- May 1998

June 2003

Revision 1.3

USBN9603/USBN9604 Universal Serial Bus

Full Speed Node Controller with Enhanced DMA Support

USBN9603/USBN9604 Universal Serial Bus Full Speed Node Controller with Enhanced DMA Support

General Description

The USBN9603/4 are integrated, USB Node controllers.

Other than the reset mechanism for the clock generation circuit, these two devices are identical. All references to “the

device” in this document refer to both devices, unless otherwise noted.

The device provides enhanced DMA support with many automatic data handling features. It is compatible with USB

specification versions 1.0 and 1.1, and is an advanced version of the USBN9602.

The device integrates the required USB transceiver with a

3.3V regulator, a Serial Interface Engine (SIE), USB endpoint (EP) FIFOs, a versatile 8-bit parallel interface, a clock

generator and a MICROWIRE/PLUS™ interface. Seven

endpoint pipes are supported: one for the mandatory control endpoint and six to support interrupt, bulk and isochronous endpoints. Each endpoint pipe has a dedicated FIFO,

8 bytes for the control endpoint and 64 bytes for the other

endpoints. The 8-bit parallel interface supports multiplexed

and non-multiplexed style CPU address/data buses. A programmable interrupt output scheme allows device configuration for different interrupt signaling requirements.

