Page 1

Hardware Manual

82400INS03

Page 2

This manual has been developed by Nitsuko America. It is intended

for the use of its customers and service personnel, and should be

read in its entirety before attempting to install or program the system. Any comments or suggestions for improving this manual

would be appreciated. Forward your remarks to:

Nitsuko America, Telecom Division

4 Forest Parkway

Shelton, CT 06484

Attention: Manager, Technical Publications

Nothing contained in this manual shall be deemed to be, and this

manual does not constitute, a warranty of, or representation with

respect to, any of the equipment covered. This manual is subject to

change without notice and Nitsuko America has no obligation to provide any updates or corrections to this manual. Further, Nitsuko

America also reserves the right, without prior notice, to make

changes in equipment design or components as it deems appropriate. No representation is made that this manual is complete or

accurate in all respects and Nitsuko America shall not be liable for

any errors or omissions. In no event shall Nitsuko America be liable

for any incidental or consequential damages in connection with the

use of this manual. This document contains proprietary information

that is protected by copyright. All rights are reserved. No part of

this document may be photocopied or reproduced without prior written consent of Nitsuko America.

©1998 by Nitsuko America. All Rights Reserved.

Printed in U.S.A.

Page 3

Section 1

Installing the Main Cabinets

In this section . . . Page

Installing the Cabinets . . . . . . . . . . . . . . .1-3

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Before Installing . . . . . . . . . . . . . . . . . . . . . . 1-3

Site Requirements. . . . . . . . . . . . . . . . . . . . . 1-3

Removing the Cover. . . . . . . . . . . . . . . . . . . 1-4

Mounting the Cabinet . . . . . . . . . . . . . . . . . . 1-4

Grounding the Cabinet . . . . . . . . . . . . . . .1-6

Connecting the Ground Wires. . . . . . . . . . . . 1-6

1. INSTALLING THE MAIN CABINET

1-1

Page 4

1-2

Page 5

INSTALLING THE CABINET

Unpacking

Unpack the equipment and check it against your equipment lists. Inspect for physical damage.

Have the appropriate tools for the job on hand, including: a test set, a punch down tool and a digital voltmeter .

Before Installing

Make sure you have a building plan showing the location of the common equipment, extensions, the telco

demarcation and earth ground. In addition, the installation site must meet the requirements outlined in the

Standard Practices Manual.

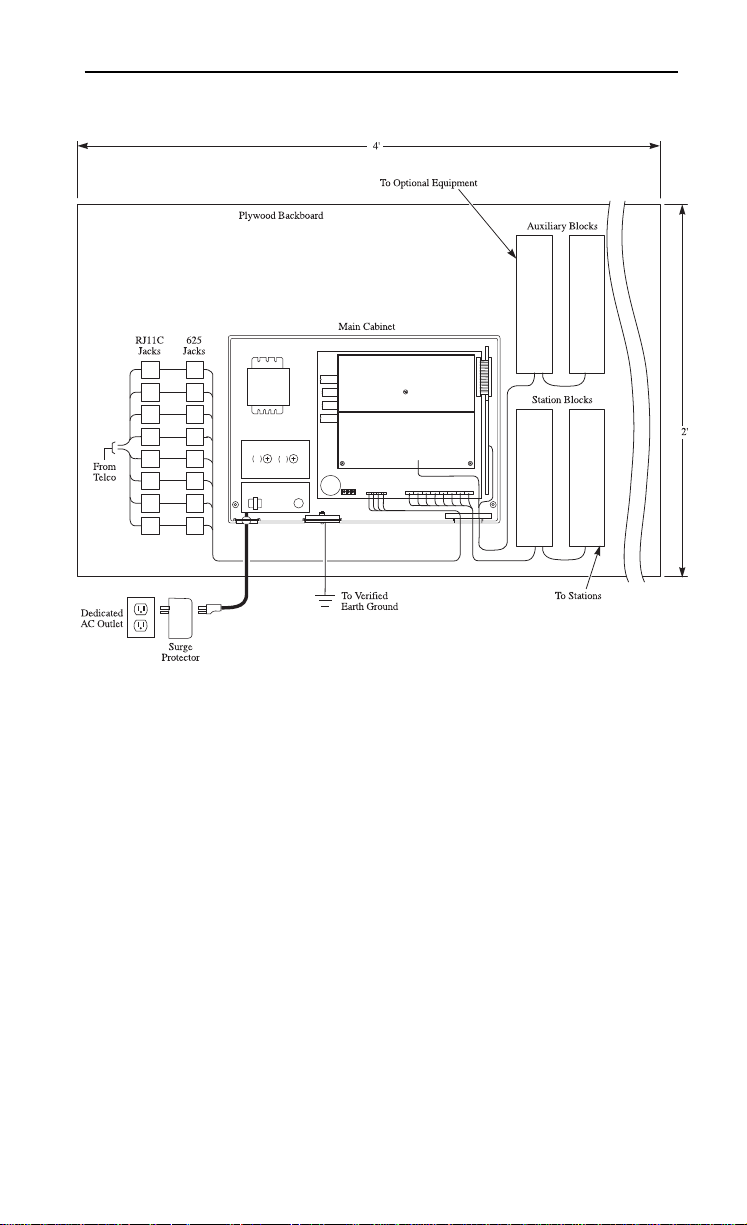

Site Requirements

The common equipment is contained in a wall-mounted

cabinet: the Main Cabinet. Choose a central location for

the cabinet that allows enough space for the equipment

— and provides enough room for you to comfortably

work. The Installation Layout (Figure 1-2 on page 1-5)

shows you

requires.

approximately how much space your system

The common equipment cabinet requires a three-prong

dedicated 117 VAC 60 Hz circuit (NEMA 5-15 receptacle) located within 6 feet of the AC receptacle. You

should install the extension block to the right of the

Main Cabinet. Telco should install the RJ11C to the

left of the Main Cabinet.

1-3

Page 6

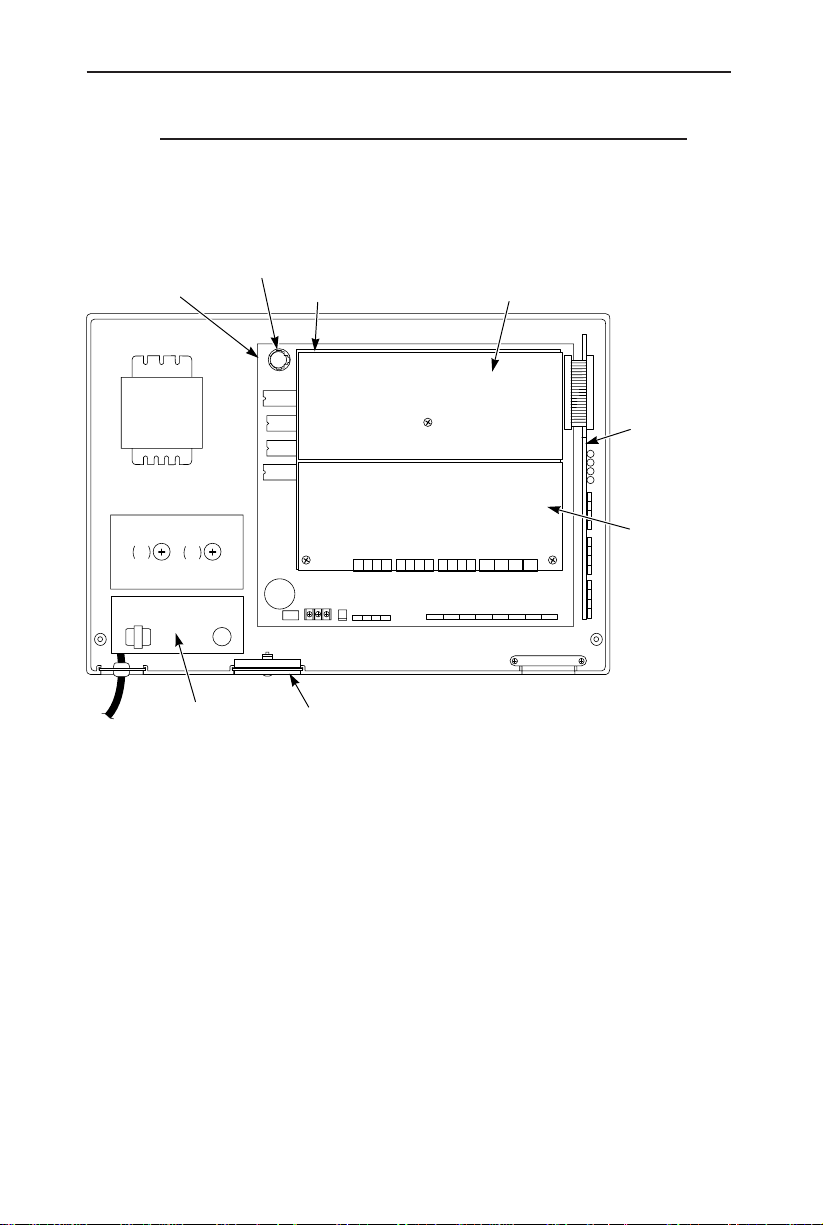

INSTALLING THE CABINET

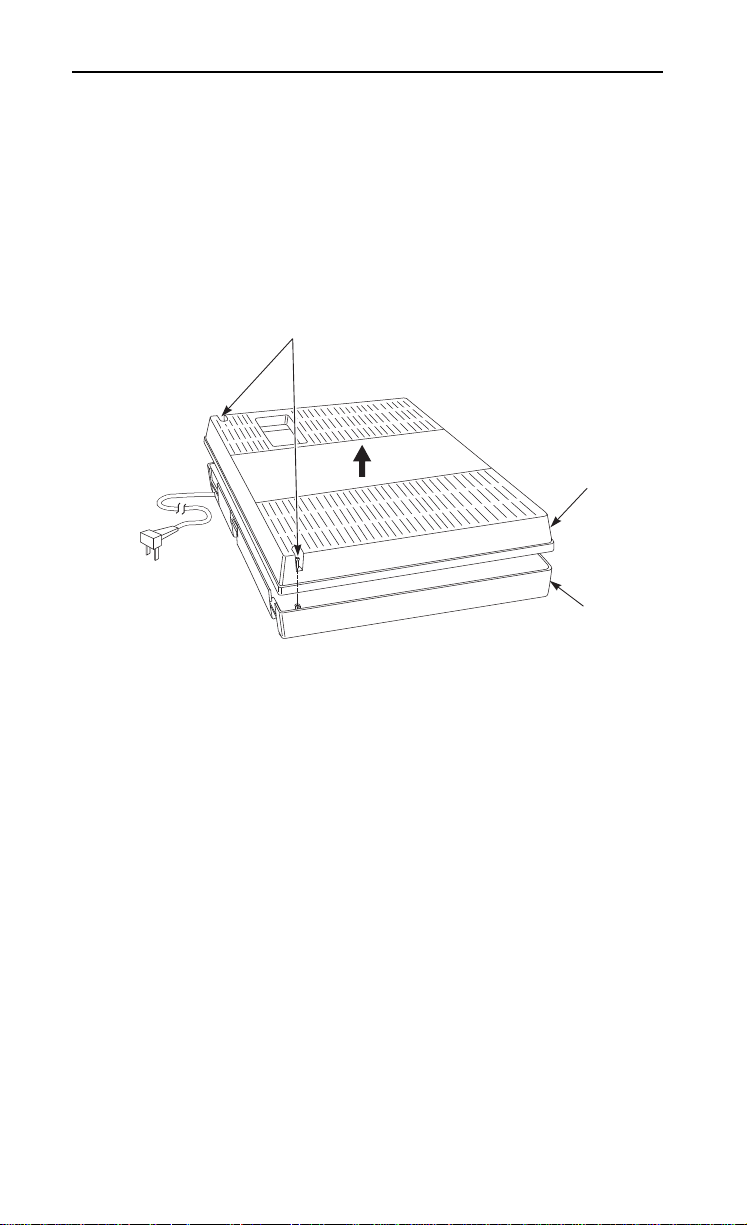

Top Cover

Base Unit

Screws

9300 0 - 8

Removing the Cover (Figure 1-1)

To make wall-mounting easier, remove the cover on the

common equipment cabinet. This allows you to use the

cabinet as a mounting template.

1. Unscrew the two captive screws on the lower half of

the cabinet cover.

2. Lift up the lower half of the cover — then slide the

cover back slightly to remove it.

Figure 1-1 REMOVING THE COVER

Mounting the Cabinet (Figure 1-2)

1. Using suitable fasteners, mount a Main Distribution

Frame (MDF) plywood backboard in a centrally

located spot.

2. Hold the Main Cabinet against the MDF and mark

all four mounting holes.

3. Drill the marked holes using a 1/8” drill bit.

4. Install two mounting screws (provided) in the top two

holes, leaving about 3/8” shank exposed.

5. Hang the Main Cabinet on the top two screws and

fasten in place.

