Page 1

Be Strong.

™

TreadClimber® Model TC916

Commercial Series

P/N: 001-7013 Rev B (11/09/2006)

Assembly Manual

Page 2

For detailed instructions and inFormation on

7 ! 2 . ) . '

! 4 4 % . 4 ) / .

$ ! . ' % 2

how to use and care For your treadclimber

commercial series exercise machine, model tc916,

reFer to the owner’s manual.

®

2

Page 3

TABLE OF CONTENTS

TREADCLIMBER

®

FEATURES ............................................................................................................................

PRODUCT SPECIFICATIONS .............................................................................................................................. 5

IMPORTANT SAFETY PRECAUTIONS .............................................................................................................. 6

WARRANTY INFORMATION:

TIME PERIOD ......................................................................................................................................... 8

WHAT THIS WARRANTY DOES NOT COVER .................................................................................... 8

LIMITATIONS .......................................................................................................................................... 8

PROCEDURES ......................................................................................................................................... 8

GETTING STARTED:

SELECT YOUR WORKOUT AREA ......................................................................................................... 9

POWER PLUG RECEPTACLE ................................................................................................................ 9

TURNING ON THE POWER .................................................................................................................. 9

UNDERSTANDING THE DISPLAY AND CONTROLS ......................................................................... 9

LIMITED ACCESS CONTROL/MAGNETIC SAFETY STOP ................................................................ 10

MAGNETIC KEY SAFETY STOP ACTIVATION ................................................................................... 10

QUICK START GUIDE ............................................................................................................................. 11

4

MOVING INSTRUCTIONS:

MOVING INSTRUCTIONS FOR FULLY ASSEMBLED UNIT:

MOVING YOUR TREADCLIMBER® TC916 ................................................................................... 12

REMOVING MACHINE FROM PALLET ......................................................................................... 13

MOVING UNIT INTO POSITION IN FACILITY .............................................................................. 14

DISASSEMBLY OF UPRIGHT UNIT:

IMPORTANT INFORMATION TO READ BEFORE DISASSEMBLING UPRIGHT UNIT .. 16

REMOVING REAR STEP ........................................................................................................ 17

REMOVING UPRIGHTS ......................................................................................................... 18

REMOVING BASE PLASTIC ................................................................................................. 19

MOVING TOOL INFORMATION ........................................................................................................... 20

ASSEMBLY INSTRUCTIONS FOR CRATED UNIT:

BEFORE YOU ASSEMBLE

BASIC ASSEMBLY PRINCIPLES ............................................................................................ 22

HARDWARE AND TOOL LIST ............................................................................................................... 23

PARTS LIST REFERENCE GUIDE .......................................................................................................... 24

UNPACKING GUIDE .............................................................................................................................. 26

ASSEMBLY GUIDE ................................................................................................................................. 29

BELT TENSION AND ALIGNMENT ................................................................................................................... 40

IMPORTANT CONTACT NUMBERS: ................................................................................................................. 41

