TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 1 / 17

by

AFTER-SALES SERVICE Hot & Cold

Brio “Easy Serving

Espresso”

BASIC TECHNICAL MANUAL

THE CONTENTS OF THIS DOCUMENT ARE INTENDED FOR NECTA’S AFTER SALES PERSONNEL

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 2 / 17

NOTE

The above units are specific to this machine.

All functional units not mentioned are used also in other machines and are described as such in a separate

manual specific to the relevant range of machines.

View of Brio “ESE” with door open

Table of Contents

1

2

3

4

5

6

7

8

9

Layout

Electrical systems and board connections

Air-break / Boilers

Pumps and by-pass

Coffee brewer unit

Mixer Unit

Powder and water dose tables

Trouble-shooting

Wiring diagrams

Page

Pages

Page

Page

Pages

Page

Page

Pages

Page

3

4/5/6/7

8

9

10/11/12/13

14

14

15/16

17

Cup Dispenser

Sugar and stirrer

release devices

Brewing unit

Powder

containers for

instant drinks

Container for

used co ffee

pods

Sugar container

Safety switch

Cup release and

rotati on unit

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 3 / 17

1 – HYDRAULIC LAYOUT

1 Water inlet solenoid valve 8 “Flow-through” Espresso boiler

2 Mechanical filter for impurities 9 “Flow-through” coil

3 Air-break 10 Three-way solenoid valve 1

4 Volumetric counter 11 Three-way solenoid valve 2

5 Vibration pump 12 ESE coffee pods

6 Pressure boiler for instant drinks 13 Liquid waste float

7 Brewer unit for coffee pods

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 4 / 17

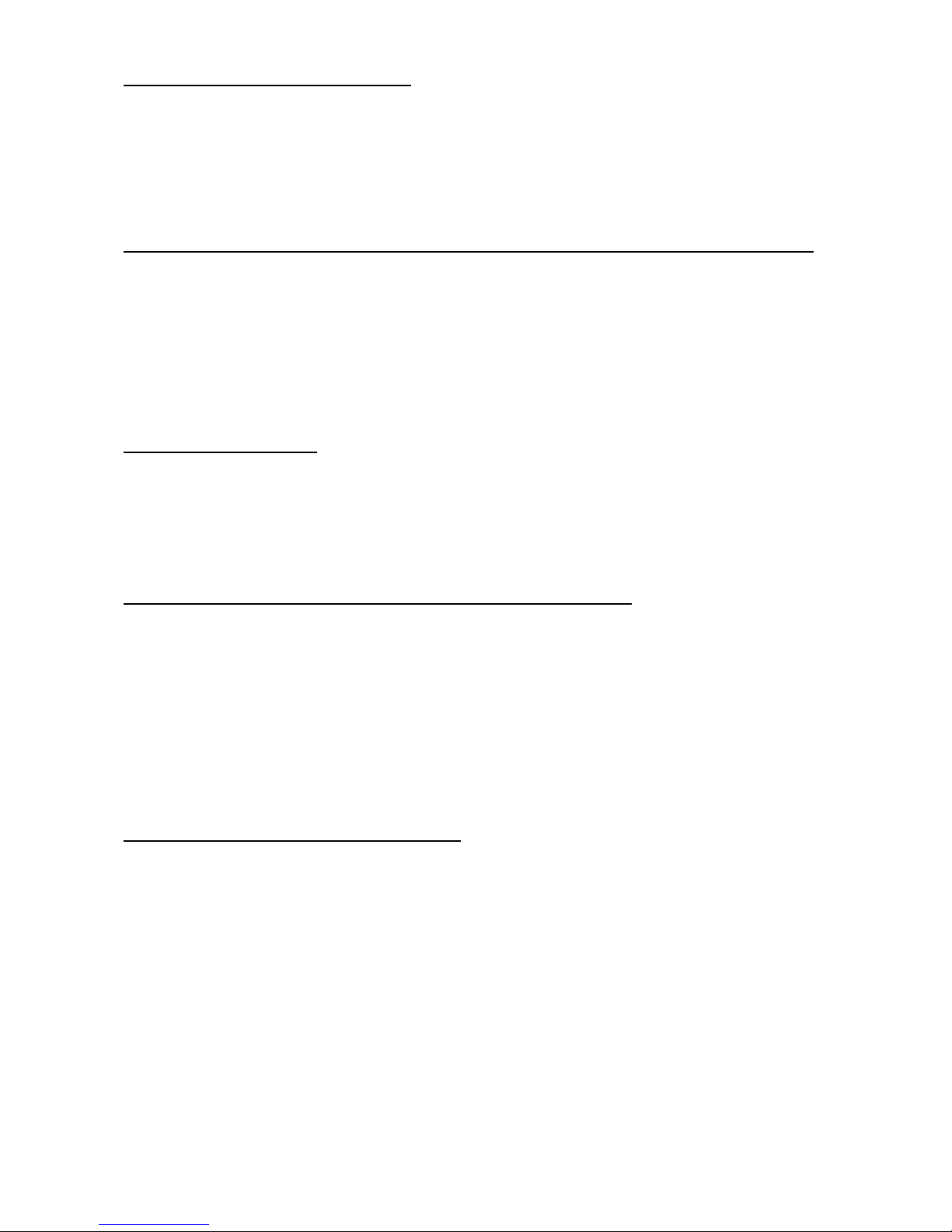

2 - ELECTRICAL WIRING AND BOARD CONNECTIONS

View rear side without casing

The Brio ESE vending machine is fitted with the same actuation

board used on the base model (with a specific Eprom); this board

processes the information from the push-button board, the

payment systems and from the sensors installed throughout the

machine; it also controls the actuations and the display board

It is built on SMT technology.

An additional board was also add ed for the specific “ESE” version,

located in the same compartment and controlling the “flowthrough” espresso boiler

(see

photo).

Two other boards are installed :

1) The display board, which processes the information from the

CPU board and converts it into readable signals, and the pushbutton board.

2) The push-button board that controls the display, the pushbutton actuations; it supports the connectors for the payment

systems.

The CPU/actuation board is set by default to achieve a

temperature of 78-82° C in the Instant boiler.

The espresso boiler cont rol board is set to achiev e a dispensing

temperature of 78-85° C.

See brewer unit paragraph for any corrections.

Machine board

Eprom

Tem perature

control trimmer

Flowthrough

boiler board

Flow-through boiler

temperature contr ol

