COLOR MONITOR

MultiSync

LCD1550ME

MODELS LCD1550ME (B) / -BK(B)

200206

08EK1ABD

08EK2ABD

SERVICE MANUAL

PART NO. 599910589

NEC-MITSUBISHI ELECTRIC VISUAL SYSTEMS CORPORATION

JUNE 2002

WARNING

The SERVICE PERSONNEL should have the appropriate technical training, knowledge and experience

necessary to:

• Be familiar with specialized test equipment, and

• Be careful to follow all safety procedures to minimize danger to themselves and their coworkers.

To avoid electrical shocks, this equipment should be used with an app ropriate power cord.

This equipment utilized a micro-gap power switch. Turn off the set by first pushing power switch. Next,

remove the power cord from the AC outlet.

To prevent fire or shock hazards, do not expose this unit to rain or moisture.

This symbol warns the personnel that un-insulated voltage within the unit may have sufficient

magnitude to cause electric shock.

This symbol alerts the personnel that important literature concerning the operation and

maintenance of this unit has been included.

Therefore, it should be read carefully in order to avoid any problems.

PRODUCT SAFETY CAUTION

1. When parts replacement is required for servicing, always use the manufacturer's specified replacement.

2. When replacing the component, always be certain that all the components are put back in the place.

3. As for a connector, pick and extract housing with fingers properly since a disconnection and improper

contacts may occur, when wires of the connector are led.

4. Use a proper screwdriver. If you use screwdriver that does not fit, you may damage the screws.

CONTENTS

Page No.

USER'S MANUAL ------------------------------------------------------------------- 1-1

SERIAL NUMBER INFORMATION --------------------------------------------- 2-1

DISASSEMBLY ----------------------------------------------------------------------- 3-1

ADJUSTMENT PROCEDURES -------------------------------------------------- 4-1

INSPECTION --------------------------------------------------------------------------- 5-1

TROUBLE SHOOTING ------------------------------------------------------------- 6-1

CIRCUIT DESCRIPTION ----------------------------------------------------------- 7-1

REPLACEMENT PARTS LIST --------------------------------------------------- 8-1

BLOCK DIAGRAM ------------------------------------------------------------------- 9-1

SCHEMATIC DIAGRAMS -------------------------------------------------------- 10-1

1-1

User's Manual

MultiSync LCD1550ME

User’s Manual

1-2

English-1

English

TO PREVENT FIRE OR SHOCK HAZARDS, DO NOT EXPOSE THIS UNIT TO RAIN

OR MOISTURE. ALSO, DO NOT USE THIS UNIT’S POLARIZED PLUG WITH AN

EXTENSION CORD RECEPTACLE OR OTHER OUTLETS UNLESS THE PRONGS

CAN BE FULLY INSERTED.

REFRAIN FROM OPENING THE CABINET AS THERE ARE HIGH VOLTAGE

COMPONENTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

CAUTION

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER

(OR BACK). NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

This symbol warns user that uninsulated voltage within the unit may have

sufficient magnitude to cause electric shock. Therefore, it is dangerous to make

any kind of contact with any part inside this unit.

This symbol alerts the user that important literature concerning the operation

and maintenance of this unit has been included. Therefore, it should be read

carefully in order to avoid any problems.

CAUTION

WARNING

RISK OF ELECTRIC SHOCK • DO NOT OPEN

Caution:

When operating the MultiSync LCD1550ME (L15XA231-BN and L15XA231-BNBK) with

a 220-240V AC power source in Europe, use the power cord provided with the monitor.

In the UK, a BS approved power cord with a moulded plug has a Black (five Amps) fuse

installed for use with this equipment. If a power cord is not supplied with this equipment

please contact your supplier.

When operating the MultiSync LCD1550ME with a 220-240V AC power source in

Australia, use the power cord provided with the monitor.

For all other cases, use a power cord that matches the AC voltage of the power outlet

and has been approved by and complies with the safety standard of your particular

country.

ENERGYSTA R is a U.S. trademark.

As an ENERGYSTAR® Partner, NEC-Mitsubishi Electronics Display of America, Inc. has

determined that this product meets the ENERGYSTA R guidelines for energy efficiency.

The ENERGYSTAR emblem does not represent EPA endorsement of any product or service.

IBM PC/XT/AT, PS/2, MCGA, VGA, 8514/A and XGA are registered trademarks of

International Business Machines Corporation.

Apple and Macintosh are registered trademarks of Apple Computer Inc.

Microsoft and Windows are registered trademarks of the Microsoft Corporation.

NEC is a registered trademark of NEC Corporation.

All other trademarks or registered trademarks are property of their respective owners.

1-3

English-2

Declaration

Declaration of the Manufacturer

We hereby certify that the colour monitor

MultiSync LCD1550ME (L15XA231-BN)

MultiSync LCD1550ME (L15XA231-BNBK)

is in compliance with

Council Directive 73/23/EEC:

– EN 60950

Council Directive 89/336/EEC:

– EN 55022

– EN 61000-3-2

– EN 61000-3-3

– EN 55024

and marked with

NEC-Mitsubishi Electric Visual Systems, Corp.

MS Shibaura Bldg., 13-23,

Shibaura 4-chome,

Minato-Ku, Tokyo 108-0023, Japan

1-4

English-3

English

For the Customer to use in

U.S.A. or Canada

Canadian Department of Communications

Compliance Statement

DOC: This Class B digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du

Règlement sur le matériel brouiller du Canada.

C-UL: Bears the C-UL Mark and is in compliance with Canadian Safety

Regulations according to CSA C22.2 #950.

Ce produit porte la marque ‘C-UL’ et se conforme aux règlements de

sûrele Canadiens selon CAN/CSA C22.2 No. 950.

FCC Information

1. Use the attached specified cables with the MultiSync LCD1550ME

colour monitor so as not to interfere with radio and television

reception.

(1)The power supply cord you use must have been approved by and

comply with the safety standards of U.S.A., and meet the following

condition.

Power supply cord Non shield type, 3-conductor

Length 2.0 m

Plug shape

(2)Shielded video signal cable. Use of other cables and adapters

may cause interference with radio and television reception.

1-5

English-4

2. This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy, and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult your dealer or an experienced radio/TV technician for help.

If necessary, the user should contact the dealer or an experienced

radio/television technician for additional suggestions. The user may

find the following booklet, prepared by the Federal Communications

Commission, helpful: “How to Identify and Resolve Radio-TV

Interference Problems.” This booklet is available from the U.S.

Government Printing Office, Washington, D.C., 20402,

Stock No. 004-000-00345-4.

Declaration of Conformity

This device complies with Part 15 of FCC Rules. Operation is subject to the following two

conditions. (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

U.S. Responsible party: NEC-Mitsubishi Electronics

Display of America, Inc.

Address: 1250 N. Arlington Heights Road

Itasca, Illinois 60143-1248

Tel. No.: (630)467-3000

Type of Product: Computer Monitor

Equipment Classification: Class B Peripheral

Models: MultiSync LCD1550ME

We hereby declare that the equipment specified above conforms

to the technical standards as specified in the FCC Rules.

1-6

English-5

English

Contents

Your new NEC MultiSync LCD monitor box* should contain the

following:

• MultiSync LCD1550ME monitor with tilt base

• Power Cord

• Video Signal Cable

• Audio Cable

• User’s Manual

• CD ROM (includes complete User’s Manual in PDF format). To see

the User’s Manual, Acrobat Reader 4.0 must be installed on your PC.

* Remember to save your original box and packing material to transport

or ship the monitor.

1550ME

M

E

User’s Manual

CD ROMVideo Signal CableAudio Cable

Power Cord

1-7

English-6

Quick Start

To attach the MultiSync LCD monitor to your system, follow these

instructions:

1. Turn off the power to your computer.

2. Remove connector cover and cable cover. Connect the audio cable to

“AUDIO INPUT” on the back of the monitor and the other end to the

“Audio out” terminal of the computer. Place the Audio cable under

Clip B (Figure A.1).

3. For PC: Connect the 15-pin mini D-SUB of the appropriate

signal cable to the connector for the display card in your system

(Figure B.1). Tighten all screws.

For Mac: Connect the MultiSync LCD1550ME Macintosh cable

adapter to the computer (Figure C.1). Attach the 15-pin mini D-SUB

end of the appropriate signal cable to the MultiSync LCD1550ME

Macintosh cable adapter (Figure C.1). Tighten all screws.

4. Connect the 15-pin mini D-SUB of the video signal cable to the

appropriate connector on the back of the monitor (Figure D.1). Place

the Video Signal Cable under Clip B.

5. Headphones may be connected to the “Headphones” output on the

front of the monitor’s bezel marked “

” (Figure E.1). While the

headphones are connected, the sound from the speakers will be

disabled. Headphones can be purchased from your local electronics

store.

