Page 1

Be Strong.

™

Assembly Manual

P/N: 001-7001 Rev A (09/28/2006)

NS 700X

Model: NS 700X

Page 2

TABLE OF CONTENTS

Before You Assemble .................... 3

Product Specifications ..................4

Product Features ........................... 4

Parts List / Box Contents .............5

Exploded View ............................... 6

Hardware and Tool List ................ 7

Assembly Guide ............................ 8

Warranty Information ................... 24

Contacting Nautilus ...................... 25

2

Page 3

BEFORE YOU ASSEMBLE

BASIC ASSEMBLY PRINCIPLES

Here are a few basic tips that will aid in the assembly of the Nautilus® NS700X. By using these

principles, you can simplify each process and save yourself extra time and effort.

1. To make the assembly process go faster, gather the pieces you need for each step and

thoroughly read the assembly instructions for that step prior to starting assembly for the step.

2. When tightening a locknut on a bolt, use a combination wrench to grip the locknut and ensure

that it is fastened securely.

3. When attaching two pieces, gently lift and look through the bolt holes to help guide the bolt

through the holes.

4. As a general rule, and for all bolts and nuts on your NS700X Home Gym, turn bolts or nuts

toward the right to tighten and left to loosen. Or you can remember the mnemonic: “Righty

tighty, lefty loosey.”

BEFORE YOU ASSEMBLE

• At least 2 persons reccomended for assembly and installation.

Familiarize yourself with the illustrations to understand what the assembled NS700X will look like.

Select where you are going to locate your NS700X carefully. Assemble your NS700X in the location

and position where you intend to use it.

the

NS700X

can be closer to the wall during use but it is difficult to move after assembly and some room is needed

during assembly.

and 36 inches (.91 meters) behind your

You will need at least 36 inches (.91 meters) on each side of

NS700X

during assembly. The rear of the

NS700X

Nautilus NS700X

3

Page 4

PRODUCT SPECIFICATIONS

NOTE: All instructions in the manual are given with the orientation

of sitting on the machine ready to exercise.

User Weight Capacity: 300lbs / 136.1Kg

Dimensions:

Shipping Weight: 672 lbs / 304.8 kg

Net Weight: 599.8 lbs / 272.1 kg

Lat Pulldown Bar

Press Arm Adjustment

96”w x 76”l x 83”h / 244 cm x 193 cm x 211cm

PRODUCT FEATURES

Exercise Placard

Multi Handle Grip

Adjustable Seat Back

Leg Extension

Seat Height Adjustment

Primary Weight Stack

Dual Floating Pulley System

4

Page 5

PARTS LIST / BOX CONTENTS

# DESCRIPTION QTY # DESCRIPTION QTY

1 Rear Base Frame .................................................................1

2 Rear Top Frame ...................................................................1

3 Rear Support Upright A ..................................................... 1

4 Rear Support Upright B .....................................................

5 Rear Upright ........................................................................ 1

6 Top Beam .............................................................................1

7 Front Upright .......................................................................1

8 Leg Extension Frame ..........................................................

9 Main Base ...........................................................................1

10 Backing Plate ...................................................................... 3

11 Corner Plate ........................................................................1

12 Connecting Plate A ............................................................

13 Connecting Plate B ............................................................

14 Connecting Plate C .............................................................1

15 Connecting Plate D ............................................................1

16 Connecting Plate E ............................................................. 1

17 Pec Fly Mount .....................................................................

18 Pec Fly Cam .........................................................................

19 Left Pec Fly Arm ..................................................................1

20 Right Pec Fly Arm ............................................................... 1

21 Pec Fly Handle .................................................................... 2

22 Press Arm Support Assembly ..........................................

23 Press Arm ............................................................................

24 Right Press Arm Handle .................................................... 1

25 Left Press Arm Handle .......................................................1

26 Press Arm Support Shaft ..................................................1

27 Press Arm Pivot Shaft ........................................................

28 Seat Pad ...............................................................................

29 Back Pad ..............................................................................1

30 T handle Pop Pin .................................................................1

31 Seat Adjuster ......................................................................1

32 Seat Cross Tube .................................................................1

33 Back Pad Tube ....................................................................1

34 Back Pad Adjustment ........................................................ 1

35 Back Pad Adjustment Plate .............................................. 1

36 Pulley Bracket .....................................................................1

37 Pec Fly Pulley Bracket .......................................................1

38 Locking Roller Bar .............................................................. 1

39 Roller Bar ............................................................................. 1

40 Plastic Washer ...................................................................2

41 PU Roller .............................................................................. 2

42 8”L Foam Roller ...................................................................2

43 PU Roller End Cap ..............................................................2

44 Round End Cap ....................................................................2

45 Power Spring Assembly .................................................... 1

46 Front Plate ...........................................................................1

47 Guide Tube ..........................................................................

48 High/Low Pulley Adjuster ..................................................

49 Swivel Arm Assembly ........................................................ 2

50 Guide Rod Holder ...............................................................2

51 Guide Rod ............................................................................4

52 Top Weight .......................................................................... 2

53 Selector Stem .....................................................................2

54 TopWeight/SelectorRodAssembly(52/53) ......................2

55 Weight Stack Bottom Plate ..............................................2

56 Weight Stack Bumper .......................................................4

57 6” Pulley ............................................................................... 1

58 41/2” Pulley ..........................................................................27

59 Shroud .................................................................................. 1

59a Accessory Hook ..................................................................3

60 Low Pulley Cover ................................................................ 2

61 Double Floating Pulley Bracket ........................................2

62 Cable Retaining Bracket ...................................................2

63 Top Weight Pulley Housing ..............................................1

64 Connecting Bench Bracket ..............................................1

65 Bench Connecting Plate ...................................................1

66 Weight Plate ........................................................................38

67 Plastic Cap ...........................................................................4

68 Snap Cap ..............................................................................2

1

1

1

1

1

2

1

1

1

1

2

1

Cable

69 #1 - Pull down Cable 263.75”L ..........................................1

70 #2 - High/Low Pulley Cable 355.5”L ..................................

