Page 1

Hardware components for VC4/VC5

Twin Feeder 2

SEPARATION

SEPARATION/WEIGHING

CPT4SBS

CONTENTS page

1 General 2

2 Operation 2

3 Installation 3

4 Set address 4

5 Adjust antenna with EWA transformer 7

6 Airflow Installation 8

7 Adjustment weigh computer 9

8 Display values 11

9 Internal test menu 12

10 Software settings 14

11 Trouble shooting 15

12 Spare part list 16

Enclosure : Figures 17

4 - 2012 Nedap Agri

D300X.eng version 0.8

Page 2

________________________________________________________________________

This documentation is part of the service manual VC4 CattleCode D300.

Documentation version 0.2, first edition.

Documentation version 0.3, weighing added

Documentation version 0.4, Eprom version 0.13 added

Documentation version 0.5, Welvaarts weighbridge added

Documentation version 0.6, Eprom version 4.00 added

Documentation version 0.7, Figure 2 : sensors connected to M+ instead of +23V

Documentation version 0.8, FCC text added

PROM overview CPT4SBS

1-2006

TwinFeeder

CPT4SBS 0.10 First field version

CPT4SBS 0.11 Weighing option added

CPT4SBS 0.12 Internal test menu : ROM/RAM test was not displayed

CPT4SBS 0.13 Identification : responder valid time shorter

CPT4SBS 4.00 - Suitable for TF model 2 and 4

- 2 hour activity added (Lacitvator, VC5 only)

FCC ID: CGD-TF2

IC: 1444A-TF2

Compliance statements (Part 15.19)

This device complies with Part 15 of the FCC Rules and to RSS210 of Industry Canada.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

Cet appareil se conforme aux normes RSS210 exemptés de license du Industry Canada. L'opération est

soumis aux deux conditions suivantes:

(1) cet appareil ne doit causer aucune interférence, et

(2) cet appareil doit accepter n'importe quelle interférence, y inclus interférence qui peut causer une

opération non pas voulu de cet appareil.

Warning (Part 15.21)

Changes or modifications not expressly approved by party responsible for compliance could void the user’s

authority to operate the equipment.

This in particular is applicable for the antenna which can be delivered with this System.

______________________________________________________________________________________________

D300X T/R Twin Separation - 1 - Version 0.8

Page 3

________________________________________________________________________

______________________________________________________________________________________________

D300X T/R Twin Separation - 2 - Version 0.8

Page 4

________________________________________________________________________

The name

of the EPROM is CPT4SBS x.xx.

Operation sequence

Operation sequence cow with no respon

der

1 General

This document contains the description of the software CPT4SBS in combination with

the T/R-Twin hardware for a separationbox.

The Transmitter/Receiver Separation Box Standard is used for identifying, separating

or separating/weighing of cows. The separation system uses one antenna.

CPT4SBS

Poiesz Twin VC4 Separation Box Standard.

Description of the code : Cattlecode

2 Operation

• Every cow is stopped at the hold-gate

• After identification of the responder the T/R sends a request for separation-data

• If weigh computer is connected, wait for weigh data

• When weigh data is received and separation data is received the separation gates

are set, the hold gate will open

• After hold gate is open the twin is waiting for IR2 (only if responder is out of the

antenna)

• As long as IR2 is activated the hold gate will not close

• When IR2 is free the hold gate will close

• When IR2 is free, IR3 is already activated

• Station is ready for the next cow as soon as IR3 is free

• Cow is stopped at the hold-gate

• IR1 is activated, twin remains waiting for responder number

• After maximum ID time the cow will be sent to the default exit

______________________________________________________________________________________________

D300X T/R Twin Separation - 3 - Version 0.8

Page 5

________________________________________________________________________

- never change a PROM when the power to the T/R is still switched on !

Antenna construction

Jumper settings

Wiri

ng the T/R

Max. cable

-

lengths, wire

-

ø's and cable colours

cable

colour

1.5 x

2.0 x

Shielding, grounding

Transmitter / Receiver

Warnings

3 Installation

The Nedap guarantee-regulations are only valid when the T/R is mounted and

installed as indicated in this chapter. The following is important :

The antenna must be installed around the station (see figure 5). When the HF-field is

To install the T/R Twin correct, some jumper settings must be checked or changed.

Figure 2 shows an overview of the T/R-Twin cable-connections.

The cable-overviews in the figures all

show Lmax. at wire-ø = 0.8 mm.

C white

The values for Lmax at ø=1.0 and ø=1.2 : D yellow

In order to protect the VC-System for over-voltages, due to severe thunderstorms,

N.B. All T/R electronics must be isolated from the parlour. This implicates that also

• Due to guarantee-regulations, the entire T/R PCB (incl. metal plate) must be

• operating temperatures -10ºC .... +40ºC

• storage temperatures -25ºC .... +70ºC

• tightness IP 65, cover and cables mounted correctly

• input voltage 28 VDC +10% / - 20%, power supply at least 40 W (continuous)

• abs. max. voltage (+/-) 40 V DC, 35 V RMS, protected against reverse polarity

- shut off the power when service is needed for the station !

adjusted correctly, the cows inside the station must be identified easily when they

are walking through the station.

Jumper J7 must be set to the left (LED is ON)

Jumpers J1 – J6 must be set to the right (brake off)

Antenna jumpers must be set to the lowest position (external adjust)

Cable C = coax, in this case it is important the shielding is connected to HF-

Lmax.(ø=1.0) =

Lmax.(ø=1.2) =

cable A in figure 2 must be a shielded cable. The cable-shield however may not

used as a wire for current-supply. The cable-shield of cable A is as follows :

the T/R bottom has to be isolated from the T/R ground-terminal.

changed.

• For continued protection against fire, always replace with same type and rating of

fuse.

Lmax.(ø=0.8)

Lmax.(ø=0.8)

- black

+ red

connected to ground-terminal

be

______________________________________________________________________________________________

D300X T/R Twin Separation - 4 - Version 0.8

Page 6

________________________________________________________________________

•

N.B.

