IP8800/S6700, IP8800/S6600, IP8800/S6300, IP8800/S3600,

IP8800/S2400

Troubleshooting Guide

IP88S36-T001-000

Thoroughly read and store this manual.

• Read and thoroughly understand safety-related explanations before using this product.

• Keep this manual in a location close at hand for easy reference.

■ Applicable products

This manual describes models IP8800/S6700, IP8800/S6600, IP8800/S6300, IP8800/S3600, and IP8800/S2400 series.

■ Caution when exporting

The necessary procedures are to be adopted when exporting this product after first confirming the regulations of the Foreign Exchange and

Foreign Trade Law, U.S. export control related regulations, etc.

If any questions remains, please consult with our sales department.

■ Trademarks

Cisco is a registered trademark of U.S. Cisco Systems, Inc. in the U.S. and other countries.

Ethernet is a product name of Xerox Corp. in the U.S.

GSRP is a registered trademark of ALAXALA Networks Corporation.

Internet Explorer is a trademark or registered trademark of Microsoft Corporation in the U.S. and other countries.

IPX is a trademark of Novell, Inc.

Microsoft is a registered trademark of Microsoft Corp. in the U.S. and other countries.

RSA and RSA SecurID are trademarks or registered trademarks of RSA Security Inc. in the U.S. and other countries.

sFlow is a registered trademark of InMon Corp. in the U.S. and other countries.

UNIX is a registered trademark in the U.S. and other countries exclusively licensed by X/Open Company Limited.

VitalQIP and VitalQIP Registration Manager are trademarks of Lucent Technologies.

VLANaccessClient is a trademark of NEC Software.

Windows is a registered trademark of Microsoft Corp. in the U.S. and other countries.

Other company names and product names are trademarks or registered trademarks of their respective companies.

■ Thoroughly read and store this manual

Read and thoroughly understand safety-related explanations before using this product.

Keep this manual in a location close at hand for easy reference.

■ Note

The contents of this manual may be modified at any time for improvement without notice.

Note that output display examples and figures may be different from the actual states.

Issue date

November, 2009 (1st Edition) IP88S36-T001-000

■ Copyright

Copyright (c) 2009, NEC Corporation, All rights reserved.

Introduction

■ Applicable product

This manual describes models IP8800/S6700, IP8800/S6600, IP8800/S6300, IP8800/S3600 and IP8800/S2400.

Please read the manual carefully and thoroughly understand the instructions and cautions contained herein before operating the

device. Keep the manual in a location close at hand for easy reference when necessary.

Unless otherwise specified, this manual describes functions common to the models. The mark below refers to functions specific

to respective models.

[IP8800/S6700]:

The description is applicable to IP8800/S6700.

[IP8800/S6600]:

The description is applicable to IP8800/S6600.

[IP8800/S6300]:

The description is applicable to IP8800/S6300.

[IP8800/S3600]:

The description is applicable to IP8800/S3600.

[IP8800/S2400]:

The description is applicable to IP8800/S2400.

If more than one mark is indicated such as [IP8800/S3600] [IP8800/S2400], the function is only supported by those two

models or the description is not applicable to other models.

The mark below refers to functions supported by option licenses.

[OP-NPAR]:

The description is applicable to option license OP-NPAR.

[OP-OPT]:

The description is applicable to option license OP-OTP.

[OP-VAA]:

The description is applicable to option license OP-VAA.

■ Correction of this manual

Contents in this manual may be corrected in the "Release note" or "manual correction document" provided with software.

■ Intended users

This manual has been written for system managers who develop and operate network systems using IP8800/S6700, IP8800/

S6600, IP8800/S6300, IP8800/S3600, or IP8800/S2400.

In addition, an understanding of the following is assumed.

• Basic knowledge of network system management

■ Manual referred to

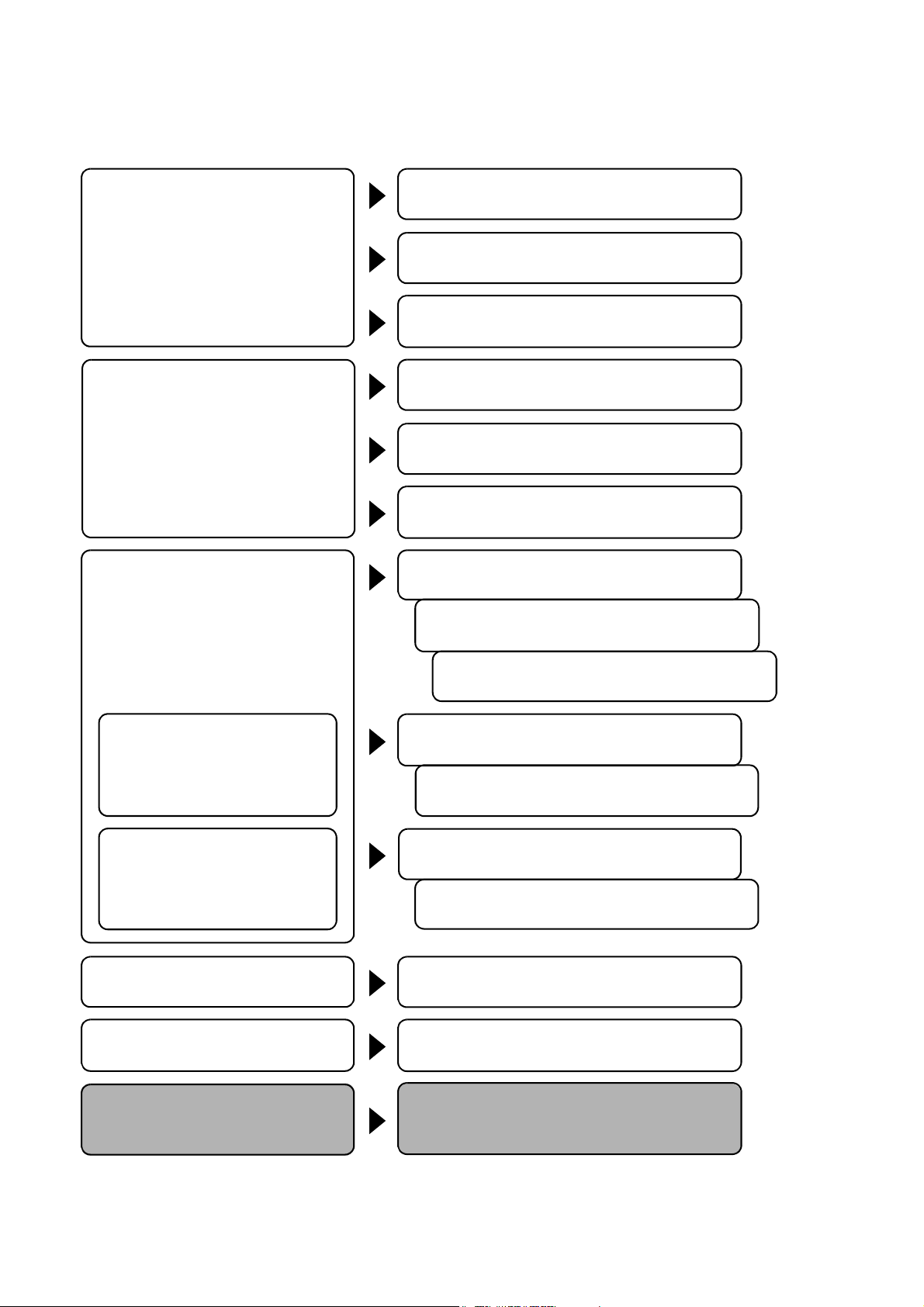

Manuals to be referenced according to the flow of tasks from installation and setup to daily operations are indicated below.

I

Introduction

Procedures from unpacking the product

to making basic settings at the initial

installation

IP8800/S6700

Quick Start Guide (IP88S67-Q001)

IP8800/S6600

Quick Start Guide (IP88S66-Q001)

IP8800/S6300

Quick Start Guide (IP88S63-Q001)

Information on the facility requirement of

the hardware

IP8800/S6700

Hardware lnstallation Guide (IP88S67-H001)

Information on handling of the hardware IP8800/S6600

Hardware lnstallation Guide (IP88S66-H001)

IP8800/S6300

Hardware lnstallation Guide (IP88S63-H001)

Information on software functions,

configuration, and confirmation by using

operation commands

IP8800/S6300 Software Manual

Configuration Settings, Vol.1 (IP88S63-S001)

IP8800/S6300 Software Manual

Configuration Settings, Vol.2 (IP88S63-S002)

IP8800/S6300 Software Manual

Configuration Settings, Vol.3 (IP88S63-S003)

Syntax and parameter details of

configuration commands

IP8800/S6300 Software Manual

Configuration Commands, Vol.1 (IP88S63-S004)

IP8800/S6300 Software Manual

Configuration Commands, Vol.2 (IP88S63-S005)

Syntax and parameter details of

operation commands

IP8800/S6300 Software Manual

Operation Commands, Vol.1 (IP88S63-S006)

IP8800/S6300 Software Manual

Operation Commands, Vol.2 (IP88S63-S007)

Details of operation messages and logs IP8800/S6300 Software Manual

Message Log Reference (IP88S63-S008)

Details of supported MIBs IP8800/S6300 Software Manual

MIB Reference (IP88S63-S009)

lnformation on troubleshooting IP8800/S6700, IP8800/S6600, IP8800/S6300,

IP8800/S3600, IP8800/S2400

Troubleshooting Guide (IP88S36-T001)

For IP8800/S6700, IP8800/S6600, and IP8800/S6300

II

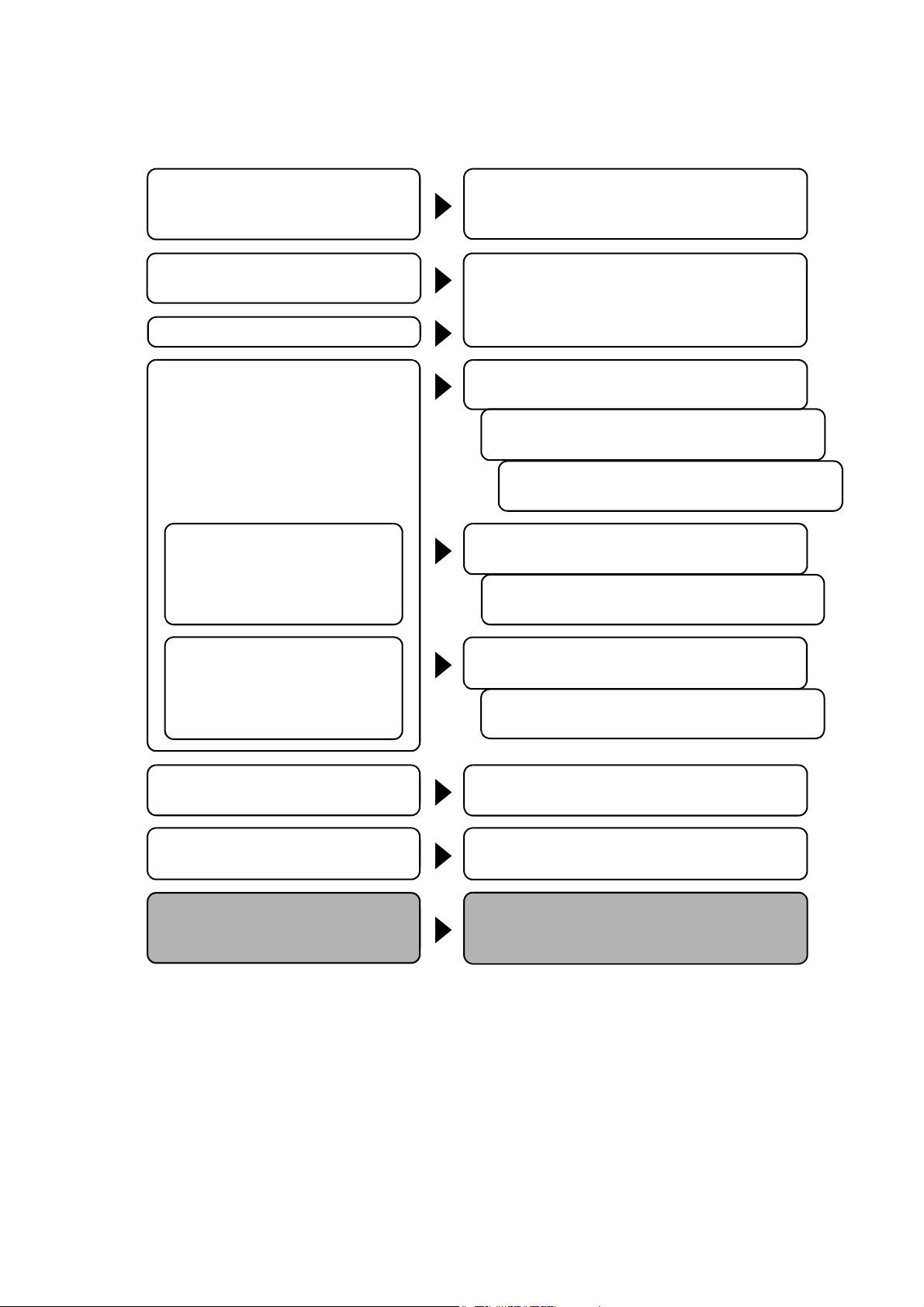

For IP8800/S3600

Procedures from unpacking the product

to making basic settings at the initial

installation

IP8800/S3600, IP8800/S2400

Quick Start Guide (IP88S36-Q001)