6. Install the bottom two screws and tighten in place.

1-4

Page 7

INSTALLING THE CABINET

824 00 - 13

FO

F1

250V

250V

6.3A

6.3A

Figure 1-2 INSTALLATION LAYOUT

1-5

Page 8

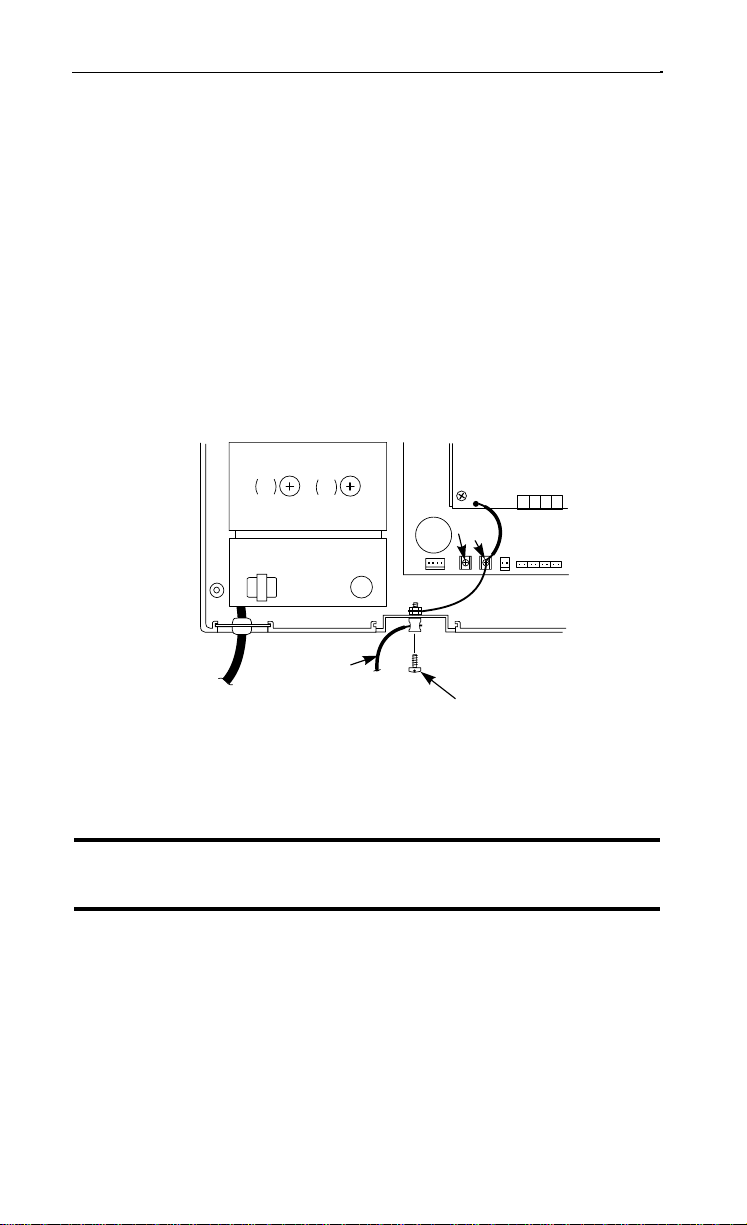

GROUNDING THE CABINET

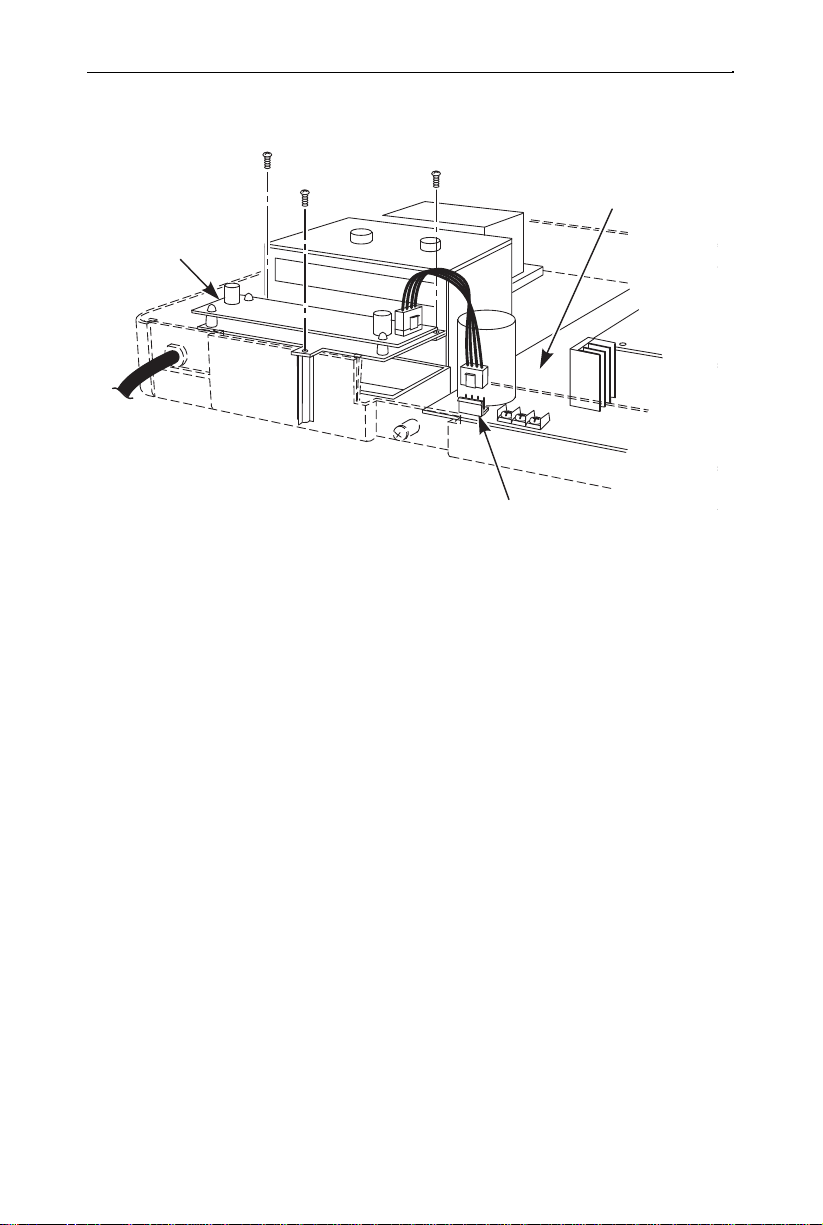

Connecting the Ground Wires (Figure 1-3)

The cabinet is grounded at the ETH (Earth Ground)

connection.

1. Loosen the lug on the ground connection.

2. Using a piece of 12 AWG stranded copper wire, connect the ETH to the ground connector .

3. Insert 12 AWG stranded copper wire into the

grounding terminal on the outside of the cabinet.

Firmly tighten the connection.

4. Connect the grounding cable to a known earth

ground.

2CO/8STA PCB

82400 - 37

FO

250V

6.3A

F1

250V

6.3A

CPU

ETH

FG

ETH/SG

PFCON

COCN

Grounding

AC Cord

Cable

Screw

Figure 1-3 GROUNDING A CABINET

Now that your cabinet is installed and grounded, go to

Part 2: PCB Installation and Startup.

DO NOT PLUG IN THE CABINET POWER CORD

WITHOUT FIRST INSTALLING THE PCBS.

1-6

Page 9

Section 2

PCB Installation and Startup

In this section . . . Page

PCB Location . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Where to Install the PCBs . . . . . . . . . . . . . . . . . . .2-3

Installing PCBs . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Central Processing Unit (CPU) PCB . . . . . . . . . . .2-4

Expansion (2CO/8STA) PCB . . . . . . . . . . . . . . . .2-6

Ring Generator PCB . . . . . . . . . . . . . . . . . . . . . . .2-7

Auxiliary PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Power Failure (4 PF XFER) PCB . . . . . . . . . . . . .2-9

SMDR PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

SMDR RS-232C Cable Assembly . . . . . . . . . . . .2-11

Powering Up the System . . . . . . . . . . . . . . . . .2-12

Power-Up Sequence . . . . . . . . . . . . . . . . . . . . . . .2-12

2. PCB INSTALLATION AND STARTUP

2-1

Page 10

2-2

Page 11

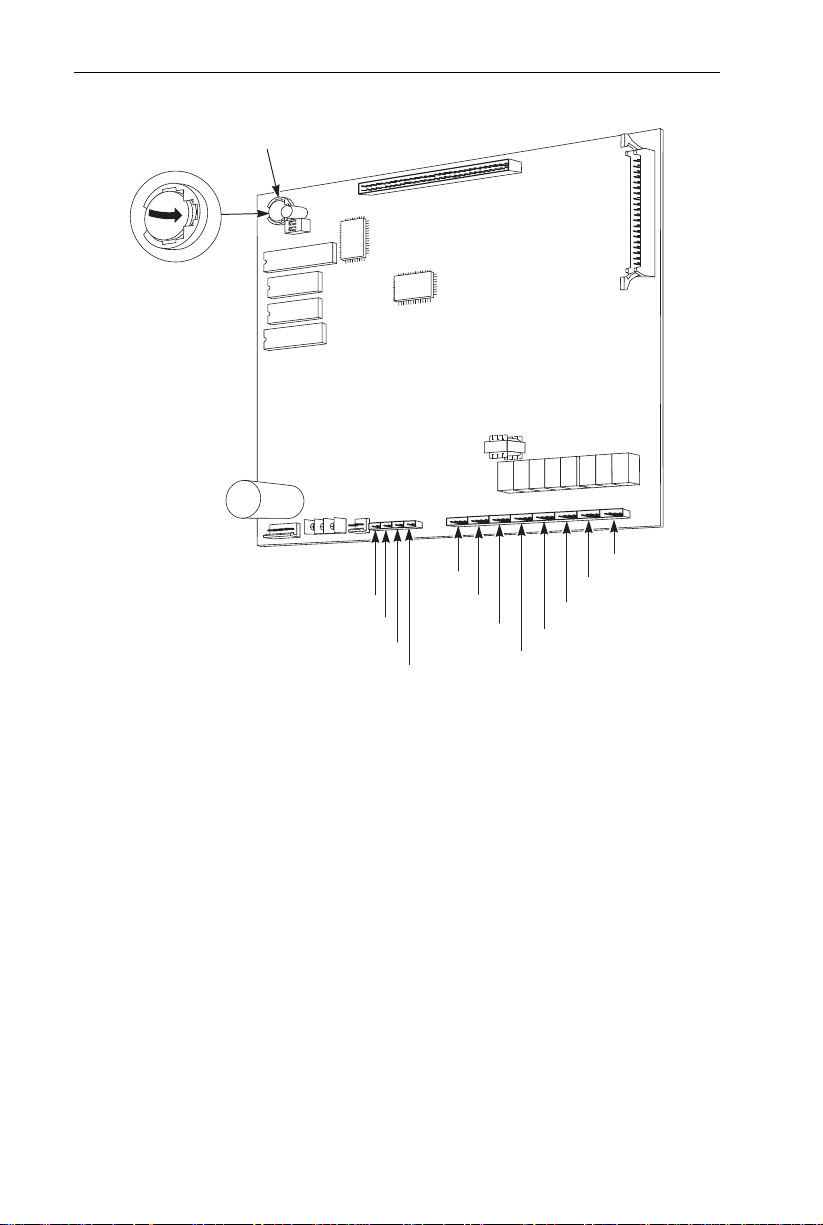

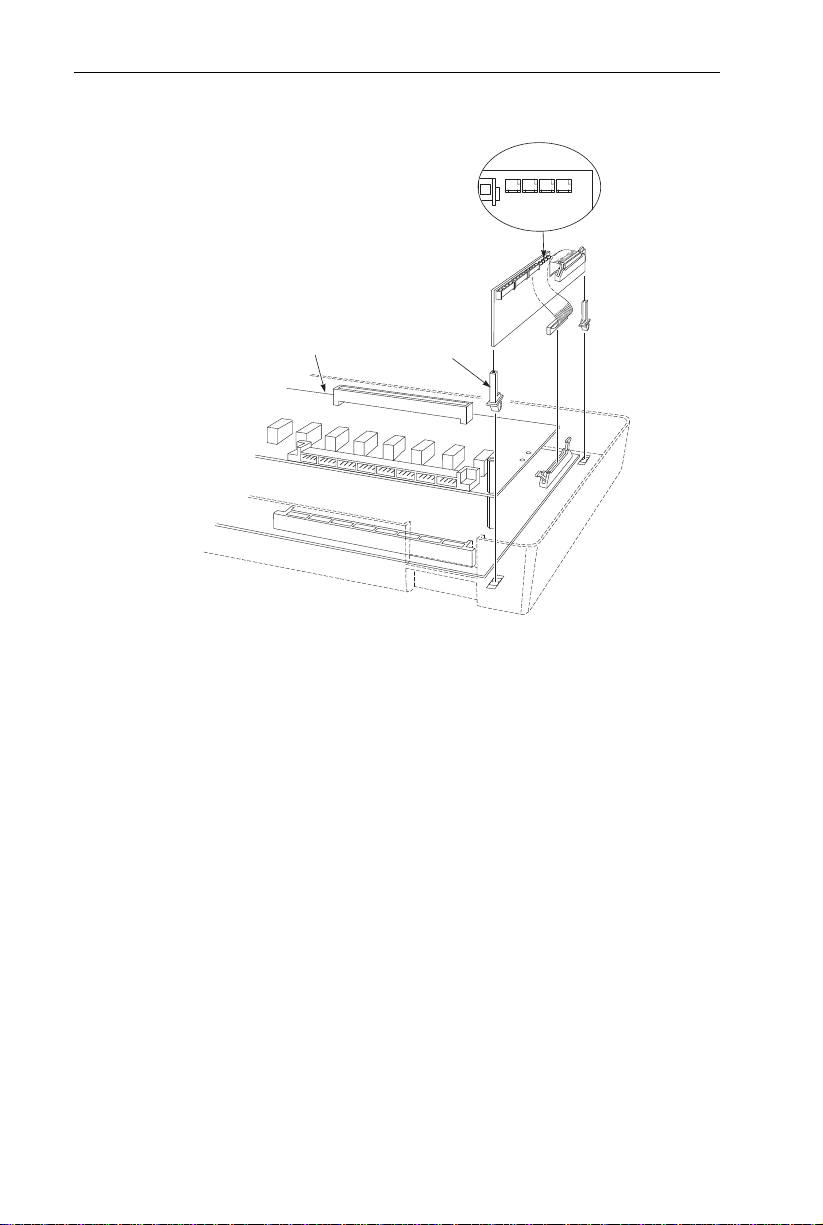

Where to Install the PCBs (Figure 2-1)

Maximum Configuration: 8 Trunks

Lithium Battery

CPU

82400 - 35

2 CO/8 STA PCB SMDR PCB or Caller ID PCB

PCB LOCATION

24 Extensions

Auxillary PCB

FO

F1

250V

250V

6.3A

6.3A

RGUCN

PFCON COCN PFSTN SLTCN

COCN

STCN

Ring Generator PCB RS-232-C Jack and Cable Assembly

Figure 2-1 PCB LOCATION

4 PF XFER PCB

2-3

Page 12

INSTALLING PCBs

82400 - 36

Station 1

Trunk 4

Battery

Trunk 3

Trunk 2

Trunk 1

Station 2

Station 3

Station 4

Station 5

Station 6

Station 7

Station 8

Central Processing Unit (CPU) PCB (Figure 2-2)

Figure 2-2 CPU PCB

The CPU PCB comes already installed in the Main Cabinet.

The CPU provides:

● The system’s central processing, stored program and mem-

ory for the customer’s site-specific data.

● Mode switch for cold (default data) or warm (customer

data) start on power-up.

● Battery for backup of the customer’s site-specific data. Use

only a SONY CR2032 Lithium Battery or equivalent.

Replace the battery when “B” flashes on the display of the

key telephones. The battery’s life is between 3.5 and 7

years - depending on how often the system is powered

down. The more the system’s power is off, the shorter the

battery’s life.

● Connection points for the CO and station DDK connectors.

2-4

Page 13

INSTALLING PCBs

To prepare the CPU PCB:

1. Slide the Switch-1 (top switch) to the INT (left) position.

This ensures that the system will load the default database on initial power-up.

2. Power the system up.

3. After the system has been powered up for a minimum of

10 seconds, insert the battery into the battery clips.

The printing on the battery should be facing up so that

it is visible when installed.

4. Slide the Switch-1 (top) to the RUN position (to the right).

Note: NEVER move the switch unless the intent is to clear

all programmed memory.

Refer to Part 4, Installing Optional Equipment for instructions on installing Background Music and Music on Hold.

