Page 1

Cat. No.

No de cat.

Cat. No.

0724-20

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

1/2" HAMMER-DRILL

PERCEUSE À PERCUSSION DE 13 mm (1/2")

TALADRO DE PERCUSIÓN DE 13 mm (1/2")

TO REDUCE THE RISK OF INJURY, USER MUST READ OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER EL MANUAL

DEL OPERADOR.

Page 2

GENERAL SAFETY RULES-FOR ALL BATTERY OPERATED TOOLS

POWER TOOL USE AND CARE

BATTERY TOOL USE AND CARE

WARNING

READ ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in electric shock, fi re and/or

serious injury. The term "power tool" in all of the warnings listed below refers to your

mains-operated (corded) power tool or battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

WORK AREA SAFETY

1. Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2. Do not operate power tools in ex-

plosive atmospheres, such as in the

presence of fl ammable liquids, gases,

or dust. Power tools create sparks which

may ignite the dust or fumes.

3. Keep children and bystanders away

while operating a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

4. Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power tools.

Unmodifi ed plugs and matching outlets

will reduce risk of electric shock.

5. Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

6. Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric

shock.

7. Do not abuse the cord. Never use the

cord for carrying, pulling, or unplugging the power tool. Keep cord away

from heat, oil, sharp edges, or moving parts. Damaged or entangled cords

increase the risk of electric shock.

8. When operating a power tool out-

doors, use an extension cord suitable

for outdoor use. Use of a cord suitable

for outdoor use reduces the risk of electric shock.

PERSONAL SAFETY

9. Stay alert, watch what you are do-

ing and use common sense when

operating a power tool. Do not use

a power tool while you are tired or

under the infl uence of drugs, alcohol

or medication. A moment of inattention

while operating power tools may result

in serious personal injury.

10. Use safety equipment. Always wear

eye protection. Safety equipment such

as dust mask, non-skid safety shoes,

hard hat, or hearing protection used

for appropriate conditions will reduce

personal injuries.

11. Avoid accidental starting. Ensure the

switch is in the off-position before plugging in. Carrying tools with your fi nger on

the switch or plugging in power tools that

have the switch on invites accidents.

12. Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

13. Do not overreach. Keep proper foot-

ing and balance at all times. This

enables better control of the power tool

in unexpected situations.

14. Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery, or long

hair can be caught in moving parts.

15. If devices are provided for the connec-

tion of dust extraction and collection

facilities, ensure these are connected

and properly used. Use of these de-

vices can reduce dust-related hazards.

16. Do not force the power tool. Use the

correct power tool for your application. The correct power tool will do the

job better and safer at the rate for which

it was designed.

17. Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

18. Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools. Such preven-

tive safety measures reduce the risk of

starting the tool accidentally.

19. Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tools or

these instructions to operate power

tools. Power tools are dangerous in the

hands of untrained users.

20. Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect the

power tool's operation. If damaged,

have the power tool repaired before

use. Many accidents are caused by

poorly maintained power tools.

21. Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

22. Use the power tool, accessories and

tool bits etc., in accordance with

these instructions and in the manner

intended for the particular type of

power tool, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

23. Ensure the switch is in the off posi-

tion before inserting battery pack.

Inserting the battery pack into power

tools that have the switch on invites

accidents.

24. Recharge only with the charger speci-

fi ed by the manufacturer. A charger

that is suitable for one type of battery

pack may create a risk of fi re when used

with another battery pack.

25. Use power tools only with specifi cally

designated battery packs. Use of any

other battery packs may create a risk of

injury and fi re.

26. When battery pack is not in use, keep

it away from other metal objects like

paper clips, coins, keys, nails, screws,

or other small metal objects that can

make a connection from one terminal

to another. Shorting the battery terminals

together may cause burns or a fi re.

27. Under abusive conditions, liquid may

be ejected from the battery, avoid

contact. If contact accidentally occurs, fl ush with water. If liquid con-

tacts eyes, additionally seek medical

help. Liquid ejected from the battery

may cause irritation or burns.

SERVICE

28. Have your power tool serviced by a

qualifi ed repair person using only

identical replacement parts. This will

ensure that the safety of the power tool

is maintained.

2 3

Page 3

SPECIFIC SAFETY RULES

Symbology

1. Maintain labels and nameplates. These carry important information. If unreadable or

missing, contact a MILWAUKEE service facility for a free replacement.

2. WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks that are specially designed

to fi lter out microscopic particles.

3. Hold tools by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

4. Keep hands away from all cutting edges and moving parts.

5. Wear ear protectors with impact drill. Exposure to noise can cause hearing loss.

6. Use auxiliary handles supplied with the tool. Loss of control can cause personal

injury.

Cat. No.

0724-20

Volts

DC

28

No Load

RPM

Low 0-600

High 0-1800

10

Volts Direct Current

No Load Revolutions

per Minute (RPM)

Underwriters Laboratories, Inc.,

United States and Canada

Specifi cations

No Load

Blows per

Minute

Low 0-9000

High 0-27000

Flat

Bit

1-1/2"

Auger

Bit

1-1/2"

Wood

Hole

Saw

2-9/16"

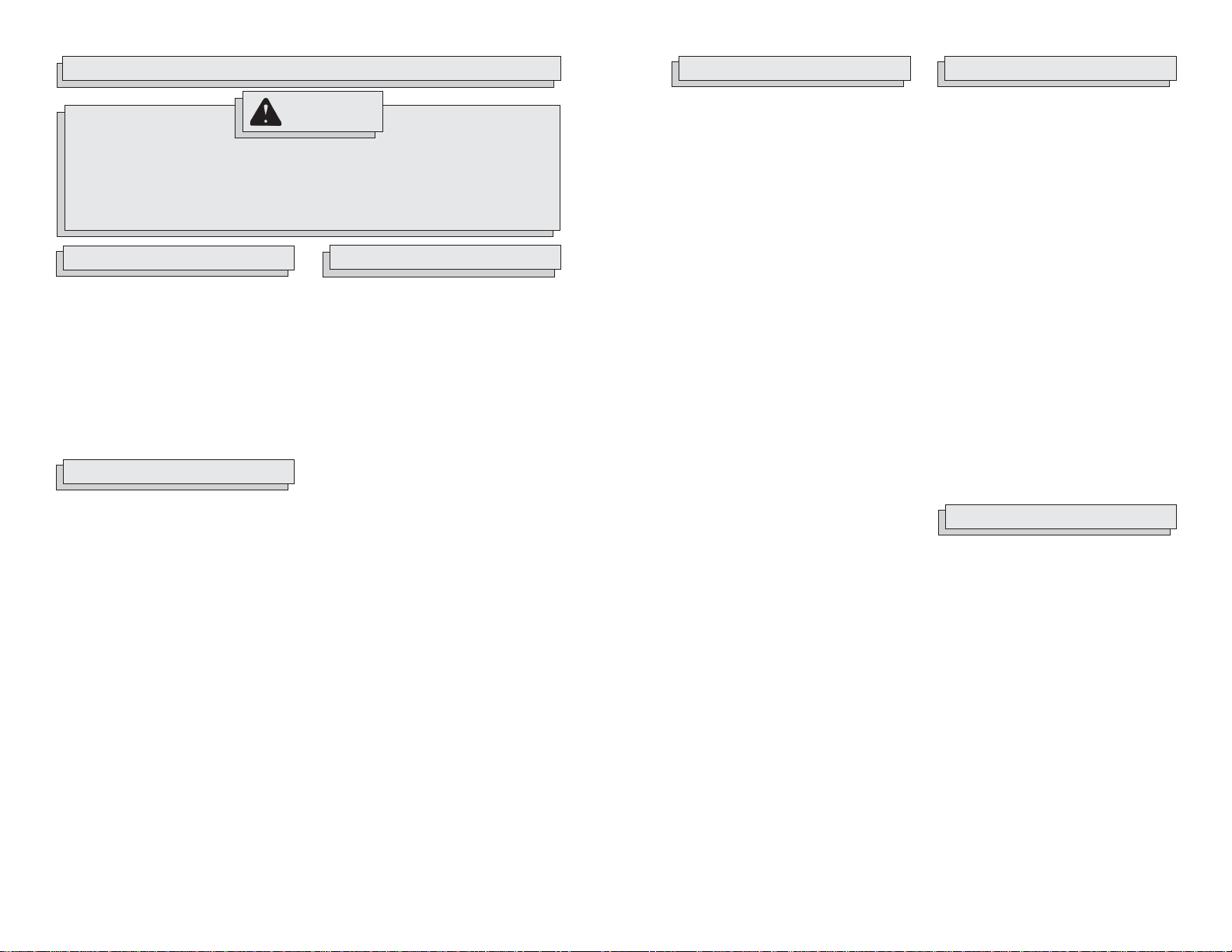

FUNCTIONAL DESCRIPTION

1

Capacities

Screws

(dia.)

1/4"

Steel

1/2"

Masonry

1/2"

9

8

1. Speed selector

2. Tool holder

3. Control switch

4. Battery pack

5. Battery latch

6. Trigger

7. Torque selector collar

8. Hammer/drill selector collar

9. Keyless chuck

10. Side handle

4 5

5

2

3

7

6

4

Page 4

TOOL ASSEMBLY

WARNING

To reduce the risk of injury, always

lock trigger or remove battery pack

before changing or removing accessories. Only use accessories specifi cally recommended for this tool.

Others may be hazardous.

Removing Battery Pack from Tool

Push in the release buttons and pull the

battery pack away from the tool.

Inserting Battery Pack into Tool

The battery pack can be inserted into the

tool in two ways. To insert the battery pack

onto the tool, slide the pack onto the body

of the tool. Make sure it latches securely

into place.

Fig. 1

For working in restricted

spaces, insert the battery

pack from the front of the

tool.

Fig. 2

For optimum weight

distribution and balance,

insert the battery pack

from the back of the tool.

Installing the Side Handle

1. To install the side handle, loosen the

side handle grip until the ring is large

enough to slide over the torque selector

collar. The raised rib on the side handle

ring fi ts inside the groove around the

tool. Rotate the handle to the desired

position and tighten the side handle until

it is secure.

2. To remove the side handle, loosen the

side handle grip until the ring is large

enough to slide off the tool.

Clip-Lok

TM

System

The Clip-Lok system consists of three

pieces; the belt clip, the tool holder, and the

bit holder.