trimmer

Espresso boiler control

board

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 5 / 17

Push-button board compone nts legend

Ref. N° Description

1 LCD brightness adjustment trimmer

2 Printer connector

3 Prog ramm er device connecto r

4 Machine board connector

5 Payment system configuration minidip

6 Jp2

7 Control board connector 2

8 Executive serial interface

9 Front validator connector

10 Jp1

11 Coin return lamp

12 NOT USED

13 MDB board power supply

14 MDB coin mechanism connector

15 Programming mode button

CPU board component legend

Ref. N. Description

1 Pressure boiler heating elem ent T RIA C

2 Pressure boiler temperature control trimmer

3 Machine configuration minidips

4 EPROM

5 Jumper

1-2 Instant versions

2-3 Espresso versions

6 JS3 - JS4 EPROM version configuration jumpers

Machine board component layout Push-button board component

layout

JS3

JS4

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 6 / 17

RELAY CODE TABLE AND ACTUATIONS

RELAY

CODE

ACTUATION DESCRIPTION

K1

Three-way relief solenoid valve

K2

Three-way relief solenoid valve 2

K3

Instant drink solenoid valve 2

K4

Pump

K5

Coffee brewer motor

K6

Instant drink solenoid valve 2

K7

Pod strip (Serving) drive motor

K8

Mixer motor 1

K9

Doser device 3

K10

Doser device 2

K11

Doser device 1

K12

Sugar doser device

K13

Cup release motor

K14

Stirrer release motor

K15

Cup stacker shift motor

K16

Water inlet solenoid valve

K17

Mixer motor 2

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 7 / 17

MACHINE CONTROL BOARD CONFIGURATION

The machine board is designed with integrated the control system (CPU) and the actuations.

It was also conceived to be used in different machine models.

In the event of replacement it will be necessary to check that the new board configuration is suitable for the

required use.

Proceed as follows:

A series of 8 minidips (3) is located at the centre of the board permitting its configuration for use in the

different versions and countries. A jumper (5) is used to configure the board for Instant or Espresso

versions. The board has also provisions for supporting 512 Kb and 1 Mb EPROMs by setting Jumpers JS3

and JS4.

For the different configurations see the following tables:

LANGUAGE CONFIGURATION

LANGUAGE

Minidip Italian French Spanish

6 OFF ON OFF

7 OFF OFF ON

MODEL CONFIGURATION

Model Espresso

MINIDIP 5 OFF

Jumper 2 - 3

STIRRER CONFIGURATION

STIRRER

Dispensed also with

unsweetened

selection s

Not dispensed

with unsweetened

selection s

MINIDIP 2 ON OFF

PAYMENT SYSTEM CONFIGURATION (FRONT COIN MECHANISM)

MINIDIP

ON OFF

1 - Fixed to OFF

3

(validator only)

Credit control No credit control

4 - Validator

8 - Fixed to OFF

PAYMENT SYSTEM CONFIGURATION (SERIAL COIN MECHANISM)

SERIAL SYSTEM

DIP 3

DIP 4

DIP 5

Executive s td.

