查询MC-4516CB646供应商查询MC-4516CB646供应商

DATA SHEET

MOS INTEGRATED CIRCUIT

MC-4516CB646

16M-WORD BY 64-BIT SYNCHRONOUS DYNAMIC RAM MODULE

UNBUFFERED TYPE

Description

The MC-4516CB646 is a 16,777,216 words by 64 bits synchronous dynamic RAM module on which 8 pieces of

128M SDRAM: µPD45128841 are assembled.

This module provides high density and large quantities of memory in a small space without utilizing the surfacemounting technology on the printed circuit board.

Decoupling capacitors are mounted on power supply line for noise reduction.

Features

• 16,777,216 words by 64 bits organization

• Clock frequency and access time from CLK

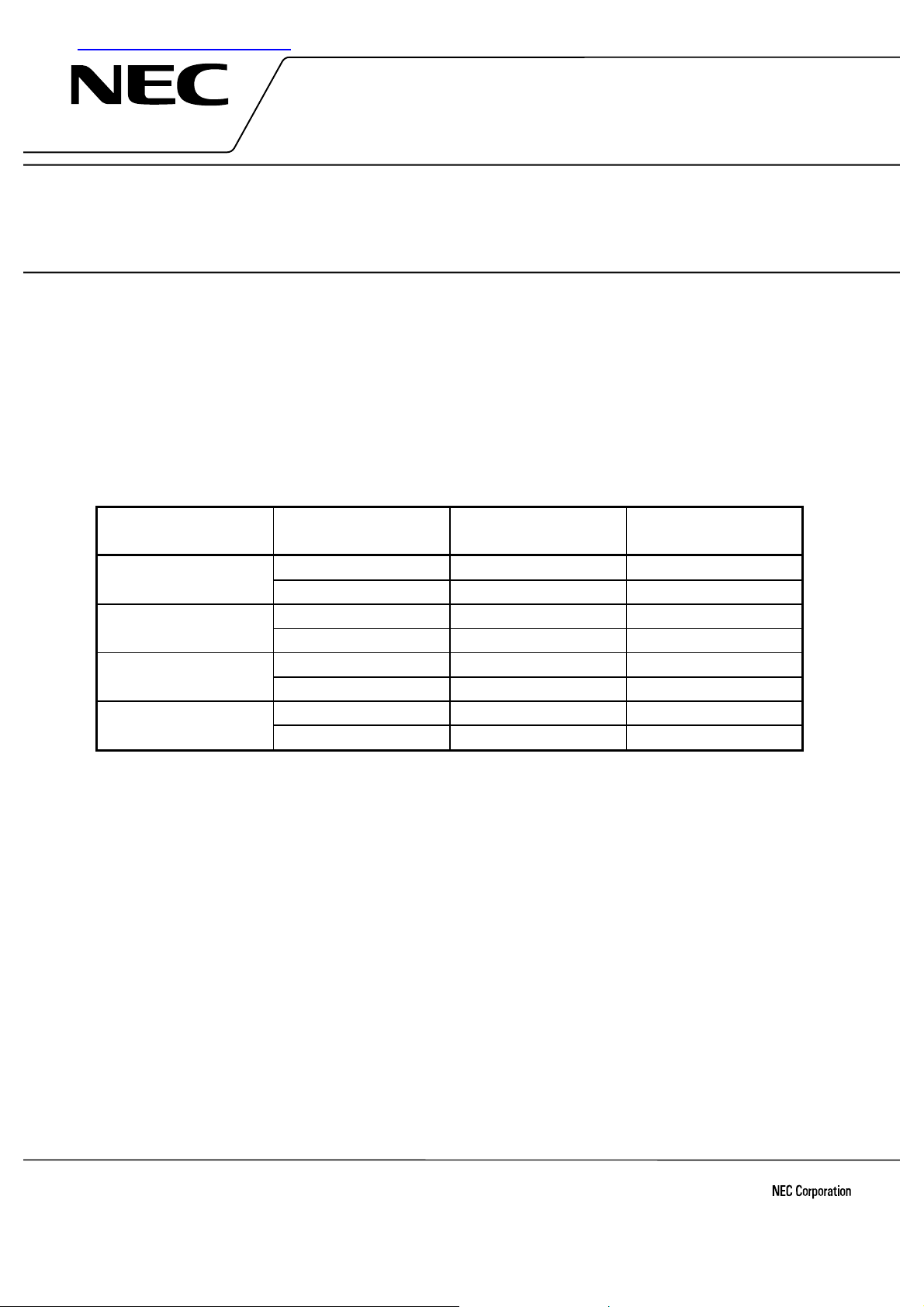

Part number /CAS latency Clock frequency Access time from CLK

(MAX.) (MAX.)

MC-4516CB646EF-A80 CL = 3 125 MHz 6 ns

CL = 2 100 MHz 6 ns

MC-4516CB646EF-A10 CL = 3 100 MHz 6 ns

CL = 2 77 MHz 7 ns

MC-4516CB646PF-A80 CL = 3 125 MHz 6 ns

★

CL = 2 100 MHz 6 ns

MC-4516CB646PF-A10 CL = 3 100 MHz 6 ns

★

CL = 2 77 MHz 7 ns

• Fully Synchronous Dynamic RAM, with all signals referenced to a positive clock edge

• Pulsed interface

• Possible to assert random column address in every cycle

• Quad internal banks controlled by BA0 and BA1 (Bank Select)

• Programmable burst-length (1, 2, 4, 8 and full page)

• Programmable wrap sequence (sequential / interleave)

• Programmable /CAS latency (2, 3)

• Automatic precharge and controlled precharge

• CBR (Auto) refresh and self refresh

• All DQs have 10 Ω ±10 % of series resistor

• Single 3.3 V ± 0.3 V power supply

• LVTTL compatible

• 4,096 refresh cycles/64 ms

• Burst termination by Burst Stop command and Precharge command

• 168-pin dual in-line memory module (Pin pitch = 1.27 mm)

• Unbuffered type

• Serial PD

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

Document No. M14334EJ2V0DS00 (2nd edition)

Date Published January 2000 NS CP(K)

Printed in Japan

The mark

••••

shows major revised points.

