Page 1

Be Strong.

™

Commercial Free Weights

Row Tower

P/N: 001-40 86 Rev A ( 03/20 /07)

Assembly Manual

Model: F3DROW

Page 2

PREFACE/TABLE OF CONTENTS

Thank you for purchasing the Nautilus® Commercial Free Weights Row Tower. For more than 30 years Nautilus®

has been producing the world’s finest fitness equipment used in health clubs and homes around the globe. We

hope this product exceeds your expectations and is a valuable tool for your facility.

Please carefully read through this manual to familiarize yourself with the operation of your new Nautilus® Row

Tower. Doing so will help to insure that your users get the most out of your tower, enjoying safe and effective

workouts ahead.

Nautilus, Inc.

World Headquarters

16400 SE Nautilus Drive

Vancouver, Washington, USA 98683

1-800-NAUTILUS

www.nautilus.com

TABLE OF CONTENTS

Safety Precautions/

Product Specifications ..............................3

Before You Assemble .................................

Hardware and Tools ...................................

Box Contents ...............................................

Assembly Guide ..........................................

4

5

6

16

Final Check ...................................................

Assembly Complete ....................................

Companion Exercise Equipment

...............32

Limited Warranty .........................................

Important Contact Numbers .....................

30

31

33

34

2

Page 3

SAFETY PRECAUTIONS/PRODUCT SPECIFICATIONS

7 ! 2 . ) . '

7 ! 2 . ) . '

7 ! 2 . ) . '

IMPORTANT SAFETY INSTRUCTIONS

The following definition applies to the word “WARNING” when used in this manual:

Used to call attention to POTENTIAL hazards that could result in personal

injury or loss of life.

READ ALL INSTRUCTIONS BEFORE USING THE MACHINE.

For your safety, perform

all assembly steps in the

sequence given. Improper

assembly can lead to injury.

SAFETY PRECAUTION

Do not lay the machine flat when the weight stack is attached. Permanent damage to the machine will result.

PRODUCT SPECIFICATIONS

User Weight Capacity: 350 lbs / 158.7 kg

Dimensions (assembled):

Shipping Weight: 391

46.5”w x 75”l x 92”h / 118.1 cm x 190.5 cm x 233.6 cm

lbs / 177.3 kg

Some components can

be heavy or awkward

to handle. Get help if

necessary.

Net Weight: 351 lbs / 159.2 kg

Power Requirements:

Self Generating

Nautilus® Commercial Free Weights Row Tower Assembly Manual

3

Page 4

BEFORE YOU ASSEMBLE

Note: Throughout this manual, all references to the left or right

side and to the front or back are made as if you were standing on

a level surface and facing the Row Tower.

Basic Assembly Principals

Here are few basic assembly tips that can make assembly of your

Nautilus® Commercial

1. You can make the assembly process go faster by gathering the

pieces you need for each step prior to starting the step.

Free Weights Row Tower

quick and easy.

2. As a general rule, and for all fasteners on your

Commercial

will tighten, turning towards the left will loosen. An easy way to

remember this is by remembering the expression, “Lefty loosey,

righty tighty.”

3. Not all of the tools needed to assemble your Nautilus

Commercial Free Weights Row Tower are provided.

the Tool List. You may find the use of a utility knife or scissors

beneficial during the unpacking and assembly process.

4. It is recommended that you use two people to assemble your

Nautilus® Commercial Free Weights Row Tower.

Positioning Your Nautilus® Commercial Free Weights Row

Tower

Take great care when moving your Commercial Free Weights

Row Tower into place prior to assembly.

The Row Tower is heavy and requires at least two people to

safely move from one location to another. Remove weights before

attempting to move the unit.