Nautilus® TreadClimber® Model TC916 Assembly Manual

3

Page 4

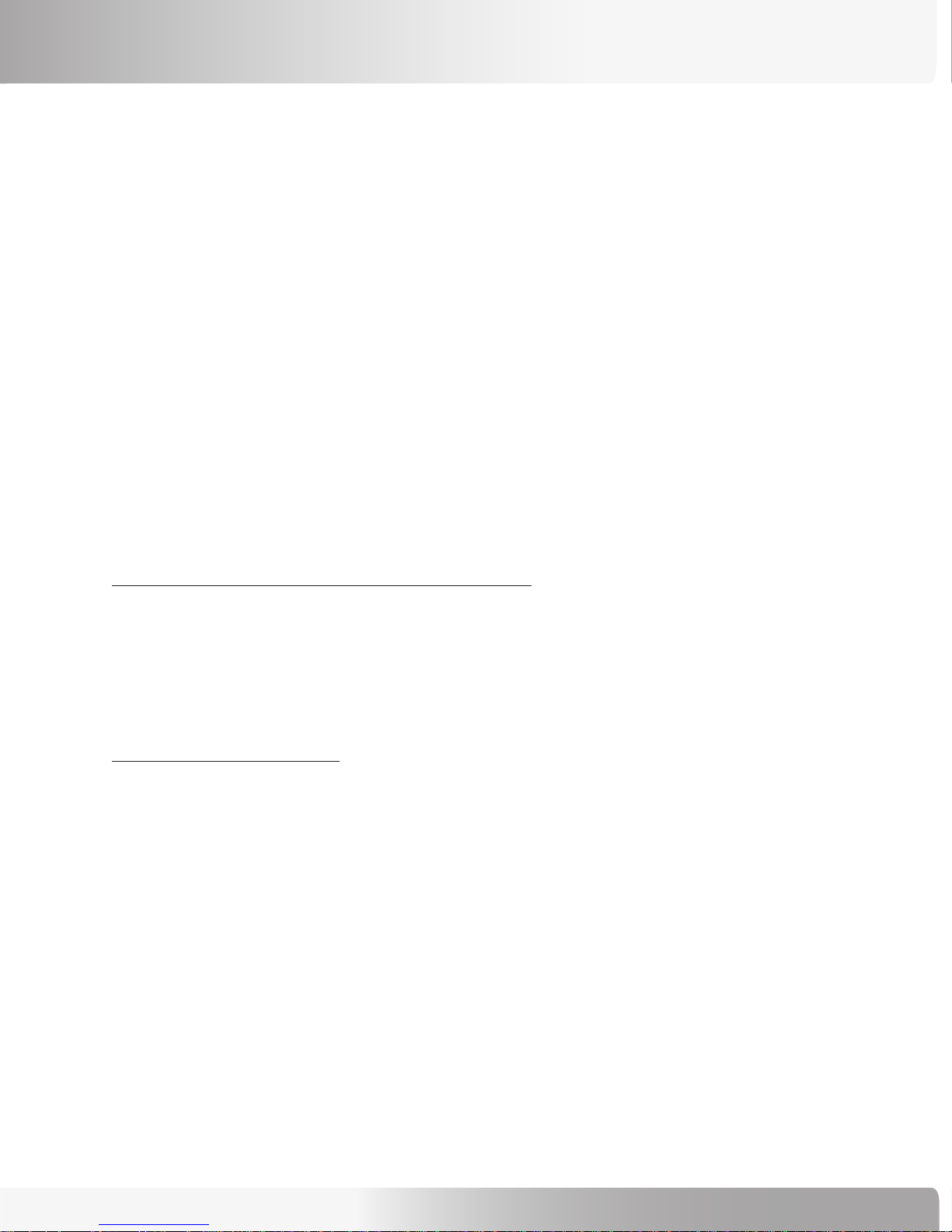

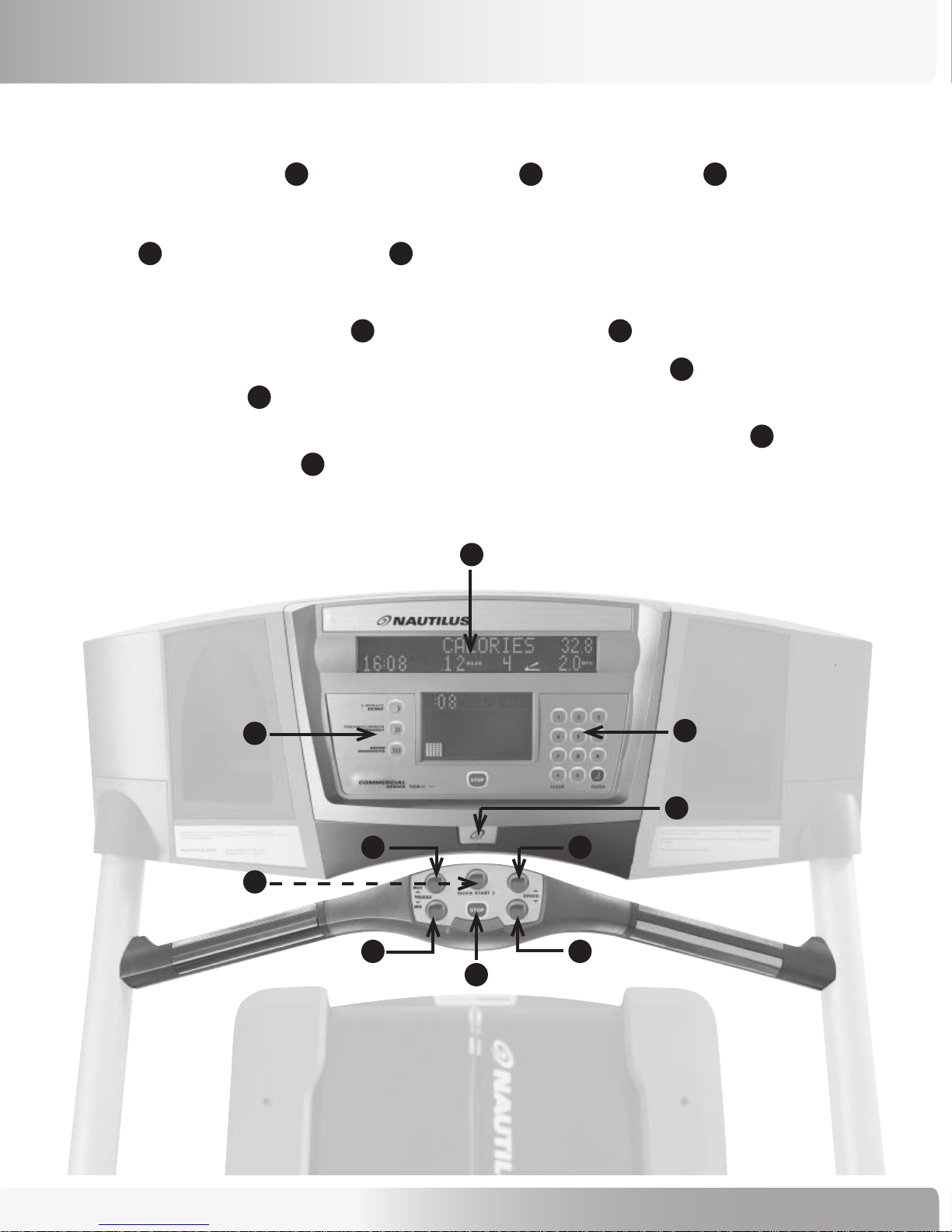

TREADCLIMBER® FEATURES

Console

Ergo Bar

Power On/Off Switch

Model: TC916

Adjustable Feet

4

Page 5

User Weight Capacity: 400 lbs (182 kg)

Speed Range: 0.5 to 6 mph (default set to 4.0 mph)

0.8 to 9.7 km/h (default set to 6.4 km/h)

Treadle Displacement Levels: MIN (half the total displacement) and

MAX (full treadle displacement)

Walk Surface (W x L): 21” x 48” defined by two separate left and right

treadmill belt assemblies (treadles), each treadle 10”

x 48” in length, with a 1” or less separation between

the belts.

(Metric Walk Surface: 53 x 122 cm.)

PRODUCT SPECIFICATIONS

Floor Space (W x L): 36” x 70” / 91.5 x 178 cm

TreadClimber® Weight: 684 lbs / 310 kg

Shipping Weight: 806 lbs / 366 kg

Power Requirements: USA: 110 Volt, 20 amp dedicated circuit.

International: 230V, 10 amp dedicated circuit

Warranty: 3 years - parts, 1 year - labor, 1 year -wear items, and

15 years - frame and AC-motor.

(May vary outside the USA.)

Regulatory Approvals:

CSA Certified, UL Listed

Meets:

FCC - Part 15

Canadian ICES-003 Regulations for Class A apparatus

Meets:

Safety - EN 60335-1

EMC Directive 89/336/EEC

Machinery Directive - 98/37/EC

Low Voltage Directive - 89/336/EEC

Model: TC916

Patent Information:

U.S. and International Patents Pending

Recycling

Do not dispose of this product as refuse. This product is to be recycled. For information

on the proper method of disposal contact a Nautilus Customer Service Representative.

Contact information is available in the Important Contact Numbers section in this manual.

Nautilus® TreadClimber® Model TC916 Assembly Manual

5

Page 6

IMPORTANT SAFETY PRECAUTIONS

7 ! 2 . ) . '

7 ! 2 . ) . '

SAVE THESE INSTRUCTIONS:

The following definition applies to the word “Warning” found throughout this manual:

Used to call attention to POTENTIAL hazards that could result in personal injury or loss

of life.

WHEN USING ELECTRICAL EQUIPMENT ALWAYS FOLLOW THESE BASIC PRECAUTIONS:

to reduce the risk of electrical shock, always unplug the external

power supply from the electrical outlet before cleaning, maintaining, or

repairing.

to reduce the risk of burns, electric shock or injury to persons read

and follow all safety warnings and instructions in this manual.

secure long hair and loose clothing before use.

do not use near water

!

READ ALL INSTRUCTIONS BEFORE USING THE MACHINE.

Read this manual in full before operating the TreadClimber® machine. Failure to follow these guidelines can produce a

serious or possible fatal electrical shock hazard or other serious injury. Consult a qualified electrician as required.

®

1. The controller Stop Key does not turn off the electrical current to the TreadClimber

TreadClimber® machine continues to draw power, even when the controller is off. To avoid electric shock, do not

remove TreadClimber® hood or place hands beneath the TreadClimber® exercise machine while the machine is plugged

into a power source.

2. Do not start the TreadClimber® machine when someone else is standing on the walk belts.

3. Keep walk speed and treadle displacement at the lowest settings when getting on and off the TreadClimber

4. Keep the area underneath and around the TreadClimber® exercise machine clear.

exercise machine. The

®

machine.

®

5. Never position the TreadClimber

objects such as furniture or other pieces of fitness equipment. Failure to keep the rear space of the machine clear can

prevent safe exit of the TreadClimber® machine in an emergency situation such as falling. Allow a minimum of four feet

behind the TreadClimber® exercise machine.

6

exercise machine with the back end (direction of belt travel) facing a wall or any other

Page 7

IMPORTANT SAFETY PRECAUTIONS

6. Before each use of this equipment, check the power receptacle for signs of damage. Do not operate the equipment if the

integrity of the power receptacle is in question.

7. To avoid potential safety and electrical problems, replace with manufacturer’s specified parts only.

8. This equipment is classified Class I, Type B, ordinary equipment. Not protected against fluid ingress. Rated for continuous

operation. Do not operate this equipment in the presence of flammable anesthetic mixtures.

9. Do not let liquid enter the controller. If it does, the controller must be inspected and tested for safety by an approved

technician before it can be used again.

10. Increased risk due to leakage current can result if this equipment is not grounded properly.

11. The TreadClimber® machine must be on an appropriate, dedicated electrical circuit. Nothing else should be connected to

the circuit.

12. Do not stand on the TreadClimber® TC916’s hood or front trim cover.

13. Close supervision is necessary whenever the machine is used by or near children, invalids, or disabled persons.

Failure to follow the conditions set forth below shall limit, to the extent allowed by law, Nautilus Inc.’s responsibility for the

safety, reliability, and performance of this equipment.

• The operator manual must be read in full by each owner and trainer before the product is first used. Each user must

be instructed in the proper use of the TreadClimber® machine and its accessories.

• Do not remove the TreadClimber® hood: dangerous voltages are present. Components are serviceable only by

qualified service personnel.

• The electrical wiring within the TreadClimber® equipment setting and the electrical installation of the TreadClimber®

machine must comply with the applicable local or provincial requirements.

• The equipment must be used in accordance with the instructions for use.

• For further information or instruction on use, maintenance or specifications, please contact your Authorized Nautilus

Fitness Dealer or Service Technician.

Nautilus® TreadClimber® Model TC916 Assembly Manual

7

Page 8

COMMERCIAL MARKET WARRANTY INFORMATION

**For warranty information outside of the United States or Canada,

contact the International office listed in the Important Contact Numbers section of this manual. **

WARRANTY INFORMATION

All Nautilus® exercise products are warranted to the commercial market purchaser to be free from defects in materials

and workmanship. Warranty coverage valid to the original purchaser only and proof of the purchase will be required. Any

product sold or placed in an application not recommended by Nautilus, Inc. will void any warranty coverage set forth by

Nautilus, Inc. warranty policies and procedures.

Time Period (May vary outside U.S.A.)

• 15 - Years - Frame and AC-motor

• 3 - Years - Mechanical and electrical parts

• 1 - Year - Labor

• 1 - Year - Wear items

What this Warranty Does Not Cover

1. Any damage, failure or loss caused by accident, misuse, neglect, abuse, improper assembly, improper maintenance or

failure to follow instructions or warnings in Owner’s Manual.

2. Use of product in a manner or environment for which it was not designed.

Limitations

The foregoing warranties are in lieu of and exclude all other warranties not expressly set forth herein, whether expressed

or implied by operation of law or otherwise, including, but not limited to, warranties of merchantability or fitness for a

particular purpose. Nautilus, Inc. shall in no event be liable for incidental or consequential losses, damages or expenses

in connection with its exercise products. Nautilus’ liability hereunder is expressly limited to the replacement of goods

not complying with this warranty or, at Nautilus’ election, to the replacement amount of the purchase price of the

exercise product in question. Some states do not permit the exclusion or limitation of implied warranties or incidental or

consequential damages, so the preceding limitations and exclusions may not apply to you.