U-Key URW 2

OFF OFF OFF

Executive Price

Holding

Parameter 36 = 2 )

OFF O N OFF

System ECS

ON OFF OFF

U-Key URW 3

OFF OFF ON

IMPORTANT NOTICE

Minidips that are not mentioned must be set to OFF.

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 8 / 17

3 - AIR BREAK / BOILERS

The Brio ESE vending machine is fitted with

two boilers, each for a specific function.

A classic pressure boiler is used for Instant

selections, normally fitted on the Base Brio as

an all-purpose boiler, but it is kept at an internal

pressure of 10 bar by means of specific setting

of the by-pass valve.

A “flow-through” boiler is used for Espresso

selections; this boiler receives water from the

base pressure boiler preheated at a temperature

of approximately 80° C and then heats it up to

95-100° C.

This solution ensures a long operating life

without premature scaling problems.

It is well known that in flow-through boilers,

where water is heated from ambient

temperature to brewing temperature in a very

short time, very shortly there are problems with

excessive scaling.

The hydraulic circuit is conceived as follows:

When the water in the air-break falls below the

minimum level, a float triggers a microswitch

that sends a signal to the board, which activates

the water inlet solenoid valve “A”, then the

water flows through the filter “B” and reaches

the air-break “C” until it is full to the max level,

controlled by the float and microswitch.

When a coffee selection is made, after

positioning the pod in the brewing chamber, the

pressure boiler two-way solenoid valves is

opened and the vibration pump is started for a

length of time determined by the volumetric

counter, that by computing the number of

rotations of an impeller wheel sets the exact

amount of water necessary for the selection.

The necessary amount of water is drawn from

the air-break and sent to the pressure boiler,

thus pushing out the same amount of hot water

(85° C) which is then delivered to the glowthrough boiler, and heated up to 95° C by

means of forced flow through a coil heated by

the Espresso boiler heating element. This water

is controlled by a pair of three-way solenoid

valves, allowing the flow of water for brewing

and for relieving the excess water in the pod,

thus leaving a perfectly dry pod

Pressure boiler

for instant

drinks

Air –break “C”

filter for

impurities “ B

”

Elettrovalvola ingresso

acqua "A ”

“

Flow-through”

Espresso boiler

Overheating protection

thermo-fuses

NOTE: The pressure boiler is fitted with manual reset

overheating protection.

The flow-through Espresso boiler is fitted with

overheating protection provided by two accurate

thermo-fuses calibrated at 120° C; these fuses must

be repl aced after they are trigg ered.

Before resetting or replacing the above protections,

the problem that caused the trigger must be identified

and corrected.

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 9 / 17

4 – PUMPS AND BY – PASS

A standard vibration pump is used, also adopted on the

base Brio, and fitted with overheating protection;

however a by-pass pre-set at 10 bar is installed, to

avoid un uneven use of the coffee pod and thus

ensuring better dispensed product quality.

To ensure greater pump reliability and better tightness

against the pressure, a check valve was added at the

boiler inlet, this way no anomalous leads are exerted on

the pump when idle.

Also the pump is fitted with a check valve, thus ensuring

optimum tightness against the boiler internal pressure.

By-pass

Vibration

pump

Check valve

Water delivery to

boiler

Connection to the

water mains

Air-break

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 10 / 17

5 - BREWER UNIT FOR COFFEE PODS

The adopted brewer unit is used to brew coffee exclusively by means of

continuous strip “ESE” pods (servings) with 100/200 doses. The pods

are made up with an optimum coffee dose.

The unit works as follows:

When a selection is made the serving drive motor positions the pod in

the brewing zone under the flow-through boiler. The unit motor lifts the

piston until hermetically closing the brewing chamber.

The three-way solenoid valve is opened so that the pressure boiler is

connected to the flow-through boiler located above the brewer unit.

The pressure boiler maintains the water at a temperature of

approximately 80° C (ideal for instant products) and the flow-through

boiler heats it up to 95-100° C (ideal for espresso coffee).

The brewing chamber is kept hot at

the same temperature of the flowthrough boiler.

