Page 1

EXPRESS5800/A1160

HW Installation Guide

Page 2

Proprietary Notice and Liability Disclaimer

The information disclosed in this document, including all designs and related materials, is the

valuable property of NEC Corporation of America, Inc. and/or its licensors. NEC Corporation

of America and/or its licensors, as appropriate, reserve all patent, copyright and other

proprietary rights to this document, including all design, manufacturing, reproduction, use,

and sales rights thereto, except to the extent said rights are expressly granted to others.

The NEC Corporation of America product(s) discussed in this document are warranted in

accordance with the terms of the Warranty Statement accompanying each product. However,

actual performance of each product is dependent upon factors such as system configuration,

customer data, and operator control. Since implementation by customers of each product

may vary, the suitability of specific product configurations and applications must be

determined by the customer and is not warranted by NEC Corporation of America.

To allow for design and specification improvements, the information in this document is

subject to change at any time, without notice. Reproduction of this document or portions

thereof without prior written approval of NEC Corporation of America is prohibited.

Trademarks

Windows is a registered trademark of Microsoft Corporation.

Intel and Itanium are registered trademarks of Intel Corporation.

All other product, brand, or trade names used in this publication are the trademarks or

registered trademarks of their respective trademark owners.

PN: 456-01805-000 December, 2008

Copyright 2008

NEC Corporation of America

10850 Gold Center Drive, Suite 200,

Rancho Cordova, CA 95670

All Rights Reserved

Page 3

Contents

Section 1

Preparing for Installation ............................................... 1-1

1.1. Documentation Updates ..................................................................... 1-1

1.2. Customer-Provided Hardware ............................................................ 1-1

1.3. Tools ................................................................................................... 1-2

1.4. Warnings and Cautions ...................................................................... 1-2

1.5. Prerequisites ...................................................................................... 1-2

1.6. Customer Support Procedures........................................................... 1-3

1.7. Cell Components ................................................................................ 1-3

1.7.1. Components on the Front of a Cell .................................................... 1-3

1.7.2. Components on the Rear of a Cell ..................................................... 1-5

1.8. Receive the Hardware........................................................................ 1-6

Section 2 Preparing the Cabinet .................................................... 2-1

2.1. Review the Cabinet Configuration ...................................................... 2-1

2.2. Install the Cell Rail Assemblies .......................................................... 2-2

Section 3 Installing the System ..................................................... 3-1

3.1. Install the Cell ..................................................................................... 3-1

3.2. Install the Optional Components ........................................................ 3-5

3.3. Install the Power Strips ....................................................................... 3-5

Section 4 Cabling the System ........................................................ 4-1

4.1. Power Cabling for 100V to 120V Systems ......................................... 4-1

4.2. Power Cabling for 200V to 240V Systems ......................................... 4-2

4.2.1. Power Strip Cabling for a System with One Cell ................................ 4-5

4.2.2. Power Strip Cabling for a System with Two Cells .............................. 4-6

4.2.3. Power Strip Cabling for a System with Three Cells ............................ 4-7

4.2.4. Power Strip Cabling for a System with Four Cells .............................. 4-8

4.3. Cell Interconnect Cabling ................................................................... 4-8

4.3.1. System with Two Cells ....................................................................... 4-9

4.3.2. System with Three Cells .................................................................. 4-10

iii

Page 4

System with Four Cells ..................................................................... 4-11

4.3.3.

4.4. Keyboard, Monitor, and Mouse Cabling ........................................... 4-12

4.5. LAN Cabling ..................................................................................... 4-12

4.5.1. LAN Configurations .......................................................................... 4-13

4.5.2. LAN Ports ......................................................................................... 4-13

4.5.3. LAN Cabling for Systems Without an Operation LAN ...................... 4-13

4.5.4. LAN Cabling for Systems with an Operations LAN .......................... 4-14

4.6. Peripheral Cabling ........................................................................... 4-15

Section 5 Completing the Installation ........................................... 5-1

5.1. Perform Cleanup and Final Check ..................................................... 5-1

5.2. Check Cabling Before Powering On the System ............................... 5-3

5.3. Apply AC Power Initially ..................................................................... 5-4

5.3.1. Systems Operating at 100 to 120 VAC .............................................. 5-4

5.3.2. System Operating at 200 to 240 VAC ................................................ 5-5

5.4. Checking and Updating Management firmware Level and the

BIOS Level ......................................................................................... 5-6

5.4.1. Initially Accessing a Partition .............................................................. 5-7

5.4.2. Checking Management Firmware Level using Remote Console

Interface ............................................................................................. 5-8

5.4.3. Checking BIOS Level using Remote Console Interface .................... 5-9

5.4.4. Obtaining Releases from the Support Site ....................................... 5-10

5.4.5. Updating Management Firmware using Remote Console

Interface ........................................................................................... 5-10

5.4.6. Updating BIOS on the EFI Flash Memory ........................................ 5-12

5.5. Verify PCI Card Installation .............................................................. 5-17

5.6. What to Do Next ............................................................................... 5-19

Appendix A Related Documents and Web Resources ........ A-1

A.1 Express5800/A1160 Documentation Library ...................................... A-1

A.2 Web Resources ................................................................................. A-2

iv

Page 5

Figures

Figure 1-1 System Serial Number Label Location ........................................................ 1-3

Figure 1-2 Front of the Cell ........................................................................................... 1-4

Figure 1-3 Rear of the Cell ............................................................................................ 1-5

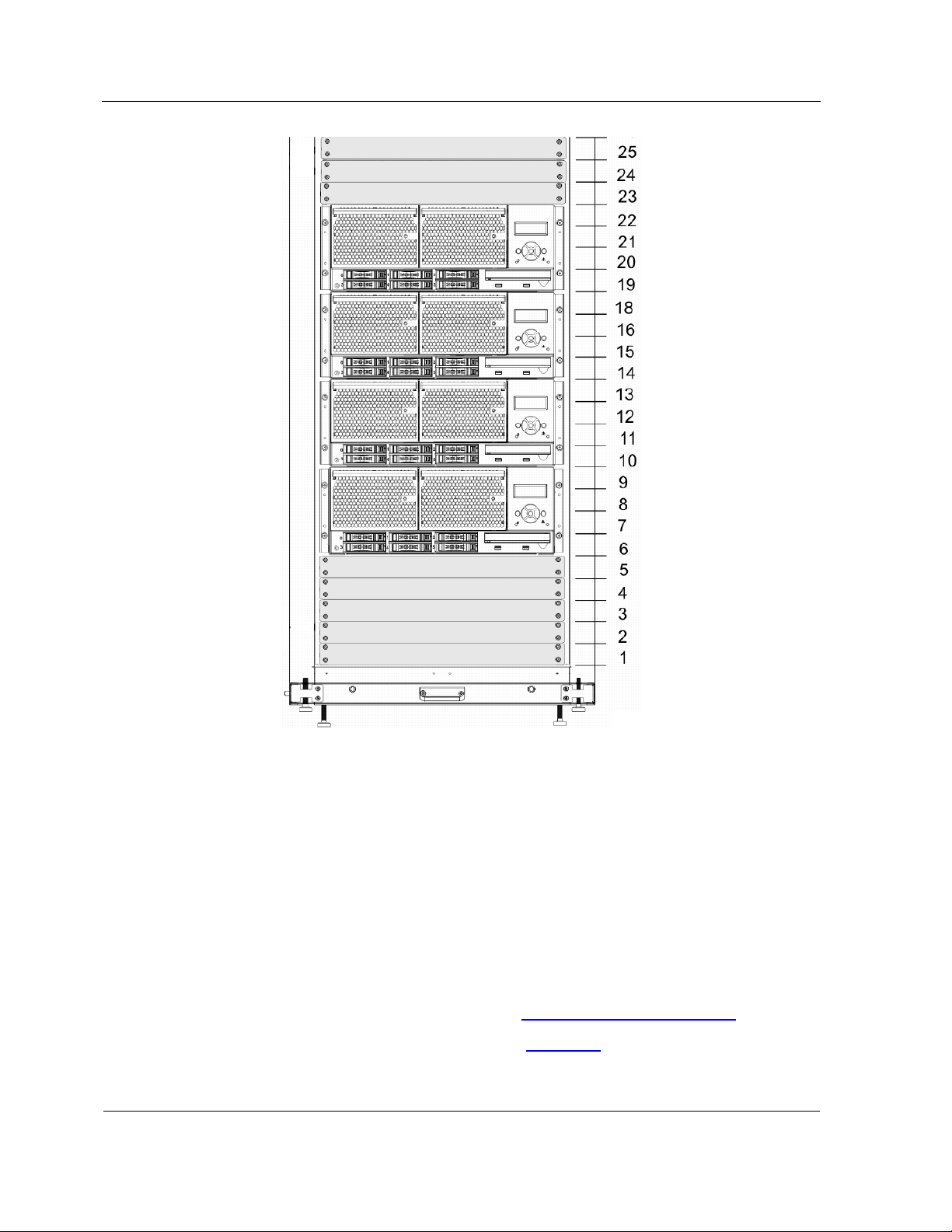

Figure 2-1 Cabinet Configuration .................................................................................. 2-2

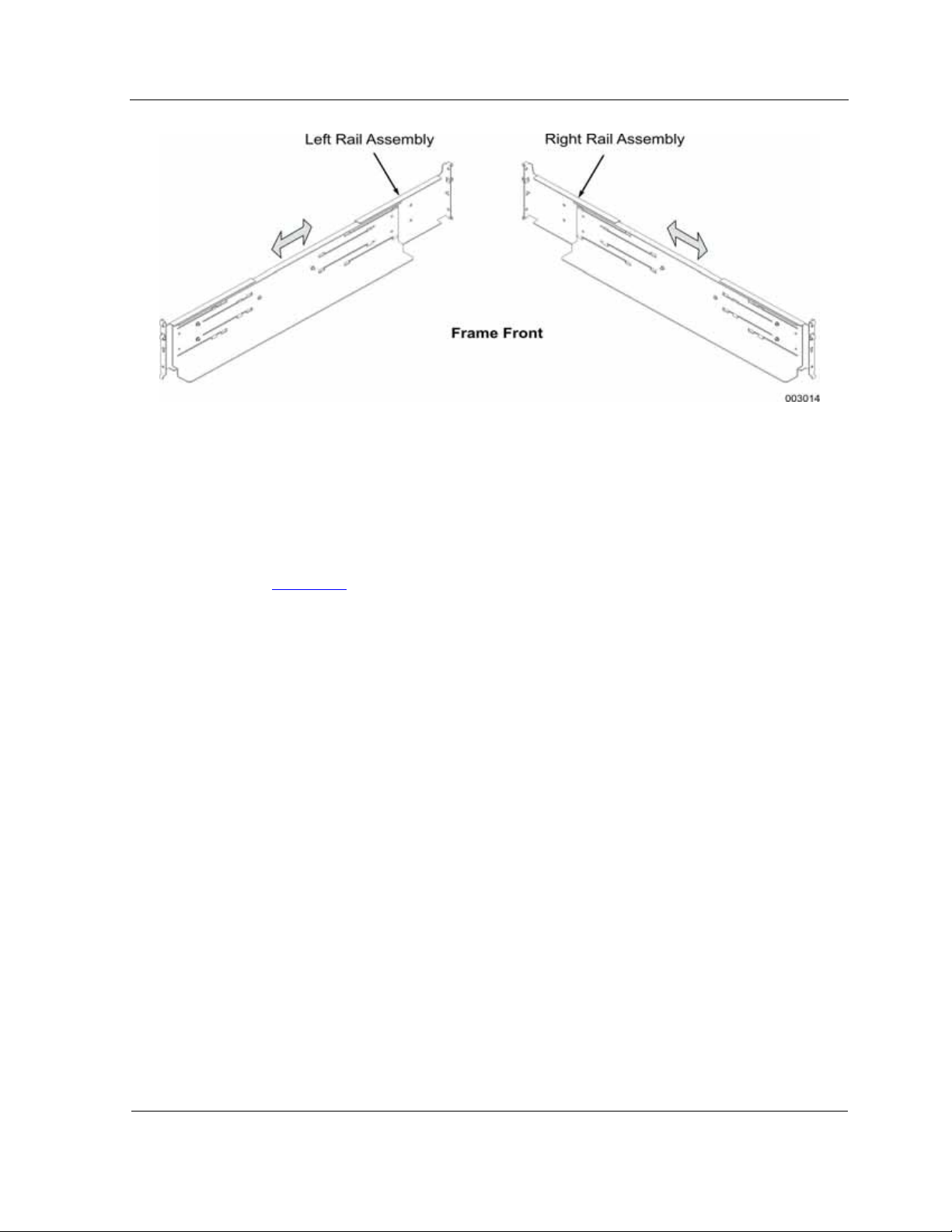

Figure 2-2 Cell Rails ..................................................................................................... 2-3

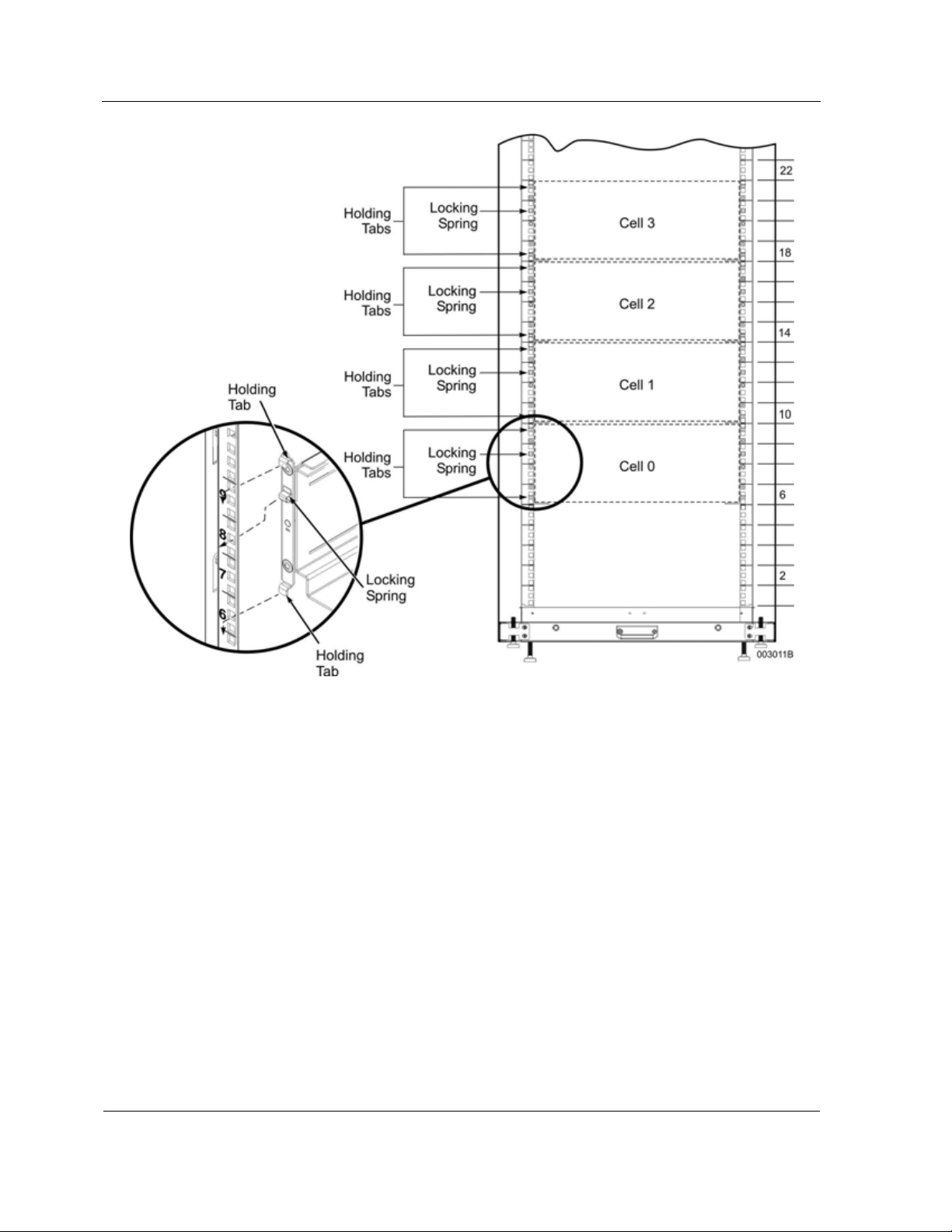

Figure 2-3 Installing Rails ............................................................................................. 2-4

