现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

LM1253A

Monolithic Triple 180 MHz I

Integrated Analog On Screen Display (OSD) Generator

2

C CRT Pre-amp With

May 2000

(OSD) Generator

LM1253A Monolithic Triple 180 MHz I

General Description

The LM1253A pre-amp is an integrated high voltage triple

CRT pre-amp and Analog On Screen Display (OSD) generator. The IC is I

rameters necessary to setup and adjust the brightness and

contrast in the CRT display. In addition, it provides a programmable period vertical blanking pulse which is used to

blank the G1.

The LM1253A pre-amp is designed to work in cooperation

with the LM2453 driver, and provides a multiplexed video

signal (VideoPlex) interface to enable the DC clamp levels at

the cathode to be varied in order to set up the CRT bias and

to allow individual adjustment for brightness.

TheAnalogOSDhas a selectable palette allowing a wide selection of colors. The preset level of the OSD can be controlled by I

is internally mixed with the video signal, before the gain section, and thus gives excellent white tracking of the OSD with

the white color point setting of the video.

The Brightness settings are also mixed into the video signal

before the gain matching controls and consequently give excellent white color point tracking with variations in the Brightness control. An active horizontal blanking signal is added to

the video at the output, giving excellent smear performance,

and preventing video content dependent DC bias offsets as

a result of high frequency over shoot.

The OSD horizontal sync and blanking signal is derived from

a positive going flyback pulse. The digital section provides

easy interfacing of this signal with the deflection circuits.

The vertical blanking signal is taken from the vertical sync

signal, and the blanking duration is programmable. This system is highly integrated and requires a minimal number of

external components.

Black level clamping of the signal is carried out directly on

the AC coupled input signal into the high impedance preamplifier input, thus eliminating the need for additional black

level clamp capacitors.

2

C controlled, and allows control of all the pa-

2

C to suit different CRT displays. The OSD signal

The outputs are referenced to a DC level produced by the

LM1253A Pre-amp, and so are guaranteed to provide stable

DC operating levels within the system without the need for

additional external feedback components.

The IC is packaged in an industry standard wide body 28lead DIL molded plastic package.

Features

n 190 two-color ROM based Character Fonts

n 64 four-color ROM based Character Fonts

n Supports a programmable page size with up to 512

characters and line definition codes

n Support for 2 Display Windows (size of each window is

configurable)