Procedures

Warranty service will in most cases be performed by an authorized Nautilus Fitness Dealer or Service Technician. The

original purchaser must provide proof of purchase, Service calls and/or transportation to and from the Nautilus Dealer is

the responsibility of the purchaser.

1. Nautilus, Inc. will have the option to repair or replace any exercise product, which requires service.

2. Nautilus, Inc. will replace any equipment frame that is structurally defective with a new frame or replace the unit with

a unit of equal value.

3. Nautilus, Inc. is not responsible for dealer labor charges for the component changeovers completed after the labor

related warranty period stated herein.

4. If you elect to repair an exercise product or part yourself, using the services of someone other than an authorized

Nautilus Fitness Dealer or Service Technician, or use a replacement part not supplied by Nautilus, Inc., Nautilus shall

not be liable for any cost, damage, failure or loss caused by the use of such unauthorized service or parts.

8

Page 9

GETTING STARTED

Select Your Workout Area

Select the location where you are going to put your

Nautilus® TreadClimber® exercise machine carefully. The

best place for your TreadClimber® machine is on a hard, level

surface. You will need at least two feet (61 cm) on each side

and in front of your TreadClimber® machine, and at least four

feet (122 cm) behind it for dismount.

Make sure that the location you choose has a grounded,

3-prong power outlet within reach of the TreadClimber®

machine power cord, preferably to the front of the machine

where you will be less likely to step on the cord during

dismount.

NOTE: The TreadClimber® machine is designed to plug into grounded, non-GFI outlets only. To determine if your

outlet or circuit breaker is GFI, look for a test and reset button on them. If they have the test and reset

button it is a GFI outlet or circuit breaker, and therefore not suitable for plugging the TreadClimber®

machine into.

GETTING STARTED

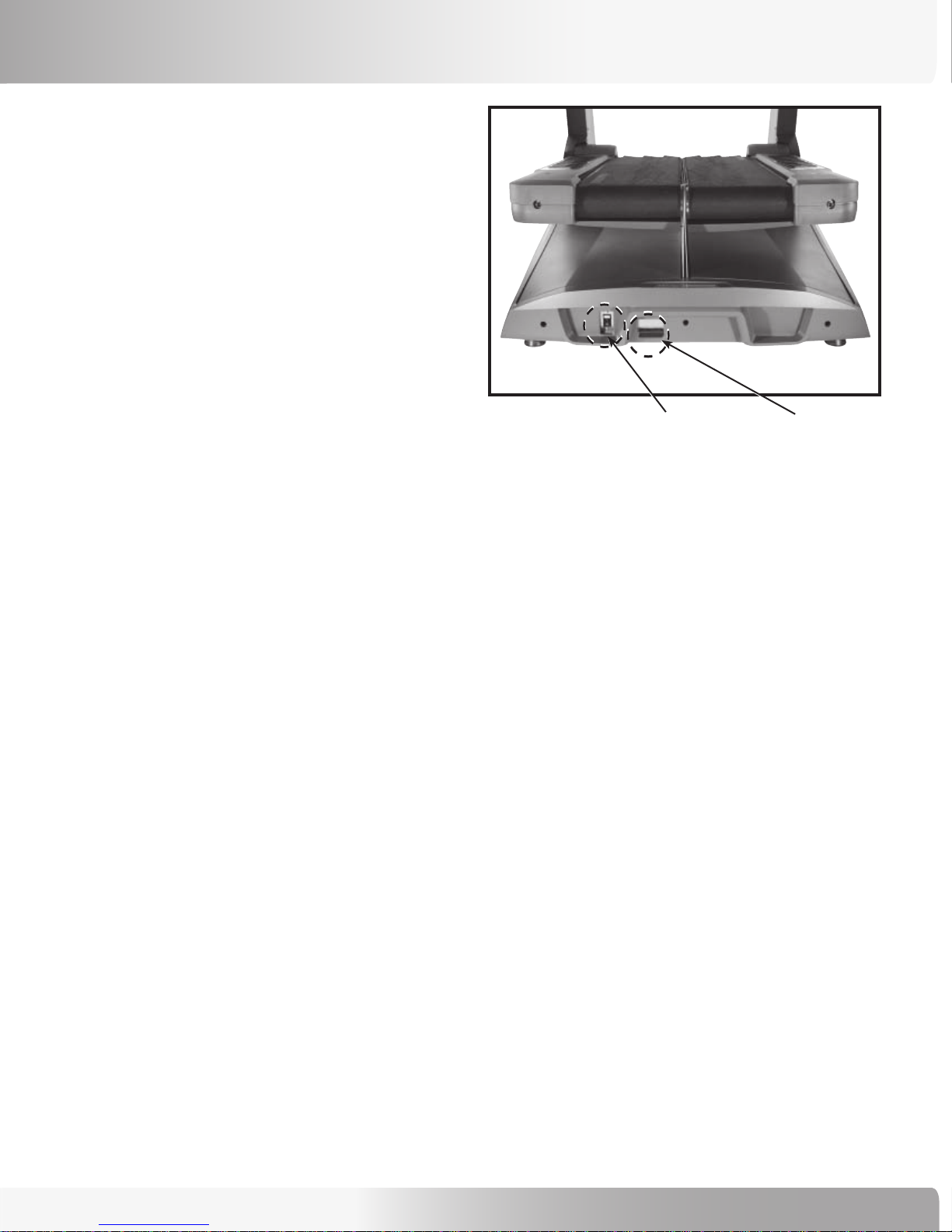

Figure 1: On/Off Switch & Power Plug

Power Plug Receptacle

The Commercial Series TreadClimber® TC916 has one power plug receptacle located on the front side of the motor pan (see

Figure 1).

Turning on the Power

The TreadClimber® exercise machine can be turned on by moving the power switch located at the front of the machine, to

the ON position (see Figure 1).

Understanding the Display and Controls

The TreadClimber® console display is a computerized panel used to operate the TreadClimber® exercise machine and see

all workout data and operational status. You should familiarize yourself with the operation of the TreadClimber® machine

and location of all keys before beginning use. Detailed descriptions and usage information is available in the TreadClimber®

Commercial Series, Model TC916, Owner’s Manual.

Nautilus® TreadClimber® Model TC916 Assembly Manual

9

Page 10

GETTING STARTED

Limited Access Control/Magnetic

Safety Stop

Limited-access control lets you restrict TreadClimber®

machine use to authorized personnel. It also lets you

stop the TreadClimber® machine in an emergency. The

magnetically-activated control is located on the bottom of

the display as shown (see Figure 2). The limited-access

control is deactivated on machines shipped from the

factory.

Magnetic Key Safety Stop Activation

To activate the limited-access control and restrict access,

place the magnetic safety stop key supplied with the

TreadClimber® machine in the designated area located

below the display (see Figure 3).

Figure 2

The magnetic key will activate the control. If you remove

the key, the TreadClimber® treadle belts will stop and the

console controller will not respond to any key presses.

Accumulated values will remain on the display until you

turn off the power, or press [CLEAR].

The console will display a message, “REPLACE MAGNET”

when you remove the magnetic key from its designated

area. You must replace the key or deactivate the control

to start the walk belt.

Figure 3

10

Page 11

Quick Start Guide

To Start:

GETTING STARTED

Insert the Magnetic Safety Stop Key and press the [QUICK START] key , or select a program key .

To Stop:

Press [STOP] to pause the workout. Press [STOP] again to end the workout.

During the workout:

• After selecting a program, follow the Display prompts and use the numeric keypad to enter information.

• Walk speed may be changed at any time during the workout by pressing the [Speed: UP] key to increase the walk speed, or

the [Speed: DOWN] key to decrease the walk speed.

• Treadle displacement may be changed at any time during the workout by pressing the [Treadle: MAX] key to increase the

height, or the [Treadle: MIN] key to decrease the height.

WARNING: For detailed information on use and safety, refer to your Owner’s Manual file located on CD ROM.

4

1

4

65

8

10

32

7

9

5

3

6

1

9

7

2

10

8

4

Nautilus® TreadClimber® Model TC916 Assembly Manual

11

Page 12

MOVING INSTRUCTIONS

7 ! 2 . ) . '

Moving your Fully Assembled TreadClimber® TC916

TO REDUCE THE RISK OF INJURY TO PERSONS READ AND

FOLLOW ALL SAFETY WARNINGS AND INSTRUCTIONS IN THIS

MANUAL.