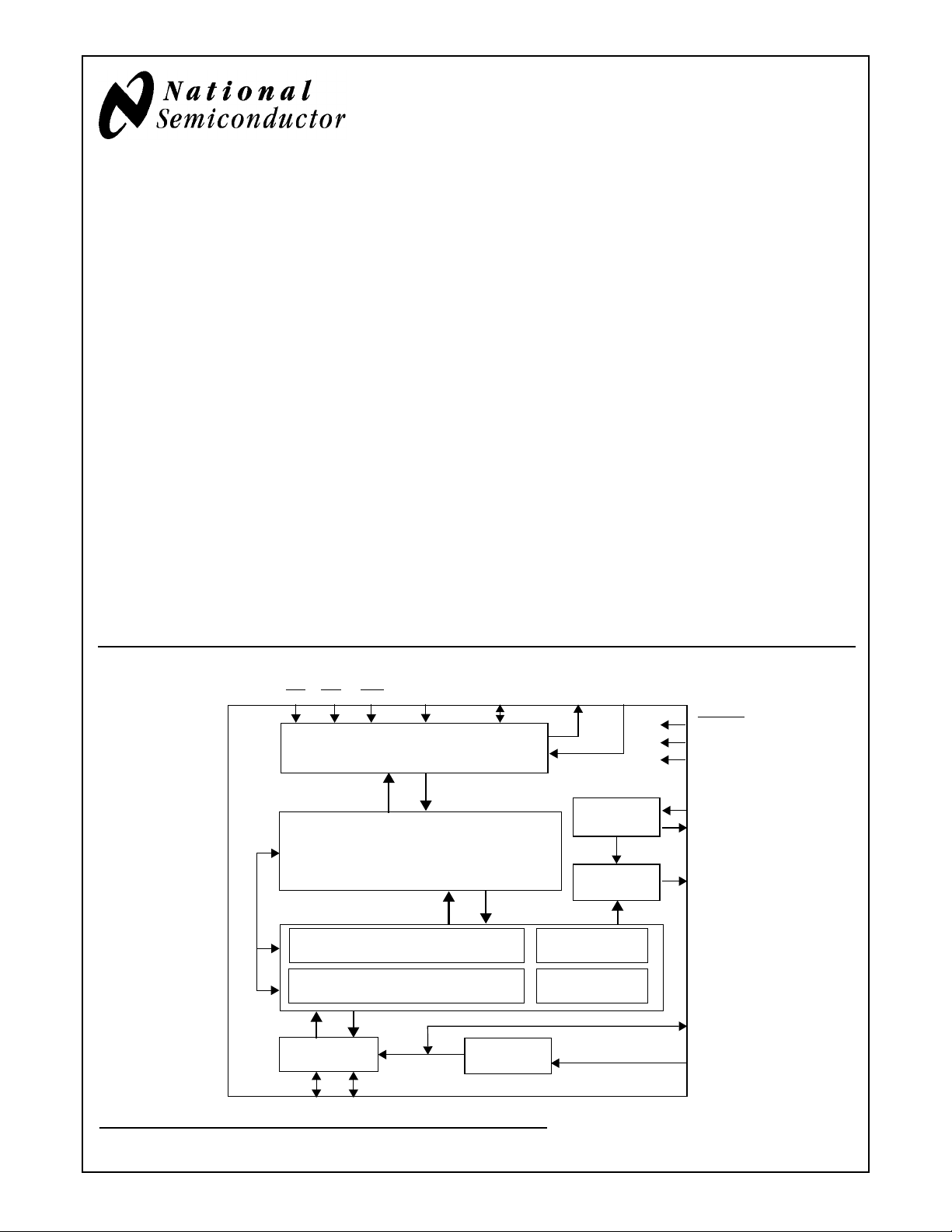

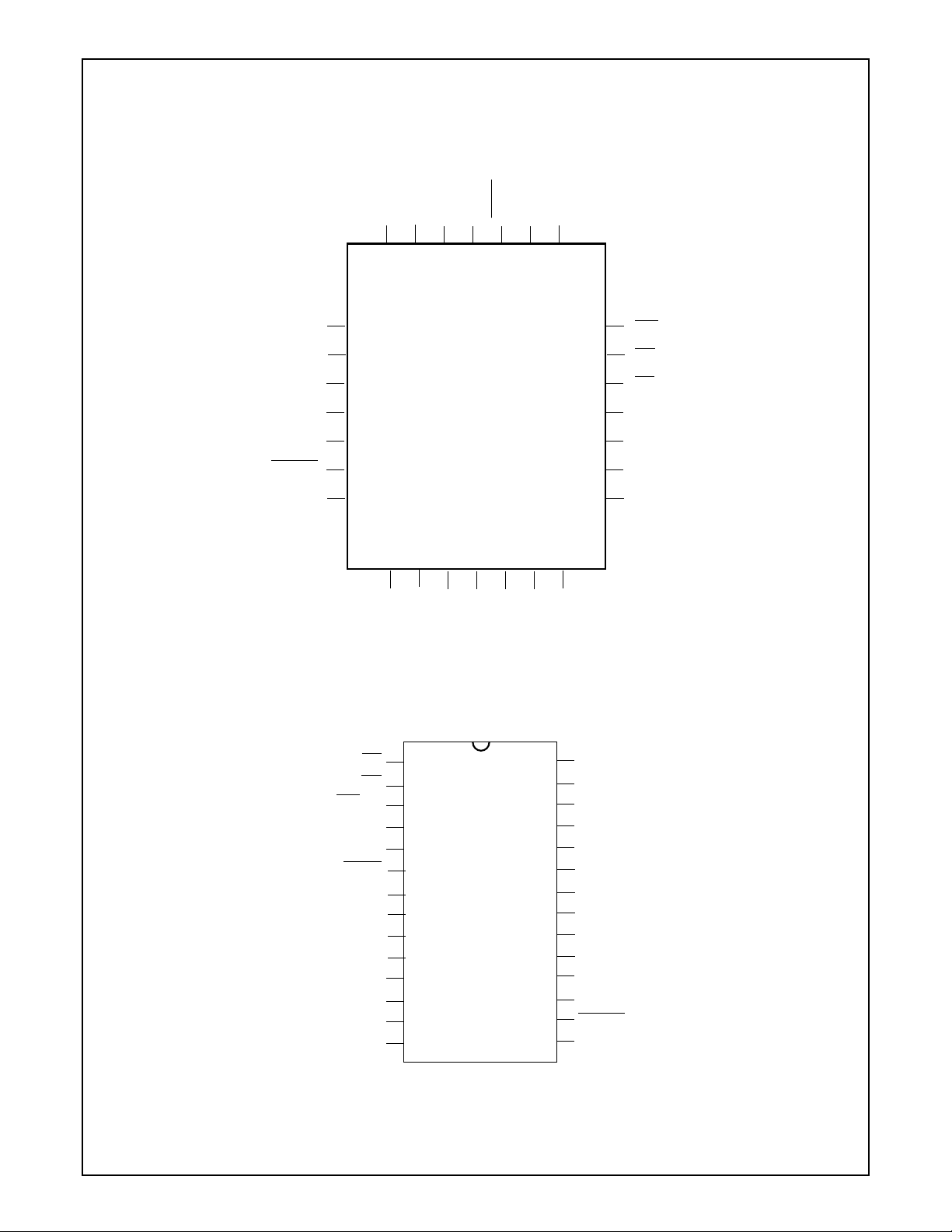

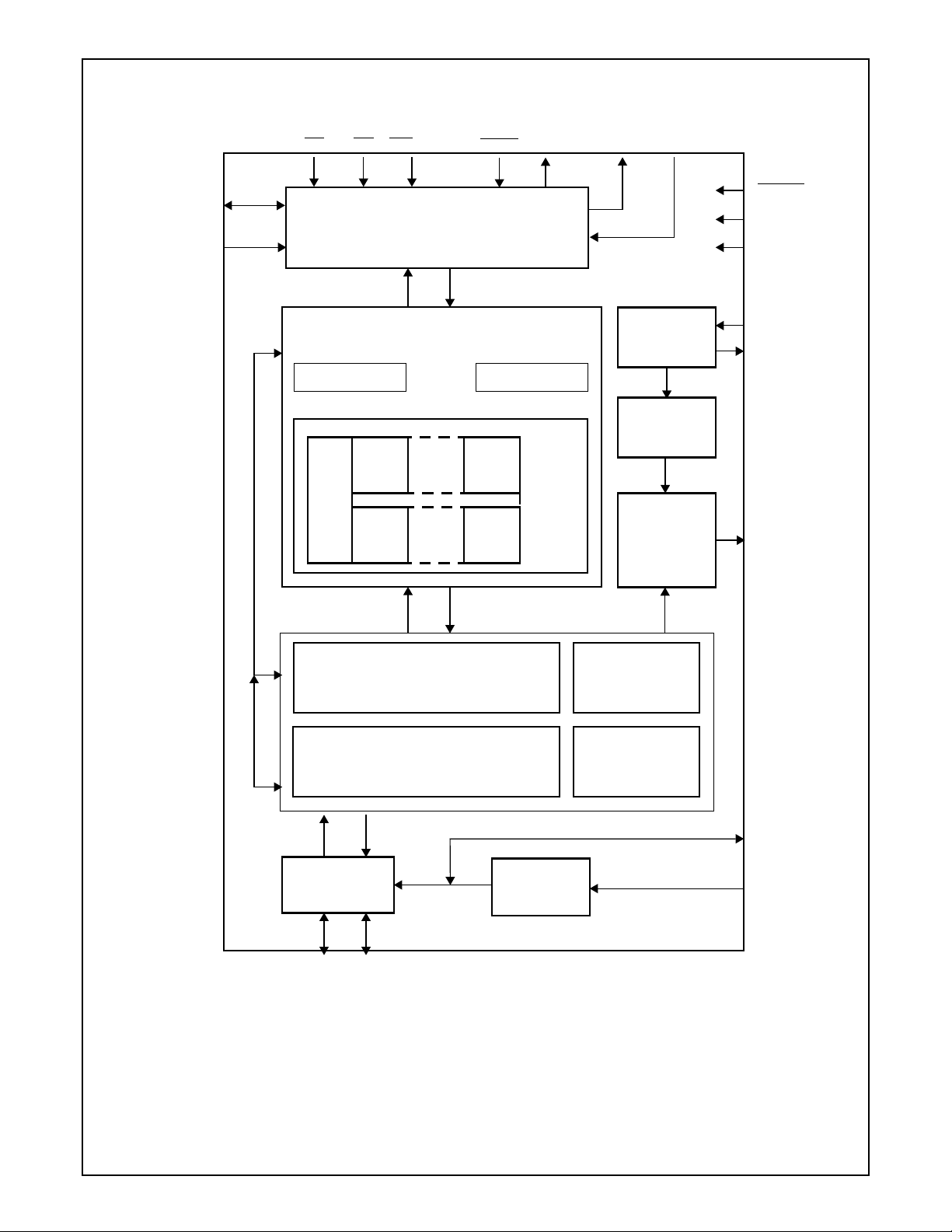

Block Diagram

CS RD WR

A0/ALE D7-0/AD7-0

Outstanding Features

●

Low EMI, low standby current, 24 MHz oscillator

●

Advanced DMA mechanism

●

Fully static HALT mode with asynchronous wake-up

for bus powered operation

●

5V or 3.3V operation

●

Improved input range 3.3V signal voltage regulator

●

All unidirectional FIFOs are 64 bytes

●

Power-up reset and startup delay counter simplify system design

●

Simple programming model controlled by external controller

●

Available in two packages

— USBN9603/4SLB: small footprint for new designs

and portable applications

— USBN9603/4-28M: standard package, pin-to-pin

compatible with USBN9602-28M

INTR

MODE1-0

Microcontroller Interface

Endpoint/Control FIFOs

Serial Interface Engine (SIE)

Media Access Controller (MAC)

Physical Layer Interface (PHY)

Transceiver

D+ D-

National Semiconductor is a registered trademark of National Semiconductor Corporation.

All other brand or product names are trademarks or registered trademarks of their respective holders.

Upstream Port

VReg

24 MHz

Oscillator

Clock

Generator

Clock

Recovery

USB Event

Detect

RESET

V

CC

GND

XIN

XOUT

CLKOUT

V3.3

AGND

© National Semiconductor Corporation, 2003

www.national.com

Features

●

Full-speed USB node device

●

Integrated USB transceiver

●

Supports 24 MHz oscillator circuit with internal 48

MHz clock generation circuit

●

Programmable clock generator

●

Serial Interface Engine (SIE) consisting of Physical

Layer Interface (PHY) and Media Access Controller

USBN9603/USBN9604

(MAC), USB Specification 1.0 and 1.1 compliant

●

Control/Status register file

●

USB Function Controller with seven FIFO-based Endpoints:

— One bidirectional Control Endpoint 0 (8 bytes)

— Three Transmit Endpoints (64 bytes each)

— Three Receive Endpoints (64 bytes each)

●

8-bit parallel interface with two selectable modes:

— Non-multiplexed

— Multiplexed (Intel compatible)

●

Enhanced DMA support

— Automatic DMA (ADMA) mode for fully CPU-inde-

pendent transfer of large bulk or ISO packets

— DMA controller, together with the ADMA logic, can

transfer a large block of data in 64-byte packets via

the USB

— Automatic Data PID toggling/checking and NAK

packet recovery (maximum 256x64 bytes of data =

16K bytes)

●

MICROWIRE/PLUS interface

www.national.com

2

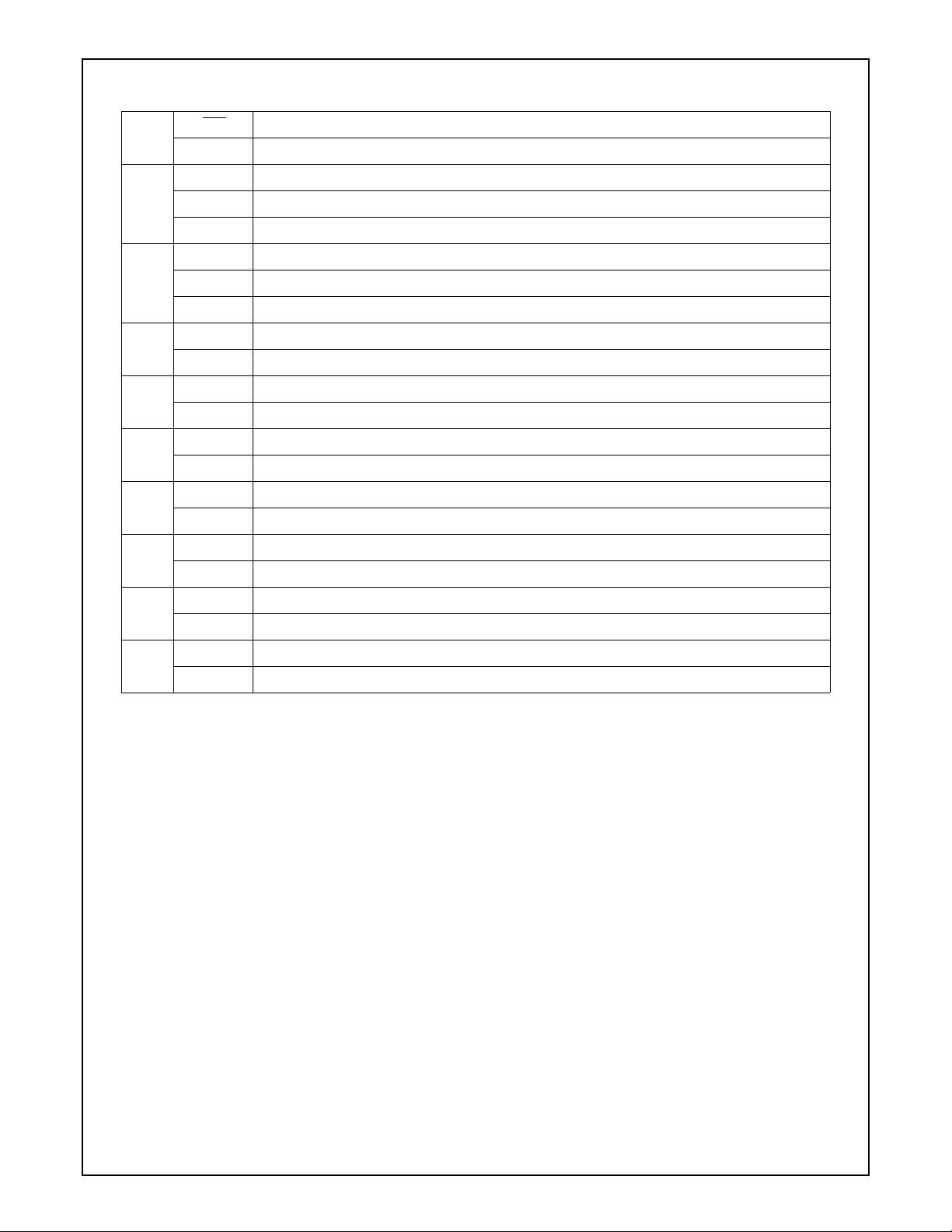

Table of Contents

1.0 Signal/Pin Connection and Description

1.1 CONNECTION DIAGRAMS ........................................................................................................6

1.2 DETAILED SIGNAL/PIN DESCRIPTIONS ..................................................................................7

1.2.1 Power Supply ................................................................................................................ 7

1.2.2 Oscillator, Clock and Reset........................................................................................... 7

1.2.3 USB Port .......................................................................................................................8

1.2.4 Microprocessor Interface............................................................................................... 8

Functional Overview

2.0

2.1 TRANSCEIVER .........................................................................................................................10

2.2 VOLTAGE REGULATOR (VREG) .............................................................................................10

2.3 SERIAL INTERFACE ENGINE (SIE) .........................................................................................10

2.4 ENDPOINT PIPE CONTROLLER (EPC) ...................................................................................12

2.5 MICROCONTROLLER INTERFACE .........................................................................................12

3.0 Parallel Interface

USBN9603/USBN9604

3.1 NON-MULTIPLEXED MODE .....................................................................................................13

3.1.1 Standard Access Mode ...............................................................................................14

3.1.2 Burst Mode ..................................................................................................................14

3.1.3 User Registers .............................................................................................................14

3.2 MULTIPLEXED MODE ..............................................................................................................15