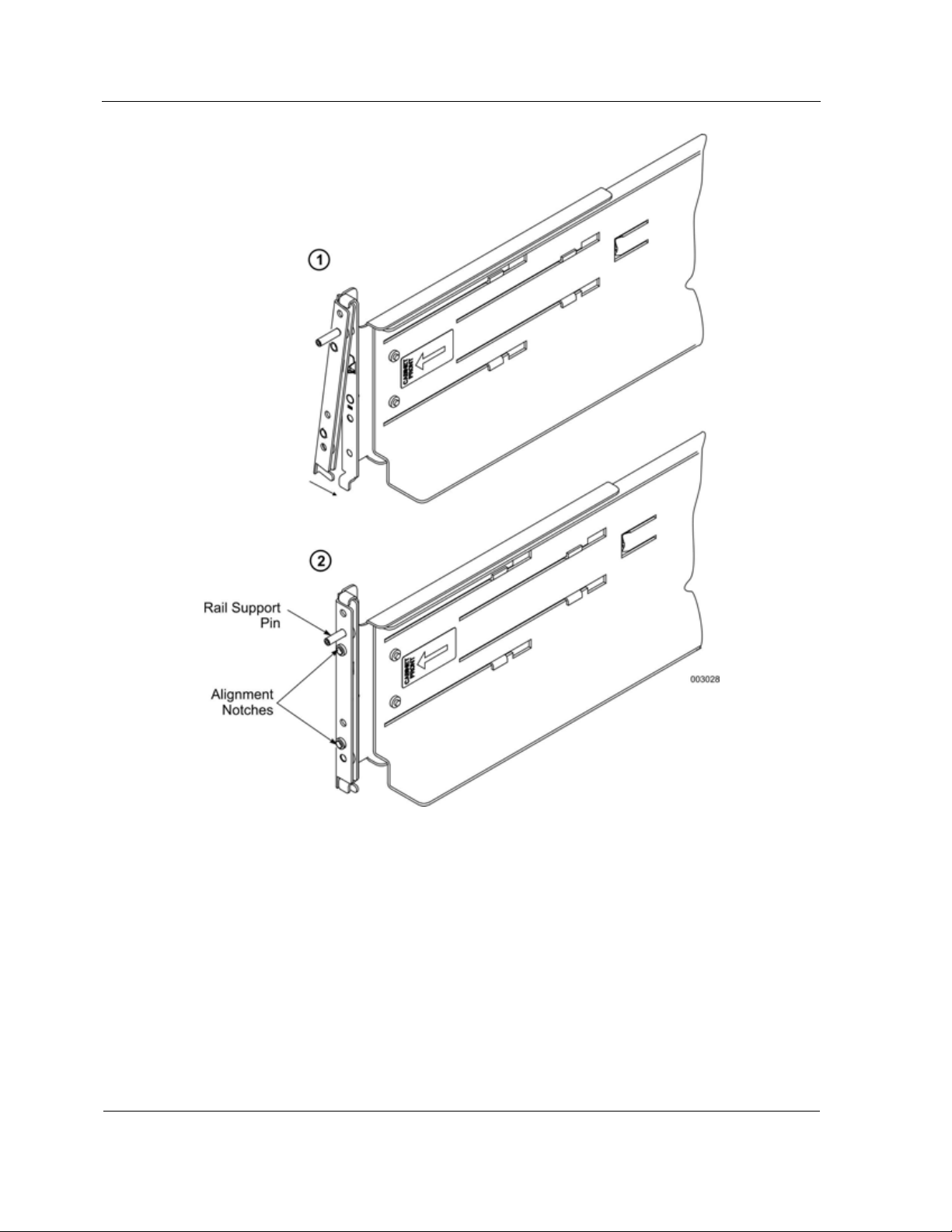

Figure 2-4 Rail Support Pin ........................................................................................... 2-5

Figure 2-5 Round-Hole Bracket Installation .................................................................. 2-6

Figure 2-6 Round-Hole Bracket Installation Location ................................................... 2-7

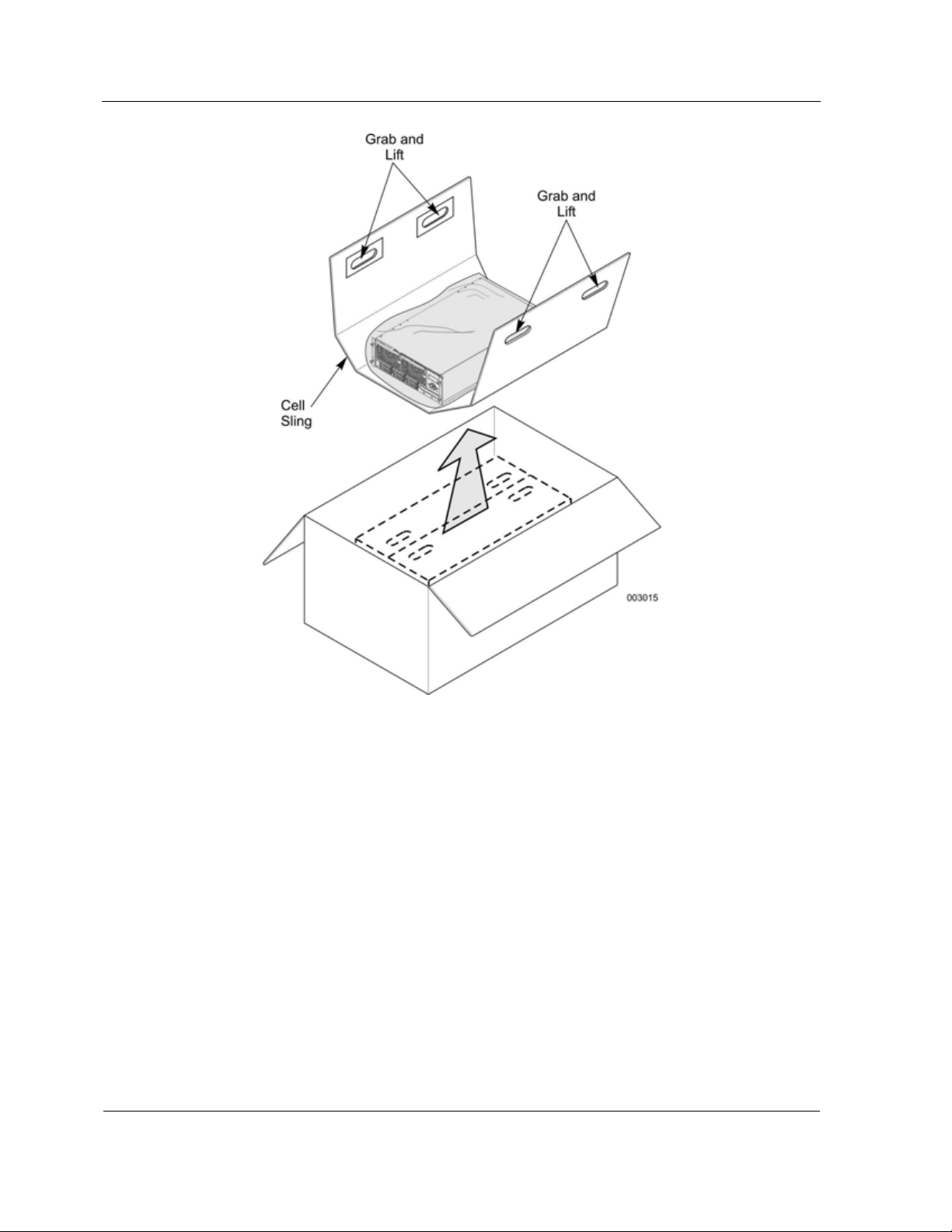

Figure 3-1 Cell Sling ..................................................................................................... 3-2

Figure 3-2 Cell Thumbscrews ....................................................................................... 3-3

Figure 3-3 Keyhole for the Security Key ....................................................................... 3-3

Figure 3-4 Security Key Location at the time of Shipment ............................................ 3-4

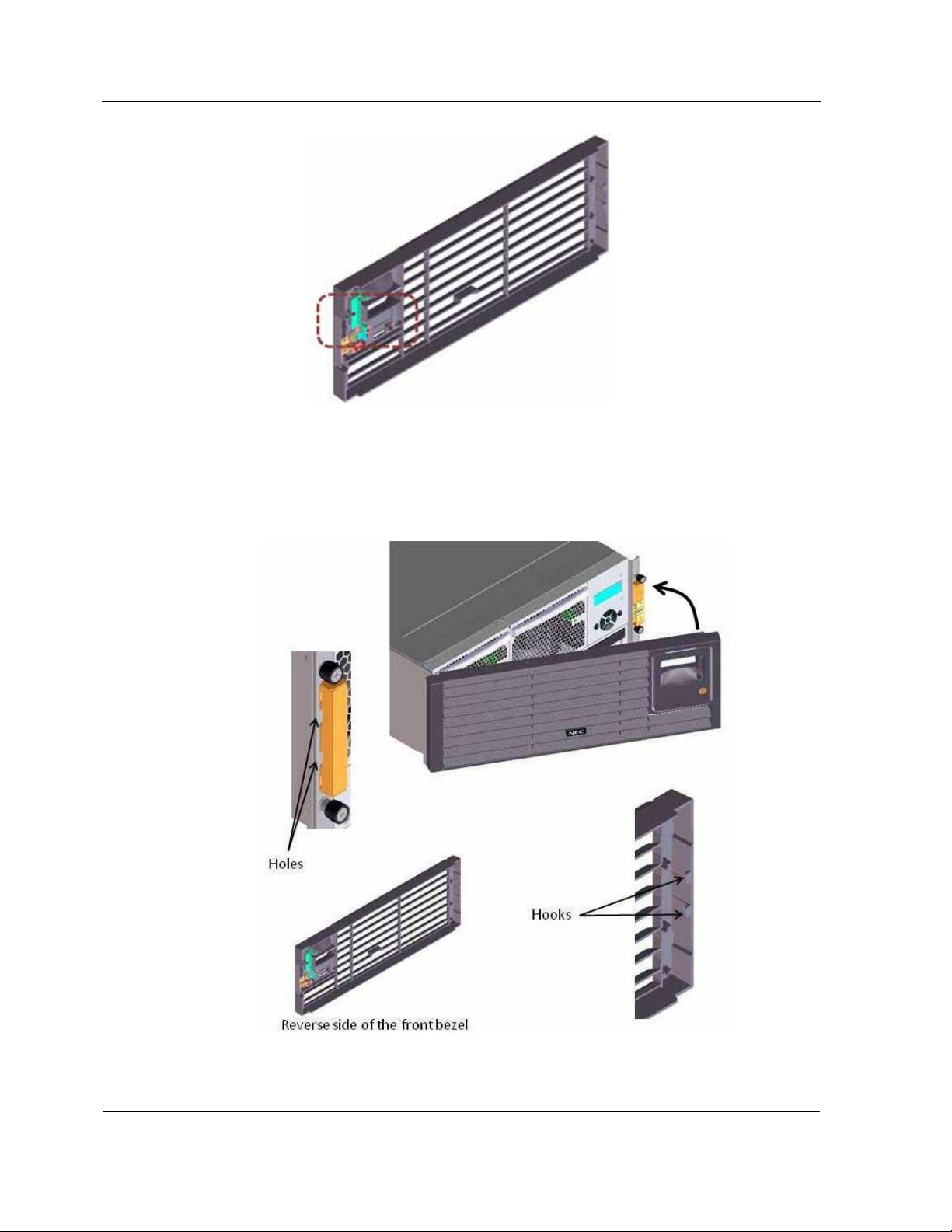

Figure 3-5 Attaching the front bezel .............................................................................. 3-4

Figure 3-6 One Four-Receptacle Power Strip Installation ............................................. 3-6

Figure 3-7 Two Four-Receptacle Power Strip Installation ............................................. 3-7

Figure 4-1 Power Cable Routing for 100V to 120V Systems ........................................ 4-2

Figure 4-2 Power-Strip Power Cord Routing ................................................................. 4-3

Figure 4-3 Velcro Straps for Power Strips ..................................................................... 4-4

Figure 4-4 Keyboard, Monitor, and Mouse Cabling .................................................... 4-12

Figure 4-5 LAN Cabling Configuration Without an Operation LAN ............................. 4-14

Figure 4-6 Cable Configuration for Systems with an Operations LAN ........................ 4-15

Figure 5-1 Front Rack Filler Panels .............................................................................. 5-2

Figure 5-2 Cell Cable Connections ............................................................................... 5-3

Figure 5-3 EXPRESSSCOPE® Monitor LCD After AC Power is Applied ..................... 5-4

Figure 5-4 Cell Power Cord .......................................................................................... 5-5

Figure 5-5 Power-Strip Power Cord .............................................................................. 5-6

Figure 5-6 Management Firmware Update Page .......................................................... 5-8

Figure 5-7 Management Firmware Revision Status ...................................................... 5-9

Figure 5-8 BIOS Version ............................................................................................. 5-10

v

Page 6

Figures

Figure 5-9 Management Firmware Updates Page ...................................................... 5-11

Figure 5-10 Management Firmware Revision Status .................................................. 5-12

Figure 5-11 BIOS Front Page ..................................................................................... 5-13

Figure 5-12 BIOS Setup Window ................................................................................ 5-14

Figure 5-13 BIOS Partition Window ............................................................................ 5-15

Figure 5-14 OS Control Window ................................................................................. 5-16

Figure 5-15 BIOS Front Page ..................................................................................... 5-18

Figure 5-16 BIOS Boot Manager ................................................................................ 5-19

vi

Page 7

Tables

Table 1-1 Warnings and Cautions ................................................................................. 1-2

Table 1-2 Components on the Front of the Cell ............................................................ 1-4

Table 1-3 Components on the Rear of a Cell ................................................................ 1-5

Table 4-1 Two-Cell Interconnect Cabling ...................................................................... 4-9

Table 4-2 Three-Cell Interconnect Cabling ................................................................. 4-10

Table 4-3 Four-Cell Interconnect Cabling ................................................................... 4-11

Tables

vii

Page 8

Page 9

Using This Guide

This guide contains information that helps you install your Express5800/A1160 server.

By following these installation procedures, you can help ensure a smooth and successful

installation of your server. This guide is intended for system administrators and facilities

personnel who are making installation of an Express5800/A1160 Server.

Proper site preparation and maintenance are vital to the reliability of any computer

system. As our customer, it is your responsibility to ensure that the proper facility

resources and conditions are maintained. This will allow us to provide support services in

accordance with the “NECCare™ Maintenance and Service Warranty Program.”