Free Weights Row Tower

, turning toward the right

Nautilus®

®

Refer to

4

Page 5

HARDWARE CARD

9

1

12

3

7

2

14

6

4

17

18

5

11

13

10

16

8

15

HARDWARE NOT TO SCALE

HARDWARE AND TOOLS

REF # DESCRIPTION QTY

1 CLIP, CARABINEER 2

2 PLASTIC PLUG 2

3 SCW-BHCS 0500x1.25 G5-BLKZ 3

4 SCW-BHCS 0500x2 G5-BLKZ 2

5 SCW, BHSC 0500x3 G5-BLKZ 6

6 SCW, BHSC 0500x3.25 G5-BLKZ 4

7 SCW, BHSC 0500x6.5 G5-BLKZ 2

8 SCW, BHSC 0500x6.75 G5-BLKZ 6

9 WSH-FLAT 0500 REGULAR BLKZ 44

10 NUT-NL 0500 G-5 BLKZ 21

11 SCW-BHSC 0375x3, G5-BLKZ 2

12 WSH-FLAT 0375 REGULAR BLKZ

2

13 SCW-SHCS 0250x1.75 G5-BLKZ 1

14 SCREW, BHCS 1/4x.75 TH CUTTING 1

15 WRENCH, ALLEN 5/32 1

16 WRENCH, ALLEN 3/16 1

17 WRENCH, ALLEN 7/32 BLK 1

TOOLS

NOT

PROVIDED

18 WRENCH, ALLEN 5/16 BLK 1

3/4” Wrench or Adjustable Wrench

9/16” Wrench or Adjustable Wrench

7/16” Wrench or Adjustable Wrench

5/16” Wrench or Adjustable Wrench

Nautilus® Commercial Free Weights Row Tower Assembly Manual

5

Page 6

5

1

4

3

2

6

8

9

10

7

BOX CONTENTS

BOX #1

REF # DESCRIPTION QTY

1 ROD, STACK GUIDE 2

2 WELDMENT, LEFT UPRIGHT 1

3 WELDMENT, RIGHT UPRIGHT 1

4 WELDMENT, REAR UPRIGHT 1

5 BOX 1, TOP, F3DLATP 1

6 BOX 1, BOTTOM, F3DMIDR 1

7 TUBE, GUIDE ROD STOP 2

8 BUMPER, UPPER GUIDE ROD 4

9 GUIDE ROD BUSHING 2

10 WASHER-FLAT 0750 NARROW BLKZ 2

6

Page 7

BOX #2

6

5

3

8

4

2

9

1

7

10

BOX CONTENTS

REF # DESCRIPTION QTY

1 ASSEMBLY, TOP WEIGHT 1

2 WELDMENT, UPPER TRIANGLE, ROW 1

3 ASSEMBLY, LOOSE PARTS, F3DROW 1

4 ASSEMBLY, HARDWARE 1, F3DROW 1

5 BOX 1, BOTTOM, F3AT 1

6 BOX 2, TOP, F3DROW 1

7 STEM PIN, CFW STACK 1

8 ASSEMBLY, STACK PULLEY 1

9 ASSEMBLY, LOWER TRIANGLE 1

10 DROW ASSEMBLY MANUAL 1

Nautilus® Commercial Free Weights Row Tower Assembly Manual

7

Page 8

3

4

5

2

1

BOX CONTENTS

BOX #3

REF # DESCRIPTION QTY

1 ASSEMBLY, ROW SEAT 1

2 ASSEMBLY, LOW ROW ATTACHMENT 1

3 BOX 3, TOP, F3DROW 1

4 BOX 3, BOTTOM, F3DROW 1

5 COVER PLATE 1

8

Page 9

BOX #4

1

3

2

BOX CONTENTS

REF # DESCRIPTION QTY

1 BOX 4, TOP, F3DLATP 1

2 BOX 4, BOTTOM, F3DLATP 1

3 ASSEMBLY, MILITARY SEAT 1

Nautilus® Commercial Free Weights Row Tower Assembly Manual

9

Page 10

3

2

WRAP PLATES IN

ONE PLASTIC BAG

PRESS BUSHINGS INTO

WEIGHT PLATES PRIOR TO SHIPPING

BOX CONTENTS

WEIGHTS, 10 LB.

REF # DESCRIPTION QTY

1 BOX, 10LB PLATES 1

2 WEIGHT PLATE, 10LB, BOTTOM 5

3 STANDARD GUIDE ROD/WEIGHT BUSHING 10

10

Page 11

WEIGHTS, 10 LB.

2

1

1

3

4

PRESS BUSHINGS INTO

WEIGHT PLATES PRIOR TO SHIPPING

WRAP PLATES IN

ONE PLASTIC BAG

BOX CONTENTS

REF # DESCRIPTION QTY

1 WEIGHT PLATE, 10LB, BOTTOM 2

2 STANDARD GUIDE ROD/WEIGHT BUSHING 6

3 WEIGHT PLATE, 10LB, SECOND 1

4 BOX, 10LB PLATES 1

Nautilus® Commercial Free Weights Row Tower Assembly Manual

11

Page 12

3

2

WRAP PLATES IN

ONE PLASTIC BAG

PRESS BUSHINGS INTO

WEIGHT PLATES PRIOR TO SHIPPING

BOX CONTENTS

WEIGHTS, 15 LB.

REF # DESCRIPTION QTY

1 BOX, 15LB PLATES 1

2 WEIGHT PLATE, 15LB, BOTTOM 5

3 STANDARD GUIDE ROD/WEIGHT BUSHING 10

12

Page 13

WEIGHTS, 15 LB.

4

2

3

PRESS BUSHINGS INTO

WEIGHT PLATES PRIOR TO SHIPPING

WRAP PLATES IN

ONE PLASTIC BAG

1

4

BOX CONTENTS

REF # DESCRIPTION QTY

1 STANDARD GUIDE ROD/WEIGHT BUSHING 6

2 WEIGHT PLATE, 15LB, SECOND 1

3 BOX, 15LB PLATES 1

4 WEIGHT PLATE, 10LB, BOTTOM 2

Nautilus® Commercial Free Weights Row Tower Assembly Manual

13

Page 14

1

2

4

3

-PLACE DECALS AND INSTRUCTIONS ON TOP

OF SMALLER PACKAGES BEFORE CLOSING

BOX CONTENTS

ALL 10 LB. WEIGHTS AND DECALS

REF # DESCRIPTION QTY

1 DECALS, 10LB WEIGHT STACK 1

2 ASSEMBLY, 10LB PLATES, BOX 2 1

3 ASSEMBLY, 10LB PLATES, BOX 1 4

4 BOX, 10LB PLATES, OVERALL 1

14

Page 15

ALL 15 LB. WEIGHTS AND DECALS

4

1

3

2

-PLACE DECALS AND INSTRUCTIONS ON TOP

OF SMALLER PACKAGES BEFORE CLOSING

BOX CONTENTS

REF # DESCRIPTION QTY

1 ASSEMBLY, 10LB PLATES, BOX 2 1

2 ASSEMBLY, 10LB PLATES, BOX 1 4

3 BOX, 10LB PLATES, OVERALL 1

4 DECALS, 15LB WEIGHT STACK 1

Nautilus® Commercial Free Weights Row Tower Assembly Manual

15

Page 16

ASSEMBLY GUIDE

The following instructions provide direction in assembling the Tower, Pulleys, Weights, Seat, and Cabling for the Nautilus®

Commercial Free Weights Row Tower. All instructions in the manual are given with the orientation of standing on a level surface and

facing the Row Tower.

Step 1: Assemble Triangle and Rear Upright

Weldments

Figure 1:

Locate the following for this step:

Parts:

• Ref 4, Rear Upright Weldment Qty. 1

• Ref 2, Upper Triangle Weldment Qty. 1

• Ref 9, Lower Triangle Weldment Qty. 1

Hardware:

• Ref 6, 1/2” x 3 1/4” Button Head Bolt Qty. 4

• Ref 10, 1/2” Nuts Qty. 4

• Ref 9, 1/2” Washers Qty. 8

Tools:

• Ref 18, 5/16” Allen Wrench

• 3/4” Wrench

Refer to Figure 1:

1-1 With the Rear Upright on is back on a clear floor

area, insert four 3 1/4” bolts.

1-2 Place the Upper and Lower Triangle Weldments

in the proper locations and loosely tighten the

hardware.