Fig. 3

Bit holder

Tool holder

Front tangs

Clamp

release

Belt clip

Stud

Clamp

Pin

Tool release lever

The system is shipped assembled for righthanded use. To change the assembly for

left-handed use:

1. Remove battery pack.

2. Remove screws holding the tool holder

and the bit holder.

3. Lift the holders at the narrow end and

pull the front tangs out of their slots.

4. Replace the pieces onto the desired

side by sliding the tangs into the slots.

Tighten the screws securely.

Attaching the Belt Clip

The belt clip can be mounted to tool belts,

bags, buckets, etc. To mount the belt clip:

1. Pull up the clamp release. The clamp

will pop out.

2. Slide the clamp over the tool belt, bag,

bucket, etc.

3. Press in the clamp to tighten.

Using the Clip-Lok Tool Holder

1. To attach the tool to the belt clip, slide

the tool holder over the stud on the belt

clip until it is held in place by the protruding pin.

2. To release the tool from the belt clip,

grasp the tool handle, push down on

the tool release lever with your thumb,

and pull up on the tool.

Using the Clip-Lok Bit Holder

The bit holder holds two standard 1/4" hex

shank bits up to two inches long.

1. Insert the bit by pressing it into the

clip.

2. Remove the bit by lifting the tip of the

bit and pulling it out of the clip.

6 7

Page 5

OPERATION

WARNING

To reduce the risk of injury, wear

safety goggles or glasses with side

shields.

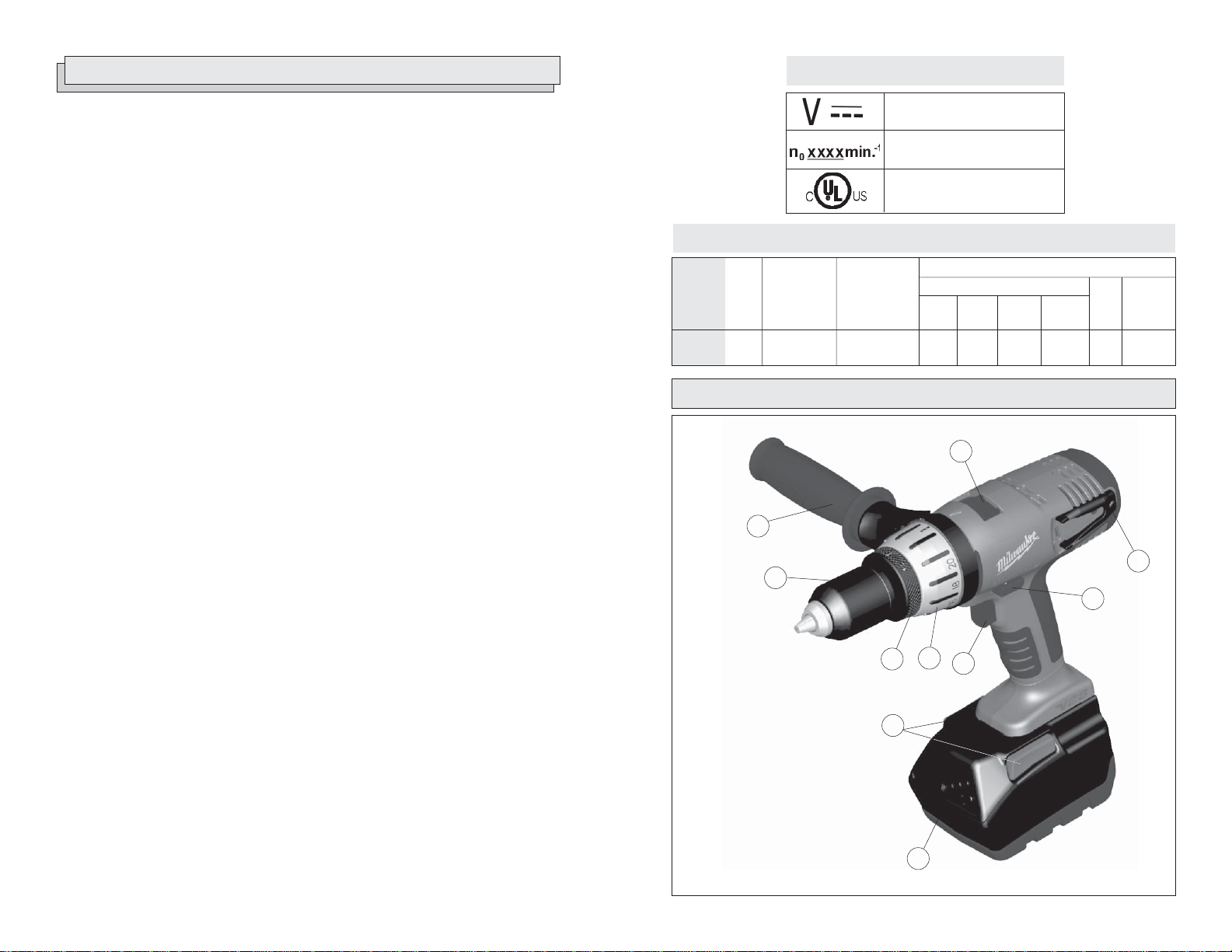

Using Keyless Chucks

Y our cordless tool is equipped with a spindle

lock. The chuck can be tightened with one

hand, creating higher grip strengths on the

bit.

Always remove the battery pack or lock the

trigger before inserting or removing bits.

Fig. 4

1. To open the chuck jaws, turn the sleeve

in the counterclockwise direction.

When using drill bits, allow the bit to

strike the bottom of the chuck. Center

the bit in the chuck jaws and lift it about

1/16" off of the bottom.

When using screwdriver bits, insert the

bit far enough for the chuck jaws to grip

the hex of the bit.

2. T o close the chuck jaws, turn the sleeve

in the clockwise direction. The bit is secure when the chuck makes a ratcheting

sound and the sleeve can not be rotated

any further.

3. To remove the bit, turn the sleeve in the

counterclockwise direction.

NOTE: A ratcheting sound may be heard

when the chuck is opened or closed. This

noise is part of the locking feature, and

does not indicate a problem with the chuck's

operation.

Sleeve

Selecting Speed

Fig. 5

The speed selector is on top of the motor

housing. Allow the tool to come to a complete

stop before changing speeds. See “Applications” for recommended speeds under

various conditions.

1. For Low speed (up to 600 RPM), push

the speed selector to the left.

2. For High speed (up to 1800 RPM), push

the speed selector to the right.

Selecting Hammer or Drill Action

MILWAUKEE Hammer-Drills are designed

for three operating modes: drilling with

hammering action, drilling only, and driving

screws. To set the operating mode, rotate

the hammer/drill selector collar and torque

selector collar to the desired symbols.

1. To use the hammer-drilling mode

(Fig. 6), rotate the hammer/drill selector

collar until the hammer symbol appears in line with the arrow. Then rotate

the Torque selector collar until the drill

symbol appears in line with the arrow. Apply pressure to the bit to engage

the hammering mechanism.

Fig. 6

To Hammer

NOTE: When using carbide bits, do not use

water to settle dust. Do not attempt to drill

through steel reinforcing rods. This will damage the carbide bits.

Low

High

2. To use the drilling only mode (Fig. 7),

rotate the hammer/drill selector collar

until the drill symbol appears in line

with the arrow. Then rotate the Torque

selector collar until the drill symbol

appears in line with the arrow.

Fig. 7

To Drill

3. To use the driving screws mode

(Fig. 8), rotate the hammer/drill selector

collar until the drill symbol appears

in line with the arrow. Then rotate the

torque selector collar until the desired

clutch setting appears in line with the

arrow.

Fig. 8

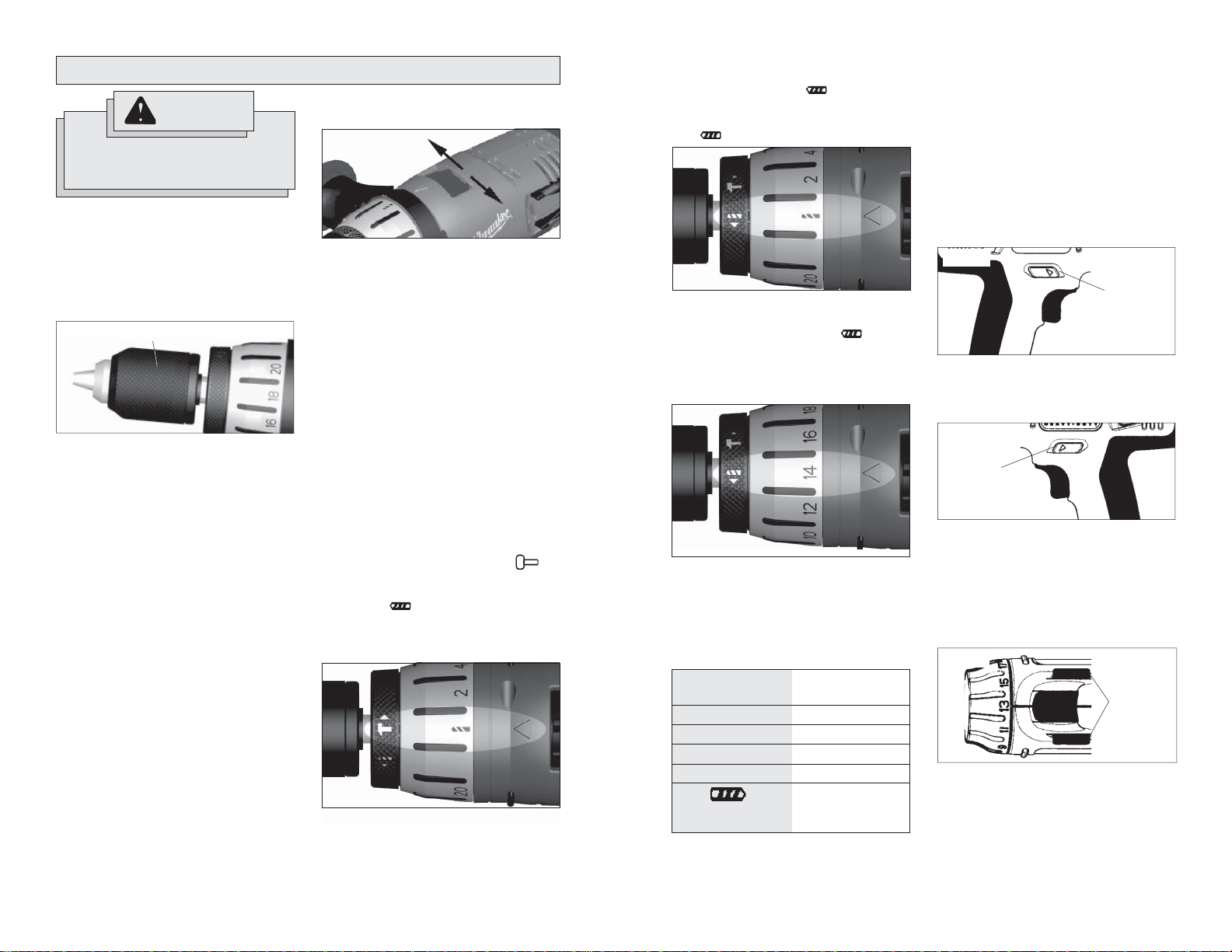

To Drive Screws

The adjustable clutch ,when properly adjusted, will slip at a preset torque to prevent

driving the screw too deep into different

materials and to prevent damage to the

screw or tool.

