N8800-155F, EXP320L

NEC Express5800/R320a-E4

N8800-154F, EXP320M

NEC Express5800/R320b-M4

User's Guide

1st Edition

10-2010

856-129125-101- A

PROPRIETARY NOTICE AND LIABILITY DISCLAIMER

The information disclosed in this document, including all designs and related materials, is

the valuable property of NEC Corporation (NEC) and /or its licensors. NE C and/or its

licensors, as appropriate, reserve all patent, copyright and other proprietary rights to this

document, including all design, manufacturing, reproduction, use, and sales rights thereto,

except to the extent said rights are expressly granted to others.

The NEC product(s) discussed in this document are warranted in accordance with the

terms of the Warranty Statement accompanying each product. However, actual

performance of each such product is dependent upon factors such as system configuration,

customer data, and operator control. Since implementation by customers of each product

may vary, the suitability of specific product configurations and applications must be

determined by the customer and is not warranted by NEC.

To allow for design and specification improvements, the information in this document is

subject to change at any time, without notice. Reproduction of this document or portions

thereof without prior written approval of NEC is prohibited.

1st Printing, October 2010

Copyright 2010

NEC Corporation

7-1 Shiba 5-Chome, Minato-Ku

Tokyo 108-8001, Japan

All Rights Reserved

Printed in Japan

Keep this User's Guide handy for quick reference when necessary.

SAFETY INDICATIONS

To use NEC Express5800 series safely, follow the instructions in this User's Guide.

This guide explains components that pose a danger, types of dangers, and actions taken to prevent

them; such components are labeled warning.

This guide and warning labels use “WARNING” and “CAUTION” to indicate a danger dependin g on

the degree. These terms are defined as follows:

WARNING

CAUTION

This guide uses the following three types of symbols to give indications and precautions against a

danger. They are defined as follows:

Indicates that there is a risk of danger. Each image symbolizes a particular type of

danger. (Attention)

Indicates what you must not do. Each image symbolizes a particular type of

prohibition. (Prohibited actions)

Indicates what you must do. Each image symbolizes a particular type of action

necessary to avoid a danger. (Mandatory actions)

(Example)

High temperature.

Term indicating a degree of danger

Symbol indicating a prohibited

action (may not always be

indicated)

Indicates a danger that could lead to a death or serious injury.

Indicates a danger that could lead to a burn, other injuries or damage to

physical assets.

Symbol to draw attention

CAUTION

Immediately after the power-off, system components such as hard disk are

very hot. Wait the server to cool down completely before adding/removing

some component.

Description of a danger

SYMBOLS USED IN THIS USER'S GUIDE AND WARNING LABELS

Attention

Indicates a risk of an electric shock.

Indicates a risk of a personal injury due to heat.

Indicates a risk of catching your fingers.

Indicates a risk of a fire or smoke.

Indicates a general precaution or warning that is not defined herein.

Indicates a risk of losing eyesight due to laser beam.

Indicates a risk of a personal injury due to explosion.

Indicates a risk of a personal injury.

Prohibited actions

Indicates a general prohibition that is not defined herein.

Do no touch the indicated area. There is a risk of an electric shock or fire.

Do not touch with wet hands. There is a risk of an electric shock.

Keep from flame. There is a risk of a fire.

Avoid using water or liquid nearby. If it spills on the equipment, there is a risk of an

electric shock or fire.

Do not disassemble, repair, or modify the equipment. There is a risk of an electric

shock or fire.

Mandatory actions

Unplug the server. There is a risk of an electric shock or fire.

Indicates a general action to take that is not defined herein. Make sure to follow the

instructions.

Be sure to provide earthing. Otherwise, an electric shock or fire may be caused.

NOTE: This equipment has been tested and foun d to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is op erated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance wit h the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

BSMI Statement

CCC Statement

KCC Statement

CE Statement

Australia EMI:

Warning: This is a Cla ss A product. In domestic environment, this product may cause radi o

interference in which case the user may be required to take adequate measures.

Canada EMI:

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le

matériel brouilleur du Canada.

CLASS 1

LASER PRODUCT

NOTE: This product provides resistance against hardware faults with its redundant hardware

modules. However, this does not mean complete fault-tolerance is assured. For example,

there is a risk of system down when:

– A fatal fault occurs in software.

– Both modules within a redundant hardware pair break down.

– A fatal fault occurs in a non-redundant component, such as the clock generator circuitry

or the interconnect backplane.

– The entire system is cut off from AC power.

This system is classified as a CLASS 1 LASER PRODUCT. This label id

located on the internal DVD-ROM installed in your system.

Trademarks and Patents

NEC EXPRESSBUILDER, NEC ESMPRO and NEC DianaScope are trademarks of NEC

Corporation.

Microsoft, Windows, Windows Server, Windows NT, and MS-DOS are registered

trademarks of Microsoft Corporation in the United States and other countries.

Intel and Pentium are registered trademarks of Intel Corporation.

AT is a registered trademark of International Business Machin es Corporation in the United

States and other countries.

Adobe, the Adobe lo go, Acrobat, and the Acrobat logo are trademarks of Adobe Systems

Incorporated.

Datalight is a registered trademark of Datalight, Inc. ROM-DOS is a trademark of Datalight,

Inc.

Xeon is a trademark of Intel Corporation in the United States. DLT and DLTtape are

trademarks of Quantum Corporation in the United States.

Mozilla is a registered trademark of Mozilla Foundation.

Netscape is a registered trademark of Netscape Communications Corporation in the

United States and other countries.

Java is a registered trademark of Sun Microsystems, Inc in the United States and other

countries.

All other product, brand, or trade names used in this publication are the trademarks or

registered trademarks of their respective trademark owners.

Windows Server 2008 R2 stands for Microsoft(R) Windows Server(R) 2008 R2 S tandard

operating system and Microsoft(R) Windows Server(R) 2008 R2 Enterprise operating

system. Windows Server 2008 is the abbreviation for Microsoft Windows Server 2008

Standard operating system and Microsoft Windows Server 2008 Enterprise operating

system. Microsoft Windows Server 2003 R2 Standard x64 Edition operating system and

Microsoft Windows Server 2003 R2 Enterprise x64 Edition operating system or Mi crosoft

Windows Server 2003 Enterprise x64 Edition operating system are called Windows Server

2003 x64 Edition for short. Microsoft Windows Server 2003 R2 32-bit Standard Edition

operating system, Microsoft Windows Server 2003 R2 32-bit Enterprise Edition operating

system, Microsoft Windows Server 2003 Standard Edition operating system and Microsoft

Windows Server 2003 Enterprise Edition operating system are called Windows Server

2003 for short. Microsoft Windows 2000 Server operating system, Microsoft Windows 2000

Advanced Server operating system and Microsoft Windows 2000 Professio nal operating

system are called Windows 2000 for short. Windows 7 stands for Microsoft(R) Windows(R)

7 Professional operating system. Microsoft Windows V ista Business operating system is

called Windows Vista for short. Microsoft Windows XP Professional x64 Edition operating

system is called Windows XP x64 Edition for short. Microsoft Windows XP Home Edition

operating system and Microsoft Windows XP Professional operatin g system are called

Windows XP for short. Microsoft Windows NT Server network operating system version

3.51/4.0 and Microsoft Windows NT Workstation operating system version 3.51/4.0 are

called Windows NT for short.

Names used with sample applications are all fictitious. They are unrelated to any existing

product names, names of organizations, or individual names.