The pump delivers the programmed amount of water that is accurately

computed by the volumetric counter. At the end the three-way solenoid

valves are closed and the water still in the flow-though boiler is expelled

through the third way of the valve. Then the unit motor is activated,

lowering the piston until opening the brewing chamber.

The “serving” drive motor is started, dragging the serving out of the

brewing chamber.

At this point the unit is ready for a new selection.

In order to maintain the correct temperature up to the dispensing point, a

special tube heated by a special permanent low-consumption heating

element is used.

Pod strip drive motor

Unit drive motor

Inner piston

Three-way solenoid valve

Pod strip (Serving) drive roller

Microswitches

Rear view of brewer unit

“

Flow- through”

Boiler

Brewing

unit

Heated tube

Heated tube power

supply cable

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 11 / 17

BREWER UNIT MAINTENANCE

Before any maintenance operations and adjustments it is necessary to wait for the unit to cool down

completely.

Cleaning / replacing the coffee filters

The coffee filters must be cleaned and descaled at least every 2500 selections. To remove the lower filter,

the flow-through boiler must be lifted (hinged to the brewer) after removing the keys 1 (front and if

necessary back), this way access is gained to the lower filter; using a screwdriver lift the edge until removed

completely. Clean and descale using suitable products. To replace the filter, press on the edges until

reinserted completely.

Upper filter

To remove the upper filter 2, undo the stainless steel screw

1.

This operation is possible after removing the upper boiler (see

above).

Filters and gaskets must be replaced not later than 25000

selections.