n Programmable start position for each Display Window

n Programmable Resolutions: from 512 to 960 pixels per

line in 64 pixel increments

n Programmable Character Height, with automatic height

control with mode change

n Programmable Row Spacing between each display

character row

n Maximum Pixel clock of 92.2 MHz

2

n I

C compatible interface to controlling micro-controller

n Button boxes

n 180 MHz preamplifier with full video signal parametric

control

n VideoPlex

n OSD mixing with 64 out of 512 color mask

programmable selection

™

interface to the LM2453 driver

Intended Applications

n 1280 x 1024 Displays up to 75 Hz requiring OSD

capability

2

C CRT Pre-amp With Integrated Analog On Screen Display

© 2000 National Semiconductor Corporation DS101265 www.national.com

Table of Contents

Block and Connection Diagrams 3

LM1253A

Absolute Maximum Ratings 5

Operating Ratings 5

Electrical Characteristics 5

Test Circuit 7

Test Settings 8

Pin Descriptions 8

Input/Output Schematics 13

National VideoPlex Video System 15

ESD and Arc-Over Protection 16

Pre-Amp Functional Description 17

Horizontal Phase Locked Loop 19

Fault Operation 19

Power Save Mode 19

Schematics 20

PCB Layout 22

OSD Generator Operation 23

Micro-Controller Interface 27

LM1253A Address Map 29

Pre-Amp Interface Registers 30

Two-Color Attribute Table 31

Four-Color Attribute Table 31

Display Page RAM 32

Controller Register Definitions 40