4.0 Direct Memory Access (DMA) Support

4.1 STANDARD DMA MODE (DMA) ...............................................................................................16

4.2 AUTOMATIC DMA MODE (ADMA) ...........................................................................................17

5.0 MICROWIRE/PLUS Interface

5.1 OPERATING COMMANDS .......................................................................................................19

5.2 READ AND WRITE TIMING ......................................................................................................20

6.0 Functional Description

6.1 FUNCTIONAL STATES .............................................................................................................22

6.1.1 Line Condition Detection .............................................................................................22

6.1.2 Functional State Transition ..........................................................................................22

6.2 ENDPOINT OPERATION ..........................................................................................................24

6.2.1 Address Detection .......................................................................................................24

6.2.2 Transmit and Receive Endpoint FIFOs .......................................................................24

6.2.3 Programming Model ....................................................................................................28

6.3 POWER SAVING MODES ........................................................................................................28

6.4 CLOCK GENERATION ..............................................................................................................29

7.0 Register Set

7.1 CONTROL REGISTERS ...........................................................................................................30

7.1.1 Main Control Register (MCNTRL) ............................................................................... 30

3

www.national.com

Table of Contents (Continued)

7.1.2 Clock Configuration Register (CCONF)...................................................................... 31

7.1.3 Revision Identifier (RID) ..............................................................................................31

7.1.4 Node Functional State Register (NFSR) ..................................................................... 32

7.1.5 Main Event Register (MAEV) .......................................................................................32

7.1.6 Main Mask Register (MAMSK) ....................................................................................33

7.1.7 Alternate Event Register (ALTEV).............................................................................. 33

USBN9603/USBN9604

7.2 TRANSFER REGISTERS ..........................................................................................................36

7.1.8 Alternate Mask Register (ALTMSK) ............................................................................34

7.1.9 Transmit Event Register (TXEV) .................................................................................34

7.1.10 Transmit Mask Register (TXMSK) ...............................................................................35

7.1.11 Receive Event Register (RXEV) ................................................................................. 35

7.1.12 Receive Mask Register (RXMSK) ...............................................................................35

7.1.13 NAK Event Register (NAKEV) .................................................................................... 36

7.1.14 NAK Mask Register (NAKMSK) ...................................................................................36

7.2.1 FIFO Warning Event Register (FWEV) ....................................................................... 36

7.2.2 FIFO Warning Mask Register (FWMSK) .....................................................................37

7.2.3 Frame Number High Byte Register (FNH) .................................................................. 37

7.2.4 Frame Number Low Byte Register (FNL) ....................................................................37

7.2.5 Function Address Register (FAR) ................................................................................38

7.2.6 DMA Control Register (DMACNTRL).......................................................................... 38

7.2.7 DMA Event Register (DMAEV) ....................................................................................39

7.2.8 DMA Mask Register (DMAMSK) .................................................................................40

7.2.9 Mirror Register (MIR) ...................................................................................................41

7.2.10 DMA Count Register (DMACNT) .................................................................................41

7.2.11 DMA Error Register (DMAERR).................................................................................. 41

7.2.12 Wake-Up Register (WKUP) ........................................................................................ 42

7.2.13 Endpoint Control 0 Register (EPC0) ............................................................................43

7.2.14 Transmit Status 0 Register (TXS0) ............................................................................. 43

7.2.15 Transmit Command 0 Register (TXC0) ..................................................................... 44

7.2.16 Transmit Data 0 Register (TXD0) ................................................................................44

7.2.17 Receive Status 0 Register (RXS0) ..............................................................................44

7.2.18 Receive Command 0 Register (RXC0) ....................................................................... 45

7.2.19 Receive Data 0 Register (RXD0) ................................................................................ 45

7.2.20 Endpoint Control X Register (EPC1 to EPC6) .............................................................46

7.2.21 Transmit Status X Register (TXS1, TXS2, TXS3) .......................................................46

7.2.22 Transmit Command X Register (TXC1, TXC2, TXC3) ................................................47

7.2.23 Transmit Data X Register (TXD1, TXD2, TXD3) .........................................................48

7.2.24 Receive Status X Register (RXS1, RXS2, RXS3) .......................................................48

7.2.25 Receive Command X Register (RXC1, RXC2, RXC3) ................................................49

7.2.26 Receive Data X Register (RXD1, RXD2, RXD3) .........................................................50

www.national.com

4

Table of Contents (Continued)

7.3 REGISTER MAP ........................................................................................................................50

Device Characteristics

8.0

8.1 ABSOLUTE MAXIMUM RATINGS ............................................................................................52

8.2 DC ELECTRICAL CHARACTERISTICS ...................................................................................52

8.3 AC ELECTRICAL CHARACTERISTICS ....................................................................................53

8.4 PARALLEL INTERFACE TIMING (MODE1-0 = 00B) ................................................................54

8.5 PARALLEL INTERFACE TIMING (MODE1-0 = 01B) ................................................................55

8.6 DMA SUPPORT TIMING ...........................................................................................................57

8.7 MICROWIRE INTERFACE TIMING (MODE1-0 = 10B) .............................................................58

8.8 RESET TIMING) ........................................................................................................................58

USBN9603/USBN9604

5

www.national.com

1.0 Signal/Pin Connection and Description

1.1 CONNECTION DIAGRAMS

D2

27

USBN9603/USBN9604

28

D1

D0/SO

26

A0/ALE/SI

DACK

25

24

DRQ

23

INTR

22

D3

D4

D5

D6

D7

RESET

AGND

1

2

3

4

5

6

7

CS

RD

WR/SK

INTR

DRQ

DACK

A0/ALE/SI

D0/SO

D1

D2

D3

D4

D5

D6

28-Pin CSP

9

8

V3.3

10

D+

USBN9603/4SLB

1

2

3

4

5

6

7

28-Pin SO

8

9

10

11

12

13

14

21

WR/SK

20

RD

CS

19

CLKOUT

18

XOUT

17

XIN

16

MODEO

15

11

12

13

14

GND

V

CC

GND

28

27

26

25

24

23

22

21

20

19

18

17

16

15

MODE1

CLKOUT

XOUT

XIN

MODE0

MODE1

GND

Vcc

GND

D–

D+

V3.3

AGND

RESET

D7

D−

www.national.com

USBN9603/4-28M

6

1.0 Signal/Pin Connection and Description (Continued)

1.2 DETAILED SIGNAL/PIN DESCRIPTIONS

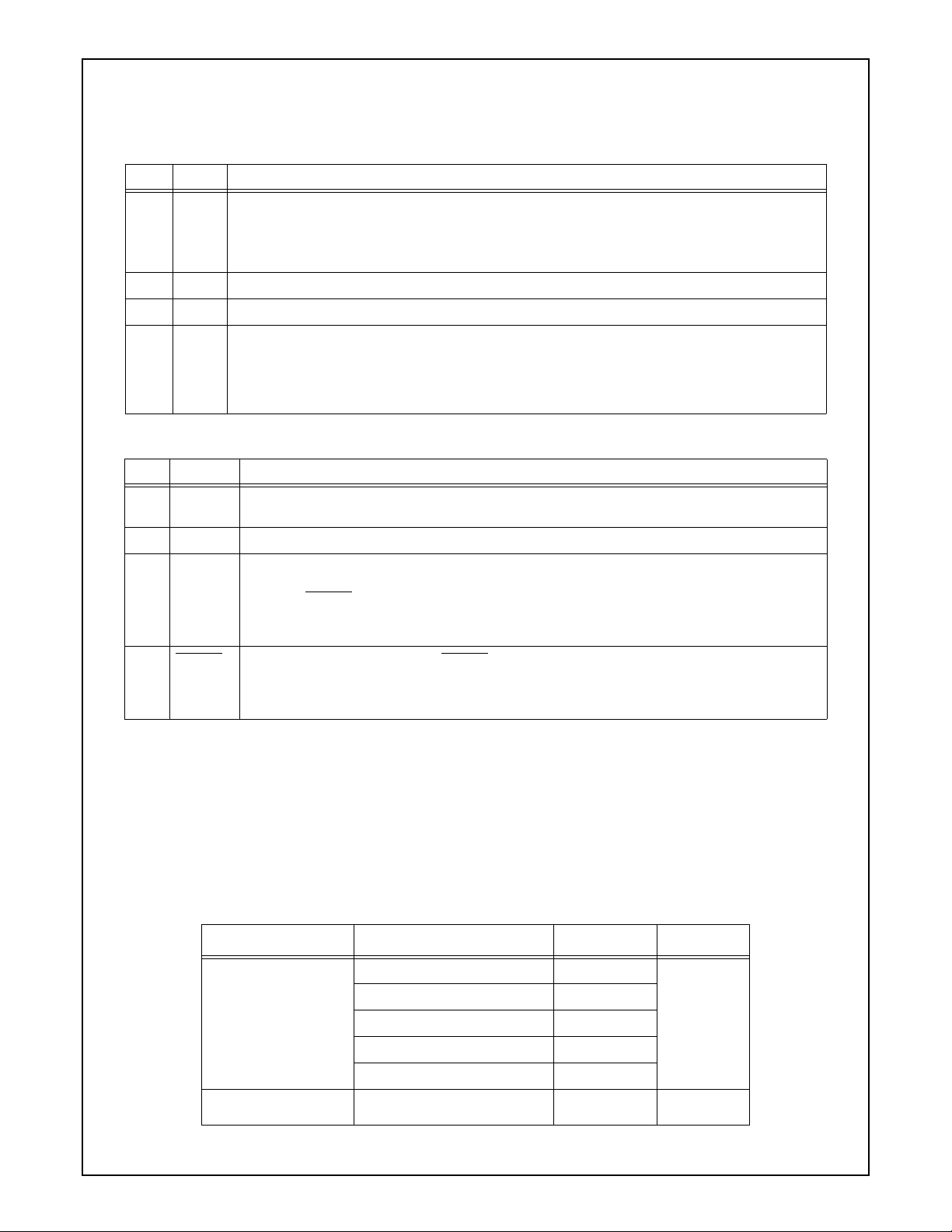

1.2.1 Power Supply I/O Name Description

NA Vcc Digital Power Supply (V

level as GND and then raised to the required V

to be set to their reset values, the clock generator to be reset and stalls the CLKOUT output for

14

2

XIN clock cycles. During this time, no internal register is accessible.