TWO PEOPLE ARE REQUIRED TO UNLOAD AND MOVE THE

TREADCLIMBER

THE FACILITY.

DELIVERY LOGISTICS

The TreadClimber® TC916 may be delivered fully-assembled, shipped on a pallet crate, and blanket wrapped;

®

TC916 EXERCISE MACHINE INTO POSITION IN

• Pallet crate shipping weight: 806 pounds

• Unit weight: 684 pounds

- OR -

Delivered in a one box configuration, requiring assembly.

• Boxed Unit shipping weight: 850 pounds

• Unit weight: 684 pounds

MOVING INSTRUCTIONS FOR FULLY ASSEMBLED UNIT INCLUDE:

1. Taking unit off pallet crate.

2. Moving unit into position in facility, if door ways are greater than 40 inches (101 cm) wide.

3. Disassembly of Upright Unit Instructions, if door ways are less than 40 inches (101 cm) wide.

4. Moving Tool Information to assist with moving fully assembled TreadClimber® unit.

ASSEMBLY INSTRUCTIONS FOR ONE BOX CONFIGURATION UNIT INCLUDE:

1. Unpacking Instructions.

2. Assembly Instructions.

12

Page 13

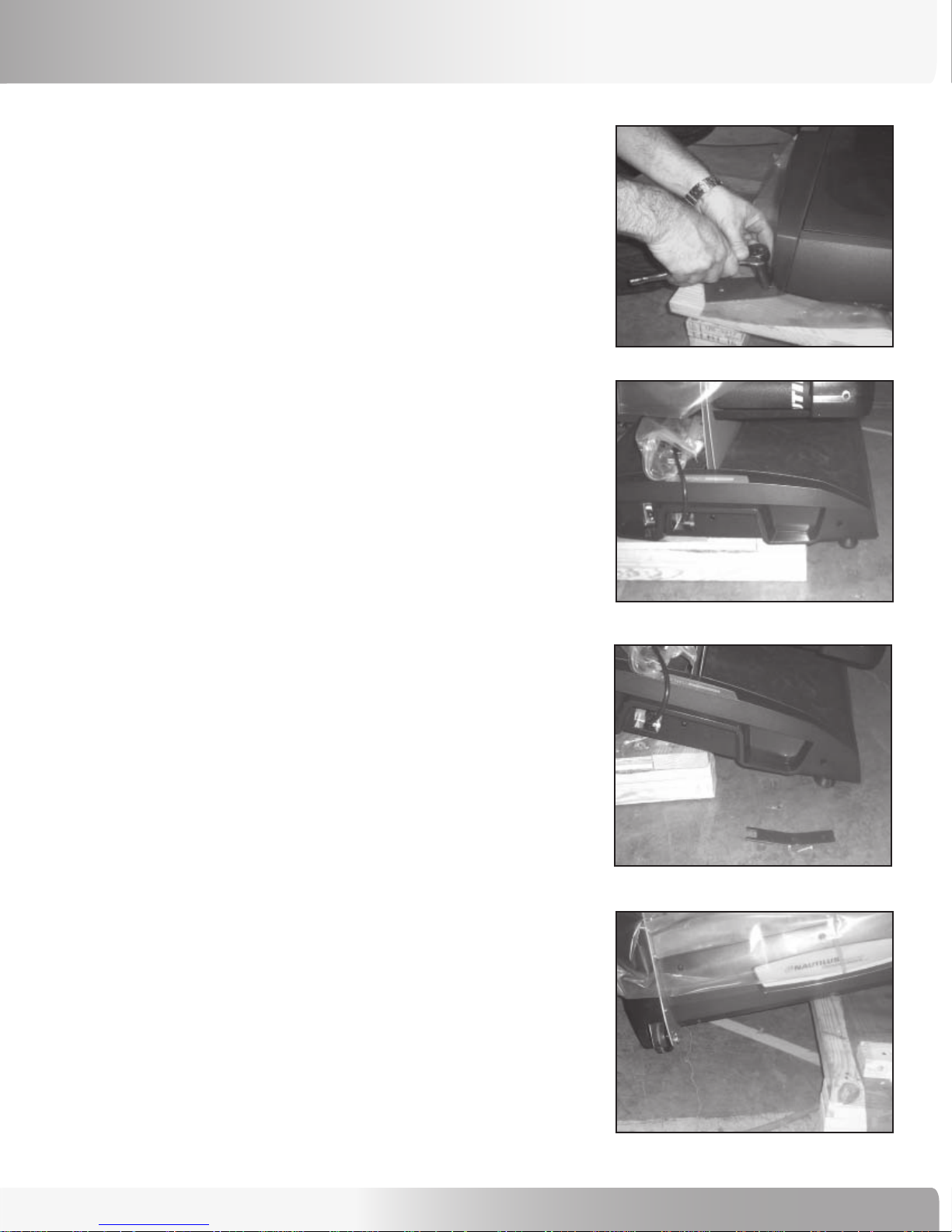

Removing Machine from Pallet

Tools Needed:

MOVING INSTRUCTIONS

7/16 Socket

Ratchet

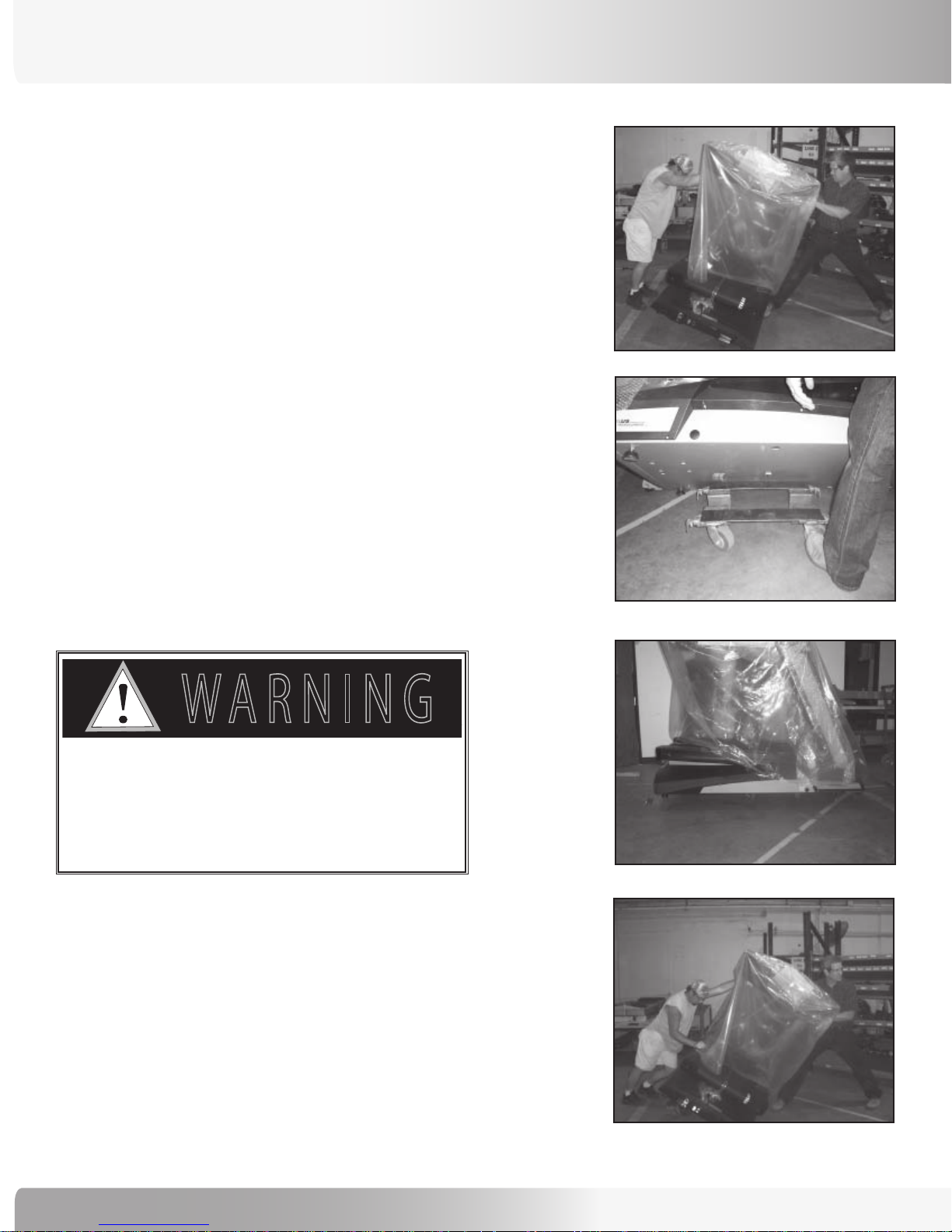

Step 1: Remove TC916 from pallet by removing restraining

stabilizer brackets with socket and ratchet from

stabilizer feet (see Figure 1).