The torque specifi cations shown here are

approximate values.

Torque selector

collar setting

1 - 5

6 - 10

11 - 15

16 - 20

Drill

Low

High

NOTE: Use a piece of scrap material to test

the different clutch positions before driving

screws into the workpiece.

0724-20 Torque

0 - 17 in. lbs.

21 - 38 in. lbs.

42 - 60 in. lbs.

65 - 85 in. lbs.

600 in. lbs.

300 in. lbs.

Using Control Switch

The control switch may be set to three positions: forward, reverse and lock. Due to a

lockout mechanism, the control switch can

only be adjusted when the ON/OFF switch

is not depressed. Always allow the motor to

come to a complete stop before using the

control switch.

For forward (clockwise) rotation, push in the

control switch from the right side of the tool

(Fig. 9). Check the direction of rotation

before use.

Fig. 9

Push in

for forward

For reverse (counterclockwise) rotation,

push in the control switch from the left side

of the tool (Fig. 10). Check direction of

rotation before use.

Fig. 10

Push in

for reverse

To lock the trigger, push the control switch

to the center position (Fig. 11). The trigger

will not work while the control switch is in

the center locked position. Always lock the

trigger or remove the battery pack before

performing maintenance, changing accessories, storing the tool and any time the tool

is not in use.

Fig. 11

Push to

center

position to

lock trigger

8 9

Page 6

Starting, Stopping and Controlling

Speed

1. To start the tool, grasp the handle fi rmly

and pull the trigger.

2. To vary the speed, increase or decrease

the pressure on the trigger. The further

the trigger is pulled, the greater the

speed.

3. To stop the tool, release the trigger.

Make sure the bit comes to a complete

stop before laying the tool down.

Electric Brake

The electric brake engages when the trigger

is released, causing the bit to stop and allowing you to proceed with your work. Generally,

the bit stops within two seconds. However,

there may be a delay between the time

you release the trigger and when the brake

engages. Occasionally the brake may miss

completely. If the brake misses frequently,

the tool needs servicing by an authorized

MILWAUKEE service facility.

Drilling

Set both the hammer/drill and torque selector

collars to the drill positions.

Place the bit on the work surface and apply fi rm pressure before starting. Too much

pressure will slow the bit and reduce drilling

effi ciency. Too little pressure will cause the

bit to slide over the work area and dull the

point of the bit.

If the tool begins to stall, reduce pressure

slightly to allow the bit to regain speed. If

the bit binds, reverse the motor to free the

bit from the workpiece.

Cold Weather Operation

The V28 Lithium-Ion battery pack can be

used in temperatures down to -4°F. When

the battery pack is very cold, it may pulse for

the fi rst minute of use to warm itself up. Put

the battery pack on a tool and use the tool in

a light application. After about a minute, the

pack will have warmed itself up and operate

normally.

APPLICATIONS

WARNING

To reduce the risk of electric shock,

check work area for hidden pipes

and wires before drilling or driving

screws.

Drilling in Wood, Composition Materials

and Plastic

When drilling in wood, composition materials

and plastic, start the drill slowly, gradually

increasing speed as you drill. When drilling

into wood, use wood augers or twist drill bits.

Always use sharp bits. When using twist drill

bits, pull the bit out of the hole frequently to

clear chips from the bit fl utes. T o reduce the

chance of splintering, back work with a piece

of scrap wood. Select low speeds for plastics

with a low melting point.

Drilling in Metal

When drilling in metal, use high speed steel

twist drills or hole saws. Use a center punch

to start the hole. Lubricate drill bits with cutting oil when drilling in iron or steel. Use a

coolant when drilling in nonferrous metals

such as copper, brass or aluminum. Back

the material to prevent binding and distortion

on breakthrough.

Drilling in Masonry

When drilling in masonry, select the hammer-drill operating mode. Use high speed

carbide-tipped bits. Drilling soft masonry

materials such as cinder block requires

little pressure. Hard materials like concrete

require more pressure. A smooth, even fl ow

of dust indicates the proper drilling rate. Do

not let the bit spin in the hole without cutting.

Do not use water to settle dust or to cool bit.

Both actions will damage the carbide.

Driving Screws and Nut Running

Drill a pilot hole when driving screws into

thick or hard materials. Set the torque selector collar to the proper position and set

the speed to low. Use the proper style and

size screwdriver bit for the type of screw

you are using.

With the screwdriver bit in the screw, place

the tip of the screw on the workpiece and

apply fi rm pressure before pulling the trig-

ger. Screws can be removed by reversing

the motor.

Overloading

Continuous overloading may cause permanent damage to tool or battery pack.

WARNING

High rotational force. To reduce the

risk of injury, always hold or brace

securely. Always use side handle

on tools.

Bit Binding

A high rotational force occurs when a bit

binds. If the bit binds, the tool will be forced

in the opposite direction of the bit rotation.

Bits may bind if they are misaligned or when

they are breaking through a hole. Wood

boring bits can also bind if they run into

nails or knots. Be prepared for bit binding

situations.

To reduce the chance of bit binding:

• Use sharp bits. Sharp bits are less likely

to bind when drilling.

• Use the proper bit for the job. There are bits

that are designed for specifi c purposes.

• Use caution when drilling pitchy, knotty,

wet or warped material or when drilling in

material that may contain nails.

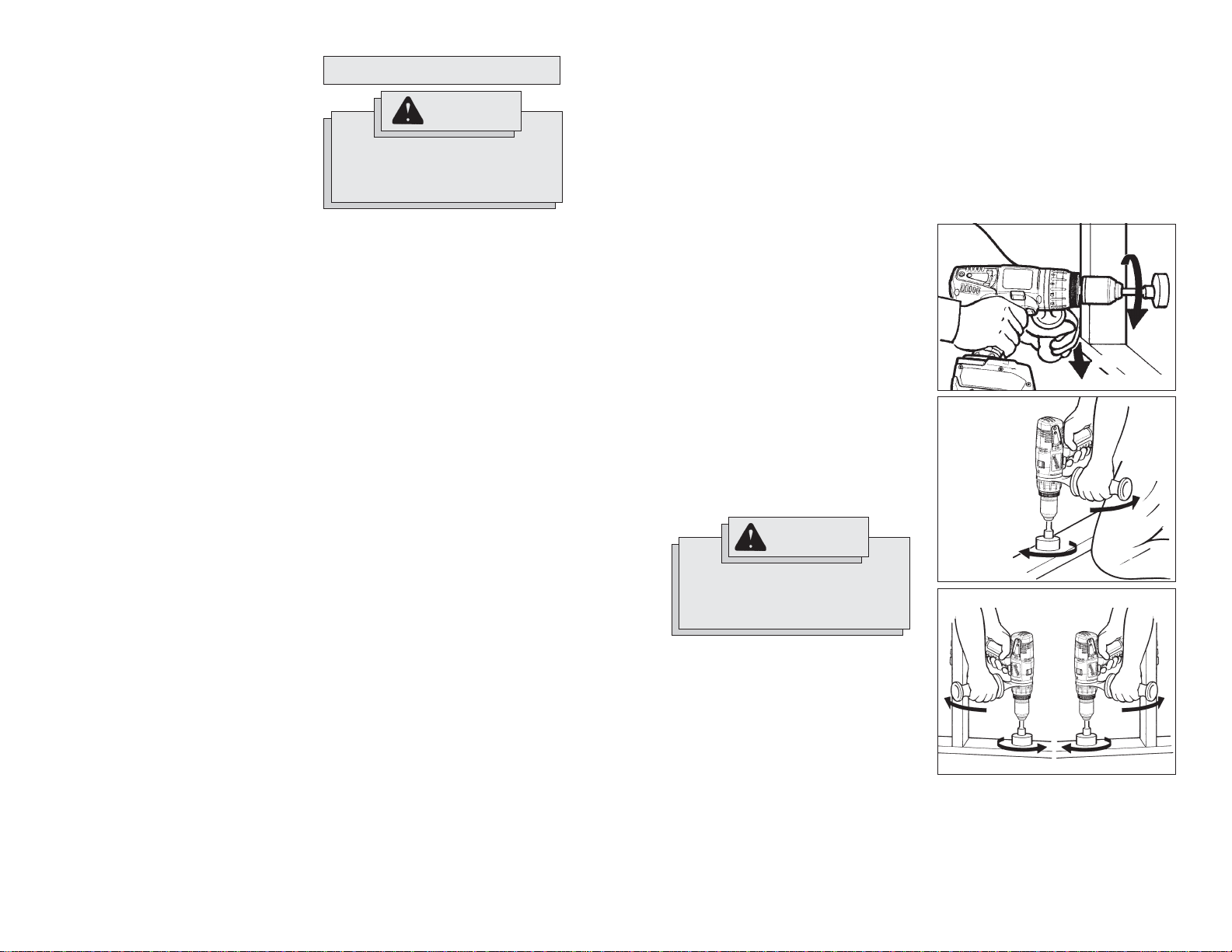

Typical Bracing Methods

Fig. 12

Bracing against the fl oor

Forward

rotation

Reaction

Fig. 13

Forward

rotation

Reaction

Bracing against

your leg

Fig. 14

Reverse rotation

Bracing against a stud

Reaction Reaction

Forward rotation

10 11

Page 7

MAINTENANCE

FIVE YEAR TOOL LIMITED WARRANTY

WARNING

To reduce the risk of personal injury, always unplug the charger and

remove the battery pack from the

charger or tool before performing any

maintenance. Never disassemble the

tool, battery pack or charger. Contact

a MILW AUKEE service facility for ALL

repairs.