NA GND Digital Power Supply (GND)

NA AGND Analog Power Supply (AGND)

). Power-on reset is detected when the input voltage is at the same

CC

level. The power-on reset causes all registers

cc

USBN9603/USBN9604

NA V3.3 Transceiver 3.3V Voltage Supply. This pin can be used as the internal 3.3V voltage regulator

output. The regulator is intended to power only the internal transceiver and one external pull-up.

An external 1 µF de-coupling capacitor is required on this pin. The voltage regulator output is disabled upon reset. When the internal voltage regulator is left disabled, this pin must be used as a

3.3V supply input for the internal transceiver. This is the case during 3.3V operation.

1.2.2 Oscillator, Clock and Reset I/O Name Description

NA XIN Crystal Oscillator Input. Input for internal 24 MHz crystal oscillator circuit. A 24 MHz funda-

mental crystal may be used.

NA XOUT Crystal Oscillator Output

O CLKOUT Clock Output. This programmable clock output may be disabled and configured for different

speeds via the Clock Configuration register. After a power-on reset and hardware reset (assertion of

In the USBN9604, a hardware reset causes CLKOUT to stall for 2

RESET), a4 MHz clock signal is output (there may be an initial phase discontinuity).

14

XIN clock cycles while the

internal DLL is synchronized to the external reference clock.

I RESET Reset. Activelow, assertion of RESETindicates a hardware reset, which causes all registers

in the device to revert to their reset values.

In the USBN9604, the hardware reset action is identical to a power-on reset. Signalconditioning is provided on this input to allow use of a simple, RC power-on reset circuit.

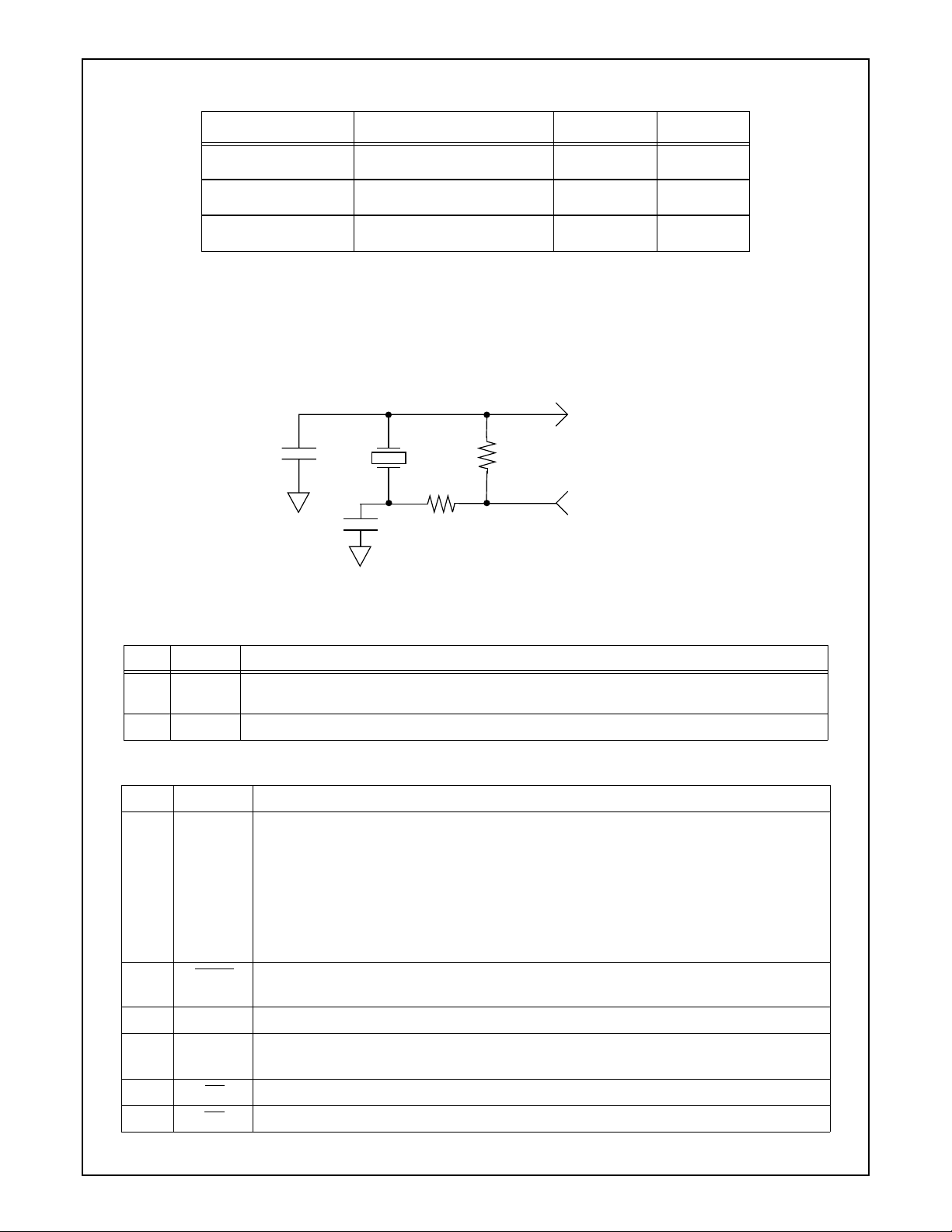

Oscillator Circuit

The XIN and XOUT pins may be connected to make a 24 MHz closed-loop, crystal-controlled oscillator. Alternately, an external 24 MHz clock source may be used as the input clock for the device. The internal crystal oscillator uses a 24 MHz

fundamental crystal. See Table 1 for typical component values and Figure 1 for the crystal circuit. For a specific crystal,

please consult the manufacturer for recommended component values.

If an external clock source is used, it is connected to XIN. XOUT should remain unconnected. Stray capacitance and inductance should be kept as low as possible in the oscillator circuit. Trace lengths should be minimized by positioning the crystal

and external components as close as possible to the XIN and XOUT pins.

Table 1. Approximate Component Values

Component Parameters Values Tolerance

Crystal Resonator Resonance Frequency 24 MHz 2500 ppm

Type AT-Cut

(max)

Maximum Serial Resistance 50 Ω

Maximum Shunt Capacitance 10 pF

Load Capacitance 20 pF

Resistor R1

1MΩ±5%

7

www.national.com

1.0 Signal/Pin Connection and Description (Continued)

Component Parameters Values Tolerance

Resistor R2

Capacitor C1

Capacitor C2

USBN9603/USBN9604

External Elements

0 ΝΑ

15 pF ±20%

15 pF ±20%

Choose C1 and C2 capacitors (see Figure 1) to match the crystal’s load capacitance. The load capacitance C

the crystal is comprised of C1 in series with C2, and in parallel with the parasitic capacitance of the circuit. The parasitic

capacitance is caused by the chip package, board layout and socket (if any), and can vary from 0 to 8 pF. The rule of thumb

in choosing these capacitors is:

= (C1*C2)/(C1+C2)+C Parasitic

C

L

XIN

XTAL

C1

R1

XOUT

C2

R2

Figure 1. Typical Oscillator Circuit

“seen” by

L

1.2.3 USB Port I/O Name Description

I/O D+ USB D+ Upstream Port. This pin requires an external 1.5k pull-up to 3.3V to signal full speed

operation.

I/O D– USB D– Upstream Port

1.2.4 Microprocessor Interface I/O Name Description

I MODE1-0 Interface Mode. Each of these pins should be hard-wired to V

or GND to select the inter-

CC

face mode:

MODE1-0 = 00. Mode 0: Non-multiplexed parallel interface mode

MODE1-0 = 01. Mode 1: Multiplexed parallel interface mode

MODE1-0 = 10. Mode 2: MICROWIRE interface mode

MODE1-0 = 11. Mode 3: Reserved

Note: Mode 3 also selects the MICROWIRE interface mode in the USBN9602, but this mode

should be reserved to preserve compatibility with future devices.

I

DACK DMAAcknowledge. This active low signal is only used if DMA is enabled. If DMA is not used,

this pin must be tied to V

CC

.

O DRQ DMA Request. This pin is used for DMA request only if DMA is enabled.

O INTR Interrupt. The interrupt signal modes (active high, active low or open drain) can be config-

ured via the Main Control register. During reset, this signal is TRI-STATE

I

I

CS Chip Select. Active low chip select

RD Read. Active low read strobe, parallel interface

.

www.national.com

8

1.0 Signal/Pin Connection and Description (Continued)

I WR Write. Active low write strobe, parallel interface

SK MICROWIRE Shift Clock. Mode 2

IA0A0 Address Bus Line. Mode 0, parallel interface

ALE Address Latch Enable. Mode 1, parallel interface

SI MICROWIRE Serial Input. Mode 2

I/O D0 Data Bus Line D0. Mode 0

AD0 Address/Data Bus LIne AD0. Mode 1

SO MICROWIRE Serial Output. Mode 2

I/O D1 Data Bus Line D1. Mode 0

AD1 Address/Data Bus Line AD1. Mode 1

I/O D2 Data Bus Line D2. Mode 0

AD2 Address/Data Bus Line AD2. Mode 1

I/O D3 Data Bus Line D3. Mode 0

AD3 Address/Data Bus Line AD3. Mode 1

I/O D4 Data Bus Line D4. Mode 0

USBN9603/USBN9604

AD4 Address/Data Bus Line AD4. Mode 1

I/O D5 Data Bus Line D5. Mode 0

AD5 Address/Data Bus Line AD5. Mode 1

I/O D6 Data Bus Line D6. Mode 0

AD6 Address/Data Bus Line AD6. Mode 1

I/O D7 Data Bus Line D7. Mode 0

AD7 Address/Data Bus Line AD7. Mode 1

9

www.national.com

2.0 Functional Overview

The device is a Universal Serial Bus (USB) Node controller compatible with USB Specification, 1.0 and 1.1. It integrates onto

a single IC the required USB transceiver with a 3.3V regulator, the Serial Interface Engine (SIE), USB endpoint FIFOs, a

versatile (8-bit parallel or serial) interface and a clock generator. A total of seven endpoint pipes are supported: one bidirectional for the mandatory control EP0 and an additional six for unidirectional endpoints to support USB interrupt, bulk and

isochronous data transfers. The 8-bit parallel interface supports multiplexed and non-multiplexed style CPU address/data

buses. The synchronous serial MICROWIRE interface allows adapting to CPUs without external address/data buses. A programmable interrupt output scheme allows adapting to different interrupt signaling requirements.