Upper boiler

opening keys

Lower piston

Lower filter

1

2

Boiler and brewing chamber section

1

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 12 / 17

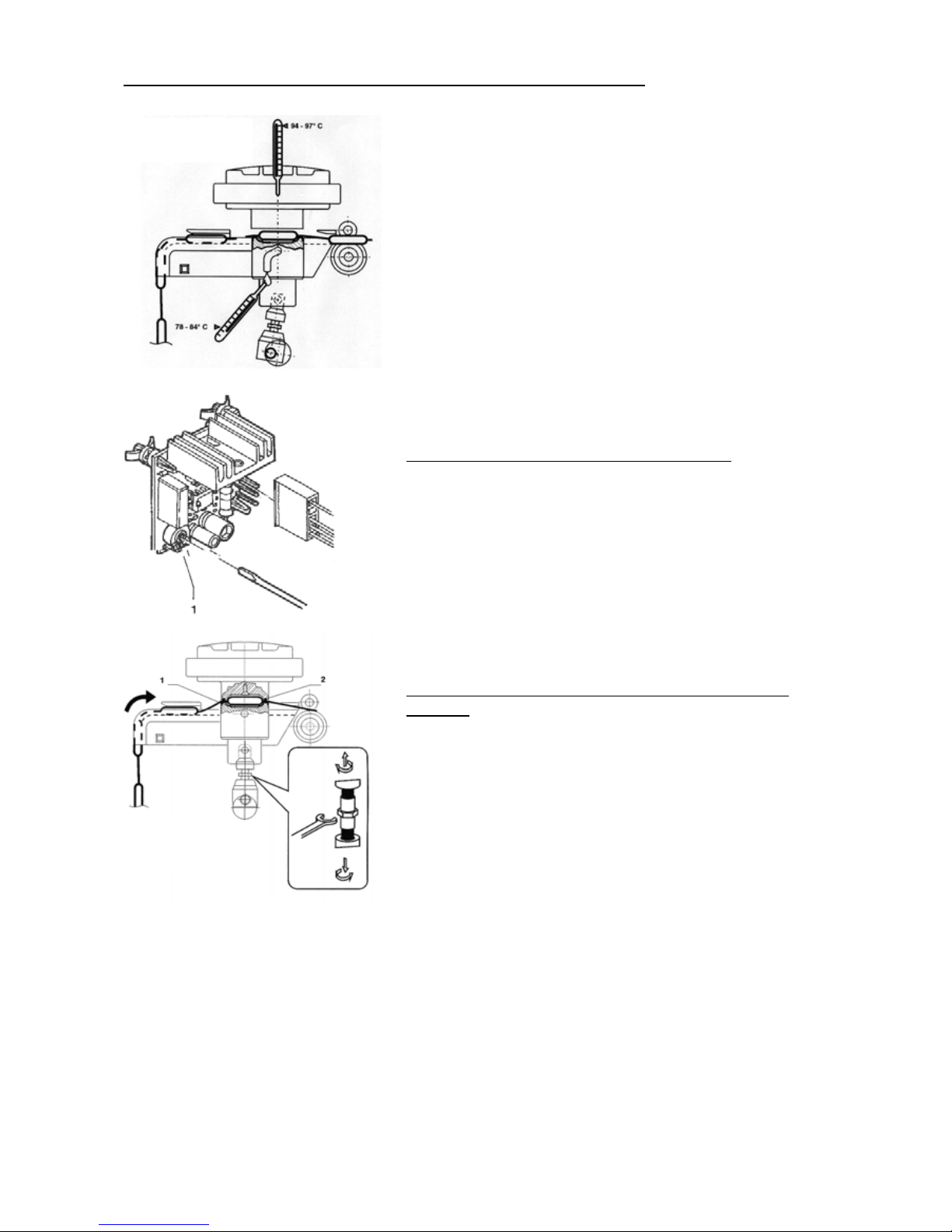

Setting the coffee water temperature (flow-through boiler)

The optimum temperature is set at the factory; should any

adjustments and small changes be necessary, proceed as

follows: Check the upper flow-through boiler temperature, which

must be between 94° and 97° C. This way the dispensing

temperature will be 78° to 84° C.

Such temperature must be considered as optimum.

If that is not the case, adjust the temperature using the trimmer

1 on the electronic board located at the back of the cabinet next

to the machine board.

It must be taken into account that:

Tightening will decrease the temperature

Loosening will increase the temperature

Make very small adjustments and check the dispensing

temperature. The instant boiler inlet water temperature is

determined by the instant boiler temperature, as pre-heated

water is sent to the flow-through boiler to reduce to a minimum

the scaling problem typical of such boilers. For adjustments to

the instant boiler see paragraph Boilers.

ADJUSTING THE POD HOLDER CLOSURE

In order to dispense a perfect coffee with the pod brewer it is

very important to have a perfect setting on the closing position.

The system is adjusted to the optimum setting at the factory,

however in the event of disassembly for cleaning and/or

replacing filters and gaskets it may be necessary to readjust the

settings; in this case proceed as follows:

To increase tightness between gasket 1 and filter 2 rotate the

pin clockwise using an 11 mm spanner.

To decrease tightness in the case of excessive interference the

pin must be rotated anticlockwise.

After the adjustment, the system is self-locking.

PERIODIC CLEANING OF THE FLOW-THROUGH

BOILER

At least once a year, or not later than 10000 selections, the

flow-through boiler must be cleaned and if necessary descaled;

at the same time the sealing gasket must be replaced.

In order to remove the boiler it is advisable to extract the brewer

unit from the machine.

Before any operations the vending machine must be

disconnected from the power supply, and the unit must cool

down completely. Disconnect the hydraulic circuits, disconnect

the electrical connectors, completely undo the fastening screws

and remove the unit from the machine. Remove the two

securing keys from the upper boiler.

Proceed to cleaning, descaling and any replacement of worn components; thoroughly rinse and reassemble in the

reverse ord er of disassembly .

Checking

dispensing

temperature

Flow-through boiler temperature

Measuring upper boiler

temperature

Adjustment pin for the

brewing chamber

closure

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 13 / 17

BREWER UNIT CLEANING CYCLE

As well as manual cleaning through setting in the “Maintenance” menu, anyway performed without

“Serving”, an automatic cleaning cycle can be set.

After a selection, if a new “Serving” is not detected within 20 seconds, a cleaning cycle is carried out and the

vending machine will be out of service for approximately 60 seconds.

Manual cleaning must be carried out every time new “Servings” are loaded; it is however advisable to leave

the automatic cycle control set at all times.

CHECKING AND ADJUSTING THE COFFEE DISPENSING PARAMETER SETTINGS

In order to get the best possible quality for the dispensed products, the vending machine was adjusted to

the optimum setting at the factory; however in relation to the products used it is advisable to check the

following points:

The water dose, which must be between 35 and 40 cc.

The coffee dispensing tempe ratu re, which must be between 78° e 85° C.

The pump by-pass valve setting, adjusted to 10 bar by default.

The dispensing time, which must be between 18 and 20 seconds, considering that a longer time (with the same water

dose) could to clog filters, and a shorter time could alter the by-pass setting towards a higher pressure, and lead to

poorer dispensing quality.

STANDARD SETTINGS

By default the vending machine is adjusted at the factory as follows:

Coffee temperature at the spout, 78-85° C

Instant boiler temperature, 78-82° C

Dispensing time, 18 to 20 seconds

Coffee water dose, 35 to 40 cc

ADJUSTING THE INSTANT BOILER WATER TEMPERATURE

The instant boiler has a dual function: it provides hot water for all instant products by means of its two-way

solenoid valve.