71 #3 - Pec Fly Cable 150.5”L ................................................. 1

72 #4 - Secondary Cable 179.5”L ............................................1

Hardware

73 Hex Bolt - 1/2” x 5 1/4”L .....................................................2

74 Hex Bolt - 1/2” x 3 1/4”L .....................................................1

75 Hex Bolt - 3/8” x 4 3/4”L .....................................................1

76 Hex Bolt - 3/8” x 4 1/4”L .....................................................5

77 Hex Bolt - 3/8” x 3 1/2”L .....................................................1

78 Hex Bolt - 3/8” x 3 1/4”L .....................................................8

79 Hex Bolt - 3/8” x 3”L ........................................................... 34

80 Hex Bolt - 3/8” x 2 3/4”L .....................................................6

81 Hex Bolt - 3/8” x 2 1/4”L .....................................................3

82 Hex Bolt - 3/8” x 2”L ........................................................... 17

83 Hex Bolt - 3/8” x 1 3/4”L .....................................................4

84 Hex Bolt - 3/8” x 1 1/2”L

with thread lock .................................................................. 3

85 Cap Head Allen Screw

3/8” x 3”L with thread lock ................................................2

86 Cap Head Allen Screw

1/4” x 1”L with thread lock ................................................4

87 Cap Head Allen Screw

1/4” x 1/2”L with thread lock ............................................2

88 Button Head Allen Screw

3/8” x 1 3/4”L .......................................................................2

89 Button Head Allen Screw

3/8” x 1”L (half threads) .....................................................1

90 Button Head Allen Screw

3/8” x 3/4”L .........................................................................4

91 Button Head Allen Screw

3/8” x 1/2”L with thread lock ............................................4

91a Button Head Self Tapping Screw 5/8” L ......................... 6

92 5/16” Set Screw 1/4”L ........................................................6

93 1 11/32 x 1/2” Flat Washer .................................................4

94 1/2” Flat Washer ................................................................. 6

95 3/8” Flat Washer ................................................................. 154

96 1/2” Lock Nut .......................................................................7

97 3/8” Lock Nut .......................................................................76

98 3/8” x 9/32t Lock Nut .......................................................... 1

99 Shim Washer .......................................................................4

100 Step Spacer 19/32”H .......................................................... 8

101 Pulley Spacer 1/2”L ............................................................ 4

114 3/8” Curved Washer ............................................................ 4