6. Connect one end of the power cord to the MultiSync LCD Series

monitor and the other end to the power outlet. Place the video signal

cable and AC power cord under the clips (Figure D.1). Replace

connector cover and cable cover.

NOTE: Adjust the position of the cable under the clips to avoid damage

for cable or monitor.

NOTE: Please refer to Caution section of this manual for proper

selection of AC power cord.

7. The Vacation Switch on the left side of the monitor must be turned on

(Figure F.1). Turn on the monitor with the Power Button and the

computer.

1-8

English-7

English

NOTE: The Vacation Switch is a true on/off switch. If this switch is on

the OFF position, the monitor cannot be turned on using the

front button. DO NOT switch on/off repeatedly.

8. No-touch auto adjust automatically adjusts the monitor to optimal

settings upon initial setup for most timings. For further adjustments,

use the following OSM controls:

• Auto Adjust Contrast

• Auto Adjust

Refer to the Controls section of this User’s Manual for a full description

of these OSM controls.

NOTE: If you have any problems, please refer to the Troubleshooting

section of this User’s Manual.

Figure C.1

Macintosh

Cable

Adapter

(not included)

Macintosh G3 and

G4 do not need a

Macintosh cable

adapter

Figure B.1

Figure A.1

Clip B

1-9

English-8

Vacation Switch

Power Button

Figure E.1

Figure D.1

1550ME

Figure F.1

Connector cover

Cable cover

Clip B

1-10

English-9

English

Tilt

Grasp both sides of the monitor screen with your hands and adjust the

tilt as desired (Figure TS.1).

Remove Monitor Stand for Mounting

To prepare the monitor for alternate mounting purposes:

1. Remove the connector cover and cable cover (Figure R.1).

2. Disconnect all cables.

3. Place monitor face down on a non-abrasive surface (Figure R.2).

4. Remove the 4 screws connecting the monitor to the stand and lift off

the stand assembly (Figure R.2) the monitor is now ready for

mounting in an alternate manner.

5. Connect the AC cord, signal cable and audio cable to the back of the

monitor (Figure R.3).

6. Reverse this process to reattach stand.

NOTE: Use only VESA-compatible alternative mounting method.

Figure TS.1

1-11

English-10

Figure R.1

Figure R.2

Figure R.3

Non-abrasive

surface

1-12

English-11

English

7. This LCD monitor is designed for use with a flexible arm. Please use

the attached screws (4pcs) when mounting. To meet the safety

requirements the monitor must be mounted to an arm which

guaranties the necessary stability under consideration of the weight

of the monitor. The LCD monitor shall only be used with an approved

arm (e.g. GS mark).

4 SCREWS

(MAX depth: 8.6 mm)

If use other screw,

check depth of hole.

Weight of LCD assembly: 3.1kg (MAX)

Replace screws

Tighten all screws

Thickness of bracket (arm)

2.0 ~ 3.2 mm

75 mm

75 mm

1-13

English-12

Sound

VOLUME

Control the sound volume of speakers and

headphones.

Brightness/Contrast Controls

BRIGHTNESS

Adjusts the overall image and background screen

brightness.

Menu

Exits the OSM controls.

Exits to the OSM main menu.

Moves the highlighted area left/right to select control

menus.

Moves the highlighted area up/down to select one of the

controls.

Moves the bar left/right to increase or decrease the

adjustment.

Activates Auto Adjust function.

Enter the sub menu.

Moves the highlighted area of main menu right to select

one of the controls.

Resets the highlighted control to the factory setting.

When no OSM menu is shown, the speaker sound will be

muted.

Controls

OSM (On-Screen-Manager) Controls

The OSM controls on the front of the monitor function as follows:

To access OSM press any of the control buttons ( , , -, +, NEXT).

NOTE: When RESET is pressed in the main and sub-menu, a warning

window will appear allowing you to cancel the RESET function

by pressing the EXIT button.

Control

EXIT

CONTROL /

ADJUST -/+

NEXT

RESET/MUTE

1-14

English-13

English

CONTRAST

Adjusts the image brightness in relation to the

background.

AUTO ADJUST

Adjusts the image displayed for non-standard

video inputs.

Auto Adjust

Automatically adjusts the Image Position, the H. Size

and Fine setting.

Position Controls

LEFT/RIGHT

Controls Horizontal Image Position within the display

area of the LCD.

DOWN/UP

Controls Vertical Image Position within the display area

of the LCD.

H. SIZE

Adjusts the horizontal size by increasing or decreasing

this setting.

FINE

Improves focus, clarity and image stability by increasing

or decreasing this setting.

Colour Control Systems

Five colour presets select the desired colour setting.

Each colour setting is adjusted at the factory.

R,G,B

Increases or decreases Red, Green or Blue colour

depending upon which is selected. The change in

colour will appear on screen and the direction (increase

or decrease) will be shown by the bars.

1-15

English-14

Tools

OSM POSITION

You can choose where you would like the OSM control

image to appear on your screen. Selecting OSM

Location allows you to manually adjust the position of

the OSM control menu left, right, down or up.

OSM TURN OFF

The OSM control menu will stay on as long as it is use.

In the OSM Turn Off submenu, you can select how long

the monitor waits after the last touch of a button to shut

off the OSM control menu. The preset choices are 10,

20, 30, 45, 60 and 120 seconds.

OSM LOCK OUT

This control completely locks out access to all OSM

control functions. When attempting to activate OSM

controls while in the Lock Out mode, a screen will

appear indicating the OSM controls are locked out.

To activate the OSM Lock Out function, press , then

and hold down simultaneously. To de-activate the OSM

Lock Out, press , then and hold down

simultaneously.

RESOLUTION NOTIFIER

This optimal resolution is 1024 x 768. If ON is selected,

a message will appear on the screen after 30 seconds,

notifying you that the resolution is not at 1024 x 768.

FACTORY PRESET

Selecting Factory Preset allows you to reset all OSM

control settings back to the factory settings. The RESET

button will need to be held down for several seconds to

take effect. Individual settings can be reset by

highlighting the control to be reset and pressing the

RESET button.

Information

DISPLAY MODE

Indicates the current display resolution and frequency

setting of the monitor.

1-16

English-15

English

MONITOR INFO.

Indicates the model and serial numbers of your monitor.

OSM Warning

OSM Warning menus disappear with Exit button.

NO SIGNAL: This function gives a warning when there

is no signal present. After power is turned on or when

there is a change of input signal or video is inactive, the

No Signal window will appear.

RESOLUTION NOTIFIER: This function gives a

warning of use with optimized resolution. After power is

turned on or when there is a change of input signal or

the video signal doesn’t have proper resolution, the

Resolution Notifier window will open. This function can

be disabled in the TOOL menu.

OUT OF RANGE: This function gives a recommendation

of the optimized resolution and refresh rate. After the

power is turned on or there is a change of input signal or

the video signal doesn’t have proper timing, the Out Of

Range menu will appear.

CHECK CABLE: This function will advise you to check

all Video Inputs on the monitor and computer to make

sure they are properly connected.

1-17

English-16

Recommended Use

Safety Precautions and Maintenance

FOR OPTIMUM PERFORMANCE, PLEASE NOTE

THE FOLLOWING WHEN SETTING UP AND

USING THE MULTISYNC LCD COLOUR MONITOR:

• DO NOT OPEN THE MONITOR. There are no user serviceable parts

inside and opening or removing covers may expose you to dangerous

shock hazards or other risks. Refer all servicing to qualified service

personnel.

• Do not spill any liquids into the cabinet or use your monitor near water.

• Do not insert objects of any kind into the cabinet slots, as they may

touch dangerous voltage points, which can be harmful or fatal or may

cause electric shock, fire or equipment failure.

• Do not place any heavy objects on the power cord. Damage to the cord

may cause shock or fire.

• Do not place this product on a sloping or unstable cart, stand or table, as

the monitor may fall, causing serious damage to the monitor.

• Do not place any objects onto the monitor and do not use the monitor

outdoors.

• The inside of the flourescent tube located within the LCD monitor

contains mercury. Please follow the bylaws or rules of your municipality

to dispose of the tube properly.

Immediately unplug your monitor from the wall outlet and refer servicing to

qualified service personnel under the following conditions:

• When the power supply cord or plug is damaged.

• If liquid has been spilled, or objects have fallen into the monitor.

• If the monitor has been exposed to rain or water.

• If the monitor has been dropped or the cabinet damaged.

• If the monitor does not operate normally by following operating

instructions.

• Do not bend power cord.

• Do not use monitor in high temperatured, humid, dusty, or oily areas.

• Do not cover vent on monitor.