It pre-heats water for the flow-through boiler to avoid the scaling problem typical of such type of boiler.

It is therefore important to have an optimum setting, as a temperature change affects also the final

temperature of the coffee.

To change such temperature the special trimmer on the machine board must be used.

Considering that:

Tightening (clockwise) will increase the temperature

Loosening (anticlockwise) will decrease the temperature

Each complete turn correspond to +/- 0.5° C change

BOILER OVERHEATING PROTECTIONS

The boilers are fitted with safety overheating protections.

The espresso boiler is fitted with two thermo-fuses located above it and sheathed in a special silicone tube.

In the event of failure that could cause boiler overheating, the two thermo-fuses melt, thus disconnecting

the power from the heating element.

After the occurrence of such melting, the problem that caused the malfunction must be identified, corrected

and BOTH THERMO-FUSES MUST BE REPLACED with identical ones or having the same characteristics.

Fuses must never be replaced with others that are not approved by the manufacturer, otherwise hazard

conditions could be created and the manufacturer declines all responsibility.

The instant boiler is fitted with manual reset overheating protection; therefore after having identified and

corrected the cause it is sufficient to press the upper red button to restore the initial conditions.

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 14 / 17

6 – MIXER UNIT

The mixer units are the same used on the Base Brio vending machine.

Motors powered with 230 V AC 50 HZ

Loadless velocity 20000 RPM

Removable powder exhaust drawer and conveyors.

Conforming with HACCP directive.

Bush seal made of self-positioning material, ensuring excellent and long

lasting seal in all conditions.

7 - POWDER AND LIQUID DOSE TABLES

Selection Notes coffee Coffee

Instant

Water

cc

Powder

gr.

Sugar

gr.

Notes

Short coffee

Time

Quantity

Pre-set

dose in a

pod

-

35”

60 cdv

40 c.c.

7,5 gr

CDV =

Wheel

counts

Long coffee

Time

Quantity

Pre-set

dose in a

pod

-

38”

95 cdv

60 c.c.

7,5 gr

Coffee with

milk

Time

Quantity

Pre-set

dose in a

pod

-

38”

60+35 cdv

42+25 cc

2,0 gr latte

7,5 gr

Cappuccino

Time

Quantity

Pre-set

dose in a

pod

-

45”

60+72 cdv

40+55 cc

6,0 gr latte

7,5 gr

Instant Coffee

(Optional)

Time

Quantity

1,3 gr.

22”

55 cdv

40c.c.

-

7,5 gr

Chocolate

Time

Quantity

32”

116 cdv

90 c.c.

23-28 gr.

-

Instant tea

Time

Quantity

32”

116 cdv

90 c.c.

12-14 gr.

-

Milk

Time

Quantity

32”

116 cdv

90 c.c.

8 gr.

7,5 gr

Note 1

The water fl ow in the mi xers is appro ximately 10 cc per second and it i s gi ven as an indicati on, as ther e are many var iables that can

affect the accur acy.

The dose of liquids is determined by pulse setting of the volumetric counter (cdv).

For both selections (coffee and instant) a vibration pump is used.

The number of pulses does not vary in a linear manner, i.e. double the amount of water does not correspond to double the number of

pulses.

For espresso coffee the volum etri c counter is reduced b ecause o f the coffee co mpress reaction that slows down the water flow, while it

is accelerated in the instant drinks selections, since ther e are no o bstr uctions to the w ater flow. T herefor e, in the event of changing the

defaul t dose setting, some measurements must be made to ch eck the accur acy of the doses.

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 15 / 17

8 – TROUBLE-SHOOTING

Problem

(and/or indication on the

display)

Possible cause Solution

The machine does not go into

the heating phase, remaining

in the installation phase

No water flow from the mains or insufficient

pressure (it must be 5-85 N/cm2)

The air-break mi croswitch is faul ty

Water inlet solenoid valve blocked by the overflow

drain of the air-break.

Water inlet solenoid valve not activated because of

faulty RELAY K16

Check the presence of one or more of

situations indicated and o nce identified the

cause do as follows:

Short-ci rcuit the air-break m icroswitch to

check its functioning

In the event of failure, r eplace with a new

that MUST HAVE the same characteristi cs

Unlock the water inlet valve, undoing the

threaded ri ng and emptyi ng the overflow

tube

Check for 230 V AC voltage at the power

supply terminals

Check the activa tion of relay K16

The display indicates the

message“No coffee”

Coffee pod spent or faulty pod detection

microswitch

Faulty “SERV ING” drive motor

Pod drive locked

Faulty RELA Y K7

When a coffee selection is made, the

“SERVING” drive ratiomotor is activated, and

the mo vement activates a microswitch. If

such m icroswitch i s not activated within 5

seconds, the SW disables all coffee based

functions.