16

Page 17

ASSEMBLY GUIDE

Step 2: Assemble Left and Right Upright Weldments

Figure 2:

Locate the following for this step:

Parts:

• Ref 2, Left Upright Weldment Qty. 1

• Ref 3, Right Upright Weldment Qty. 1

Hardware:

• Ref 7, 1/2”x 6 1/2” Button Head Bolt Qty. 2

• Ref 8, 1/2”x 6 3/4” Button Head Bolt Qty. 6

• Ref 10, 1/2” Nuts Qty. 6

• Ref 9, 1/2” Washers Qty. 14

Tools:

• Ref 18, 5/16” Allen Wrench

• 3/4” Wrench

Refer to Figure 2:

2-1 With the Assembly still on its back, place the Left

and Right Uprights in place and loosely secure

with 6 1/2” bolts.

2-2 Lift the Tower to the upright position and

tighten all hardware.

2-3 Be sure the feet are all sitting level.

Nautilus® Commercial Free Weights Row Tower Assembly Manual

17

Page 18

ASSEMBLY GUIDE

GAP MUST BE FROM 0.0MM TO 22.4MM

DURING NORMAL OPERATION TO ALLOW

MINIMUM THREAD ENGAGEMENT.

TOP NUT MUST BE FULLY

TIGHTENED BEFORE

MEASURING GAP

25.4 MINIMUM

THREAD ENGAGEMENT

22.4

25.4

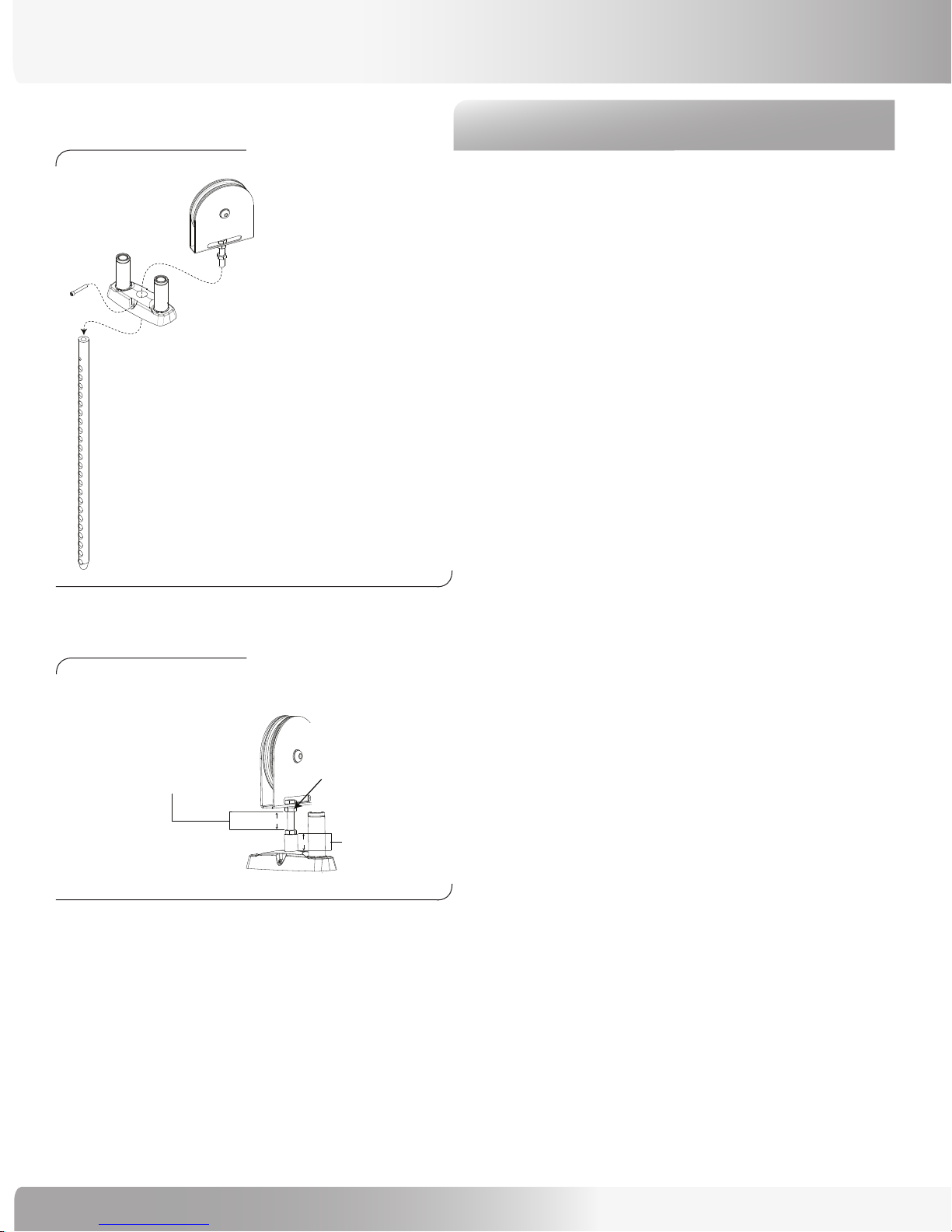

Step 3: Assemble Stack Pulley and Top Weight Plate

Figure 3:

Locate the following for this step:

Parts:

• Ref 8, Stack Pulley Assembly Qty. 1

• Ref 1, Top Weight Plate Assembly Qty. 1

Hardware:

• None

Tools:

• Ref 16, 3/16” Allen Wrench

Refer to Figures 3 and 4:

3-1 Prepare the Top Weight Assembly by loosely

attaching the Stack Pulley Assembly.

3-2 Attach the Stem Pin.

3-3 Set aside the Assembly.

Figure 4:

Note: When attaching the Weight Stack Pulley, make

sure that there is 25.4 mm (1in.) of thread engagement

(Figure 4). In order to ensure proper thread engagement,

set the bottom nut at the 25.4 mm (1in.) minimum

distance, then thread the Pulley Assembly into the Top

Weight (refer to Step 12 for the procedure to thread the

Pulley Assembly). To check that you have the proper

engagement after the Pulley is installed, measure the

distance between the two nuts when the top nut is fully

tightened. The distance between nuts can not exceed

22.4 (.88 in.) mm.