• If monitor is broken, do not come in contact with the liquid crystal.

• If glass is broken. Handle with care.

1-18

English-17

English

CAUTION

• Allow adequate ventilation around the monitor so that

heat can properly dissipate. Do not block ventilated

openings or place the monitor near a radiator or other

heat sources. Do not put anything on top of monitor.

• The power cable connector is the primary means of

detaching the system from the power supply. The

monitor should be installed close to a power outlet which

is easily accessible.

• Handle with care when transporting. Save packaging for

transporting.

CORRECT PLACEMENT AND ADJUSTMENT OF

THE MONITOR CAN REDUCE EYE, SHOULDER

AND NECK FATIGUE. CHECK THE FOLLOWING

WHEN YOU POSITION THE MONITOR:

• For optimum performance, allow

20 minutes for warm-up.

• Adjust the monitor height so that the top of

the screen is at or slightly below eye level.

Your eyes should look slightly downward

when viewing the middle of the screen.

• Position your monitor no closer than 40 cm

and no further away than 70 cm from your

eyes. The optimal distance is 53 cm.

• Rest your eyes periodically by focusing on

an object at least 6 m away. Blink often.

• Position the monitor at a 90° angle to windows and other light sources to

minimize glare and reflections. Adjust the monitor tilt so that ceiling lights

do not reflect on your screen.

• If reflected light makes it hard for you to see your screen, use an

antiglare filter.

• Clean the LCD monitor surface with a lint-free, non-abrasive cloth. Avoid

using any cleaning solution or glass cleaner!

• Adjust the monitor’s brightness and contrast controls to enhance

readability.

• Use a document holder placed close to the screen.

• Position whatever you are looking at most of the time (the screen or

reference material) directly in front of you to minimize turning your head

while you are typing.

1-19

English-18

• Avoid displaying fixed patterns on the monitor for long periods of time to

avoid image persistence (after-image effects).

• Get regular eye checkups.

Ergonomics

To realize the maximum ergonomics benefits, we recommend the following:

• Use the preset Size and Position controls with standard signals.

• Use the preset Colour Setting.

• Use non-interlaced signals with a vertical refresh rate between

60-75 Hz.

• Do not use primary colour blue on a dark background, as it is difficult to

see and may produce eye fatigue to insufficient contrast.

1-20

English-19

English

16,777,216

31.5 kHz to 60.0 kHz

56.2 Hz to 75.1 Hz

720 x 400*1 :VGA text

640 x 480*1 at 60 Hz to 75 Hz

800 x 600*1 at 56 Hz to 75 Hz

832 x 624*1 at 75 Hz

1024 x 768*2 at 60 Hz to 75 Hz

304 mm/12 inches

228 mm/9.0 inches

AC 100-120 V/220-240 V 50/60 Hz

0.7 A @ 100-120 V, 0.35 A @ 220-240 V

Monitor Specifications

LCD Module Diagonal:

Viewable Image Size:

Native Resolution (Pixel Count):

Display Colours Analog input:

Synchronization Range Horizontal:

Vertical:

Resolutions Supported

Active Display Horizontal:

Area Vertical:

Power Supply

Input Signal Video:

Sync:

Current Rating

MultiSync LCD1550ME Monitor

38 cm/15 inches

38 cm/15 inches

1024 x 768

ANALOG 0.7 Vp-p/75 Ohms

Separate sync.TTL Level

Horizontal sync. Positive/Negative

Vertical sync. Positive/Negative

Notes

Active matrix; thin film

transistor (TFT) liquid

crystal display (LCD);

0.30 mm dot pitch;

250cd/m2 white luminence,

typical; 400:1 contrast ratio,

typical.

Depends on display card

used.

Automatically

Automatically

Some systems may not

support all modes listed.

Dependent upon signal

timing.

Specifications

Viewing Angle Left/Right:

Up/Down:

± 60°

+ 45°/- 55°

345.2 mm (W) x 362.6 mm (H) x 162.0 mm (D)

13.6 inches (W) x 14.3 inches (H) x 6.4 inches (D)

5 °C to 35 °C

30% to 80%

0 to 3,000 m

-10 °C to +60 °C

10% to 85%

0 to 9,500 m

Dimensions

Weight

Environmental Considerations

Operating Temperature:

Humidity:

Altitude:

Storage Temperature:

Humidity:

Altitude:

3.9 kg (8.6 lbs)

Speakers Practical Audio Output

1.0W + 1.0W

1-21

English-20

*1 Interpolated Resolutions: When resolutions are shown that are lower than the pixel count of the

LCD module, text may appear different. This is normal and necessary for all current flat panel

technologies when displaying non-native resolutions full screen. In flat panel technologies, each dot

on the screen is actually one pixel, so to expand resolutions to full screen, an interpolation of the

resolution must be done.

*2 NEC-Mitsubishi Electronics Display cites recommended resolutions at 75 Hz for optimal display

performance.

NOTE: Technical specifications are subject to change without notice.

1-22

English-21

English

Features

Colour Control System: Allows you to adjust the colours on your

screen and customize the colour accuracy of your monitor to a variety of

standards.

Reduced Footprint: Provides the ideal solution for environments

requiring superior image quality but with size and weight limitations.

The monitor’s small footprint and low weight allow it to be moved or

transported easily from one location to another.

OSM (On-Screen Manager) Controls: Allow you to quickly and easily

adjust all elements of your screen image via simple to use on-screen

menus.

No-touch Auto Adjust: No-touch auto adjust automatically adjusts the

monitor to optimal settings upon initial setup.

ErgoDesign Features: Enhance human ergonomics to improve the

working environment, protect the health of the user and save money.

Examples include OSM controls for quick and easy image adjustments,

tilt base for preferred angle of vision, small footprint and compliance with

MPRII and TCO guidelines for lower emissions.

Plug and Play: The Microsoft solution with the Windows 95/98/ME/

2000/XP operating system facilitates setup and installation by allowing

the monitor to send its capabilities (such as screen size and resolutions

supported) directly to your computer, automatically optimizing display

performance.

IPM (Intelligent Power Manager) System: Provides innovative

power-saving methods that allow the monitor to shift to a lower power

consumption level when on but not in use, saving two-thirds of your

monitor energy costs, reducing emissions and lowering the air

conditioning costs of the workplace.

Multiple Frequency Technology: Automatically adjusts monitor to the

display card’s scanning frequency, thus displaying the resolution

required.

FullScan Capability: Allows you to use the entire screen area in most

resolutions, significantly expanding image size.

1-23

English-22

VESA Standard Mounting Interface: Allows users to connect their

MultiSync monitor to any VESA standard (75 mm pitch) third party

mounting arm or bracket. Allows for the monitor to be mounted on a wall

or an arm using any third party compliant device.

1-24

English-23

English

Troubleshooting

No picture

• The signal cable should be completely connected to the display card/

computer.

• The display card should be completely seated in its slot.

• Check the Vacation Switch should be in the ON Position. Front power

Switch and computer power switch should be in the ON position.

• Check to make sure that a supported mode has been selected on the

display card or system being used. (Please consult display card or

system manual to change graphics mode.)

• Check the monitor and your display card with respect to compatibility

and recommended settings.

• Check the signal cable connector for bent or pushed-in pins.

Power Button does not respond

• Unplug the power cord of the monitor from the AC outlet to turn off

and reset the monitor.

• Check the Vacation Switch on the left hand side of the monitor.

Image persistence

• Image persistence is when a “ghost” of an image remains on the

screen even after the monitor has been turned off. Unlike CRT

monitors, LCD monitors’ image persistence is not permanent.

To alleviate image persistence, turn the monitor off for as long as an

image was displayed. If an image was on the monitor for one hour

and a “ghost” of that image remains, the monitor should be turned off

for one hour to erase the image.

NOTE: As with all personal display devices, NEC-Mitsubishi Electronic

Displays recommends using a screen saver at regular intervals

whenever the screen is idle.

1-25

English-24

Image is unstable, unfocused or swimming

is apparent

• Signal cable should be completely attached to the computer.

• Use the OSM Image Adjust controls to focus and adjust display by

increasing or decreasing the fine total. When the display mode is

changed, the OSM Image Adjust settings may need to be readjusted.

• Check the monitor and your display card with respect to compatibility

and recommended signal timings.

• If your text is garbled, change the video mode to non-interlace and

use 60 Hz refresh rate.

Message “OUT OF RANGE” is displayed (screen is

either blank or shows rough images only)

• OSM warning “OUT OF RANGE” is displayed on a blank screen:

Signal frequency is out of range. Choose one of the supported

modes.

LED on monitor is not lit (no green or amber colour

can be seen)

• Power Switch should be in the ON position and power cord should be

connected.