Check for one or more of the situations

indicated

The display indicates the

message“Boiler failure”

The boi ler does not reach the operating

temperature

Faulty temperature probe

Overheating protection triggered

For the espresso boiler, melted thermo-fuse

The vending machine is locked if the set

temperature is not reached within 10

minutes.

Check the correc t operation of the heating

element, the probe and of the ac tuation triac.

NOTE:

1) at 25° C the probe must have a resistance

of 12 k ohm

2) at 100°C C the probe must have a

resistance of 963 ohm

(± 4 ohm tolerance)

3) In the even t of faulty flow-through boiler,

the problem is not signaled by the SW,

therefo re it must be ch ecked wh ether the

thermo-fuse was triggered or the failure is in

the power supply board (specific)

The display indicates the

message “No cups”

No cups in the dispenser

Faulty cup detection microswitch

Faulty RELAYS K13-15

If no cups were present when starting the

machi ne, the column rotation rati omotor is

activa ted to search for a full column and i f no

cups are found within a 60 sec (i ndicated by

the speci fic cup detection microswitch) the

machine is locked.

Excluding the fact of a r eal lack of cups, the

correct microswitch functioning must be

checked and in the event of fail ure it MUST

BE replaced with an identi cal one.

In the event of locked release motor o r

column motor, check for the correct a ctua tion

of relays K13-15.

The display indicates the

message

“Brewer unit”

The unit failed to reposition.

Faulty unit positioning microswitch (upper dead

centre)

Faulty unit positio ning microswitch (lower dead

centre)

Faulty RELA Y K5

Check the correct functioning of the upper

and lower position microswitch using a

multimeter

In the event of correct fun ctio ning, check the

correct setting.

In the end, check the correct setting of the

adjustable rod that closes the b rewing

chamber.

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 16 / 17

The display indicates the

message

“Volumetric counter”

(Wheel)

The expected liquid dose is not reached (computed)

within 60 seconds from starting the selection.

The water am ount for bo th espresso coffee

and instant drink selections is ensured by a

volumetric co unter; with the water flow

(drawn by the pump) a wheel ro tates and

through an electronic sensor sends a number

of pulses, and when the number of pulses

corresponding to the water dose set during

programming is reached, the pump is

stopped.

If such value is not reached within 60 sec it

means that there is a probl em:

Then, check for the correc t functioning of the

volumetric counter; there must be 5 V AC on

the term inals duri ng the counter operati on.

Check that the filters are not cl ogged.

Check that the by-pass is no t locked o pen.

The display indicates the

message “Air-break failure”

No water from the mains.

Faulty air- break mi croswitch

Failure to the level detection system (float)

If in the period taken to make any 6

selection the microswitch controlled

by the float is not triggered, the

vending machine is locked for airbreak failure.

The malfuncti on could occur for lack o f water

from the mains, or because of a failure to the

float/microswitch system.

Replace the microswitch with one that MUST

HAVE the same characteristics.

Otherwise various malfunctions could occur.

The display indicates the

message “RAM data”

System lock

Wrong RAM data, which must be retrieved by

initialising the EPROM.

Access the installation procedure and initialise

the Software.

If the problem persists, replace the entire

CPU board.

The display indicates the

message“Coin mech failure”

If the ere is no communi cation between coin

mechanism and CPU board for 30 seco nds (for

serial coin mechanisms only)

Check for correct connection and

configuration of the minidips, if all correct

replace the coin mechanism.

The display indicates the

message“Water failure”

Models with water supply from the m ains:

If the air-break microswitch is activated for more

than a minute

Models with water supply from an i nternal tank:

If the water level is less than 300 cc

Check the water inlet solenoid valve.

Check the correct actuation of relay

K 16

Check the air-break microswitch functioning.

Check the float/microswitch system

functioning.

Coffee is dispensed too

slowly and it tastes burnt

Faulty pump by-pass (open)

Clogged coffee filters.

Excessive t emperature in the flo w-through boil er

Flow-through coffee boiler clogged

Replace the by-pass valve with o ne s et at 10

bars. Consider that coffee must be dispensed

in a maximum time of 15 to 20 seconds;

longer times can clog the filters.

The coffee is dispensed too

quickly and lacks body and

cream

Faulty pump by-pass (closed)

Insufficient tem perature in the flow-through bo iler

Faulty heating element in the he ating pipe

Replace the by-pass with one set at 10 bars.