Who Should Use This Guide

This guide is intended for system administrators and facilities personnel who are

preparing the site for an Express5800/A1160 server installation.

Symbols and Conventions

This guide uses the following text conventions and graphic symbols.

Warnings, cautions, and notes have the following meanings:

WARNING

Warnings alert you to situations that could result in serious personal injury or loss

of life.

CAUTION

Cautions indicate situations that can damage the system hardware or software.

Note: Notes give important information about the material being described.

Names of keyboard keys are printed as they appear on the keyboard. For example, Ctrl,

Alt, or Enter.

Text or keystrokes that you enter appear as boldface type. For example, type abc123

and press ENTER.

File names are printed in uppercase letters. For example, AUTOEXEC.BAT.

ix

Page 10

Related Documents

Related Documents

In addition to this guide, the following system documentation is useful.

NECCare™ Guide

The NECCare Guide contains information about NEC’s warranty and server registration.

x

Page 11

Safety Notices

WARNING

To avoid a risk of injuries, maintenance procedures require trained technical

personnel.

In maintenance procedures with voltages of 42.4V peak or 60Vdc or more, take

safety measures, such as wearing insulated rubber gloves. Performing work

without these measures may cause electric shock.

In an emergency, such as a dangerous event that requires turning off the power

supply, turn off the breaker at the rear of the server. Turning off the breaker may

cause data destruction. Therefore, users should determine when to turn off the

breaker in accordance with specified operation criteria.

The server is equipped with a front stabilizer. Engage the front stabilizer during

installation. For stability and to distribute the weight, also attach side stabilizers.

Otherwise, the rack may topple over and cause injuries.

Safety Notices

If you extend two or more devices from the rack at the same time, the rack may

topple over on you. Extend only one device from the rack at a time.

Exercise great care not to hurt your fingers on the rail when you mount/dismount

the equipment into/from the rack.

Lithium batteries can be dangerous. Improper handling of lithium batteries may

result in an explosion. Dispose of lithium batteries as required by local ordinance.

Replace only with the same or equivalent type battery.

A liquid crystal display is used in this server. When handling a damaged liquid

crystal display, take care to avoid exposure to the liquid inside the liquid crystal

display. The liquid can cause bodily harm. In the event the liquid is ingested,

gargle at once and consult a doctor immediately. If the liquid comes in contact

with skin or gets into the eyes, wash the skin with cool running water, or flush the

eye with cool running water for at least 15 minutes and consult a doctor.

The DVD-ROM drive uses a laser beam. Do not look or insert a mirror inside

while the system is on. A laser beam is invisible; if your eyes get exposed to it,

there is a risk of losing your eyesight.

Elevated Operating Ambient Temperature – If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may be greater

than the room ambient environment. Therefore, consideration should be given to

installing the equipment in an environment compatible with the maximum rated ambient

xi

Page 12

Safety Notices

temperature of 89.6°F.

Reduced air Flow – Installation of the equipment in a rack should be such that the

amount of air flow required for safe operation of the equipment is not compromised.

To prevent fires, and damage to rack equipment and supply wiring, make sure that the

rated load of the power branch circuit is not exceeded. Equipment nameplate ratings

should be used when addressing this concern. For more information on installation and

wiring of power-related facilities, contact your electrician or local power company.

To prevent electrical shock, connect all rack and rack support equipment to the same

electrical circuit of the building wiring. If you are unsure, check the building wiring to

avoid remote earth conditions.

For safe operation, only connect the equipment to a building supply that is in accordance

with current wiring regulations in your country. In the USA those wiring standards are

regulated by Underwriter Laboratories (UL); in the U.K. by the Institution of Electrical

Engineers, (IEE) and in Canada by the Canadian Standards Association (CSA).

WARNING

Some locations within the server have high voltage and therefore are very

dangerous. To avoid risk of electric shock, turn off all server power and

disconnect power cables before working inside the server unit.

The main power of your server is turned off by turning off the power source to the

server or removing the power cable.

Before touching the parts in the server, wait for at least 10 to 15 seconds until

residual voltage is discharged.

Online maintenance – During and after servicing, do not leave the server door open

unless necessary to perform servicing.

xii

Page 13

Safety Notices for Users Outside of the U.S.A. and Canada

WARNING

Take care not to short live components with conductive tools, such as an

adjustable wrench.

To prevent shock, take care not to drop or leave conductive parts, such as a

screw, in the server when servicing the system.

Be careful when accessing a fan or rotating parts to avoid cutting your hand or

fingers.

Safety inspections – When servicing the system, check equipment that can cause harm

due to deterioration, and if necessary, replace the part.

Safety Notices for Users Outside of the U.S.A. and Canada

PELV (Protected Extra-Low Voltage) Integrity: To ensure the extra-low voltage integrity

of the equipment, connect only equipment with mains-protected electrically-compatible

circuits to the external ports.

Remote Earths: To prevent electrical shock, connect all local (individual office)

computers and computer support equipment to the same electrical circuit of the building

wiring. If you are unsure, check the building wiring to avoid remote earth conditions.

Earth Bonding: For safe operation, only connect the equipment to a building supply that

is in accordance with current wiring regulations in your country. In the USA those wiring

standards are regulated by Underwriter Laboratories (UL); in the U.K., by the Institution

of Electrical Engineers, (IEE) and in Canada by the Canadian Standards Association

(CSA).

xiii

Page 14

Page 15

Section 1

Preparing for Installation

This installation document describes how to install your new Express5800/A1160

system. The installer must have knowledge and experience with server hardware

installation.

Because of the server weight, the hardware installation requires a minimum of two

people to ensure a safe installation.

After installing system hardware, you will also need to do the following:

1. Install Server Management software on your management server, if you have not

already done so.

2. Install operating system software and Server Management software on the

Express5800/A1160 partitions and then configure the software.

Complete the procedures in the order in which they are shown. Depending on your

specific configuration, some procedures may not apply; just skip them.

1.1. Documentation Updates

This document contains all the information that was available at the time of publication.

The latest version of the document may be found in the Product Support Web Site:

http://support.necam.com/servers/Enterprise/

1.2. Customer-Provided Hardware

The following customer-provided hardware is required to complete the installation:

y LAN cable for the maintenance LAN

- CAT5 cable

y Additional LAN cables (CAT5 or CAT6 — Gigabit) for connection to the public LAN

y Keyboard, video, and mouse for each partition

- USB keyboard and mouse for each partition

- Monitor for the partition

The keyboard, video display, and mouse (KVM) must be directly connected to

the component during installation and cannot be redirected to a remote

workstation. After installation is complete, the keyboard, video display, and

1-1

Page 16

Tools

mouse need not remain connected and can be removed. Multiple keyboard,

video, and mouse connections can be provided by the use of a KVM switch in

larger system configurations.

y Dedicated Ethernet hub, router, or gateway depending on the LAN topology at your

site

1.3. Tools

A number 2 Phillips screwdriver is the only tool required for installation.

Optionally, a 3-mm flat-blade screwdriver might be helpful when installing the cell

interconnect cables.

1.4. Warnings and Cautions

Observe the warnings and cautions in Table 1-1 when installing the system. Additional

warnings and cautions are included as required throughout the document.

Table 1-1 Warnings and Cautions

Type of Note Instruction

Warning

Warning

Warning

Caution

Wear goggles or eye protection when cutting the bands that

secure shipping containers.

Do not push on the upper portion of a server cabinet, and use

caution when moving the cabinet on its casters. The cabinet

can tip over if not handled properly.

Have two people lift each cell. A fully loaded cell weighs about

45 kg (100 lb).

Wear a wrist strap connected to a ground point when

performing maintenance on the server.

1.5. Prerequisites

Before beginning the system installation, ensure that all site-provided power sources

and cabling are in place and that the optional (but recommended) uninterruptible power

supply (UPS) is in place and functioning properly. For more information, see the System

Planning Guide.

1-2

Page 17

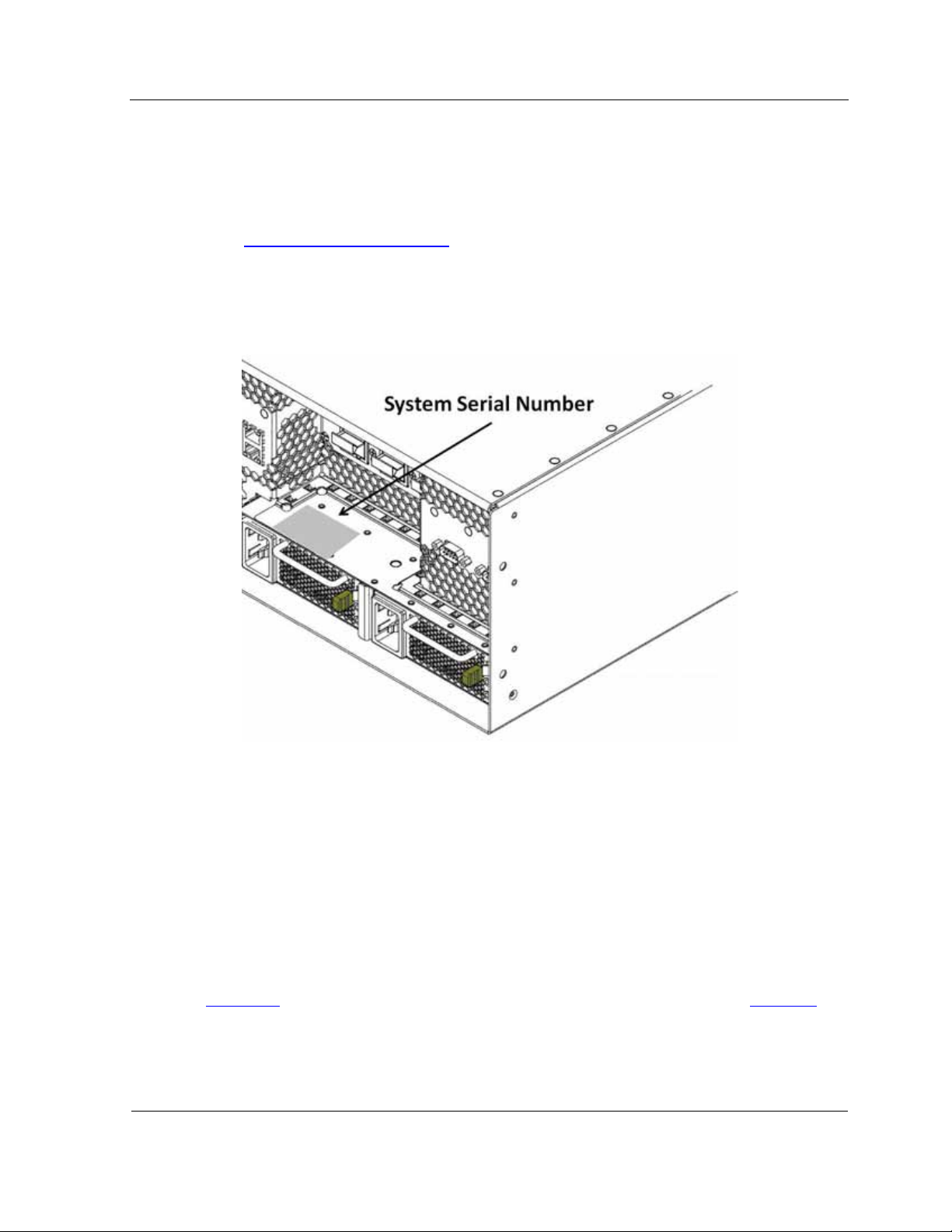

1.6. Customer Support Procedures

If you require assistance during the installation

1. Contact the NEC Technical Support by phone (1-866-269-1239) or e-mail

(server.support@necam.com

support request.

Have the system serial number available for the NEC Technical Support operator.

The system serial number is on the back of the cell on the same label as the cell

number.

) and let the operator know that you want to open a

Customer Support Procedures

Figure 1-1 System Serial Number Label Location

1.7. Cell Components

The following text identifies the main components, ports, and connectors that are visible

on the front and back of a cell.

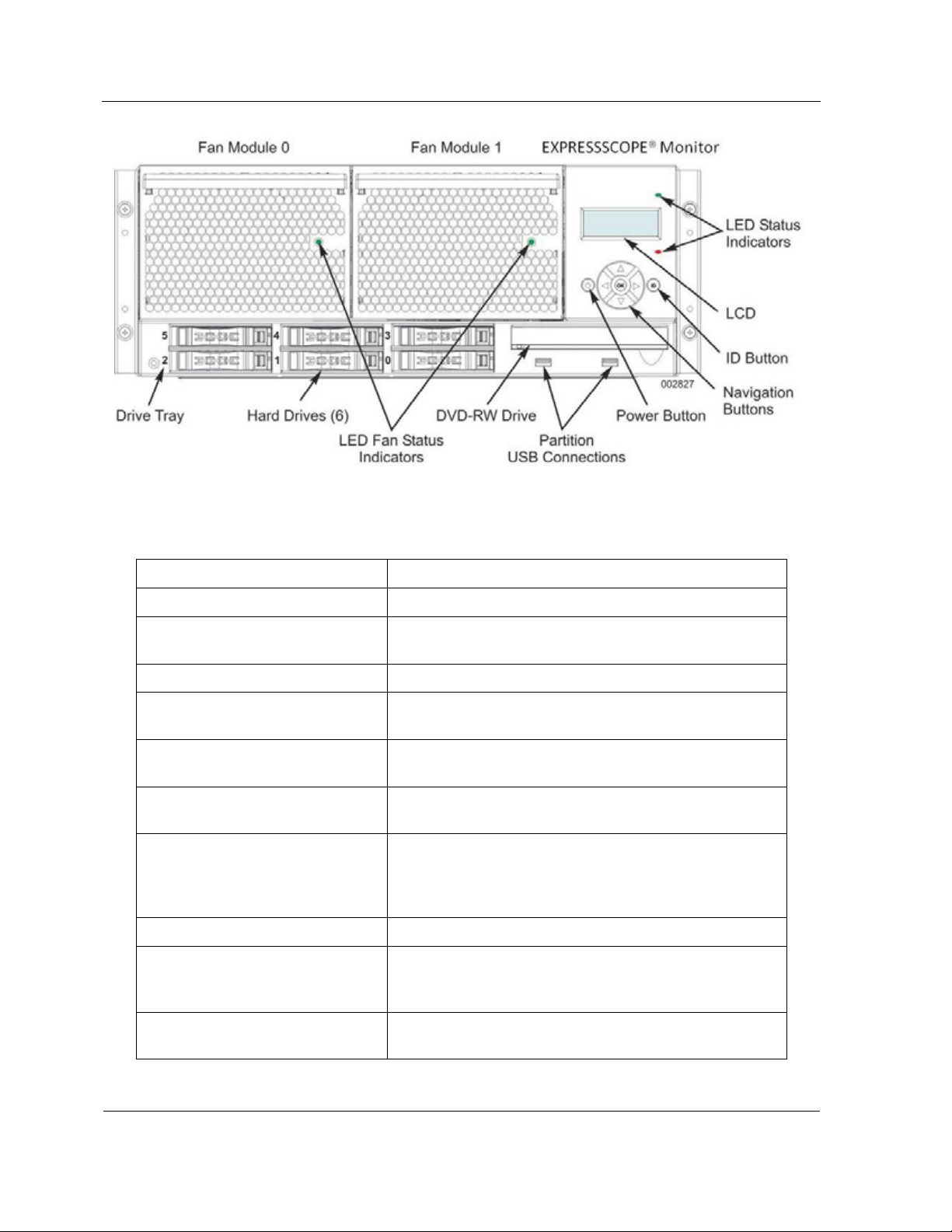

1.7.1. Components on the Front of a Cell

Figure 1-2 identifies the components that are visible on the front of the cell. Table 1-2

describes each component in more detail.