Maintaining Tool

Keep your tool, battery pack and charger

in good repair by adopting a regular maintenance program. After six months to one

year, depending on use, return the tool,

battery pack and charger to a MILWAUKEE

service facility for:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

• Electrical inspection (battery pack,

charger, motor)

• T esting to assure proper mechanical and

electrical operation

If the tool does not start or operate at full

power with a fully charged battery pack,

clean the contacts on the battery pack. If

the tool still does not work properly, return

the tool, charger and battery pack to a

MILWAUKEE service facility for repairs.

WARNING

To reduce the risk of personal injury and damage, never immerse your

tool, battery pack or charger in liquid

or allow a liquid to fl ow inside them.

Cleaning

Clean out dust and debris from vents and

electrical contacts by blowing with compressed air. Keep tool handles clean, dry and

free of oil or grease. Use only mild soap and

a damp cloth to clean the tool, battery pack

and charger, keeping away from all electrical contacts. Certain cleaning agents and

solvents are harmful to plastics and other

insulated parts. Some of these include gasoline, turpentine, lacquer thinner, paint thinner ,

chlorinated cleaning solvents, ammonia and

household detergents containing ammonia.

Never use fl ammable or combustible sol-

vents around tools.

Repairs

For repairs, return the tool, battery pack and

charger to the nearest authorized service

center.

ACCESSORIES

WARNING

Always remove battery pack before

changing or removing accessories.

Only use accessories specifically

recommended for this tool. Others

may be hazardous.

For a complete listing of accessories refer to

your MILWAUKEE Electric Tool catalog or go

on-line to www.milwaukeetool.com. To obtain

a catalog, contact your local distributor or a

service center.

Every MILWAUKEE electric power tool (including battery charger) is warranted to the original

purchaser only to be free from defects in material and workmanship. Subject to certain exceptions, MILWAUKEE will repair or replace any part on a electric power tool which, after examina-

tion, is determined by MILWAUKEE to be defective in material or workmanship for a period of

fi ve (5) years* after the date of purchase. Return the electric power tool and a copy of proof

of purchase to a MILWAUKEE factory Service/Sales Support Branch location or MILWAUKEE

Authorized Service Station, freight prepaid and insured, are requested for this warranty to be

effective. This warranty does not apply to damage that MILWAUKEE determines to be from

repairs made or attempted by anyone other than MILWAUKEE authorized personnel, misuse,

alterations, abuse, normal wear and tear, lack of maintenance, or accidents.

* The warranty period for Hoists (lever, hand chain, & electric chain hoists), all Ni-CD battery

packs, Work Lights (cordless fl ashlights), Job Site Radios, and Trade Titan™ Industrial W ork

Carts is one (1) year from the date of purchase. *The warranty period for Li-Ion battery packs

that do not contain V™-technology – 4.0 volts through 18.0 volts - is two (2) years from the

date of purchase.

*There is a separate warranty for V™-technology Li-Ion Battery Packs V™18 volts and above

that accompany V™-technology cordless power tools:

*Every MILWAUKEE V™-technology Li-Ion Battery Pack 18 volts or above is covered by an

initial 1000 Charges/2 Years free replacement warranty. This means that for the earlier of

the fi rst 1000 charges or two (2) years from the date of purchase/fi rst charge, a replacement

battery will be provided to the customer for any defective battery free of charge. Thereafter,

customers will also receive an additional warranty on a pro rata basis up to the earlier of the

fi rst 2000 charges or fi ve (5) Years from the date of purchase/fi rst charge. This means that

every customer gets an additional 1000 charges or three (3) years of pro rata warranty on

the V™-technology Li-Ion Battery Pack 18 volts or above depending upon the amount of use.

During this additional warranty period, the customer pays for only the useable service received

over and above the fi rst 1000 Charges/2 years, based on the date of fi rst charge and number

of charges found on the battery pack via Milwaukee’s V™-technology Service Reader.

Warranty Registration is not necessary to obtain the applicable warranty on a MILWAUKEE

product. However, proof of purchase in the form of a sales receipt or other information deemed

suffi cient by MILWAUKEE, is requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN IS A CONDITION OF THE CONTRACT FOR THE PURCHASE OF

EVERY MILWAUKEE PRODUCT. IF YOU DO NOT AGREE TO THIS CONDITION, YOU

SHOULD NOT PURCHASE THE PRODUCT. IN NO EVENT SHALL MILWAUKEE BE LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL OR PUNITIVE DAMAGES,

OR FOR ANY COSTS, ATTORNEY FEES, EXPENSES, LOSSES OR DELAYS ALLEGED

TO BE AS A CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN ANY

PRODUCT INCLUDING, BUT NOT LIMITED TO, ANY CLAIMS FOR LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR IMPLIED. WITHOUT LIMITING THE

GENERALITY OF THE FOREGOING, MILWAUKEE DISCLAIMS ANY IMPLIED W ARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE OR PURPOSE, AND ALL

OTHER WARRANTIES.

This warranty applies to product sold in the U.S.A., Canada and Mexico only.

12 13

Page 8

RÈGLES GÉNÉRALES DE SÉCURITÉ POUR LES OUTILS

ALIMENTÉS PAR BATTERIE

AVERTISSEMENT

LIRE SOIGNEUSEMENT TOUTES LES INSTRUCTIONS

Le non respect des instructions ci-après peut entraîner des chocs électriques, des

incendies et/ou des blessures graves. Le terme «outil électrique» fi gurant dans les

avertissements ci-dessous renvoie à l’outil électrique à alimentation par le réseau

(à cordon) ou par batterie (sans fi l).

CONSERVER CES INSTRUCTIONS

SÉCURITÉ DU LIEU

DE TRAVAIL

1. Maintenir la zone de travail propre et bien

éclairée. Les zones encombrées ou mal

éclairées sont favorables aux accidents.

2. Ne pas utiliser d’outil électrique dans

une atmosphère explosive, telle

qu’en en présence de liquides, de

gaz ou de poussières infl ammables.

Les outils électriques génèrent des

étincelles qui peuvent enfl ammer les

poussières ou les fumées.

3. Tenir les enfants et les personnes

non autorisées à l’écart pendant le

fonctionnement d’un outil électrique.

Un manque d’attention de l’opérateur risque

de lui faire perdre le contrôle de l’outil.

SÉCURITÉ ÉLECTRIQUE

4. La fi che de l’outil électrique doit cor-

respondre à la prise d’alimentation.

Ne jamais modifier la fiche d’une

manière quelconque. Ne pas utiliser

d’adaptateur avec les outils électriques mis à la terre (à la masse).

Des fi ches non modifi ées et des prises

d’alimentation assorties réduisent le

risque de choc électrique.

5. Éviter tout contact corporel avec des

surfaces reliées à la masse ou à la

terre telles que tuyaux, radiateurs,

cuisinières et réfrigérateurs. Un risque

de choc électrique plus élevé existe si le

corps est relié à la masse ou à la terre.

6. Ne pas exposer les outils électriques

à la pluie ou à l’humidité. Le risque de

choc électrique augmente si de l’eau

s’infi ltre dans un outil électrique.

7. Prendre soin du cordon. Ne jamais

utiliser le cordon pour transporter,

tirer ou débrancher l’outil électrique.

Tenir le cordon à l’écart de la chaleur ,

des huiles, des arêtes coupantes ou

des pièces en mouvement. Un cordon

endommagé ou emmêlé présente un

risque accru de choc électrique.

8. Se procurer un cordon d’alimentation

approprié en cas d’utilisation

d’un outil électrique à l’extérieur.

L’utilisation d’un cordon d’alimentation

pour usage extérieur réduit le risque de

choc électrique.

SÉCURITÉ INDIVIDUELLE

9. Être sur ses gardes, être attentif et

faire preuve de bon sens en utilisant

un outil électrique. Ne pas utiliser

un outil électrique en cas de fatigue

ou sous l’influence de drogues,

d’alcool ou de médicaments. Un

instant d’inattention lors de l’utilisation

d’un outil électrique peut entraîner des

blessures graves.

10. Utiliser un équipement de sécurité.

Toujours porter des lunettes de protection. Un équipement de sécurité

comprenant masque anti-poussière,

chaussures de sécurité anti-dérapantes,

casque ou dispositif de protection antibruit peut, dans les circonstances appropriées, réduire le risque de blessure.

11. Éviter tout démarrage accidentel de

l’outil. S’assurer que le commutateur

est en position OFF (Arrêt) avant de

brancher l’outil. Le port de l’outil avec

un doigt sur le commutateur ou son

branchement avec le commutateur en

position ON (Marche) sont favorables

aux accidents.

14 15

12. Retirer toute clé de réglage avant de

mettre l’outil sous tension. Une clé

laissée attachée sur une pièce mobile

de l’outil électrique peut entraîner des

blessures.

13. Ne pas travailler à bout de bras. Bien

garder un bon équilibre à tout instant.

Ceci permet de mieux préserver la

maîtrise de l’outil électrique dans des

situations imprévues.

14. Porter des vêtements adéquats. Ne

pas porter de vêtements amples

ni de bijoux. Ne pas approcher les

cheveux, vêtements et gants des

pièces en mouvement. Les vêtements

amples, les bijoux ou les cheveux longs

risquent d’être happés par les pièces en

mouvement.

15. Si des dispositifs sont prévus pour

l’extraction et la récupération des

poussières, vérifi er qu’ils sont con-

nectés et utilisés correctement.

L’utilisation de ces dispositifs peut réduire les risques liés aux poussières.

UTILISATION ET ENTRETIEN

DE L’OUTIL ÉLECTRIQUE

16. Ne pas forcer l’outil électrique.

Utiliser l’outil électrique approprié

à l’application considérée. L’outil

électrique adapté au projet considéré

produira de meilleurs résultats, dans

des conditions de sécurité meilleures, à

la vitesse pour laquelle il a été conçu.

17. Ne pas utiliser l’outil électrique si le

commutateur ne le met pas sous ou

hors tension. Tout outil électrique dont

le commutateur de marche-arrêt est inopérant est dangereux et doit être réparé.