Accessories

102 Lat Bar .................................................................................. 1

103 AB Strap ............................................................................... 1

104 Felt Back Ankle Strap ........................................................1

105 Handle Strap with 2 rings .................................................. 2

106 Cable Clip ............................................................................. 3

107 Weight Selector Pin ........................................................... 2

108 M4 Allen Wrench ...............................................................1

109 M5 Allen Wrench ...............................................................1

110 M6 Allen Wrench ...............................................................1

111 M8 Allen Wrench ...............................................................1

112 Weight Stack Decals ......................................................... 38

113 Shoulder Strap .................................................................... 2

1

Nautilus NS700X

5

Page 6

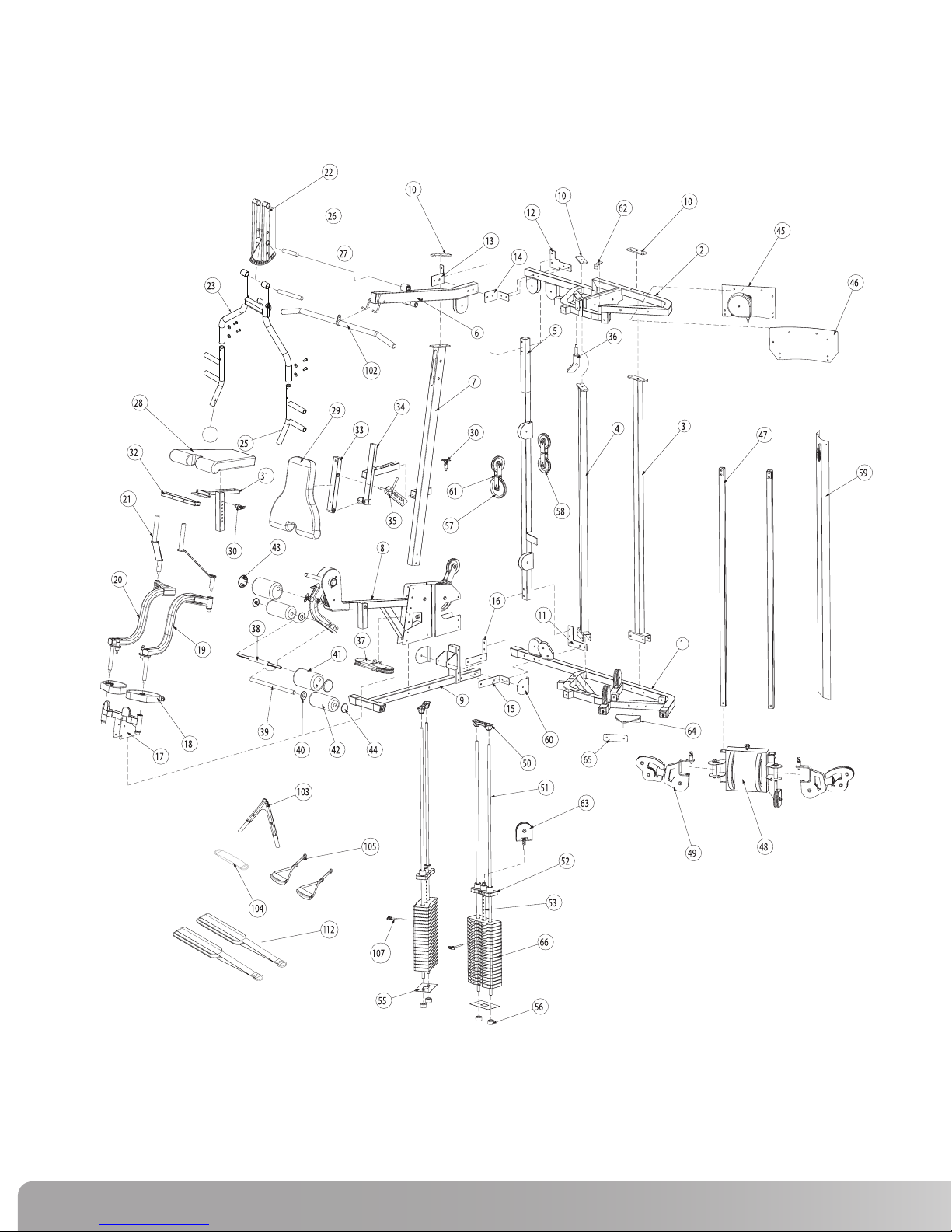

24

EXPLODED VIEW

A. Compare the Bill of Materials to the box contents to insure that all parts are present before installation begins.

B. Unpackage parts and place them near the final asssembled location to avoid moving the gym when fully assembled.

6

Page 7

HARDWARE AND TOOLS

Nautilus NS700X

7

Page 8

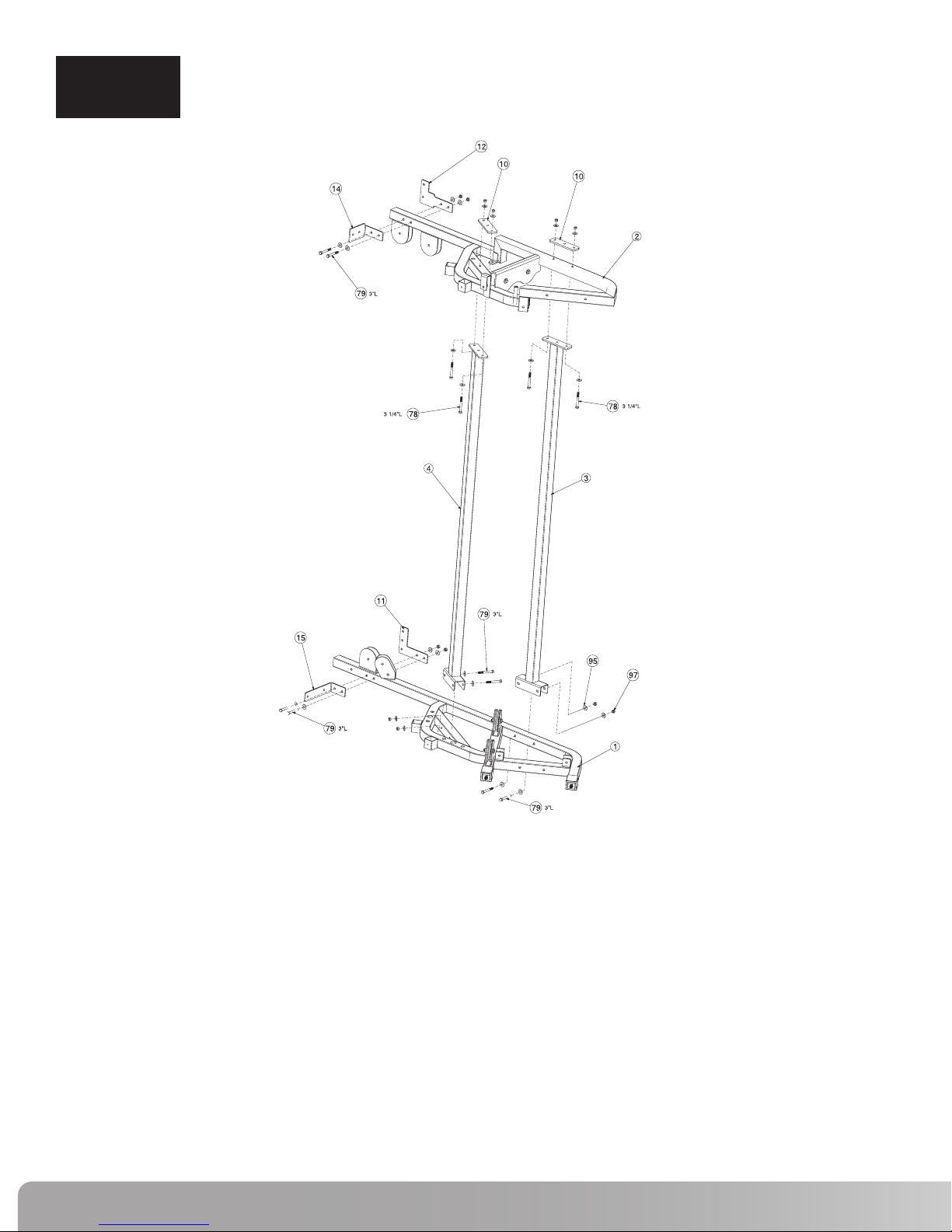

STEP 1

ASSEMBLY

Step 1 Components: Procedure:

# Component Qty

1 Rear Base Frame 1

2 Rear Top Frame 1

3 Rear Support Upright A 1

4 Rear Support Upright B 1

10 Backing Plate 2

11 Corner Plate 1

12 Connecting Plate A 1

14 Connecting Plate C 1

15 Connecting Plate D 1

78 Hex Bolt - 3/8” x 3 1/4”L 4

79 Hex Bolt - 3/8” x 3”L 8

95 3/8” Flat Washer 24

97 3/8” Lock Nut 12

8

A. Set the Rear Base Frame (1) in a position close to the gym’s final position.

B. Attach Rear Support Upright A and B (3) (4) to Rear Base Frame (1) using the

hardware shown. Do not tighten hardware. NOTE: Rear Support Upright A (3) is

the longer piece.

