Page 1

INVERTER

150PW231

DATA SHEET

DOD-PD-1355 (2nd edition)

This DATA SHEET is updated document from

DOD-PD-0924(1).

All information is subject to change without

notice. Please confirm the sales representative

before starting to design your system.

Document Number: DOD-PD-1355 (2nd edition)

Published date: March 2006 CP(N)

1

© NEC LCD Technologies, Ltd.

2005-2006 All rights reserved.

Page 2

INTRODUCTION

The Copyright to this document belongs to NEC LCD Technologies, Ltd. (hereinafter called "NEC").

No part of this document will be used, reproduced or copied without prior written consent of NEC.

NEC does and will not assume any liability for infringement of patents, copyrights or other intellectual

property rights of any third party arising out of or in connection with application of the products

described herein except for that directly attributable to mechanisms and workmanship thereof. No license,

express or implied, is granted under any patent, copyright or other intellectual property right of NEC.

Some electronic parts/components would fail or malfunction at a certain rate. In spite of every effort to

enhance reliability of products by NEC, the possibility of failures and malfunction might not be avoided

entirely. To prevent the risks of damage to death, human bodily injury or other property arising out

thereof or in connection therewith, each customer is required to take sufficient measures in its safety

designs and plans including, but not limited to, redundant system, fire-containment and anti-failure.

The products are classified into three quality grades: "Standard", "Special", and "Specific" of the

highest grade of a quality assurance program at the choice of a customer. Each quality grade is designed

for applications described below. Any customer who intends to use a product for application other than

that of Standard quality grade is required to contact an NEC sales representative in advance.

The Standard quality grade applies to the products developed, designed and manufactured in

accordance with the NEC standard quality assurance program, which are designed for such application as

any failure or malfunction of the products (sets) or parts/components incorporated therein a customer uses

are, directly or indirectly, free of any damage to death, human bodily injury or other property, like general

electronic devices.

Examples: Computers, office automation equipment, communications equipment, test and measurement

equipment, audio and visual equipment, home electronic appliances, machine tools, personal

electronic equipment, industrial robots, etc.

The Special quality grade applies to the products developed, designed and manufactured in accordance

with an NEC quality assurance program stricter than the standard one, which are designed for such

application as any failure or malfunction of the products (sets) or parts/components incorporated therein a

customer uses might directly cause any damage to death, human bodily injury or other property, or such

application under more severe condition than that defined in the Standard quality grade without such

direct damage.

Examples: Control systems for transportation equipment (automobiles, trains, ships, etc.), traffic control

systems, anti-disaster systems, anti-crime systems, medical equipment not specifically

designed for life support, safety equipment, etc.

The Specific quality grade applies to the products developed, designed and manufactured in accordance

with the standards or quality assurance program designated by a customer who requires an extremely

higher level of reliability and quality for such products.

Examples: Military systems, aircraft control equipment, aerospace equipment, nuclear reactor control

systems, medical equipment/devices/systems for life support, etc.

The quality grade of this product is the "Standard" unless otherwise specified in this document.

150PW231

DATA SHEET DOD-PD-1355 (2nd edition)

2

Page 3

150PW231

CONTENTS

INTRODUCTION ..........................................................................................................................................2

1. OUTLINE....................................................................................................................................................4

2. SPECIFICATION.......................................................................................................................................4

2.1 GENERAL SPECIFICATIONS..............................................................................................................4

2.2 ABSOLUTE MAXIMUM RATINGS....................................................................................................4

2.3 ELECTRICAL CHARACTERISTICS...................................................................................................5

2.4 FUSE.......................................................................................................................................................5

2.5 POWER SUPPLY VOLTAGE SEQUENCE ..........................................................................................6

2.6 CONNECTIONS AND FUNCTIONS FOR INTERFACE PINS...........................................................7

2.7 LUMINANCE CONTROL.....................................................................................................................8

2.7.1 Luminance control methods...........................................................................................................8

2.7.2 Detail of BRTP timing...................................................................................................................9

3. RELIABILITY TEST...............................................................................................................................10

4. PRECAUTIONS .......................................................................................................................................10

4.1 MEANING OF CAUTION SIGNS......................................................................................................10

4.2 CAUTIONS..........................................................................................................................................10

4.3 A TTENTI ONS......................................................................................................................................10

4.3.1 Handling of the product...............................................................................................................10

4.3.2 Environment.................................................................................................................................11

4.3.3 Other............................................................................................................................................11

5. OUTLINE DRAWINGS...........................................................................................................................12