©

1999

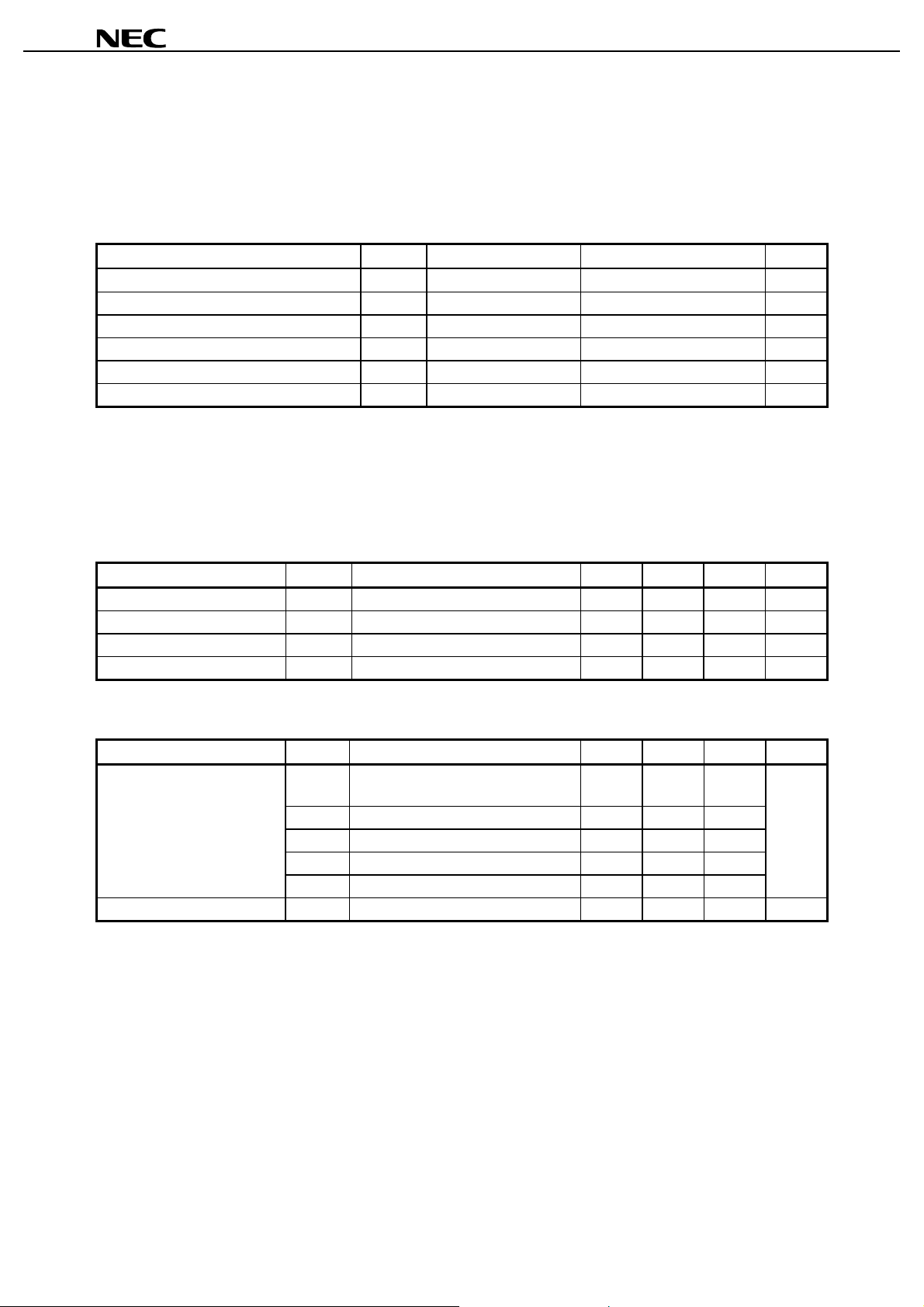

Ordering Information

MC-4516CB646

Part number Clock frequency

MHz (MAX.)

MC-4516CB646EF-A80 125 MHz 168-pin Dual In-line Memory Module 8 pieces of µPD45128841G5 (Rev. E)

MC-4516CB646EF-A10 100 MHz (Socket Type) (10.16 m m (400) TSOP (II))

MC-4516CB646PF-A80 125 MHz Edge connector : Gold plated 8 pieces of µPD45128841G5 (Rev. P)

★

★

MC-4516CB646PF-A10 100 MHz 34.93 mm height (10.16 mm (400) TSOP (II))