Step 2: Manually slide TC916 to one side of the pallet -

over hanging approximately 12 to 15 inches off the

side of the pallet (see Figure 2).

Step 3: Tilt unit to side and slide edge of frame to ground

(see Figure 3).

Step 4: Tilt to 40 degrees and move pallet out of the way,

lowering TC916 to ground (see Figure 4).

NOTE: If removing the TreadClimber® TC916 from

pallet you should be placing the unit in its

final position in the facility when removing

it from the pallet.

Figure 1

Figure 2

Figure 3

Figure 4

Nautilus® TreadClimber® Model TC916 Assembly Manual

13

Page 14

MOVING INSTRUCTIONS

7 ! 2 . ) . '

Moving Unit into Position in Facility

NOTE: Perform the following moving procedure to position

your TreadClimber® Model TC916 in your facility if

your door ways are greater than 40 inches wide.

Tools Needed:

7/16 Socket

Ratchet

Moving Dolly

Lift Bar

Step 1: Remove TC916 from pallet by performing steps

in section “Removing Machine from Pallet” in

this manual.

Figure 1

Figure 2

Step 2: Tilt to 40 degrees (see Figure 1).

place 4-wheel moving dolly under center of

TreadClimber® frame (see Figure 2).

WHEN LOWERING THE TREADCLIMBER®

UNIT ONTO DOLLY BE SURE THAT THE

CASTORS ARE LOCKED SO THAT IT DOES

NOT MOVE OUT FROM UNDER THE

TREADCLIMBER

Step 3: Carefully, lower the TreadClimber

onto 4-wheel moving dolly (see Figure 3).

®

UNIT.

While tilted

®

Model TC916

Figure 3

Step 4:

14

Once in position in the facility, prepare to

remove unit from 4-wheel dolly by locking

castors.

Figure 4

Page 15

Step 5: Carefully tilt TreadClimber®machine onto one-side

of frame towards ground (see Figure 4).

Step 6: Tilt unit to 40 degrees and remove moving dolly.

Step 7: Place Moving Tool under the machine according to

the “Moving Tool Instructions” section located in

this manual and wheel the unit into position.

MOVING INSTRUCTIONS

Nautilus® TreadClimber® Model TC916 Assembly Manual

15

Page 16

7 ! 2 . ) . '

! 4 4 % . 4 ) / .

$ ! . ' % 2

MOVING INSTRUCTIONS

Disassembly of Upright Unit

IMPORTANT INFORMATION TO READ

BEFORE DISASSEMBLING UPRIGHT UNIT.

During delivery of this unit it may become necessary to disassemble the upright portion of the unit to reduce the size and

weight. The upright portion of the unit has wheels integrated into it, making it possible to wheel it away from the base

and handle it as a separate unit.

Only use this option if delivery of the unit is not possible using one of the two preferred moving options:

Moving unit into position in facility, if door ways are greater than 40 inches (101 cm) wide, or

One boxed configuration, requiring assembly before use.

to avoid electrical shock or damage to the unit you

must power oFF the unit and make sure all power has

been drained From the unit and capacitors by ensuring

there are no lighted leds on the console.

detaching and moving the upright portion oF this

product requires two people! you must have a minimum

oF two people to properly support the heavy upright

structure so the console does not Fall and cause

damage to the unit.

16

Page 17

1.0 REMOVING REAR STEP

7 ! 2 . ) . '

MOVING INSTRUCTIONS

Tools Needed:

• Phillips head screw driver

• Magnetic 3/8” Nut Driver with long shaft

• Magnetic 3/8” socket

• Ratchet

Step 1: Unplug the unit from the power source and ensure

that all power has been drained from the unit.

Step 2: Remove two (2) middle screws (see Figure 1-1).

Step 3: Slide step cover plate back to remove

(see Figure 1-2).

Step 4: Depending upon the Step Weldment style of the

unit:

4A: Remove the four corner screws and slide the

weldment outward (see Figure 1-3).

- OR -

Figure 1-1

Figure 1-2

4B: Remove the two side screws. One screw on

left and right, then slide the weldment outward

(see Figure 1-4).

Removing the step cover plate provides access to the I/O

cables needed for the next step.

to avoid electrical shock or damage

to the unit you must power oFF the

unit and make sure all power has been

drained From the unit and capacitors by

ensuring there are no lighted leds on

the console.

Figure 1-3

Four Screws

Figure 1-4

Two Screws

Nautilus® TreadClimber® Model TC916 Assembly Manual

17

Page 18

7 ! 2 . ) . '

MOVING INSTRUCTIONS

2.0 REMOVING UPRIGHTS

Tools Needed:

• Phillips head screw driver

• 5/32 Allen wrench

• 3/4 inch wrench or socket

• 1/2 inch drive Ratchet

• 1/2 inch drive Torque wrench

Step 1: Remove for the four Button head screws at-

taching the console to the Upright weldment,

disconnect the cables and remove the console

Step 2: Remove the Rear Step as directed in Section 1:

Step 3: Disconnect the Base Cable (P/N - 17826) from

from the machine.

Removing Rear Step.

the Handrail Cable (P/N - 17824) located in the

lower left hand corner (see Figures 2-1 and 2-2).

Figure 2-1

Figure 2-2

Step 4:

Remove rear plastic cover by loosening six (6)

screws (see Figure 2-3 and Figure 2-4).

Step 5:

Remove right and left lower plastic parts by

removing seven (7) screws located on the right

and left upright inside panels (see Figure 2-5 and

Figure 2-6).

Step 6:

Step 7:

Remove the four (4) upright bolts (see Figure 2-7)

Wheel upright structure away to safe location

(wheels are integrated into upright portion of

unit).

NOTE: To replace the upright unit, reverse the

directions. The four handrail screws are

to be torqued to a setting of 75 ft. lbs.

detaching and moving the upright portion oF

Figure 2-3

Figure 2-5:

Lower plastic parts.

Figure 2-4:

Rear plastic cover off.

Figure 2-6

this product requires two people! you must

have a minimum oF two people to properly

support the heavy upright structure so the

console does not Fall and cause damage to

the unit.

18

Figure 2-7

Page 19

NOTE: You should only use this step if you need to

rotate the lower base unit up onto its side to

transport it.

MOVING INSTRUCTIONS

3.0 REMOVING BASE PLASTIC

Tools Needed: 1/8 Allen bit

Step 1: Remove three (3) front plastic screws

(see Figure 3-1).

Step 2: Remove right and left side plastic covers - four (4)

screws each side (see Figure 3-2).

Step 3: Remove right and left side pan covers - two (2)

screws each side (see Figure 3-3 and Figure 3-4).

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4:

Pan without

covers.

Nautilus® TreadClimber® Model TC916 Assembly Manual

19

Page 20

MOVING INSTRUCTIONS

Moving Tool Information

MOVING TOOL PARTS:

The following parts are shown in the figure to the

right, in order listed:

• Wheel Bar – one frame, two wheels, two clevis clips

• Caster Cart – one base, two wheels

• Lifting Tool – one piece

• Two 4x4x6 inch (ca. 10x10x15.5 cm) Blocks of Wood

- not pictured

BEFORE MOVING THE TC916 UNIT:

1 - Make sure the power cord is not running under

the machine.

USAGE DIRECTIONS:

Step 1: Lift the right side of the TC916 and brace with a

4x4x6 inch (ca. 10x10x15.5 cm) block of wood near

the middle of the machine.

Step 2:

Lift the left side of the TC916 and brace with a

4x4x6 inch (ca. 10x10x15.5 cm) block of wood near

the middle of the machine.

CLEVIS CLIP

Caster Cart

FRAME

Wheel Bar

Figure 1

WHEEL

Step 3: Slide the Wheel Bar under the machine near the

front of the TC916. Tilt the TC916 towards the rear,

raising the front of the machine to provide room to

slide the Wheel Bar underneath.

Step 4: Tilt the machine forward, towards the Console and

slide the Caster Cart under the rear of the machine

(see Figure 1). Position the Caster Cart under the

machine flush with the bottom of the frame so that

it hooks between the frame and the leveling pads.

20

Figure 2

Page 21

MOVING INSTRUCTIONS

Step 5: On the right side, lift the machine and remove the block of wood, lowering the machine onto the Caster Cart and

Wheel Bar, ensuring the wheels are straight.