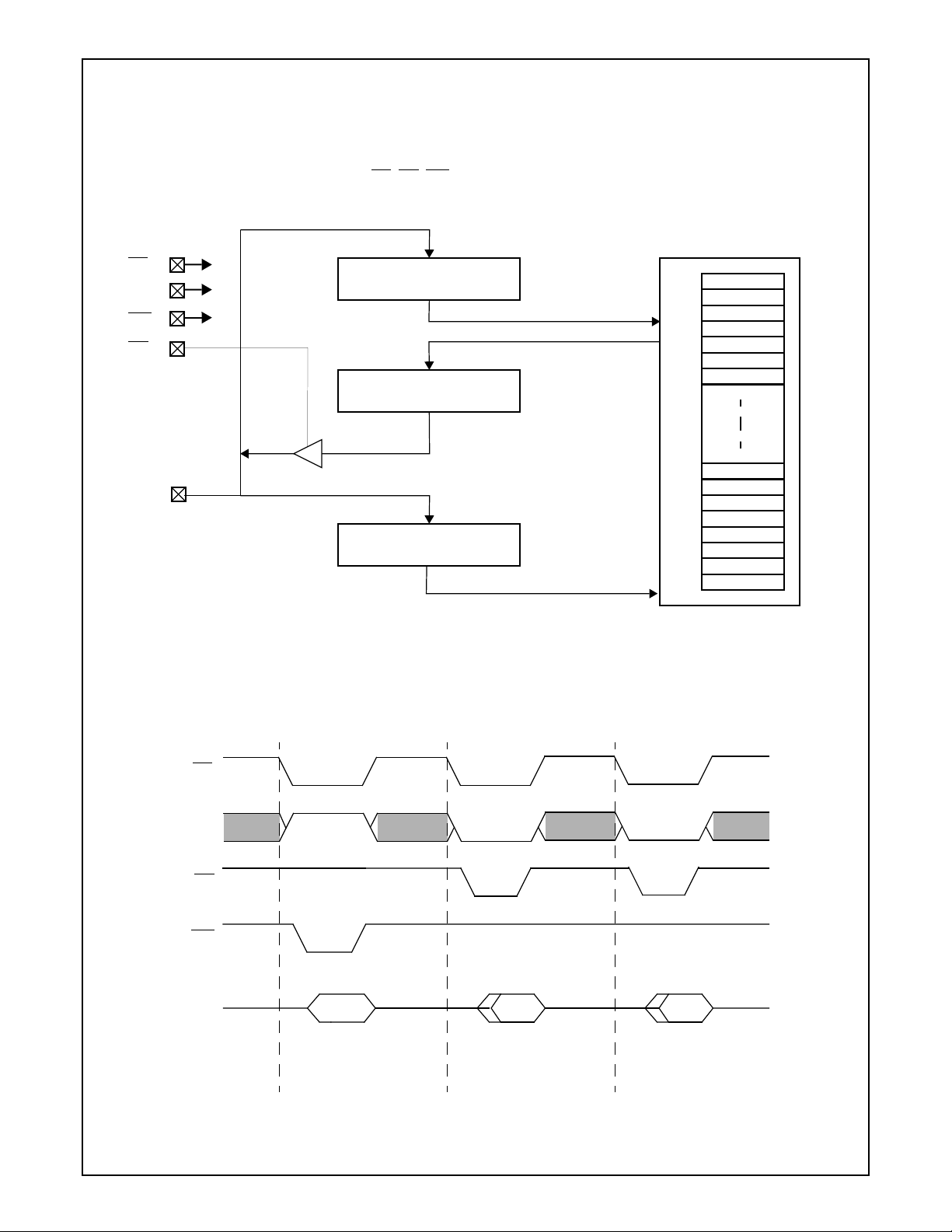

Refer to Figure 2 for the major functional blocks, described in the following sections.

2.1 TRANSCEIVER

USBN9603/USBN9604

The device contains a high-speed transceiver which consists of three main functional blocks:

— Differential receiver

— Single-ended receiver with on-chip voltage reference

— Transmitter with on-chip current source.

This transceiver meets the performance requirements described in Chapter 7 of the USB Specification, Version 1.1.

To minimize signal skew, the differential output swings of the transmitter are well balanced. Slew-rate control is used on the

driver to minimize radiated noise and crosstalk. The drivers support TRI-STATE operation to allow bidirectional, half-duplex

operation of the transceiver.

The differential receiver operates over the complete common mode range, and has a delay guaranteed to be larger than

that of the single-ended receivers. This avoids potential glitches in the Serial Interface Engine (SIE) after single-ended zeros.

Single-ended receivers are present on each of the two data lines. These are required, in addition to the differential receiver, to

detect an absolute voltage with a switching threshold between 0.8V and 2.0V (TTL inputs). To increase V

glitching, a voltage reference sets the single-ended switching reference. An external 1.5 ± 5% KΩ resistor is required on D+ to

indicate that this is a high-speed node. This resistor should be tied to a voltage source between 3.0V and 3.6V, and referenced

to the local ground, such as the output provided on pin V3.3.

rejection, without

cc

2.2 VOLTAGE REGULATOR (VREG)

The voltage regulator provides 3.3V for the integrated transceiver from 5.0V device power or USB bus power. This output

can be used to supply power to the 1.5 KΩ pull-up resistor. This output must be decoupled with a 1 µF tantalum capacitor

to ground. It can be disabled under software control to allow using the device in a 3.3V system.

2.3 SERIAL INTERFACE ENGINE (SIE)

The SIE is comprised of physical (PHY) and Media Access Controller (MAC) modules. The PHY module includes the digitalclock recovery circuit, a digital glitch filter, End Of Packet (EOP) detection circuitry, and bit stuffing and unstuffing logic. The

MAC module includes packet formatting, CRC generation and checking, and endpoint address detection. It provides the

necessary control to give the NAK, ACK and STALL responses as determined by the Endpoint Pipe Controller (EPC) for the

specified endpoint pipe. The SIE is also responsible for detecting and reporting USB-specific events, such as NodeReset,

NodeSuspend and NodeResume. The module output signals to the transceiver are well matched (under 1 nS) to minimize

skew on the USB signals.

The USB specifications assign bit stuffing and unstuffing as the method to ensure adequate electrical transitions on the line

to enable clock recovery at the receiving end. The bit stuffing block ensures that whenever a string of consecutive 1’s is

encountered, a 0 is inserted after every sixth 1 in the data stream. The bit unstuffing logic reverses this process.

The clock recovery block uses the incoming NRZI data to extract a data clock (12 MHz) from a 48 MHz input clock. This

input clock is derived from a 24 MHz oscillator in conjunction with PLL circuitry (clock doubler). This clock is used in the data

recovery circuit. The output of this block is binary data (decoded from the NRZI stream) which can be appropriately sampled

using the extracted 12 MHz clock. The jitter performance and timing characteristics meet the requirements set forth in Chapter 7 of the USB Specification.

www.national.com

10

2.0 Functional Overview (Continued)

USBN9603/USBN9604

D7-0/AD7-0/SO

A0/ALE/SI

CS RD WR/SK

Microcontroller Interface

(Parallel and Serial)

Endpoint/Control FIFOs

EP2

Endpoint0

EP1

DACK

EP6EP5

StatusControl

DRQ

RX

TX

INTR

MODE1-0

24 MHz

Oscillator

PLL

x 2

Clock

Generator

RESET

V

CC

GND

XIN

XOUT

CLKOUT

SIE

Media Access Controller (MAC)

Physical Layer Interface (PHY)