Package Mounted devices

2

Data Sheet M14334EJ2V0DS00

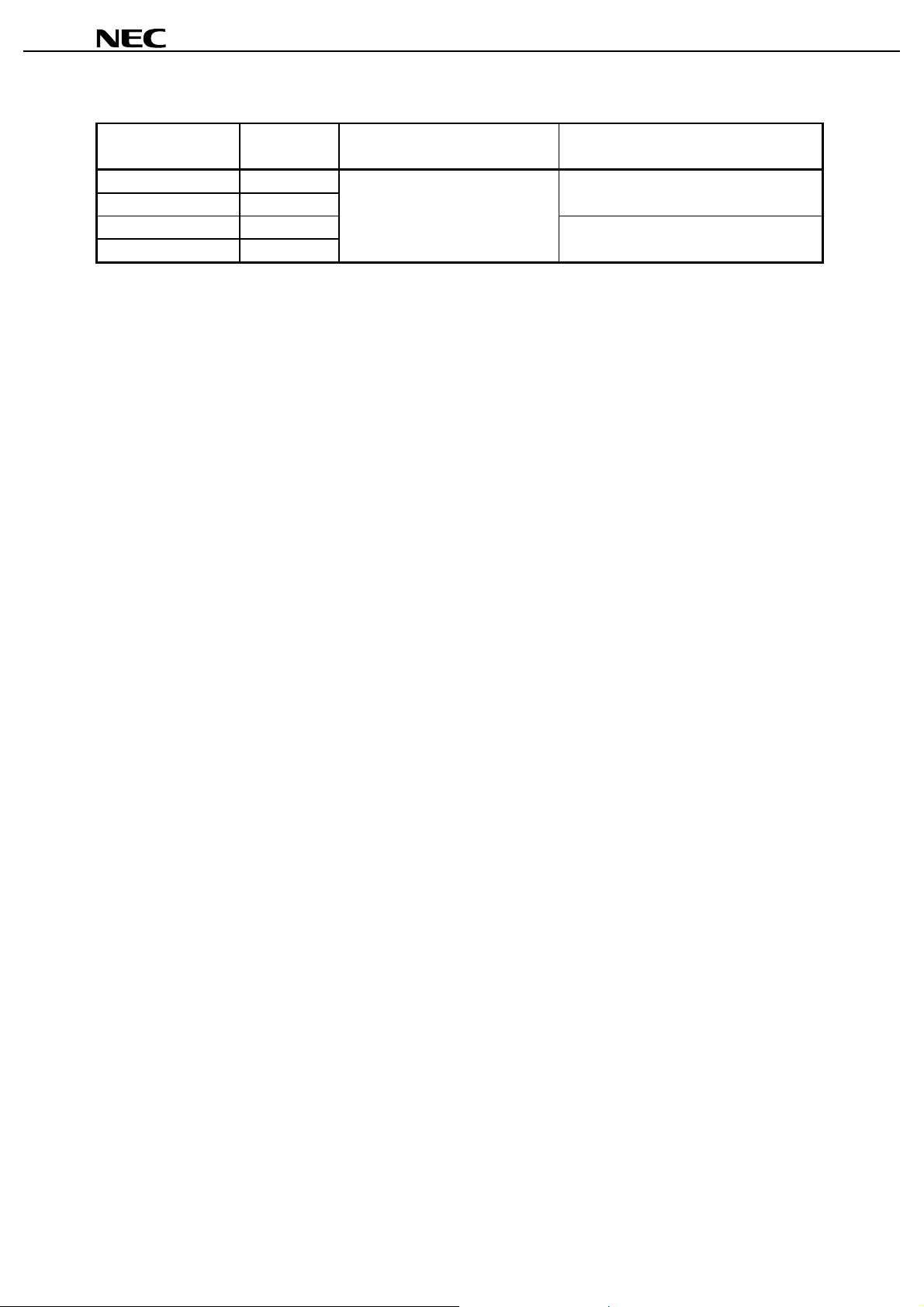

Pin Configuration

★

168-pin Dual In-line Memory Module Socket Type (Edge connector: Gold plated)

MC-4516CB646

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

SS

V

DQ32

DQ33

DQ34

DQ35

Vcc

DQ36

DQ37

DQ38

DQ39

DQ40

V

SS

DQ41

DQ42

DQ43

DQ44

DQ45

Vcc

DQ46

DQ47

NC

NC

V

SS

NC

NC

Vcc

/CAS

DQMB4

DQMB5

NC

/RAS

V

SS

A1

A3

A5

A7

A9

BA0

(A13)

A11

Vcc

CLK1

NC

V

SS

CKE0

NC

DQMB6

DQMB7

NC

Vcc

NC

NC

NC

NC

V

SS

DQ48

DQ49

DQ50

DQ51

Vcc

DQ52

NC

NC

NC

V

SS

DQ53

DQ54

DQ55

SS

V

DQ56

DQ57

DQ58

DQ59

Vcc

DQ60

DQ61

DQ62

DQ63

V

SS

CLK3

NC

SA0

SA1

SA2

Vcc

DQMB0

DQMB1

BA1

DQMB2

DQMB3

V

DQ0

DQ1

DQ2

DQ3

Vcc

DQ4

DQ5

DQ6

DQ7

DQ8

V

DQ9

DQ10

DQ11

DQ12

DQ13

Vcc

DQ14

DQ15

NC

NC

V

NC

NC

Vcc

/WE

/CS0

NC

V

A10

(A12)

Vcc

Vcc

CLK0

V

NC

/CS2

NC

Vcc

NC

NC

NC

NC

V

DQ16

DQ17

DQ18

DQ19

Vcc

DQ20

NC

NC

NC

V

DQ21

DQ22

DQ23

V

DQ24

DQ25

DQ26

DQ27

Vcc

DQ28

DQ29

DQ30

DQ31

V

CLK2

NC

WP

SDA

SCL

Vcc

SS

SS

SS

SS

A0

A2

A4

A6

A8

SS

SS

SS

SS

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

/xxx indica tes active low signal.

A0 - A11 : Address Inputs

[Row: A0 - A11, Column: A0 - A9]