1-3

Page 18

Cell Components

Figure 1-2 Front of the Cell

Table 1-2 Components on the Front of the Cell

Component Description

Fan module Provides the airflow needed to cool the cell.

LED fan status indicators Provide fan status with one LED light on each fan module. A

green light indicates normal operations.

Drive tray Provides slots for up to six 2.5-inch SAS hard drives.

Hard drives Six 2.5-inch SAS hard drives enclosed in individual drive

carriers.

EXPRESSSCOPE® Monitor A control and display interface for the cell and the partition

containing the cell.

LED fan status indicators Provide fan status with one LED light on each fan module. A

green light indicates normal operations.

LCD Displays status information and provides a menu of

management tasks for the cell on a 4-line by 20-character

liquid crystal display (LCD) panel. Refer to the User’s Guide

for information on using the LCD.

Power button Turns on or off power for the cell.

ID button Turns on a blue LED in the back of the cell for identification

purposes during servicing. A button on the back of the cell

turns off the LED.

Navigation buttons Enables the selection of EXPRESSSCOPE® Monitor menu

options.

1-4

Page 19

Component Description

LED status indicators Provides status for the cell. The top light indicates power

status. The bottom light indicates cell status. See the

EXPRESSSCOPE® Monitor LCD or the remote console

interface for additional information on the power or cell status.

DVD-RW drive A DVD-RW drive for your use.

Partition USB connections Provides two universal serial bus (USB) 2.0 ports.

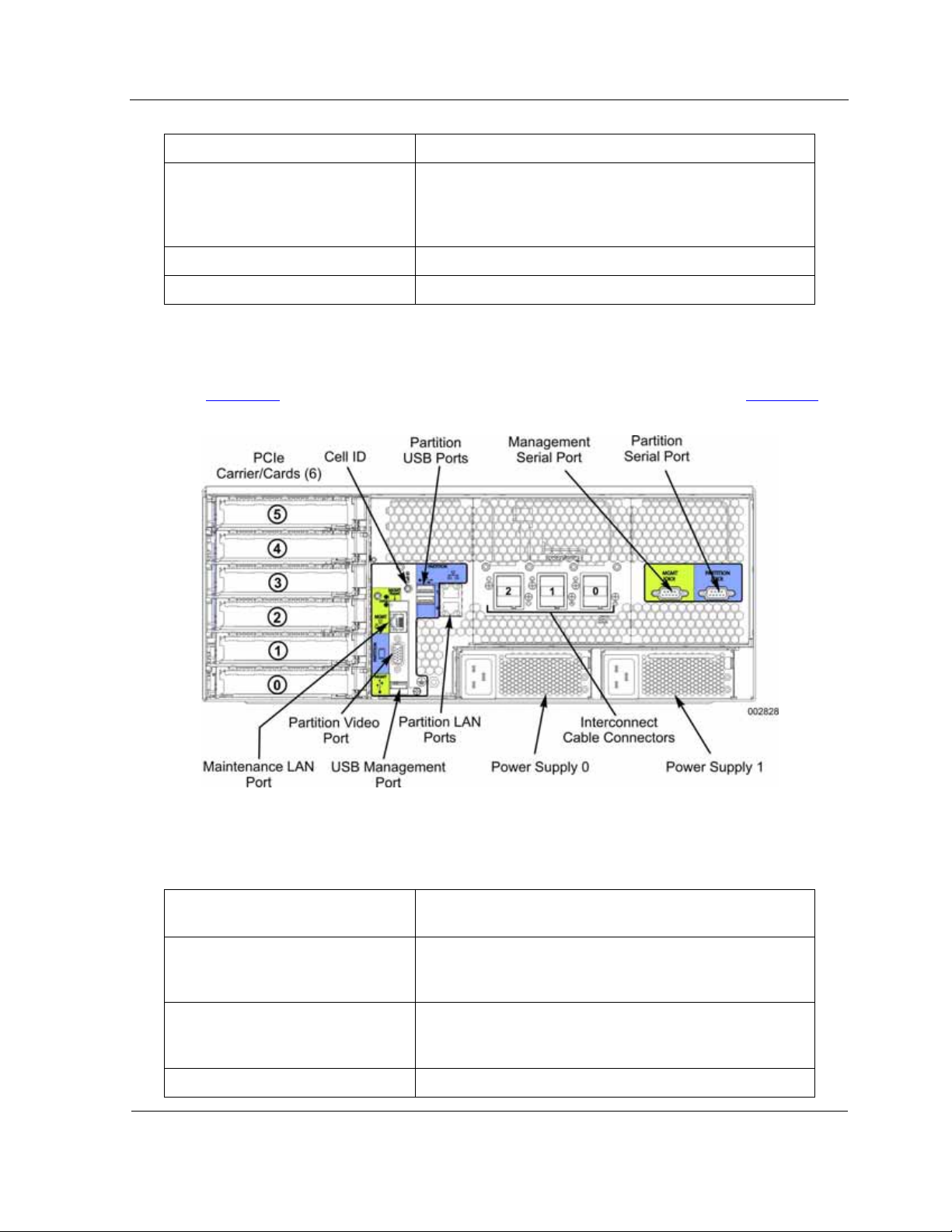

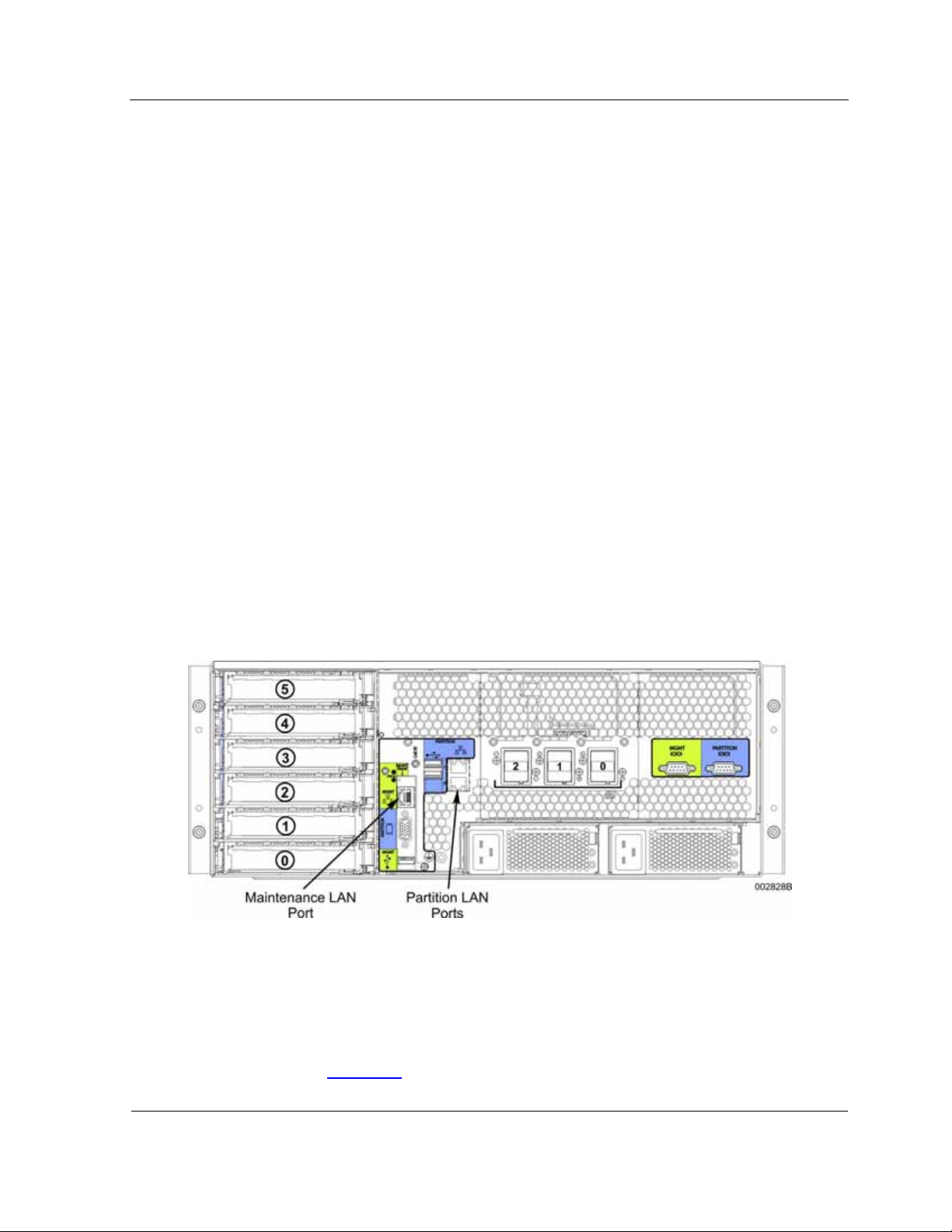

1.7.2. Components on the Rear of a Cell

Figure 1-3 identifies the components that are visible on the rear of the cell. Table 1-3

describes these components in more detail.

Cell Components

Figure 1-3 Rear of the Cell

Table 1-3 Components on the Rear of a Cell

Component Description

PCIe carrier/cards Six hot-plug switched PCIe 8x card slots. Slots 1 and 4 can

support full-length cards. Each PCIe card is housed in an

individual carrier.

Cell ID An LED that is lit when the ID button on the

EXPRESSSCOPE® Monitor is pressed. Press the cell ID

button on the rear of the cell to turn off the light.

Partition USB ports Two universal serial bus (USB) 2.0 ports.

1-5

Page 20

Receive the Hardware

Component Description

Management serial port A 9-pin serial port for the management board.

Partition serial port A 9-pin serial port for the operating system.

Maintenance LAN port An RJ45 port that provides a 10/100 Mbps Ethernet network

connection to the maintenance LAN.

Partition video port A 15-pin SVGA port.

USB management port A USB 2.0 port for use with the management board.

Partition LAN ports Two RJ45 ports that provide 10/100/1000 Mbps Ethernet

network connections for the operating system. These ports

are typically connected to the public LAN.

Navigation buttons Enables the selection of EXPRESSSCOPE® Monitor menu

options.

LED status indicators Provides status for the cell. The top light indicates power

status. The bottom light indicates cell status. See the

EXPRESSSCOPE® Monitor LCD or the remote console

interface for additional information on the power or cell status.

Power supplies Two power supplies that provide n+1 redundancy when used

in high-voltage configurations. Each power supply has its own

AC power cord.

Interconnect cable connectors High-speed serial interface and management LAN

connections between the cells in configurations with two or

more cells.

1.8. Receive the Hardware

System components are shipped to you from a number of sources.

Your order may contain a number of boxes shipped from different locations. Each box

containing a cell is marked to indicate which cell is contained in it. When you unpack

each cell, ensure that the cell is labeled and that the label information matches the cell

number indicated on its box.

y Inspect the exterior of each shipping box and pallet. If any damage is visible, make

an appropriate note on the shipping paperwork.

y Move the packaged hardware as close to its final destination as possible.

y Take an inventory of the hardware to ensure that all required items are present.

To report any missing, incorrect, or defective parts during unpacking, contact the NEC

Technical Support. Refer to 1.6 Customer Support Procedures

1-6

Page 21

Section 2

Preparing the Cabinet

Familiarize yourself with the component layout of your system and prepare your cabinet

for installation.

Side access to the cabinet is required for power strip installation. If the new cabinet will

be placed between existing cabinets, perform 3.3 Install the Power Strips

reattach the side skins and move the cabinet in place.

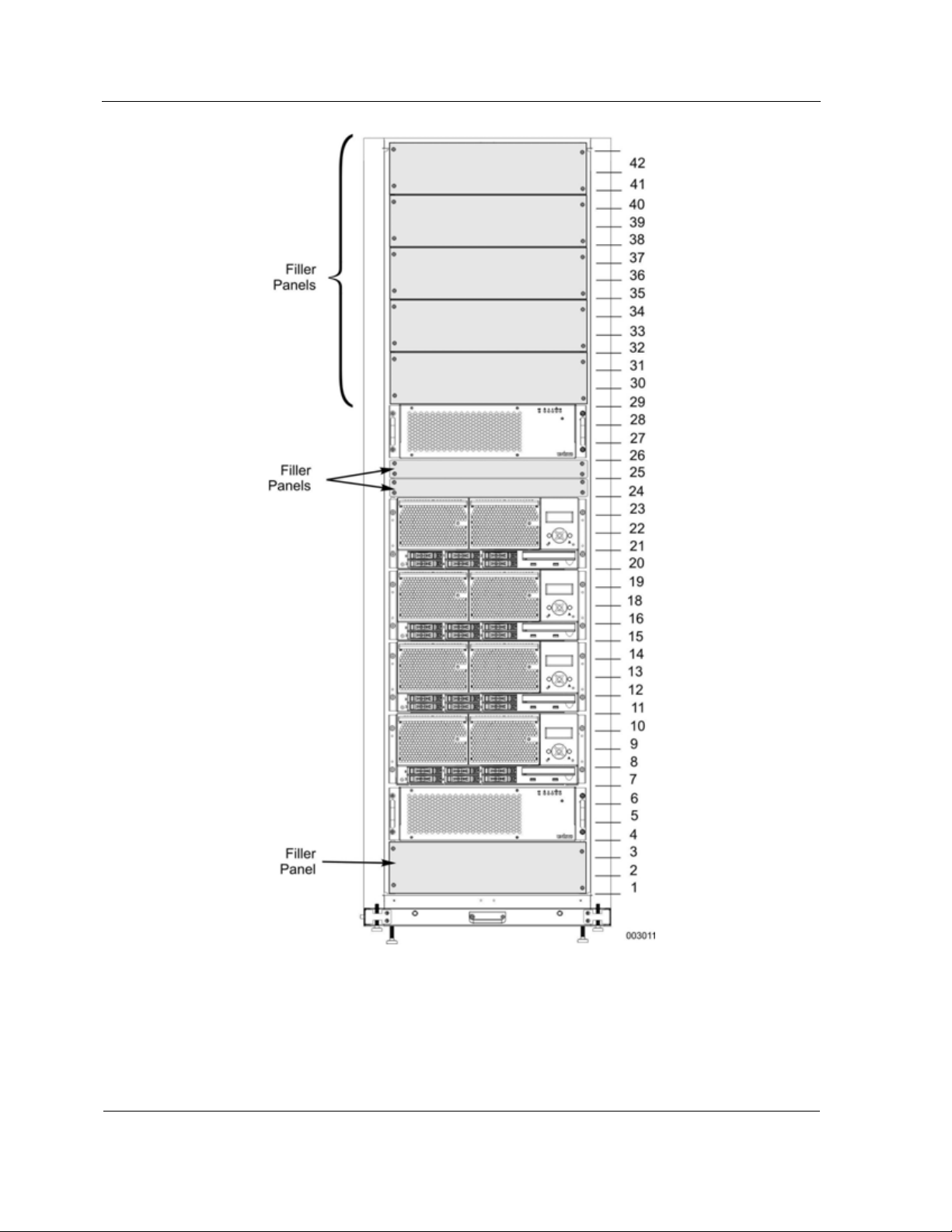

2.1. Review the Cabinet Configuration

Figure 2-1 shows the cabinet configuration. A four-cell system starts with cell 0 at the 6U

location. Smaller configurations are built similarly from the bottom of the cabinet upward,

starting with cell 0 at the 6U location. This figure shows cells and optional equipment

that might not be part of your order.

first. Then

2-1

Page 22

Install the Cell Rail Assemblies

Figure 2-1 Cabinet Configuration

2.2. Install the Cell Rail Assemblies

This procedure is for installing cell rail assemblies in a NEC cabinet; however, the rails

are designed to fit in most cabinets. Installation instructions are provided for cabinets

with square-hole or round-hole brackets. If you ordered a cabinet with your system,

follow the procedures for installing rails in a cabinet with square-hole brackets.