• Make certain the computer is not in a power-saving mode (touch the

keyboard or mouse).

Display image is not sized properly

• Use the OSM Image Adjust controls to increase or decrease the

H.Size.

• Check to make sure that a supported mode has been selected on the

display card or system being used. (Please consult display card or

system manual to change graphics mode.)

Selected resolution is not displayed properly

• Use OSM Display Mode to enter Information menu and confirm that

the appropriate resolution has been selected. If not, select

corresponding option.

1-26

English-25

English

No Sound

• Check to see if speaker cable is properly connected.

• Check to see if mute is activated.

• Check to see if volume in OSM is set at minimum.

1-27

English-26

TCO’99

This is a translation of the original English TCO'99 document.

MultiSync LCD1550ME White Model (L15XA231-BN)

Congratulations! You have just purchased a TCO’99

approved and labeled product! Your choice has

provided you with a product developed for

professional use. Your purchase has also contributed

to reducing the burden on the environment and also

to the further development of environmentally

adapted electronics products.

Why do we have environmentally labelled computers?

In many countries, environmental labelling has become an established

method for encouraging the adaptation of goods and services to the

environment. The main problem, as far as computers and other

electronics equipment are concerned, is that environmentally harmful

substances are used both in the products and during the manufacturing.

Since it has not been possible for the majority of electronics equipment

to be recycled in a satisfactory way, most of these potentially damaging

substances sooner or later enter Nature.

There are also other characteristics of a computer, such as energy

consumption levels, that are important from the viewpoints of both the

work (Internal) and natural (external) environments. Since all methods of

conventional electricity generation have a negative effect on the

environment (acidic and climate-influencing emissions, radioactive

waste, etc.), it is vital to conserve energy. Electronics equipment in

offices consume an enormous amount of energy since they are often left

running continuously.

What does labelling involve?

This product meets the requirements for the TCO’99 scheme which

provides for international and environmental labelling of personal

computers. The labelling scheme was developed as a joint effort by the

TCO (The Swedish Confederation of Professional Employees), Svenska

Naturskyddsforeningen (The Swedish Society for Nature Conservation)

and Statens Energimyndighet (The Swedish National Energy

Administration).

1-28

English-27

English

The requirements cover a wide range of issues: environment,

ergonomics, usability, emission of electrical and magnetic fields, energy

consumption and electrical and fire safety.

The environmental demands concern restrictions on the presence and

use of heavy metals, brominated and chlorinated flame retardants,

CFCs (freons) and chlorinated solvents, among other things. The

product must be prepared for recycling and the manufacturer is obliged

to have an environmental plan which must be adhered to in each

country where the company implements its operational policy. The

energy requirements include a demand that the computer and/or

display, after a certain period of inactivity, shall reduce its power

consumption to a lower level in one or more stages. The length of time to

reactivate the computer shall be reasonable for the user.

Labelled products must meet strict environmental demands, for

example, in respect of the reduction of electric and magnetic fields,

physical and visual ergonomics and good usability.

Environmental Requirements

Flame retardants

Flame retardants are present in printed circuit boards, cables, wires,

casings and housings. In turn, they delay the spread of fire. Up to thirty

percent of the plastic in a computer casing can consist of flame

retardant substances. Most flame retardants contain bromine or chloride

and these are related to another group of environmental toxins, PCBs,

which are suspected to give rise to severe health effects, including

reproductive damage in fisheating birds and mammals, due to the

bioaccumulative* processes. Flame retardants have been found in

human blood and researchers fear that disturbances in foetus

development may occur.

TCO’99 demand requires that plastic components weighing more than

25 grams must not contain flame retardants with organically bound

chlorine and bromine. Flame retardants are allowed in the printed circuit

boards since no substitutes are available.

Lead**

Lead can be found in picture tubes, display screens, solders and

capacitors. Lead damages the nervous system and in higher doses,

causes lead poisoning.

TCO’99 requirement permits the inclusion of lead since no replacement

has yet been developed.

1-29

English-28

Cadmium**

Cadmium is present in rechargeable batteries and in the

colourgenerating layers of certain computer displays. Cadmium

damages the nervous system and is toxic in high doses.

TCO’99 requirement states that batteries, the colourgenerating layers of

display screens and the electrical or electronics components must not

contain any cadmium.

Mercury**

Mercury is sometimes found in batteries, relays and switches, Mercury

damages the nervous system and is toxic in high doses.

TCO’99 requirement states that batteries may not contain any Mercury.

It also demands that no mercury is present in any of the electrical or

electronics components associated with the display unit.

CFCs (freons)

CFCs (freons) are sometimes used for washing printed circuit boards.

CFCs break down ozone and thereby damage the ozone layer in the

stratosphere, causing increased reception on Earth of ultraviolet light

with consequent increased risks of skin cancer (malignant melanoma).

The relevant TCO’99 requirement; Neither CFCs nor HCFCs may be

used during the manufacturing and assembly of the product or its

packaging.

* Bio-accumulative is defined as substances which accumulate within

living organisms.

** Lead, Cadmium and Mercury are heavy metals which are

Bioaccumulative.

To obtain complete information on the environmental criteria document,

order from:

TCO Development Unit

SE-114 94 Stockholm

SWEDEN

FAX Number: +46 8 782 92 07

E-mail (Internet): development@tco.se

You may also obtain current information on TCO’99 approved and

labelled products by visiting their website at:

http://www.tco-info.com/

1-30

English-29

English

TCO’95

This is a translation of the original English TCO'95 document.

MultiSync LCD1550ME Black Model (L15XA231-BNBK)

Congratulations! You have just purchased a TCO’95

approved and labeled product! Your choice has

provided you with a product developed for

professional use. Your purchase has also

contributed to reducing the burden on the

environment and also, to the further development of

environmentally adapted electronics products.

Why do we have environmentally labelled computers?

In many countries, environmental labelling has become an established

method for encouraging the adaptation of goods and services to the

environment. The main problem, as far as computers and other

electronics equipment are concerned, is that environmentally harmful

substances are used both in the products and during the manufacturing.

Since it has not been possible for the majority of electronics equipment

to be recycled in a satisfactory way, most of these potentially damaging

substances sooner or later enter Nature.

There are also other characteristics of a computer, such as energy

consumption levels, that are important from the viewpoints of both the

work (Internal) and natural (external) environments. Since all methods of

conventional electricity generation have a negative effect on the

environment (acidic and climate-influencing emissions, radioactive

waste, etc.), it is vital to conserve energy. Electronics equipment in

offices consume an enormous amount of energy since they are often left

running continuously.

What does labelling involve?

This product meets the requirements for the TCO’95 scheme which

provides for international and environmental labelling of personal

computers. The labelling scheme was developed as a joint effort by the

TCO (The Swedish Confederation of Professional Employees),

Naturskyddsforeningen (The Swedish Society for Nature Conservation)

and NUTEK (The National Board for Industrial and Technical

Development in Sweden).

The requirements cover a wide range of issues: environment,

ergonomics, usability, emission of electrical and magnetic fields, energy

consumption and electrical and fire safety.

1-31

English-30

The environmental demands concern restrictions on the presence and

use of heavy metals, brominated and chlorinated flame retardants,

CFCs (freons) and chlorinated solvents, among other things. The

product must be prepared for recycling and the manufacturer is obliged

to have an environmental plan which must be adhered to in each

country where the company implements its operational policy. The

energy requirements include a demand that the computer and/or

display, after a certain period of inactivity, shall reduce its power

consumption to a lower level in one or more stages. The length of time to

reactivate the computer shall be reasonable for the user.

Labelled products must meet strict environmental demands, for

example, in respect of the reduction of electric and magnetic fields,

physical and visual ergonomics and good usability.

TCO’95 is a co-operative project between TCO (The Swedish

Confederation of Professional Employees), Naturskyddsforeningen

(The Swedish Society for Nature Conservation) and NUTEK

(The National Board for Industrial and Technical Development in

Sweden).

Environmental Requirements

Brominated flame retardants

Brominated flame retardants are present in printed circuit boards,

cables, wires, casings and housings. In turn, they delay the spread of

fire. Up to thirty percent of the plastic in a computer casing can consist

of flame retardant substances. These are related to another group of

environmental toxins, PCBs, which are suspected to give rise to similar

harm, including reproductive damage in fisheating birds and mammals,

due to the bio-accumulative* processes. Flame retardants have been

found in human blood and researchers fear that disturbances in foetus

development may occur.

TCO’95 demand requires that plastic components weighing more than

25 grams must not contain organically bound chlorine and bromine.

Lead**

Lead can be found in picture tubes, display screens, solders and

capacitors. Lead damages the nervous system and in higher doses,

causes lead poisoning.

TCO’95 requirement permits the inclusion of lead since no replacement

has yet been developed.