BA0

(A13), BA1 (A12) : SDRAM Bank Select

DQ0 - DQ63 : Data Inputs/Outputs

CLK0 - CLK3 : Clock Input

CKE0 : Clock Enable Input

/CS0, /CS2 : Chip Select Input

/RAS : Row Address Strobe

/CAS : Column Address Strobe

/WE : Write Enable

DQMB0

-

DQMB7 : DQ Mask Enable

SA0 - SA2 : Address Input for EEPROM

SDA : Serial Data I/O for PD

SCL : Clock Input for PD

CC

V

SS

V

: Power Supply

: Ground

WP : Write Protect

NC : No Connection

Data Sheet M14334EJ2V0DS00

3

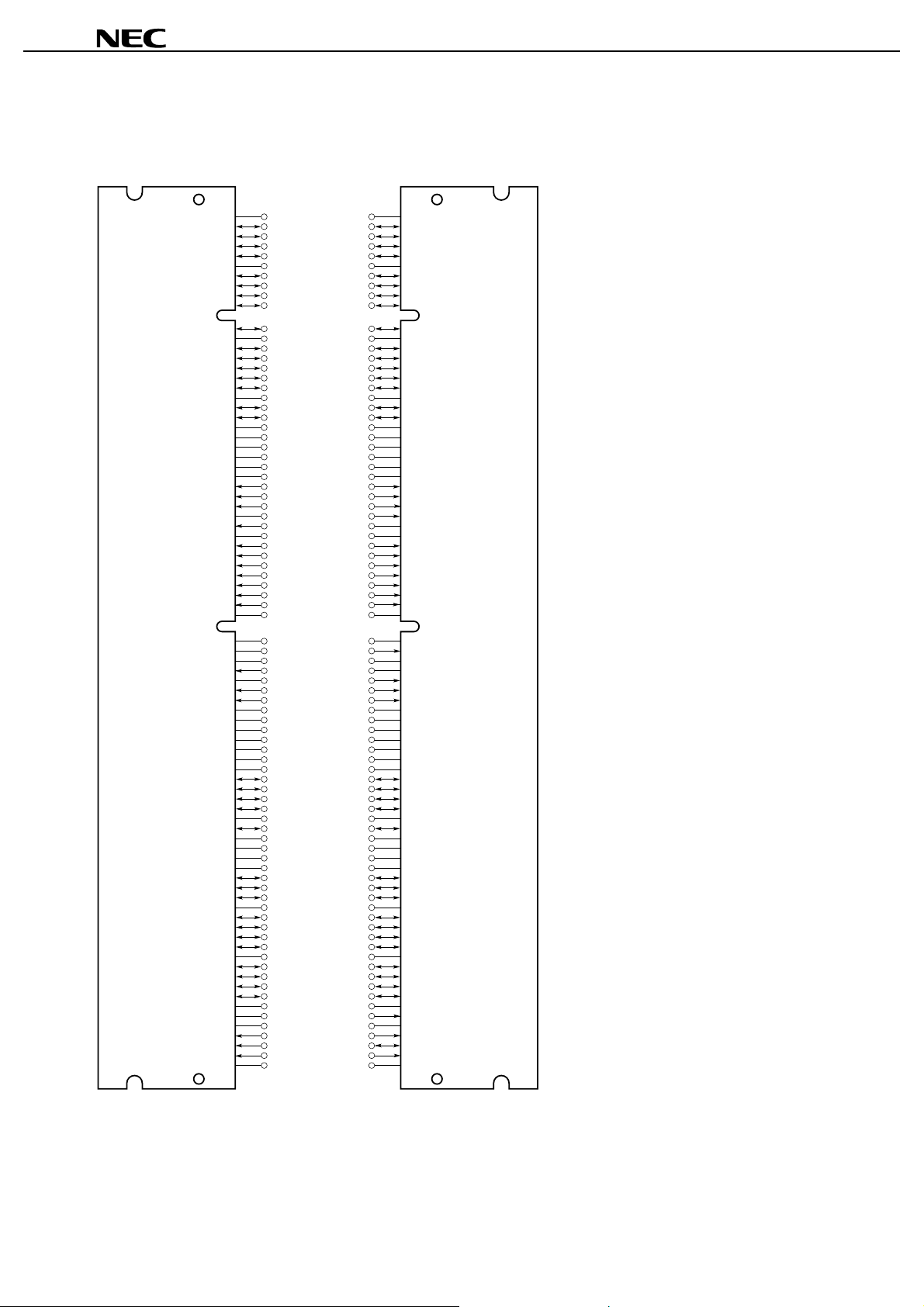

Block Diagram

/WE

/CS0

DQMB0

DQ 0

DQ 1

DQ 2

DQ 3

DQ 4

DQ 5

DQ 6

DQ 7

DQ 7

DQ 6

DQ 5

DQ 4

DQ 3

DQ 2

DQ 1

DQ 0

DQM

MC-4516CB646

/CS2

DQMB2

/WE

/CS

D0

DQ 16

DQ 17

DQ 18

DQ 19

DQ 20

DQ 21

DQ 22

DQ 23

DQMD2/CS /WE

DQ 7

DQ 6

DQ 5

DQ 4

DQ 3

DQ 2

DQ 1

DQ 0

DQMB1

DQ 8

DQ 9

DQ 10

DQ 11

DQ 12

DQ 13

DQ 14

DQ 15

DQMB4

DQ 32

DQ 33

DQ 34

DQ 35

DQ 36

DQ 37

DQ 38

DQ 39

DQMB5

DQ 40

DQ 41

DQ 42

DQ 43

DQ 44

DQ 45

DQ 46

DQ 47

DQ 7

DQ 6

DQ 5

DQ 4

DQ 3

DQ 2

DQ 1

DQ 0

DQ 4

DQ 7

DQ 6

DQ 5

DQ 3

DQ 2

DQ 1

DQ 0

DQ 5

DQ 7

DQ 6

DQ 4

DQ 3

DQ 2

DQ 1

DQ 0

DQM

/CS

D1

DQM /CS

D4

DQM

/CS

D5

/WE

/WE

/WE

DQMB3

DQ 24

DQ 25

DQ 26

DQ 27

DQ 28

DQ 29

DQ 30

DQ 31

DQMB6

DQ 48

DQ 49

DQ 50

DQ 51

DQ 52

DQ 53

DQ 54

DQ 55

DQMB7

DQ 56

DQ 57

DQ 58

DQ 59

DQ 60

DQ 61

DQ 62

DQ 63

DQ 4

DQ 7

DQ 6

DQ 5

DQ 3

DQ 2

DQ 1

DQ 0

DQ 7

DQ 6

DQ 5

DQ 4

DQ 3

DQ 2

DQ 1

DQ 0

DQ 7

DQ 6

DQ 5

DQ 4

DQ 3

DQ 2

DQ 1

DQ 0

DQM

DQM

DQM

/WE

/CS

D3

/WE

/CS

D6

/CS

/WE

D7

Remarks 1.

4

CLK0

CLK2

CLK1, CLK3

V

V

CC

SS

CLK : D0, D1, D4, D5

3.3 pF

CLK : D2, D3, D6, D7

3.3 pF

10 pF

D0 - D7

C

D0 - D7

The value of all resistors is 10 Ω except WP.

2.