Check for the cor rect temp erature, which

must be between 95° and 97° C.

Check that there is flow i n the dispensing

tube and that the temperatur e i s at least 60°

C.

Check the functi oning of the specific power

supply board.

Check that the thermo-fuse was not

triggered; if triggered replace with one

having the same ch aracteristics.

The mixers clog up

The whipper failed to rotate

Powder removal drawer full

Insuffici ent water to powder ratio.

Check for the mixer motor overheat

protection trigger, if that is the case check

the cause of such trigger. Empty the powder

collection drawers and check the functioning

of steam suction fan.

Check the powder/li quid setting

TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 17 / 17

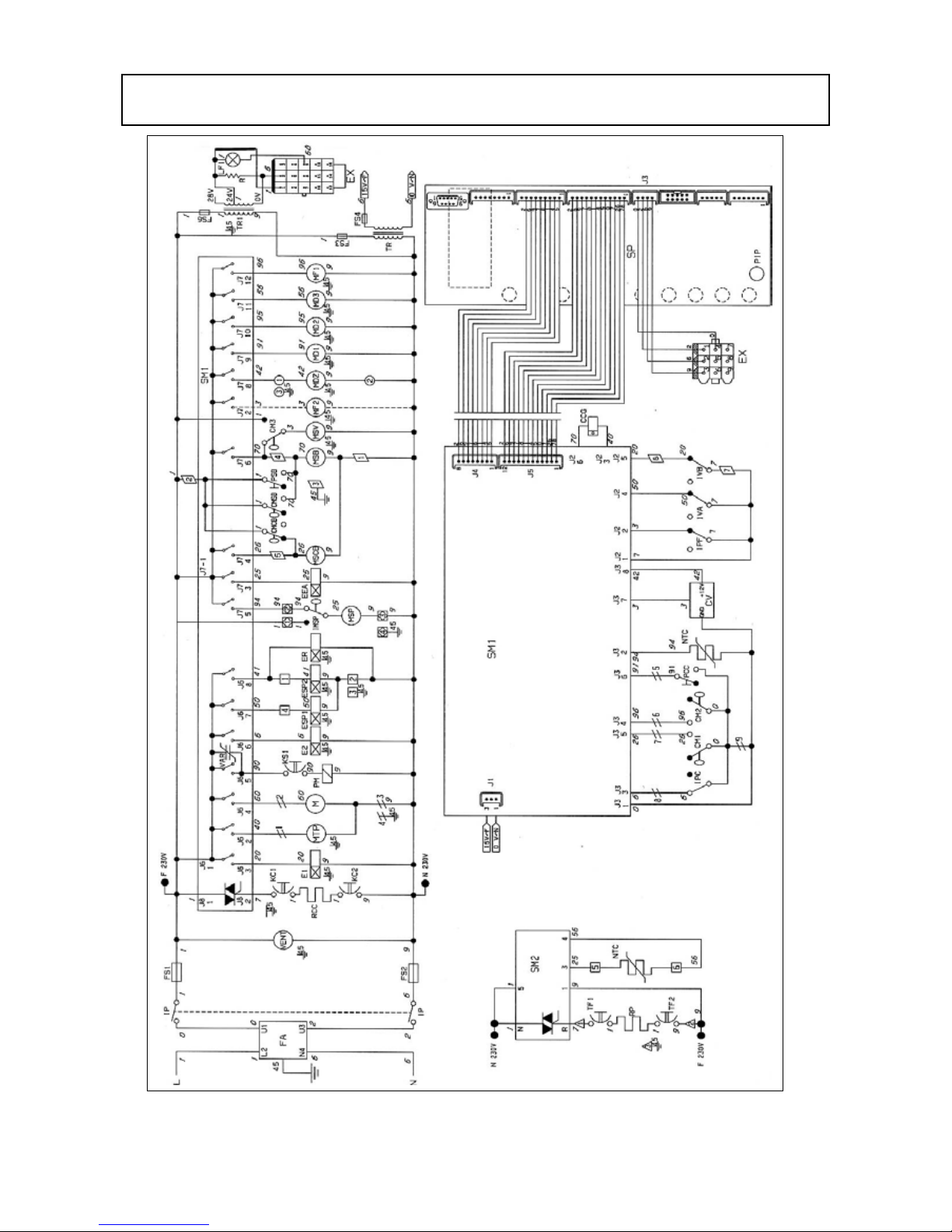

9 - WIRING DIAGRAMS

Loading...

Loading...