DATA SHEET DOD-PD-1355 (2nd edition)

3

Page 4

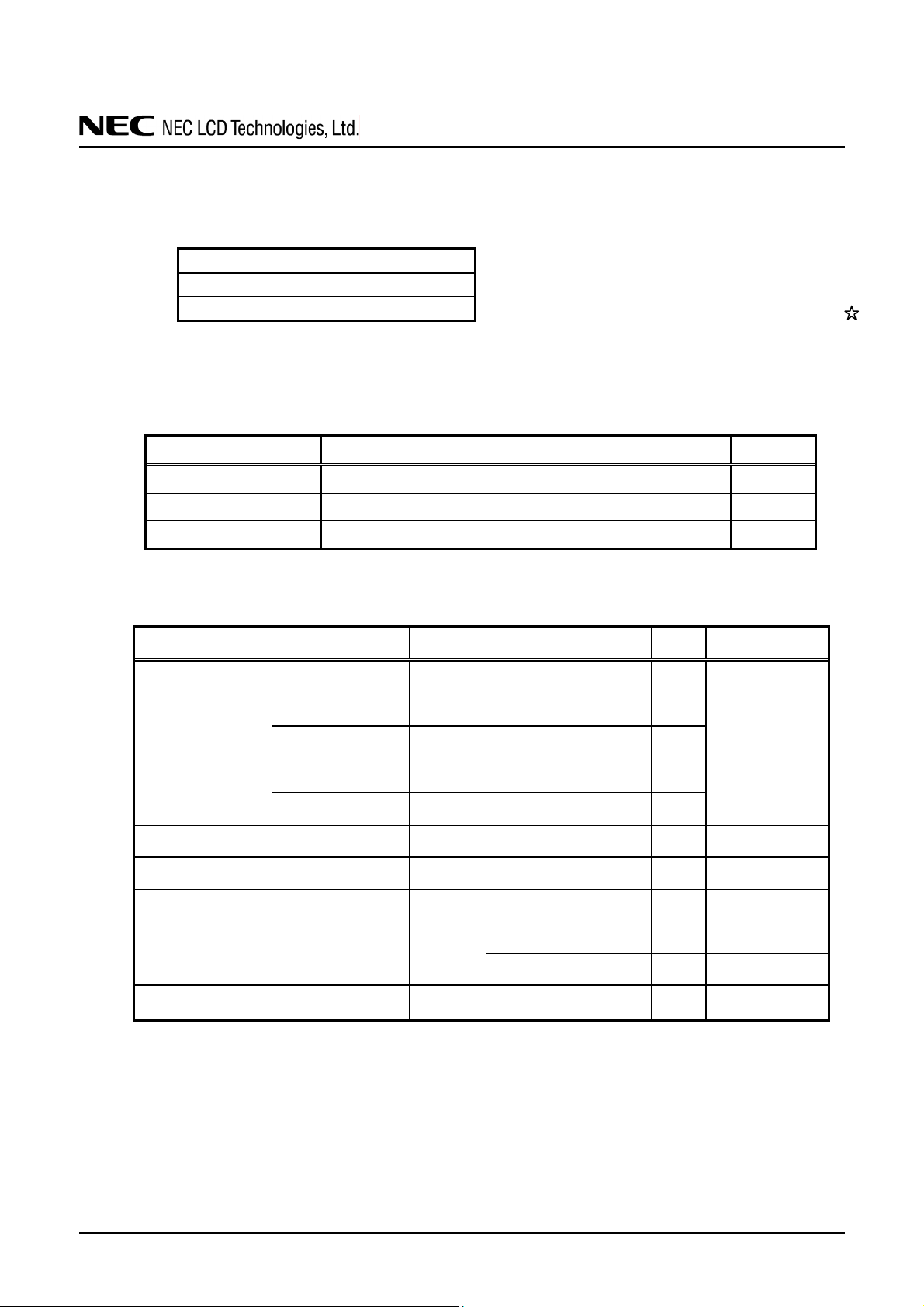

1. OUTLINE

This 150PW231 inverter is for LCD modules. Adaptable LCD modules are as follows.