Step 6

: On the left side, lift the machine and remove the block of wood, lowering the machine onto the Caster Cart and

Wheel Bar, ensuring the wheels are straight (see Figure 2).

Step 7:

The machine is now ready to move.

a. This moving tool is designed to move the TC916 in and out of a row of machines. It is not intended to move the

machine long distances or over obstacles.

b. Once the machine is out of the row other moving methods can be employed to move the machine to another room

or in/out of the club.

c. This tool is designed as a service aid and not for transportation.

d. DO NOT operate the TC916 while it is on the Caster Cart.

Step 8:

When service is completed or the machine needs to be operated place the machine where it is desired and reverse

the steps removing the Caster Cart and Wheel Bar.

Nautilus® TreadClimber® Model TC916 Assembly Manual

21

Page 22

ASSEMBLY INSTRUCTIONS

7 ! 2 . ) . '

BEFORE YOU ASSEMBLE

Basic Assembly Principles

Here are a few basic assembly tips that can make

®

assembly of your Nautilus

exercise machine quick and easy.

1. You can make the assembly process go faster by

gathering the pieces you need for each step prior to

starting the step.

2. As a general rule, and for all bolts and locknuts on your

®

Nautilus

toward the right will tighten, turning towards the left will

loosen. An easy way to remember this is by remembering

the expression, “Lefty loosey, righty tighty.”

TreadClimber® exercise machine, turning

Commercial TreadClimber®

3. Gather all of the tools needed for assembly before

beginning. The tools are listed in the Hardware and

Tools list of this manual. You may find the use of a utility

knife or scissors beneficial during the unpacking and

assembly process.

TO REDUCE THE RISK OF INJURY TO PERSONS READ AND

FOLLOW ALL SAFETY WARNINGS AND INSTRUCTIONS IN THIS

MANUAL.

TWO PEOPLE ARE REQUIRED TO UNLOAD, UNPACK, ASSEMBLE

AND MOVE THE TREADCLIMBER

POSITION.

®

TC916 EXERCISE MACHINE INTO

22

Page 23

HARDWARE AND TOOL LIST

Tools needed: (not provided)

• 3/4 inch Socket, for a 1/2 inch Drive Ratchet

• 1/2 inch drive Ratchet

• 7/32 Allen bit

• 5/32 Allen bit

• 1/8 Allen bit

• Torque wrench with 1/2 inch drive

• Phillips screw driver

*Hardware not illustrated to actual size.

ASSEMBLY INSTRUCTIONS

Qty: 4

Descr: Screw, .500-13 x 3.25 HHC

Part Number: 17683

Qty: 8

Descr: Screw, .375 -16 x 1.00, BH, SS

Part Number: 25796

Qty: 4

Descr: Washer, .50 SAE Flat

Part Number: 22091

Qty: 4

Descr: Screw, 1/4 - 20 x 3/8 Button, HD, SO

Part Number: 24162

Qty: 36

Descr: Screw, Button HD Cap, 10-32 x 5 / 8L

Part Number: 17815

Qty: 2

Descr: Screw, #10-32 x 0.375 Flat Hd Phillips

Part Number: 17695

Qty: 4

Descr: Washer, Split Lock .50

Part Number: 22222

Qty: 8

Descr: Internal/External Washer .375

Part Number: 17775-007

Qty: 36

Descr: Washer, Lock, Int. Star, #10, SS

Part Number: 17578

Nautilus® TreadClimber® Model TC916 Assembly Manual

23

Page 24

ASSEMBLY INSTRUCTIONS

Parts List Reference Guide

NOT ILLUSTRATED:

Qty: 1

Descr: Assembly/Owner’s Manual Kit and Hardware Kit Bag

Qty: 1

Descr: Power cord

Part Number: DEPENDING UPON YOUR COUNTRY AND REGION YOU WILL HAVE

A POWER CORD CONFIGURED TO YOUR COUNTRY’S/REGION’S

POWER SUPPLY. IF THE POWER CORD IS MISSING OR NOT

COMPATIBLE CONTACT A NAUTILUS REPRESENTATIVE FOR A

REPLACEMENT.

Qty: 1

Descr: Console Assembly

Part Number: 17670 - Domestic

17835 - TV, Domestic

17837 - TV, International

Qty: 1

Descr: Left Upright Plastic Cover

Part Number: 17669

Qty: 1

Descr: Left Bottom Plastic Pivot Cover

Part Number: 17918

Qty: 1

Descr: Right Upright Plastic Cover

Part Number: 17668

Qty: 1

Descr: Right Bottom Plastic Pivot Cover

Part Number: 17919

Qty: 1

Descr: Rear Step Cover

Part Number: 17733

Qty: 1

Descr: Rear Step Weldment

Part Number: 17591

Qty: 1

Descr: One Rear Motor Cover

Part Number: 17874

24

Page 25

ASSEMBLY INSTRUCTIONS

Qty: 1

Descr: TC916 TreadClimber® Base Assembly

Part Number: 17500

Qty: 1

Descr: TC916 TreadClimber® Handrail Assembly

Part Number: 17793

Qty: 1

Descr: TC916 TreadClimber® Handrail Upright Support

Assembly

Part Number: 17794

Nautilus® TreadClimber® Model TC916 Assembly Manual

25

Page 26

ASSEMBLY INSTRUCTIONS

Unpacking Guide

The following instructions provide direction in unpacking the boxed unit for the Nautilus® Commercial Series

TreadClimber® model TC916.

Step 1: Opening Crate

Tools:

• Scissors or utility knife

1-1 Remove the outer cardboard to reveal the

contents of crate.

Step 2: Unpacking Crate

Tools:

• Scissors or utility knife

2-1 Remove the three enclosed boxes within the

crate and place to the side.

2-2 Remove the Upper Upright Weldment and Lower

Upright Weldment.

26

Upper Upright Weldment

Lower Upright Weldment

Page 27

Step 3: Verifying Box Contents

Locate the following for this step:

ASSEMBLY INSTRUCTIONS

• Box 1 - Parts Master Carton

• Box 2 - Top Plate Carton

• Box 3 - Short Side Panel Carton

Tools:

• Scissors or utility knife

3-1 Verify the contents of Box 1: “PARTS MASTER

CARTON”.

The carton should contain the following:

• Box #1A - Left and right top Upright Covers.

Marked “Long Side Panels” on the box.

• Box #1B - Console. Marked “Control Panel”

on the box.

• Rear Step weldment (see Figure 1).

• Hardware Bag containing: TV Cable (if

applicable), Owners Manual, Magnet,

Cord Clamp, Grounding Harness, 5/16 Allen

Wrench, Service Bulletin, and hardware

for attaching the Weldment, Console, and

Covers.

3-2 Verify the contents of Box 2: “TOP PLATE

CARTON”.

BOX 1

BOX 2

BOX 3

Figure 1

Figure 2

• Rear Step, insert molded (see Figure 2).

• Lower Front Cover (see Figure 3).

3-3 Verify the contents of Box 3: “SHORT SIDE

PANEL CARTON”.

• Left and Right Pivot Covers (see Figure 4).

Figure 3

Figure 4

Nautilus® TreadClimber® Model TC916 Assembly Manual

27

Page 28

ASSEMBLY INSTRUCTIONS

Step 4: Dismantling Crate

Tools:

• Hammer

4-1 Carefully dismantle the wooden crate to allow

access to the bottom half of the TreadClimber®

TC916 frame.

NOTE: The TreadClimber

®

TC916 base frame should

be close to the final location for the fully

assembled machine during this step.

Step 5: Removing from Pallet

Tools:

• 7/16 Socket

• Ratchet

5-1 Remove TC916 from pallet by removing

restraining stabilizer brackets with socket and

ratchet from stabilizer feet (see Figure 1).

Remove wooden supports

around base assembly.

Figure 1

5-2 Manually slide TC916 to one side of the pallet

- over hanging approximately 12 to 15 inches off

the side of the pallet (see Figure 2).

5-3 Tilt unit to side and slide edge of frame to ground

(see Figure 3).

5-4 Tilt to 40 degrees and move pallet out of the way,

lowering TC916 to ground.

NOTE: When removing the TreadClimber

from pallet you should be placing the unit in its

final position in the facility.

28

®

TC916

Figure 2

Figure 3

Page 29

ASSEMBLY INSTRUCTIONS

Assembly Guide

The following instructions provide direction in assembling the boxed units for the Nautilus® Commercial Series

TreadClimber® model TC916. All instructions in the manual are given with the orientation of standing on the

TreadClimber® facing the console. The console is the front, while the rear roller is the back.