Information on the facility requirement of

the hardware

IP8800/S3600, IP8800/S2400

Hardware lnstallation Guide (IP88S36-H001)

Information on handling of the hardware

Information on software functions,

configuration, and confirmation by using

operation commands

IP8800/S3600 Software Manual

Configuration Settings, Vol.1 (IP88S36-S001)

IP8800/S3600 Software Manual

Configuration Settings, Vol.2 (IP88S36-S002)

IP8800/S3600 Software Manual

Configuration Settings, Vol.3 (IP88S36-S003)

Syntax and parameter details of

configuration commands

IP8800/S3600 Software Manual

Configuration Commands, Vol.1 (IP88S36-S004)

IP8800/S3600 Software Manual

Configuration Commands, Vol.2 (IP88S36-S005)

Syntax and parameter details of

operation commands

IP8800/S3600 Software Manual

Operation Commands, Vol.1 (IP88S36-S006)

IP8800/S3600 Software Manual

Operation Commands, Vol.2 (IP88S36-S007)

Details of operation messages and logs IP8800/S3600 Software Manual

Message Log Reference (IP88S36-S008)

Details of supported MIBs IP8800/S3600 Software Manual

MIB Reference (IP88S36-S009)

lnformation on troubleshooting IP8800/S6700, IP8800/S6600, IP8800/S6300,

IP8800/S3600, IP8800/S2400

Troubleshooting Guide (IP88S36-T001)

Introduction

III

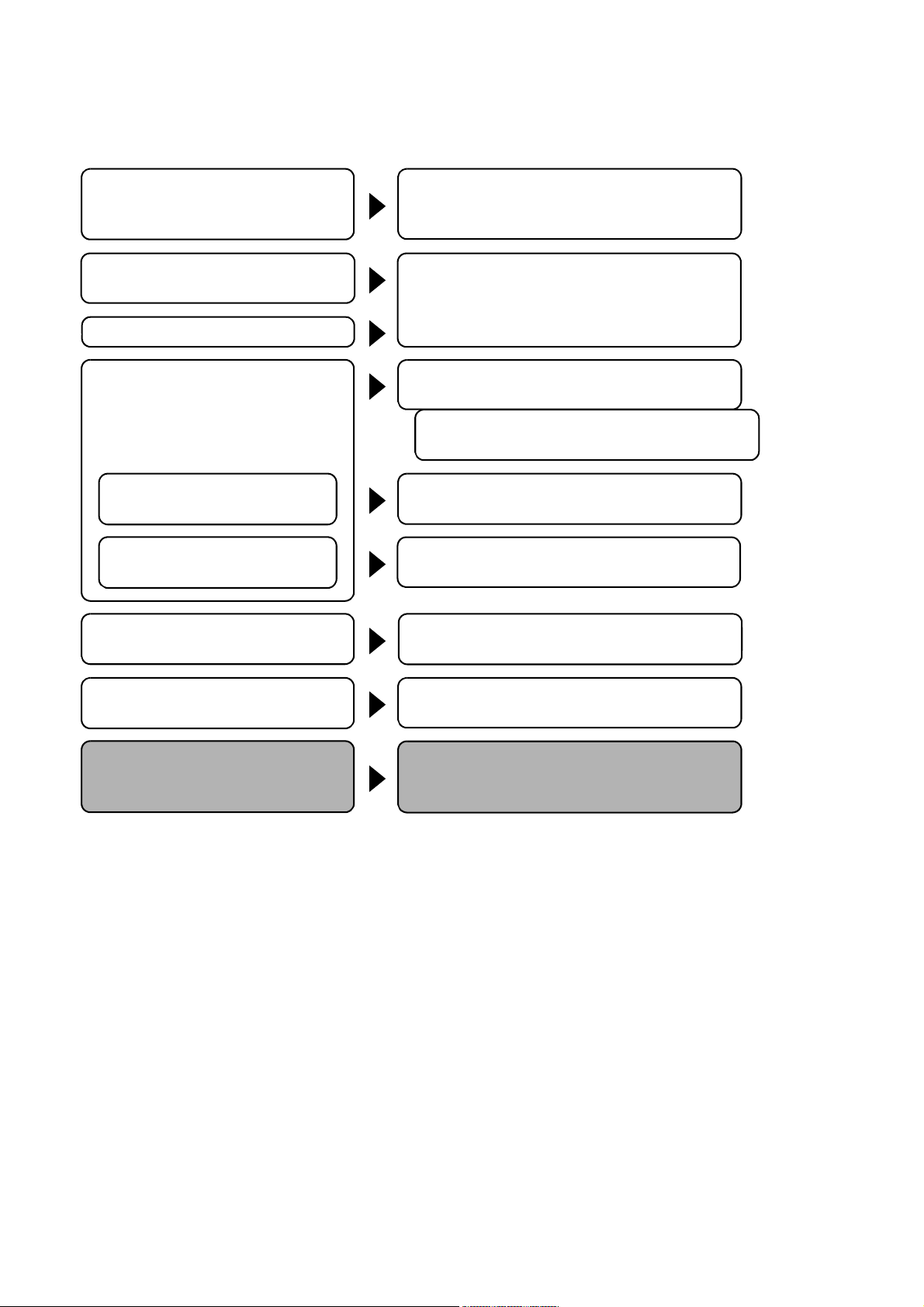

Introduction

Procedures from unpacking the product

to making basic settings at the initial

installation

IP8800/S3600, IP8800/S2400

Quick Start Guide (IP88S36-Q001)

Information on the facility requirement of

the hardware

IP8800/S3600, IP8800/S2400

Hardware Installation Guide (IP88S36-H001)

Information on handling of the hardware

Information on software functions,

configuration, and confirmation by using

operation commands

IP8800/S2400 Software Manual

Configuration Settings, Vol.1 (IP88S24-S001)

IP8800/S2400 Software Manual

Configuration Settings, Vol.2 (IP88S24-S002)

Syntax and parameter details of

configuration commands

IP8800/S2400 Software Manual

Configuration Commands (IP88S24-S003)

Syntax and parameter details of

operation commands

IP8800/S2400 Software Manual

Operation Commands (IP88S24-S004)

Details of operation messages and logs IP8800/S2400 Software Manual

Message Log Reference (IP88S24-S005)

Details of supported MIBs IP8800/S2400 Software Manual

MIB Reference (IP88S24-S006)

Information on troubleshooting IP8800/S6700, IP8800/S6600, IP8800/S6300,

IP8800/S3600, IP8800/S2400

Troubleshooting Guide (IP88S36-T001)

For IP8800/S2400

■ Conventions: abbreviations

AC Alternating Current

ACK ACKnowledge

ADSL Asymmetric Digital Subscriber Line

ALG Application Level Gateway

ANSI American National Standards Institute

ARP Address Resolution Protocol

AS Autonomous System

AUX Auxiliary

BCU Basic Control Unit

BGP Border Gateway Protocol

BGP4 Border Gateway Protocol - version 4

BGP4+ Multiprotocol Extensions for Border Gateway

bit/s bits per second *Usually, abbreviated as bps.

BPDU Bridge Protocol Data Unit

BRI Basic Rate Interface

BSU Basic Switching Unit

CC Continuity Check

CDP Cisco Discovery Protocol

CFM Connectivity Fault Management

CIDR Classless Inter-Domain Routing

Protocol - version 4

IV

Introduction

CIR Committed Information Rate

CIST Common and Internal Spanning Tree

CLNP ConnectionLess Network Protocol

CLNS ConnectionLess Network System

CONS Connection Oriented Network System

CRC Cyclic Redundancy Check

CSMA/CD Carrier Sense Multiple Access with Collision

Detection

CSNP Complete Sequence Numbers PDU

CST Common Spanning Tree

CSU Control and Switching Unit

DA Destination Address

DC Direct Current

DCE Data Circuit terminating Equipment

DHCP Dynamic Host Configuration Protocol

DIS Draft International Standard/Designated

Intermediate System

DNS Domain Name System

DR Designated Router

DSAP Destination Service Access Point

DSCP Differentiated Services Code Point

DTE Data Terminal Equipment

DVMRP Distance Vector Multicast Routing Protocol

E-Mail Electronic Mail

EAP Extensible Authentication Protocol

EAPOL EAP Over LAN

EFM Ethernet in the First Mile

ES End System

FAN Fan Unit

FCS Frame Check Sequence

FDB Filtering DataBase

FQDN Fully Qualified Domain Name

FTTH Fiber To The Home

GBIC GigaBit Interface Converter

GSRP Gigabit Switch Redundancy Protocol

HMAC Keyed-Hashing for Message Authentication

IANA Internet Assigned Numbers Authority

ICMP Internet Control Message Protocol

ICMPv6 Internet Control Message Protocol version 6

ID Identifier

IEC International Electrotechnical Commission

IEEE Institute of Electrical and Electronics

Engineers, Inc.