Changing addresses

set decimal

-

digit

0

-

5

-

set unit

-

digit

•

The following points should be noted

•

Show addresses

4 Set Address

The address setting concerns the following menus and procedures (see figure 3):

For communication the Transmitter / Receiver needs an address. Then the computer

knows where to send the information to. At the transmitter / receiver with help of the

display and the push button the stations address is configured.

The two segment display and the yellow push-button must also be used for several

adjustments of the Transmitter / receiver. A number of different codes will appear on

the display when the push-button is pushed, these codes represent the so-called

menus. Each menu on its turn is divided into a number of functions. By varying the

pushing time of the push-button, you will get access to the different menus and/or

functions.

The first time you switch on the power of the T/R, the display will show "0-". The

Transmitter / Receiver asks now for the first address. When an address is entered the

display will blank out and the transmitter / receiver returns to the normal status.

Address menu

- Set Address

- display Address

The address-range of all connected peripherals on the same controller channel

is from 1-50.

Remember that the used peripheral-address has to be unique on this controller

channel.

When the display shows SA, the "Set Address procedure" is entered by pressing the

button until the display blinks. The procedure is as follows :

display scrolls from

display scrolls from x0 through x9

to indicate that the "Set Address procedure" has been entered, the display will

show "0-"

• by pressing the button short, the next decimal will be displayed ("1-","2-"...."5-")

• the displayed decimal is entered by pressing the button until the display blinks

• when the decimal has been entered, the display will show "x0" (where x = entered

decimal), the unit-digit now can be entered

• by pressing the button short, the next unit will be displayed ("x1", "x2", .. , "x9")

• the displayed unit is entered by pressing the button until the display blinks

the "Set Address procedure" can be quit by pressing the button until the

display blanks. The entered digits then are not stored

• the T/R will restart when the address is changed

When the display shows dA, the "display Address procedure" is entered by pressing

the button until the display blinks. The display then shows the T/R address.

through

______________________________________________________________________________________________

D300X T/R Twin Separation - 5 - Version 0.8

Page 7

________________________________________________________________________

Jumper settings on the transmitter / receiver

Responder Select

Adjust antenna

5 Adjust antenna with EWA transformer

The antenna adjustment has to be done with help of the display, push button, P1 on the

T/R and the antenna transformer settings. Below you find the HF-menu, see also figure

3.

When using an EWA antenna transformer jumpers J11 and J12 should be set to

position B

HF menu

• selection of responder type

• adjust antenna by means of tuning capacitor Ct

• adjust transmitter-power by means of potentio meter P1

• adjust receiver-sensitivity (0,1,2,3)

• adjust neutrodynisation

• Test identification

⇒⇒⇒⇒

⇒⇒⇒⇒

Responder Select

Adjust Antenna

Adjust Power

Adjust Squelch

Adjust Neutro

Identification

The antenna adjustment-procedure consists of several steps. It is essential that

these steps are executed in the sequence as in the manual described.

During T/R start up there is auto detect of T/R type, 120kHz (for rA and rP) or 134.2

kHz (for ri and r2)

rA = AM labels, X-ponder and Respactor (default)

rP = PM labels, ear button and Phase code responders

ri = ISO responder types (default)

r2 = Nedap 2 hour activity meter (Lactivator)

Select rS on the display and select the required type, press until display blinks to

store the setting.

HF menu, select H1 for antenna 1 or H2 for antenna 2

The antenna adjustment-procedure consists of several steps. It is essential that these

steps are executed in the sequence as described. First "AA", then "AP" and last "AS",

described in step 1, 2, 3 and 4.

While tuning Lt the following must be noted

• The tuning of Lt must be done with a non-metal screw-driver (e.g. plastic)

• This tuning of Lt requires a short circuit of the "Antenna adjust input" on the T/R,

see jumper settings.

• It is possible that the trimmer-coil must be turned so far out of the coil housing that

the transformer box does not close anymore. In that case, turn the trimmer-coil

completely in the coil housing. In this way the same adjustment can be achieved.