1-32

English-31

English

Cadmium**

Cadmium is present in rechargeable batteries and in the

colourgenerating layers of certain computer displays. Cadmium

damages the nervous system and is toxic in high doses.

TCO’95 requirement states that batteries may not contain more than

25 ppm (parts per million) of cadmium. The colourgenerating layers of

display screens must not contain any cadmium.

Mercury**

Mercury is sometimes found in batteries, relays, switches, and back-light

systems, Mercury damages the nervous system and is toxic in high

doses.

TCO’95 requirement states that batteries may not contain more than

25 ppm (parts per million) of mercury. It also demands that no mercury

is present in any of the electrical or electronics components concerned

with the display unit, except the back-light system.

CFCs (freons)

CFCs (freons) are sometimes used for washing printed circuit boards

and in the manufacturing of expanded foam for packaging. CFCs break

down ozone and thereby damage the ozone layer in the stratosphere,

causing increased reception on Earth of ultraviolet light with consequent

increased risks of skin cancer (malignant melanoma).

The relevant TCO’95 requirement; Neither CFCs nor HCFCs may be

used during the manufacturing of the product or its packaging.

* Bio-accumulative is defined as substances which accumulate within

living organisms.

** Lead, Cadmium and Mercury are heavy metals which are

Bioaccumulative.

To obtain complete information on the environmental criteria document,

order from:

TCO Development Unit

SE-114 94 Stockholm

SWEDEN

FAX Number: +46 8 782 92 07

E-mail (Internet): development@tco.se

You may also obtain current information on TCO’95 approved and

labelled products by visiting their website at:

http://www.tco-info.com/

2-1

Serial Number Information

Refer to the serial number information shown below.

g g g g g g g g g

Manufactured Year :

( Last digit )

Manufactured Month :

January to September 1 to 9

October X

November Y

December Z

Factory Code:

LITE-ON Taiwan factory ...... “U”

LITE-ON China factory ...... “G”

Control Code:

A: A ver. (for U.S.A.)

B: B ver. (for Europe, Asia and Pacific)

C: C ver. (for China)

EX.) SERIAL NUMBER LABEL

Model Name : LCD1550ME

LCD1550ME-BK

SERIAL NO. :

Serial Number(5-digit)

(sequential numbe

r

at production month,

00001-99999

)

3-1

DISASSEMBLY

g Before you disassemble the set, turn off power and pull out the power plug.

g Use the proper screwdriver. If oversize or undersize screwdriver is used, screws may be damaged.

g Assembly is the opposite process of disassembly.

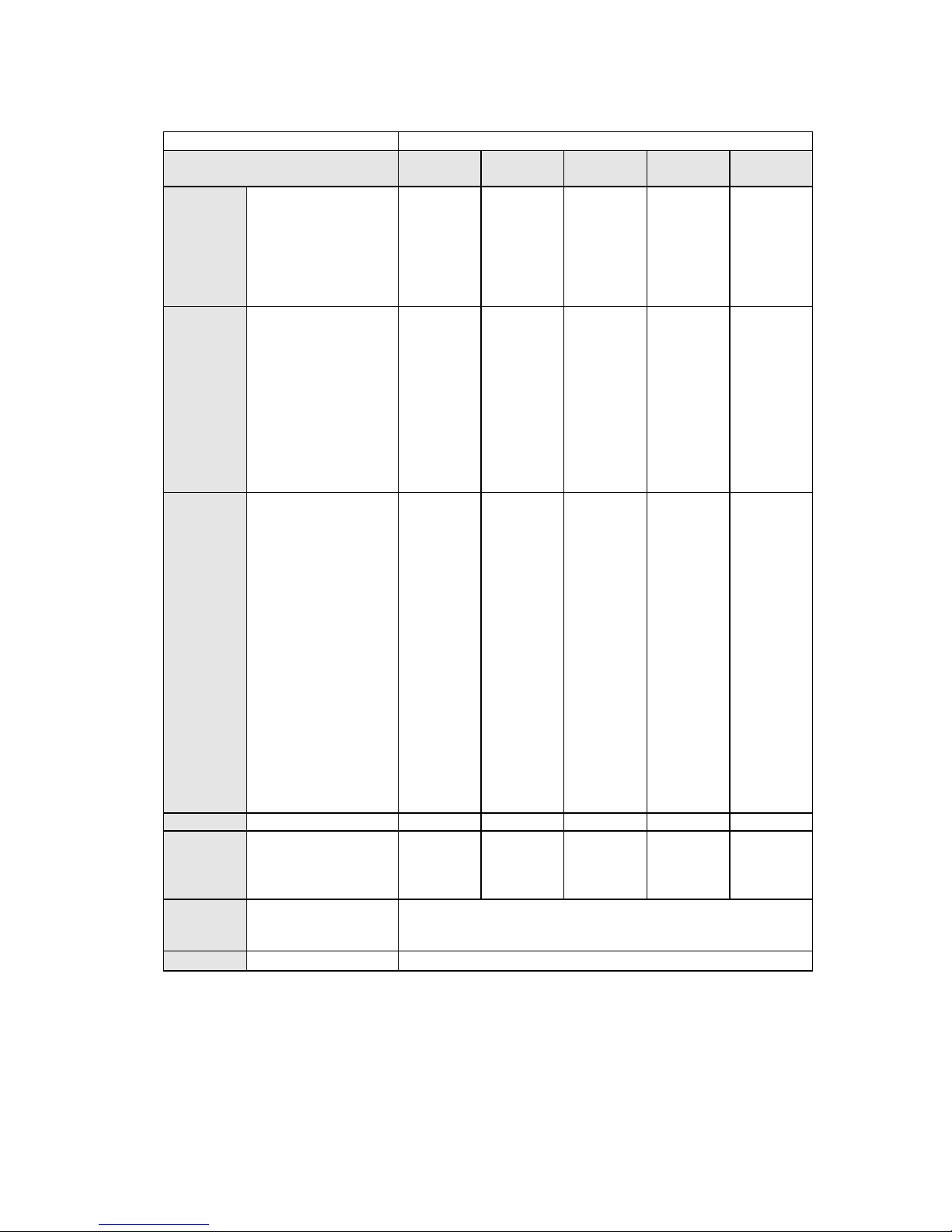

SYMBOL CODE DESCRIPTION CABINET COLOR

1 79PL1836 COVER(CONNECTOR) White

1 79PL1844 COVER-CONNECTOR-NMV(NEC)- Black

2 79PL1825 COVER CABLE White

2 79PL1833 COVER CABLE(LCD1550MBK B) Black

3 --- SCREW-M4*12

4 --- SCREW-T3*12

2 1

3

4

3-2

SYMBOL CODE DESCRIPTION CABINET COLOR

5 79PL1897 REAR COVER ASS'Y-NMV-NEC White

5 79PL2043 REAR COVER ASS’Y-NEC-NEC- Black

SYMBOL CODE DESCRIPTION

6 --- BRACKET VESA ASS’Y

7 79PL1915 RUBBER CUSHION(REAR COVER)

5

6

7

3-3

SYMBOL CODE DESCRIPTION

8 --- SCREW-M3*6

9 79PL1910 SHIELD-ASS'Y-NEC-FA150ATU

SYMBOL CODE DESCRIPTION

11 79PL1912 INSULATOR-NEC-FA150ATUA-B

12 79PL1913 INSULATOR-NEC-FA150ATUA-P

13 79PL1911 INSULATOR-NEC-FA150ATUA-P

11

12

13

9

8

3-4

SYMBOL CODE DESCRIPTION

14 79PL2044 INTERFACE BD

15 79PL2047 POWER BD

16 79PL1982 INVERTER-DC-AC-AMBIT:T15I

8 --- SCREW-M3*6

17 --- SCREW-M4*8

18 --- SCREW-M3*6(Flat)

19 --- SPECIAL(HEX)

14

P306 P307

P301

P304

P003

8

19

16

CN2

CN3

CN1

17

18

8

15

P804

3-5

SYMBOL CODE DESCRIPTION

20 79PL1819 FUNCTION KEY BD-NEC-FA150

21 79PL1901 HEAD PHONE BD-NEC-F A15AA

22 --- SCREW-M3*8

23 79PL1464 SPEAKER 4P N13AA12PCH22 J

24 --- SCREW-M2.6*10

25 79PL1462 SW POWER HF606A1GGATA HUA

SYMBOL CODE DESCRIPTION CABINET COLOR

26 --- SCREW-M3*12

27 79PL2041 FRONT COVER ASS’Y-NMV-NEC White

27 79PL2042 FRONT COVER ASS’Y-NEC-NEC Black

20

21

23

24

22

25

27

26

3-6

SYMBOL CODE DESCRIPTION

28 --- SCREW-M3*5

29 --- BRACKET CHASSIS BASE ASS'Y

30 79PL2039 LCD-15-CLAA150XG01-CPT”

