NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 1 / 42

SERVICE MANUAL

New Dispenser

“Koro”

A

A

A

F

F

F

T

T

T

E

E

E

R

R

R

-

-

-

S

S

S

A

A

A

L

L

L

E

E

E

S

S

S

S

S

S

E

E

E

R

R

R

V

V

V

I

I

I

C

C

C

E

E

E

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 2 / 42

TABLE OF CONTENTS

1

2

2.1

2.2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

PLANNED MODELS

MAIN EXTERNAL COMPONENTS

MAIN INTERNAL COMPONENTS

REAR COMPARTMENT WITHOUT PROTECTIVE CASING

LIST OF MAIN COMPONENTS

TECHNICAL DATA AND FEATURES

ELECTRICAL SAFETY AND RELEVANT STANDARDS

REQUIREMENT FOR THE USERS

HYDRAULIC LAYOUT OF ESPRESSO VERSION

HYDRAULIC LAYOUT OF INSTANT VERSION

HYDRAULIC LAYOUT OF FRESH BREWER VERSION

HYDRAULIC LAYOUT OF VARIABLE CHAMBER ESPRESSO

INTERNAL LAYOUTS

ELECTRICAL SYSTEMS – CONNECTIONS

CONNECTION OF ELECTRONIC BOARDS

WIRING DIAGRAMS

ACTUATION BOARD – CONFIGURATIONS

SIGMA BREWER CONTROL BOARD

PUSH-BUTTON BOARD

BOILER CONTROL BOARD

AIR-BREAK AND BOILERS (INSTANT & ESPRESSO)

PUMPS AND BYPASS

ESPRESSO COFFEE, FRESH-BREWER UNIT & SIGMA

BREWER

SPOUTS ASSEMBLY

POWDER PRODUCT CONTAINER AND DOSER DEVICES

ASSY.

MIXER UNIT

COFFEE GRINDER AND DOSER DEVICE ASSEMBLY

POWDER AND LIQUID DOSE TABLES

ROUTINE AND EXTRAORDINARY MAINTENANCE

PROGRAM

TROUBLE-SHOOTING

HACCP DIRECTIVE

DAILY CLEANING AND HYGIENE PROGRAM

DAILY CLEANING AND HYGIENE PROGRAM FRESHBREWER UNIT

MONTHLY CLEANING AND HYGIENE PROGRAM

Pag. 3 - 4

Pag. 5

Pag. 6

Pag. 7-8

Pag. 9

Pag. 10

Pag. 11

Pag. 11

Pag. 12

Pag. 13

Pag. 14

Pag. 15

Pag. 16

Pag. 17

Pag. 17- 18

Pag. 19

Pag. 20-21

Pag. 22

Pag. 23

Pag. 23

Pag. 24 - 26

Pag. 27

Pag. 28 -29

Pag. 30

Pag. 31

Pag. 32

Pag. 33

Pag. 34

Pag. 35

Pag. 36 - 38

Pag. 39

Pag. 40

Pag. 41

Pag. 42

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 3 / 42

I

NSTANT VERSION (OPEN AND CLOSED DOOR)

E

SPRESSO VERSION (OPEN AND CLOSED DOOR)

1 -

PLANNED MODELS

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 4 / 42

External water supply tank

Internal water supply tank

FRESH-BREWER VERSION (OPEN AND CLOSED DOOR)