______________________________________________________________________________________________

D300X T/R Twin Separation - 6 - Version 0.8

Page 8

________________________________________________________________________

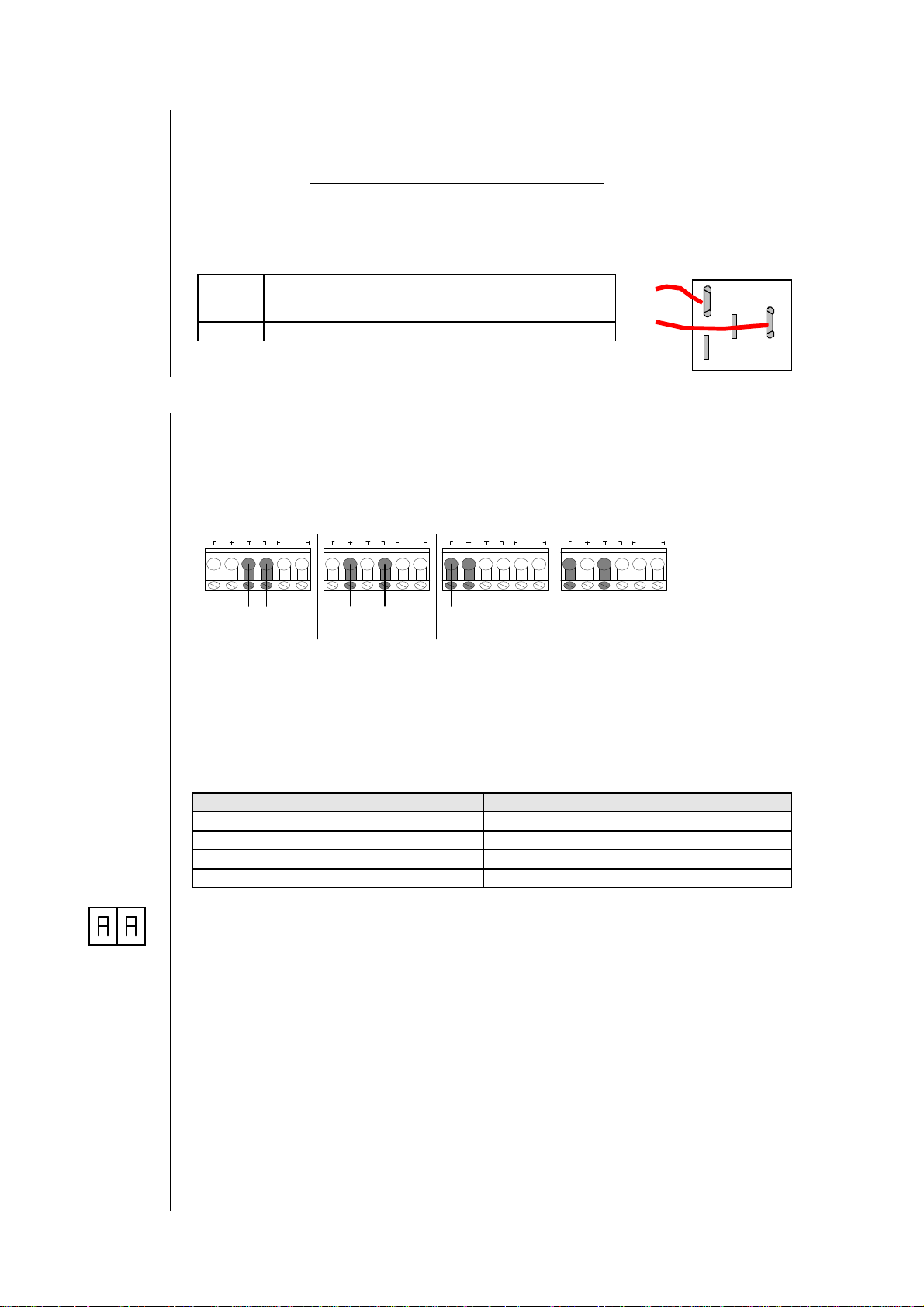

Step 1

Jumper setting on Antenna

-

Transformer

•

NR. Combination

Antenna length

2 A0 B2

4.2 –

6.6 meters

Step 2

Transformer

-

ratio on the Antenna

-

Transformer and Lt adjustment

•

4,8 -

6,6 m

11 : 1

•

•

B

measure the circumference of the antenna-loop

• set jumpers to combination as described in table on Antenna-Transformer PCB,

note that the highest possible number should be chosen

e.g. Antenna circumference = 6 meters.

According to the table on the Antenna-Transformer PCB, 2 combinations are

possible :

.

1 A0 B0 5.8 - 8.2 meters

In this example, the jumpers should be set to combination

2. (2 is highest number and shortest length)

A

0

1

0

2

The transformer-ratio determines the HF-current through the loop-antenna, which

determines the power of the HF-field. In principle the highest transformation-ratio

should be selected. This however can be limited by the fact that the antenna-circuit

then can not be brought in resonance anymore (= highest value on the display).

13 2 9 neutro

Z/O M (HF+/-)

9 : 1

13 2 9 neutro

Z/O M (HF+/-)

11 : 1

13 2 9 neutro

Z/O M (HF+/-)

13 : 1

13 2 9 neutro

Z/O M (HF+/-)

15 : 1

Figuur :

Transformatieverhouding

aansluitingen

The following has to be done

turn the trimmer coil (Lt) completely in the coil housing.

• connect HF-output of T/R (HF +/-) to input of ANT-T with the transformation-ratio

according to the table below for rough adjustment.

Note : The length of the example is about 6 m

Length of Antenna Transformer ratio

till 3,5 m 15 : 1

3,6 - 4,7 m 13 : 1

6,7 or larger 9 : 1

select AA (Adjust Antenna see figure 2) on the display, then push the button until

the display starts to blink.

• with P1 (figure 1) the displayed value must be set to 30

• after adjusting P1, the value must be adjusted with Lt (figure 1) on the EWA

transformer to a maximum value. Tune (with plastic screw driver) the trimmer Lt

on the antenna transformer until the highest point has been found (is highest

display value, this means when you are turning further in the same direction the

display value must go down after the highest level has been found, if not select a

different transformer ratio.)

• connect HF-output to the next transformer-ratio 9 : 1, or 11 : 1 (do not change HF+

and HF-), try if a higher value on the display can be found by tuning Lt.

connect HF-output to the highest transformation-ratio (with the highest value on

the display) where it is still possible to find the highest point, this is the right

adjustment.