C. Attach Rear Top Frame (2) to Rear Support Upright A and B (3) (4) using Backing

Plate (10) and the hardware shown. Tighten all hardware securely.

D. Attach Corner Plate (11) and Connecting Plate D (15) to the Rear Base Frame (1)

using the hardware shown. Do not tighten hardware.

E. Attach Connecting Plate A and C (12) (14) to Rear Top Frame (2) using the

hardware shown. Do not tighten hardware.

Page 9

STEP 2

ASSEMBLY

Step 2 Components: Procedure:

# Component Qty

5 Rear Upright 1

6 Top Beam 1

7 Front Upright 1

8 Leg Extension Frame 1

9 Main Base 1

10 Backing Plate 1

13 Connecting Plate B 1

16 Connecting Plate E 1

76 Hex Bolt - 3/8” x 4 1/4”L 5

79 Hex Bolt - 3/8” x 3”L 13

95 3/8” Flat Washer 36

97 3/8” Lock Nut 18

A. Attach Main Base (9) to Rear Base Frame (1) using Connecting Plate E (16) and the

hardware shown. Do not tighten hardware.

B. Attach Rear Upright (5) to Rear Base Frame (1) and Rear Top Frame (2) using

Connecting Plate B (13) and the hardware shown. Do not tighten hardware.

C.

Attach Leg Extension Frame (8) to Main Base (9) usingthe hardware shown. Tighten

hardware securely.

CAUTION:

component.

D. Attach Front Upright (7) to Leg Extension Frame (8) using the hardware shown.

Tighten hardware securely.

E. Attach Top Beam (6) to Front Upright (7) and Rear Top Frame (2) using Backing

Plate (10) and the hardware shown. Tighten all frame hardware securely..

Leg Extension Frame (8) is heavy. Use two people to assemble this

Nautilus NS700X

9

Page 10

STEP 3

ASSEMBLY

Step 3 Components: Procedure:

# Component Qty

17 Pec Fly Mount 1

18 Pec Fly Cam 2

19 Left Pec Fly Arm 1

20 Right Pec Fly Arm 1

21 Pec Fly Handle 2

37 Pec Fly Pulley Bracket 1

67 Plastic Cap 4

78 Hex Bolt - 3/8” x 3”L 2

87 Cap Head Allen Screw

1/4” x 1/2”L with thread lock 2

93 1 11/32 x 1/2” Flat Washer 4

95 3/8” Flat Washer 8

96 1/2” Lock Nut 4

97 3/8” Lock Nut 4

99 Shim Washer 4

10

A. Attach Pec Fly Pulley Bracket (37) to Leg Extension Frame (8) using the hardware shown.

Tighten hardware securely.

B. Attach Pec Fly Mount (17) to Main Base (9) using the hardware shown.

Tighten hardware securely.

C. Slide Pec Fly Cam (18) onto Left Pec Fly Arm (19) paying close attention to the orientation

shown above. Attach the Left Pec Fly Arm (19) to the Pec Fly Mount (17) using the hardware

shown. Tighten hardware securely making sure that the Pec Fly Arm can rotate freely.

D. Repeat Step C using Right Pec Fly Arm (20).

E. Install Pec Fly Handle (21) in Left Pec Fly Arm (19) using the hardware shown. Tighten

hardware securely making sure that the Pec Fly Handle (21) can rotate freely. Install Cap

Head Allen Screw (87) to Pec Fly Handle (21) as shown. Tighten firmly.

NOTE: Make sure that the path of the Pec Fly Handle has a similar path shown in the TOP VIEW.

F. Repeat Step E using the Right Pec Fly Arm (20).

G. Install Plastic Cap (67) in the four locations shown. The Plastic Cap (67) should snap into place

locking around the Shim Washer (99).

Page 11

STEP 4

114

59a

91a

ASSEMBLY

Step 4 Components: Procedure:

# Component Qty

22 Press Arm Support Assembly 1

23 Press Arm 1

24 Right Press Arm Handle 1

25 Left Press Arm Handle 1

26 Press Arm Support Shaft 1

27 Press Arm Pivot Shaft 1

90 Button Head Allen Screw

3/8” x 3/4”L with thread lock 4

59a Accessory Hook 3

91a Self Tapping Screw 5/8” L 6

114 3/8” Curved Washer 4

92 5/16” Set Screw 1/4”L 6

A. Attach Press Arm Support Assembly (22) to the Top Beam (6) using the Press Arm

Support Shaft (26). Align shaft and tighten the 4 Set Screws (92) firmly.

B. Remove Pop Pin from Press Arm (23). Attach Press Arm (23) to Press Arm Support

Assembly (22) using the Press Arm Pivot Shaft (27). Align shaft and tighten the two

Set Screws (92) firmly.

C. Attach Press Arm Handles (24) (25) using hardware shown. Tighten hardware

firmly.

D. Attach three Accessory Hooks (59a) Using the self tapping screws (91a) shown.

Tighten the hardware securly.

Nautilus NS700X

11

Page 12

STEP 5

ASSEMBLY

Step 5 Components: Procedure:

# Component Qty

28 Seat Pad 1

29 Back Pad 1

30 T handle Pop Pin 2

31 Seat Adjuster 1

32 Seat Cross Tube 1

33 Back Pad Tube 1

34 Back Pad Adjustment 1

35 Back Pad Adjustment Plate 1

74 Hex Bolt - 1/2” x 3 1/4”L 1

79 Hex Bolt - 3/8” x 3”L 2

81 Hex Bolt - 3/8” x 2 1/4”L 2

83 Hex Bolt - 3/8” x 1 3/4”L 3

94 1/2” Flat Washer 3

95 3/8” Flat Washer 9

96 1/2” Lock Nut 2

97 3/8” Lock Nut 2

12

A. Attach Seat Cross Tube (32) to Seat Adjuster (31) using hardware shown. Tighten hardware

securely.