D0 - D7:

µ

PD45128841 (4M words × 8 bits × 4 banks)

Data Sheet M14334EJ2V0DS00

A0 - A11

SCL

BA0

BA1

/RAS

/CAS

CKE0

SERIAL PD

A0

SA1 SA2

SA0

A1 A2

A0 - A11 : D0 - D7

A13 : D0 - D7

A12 : D0 - D7

/RAS : D0 - D7

/CAS : D0 - D7

CKE : D0 - D7

SDA

WP

47 kΩ

MC-4516CB646

Electrical Specifications

• All voltages are referenced to VSS (GND).

µ

• After power up, wait more than 100

device operation is achieved.

Absolute Maximum Ratings

Parameter Symbol Condition Rating Unit

Voltage on power supply pin relative to GND V

Voltage on input pin relative to GND V

Short circuit output c urrent I

Power dissipation P

Operating ambient tem perature T

Storage temperature T

Caution Exposing the device to stress above those listed in Absolute Maximum Ratings could cause

permanent damage. The device is not meant to be operated under conditions outside the limits

described in the operational section of this specification. Exposure to Absolute Maximum Rating

conditions for extended periods may affect device reliability.

s and then, execute power on sequence and CBR (Auto) refresh before proper

CC

T

O

D

A

stg

–0.5 to +4.6 V

–0.5 to +4.6 V

50 mA

8W

0 to +70

–55 to +125

C

°

C

°

Recommended Operating Conditions

Parameter Symbol Condition MIN. TYP. MAX. Unit

Supply voltage V

High level input voltage V

Low level input voltage V

Operating ambient tem perature T

Capacitance (TA = 25

C, f = 1 MHz)

°°°°

Parameter Symbol Test condition MIN. TYP. MAX. Unit

Input capacitance C

Data input/output capaci t ance C

CC

IH

IL

A

I1

I2

C

I3

C

I4

C

I5

C

I/O

3.0 3.3 3.6 V

2.0 VCC + 0.3 V

0.3 +0.8 V

−

A0 - A11, BA0(A13), BA1(A12), /RAS,

070

38 62 pF

°

/CAS, /WE

CLK0, CLK2 24 40

CKE0 32 52

/CS0, /CS2 17 29

DQMB0 - DQMB7 7 13

DQ0 - DQ63 7 13 pF

C

Data Sheet M14334EJ2V0DS00

5

DC Characteristics (Recommended Operating Conditions Unless Otherwise Noted)

Parameter Symbol Test condition Grade MIN. MAX. Unit Notes

Operating current I

Precharge standby current in I

power down mode I

★

Precharge standby current in

non power down mode

Active standby current i n I

power down mode I

Active standby current i n I

non power down mode Input signals are changed one time during 30 ns.

CC1

Burst length = 1

RC ≥ tRC(MIN.)

t

CC2

P CKE ≤ V

CC2

PS CKE ≤ V

CC2

I

NCKE

, IO = 0 mA -A10 800

IL(MAX.)

CK = 15

IL(MAX.)

≥ VIH(MIN.)

, t

, t

, t

ns 8 mA

CK =

∞

CK = 15

ns, /CS

Input signals are changed one time during 30

CC2

I

NS CKE ≥ V

IH(MIN.)

CK =

, t

∞

Input signals are stable.

CC3

P CKE ≤ V

CC3

PS CKE ≤ V

CC3

NCKE

CC3

I

NS CKE ≥ V

IL(MAX.)

IL(MAX.)

≥ VIH(MIN.)

IH(MIN.)

CK = 15

, t

CK =

, t

CK = 15

, t

CK =

, t

ns 40 mA

∞

ns, /CS

∞

Input signals are stable.

≥ VIH(MIN.)

≥ VIH(MIN.)

/CAS latency = 2

/CAS latency = 3

,

, 240 mA

MC-4516CB646

-A80 800 mA 1

-A80 800

-A10 800

8

160 mA

ns.

64

32

160

Operating current I

CC4tCK ≥ tCK(MIN.)

/CAS latency = 2

-A80 960 mA 2

(Burst mode) IO = 0 mA -A10 760

/CAS latency = 3

-A80 1,160

-A10 1,000

CBR (Auto) refresh current I

★

CC5tRC ≥ tRC(MIN.)

/CAS latency = 2

-A80 1,840 mA 3

-A10 1,840

★

/CAS latency = 3

-A80 1,840

-A10 1,840

Self refresh current I

Input leakage current I

Output leakage current I

CC6

CKE ≤ 0.2 V16mA

=

I(L)VI

O(L)DOUT

0 to 3.6 V, All other pins not under test = 0 V – 8+ 8µA

is disabled, VO = 0 to 3.6 V–

1.5 + 1.5µA

High level output voltage VOHIO = – 4.0 mA 2.4 V

Low level output voltage VOLIO = + 4.0 mA 0.4 V

Notes 1.

CC1

I

depends on output loading and cycle rates. Specified values are obtained with the output open. In

CC1

addition to this, I

CC4

2

.I

depends on output loading and cycle rates. Specified values are obtained with the output open. In

addition to this, I

CC5

3

.I

is measured on condition that addresses are changed only one time during t

is measured on condition that addresses are changed only one time during t

CC4

is measured on condition that addresses are changed only one time during t

CK (MIN.)

.

CK (MIN.)

CK (MIN.)

.

.