Character Font 51

List of Tables

Table 1 Control Test Settings 7

Table 2 Registers Controlling the Output

Video and Clamp Signal 18

Table 3 Character ROM Address Map 29

Table 4 Display Page RAM Address Map 29

Table 5 OSD Interface Registers 30

Table 6 Pre-Amp Interface Registers 31

Table 7 Two-Color Attribute Registers 31

Table 8 Four-Color Attribute Registers 31

Table 9 Example 1 I

Table 10 Example 2 I

Table 11 Example 3 I

Table 12 PLL Setting (Register 843Eh) 46

Table 13 Attribute Tables to I

2

C Transmission 35

2

C Transmissions 36

2

C Transmissions 39

2

C Address 48

www.national.com 2

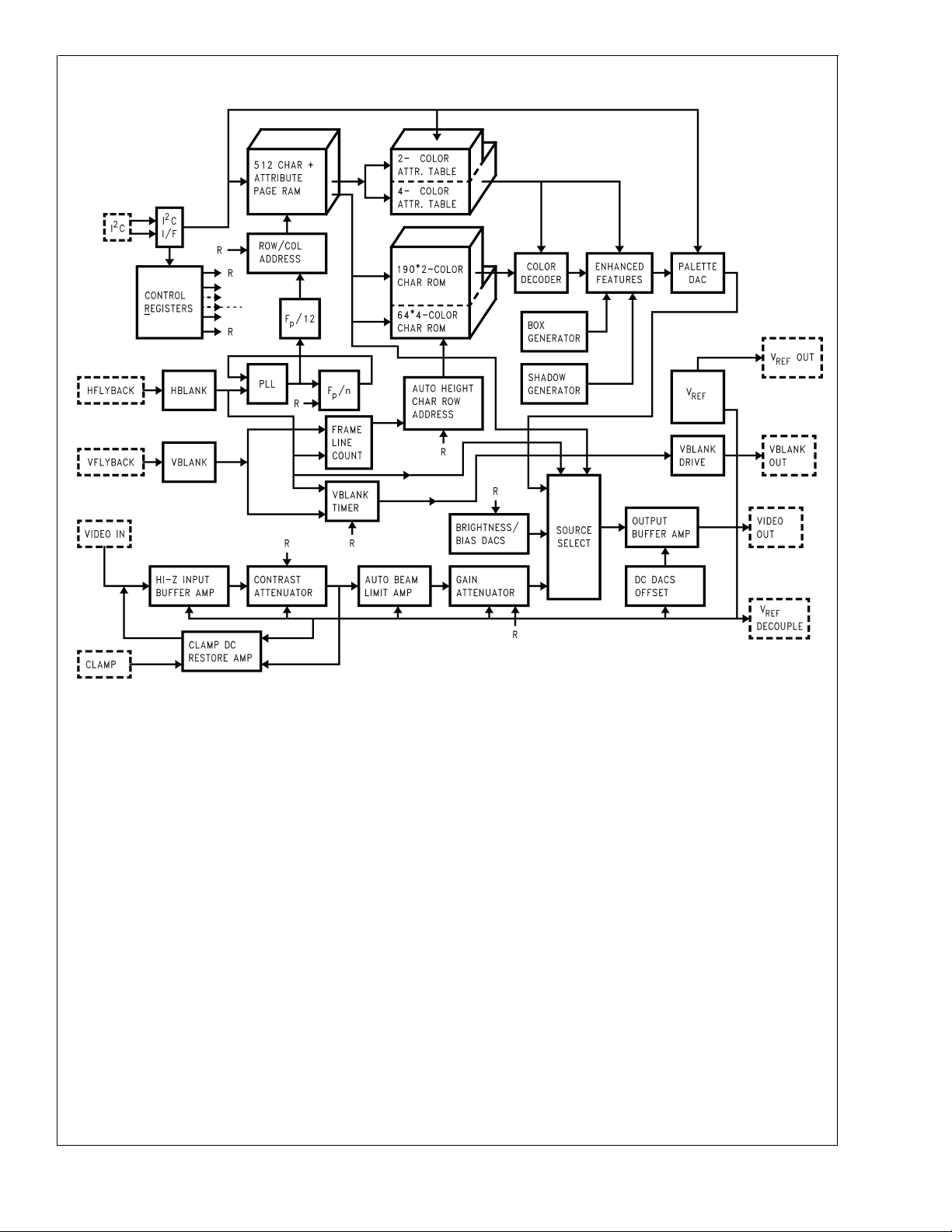

Block and Connection Diagrams

LM1253A

FIGURE 1. Block Diagram

DS101265-1

www.national.com3

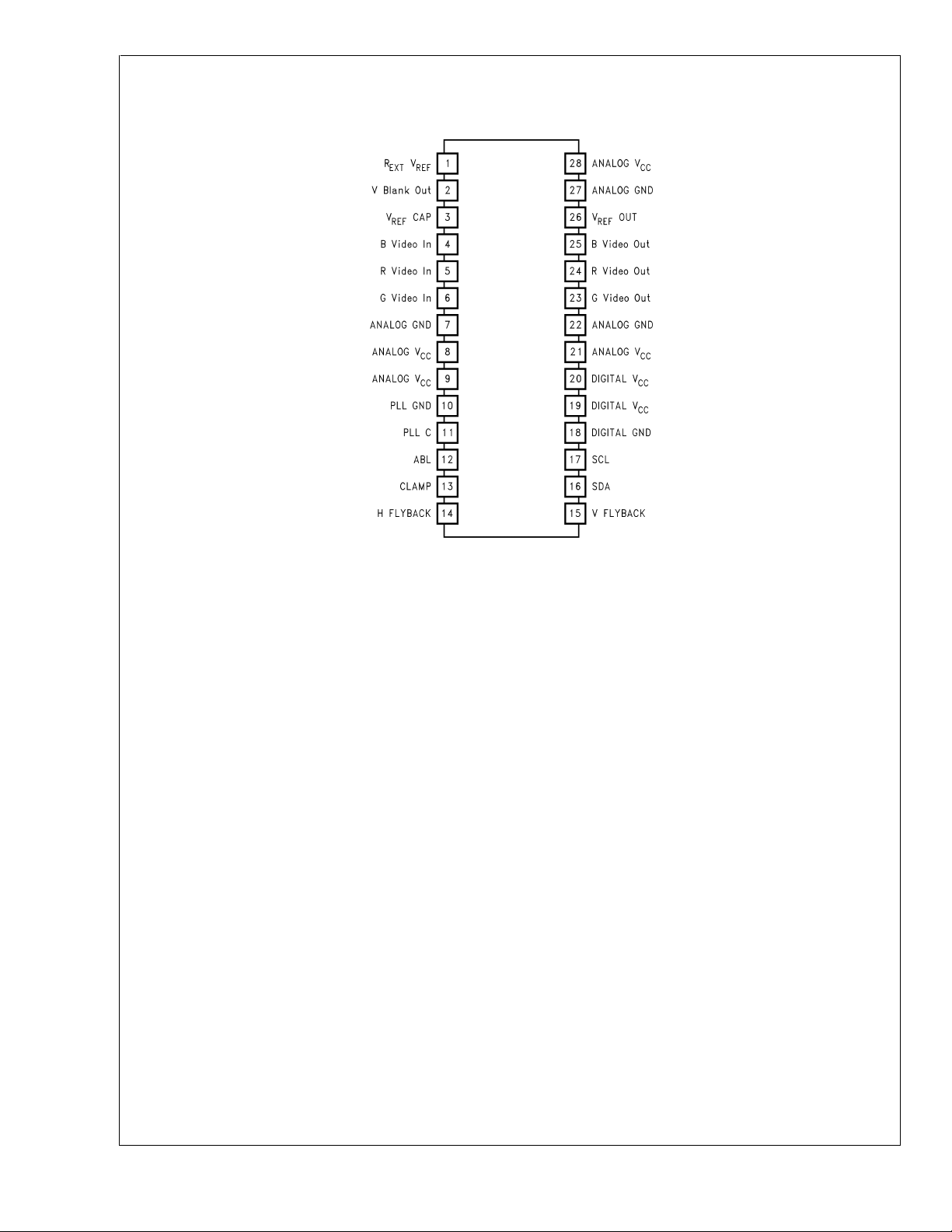

Block and Connection Diagrams (Continued)

LM1253A

28-Lead (0.600’’ wide) Molded Dual-In-Line Package

DS101265-2

Order Number LM1253AN

See NS Package Number N28B

FIGURE 2. Connection Diagram

www.national.com 4

LM1253A

Absolute Maximum Ratings (Notes 1, 3)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Lead Temperature (Soldering,

ESD Tolerance, Human Body Model 3 kV

<

10 sec.) 300˚C

Machine Model 300V

Distributors for availability and specifications.

Supply Voltage, (V

Input Voltage, (V

)6V

CC

)6V

IN

Storage Temperature Range, (T

T

JMAX

) −65˚C to +150˚C

STG

150˚C

Operating Ranges (Note 2)