IETF the Internet Engineering Task Force

IGMP Internet Group Management Protocol

IP Internet Protocol

IPCP IP Control Protocol

IPv4 Internet Protocol version 4

IPv6 Internet Protocol version 6

IPV6CP IP Version 6 Control Protocol

IPX Internetwork Packet Exchange

ISO International Organization for Standardization

ISP Internet Service Provider

IST Internal Spanning Tree

L2LD Layer 2 Loop Detection

LAN Local Area Network

LCP Link Control Protocol

LED Light Emitting Diode

LLC Logical Link Control

LLDP Link Layer Discovery Protocol

LLPQ Low Latency Priority Queueing

LLQ+3WFQ Low Latency Queueing + 3 Weighted Fair Queueing

LLRLQ Low Latency Rate Limited Queueing

LSP Label Switched Path

LSP Link State PDU

LSR Label Switched Router

MA Maintenance Association

MAC Media Access Control

MC Memory Card

MD5 Message Digest 5

MDI Medium Dependent Interface

MDI-X Medium Dependent Interface crossover

MEP Maintenance association End Point

MIB Management Information Base

V

Introduction

MIP Maintenance domain Intermediate Point

MRU Maximum Receive Unit

MSTI Multiple Spanning Tree Instance

MSTP Multiple Spanning Tree Protocol

MSU Management and Switching Unit

MTU Maximum Transfer Unit

NAK Not AcKnowledge

NAS Network Access Server

NAT Network Address Translation

NCP Network Control Protocol

NDP Neighbor Discovery Protocol

NET Network Entity Title

NIF Network Interface

NLA ID Next-Level Aggregation Identifier

NPDU Network Protocol Data Unit

NSAP Network Service Access Point

NSSA Not So Stubby Area

NTP Network Time Protocol

OADP Octpower Auto Discovery Protocol

OAM Operations,Administration,and Maintenance

OSPF Open Shortest Path First

OUI Organizationally Unique Identifier

PAD PADding

PAE Port Access Entity

PC Personal Computer

PCI Protocol Control Information

PDU Protocol Data Unit

PICS Protocol Implementation Conformance Statement

PID Protocol IDentifier

PIM Protocol Independent Multicast

PIM-DM Protocol Independent Multicast-Dense Mode

PIM-SM Protocol Independent Multicast-Sparse Mode

PIM-SSM Protocol Independent Multicast-Source Specific

Multicast

PoE Power over Ethernet

PRI Primary Rate Interface

PS Power Supply

PSNP Partial Sequence Numbers PDU

PSP Packet Switching Processor

QoS Quality of Service

RA Router Advertisement

RADIUS Remote Authentication Dial In User Service

RDI Remote Defect Indication

REJ REJect

RFC Request For Comments

RGQ Rate Guaranteed Queueing

RIP Routing Information Protocol

RIPng Routing Information Protocol next generation

RMON Remote Network Monitoring MIB

RPF Reverse Path Forwarding

RQ ReQuest

RSTP Rapid Spanning Tree Protocol

SA Source Address

SD Secure Digital

SDH Synchronous Digital Hierarchy

SDU Service Data Unit

SEL NSAP SELector

SFD Start Frame Delimiter

SFP Small Form factor Pluggable

SMTP Simple Mail Transfer Protocol

SNAP Sub-Network Access Protocol

SNMP Simple Network Management Protocol

SNP Sequence Numbers PDU

SNPA Subnetwork Point of Attachment

SOP System Operational Panel

SPF Shortest Path First

SSAP Source Service Access Point

STP Spanning Tree Protocol

TA Terminal Adapter

TACACS+ Terminal Access Controller Access Control System

Plus

TCP/IP Transmission Control Protocol/Internet Protocol

TLA ID Top-Level Aggregation Identifier

TLV Type, Length, and Value

VI

Introduction

TOS Type Of Service

TPID Tag Protocol Identifier

TTL Time To Live

UDLD Uni-Directional Link Detection

UDP User Datagram Protocol

UPC Usage Parameter Control

UPC-RED Usage Parameter Control - Random Early Detection

uRPF unicast Reverse Path Forwarding

VAA VLAN Access Agent

VLAN Virtual LAN

VPN Virtual Private Network

VRF Virtual Routing and Forwarding/Virtual Routing

VRRP Virtual Router Redundancy Protocol

WAN Wide Area Network

WDM Wavelength Division Multiplexing

WFQ Weighted Fair Queueing

WGQ Weighted Guaranteed Queueing

WRED Weighted Random Early Detection

WS Work Station

WWW World-Wide Web

XFP 10 gigabit small Form factor Pluggable

and Forwarding Instance

■ Conventions: kB, MB, GB, and TB

1 kB(kilobytes), 1 MB(megabytes), 1 GB(gigabytes), and 1 TB(terabytes) indicate 1024 bytes, 10242 bytes, 10243 bytes, and

4

bytes respectively.

1024

VII

Contents

Introduction I

Safety Guide [IP8800/S6700] v

Safety Guide [IP8800/S6600] xvii

Safety Guide [IP8800/S6300] xxix

Safety Guide [IP8800/S3600] [IP8800/S2400] xli

1 Overview 1

1.1 Failure Analysis Overview 2

1.2 System and Partial Failure Analysis Overview 3

1.2.1 Failure Analysis for IP8800/S6700, IP8800/S6600, and IP8800/S6300 3

1.2.2 Failure Analysis for IP8800/S3600 and IP8800/S2400 4

1.3 Functional Failure Analysis Overview 7

2 Troubleshooting System Failures 11

2.1 Troubleshooting for IP8800/S6700, IP8800/S6600, and IP8800/S6300 12

2.1.1 Troubleshooting Procedure on System Failures 12

2.1.2 Replacement Method of Optional Components 14

2.2 Troubleshooting for IP8800/S3600 and IP8800/S2400 15

2.2.1 Troubleshooting Procedure on System Failures 15

2.2.2 Isolating Failures on External Power Unit 17

2.2.3 Replacement Method of System and Optional Components 18

3 Troubleshooting Functional Failures in Operation 19

3.1 Problems on Login Password 21

3.1.1 Forgot the Login User Password 21

3.1.2 Forgot the System Administrator Password 21

3.2 Problems on MC 22

3.2.1 "MC:--------" is displayed by entering the show system command or the show mc command 22

3.2.2 "MC not found" is displayed when MC is accessed 22

3.3 Problems on Operation Terminal 23

3.3.1 Unable to Input/Display from the Console Correctly 23

3.3.2 Login from the Remote Operation Terminal Is Failed 24

3.3.3 Login Authentication Using RADIUS/TACACS+ Is Disabled 25

3.3.4 Command Authorization Using RADIUS/TACACS+ Is Disabled 25

i

Contents

3.4 Network Interface Communication Failure 27

3.4.1 Ethernet Port Cannot Be Connected 27

3.4.2 Communication Failure in Basic Switching Unit BSU/PSP 29

3.4.3 Actions against Troubles on 10BASE-T/100BASE-TX/1000BASE-T 30

3.4.4 Actions against Troubles on 1000BASE-X 32

3.4.5 Actions against Troubles on 10GBASE-R 33

3.4.6 Communication Failure on Using PoE 35

3.4.7 Communication Failure on Using Link Aggregation 36

3.5 Layer 2 Network Communication Failure 38

3.5.1 Layer 2 Communication by VLAN Is Disabled 38

3.5.2 Failures on Using Spanning Tree 40

3.5.3 Failures on Using Ring Protocol 41

3.5.4 Multicast Relay by IGMP snooping Is Disabled 44

3.5.5 Multicast Relay by MLD snooping Is Disabled 47

3.6 IPv4 Network Communication Failure 50

3.6.1 Communication Is Disabled or Is Disconnected 50

3.6.2 IP Addresses Cannot Be Assigned Using DHCP Function 54

3.6.3 DynamicDNS Cooperation in DHCP Function Is Disabled 58

3.7 IPv4 Unicast Routing Communication Failure 61

3.7.1 No RIP Routing Information Exists 61

3.7.2 No OSPF Routing Information Exists 61

3.7.3 No BGP4 Routing Information Exists 62

3.7.4 No Routing Information Exist [OP-NPAR] 62

3.8 IPv4 Multicast Routing Communication Failure 63

3.8.1 Communication on IPv4 PIM-SM Network Is Disabled 63

3.8.2 Multicast Data Is Double-relayed on IPv4 PIM-SM Network 66

3.8.3 Communication on IPv4 PIM-SSM Network Is Disabled 67

3.8.4 Multicast Data Is Double-relayed on IPv4 PIM-SSM Network 69

3.8.5 IPv4 Multicast Communication Failure In VRF [OP-NPAR] 70

3.9 IPv6 Network Communication Failure 71

3.9.1 Communication Is Disabled or Is Disconnected 71

3.9.2 IPv6 DHCP Troubleshooting 73

3.10 IPv6 Unicast Routing Communication Failure 79

3.10.1 No RIPng Routing Information Exists 79

3.10.2 No OSPFv3 Routing Information Exists 79

3.10.3 No BGP4+ Routing Information Exists 80

3.11 IPv6 Multicast Routing Communication Failure 81

3.11.1 Communication on IPv6 PIM-SM Network Is Disabled 81

3.11.2 Multicast Data Is Double-relayed on IPv6 PIM-SM Network 84

3.11.3 Communication on IPv6 PIM-SSM Network Is Disabled 85

3.11.4 Multicast Data Is Double-relayed on IPv6 PIM-SSM Network 87

3.12 Layer 2 Authentication Communication Failure 89

3.12.1 Communication Failure on Using IEEE 802.1X 89

3.12.2 Communication Failure on Using Web Authentication 92

3.12.3 Communication Failure on Using MAC Authentication 97

3.12.4 Communication Failure on Using Authentication VLAN [OP-VAA] 99

ii

Contents

3.13 Communication Failure on High-reliability Function 103

3.13.1 GSRP Communication Failures 103

3.13.2 Communication with VRRP Configuration in IPv4 Network Is Disabled 105

3.13.3 Communication with VRRP Configuration in IPv6 Network Is Disabled 107

3.14 SNMP Communication Failure 110

3.14.1 MIBs Cannot Be Obtained from SNMP Manager 110

3.14.2 Traps Cannot Be Received by SNMP Manager 110

3.15 Troubleshooting of sFlow Statistics (Flow Statistics) Function 112

3.15.1 sFlow Packets Do Not Reach Collector 112

3.15.2 Flow Sample Does Not Reach Collector 115

3.15.3 Counter Sample Does Not Reach Collector 115

3.16 Communication Failures on Neighboring System Managing Function 116

3.16.1 Unable to Obtain Neighboring System Information via LLDP Function 116

3.16.2 Unable to Obtain Neighboring System Information via OADP Function 116

3.17 NTP Communication Failure 118

3.17.1 Time Synchronization by NTP Is Disabled 118

3.18 Communication Failure on IEEE802.3ah/UDLD Function 119

3.18.1 Port Becomes Inactive Due to IEEE802.3ah/UDLD Function 119

3.19 Problems on Redundant Configuration of Basic Control Unit (BCU)/Control and Switching Unit (CSU)/

Management and Switching Unit (MSU) [IP8800/S6700] [IP8800/S6600] [IP8800/S6300] 120

3.19.1 Active System Switchover Is Disabled 120

3.20 Problems on Redundant Configuration of Basic Switching Unit (BSU) [IP8800/S6700] 121

3.20.1 Active BSU Switchover Is Disabled 121

3.21 Problems on Power Saving Feature 123

3.21.1 Schedule Is Disabled [IP8800/S6700] [IP8800/S6600] 123

3.22 Congestion Caused by Packets Processed Through CPU Is Not Recovered 124

3.23 Communication Failure Caused by Settings of Filtering/QoS 126

3.23.1 Checking Filtering/QoS Setting Information 126

4 Troubleshooting Communication Failures Due to Resource Shortage [IP8800/S6700]

[IP8800/S6600] [IP8800/S6300] 129

4.1 MAC Address Table Resource Shortage 130

4.1.1 Checking Resource Usage of MAC Address Table 130

4.1.2 Action to Be Taken When MAC Address Table Resource Shortage Occurs 130

4.2 When Resource Shortage of VLAN Identification Table Occurs 133

4.2.1 Checking VLAN Identification Table Resource Usage 133

4.2.2 Action to Be Taken When VLAN Identification Table Resource Shortage Occurs 133

4.3 When Resource Shortage Occurs in Shared Memory 135

4.3.1 Checking Resource Usage of Shared Memory 135

4.3.2 Action to Be Taken When Resource Shortage of Shared Memory Occurs 135

5 Collecting Failure Information 137

5.1 Collecting Failure Information 138

5.1.1 Collecting Failure Information Using ftp Command from the Operation Terminal 138

iii

Contents

5.1.2 Collecting Failure Information Using dump Command [IP8800/S6700] [IP8800/S6600]

[IP8800/S6300] 140

5.2 Transferring Files for Maintenance Information 144

5.2.1 Transferring Files Using ftp Command 145

5.2.2 Transferring Files Using zmodem Command [IP8800/S3600] [IP8800/S2400] 148

5.2.3 Transferring Maintenance Information Files Using show tech-support Command 148

5.2.4 Transferring Files Using ftp Command from the Operation Terminal 150

5.3 Writing to MC 152

5.3.1 Writing File to MC Using Operation Terminal 152

6 Line Test 153

6.1 Testing Line 154

6.1.1 Ethernet Port 154

7 Restarting the System 159

7.1 Restarting the System 160

7.1.1 Restarting the System 160

Appendix 165

Appendix A Contents of show tech-support Command Display 166

Appnedix A.1 Contents of show tech-support Command Display 166

Index 187

iv

Safety Guide [IP8800/S6700]

■ Safety guide for the IP8800/S6700 series

• This document provides safety-related notices for use of the IP8800/S6700 series. To utilize the functions

of this device, read this document completely and carefully before using the device.

• Keep this document at hand after you read it, so that you can always refer it later.

• For any operation, follow the directions and procedures given by this document.

• Observe the cautions labeled on the device or those presented by this document. If you fail to do so, you

will cause damage to yourself or the device.

■ Symbols

• We have various symbols displayed on the IP8800/S6700 series and in the manuals to guide you in using

the IP8800/S6700 series correctly and safely without injuring yourself and others, or damaging equipment

assets. Below are the symbols and their meanings. Fully understand the description and then proceed with

reading the main part of the manual.

If you ignore instructions preceded by this symbol, you could cause personal injury or

WARNING

death to yourself and others.

If you ignore instructions preceded by this symbol, you could cause personal injury to

CAUTION

CAUTION

NOTE

yourself and others, or serious damage to the device or surroundings.

If you ignore instructions preceded by this symbol, you could cause physical damage

to the device or surroundings.

A note is informational in nature. Unlike warning and caution notices, notes (for

prevention of malfunction, prevention of product minor damages) are not related to the

physical injury or damage to the device.