AVOCENT and DVC (DAMBRACKAS VIDEO COMPRESSION) are registered trademarks

of US AVOCENT in the United St ates and other countries.

The patent numbers for the DVC technology of AVOCENT US:

US Patent Number: 5,732,212/5,937,176/6,633,905/6,681,250/6,701,380 (other patents

pending)

Taiwanese Patent Number: 173784

European Patent Number: 0 740 811

To prevent voltage sag:

This product may be affected by voltage sag cau sed due to lightning. To prevent voltage

sag, you are recommended to use an AC uninterruptible power supply (UPS) unit.

Notes:

(1) No part of this manual may be reproduced in any form without prior written permission

of NEC Corporation.

(2) The contents of this manual are subject to change without prior notice.

(3) The contents of this manual shall not be copied or altered without prior written

permission of NEC Corporation.

(4) All efforts have been made to ensure the accuracy of all information in this manual. If

you find any part unclear, incorrect, or omitted in this manual, contact the sales agent

where you purchased this product.

(5) NEC assumes no liability arising from the use of this product, nor any liability for

incidental or consequential damage arising from the u se of this ma nual regardless of

(4) above.

© NEC Corporation 2010

(This page is intentionally left blank.)

PREFACE

Welcome to the NEC Express5800/ft series.

NEC Express5800/ft series is a “fault-tolerant (ft)” server focusing on “high reliability” in

terms of fault-tolerance, in addition to “high performance,” “scalability,” and “general

versatility” provided by NEC Express5800 series. In the event of trouble, its dual

configuration will allow the system to instantaneously isolate the failed parts to assure

non-stop running; operation will be moved smoothly from one module to the other,

minimizing damage to it. You can use this NEC Express5800/ft series in a mission-critical

system where high availability is required. By the use of Windows operating system, it also

provides outstanding openness for general-purpose applications, etc.

To make the best use of these features, read this User's Guide thoroughly to und erstand

how to operate NEC Express5800/ft series.

i

ii

ABOUT THIS USER'S GUIDE

This User's Guide helps a user to properly setup and use the product.

Consult this guide to ensure safety as well as to cope with trouble during a system setup and daily

operation.

Keep this manual handy.

This User's Guide is intended for users who have a good kn owl edge on the basic use of Windows

operating systems and general I/O devices such as a keyboard and mouse.

How to Use This User's Guide

This guide consists of eight chapters and appendices. To help you find a solution quickly,

the guide contains the following information:

For descriptions on setting up this product, see the separate volume “User’s Guide

(Setup).”

Read “Precautions for Use” first.

Before going on to main chapters, be sure to read “Precautions for Use.” These

precautions are very important for using the product safely.

Chapter 1 Precautions for Use

This chapter describes precautions necessary to use the product safely and properly. Be

sure to read this chapter before using the product. It also provides information on user

support. It will be helpful when you need maintenance service, support, etc.

Chapter 2 General Description

This chapter describes what you should know about the product: its component names,

functions, operating procedures as well as handling of devices and other parts.

Chapter 3 Windows Setup and Operation

This chapter describes setup and operation specific to the product when it is on

Windows.

Chapter 4 System Configuration

This chapter describes how to make settings of built-in basic input/output system. It also

describes factory-shipped parameters.

Chapter 5 Installing and Using Utilities

This chapter describes features and operating procedures of a standard utility “NEC

EXPRESSBUILDER.” It also describes procedures to install and operate various

software programs contained in its DVD.

Chapter 6 Maintenance

This chapter describes maintenance procedures and use of maintenance tools. If you

need to move the product for maintenance purposes, follow the steps provided in this

chapter.

Chapter 7 Troubleshooting

If the product does not work properly, see this chapter before deciding that it is a

breakdown.

Chapter 8 System Upgrade

This chapter describes procedures to add options and precautions. See also this chapter

when you replace failed components.

Appendix A Specifications

This appendix lists specifications of the product.

Additional symbols

The following symbols are used throughout this User's Guide in addition to the caution

symbols describe at the beginning.

iii

IMPORTANT:

CHECK:

TIPS:

Important points or instructions to keep in mind when using the

server or software

Something you need to make sure when using the server of

software

Helpful information, something useful to know

About our Web Service

Information on NEC Express5800/ft series including modification modules is also available

on our web site, NEC Global Site:

http://www.nec.com/

iv

ACCESSORIES

This product is shipped with various accessories. See the packin g list to make sure

everything is included and check the individual items. If some component is missing or

damaged, contact your sales agent.

Keep the accessories in a safe place. You will need them when you perform setup,

addition of options, or replacement of failed components.

To check NEC EXPRESSBUILDER components, see the attached list.

Be sure to fill out and mail the software registration card that is attached to your

operating system.

Make backup copies of included floppy disks or Flash FDD, if any. Keep the

original disks as the master disks; use these copies in operation.

Improper use of an included floppy disk, Flash FDD, or DVD may alter your

system environment. If you find something unclear, stop using them and contact

your sales agent.

CONTENTS

SAFETY INDICATIONS....................................................................................................

PREFACE...........................................................................................................................i

ABOUT THIS USER'S GUIDE ........................................................................................ii

How to Use This User's Guide ...................................................................................................ii

Additional symbols ...................................................................................................................iii

About our Web Service .............................................................................................................iii

ACCESSORIES....................................................................................................................iv

CHAPTER 1 PRECAUTIONS FOR USE...............................................1-1

PRECAUTIONS FOR SAFETY.................................................................................... 1-3

General....................................................................................................................................1-3

During Operation.....................................................................................................................1-9

ABOUT OUR WEB SERVICE....................................................................................1-17

CHAPTER 2 GENERAL DESCRIPTION............................................... 2-1

HOW THE OPERATING SYSTEM SEES THE CPU MODULES.............................................2-6

How CPU modules appear on Task Manager..........................................................................2-6

NAMES AND FUNCTIONS OF COMPONENTS........................................................2-7

Front View ..............................................................................................................................2-8

Rear View..............................................................................................................................2-10

Optical disk drive..................................................................................................................2-12

CPU/IO Module ....................................................................................................................2-13

Mother Board........................................................................................................................2-14

LEDs .....................................................................................................................................2-15

POWER UNIT LED ........................................................................................................2-19

BASIC OPERATION...................................................................................................2-20

Installing/removing the front bezel .......................................................................................2-21

Power ON..............................................................................................................................2-22

Power OFF............................................................................................................................2-23

POST Check..........................................................................................................................2-23

Floppy Disk Drive (Option)..................................................................................................2-27

Flash FDD.............................................................................................................................2-29

Optical Disk Drive ................................................................................................................2-31

v

CHAPTER 3 WINDOWS SETUP AND OPERA TION............................3-1

PRECAUTIONS FOR USING HYPER-V ..............................................................................3-2

System Down Time Caused by Duplexing CPU Module........................................................3-2

Virtual Network Setting and Active Upgrade..........................................................................3-2

DISK OPERATIONS.....................................................................................................3-3

Disk Operations Using the RDR (Rapid Disk Resync) Function............................................3-3

Replacing Failed Hard Disk Drives.......................................................................................3-21

CHANGE DRIVE LETTER.........................................................................................3-24

DUPLEX LAN CONFIGURATION............................................................................3-25

Overview...............................................................................................................................3-25

Rules of Duplex Configuration on NEC Express5800/ft series............................................3-26

vi

Configuring Duplex LAN......................................................................................................3-27

Removing Duplex/Dual LAN................................................................................................3-34