Note: A cell requires 4U of space in the frame.

Before you begin, remove the cell rails, hardware, and power cables from the cell

shipping carton. Set the power cables aside for Section 4 Cabling the System

The left and right rails are different, as shown in Figure 2-2

2-2

.

Page 23

Install the Cell Rail Assemblies

Figure 2-2 Cell Rails

Installing Rails in a Cabinet with Square-Hole Brackets

Perform the following procedure to install each set of rails. If you have a multiple-cell

system, install each set of rails for all cells before installing the cells.

1. Use Figure 2-3

proper placement of each rail.

as a guide to install the rails in the cabinet. The figure illustrates the

2-3

Page 24

Install the Cell Rail Assemblies

Figure 2-3 Installing Rails

2. Beginning with either the front or back of the rail, insert the holding tabs in the

specified locations and push down until the locking spring clicks into place.

3. Repeat on the other end of the rail

4. Repeat steps 1 through 3 to install the other rail.

To remove a rail, press in the locking spring with your finger or a flat-blade screwdriver

and push up on the rail.

Installing Rails in a Cabinet with Round-Hole Brackets

If you have a multiple-cell system, perform the following procedure for each set of rails

for all cells before installing the cells:

1. Locate the bracket conversion kit that is provided with the rails to convert the

square-hole brackets for use in a cabinet with round-hole brackets. The kit includes

two metal brackets, four screws, and two rail support pins for each rail.

2. Attach a rail support pin on each metal bracket. This pin is used to ease the

2-4

Page 25

Install the Cell Rail Assemblies

installation of the rail in the cabinet. Once the rails are installed in the cabinet these

pins are removed.

Figure 2-4 Rail Support Pin

3. Attach a round-hole bracket over the front and back end of each rail. Use Figure 2-5

as a guide.

2-5

Page 26

Install the Cell Rail Assemblies

Figure 2-5 Round-Hole Bracket Installation

4. Align one end of the rail in the cabinet using the alignment notches as a guide, and

secure the rail to the cabinet using two screws for each side of the rail.

2-6

Page 27

Install the Cell Rail Assemblies

Figure 2-6 Round-Hole Bracket Installation Location

5. Remove the rail support pin.

6. Repeat steps 3 and 4 to install the other rail.

2-7

Page 28

Page 29

Section 3

Installing the System

Use the following procedures to install the hardware modules of your system.

3.1. Install the Cell

Use the following procedure to install all the cells in your system.

Removing the cell from the box requires two people. A fully loaded cell weighs

about 50 kg (110 lb).

WARNING

1. Carefully lift the cell from the box using the cell sling and place the cell on a flat

surface.

3-1

Page 30

Install the Cell

Figure 3-1 Cell Sling

2. Remove the cell from the protective packaging, and then slide it onto the rails in the

cabinet.

3. Tighten the thumbscrews to secure the cell to the cabinet.

3-2

Page 31

Install the Cell

Figure 3-2 Cell Thumbscrews

If you want to attach the bezel to the front of the Cell, follow the following steps.

1. Insert the security key into the keyhole of the front bezel.

Figure 3-3 Keyhole for the Security Key

2. Turn left while pushing the security key straight to unlock.

Note: At the time of shipment, the security key is located in the bag taped at the

reverse side of the front bezel.

3-3

Page 32

Install the Cell

3. Put the hooks on the reverse side of the front bezel into the holes on the left

mounting frame between thumbscrews, and push the rightmost of the bezel to

attach.

Figure 3-4 Security Key Location at the time of Shipment

Figure 3-5 Attaching the front bezel

4. Insert the security key into the keyhole, and turn right to lock while pushing the

3-4

Page 33

security key straight.

3.2. Install the Optional Components

Depending on the server you purchased, the following items might be part of your order

or might be procured locally.

y Keyboard/LCD monitor drawer

It is recommended that the drawer be placed in the 22U or 23U location. This

position enables a user of average height to use the keyboard when standing.

y Keyboard, video display, mouse (KVM) switch

y KVM cables

y Keyboard and mouse

y Video display (monitor)

Follow the procedures that are supplied with the optional components to install these

items in the cabinet. Some components can be installed in locations outside the cabinet.

Cables are connected later as described in 4.4 Keyboard, Monitor, and Mouse Cabling

Install the Optional Components

.

Note: If you did not purchase a keyboard, video display, and mouse with the order, you

need to procure them locally.

3.3. Install the Power Strips

For high-range AC power (200 to 240 V) input, the number of required power strips

depends on the system configuration, which should have been determined during the

system planning process.

Note: Power strips are not required for systems operating at 100 to 120 volts.

Several types of power strips and mounting brackets are currently available. The two

most common options are

y Four-receptacle power strips for use in customer-supplied cabinets

y Two four-receptacle power strips in a mounting bracket for use in NEC cabinets

Note: These figures show NEC cabinets and hardware. If your cabinet is not compatible

with the brackets and hardware, simply discard the unused pieces.

Follow these steps to install the power strips:

1. Remove the power strips from the shipping carton.

2. Attach a Velcro strap, included in the packaging with the power strips, next to each

receptacle. Velcro straps are used to secure the power cables to the power strips,

which is done during Section 4 Cabling the System

. Figure 4-3 illustrates the use of

3-5

Page 34

Install the Power Strips

the Velcro straps.

3. Install the power strips at the rear of the cabinet. Position the power strips so that

the cables from the cells and any peripherals reach the appropriate strip when the

cables are routed and secured to the frame.

4. Use the illustration provided for the type of power strip to be installed.

Four-Receptacle Power Strips

Use this procedure if you did not purchase a cabinet from NEC.

To install the four-receptacle power strips to the frame, screw two screws through the

frame into the rear of the power strip, as shown in Figure 3-6

for round or square-hole cabinets.

. Use the same procedure

Figure 3-6 One Four-Receptacle Power Strip Installation

Two Four-Receptacle Power Strips in a Mounting Bracket

Before you begin the installation, mount the power strips to the mounting bracket using

the instructions provided in the box with the power strips.

3-6

Page 35

Install the Power Strips

1. Install the top and bottom nut clips. To do this, install each nut clip in the front center

hole in the cabinet location. See Figure 3-7

Note: A screwdriver can be used to compress the flange to ease the installation of

the clip.

2. Slide the mounting bracket between the top and bottom cabinet rails until the

bracket clicks into place. The mounting bracket holding tab is positioned in the

center hole behind the nut clip.

3. Secure the mounting bracket to the cabinet rails using two screws.

.

Figure 3-7 Two Four-Receptacle Power Strip Installation

3-7

Page 36

Page 37

Section 4

Cabling the System

Labels and cable ties are included with your order to use when cabling the system.

During the cabling process, mark the labels with the appropriate identification, such as

the cell number, power supply number, and power source location, and then attach the

labels to both ends of each cable.

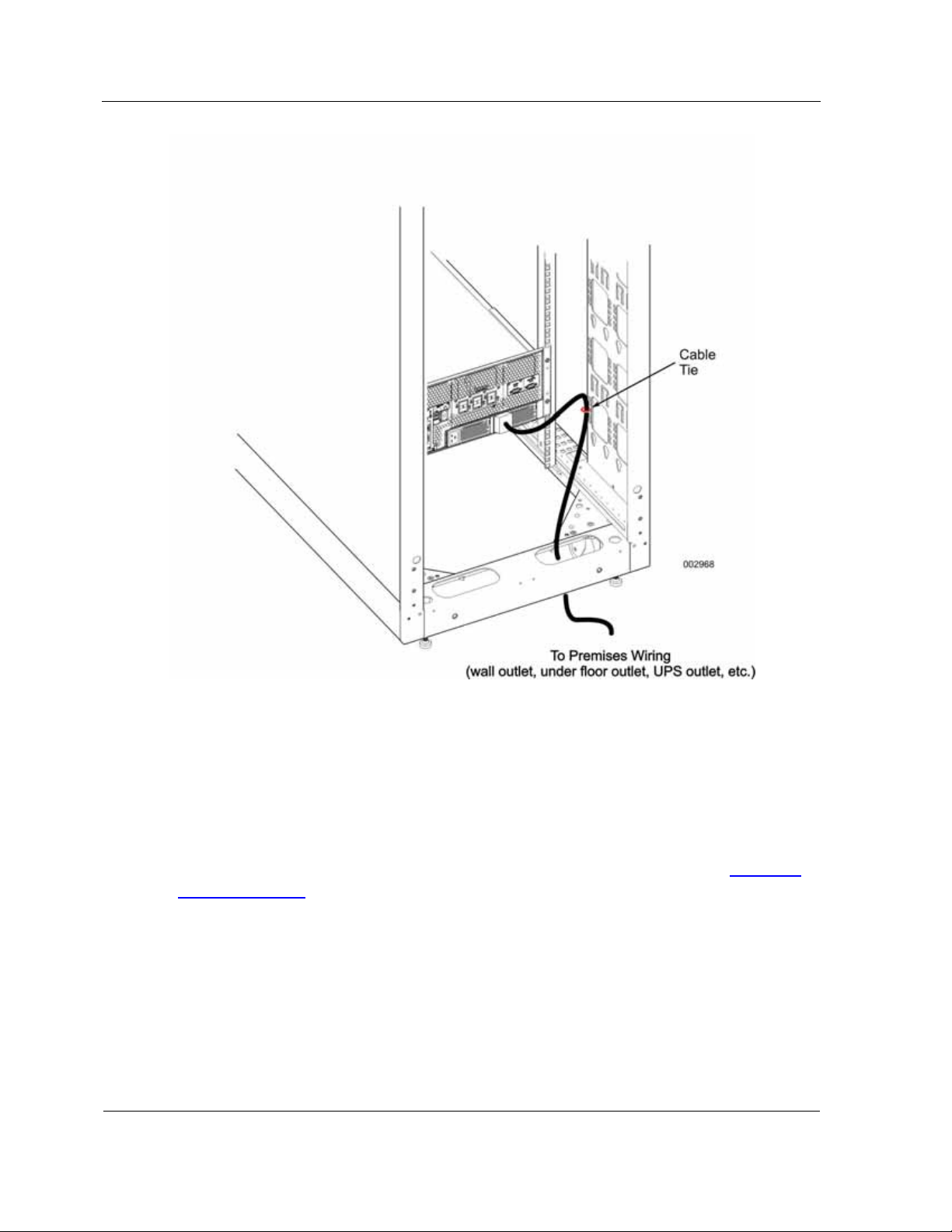

4.1. Power Cabling for 100V to 120V Systems

Use the following procedure to connect component power cables:

1. Connect the cell power cables to the cell.

2. Route the power cables down the right side of the cable manager and exit the

bottom of the cabinet as shown in Figure 4-1

secure the cables to the cabinet frame using cable ties.

. After all power cables are routed,

Do not connect the cell power cables to the premises wiring at this time. Cell power

cables are connected to the premises wiring during 5.3 Apply AC Power Initially

.

4-1

Page 38

Power Cabling for 200V to 240V Systems

Figure 4-1 Power Cable Routing for 100V to 120V Systems

3. Connect the remaining system component (such as the KVM switch) power cables

to the components.

4. Route the power cables to the appropriate power source. After all power cables are

routed, secure the cables to the cabinet frame with cable ties.

Do not connect the component power cables to the premises wiring at this time.

Component power cables are to be connected to the premises wiring during 5.3 Apply

AC Power Initially.

4.2. Power Cabling for 200V to 240V Systems

Use the following procedure to connect components to the power strips. Before you

begin, review the power strip cabling topic for your system for guidance on cable

placement. The illustrated layout is a recommended layout. Your layout might look

different depending on your configuration requirements. If you are using 30-amp power

strips, your accessory strip might be eight receptacles instead of four.

4-2

Page 39

Power Cabling for 200V to 240V Systems

1. Route the power-strip power cords down the cable manager and exit the bottom of

the cabinet. After all power cables are routed, secure the cables to the cabinet

frame using cable ties.

Do not connect the power strips to the premises wiring at this time.

Figure 4-2 Power-Strip Power Cord Routing

2. Connect the cell power cables between the cell and the appropriate power strips.

Route the cables in the cable manager and secure them.

4-3

Page 40

Power Cabling for 200V to 240V Systems

3. Connect the remaining system component power cables (such as the power cable

for the KVM switch) to the appropriate power strips.

Route the cables in the cable manager and secure them.

4. Secure the power cords to the power strip using Velcro straps.

Figure 4-3 Velcro Straps for Power Strips

4-4

Page 41

Power Cabling for 200V to 240V Systems

4.2.1. Power Strip Cabling for a System with One Cell

4-5

Page 42

Power Cabling for 200V to 240V Systems

4.2.2. Power Strip Cabling for a System with Two Cells

4-6

Page 43

Power Cabling for 200V to 240V Systems

4.2.3. Power Strip Cabling for a System with Three Cells

Note: If you are using 30-amp power strips, only two strips are required for cabling three

cells.

4-7

Page 44

Cell Interconnect Cabling

4.2.4. Power Strip Cabling for a System with Four Cells

4.3. Cell Interconnect Cabling

For systems with more than one cell, interconnect cables are used to connect the cells.

The correct end of each cable must be used to connect the cells. Each end of the

interconnect cable is identified by a color.

y The A connector has an amber band.

4-8

Page 45

y The B connector has a blue band.

Use the following procedure to connect the interconnect cables:

1. Review the table showing the cell interconnect cabling for your configuration.

Follow the order presented in this table when cabling the cells.

2. To connect the cables to the cells, fully seat the cable on the socket, and then

tighten the retaining screws with your fingers.

3. Route and secure each cable in the cable manager, located on the right side of the

cabinet when facing the back, before proceeding to the next cable.