■ Operations and actions

• Do not attempt to perform any operations not specifically described in this document.

In case of a problem on the device, contact the maintenance personnel after performing the following.

• For the device with AC power supply mounted, power off the device and unplug the power cable from the outlet.

• For the device with DC power supply mounted, power off the device and turn off the breaker in the power supply

equipment.

■ Be careful in operation

• The instructions shown on the device or in this manual are the results of our thorough consideration.

However, an unexpected situation may occur. For operations, not only follow the instructions but also

always be careful with your judge.

v

Safety Guide [IP8800/S6700]

WARNING

■ In case a failure should occur, power off the device immediately.

• In case fume or unusual odor should occur, or foreign matters should come into the device, power off the

device as follows. If the device is used in a faulty state, fire disasters or electric shock may be caused.

• For the device with AC power supply mounted, power off the device and unplug the power cable from the

outlet.

• For the device with DC power supply mounted, power off the device and turn off the breaker in the power

supply equipment because the power cable is connected via a terminal.

■ Do not place the device in an unstable location.

• If the device is being placed on a table, be sure to install it horizontally on a workbench or the like that can

sufficiently bear the weight of the device. If the device is placed on an unstable location such on a shaky

table or slope, the device may fall and drop and consequently personal injury may occur.

■ Do not remove the device cover.

• Do not remove the device cover. Electric shock may be caused.

■ Do not put foreign matters in the device.

• Do not insert or drop metals or combustibles into the device through the intake/exhaust port. Fire disasters

or electric shock may be caused.

■ Modification is not permissible.

• Device modification is not permissible. Fire disasters or electric shock may be caused.

■ Do not give a shock.

• In case the device is dropped or parts are damaged, power off the device, pull the cable out of the outlet,

and call the maintenance engineer. Otherwise it can cause a fire or electric shock.

■ Do not put any material on the device.

• Do not put a metal such as pin or clip or a container with water in it such as vase or flower pot on the device.

Fire disasters or electric shock may be caused.

■ Do not use power not specified.

• Do not use a supply voltage not specified. Fire disasters or electric shock may be caused.

■ The current capacity supplied to the power distribution panel must be larger than the

operating current of the breaker.

• The current capacity supplied to the power distribution panel must be larger than the operating current of

the breaker. Otherwise, the breaker may not work in the event of a failure and cause fire disasters.

vi

Safety Guide [IP8800/S6700]

■ Grounding is required.

• When the device is connected to the power supply of 100VAC, leak current of up to 3.5mA flows for each

device. Be sure to use the grounded outlet. If the power supply is used without grounding, an electric shock

may be caused and failures may occur due to electric noise.

• When the device is connected to the power supply of 200VAC, leak current of up to 5mA flows for each

device. Choose a grounded outlet and make sure that the outlet is grounded to a ground plate in the

building. Request the maintenance personnel or specialized installation workers to check the grounding. If

the power supply is used without grounding, an electric shock may be caused and failures may occur due

to electric noise. The label below is attached to the device.

• When the device is connected to the DC power supply, be sure to connect the grounding terminal. If the

power supply is used without grounding, an electric shock may be caused and failures may occur due to

electric noise.

■ Installing/uninstalling of the DC power cable must be performed by the trained

engineer or maintenance personnel.

• Installing/uninstalling of the DC power cable must be performed by the trained engineer or maintenance

personnel. DC power cable is connected to the power supply via a terminal. Therefore, inadvertent

handling of the DC power cable may result in fire disasters or electric shock.

■ Before installing or removing a DC power cable, turn off the breaker on power supply

facilities.

• Before installing or removing a DC power cable, turn off the breaker on power supply facilities. Operation

with the breaker on may cause electric shock.

■ Attach insulation covers on the 0V and -48V terminals of a DC power cable.

• Attach insulation covers on the 0V and -48V terminals of a DC power cable (the side of which connects to

power supply facilities). Operation without insulation covers may cause electric shock.

■ When using the DC power supply, do not leave the terminal board uncovered.

• When using the DC power supply, be sure to attach the cover to the terminal board after connecting the

power cable. Operating it without the terminal board cover can cause an electric shock.

■ Do not touch the potential tap.

• The power supply is provided with the potential tap. This tap is used for inspection at shipment. Customer

should not use this tap. Do not insert a sharp material such as pin or clip into the potential tap. Fire disasters

or electric shock may be caused.

vii

Safety Guide [IP8800/S6700]

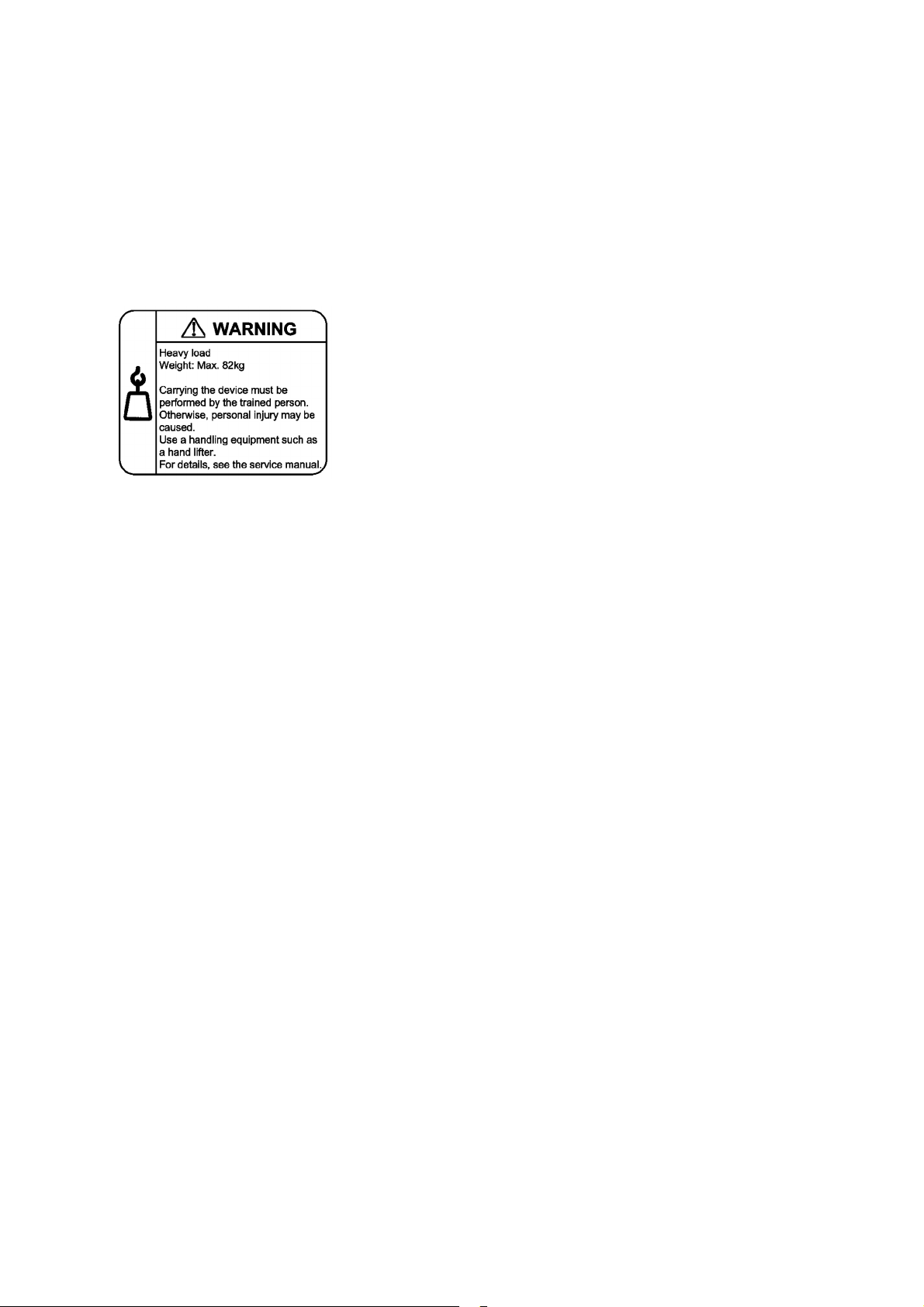

■ The device must be carried and installed by the trained personnel or specialized

carrier.

• The weight of the device is 82 kg/182 lb at the maximum. The device must be carried and installed by the

trained personnel or specialized carrier. Otherwise, a personal injury due to drop or fall may be caused.

For installation and carrying of the device, use a handling equipment such as a hand lifter. Otherwise, a

personal injury due to drop or fall may be caused. The label below is attached to the device.

■ Handle the power cable with caution.

• Do not put a heavy material on the power cable or do not pull, bend, or modify the power cable. The power

cable will be damaged and fire disasters or electric shock may be caused. A heavy material may be placed

as a result of covering the cable with a floor carpet.

• Use the attached power cable or the power cable complying with the specifications. If any other cable is

used, fire disasters or electric shock may be caused. Do not use the attached power cable for other

purposes. In such a case, fire disasters or electric shock may be caused.

• If the power cable is degraded (e.g., wire cores exposed or broken), ask the service personnel for

replacement. Otherwise it can cause a fire or electric shock.

• Check to see if dust is deposited on the power plug. Insert the plug securely to the end so that shakiness

will not occur. If dust is deposited or connection is incomplete, fire disasters or electric shock may be

caused.

■ Do not plug too many leads into a single outlet.

• Do not plug too many power plugs into a single outlet. Many loads on an electrical outlet may result in fire

disasters and the electric energy in use may be exceeded, the breaker may go off, and other components

may be affected.

viii

Safety Guide [IP8800/S6700]

■ Before powering off, turn off all power switches or breakers on the device.

• Multiple input power supplies are provided to the device. Before powering off, turn off all power switches

(when AC power supply is mounted) or breakers (when DC power supply is mounted) on the device. The

label below is attached to the device.

■ Work to add or replace equipment must be performed by a trained engineer or

maintenance personnel.

• To add or replace optional components must be performed by a trained engineer or maintenance

personnel. To add or replace a power supply involves to plug and unplug power cables; a person other than

the preceding ones may fail to handle things, which can cause fire disaster, electric shock, and equipment

failure. Other optional components, if handled mistakenly, can also cause fire disaster, wounds, and

equipment failure.

■ Do not press the switch on the basic control unit with a fragile tip, pin, or clip that may

get stuck and cannot be removed.

• Do not press the switch on the front panel of the basic control unit with a fragile tip, pin, or clip that may get

stuck and cannot be removed. Fire disasters or electric shock may be caused.

■ Before addition or replacement of the power supply, unplug the power cable.

• Remove the power cable from the power supply when adding or replacing it. With the power cable

connected, the power supply equipment may remain energized from some circuits even the power switch

is turned off. Therefore, adding or replacing the power supply with the power cable connected may cause

a fire or electric shock.

■ Keep air dusters away from fire.

• If you use an air duster with combustible gas to clean the optical connector, keep away from fire. Otherwise,

fire disaster may occur.

ix

Safety Guide [IP8800/S6700]

CAUTION

■ Do not install the device in a humid or dusty environment.

• Do not install the device in a humid or dusty environment. Fire disasters or electric shock may be caused.

• Moving the device from a cold place to a warm place may form condensation on the surface or internal of

the device. If the device is operated immediately a fire or electric shock can be caused. Thus, in this case,

leave the device as it is for several hours before starting operation.

■ Do not stack the devices.

• Do not stack the devices. The device may be damaged. The device may be damaged or lose its balance

and fall or drop. As a result, personal injury may occur.

■ Do not recline on the device, or place a heavy loading on it.

• Do not ride on or cling to the device or do not put a heavy material on it. The device may be damaged. The

device may be damaged or lose its balance and fall or drop. As a result, personal injury may occur.

■ When installing the device on the rack, use the guide rail or shelf.

• The rack mounting bracket supplied with this device is used to fasten the device on the rack but not to

support the weight of the device. Be sure to use the guide rail or shelf. The guide rail or shelf must be the

one attached to the rack and capable of supporting the weight of the fully mounted switch.

■ Do not block the intake and/or exhaust port.

• Do not block the intake/exhaust port of the device. Blocking the intake/exhaust port keeps heat inside and

fire disasters may be caused. Keep a space of at least 70mm from the intake/exhaust port.

■ Do not bring hairs or any foreign matters close to the intake/exhaust port of the

device.