Adaptable LCD modules

NL10276BC30-17

NL10276BC30-18

2. SPECIFICATION

2.1 GENERAL SPECIFICATIONS

Item Specification Unit

Size See "5.OUTLINE DRAWINGS". mm

Weight 70 (max.) g

Delivery unit 10 (min.) set

2.2 ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Rating Unit Remarks

150PW231

Power supply voltage VDDB 0 to +14.0 V

BRTC signal VBC -1.0 to VDDB+1.0 V

Input voltage

Storage temperature Tst -20 to +80

Operating temperature Top -10 to +75

Relative humidity

Note1

Absolute humidity

Note1

BRTP signal VBP V

PWSEL signal VPSL

BRTI signal VBI 0 to +5.0 V

RH

AH

Note1: No condensation

Note2: Water amount at Ta=55°C and RH=70%

0 to +6.0

≤ 95

≤ 85

≤ 70

≤ 73

Note2

V

°C

°C

%

%

%

g/m3

-

-

-

Ta ≤ 40°C

40 < Ta ≤ 50°C

50 < Ta ≤ 55°C

Ta > 55°C

DATA SHEET DOD-PD-1355 (2nd edition)

4

Page 5

2.3 ELECTRICAL CHARACTERISTICS

Parameter Symbol min. typ. max. Unit Remarks

Power supply voltage VDDB 11.4 12.0 12.6 V Note1, Note2

Power supply current IDDB - 1,550 1,900

BRTC signal

Input voltage

Input current

Output voltage

Output current

Oscillation frequency FO 38 43 48 kHz -

Luminance control frequency FB 271 279 287 Hz -

BRTP signal

PWSEL signal

BRTI signal VBI 0 - 2.5 V

BRTC signal

BRTP signal

PWSEL signal

BRTI signal IBI -1.0 - 4.7 mA

Open lamp voltage VO 850 - - Vrms

Lamp voltage

(at steady state)

AM signal

Lamp current

(per lamp)

Note1: When designing of the power supply , take the measures for the prevention of surge voltage.

Note2: The power supply lines (VDDB and GNDB) have large ripple voltage during luminance control of

LCD lamps. There is the possibility that the ripple voltage produces acoustic noise and signal

wave noise in audio circuit and so on. Put a capacitor (5,000 to 6,000

supply lines (VDDB and GNDB) to reduce the noise, if the noise occurred in the circuit.

Note3: Measured value with high voltage probe of a load capacitance of 3pF.

It is guaranteed that the adaptable LCD module can be turned on at Ta= -10 to +75°C.

2.4 FUSE

Parameter

Type Supplier

150PW231

(Ta=25°C)

VDDB= 12.0V,

mΑ

High VBCH 2.5 - VDDB V

Low VBCL 0 - 0.4 V

High VBPH 2.0 - 5.0 V

Low VBPL 0 - 0.4 V

High VPSLH 2.0 - 5.0 V

Low VPSLL 0 - 0.4 V

High IBCH - - 0.6 mA

Low IBCL -1.0 - - mA

High IBPH - - 1.0 mA

Low IBPL -1.0 - - mA

High IPSLH - - 1.0 mA

Low IPSLL -1.0 - - mA

VBLH - 620 - Vrms -

High VAMH 5.0 5.3 5.6 V at malfunction

Low VAML - 0 0.5 V at normal

IBL 5.5 6.0 6.5 mArms -

Fuse

Rating Fusing current Remarks

at the maximum

luminance control

Note2

-

-

-10 to +75°C

Note3

µ

F) between the power

VDDB 11CT3.15A SOC Corporation

3.15A

72V

6.3A

60s max.

Note1

Note1: The power supply capacity should be more than the fusing current. If it is less than the fusing

current, the fuse may not blow in a short time, and then nasty smell, smoke and so on may

occur.

DATA SHEET DOD-PD-1355 (2nd edition)

5

Page 6

2.5 POWER SUPPLY VOLTAGE SEQUENCE

VDDB

11.4V

0V

800ms max.

BRTC

0V

PWSEL

0V

0s min.

0s min.

150PW231

11.4V

0s min.

0s min.

DATA SHEET DOD-PD-1355 (2nd edition)

6

Page 7

2.6 CONNECTIONS AND FUNCTIONS FOR INTERFACE PINS

CN1 socket (Inverter side): 53261-1171 (MOLEX Inc.)

Adaptable plug: 51021-1100 (MOLEX Inc.)

Pin No. Symbol Function Remarks

1 VDDB Power supply

150PW231

2 VDDB Power supply

3 GNDB Ground

4 GNDB Ground

5 BRTC Backlight ON/OFF signal

6 BRTI

7 BRTH

8 AM Alert signal output at malfunction Note3

9 N.C. - Keep this pin Open.

10 PWSEL

11 BRTP BRTP signal Note2

Luminance control terminal Note2

Selection signal of luminance control

method

Note1

High or Open: Backlight ON

Low: Backlight OFF

This pin is pulled-up to VDDB in the product.