2-5

Page 14

INSTALLING PCBs

82400 - 19

CPU

2CO/8STA PCB

ETH

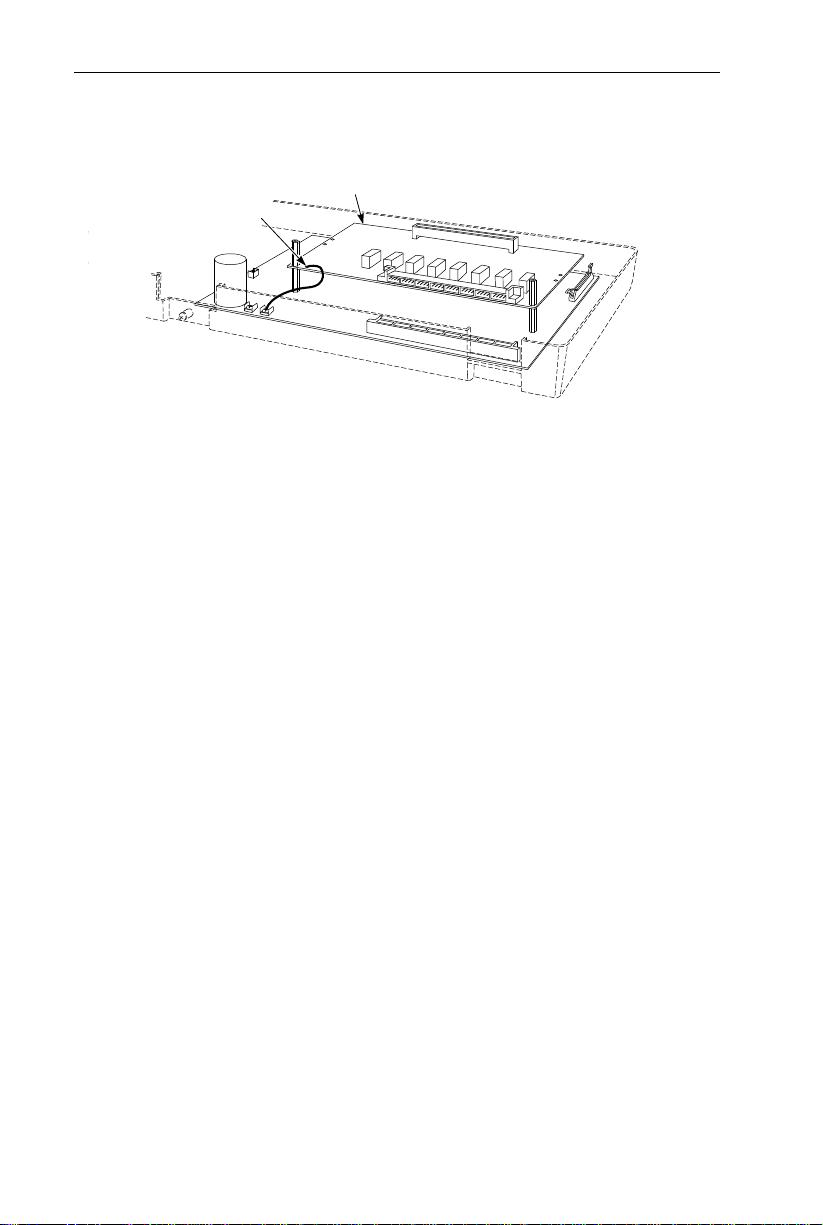

Expansion (2CO/8STA) PCB (Figure 2-3)

Figure 2-3 EXPANSION (2CO/8STA) PCB

The Expansion (2CO/8STA) PCB provides DDK connectors

for two additional CO lines and eight additional telephones.

To install a 2CO/8STA PCB:

1. Place the 2CO/8STA PCB on top of the CPU. Align the

EXPCN female connector on the bottom of the 2CO/8STA

PCB over the EXPCN male connector on the PCB below.

Push down firmly on the expansion PCB to ensure that the

EXPCN connectors are firmly together. Using the additional spacers included with the 2CO/8STA PCB, attach

the PCB to the card below.

2. Connect the green earth ground lead terminal to the ETH

screw on the CPU. An earth ground is always required.

3. Refer to Part 3: Installing Extensions and Trunks for

cabling instructions.

4. If installing a second Expansion PCB, simply place the

card over the first PCB and repeat steps 1-3.

5. To install an Expansion PCB if an SMDR or Power Failure

PCB has been previously installed:

2-6

● Power down the system

● Remove the SMDR and/or Power Failure PCB

● Install the Expansion PCB

● Reinstall the SMDR and/or Power Failure PCBs

● Power up the system.

Page 15

INSTALLING PCBs

82400 - 32

CPU

CPU

RGUCN

Ring Generator

PCB

Ring Generator PCB (Figure 2-4)

Figure 2-4 RING GENERATOR PCB

The Ring Generator PCB provides the ring generator source

when connecting a single line telephone, modem, voice mail,

or answering machine as a system extension. This must be

installed when any single line telephones are used in the system.

To install a Ring Generator PCB:

1. Align the PCB on the left side of the Main Cabinet, below

the power switch. Using the three screws provided, attach

the PCB to the Main Cabinet.

2. Attach the cable from the Ring Generator PCB to the connector labeled RGUCN mounted on the CPU.

2-7

Page 16

INSTALLING PCBs

Auxiliary PCB (Figure 2-5)

Volume Control

VR3VR4VR1VR2

2CO/8STA PCB

Card Holder

CPU

82400 - 20

Figure 2-5 AUXILIARY PCB

The Auxiliary PCB provides:

● 2-pin DDK connectors for two External Paging Zones.

● 2-pin DDK connectors for two Door Boxes.

● 2-pin DDK connectors for two common-use relay contacts.

● 2-pin DDK connectors for Background Music source.

● 2-pin DDK connectors for Music On Hold source.

To install an Auxiliary PCB:

1. Insert the two card holders (included with the PCB) into

the outer holes on the right-hand side of the Main Cabinet.

2. Insert the Auxiliary PCB into the card holders.

3. Connect the ribbon cable (included with the PCB) to the

Auxiliary PCB and then to the DHUCN connector on the

CPU.

4. Refer to Part 4: Installing Optional Equipment for more

on installing Door Boxes, External Paging Equipment and

Alarm Sensors.

2-8

Page 17

INSTALLING PCBs

625

Modular

Jack

Single Line

Telephone

BLK

YEL

RED

GRN

BLU-WHT

WHT-BLU

82400 - 18

Nylon Spacer

Metal Spacer

CPU

2CO/8STA PCB

4 PF XFER PCB

PFCON

To CO Connection

on CPU Card

To Telco

Connection

COCN PFSTN SLTCN

PFUCN

Attached Wire

PFUCN

Power Failure (4 PF XFER) PCB (Figure 2-6)

Figure 2-6 POWER FAILURE (4 PF XFER) PCB

The Power Failure (4 PF XFER) PCB provides DDK connectors for four power failure cut through circuits to four single

line telephones.

To install a 4 PF XFER PCB:

1. Place the two nylon spacers included with the 4 PF XFER

PCB in the lower holes in the middle of the CPU (or

2CO/8STA PCB, if installed).

2. Align the 4 PF XFER PCB over the metal and nylon spacers.

3. Using the two metal spacers included with the 4 PF XFER

PCB, attach the PCB to the lower PCB.

4. Refer to Part 4: Installing Optional Equipment for more

on installing Power Failure telephones.

2-9

Page 18

INSTALLING PCBs

82400 - 17

Set SW1 to the proper baud rate position by

placing the jumper over the pins of the

desired baud rate.

SMDR Jack and

Cable Assembly

Nylon Spacer

SMDR

2 CO/8STA

CPU

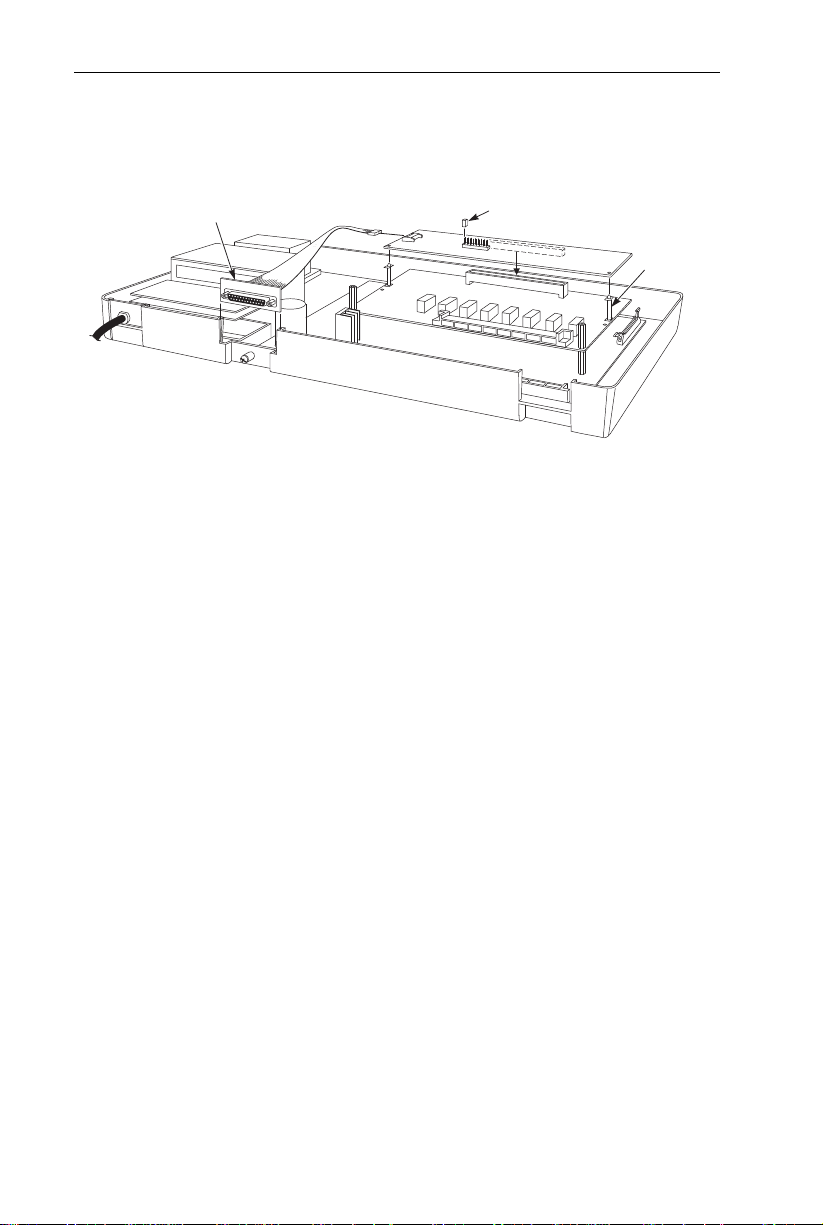

SMDR PCB (Figure 2-7)

Figure 2-7 SMDR PCB

The SMDR (Station Message Detail Recording) PCB provides a record of the system’s outside calls. Typically, the

record outputs to a customer-provided printer, terminal or

SMDR data collection device. Use SMDR when you need to

monitor the usage at each extension and trunk.

To install a SMDR PCB:

1. Place the two nylon spacers included with the SMDR PCB

in the upper holes in the middle of the CPU (or 2CO/8STA

PCB, if installed).

2. Align the SMDR PCB over the nylon spacers. Press the

PCB into the connector labeled EXPCN on the CPU or

2CO/8STA PCB.

3. Connect the SMDR jack and cable assembly to the Main

Cabinet base. Insert the other end of the cable into the

RSCN connector on the SMDR PCB.

4. Using an RS-232C cable (Figure 2-8), plug the printer into

the SMDR jack assembly. Set the interface conditions of

the printer as follows:

Word length: 7 bits

Parity bit: Even parity

Stop bit length: 2 bits

2-10

Page 19

INSTALLING PCBs

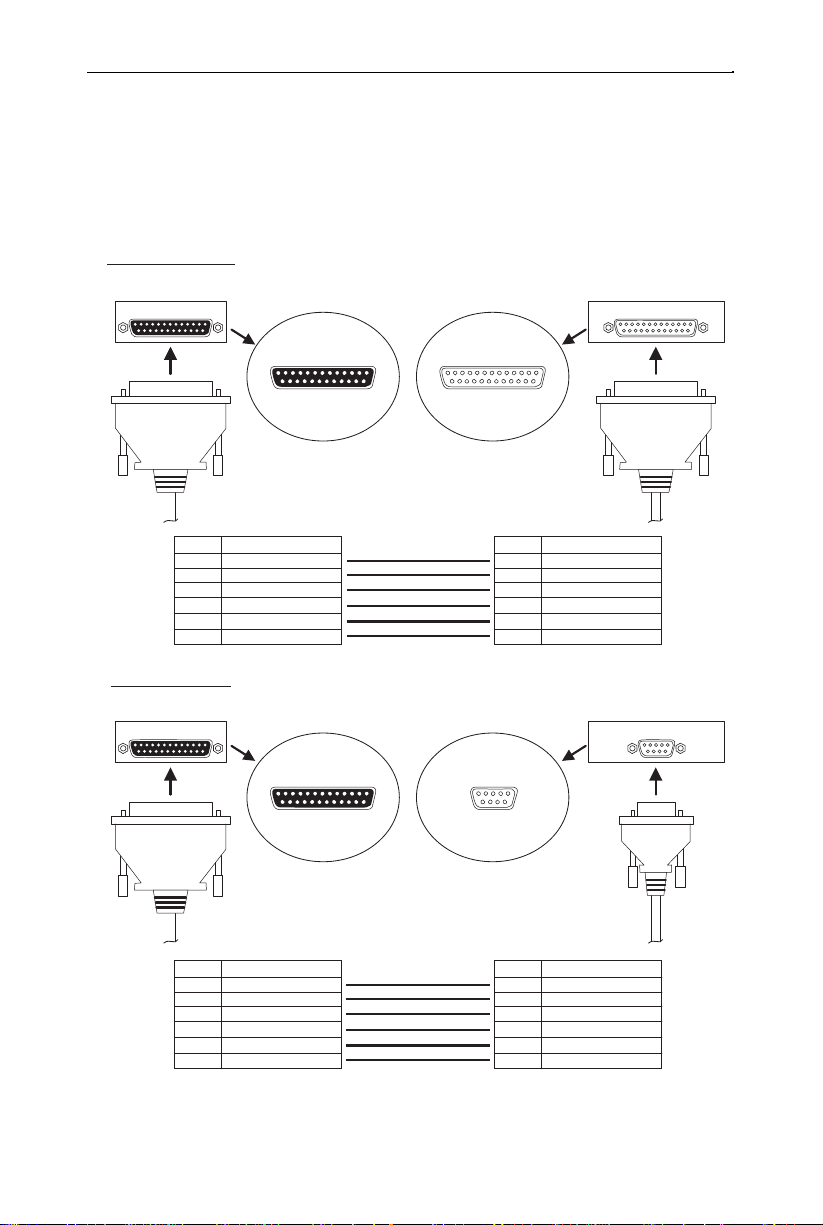

SMDR RS-232C Cable Assembly (Figure 2-8)

To connect the SMDR and printer, an RS-232C cable is required.