6

Data Sheet M14334EJ2V0DS00

AC Characteristics (Recommended Operating Conditions Unless Otherwise Noted)

Test Conditions

★

Parameter Value Unit

AC high level input voltage / low level input voltage 2.4 / 0.4 V

Input timing measurement ref erence level 1.4 V

Transition time (Input rise and fall time) 1 ns

Output timing measurement ref erence level 1.4 V

t

CK

t

CH

2.4 V

CLK

Input

1.4 V

0.4 V

2.4 V

1.4 V

0.4 V

t

SETUPtHOLD

t

AC

t

OH

MC-4516CB646

Notes

t

CL

Output

Data Sheet M14334EJ2V0DS00

7

Synchronous Characteristics

Parameter Symbol -A80 -A 10 Unit Note

Clock cycle time /CAS latency = 3 t

/CAS latency = 2 t

Access time from CLK /CAS latency = 3 t

/CAS latency = 2 t

CLK high level width t

CLK low level width t

Data-out hold time t

Data-out low-impedance tim e t

Data-out high-impedance time /CAS latency = 3 t

/CAS latency = 2 t

Data-in setup time t

Data-in hold time t

Address setup time t

Address hold time t

CKE setup time t

CKE hold time t

CKE setup time (P ower down exit) t

Command (/CS0, /CS2, /RAS, /CAS, /WE,

DQMB0 - DQMB7) setup time

Command (/CS0, /CS2, /RAS, /CAS, /WE,

DQMB0 - DQMB7) hold time

CK3

CK2

AC3

AC2

CH

CL

OH

LZ

HZ3

HZ2

DS

DH

AS

AH

CKS

CKH

CKSP

CMS

t

CMH

t

MC-4516CB646

MIN. MAX. MIN. MAX.

8 (125 MHz) 10 (100 MHz) ns

10 (100 MHz) 13 (77 MHz) ns

66ns1

67ns1

33ns

33ns

33ns1

00ns

3636ns

3637ns

22ns

11ns

22ns

11ns

22ns

11ns

22ns

22ns

11ns

Note 1.

Remark

Output load

Z = 50 Ω

Output

50 pF

These specifications are applied to the monolithic device.

8

Data Sheet M14334EJ2V0DS00

Asynchronous Characteristics

Parameter Symbol -A80 -A10 Unit Note

ACT to REF/ACT comm and peri od (Operat i on) t

REF to REF/ACT command period (Refresh) t

ACT to PRE command period t

PRE to ACT command period t

Delay time ACT to READ/WRITE command t

ACT(one) to ACT(another) command period t

Data-in to PRE command period t

Data-in to ACT(REF) command /CAS latency = 3 t

period (Auto precharge) /CAS latency = 2 t

Mode register set cycle time t

Transition time t

Refresh time (4,096 refres h cycles) t

MIN. MAX. MIN. MAX.

RC

RC1

RAS

RP

RCD

RRD

DPL

DAL3

DAL2

RSC

T

REF

70 70 ns

70 78 ns

48 120,000 50 120,000 ns

20 20 ns

20 20 ns

16 20 ns

810ns

1CLK+20 1CLK+20 ns

1CLK+20 1CLK+20 ns

22CLK

0.5 30 1 30 ns

64 64 ms

MC-4516CB646

Data Sheet M14334EJ2V0DS00

9

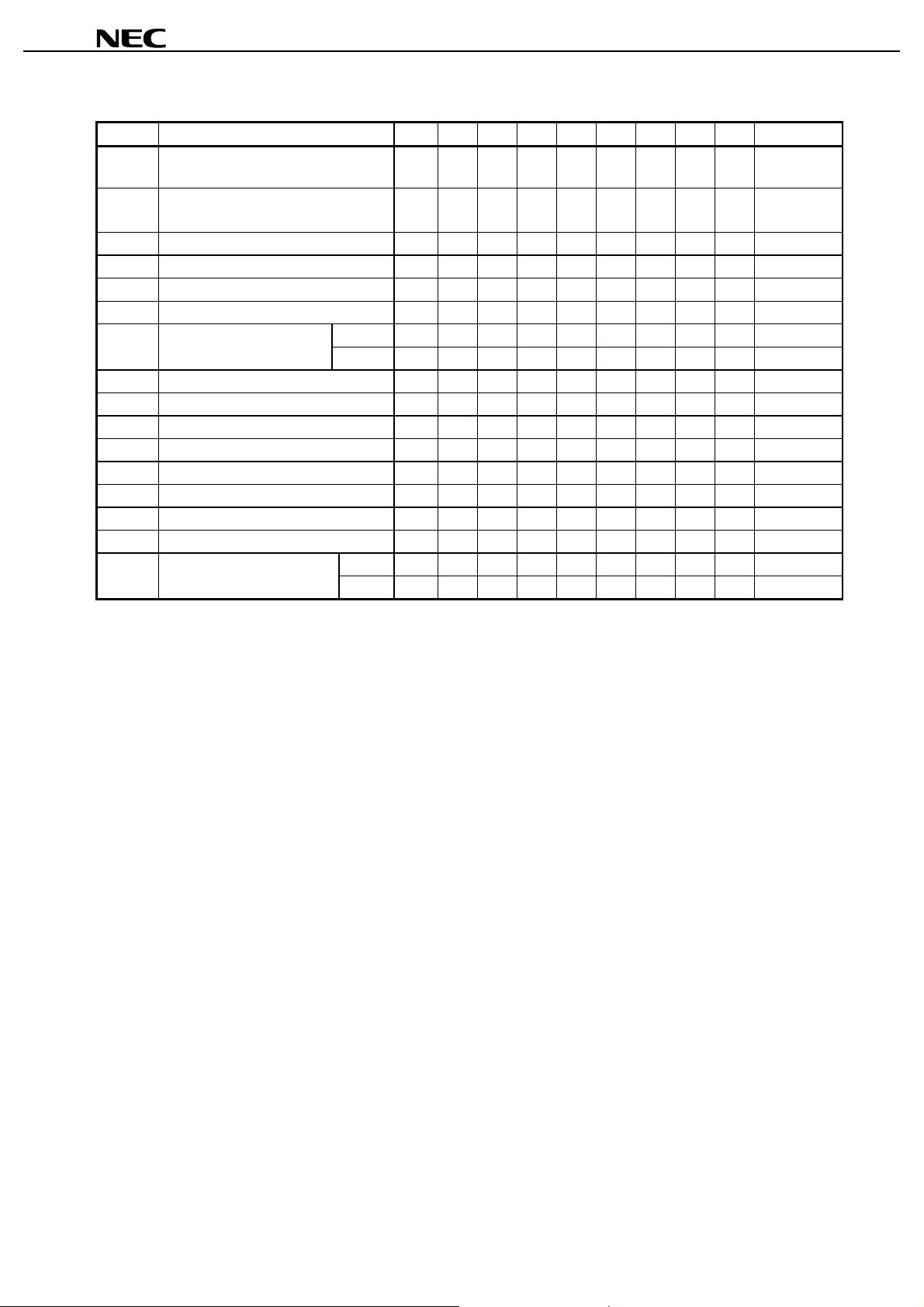

MC-4516CB646

Serial PD

Byte No. Function Described Hex Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Notes