18

Page 19

ASSEMBLY GUIDE

Step 4: Install Guide Rods and Bumpers

Figure 5:

Locate the following for this step:

Parts:

• Ref 2, Guide Rod Qty. 2

• Ref 2, Bumper Guide Rod Qty. 2

Hardware:

• None

Tools:

• None

Refer to Figure 5:

4-1 Place the Guide Rods and Bumpers in the Bottom

Triangle Weldment, allowing the Rods to lean

forward.

Nautilus® Commercial Free Weights Row Tower Assembly Manual

19

Page 20

ASSEMBLY GUIDE

Step 5: Install Weight Plates

Figure 6:

Locate the following for this step:

Parts:

• 10 lb Weight Plates, CFW Qty. 23

-OR-

• 15 lb Weight Plates, CFW Qty. 23

• Top Weight Assembly from Step 3

Hardware:

• None

Tools:

• None

Refer to Figures 6 and 7:

5-1 Locate and set aside the 10 lb or 15 lb Weight Plate

with the extra hole in the front to retain the Weight

pin. This is the “Second Plate” and is the last plate

you place before adding the Top Weight Assembly

(Figure 6).

Figure 7:

Note: Make sure that the extra hole in the “Second

Plate” is facing to the left (as you face the machine).

5-2 Carefully slide all the Weight plates onto the Guide

Rods, finishing with the ”Second Plate” and the Top

Weight Assembly (Figure 7).

20

Page 21

ASSEMBLY GUIDE

Figure 8:

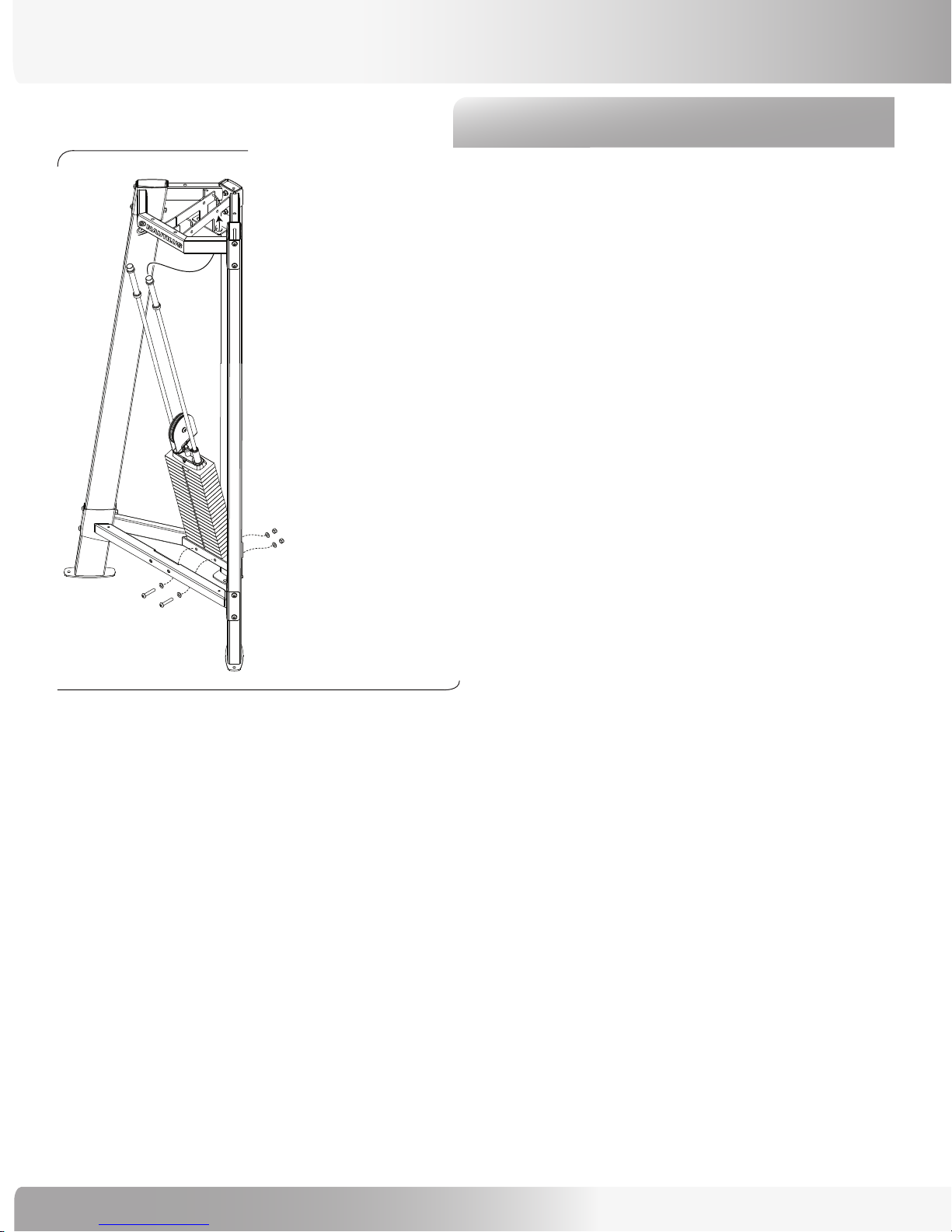

Step 6: Install Guide Rods

Locate the following for this step:

Parts:

• Ref 8, Bumper, Guide Rod Qty. 2

• Ref 7, Tube, Guide Rod Qty. 2

• Ref 9, Guide Rod Bushing Qty. 2

Hardware:

• Ref 12, 3/4” Washers Qty. 2

Tools:

• None

Refer to Figure 8:

6-1 Place the components onto the Guide Rod ends in

the order shown.

Note: Do not lift the Guide Rods into place at this time.