If you make your own cable, it must be a straight-through cable

connecting pins 2, 3, 6, 7, 8 and 20. Refer to the Figure 2-8.

Note that the cable length should not exceed 50’in length.

25 pin - 25 pin Cable

SMDR Jack

Output Terminal

Pin No.

2

3

6

7

8

20

25 pin - 9 pin Cable

SMDR Jack

RS-232C (25 pin)

13

25

(female)

Description

Receive Data

Transmit Data

Data Terminal Ready

Signal GND

Request To Send

Data Set Ready

RS-232C (25 pin)

13

25

(female)

RS-232C (25 pin)

1

14

1

14

13

25

(male)

Pin No.

RS-232C (9 pin)

1

6

(male)

1

14

2

Receive Data

3

Transmit Data

6

Data Terminal Ready

7

Signal GND

8

Request To Send

20

Data Set Ready

5

9

82400 - 31

Description

Output Terminal

Pin No.

* The other Pins are not used. These Pin conditions are "Open".

Description

2

Receive Data

3

Transmit Data

6

Data Terminal Ready

7

Signal GND

8

Request To Send

20

Data Set Ready

Pin No.

Figure 2-8 RS-232C CABLE ASSEMBLY

Description

3

Transmit Data

2

Receive Data

6

Data Set Ready

5

Signal GND

1

Data Carrier Detect

4

Data Terminal Ready

2-11

Page 20

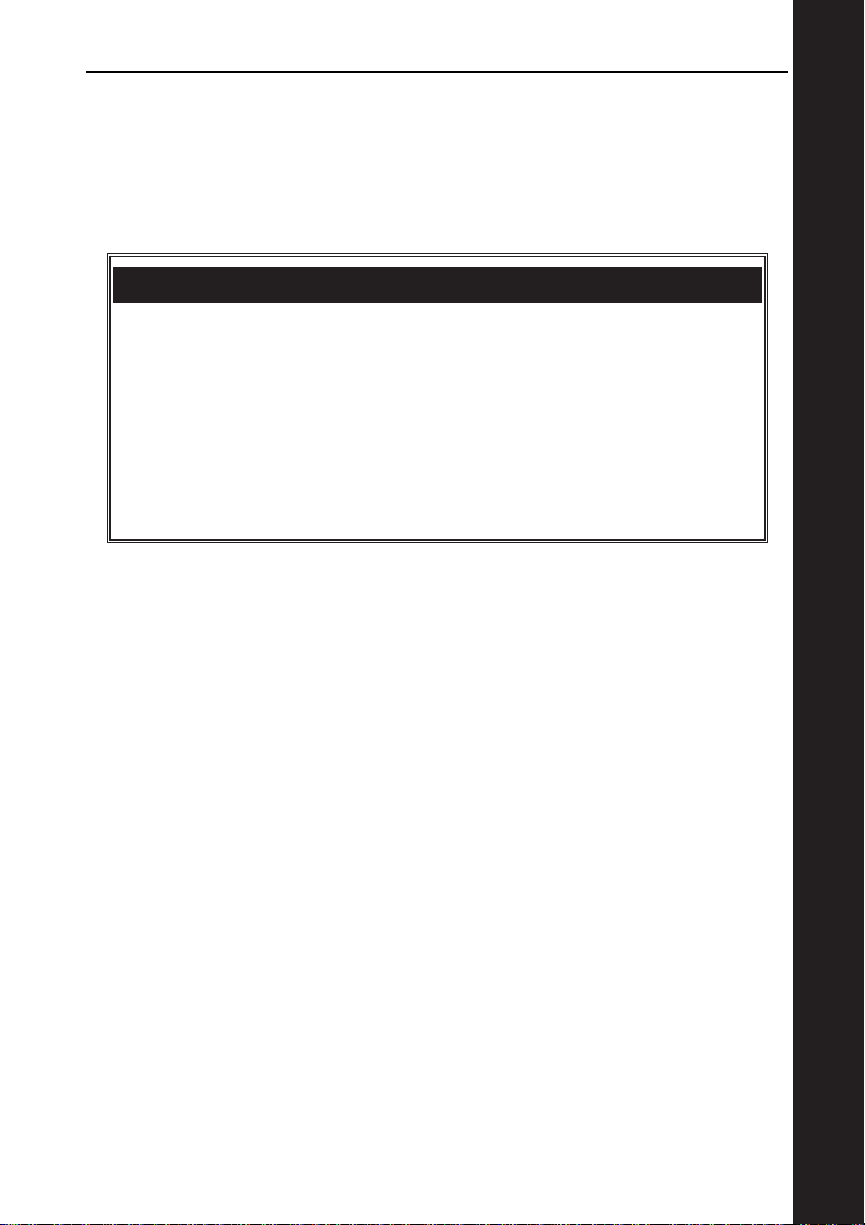

POWERING UP THE SYSTEM

Power-Up Sequence

Now that all the PCBs you need are installed, you can powerup the system.

1. Install a surge protector in the AC outlet you intend to use

for system power.

2. Plug the AC power cord for the Main Cabinet into its surge

protector.

System LEDs on Power-Up

PCB LED Status

CPU Processor LED About 5 seconds after power-up,

flashes quickly (red)

2-12

Page 21

Section 3

Installing Extensions and Trunks

In this section . . . Page

Connecting Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Working With DDK Connectors . . . . . . . . . . . . . . . . . . .3-3

Making Additional DDK Connectors . . . . . . . . . . . . . . .3-3

Punching Down a DDK Installation Cable . . . . . . . . . . .3-4

Connecting Extensions . . . . . . . . . . . . . . . . . . . . . . . .3-7

Station Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Connecting Trunks . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Trunk Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3. INSTALLING EXTENSIONS AND TRUNKS

3-1

Page 22

3-2

Page 23

CONNECTING BLOCKS

Working With DDK Connectors

The system uses DDK-type connectors for extensions, trunks and

optional equipment. Using the optional DDK Installation Cables (4pin station cable=P/N 82490, 2-pin power failure cable=82491, and

2-pin C.O. line cable=82492) makes it easy to connect the PCBs to

standard 66M1-50 connecting blocks. The cables available for the

system are for CO lines (one-pair), keysets (2-pair), and Power

Failure Jumpers/auxiliary options (one-pair). If desired, separate

DDK connectors without cable can be purchased. In general, each

cabinet needs:

● Two 66M1-50 block and DDK Installation Cable for extensions.

● One 66M1-50 block and DDK Installation Cable for optional

equipment

● One to eight (depending on your requirements) RJ11C modular

jacks and one DDK Installation Cable for trunks.

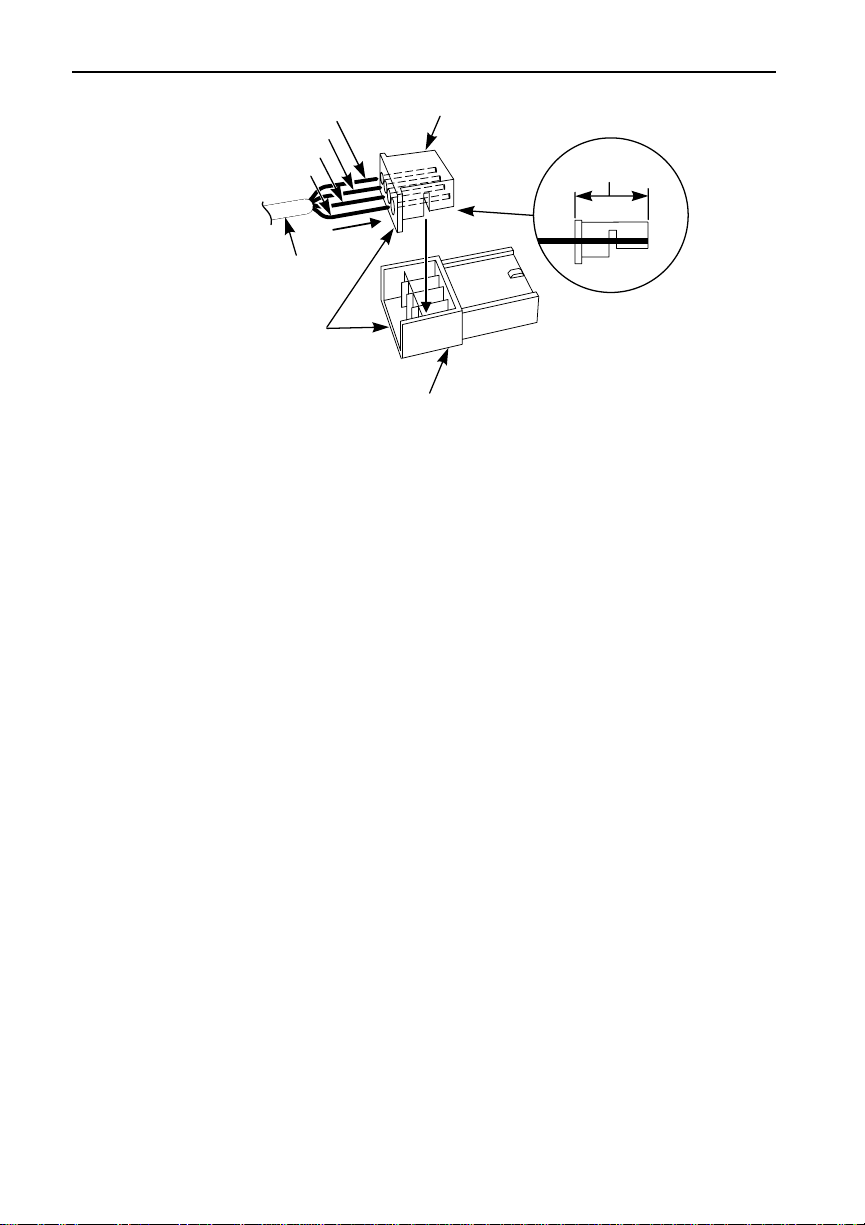

Making Additional DDK Connectors

(Figure 3-1)

To make DDK connectors, using 22 or 24 gauge solid 2-pair twisted

wire for keysets or 22 or 24 gauge solid 1-pair twisted wire for CO

lines, single line telephones, Power Failure Jumpers, or auxiliary

functions, do the following:

1. Do not strip the wires. Insert the wires into the top piece (clear

plastic) of the connector. Following the standard color code:

#1=White/Blue, #2=Blue/White,

#3=White/Orange, #4=Orange/White

(Ignore #3 and #4 if only using 1-pair twisted wire)

Refer to Figure 3-4 for additional help with the color code. Make

sure that the wire ends do not protrude beyond the back of the

connector.

2. Place the top half of the connector over the lower half and press

down or use pliers to snap together. Verify that the connector

will not come apart and that all the wires are secure. Once

together, these connectors will not separate without breaking.

3-3

Page 24

CONNECTING BLOCKS

Upper Half

82400 - 30

Approx. 5/16"

Lower Half

DDK Connector

Two pair twisted

telephone wire

WHT/BLU

BLU/WHT

WHT/ORN

ORN/WHT

1 (T)

2 (R)

3 (H)

4 (L)

Figure 3-1 MAKING DDK CONNECTORS

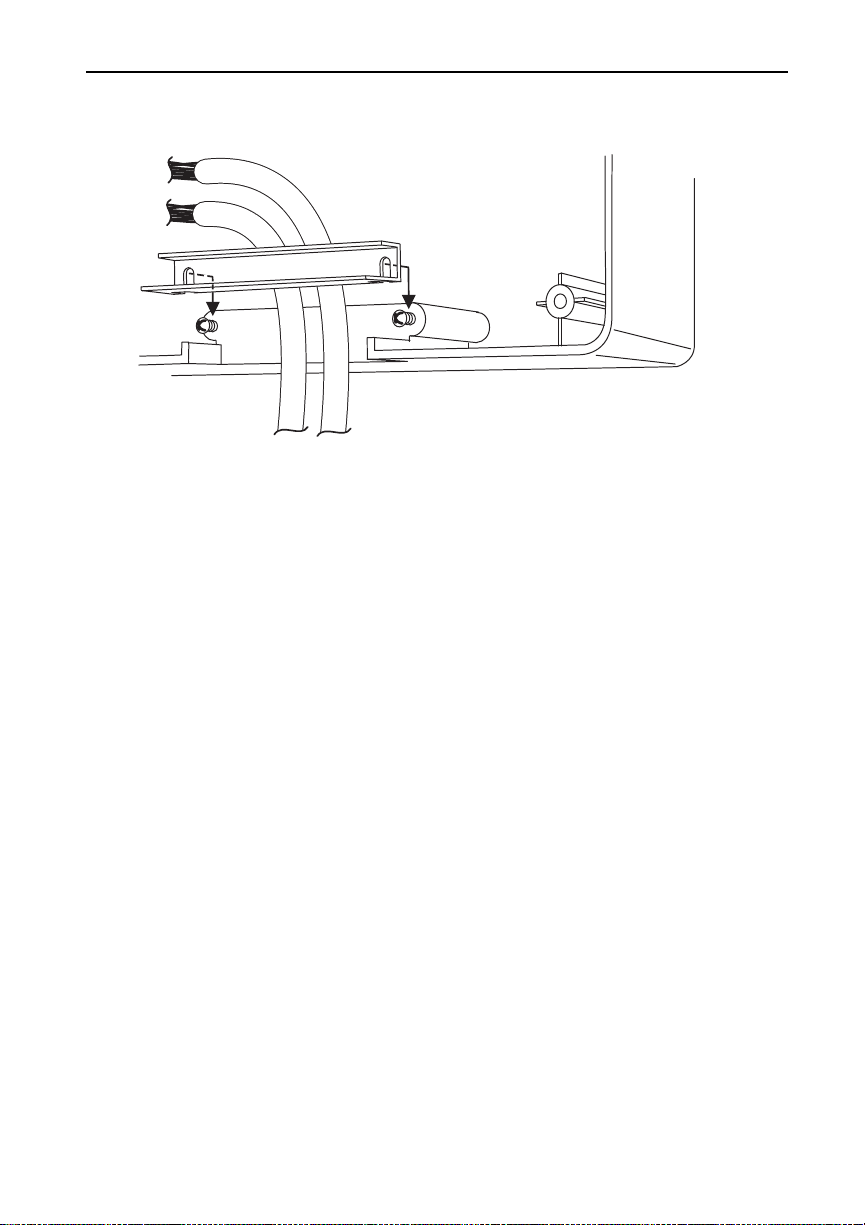

Punching Down a DDK Installation Cable

The DDK Installation Cables have 4-pin DDK connectors installed

on one end and are unterminated on the other.

1. For each 66M1-50 block, punch down the DDK Installation

Cable in standard color-code order.