CHECKING THE DUPLICATING OPERATION OF MODULES............................ 3-36

Evaluate Startup and Stop of PCI Modules...........................................................................3-36

Confirm Start and Stop of CPU Modules..............................................................................3-40

NEC EXPRESS5800/FT SERIES SERVICE PROGRAM CONFIGURATION...............3-42

CHAPTER 4 SYSTEM CONFIGURATION ............................................4-1

SYSTEM BIOS –SETUP–............................................................................................. 4-2

Starting SETUP Utility............................................................................................................4-3

Description of On-Screen Items and Key Usage.....................................................................4-4

Configuration Examples..........................................................................................................4-6

Menu and Parameter Descriptions...........................................................................................4-8

SAS BIOS – SAS Configuration Utility –.............................................................................4-40

FORCED SHUTDOWN.............................................................................................. 4-44

Forced Shutdown...................................................................................................................4-44

REMOTE MANAGEMENT FUNCTION............................................................................. 4-45

CHAPTER 5 INSTALLING AND USING UTILITIES..............................5-1

NEC EXPRESSBUILDER............................................................................................ 5-2

Boot Selection Menu...............................................................................................................5-2

Autorun Menu .........................................................................................................................5-5

PARAMETER FILE CREATOR............................................................................................ 5-6

Parameter File Creator.............................................................................................................5-7

NEC ESMPRO AGENT AND MANAGER....................................................................... 5-17

Overview...............................................................................................................................5-17

NEC ESMPRO Agent............................................................................................................5-25

NEC ESMPRO Manager.......................................................................................................5-43

Maintenance of NEC Express5800/ft series..........................................................................5-64

NEC DIANASCOPE....................................................................................................... 5-92

Notes......................................................................................................................................5-92

NEC PRODUCT INFO COLLECTION UTILITY .....................................................5-93

ACTIVE UPGRADE........................................................................................................ 5-95

Introduction...........................................................................................................................5-95

Notes......................................................................................................................................5-95

Overview...............................................................................................................................5-96

Preparing for the Active Upgrade Process...........................................................................5-104

Configuring the Active Upgrade Process.............................................................................5-125

Performing the Upgrade......................................................................................................5-147

Troubleshooting...................................................................................................................5-179

CHAPTER 6 MAINTENANCE................................................................6-1

DAILY MAINTENANCE............................................................................................. 6-2

Checking Alert.........................................................................................................................6-2

Checking STATUS LEDs ........................................................................................................6-2

Making Backup Copies ...........................................................................................................6-3

Cleaning...................................................................................................................................6-3

SYSTEM DIAGNOSTICS............................................................................................6-7

Test Items.................................................................................................................................6-7

vii

Startup and Exit of System Diagnostics..................................................................................6-7

MAINTENANCE TOOLS .................................................................................................6-10

Starting the Off-line Maintenance Utility..............................................................................6-10

Function of Maintenance Tools.............................................................................................6-12

RELOCATING/STORING THE NEC EXPRESS5800/FT SERIES............................6-14

TO THE ACCIDENT OF PCI MODULE.....................................................................6-16

Procedure to Confirm............................................................................................................6-16

Procedure to Recover............................................................................................................6-17

Procedure to Check...............................................................................................................6-19

CHAPTER 7 TROUBLESHOOTING .....................................................7-1

TO LOCATE THE ERRORS..........................................................................................7-2

Error Messages by LED Indication.........................................................................................7-3

POST Error Messages.............................................................................................................7-4

Windows Server 2008R2, Enterprise Edition Error Messages................................................7-9

Server Management Application Error Message...................................................................7-10

TROUBLESHOOTING ......................................................................................................7-11

Problems with NEC Express5800/ft series............................................................................7-11

Event Log..............................................................................................................................7-24

Problems with NEC EXPRESSBUILDER............................................................................7-29

Problems with Windows Autorun Menu ...............................................................................7-30

Problems with Parameter File Creator ..................................................................................7-31

Problems with NEC ESMPRO..............................................................................................7-32

COLLECTING TROUBLE LOGS ..............................................................................7-41

Collection of Server Types....................................................................................................7-41

Collection of Event Logs.......................................................................................................7-41

Collection of Configuration Information...............................................................................7-43

Collection of Diagnostic Information by Dr. Watson............................................................7-43

COLLECTING THE MEMORY DUMP.......................................................................7-44

CHAPTER 8 SYSTEM UPGRADE........................................................8-1

SAFETY PRECAUTIONS.............................................................................................8-2

ANTI-STATIC MEASURES..........................................................................................8-3

PRE-UPGRADE VERIFICATION .........................................................................................8-4

PREPARING YOUR SYSTEM FOR UPGRADE.........................................................8-5

2.5-INCH HARD DISK DRIVE.....................................................................................8-6

Installing 2.5-inch Hard Disk Drive........................................................................................8-7

Removing 2.5-inch Hard Disk Drive.......................................................................................8-9

Replacing 2.5-inch Hard Disk Drive.....................................................................................8-10

CPU/IO MODULE .........................................................................................................8-11

Precautions............................................................................................................................ 8-11

Removing CPU/IO Module...................................................................................................8-12

Installing CPU/IO Module ....................................................................................................8-15

DIMM...........................................................................................................................8-17

Precautions............................................................................................................................8-18

Installing DIMM ...................................................................................................................8-19

Removing DIMM..................................................................................................................8-22

Replacing DIMM ..................................................................................................................8-24

PROCESSOR (CPU)....................................................................................................8-25

viii

Installing CPU.......................................................................................................................8-26

Removing CPU......................................................................................................................8-29

PCI BOARD................................................................................................................ 8-30

Installing PCI Board..............................................................................................................8-33

Removing PCI Board.............................................................................................................8-38

Replacing PCI Board.............................................................................................................8-38

Setup of Optional PCI Board.................................................................................................8-39

APPENDIX A SPECIFICATIONS.......................................................... A-1

Chapter 1

Precautions for Use

This chapter includes information necessa ry fo r pr o per an d safe operation of the server.

1-2 Precautions for Use

WARNING LABELS

Warning label is placed in the certain part of the system so that the user stays alert to possible risks.

Do not remove or damage the label.

If this label is missing, about to peel off, or illegible, contact your sales agent.

The figures below show the location of this label on the server.

Front of Device

Back of Device

Precautions for Use 1-3

PRECAUTIONS FOR SAFETY

This section provides precautions for using the server safely. Read this section carefully to ensure

proper and safe use of the server. For symbol meanings, see "SAFETY INDICATIONS" described

in the previous section.

General

WARNING

Do not use the equipment in an operation where human l ives are involved or

high reliability is required.

This equipment is not intended for use and control in facilities/systems where

human lives are involved or high reliability is required, including medical

devices, nuclear facilities, aerospace equipments, transportation facilities or

traffic control facilities. NEC assumes no liability for any accidents or damage to

physical assets resulting from the use of this equipment in such systems or

facilities.

Do not continue to use the equipment if you detect smoke, odor, or noise.

If the equipment emits smoke, odor, or noise, immediately flip off the POWER

switch, unplug the cord, and contact your sales agent. There is a risk of a fire if

you continue to use the equipment.

Do not insert a wire or metal object.

Do not insert a wire or metal objects into a vent or disk drive slot. There is a risk

of an electric shock.

Prevent water or foreign objects from getting into the equipment.

Do not let water or foreign objects (e.g., pins or paper clips) enter the

equipment. There is a risk of a fire, electric shock, and breakdown. When such

things accidentally enter the equipment, immediately turn off the power and

unplug the cord. Contact your sales agent without trying to disassemble it

yourself.