18. Débrancher la fiche de la prise

d’alimentation et/ou la batterie de

l’outil électrique avant d’effectuer des

réglages, de changer d’accessoires

ou de ranger l’outil. De telles mesures

de sécurité préventive réduisent le

risque de mettre l’outil en marche accidentellement.

19. Ranger les outils électriques inutili-

sés hors de la portée des enfants et

ne pas laisser des personnes qui

connaissent mal les outils électriques ou ces instructions utiliser

ces outils. Les outils électriques sont

dangereux dans les mains d’utilisateurs

non formés à leur usage.

20. Entretien des outils électriques.

S’assurer de l’absence de tout désalignement ou de grippage des

pièces mobiles, de toute rupture de

pièce ou de toute autre condition

qui pourrait affecter le bon fonctionnement de l’outil électrique. En

cas de dommages, faire réparer l’outil

avant de l’utiliser de nouveau. Les

outils électriques mal entretenus sont à

la source de nombreux accidents.

21. Garder les outils de coupe affûtés et

propres. Les outils de coupe correctement entretenus et bien affûtés risquent

moins de se gripper et sont plus faciles

à manier.

22. Utiliser cet outil électrique, les acces-

soires, les mèches, etc. conformément à ces instructions et de la façon

prévue pour ce type particulier d’outil

électrique, tout en prenant en compte

les conditions de travail et le type de

projet considérés. L’utilisation de cet

outil électrique pour un usage autre que

l’usage prévu peut créer des situations

dangereuses.

UTILISATION ET ENTRETIEN

DE LA BATTERIE

23. S’assurer que le commutateur est en

position OFF (Arrêt) avant d’insérer la

batterie. L’insertion de la batterie dans

un outil électrique dont le commutateur

est en position ON (Marche) est favorable aux accidents.

24. Ne recharger la batterie qu’avec le

chargeur spécifi é par le fabricant.

Un chargeur qui convient à un type de

batterie peut créer un risque d’incendie

s’il est utilisé avec un autre type de batterie.

25. N’utiliser les outils électriques

qu’avec les batteries spécialement

conçues pour eux. L’utilisation de

batteries d’autres marques peut créer

un risque de blessure et d’incendie.

26. Lorsque la batterie est hors service,

la ranger à l’écart d’autres objets métalliques tels que trombones, pièces

de monnaie, clés, clous, vis et autres

petits objets métalliques qui peuvent

établir une connexion d’une borne à

l’autre. Un court-circuit aux bornes de

la batterie peut provoquer des brûlures

ou un incendie.

Page 9

27. Du liquide peut être éjecté de la bat-

terie en cas de manutention abusive

; éviter tout contact. En cas de contact accidentel avec les projections,

rincer à l’eau. En cas de contact

avec les yeux, consulter un médecin.

Le liquide s’échappant de la batterie

peut provoquer des irritations ou des

brûlures.

ENTRETIEN

28. Faire effectuer l’entretien de l’outil

électrique par un technicien qualifié qui n’utilisera que des pièces

de rechange identiques. La sé-

curité d’utilisation de l’outil en sera

préservée.

Pictographie

Tension CD seul.

Tours-minute á vide (RPM)

Underwriters Laboratories, Inc.,

États-Unis et Canada

RÈGLES DE SÉCURITÉ SPÉCIFIQUES

1. Maintenir en l’état les étiquettes et les plaques d’identifi cation.Des informations

importantes y fi gurent. Si elles sont illisibles ou manquantes, contacter un centre de

services et d’entretien MILWAUKEE pour un remplacement gratuit.

2. AVERTISSEMENT : Certaines poussières générées par les activités de ponçage, de

coupe, de rectifi cation, de perforage et d’autres activités de construction contiennent des

substances considérées être la cause de malformations congénitales et de troubles de

l’appareil reproducteur. Parmi ces substances fi gurent:

• le plomb contenu dans les peintures à base de plomb;

• la silice cristalline des briques, du ciment et d’autres matériaux de maçonnerie, ainsi

que

• l’arsenic et le chrome des sciages traités chimiquement.

Les risques encourus par l’opérateur envers ces expositions varient en fonction de la

fréquence de ce type de travail. Pour réduire l’exposition à ces substances chimiques,

l’opérateur doit: travailler dans une zone bien ventilée et porter l’équipement de sécurité

approprié, tel qu’un masque anti-poussière spécialement conçu pour fi ltrer les particules

microscopiques.

3. Tenir l’outil par les surfaces de prise isolées si, au cours des travaux, l’outil de

coupe risque d’entrer en contact avec des fi ls cachés ou avec son propre cordon.

Le contact avec un fi l sous tension met les parties métalliques exposées de l’outil sous

tension, ce qui infl igera un choc électrique à l’opérateur.

4. Ne pas approcher les mains des arêtes coupantes et des pièces en mouvement.

5. Porter des protège-oreilles avec un marteau perforateur. Une exposition au bruit peut

provoquer une perte auditive.

6. Utiliser les poignées auxiliaires fournies avec l’outil. Une perte de contrôle peut

provoquer des blessures.

No de

cat.

0724-20

Volts

cd

28

Tr/min.

à vide

Bas 0-600

Haut 0-1 800

10

9

Spécifi cations

Caractéristiques

Bois

coups par

minute à vide

Bas 0-9 000

Haut 0-27 000

Mèche

plate

38 mm

(1-1/2")

Mèche de

tarière

38 mm

(1-1/2")

Scie-

cloche

65 mm

(2-9/16")

DESCRIPTION FONCTIONNELLE

1

7

8

6

Vis

(Ø)

6 mm

(1/4")

Acier

13 mm

(1/2")

Maçonnerie

13 mm

(1/2")

2

3

1. Sélecteur de vitesse

2. Porte-outils

5

3. Commutateur

4. Batterie

5. Verrou de la batterie

6. Détente

7. Collier de sélection de couple

8. Collier de sélection marteau/perforateur

9. Mandrin sans clé

10. Poignée latérale

16 17

4

Page 10

MONTAGE DE L'OUTIL

AVERTISSEMENT

Pour éviter les risques de blessure,

toujours verrouiller la détente ou retirer la batterie avant de changer ou de

démonter les accessoires. N’utiliser

que les accessoires spécialement

conçus pour cet outil. Les accessoires non recommandés peuvent

présenter des dangers.

Retrait de la batterie de l’outil

Pousser les boutons d’ouverture vers

l’intérieur et retirer la batterie de l’outil.

Insertion de la batterie dans l’outil

La batterie peut être insérée dans l’outil

de deux façons. Pour insérer la batterie

dans l’outil, la glisser sur le corps de l’outil.

S’assurer qu’elle se loge fermement en

place.

Fig. 1

Pour le travail

dans des espaces

restreints, insérer la

batterie par l’avant de

l’outil.

Fig. 2

Pour une distribution

du poids et un équilibre

optimaux, insérer la

batterie par l’arrière

de l’outil.

Installation de la poignée latérale

1. Pour installer la poignée latérale,

desserrer la saisie de la poignée latérale

jusqu’à ce que la bague soit suffi sam-

ment large pour glisser sur le collier de

sélection de couple. La rainure relevée

de la bague de la poignée latérale

s’adapte dans la gorge autour de l’outil.

Faire tourner la poignée sur la position

souhaitée et serrer la poignée latérale

jusqu’à ce qu’elle soit bien fi xée.

2. Pour retirer la poignée latérale,

desserrer la saisie de la poignée latérale

jusqu’à ce que la bague soit suffi sam-

ment large pour glisser de l’outil.

Système Clip-Lok

TM

Le système Clip-Lok consiste en trois éléments: l’attache de ceinture, le porte-outils

et le porte-mèches.

Fig. 3

Porte-outils

Tenons avant

Attache de ceinture

Goujon

Broche

Levier de libération de l’outil

Porte-mèches

Dispositif de

déverrouillage

de la bride

Bride

Le système est expédié assemblé pour un

utilisateur droitier. Pour modifi er le montage

pour un utilisateur gaucher:

1. Retirer la batterie.

2. Retirer les vis retenant le porte-outils et

le porte-mèches.

3. Les relever à l’extrémité la plus étroite

et tirer les tenons avant hors de leurs

encoches.

4. Remettre les éléments sur le côté désiré

en glissant les tenons dans les encoches. Serrer les vis fermement.

Fixation du clip de ceinture

L’attache de ceinture peut être montée

sur des ceintures porte-outils, des sacs,

des seaux, etc. Pour monter la bride de

ceinture:

1. Relever le dispositif de déverrouillage

de la bride. La bride se détache.

2. Faire glisser la bride sur la ceinture

porte-outil, le sac, le seau, etc.

3. Enfoncer la bride pour serrer.

Utilisation du porte-outils Clip-Lok

1. Pour fi xer l’outil à l’attache de ceinture,

faire glisser le porte-outil sur le goujon

de l’attache de ceinture jusqu’à ce qu’il

soit maintenu en place par la broche

protubérante.

2. Pour libérer l’outil de l’attache de cein-

ture, saisir le manche de l’outil, pousser

le levier de libération de l’outil avec le

pouce et extraire l’outil.

Utilisation du porte-mèches Clip-Lok

Le porte-mèches porte deux mèches standard hexagonales d’1/4 pouce allant jusqu’à

2 pouces de long.

1. Insérer la mèche en l’appuyant dans

l’attache.

2. Retirer la mèche en relevant l’extrémité

de la mèche et en la tirant hors de

l’attache.

18 19

Page 11

MANIEMENT

AVERTISSEMENT

Pour minimiser les risques de blessures, portez des lunettes à coques

latérales.

Utilisation des mandrins sans clé

L’outil sans fi l est équipé d’une commande

de verrouillage de la broche. Le mandrin peut

être serré d’une main, créant des forces de

prise supérieures sur la mèche.

Fig. 4

Toujours retirer la batterie ou verrouiller la

détente avant d’insérer ou de retirer des

mèches.

1. Pour ouvrir les mâchoires du mandrin,

Lors de l’utilisation de mèches de perfor-

Lors de l’utilisation de mèches de tourn-

2. Pour fermer les mâchoires du mandrin,

3. Pour retirer la mèche, faire tourner le

REMARQUE: Un cliquetis peut être entendu

lorsque le mandrin est ouvert ou fermé. Ce

bruit est une caractéristique du système de

verrouillage et n’indique pas un problème de

fonctionnement du mandrin.