Refer to Figure 3-3 if you need help with the color code.

2. After you have punched down your cables, route them through

the bottom of the cabinet and secure them with the strain relief

bar (Figure 3-2).

3-4

Page 25

CONNECTING BLOCKS

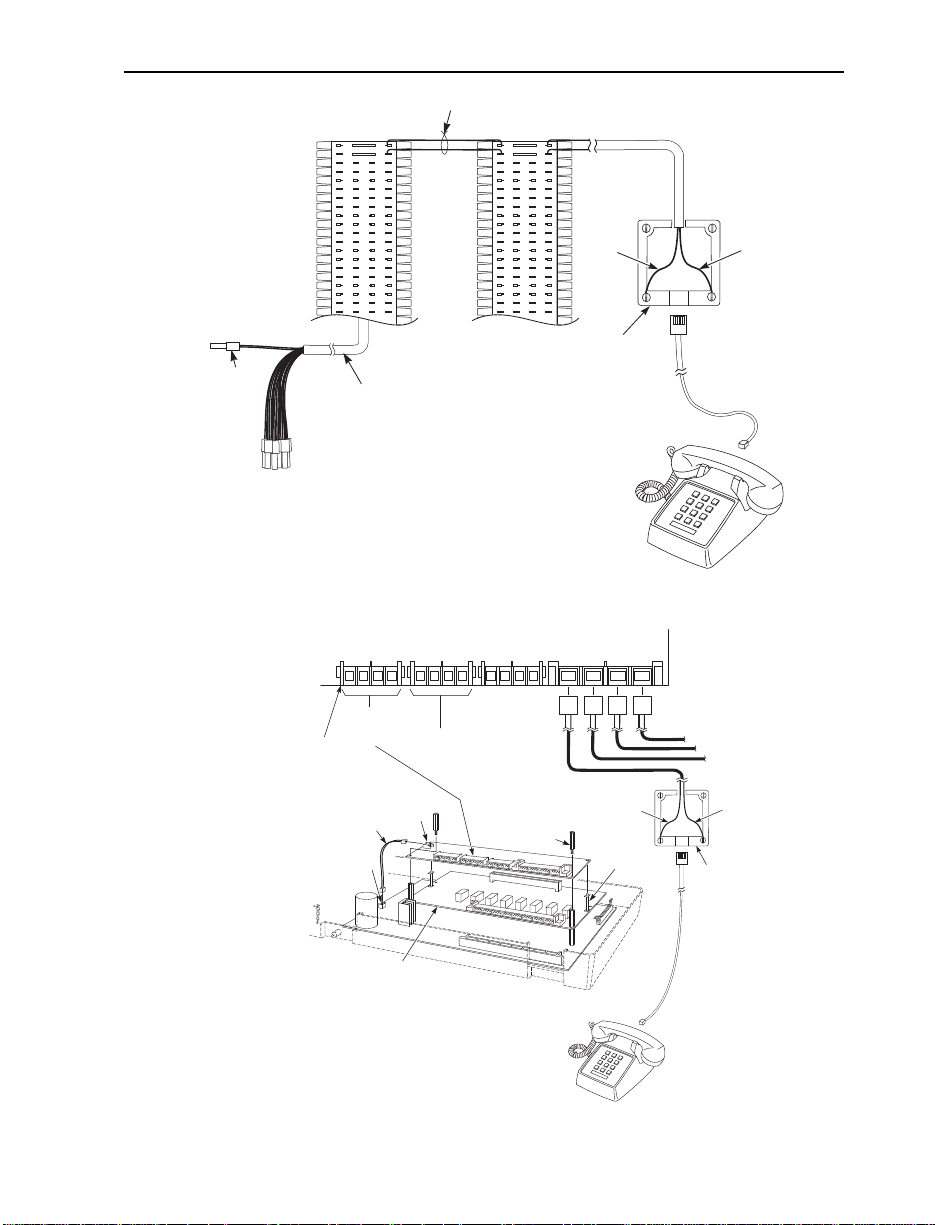

Figure 3-2 SECURING THE CABLES

82400 - 29

3-5

Page 26

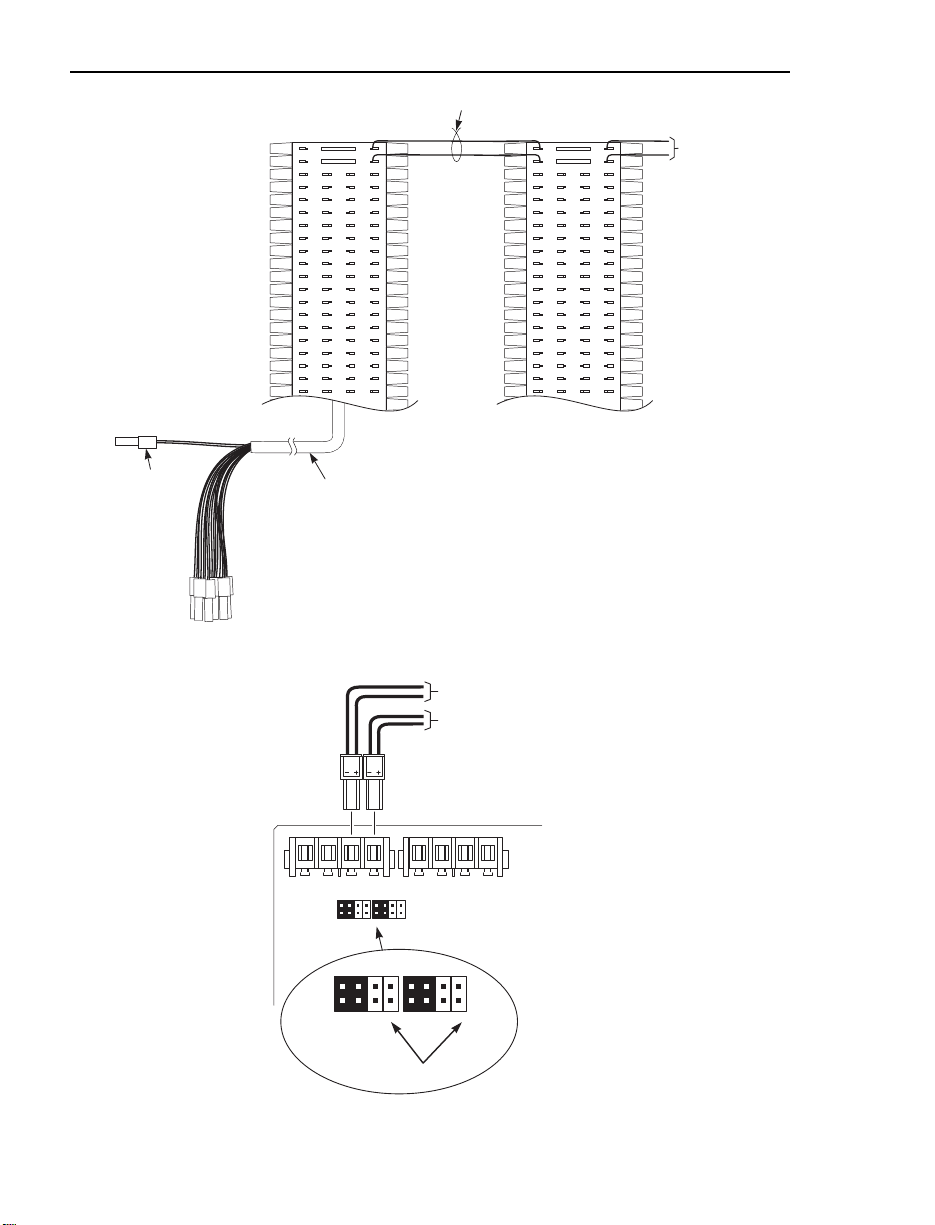

CONNECTING BLOCKS

- Only CPU

No Connection

- With one

expansion PCB

- With two

expansion PCB’s

T

R

H

L

= Tip

= Ring

= High

= Low

3-6

Figure 3-3 CONNECTING BLOCK

Page 27

STCN

STCN

CPU

2CO/8STA PCB

TEL9/17

TEL1

10/18

TEL2

11/19

TEL3

12/20

TEL4

13/21

TEL5

14/22

TEL6

15/23

TEL7

16/24

TEL8

82400 - 25

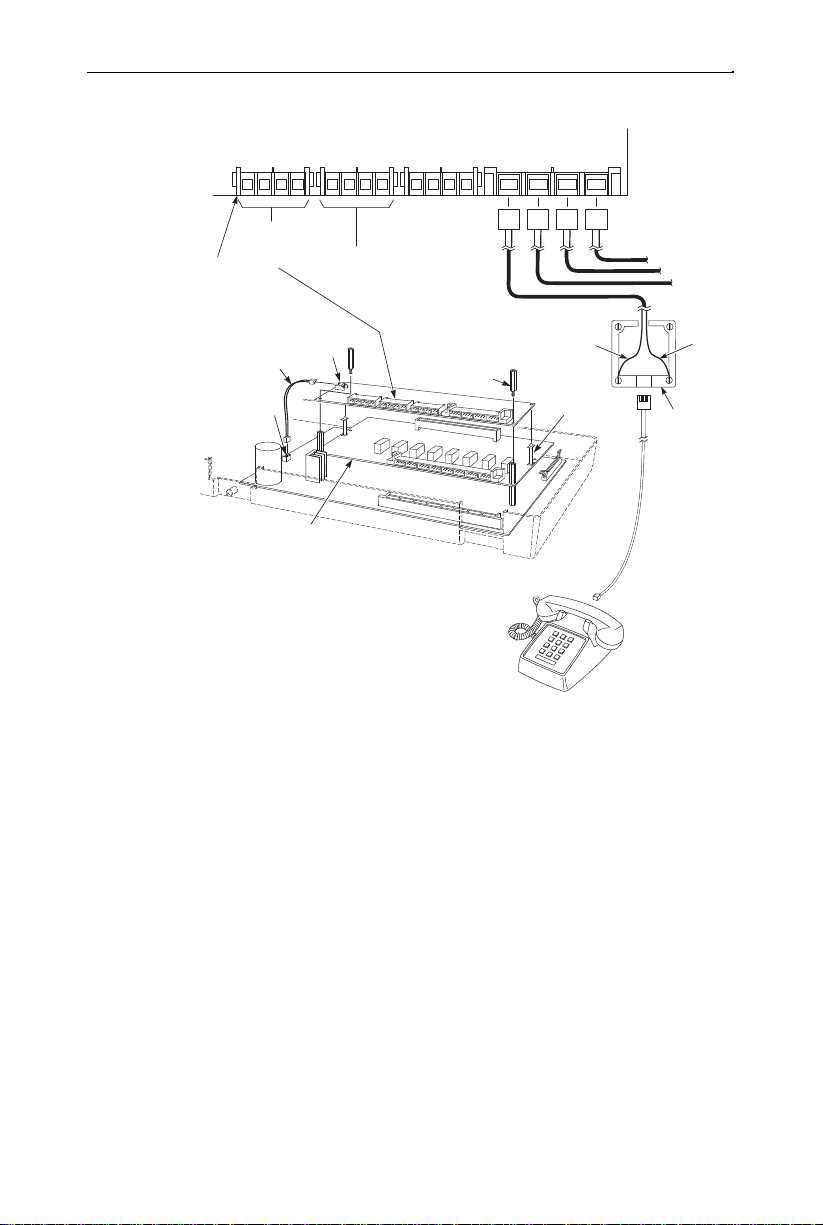

CONNECTING EXTENSIONS

Station Connections (Figure 3-4)

The CPU has 4-pin DDK connectors for eight stations. Each

Expansion (2CO/8STA) PCB provides for an additional eight stations. Two Expansion PCB’s are allowed per system providing a

total of twenty-four stations per system.

Refer to Part 4: Installing Optional Equipment for instructions on connecting a power failure telephone.

Figure 3-4 STATION CONNECTIONS

1. Following the conventional color code, insert the DDK connectors into the PCB. For example, the first eight stations in the system would have these connections:

Ext./Port DDK Connector Pair

10 WHT-BLU / BLU-WHT / WHT-ORN / ORN-WHT

11 WHT-GRN / GRN-WHT / WHT-BRN / BRN WHT

12 WHT-SLT / SLT-WHT / RED-BLU / BLU-RED

13 RED-ORN / ORN-RED / RED-GRN / GRN-RED

14 RED-BRN / BRN-RED / RED-SLT / SLT-RED

15 BLK-BLU / BLU-BLK / BLK-ORN / ORN-BLK

16 BLK-GRN / GRN-BLK / BLK-BRN / BRN-BLK

17 BLK-SLT / SLT-BLK / YEL-BLU / BLU-YEL

Note that single line telephones only use one-pair wire

(T/R). When installing a single line set, the second pair is

not used (H/L).

2. Install a modular jack for each extension within six feet of the

telephone’s location. See Figure 3-5.

3-7

Page 28

CONNECTING EXTENSIONS

3. For each keyset, run two-pair 24 AWG station cable from the

cross-connect block to the modular jack. For each single line

phone, run one-pair 24 AWG station cable from the cross-connect block to the modular jack.

4. Terminate the station cable to the module jack lugs:

WHT-BLU to GREEN lug

BLU-WHT to RED lug

WHT-ORN to BLACK lug *

ORN-WHT to YELLOW lug *

* Lug not used when installing a single line phone.

5. Back at the MDF, run two pairs of cross-connect wires (or one

pair of cross-connect wires for single line phones) between the

pins on the B block and cross-connect block to complete the

connection.

6. Install bridging clips as required.

7. After completing step 6, you should be able to place and answer

calls at the extension.