Temperature Range 0˚C to +70˚C

V

CC

+4.75V to +5.25V

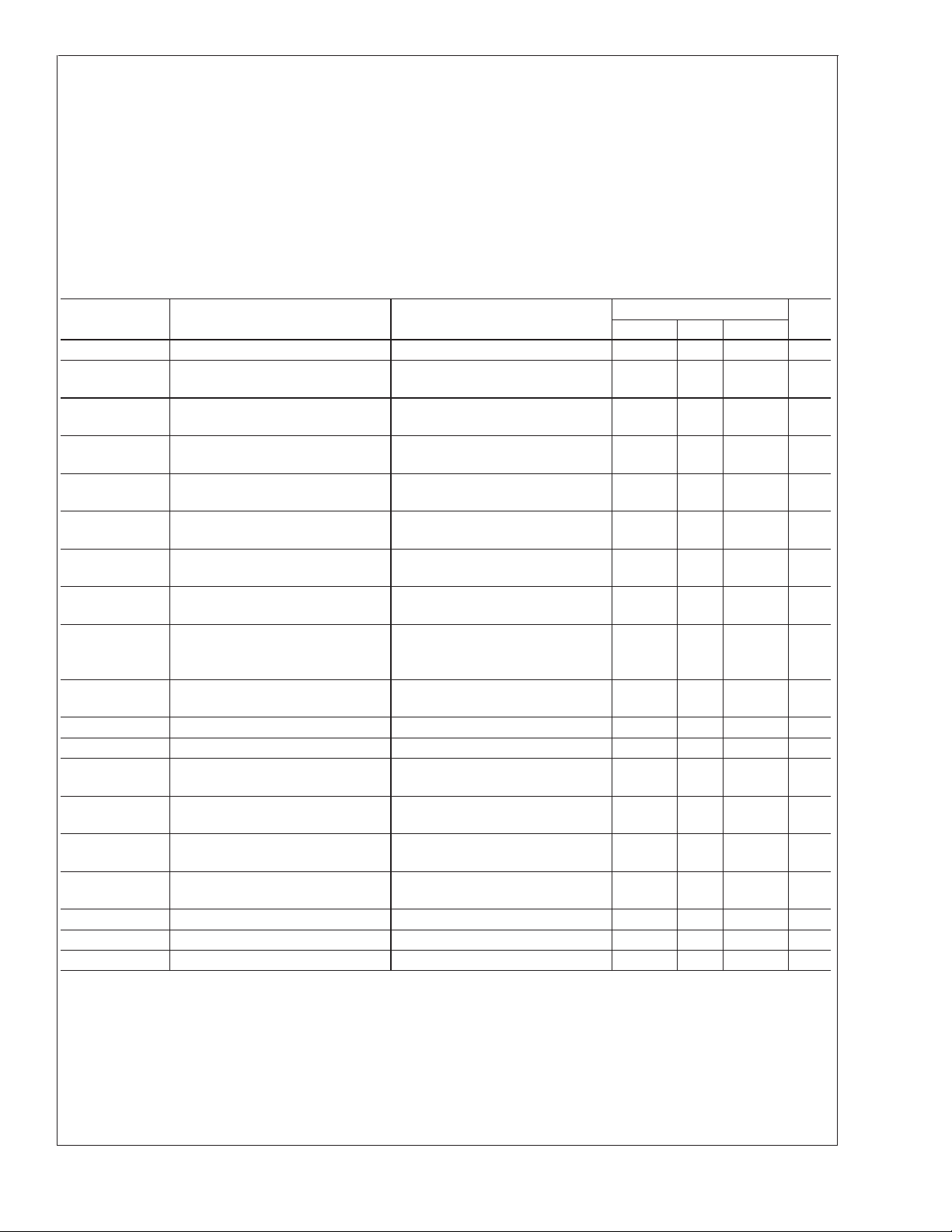

Active Video Signal Electrical Characteristics

(See

Figure 3

Unless otherwise noted: V

Symbol Parameter Conditions

I

CC1MAX

V

OUT BLK

LE Linearity Error Test Setting 3, (Note 4), Triangular

V

OUT WHITE

t

r

t

f

OS

R

OS

F

f(−3dB) Video Amplifier Bandwidth Measured in AC2DC002 Demo

A

CONTRAST

A

GAIN

A

MAX

V

ABL TH

V

ABL RANGE

∆A

ABL

I

ABL MAX

C

IP

V

REF

XT Channel to Channel Crosstalk 10 MHz 40 dB

for Test Circuit, and

CC

Table 1

for Control Test Settings Chart)

= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

ABL=VCC

.

LM1253A

Min Typ Max

Maximum Supply Current Test Setting 1, No Output Load 245 mA

Active Video Black Level Minimum

Output Voltage

Active Video White Level Max

Output Voltage

Rise Time Test Setting 3, (Note 5), 10% to

Fall Time Test Setting 3, (Note 5), 90% to

Rising Edge Overshoot Test Setting 3, (Note 5), AC Input

Falling Edge Overshoot Test Setting 3, (Note 5), AC Input

Test Setting 1, No AC Input Signal

Step Signal Input

Test Setting 3, AC Input Signal

90%, AC Input Signal

10%, AC Input Signal

Signal

Signal

Board. LM1253A set for 40 V

PP

V

REF

1%

2.7 V

3.0 ns

3.0 ns

5%

5%

180 MHz

swing at LM2453 output

Contrast Max-Min Adjustment

Range

Test Setting 2, AC Input Signal

20 dB

Gain Max-Min Adjustment Range Test Setting 2, AC Input Signal 10 dB

Max Signal Voltage Gain Test Setting 2, AC Input Signal 1.8 V/V

Auto Beam Limit Control Upper

Limit

Auto Beam Limit Control Voltage

Range

Auto Beam Limit Control Range Test Setting 3, (Note 6), AC Input

Auto Beam Limit Input Current

Sink Capability

Test Setting 3, (Note 6), AC Input

Signal

Test Setting 3, (Note 6), AC Input

Signal

Signal

Test Setting 3, (Note 6), AC Input

Signal

4.5 V

3V

−10 dB

1mA

Input AC Coupling Capacitor Test Setting 3 4.7 nF

Typical V

Output Voltage 1.55 1.65 1.75 V

REF

Units

V

DC

www.national.com5

Brightness/Bias Signal Electrical Characteristics

(See

Figure 3

Unless otherwise noted: VCC= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

LM1253A

for Test Circuit, and

Table 1

for Control Test Settings Chart)