CAUTION

1-4 Precautions for Use

Use of Power Supply and Power Cord

WARNING

Do not handle a power plug with a wet hand.

Do not plug/unplug a power cord with a wet hand.

There is a risk of an electric shock.

Do not connect the ground wire to a gas pipe.

Never connect the ground wire to a gas pipe.

There is a risk of a gas explosion.

CAUTION

Do not plug the attached cord in a nonconforming outlet.

Use a wall outlet with specified voltage and power type.

There is a risk of a fire or electricity leakage if you use a nonconforming outlet.

Avoid installing the equipment where you may need an extension c ord. If the

cord that does not meet the power specifications, there is a risk of overheating

that could lead to a fire.

Do not plug multiple cords in a single outlet.

If the rated current exceeds the rating, there is a risk of overheating that could

lead to a fire.

Do not plug the cord insecurely.

Insert the plug firmly into an outlet. There is a risk of heat or fire due to poor

contact when you insert the plug insecurely. If dust settles on the slots and it

absorbs moisture, there is also a risk of heat or fire.

Do not use nonconforming power cords.

Do not use any AC cord other than the enclosed one. There is a risk of fire

when the current exceeds the rating on the cord.

You also have to observe the following prohibitions about handling and

connecting interface cables.

Do not pull on the cord.

Do not pinch the cord.

Do not bend the cord.

Keep chemicals away from the cord.

Do not twist the cord.

Do not place any object on the cord.

Do not step on the cable.

Do not use cords as bundled.

Do not alter, modify, or repair the cord.

Do not staple the cord.

Do not use any damaged cord. (Replace it with a new one of the same

specifications. For replacement procedures, contact your sales agent.)

Precautions for Use 1-5

CAUTION

Do not use any power outlet other than one for 3-prong.

This equipment has a 3-prong plug attached. You can only p lug-in to a 3-prong

outlet. If you plug in to any outlets other than the 3-prong one, you may get

electric shock.

Do not use the enclosed power cord for other devices or purposes.

The attached power cord is specifically designed for use in connecting to this

equipment and its safety is confirmed. Do not use the power cord to other

devices Doing so may result in fire or electric shock.

1-6 Precautions for Use

Installation, Relocation, Storage and Connection

CAUTION

Do not install or store the equipment in an unsuitable place.

Install or store the equipment in such a place as specified in this User's Guide.

There is a risk of a fire if you place the server in a place such as follows.

a dusty place

a humid place located near a boiler, etc

a place exposed to direct sunlight

an unstable place

Do not use or store this product under corrosive gas environment.

Avoid the usage or storage of this product in an environment which may be

exposed to corrosive gases, such as those including but not limited to:

sodium chloride, sulfur dioxide, hydrogen sulfide, nitrogen dioxide, chlorine,

ammonia and/or ozone.

Avoid installing this product in a dusty environment or one that may be exposed

to corrosive materials such as sodium chloride and/or sulfur.

Avoid installing this product in an environment which may have excessive metal

flakes or conductive particles in the air.

Such environments may cause corrosion or short circuits of the printed board

within this product, resulting in not only damage to this product, but may even

lead to be a fire hazard.

If there are any concerns regarding the environment at the planned site of

installation or storage, please contact your sales agent.

Do not use any non-designated interface cable.

Use only interface cables designated by NEC; identify which component or

connector to attach beforehand. If you use an inappropriate cable or make a

wrong connection, there is a risk of short-circuit that could lead to a fire.

You also have to observe the following prohibitions about handling and

connecting interface cables:

Do not use any damaged cable connector.

Do not step on the cable.

Do not place any object on the cable.

Do not use the equipment with loose cable connections.

Do not use any damaged cable.

Do not disable the lock mechanism.

Do not use this product with the lock mechanism being removed or disabled.

Doing so may cause personal injury if this product drops.

Cleaning and Handling of Internal Devices

WARNING

Do not disassemble, repair, or alter the server.

Unless described herein, never attempt to disassemble, repair, or alter the

equipment. There is a risk of an electric shock or fire as well as malfunction.

Do not look into the optical disk drive.

The optical disk drive uses a laser beam. Do not look or insert a mirror inside

while the system is on. A laser beam is invisible; if your eyes are exposed to

the laser beam, there is a risk of losing eyesight.

Do not detach a lithium battery yourself.

This equipment has a lithium battery. Do not detach it yourself.

If the battery is exposed to fire or water, it could explode.

When the equipment does not work correctly because of lithium battery life,

contact your sales agent. Do not disassemble replace or recharge

the battery yourself.

Caution for electric shock

You can replace internal, optional devices while the equipment is powered-on.

However, carefully follow the instructions on this guide when you do so. If you

touch the internal devices other than the ones described in this guide, there is a

risk of electrical shock.

Make sure to power off the equipment and disconnect the power plug from a

power outlet before cleaning or installing/removing internal optional devices.

Touching any internal device of the equipment with its power cord connected to

a power source may cause an electric shock even if the server is off-powered.

Disconnect the power plug from the outlet occasionally and clean the plug with

a dry cloth. Heat will be generated if condensation is formed on a dusty plug,

which may cause a fire.

Precautions for Use 1-7

1-8 Precautions for Use

CAUTION

High temperature

Immediately after powering off the system, system components such as hard

disk drive may be very hot. Wait for the server to cool down completely before

adding/removing components.

Make sure to complete installation.

Firmly install all power cords, interface cables and/or boards. An incompletely

installed component may cause a contact failure, resulting in fire and/or smoke.

Protect the unused connectors with the protective cap.

The unused power cord connectors are covered with the protective cap to

prevent short circuits and electrical hazards. Attach the protective cap to the

unused connector. Failure to follow this warning may cause a fire or an electric

shock.

During Operation

Keep animals away.

Animal’s waste or hair may get inside the equipment to cause a fire or electric

shock.

Do not place any object on top of the server.

The object may fall off to cause injuries, damage to hardware and/or a fire.

Do not leave the optical disk drive’s tray ejected.

Dust may get in the equipment to cause malfunction. The ejected tray may also

become a cause of injuries.

Do not touch the equipment when it thunders.

Unplug the equipment when it threatens to thunder. If it starts to thunder before

you unplug the equipment, do not touch the equipment and cables. There is a

risk of a fire or electric shock.

CAUTION

Precautions for Use 1-9

1-10 Precautions for Use

Rack-mount Model

Do not install the equipment on a nonconforming rack.

Install the equipment on a 19-inch rack conforming to the EIA standar d. Do not

use the equipment without a rack or install it on a nonconforming rack. The

equipment may not function properly, and there is a risk of damage to physical

assets or injuries. For suitable racks, contact your sales agent.

Do not use in the spot other than the designated one.

Install this equipment in the spot where it satisfies the conditions of installation.

Installing this equipment in an undesirable spot causes negative effects on the

equipment itself and other systems. There is also a risk of a fire as well as an

injury caused by the rack that falls. Refer to the description that is attached the

rack, or contact your maintenance service agent for the detailed accounts of the

installation spot or a seismic construction.

WARNING

Precautions for Use 1-11

CAUTION

Be careful not to hurt your fingers.

Exercise great care not to hurt your fingers on the rail when you

mount/dismount the server into/from the rack.

Do not attempt to install the server yourself.

Transport and install the rack with three and more people. Doing so with two

people and less could cause the falling of the rack and damaging the

surroundings. Make sure to support a rack, transport and install it particularly

when it is a high one (such as 44U rack) that is not anchored with stabilizers.