Nautilus® Commercial Free Weights Row Tower Assembly Manual

21

Page 22

Figure 9:

ASSEMBLY GUIDE

Step 7: Install Seat Guide Rods into Upper Triangle

Weldment

Locate the following for this step:

Parts:

• Ref 2, Weldment, Upper Triangle, Row Qty. 1

Hardware:

• Ref 4, 1/2”x 3” Button Head Bolt Qty. 2

• Ref 14, 1/4” x 3/4” Thread Cutting Screw Qty. 1

• Ref 10, 1/2” Nuts Qty. 2

• Ref 9, 1/2” Washers Qty. 4

Tools:

• Ref 18, 5/16” Allen Wrench

• Ref 15, 5/32” Allen Wrench

• 3/4” Wrench

Refer to Figure 9:

7-1 Tip the Guide Rods to a vertical position. Lift the

Guide Rods one at a time so that the Guide Rod

Bushing is seated completely into the Upper

Triangle Weldment.

7-2 Place the 1/2” x 3” retaining bolt into the hole

just below the Guide Rod and secure with a 1/2”

nut.

7-3 Repeat 7-1 and 7-2 for both sides.

7-4 Attach the Pin Rope to the Weight Stack using

the 1/4” x 3/4” Thread Cutting Screw.

7-5 Firmly tighten the hardware.

22

Page 23

ASSEMBLY GUIDE

Step 8: Adhere Weight Stack Decals

Figure 10:

Locate the following for this step:

Parts:

• Ref 1, 10 lb Weight Plate Decals Qty. 23

-OR-

• Ref 4, 15 lb Weight Plate Decals Qty. 23

Hardware:

• None

Tools:

• None

Refer to Figure 10:

8-1 Prepare the Weight Plates by degreasing with

denatured alcohol and a primer solution.

8-2 From each Decal strip (12 Decals to a strip

column), remove, separately, one side of the

backing.

8-3 Align the backing to the Plates and press gently

against the backing.

8-4 Firmly rub the decals to secure adhesion to the

Weight Plates.

Nautilus® Commercial Free Weights Row Tower Assembly Manual

23

Page 24

ASSEMBLY GUIDE

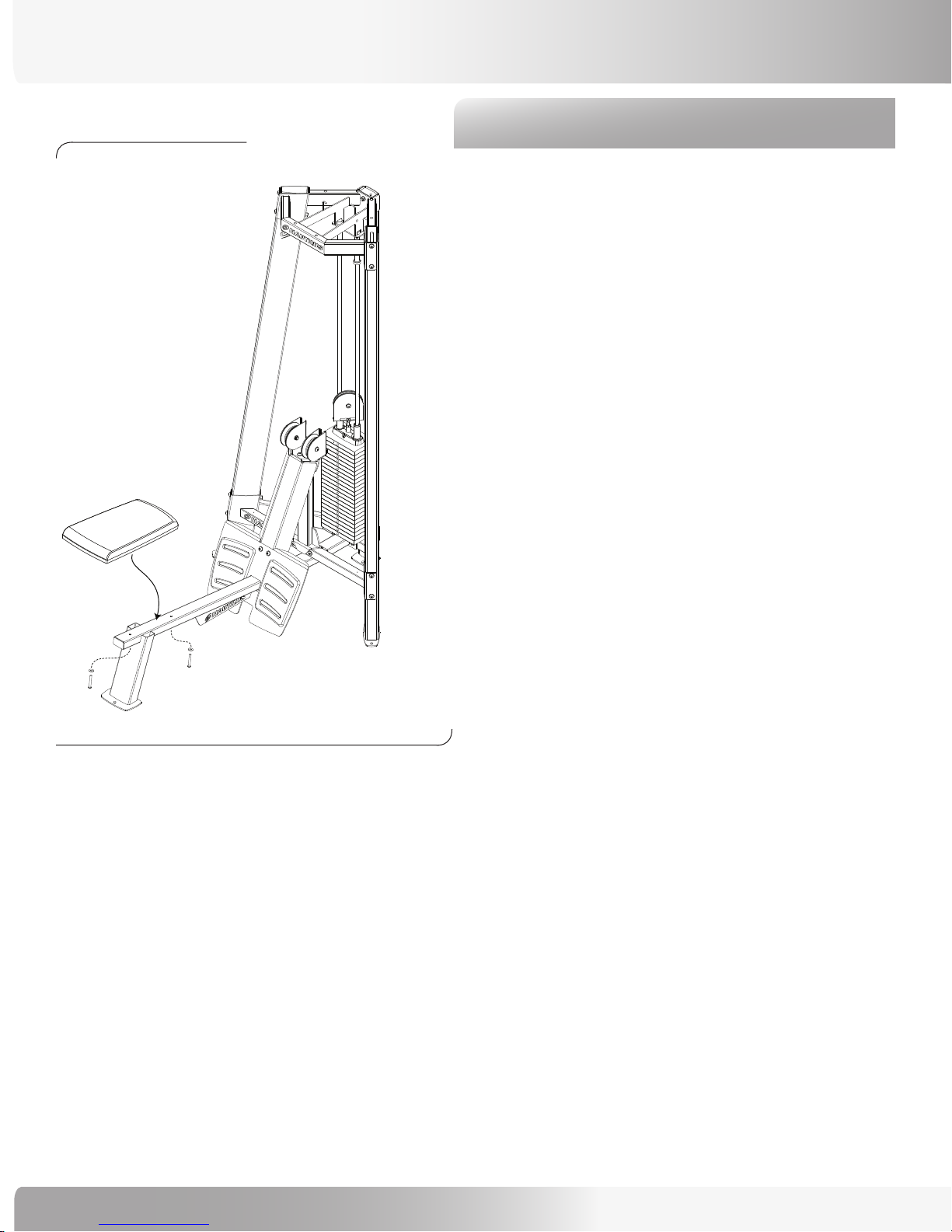

Step 9: Install Row Seat Assembly

Figure 10:

Locate the following for this step:

Parts:

• Ref 1, Row Seat Assembly Qty. 1

Hardware:

• Ref 3, 1/2 x 1 1/4” Button Head Bolt Qty. 2

• Ref 5, 1/2”x 3”” Button Head Bolt Qty. 4

• Ref 10, 1/2” Nuts Qty. 6

• Ref 9, 1/2” Washers Qty. 12

Tools:

• Ref 18, 5/16” Allen Wrench

• 3/4” Wrench

Refer to Figure 10:

9-1 Attach the Row Seat Assembly to the rear tube of

the Lower Triangle Weldment.