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 5 / 42

3 4 6 5 1 2 7 8 9 10 11

2 -

MAIN EXTERNAL COMPONENTS

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 6 / 42

1 6 2 8 4

Fustino

fondi liquidi

Mixer

Ugelli mobili

Contenitori

solubili

2

.1

- MAIN INTE

RNAL COMPONENTS

13 14 17 16 15 12 18 19 20 21 22

Espresso

Version

26 27 28 29

23 24 25

Fresh

Brewer

Version

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 7 / 42

VISTA

CON PORTA APERTA

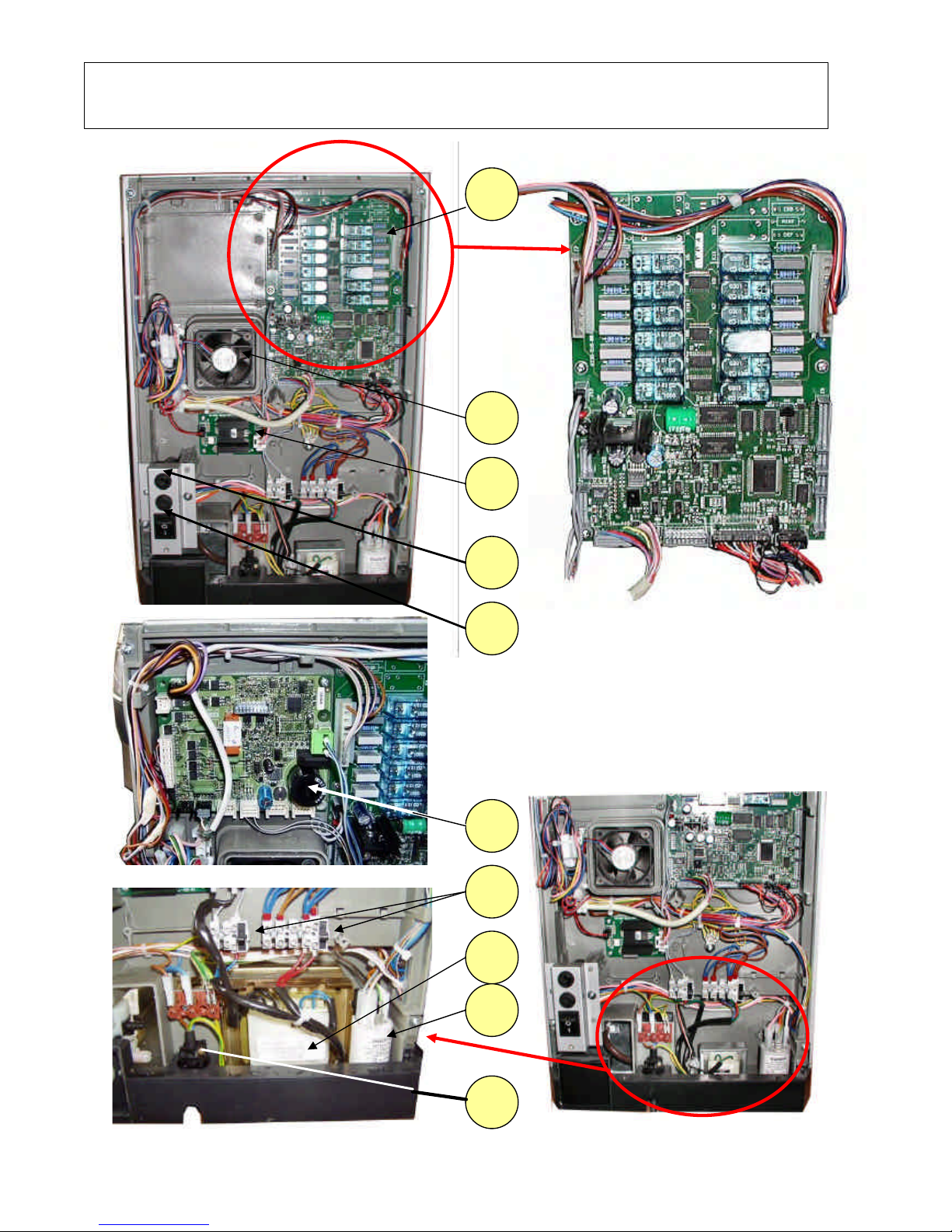

2.2 REAR COMPARTMENT WITHOUT PROTECTIVE

CASING

Detail of CPU / actuation machine board

Detail of machine board

(FRESH-BREWER version only)