Symbol Parameter Conditions

V

BLANK MAX

V

BLANK MIN

t

BLK r

t

BLK f

OS

BLK MAX

Maximum Blanking Level Test Setting 1 V

Minimum Blanking Level Test Setting 4 V

Blanking Rise Time Test Setting 1, 10% to 90%, 10 ns

Blanking Fall Time Test Setting 1, 90% to 10%, 10 ns

Maximum Rise or Fall Edge

Overshoot

Test Setting 1, 10% to 90% or

90% to 10%, Settling Time Must

be Less Than 50 ns

OSD Electrical Characteristics

(See

Figure 3

Unless otherwise noted: VCC= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

Symbol Parameter Conditions

V

OSDHIGH MAX

V

OSDHIGH 10

V

OSDHIGH 01

V

OSDHIGH 00

for Test Circuit)

Maximum OSD Level with OSD

Contrast 11

Maximum OSD Level with OSD

Contrast 10

Maximum OSD Level with OSD

Contrast 01

Maximum OSD Level with OSD

Contrast 00

Palette Set at 111. OSD Contrast

Level 11, Test Setting 3

Palette Set at 111. OSD Contrast

Level 10, Test Setting 3

Palette Set at 111. OSD Contrast

Level 01, Test Setting 3

Palette Set at 111. OSD Contrast

Level 00, Test Setting 3

ABL=VCC

.

LM1253A

Min Typ Max

REF

−

0.90

REF

20 %

ABL=VCC

.

LM1253A

Min Typ Max

V

REF

+

0.95

V

REF

+

0.77

V

REF

+

0.59

V

REF

+

0.41

Units

V

V

Units

V

V

V

V

External Interface Signals Electrical Characteristics

(See

Figure 3

Unless otherwise noted: VCC= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

Symbol Parameter Conditions

I

IN−MAX

V

HBLANK TRIG

I

IN+MAX

t

min hflb

t

H

t

PW CLAMP

V

CLAMP L MAX

V

CLAMP H MIN

V

VBLANK HIGH

V

VBLANK LOW

www.national.com 6

for Test Circuit)

Maximum normal forward scan current at

lowest horizontal frequency that input can

−150 µA

withstand

Voltage on H Flyback (Pin 14) which will

Trigger an HBLANK Signal

100V H Flyback Signal

through a 100 kΩ

Resistor

Maximum flyback scan current at 125 kHz

that input can withstand

Minimum Flyback Width 1 µs

Horizontal Period 20 125 kHz

Minimum Clamp Pulse Width 200 ns

Maximum Low Level Clamp Pulse Voltage 1 V

Minimum High Level Clamp Pulse Voltage 3 V

Minimum High Level of Vertical Blank

V

VREF BLANK

<

0.75V V

Output

Maximum Low Level of Vertical Blank

I

VBLANK OUT

= 100 µA V

Output

ABL=VCC

.

LM1253A

Min Typ Max

0.8 V

1.5 mA

REF

+1

REF

−1

Units

V

V

External Interface Signals Electrical Characteristics (Continued)

(See

Figure 3

Unless otherwise noted: VCC= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

Symbol Parameter Conditions

V

CCDET

F

FREE_RUN

V

IL

V

IH

V

OL

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

Note 2: Operating Ranges indicate conditions forwhichthedevice is functional, but do not guarantee specific performance limits. For guaranteed specifications and

test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may

change when the device is not operated under the listed test conditions.

Note 3: All voltages are measured with respect to GND, unless otherwise specified.

Note 4: Linearity Error = 100

Where: The input signal is a 16 step staircase signal waveform with 0.7 V

step

max

step

min

step

ave

Note 5: Input from signal generator: t

Note 6: ABL should provide smooth decrease in gain over the operational range of 0 dB to −5 dB

∆A

= A(V

ABL

for Test Circuit)

VCCUndervoltage Detection Threshold 3.9 V

Free Run HBLANK Frequency 30 60 kHz

Low Level Input Voltage for SDA and SCL

Pins

High Level Input Voltage for SDA and SCL

Pins

Low Level Output Voltage for SDA and SCL

Pins

*

(step

–step

max

is the maximum voltage step at the output

is the minimum voltage step at the output

is the average voltage of the 16 steps at the output.

ABL=VABL MAX GAIN

)–A (V

)/step

min

<

1 ns.

r,tf

ABL=VABL MIN GAIN

ave

ABL=VCC

.

LM1253A

Min Typ Max

1.5 V

3V

3 mA Sink Current

level, subdivided into 16 equal steps, with each step approximately 100 ns in width

P-P

)

0 0.4 V

LM1253A

Units

Test Circuit

Note: 8 pF load includes parasitic capacitance

DS101265-3

FIGURE 3. Test Circuit

www.national.com7

Test Settings

LM1253A

No.

Control

of

Bits

Setting 1

Contrast 7 Max

R,G,B Gain 7 Max

Brightness 8 Max

R,G,B Bias 8 Max

DC Offset 3 Min

Pedestal Offset 3 Max

Pin Descriptions

Pin 1—R

EXTVREF

pin to set up the internal current sources. The LM1253A is

optimized for this value of resistor. A DC voltage only will be

on this pin. Decreasing the value of this resistor will increase

supply current while degrading performance; increasing the

value of the resistor will decrease supply current and also

degrade the performance. Do not place the resistor close to

sources of heat such as the CRT driver.

components connected to pin 1,

schematic of pin 1.