Transceiver

D+ D-

Figure 2. USBN9603/4 Block Diagram

Upstream Port

VReg

Clock

Recovery

USB Event

Detect

V3.3

AGND

11

www.national.com

2.0 Functional Overview (Continued)

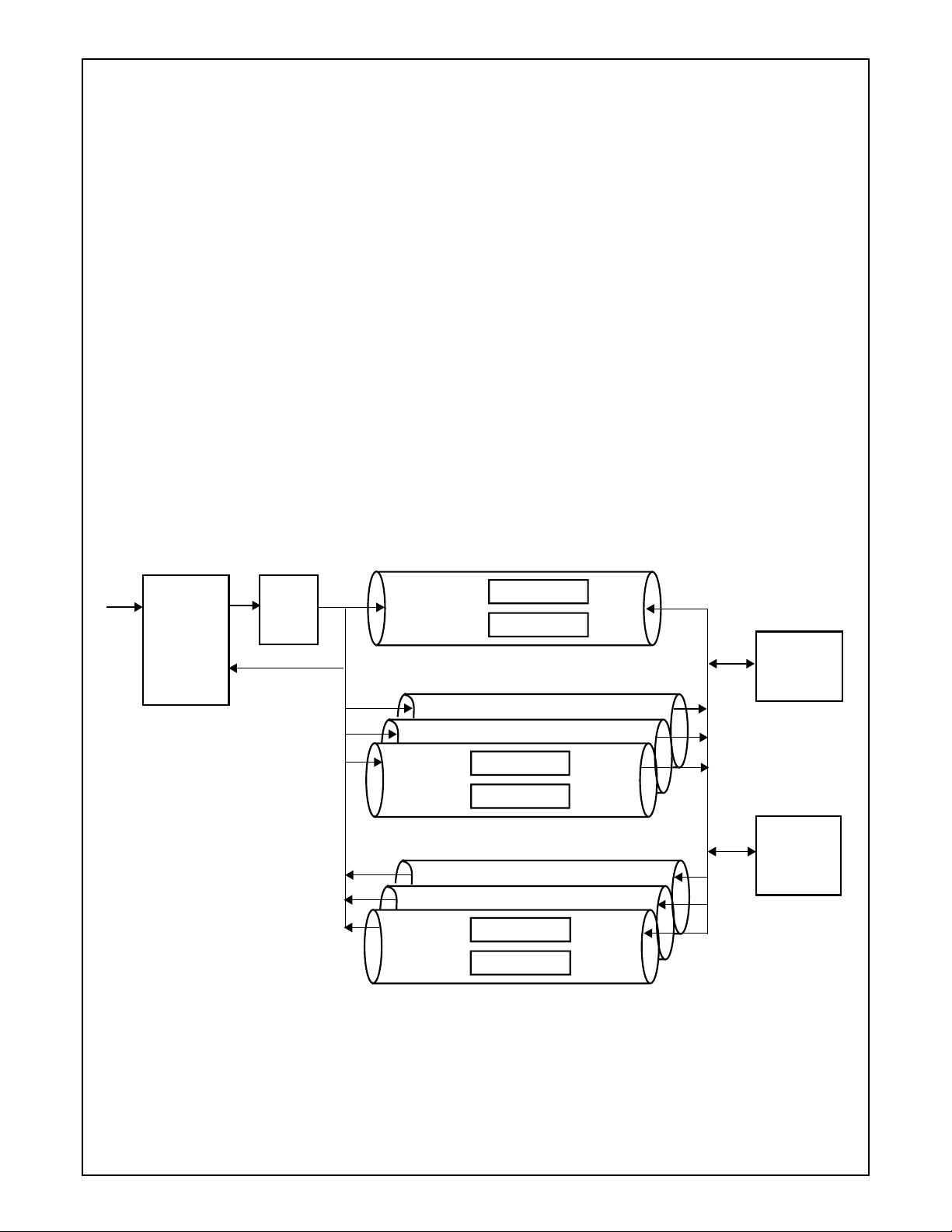

2.4 ENDPOINT PIPE CONTROLLER (EPC)

The EPC provides the interface for USB function endpoints. An endpoint is the ultimate source or sink of data. An endpoint

pipe facilitates the movement of data between USB and memory, and completes the path between the USB host and the

function endpoint. According to the USB specification, up to 31 such endpoints are supported at any given time. USB allows

a total of 16 unidirectional endpoints for receive and 16 for transmit. As the control endpoint 0 is always bidirectional, the

total number is 31. Seven endpoint pipes with the same function address are supported. See Figure 3 for a schematic diagram of EPC operation.

A USB function is a USB device that is able to transmit and receive information on the bus. A function may have one or more

configurations, each of which defines the interfaces that make up the device. Each interface, in turn, is composed of one or

USBN9603/USBN9604

more endpoints.

Each endpoint is an addressable entity on USB and is required to respond to IN and OUT tokens from the USB host (typically

a PC). IN tokens indicate that the host has requested to receive information from an endpoint, and OUT tokens indicate that

it is about to send information to an endpoint.

On detection of an IN token addressed to an endpoint, the endpoint pipe should respond with a data packet. If the endpoint

pipe is currently stalled, a STALL handshake packet is sent under software control. If the endpoint pipe is enabled but no

data is present, a NAK (Negative Acknowledgment) handshake packet is sent automatically. If the endpoint pipe is isochronous and enabled but no data is present, a bit stuff error followed by an end of packet is sent on the bus.

Similarly, on detection of an OUT token addressed to an endpoint, the endpoint pipe should receive a data packet sent by

the host and load it into the appropriate FIFO. If the endpoint pipe is stalled, a STALL handshake packet is sent. If the endpoint pipe is enabled but no buffer is present for data storage, a NAK handshake packet is sent. If the endpoint is isochronous and enabled but cannot handle the data, no handshake packet is sent.

A disabled endpoint does not respond to IN, OUT, or SETUP tokens.

The EPC maintains separate status and control information for each endpoint pipe.

For IN tokens, the EPC transfers data from the associated FIFO to the host. For OUT tokens, the EPC transfers data in the

opposite direction.

USB

USB SIE

Function

Address

Compare

EP0

EPB

EPC.

EPY

EPZ

Control Registers

FIFOs

Control Endpoint Pipe

EPA

Control Registers

FIFO

Receive Endpoint Pipes

EPX

Control Registers

FIFO

Transmit Endpoint Pipes

DMA

Controller

Microcontroller

Interface

Figure 3. EPC Operation

2.5 MICROCONTROLLER INTERFACE

The device can be connected to a CPU or microcontroller via the 8-bit parallel or MICROWIRE interface. The interface type

is selected by the input mode pins MODE0 and MODE1. In addition, a configurable interrupt output is provided. The interrupt

type can be configured to be either open-drain active-low or push-pull active high or low.

www.national.com

12

3.0 Parallel Interface

The parallel interface allows the device to function as a CPU or microcontroller peripheral. This interface type and its addressing mode (multiplexed or non-multiplexed) is determined via device input pins MODE0 and MODE1.

3.1 NON-MULTIPLEXED MODE

Non-multiplexed mode uses the control pins

in Figure 4. This mode is selected by tying both the MODE1 and MODE0 pins to GND.

CS, RD, WR, the address pin A0 and the bidirectional data bus D7-0 as shown

USBN9603/USBN9604

CS

A0

WR

RD

D7-0

Figure 4. Non-Multiplexed Mode Block Diagram

The CPU has direct access to the DATA_IN, DATA_OUT and ADDR registers. Reading and writing data to the device can

be done either in standard access or burst mode. See Figure 5 for timing information.

DATA_IN

DATA_OUT

ADDR

0x00

Data In

Data Out

Address

0x3F

Register File

CS

A0

RD

WR

D7-0

OutInput

Write Address

Figure 5. Non-Multiplexed Mode Timing Diagram

Read Data Burst Read Data

13

Out

www.national.com

3.0 Parallel Interface (Continued)

3.1.1 Standard Access Mode

The standard access sequence for non-multiplexed mode is to write the address to the ADDR register and then read or write

the data from/to the DATA_OUT/DATA_IN register. The DATA_OUT register is updated after writing to the ADDR register.

The ADDR register or the DATA_OUT/DATA_IN register is selected with the A0 input.

3.1.2 Burst Mode

In burst mode, the ADDR register is written once with the desired memory address of any of the on-chip registers. Then

consecutive reads/writes are performed to the DATA_IN/DATA_OUT register without previously writing a new address. The

content of the DATA_OUT register for read operations is updated once after every read or write.

USBN9603/USBN9604

3.1.3 User Registers

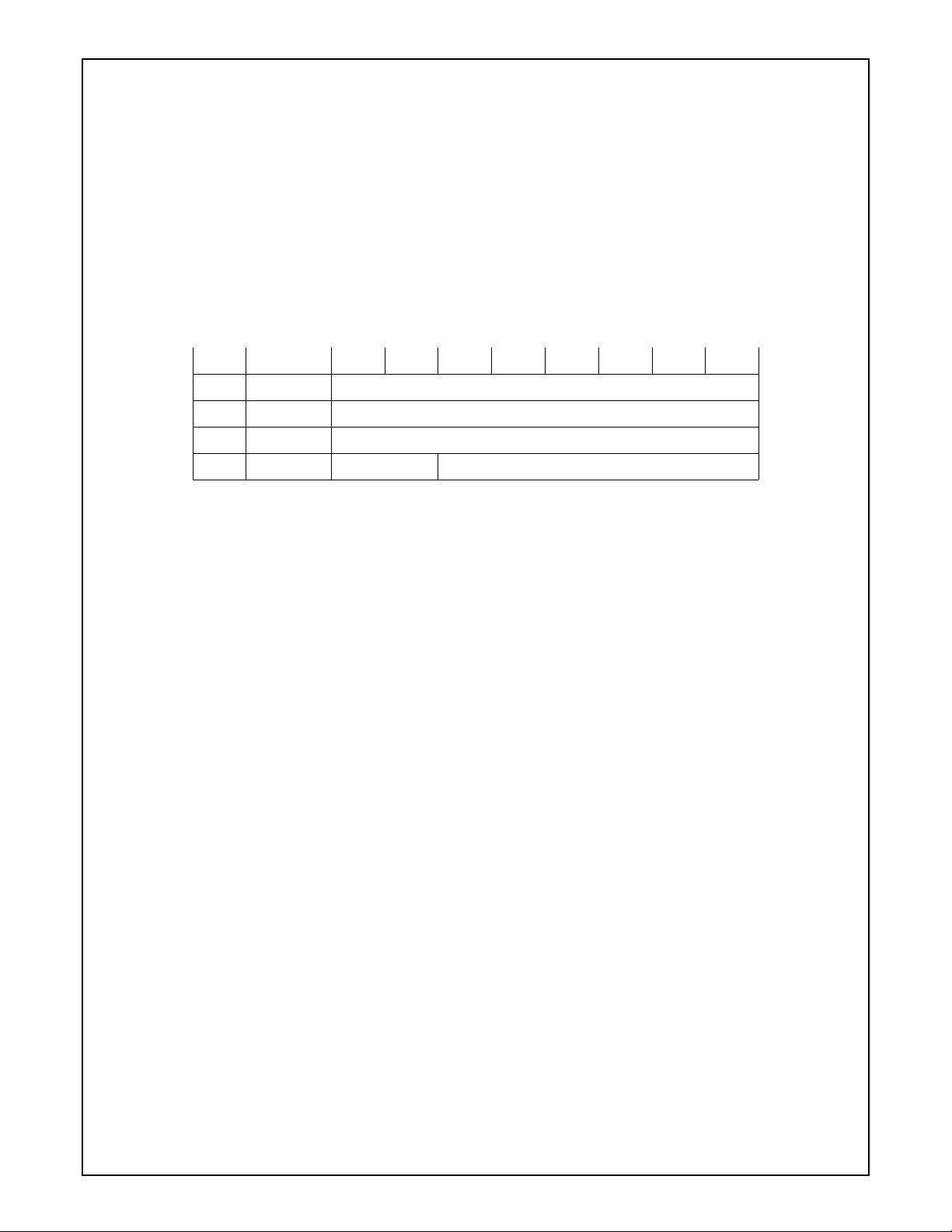

The following table gives an overview of the parallel interface registers in non-multiplexed mode.