30 31 32 36 35 37 39 33 34 38

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 8 / 42

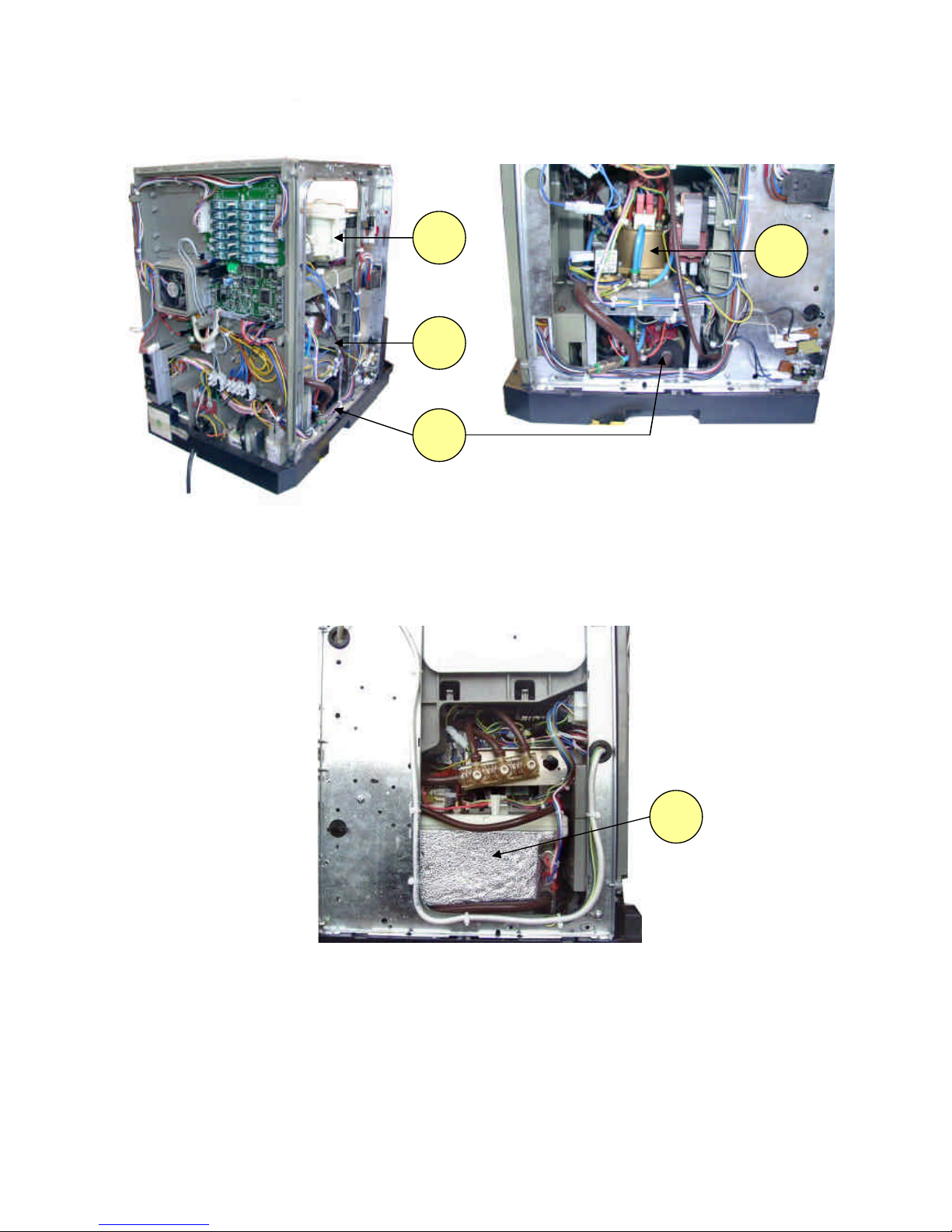

Perspective view without protective casing

Side view without protective casing

– espresso boiler side

Side view without protective casing

open-top boiler side (FB – Instant)

42 40 44 41 43

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 9 / 42

3 - LIST OF MAIN COMPONENTS

N° Ref.