0 Defines the number of bytes written into

serial PD memory

1 Total number of bytes of serial PD memory

2 Fundamental mem ory type

3 Number of rows

4 Number of columns

5 Number of banks

6 Data width

7 Data width (continued)

8 Voltage interface

9 CL = 3 Cycle time -A80 80H 1 0 0 0 0 0 0 0 8 ns

-A10 A0H 1 0 1 0 0 0 0 0 10 ns

10 CL = 3 Access tim e -A 80 60H 0 1 1 0 0 0 0 0 6 ns

-A10 60H 0 1 1 0 0 0 0 0 6 ns

11 DIMM configuration type

12 Refresh rate/type

13 SDRAM width

14 Error checking SDRAM width

15 Minimum clock del ay

16 Burst length supported

17 Number of banks on each SDRAM

18 /CAS latency supported

19 /CS latency supported

20 /WE lat ency supported

21 SDRAM module attributes

22 SDRAM device attributes : General

23 CL = 2 Cycle time -A80 A0H 1 0 1 0 0 0 0 0 10 ns

-A10 D0H 1 1 0 1 0 0 0 0 13 ns

24 CL = 2 Access tim e -A 80 60H 0 1 1 0 0 0 0 0 6 ns

-A10 70H 0 1 1 1 0 0 0 0 7 ns

25-26 00H 0 0 0 0 0 0 0 0

RP(MIN.)

-A80 14H 0 0 0 1 0 1 0 0 20 ns27 t

-A10 14H 0 0 0 1 0 1 0 0 20 ns

RRD(MIN.)

28 t

-A80 10H 0 0 0 1 0 0 0 0 16 ns

-A10 14H 0 0 0 1 0 1 0 0 20 ns

RCD(MIN.)

-A80 14H 0 0 0 1 0 1 0 0 20 ns29 t

-A10 14H 0 0 0 1 0 1 0 0 20 ns

RAS(MIN.)

30 t

-A80 30H 0 0 1 1 0 0 0 0 48 ns

-A10 32H 0 0 1 1 0 0 1 0 50 ns

31 Module bank density 20H 0 0 1 0 0 0 0 0 128M bytes

80H 1 0 0 0 0 0 0 0 128 bytes

08H 0 0 0 0 1 0 0 0 256 bytes

04H00000100SDRAM

0CH0000110012 rows

0AH0000101010 columns

01H 0 0 0 0 0 0 0 1 1 bank

40H0100000064 bits

00H000000000

01H00000001LVTTL

00H 0 0 0 0 0 0 0 0 Non-parity

80H10000000Normal

08H00001000×8

00H00000000None

01H000000011 clock

8FH 1 0 0 0 1 1 1 1 1, 2, 4, 8, F

04H 0 0 0 0 0 1 0 0 4 banks

06H000001102, 3

01H000000010

01H000000010

00H00000000

0EH00001110

(1/2)

10

Data Sheet M14334EJ2V0DS00

MC-4516CB646

(2/2)

Byte No. Function Described Hex Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Notes

32 Command and address signal input

setup time

33 Command and address signal input

hold time

34 Data signal input setup time 20H 0 0 1 0 0 0 0 0 2 ns

35 Data signal input hold time 10H 0 0 0 1 0 0 0 0 1 ns

36-61 00H 0 0 0 0 0 0 0 0

62 SPD revision 12H 0 0 0 1 0 0 1 0 1.2

63 Checksum for bytes 0 - 62 -A80 F0H 1 1 1 1 0 0 0 0

-A1056H01010110

64-71 Manufacture’s JEDEC ID code

72 Manufacturing location

73-90 Manufacture’s P/N

91-92 Revision code

93-94 Manufacturing date

95-98 Assembly serial number

99-125 Mfg specif i c

126 Intel specification frequency 64H 0 1 1 0 0 1 0 0 100 MHz

127 Intel specification /CAS -A80 A7H 1 0 1 0 0 1 1 1

latency support -A10 A5H 1 0 1 0 0 1 0 1

20H001000002 ns

10H000100001 ns

Timing Chart

Refer to the

SYNCHRONOUS DRAM MODULE TIMING CHART Information (M13348E)

.