Manchon

tourner le manchon dans le sens antihoraire.

age, s’assurer que la mèche s’engage à

fond dans le mandrin. Centrer la mèche

dans les mâchoires du mandrin et la

relever d’environ 1/16 pouce du fond.

evis, insérer la mèche suffi samment

loin pour que les mâchoires du mandrin

prennent l’extrémité hexagonale de la

mèche.

tourner le manchon dans le sens horaire. La mèche est fi xée quand le mandrin

émet un cliquetis et que le manchon ne

peut plus être tourné.

manchon dans le sens anti-horaire.

Sélection de la vitesse

Fig. 5

Le sélecteur de vitesse est au-dessus du

carter du moteur. Laisser l’outil s’arrêter

complètement avant de changer de vitesse.

Voir «Applications» pour les vitesses recommandées dans diverses conditions.

1. Pour la vitesse lente (jusqu’à 600 tr/

mn), pousser le sélecteur de vitesse à

gauche.

2. Pour la vitesse rapide (jusqu’à 1 800

tr/mn), pousser le sélecteur de vitesse

à droite.

Sélection de l’action de martelage ou de

perforage

Les marteaux perforateurs de MILWAUKEE

sont conçus pour trois modes de fonctionnement: perforage avec action de

martelage, perforage uniquement et entraînement de vis. Pour régler le mode de

fonctionnement, faire tourner le collier de

sélection marteau/perforateur jusqu’au

symbole désiré.

1. Pour utiliser le mode martelage-

perforage (Fig. 6), faire tourner le

collier de sélection jusqu’à ce que le

symbole marteau apparaisse en

ligne avec la fl èche. Puis faire tourner

le collier de sélection de couple jusqu’à

ce que le symbole perforateur ......

soit aligné avec la fl èche. Exercer une

pression sur la mèche pour enclencher

le mécanisme de martelage.

Fig. 6

Lent

Rapide

REMARQUE: Lors de l’utilisation de mèches

en carbure, ne pas utiliser d’eau pour éliminer la poussière. Ne pas tenter de percer des

tiges de renforcement en acier. Ceci endommagerait les mèches en carbure.

2. Pour utiliser le mode perforage

uniquement (Fig. 7), faire tourner le

collier de sélection jusqu’à ce que le

symbole perforateur apparaisse en

ligne avec la fl èche. Puis faire tourner

le collier de sélection de couple jusqu’à

ce que le symbole perforateur soit

aligné avec la fl èche.

Fig. 7

Pour percer

3. Pour utiliser le mode tournevis

(Fig. 8), faire tourner le collier de sélection marteau-perforateur jusqu’à ce que

le symbole perforateur apparaisse

en ligne avec la fl èche. Puis faire tourner

le collier de sélection de couple jusqu’à

ce que le réglage désiré soit aligné avec

la fl èche.

Fig. 8

Pour entraîner des vis

Bien réglé, l’embrayage réglable glisse à un

couple préréglé pour éviter de visser trop

profondément dans différents matériaux et

pour éviter d’endommager la vis ou l’outil.

Les spécifi cations de couple indiquées ici sont

approximatives.

Réglage du collier de

sélection de couple

1 - 5

6 - 10

11 - 15

16 - 20

Perforage

Lent

Rapide

REMARQUE: Utiliser un déchet de ma-

tériau pour tester les différentes positions

d’embrayage avant de visser dans la pièce

de travail.

Utilisation du commutateur

Le commutateur peut être réglé sur trois

positions: marche avant, marche arrière et

verrouillée. En raison d’un mécanisme de

verrouillage, le commutateur ne peut être

réglé que lorsque la commande MARCHE/

ARRÊT n’est pas enfoncée. Toujours laisser le moteur s’arrêter complètement avant

d’utiliser le commutateur.

Pour une rotation en marche avant (dans

le sens horaire), pousser le commutateur du

côté droit de l’outil (Fig. 9). Vérifi er la direc-

tion de rotation avant utilisation.

Fig. 9

Pour une rotation en marche arrière (dans le

sens anti-horaire), pousser le commutateur

sur le côté gauche de l’outil (Fig. 10). Vérifi er

la direction de rotation avant utilisation.

Fig. 10

Enfoncer

pour la

marche

arrière

Couple

0 - 1,9 N•m

2,4 - 4,3 N•m

4,7 - 6,8 N•m

7,3 - 9,6 N•m

68 N•m

34 N•m

Enfoncer

pour la

marche avant

Pour marteler

20 21

Page 12

Pour verrouiller la détente, pousser le

commutateur vers la position centrale

(Fig. 11). La détente ne fonctionne pas

tant que le commutateur est sur la position

verrouillée centrale. Toujours verrouiller la

détente ou retirer la batterie avant d’effectuer

un entretien, de changer d’accessoire, de

remiser l’outil et toutes les fois que l’outil

est inutilisé.

Fig. 11

Pousser

en position

centrale

pour verrouiller la

détente

Marche, arrêt et contrôle de la vitesse

1. Pour mettre l’outil en marche, saisir

fermement la poignée et tirer sur la

détente.

2. Pour faire varier la vitesse, augmenter

ou réduire la pression sur la détente.

La vitesse augmente en fonction de la

pression exercée sur la détente.

3. Pour arrêter l’outil, relâcher la détente.

S’assurer que la mèche s’arrête complètement avant de poser l’outil.

Frein électrique

Le frein électrique s’enclenche lorsque la

détente est relâchée, ce qui a pour effet

d’immobiliser la mèche et de permettre à

l’opérateur de poursuivre son travail. La

mèche s’immobilise généralement dans

les deux secondes. Un délai peut se

produire toutefois entre le relâchement

total de la pression exercée sur la détente

et l’enclenchement du frein. Il se peut

qu’occasionnellement le frein ne s’enclenche

pas du tout. En cas de dysfonctionnement

fréquent du frein, faire réparer l’outil par un

centre d’entretien MILWAUKEE agréé.

Perforage

Régler les colliers de sélection marteau/

perforateur et de couple sur la position

perforage.

Mettre la mèche sur la surface de travail et

exercer une pression ferme avant de démarrer. Trop de pression ralentit la mèche et

réduit l’effi cacité du perforage. Une pression

insuffi sante cause le glissement de la mèche

sur la surface de travail et émousse la pointe

de la mèche.

Si l’outil commence à caler, réduire légèrement la pression pour permettre à la mèche

de regagner de la vitesse. Si la mèche se

grippe, inverser le moteur pour dégager la

mèche de la pièce de travail.

Fonctionnement par temps froid

Il est possible d’utiliser la batterie au lithiumion V28 à des températures ambiantes allant

jusqu’à -20°C (-4°F). Lorsque la température

de la batterie est très basse, elle peut envoyer des impulsions pendant la première

minute d’utilisation pour se réchauffer. Mettre

la batterie sur un outil et utiliser cet outil sur

une application légère. Au bout d’une minute

d’utilisation, la batterie se sera suffi samment

réchauffée et fonctionnera normalement.

APPLICATIONS

AVERTISSEMENT

Pour réduire les risques de chocs

électriques, vérifi er la zone de travail

à la recherche de tuyaux et de fi ls ca-

chés avant de percer ou de visser.

Perforage dans du bois, des matériaux

synthétiques et du plastique

Lors du perforage dans du bois, des matériaux synthétiques et du plastique, commencer à percer lentement en augmentant la

vitesse au fur et à mesure. Lors du perforage

du bois, utiliser des mèches à bois ou des

mèches hélicoïdales. Toujours utiliser des

mèches affûtées. Lors de l’utilisation de

mèches hélicoïdales, faire sortir fréquemment la mèche du trou pour éliminer les

copeaux des cannelures. Pour réduire les

risques d’éclatement, doubler l’ouvrage d’un

morceau de chute de bois. Sélectionner des

vitesses lentes pour les plastiques ayant un

point de fusion bas.

Perforage du métal

Pour le perforage du métal, utiliser des

mèches hélicoïdales en acier à haute vitesse

ou des scies-cloches. Utiliser un poinçon

pour amorcer le trou. Graisser les mèches

avec de l’huile de coupe lors du perforage de

fer ou d’acier. Utiliser du fl uide de refroidisse-

ment lors du perforage de métaux comme du

cuivre, de l’étain ou de l’aluminium. Doubler

le matériau pour éviter les courbes ou les

distorsions.

Perforage dans de la maçonnerie

Lors du perforage dans de la maçonnerie,

sélectionner le mode de fonctionnement

marteau perforateur. Utiliser des mèches à

pointe au carbure à haute vitesse. Le perforage de matériaux de maçonnerie souples

tels que les blocs de mâchefer nécessitent

moins de pression. Les matériaux durs tels

que le béton nécessitent plus de pression.

Un débit de poussière régulier et constant

indique un taux de perforage correct. Ne pas

laisser la mèche tourner dans le trou sans

couper. Ne pas utiliser d’eau pour fi xer la

poussière ou refroidir la mèche. Ces deux

actions endommageraient le carbure.

Entraînement de vis et vissage d’écrous

Percer un trou pilote lors de l’entraînement

de vis dans un matériau épais ou dur. Régler

le collier de sélection de couple sur la position correcte et régler la vitesse sur lente.

Utiliser la mèche de tournevis de style et de

taille corrects pour le type de vis utilisé.

Avec la mèche de tournevis dans la vis,

placer l’extrémité de la vis sur la pièce de

travail et appuyer fermement avant de tirer

sur la détente. Les vis peuvent être retirées

en inversant le moteur.

Surcharge

Une surcharge continue peut endommager

irrémédiablement l’outil ou la batterie.

22 23

Page 13

AVERTISSEMENT

Force de rotation élevée. Pour minimiser les risques de blessures, tenir

fermement l’outil. Toujours utiliser

la poignée latérale des outils.

Grippage de la mèche

Une force de rotation élevée survient

lorsqu’une mèche se grippe. Si la mèche

se grippe, l’outil est forcé dans la direction

opposée de la rotation de la mèche. Les

mèches peuvent se gripper si elles sont

incorrectement alignées ou quand elle percent un trou. Les mèches à bois peuvent

aussi se gripper au contact de pointes ou

de nœuds. Se préparer à une situation de

grippage de mèche.

Pour minimiser les risques de grippage de

mèche:

• Utiliser des mèches affûtées. Des

mèches affûtées sont moins sujettes au

risque de grippage lors du perçage.