DESCRIPTION

1 Lock

2 Cabinet

3 User interface

4 Selection keypad

5 Dispensing unit

6 Dispensing compartment

7 Back protective casing

8 Grid fuses

9 Main switch

10 Water inlet solenoid valve

11 Power supply cable

12 Grinder / doser device

13 Instant product container

14 Mixers

15 Door

16 Coffee beans door

17 Coffee beans hopper

18 Decaf coffee door (powder)

19 Water supply tank (espresso)

20 Drip tray

21 Solid waste container

22 Brewer unit Z3000

23 Coffee container for FB (powder)

24 Instant product container

25 Dispensing compartment

26 Hot water nozzle

27 FB unit SIGMA BREWER

28 Mixers

29 Protective casing

30 Actuation board

31 Steam exhauster

32 Boiler heating element actuation board

33 Grid fuses

34 Main switch

35 Sigma Brewer control board (FB version only)

36 Transformer fuses

37 Transformer

38 Grid noise suppressor

39 Power supply cable clamp

40 Coffee grinder unit

41 Espresso boiler compartment

42 Espresso boiler

43 Electromagnetic pump

44 Open-top boiler (Instant & Fresh brewer)

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 10 / 42

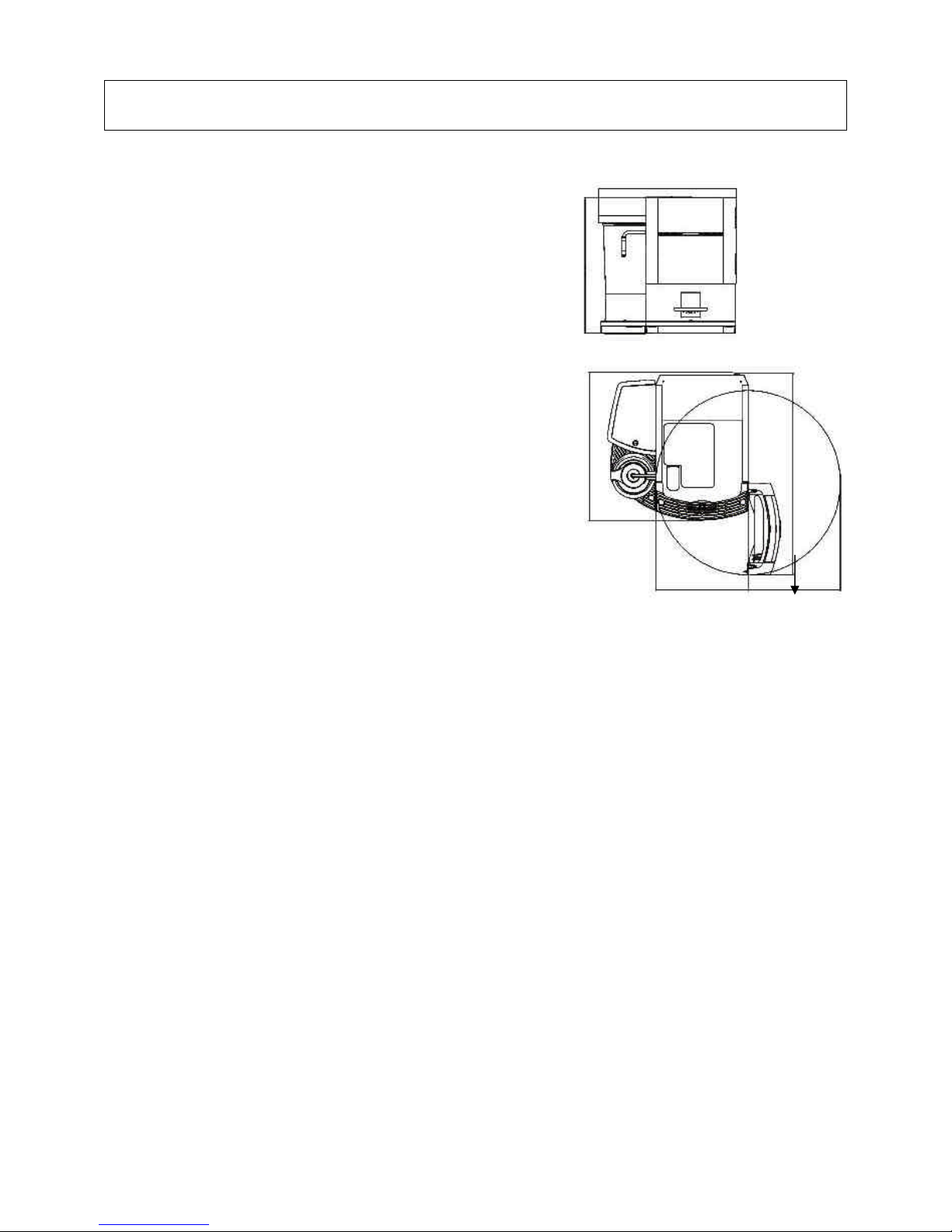

4 – TECHNICAL DATA AND FEATURES

Height 500 mm

Width 508 mm

Depth 528 mm

Overall depth with door open 724 mm

Weight 28 Kg

Power supply voltage 230 V AC - 50 Hz

Installed power 1500 W (espresso)

2400 W (FB / I)

Payment systems used

The machine is pre-set to use

(by means of specific kits) payment systems

coin mechanisms and 24 V DC validators with protocols

EXECUTIVE BDV, MDB

Water supply:

From the mains with a water pressure of 5 to 85 N/cm2

BASE VERSIONS:

Espresso – Instant – Fresh brewer

INSTALLED BOILERS AND TEMPERATURE

One pressure boiler for the espresso version

One open-top boiler for instant and Fresh-brew

versions

Temperature setting via software

SAFETY DEVICES

Main switch (at the back) – Main switch upon opening the door

Water inlet solenoid valve with overflow device

Manual-reset boiler safety thermostat

Manual-reset instant boiler anti-boiling thermostat

Air-break float block

Presence of liquid waste tray – Presence of coffee grounds tray

Boiler sensor control (short-circuit or failure)

Double heating and timing protection for:

Pump – Doser devices – Coffee unit ratiomotor – Coffee grinder – Mixer motors

Fuse protection for: Transformers, electronic boards and main wiring

CONTROLS

Presence of water

Presence of coffee

Operating temperature reached

508 500 528 331 724 331

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 11 / 42

5 - ELECTRICAL SAFETY AND RELEVANT STANDARDS

The vending machine New Dispenser was designed and made in conformity with the

provisions of the following directives and related European standards:

MACHINE SAFETY DIRECTIVE EEC 98/37

EN 60529 UNI EN 292 –1-2 IEC 695-2-2

LOW VOLTAGE DIRECTIVE EEC 73/23; EEC 89/392; EEC

89/336

(the low voltage directive covers all equipment powered with voltage below 400 V AC)

The following European standards are applied:

EN 60335-2-14 EN 60335-2-15 EN 60335-2-24 EN 60335-2-75

ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

EN 61000-3-3 EN 61000-4-2 EN 61000-4-3 EN 61000-4-4 EN 61000-4-5 EN 61000-4-11

---…----…---…---

With regard to Low Voltage and Electromagnetic Compatibility this vending machine was tested and

certified by a certifying body authorised by ministerial decree: IMQ.

It is therefore prohibited (on pain of voiding the warranty and the responsibility of the certification) to

replace any electrical component with non-original parts during the routine and extraordinary maintenance

operations.

Therefore it is also prohibited to:

Tamper with or deactivate the safety systems installed in the vending machine.

Install the vending machine outdoor or in any case in a place that is not protected from the weather.

Use the vending machine for purposes other than those indicated in the sales contract.

Connect the vending machine by means of extension cords or multiple sockets and/or adapters.

Use water jets for cleaning.

Then, it is also compulsory to:

Verify the conformity and suitability of power supply line and of the power outlet.

6 – REQUIREMENT FOR THE USERS

For safety purposes, three different operators with different qualifications have been defined.

USER

The user is practically the final user who buys the products from the machine.

The user must not have any access whatsoever to the inside of the machine.

PERSON RESPONSIBLE FOR REFILLING AND ROUTINE CLEANING

The person responsible for refilling has the key for opening the machine and is in charge of the refilling,

cleaning and internal hygiene of the machine.

He must not have any access to energised parts or moving parts.

MAINTENANCE TECHNICIAN

The maintenance technician must be a highly skilled person and must be aware of the electrical hazards in

the event of complex technical operations and can operate with the machine switched on and the door

open, using the safety key supplied.

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 12 / 42

7 – HYDRAULIC LAYOUT “ESPRESSO”

ESPRESSO VERSION COMPONENTS

N.B. The diagram shown is given only as a reference as it may differ for each version.

REF. DESCRIPTION REF. DESCRIPTION REF. DESCRIPTION

1

Spouts assembly 2 Pump 3 Mixers

4

Boiler assembly 5 Brewer unit 6 Solenoid valve block

7

Bypass 8 Water supply tank 9 Volumetric counter

3 5 1 2 4 6

8 9 7

NW Global Vending – TECHNICAL MANUAL

This document was produced by MARK AC for the exclusive use of the technical personnel in the after-sales service.

. No part of this document may be divulged to a third party or reproduced partially or entirely without the prior permission of NW GLOBAL VENDING

. All rights reserved.

New dispenser “KORO” 07/10/2005 page 13 / 42

INSTANT VERSION COMPONENTS

N.B. The diagram shown is given only as a reference as it may differ for each version.

8 – HYDRAULIC LAYOUT INSTANT

REF. DESCRIPTION REF. DESCRIPTION REF. DESCRIPTION

1

Spouts assembly 2 Mixers 3 Solenoid valves

4

Boiler assembly 5 Water supply pump 6 Water supply tank

2 1 6 5 4 3

Loading...

Loading...