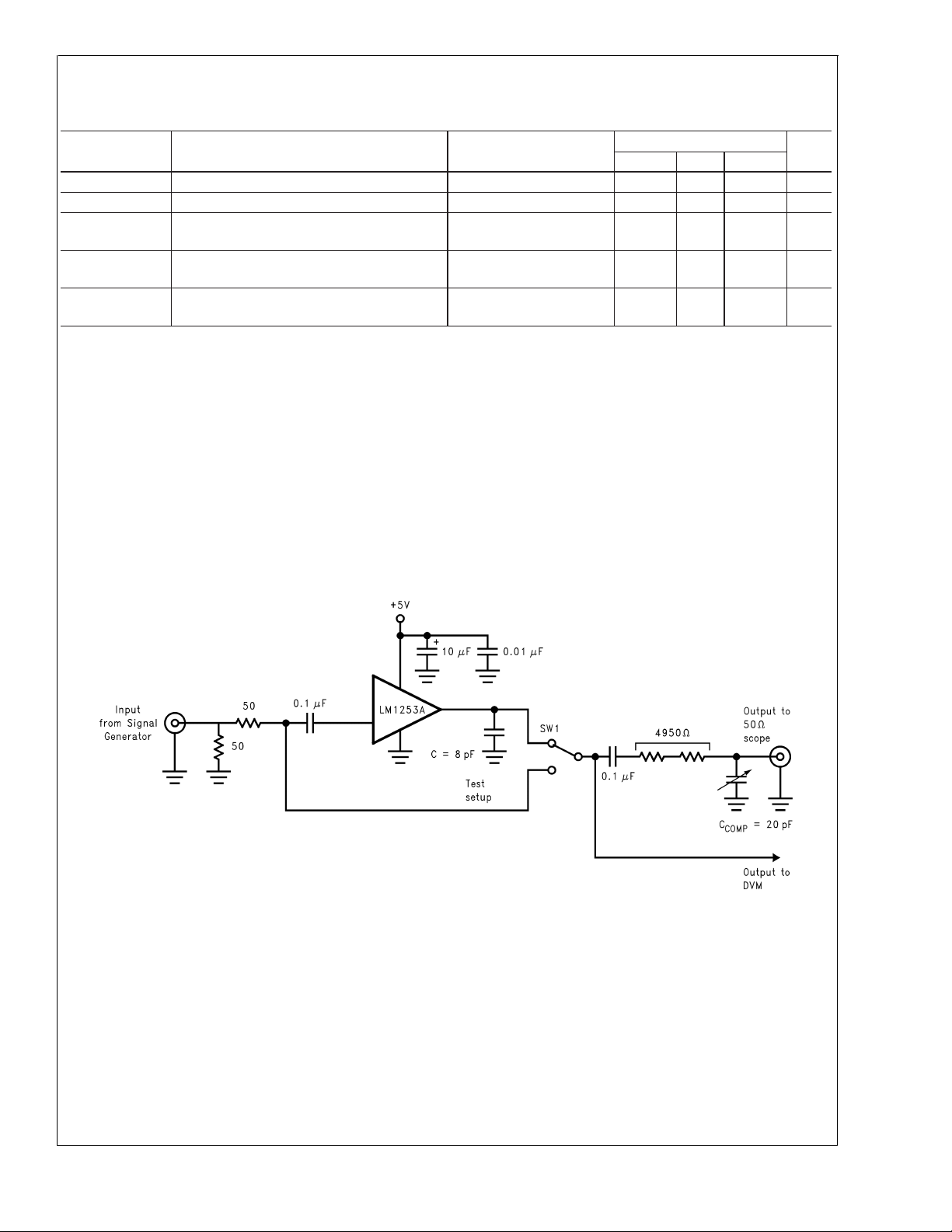

Pin 2—V Blank Out This pin supplies a variable width,

negative going pulse at the vertical rate to the CRT Driver. V

Blank is triggered from the signal on pin 15, which comes

from the vertical flyback. The CRT Driver supplies the pull up

for this pin. The width of this pulse is set by the value in the

VBLANKDUR register (8403h).

sulting V Blank Out pulse with various values in register

8403h. The trace connecting pin 2 of the LM1253A to the

LM2453 must be kept away from the output circuitry of the

LM2453.

Figure 12

Figure 29

shows the internal schematic of pin 2.