31 79PL2036 HARNESS-FFC-45P(0.5)-95/1

32 79PL2037 HARNESS-FFC-30P(0.5)-115/

31

32

30

29

28

28

3-7

SYMBOL CODE DESCRIPTION CABINET COLOR

33 79PL1905 HINGE-L-NEC-NEC-FA150ATUA

34 79PL1906 HINGE-R-NEC-NEC-FA150ATUA

35 79PL1835 STAND FRONT White

35 79PL1845 COVER-STAND FRONT-NMV(NEC Black

36 --- SCREW-M4*8(SPECAL)

SYMBOL CODE DESCRIPTION CABINET COLOR

37 79PL1898 STAND-BASE-NMV-NEC-FA15AA White

37 79PL2040 BASE ASS’Y-NEC-NEC-FA15AA Black

38 79PL1907 BRACKET-HINGE-NEC-FA150AT

39 --- SCREW-M4*16(DOUBLE WASHER)

33

34

35

36

37

38

39

3-8

SYMBOL CODE DESCRIPTION

40 79PL1875 BRACKET-STAND PLATE-NEC41 79PL1869 FOOT RUBBER

42 --- SCREW-M3*10

40

42

41

4-1

ADJUSTMENT PROCEDURES

TABLE OF CONTENS

Page

1.

Application ------------------------------------------------------------------------------------------------------------- 4-2

2.

Basic operation-------------------------------------------------------------------------------------------------------- 4-2

2.1. General conditions --------------------------------------------------------------------------------------------------- 4-2

2.2. Basic function --------------------------------------------------------------------------------------------------------- 4-2

2.2.1. Key layout ----------------------------------------------------------------------------------------------------------- 4-2

2.2.2. Aging ----------------------------------------------------------------------------------------------------------------- 4-2

2.2.3. Service mode------------------------------------------------------------------------------------------------------- 4-3

3.

Set adjustments------------------------------------------------------------------------------------------------------- 4-4

3.1. Measuring instruments to be used ------------------------------------------------------------------------------- 4-4

3.2. Power source voltage ----------------------------------------------------------------------------------------------- 4-4

3.3. Electrification ---------------------------------------------------------------------------------------------------------- 4-4

3.4. Input signals ----------------------------------------------------------------------------------------------------------- 4-4

3.5. POWER ON and signal input-------------------------------------------------------------------------------------- 4-4

3.6. Manual adjustments ------------------------------------------------------------------------------------------------- 4-5

3.6.1. Input video signal-------------------------------------------------------------------------------------------------- 4-5

3.6.2. VIDEO gain adjustments ---------------------------------------------------------------------------------------- 4-6

3.6.3. Factory setting--------------------------------------------------------------------------------------------------------4-7

4-2

1. Application

This specification shall be applied to the adjustment of the LCD1550ME set.

2. Basic operation

2.1. General conditions

Unless otherwise specified, adjustments shall be carried out under the following conditions:

1) Power source voltage: AC 100 - 120V/ 220 - 240V ± 5%, 50/60Hz

2) Equipment to be used: Equipment that can generate an output of the adjusted VG-819 unit or equivalent

3) Connections: Connections are made to the D-Sub connector of the unit under inspection by means of the

connector that can carry each output of the VG-819.

2.2. Basic function

2.2.1. Key layout

Exit : Menu Close, Sub menu exit

Control : Menu Open, Cursor Move, Item Select

Adjust : Menu Open, Adjust select item, Enter Sub menu

Next : Menu Open, Tag Select, Function execute

Reset : Open reset menu, Sound Mute

2.2.2. Aging

Prior to the adjustment of this model, 30 minutes of aging shall be carried out. The method of aging mode

setting shall conform to the following:

1) Turn the POWER switch on while there are no inputs of the VIDEO and SYNC signals.

2) Press the (4) RIGHT or(3) LEFT or (+) PLUS or (-) MINUS key to display the information OSM.

3) Then, Press the (+) PLUS and (-) MINUS keys simultaneously with the RESET key kept pressed. Then

the mode moves to the aging mode.

Push (+) PLUS and (-) MINUS and RESET

EXIT wCONTROL8 −ADJUST+ NEXT RESET/MUTE

4-3

4) If there is no particular operation, an all white screen (255/255 gradation) is displayed.

5) Operate the(4) RIGHT and (3)LEFT keys in this state. Then, operation for the gradation becomes

possible. It is also possible to change the pattern by operating the (4)RIGHT and (3)LEFT keys.

6) When withdrawing from the aging mode, press the EXIT key.

During operation in the aging mode, the power save mode is not assumed. The LED maintains the green

display.

2.2.3. Service mode

At the time of adjustment of this model, a suggestion may be given to enter the service (factory) mode. This

will be explained below.

(1) Service mode:

1) In the “display mode” menu, press the (+) and (−) LEFT keys at the same time while pressing the

RESET key.

2) When the NEXT key is pressed under the condition that the WARNING screen is displayed, the mode

moves to the SERVICE mode. At that time, the LED is kept lit in green. The OSM AUTO-OFF function

is disabled.

3) When withdrawing from the SERVICE mode, press the EXIT key in the highest hierarchy of the

SERVICE menu, or make a signal changeover, or take an action of POWER OFF.

(2) Service menu:

This is an OSM menu to be displayed when the mode is changed over to the SERVICE mode. The

conditions differ in each mode, in regard to entering and withdrawal, and whether the data are recorded

in the EEPROM. Items of the service menu are used in common.

Push (+) PLUS and (-) MINUS and RESET

4-4

3. Set adjustments

3.1. Measuring instruments to be used

The measuring instruments considered necessary for the adjustment of the LCD1550ME set are specified

below.

1) Equipment that can generate an output of the adjusted VG-819 unit or equivalent

3.2. Power source voltage

100 - 120V/ 220 - 240V ± 5%, 50/60Hz

3.3. Electrification

1) Make connections according to the mode intended for VG-819 cable setting.

2) Turn on the POWER switch of the VG-819 unit.

3) Connect an AC power cable to the unit under inspection.

4) Confirm that the vacation switch (seesaw switch) at the left side of the unit being inspected has been

moved to the “I” side, and turn the POWER switch ON at the right side of the front.

5) The LED of the unit under inspection is lit in amber. (In the middle of signal discrimination)

6) After the completion of signal discrimination, the LED is lit in green.

Note 1: When the POWER source switch is turned on for the first time, the initialization of EEPROM is

effected regardless of the ON/OFF position of the POWER switch. In this period (about 1

minutes), the POWER switch must not be moved to the ON or OFF position. Upon the

completion of the initialization, a normal screen is displayed. (If no signal input is entered, the

information OSM is displayed.) If the screen is not displayed for more than 5 minutes after the

electrification, however, this seems to have resulted from failure in the initialization of EEPROM.

Such a condition is regarded as NG.

Note 2: Connections for the connectors should be carried out always under the condition that the AC

POWER cord plug has been pulled out.

3.4. Input signals

Refer to Paragraph 3.6.1 for each adjustment item.

3.5. POWER ON and signal input

1) Turn on the vacation switch located on the side of the main unit (the power supply for the signal

generator turned off) and turn on the power circuit by pressing the POWER key on the front panel.

Confirm in this case that the LED is lit in amber. When the power supply is turned on for the first time

after the completion of PWB assembly, do not turn off the power supply for at least 10 seconds because

initialization is required to be performed.

2) Turn on the power supply of the signal generator and enter an input of Signal 1. Confirm that the LED is

turned from amber to green.

* If this LED is not lit in green at that time, it is regarded as a defective LED.

3) Prior to adjustments, execute the factory reset procedure without fail. The method of this action is

described below.

a) Display the SERVICE menu and adjust the cursor to the item of [FACTORY RESET].

b) Enter a signal 2 input of VGA 640x480(Solid all white pattern).

c) Press the (+) PLUS or (-) MINUS keys to execute the factory reset procedure.