Step 1: Connecting Wiring Harness

Locate the following for this step:

Parts:

• Base Assembly (P/N - 17500)

• Handrail Upright Support Assembly (P/N - 17794)

1-1 Locate the three Ground Wire Straps on either

side of the Base Assembly, making sure that the

wire is extended towards the front of the unit

and doesn’t become hidden behind the Handrail

Upright Support during Step 1-2.

1-2 With the help of another person, connect wiring

harness (P/N - 17826) from the TreadClimber

TC916 Base Assembly to the wiring harness

(P/N - 17824) in the Handrail Upright Support

Assembly. See Figure 1.

®

Figure 1: Connecting Wiring Harness

Handrail Upright Support Assembly

Base Assembly

Ground Wire Strap

Locations

Wiring Harness

Connection

Nautilus® TreadClimber® Model TC916 Assembly Manual

29

Page 30

ASSEMBLY INSTRUCTIONS

Step 2: Connecting Handrail Support to Base Assembly

Locate the following for this step:

Parts:

• Assembly from Step 1

Hardware:

• 4 bolts (P/N 17683)

• 4 Lock Washers (P/N - 22222)

• 4 Washers (P/N 22091)

Tools:

• 3/4 inch socket for 1/2 drive

• Torque wrench (1/2 inch), set at 75 ft. lbs. (100 NM)

• 1/2 inch drive Ratchet

2-1 On right side, connect Handrail Upright Support

Assembly to TreadClimber

bolts, 2 lock washers, and 2 washers. Finger tighten

only, being careful not to pinch wiring harness. See

Figure 2 and Figure 2A.

®

Base Assembly using 2

Figure 2: Connecting Handrail Support to Base Assembly

Handrail Upright Support Assembly

Base

Assembly

2-2 Repeat Step 2-1 on the left side.

2-3 Using the drive ratchet, tighten the 2 lower bolts on

each side first, and then the 2 upper bolts on each

side installed in Step 2-1 and Step 2-2. Then use the

Torque wrench to set the tightness for all 4 bolts to 75

ft. lbs. (100 NM)

IMPORTANT! M A K E S U RE T H AT THE WIRI N G

HARN E S S C A B LES DO N OT BECO M E P I N CHED.

Washer

Lock Washer

Bolt

Figure 2A: Close-up of hardware stack.

30

Page 31

ASSEMBLY INSTRUCTIONS

Step 3: Connecting Ground Wire Straps to Base Assembly

Locate the following for this step:

Parts:

• Assembly from Step 2

• 3 Grounding Straps

Hardware:

• 4 Self-tapping screws - .25 x .50 (P/N 22139)

• 5 Lock Washers (P/N - 41260)

Tools:

• Phillips screw driver

3-1 Remove the 3 Grounding straps, 4 Self-Tapping Screws,

and 5 Lock Washers from the parts bag.

3-2 Attach one end of a grounding strap to the right side

of base frame with one screw and lock washer. (See

Figure 3 - Grounding Strap #1.)

Figure 3: Connecting Ground Wire Straps

Ground Wire

Strap - #3

Ground Wire

Strap - #2

Ground Wire

Strap - #1

IMPORTANT! PL A CE R ING T ERMI N A L OF THE

CABL E BE T WEEN THE SCR E W AND LOC K WA SHER .

3-3 Attach the other end of grounding strap to the cross

bar of the lower Upright weldment with a screw and

lock washer . (See Figure 3 - Grounding Strap #1.)

3-4 Attach one end of second grounding strap to the left

side of base frame with one screw and washer. (See

Figure 3 - Grounding Strap #2.)

3-5 Attach the other end of second grounding strap with

one end of third grounding strap to the cross bar of

the lower Upright weldment with a screw and two

washers. (See Figure 3 - Grounding Strap #2 and #3,

and Figure 3A.)

IMPORTANT! L E AVE OT H ER E ND O F TH I RD

GR O UNDING STRAP FREE . I T WIL L BE INSTALLE D

IN STEP 10 O F ASSE M BLY PROCE S S.

Figure 3A: Connecting Ground Wire Straps #2 & #3

Ground Wire Strap - #3

Ground Wire

Strap connection

between - #2 & #3.

Ground Wire Strap - #2

Nautilus® TreadClimber® Model TC916 Assembly Manual

31

Page 32

ASSEMBLY INSTRUCTIONS

Step 4: Connecting Wiring Harness from Upright Supports to Handrails

Locate the following for this step:

Parts:

• Assembly from Step 3

• Handrail Assembly (P/N - 17793)

4-1 Connect the wiring harness (P/N - 17824) from the

Handrail Upright Support Assembly (P/N - 17794) to

the Handrail Assembly. See Figure 4.

Wiring Harness

Connection

Figure 4: Connecting Wiring Harness to Handrail

Handrail Assembly

NOTE: Carefully slide the Upper Upright Cables (TV

Cable if applicable) inside Handrail Upright

Support Assembly, until they come out the

bottom as you place the Handrail Assembly

on.

32

Base Assembly

Page 33

ASSEMBLY INSTRUCTIONS

Step 5: Connecting Handrail Support to Base Assembly

Locate the following for this step:

Parts:

• Assembly from Step 4

Hardware:

• 8 screws (P/N 25796)

• 8 washers (P/N 17775-007)

Tools:

• 7/32 Allen bit

5-1 Bolt Handrail Assembly (P/N - 17793) to Handrail

Upright Support Assembly (P/N - 17794) using 8

screws and 8 washers. See Figure 5.

IMPORTANT! M A K E S U RE T H AT THE WIRI N G

HARN E S S C A B LES DO N OT BECO M E P I N CHED.

Figure 5: Connecting Handrail Support to Base Assembly

Handrail Assembly

Screw

Washer

Base Assembly

Nautilus® TreadClimber® Model TC916 Assembly Manual

33

Page 34

ASSEMBLY INSTRUCTIONS

Step 6: Connecting Wiring Harness to Console

Locate the following for this step:

Parts:

• Assembly from Step 5

• Console (P/N 17670)

6-1 Connect the wiring harness from the Handrail

Upright Support Assembly (P/N - 17794) to Console

(P/N - 17670) on the left and right side. See Figure 6.

NOTE: If TV Cable present, connect to mating cable

from the console.

6-2 Being careful not to pinch the wiring harness, slide

the console into the open tubes of the handlebar.

IMPORTANT! M A K E S U RE T H AT THE WIRI N G

HARN E S S C A B LES DO N OT BECO M E P I N CHED.

Figure 6: Connecting Wiring Harness to Console

Console

Handrail Assembly

Base Assembly

Wiring Harness

Connection

34

Page 35

Step 7: Securing Console

ASSEMBLY INSTRUCTIONS

Locate the following for this step:

Parts:

• Assembly from Step 6

Hardware:

• 4 screws (P/N 24162)

Tools:

• 5/32 Allen bit

7-1 Align the holes on the tubing of the console with

the holes on the handrail and secure Console (P/N

- 17670) in place using 4 screws (P/N - 24162). See

Figure 7.

Figure 7: Securing Console

Console

Handrail Assembly

Screws

Base Assembly

Step 8: Attaching Lower Plastic Covers

Locate the following for this step:

Parts:

• Assembly from Step 7

• Right Bottom Plastic Pivot Cover (P/N 17919)

• Left Bot tom Plastic Pivot Cover (P/N 17918)

Hardware:

• 14 screws (P/N 17815)

• 14 washers (P/N 17578)

Tools:

• 1/8 Allen bit

8-1 On the right side, attach Right Bottom Plastic Pivot

Cover (P/N - 17919) using the 7 screws (P/N - 17815)

and 7 washers (P/N - 17578). See Figure 8.

8-2 Repeat Step 8-1 on the left side.

Figure 8: Attaching Lower Plastic Covers

Left Bot tom

Plastic Pivot

Cover

Screws

Washers

Base Assembly

Right Bottom

Plastic Pivot

Cover

Nautilus® TreadClimber® Model TC916 Assembly Manual

35

Page 36

ASSEMBLY INSTRUCTIONS

Step 9: Attaching Rear Motor Cover

Locate the following for this step:

Parts:

• Assembly from Step 8

• Rear Motor Cover (P/N 17874)

Hardware:

• 6 screws (P/N - 17815)

• 6 washers (P/N 17578)

Tools:

• Phillips screw driver

9-1 Attach the Rear Motor Cover using 6 screws and 6

washers. See Figure 9.

IMPORTANT! M A K E S U RE T H AT FR EE E ND

OF GRO U N DING STR A P I N S TA L L ED IN S T EP 3

IS ABOV E RE AR MOT OR C OVER . IT WILL BE

IN S TALL E D I N STE P 10 O F A S S EMBLY PRO C ESS.