24

Page 25

ASSEMBLY GUIDE

Step 10: Install Row Attachment Assembly

Figure 11:

Figure 12:

Locate the following for this step:

Parts:

• Ref 2, Row Attachment Assembly Qty. 1

Hardware:

• Ref 3, 1/2 x 1 1/4” Button Head Bolt Qty. 1

• Ref 3, 1/2 x 1 1/4” Button Head Bolt Qty. 2

• Ref 5, 1/2”x 3”” Button Head Bolt Qty. 4

• Ref 10, 1/2” Nuts Qty. 7

• Ref 9, 1/2” Washers Qty. 14

Tools:

• Ref 18, 5/16” Allen Wrench

• 3/4” Wrench

Refer to Figures 11 and 12:

10-1 Secure the Cover Plate to the c-channel of the

Row Attachment Assembly (Figure 11).

10-2 Place the c-channel of the Row Attachment

Assembly on the front tube of the Lower Triangle

Weldment (Figure 12).

10-3 Loosely secure the Row Attachment Assembly

to the Lower Triangle and Seat Rail.

10-4 Completely tighten all hardware after everything

is in place, ensuring the foot of the Row Seat

remains flat on the floor.

Nautilus® Commercial Free Weights Row Tower Assembly Manual

25

Page 26

ASSEMBLY GUIDE

Figure 13:

Step 11: Attach Seat Upholstery

Locate the following for this step:

Parts:

• Ref 3, Seat Upholstery Qty. 1

Hardware:

• Ref 11, 3/8”x 3” Button Head Bolt Qty. 2

• Ref 12, 3/8” Washers Qty. 2

Tools:

• Ref 18, 5/16” Allen Wrench

• 3/4” Wrench

Refer to Figure 13:

11-1 Align the holes of the Seat Upholstery with the

holes of the Lateral Pulley Seat Weldment and

fasten with the 3/8” hardware.

26

Page 27

ASSEMBLY GUIDE

Side against the frame

Side facing inward

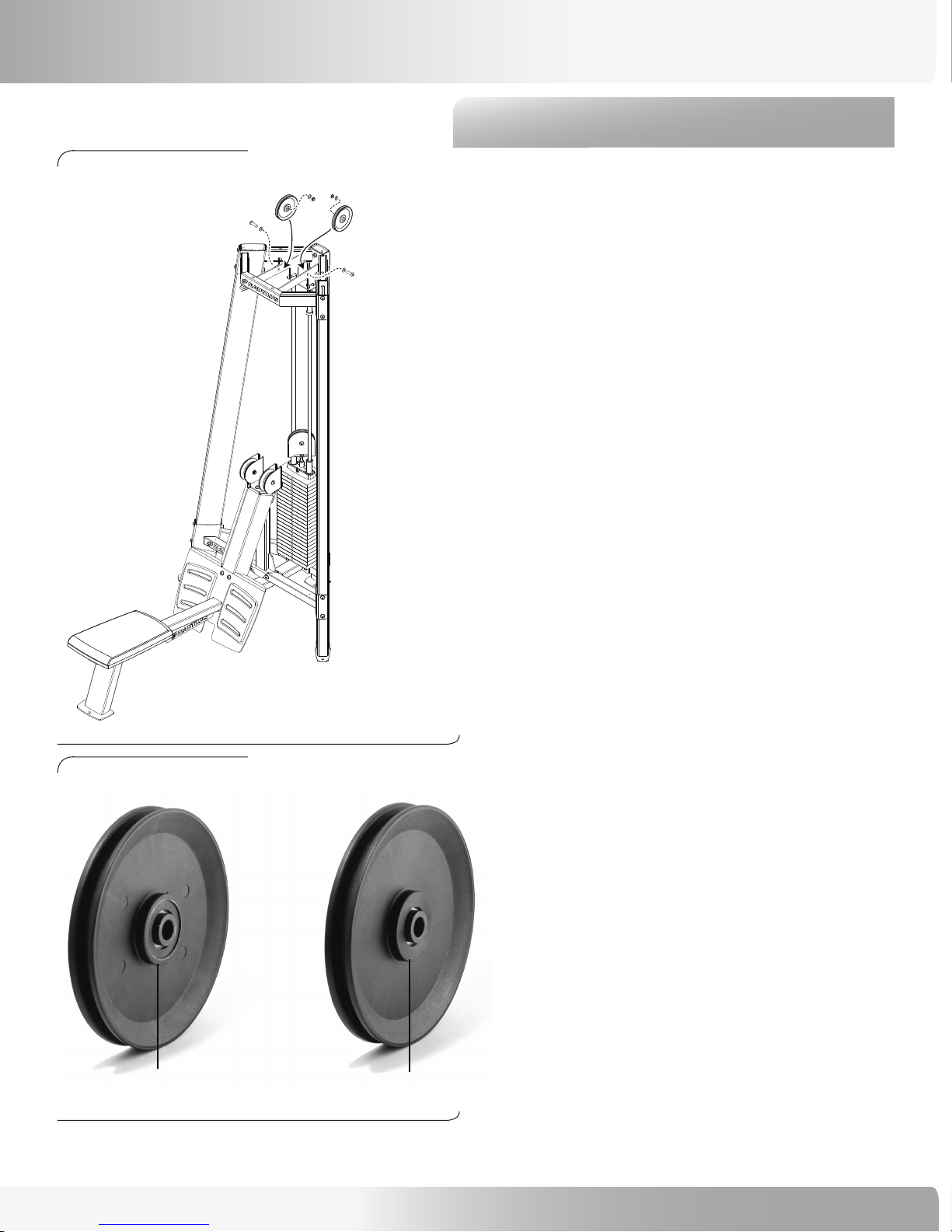

Step 12: Install Upper Pulley Assemblies

Figure 14:

Locate the following for this step:

Parts:

• Ref 3, 6” Pulley Assembly Qty. 2

Hardware:

• Ref 4, 1/2”x 2” Button Head Bolt Qty. 2

• Ref 10, 1/2” Locknuts Qty. 2

• Ref 9, 1/2” Washers Qty. 4

Tools:

• Ref 18, 5/16” Allen Wrench

• 3/4” Wrench

Refer to Figures 14 and 15:

12-1 Fasten the Pulleys to the Upper Triangle

Weldment using the 1 3/4” hardware. Loosely

tighten the hardware until the cable is routed

(Figure 14).