• The cooling fan unit is provided on the device. Do not put any material close to the intake/exhaust port. The

internal temperature rise may result in a failure. Do not put hair or any material close to the intake/exhaust

port. You may be caught and injured.

■ When moving an optional component, do not carry it by holding its handle.

• When moving a fan unit or power supply, do not hold its handle. The handle may come off and the device

may drop. As a result, a personal injury may occur. Or the fan unit or power supply may be deformed that

may cause a fire or electric shock.

■ Before carrying the device, remove the cables.

• When moving the device, power off the device, remove all the cables from the device, and then move the

device. Otherwise the device or cable may be deformed or damaged. As a result, fire disasters or electric

shock may be caused.

x

Safety Guide [IP8800/S6700]

■ Do not drop an optional component.

• Handle the optional component carefully not to drop it. If dropped, personal injury may be caused.

• The weight and depth of the DC power supply are 5.6 kg/12.4 lb and 163 mm/6.4 in respectively. When

removing the DC power supply, hold it securely. If pulling it forward carelessly, it may drop and cause a

personal injury. The label below is attached to the DC power supply.

■ Do not touch the inside of the device.

• Do not put your hand inadvertently inside the device. Mechanical parts may cause a personal injury.

■ The basic control unit and network interface component may be hot. Be careful when

removing them.

• Parts mounted on the basic control unit and network interface component may be hot: Do not touch them

to prevent getting burned.

■ When removing the fan unit, do not put your hand close to the rotating fan.

• The fan may still be rotating immediately after the removal of the fan unit. While the fan is rotating, do not

put your hand or finger close to it. Personal injury may be caused. The label below is attached to the fan

unit.

■ Do not roughly handle the power cable.

• Do not put the power cable close to the heating apparatus. The cable sheath may be melted and fire

disasters or electric shock may be caused.

• When inserting the power cable into the outlet or removing from it, be sure to hold the cable plug. Pulling

up the cable with the cable grasped, the wire can be broken.

■ Do not touch the device directly if you have metal allergies.

• This device is coated with metals including zinc, nickel, and gold. If you have allergies to them, do not touch

the device directly to prevent getting dermatitis.

xi

Safety Guide [IP8800/S6700]

Caution. Hot! (all sides)

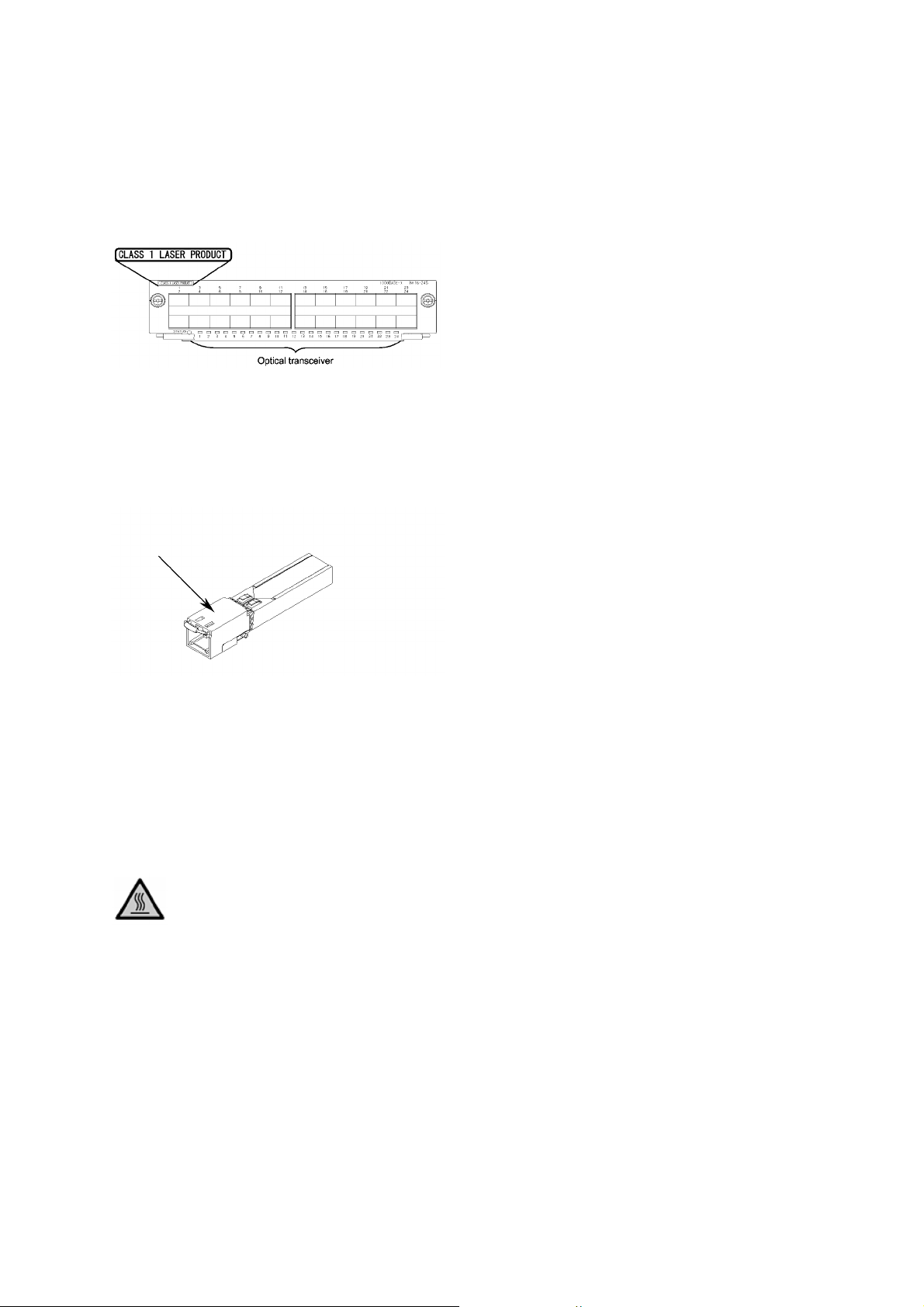

■ Be careful of laser beams.

• The network interface module as indicated below uses laser beams. Do not peep in the optical transceiver

directly.

■ Do not touch a working (including immediately after stopping) SFP-T.

• A working (establishing a link) SFT-P can have up to 65 °C/140 °F in temperature. Do not touch it when

working or immediately after stopping to prevent getting burned.

• To remove an SFP-T, follow the following procedures. Otherwise, you may get burned.

• To remove an SFP-T without turning off the device, execute the inactivate command, and remove the SFP-T

five minutes later.

• To remove an SFP-T from the device turned off, power off the switch of the device, and remove the SFP-T five

minutes later.

• An SFP-T has the following label attached.

■ Lithium battery

• This device mounts a lithium battery for the real-time clock. If the lithium battery is inadvertently handled,

a personal injury or fire may be caused as a result of heat generation, burst, or ignition. Do not remove the

lithium battery from the device or disassemble it, heat it to 100

water.

■ Cleaning

• Remove dust on and around the device on a regular basis. Device shutdown and fire disasters or electric

shock may be caused.

°C/212 °F or higher, burn it, or wet it with

xii

Safety Guide [IP8800/S6700]

CAUTION

■ Do not power off the device during software update (when the ppupdate command

is being executed).

• By the execution of the ppupdate command, the device automatically restarts. Do not power off the device

during restart (until the STATUS LED on the basic control unit changes from blinking in green into steady

light). The device may be damaged.

■ Handle a memory card with care.

• Do not forcedly push or flip a memory card to insert. Do not forcedly pull out a locked memory card to

remove. Otherwise, the connector of the memory card slot may be damaged.

• Remove the memory card to reposition the device. Moving the device may cause force against the memory

card, which can damage the connector of the memory card slot.

■ Do not remove the memory card or disconnect power while the ACC LED is lit.

• Lighting of the ACC LED on the basic control unit indicates that the memory card is being accessed. Do

not remove the memory card or disconnect power during access. The memory card may be damaged.

Some commands require a considerable time before completing access to the memory card after the entry

of the commands. Ensure that access is completed and then remove the memory card or disconnect

power.

■ Do not attach a label or the like to the transceivers.

• The transceiver has a label indicating its manufacturer and that it is our standard supply. However, this label

is attached to the part that does not obstruct heat radiation from the transceiver or the mechanism

preventing slip-off from the cage. If a label or the like is attached to such an obstructing part, the transceiver

or the network interface module may be damaged.

■ For the power supply equipment, considerations must be given not to cause voltage

drop due to rush current.

• When this device is powered on, a rush current flows. Considerations must be given not to cause voltage

drop due to such a rush current. The voltage drop affects not only this device but other devices connected

to the same power supply equipment.

■ When installing/uninstalling the power cable, turn off the power switch.

• To install or uninstall the power cable, turn off the switch on the power supply to be installed or uninstalled.

■ When replacing the fan unit while the device powered on, complete the task within

the specified duration of time.

• When replacing the fan unit while the device powered on, complete the entire task from removal to

installation within one minute. If it takes more than one minute, other modules may be affected by

temperature rise in the device.

xiii

Safety Guide [IP8800/S6700]

■ For carrying or packaging the device and optional component, use an antistatic wrist

strap.

• Use an antistatic wrist strap. If you handle the device without the antistatic wrist strap, the device can be

damaged by the static electricity.

■ After removing an optional component, be sure to attach a blank panel.

• After removing an optional component, be sure to attach a blank panel. Using the device without the blank

panel attached, the air flow in the device cannot be maintained. In such a case, the temperature rise inside

the device may cause a failure.