4-5

3.6. Manual adjustments

3.6.1. Input video signal

VG-819 setting values

MODE Signal 1

VESA 1024x768@75Hz

Signal 2

VGA 640x480

H DOT CLOCK

TOTAL

DISP

SYNC PULSE

BACK

HDstrat

Hdwidth

[MHz]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

78.75

1312

1024

96

176

0

0

25.18

800

640

96

48

0

0

V INTERLACE

TOTAL

DISP

SYNC PULSE

BACK PORCH

EQPfp

EQPbp

SERRATION

EDP

VDs

VBf

[H]

[H]

[H]

[H]

[H]

[H]

[H]

[H]

[H]

[H]

NON

800

768

3

28

0

0

OFF

OFF

0

0

NON

525

480

2

33

0

0

OFF

OFF

0

0

OUTPUT OUTPUT MODE

NRZ/RZ

CV

HS

VS

CS

HD

VD

RGB

HT

C

VIDEO

Set-up

Sync

ANALOG

NRZ

POS

POS

NEG

NEG

NEG

POS

POS

POS

0.70

OFF

0.3

ANALOG

NRZ

NEG

NEG

NEG

NEG

NEG

POS

POS

POS

0.70

OFF

0.3

Display setting Gray scale + External frame

(16 gradations)

0 ~ 100%

Solid all white

4-6

3.6.2. VIDEO gain adjustments

Use the signal source for which the analog output (R/G/B) has been adjusted to 0.7V.

1) Enter a signal 1 input of SXGA 1024x768(75Hz).

2) Turn off the display pattern completely and obtain an all black screen.

3) Assume the FACTORY mode in the procedures of Paragraph 2.2.3 and display the SERVICE menu.

4) Press the NEXT key once and advance to the tag [2].

5) Adjust the display pattern to Gray Scale (0 to 100%: in 16 gradations) + External Frame.

6) Use the (4) RIGHT or (3) LEFT keys and adjust the cursor to [AUTO OFFSET]. Make adjustments by

pressing the (+) PLUS or (-) MINUS keys.

7) When adjustments are over and the original screen has been recovered, confirm that all the 16

gradations of black to white are displayed.

8) Use the (4) RIGHT or (3) LEFT keys and adjust the cursor to [AUTO CONT MAX].

9) Press the EXIT key and withdraw from the SERVICE mode.

4-7

3.6.3. Factory setting

1) Enter a signal input. (no prescribe)

2) Assume the FACTORY mode in the procedures of Paragraph 2.2.3 and display the SERVICE menu.

3) Press the NEXT key three times and advance to the tag |4|.

4) Use the (4) RIGHT or (3) LEFT keys and adjust the cursor to [OSD DESIGN],[OSM SELECT] and

[URL]. Set by pressing the (+) PLUS or (-) MINUS keys.

OSD DESIGN 0

OSM SELECT 0

URL 1

5) Press the EXIT key and withdraw from the SERVICE mode.

5-1

INSPECTION

TABLE OF CONTENS

Page

1.

Set Inspection----------------------------------------------------------------------------------------------------- 5-2

1.1.1. Application ----------------------------------------------------------------------------------------------------------- 5-2

1.2. Inspection conditions --------------------------------------------------------------------------------------------- 5-2

1.2.1. Power source voltage --------------------------------------------------------------------------------------------- 5-2

1.2.2. Equipment to be used--------------------------------------------------------------------------------------------- 5-2

1.2.3. Inspection cables/connections---------------------------------------------------------------------------------- 5-2

1.2.4. Brightness setting -------------------------------------------------------------------------------------------------- 5-2

1.2.5. Inspection mode---------------------------------------------------------------------------------------------------- 5-2

1.2.6. OSM functions ------------------------------------------------------------------------------------------------------ 5-2

1.2.7. Configuration of inspection jigs --------------------------------------------------------------------------------- 5-2

1.2.8. Inspection mode setting ------------------------------------------------------------------------------------------ 5-3

1.3. OSM control operation ------------------------------------------------------------------------------------------5-12

1.3.1. Switch functions ---------------------------------------------------------------------------------------------------5-12

1.3.2. Basic operational procedures ----------------------------------------------------------------------------------5-12

1.4. Power ON ----------------------------------------------------------------------------------------------------------5-13

1.5. Inspection ----------------------------------------------------------------------------------------------------------5-13

1.5.1. Inspection on LCD brightness and contrast ----------------------------------------------------------------5-13

1.5.2. Inspection on automatic adjustment function---------------------------------------------------------------5-14

1.5.3. Inspection on input signal identification----------------------------------------------------------------------5-15

1.5.4. Inspection on Audio function -----------------------------------------------------------------------------------5-16

1.6.

Setting before shipment-----------------------------------------------------------------------------------------5-17

1.7. Safety test ----------------------------------------------------------------------------------------------------------5-17

1.7.1. Input current measurements -----------------------------------------------------------------------------------5-17

1.7.2. Power source/earth connections ------------------------------------------------------------------------------5-18

1.7.3. Dielectric strength test -------------------------------------------------------------------------------------------5-18

1.7.4. Leakage current test----------------------------------------------------------------------------------------------5-19

1.7.5. Insulation resistance test----------------------------------------------------------------------------------------5-19

2.

External inspection on the LCD module --------------------------------------------------------------------5-20

2.1. External inspection of the display surface------------------------------------------------------------------5-20

2.1.1. Inspection items ---------------------------------------------------------------------------------------------------5-20

2.1.2. Inspection standards ---------------------------------------------------------------------------------------------5-20

3.

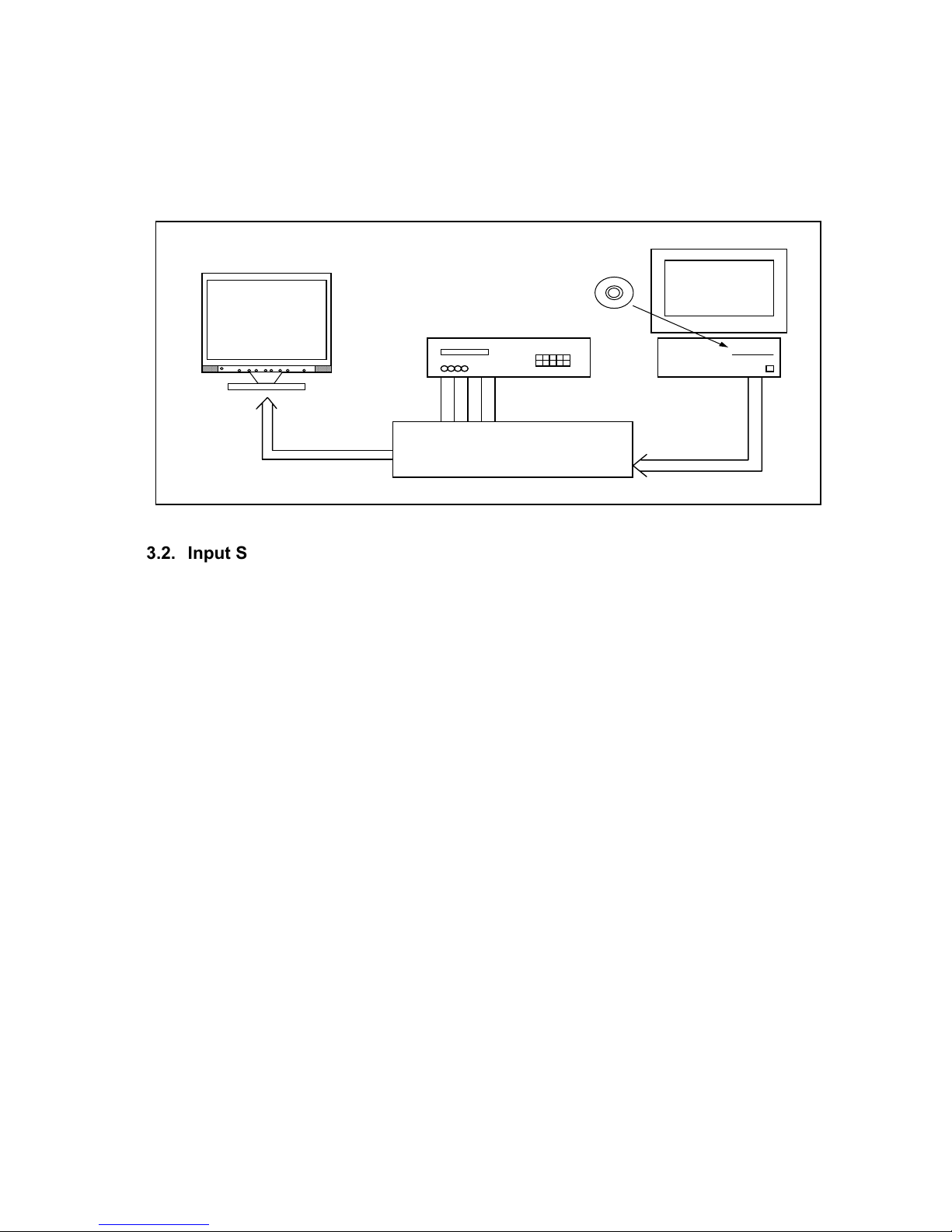

Inspection of PLUG & PLAY communication and OSM "MONITOR INFORMATION" for

model name/ serial number ------------------------------------------------------------------------------------5-22

3.1. A construction of System ---------------------------------------------------------------------------------------5-22

3.2. Input Signal --------------------------------------------------------------------------------------------------------5-22

3.3. Operational procedures-----------------------------------------------------------------------------------------5-23

3.4. EDID data file------------------------------------------------------------------------------------------------------5-24

5-2

1. Set Inspection

1.1.1. Application

The inspection procedures specified in this item shall be applied to the inspection of the LCD1550ME unit.