Figure 9: Attaching Rear Motor Cover

Screws

Base Assembly

Rear Motor Cover

Washers

36

Page 37

Step 10: Attaching Rear Step Assembly

ASSEMBLY INSTRUCTIONS

Locate the following for this step:

Parts:

• Assembly from Step 9

• Rear Step Weldment (P/N 17591)

• Rear Step Cover (P/N 17733)

Hardware:

• 2 screws (P/N - 17809)

• 2 washers (P/N - 22637)

• 2 screws (P/N - 17695)

• 1 Self-tapping screws - .25 x .50 (P/N 22139)

• 1 Lock Washers (P/N - 41260)

Tools:

• Phillips screw driver

• 3/8 Socket driver

10-1 Attach the Rear Step Weldment to the Base

Assembly using two screws (P/N - 17809) and two

washers (P/N - 22637).

Figure 10: Attaching Rear Step Cover

Screws

Rear Step Cover

Base Assembly

Rear Step

Weldment

Figure 10-A: Attaching Grounding Strap

NOTE: Due to the tight spacing a magnetic tool is

recommended during this step.

10-2 Secure the loose end of third grounding cable that

was installed in Step 3 to the Step weldment on the

left side with a Self-tapping Screw and Lock Washer.

(See figure 10-A.)

10-3 At tach the Rear Step Cover to the Rear Step Frame

(P/N - 17591) using two screws (P/N - 17695). See

Figure 10.

Ground Wire

Strap - #3

Third Ground Wire Strap

connection to Rear Step

Weldment

Rear Step

Weldment

Nautilus® TreadClimber® Model TC916 Assembly Manual

37

Page 38

ASSEMBLY INSTRUCTIONS

Step 11: Attaching Upright Plastic Covers

Locate the following for this step:

Parts:

• Assembly from Step 10

• Right Upright Plastic Cover (P/N - 17668)

• Left Upright Plastic Cover (P/N - 17669)

Hardware:

• 16 screws (P/N - 17815)

• 16 washers (P/N - 17578)

Tools:

• 1/8 Allen bit

11-1 On the right side, attach the Right Upright Plastic

Cover using 8 screws (P/N - 17815) and 8 washers

(P/N - 17578). See Figure 10.

Figure 11: Attaching Upright Plastic Covers

Left Upright

Plastic Cover

Washer

Screw

11-2 Repeat Step 11-1 on the left side of the unit.

Step 12: Installing Power Cord

Locate the following for this step:

Parts:

• Assembly from Step 11

• Power Cord

12-1 Locate the power cord for your region.

12-2 Attach the power cord to the AC Inlet on the

Front Motor Pan and then to the wall outlet

(see Figure 12).

Right Upright

Plastic Cover

Figure 12: Installing Power Cord

38

Power Cord Outlet

Page 39

7 ! 2 . ) . '

Step 13: Turning on the Power

ASSEMBLY INSTRUCTIONS

Locate the following for this step:

Parts:

• Assembly from Step 12

13-1 Locate the power switch at the front of the

machine.

13-2 Move the power switch to the ON position (see

Figure 13).

IMPORTANT! REFE R T O T H E O W N ER’S

MANUA L FO R DE TAIL E D I N S T RUCTIO N S A ND

IN F O RMAT ION O N H O W TO U SE A N D CARE FOR

YO UR T RE A D CLIM B ER® COMME RCIAL SER I ES

EXER C ISE M ACHI N E, M O DEL TC916.

Figure 13: Turning on Power

Power Switch

Step 14: Inspecting Assembly

Congratulations!

Now that you have assembled your Nautilus

TreadClimber® Model TC916, it is VERY IMPORTANT to

tighten all screws and bolts, and visually inspect the

TreadClimber® exercise machine. If your TreadClimber®

machine sits unevenly you may adjust the leveling feet

on each corner of the machine by hand to make the unit

stable on your floor. Make sure that your TreadClimber

exercise machine has been assembled correctly and

securely, and that there are no loose, uncovered, or

unattached parts prior to use.

®

Failure to visually check and test assembly

before use can cause damage to the

®

Nautilus

®

exercise machine and serious injury

TreadClimber® Model TC916

to users and bystanders and can also

compromise the effectiveness of your

exercise program.

Nautilus® TreadClimber® Model TC916 Assembly Manual

39

Page 40

BELT TENSION AND ALIGNMENT

During initial installation, within the first 1- to -4 hours of

use, and daily for the first week of use, the treadle belts on

the TreadClimber® TC916 need the tension and alignment

inspected and adjusted. As the TreadClimber® treadle belts

stretch through use it will become necessary to tension the

belts. Adjust the belt tension whenever the belt slips or

moves unsteadily during operation. Failure to follow these

instructions could seriously impact performance.

Alignment adjustment

IMPORTANT- Do not over tighten treadle

belts! The belt need only be tight enough to prevent it from

slipping during use. Excessive belt tension will decrease belt

life and can damage the TreadClimber® rollers and drive

system.

Tools Needed: 5/16 Allen wrench

Belt alignment and tensioning adjustments (see Figure 1).

NOTE: The adjustments are the same on the right

and left side of the machine.

To check for proper belt alignment:

Step 1: Operate TreadClimber® machine so belt is

running at 2.5 - 3 mph (4.0 - 4.8 km/h).

Step 2: Belt is aligned when 1/8” of roller is showing

(see Figure 2).

Step 3: Tightening alignment screw clockwise moves

belt out, loosening screw counter-clockwise

moves belt in.

Tensioning adjustment

Figure 1

Figure 2:

Belts are correctly aligned when

1/8 inch of roller is showing.

To check for proper belt tension:

Step 1: Tension is correct when gap between treadles

is even and centered. See Figure 3 for an

example of INCORRECT tension.

Step 2: Tighten (clockwise turn) or loosen (counter-

clockwise turn) tensioning adjustment located

at the end of the treadle.

To completely loosen belt if you want to start from scratch:

Step 1: Totally loosen off alignment screw by turning

counter-clockwise.

Step 2: Loosen tensioning screw by turning counter-

clockwise.

40

Tension is slightly off.

Figure 3:

Tension is too tight, treadle guards are rubbing.

To correct loosen tensioning adjustment screw.

Page 41

IMPORTANT CONTACT NUMBERS

If you need assistance, please have both the serial number

of your machine and the date of purchase available when

you contact the appropriate Nautilus office listed below.

OFFICES IN THE UNITED STATES:

• TECHNICAL/CUSTOMER SERVICE

Nautilus, Inc.

World Headquarters

16400 SE Nautilus Drive

Vancouver, Washington, USA 98683

Phone: 800-NAUTILUS (800-628-8458)

Email: customerservice@nautilus.com

Fax: 800-523-1049

• CORPORATE HEADQUARTERS

Nautilus, Inc.

World Headquarters

16400 SE Nautilus Drive

Vancouver, Washington, USA 98683

Phone: 800-NAUTILUS (800-628-8458)

For technical assistance and a list of distributors

in your area, please call or fax one of the following

numbers.

INTERNATIONAL CUSTOMER SERVICE:

• INTERNATIONAL OFFICE

Nautilus International S.A.

Rue Jean Prouvé 6

1762 Givisiez / Switzerland

Tel: + 41-26-460-77-77

Fax: + 41-26-460-77-70

Email: technics@nautilus.com

INTERNATIONAL OFFICES:

• SWITZERLAND OFFICE

Nautilus Switzerland S.A.

Tel: + 41-26-460-77-66

Fax: + 41-26-460-77-60

• GERMANY and AUSTRIA OFFICE

Nautilus GmbH

Tel: +49-2203-20-20-0

Fax: +49-2203-20-20-45-45

• ITALY OFFICE

Nautilus Italy s.r.l.

Tel: +39-051-664-6201

Fax: +39-051-664-7461

• UNITED KINGDOM OFFICE

Nautilus UK Ltd.

Tel: +44-1908-267-345

Fax: +44-1908-267-346

• CHINA OFFICE

Nautilus Representative Office

Tel: +86-21-523-707-00

Fax: +86-21-523-707-09

Nautilus® TreadClimber® Model TC916 Assembly Manual

41

Page 42

Page Intentionally Left Blank

42

Page 43

Page Intentionally Left Blank

Nautilus® TreadClimber® Model TC916 Assembly Manual

43

Page 44

Model TC916

©2006. Nautilus, Inc. All rights reserved. Nautilus, the Nautilus logo, TreadClimber, and Be Strong are either registered trademarks or trademarks of

Nautilus, Inc.

Nautilus, Inc.

World Headquarters

16400 SE Nautilus Drive, Vancouver, Washington, USA 98683

1-800-NAUTILUS www.nautilus.com

Loading...

Loading...