• Utiliser la mèche correcte pour le travail.

Certaines mèches sont conçues pour

des travaux spécifi ques.

• Faire preuve de prudence en perçant un

matériau poisseux, noueux, mouillé ou

gauchi ou en perçant du matériau qui

peut contenir des clous.

Méthodes de calage typiques

Fig. 12

Réaction

Calage contre le sol

Fig. 13

Rotation

avant

Calage contre

la jambe

Fig. 14

Calage contre un montant

Réaction Réaction

Rotation inverse

Rotation avant

Rotation

avant

Réaction

ENTRETIEN

AVERTISSEMENT

Pour réduire le risque de blessure,

toujours débrancher le chargeur et

retirer la batterie du chargeur ou de

l’outil avant d’effectuer un quelconque

entretien. Ne jamais démonter l’outil,

la batterie ou le chargeur. Contacter

un centre d’entretien MILWAUKEE

pour TOUTES les réparations.

Entretien de l’outil

Maintenir l’outil, la batterie et le chargeur

en bon état en adoptant un calendrier

d’entretien périodique. Après six mois ou un

an, en fonction de l’usage qu’il en est fait,

renvoyer l’outil, la batterie et le chargeur à un

centre d’entretien MILWAUKEE pour:

• Lubrifi cation

• Inspection et replacement du balai

• Inspection et nettoyage des composants

mécaniques (engrenages, axes, roulements, carter, etc.)

• Inspection des composants électriques

(batterie, chargeur et moteur)

• Essai, afin de vérifier le bon fonctionnement des composants mécaniques et électriques de l’outil

Nettoyer les contacts de la batterie s’il est

impossible de mettre l’outil en marche ou si

l’outil ne fonctionne pas à pleine capacité en

dépit d’une batterie complètement chargée.

Si l’outil ne fonctionne toujours pas correctement, renvoyer l’outil, le chargeur et la

batterie à un centre d’entretien MILWAUKEE

pour réparation.

AVERTISSEMENT

Pour réduire le risque de blessure

ou de dommage, ne jamais plonger

l’outil, la batterie ou le chargeur dans

un liquide et ne jamais laisser l’eau

s’y infi ltrer.

Nettoyage

Nettoyer la poussière et les débris des

évents et des contacts électriques à l’air

comprimé. Maintenir les poignées de l’outil

propres, sèches et exemptes de graisse ou

d’huile. N’utiliser que du savon doux et un

chiffon humide pour nettoyer l’outil, la batterie et le chargeur, en évitant les contacts

électriques. Certains produits de nettoyage

ou solvants sont nocifs pour les plastiques

et les pièces isolées, notamment : essence,

essence de térébenthine, diluant pour vernis,

diluant pour peintures, solvant chloré, ammoniaque et détergents ménagers contenant de l’ammoniaque. Ne jamais utiliser de

solvants infl ammables ou combustibles à

proximité d’outils.

Réparations

Pour toutes réparations, renvoyer l’outil, la

batterie et le chargeur au centre d’entretien

agréé le plus proche.

ACCESSOIRES

AVERTISSEMENT

Toujours enlever la batterie

avant de changer ou de retirer un

accessoire. N’utiliser que les accessoires spécialement conçus pour

cet outil. Les accessoires non recommandés peuvent présenter des

dangers.

24 25

Pour une liste complète des accessoires, consulter le catalogue des outils

MILWAUKEE Electric Tool ou aller en

ligne à l’adresse www.milwaukeetool.com.

Pour obtenir un catalogue, contacter le distributeur local ou un centre d’entretien.

Page 14

GARANTIE LIMITÉE DE L’OUTIL DE CINQ ANS

Chaque outil électrique MILWAUKEE (y compris le chargeur de batterie) est garanti à l’acheteur

d’origine être exempt de vice du matériau et de fabrication. Sous réserve de certaines exceptions, MILWAUKEE réparera ou remplacera toute pièce d’un outil électrique qui, après examen,

sera avéré par MILWAUKEE être affecté d’un vice du matériau ou de fabrication pendant une

période de cinq (5) ans* après la date d’achat. Le retour de l’outil électrique, accompagné

d’une copie de la preuve d’achat à un site d’entretien d’usine/de promotion des ventes de

MILWAUKEE ou à un poste d’entretien agréé MILWAUKEE, en port prépayé et assuré, est

requis pour que cette garantie s’applique. Cette garantie ne couvre pas les dommages que

MILWAUKEE détermine être causés par des réparations ou des tentatives de réparation

par quiconque autre que le personnel agréé par MILWAUKEE, des utilisations incorrectes,

des altérations, des utilisations abusives, une usure normale, une carence d’entretien ou les

accidents.

* La période de garantie pour les palans (palans à levier, à chaîne manuelle et à chaîne

électrique), tous les blocs de batteries au NiCd, les projecteurs de travail (lampes torches

sans fi l), les radios de chantier et les chariots de travail industriels Trade Titan™ est d’un (1)

an à partir de la date d’achat. *La période de garantie pour les blocs de batteries au lithiumion qui ne sont pas équipés de la technologie V™ (entre 4 et 18 volts) est de deux (2) ans à

partir de la date d’achat.

*Il existe une garantie séparée pour les blocs de batteries au lithium-ion avec technologie V™

de 18 volts et plus qui accompagnent les outils électriques sans fi l de technologie V™ :

*Chaque batterie au lithium-ion 18 volts ou plus de technologie MILWAUKEE V™ est couverte

par une garantie de remplacement gratuit initial pour 1 000 charges/2 ans. Ceci signifi e qu’avant

les 1 000 premières charges ou deux (2) années suivant la date d’achat/la première charge,

une batterie de rechange sera fournie gratuitement au client pour toute batterie défectueuse.

Par la suite, les clients recevront aussi une garantie supplémentaire calculée au prorata dans

la limite de 2 000 charges ou cinq (5) années suivant la date d’achat/la première charge, à la

première échéance. Ceci signifi e que chaque client obtient une garantie au prorata supplémen-

taire de 1 000 charges ou de trois (3) années sur les batteries au lithium-ion 18 volts ou plus de

technologie V™ en fonction de l’utilisation. Pendant cette période de garantie supplémentaire,

le client ne paye que pour le service utilisable reçu au-delà des 1 000 premières charges/2

premières années, en fonction de la date de la première charge et du nombre de charges des

batteries déterminés par le lecteur de service MILWAUKEE de technologie V™.

L’enregistrement de la garantie n’est pas nécessaire pour bénéfi cier de la garantie en vigueur

sur un produit MILWAUKEE. Une preuve d’achat sous la forme d’un reçu de vente ou d’autres

informations considérées suffi santes par MILWAUKEE est cependant requise.

L’ACCEPT A TION DES RECOURS EXCLUSIFS DE RÉP ARA TION ET DE REMPLACEMENT

DÉCRITS PAR LES PRÉSENTES EST UNE CONDITION DU CONTRA T D’ACHA T DE T OUT

PRODUIT MILWAUKEE. SI VOUS N’ACCEPTEZ PAS CETTE CONDITION, VOUS NE

DEVEZ PAS ACHETER LE PRODUIT. EN AUCUN CAS MILWAUKEE NE SAURAIT ÊTRE

RESPONSABLE DE TOUT DOMMAGE ACCESSOIRE, SPÉCIAL OU INDIRECT, DE DOMMAGES-INTÉRÊTS PUNITIFS OU DE TOUTE DÉPENSE, D’HONORAIRES D’A VOCA TS, DE

FRAIS, DE PERTE OU DE DÉLAIS ACCESSOIRES À TOUT DOMMAGE, DÉF AILLANCE OU

DÉFAUT DE TOUT PRODUIT, Y COMPRIS NOTAMMENT LES PER TES DE PROFIT . CETTE

GARANTIE EST EXCLUSIVE ET REMPLACE TOUTE AUTRE GARANTIE OU CONDITION,

ÉCRITE OU VERBALE, EXPRESSE OU IMPLICITE. SANS LIMITER LA GÉNÉRALITÉ DES

DISPOSITIONS PRÉCÉDENTES, MILWAUKEE DÉCLINE TOUTE GARANTIE IMPLICITE

DE QUALITÉ MARCHANDE OU D’ADAPTATION À UNE UTILISATION OU À UNE FIN

PARTICULIÈRE ET TOUTE AUTRE GARANTIE.

Cette garantie s’applique aux produits vendus aux États-Unis, au Canada et au Mexique

uniquement.

26 27

REGLAS DE SEGURIDAD GENERALES PARA HERRAMIENTAS

OPERADAS POR BATERÍA

ADVERTENCIA

LEA TODAS LAS INSTRUCCIONES

Si no se siguen todas las siguientes instrucciones se puede provocar una descarga

eléctrica, un incendio y/o lesiones graves. El término “herramienta eléctrica” en

todas las advertencias incluidas más abajo se refi ere a su herramienta operada por

conexión (cable) a la red eléctrica o por medio de una batería (inalámbrica).

GUARDE ESTAS INSTRUCCIONES

SEGURIDAD EN EL ÁREA

DE TRABAJO

1. Mantenga limpia y bien iluminada el

área de trabajo. Las áreas desorde-

nadas u oscuras contribuyen a que se

produzcan accidentes.

2. No utilice herramientas eléctricas

en atmósferas explosivas, como en

la presencia de líquidos, gases o

polvo infl amables. Las herramientas

eléctricas crean chispas que pueden

incendiar el polvo o las emanaciones.

3. Mantenga a los niños y otras perso-

nas alejadas mientras utiliza una herramienta eléctrica. Las distracciones

pueden hacerle perder el control.

SEGURIDAD ELÉCTRICA

4. Los enchufes de las herramientas

eléctricas deben ser del mismo tipo

que el tomacorrientes. Nunca realice

ningún tipo de modifi cación en el

enchufe. No use enchufes adaptadores con herramientas eléctricas con

conexión a tierra. Se reducirá el riesgo

de descarga eléctrica si no se modifi can

los enchufes y los tomacorrientes son

del mismo tipo.

5. Evite el contacto corporal con

superfi cies con conexión a tierra,

como tuberías, radiadores, estufas y

refrigeradores. El riesgo de descarga

eléctrica aumenta si su cuerpo está

conectado a tierra.

6. No exponga la herramientas eléc-

tricas a la lluvia o a condiciones de

humedad. El agua que entra en una

herramienta eléctrica aumenta el riesgo

de descarga eléctrica.