Two Pair

Cross Connect

3-8

ORN-WHT WHT-ORN

"B"

Block

YEL

BLU-WHT

Cross

Connect

Block

DDK Installation Cable

RED

625

Modular

Jack

BLK

WHT-BLU

GRN

Figure 3-5 CONNECTING KEYSET TELEPHONES

82400 - 5

Page 29

CONNECTING EXTENSIONS

625

Modular

Jack

Single Line

Telephone

BLKYEL

RED GRN

BLU-WHT

WHT-BLU

One-Pair Cross-Connect

DDK

Connector

25-Pair DDK

Installation Cable

"B" Block

Cross

Connect

Block

82400 - 48

Figure 3-6 CONNECTING SINGLE LINE TELEPHONES

3-9

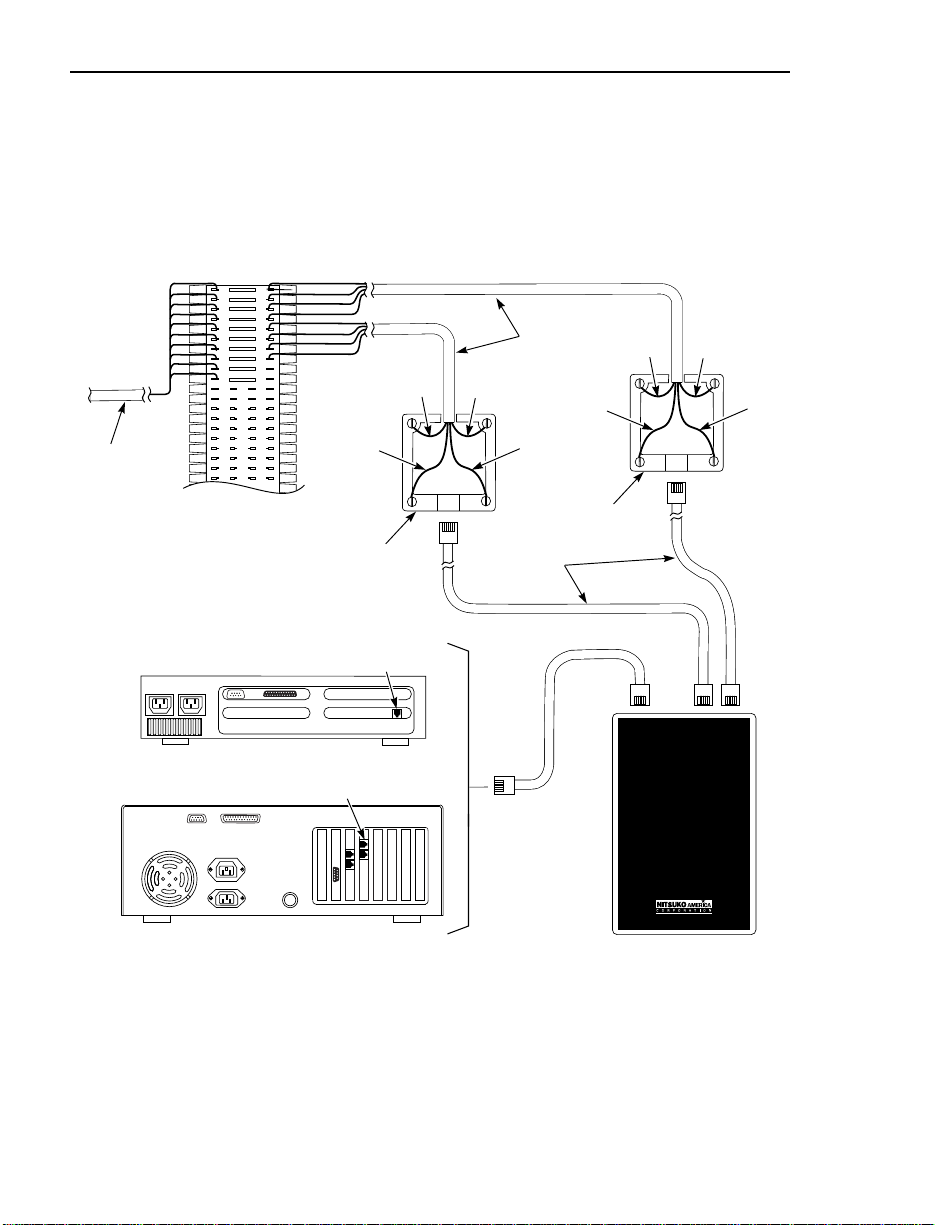

Page 30

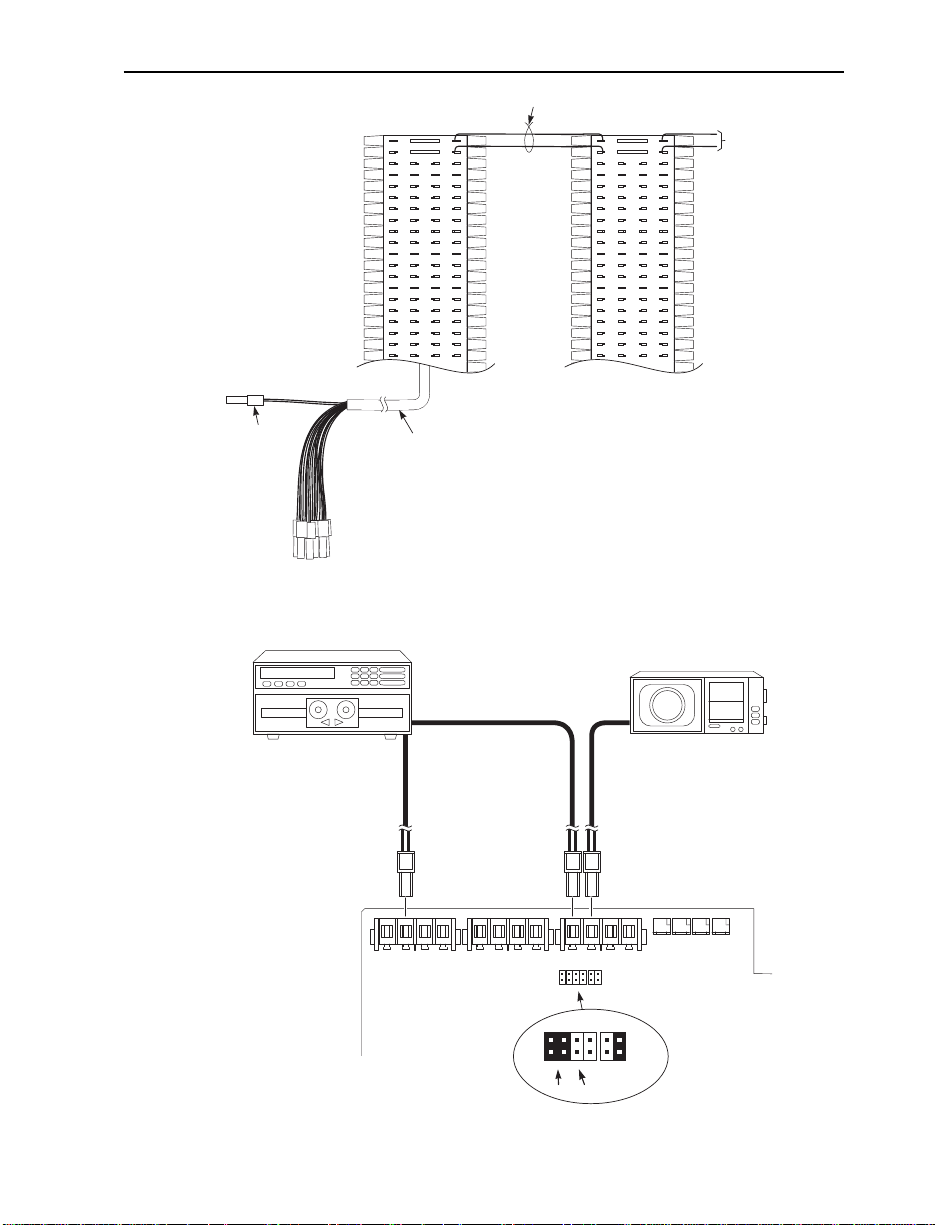

CONNECTING TRUNKS

82400 - 26

CO2 CO3 CO4

COCN

CO1

CPU

CO/PBX Line 4

CO/PBX Line 2

CO/PBX Line 3

CO/PBX Line 1

Trunk Connections (Figure 3-7)

The CPU has 2-pin DDK connectors for four loop start CO trunks.

Each Expansion (2CO/8STA) PCB provides an additional two CO

trunk connections. Two Expansion PCB’s are allowed per system

providing a total of eight trunks per system.

Refer to Part 4: Installing Optional Equipment for instructions on connecting a power failure telephone.

2CO/8STA PCB

COCN

CO6/8

CO5/7

82400 - 24

CO/PBX Line 6 or 8

CO/PBX Line 5 or 7

Figure 3-7 TRUNK CONNECTIONS

1. Following the conventional color code, insert the DDK connectors into the PCB. For example, the CPU would have these connections:

Trunk DDK Connector Pair

1 WHT-BLU / BLU-WHT

2 WHT-ORN / ORN-WHT

3 WHT-GRN / GRN-WHT

4 WHT-BRN / BRN WHT

2. For each trunk, run one pair of wires from the DDK connection

to a 625 modular jack, which then connects to the telco’s RJ11C

jacks using a standard line cord (Figure 3-8 on the following

page).

3. After completing step 2, you should be able to place and answer

calls over the connected trunk.

3-10

Page 31

CONNECTING TRUNKS

625

Modular

Jack

Line

Cord

RED

GRN

BLU-WHT

WHT-BLU

DDK

Connector

To CO connector

on CPU or

2CO/8STA PCB

25-Pair DDK

Installation Cable

To Central Office

Telco

RJ11C

82400 - 12

Figure 3-8 CONNECTING TRUNKS

3-11

Page 32

3-12

Page 33

Section 4

Installing Optional Equipment

In this section . . . Page

Alarm Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Using External Alarm Sensors . . . . . . . . . . . . . . . . . . . . . .4-3

Installing an External Alarm Sensor Circuit . . . . . . . . . . . .4-3

Caller ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Using Caller ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Installing Caller ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

DSS Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Using a Direct Station Selection Console . . . . . . . . . . . . . .4-8

Installing a DSS Console . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

External Paging and Page Relays . . . . . . . . . . . . . . . . .4-9

Using External Paging . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Installing External Paging and Page Relays . . . . . . . . . . . .4-9

Door Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Using the Door Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Installing a Door Box . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Installing Door Strike Control Relays . . . . . . . . . . . . . . . .4-14

Music Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Music on Hold and Background Music . . . . . . . . . . . . . .4-16

Installing a Music Source on an Auxiliary PCB . . . . . . . .4-16

Power Failure Telephones . . . . . . . . . . . . . . . . . . . . . .4-18

Power Failure Cut-Through . . . . . . . . . . . . . . . . . . . . . . .4-18

Installing a Power Failure Telephone . . . . . . . . . . . . . . . .4-18

Voice Mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Using Voice Mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Wall-Mount Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Using the Wall-Mount Kit . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Installing the Wall-Mount Handset Hanger . . . . . . . . . . .4-23

Wall-Mounting a Key Telephone . . . . . . . . . . . . . . . . . . .4-24

4. INSTALLING OPTIONAL EQUIPMENT

4-1

Page 34

4-2

Page 35

ALARM SENSORS

Using External Alarm Sensors

The Auxiliary PCB provides two alarm circuits which detect a make

(open) or break (closed) contact from an alarm. Programming determines if the alarm inputs require an open or closed circuit.

An alarm detection causes the system to send a signal to stations programmed to receive the alarms. The alarm signal can also be sent to

external paging speakers.

Note: The Auxiliary PCB alarm feature can use a 10-30 VDC power

supply installed in series with the alarm circuit.

Installing an External Alarm Circuit

CAUTION

Be sure the requirements of the alarm system sensors do not exceed

the system specifications.

With Internal Power: loop resistance of less than 100 Ohms

With External DC Power: 5 to 24 VDC with 0.65 mA to 4.5 mA

Note: External powered alarm sensors are polarity sensitive

(see Figure 4-2). Additionally, the external powershould

provide current limiting.

1. Locate an available 2-pin DDK connector in an auxiliary (C)

block.

2. For the DDK connector chosen, cross-connect the associated wire

pair from the C block to the cross-connect block.

3. Install bridging clips as required.

4. Connect the two leads from the first external alarm to the associated terminals on the cross-connect block.

5. Plug the DDK connector into the ALM1 connector on the

Auxiliary PCB.

6. Repeat steps 1-4 for the second external alarm, if required.

(Figure 4-1)

7. Plug the DDK connector into the ALM2 connector on the

Auxiliary PCB.

Note: When using internal power to connect the dry contact of an

alarm-detecting device to the system, set the SW3 switch (Alarm

1) and SW4 switch (Alarm 2) on the Auxiliary PCB to INPOW.

4-3

Page 36

ALARM SENSORS

One-Pair Cross-Connect

DDK

Connector

To alarm input

on Auxiliary PCB

25-Pair DDK

Installation Cable

"C" Block

Cross

Connect

Block

Input from

alarm

system

82400 - 11

4-4

Figure 4-1 CONNECTING AN ALARM

SW3

power

CTR2RL2

EXPOW

Alarm Input 2

Alarm Input 1

CN2CN1

SPK2RL1

CTR1ALM2

SW3

SPK1ALM1

Auxiliary PCB

11

22

SW4

EXPOW EXPOW

INPOW INPOW

82400 - 40

SW4

EXPOW

INPOW INPOW

(ALM2) (ALM1)

Using internal

Figure 4-2 CONNECTING TO THE AUXILIARY PCB

Page 37

CALLER ID

1

1

2

2

INT RST

RUN

Using Caller ID

Caller ID allows a display keyset to show an incoming caller’s telephone number and/or name with the time and date on the phones display. The caller’s information can be checked before answering an

incoming call. The information received by the system depends upon

the capabilities of your local telco.

The system requires the following:

● System Software 2.1B or higher

● Caller ID/SMDR PCB (P/N 82421)

This PCB is used in place of the SMDR PCB (P/N 82420) and

provides both Caller ID and SMDR capability.

● Caller ID Adaptor (P/N 82425)

The Caller ID Adaptor provides 8 detection circuits for Caller

ID data.

Installation (Figure 4-3)

1. Locate a clean, dry spot that is out of direct sunlight and near the

Portrait KSU. The Caller ID Adaptor must be installed within 2’ of

the lower right side of the KSU (determined by the length of the

interconnecting cable). The area should be well ventilated and the

temperature should remain at a normal level.

2. Remove the cover from the Caller ID Adaptor.

3. Tack-fasten two of the four wood screws (provided) on the wall at

about 8 11/16” apart. For easier installation, you can use the base

as a mounting template.

4. Place the Caller ID Adaptor over the tacked screws. Fully tighten

the screws and install the remaining two wood screws.

5. Remove the cover from the KSU by unscrewing the two captive

screws on the lower half of the cabinet cover. Lift up the lower

half of the cover -- then slide it back slightly to remove it.

6. Before proceeding further, make sure switches

1 & 2 of the CPU Mode Switch are set to the

RUN position and the battery is installed in

the system. This is necessary in order to

retain the current system programming.

7. Unplug the AC power cord for the KSU from its surge protector.

4-5

Page 38

CALLER ID

8. Set the jumpers on the Caller ID/SMDR PCB. Set jumper-SW1 to

match the baud rate of the SMDR Unit. Set jumper-SW2 to the

“RUN” position, this setting allows the system to use the customer’s current programming.

9. Place the two nylon spacers included with the Caller ID/SMDR

PCB in the upper holes in the middle of the CPU (or 2CO/8STA

PCB, if installed).

10. Align the Caller ID/SMDR PCB over the nylon spacers. Press the

PCB into the connector labeled EXPCN on the CPU or 2CO/8STA

PCB. The PCB should then be snapped on to the spacers.

11. Connect the Caller ID cable to the CBCN connector and G termi-

nal on the Caller ID/SMDR PCB. Connect the opposite end to the

SMDCN connector and G terminal on the Caller ID Adaptor.