The reserved bits return undefined data on read and should be written with 0.

A0 Access bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

0 Read DATA_OUT

0 Write DATA_IN

1 Read Reserved

1 Write Reserved ADDR5-0

Address Register (ADDR)

The ADDR register acts as a pointer to the internal memory. This register is write only and is cleared on reset.

Data Output Register (DATA_OUT)

The DATA_OUT register is updated with the contents of the memory register to which the ADDR register is pointing. Update

occurs under the following conditions:

1. After the ADDR register is written.

2. After a read from the DATA_OUT register.

3. After a write to the DATA_IN register.

This register is read only and holds undefined data after reset.

Data Input Register (DATA_IN)

The DATA_IN register holds the data written to the device address to which ADDR points. This register is write only and is

cleared on reset.

www.national.com

14

3.0 Parallel Interface (Continued)

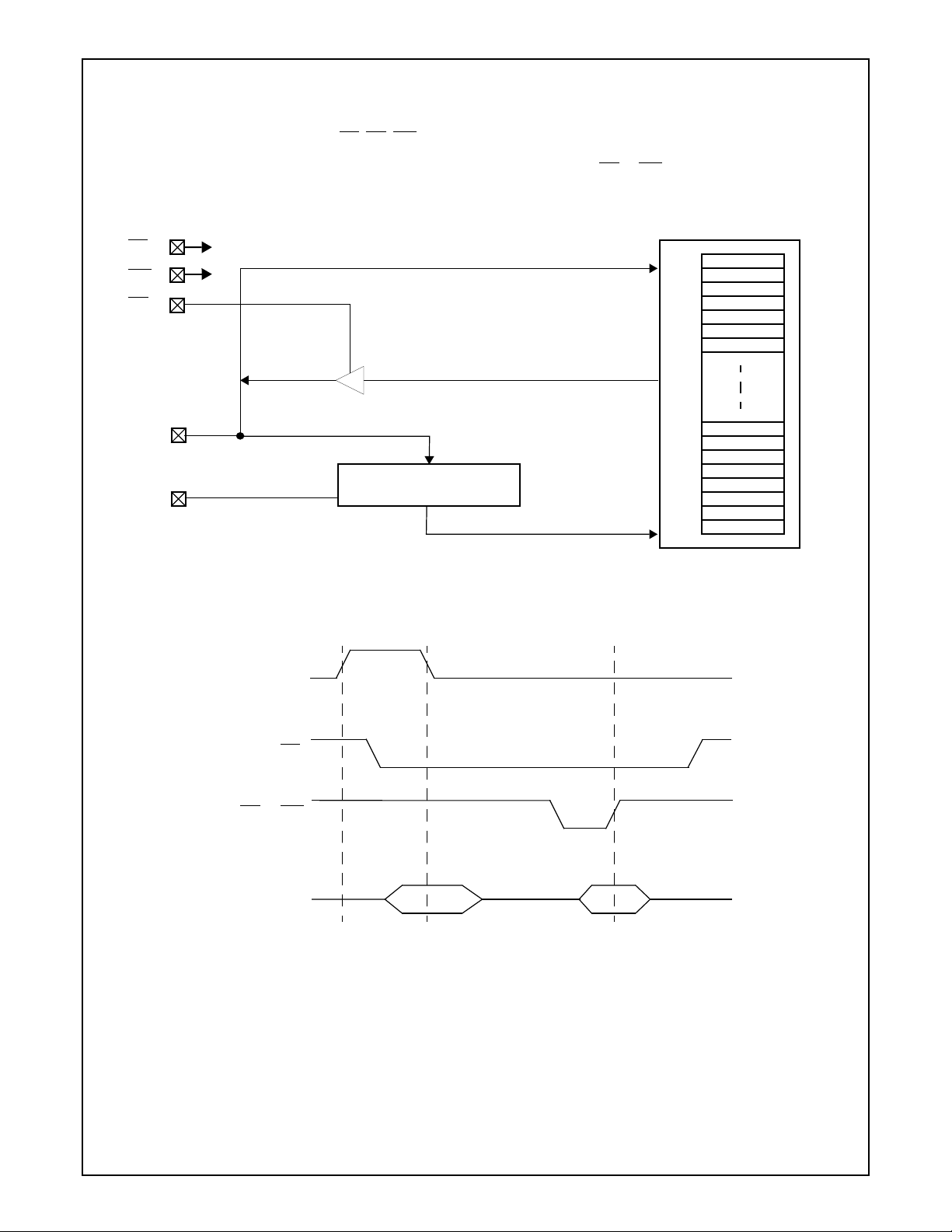

3.2 MULTIPLEXED MODE

Multiplexed mode uses the control pins

bus AD7-0 as shown in Figure 6. This mode is selected by tying MODE1 to GND and MODE0 to V

into the ADDR register when ALE is high. Data is output/input with the next active

accessible in this interface mode.

Figure 7 shows basic timing of the interface in Multiplexed mode.

CS, RD, WR, the address latch enable signal ALE and the bidirectional address data

RD or WR signal. All registers are directly

. Theaddress is latched

CC

USBN9603/USBN9604

CS

WR

RD

AD7-0

ALE

ALE

Data Out

EN

Figure 6. Multiplexed Mode Block Diagram

ADDR

Address

Data In

0x00

0x3F

Register File

CS

RD or WR

AD7-0

ADDR

Figure 7. Multiplexed Mode Basic Read/Write Timing

15

DATA

www.national.com

4.0 Direct Memory Access (DMA) Support

The device supports DMA transfers with an external DMA controller from/to endpoints 1 to 6. This mode uses the device

pins DRQ and

with parallel interface mode (MODE1 must be grounded). The read or write address is generated internally and the state of

the A0/ALE pin is ignored during a DMA cycle.

The DMA support logic has a lower priority than the parallel interface.

comes active,

given time to issue a DMA request when data is received or transmitted.

Two different DMA modes are supported: standard and automatic.

4.1 STANDARD DMA MODE (DMA)

USBN9603/USBN9604

To enable DMA transfers in standard DMA mode, the following steps must be performed:

1. The local CPU programs the DMA controller for fly-by demand mode transfers. In this mode, transfers occur only when

the device requests them via the DRQ pin. The data is read/written from/to the device receive/transmit FIFO and written/read into/from local memory during the same bus transaction.

2. The DMA address counter is programmed to point to the destination memory block in the local shared memory, and the

Byte Count register is programmed with the number of bytes in the block to be transferred. If required the automatic error

handling should be enabled at this point along with the error handling counter. In addition the user needs to set the respective Endpoint enable bit.

3. The DMA Enable bit and DMA Source bits are set in the DMACNTRL register.

4. The USB host can now perform USB bulk or isochronous data transfers over the USB bus to the receive FIFO or from

the transmit FIFO in the device.

5. If the FIFOs warning limit is reached or the transmission/reception is completed, a DMA request/acknowledge sequence

is initiated for the predetermined number of bytes. The time at which a DMA request is issued depends on the selected

DMA mode (controlled by the DMOD bit in the DMACNTRL register), the current status of the endpoint FIFO, and the

FIFO warning enable bits. A DMA request can be issued immediately.

6. After the DMA controller has granted control of the bus, it drives a valid memory address and asserts

WR, thus transferring a byte from the receiveFIFO to memory, or from memory to the transmit FIFO. This process continues until the DMA byte count, within the DMA controller, reaches zero.

7. After the programmed amount of data is transferred, the firmware must do one of the following (depending on the transfer

direction and mode):

— Queue the new data for transmission by setting the TX_EN bit in the TXCx register.

— Set the End Of Packet marker by setting the TX_LAST bit in the TXCx register. Re-enable reception by setting the

RX_EN bit in the RXCx register.

— Check if the last byte of the packet was received (RX_LAST bit in the RXSx register).

The DMA transfer can be halted at any time by resetting the DMA Request Enable bit. If the DMA Request Enable bit is

cleared during the middle of a DMA cycle, the current cycle is completed before the DMA request is terminated.