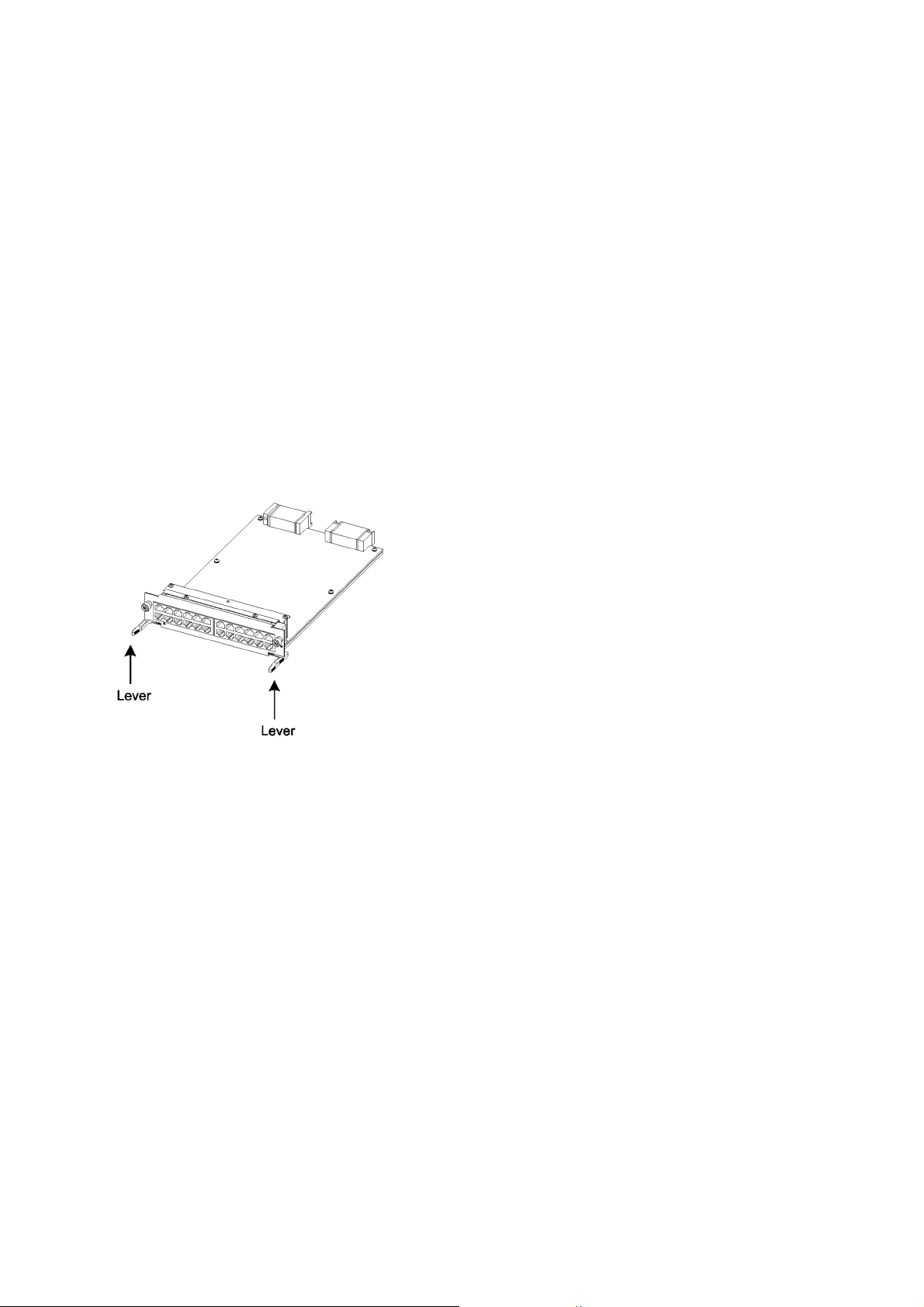

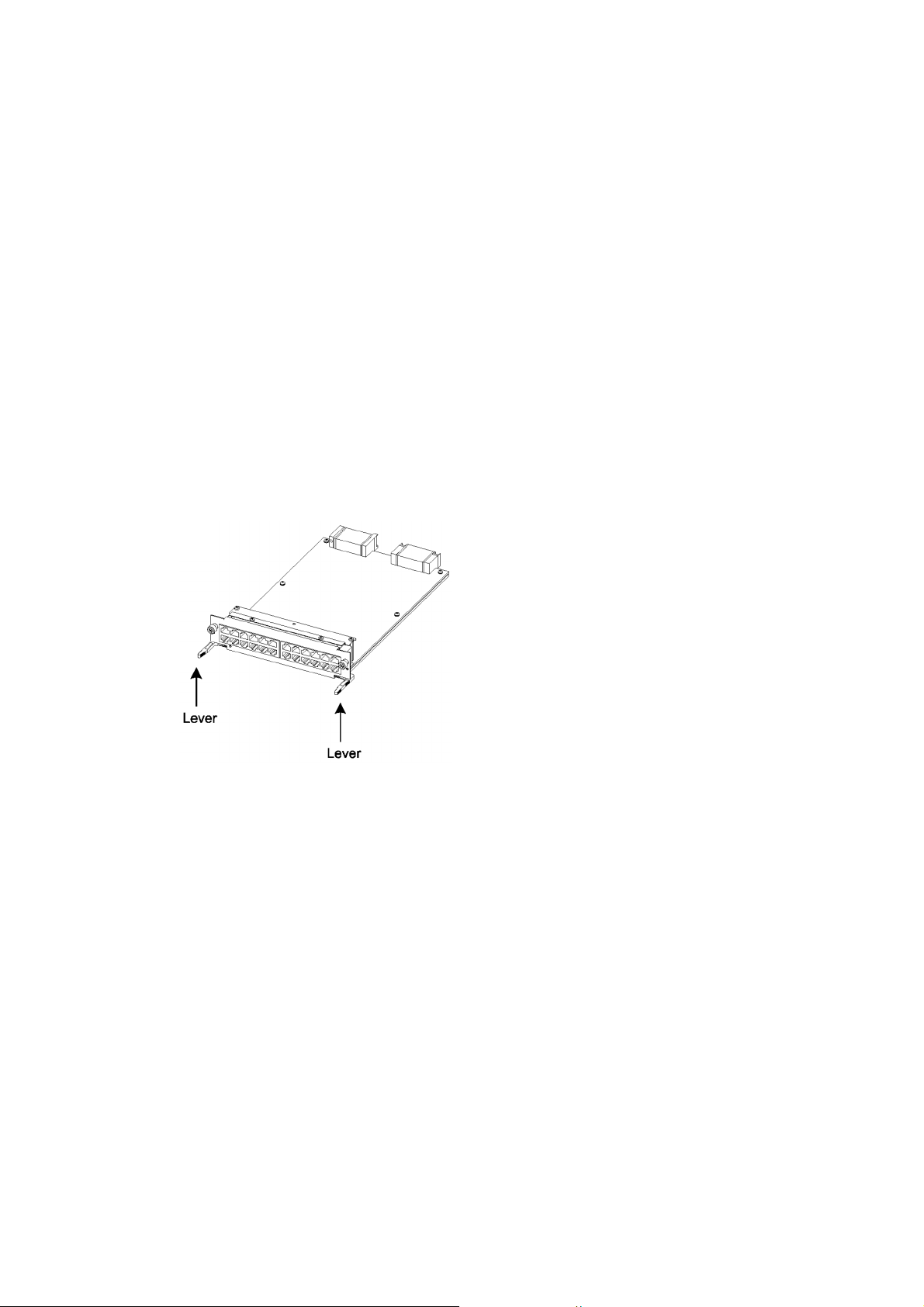

■ Attach an option component with care.

• Follow the following procedures to attach an option component. Otherwise, a problem may occur on the

device.

1. Open the levers as the figure below.

2. With the levers in hands, push the component slowly into the device, to the point where the levers touch the device.

3. Use the levers to insert the component all the way. Move the levers slowly (taking more than one second) but not forcedly.

■ Before removing an optional component, loosen the screws completely.

• Use levers to remove the basic control unit, basic switching unit or network interface module. If screws are

not completely loosened, the optional component may be damaged when the levers are pressed down.

■ When carrying or packing an optional component, take care for handling.

• Take care not to handle the connector when carrying or packing optional components such as the basic

control unit, basic switching unit, network interface module, memory card, transceiver, and power supply.

They must be stored in antistatic bags when they are not in use.

■ Do not install the device in any place possibly reaching a high temperature.

• Be careful that the parts may be damaged if left in a place exposed to direct sunlight or close to a heating

apparatus.

xiv

Safety Guide [IP8800/S6700]

■ Do not bring a TV or radio close to the device.

• Leaving a TV or radio close to the device can adversely influence to each other. If a TV or radio interferes

the device, remedy as follows:

1. Keep the device from the television or radio set as far away as possible.

2. Change the direction of the antenna for the television or radio set.

3. Use different outlets.

■ Keep the device away from a place with hydrogen sulfide or much salt.

• Places with hydrogen sulfide including hot spring resorts, and places with much salt including coasts may

shorten lifetime of the device.

■ Use air dusters with care.

• Choose an air duster designated to clean optical connectors. Other air dusters may get the end face of the

ferrule dirty.

• Avoid the nozzle or container of an air duster from touching the end face of the ferrule. Otherwise, the

ferrule may be damaged.

■ Handle the optical connector with care.

• Use the designated optical connector cleaner. Other optical connector cleaners may get the end face of

the ferrule dirty.

• Make sure of no problems on the head part of an optical connector cleaner, including attached fabric,

grime, and other foreign substances. Otherwise, the end face of the ferrule may be damaged.

• Do not push the optical connector forcedly to clean. Otherwise, the end face of the ferrule may be

damaged.

• Rotate an optical connector cleaner (stick type) only in a clockwise direction. An optical connector cleaner

rotating clockwise as well as counterclockwise may damage the end face of the ferrule.

■ Maintenance and cleaning

• Wipe off the dirt on the device's outer surface with a dry, clean cloth or a well-wrung wet cloth containing

water or neutral cleanser. Do not apply volatile organic solvents or chemicals including benzine and thinner

pre-moistened cloths or insect killers, since they can deform, discolor or damage the device.

■ Long-term downtime

• For a long downtime, such as due to a long vacation or travel, be sure to unplug the power cable from the

wall outlet for safety. For a configuration using DC power supply, turn off the breaker on the power facility.

■ Discarding this device

• Discard the device according to the ordinance or rule of the local government or call the local waste

material handling facility.

xv

Safety Guide [IP8800/S6600]

■ Safety guide for the IP8800/S6600 series

• This document provides safety-related notices for use of the IP8800/S6600 series. To utilize the functions of

this device, read this document completely and carefully before using the device.

• Keep this document at hand after you read it, so that you can always refer it later.

• For any operation, follow the directions and procedures given by this document.

• Observe the cautions labeled on the device or those presented by this document. If you fail to do so, you will

cause damage to yourself or the device.

■ Symbols

• We have various symbols displayed on the IP8800/S6600 series and in the manuals to guide you in using the

IP8800/S6600 series correctly and safely without injuring yourself and others, or damaging equipment assets.

Below are the symbols and their meanings. Fully understand the description and then proceed with reading

the main part of the manual.

If you ignore instructions preceded by this symbol, you could cause personal injury or

WARNING

death to yourself and others.

If you ignore instructions preceded by this symbol, you could cause personal injury to

CAUTION

CAUTION

NOTE

yourself and others, or serious damage to the device or surroundings.

If you ignore instructions preceded by this symbol, you could cause physical damage

to the device or surroundings.

A note is informational in nature. Unlike warning and caution notices, notes (for

prevention of malfunction, prevention of product minor damages) are not related to the

physical injury or damage to the device.

■ Operations and actions

• Do not attempt to perform any operations not specifically described in this document.

In case of a problem on the device, contact the maintenance personnel after performing the following.

• For the device with AC power supply mounted, power off the device and unplug the power cable from the outlet.

• For the device with DC power supply mounted, power off the device and turn off the breaker in the power supply

equipment.

■ Be careful in operation

• The instructions displayed on the device or in this manual are the results of our thorough consideration.

However, an unexpected situation may occur. For operations, not only follow the instructions but also always

be careful yourself.

xvii

Safety Guide [IP8800/S6600]

WARNING

■ In case a failure should occur, power off the device immediately.

• In case fume or unusual odor should occur, or foreign matters should come into the device, power off the device

as follows. If the device is used in a faulty state, fire disasters or electric shock may be caused.

• For the device with AC power supply mounted, power off the device and unplug the power cable from the outlet.

• For the device with DC power supply mounted, power off the device and turn off the breaker in the power supply

equipment because the power cable is connected via a terminal.

■ Do not place the device in an unstable location.

• If the device is being placed on a table, be sure to install it horizontally on a workbench or the like that can

sufficiently bear the weight of the device. If the device is placed on an unstable location such on a shaky table

or slope, the device may fall and drop and consequently personal injury may occur.

■ Do not remove the device cover.

• Do not remove the device cover. Electric shock may be caused.

■ Do not put foreign matters in the device.

• Do not insert or drop metals or combustibles into the device through the intake/exhaust port. Fire disasters or

electric shock may be caused.

■ Modification is not permissible.

• Device modification is not permissible. Fire disasters or electric shock may be caused.

■ Do not give a shock.

• In case the device is dropped or parts are damaged, power off the device, pull the cable out of the outlet, and

call the maintenance engineer. Otherwise it can cause a fire or electric shock.

■ Do not put any material on the device.

• Do not put a metal such as pin or clip or a container with water in it such as vase or flower pot on the device.

Fire disasters or electric shock may be caused.

■ Do not use power not specified.

• Do not use a supply voltage not specified. Fire disasters or electric shock may be caused.

■ The current capacity supplied to the power distribution panel must be larger than the

operating current of the breaker.

• The current capacity supplied to the power distribution panel must be larger than the operating current of the

breaker. Otherwise, the breaker may not work in the event of a failure and cause fire disasters.

xviii

Safety Guide [IP8800/S6600]

■ Grounding is required.

• Leak current of up to 3.5mA flows for each device. If connecting the device with AC power, be sure to use the

grounded outlet. If the power supply is used without grounding, an electric shock may be caused and failures

may occur due to electric noise.

• When the device is connected to the DC power supply, be sure to connect the grounding terminal. If the power

supply is used without grounding, an electric shock may be caused and failures may occur due to electric

noise.

■ Installing/uninstalling of the DC power cable must be performed by the trained

engineer or maintenance personnel.

• Installing/uninstalling of the DC power cable must be performed by the trained engineer or maintenance

personnel. DC power cable is connected to the power supply via a terminal. Therefore, inadvertent handling

of the DC power cable may result in fire disasters or electric shock.

■ Before installing or removing a DC power cable, turn off the breaker on power supply

facilities.

• Before installing or removing a DC power cable, turn off the breaker on power supply facilities. Operation with

the breaker on may cause electric shock.

■ Attach insulation covers on the 0V and -48V terminals of a DC power cable.

• Attach insulation covers on the 0V and -48V terminals of a DC power cable (the side of which connects to

power supply facilities). Operation without insulation covers may cause electric shock.

■ When using the DC power supply, do not leave the terminal board uncovered.

