl computer)

Velos cable

Last VP1006 : Jumper

up !!

Power

Supply

(VP2001

-

VP2002

)

twisted pair shielded

80 meter from power supply

2

e

gth Velos cable

Wires : min. 0.34 mm

Max length between PC and last VP1006 1200m

Velos cabl

Max len

to last VP1006

Max. number of VP1006

interface

of computer

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 19

Page 24

Appendix G: RS232 connections

RS 232 port of

computer

RxD pin2 GND pin5

RS232 cable specifications :

Shielded cable

Wires min. 0.34 mm2

Max length between PC and VP1006 15 meters

Power supply

Communication jumper

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 20

Page 25

Appendix H: VP1006 connected to a Velos VP8001 (VPU)

VP8001

(V-pu)

VP1006

VP1006

VP1006

next

next

orange

orange/white

orange

orange/white

orange

orange/white

orange

orange/white

orange

orange/white

orange

orange/white

CAN channel 2

CAN channel 1

orange

orange/white

orange

orange/white

Power

supply

(VP2

001)

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 21

Page 26

Appendix I: Neutrodynisation unit between two antennas

Two large antennas can have coupling with antenna fields. Result : tag is identified in both antennas. A

solution is to install a neutrodynisation unit.

Required equipment:

- Readers with the option Neutro in the HF menu

- A neutrodynisation unit

- Coax cable, specification RG58

- Cable between the readers to connect SYNC OUT and SYNC IN

shield

core

shield

core

READER A

READER B

Display value

(0- 99)

Turn to max display value

Neutrodynisation adjustment

1. Set reader A in neutro transmit mode

(HF menu option nc - nt)

2. Set reader B in neutro receive mode

(HF menu option nc - nr)

3. Turn the wheels apart to the highest

display value at reader B

The display value and wheel distance

apart can vary. Low display value means

usually low coupling.

COAX RG58 COAX RG58

COAX RG58

COAX RG58

Neutrodynisation unit

VP1006-200PM-00 OEM ISO Reader Manual version 2.6 / Page 22

Page 27

Loading...

Loading...