Do not install the equipment in such a manner that its weight is imposed on a

single place.

To distribute the weight, attach stabilizers or install two or more racks. It may

fall down to cause injuries.

Do not assemble parts alone. Check the hinges and gudgeons.

Mount doors and trays to a rack with two and more people. Make sure that the

hinges and gudgeons on the top and the bottom of the door when you install it.

Neglecting this check could lead to dropping some parts and cause a br eakage

of them or could result in injuries.

Do not pull an equipment out of the rack if it is unstable.

Before pulling out a equipment, make sure that the rack is fixed (by stabilizers

or quake-resistant engineering). It may fall down to cause injuries.

Do not leave two or more equipments pulled out from the rack.

If you pull out two or more equipments, it may fall down to cause injuries. You

can only pull out one equipment at a time.

Do not install excessive wiring.

To prevent burns, fires, and damage to the equipment, make sure that the rated

load of the power branch circuit is not exceeded. For more information on

installation and wiring of power-related facilities, contact your electrician or local

power company.

Do not pull out a equipment from the rack during operation.

Do not pull out a equipment while it works. There is a risk of malfunction and

injuries.

1-12 Precautions for Use

For Proper Operation

Observe the following instructions for successful operation of the server. Failure to observe them

could lead to malfunction or breakdown.

Do not use a cellular phone or pager around the equipment. Turn off your cellular phone or

pager when you use the equipment. Their radio waves may cause the equipment to

malfunction.

Perform installation in a place where the system can operate correctly. For details, see the

separate volume “User’s Guide (Setup).”

Before turning off the power or ejecting a CD/DVD-ROM or disk, make sure that the access

LED is off.

When you have just turned off the power, wait at least 30 seconds before turning it on again.

Once you have turned on the server, do not turn it off until the “NEC” logo appears on the

screen.

After plugging in the power cord, do not turn on the power of the equipment for 30 seconds.

For safe operation, it is recommended to reboot the OS after duplication is completed.

Before you move the equipment, turn off the power and unplug the cord.

We do not guarantee reproduction of copy-protect DVDs and CDs using reproduction

equipment if such disks do not comply with the standards.

Clean the equipment regularly. (For procedures, see Chapter 6.) Regular cleaning is effective

in preventing various types of trouble.

Lightning may cause voltage sag. As a preventive measure, it is recommended to use UPS

(uninterruptible power supply).

This equipment does not support the connection through an UPS serial port (RS-232C) or the

control using PowerChute Plus.

Check and adjust the system clock before operation in the following conditions:

- After transporting the equipment

- After storing the equipment

- After the equipment halt under the conditions which is out of the guranteed

environment conditions (Temperature: 10 to 35°C, Humidity: 20 to 80%)

.

Check the system clock once in a month. It is recommended to operate the system clock

using a time server (NTP server) if it is installed on the system which requires high level of

time accuracy. If the system clock goes out of alignment remarkably as time goes by, though

the system clock adjustment is performed, contact your sales agent.

When you store the equipment, keep it under storage en vironment conditions (Temperature:

-10 to 55°C, Humidity: 20 to 80%, non-condensing).

Precautions for Use 1-13

If NEC Express5800/ft series, the built-in optional devices, and the media set for the backup

devices (tape cartridges) are moved from a cold place to a warm place in a short time,

condensation will occur and cause malfunctions and breakdown when these are used in such

state. In order to protect important stored data and assets, make sure to wait for a sufficient

period of time to use the server or components in the operating environment.

Reference: Length of the time effective at avoiding condensation in winter (more than 10°C

differences between room temperature and atmospheric temperature)

Disk devices: Approximately 2-3 hours

Tape media: Approximately 1 day

Make sure that the optional devices are attachable and connectable to the equipment. There is

a risk of malfunctions that could lead to a br eakdown of the equipment even if you could

attach and connect.

Make sure that your options are compatible with the system. If you attach any incompatible

option, there is a risk of malfunction that could lead to a breakdown.

It is recommended to use NEC's genuine option products. Some competitors’ products are

compatible with this server. However, servicing for trouble or damage resulting from such a

product will be charged even within the warranty period.

1-14 Precautions for Use

Transferring to Third Party

Observe the following notes for transferring the main unit or other embedded devices to third

party.

Main unit

Attach this manual when you alienate or sell this device.

IMPORTANT:

Data in the hard disk drives:

Make sure to delete all the important data such as client information or corporate

accounting information stored in the hard disk drives installed on the device to be

alienated.

Operations such as Empty Recycle Bin on Windows or Linux, or commands such as

formatting seem to delete data completely. However, the data still remains on the hard

disk drives. Such undeleted data can be restored by special software, and may be

diverted.

To avoid this kind of troubles, it is strongly recommended to use commercial software or

services to completely delete the data. For the details on data deletion, contact your local

reseller.

We are not responsible for any data leakage from alienating or selling the dev ice if you

do not delete the data completely.

Bundled software

The following conditions must be satisfied when you alienate or sell the bundled software.

- Alienate all the bundled. After alienating, do not save any copy of them.

- Alienation or transferring of Software User License Agreement must be satisfied.

- For software that alienation or transferring is not allowed, uninstall from the device

before alienate it.

Precautions for Use 1-15

Disposal of Equipment and Consumables

When you dispose of the main unit, hard disk drives, floppy disks, Flash FDDs, optical

disks, optional boards, batteries, etc., you need to observe your local disposal rules.

the attached power cable along with the equipment to avoid being used with other equipment.

For details, ask your municipal office.

IMPORTANT:

For disposal (or replacement) of batteries on the motherboard, consult with your sales

agent.

You are responsible for wiping out such data before disposal. Erase all data on the hard

disk, backup data cartridges, floppy disks, Flash FDDs, or other writable media (such as

CD-R, CD-RW, and DVD-R); prevent your data from being restored and re used by a

3rd party. You need to exercise sufficient care to protect privacy and confidential

information.

Some of the system components have limited lifetime (e.g., cooling fans, built-in batteries,

built-in DVD-ROM drive, floppy disk drive and mouse). For stable operation, it is

recommended to replace them regularly. For lifetime of individual components and replacing

procedures, ask your sales agent.

Dispose

1-16 Precautions for Use

Transporting Device

This unit and options use lithium-metal battery or lithium-ion battery.

Contact your local reseller for transporting the unit by air or shipping since the regulation is applied

to air and maritime transportation of lithium battery

Precautions for Use 1-17

ABOUT OUR WEB SERVICE

Information on NEC Express5800/ft series including modification modules is also available on ou r

web site, NEC Express5800 Web Site Asia Pacific, at

http://www.nec.co.jp/express/index.html

1-18 Precautions for Use

Advice for Your Health

Prolonged use of a computer may affect your health. Keep in mind the

following to reduce stresses on your body:

Sit in a good posture

Sit on your chair with your back straight. If the desk height is appropria te,

you will slightly look down at the screen and your forearms will be parallel to

the floor. This “good” work posture can minimize muscle tension caused by

sedentary work.

If you sit in a “bad” posture—for example, sit round-shouldered or with you

face too close to the display—you may easily suffer fatigue or have your

eyesight affected.

Adjust the installation angle of Display

Most types of displays allow you to adjust the angle vertically and

horizontally. This adjustment is very important to prevent the reflection of

light as well as to make the screen more comfortable to see. Without this

adjustment, it is difficult to maintain a “good” work posture and may get tired

soon. Be sure to adjust the angle before using the display.