1.2. Inspection conditions

Unless otherwise specified, inspection shall be carried out under the following conditions.

1.2.1. Power source voltage

AC voltage: AC 100 - 120V/ 220 - 240V ± 5%, 50/60Hz

1.2.2. Equipment to be used

Equipment that can generate an output of the adjusted VG-819 unit or equivalent.

The signal timing for the inspection ROM shall conform to the table provided in Paragraph 1.2.8 herein.

1.2.3. Inspection cables/connections

1) Connections between the unit under inspection and the VG-819 shall be made through D-SUB

connector of the unit under inspection and the cable that can carry each output of the VG-819, as

specified below.

BNC-DSUB (female) connector

2) For connections to the power supply, an AC cable for LCD1550VM shall be used.

1.2.4. Brightness setting

Unless otherwise specified, inspection shall be carried out under the condition that the LCD brightness is

set at the highest level.

1.2.5. Inspection mode

Each inspection shall be carried out in the inspection mode specified in each relevant inspection item.

The detailed setting for each mode shall be specified in Paragraph 1.2.8 herein.

1.2.6. OSM functions

If checking and operation by OSM are specified in each inspection item, display and operation of the

OSM shall be carried out by operating the push switches of the unit under inspection, according to the

instructions.

Outline operation is described in Item 1.3, “Operation of OSM control.”

1.2.7. Configuration of inspection jigs

Signal source

1) A video signal generator shall be used, which can generate an output of the VG-819 unit or

equivalent.

5-3

1.2.8. Inspection mode setting

The respective setting data shall be the data for the VG-819.

Signal VG-819 setting values

Mode 01 02 03

Not used

04 05

H CLOCK

HPERIOD

HDISP

HSYNC

HBACKP

HDSTART

HDWIDTH

[MHz]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

28.322

900

720

108

54

0

0

35.500

936

720

72

108

0

0

21.053

848

640

64

84

0

0

28.322

900

720

108

54

0

0

35.500

936

720

72

108

0

0

V VTOTAL

VDISP

VSYNC

VBACKP

EQP FP

EQP BP

SERRATION

EQP

VDSTART

VDLINE

SCAN

[H]

[H]

[H]

[H]

[H]

[H]

[H]

[H]

449

350

2

60

0

0

OFF

OFF

0

0

Nonint

446

350

3

61

0

0

OFF

OFF

0

0

Nonint

440

400

8

25

0

0

OFF

OFF

0

0

Nonint

449

400

2

35

0

0

OFF

OFF

0

0

Nonint

446

400

3

42

0

0

OFF

OFF

0

0

Nonint

OUTPUT NRZ/RZ

HS

VS

CS

HD

VD

CLOCK

SYNC ON

RGB

VIDEO

SETUP

CLKMODE

CLKOUT

DISP,1CH,2CH

SW0,SW1

RGB

R(7-0),G(7-0),B(7-0)

DELAY

CLOCK DELAY

NRZ

POSI

NEGA

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

POSI

NEGA

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

NEGA

NEGA

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

NEGA

POSI

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

NEGA

POSI

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

PAT SEL OPTION 2 OPTION 2 OPTION 2 OPTION 2 OPTION 2

CHRA

PATTERN

Format

Code

Font

Cell

1

82

16*16

16*16

1

82

16*16

16*16

1

82

16*16

16*16

1

82

16*16

16*16

1

82

16*16

16*16

GRAY Direction : 0 L0: 0

L7: 127

LE: 239

L1: 17

L8: 143

LF: 255

L2: 34

L9: 159

L3: 51

LA: 175

L4: 68

LB: 191

L5: 85

LC: 207

L6: 102

LD: 223

OPTION 2 (Note 2)

5-4

Signal VG-819 setting values

Mode 06 07 08 09 10

H CLOCK

HPERIOD

HDISP

HSYNC

HBACKP

HDSTART

HDWIDTH

[MHz]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

25.18

800

640

96

48

0

0

30.24

864

640

64

96

0

0

31.5

832

640

40

128

0

0

31.5

840

640

64

120

0

0

36.0

832

640

56

80

0

0

V VTOTAL

VDISP

VSYNC

VBACKP

EQP FP

EQP BP

SERRATION

EQP

VDSTART

VDLINE

SCAN

[H]

[H]

[H]

[H]

[H]

[H]

[H]

[H]

525

480

2

33

0

0

OFF

OFF

0

0

Nonint

525

480

3

39

0

0

OFF

OFF

0

0

Nonint

520

480

3

28

0

0

OFF

OFF

0

0

Nonint

500

480

3

16

0

0

OFF

OFF

0

0

Nonint

509

480

3

25

0

0

OFF

OFF

0

0

Nonint

OUTPUT NRZ/RZ

HS

VS

CS

HD

VD

CLOCK

SYNC ON

RGB

VIDEO

SETUP

CLKMODE

CLKOUT

DISP,1CH,2CH

SW0,SW1

RGB

R(7-0),G(7-0),B(7-0)

DELAY

CLOCK DELAY

NRZ

NEGA

NEGA

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

NEGA

NEGA

NEGA

NEGA

NEGA

NEGA

G

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

NEGA

NEGA

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

NEGA

NEGA

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

NEGA

NEGA

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

PAT SEL OPTION 2 OPTION 2 OPTION 2 OPTION 2 OPTION 2

CHRA

PATTERN

Format

Code

Font

Cell

1

82

16*16

16*16

1

82

16*16

16*16

1

82

16*16

16*16

1

82

16*16

16*16

1

82

16*16

16*16

GRAY Direction : 0 L0: 0

L7: 127

LE: 239

L1: 17

L8: 143

LF: 255

L2: 34

L9: 159

L3: 51

LA: 175

L4: 68

LB: 191

L5: 85

LC: 207

L6: 102

LD: 223

OPTION 2 (Note 2)

5-5

Signal VG-819 setting values

Mode 11 12 13 14 15

H CLOCK

HPERIOD

HDISP

HSYNC

HBACKP

HDSTART

HDWIDTH

[MHz]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

36.0

1024

800

72

128

0

0

40.0

1056

800

128

88

0

0

49.5

1056

800

80

160

0

0

50.0

1040

800

120

64

0

0

56.25

1048

800

64

152

0

0

V VTOTAL

VDISP

VSYNC

VBACKP

EQP FP

EQP BP

SERRATION

EQP

VDSTART

VDLINE

SCAN

[H]

[H]

[H]

[H]

[H]

[H]

[H]

[H]

625

600

2

22

0

0

OFF

OFF

0

0

Nonint

628

600

4

23

0

0

OFF

OFF

0

0

Nonint

625

600

3

21

0

0

OFF

OFF

0

0

Nonint

666

600

6

23

0

0

OFF

OFF

0

0

Nonint

631

600

3

27

0

0

OFF

OFF

0

0

Nonint

OUTPUT NRZ/RZ

HS

VS

CS

HD

VD

CLOCK

SYNC ON

RGB

VIDEO

SETUP

CLKMODE

CLKOUT

DISP,1CH,2CH

SW0,SW1

RGB

R(7-0),G(7-0),B(7-0)

DELAY

CLOCK DELAY

NRZ

POSI

POSI

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

POSI

POSI

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

POSI

POSI

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

POSI

POSI

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

NRZ

POSI

POSI

NEGA

NEGA

NEGA

NEGA

POSI

0.70V

OFF

1/2

ALL

POSI

OFF

8 bit

11111111

ON

4 nsec

PAT SEL OPTION 2 OPTION 2 OPTION 2 OPTION 2 OPTION 2

CHRA

PATTERN

Format

Code

Font

Cell

1

82

16*16

16*16

1

82

16*16

16*16

1

82

16*16

16*16

1

82

16*16

16*16

1

82

16*16

16*16

GRAY Direction : 0 L0:0

L7:127

LE:239

L1:17

L8:143

LF:255

L2:34

L9:159

L3:51

LA:175

L4:68

LB:191

L5:85

LC:207

L6:102

LD:223

OPTION 2 (Note 2)

5-6

Signal VG-819 setting values

Mode 16 17 18 19 20

H CLOCK

HPERIOD

HDISP

HSYNC

HBACKP

HDSTART

HDWIDTH

[MHz]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

[DOT]

57.28

1152

832

64

224

0