12. Mount the SMDR jack (RS-232 connector) to the base of the

KSU. Connect the opposite end of the cable to the RSCN connector on the Caller ID/SMDR PCB.

13. Connect the FG ground on the KSU to the ETH ground connector

on the Caller ID Adaptor using the green wire with spade lug ends

provided.

14. With DDK connectors attached to both ends, connect a one-pair

jumper from the TRCN connector on the Caller ID Adaptor to the

corresponding COCN connector on either the CPU or Expansion

(2CO/8STA) PCB. Repeat this step for additional CO lines.

15. For each CO trunk, run one pair of wires with DDK connectors on

one end from the COCN connector on the Caller ID Adaptor to a

625 modular jack. The jack is then connected to telco’s RJ11C

jack using a standard line cord.

16. Replace the front cover on the KSU, and the front cover on the

Caller ID Adaptor.

17. Plug the AC power cord for the KSU into its surge protector.

18. Refer to the Portrait Pocket Guide (P/N 824000PKT**) for

required programming.

4-6

Page 39

82400 - 58

FG

SG

COCN

CO1

CO4

CPU

2 CO/8 STA

ETH

COCN CO1CO8TRCN COTR1COTR8SMDCN

G

COTR8

625

Jack

Caller ID Adaptor

Portrait KSU

SMDR Jack and

Cable Assembly

Set SW1 to the proper

baud rate position placing

the jumper over the pins

of the desired baud rate.

To

Telco

Nylon

Spacer

CBCN

G

SW2

TEST RUN

Caller ID/SMDR PCB

CALLER ID

Figure 4-3 CONNECTING CALLER ID

4-7

Page 40

DSS CONSOLE

Using a Direct Station Selection Console

The DSS Console gives a

extensions. The system supports a maximum of 3 DSS Consoles.

Installing a DSS Console (Figure 4-4)

1. Unplug the telephone and remove the handset cord from the telephone’s base.

2. Remove the four screws on the bottom of the telephone.

3. Using a knife remove the plastic piece on the base to allow space

for the ribbon cable, using care not to leave any rough edges which

could cause damage to the cable.

4. Insert the ribbon cable from the DSS into the CN3 connector on

the PCB in the telephone.

5. Replace the bottom plate of the telephone and attach with the four

screws.

display keyset user one-button access to

4-8

82400 - 14

Use a knife to

scrape away.

Figure 4-4 CONNECTING THE DSS CONSOLE

Page 41

EXTERNAL PAGING AND PAGE RELAYS

Using External Paging

Each Auxiliary PCB has two External Paging audio outputs and two

associated control relays. The External Page zones are two way which

provide for the ability to do talk back paging (no additional programming required). The audio outputs are connected to audio inputs on

customer-provided paging systems. In some paging systems, you can

use the control relays to automatically turn the amplifiers on and off.

The control relays are normally open and close whenever a user calls

the External Paging zone.

Installing External Paging and Page Relays (Figure 4-5)

CAUTION

Be sure the audio input requirements of the paging equipment are

compatible with the audio output specifications of the system.

Output Impedance: 600 Ohms

Output Level: Nominal 250 mV (-10 dBm)

Maximum Output: 400 mV RMS

Minimum Initial Contact Resistance: 50 mOhms

Relay Contact: 250 mA @ 24 VDC

1. Locate an available 2-pin DDK connector in an auxiliary (C) block.

2. For the DDK connector chosen, cross-connect the associated wire

pair from the C block to the cross-connect block.

3. Install bridging clips as required.

4. Connect two leads to the paging system audio inputs.

5. For External Zone 1, loop the cable once through a ferrite bead

(supplied with the Auxiliary PCB) then plug the DDK connectors

into the Auxiliary PCB. One connector is plugged into the connector on the PCB labeled SPK1, the other goes to CTR1.

6. For External Zone 2, loop the cable once through the same ferrite

bead used for External Zone 1, then plug the DDK connectors into

the Auxiliary PCB. One connector is plugged into the connector on

the PCB labeled SPK2, the other goes to CTR2.

7. Adjust the volume level of each External Zone. VR1 controls zone

1 (accessed by dialing 86), VR2 controls zone 2 (accessed by dialing 87).

4-9

Page 42

EXTERNAL PAGING AND PAGE RELAYS

One-Pair Cross-Connect

DDK

Connector

To External Page

audio output on

Auxiliary PCB

25-Pair DDK

Installation Cable

"C" Block

Cross

Connect

Block

Output to

paging

system

control

inputs

82400 - 10

One-Pair Cross-Connect

DDK

Connector

To Control Relay

on Auxiliary PCB

25-Pair DDK

Installation Cable

"C" Block

Cross

Connect

Block

Output to

paging

system

control

inputs

82400 - 9

Figure 4-5 CONNECTING EXTERNAL PAGING/RELAYS

4-10

Figure 4-6 CONNECTING EXTERNAL PAGING

Page 43

EXTERNAL PAGING AND PAGE RELAYS

Ferrite bead

To Paging

or Door Box

connection

Loop each cable once

through Ferrite bead

DDK connectors

to Auxiliary PCB

82400 -53

Figure 4-7 ATTACHING THE FERRITE BEAD

Paging Speaker #2 Paging Speaker #1

Amplifier Amplifier

SPK1/SPK2: External paging audio signal output.

CTR1/CTR2: Normally open relay contacts. If a zone

EXMOHCTR2RL2

82400 - 21

Figure 4-8 CONNECTING CONTROL RELAYS TO THE AUXILIARY PCB

SPK1ALM1

Auxiliary PCB

is activated, the contacts close.

(SPK2)

BGMSPK2RL1

DH2CTR1ALM2

DH1

VR3VR4VR1VR2CN3CN2CN1

(SPK1)

(DH2)

(DH1)

4-11

Page 44

DOOR BOX

Using the Door Box

Each Auxiliary PCB supports two Door Boxes. In addition, you can

connect each circuit’ s control relay to an electric door strike. This

allows an extension user to remotely activate the door strike while talking to a visitor at the Door Box. The control relays are normally open.

Installing a Door Box (Figure 4-9)

1. Locate an available 2-pin DDK connector in an auxiliary (C) block.

2. For the DDK connector chosen, cross-connect the associated wire

pair from the C block to the cross-connect block.

3. Connect leads from lugs 1 and 2 on the Door Box to the cross-connect block. Be sure to maintain the proper polarity.

4. Loop the cable once through a ferrite bead (supplied with the

Auxiliary PCB), then plug the DDK connector into the Door Box

(1 or 2) connector on the Auxiliary PCB. The first Door Box is

labeled DH1 on the PCB. The second Door Box is labeled DH2.

If both Door Boxes are to be used, loop both cables through

the same ferrite bead.

5. Install bridging clips as required.

6. Use VR3 or VR4 to adjust the volume of the Door Box. VR3 corresponds to Door Box 1, VR4 corresponds to Door Box 2.

4-12

5

L

T

6

C

T

1

2 3 4

L F

*

RED-BRN

BRN-RED

*

RED-SLT

SLT-RED

Misc Block

* typical installation

To Door Chime Box 1

21

22

23

24

Holes for

mounting screws

To Door

Chime Box 2

Rear view

92 0 - 1 59 A

Figure 4-9 CONNECTING A DOOR BOX

Page 45

Figure 4-10 ATTACHING THE FERRITE BEAD

One-Pair Cross-Connect

DDK

Connector

To DHI or DH2 connector

on Auxiliary PCB

25-Pair DDK

Installation Cable

"C" Block

Cross

Connect

Block

Output to

door box

82400 - 42

Ferrite bead

To Paging

or Door Box

connection

Loop each cable once

through Ferrite bead

DDK connectors

to Auxiliary PCB

82400 -53

DOOR BOX

Figure 4-11 CONNECTING A DOOR BOX

4-13

Page 46

DOOR BOX

Installing Door Strike Control Relays (Figure 4-12)

CAUTION

Be sure the requirements of the door strike are compatible with the

control relay output specifications of the system.

Contact Configuration: Normally open

Maximum Load: 250 mA@ 24 VDC

Maximum Initial Contact Resistance: 50 mOhms

1. Locate an available 2-pin DDK connector in an auxiliary (C)

block.

2. For the DDK connector chosen, cross-connect the associated wire

pair from the C block to the cross-connect block.

3. Connect two leads from the door strike to the associated terminals

on the cross-connect block.

If the door strike is a high current device, you may have to

install an auxiliary relay that powers the door strike relay.

4. Plug the DDK connector into the Auxiliary PCB connector labeled

RL1 or RL2. RL1 controls the door strike relay for Door Box 1,

RL2 controls Door Box 2.

5. Install bridging clips as required.

4-14

Page 47

82400 - 43

EXMOHCTR2RL2 DH1SPK1ALM1 BGM

SW2

INT

(MOH)

(BGM)

EXTOFF ON

SW1

SPK2RL1 DH2CTR1ALM2

(SPK2)(SPK1) (DH2) (DH1)

Auxiliary PCB

Door Box

To Door Strike

Terminals

VR3VR4VR1VR2CN3CN2CN1

One-Pair Cross-Connect

DOOR BOX

Output to

door strike

To Control Relay

on Auxiliary PCB

DDK

Connector

"C" Block

25-Pair DDK

Installation Cable

Connect

82400 - 8

Cross

Block

Figure 4-12 CONNECTING TO THE DOOR STRIKE

Figure 4-13 CONNECTING DOOR BOX/DOOR STRIKE RELAYS TO THE

AUXILIARY PCB

4-15

Page 48

MUSIC SOURCES

Music on Hold and Background Music

Music on Hold (MOH) provides music to callers on Hold and calls

parked in orbit. The system’s default setting provides an internal

(synthesized) MOH music source, or a customer-provided music

source connected to the Auxiliary PCB can be used instead (see

below).

Background Music sends music from a customer-provided music

source (via a connector on the Auxiliary PCB) to keyset speakers.

Installing a Music Source on the Auxiliary PCB (Figure 4-14)

CAUTION

Be sure the music source is compatible with the MOH and BGM

input specifications on the CPU PCB.

Input Impedance: 600 Ohm

Input Level: Nominal 250 mV (-10 dBm)

Maximum Input: 1V RMS

1. Locate an available 2-pin DDK connector in an auxiliary (C) block.

2. For the DDK connector chosen, cross-connect the associated wire

pair from the C block to the cross-connect block.

3. Connect two leads from the customer-provided music source to the

associated terminals on the cross-connect block.

4. For Music on Hold . . .

a. Plug the DDK connector into the EXMOH input on the

Auxiliary PCB.

b. Set the SW2 strap to the EXT position.

If MOH not is not required (either from an external source or

from the system’s synthesized MOH), set the SW2 strap in the

EXT position and do not plug any music source into the

EXMOH input on the Page/Door Box card.

For Background Music . . .

a. Plug the DDK connector into the BGM input on the Auxiliary

PCB.

b. Set the SW1 strap to the ON position. If BGM is not required,

set the SW2 strap to the OFF position.

5. Install bridging clips as required.

6. Adjust the volume for the MOH and BGM on the external sources.

4-16

Page 49

MUSIC SOURCES

One-Pair Cross-Connect

DDK

Connector

To MOH or BGM

on Auxiliary PCB

25-Pair DDK

Installation Cable

"C" Block

Cross

Connect

Block

To

music

source

82400 - 7

Figure 4-14 CONNECTING MUSIC SOURCES

External MOH Source

(MOH)

INT

EXMOHCTR2RL2 DH1SPK1ALM1 BGM

(MOH)

INT

Off

(SPK2)(SPK1) (DH2) (DH1)

SW2

SW1

(BGM)

EXT

OFF

SW2

SW1

OFFONON

(BGM)

EXT

On

The relay contacts RL1 and

RL2 can be used as

MOH/BGM device control.

The remote control terminal

on the device must be

connected to these contacts.

(see Program 56)

SPK2RL1 DH2CTR1ALM2

Auxiliary PCB

82400 - 22

Figure 4-15 CONNECTING TO THE AUXILIARY PCB

BGM Source

VR3VR4VR1VR2CN3CN2CN1

4-17

Page 50

POWER FAILURE TELEPHONES

Power Failure Cut-Through (Figure 4-16)

When system AC power fails, the 4 PF XFER PCB automatically

connects up to four trunks to the Power Failure Telephones.

Installing a Power Failure Telephone

1. Plug a 2-pin DDK connector to a COCN connector on the CPU or

2CO/8STA PCB. Plug the other end into a PFCON connector on

the 4 PF XFER PCB.

2. Plug a 2-pin DDK connector to a COCN connector on the 4 PF

XFER PCB. Connect the other end to the 625 modular jack leading to the RJ11C telco jack.

3. Plug a 2-pin DDK connector into the SLTCN connector on the 4

PF XFER PCB. Connect the other end to the auxiliary (C) block.

4. Cross-connect the associated wire pair from the C block to the

cross-connect block.

5. Install a modular jack for the Power Failure Telephone within six

feet of the telephone’s location.

6. Run one-pair of 24 AWG station cable from the cross-connect

block to the Power Failure Telephone modular jack.

7. Terminate the station cable WHT/BLU - BLU/WHT leads to the

GRN and RED lugs in the modular jack.

8. Install bridging clips as required.

9. Plug a line cord into the Power Failure Telephone and the phone’s

modular jack.

No programming is required to enable the Power Failure

Telephone.

To test the Power Failure Telephone:

1. Make sure the Switch-1 on the CPU PCB is set to the right side.

This ensures that your programming and configuration is

retained when you power down the system.

2. Power down the system.

3. At the Power Failure Telephone, lift the handset and place a test call.

The call will go out on the trunk in the 4 PF XFER PCB to

which the telephone is connected.

4-18

Page 51

POWER FAILURE TELEPHONES

625

Modular

Jack

Single Line

Telephone

BLK

YEL

RED

GRN

BLU-WHT

WHT-BLU

82400 - 18

Nylon Spacer

Metal Spacer

CPU

2CO/8STA PCB

4 PF XFER PCB

PFCON

To CO Connection

on CPU Card

To Telco

Connection

COCN PFSTN SLTCN

PFUCN

Attached Wire

PFUCN

625

Modular

Jack

Power

Failure

Telephone

BLKYEL

RED GRN

BLU-WHT

WHT-BLU

One-Pair Cross-Connect

DDK

Connector

To Power Failure

Telephone

connector on

4 PF XFER PCB

25-Pair DDK

Installation Cable

"C" Block

Cross

Connect

Block

82400 - 2

Figure 4-16 CONNECTING A POWER FAILURE TELEPHONE

Figure 4-17 CONNECTING TO THE 4 PF XFER PCB

4-19

Page 52

VOICE MAIL

Using Voice Mail

The Portrait System is compatible with the NVM-202ex, NVM-22

(P/N 17590A), and NVM-2000 Voice Mail Systems. This feature provides telephone users with comprehensive Voice Messaging and Auto

Attendant capabilities. Voice Messaging ends the frustration and cost

of missed calls, inaccurate written messages and telephone tag. Voice

Messaging frees a company’s busy receptionist and secretaries for

more productive work.