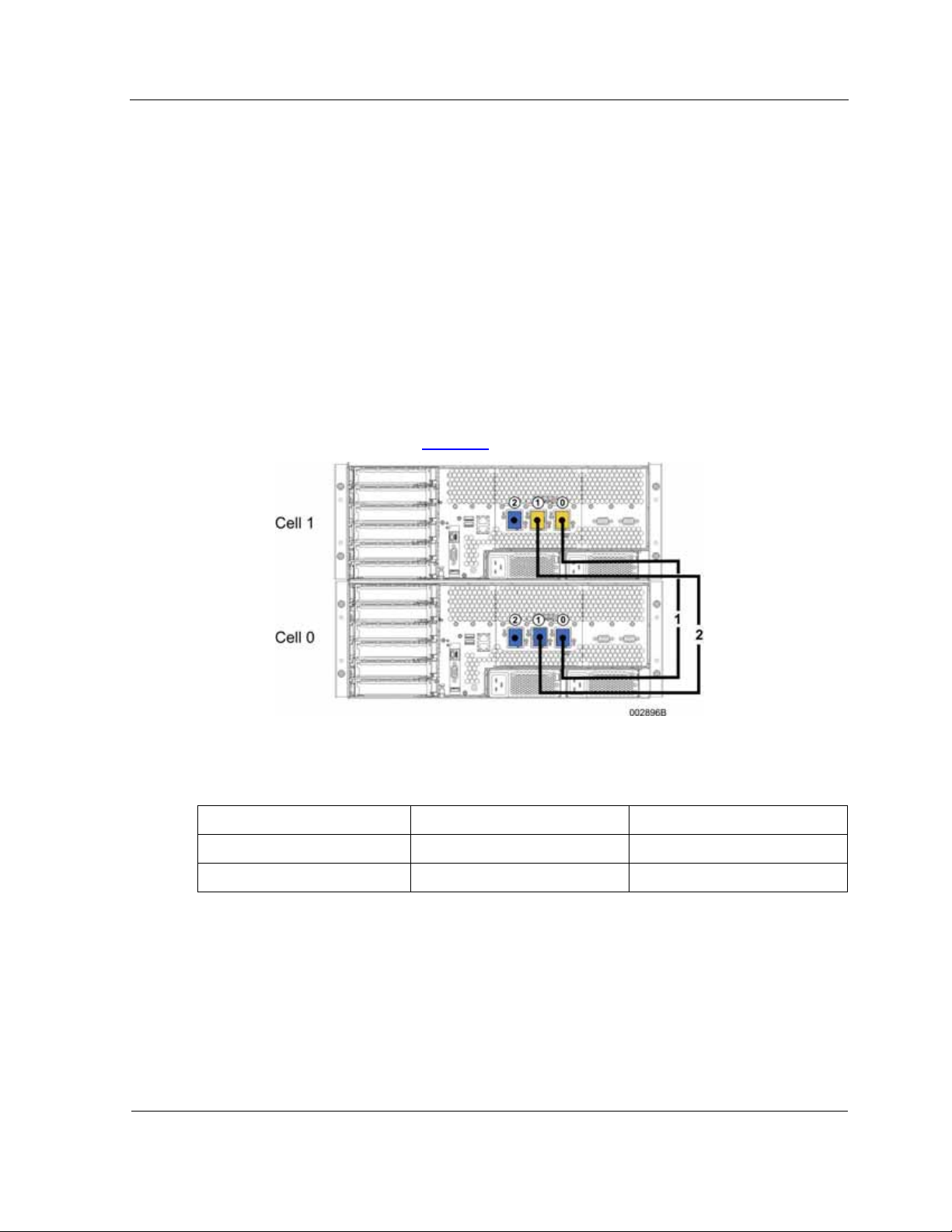

4.3.1. System with Two Cells

Follow the order presented in Table 4-1 for correct placement of interconnect cables.

Cell Interconnect Cabling

Table 4-1 Two-Cell Interconnect Cabling

Line # Connect From (Blue) Connect To (Amber)

1 Cell 0 Port 0 Cell 1 Port 0

2 Cell 0 Port 1 Cell 1 Port 1

4-9

Page 46

Cell Interconnect Cabling

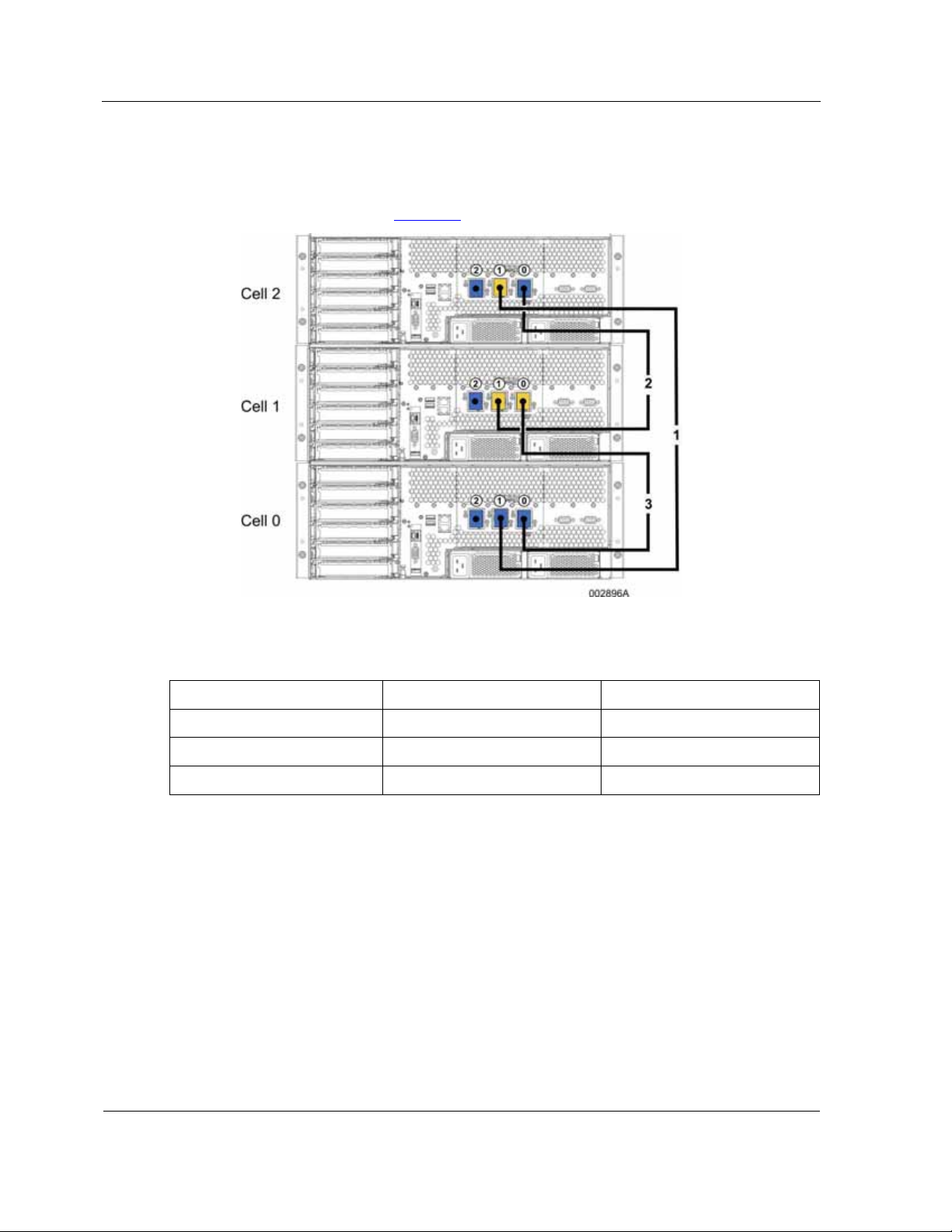

4.3.2. System with Three Cells

Follow the order presented in Table 4-2 for correct placement of interconnect cables.

Table 4-2 Three-Cell Interconnect Cabling

Line # Connect From (Blue) Connect To (Amber)

1 Cell 0 Port 1 Cell 2 Port 1

2 Cell 2 Port 0 Cell 1 Port 1

3 Cell 0 Port 0 Cell 1 Port 0

4-10

Page 47

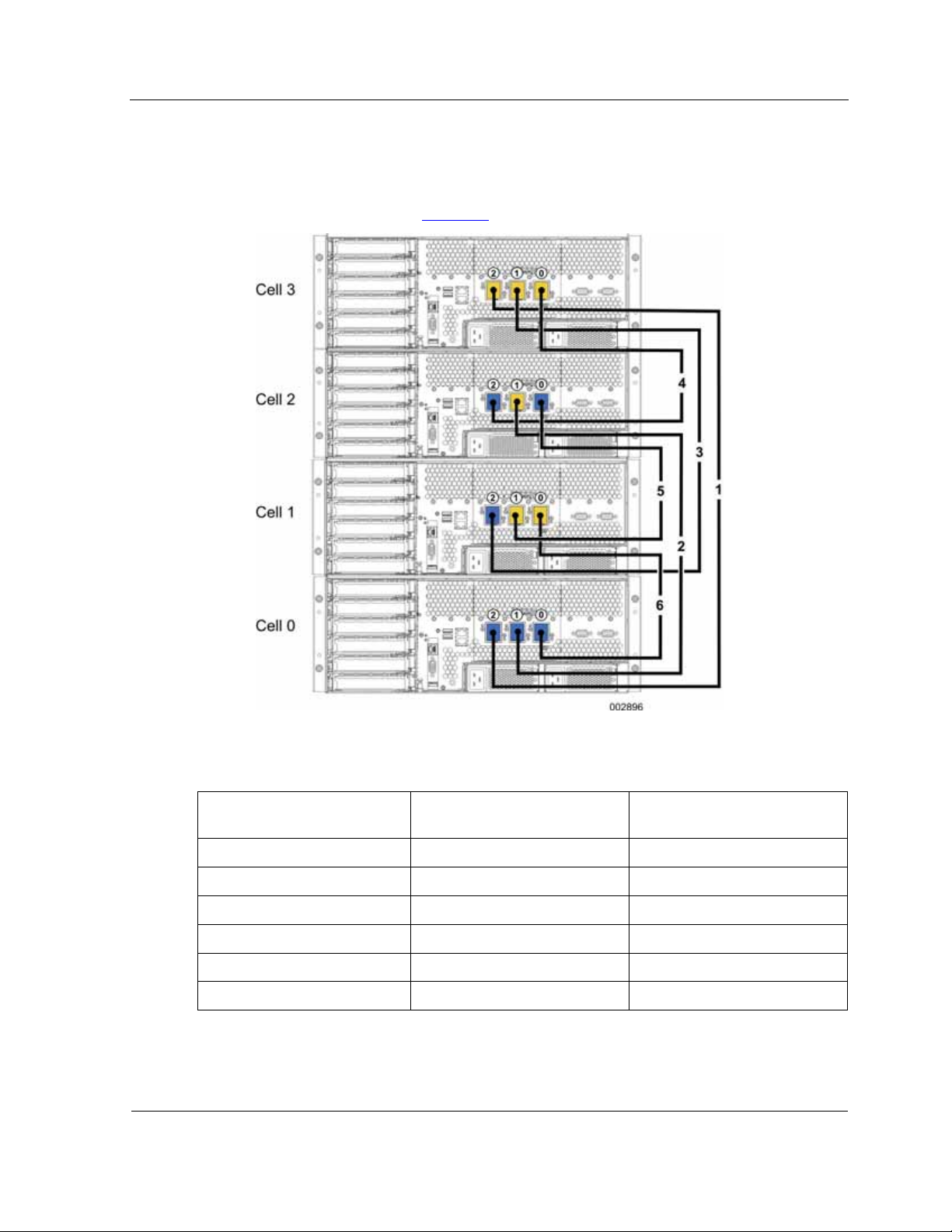

4.3.3. System with Four Cells

Follow the order presented in Table 4-3 for correct placement of interconnect cables.

Keyboard, Monitor, and Mouse Cabling

Table 4-3 Four-Cell Interconnect Cabling

Line #

Connect From (Blue) Connect To (Amber)

1 Cell 0 Port 2 Cell 3 Port 2

2 Cell 0 Port 1 Cell 2 Port 1

3 Cell 1 Port 2 Cell 3 Port 1

4 Cell 2 Port 2 Cell 3 Port 0

5 Cell 2 Port 0 Cell 1 Port 1

6 Cell 0 Port 0 Cell 1 Port 0

4-11

Page 48

Keyboard, Monitor, and Mouse Cabling

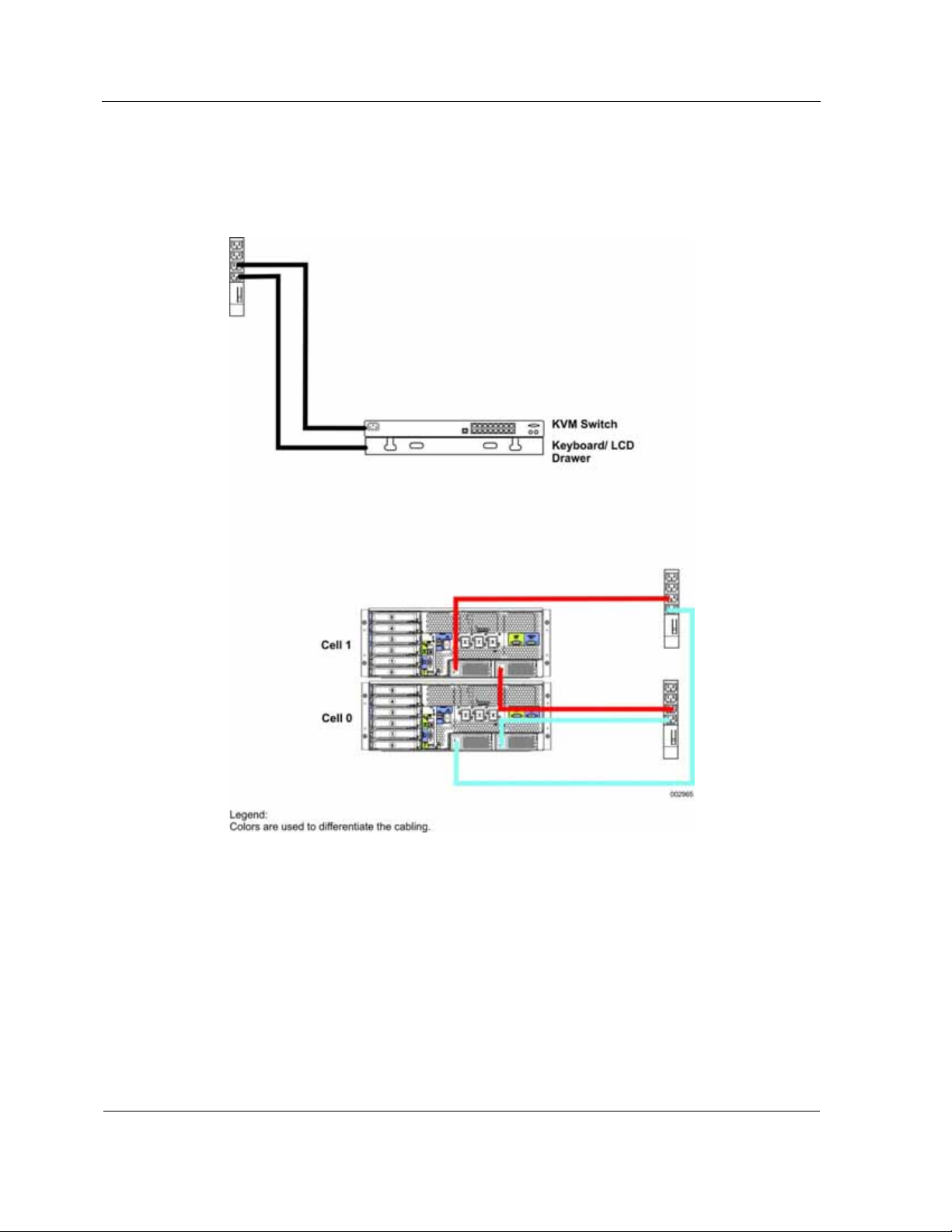

4.4. Keyboard, Monitor, and Mouse Cabling

If your system contains an optional keyboard, monitor, and mouse, route the appropriate

cables to the partition, as shown in Figure 4-4. Route the cables in the cable manager on

the left side of the cabinet.

Figure 4-4 Keyboard, Monitor, and Mouse Cabling

4.5. LAN Cabling

LAN cabling requirements for your environment should have been determined during

the planning process. For detailed information on LAN configuration, see the System

Planning Guide.

Note: A management server is required to monitor the system and communicate

support information to the support center. For detailed information on monitoring your

system, refer to the Server Management Software Installation, Configuration, and

Upgrade Guide.

4-12

Page 49

4.5.1. LAN Configurations

Your LAN topology will determine how you integrate the system into your environment.