Adjust Brightness and Contrast

Displays allow you to adjust brightness and contrast. Optimum brightness

and contrast vary depending on the individual, age, bright ness of the room,

etc; you need to make an adjustment accordingly. If the screen is too bright

or too dark, it is bad for your eyes.

Adjust the installation angle of Keyboard

Some types of keyboards allow you to adjust the angl e. If you adjust the

angle to make the keyboard more comfortable to use, you can greatly

reduce stresses on your shoulders, arms, and fingers.

Clean the Equipment

Cleanliness of the equipment is very important not only for reasons of

appearance but also from the viewpoints of function and safety. Especially,

you need to regularly clean the display, which gets unclear due to the

accumulation of dirt.

Take a break when you get tired

If you feel tired, you are recommended to refresh yourself by taking a short

break or doing a light exercise.

Chapter 2

General Description

This chapter describes what you need to know to use the NEC Express5800/ft series. Refer to

this chapter when you want to know about certain components and how to operate them.

2-2 General Description

STANDARD FEATURES

The NEC Express5800/ft series is the server that has hardware for two servers.

High performance Various Features

Intel® Xeon® Processor

(2.00GHz/2.93GHz)

High-speed Ethernet interface

(1000Mbps/100Mbps/10Mbps supported)

High-speed disk access (SAS (Serial

Attached SCSI))

Expandability Self-diagnosis

Various IO optional slots

- PCI Express REV1.1 (4 lane)

2 slots (Low Profile)

- PCI Wxpress REV2.0(4 lane)*

2 slots (Full Hight)

Large capacity memory supported

: Max 96 GB

USB supported

High-reliability Maintainability

Memory monitoring feature (Correctable

error correction/ Uncorrectable error

detection)

Bus parity error detection

Error notification

BIOS password feature

Management Utilities Easy and Fine Setup

NEC ESMPRO

Ready-to-use

Quick cableless connection: hard disk,

CPU/IO module

Graphic accelerator “PILOT2” supported

Power On Self-Test (POST)

Test and Diagnosis (T&D) Utility

Off-line Maintenance Utility

NEC EXPRESSBUILDER (system setup

utility)

SETUP (BIOS setup utility)

Fault-tolerant Feature

Redundant modules achieved within a

system

Higher hardware availability by isolation of

failed module

* For R320b-M4 only.

General Description 2-3

Hardware modules work while synchronizing and comparing with each other. Even if one

hardware module stops, the server can continue its operation as the service with the other

hardware module.

Even if one hardware module stops, the server can continue operation with the other module. After the

failed module is replaced, the new module will obtain information from the other and resume operation.

NEC Express5800/ft series is a highly fault-tolerant server that achieves continuous computing

operations, data storage mirror, and continuous network connection. It allows you to run

Windows Server-based applications.

NEC Express5800/ft series achieves continuous computing operations for the Windows server

and server-based applications with its redundant CPU processing and redundan t memory. It

assures data redundancy through duplication of server data on an independent storage system.

These features eliminate server downtime that is usually caused by network disconnection or

trouble with the I/O controller, Ethernet adapter or disk drive, and support operation of the

network and server applications continuously. While being transparent to application software,

NEC Express5800/ft series achieves high fault-tolerance.

NEC Express5800/ft series detects status changes, errors and other events and notifies the Log of

these events. If you use an alarm notification tool, you can configure NEC Express5800/ft series

to notify you when certain events occur.

NEC ESMPRO is installed on the system as a server management solution. NEC ESMPRO, a

GUI-based management tool, allows you to monitor, view, and configure NEC Express5800/ft

series. This tool also supports both local and remote management of NEC Express5800/ft series.

2-4 General Description

NEC Express5800/ft series mainly provides the following advantages:

Highly fault-tolerant processing and I/O subsystems

NEC Express5800/ft series use redundant hardware and software to assure server

operation even if one module suffers trouble with its processor, memory, I/O

(including trouble related to the I/O controller), disk drive, or Ethernet adapter.

Continuous network connection

NEC Express5800/ft series maintains continuous network connection by detecting

any trouble with the network adapter, connection, etc. If trouble occurs, the standby

network connection will take over all network traffic processing and thus securely

maintain the network system connection of NEC Express5800/ft series without

losing network traffic or client connection.

Support of multiple network connections

Since NEC Express5800/ft series can support multiple Ethernet connections, you can

add network redundant control or network traffic control.

Industry standard hardware platform

NEC Express5800/ft series uses IA (Intel Architecture)-based system hardware.

No need to modify applications

You can run Windows Server 2008-compliant applications on NEC Ex pres s5800/ft

series. Thus, unlike other highly fault-tolerant products, special API or scripts are not

necessary.

Automati c mi rroring

NEC Express5800/ft series automatically maintains data as the current data.

Automatic detection and notification of faults

NEC Express5800/ft series detects and sorts out all events such as general status

changes and faults, and notifies Log of these events.

Transparent migration

NEC Express5800/ft series constantly monitors events. If trouble occurs on NEC

Express5800/ft series’ server module, it will transparently use a redundant module of

the failed module. This feature maintains data and user access without losing

application service.

Automatic reconfiguration

When the failed module restarts after the trouble is corrected, NEC Express5800/ft

series will perform reconfiguration automatically, and if necessary, resynchronize the

affected modules. Reconfiguration can include CPU processing (e.g., CPU memory),

server's operating system (and related applications), and system data stored on the

hard disks. In most cases, NEC Express5800/ft series automatically restores

redundancy of the server modules after recovery.

General Description 2-5

Local and remote management

NEC Express5800/ft series uses NEC ESMPRO as a server management tool. This

tool uses a GUI that enables monitoring and setting of NEC Express5800/ft series.

NEC ESMPRO can be used both locally and remotely on work station PCs or server

PCs.

Event notification function

When trouble or other events are detected on NEC Express5800/ft series, they will

be notified to Log and saved. Therefore, you can view the log items locally or

remotely by a usual Windows procedure. Since an NEC Express5800/ft series events

use unique IDs, they are easy to distinguish.

In-service repairing

You can repair or replace a failed module even if NEC Express5800/ft series is

operating.

Partition structure

On this server model, the first logical drive will be the following state when the

setup by NEC EXPRESSBUILDER is complete.

CHECK:

The partition for operating system is not mirrored at the time of NEC

EXPRESSBUILDER setup completion. Mirror the partition separately.

NOTE:

When new partition is created, initial 100MB is assigned as boot partition by

Windows OS.

Windows OS and media

The Windows OS media used on NEC Express5800/ft series are not specifically

processed for it. The standard operating methods of Windows are same as general.

* The size varies depending on the specification at setup.

2-6 General Description

HOW THE OPERATING SYSTEM SEES THE CPU

MODULES

On NEC Express5800/ft series, the CPU modules are redundantly configured and all processors

installed on this server are shown.

How CPU modules appear on Task Manager

CPUs are displayed as many as there are.

System with one CPU (Quad-Core)

* The above are screens when NEC Express5800/R320a-E4 is used.

For NEC Express5800/R320b-M4, up to 12 logical CPUs are displayed in the one-CPU

configuration, and up to 24 logical CPUs are displayed in the two-CPU configuration.

System with two CPUs (Quad-Core)

General Description 2-7

NAMES AND FUNCTIONS OF COMPONENTS

Names and functions of components are shown below:

(1) Front bezel

The cover to protect devices in the front.

(2) LEDs

For more information, see the description on the front view on page 2-8 and rear view

on page 2-10.