B. Attach Seat Pad (28) to Seat Cross Tube (32) and Seat Adjuster (31) using hardware shown.

Tighten hardware securely.

C. Install Seat Adjuster (31) in Leg Extension Frame (8) in the slot shown. Install Pop Pin (30)

using an adjustable wrench.

NOTE: Pop Pin is threaded so that the seat can be locked into position.

D. Attach Back Pad Tube (33) to Back Pad (29) using hardware shown. Tighten hardware

securely.

E. Attach Back Pad Tube (33) to Back Pad Adjuster (34) using hardware shown. Tighten

hardware securely making sure that the Back Pad Tube can rotate freely.

F. Attach Back Pad Adjustment Plate (35) to Back Pad Tube (33) using hardware shown, making

sure that the Back Pad Adjustment Pin rests inside the slot of the Back Pad Adjustment Plate

(35). Tighten hardware securely make sure the Back Pad Adjustment Plate can rotate freely.

G. Install Back Pad Adjuster (34) in Front Upright (7) in the slot shown. Install Pop Pin (30) using

an adjustable wrench.

Page 13

STEP 6

ASSEMBLY

Step 6 Components: Procedure:

# Component Qty

38 Locking Roller Bar 1

39 Roller Bar 1

40 Plastic Washer 2

41 PU Roller 2

42 8”L Foam Roller 2

43 PU Roller End Cap 2

44 Round End Cap 2

A. Slide Roller Bar (39) through the Leg Extension Tube. Either of the bottom two holes

can be used depending on the best fit for the user.

B. Slide a Plastic Washer (40) followed by a Foam Roller (42) on the Roller Bar (39).

Press the Roller End Cap (44) firmly into the Roller Bar (39). Repeat for the opposite

side.

C. Slide the Locking Roller Bar (38) through the Leg Extension Tube as shown making

sure that it is centered. Slide the Eccentric Roller (41) on the Locking Roller Bar

(38). Press the Locking Roller End Cap (43) into the Locking Roller Bar (38). Repeat

for the opposite side making sure that the Eccentric Rollers are aligned.

Nautilus NS700X

13

Page 14

STEP 7

ASSEMBLY

Step 7 Components: Procedure:

# Component Qty

45 Power Spring Assembly 1

46 Front Plate 1

47 Guide Tube 2

48 High/Low Pulley Adjuster 1

49 Swivel Arm Assembly 2

73 Hex Bolt - 1/2” x 5 1/4”L 2

75 Hex Bolt - 3/8” x 4 3/4”L 1

79 Hex Bolt - 3/8” x 3”L 6

80 Hex Bolt - 3/8” x 2 3/4”L 2

89 Button Head Allen Screw

3/8” x 1”L (half threads) 1

94 1/2” Flat Washer 2

95 3/8” Flat Washer 18

97 3/8” Lock Nut 9

98 3/8” x 9/32t Lock Nut 1

14

A. Place Guide Tubes (47) side by side on the floor with the adjustment holes facing each other.

Slide the Hi/Low Pulley Adjuster (48) onto the Guide Tubes (47) making sure that the Guide

Tubes are even and the Hi/Low Pulley Adjuster is locked into the middle adjustment holes.

Make sure that the plastic sleeves are still properly attached to the Hi/Low Pulley Adjuster

(48).

B. Attach the Guide Tubes (47) to the Rear Base Frame (1) using the hardware shown. Do not

tighten hardware. Carefully slide the Hi/Low Pulley Adjuster (48) to the bottom adjustment

hole. Align the guide rods and snug the hardware but do not tighten.

C. Attach the Power Spring Assembly (45) and Front Plate (46) to the Rear Top Frame (2) and

Guide Tubes (47) using the hard ware shown. Once assembled, tighten all hardware except

for the four bolts attaching the Guide Tubes (47) to the plates. Carefully raise the Hi/Low Pul

ley Adjuster (48) to the top adjustment hole. Align the guide rods and snug the hardware

but do not tighten.

D. Connect the Hi/Low Pulley Adjuster (48) to the Power Spring Cable using the hardware

shown. Tighten hardware securely.

E. Slide the Hi/Low Pulley Adjuster (48) up and down the Guide Tubes (47) making sure that it

does not bind. If necessary, loosen the connecting hardware for the Guide Tubes (47) and

reposition for better alignment. Once the Guide Tubes (47) are well aligned, tighten hardware

securely.

F. Attach the Swivel Arms (49) to the Hi/Low Pulley Adjuster (48) using the hardware shown.

Tighten hardware securely but allowing the Swivel Arms to rotate freely.

Page 15

STEP 8

ASSEMBLY

Step 8 Components: Procedure:

# Component Qty

36 Pulley Bracket 1

50 Guide Rod Holder 2

51 Guide Rod 4

52 Top Weight 2

53 Selector Stem 2

55 Weight Stack Bottom Plate 2

56 Weight Stack Bumper 4

66 Weight Plate 38

86 Cap Head Allen Screw

1/4” x 1”L with thread lock 4

94 1/2” Flat Washer 1

96 1/2” Lock Nut 1

107 Weight Selector Pin 2

A. Slide Weight Stack Cushion (56) on two Guide Rods (51) allowing approximately 3” of Guide

Rod showing below the Weight Stack Cushion. Insert Guide Rods (51) into the holes in the

Rear Base Frame (1) as shown.

B. Slide Weight Stack Bottom Plate (55) on top of Weight Stack Cushions (56).

C. Place nineteen Weight Plates (66) and the Selector Rod/Top Plate Assembly (52 & 53) on the

Guide Rods (51) as shown. Install Weight Plates (66) so that the selector pin hole faces for

ward and is located on the bottom of the plate. Install the Selector Rod/Top Plate Assembly

(52 & 53) so that the head of the bolt is facing forward. This gym is supplied with individual

weight plate numbering decals that should be applied to the gym after the

weight stack is assembled.