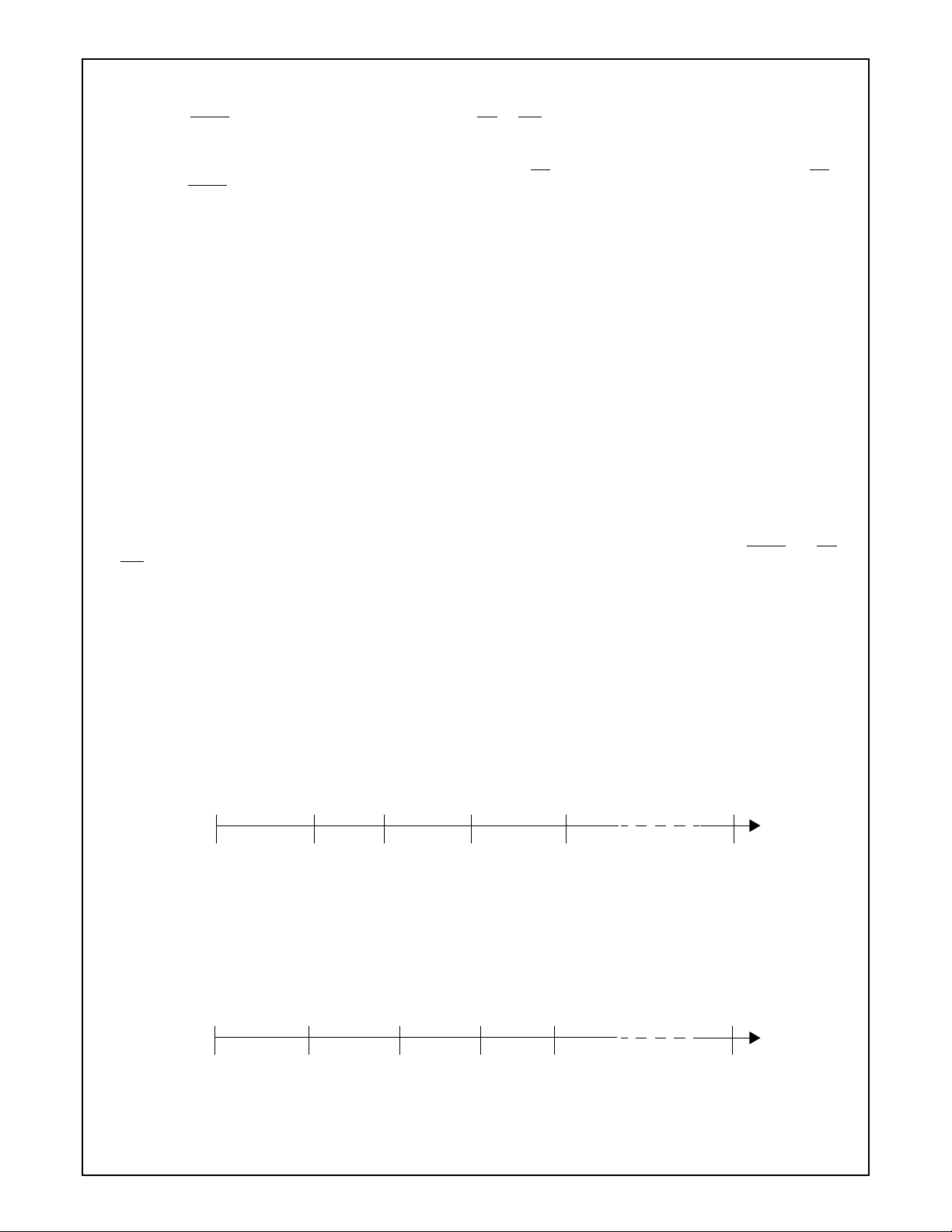

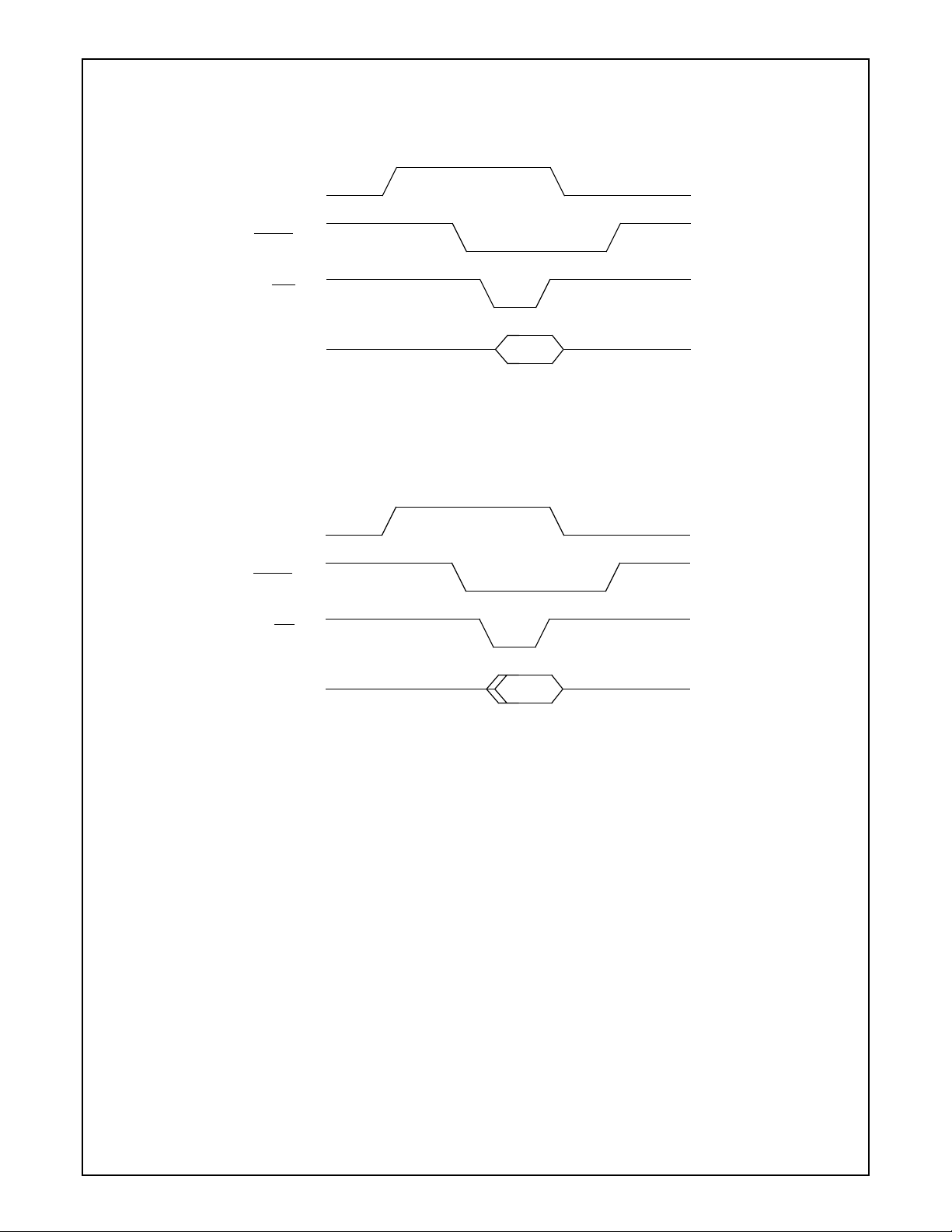

See Figures 8 and 9 for the transmit and receive sequences using standard DMA mode.

DACK in addition to the parallel interface pins RD or WR and D7-0 data pins. DMA mode can only be used

CS must stay inactive during a DMA cycle. If CS be-

DACK is ignored and a regular read/write operation is performed. Only one endpoint can be enabled at any

DACK and RD or

www.national.com

MIcrocontroller

Set up DMA

Figure 8. Transmit Operation in Standard DMA Mode

Microcontroller

Set up DMA

Transaction

Read FIFO

16

USB

DMA

DMA

Fill FIFO

Microcontroller

Enable RX

DMA

Fill FIFO

Microcontroller

Enable RX

Figure 9. Receive Operation in Standard DMA Mode

Microcontroller

Enable TX

USB

Transaction

time

time

4.0 Direct Memory Access (DMA) Support (Continued)

4.2 AUTOMATIC DMA MODE (ADMA)

The ADMA mode allows the CPU to transfer independently large bulk or isochronous data streams to or from the USB bus.

The application’s DMA controller, together with the ADMA logic, have the capability to split a large amount of data and transfer it in (FIFO size) packets via the USB. In addition, automatic error handling is performed in order to minimize firmware

intervention. The number of transferred data stream bytes must be of a modulo 64 size. The maximum amount of data is

restricted to 256*64 bytes = 16 Kbytes.

To enable an ADMA transfer, the following steps must be performed:

1. The local CPU programs the DMA controller for fly-by demand mode transfers. In this mode, transfers occur only in response to DMA request via the DRQ pin. The data is read/written from/to the receive/transmit FIFO and written/read into/from local memory during the same bus transaction.

2. The DMA address counter is programmed to point to the destination memory block in the local shared memory, and the

Byte Count register is programmed with the number of bytes in the block to be transferred. The DMA Count register must

be configured with the number of packets to be received or transmitted. Ifrequired, the Automatic Error Handling register

must also be configured at this time.

3. The ADMA enable bit must be set prior to, or at the same time as the DMA enable bit. The DMA enable bit must be

cleared before enabling ADMA mode.

4. The DMA Request Enable bit and DMA Source bits are set in the device.The respective endpoint Enable bit must also

be set.

5. The USB host can now perform USB bulk or isochronous data transfers over the USB bus to the receive FIFO or from

the transmit FIFO. Steps 5 to 7 of the normal DMA mode are perfromed automatically. The ADMA is stopped either when

the last packet is received or when the DMA Count register has reached the value zero.

See Figures 10 and 11 for the transmit and receive sequences using ADMA mode. See Figures 12 and 13 for the basic

DMA write timing and read timing.

USBN9603/USBN9604

Microcontroller

Set up ADMA

Microcontroller

Set up ADMA

DMA

Fill FIFO

Figure 10. Transmit Operation Using ADMA Mode

USB

Transaction

Figure 11. Receive Operation Using ADMA Mode

USB

Transaction

DMA

Read FIFO

DMA

Fill FIFO

USB

Transaction

USB

Transaction

DMA

Read FIFO

USB

Last

Transaction

DMA

Last

Read FIFO

time

time

17

www.national.com

4.0 Direct Memory Access (DMA) Support (Continued)

DRQ

DACK

USBN9603/USBN9604

WR

D7-0

DRQ

DACK

RD

D7-0

Input

Figure 12. DMA Write to USBN9603/4

Output

Figure 13. DMA Read from USBN9603/4

www.national.com

18

Loading...

Loading...