Pull-up resistance: 66kΩ

This pin is pulled-down to GNDB in the product.

Pull-down resistance: 16kΩ

Note2

Note1: All GNDB and VDDB terminals should be used without any non-connected lines.

Note2: See "2.7 LUMINANCE CONTROL".

Note3: If anyone of terminals Pin No.1 or 2 (CN2-CN5) opens, then the alert signal (+5.3V typ.) is

output.

CN2-CN5 socket (Inverter side): SM02(8.0)B-BHS-1-TB(LF)(SN) (J.S.T. Mfg Co., Ltd.)

Adaptable plug (Backlight side): BHR-03VS-1 (J.S.T. Mfg Co., Ltd.)

Pin No. Symbol Signal Remarks

1 VBLH High voltage (Hot) 2 N. C. - Keep this pin Open.

3 VBLC Low voltage (Cold) -

Note1: VBLH and VBLC must be connected correctly. Wrong connections will cause electric shock

and also break down of the product.

DATA SHEET DOD-PD-1355 (2nd edition)

7

Page 8

2.7 LUMINANCE CONTROL

2.7.1 Luminance control methods

Method Adjustment and luminance ratio PWSEL terminal BRTP terminal

• Adjustment

The variable resistor (R) for luminance control should be

10kΩ ±5%, 1/10W. Minimum point of the resistance is the

minimum luminance and maximum point of the re sistance

is the maximum luminance.

The resistor (R) must be connected between BRTH-BRTI

terminals.

Variable resistor

control

Note1

Voltage control

Note1

Pulse width

modulation

Note1

Note2

Note4

(BRTH is connected to GNDB in the product.)

• Luminance ratio Note3

• Adjustment

Voltage control method works, when BRTH terminal is 0V

and VBI voltage is input between BRTI-BRTH terminals.

This control method can carry out continuation adjustment

of luminance.

Luminance is the maximum when BRTI terminal is Open.

• Luminance ratio Note3

• Adjustment

Pulse width modulation (PWM) method works, when

PWSEL signal is High and PWM signal (BRTP signal) is

input into BRTP terminal. The luminance is controlled by

duty ratio of BRTP signal.

• Luminance ratio Note3

Note1: In case of the resistor control method and the voltage control method, noises may appear on

the display image depending on the input signals timing for LCD panel signal processing

board.

Use PWM method, if interference noises appear on the display image!

Note2: The inverter will stop working, if the Low period of BRTP signal is more than 1s while

BRTC signal is High or Open. Then the backlight will not turn on anymore, even if BRTP

signal is input again. This is not out of order. The inverter will start to work when power is

supplied again.

Note3: These data are the target values.

Note4: See "2.7.2 Detail of BRTP timing".

BRTH

Resistance Luminance ratio

0Ω

10kΩ

BRTI signal (VBI) Luminance ratio

0V 20% (Min. luminance)

2.5V 100% (Max. luminance)

Duty ratio Note4 Luminance ratio

0.2 20% (Min. luminance)

1.0 100% (Max. luminance)

DATA SHEET DOD-PD-1355 (2nd edition)

R

20% (Min. luminance)

100% (Max. luminance)

BRTI

150PW231

Low or Open Open

High BRTP signal

8

Page 9

≤

2.7.2 Detail of BRTP timing

(1) Timing diagrams

• Outline chart

BRTC

PWSEL (Low)

BRTP

• Detail of A part

BRTP

VBPH

VBPL

(2) Each parameter

Parameter Symbol min. typ. max. Unit Remarks

Luminance control frequency FL 271 279 287 Hz Note1, Note2

Duty ratio DL 0.2 - 1.0 - Note1, Note3

Low period tPWL 0 - 1 s Note4

Note1: Definition of parameters is as follows.

FL=

Note2: See the following formula for luminance control frequency.

Luminance control frequency= 1/tv × (n+0.25) [or (n+0.75)]

n = 1, 2, 3 · · · · · ·

tv: Vertical cycle

The interference noise of luminance control frequency and input signal frequency

for LCD panel signal processing board may appear on a display. Set up luminance

control frequency so that the interference noise does not appear!

Note3: See "2.7.1 Luminance control methods".

Note4: If tPWL is more than 1s, the backlight will be turned off by a protection circuit for

inverter. The inverter will start to work when power is supplied again.