You can integrate the system in a typical LAN environment where all traffic passes

through your public LAN. An operations LAN, where operations traffic is isolated from

your other network traffic, adds additional security. Because LAN topology is so diverse,

there can be other considerations that apply to your configuration.

4.5.2. LAN Ports

The following LAN ports are accessible on the rear panel of each cell:

y One maintenance LAN port

An RJ45 port on the rear of each cell provides a 10/100 Mbps Ethernet network

connection to the maintenance LAN.

y Two partition LAN ports

Two RJ45 ports on the rear of each cell provide 10/100/1000 Mbps Ethernet

network connections for the operating system to use. These are normally

connected to your public LAN.

LAN Cabling

The following illustration shows the LAN ports that are accessible on the rear panel of

each cell.

4.5.3. LAN Cabling for Systems Without an Operation LAN

The following illustration shows LAN cabling for systems that are not connected to an

operations LAN. Figure 4-5

multiple partitions, each partition must be cabled as illustrated. Cables should be routed

shows the cabling for each partition. If the system includes

4-13

Page 50

LAN Cabling

and secured in the cable manager on the right side of the cabinet.

Route the cable to the public LAN, but do not connect it to the LAN. Connection to the

public LAN is made during system configuration.

Figure 4-5 LAN Cabling Configuration Without an Operation LAN

4.5.4. LAN Cabling for Systems with an Operations LAN

Figure 4-6 shows LAN cabling for systems that are connected to an operations LAN.

The figure shows the cabling for each partition. If the system includes multiple partitions,

each partition must be cabled as illustrated.

Route the cables to the operations LAN and the public LAN, but do not connect them to

the LAN. Connection to the operations LAN and public LAN are made during system

configuration as described in the Software Installation and Configuration Guide.

4-14

Page 51

Peripheral Cabling

Figure 4-6 Cable Configuration for Systems with an Operations LAN

4.6. Peripheral Cabling

Cells can contain PCI cards that require peripheral cabling.

Route the cables in the cable manager on the left side of the cabinet.

4-15

Page 52

Page 53

Section 5

Completing the Installation

Use the procedures in this section to complete your hardware installation and power up

your system.

5.1. Perform Cleanup and Final Check

Complete your hardware installation and power up your system as follows:

1. Make sure the server frame is level and secure (if necessary, you can lower the

feet).

2. Ensure that all cables are connected, fastened securely, and bundled neatly.

3. Install filler panels from the cabinet panel kit in all unfilled spaces in the front of the

frame, as shown in Figure 5-1

.

Caution

Recirculating air in the cabinet can cause overheating. This overheating can

result in data loss or damage to the equipment. Cover any open spaces at the

front of the cabinet with filler panels.

5-1

Page 54

Perform Cleanup and Final Check

Figure 5-1 Front Rack Filler Panels

4. Reattach side skins if you removed them during installation.

5. Reattach front and rear doors if you removed them during installation.

6. Remove all packing material from the area.

5-2

Page 55

Check Cabling Before Powering On the System

5.2. Check Cabling Before Powering On the System

Loose or improperly attached cable connectors can adversely affect the system

power-on processes. Check the cabling before applying AC power for the first time.

The following figure shows the cable connections at the rear of the cell.

Figure 5-2 Cell Cable Connections

At the rear of the cabinet, check the following cable connections on each cell:

y LAN cable connections (maintenance LAN and partition LAN)

1. Gently pull on the LAN cable to ensure that it is attached completely in the

connector receptacle.

2. If the cable pulls out, check the latching lever. Sometimes the latching lever is

flattened against the connector body and therefore does not latch properly. If

this is the case, pry the lever away from the connector body and reinsert the

connector to see if it latches properly.

3. If the connector still does not latch, try substituting another LAN cable that you

know has a properly latching connector. If the substitute cable latches properly,

the original cable probably has a broken or obstructed connector and should be

replaced.

y USB cable connections (partition)

Ensure that the USB connectors are fully seated.

y Video cable connection (partition)

5-3

Page 56

Apply AC Power Initially

Ensure that the connector is fully seated and the thumbscrews are completely

tightened (finger tight).

y Power cables

Ensure that each power cable is secure in the power supplies in the cell and that

the other end of each power cable is fully seated in the power strip connector.

y Interconnect cable connections (0 through 2)

Ensure that the cable is fully seated in the connector and that the retaining screws

are finger-tightened.

5.3. Apply AC Power Initially

Use the procedure for your system to apply AC power.

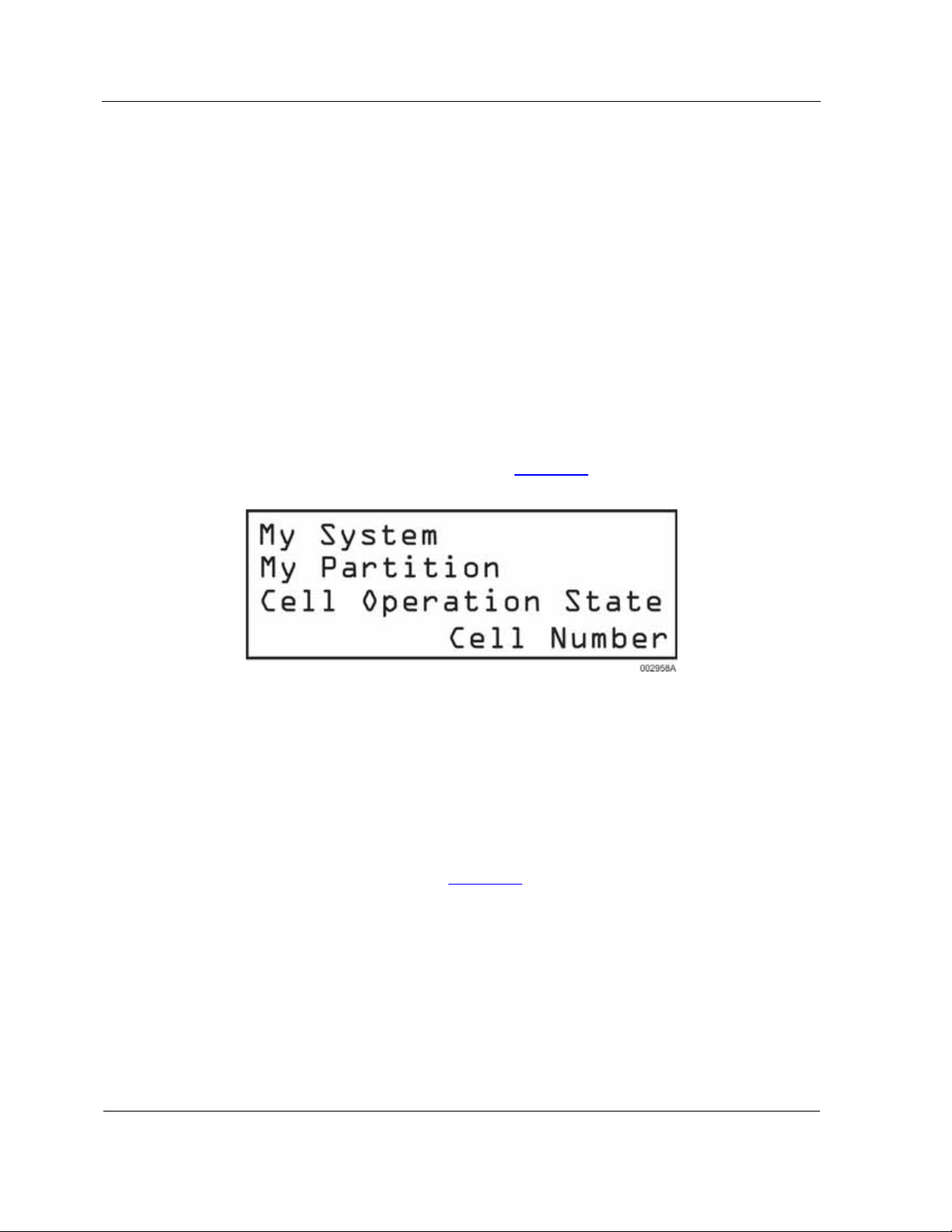

When internal hardware checks are complete, Figure 5-3

EXPRESSSCOPE® Monitor LCD.

Figure 5-3 EXPRESSSCOPE® Monitor LCD After AC Power is Applied

If an error displays, verify the cabling is installed correctly. If you continue to receive an

error, contact the support center.

5.3.1. Systems Operating at 100 to 120 VAC

Plug the cell power cords into the premises wiring (for example, the floor or wall

receptacles or the UPS receptacles). Figure 5-4

shows the cell power cord.

displays on the

5-4

Page 57

Apply AC Power Initially

Figure 5-4 Cell Power Cord

5.3.2. System Operating at 200 to 240 VAC

To apply AC power to a 200 to 240 VAC system, perform the following procedure:

1. Verify the power strips are set to the off position.

2. Plug the power strip power cord into the premises wiring (for example, the floor or

wall receptacles or the UPS receptacles). Figure 5-5

cord.

shows the power strip power

5-5

Page 58

Checking and Updating Management firmware Level and the BIOS Level

Figure 5-5 Power-Strip Power Cord

3. Turn the switch on the power strips to the on position.

5.4. Checking and Updating Management firmware Level

and the BIOS Level

Now that AC power is on, check the Management firmware levels and the BIOS levels

on each partition.

5-6

Page 59

Checking and Updating Management firmware Level and the BIOS Level

To do this, you need to know how many partitions were configured in the factory and

what the boot cell is for each partition. The boot cell is identified by a B next to the cell

number in the bottom right corner of the EXPRESSSCOPE® Monitor LCD.

Perform the following procedures on each partition:

1. 5.4.1 Initially Accessing a Partition

2. 5.4.2 Checking Management Firmware Level using Remote Console Interface

3. 5.4.3 Checking BIOS Level using Remote Console Interface

4. 5.4.4 Obtaining Releases from the Support Site

5. 0 If you need to install later release

you can obtain the desired versions from the Product Support Web Site:

http://support.necam.com/servers/Enterprise/

6.

Updating Management Firmware using Remote Console Interface

7. 5.4.6 Updating BIOS on the EFI Flash Memory

levels, such as management firmware or BIOS,

5.4.1. Initially Accessing a Partition

Perform the following procedure to access a partition.

1. Connect a LAN cable from the maintenance LAN port in the partition boot cell to a

PC or laptop.

2. Turn on the monitor that is either directly connected to the partition in the cell or

indirectly connected through a KVM switch.

3. Using the PC or laptop connected to the maintenance LAN port

a. Launch Internet Explorer.

b. In the browser address box, type the default IP address for the partition boot

cell to access the remote console interface.

The default IP address used to access the partition is 172.26.2.x, where x is the

boot cell number in that partition. For example, if you see B0 in the bottom right

corner of the EXPRESSSCOPE® Monitor LCD, the boot cell is cell 0; type

172.26.2.0 to access the partition. If there is a second partition and its boot cell

is cell 2, type 172.26.2.2 to access the partition.

Note: If entering the IP address in the address box does not work, try again by

typing https:// before the IP address.

c. Type the user name and password, which is Administrator and

Administer4Me.

The Summary page displays.

5-7

Page 60

Checking and Updating Management firmware Level and the BIOS Level

5.4.2. Checking Management Firmware Level using Remote Console

Interface

Check the management firmware level on the Service Processors for the partition, as

follows:

1. Click Firmware Update in the left column.

The firmware update page appears, as shown in Figure 5-6

.

Figure 5-6 Management Firmware Update Page

2. Click Display Current Firmware Status and Revision.

A dialog box appears containing the current management firmware revision level for

each cell in the partition, as shown in Figure 5-7

have the same firmware level.

Note: If a cell is not listed in the dialog box, it is AC powered off or otherwise not

communicating properly.

5-8

. All cells in the partition should

Page 61

Checking and Updating Management firmware Level and the BIOS Level

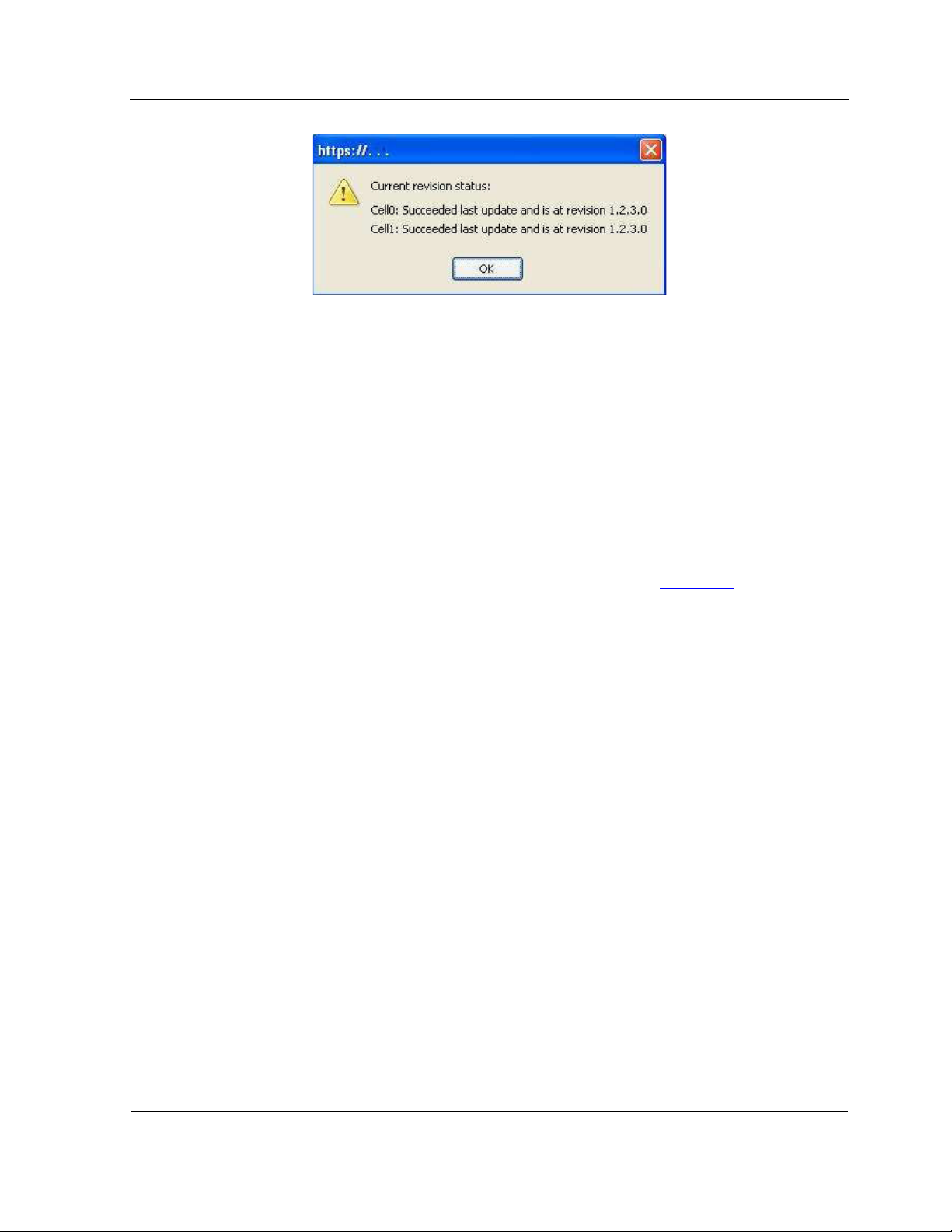

Figure 5-7 Management Firmware Revision Status

5.4.3. Checking BIOS Level using Remote Console Interface

Check the BIOS level on the Service Processors for the partition, as follows:

1. Click FRU Inventory in the left column.

The FRU inventory page appears.