• When the right transformation ratio has been found Lt must be tuned to the

maximum

______________________________________________________________________________________________

D300X T/R Twin Separation - 7 - Version 0.8

Page 9

________________________________________________________________________

step 3

Adjust power

set power

-

level

step 4

Adjust squelch procedure

Normally squelch does not have to be adjusted (default is automa

tically set

Advised and Default Squelch settings CPT4SBS

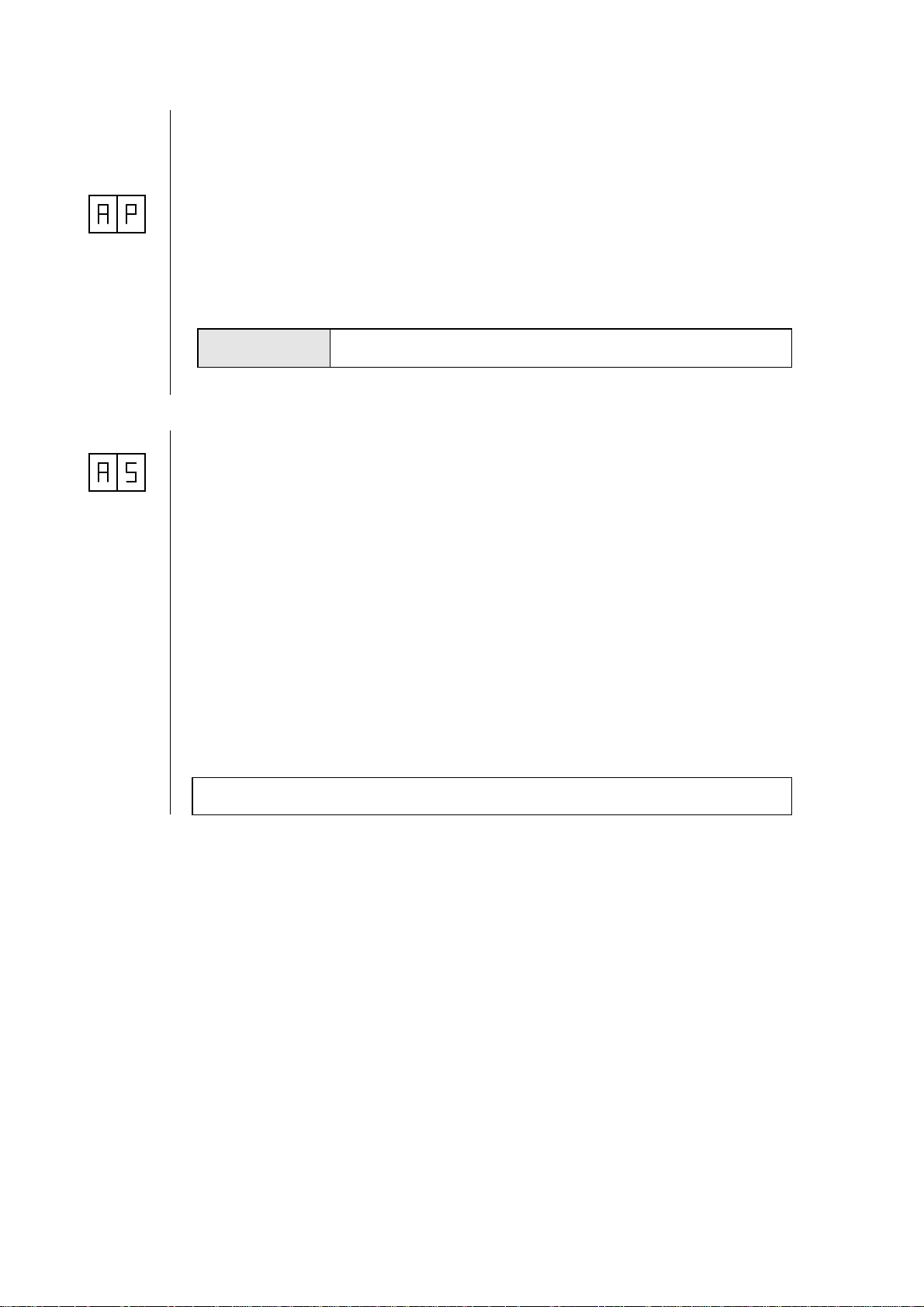

After correct processing the antenna adjustment procedure, step 1 and 2 are done

and Lt is adjusted (highest value is on the display now ), P1 must be adjusted with

help of AP.

When the display shows AP, the "Adjust Power procedure" is entered by pressing the

button until the display blinks. The display now shows the percentage of the

maximum transmitting-power of the T/R. The T/R is equipped with a power-limitter.

When the transmitted HF-power exceeds a certain level, the HF-current will be limited

automatically. To indicate this, the display will blink, after this point power-increase

(P1) is not desirable.

The tuning-procedure is as follows :

You can continue by pressing the button short

The adjusted squelch determines the sensitivity of the receiver in the T/R. In case

Twin Feeder Model 1 Squelch = 0

Twin Feeder Model 2 AM CODE Squelch = -2

Twin Feeder Model 2 PM CODE Squelch = -1

Note : AS can be used to reduce the HF-field if animals are identified outside the

e.g. calves outside the station are identified, the transmitted power can be reduced

("Adjust Power procedure") or the receiver-sensitivity can be reduced by means of the

squelch-adjustment.

When the display shows AS, the "Adjust Squelch procedure" is entered by pressing

the button until the display blinks. The display now shows the actual sensitivity of the

receiver, a value from "-0" (most sensitive, i.e. default setting) until "-3" (least

sensitive).

By shortly pressing the button, the desired squelch can be adjusted. The setting can

be entered by pressing the button until the display blinks.

station, check if the identification is still sufficient

tune P1 maximal until just before the point where the display

starts to blink

______________________________________________________________________________________________

D300X T/R Twin Separation - 8 - Version 0.8

Page 10

________________________________________________________________________

6 Airflow Installation

• The main pressure has to be 85 P.S.I. (6 bar) With this pressure the main

cylinders are controlled. The speed of the out going cylinders is controlled by the

regulator at the point R and the speed in going cylinders by regulator at point S on

the control plate.

M+ Mx

R

A

P

AIR

S

B

______________________________________________________________________________________________

D300X T/R Twin Separation - 9 - Version 0.8

Page 11

________________________________________________________________________

Calibration mode

7 Adjustment weigh computer

This weigh computer can automatically weigh animals. The weight is sent to the Twin

T/R and then transferred to the VC computer.

The weigh computer has 3 modes, namely:

• weighing mode

• calibration mode

• setting mode

Figure 3 :

Weigh computer

connections

Charge

TYPE W-2000

GROSS

NET

kg

TOTAL

GROSS/NET

TARE/ZERO

Weigh computer

ON/OFF

TWIN Transmitter / Receiver

-

Pen 2

Rx

Pen 3

not usedTx

+

Pen 1

Weigh platform

Horizontal floor level

TOTAL

PRINT

Weighing mode

When the weigh computer is switched on, the computer will automatically go over to

the weighing mode. The computer is now ready for normal use.