2-8 General Description

Front View

(1) CPU/IO module 0

This is a module with a set of CPU (processor), memory (DIMM), PCI board, cooling

fan unit, and hard disk drive.

(2) Hard disk drive bay

This is the bay to mount the hard disk drive. The number after the numbers in

parentheses indicates a slot number.

(3) UID (Unit ID) switch

This is to switch ON/OFF the UID LED on the front of the device.

When processing the switch once, UID LED lights and it goes off when pressing it

again.

(4) Dump (NMI) switch

Memory dump is executed when pressing the button.

With front bezel attached

With front bezel removed

(5) Disk access LED

This LED illuminates/blinks while accessing the installed hard disks.

(6) Optical disk drive

This device is used to read data from the disks such as DVDs and CD-ROMs (see

page 2-31).

(7) System POWER LED

This illuminates in green when one of the powers of the CPU/IO modules is ON. LED

goes off when both powers of CPU/IO module are OFF.

(8) System FAULT LED

When one of the CPU/IO modules has an error, the LED illuminates in amber. Details

can be confirmed by checking EXPRESSSCOPE. The LED illuminates in amber when

it cannot identify which one of the CPU/IO moulds has an error.

(9) System FT LED

This LED displays the device status. The LED illuminates in green when operating

under duplex condition. The LED goes off if it’s not duplex. The LED illuminates in

green when executing Active Upgrade.

(10) System ID LED

The system ID LED illuminates in blue on the front bezel if pressing UID switch when

there are multiple devices installed on one rack. This enables to identify the device to

be maintained. This LED blinks in blue when there are device identification requests

remotely.

(11) USB connector

It connects with the device supporting USB interface.

(12) Power switch

This switch is to turn ON/OFF the power. When pressing it once, the power will be ON.

When pressing it again, the power will be OFF. Forced shut down takes place when

pressing it for 4 seconds or longer.

(13) CPU/IO module 1

This is a module with a set of CPU (processor), memory (DIMM), PCI board, cooling

fan unit, and hard disk drive. The name of each part is the same as CPU/IO module 0.

(14)

(15)

EXPRESSSCOPE various LEDs (green/amber)

This LED indicates the status of CPU/IO modules (see page 2-17).

SLIDE-TAG

A Label where N-Code and Serial number are printed is pasted to this tag.

General Description 2-9

2-10 General Description

Rear View

R320a-E4

⑧

R320b-M4

General Description 2-11

(1) USB connector (3 ports)

This connects with the device supporting USB interface.

(2) Management port

Ethernet connector supporting 100BASE-TX/10BASE-T.

(3) Module ID(ID LED)

The Module ID LED illuminates in green on side of CPUIO module in back if pressing

UID switch when there are multiple devices installed on one rack. This enables to

identify the device to be maintained. This LED blinks in green when there are device

identification requests remotely.

(4) LAN connector

This is the connector supporting 1000BASE-T/100BASE-TX/10BASE-T. It connects

with the network system on LAN. The number “1” indicates LAN 1 and “2” indicates

LAN 2 after the circled numbers.

(5) Power unit

This is a power unit, a standard equipment.

(5)-1 Stopper

This is a lever for the CPU/IO module not to be disconnected with the power

code connected. Ensure that the bar is not unset to remove CPU/IO module.

(5)-2 Ejector

(5)-3 AC inlet connector

(5)-4 Handle

(6) PCI slot

This is a slot to mount an optional PCI board (see page 8-30). The number after the

circled numbers indicates a slot number.

(7) Serial Port for maintenance(COM)

Do not use this port. Maintenance personnel only.

(8) Monitor connector

This is a connector to connect with a display device.

This is a socket to connect power code. Connect power code to the inlet of

CPU/IO module first which is desired to be primary.

2-12 General Description

Optical disk drive

(1) Status LED

The LED that lights while accessing the loaded DVD/CD-ROM

(2) Tray eject button

The button to eject the tray.

(3) Manual release

The hole to be forced to eject DVD tray by pinpricking when optical disk can’t be

ejected through despite pushing tray eject button.

CPU/IO Module

General Description 2-13

R320a-E4 (top cover removed)

R320b-M4 (top cover removed)

(1) PCI Riser card

2-14 General Description

Mother Board

(1) DIMM slot (5) LAN connector

DIMM 1 – DIMM6 from the top.

(5)-2 LAN2

(2) Processor(CPU) socket

(2)-1 Processor #1(CPU#1) (6) Lithium battery

(2)-2 Processor #2(CPU#2)

(7) Management port

(3) DIMM slot

DIMM7 – DIMM12 from the bottom.

(4) Connector for PCI card

(4)-1 PCI slot #1

(4)-2 PCI slot #2

CPU/IO module mother board

(5)-1 LAN1

(8) Connector for PCI riser card

Used for R320b-M4 model only.

General Description 2-15

LEDs

System POWER LED

When one of the power of CPU/IP modules is ON, the LED illuminates in gree n. The LED goes

off when both powers of CPU/ I O module are OFF.

System FAULT LED

When one of the CPU/IO modules has an error, the LED illuminates in amber. Details can be

confirmed by checking EXPRESSSCOPE. The LED illuminates in amber when it cannot identify

which one of the CPU/IO modules has an error.

System FT LED

This LED displays the device status. The LED illuminates in green when operating under duplex

condition. The LED goes off if it’s not duplex. The LED illuminates in green when executing

Active Upgrade.

System ID LED

The system ID LED illuminates in blue on the front bezel if pressing UID switch when there are

multiple devices installed on one rack. This enables to identify the device to be maintained. This

LED blinks in blue when there are device identification requests remotely.

2-16 General Description

Hard Disk Drive LED

Hard Disk LED Description Action

Not on The disk is in the idle state.

Green Accessing the disk

Amber Disk failure

Blinking in amber

(Illuminate in green when

accessing the disk)

Blinking in green and amber

in turn

The mirror of the disk is

disconnected.

The hard disk drive configuration

(rebuild) is on going.

Contact a maintenance

service company.

Perform mirroring.

Wait for a while; the LED

blinks in green after

rebuild finishes. If the

rebuild fails, the LED

illuminates in amber.

Access LED on the DVD-ROM drive

This LED illuminates when the installed DVD or CD-ROM is being accessed.

LAN Connector LED

LINK/ACT LED

The LINK/ACT LED shows the status of a standard network port. It is green if

power is supplied to the main unit and hub, and they are connected correctly

(“LINK”). It blinks green while the network port sends or receives data (ACT).

When the LED does not illuminate during “LINK,” check the condition and

connection of network cables. If there is nothing wrong with the cables, a defect is

suspected in the network (LAN) controller. In this case, contact your sales agent.

Speed LED

This LED indicates the network interface of the communication mode used by a

network port.

1000BASE-T and 100BASE-TX are the supported LAN port types. When this LED

illuminates in amber, the port is operating on 1000BASE-T; when in green,

100BASE-TX; and when not illuminate, 10BASE-T.