D. Slide Guide Rod Holder (50) on the top of the Guide Rods (51) and attach the Guide Rod Holder

(50) to the Rear Top Frame (2) using the hardware shown. Tighten hardware securely.

E. Place Weight Selector Pin (107) in the bottom weight plate.

F. Repeat Steps A-E for the second weight stack.

G. Attach Pulley Bracket (36) to Rear Top Frame (2) using the hardware shown. Do not tighten

hardware.

Nautilus NS700X

15

Page 16

STEP 9

ASSEMBLY

Step 9 Components: Procedure:

# Component Qty

58 4 1/2” Pulley 4

62 Cable Retaining Bracket 1

70 Cable #2 - High/Low Pulley Cable

356”L 1

79 Hex Bolt - 3/8” x 3”L 1

82 Hex Bolt - 3/8” x 2”L 2

84 Hex Bolt - 3/8” x 1 1/2”L

with thread lock 1

95 3/8” Flat Washer 7

97 3/8” Lock Nut 3

101 Pulley Spacer 1/2”L 2

16

A. Remove the Ball, Washer, and U-Bracket from one side of Cable #2 (70).

B. Route Cable #2 (70) through the Pulleys in the left Swivel Arm as shown. Continue to route

Cable around the two pulleys connected to the Rear Base Frame and then around the pulleys

located in the Rear Top Frame as shown.

C. Loop Cable #2 (70) around a 4 1/2” Pulley (58) and attach pulley to the Top Weight Pulley

Housing (63) using the hardware shown

in detail A. Tighten hardware securely. Attach the Top Weight Pulley Housing (63) to the

Selector Rod/Top Weight Assembly (52 & 53). Do not tighten hardware.

D. Loop Cable #2 (70) over a 4 1/2” Pulley (58) and attach pulley to the Rear Top Frame using the

hardware shown. Loop cable around a 4 1/2” Pulley (58) and attach pulley to the Rear Top

Frame using the Cable Retaining Bracket (62) and the hardware shown. Tighten hardware

securely.

E. Route Cable #2 (70) through the top tube of the Rear Top Frame making sure that the cable is

above the bolts. Remove bolt if necessary Loop Cable around a 4 1/2” Pulley (58) and attach

pulley using the hardware shown in detail B. Tighten hardware securely.

F. Route Cable #2 (70) around the pulley located on the Hi/Low Pulley Adjuster and continue to

route cable through the pulleys in the right swivel arm as shown.

G. Re-Install the Ball, Washer, and U-bracket to Cable #2 (70).

Page 17

STEP 10

ASSEMBLY

(See Diagram On Next Page)

Step 10 Components:

# Component Qty

58 4 1/2” Pulley 14

61 Double Floating Pulley Bracket 2

62 Cable Retaining Bracket 1

68 Snap Cap 2

69 Cable #1 - Pull down Cable 263.75”L 1

80 Hex Bolt - 3/8” x 2 3/4”L 4

82 Hex Bolt - 3/8” x 2”L 8

85 Cap Head Allen Screw 3/8” x 3”L

with thread lock 2

95 3/8” Flat Washer 16

97 3/8” Lock Nut 12

100 Step Spacer 19/32”H 8

Procedure:

A. Thread one end of Cable #1 (69) into the Selector Rod/Top Plate Assembly as shown in

Detail A. Do not tighten locking nut.

B. Draw Cable #1 (69) over a 4 1/2” Pulley (58) and place it in the Pulley Bracket (36) making sure

that the lower section on the Pulley Bracket is between the guide rods. Attach the Pulley to

the Pulley Bracket using the hardware shown. Tighten hardware securely.

C. Loop Cable #1 (69) around a 4 1/2” Pulley (58) and attach the pulley to the Rear Top Frame (2)

using the Cable Retaining Bracket (62) and the hardware shown. Tighten hardware securely.

D. Loop Cable #1 (69) around a 4 1/2” Pulley (58) and attach the pulley to the bracket on the Rear

Top Frame (2) using the hardware shown. Proceed by looping the cable around another 4 1/2”

Pulley (58) and attaching it to inner hole of the Double Floating Pulley Bracket (61) using the

hardware shown. Tighten hardware securely.

E. Loop Cable #1 (69) around a 4 1/2” Pulley (58) and attach the pulley to the second bracket on

the Rear Top Frame (2) using the hardware shown. Proceed by looping the cable around

another 4 1/2” Pulley (58) and attach it to the top bracket on the Front Upright (7) using the

hardware shown. Tighten hardware securely.

F. Loop Cable #1 (69) around a 4 1/2” Pulley (58) and attach the pulley to the bracket on the Top

Beam (6) using the hardware shown. Proceed by looping the cable around another 4 1/2” Pul

ley (58) and attaching it to the outer hole of the Double Floating Pulley (61) using the hardware

shown. Tighten hardware securely.

G. Draw Cable #1 (69) over a 4 1/2” Pulley (58) and place the pulley in the slot on the Front Up

right (7) using the lower hole. Attach the pulley with the hardware shown in Detail B. Tighten

hardware securely.

H. Loop Cable #1 (69) around a 4 1/2” Pulley (58) and place it in the Press Arm Support

Assembly (22). Attach the pulley using the lower hole with the hardware shown in Detail B.

Tighten Hardware securely.

I. Loop Cable #1 (69) around a 4 1/2” Pulley (58) and place the pulley in the slot on the Front

Upright (7) using the upper hole. Attach the pulley using the hardware shown in Detail B.

Proceed by looping the cable around another 4 1/2” Pulley (58) and attaching the pulley to the

top hole in the Press Arm Support Assembly (22) using the hardware shown in Detail B.