The calibration mode is selected to adapt the computer to the weighing platform or to

calibrate the computer. This is done as follows: Switch the computer on and hold

down the "TOTAL" key. After a standard text message, the computer gives a bleep

signal. You will now see the word "POS --" on the screen. Now release the "TOTAL"

key and press any key you like.

Set the computer to gross by pressing the "GROSS/NETT" key. The scale zero can

now be set. To do this, open up the weigh computer. Two potentio meters which have

to be calibrated are located on the PCB in the housing cover. The left hand potentio

meter is used to set the zero weight and the right hand potentio meter is used to set

the correct weight. Use the left hand potentio meter, set the computer to zero. If you

want to reduce the value, turn clockwise and if you want to increase it, turn in the

opposite direction. Now place a known weight on the scale, preferably about the

same weight as the animals to be weighed. Using the right hand potentio meter, set

the computer to the right weight. Remember, clockwise for higher values, and anticlock wise for lower values. When you want value's in pounds (lb) you have to turn

the weight to the lb value. Remove the calibration weight from the scale and check

the zero position on the computer. Correct if necessary. The computer is now

calibrated. It is possible to weigh normally again by simply switching the computer off

and on again.

______________________________________________________________________________________________

D300X T/R Twin Separation - 10 - Version 0.8

Page 12

________________________________________________________________________

Setting mode

Summary

The behaviour of the weighing computer may be influenced by three parameters. To

change these parameters, the computer has to be in the setting mode. This is done

by switching the computer on and holding down the "TOTAL" and the "PRINT" key at

the same time. When the screen message has disappeared, the computer gives a

bleep signal and you will now see "P-" appear on the screen. Now release the two

keys and press the "GROSS/NETT" key once. The computer now displays "PI XX",

when XX represents the value of parameter 1. Therefore, you do not actually see "PI

XX", on the screen, but "PI 25", for example. The damping of the scales is set with

parameter1. This value can be set from 0 - 63, inclusive, when 0 indicates the

minimum damping. This adjustment is made with the "TOTAL" key increases the

value of the parameters, the "PRINT" key reduces it. (Best value of P1 = 10)

After setting the damping, you can switch over to the second parameter, P2

done by pressing the "GROSS/NETT" key. Parameter 2 indicates the stable factor.

The computer only transmits data to the VC computer if the weight is "stable". "P2"

sets exactly how stable the weight must be. Possible values for "P2" are 1 - 99. At 1

the weight must be very stable and when at a value of 99 practically everything is

regarded as stable. (Best value of P2 = 15)

The third parameter P3

The peak value of "P3" can be set between 1 - 5 inclusive. "P3" is a multiplying

factor. Normally "P3" is set at 1. If the "P3" is set to 5, the weight is multiplied by 5.

This weight is then displayed and may also be transmitted to the VC computer. After

setting "P1", "P2" and "P3", inclusive, the "GROSS/NETT" key has to e set once

more. The computer is now ready for use and does not have to be switched off and

on. The values "P1", "P2" and "P3", inclusive are stored even when the computer is

switched off. If the computer is switched to calibration mode, parameter "P3" is set to

1 automatically. This is still the case after leaving the calibration mode. Therefore, if

another multiplying factor is needed, this has to be set again after leaving the

calibration mode. (Best value of P3 = 1).

can be set by pressing the "GROSS/NETT" key once more.

. This is

normal start weighing mode

switching on with "TOTAL" key

left hand potention meter: zero setting

right hand side potention meter: weight setting

switching on with "TOTAL" and "PRINT"

key

P1 damping factor 0-63

P2 stability factor 1-99

P3 multiplying factor 1-5

calibration mode

setting mode

(i.e. 10)

(i.e. 15)

(i.e. 1)

______________________________________________________________________________________________

D300X T/R Twin Separation - 11 - Version 0.8

Page 13

________________________________________________________________________

Start process : status 0

-5

status

description of the status

Display during normal operation

status

Description of the status

8 Display values

During operation, the program steps through different program-states which are

monitored on the display. This gives information about the state of the T/R and

therefore can be used as an extra service tool.

00 processor-initialisation, opening network

01 wait for valid address, "SA"-menu is started automatically

02 No communication with process computer. Request for total

peripheral number. At installation the controller asks here for

peripheral information

03 request for external data

04 T/R under test

05 start-up process finished, task is killed

• left & right display "--" when the T/R tries to identify a responder.

• decimal point left display Cow-responder currently identified

• decimal point right display HF1 field on

10 Initiate station

11 Wait for responder number

12 Sensor at antenna (IR1) occupied, no responder ID

13 Check gate positions (waiting for weigh data)

14 Wait for station to be free

15 Wait for hold gate sensor (IR2) to be active

16 Wait for hold gate sensor (IR2) to be free

17 Manual Control

21 Wait for separation sensor (IR3) to be active

22 Wait for cow-id (second cow identified, first cow has

not left yet)

23 Check gate position (second cow identified, first cow

has not left yet)

24 Wait for station to be free (second cow identified, first

cow has not left yet)

25 Wait for separation sensor (IR3) to be active

Responder still identified in antenna when IR2

became free

26 Wait for separation sensor (IR3) to be free

The display returns blank when the button is not touched for 30 minutes.

______________________________________________________________________________________________

D300X T/R Twin Separation - 12 - Version 0.8

Page 14

________________________________________________________________________

Internal test menu

Display error procedure

Error

Description

how to handle

- -

Self test menu

Test output 1

– 8

9 Internal test menu

The different functions of the transmitter / receiver can be tested by means of the

push-button. A special program is build into the prom of the T/R. On the display this

option is called “It”, which stands for “Internal test”

The Internal test menu is a powerful service tool in case of system-service. The T/R

stores registered errors which can be displayed on demand of the trouble-shooter.

Also the T/Ran execute a complete self test on demand, the test results also are

displayed.

− display Error procedure

− Self test menu :

The detected errors are stored by the T/R itself and can be monitored on the display.