A10kΩ1% resistor is connected to this

Figure 29

Figure 11

shows the internal

Figures 4, 5, 6

shows the external schematic of pin 2,

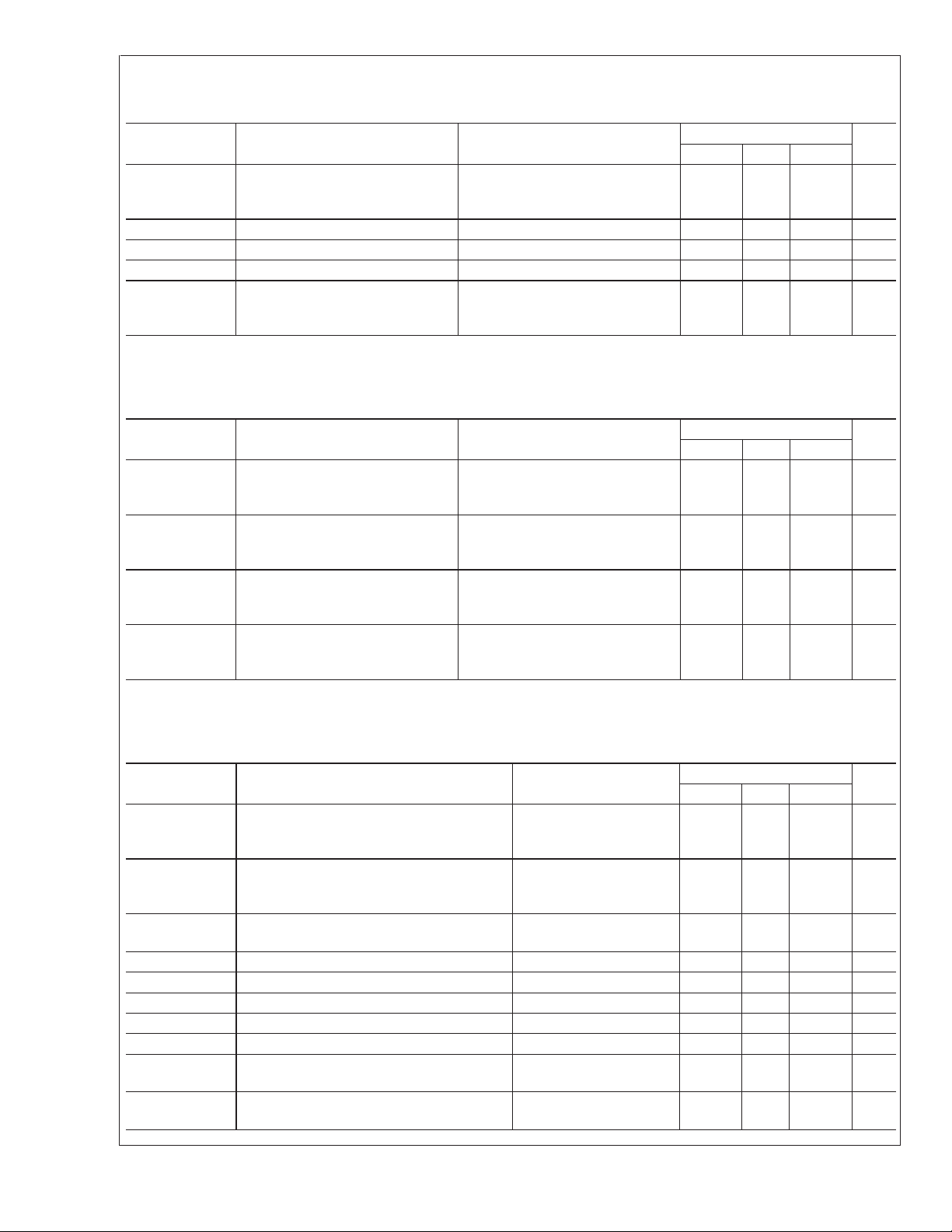

TABLE 1. Control Test Settings

Basic

Test

Basic

Test

Setting 2

Max

(Hex 7F)

(Hex 7F)

Max

(Hex 7F)

(Hex 7F)

Max

(Hex FF)

(Hex FF)

Max

(Hex FF)

(Hex FF)

Max

(Hex 07)

(Hex 00)

Max

(Hex 07)

(Hex 07)

shows the

show the re-

Basic

Test

Setting 3

Max

(Hex 7F)

Set for 1 V

P-P

on all Channels

Min

(Hex 00)

Min

(Hex 00)

Min

(Hex 07)

Min

(Hex 00)

FIGURE 5. V Blank = 63

Basic

Test

Setting 4

Max

(Hex 7F)

Max

(Hex 7F)

Min

(Hex 00)

Min

(Hex 00)

Min

(Hex 07)

Min

(Hex 00)

DS101265-8

DS101265-7

FIGURE 4. V Blank = 10

www.national.com 8

DS101265-9

FIGURE 6. V Blank = 127

Pin 3—V

pin to decouple V

nel circuits to make the VideoPlex signal.

the external schematic of pin 3,

Cap A 0.1 µF capacitor is placed close to this

REF

REF.VREF

is used by the three video chan-

Figure 29

Figure 13

shows the internal

shows

schematic of pin 3.