Tighten hardware securely.

J. Loop Cable #1 (69) around a 4 1/2” Pulley (58) and attach the pulley to the Top Beam (6) using

the hardware shown in Detail C. Tighten hardware securely. NOTE: Leave the end of the cable

inside the Top Beam tube.

K. Feed Cable #1 (69) through the Top Beam tube and out the front slot. Draw cable around a 4

1/2” Pulley (58) and attach the pulley in the front slot using the hardware shown in Detail C.

Tighten hardware securely.

L. Attach Snap Caps (68) in the Press Arm Support Assembly (22) as shown.

Nautilus NS700X

17

Page 18

NS700X Press Arm

STEP 10

ASSEMBLY

18

Page 19

NS700X Press Arm

STEP 11

ASSEMBLY

Step 11 Components: Procedure:

# Component Qty

58 4 1/2” Pulley 5

72 Cable #4 - Secondary Cable 179.5”L 1

77 Hex Bolt - 3/8” x 3 1/2”L 1

81 Hex Bolt - 3/8” x 2 1/4”L 1

82 Hex Bolt - 3/8” x 2”L 4

83 Hex Bolt - 3/8” x 1 3/4”L 1

95 3/8” Flat Washer 14

97 3/8” Lock Nut 7

101 Pulley Spacer 1/2”L 2

A. Attach the looped end of Cable #4 (72) to the side of the Rear Upright (5) using the hardware

shown in Detail A. Tighten hardware securely, but do not overtighten.

B. Loop Cable #4 (72) around a 4 1/2” Pulley (58) and attach the pulley to the lever bracket on the Leg

Extension Frame (8) using the hardware shown. Tighten hardware securely.

C. Loop Cable #4 (72) around a 4 1/2” Pulley (58) and attach the pulley to the lower bracket on the

Rear Upright (5) using the hardware shown. Proceed by looping the cable around a 4 1/2”

pulley (58) and attaching the pulley to the bracket on the Rear Base Frame (1) using the hardware

shown. Tighten hardware securely.

D. Loop Cable #4 (72) around a 4 1/2” Pulley (58) and attach it to the lower hole in the Double

Floating Pulley (61) using the hardware shown. Proceed by looping the cable around a 4 1/2”

Pulley (58) and attach the pulley to the angled bracket on the Rear Base Frame (1) using the

hardware shown. Tighten hardware securely.

E. Attach the looped end of Cable #4 (72) to the bracket on the Rear Upright (5) using the hardware

shown. Tighten hardware firmly, but do not overtighten. NOTE: This cable termination can be

used for exercise attachments such as the leg press. If an attachment is installed, attach the

looped end of the Cable #4 (72) to the coupling on the attachment cable. Please refer to

attachment instructions for more details.

Nautilus NS700X

19

Page 20

STEP 12

ASSEMBLY

Step 12 Components: Procedure:

# Component Qty

57 6” Pulley 1

58 4 1/2” Pulley 4

60 Low Pulley Cover 2

71 #3 Pec Fly cable 150.5”L 1

82 Hex Bolt - 3/8” x 2”L 3

84 Hex Bolt - 3/8” x 1 1/2”L

with thread lock 2

88 Button Head Allen Screw

3/8” x 1 3/4”L 2

95 3/8” Flat Washer 12

97 3/8” Lock Nut 5

20

A. Attach two 4 1/2” Pulleys (58) to the Pec Fly Pulley Bracket (37). Attach two 4 1/2” Pulleys (58) to

either side of the Leg Extension Frame (8) using the Low Pulley Cover (60) and the hardware

shown. Note the orientation of the Low Pulley Cover. Attach 6” Pulley (57) to the lower hole of the

Double Floating Pulley Bracket (61) using the hardware shown. Tighten all hardware securely.

B. Attach Cable #3 (71) termination to the left Pec Fly Cam (18) using the hardware shown. Be sure

to place the groove on the termination bracket against the Pec Fly Cam as shown in Detail A.

Tighten hardware securely

C. Draw Cable #3 (71) around the left pulley in the Pec Fly Pulley Bracket (37) as shown. Proceed by

looping the cable around the pulley on the left side of the Leg Extension Frame (8) as shown.

Be sure that the Low Pulley Cover does not interfere with the cable.

D. Loop Cable #3 (71) around the 6” Pulley in the Double Pulley Bracket (61) as shown. Proceed by

looping the cable around the pulley on the right side of the Leg Extension Frame (8) as shown.

Be sure that the Low Pulley Cover does not interfere with the cable.

E. Draw Cable #3 (71) around the right pulley in the Pec Fly Pulley

Bracket (37) as shown and attach the cable termination to the right Pec Fly Cam (18) using the

hardware shown. Be sure to place the groove on the termination bracket against the Pec Fly

Cam as shown in Detail A. Tighten hardware securely. NOTE: If

the cable termination does not reach the connection hole on the Pec Fly Cam, adjust the Pulleys

(58) in the Double Floating Pulley Brackets (61) to increase cable length.

Page 21

STEP 13

ASSEMBLY

Step 13 Components: Procedure:

# Component Qty

59 Shroud 1

91 Button Head Allen Screw

3/8” x 1/2”L with thread lock 4

95 3/8” Flat Washer 4

112 Weight Stack decals 38

A. Attach the Shroud (59) to the gym using the hardware shown.

B. Adhere the Weight stack decals (112) to the Weight Plates in the position shown.

Nautilus NS700X

21

Page 22

ASSEMBLY

STEP 14

Attach Accessories

A. Attach the Handles, Lat Bar, Ankle Cuff, Shoulder Straps,

and Ab Strap to the cable ends using the Cable Clips.

Lubrication and Final Check

A. Lubricate Guide Rods and Guide Tubes using a silicon based

lubricant.