When the display shows dE, the “display Error procedure” is entered by pressing the

button until the display blinks. Two types of messages can be displayed by the T/R :

• error-messages (E1)

• warning-messages (E2, not used yet)

The procedure shows all registered errors on the display, one after the other,

proceeded by the message-type. First all error-messages will be shown, then all

warning-messages.

no errors

01

09

10

11

12

Tare too high for more than 20

seconds

No HF1- current detected

Antenna error See error 09

RAM ERROR:

• data written does not match

data

ROM ERROR:

• calculated checksum does

not match checksum of

EPROM

Clear the weighing platform or reset the

weighing unit

• Check antenna wiring

• Check HF-field (test responder)

• Replace T/R T-PCB

Replace T/R T-PCB

Replace T/R T-PCB

______________________________________________________________________________________________

D300X T/R Twin Separation - 13 - Version 0.8

When the display shows St, the “Self test menu” is entered by pressing the button

until the display blinks.

By shortly pressing the button, the T/R self tests can be selected. The selected test

is executed by pressing the button until the display blinks.

When the displays shows LX, the “test output procedure” is executed by pressing the

button until the display blinks. The device connected to the output will now be

switched ON

Page 15

________________________________________________________________________

Test input 1

- 8

Test inpu

t Im7

–8

Test identification procedure

Test weighing unit

Test ROM / RAM

E1

E2

E3

When the displays shows iX, the “test input procedure” is executed by pressing the

button until the display blinks.

01 = contact open

00 = contact closed

When the displays shows IX, the “test input procedure” is executed by pressing the

button until the display blinks.

01 = contact open

00 = contact closed

When the displays shows id, the "test identification procedure" is executed by

pressing the button until the display blinks. The HF-field now continuously will be on.

The ID-status is displayed as follows (switching HF1 / HF2):

- - = no responder identified

xx = responder identified ( xx = last two digits of responder number)

Weighing status is displayed, when weighing bridge connected.

- - = no weighing data read

xx = absolute weighing result (xx = last two digits of weighing data)

When the display shows rr, the "test ROM / RAM procedure" is executed by

pressing the button until the display blinks. The T/R now will restart, during which the

memory-tests are executed. The table underneath shows an overview of the return

values of these tests.

RAM error

ROM error

RAM and ROM error

______________________________________________________________________________________________

D300X T/R Twin Separation - 14 - Version 0.8

Page 16

________________________________________________________________________

S W

S = separation box W = weighing / separation box

1.

Weighing enable

2.

Max ID Time

3.

Not used

4.

Default exit

5.

Scale type

6.

Max. weigh var.

7.

Max. tare weight

8.

Min. weight

9.

Max. weight

10.

Gate switch time

11.

Sensor free y/n

12.

Return to default

13.

Not used

14.

Max. track time

10 PC-software settings VC4

In the installation program the following must be keyed in at the screen separation:

System >> Service >> Installation >> Installation

Recommended settings for CPT4SBS 0.12/0.13 and X-Act version 2.11/3.01

0 1 Weighing enable / disable

10 60 If the animal is not identified during this time, the animal will

be send to the default exit (sec.)

0 0

5 5 Default exit

0 1 1 = standard weigh computer

0 50 Max. variation between two weighings (kg)

0 30 Max. tare weight (kg)

0 50 Min. accepted weight (kg)

0 1000 Max. accepted weight (kg)

5 5 Wait time between gate actions (0.1sec.)

1 1 1= Station is free if sensor is NOT made

0= Station is free if sensor is made

1 1 1= Always return back to default gate settings

0= Set gate when new cow is identified

0 0

5 = no exits selected

1 = exit 1

2 = exit 2

______________________________________________________________________________________________

D300X T/R Twin Separation - 15 - Version 0.8

60 60 Max. time an animal can occupy the station (sec.)

Page 17

________________________________________________________________________

11 PC-software settings VC5

First create locations. Select tab sheet locations at the left. Select the farm icon in

the tree and press button “NEW”. After saving the new location will appear in the

tree.

When ready creating locations, select button “service” and start scanning devices.

After scanning the devices connect the separation locations to the exits.

______________________________________________________________________________________________

D300X T/R Twin Separation - 16 - Version 0.8

Page 18

________________________________________________________________________

•

•

•

•

•

•

•

•

•

11 Trouble shooting

symptom cause solution

T/R does not start

up display remains

blank

T/R does not start

up display shows

"E1, "E2" or "E3"

T/R does not start

up, display shows

"02"

Poor identification

no power

RAM, ROM or both

failed

T/R not supported by

the controller

• communication fails

antenna badly adjusted • Check T/R-power (P1)

non-sensitive squelch-

adjustment

check power supply

• check wiring

replace T/R PCB

check T/R address

• install the T/R at the PC

• check communication wiring

• perform "Adjust Antenna" re-

adjust Lt if necessary

check adjusted squelch

______________________________________________________________________________________________

D300X T/R Twin Separation - 17 - Version 0.8

Page 19

________________________________________________________________________

No. Art

icle number

Description

12 Spare part list

2805863 E-prom CPT4SBS

9835733 Antenna transformer EWA, adjustable

9808418 Accessories antenna transformer, consisting of:

- bolt M4x30 (6x)

- bolt M4 (6x)

- washer spring A4 (6x)

- bolt M8x100 stainless steel (4x)

- bolt M8 stainless steel(6x)

- washer spring A8 stainless steel (10x)

- isolation plate antenna transformer (1x)

- pipe brace including nuts (2x)

- strip (2x)

9852514 Antenna-set walk through identification, consisting of:

9800263 Antenna strip stainless steel

9800271 Accessories Antenna, consisting of:

- bolt M8x25 stainless steel (10x)

- bolt M8 stainless steel (10x)

- washer spring A8 stainless steel (10x)