Figure 15:

Note: Be sure to orient Pulleys as shown in Figure 15.

12-2 Securely tighten the hardware.

Nautilus® Commercial Free Weights Row Tower Assembly Manual

27

Page 28

ASSEMBLY GUIDE

Step 13: Attach Cable Ball and Fork and Route Cable

Figure 16:

Figure 17:

Locate the following for this step:

Parts:

• Ref 3, Assembly, Slotted Strap Forks Qty. 2

• Ref 1, Clip, Carabineer Qty. 2

Hardware:

• None

Tools:

• Ref 17, 7/32” Allen Wrench

• 9/16” Wrench

Refer to Figure 16:

13-1 Attach Cable Ball and Slotted Strap Fork to one

end of the cable. Cable terminations come

attached. Remove one set of the terminations.

Refer to Figures 17 and 18:

13-2 Follow this sequence to install the cable:

a. Start threading the cable into the left side

under the pulley of the Row Attachment

system (Figure 17).

b. Continue threading the cable to the 6” top

pulley and wrap over it.

28

Page 29

Figure 18:

ASSEMBLY GUIDE

Step 13: Attach Cable Ball and Fork and Route

Cable, continued

c. From there, thread the cable back down in

front of the Weight Stack Pulley Assembly

(Figure 18).

d. Thread the cable under the Weight Stack

Pulley Assembly and up behind it.

Note: To align the Weight Stack Pulley, first

make sure that the tension nuts are loose

(assembly should rotate freely) and that all

other steps have been completed.

With the weight pin inserted (amount of

weight is unimportant; simply ensure there is

some weight), pull the cable handles until the

cable is just tight. This should rotate the

pulley to the correct orientation. Tighten the

tension nuts while the cable is tight.

e. Going up, thread the cable over the 6” pulley

on the right side of the Tower (Figure 18).

f. Complete the cable installation by threading

the cable down to the Adjustable Dual Pulley

right side and thread the cable under the

pulley.

g. Attach the remaining Cable Ball and Slotted

Strap Fork.

13-3 Tighten the hardware on the Top Pulley

Assemblies.

13-4 Attach remaining accessories (carabineers,

handles).

Nautilus® Commercial Free Weights Row Tower Assembly Manual

29

Page 30

FINAL CHECK

Step 14: Lubrication and Cable Tensioning

Figure 19:

Perform this step as the final check.

Refer to Figure 19:

Lubrication

14-1 Lubricate the guide rods using a silicone based

lubricant.

14-2 Carefully inspect all cables and insure that they

are properly seated on the pulleys and that they

pass between the pulleys and cable retainers.

14-3 Make sure all hardware is securely tightened.

Cable Tensioning

14-4 The cables should be as tight as possible while still

allowing the selector pin to freely engage all of

the weights.

14-5 Once the cables are tensioned, load the weight

stack with as much weight as you feel comfortable

with, and pull each cable several times to set and

stretch the cables.

14-6 After the cables are stretched, they may need to

be re-tensioned.

14-7 Over time, the cables may stretch and need to be

re-tensioned.

30

When cables are properly tensioned, the ball stop

should rest within 1/4” of the Dual Pulley System and

the top weight should sit flush. If the cable is loose

(more than a 1/4” of play), move the bottom tension

nut up the bolt. Next, screw the bolt further down into

the weight stack. If the cable is too tight, unscrew the

bolt from the Weight Stack. Finish by retightening the

bottom tension nut. Make sure to follow the guidelines

above regarding thread engagement.

Page 31

7 ! 2 . ) . '

ASSEMBLY COMPLETE

Step 15: Inspect Assembly

Congratulations!

®

15-1 Assembly of your Nautilus

Weights Row Tower is now complete.

Be sure to fully inspect your Nautilus

cial Free Weights Smith Machine Rack before

using it for the first time.

Commercial Free

®

Commer

Failure to visually check and

test the assembly before use can

cause damage to the Nautilus®

Commercial Free Weights Row

Tower and serious injury to users and bystanders and can also

compromise the effectiveness of

your exercise program.

Nautilus® Commercial Free Weights Row Tower Assembly Manual

31

Page 32

COMPANION EXERCISE EQUIPMENT

The Nautilus® Racks are designed for use with Nautilus® Free Weights equipment. The Nautilus® Free

Weights line includes the following models:

Utility Benches & Exercise Machines

Commercial Free Weights F3 0-90 Adjustable Utility Bench

•

Commercial Free Weights F3AD Adjustable Decline Utility Bench

•

Commercial Free Weights F3AHE Adjustable Hip Extension

•

Commercial Free Weights F3AAB Adjustable Abdominal Bench

•

Commercial Free Weights F3PC Preacher Curl Bench

•

Commercial Free Weights F3TBR T-Bar Row

•

Commercial Free Weights F3CD Chin Dip Leg Raise

•

Commercial Free Weights F3FU Flat Utility Bench

•

Commercial Free Weights F3SU Seated Utility

•

Olympic Benches & Squat Rack

Commercial Free Weights F3OSB Olympic Supine Bench

•

Commercial Free Weights F3ODB Olympic Decline Bench

•

Commercial Free Weights F3OIB Olympic Incline Bench

•

Commercial Free Weights F3OMB Olympic Military Bench

•

Commercial Free Weights F3SR Squat Rack

•

Towers

Commercial Free Weights F3CC Cable Crossover Tower

•

Commercial Free Weights F3DLATP Dual Pulley Lateral Pulldown Tower

•

Commercial Free Weights F3DROW Row Tower

•

Commercial Free Weights F3AT Adjustable Tower

•

Racks

Commercial Free Weights F3SM Smith Machine

•

Commercial Free Weights F3PR Power Rack

•

Equipment Storage

Commercial Free Weights F3BR Barbell Rack

•

Commercial Free Weights F3 2TDR Two Tier Dumbbell Rack

•

Commercial Free Weights F3 1TDR One Tier Dumbbell Rack

•

Commercial Free Weights F3WT Weight Tree

•

Please contact Nautilus, Inc. or a Nautilus® Representative for information about other products, or go to

www.nautilus.com.