1

tPW

,

DL=

tPWH

tPW

A

tPWH

tPW

0ms ≤ tPWL ≤ 1s

tPWL

150PW231

0ms ≤ tPWL

1s 0ms ≤ tPWL ≤ 1s

DATA SHEET DOD-PD-1355 (2nd edition)

9

Page 10

3. RELIABILITY TEST

This test is in accordance with the Reliability Test of the adaptable LCD module. Refer to Reliability

Test of the adaptable LCD module.

4. PRECAUTIONS

4.1 MEANING OF CAUTION SIGNS

The following caution signs have very important meaning. Be sure to read "4.2 CAUTIONS" and

"4.3 ATTENTIONS", after understanding these contents!

This sign has the meaning that customer will be injured by himself or the product will

!

sustain a damage, if customer has wrong operations.

This sign has the meaning that customer will get an electrical shock, if customer has

wrong operations.

This sign has the meaning that customer will be injured by himself, if customer has wrong

operations.

4.2 CAUTIONS

∗ Do not touch the inverter while the inverter is working, because there is a danger

of an electric shock.

∗ Do not remove the inverter protection sheet, because there is a danger of an

electric shock.

∗ Be sure to wait some time after turning power OFF before starting replacement

work, because the inverter is charged at a high voltage after working.

∗ Be sure to wait some time after turning power OFF before starting replacement

work, because the inverter is hot after working.

∗ Do not shock the inverter, because there is a danger of breaking.

4.3 ATTENTIONS

!

4.3.1 Handling of the product

① Take hold of both ends without touching the circuit board when the product (LCD module) is picked

up from inner packing box to avoid broken down or misadjustment, because of stress to mounting

parts on the circuit board.

② When handling the product, take the measures of electrostatic discharge with such as earth band, ionic

shower and so on, because the product may be damaged by electrostatic.

③ Do not push nor pull the interface connectors while the product is working.

④ Do not hook nor pull cables such as lamp cable, and so on, in order to avoid any damage.

⑤ Properly connect the adaptable plug (backlight side) to socket (inverter side) without incomplete

connection. After connecting, be careful not to hook the lamp cables because incomplete connection

may occur by hooking the lamp cables. This incomplete connection may cause abnormal operation of

high voltage circuit.

150PW231

DATA SHEET DOD-PD-1355 (2nd edition)

10

Page 11

4.3.2 Environment

① Do not operate or store in high te mperature, high humidity, dewdrop atmosphere or corrosive gases.

② In order to prevent dew condensation occurring by temperature difference, the product packing box

③ Do not operate in high magnetic field. Product may be broken down by it.

④ This product is not designed as radiation hardened.

4.3.3 Other

① All GNDB and VDDB terminals should be used without any non-connected lines.

② Do not disassemble a product.

③ Pack the product with original shipping package, in order to avoid any damages during transportation,

④ Put the spacer of 1.0mm thickness or more on a product rear side, because of the protection for

150PW231

Keep the product in packing box with antistatic pouch in room temperature to avoid dusts and

sunlight, when storing the product.

should be opened after enough time being left under the environment of an un packing roo m. Evaluate

the leaving time sufficiently because a situation of dew condensation occurring is changed by the

environmental temperature and humidity. (Recommended leaving time: 6 hours or more with packing

state)

when returning the product to NEC.

contortion.

Spacer example: Thickness= 1.0mm (min.)

Diameter (φ) = 5.0mm (Recommendation)

DATA SHEET DOD-PD-1355 (2nd edition)

11

Page 12

5. OUTLINE DRAWINGS

Note1: The values in parentheses are for reference.

φ

3.6

4×

φ

6

4×

(Connec ted to GNDB )

±0 .5

143 .0

CN 3

P ro tec t ion cove r

68 (ma x . )

±0 .5

66 .0

(43 .5 )

±0 .2

59

CN 2

1

H IGH VOL T AGE

RISK0FELECTRIC SHOCK.

DISCONNECT THE ELECTRIC

POWERB EFORE SERV ICE .

3

3

CAUT ION

1

(43 .5 )

3

1

CN 4 CN 5

POWER BEFORE SERV ICE .

DISCONNECT THE ELECTRIC

RISK0FELECTRICSHOCK.

CAUT ION

HIGHVOLTAGE

(15 .5 )

1

3

(15 .5 )

150PW231

(Connec ted to GNDB )

(68 )

±0 .2

111

136

CN 1

11 .5 (ma x . )

CN 1

(Unit: mm)

DATA SHEET DOD-PD-1355 (2nd edition)

12

Loading...

Loading...