______________________________________________________________________________________________

D300X T/R Twin Separation - 18 - Version 0.8

Page 20

________________________________________________________________________

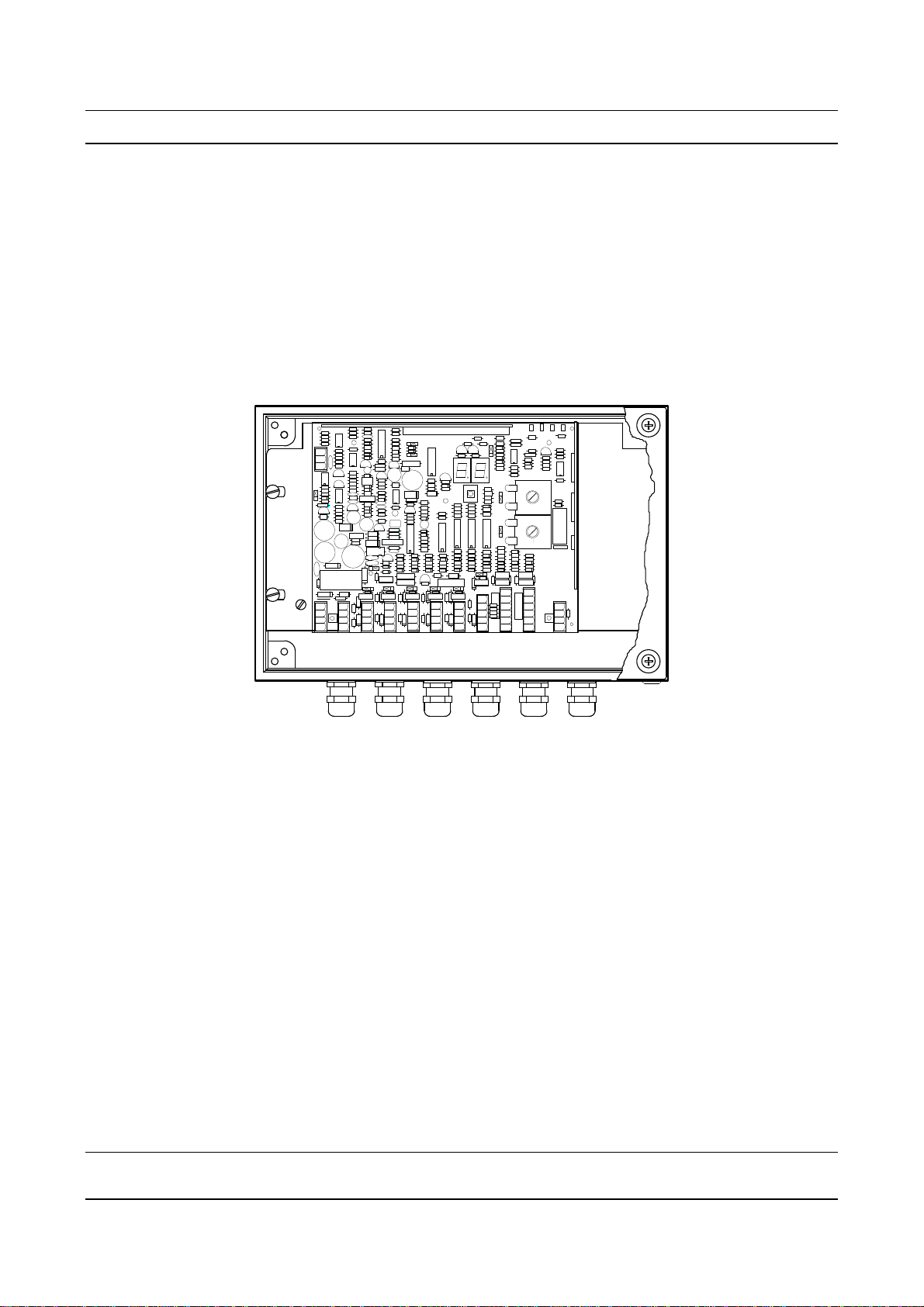

A

O

TWIN 2

EPROM

A

B

C

9829601

HF2HF2+

HF1HF1+

X4X9X6 X8

D

E

F

G

P1

H

I

J

J12

J11,12

EXTERN

ADJUST

J11

I8

+23V

I-

I2

M2

M+

X7

+23V

M1

M+

C2

C1

J1 t/m 6

BREAK ON

I7

I-

I1

VC3

VC4

M5

M+

J8

J9

I-

I5

I-

I4

M4

M+

J15

PCF

J1

J2J3J4J5J6

+23V

I-

I3

M3

M+

J8

T

VC4

J10

R

_

J7

P

J9

O

C

D

-

+

N

Rx

Tx

+

M L K

I-

Im8

M8

M+

I-

Im7

M7

M+

I-

I6

M6

M+

J1 J2 J3 J4 J5 J6

EPROM

B

Micro processor module

C

Display’s

D

Drukknop

E

HF ID module

F

HF trimmer antenne 2 (C2)

G

HF trimmer antenne 1 (C1)

H

HF power potentio meter (P1)

I

Connector antenne 2

J

Connector antenne 1

K

+ 23 Volt

L

Ingang / uitgang connectors

M

VC3 connector

N

VC4 connector

Figure 1 : overview T/R Twin PCB

LED “motor hardware safeguard” uit

P

RS232 connector

J1

J1 - J6 “Enable brake” jumpers

J7

Jumper “motor hardware safeguard” aan/uit

J8

J8 - J9 jumpers VC3 - VC4

J10

Jumper VC3 - VC4 communicatie kanaal

J11

J11 - J12 Jumper HF1 en HF2

J15

Jumper Phase code ID aan/uit

X7

Signal ground

X6

Responder signal

X9

TP2

X8

TP1

X4

AGC

______________________________________________________________________________________________

D300X T/R Twin Separation - 19 - Version 0.8

Page 21

________________________________________________________________________

Cable nr.