Data Sheet M14334EJ2V0DS00

11

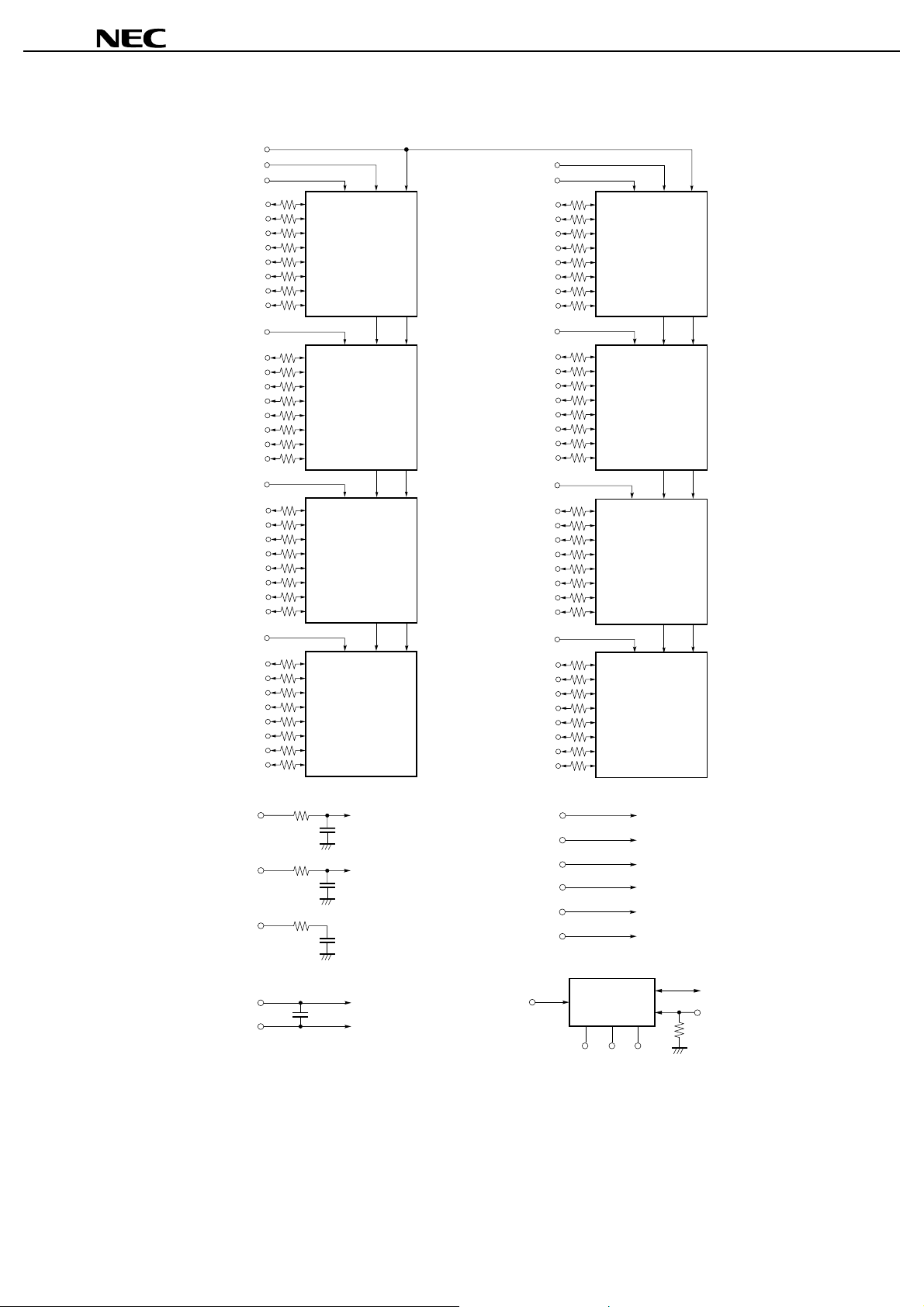

Package Drawing

★

168-PIN DUAL IN-LINE MODULE (SOCKET TYPE)

F1

R2

Y1

Y2

A (AREA B)

Z1

Z2

MC-4516CB646

N

F2

Q

M

R1

M2 (AREA A)

M1 (AREA B)

L

A

J

B

H

K

C

I G

B

S

(OPTIONAL HOLES)

E

U

T

D

A1 (AREA A)

ITEM MILLIMETERS

A

133.35

133.35±0.13

A1

11.43

B

36.83

C

6.35

D

2.0

D1

3.125

D2

54.61

E

2.44

F1

F2

3.18

G 6.35

H

detail of A part

W

V

detail of B part

D2

P

X

D1

1.27 (T.P.)

8.89

I

J 24.495

42.18K

17.78

L

34.93±0.13

M

15.15

M1

19.78

M2

3.0 MAX.

N

1.0

P

R2.0

Q

4.0±0.10

R1

R2

9.53

φ

S 3.0

T

1.27±0.1

4.0 MIN.

U

V 0.2±0.15

1.0±0.05W

X

2.54±0.10

Y1 3.0 MIN.

Y2

2.26

3.0 MIN.Z1

Z2 2.26

M168S-50A110

12

Data Sheet M14334EJ2V0DS00

[MEMO]

MC-4516CB646

Data Sheet M14334EJ2V0DS00

13

[MEMO]

MC-4516CB646

14

Data Sheet M14334EJ2V0DS00

MC-4516CB646

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note:

Strong electric field, when exposed to a MOS device, can cause destruction of the gate oxide and

ultimately degrade the device operation. Steps must be taken to stop generation of static electricity

as much as possible, and quickly dissipate it once, when it has occurred. Environmental control

must be adequate. When it is dry, humidifier should be used. It is recommended to avoid using

insulators that easily build static electricity. Semiconductor devices must be stored and transported

in an anti-static container, static shielding bag or conductive material. All test and measurement

tools including work bench and floor should be grounded. The operator should be grounded using

wrist strap. Semiconductor devices must not be touched with bare hands. Similar precautions need

to be taken for PW boards with semiconductor devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note:

No connection for CMOS device inputs can be cause of malfunction. If no connection is provided

to the input pins, it is possible that an internal input level may be generated due to noise, etc., hence

causing malfunction. CMOS devices behave differently than Bipolar or NMOS devices. Input levels

of CMOS devices must be fixed high or low by using a pull-up or pull-down circuitry. Each unused

DD

pin should be connected to V

being an output pin. All handling related to the unused pins must be judged device by device and

related specifications governing the devices.

or GND with a resistor, if it is considered to have a possibility of

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note:

Power-on does not necessarily define initial status of MOS device. Production process of MOS

does not define the initial operation status of the device. Immediately after the power source is

turned ON, the devices with reset function have not yet been initialized. Hence, power-on does

not guarantee out-pin levels, I/O settings or contents of registers. Device is not initialized until the

reset signal is received. Reset operation must be executed immediately after power-on for devices

having reset function.

Data Sheet M14334EJ2V0DS00

15

MC-4516CB646

CAUTION FOR HANDLING MEMORY MODULES

When handling or inserting memory modules, be sure not to touch any components on the modules, such as

the memory IC, chip capacitors and chip resistors. It is necessary to avoid undue mechanical stress on these

components to prevent damaging them.

When re-packing memory modules, be sure the modules are NOT touching each other. Modules in contact

with other modules may cause excessive mechanical stress, which may damage the modules.

• The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

• While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

• NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

M7 98. 8

Loading...

Loading...