32

Page 33

LIMITED WARRANTY

Commercial Market Warranty Information

All Nautilus® exercise products are warranted to the

commercial market purchaser to be free from defects in

materials and workmanship. Warranty coverage valid to

the original purchaser only and proof of the purchase will

be required. Any product sold or placed in an application

not recommended by Nautilus will void any warranty

coverage set forth by Nautilus warranty policies and

procedures.

Time Period

15 Years - Frame

3 Years- Mechanical and electrical parts

1 Year- Labor

1 Year - Wear items

What this warranty does not cover

warranty or, at Nautilus’ election, to the replacement

amount of the purchase price of the exercise product

in question. Some states do not permit the exclusion

or limitation of implied warranties or incidental or

consequential damages, so the preceding limitations and

exclusions may not apply to you.

Procedures

Warranty service will in most cases be performed by an

authorized Nautilus Fitness Dealer or Service Technician.

The original purchaser must provide proof of purchase,

Service calls and/or transportation to and from the

Nautilus Dealer is the responsibility of the purchaser.

1. Nautilus will have the option to repair or replace any

exercise product, which requires service.

2. Nautilus will replace any equipment frame that is

structurally defective with a new frame or replace the

unit with a unit of equal value.

1. Users weighing more than 350 lbs.

2. Any damage, failure or loss caused by accident,

misuse, neglect, abuse, improper assembly, improper

maintenance or failure follow instructions or warnings

in this Assembly/Service Manual.

3. Use of product in a manner or environment for which it

was not designed.

Limitations

The foregoing warranties are in lieu of and exclude all

other warranties not expressly set forth herein, whether

expressed or implied by operation of law or otherwise,

including, but not limited to, warranties of merchantability

or fitness for a particular purpose. Nautilus shall in no

event be liable for incidental or consequential losses,

damages or expenses in connection with its exercise

products. Nautilus’ liability hereunder is expressly limited

to the replacement of goods not complying with this

3. Nautilus is not responsible for dealer labor charges for

the component changeovers completed after the labor

related warranty period stated herein.

4. If you elect to repair an exercise product or part

yourself, using the services of someone other than

an authorized Nautilus Fitness Dealer or Service

Technician, or use a replacement part not supplied

by Nautilus, Nautilus shall not be liable for any cost,

damage, failure or loss caused by the use of such

unauthorized service or parts.

[INCLUDE A WARRANTY REGISTRATION CARD ‘PAGE’

OR A REFERENCE TO AN ON-LINE WARRANTY

REGISTRATION FORM??]

Nautilus® Commercial Free Weights Row Tower Assembly Manual

33

Page 34

IMPORTANT CONTACT NUMBERS

If you need assistance, please have both the serial number of your machine and the date of purchase available when you

contact the appropriate Nautilus office listed below.

WORLDWIDE CUSTOMER SERVICE

• NORTH AMERICA OFFICE

Nautilus, Inc.

World Headquarters

16400 S.E. Nautilus Drive

Vancouver, Washington, USA 98683

Phone: 800-NAUTILUS (628-8458)

Fax: 800-686-6466

e-mail: cstech@nautilus.com

• NAUTILUS INNOVATION CENTER

Nautilus, Inc.

1886 Prairie Way

Louisville, Colorado, USA 80027

Phone: 800-864-1270

Fax: 800-898-9410

• CORPORATE HEADQUARTERS

Nautilus, Inc.

World Headquarters

16400 S.E. Nautilus Drive

Vancouver, Washington, USA 98683

Phone: 800-NAUTILUS

INTERNATIONAL CUSTOMER SERVICE

• INTERNATIONAL OFFICE

Nautilus International S.A.

Rue Jean Prouvé 6

1762 Givisiez / Switzerland

Tel: +41-26-460-77-77

Fax: +41-26-460-77-70

E-mail: technics@nautilus.com

INTERNATIONAL OFFICES:

• SWITZERLAND OFFICE

Nautilus Switzerland S.A.

Tel: +41-26-460-77-66

Fax: +41-26-460-77-60

• GERMANY and AUSTRIA OFFICE

Nautilus GmbH

Tel: +49 2203 /20 20-0

Fax: +49 2203/20 20-45 45

• ITALY OFFICE

Nautilus Italy s.r.l.

Tel: +39-051-664-6201

Fax: +39-051-664-7461

34

• UNITED KINGDOM OFFICE

Nautilus UK Ltd.

Tel: +44-1908-267-345

Fax: +44-1908-267-346

• CHINA OFFICE

Nautilus Representative Office

Tel: +86-21-523-707-00

Fax: +86-21-523-707-09

Page 35

For more information about our Commercial Series exercise equipment or other Nautilus®

© 20 07 Nauti lus, Inc. A ll right s reser ved. Naut ilus, th e Nautilu s logo, Naut ilus Ins titut e and Be St rong are ei ther regi stered t rademark s or tradem arks of Nau tilus, I nc.

Naut ilus, Inc. W orld Headq uarter s, 164 00 SE Nau tilus Dri ve, Vancou ver, Washing ton, US A 986 83, 1-8 00- 628 -84 58, ww w.Naut ilus.c om.

Be Strong.

equipment for your home, visit www.Nautilus.com.

™

Loading...

Loading...