7. No abuse del cable. Nunca use el

cable para transportar la herramienta

eléctrica, tirar de ella o desenchufarla. Mantenga el cable alejado del

calor, los bordes afi lados o las piezas

en movimiento. Los cables dañados o

enmarañados aumentan el riesgo de

descarga eléctrica.

8. Cuando se utiliza una herramienta

eléctrica en el exterior, use una

extensión que sea apropiada para

uso en el exterior. El uso de un cable

apropiado para el exterior reduce el

riesgo de descarga eléctrica.

SEGURIDAD PERSONAL

9. Manténgase alerta, ponga cuidado a

lo que está haciendo y use el sentido

común cuando utilice una herramienta eléctrica. No use una herramienta

eléctrica cuando está cansado o bajo

la infl uencia de drogas, alcohol o

medicinas. Despistarse un minuto cu-

ando se utiliza una herramienta eléctrica

puede tener como resultado lesiones

personales graves.

10. Use equipo de seguridad. Lleve

siempre protección ocular. Llevar

equipo de seguridad apropiado para la

situación, como una máscara antipolvo,

zapatos de seguridad antideslizantes

casco o protección auditiva, reducir á

las lesiones personales.

11. Evite los arranques accidentales.

Asegúrese de que el interruptor esté

en la posición de apagado antes de

enchufar la herramienta. Mover her-

ramientas con el dedo en el interruptor o

enchufar herramientas con el interruptor

en la posición de encendido contribuye

a que se produzcan accidentes.

Page 15

12. Quite todas las llaves de ajuste antes

de encender la herramienta. Una llave

que esté acoplada a una pieza giratoria

de la herramienta puede provocar lesiones personales.

13. No se estire demasiado. Mantenga

los pies bien asentados y el equilibrio

en todo momento. Esto permite tener

mejor control de la herramienta eléctrica

en situaciones inesperadas.

14. Vístase de manera apropiada. No

lleve ropa suelta ni joyas. Mantenga

el cabello, la ropa y los guantes lejos

de la piezas en movimiento. La ropa

fl oja, las joyas o el cabello largo pueden

quedar atrapados en las piezas en

movimiento.

15. Si se proporcionan dispositivos

para la conexión de sistemas de

recolección y extracción de polvo,

asegúrese de que estén conectados

y se usen apropiadamente. El uso

de estos dispositivos puede reducir los

peligros relacionados con el polvo.

USO Y CUIDADO DE LAS

HERRAMIENTAS ELÉCTRICAS

16. No fuerce la herramienta eléctrica.

Use la herramienta eléctrica correcta

para la aplicación. La herramienta

eléctrica correcta funcionará mejor y de

manera más segura a la velocidad para

la que se diseñó.

17. No use la herramienta eléctrica si el

interruptor no la enciende ni la apaga.

Cualquier herramienta eléctrica que no

se pueda controlar con el interruptor es

peligrosa y se debe reparar.

18. Desconecte el enchufe de la toma de

alimentación y/o la batería de la herramienta eléctrica antes de realizar

cualquier ajuste, cambiar accesorios o

almacenar las herramientas eléctricas.

Dichas medidas preventivas de seguridad

reducen el riesgo de que la herramienta

se prenda accidentalmente.

19. Almacene las herramientas eléctricas

fuera del alcance de los niños y no

permita que personas no familiarizadas con ellas o estas instrucciones

las utilicen. Las herramientas eléctricas

son peligrosas en las manos de usuarios no capacitados.

20. Mantenimiento de las herramientas

eléctricas. Revise que no haya piezas móviles que estén desalineadas

o que se atasquen, piezas rotas ni

ninguna otra condición que pueda

afectar el funcionamiento de la herramienta eléctrica. Si se encuentran

daños, haga que le reparen la herramienta antes de usarla. Las herra-

mientas mal mantenidas son la causa

de muchos accidentes.

21. Mantenga las herramientas de corte

limpias y afi ladas. Es menos probable

que se atasquen las herramientas de

corte con fi los afi lados que se man-

tienen de manera apropiada y también

son más fáciles de controlar.

22. Use la herramienta eléctrica, los ac-

cesorios y las brocas, etc. siguiendo

estas instrucciones y de la manera

para la que dicha herramienta eléctrica en particular fue diseñada, teniendo en cuenta las condiciones de

trabajo y la tarea que se va a realizar.

El uso de la herramienta eléctrica para

operaciones diferentes de aquellas para

las que se diseño podría resultar en una

situación peligrosa.

USO Y CUIDADO DE LAS

HERRAMIENT AS CON BATERÍA

23. Asegurarse de que el interruptor esté

en la posición apagada antes de colocar

la batería. Colocar la batería en las herra-

mientas eléctricas que tienen el interruptor

en la posición de encendido contribuye a

que se produzcan accidentes.

24. Recárguela solamente con el cargador

especifi cado por el fabricante. Un car-

gador que sea apropiado para un tipo de

batería puede crear riesgo de incendio

cuando se use con otra batería.

25. Use las herramientas eléctricas sola-

mente con baterías específi camente

diseñadas. El uso de cualquier otro

tipo de batería puede crear riesgo de

lesiones o incendio.

26. Cuando no se use la batería man-

téngala alejada de otros objetos

de metal como clips para papel,

monedas, llaves, clavos, tornillos u

otros objetos de metal pequeños que

puedan realizar una conexión entre

los bornes. Realizar un cortacircuito

en los terminales de la batería puede

provocar quemaduras o un incendio.

28 29

27. Bajo condiciones abusivas, puede

salir líquido expulsado de la batería;

evitar el contacto. Si se produce un

contacto accidental, lavar con agua.

Si el líquido entra en contacto con

los ojos buscar ayuda médica adicional. El líquido que sale despedido

de la batería puede causar irritaciones

o quemaduras.

REGLAS DE SEGURIDAD ESPECÍFICAS

1. Mantenga las etiquetas y las placas identifi cativas.Tienen información importante. Si

no se pueden leer o si faltan, póngase en contacto con un centro de servicio MILWAUKEE

para obtener un repuesto gratuito.

2. ADVERTENCIA: Ciertos polvos creados al lijar, serrar , esmerilar, perforar y realizar otras

actividades de construcción contienen productos químicos que se sabe que causan

cáncer, defectos congénitos u otros daños al aparato reproductor. Algunos ejemplos de

dichos productos químicos son:

• plomo de pintura con base de plomo

• sílice cristalino de los ladrillos y cemento y de otros productos de mampostería, y

• arsénico y cromo provenientes de madera tratada químicamente.

Su riesgo de exposición varía dependiendo de la frecuencia con la que realice este tipo

de trabajo. Para reducir su exposición a estos productos químicos: trabaje en un área

bien ventilada, y trabaje con equipo de seguridad aprobado, como máscaras antipolvo

especialmente diseñadas para fi ltrar partículas microscópicas.

3. Agarre la herramienta por los asideros aislados cuando realice una operación en

la que la herramienta de corte pueda entrar en contacto con cables ocultos o con

su propio cable. El contacto con un cable “con corriente” hará que las partes de metal

expuesto de la herramienta pasen la corriente y produzcan una descarga al operador.

4. Mantenga las manos alejadas de todos los fi los y piezas en movimiento.

5. Lleve protectores auditivos cuando use la broca de impacto. La exposición a ruido

puede producir la pérdida de la audición.

6. Use los asideros auxiliares que se suministran con la herramienta. La pérdida de

control puede provocar lesiones personales.

MANTENIMIENTO

28. Haga que un técnico calificado

realice el mantenimiento de la herramienta eléctrica utilizando solamente

piezas de repuesto idénticas. Esto

asegurará que se mantiene la seguridad

de la herramienta eléctrica.

Page 16

Simbología

ENSAMBLAJE DE LA HERRAMIENTA

Cat.

No.

0724-20

Volts

cd

28

RPM sin

carga

Baja 0-600

Alta 0-1 800

10

9

Volts corriente directa

Revoluciones por minuto

sin carga (RPM)

Underwriters Laboratories, Inc.,

Estados Unidos y Canadá

Especifi caciones

Golpes por

minuto sin

carga

Baja 0-9 000

Alta 0-27 000

Broca

plana

38 mm

(1-1/2")

Broca de

berbiquí

38 mm

(1-1/2")

Madera

Broca de

perforación

65 mm

(2-9/16")

DESCRIPCIÓN FUNCIONAL

1

Capacidades

Tornillos

(diá)

6 mm

(1/4")

Acero

13 mm

(1/2")

Mampostería

13 mm

(1/2")

2

3

ADVERTENCIA

Para reducir el riesgo de lesiones,

siempre póngale el seguro al gatillo

o quite la batería antes de cambiar o

quitar accesorios. Use solamente accesorios específi camente reco men-

dados para esta herramienta. El uso

de otros puede resultar peligroso.

Extracción de la batería de la herramienta

Presione los botones de liberación y jale de

la batería para sacarla de la herramienta.

Inserción de la batería en la herramienta

La batería puede colocarse en la herramienta de dos maneras diferentes. Para insertar

la batería en la herramienta, deslícela sobre

el cuerpo de la herramienta. Asegúrese de

que se asegura bien en su posición.

Fig. 1

Cuando se trabaje en

espacios reducidos,

introduzca la batería

desde la parte

delantera de la herramienta.

Instalación del asidero lateral

1. Para instalar el asidero lateral, afl oje

el dispositivo de sujeción del asidero

lateral hasta que el aro sea lo sufi ci-

entemente grande como para deslizarse sobre el collarín selector de par

de torsión. El saliente elevado del aro

del asidero lateral encaja dentro de la

ranura, alrededor de la herramienta.

Gire el asidero a la posición deseada y

apriételo hasta que quede asegurado.

2. Para extraer el asidero lateral, afl oje

el dispositivo de sujeción del asidero

lateral hasta que el aro sea lo sufi ciente-

mente grande como para deslizarse de

la herramienta.

1. Selector de velocidad

2. Portaherramientas

3. Interruptor de control

4. Batería

5. Cerrojo de la batería

6. Gatillo

7. Anillo selector del par de torsión

8. Collarín selector de martillo/taladro

9. Portabrocas

10. Asidero lateral

7

8

6

Fig. 2

5

Para obtener un buen

equilibrio y distribución del peso, meta la

batería desde la parte

trasera de la herramienta.

4