2. Select the cell identifier of the boot cell in the Location list.

3. Select BIOS_EFI in the FRU Name list.

Information about the BIOS EFI is displayed, as shown in Figure 5-8

the version for later use.

. Write down

5-9

Page 62

Checking and Updating Management firmware Level and the BIOS Level

Figure 5-8 BIOS Version

5.4.4. Obtaining Releases from the Support Site

If you need to install later release levels, such as management firmware or BIOS, you

can obtain the desired versions from the Product Support Web Site:

http://support.necam.com/servers/Enterprise/

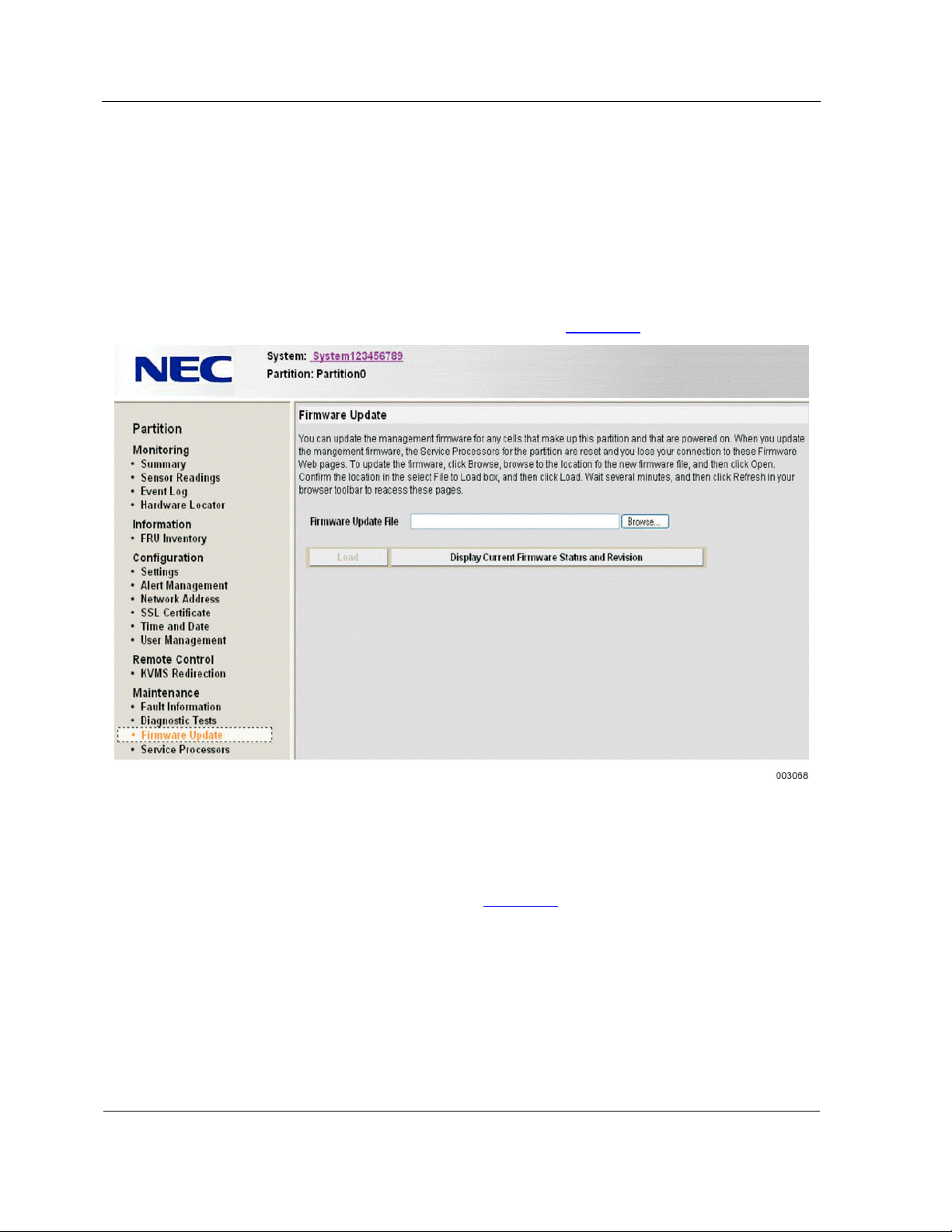

5.4.5. Updating Management Firmware using Remote Console

Interface

You can determine the management firmware levels on the Service Processors and

update the firmware if necessary, provided you can access the remote console interface

for the partition, as follows:

1. Navigate to the firmware update page of the remote console interface for the

partition, as shown in Figure 5-9

.

5-10

Page 63

Checking and Updating Management firmware Level and the BIOS Level

Figure 5-9 Management Firmware Updates Page

2. To update the management firmware on the partition, click Browse on the firmware

update page, navigate to the location of the saved firmware update file, and click

Load.

The firmware revision is loaded and distributed to the Service Processor of each

member cell of the partition that is powered on. The update takes several minutes

to complete. Initially, a dialog box is displayed saying that the update is in progress.

When the update finishes, all cells should have the same firmware level. Each

Service Processor performs a reset action, and the connection to the remote

console interface is lost.

3. Refresh the page and log on to restore the partition Web interface.

4. Navigate to the firmware update page and click Display Current Firmware Status

and Revision to check that the current management firmware level is correct.

A dialog box appears containing the current management firmware revision level for

each cell in the partition, as shown in Figure 5-10

have the same firmware level.

Note: If a cell is not listed in the dialog box, it is AC powered off or otherwise not

communicating properly.

. All cells in the partition should

5-11

Page 64

Checking and Updating Management firmware Level and the BIOS Level

Figure 5-10 Management Firmware Revision Status

5.4.6. Updating BIOS on the EFI Flash Memory

When you update the BIOS firmware (EFI) on the flash memory, operating system

settings are set to default values. If you need different values for certain BIOS settings,

you must change these settings after completing the update. Refer to User’s Guide for

the BIOS default values for operating systems.

To update the BIOS firmware (EFI) when the partition is powered off

1. Prepare a USB drive, as follows:

a. Format the USB drive as FAT32.

b. Copy the BIOS update package to the USB drive with the following path name:

(USB drive root):¥efi¥update¥UPDATEX64.efi

2. Insert the USB drive in one of the host USB ports on the boot cell.

3. Click Power Up/Down on the summary page of the remote console interface.

During the boot process, the logo screen appears twice. The second time, a

command to press the spacebar to enter the BIOS menu appears at the bottom.

4. Press the spacebar when the command appears on the second logo screen.

The BIOS front page appears, as shown in Figure 5-11

.

5-12

Page 65

Checking and Updating Management firmware Level and the BIOS Level

Figure 5-11 BIOS Front Page

5. Select BIOS Setup and press Enter.

The BIOS Setup window appears, as shown in Figure 5-12

.

5-13

Page 66

Checking and Updating Management firmware Level and the BIOS Level

Figure 5-12 BIOS Setup Window

6. Select Partition and press Enter.

The Partition window appears, as shown in Figure 5-13

.

5-14

Page 67

Checking and Updating Management firmware Level and the BIOS Level

Figure 5-13 BIOS Partition Window

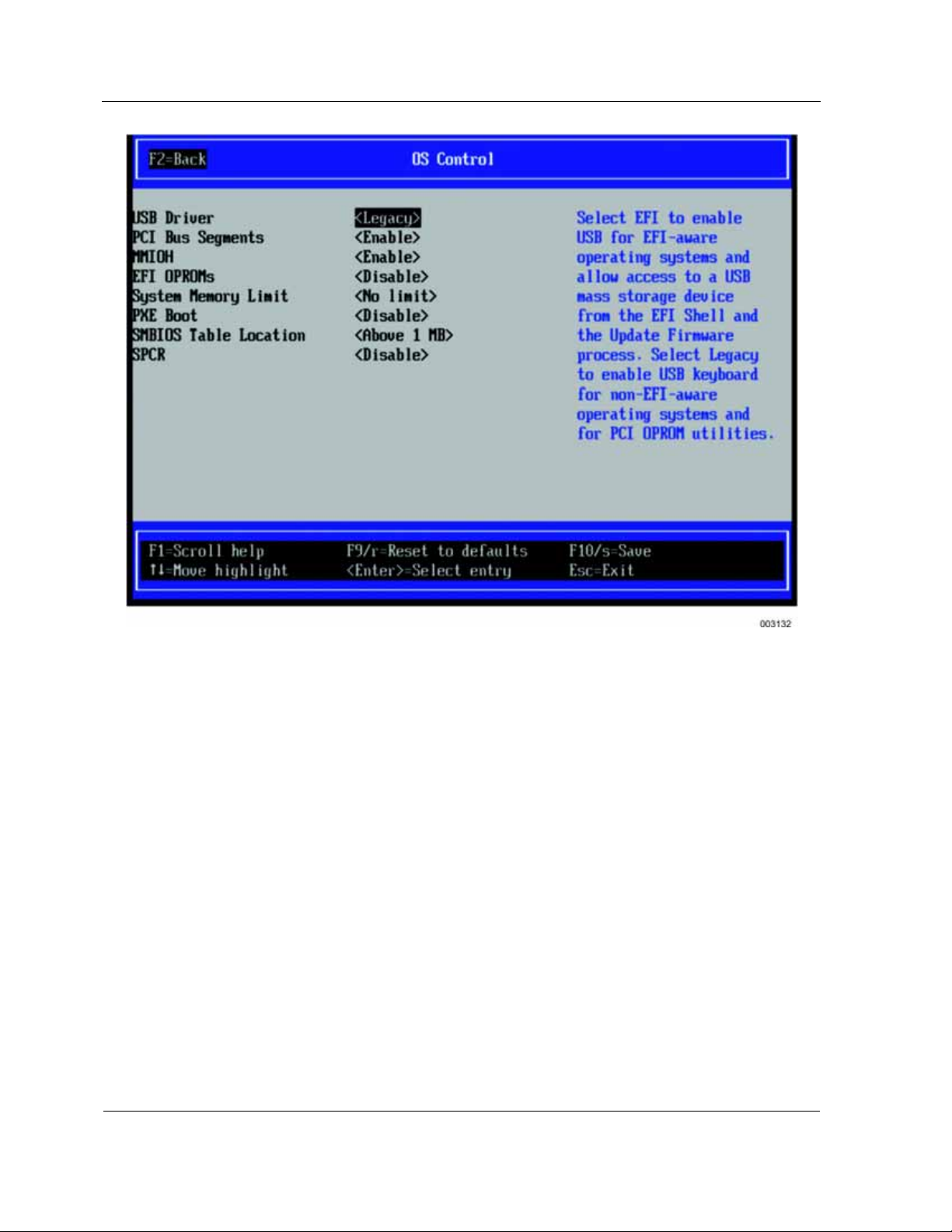

7. Select OS Control and press Enter.

The OS Control window appears, as shown in Figure 5-14

.

5-15

Page 68

Checking and Updating Management firmware Level and the BIOS Level

Figure 5-14 OS Control Window

8. Make sure that the USB driver setting is USB EFI. If this setting is Legacy, use the

controls to change it to USB EFI, and press F10 to save changes.

9. Press Esc twice to return to the BIOS front page, select Continue, and press

Enter.

A dialog box appears with a query to reboot the partition.

Note: If you did not change the USB driver setting, no reboot is required and you

can skip to step 12.

10. Select Yes and press Enter.

The partition reboots.

11. Press the spacebar when the command appears on the second logo screen.

The BIOS front page appears.

12. Select Update Firmware and press Enter.

A confirmation dialog box appears if the update package is found on the USB drive.

13. Select Yes and press Enter.

The BIOS flash update tool window appears.

5-16

Page 69

14. Select Update All and press Enter.

An asterisk character appears next to your selection.

15. Select OK and press Enter.

The EFI flash update starts and progress information is displayed. When the update

completes and the flash memory is verified, a five-second countdown starts, and

then the partition reboots using the new BIOS.

5.5. Verify PCI Card Installation

To verify the correct PCI cards are installed and visible to the system, run PciView from

the EFI BIOS shell on each partition in the system.

Perform the following procedure on each partition in your system to verify the PCI card

installation.

Verify PCI Card Installation

1. Access the partition as described in 5.4.1 Initially Accessing a Partition

2. Click Power Up/Down on the Summary page.

A logo screen appears for a few seconds on the monitor connected to the partition,

with an instruction at the bottom to press the space bar to enter BIOS.

3. Using the monitor and keyboard connected to the partition

a. Press the space bar while the logo screen is displayed.

The BIOS front page appears, as shown in Figure 5-15

.

.

5-17

Page 70

Verify PCI Card Installation

Figure 5-15 BIOS Front Page

b. Select Boot Manager and press Enter.

The Boot Manager window appears and displays the current boot order, as

shown in Figure 5-16

.

5-18

Page 71

What to Do Next

Figure 5-16 BIOS Boot Manager

c. Select Internal EFI shell and press Enter.

d. At the shell command prompt, type PciView.

e. Review the output to verify that the correct PCI cards are installed and visible to

the system.

f. Type exit to return to the BIOS front page when you are finished.

4. Power down the partition using the remote console interface:

a. Select Power Up/Down on the Summary page.

You receive a message that this is a non-graceful termination of the OS host.

b. Click OK.

5. Repeat steps 1 through 4 for each partition in the system.

5.6. What to Do Next

You must now do as follows:

1. Install Server Management software on your management server, if you have not

5-19

Page 72

What to Do Next

already done so.

2. Install operating system software and Server Management software on the

Express5800/A1160 partitions and then configure the software.

5-20

Page 73

Appendix A

Related Documents and Web Resources

This appendix lists documents and Web resources that provide additional information

about Express5800/A1160 systems.

A.1 Express5800/A1160 Documentation Library

The documentation library for Express5800/A1160 systems includes the following

categories and documents:

y Planning for Server Arrival

- Express5800/A1160 System Planning Guide

y Installing and Configuring the Server

- Express5800/A1160 Hardware Installation Guide

- Express5800/A1160 Hardware Installation Quick-Setup Guide

- Express5800/A1160 Software Installation and Configuration Guide

y Reinstalling Software

- Express5800/A1160 Service Processor Troubleshooting and Upgrade Guide

y Servicing the Server (service representatives only)

- Express5800/A1160 Service Guide

y Operating the Server

- Express5800/A1160 User’s Guide

- ESMPRO Agent for Linux User’s Guide

- ESMPRO Agent for Windows User’s Guide

- ESMPRO Alert Manager User’s Guide

- ESMPRO Manager User’s Guide

y Conceptual Information

- Express5800/A1160 Technical Overview

Individual copies of these documents can be downloaded from the Product Support Web

Site (support.necam.com/Servers/Enterprise/

).

A-1

Page 74

Web Resources

A.2 Web Resources

Visit the following Web sites for information about your system.

Products and Services (www.necam.com/products/)

This is the home page for products and services NECAM is offering.

Product Support (support.necam.com/Servers/Enterprise/)

This is the home page for customer support. You can find many support resources

through this page as well as information about who to contact for further support if

needed.

A-2

Page 75

Note:

Consumers are cautioned that Product performance is affected by system configuration,

software, the application, Customer data, and operator control of the system, among other

factors. While NEC Corporation of America products is considered to be compatible with

many systems, the specific functional implementation by the Customers of the product may

vary.

Therefore, the suitability of a product for a specific purpose or application must be

determined by the Customer and is not warranted by NEC Corporation of America. For more

information, telephone 1-866-269-1239

Page 76

456-01805-000

Loading...

Loading...