General Description 2-17

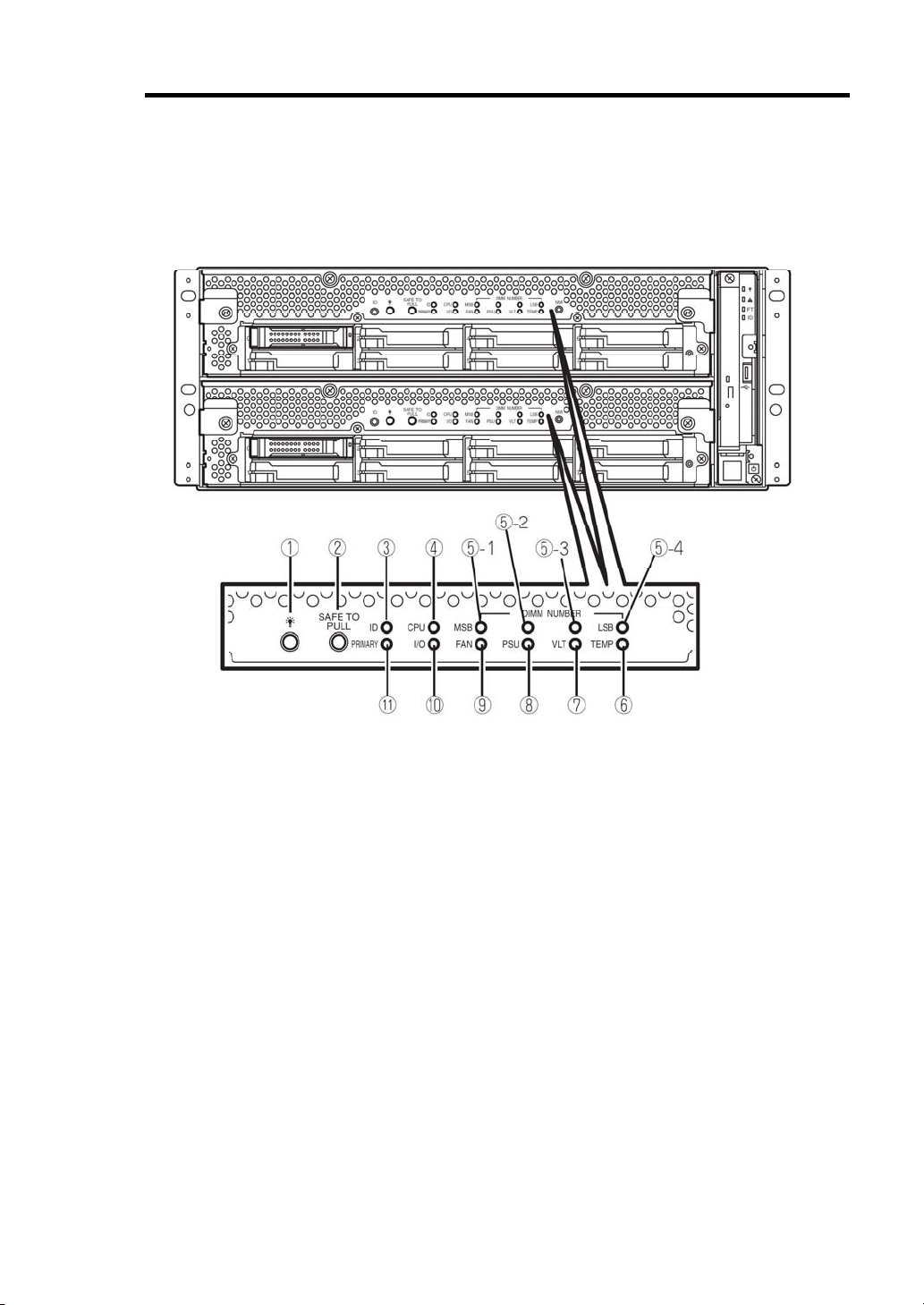

EXPRESSSCOPE

Corresponding EXPRESSSCOPE LEDs (amber) illuminate when modules have failures.

(1) Module POWER LED

While the power of CPU/IO module is ON, the LED illuminates in green. When the

power is not supplied to CPU/IO module, the LED goes off. The LED blinks when

standing by.

Amber LED illuminates when failure occurs on CPU of CPU/IO module.

(2) SAFE TO PULL

This is the LED indicating the possibility to remove CPU/IO module safely. The LED

lights in green when it is able to remove CPU/IO module.

The LED blinks in green when it is unable to remove CPU/IO module.

The LED goes off when CPU/IO module is off line and it is able to remove it.

(3) Module ID(ID LED)

The system ID LED illuminates in green on the front bezel if pressing UID switch when

there are multiple devices installed on one rack. This enables to identify the device to

be maintained. This LED blinks in blue when there are device identification requests

remotely.

(4) CPU(CPU FAULT LED)

The LED illuminates in amber when the CPU part of CPU/IO modules has an error.

2-18 General Description

(5) MEM NUMBER(Memory slot error LED)

Amber LED illuminates when failure occurs on the memory slot 0 of CPU/IO module.

Memory slots with errors can be identified by illumination status of the following (5)-1

to 4.

Each Memory Slot Error LED Status

5-1

(MSB)

- - - - Operating normally.

- - -

- -

- -

-

-

-

-

√

√

√

√

√ √

√ √ √ √

5-2 5-3

√

√ √

√

√

√ √

√ √ √

- - -

- -

-

-

- -

-

√

√ √

- -

5-4

(LSB)

√

-

√

√

-

An error occurred on memory slot 1.

An error occurred on memory slot 2.

An error occurred on memory slot 3.

An error occurred on memory slot 4.

An error occurred on memory slot 5.

An error occurred on memory slot 6.

An error occurred on memory slot 7.

An error occurred on memory slot 8.

An error occurred on memory slot 9.

An error occurred on memory slot 10.

An error occurred on memory slot 11.

An error occurred on memory slot 12.

An error occurred on unknown memory slot.

Description

LED is lit.

√

- LED is not lit.

(6) TMP (Abnormal temperature LED)

The LED lights in amber when temperature in CPU/IO module becomes abnormal.

(7) VLT (Power error LED)

The LED lights in amber when electric voltage failure occurs in CPU/IO module.

(8) PSU(Power supply unit error LED)

The LED lights in amber when failure occurs on the power supply unit of CPU/IO

module.

(9) FAN (Fan error LED)

The LED lights in amber when failure occurs on the cooling fan for CPU of CPU/IO

module.

(10) I/O(I/O FAULT LED)

The LED lights in amber when failure occurs on the I/O (PCI) part of CPU/IO module..

(11) PRIMARY(Primary LED)

The LED lights in green when CPU/IO module is primary.

General Description 2-19

POWER UNIT LED

There is a power unit LED in the power unit on the rear. The LED blinks in green when

connecting the power code to AC inlet and the power unit receives the power. The LED

illuminates in green when turning the power of the device

The power unit may be failing if the LED does not illuminate in green or the LED illuminates or

blinks in amber when turning the switch ON. Contact your sales agent to have the power unit

replaced.

2-20 General Description

BASIC OPERATION

This section describes basic operation procedures of NEC Express5800/ft series.

General Description 2-21

Installing/removing the front bezel

When you power on/off the server, handle the DVD-ROM drive, or remove/install a hard disk

drive or CPU/IO module, remove the front bezel.

IMPORTANT: The front bezel can only be removed by unlocking

the lock with the security key attached. bezel.

1. Insert the product-accessory

security key into the key slot and

push lightly. Turn the key to the left

to unlock.

2. Hold the right edge of the front

bezel and pull it forward.

3. Slide the front bezel to take the tab

off the frame and remove the front

bezel.

When attaching the front bezel, hook the left tab into the server’s frame first, then push

forward on the right side.

2-22 General Description

Power ON

To power on NEC Express5800/ft series, press the POWER switch (the one whose in-built

LED is lit).

Follow the steps below to turn on the power.

1. Power on the display unit and other peripheral devices connected to the server.