• When using the DC power supply, be sure to attach the cover to the terminal board after connecting the power

cable. Operating it without the terminal board cover can cause an electric shock.

■ Do not touch the potential tap.

• The power supply is provided with the potential tap. This tap is used for inspection at shipment. Customer

should not use this tap. Do not insert a sharp material such as pin or clip into the potential tap. Fire disasters

or electric shock may be caused.

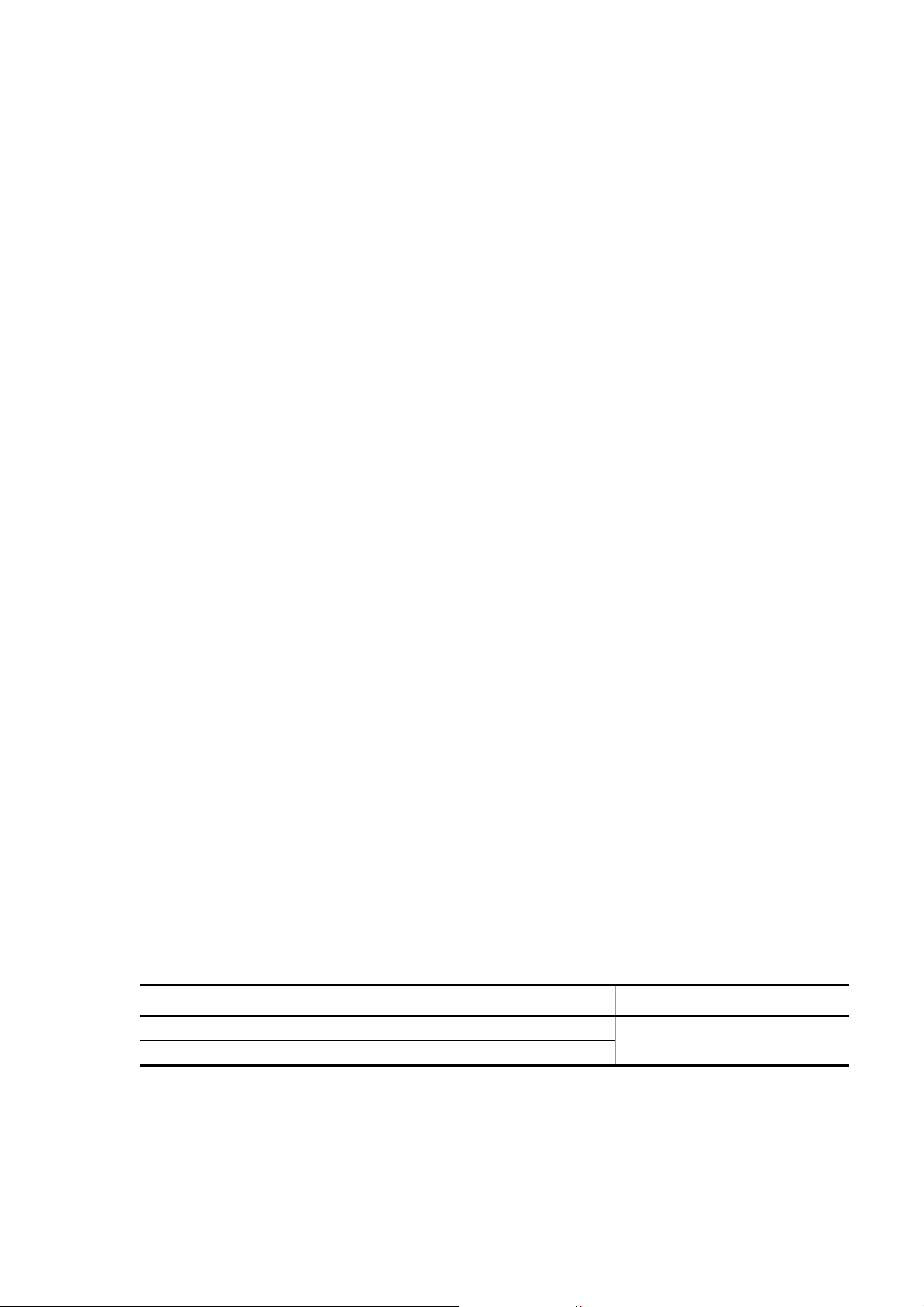

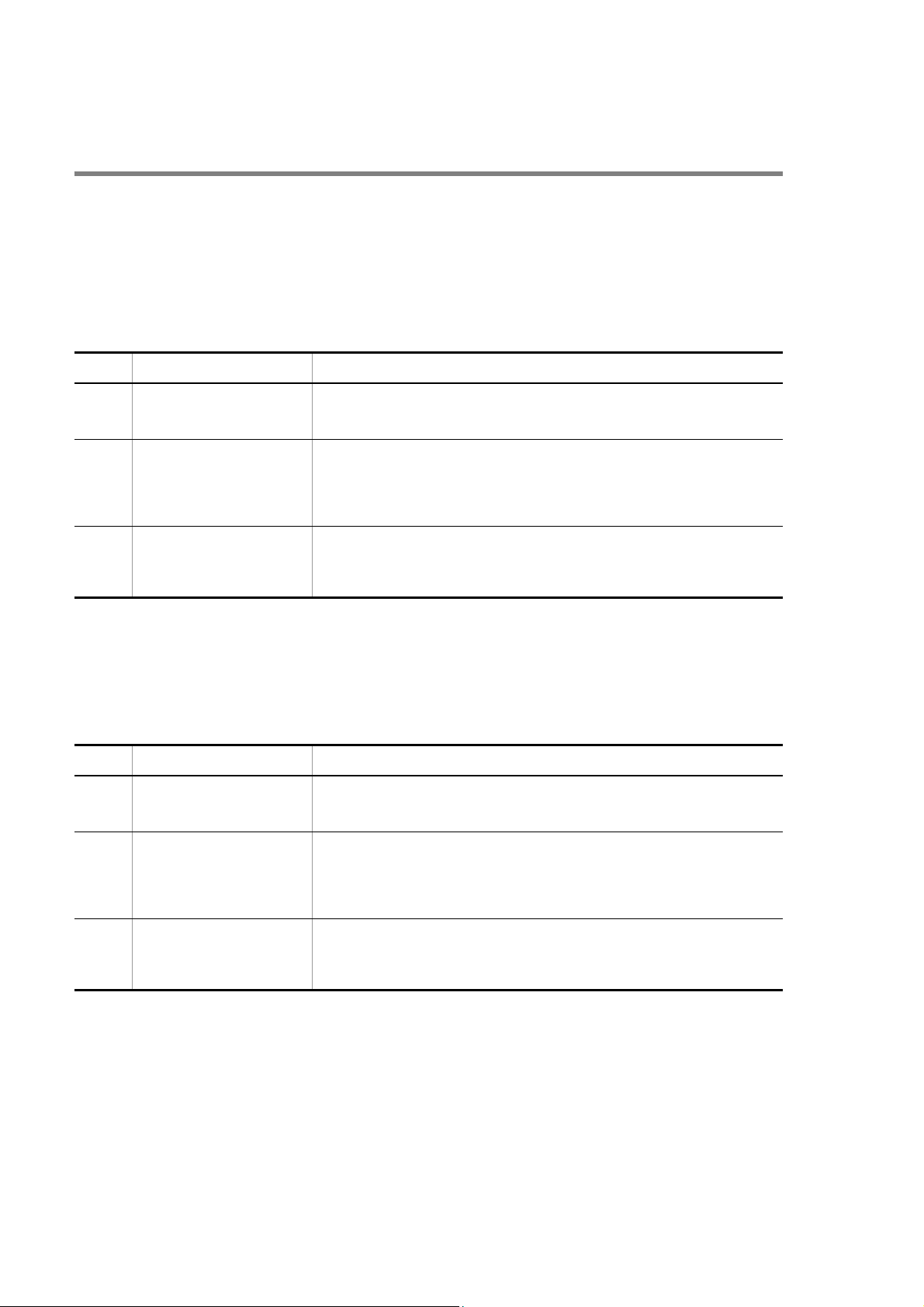

■ The device must be carried and installed by at least three people.

• The table below shows mass of the devices. The device must be carried and installed by at least three people.

Otherwise, a personal injury due to drop or fall may be caused.

Number of people to carry the device

Model Mass Number of people

IP8800/S6604 45 kg/100 lb 3 or more

IP8800/S6608 64 kg/142 lb

xix

Safety Guide [IP8800/S6600]

45kg 64kg

IP8800/S6604 IP8800/S6608

The label below is attached to the device.

■ Handle the power cable with caution.

• Do not put a heavy material on the power cable or do not pull, bend, or modify the power cable. The power

cable will be damaged and fire disasters or electric shock may be caused. A heavy material may be placed as

a result of covering the cable with a floor carpet.

• Use the attached power cable or the power cable complying with the specifications. If any other cable is used,

fire disasters or electric shock may be caused. Do not use the attached power cable for other purposes. In such

a case, fire disasters or electric shock may be caused.

• If the power cable is degraded (e.g., wire cores exposed or broken), ask the service personnel for replacement.

Otherwise it can cause a fire or electric shock.

• Check to see if dust is deposited on the power plug. Insert the plug securely to the end so that shakiness will

not occur. If dust is deposited or connection is incomplete, fire disasters or electric shock may be caused.

■ Do not plug too many leads into a single outlet.

• Do not plug too many power plugs into a single outlet. Many loads on an electrical outlet may result in fire

disasters and the electric energy in use may be exceeded, the breaker may go off, and other components may

be affected.

■ Before powering off, turn off all power switches or breakers on the device.

• Multiple input power supplies are provided to the device. Before powering off, turn off all power switches (when

AC power supply is mounted) or breakers (when DC power supply is mounted) on the device. The label below

is attached to the device.

xx

Safety Guide [IP8800/S6600]

■ Work to add or replace equipment must be performed by a trained engineer or

maintenance personnel.

• To add or replace optional components must be performed by a trained engineer or maintenance personnel.

To add or replace a power supply involves to plug and unplug power cables; a person other than the preceding

ones may fail to handle things, which can cause fire disaster, electric shock, and equipment failure. Other

optional components, if handled mistakenly, can also cause fire disaster, wounds, and equipment failure.

■ Do not press the switch on the basic control unit with a fragile tip, pin, or clip that may

get stuck and cannot be removed.

• Do not press the switch on the front panel of the basic control unit with a fragile tip, pin, or clip that may get

stuck and cannot be removed. Fire disasters or electric shock may be caused.

■ Before addition or replacement of the power supply, unplug the power cable.

• Remove the power cable from the power supply when adding or replacing it. With the power cable connected,

the power supply equipment may remain energized from some circuits even the power switch is turned off.

Therefore, adding or replacing the power supply with the power cable connected may cause a fire or electric

shock.

■ Keep air dusters away from fire.

• If you use an air duster with combustible gas to clean the optical connector, keep away from fire. Otherwise,

fire disaster may occur.

xxi

Safety Guide [IP8800/S6600]

CAUTION

■ Do not install the device in a humid or dusty environment.

• Do not install the device in a humid or dusty environment. Fire disasters or electric shock may be caused.

• Moving the device from a cold place to a warm place may form condensation on the surface or internal of the

device. If the device is operated immediately a fire or electric shock can be caused. Thus, in this case, leave

the device as it is for several hours before starting operation.

■ Do not stack the devices.

• Do not stack the devices. The device may be damaged. The device may be damaged or lose its balance and

fall or drop. As a result, personal injury may occur.

■ Do not recline on the device, or place a heavy loading on it.

• Do not ride on or cling to the device or do not put a heavy material on it. The device may be damaged. The

device may be damaged or lose its balance and fall or drop. As a result, personal injury may occur.

■ When installing the device on the rack, use brackets to support the weight of the

device.

• The rack-attaching brackets supplied with this device are used to fasten the device on the rack but not to

support the weight of the device. Use either of the following.

Model Items

IP8800/S6604

IP8800/S6608

The guide rail or shelf, if you use, must be the one attached to the rack and capable of supporting the weight

of the fully mounted device.

guide rail, shelf, support brackets

guide rail, shelf

■ Use support brackets only for IP8800/S6604.

• The support brackets support only IP8800/S6604. Do not use for others. Otherwise, the equipment may fall or

drop and damage you.

■ Use support brackets with care.