# of wires

L.max. (m)*

A 4 40 * at wire-D = 0.8mm. (other D’s see text)

B 4 3**

C coax 10

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

M+ / M1

M+ / M2

M+ / M3

M+ / M4

M+ / M5

M+ / M6

M+ / M7

M+ / M8

I- / I1 / M+

I- / I2 / M+

I- / I3 / M+

I- / I4 / M+

Hold gate

Signal lamp

Not used

Entrance gate (only weigh bridge station)

Separation gate 1

Separation gate 2

Not used

Not used

IR1, Cow detector

IR2, Cow-detect through hold-gate

IR3, Cow-leave through exits sensor

Manual

** Longer cable no problem, but not CE approved

13.

14.

15.

16.

17.

18.

I5

I6

I7

I8

- / Rx / +

+ / - / D / C

Manual, entrance gate

Manual, hold-gate

Manual, separation gate 1

Manual, separation gate 2

Weigh bridge

Interface Bridge VC4 / X-act Controller

Figure 2: Overview T/R Separation cable connections

______________________________________________________________________________________________

D300X T/R Twin Separation - 20 - Version 0.8

Page 22

________________________________________________________________________

Normal state : display is blank or shows program state

Ad

HF

SA

dA

r S

Set Address

Display Address

r A

r P

r i

r 2

H1 AA

AP

AS

An

i d

H2

Not used

Resp. AM (X-ponder/Respactor)

Resp. PM (Phase code)

Resp. ISO

Resp. ISO (Lactivator)

Adjust Antenna

Adjust Power

Adjust Squelch

Adjust Neutrodynisation

Test Identification

I t

dE

St

Figure 3 : overview T/R display-menus

Display error

i d

ui

L-

i -

I -

r r

Test Identification

Test Weighing

Test Output 1 - 8

Test Input 1 - 8

Test Im7 - Im8

Test ROM/RAM reboot

______________________________________________________________________________________________

D300X T/R Twin Separation - 21 - Version 0.8

Page 23

________________________________________________________________________

M10 bolt

ANT-T

nut + washer

antenna-strip

8.5 mm, bolt M8 x 16 stainless steel

pipe

isolation

Parlour : front view

PVC mounting part

antenna-wire

Antenna-strip

6.0

140.0

12.5

25.0

All sizes in mm.

Material antenna : Stainless Steel strip 25x6 mm.

Material rod : galvanised, 1 " (inside Diameter)

12.5

O 12.0 (2x)

ATTENTION:

no iron through the antenna

and no metal that could cause

a loop close to antenna

M10 bolt PVC

ANT-T

nut + washer

antenna-strip

Parlour : front view

Bottom side may be

poured in parlourcement, or mounted

to floor (bolts)

antenna-wire

welding

Antenna-parts

dimensions as above

bended angle

width depends on parlour-width

(see also installation)

plastic pipe, necessary for

isolation of antenna from parlourframe (minimum 3 cm distance)

height = 2m.

welded to each other

ATTENTION: When installing in or on the floor, the antenna + installation material should not hit

iron. The in the floor present (concrete) iron can cause problems at the identification when there is

contact to the iron.

Figure 4 : Overview walk through antenna-construction

______________________________________________________________________________________________

D300X T/R Twin Separation - 22 - Version 0.8

Page 24

________________________________________________________________________

Extra antenna-strip Top view

antenna-strip

200

1200

900

ANT-T

3.0

10

20.0

All sizes in mm.

Material antenna : Stainless Steel strip 20x3 mm.

10

O 9.0 (2x)

Main-part antenna-strip

500

1000

O 9.0 (7x)

20

120

120

30

880

extension (welded)

800 (=max)

iron

antenna

transf.

floor

> 70 mm

When installing in or on the floor, the antenna + installation material should not hit iron. The antenna can be

installed in or on the floor but the reinforcement in the floor must be in sufficient distance.

Figure 5 : overview construction walk-over antenna (only for foot types)

______________________________________________________________________________________________

D300X T/R Twin Separation - 23 - Version 0.8

Page 25

________________________________________________________________________

- (Output 4)

II4

Manual on/of

Gate 2

M6

I8

M5

Gate 1

I7

Exit gate

M1

I6

Figure 6: Manual control box connections since CPT4SBS 0.11

Entrance gate

M4

(only weigh bridge)

I5

M+

+ (Output 4)

______________________________________________________________________________________________

D300X T/R Twin Separation - 24 - Version 0.8

Page 26

________________________________________________________________________

1000 mm

800 mm

IR3 IR3

IR2

IR1

HF2

300 mm

600 mm

100 mm

1200 mm

Figure 5: overview IR and antenna positions (2 IR sensors before separation door)

1000 mm

800 mm

IR3 IR3

IR3

IR2

IR1

HF2

300 mm

600 mm

100 mm

1200 mm

Note 1: Before the cow leaves IR2, the cow must be out the antenna field

Note 2: Before the cow comes into IR3, the cow must be out of the antenna field

Max width of the box 80 cm, In case of small cows it is better to make it as small as possible

Figure 7: overview IR and antenna positions (3 IR sensors at separation door)

______________________________________________________________________________________________

D300X T/R Twin Separation - 25 - Version 0.8

Page 27

________________________________________________________________________

100 mm

IR3

IR3

FRONT LEG ID

100 mm

1200 mm

1200 mm

IR2

IR1

HF1

600 mm

1300-1700 mm

IR3

IR2

IR1

1200 mm

IR3

HF1

600 mm

100 mm

1200 mm

BACK LEG ID (antenna position depending on cow length)

Figure 8 : overview dimensions separation box with foot identification

______________________________________________________________________________________________

D300X T/R Twin Separation - 26 - Version 0.8

Page 28

________________________________________________________________________

1000 mm

800 mm

IR3

IR2

IR1

IR3

HF1

300 mm

600 mm

100 mm

1200 mm

Figure 9 : overview dimensions separation box with identification on the side (ear button

identification)

______________________________________________________________________________________________

D300X T/R Twin Separation - 27 - Version 0.8

Loading...

Loading...