The system requires the following:

● Voice Mail Interface Unit (P/N 82440)

Maximum of 4 Voice Mail Interface Units or 8 Voice Mail

ports.

● NVM-202ex (P/N 17670), NVM-22 (P/N 17590A), or NVM-2000

(P/N 17500 or 17510, version 7.0 or higher) Voice Mail Unit

● One of the following Portrait setups:

Setup 1

●

Portrait 824 main cabinet (P/N 82400) with Software version

2.1B or higher and 2CO/8STA PCB (P/N 82402A)

NOTE: The Voice Mail ports must be connected to the

2CO/8STA PCB (P/N 82402A).

OR

Setup 2

●

Portrait 824 main cabinet (P/N 82400A) with Software version

2.1B or higher

NOTE: The Voice Mail ports must be connected to station

ports 1-8.

OR

Setup 3

●

Portrait 824 main cabinet (P/N 82400A) with Software version

2.1B or higher and 2CO/8STA PCB (P/N 82402)

NOTE: The Voice Mail ports must be connected to station

ports 1-8.

To confirm if your equipment can support voice mail, you can also

use Program 93 - Sub-CPU Version in the Portrait system. The ver-

sion number of the CPU (Unit 1), First Expansion PCB (Unit 2), and

Second Expansion PCB (Unit 3) should be “08” or above. If the version number is “04” for any unit, the corresponding equipment can

4-20

Page 53

VOICE MAIL

not support the voice mail option. The following is an example of

what you may see.

Unit 1 (CPU - P/N 82400A) = 08

Unit 2 (First Expansion PCB - P/N 82402) = 04

Unit 3 (Second Expansion PCB - P/N 82402A) = 08

The above indicates that the CPU and Second Expansion PCB can

support voice mail, but it is not supported on the First Expansion

PCB. When connecting the voice mail ports, they would be connected

to either the CPU or the Second Expansion PCB.

Each voice mail port uses an intercom link. The Portrait system provides six intercom links at the default setting. When the voice mail

ports exceed the available intercom links (possible when using the

NVM-202ex or NVM-2000), the Portrait system must be reprogrammed to allow unused line circuits to be used as intercom links.

Otherwise, blocking may occur due to the lack of intercom links. This

can be accomplished in Portrait Program 45 - Intercom Link

Increase.

Installation (Figure 4-18)

1. Using a four-conductor line cord, connect the first Voice Mail port

to “LINE1” on the Voice Mail Interface and the second Voice Mail

port to “LINE2” on the Voice Mail Interface.

NOTE: The two ports for each Voice Mail Interface must be

from the same PCB (e.g., 7 & 8 of the CPU or 15 & 16 of the

2 CO/8 STA PCB).

2. Connect a four-conductor line cord from the Port 1 & 2 jack on the

back of the Voice Mail, to the Voice Mail port on the Voice Mail

Interface.

3. Refer to the Portrait Pocket Guide (P/N 82400PKT**) for required

programming information.

4. Refer to the Voice Mail Manual for further programming.

System

NVM - 22 17590INS** Chapter 1 - Installation

NVM-202ex 17570SWG** Chapter 2 - Starting Up and

Manual P/N See

Chapter 2 - Programming

Installing NVM-202ex

4-21

Page 54

BLK

RED

GRN

BLU-WHT

ORN-WHT WHT-ORN

WHT-BLU

8240 - 62a

YEL

BLK

RED

GRN

BLU-WHT

ORN-WHT

WHT-ORN

WHT-BLU

YEL

BLU-WHT

ORN-WHT

WHT-ORN

WHT-BLU

BLU-WHT

ORN-WHT

WHT-ORN

WHT-BLU

25-Pair Cable

to Portrait KSU

Extension

Modular

Jack

Extension

Modular

Jack

Twisted Pair

Station Cable

VOICE MAIL INTERFACE

VOICE MAIL LINE2 LINE1

4-Conductor

Line Cord

NVM-22

Connector for

Ports 1 and 2

NVM-202ex

Connector for

Ports 1 and 2

VOICE MAIL

Chapter 5 - Customizing

System and Port Options

17570INS** Chapter 3 - Starting Up and

Installing NVM-202ex

4-22

Figure 4-18 CONNECTING THE VOICE MAIL

Page 55

WALL MOUNT KIT

Using the Wall-Mount Kit

You can use a wall-mount kit to attach any key telephone to a wall.

The wall-mount kit includes a mounting bracket, wall-mount screws

and a handset hanger.

Note: The wall-mount kit currently does not accommodate installing

on a wall plate.

A telephone with a DSS console attached can not be wall-

mounted.

Installing the Wall-Mount Handset Hanger (Figure 4-19)

1. Insert the handset hanger in the slot provided beneath the telephone’s hookswitch.

82400 - 34

Handset Hook

Figure 4-19 INSTALLING THE WALL-MOUNT HANGER

4-23

Page 56

WALL MOUNT KIT

82400 - 33

Wall-Mounting a Key Telephone (Figure 4-20)

1. Mount the wall-mount kit’s plastic bracket in the desired location

using the screws provided.

2. Insert the telephone’s line cord from the 625 modular jack through

the plastic bracket using the space provided in the bracket.

4. Place the telephone on top of the plastic bracket on the clips provided.

Gently push the bottom of the bracket in until it snaps into the slots on

the phone.

4-24

Figure 4-20 INSTALLING THE WALL MOUNT BRACKETS

Page 57

Section 5

Specifications and Parts List

In this section . . . Page

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5. SPECIFICATIONS AND PARTS LIST

5-1

Page 58

5-2

Page 59

SPECIFICATIONS

System Capacities

Alarm Sensors: 2

Analog Trunks (CO/PBX lines): 8

Cabinets: 1

Caller ID Circuits: 8

Door Boxes: 2

Door Box/Music On Hold Relays: 2

DSS Consoles: 3 max. per system

Electronic Key and/or Analog Telephones: 24

External Paging Zones: 2

Internal Paging Zones: 4

Power Failure Telephones: 4

Speed Dial, Personal: 10

Speed Dial, System: 100

Talk Timeslots (Intercom/line): 6 (expandable)

Tenant Groups: 4

Voice Mail Ports: 8

PCBs

2CO/8STA PCB: 2

Auxillary PCB: 1

CPU Central Processing Unit: 1

4 PF XFER PCB: 1

Ring Generator PCB: 1

SMDR PCB or Caller ID/SMDR PCB 1

Environmental Requirements

Meeting established environmental standards maximizes the life of the system. Refer to the

Standard Practices Manual for further information. Be sure that the site is not:

1. In direct sunlight or in hot, cold or humid places.

2. In dusty areas or in areas where sulfuric gases are produced.

3. In places where shocks or vibrations are frequent or strong.

4. In places where water or other fluids comes in contact with the main equipment.

5. In areas near high-frequency machines or electric welders.

6. Near computers, telexes, microwaves, air conditioners, etc.

7. Near radio antennas (including shortwave).

5-3

Page 60

SPECIFICATIONS

Power Requirements

A dedicated 110 VAC 60 Hz 15 amp circuit (terminated in a NEMA 5-15R receptable) located

within six feet of the cabinet is required. You should install a separate dedicated outlet for each

cabinet.

Environmental Specifications

Cabinets and Key Telephones Door Box

Temperature: 0-45oC (32-113oF) Temperature: -20-60oC (-4-140oF)

Humidity: 10-95% (non-condensing) Humidity: 10-95% (non-condensing)

Electrical Specifications

Power Supply: 110 VAC ±- 10% @ 50-60 Hz 15 amp

Power Requirements: 85 VA-(max 75 W)

.7 Amps

Grounding Requirements: 12 AWG copper wire

5-4

External Paging

Output Impedance: 600 Ohm

Output Level: Nominal 250 mV (-10 dBm)

Maximum Output: 400 mV RMS

Door Box/External Paging Contacts

Contact Configuration: Normally open

Relay Contact: 250 mA @ 24 VDC

Alarm Sensors

Loop Resistance: Less than 100 ohms

Page 61

SPECIFICATIONS

BGM/MOH Music Source Input

Input Impedance: 600 Ohm

Input Level: Nominal 250 mV (-10 dBm)

Maximum Input: 1V RMS

Inputs for MOH and BGM are located on the Auxillary PCB.

FCC Registration Information

Model: Portrait 824

Manufacturer: Nitsuko America

Load Number (DOC): N/A

FCC Part 15 Registration: Class A

Sample FCC Registration Number: 1ZDTHA-12345-MF-E

(Refer to the label on the Main Cabinet for the FCC Registration Number.)

Reg. MTS/WATS Mfrs. Port Ringer SOC Network

Status Interfaces Identifier Eq. Number Jacks

Original 02LS2 NX7NA-408M-A 0.6B 9.0F RJ11C

NX7E-208M

Cabling Requirements

1. Do not run station cable in parallel with the AC source, telex or computer, etc. If the

cables are near cable runs to those devices, use shielded cable with grounded shields or

install the cable in conduit.

2. When cables must be run on the floor, use cable protectors.

3. Cable runs for key telephones, single line telephones and Door Boxes must be a dedicated,

isolated cable pair.

Device Cable Type Cable Run Length (ft) Notes

Key Telephone 2-pair twisted 24 AWG 1000

Single Line 2-wire 24 AWG 3,700 at constant 20 mA

Telephone

Door Box 2-wire 24 AWG 500

5-5

Page 62

SPECIFICATIONS

Mechanical Specifications

Type of Equipment Width Depth Height Weight

Equipment Cabinet 19” 13” 4 1/2” 11 lbs *

(* Base unit with only CPU card installed)

22-Button Display Telephone 6 11/16” 8 11/16” 3 7/16” 1 lb 12 1/2 oz

22-Button Standard Telephone 6 11/16” 8 11/16” 3 7/16” 1 lb 10 1/2 oz

16-Button Standard Telephone 6 11/16” 8 11/16” 3 7/16” 1 lb 10 1/2 oz

24-Button DSS Console 2 1/2” 8 11/16” 2 1/2” 1/2 lb

Door Box 5.28” 4” 1.4” 1/2 lb

5-6

Page 63

PARTS LIST

Station Equipment

Description Part Number

22-Button Display Telephone (Gray) 82473

22-Button Display Telephone (White) 82473W

22-Button Standard Telephone (Gray) 82470

22-Button Standard Telephone (White) 82470W

22-Button Standard Handsfree Telephone (Gray) 82471

22-Button Standard Handsfree Telephone (White) 82471W

16-Button Standard Telephone (Gray) 82460

16-Button Standard Telephone (White) 82460W

ST4 Single Line Telephone (White) 85403W

ST4 Single Line Telephone (Black) 85403B

DSS Console (Gray) 82456

DSS Console (White) 82456W

Wall Mount Kit (Gray) 82479

Wall Mount Kit (White) 82479W

Analog Telephones (customer provided)

Peripheral Station Equipment

Description Part Number

Door Box 92245

Common Equipment

Description Part Number

Cabinet (Includes CPU Central Processing Unit) 82400

Cabinet (Includes CPU Central Processing Unit) with

Voice Mail 82400A

PCBs

Description Part Number

CPU Central Processing Unit Included in 82400

2CO/8STA PCB 82402

2CO/8STA PCB with Voice Mail 82402A

4 PF XFER PCB 82415

Auxiliary PCB 82410

Caller ID PCB 82425

Caller ID/SMDR PCB 82421

Ring Generator PCB 82405

SMDR PCB 82420

5-7

Page 64

PARTS

Handset (Gray) 82496

Handset (White) 82496W

Handset and Cord Assembly (Gray) 82495

Handset and Cord Assembly (White) 82495W

Handset Coil Cord - 6’ (Gray) 82475-6

Handset Coil Cord - 9’ (Gray) 82475-9

Handset Coil Cord - 13’ (Gray) 82475-13

Handset Coil Cord - 6’ (White) 82475-6W

Handset Coil Cord - 9’ (White) 82475-9W

Handset Coil Cord - 13’ (White) 82475-13W

Line Cord - 7’ (Ash) 82476-7

Line Cord - 14’ (Ash) 82476-14

Line Cord - 25’ (Ash) 82476-25

Line Cord - 7’ (White) 82476-7W

Line Cord - 14’ (White) 82476-14W

Line Cord - 25’ (White) 82476-25W

16-Button Display Telephone Plastic C.O. Cover 82488-6

22-Button Display Telephone Plastic C.O. Cover 82488-12

DSS Console Plastic Cover 82488-SDS

Top Directory Plastic Cover 82488-D

Station # Plastic Cover 92600-EN

16-Button Telephone Paper Insert 82489-6

22-Button Telephone Paper Insert 82489-12

DSS Console Paper Insert 82489-SDS

Top Directory Paper Insert 82489-D

Station # Designation Strip 92605-EN

DDK Connectors, 2 pin (qty: 25) 85993

DDK Connectors, 4 pin (qty: 25) 85995

DDK Installation Cable, 4 wire for extension connection 82490

DDK Installation Cable, 2 wire for trunk connection 82492

DDK Installation Cable, 6” 2 wire for power failure

Replacement Parts

Description Part Number

connection 82491

5-8

Page 65

Replacement Parts

Description Part Number

Flying Directory Attachment 82481

Flying Directory Paper Card & Plastic Holder Assembly 82482

Flying Directory Clear Plastic Holder 82483

Flying Directory Paper Card Insert 82484

Flying Directory Card Assembly (Kit) 82480

Consists of: (1) 82481, (1) 82482

Bottom Directory Tray Assembly (Card & Holder) 82485

Bottom Directory Clear Plastic Card Holder 82486

Bottom Directory Paper Card 82487

Door Box/Page Ribbon Cable 82492

Ring Generator Cable 82493

SMDR Connector & Cable Assembly 82494

Music on Hold Disable Connector 82411

Wall Mount Hook 82499

PARTS

5-9

Page 66

PARTS

5-10

Page 67

Nitsuko America, Telecom Division

4 Forest Parkway

Shelton, CT 06484

TEL: 203-926-5400

FAX: 203-929-0535

Other Important Telephone Numbers

Sales: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203-926-5450

Customer Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203-926-5444

Customer Service FAX: . . . . . . . . . . . . . . . . . . . . . . . . . . .203-926-5454

Technical Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203-925-8801

Discontinued Product Service: . . . . . . . . . . . . . . . . . . . . . .900-990-2541

Technical Training: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203-926-5430

Emergency Technical Service (After hours) . . . . . . . . . . . .203-929-7920

(Excludes discontinued products)

Page 68

4 Forest Parkway, Shelton, CT 06484

TEL: 203-926-5400 FAX: 203-929-0535

Part No. 82400INS03 May 1998

Issue 1-0 Printed in U.S.A. (183)

Loading...

Loading...