• When you mount the device on a rack with support brackets, support the device flatly from both front and rear

sides while mounting the device and fastening screws. A tilted device may fall or drop and damage you and

other equipment mounted on the same rack.

• To mount the device on a rack with support brackets means weight of the device is supported only by

rack-attaching brackets and the support brackets. Make sure to fasten screws of the rack-attaching brackets

and the support brackets tightly.

xxii

Safety Guide [IP8800/S6600]

■ Do not block the intake and/or exhaust port.

• Do not block the intake/exhaust port of the device. Blocking the intake/exhaust port keeps heat inside and fire

disasters may be caused. Keep a space of at least 70mm from the intake/exhaust port.

■ Do not bring hairs or any foreign matters close to the intake/exhaust port of the

device.

• The cooling fan unit is provided on the device. Do not put any material close to the intake/exhaust port. The

internal temperature rise may result in a failure. Do not put hair or any material close to the intake/exhaust port.

You may be caught and injured.

■ When moving an optional component, do not carry it by holding its handle.

• When moving a fan unit or power supply, do not hold its handle. The handle may come off and the device may

drop. As a result, a personal injury may occur. Or the fan unit or power supply may be deformed that may cause

a fire or electric shock.

■ Before carrying the device, remove the cables.

• When moving the device, power off the device, remove all the cables from the device, and then move the

device. Otherwise the device or cable may be deformed or damaged. As a result, fire disasters or electric shock

may be caused.

■ Do not drop an optional component.

• Handle the optional component carefully not to drop it. If dropped, personal injury may be caused.

• The weight and depth of the DC power supply are 5.6kg and 163mm respectively. When removing the DC

power supply, hold it securely. If pulling it forward carelessly, it may drop and cause a personal injury. The label

below is attached to the DC power supply.

■ Do not touch the inside of the device.

• Do not put your hand inadvertently inside the device. Mechanical parts may cause a personal injury.

■ The basic switching unit and network interface component may be hot. Be careful

when removing them.

• Parts mounted on the basic switching unit and network interface component may be hot: Do not touch them to

prevent getting burned.

xxiii

Safety Guide [IP8800/S6600]

■ When removing the fan unit, do not put your hand close to the rotating fan.

• The fan may still be rotating immediately after the removal of the fan unit. While the fan is rotating, do not put

your hand or finger close to it. Personal injury may be caused. The label below is attached to the fan unit.

■ Do not roughly handle the power cable.

• Do not put the power cable close to the heating apparatus. The cable sheath may be melted and fire disasters

or electric shock may be caused.

• When inserting the power cable into the outlet or removing from it, be sure to hold the cable plug. Pulling up

the cable with the cable grasped, the wire can be broken.

■ Do not touch the device directly if you have metal allergies.

• This device is coated with metals including zinc, nickel, and gold. If you have allergies to them, do not touch

the device directly to prevent getting dermatitis.

■ Be careful of laser beams.

• The network interface module as indicated below uses laser beams. Do not peep in the optical transceiver

directly.

xxiv

Safety Guide [IP8800/S6600]

Caution. Hot! (all sides)

■ Do not touch a working (including immediately after stopping) SFP-T.

• A working (establishing a link) SFT-P can have up to 65 °C/140 °F in temperature. Do not touch it when working

or immediately after stopping to prevent getting burned.

• To remove an SFP-T, follow the following procedures. Otherwise, you may get burned.

• To remove an SFP-T without turning off the device, execute the inactivate command, and remove the SFP-T

five minutes later.

• To remove an SFP-T from the device turned off, power off the switch of the device, and remove the SFP-T five

minutes later.

• An SFP-T has the following label attached.

■ Lithium battery

• This device mounts a lithium battery for the real-time clock. If the lithium battery is inadvertently handled, a

personal injury or fire may be caused as a result of heat generation, burst, or ignition. Do not remove the lithium

battery from the device or disassemble it, heat it to 100

°C/212 °F or higher, burn it, or wet it with water.

■ Cleaning

• Remove dust on and around the device on a regular basis. Device shutdown and fire disasters or electric shock

may be caused.

xxv

Safety Guide [IP8800/S6600]

CAUTION

■ Do not power off the device during software update (when the ppupdate command

is being executed).

• By the execution of the ppupdate command, the device automatically restarts. Do not power off the device

during restart (until the STATUS LED on the control swithcing unit changes from blinking in green into steady

light). The device may be damaged.

■ Handle a memory card with care.

• Do not forcedly push or flip a memory card to insert. Do not forcedly pull out a locked memory card to remove.

Otherwise, the connector of the memory card slot may be damaged.

• Remove a memory card to reposition the device. Moving the device may cause force against the memory card,

which can damage the connector of the memory card slot.

■ Do not remove the memory card or disconnect power while the ACC LED is lit.

• Lighting of the ACC LED on the basic switching unit indicates that the memory card is being accessed. Do not

remove the memory card or disconnect power during access. The memory card may be damaged. Some

commands require a considerable time before completing access to the memory card after the entry of the

commands. Ensure that access is completed and then remove the memory card or disconnect power.

■ Do not attach a label or the like to the transceivers.

• The transceiver has a label indicating its manufacturer and that it is our standard supply. However, this label is

attached to the part that does not obstruct heat radiation from the transceiver or the mechanism preventing

slip-off from the cage. If a label or the like is attached to such an obstructing part, the transceiver or the network

interface module may be damaged.

■ For the power supply equipment, considerations must be given not to cause voltage

drop due to rush current.

• When this device is powered on, a rush current flows. Considerations must be given not to cause voltage drop

due to such a rush current. The voltage drop affects not only this device but other devices connected to the

same power supply equipment.

■ When installing/uninstalling the power cable, turn off the power switch.

• To install or uninstall the power cable, turn off the switch on the power supply to be installed or uninstalled.

■ When replacing the fan unit while the device powered on, complete the task within

the specified duration of time.

• When replacing the fan unit while the device powered on, complete the entire task from removal to installation

within one minute. If it takes more than one minute, other modules may be affected by temperature rise in the

device.

xxvi

Safety Guide [IP8800/S6600]

■ For carrying or packaging the device and optional component, use an antistatic wrist

strap.

• Use an antistatic wrist strap. If you handle the device without the antistatic wrist strap, the device can be

damaged by the static electricity.

■ After removing an optional component, be sure to attach a blank panel.

• After removing an optional component, be sure to attach a blank panel. Using the device without the blank

panel attached, the air flow in the device cannot be maintained. In such a case, the temperature rise inside the

device may cause a failure.

■ Attach an option component with care.

• Follow the following procedures to attach an option component. Otherwise, a problem may occur on the device.

1. Open the levers as the figure below.

2. With the levers in hands, push the component slowly into the device, to the point where the levers touch the device.

3. Use the levers to insert the component all the way. Move the levers slowly (taking more than one second) but not forcedly.

■ Before removing an optional component, loosen the screws completely.

• Use levers to remove the basic switching unit or network interface module. If screws are not completely

loosened, the optional component may be damaged when the levers are pressed down.

■ When carrying or packing an optional component, take care for handling.

• Take care not to handle the connector when carrying or packing optional components such as the basic

switching unit, network interface module, memory card, transceiver, and power supply. They must be stored in

antistatic bags when they are not in use.

■ Do not install the device in any place possibly reaching a high temperature.

• Be careful that the parts may be damaged if left in a place exposed to direct sunlight or close to a heating

apparatus.

xxvii

Safety Guide [IP8800/S6600]

■ Do not bring a TV or radio close to the device.

• Leaving a TV or radio close to the device can adversely influence to each other. If a TV or radio interferes the

device, remedy as follows:

1. Keep the device from the television or radio set as far away as possible.

2. Change the direction of the antenna for the television or radio set.

3. Use different outlets.

■ Keep the device away from a place with hydrogen sulfide or much salt.

• Places with hydrogen sulfide including hot spring resorts, and places with much salt including coasts may

shorten lifetime of the device.

■ Use air dusters with care.

• Choose an air duster designated to clean optical connectors. Other air dusters may get the end face of the

ferrule dirty.

• Avoid the nozzle or container of an air duster from touching the end face of the ferrule. Otherwise, the ferrule

may be damaged.

■ Handle the optical connector with care.

• Use the designated optical connector cleaner. Other optical connector cleaners may get the end face of the

ferrule dirty.

• Make sure of no problems on the head part of an optical connector cleaner, including attached fabric, grime,

and other foreign substances. Otherwise, the end face of the ferrule may be damaged.

• Do not push the optical connector forcedly to clean. Otherwise, the end face of the ferrule may be damaged.

• Rotate an optical connector cleaner (stick type) only in a clockwise direction. An optical connector cleaner

rotating clockwise as well as counterclockwise may damage the end face of the ferrule.

■ Maintenance and cleaning

• Wipe off the dirt on the device's outer surface with a dry, clean cloth or a well-wrung wet cloth containing water

or neutral cleanser. Do not apply volatile organic solvents or chemicals including benzine and thinner

pre-moistened cloths or insect killers, since they can deform, discolor or damage the device.

■ Long-term downtime

• For a long downtime, such as due to a long vacation or travel, be sure to unplug the power cable from the wall

outlet for safety. For a configuration using DC power supply, turn off the breaker on the power facility.

■ Discarding this device

• Discard the device according to the ordinance or rule of the local government or call the local waste material

handling facility.

xxviii

Safety Guide [IP8800/S6300]

■ Safety guide for the IP8800/S6300 series

• This document provides safety-related notices for use of the IP8800/S6300 series. Read this document

completely and carefully before using the device.

• Keep this document at hand after you read it, so that you can always refer it later.

• For any operation, follow the directions and procedures given by this document.

• Observe the cautions labeled on the device or those presented by this document. If you fail to do so, you will

cause damage to yourself or the device.

■ Symbols

• We have various symbols displayed on the IP8800/S6300 series and in the manuals to guide you in using the

IP8800/S6300 series correctly and safely without injuring yourself and others, or damaging equipment assets.

Below are the symbols and their meanings. Fully understand the description and then proceed with reading

the main part of the manual.

If you ignore instructions preceded by this symbol, you could cause personal injury or

WARNING

death to yourself and others.

If you ignore instructions preceded by this symbol, you could cause personal injury to

CAUTION

CAUTION

NOTE

yourself and others, or serious damage to the device or surroundings.

If you ignore instructions preceded by this symbol, you could cause physical damage

to the device or surroundings.

A note is informational in nature. Unlike warning and caution notices, notes (for

prevention of malfunction, prevention of product minor damages) are not related to the

physical injury or damage to the device.

■ Operations and actions

• Do not attempt to perform any operations not specifically described in this document.

In case of a problem on the device, contact the maintenance personnel after performing the following.

• For the device with AC power supply mounted, power off the device and unplug the power cable from the outlet.

• For the device with DC power supply mounted, power off the device and turn off the breaker in the power supply

equipment.

■ Be careful in operation

The instructions displayed on the device or in this manual are the results of our thorough consideration.

• However, an unexpected situation may occur. For operations, not only follow the instructions but also always

be careful yourself.

xxix

Safety Guide [IP8800/S6300]

WARNING

■ In case a failure should occur, power off the device immediately.

• In case fume or unusual odor should occur, or foreign matters should come into the device, power off the device

as follows. If the device is used in a faulty state, fire disasters or electric shock may be caused.

• For the device with AC power supply mounted, power off the device and unplug the power cable from the outlet.

• For the device with DC power supply mounted, power off the device and turn off the breaker in the power supply

equipment because the power cable is connected via a terminal.

■ Do not place the device in an unstable location.

• If the device is being placed on a table, be sure to install it horizontally on a workbench or the like that can

sufficiently bear the weight of the device. If the device is placed on an unstable location such on a shaky table

or slope, the device may fall and drop and consequently personal injury may occur.

■ Do not remove the device cover.

• Do not remove the device cover. Electric shock may be caused.

■ Do not put foreign matters in the device.

• Do not insert or drop metals or combustibles into the device through the intake/exhaust port. Fire disasters or

electric shock may be caused.

■ Modification is not permissible.

• Device modification is not permissible. Fire disasters or electric shock may be caused.

■ Do not give a shock.

• In case the device is dropped or parts are damaged, power off the device, pull the cable out of the outlet, and

call the maintenance engineer. Otherwise it can cause a fire or electric shock.

■ Do not put any material on the device.

• Do not put a metal such as pin or clip or a container with water in it such as vase or flower pot on the device.

Fire disasters or electric shock may be caused.

■ Do not use power not specified.