B. Carefully inspect all cables and insure that they are properly

seated on the pulleys and that they pass between the cable

stops and pulleys.

C. Double check all hardware and make sure everything is

tightened properly.

Cable Tensioning

A. Tighten the Cable System using a combination of five

adjustment locations. These locations are the Double

Floating Pulley Brackets, the Selector Rod Top Plate Assembly,

the Top Weight Pulley Housing, the Set Screws on the

Leg Extension Cams, and the Leg Extension Tensioner Pulley.

B. After the cables are tensioned, load the gym with as high a

weight as you feel comfortable with and pull each cable several

times to set and stretch the cables.

C. After the cables are set and stretched, the Cable System may

need to be re-tensioned. Tension the cables as described in

Step A.

D. The cables may need to be tensioned periodically as they may

stretch slightly over time.

22

Page 23

NS700X Press Arm

NS50X Bench

STEP 15

(Optional Accessory)

ASSEMBLY

Step 11 Components: Procedure:

# Component Qty

NS-50X Bench 1

64 Connecting Bench Bracket 1

65 Bench Connecting Plate 1

78 Hex Bolt - 3/8” x 3 1/4”L 2

79 Hex Bolt - 3/8” x 3”L 2

95 3/8” Flat Washer 8

97 3/8” Lock Nut 4

A. Attach the Connecting Bench Bracket (64) to the Rear Base Frame (1) using the

hardware shown. Tighten hardware securely.

B. Remove the hardware used on the NS-50X Bench that connects the Bench Frame

Assembly to the Rear Stabilizer Assembly. Attach the Bench Connecting Plate (65) to

the NS-50X Bench using the new hardware shown. Tighten hardware securely.

Nautilus NS700X

23

Page 24

WARRANTY INFORMATION

What Is Covered

Nautilus Fitness Products warrants to the original purchaser

of this Nautilus Home Gym to be free from defects in

materials or workmanship, with the exceptions stated below.

This warranty is not transferable or applicable to any person

other than the original purchaser.

Nautilus Home Gyms

The frame and welds of the Nautilus Home Gyms are

warrantied to the original purchaser for life from date of

original purchaser. Upholstery, pulleys, bushings and

bearings are warrantied for ten years to the original

purchaser from date of purchase. Cables, grips, and all other

parts are warrantied to the original purchaser for a period of

1 year from date of purchase.

Warranties Do Not Cover

• A machine purchased for commercial or institutional use.

• Damage due to use by persons who weigh more than 300

pounds.

• Damage due to abuse, misuse, accident or acts of God

(such as floods).

• Consequential or incidental damages.

What We Will Do

Nautilus Fitness Products will repair any product that proves

to be a defect in materials or workmanship. In the event repair

is not possible, Nautilus Fitness Products, at its option, will

either replace your Nautilus Home Gym or refund your

purchase price.

How To Get Service

To obtain service for a Nautilus Fitness Product, contact an

authorized Nautilus Fitness Retailer. You may also contact a

Nautilus company representative at 800-864-1270 to help you

locate a dealer in your area.

How State Law Applies

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

24

Page 25

IMPORTANT CONTACT NUMBERS

If you need assistance, please have both the serial number of your machine and the date of purchase available when you

contact the appropriate Nautilus office listed below.

WORLDWIDE CUSTOMER SERVICE

• NORTH AMERICA OFFICE

Nautilus, Inc.

World Headquarters

16400 S.E. Nautilus Drive

Vancouver, Washington, USA 98683

Phone: 800-NAUTILUS (628-8458)

Fax: 800-686-6466

e-mail: cstech@nautilus.com

• NAUTILUS INNOVATION CENTER

Nautilus, Inc.

1886 Prairie Way

Louisville, Colorado, USA 80027

Phone: 800-864-1270

Fax: 800-898-9410

• CORPORATE HEADQUARTERS

Nautilus, Inc.

World Headquarters

16400 S.E. Nautilus Drive

Vancouver, Washington, USA 98683

Phone: 800-NAUTILUS

INTERNATIONAL CUSTOMER SERVICE

• INTERNATIONAL OFFICE

Nautilus International S.A.

Rue Jean Prouvé 6

1762 Givisiez / Switzerland

Tel: +41-26-460-77-77

Fax: +41-26-460-77-70

E-mail: technics@nautilus.com

INTERNATIONAL OFFICES:

• SWITZERLAND OFFICE

Nautilus Switzerland S.A.

Tel: +41-26-460-77-66

Fax: +41-26-460-77-60

• GERMANY and AUSTRIA OFFICE

Nautilus GmbH

Tel: +49 2203/20 20-0

Fax: +49 2203/20 20-45 45

• ITALY OFFICE

Nautilus Italy s.r.l.

Tel: +39-051-664-6201

Fax: +39-051-664-7461

• UNITED KINGDOM OFFICE

Nautilus UK Ltd.

Tel: +44-1908-267-345

Fax: +44-1908-267-346

• CHINA OFFICE

Nautilus Representative Office

Tel: +86-21-523-707-00

Fax: +86-21-523-707-09

Nautilus NS700X

25

Page 26

For more information about our Nautilus Home Gyms or other Nautilus®

© 20 06 Nauti lus, Inc. A ll right s reserv ed. Naut ilus, the N autilus l ogo, My Nau tilus, H eart St rong, Chan ging the Gam e in Healt h and Fitn ess, RE ACT, ROC , Remote O peratio n Contro l, Super Soft , Hyperdr ive, Be S trong

Naut ilus, Inc. W orld Headq uarter s, 164 00 SE Naut ilus Dri ve, Vancouv er, Washing ton, US A 986 83, 1-8 00- 628 -84 58, ww w.Naut ilus.co m.

26

Be Strong.

equipment for your home, visit www.Nautilus.com.

are eit her regis tered tr ademarks o r trademar ks of Naut ilus, Inc .

™

Loading...

Loading...