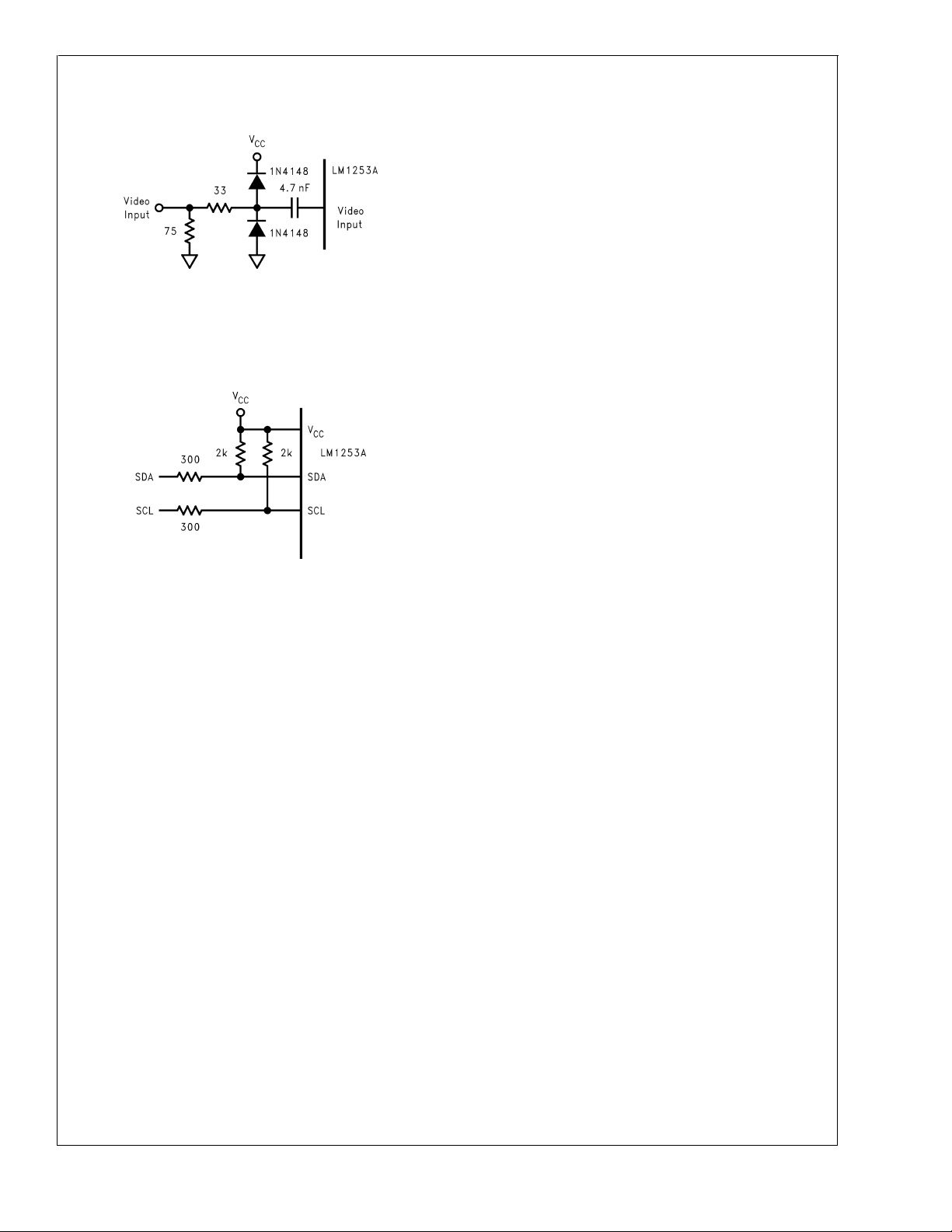

Pin 4, 5, 6 —Blue, Red, and Green Video In The red, blue,

and green video signal is AC coupled into these pins. The

value of the capacitors is very important as they also serve

Pin Descriptions (Continued)

as the DC clamp control capacitors. A value of 0.0047 µF is

used in the demo boards. The schematic shown in

which has a series resistance of 33Ω and clamp diodes to

V

and ground should be used to protect the LM1253A

CC

from ESD. A good ground should be between the input connector and the LM1253A. The video traces should be kept

short.

and 6,

Figure 29

Figure 14

shows the external schematic of pins 4, 5,

shows the internal schematic of pins 4, 5,

and 6.

Pin 7 — Analog Ground Ground for the video section of the

LM1253A. All ground pins of the LM1253A should be connected together by a ground plane under the LM1253A. See

Figure 31

, which shows a sample layout.

Pin 8 —Analog Supply 5V supply for the video section of

the preamp. A 0.1 µF capacitor should be connected between pin 7 and pin 8, as close as possible to the LM1253A.

A 100 µF capacitor should also be connected between pin 7

and pin 8.

Pin 9— Analog Supply 5V supply for the PLL section of the

LM1253A. A 0.1 µF capacitor should be connected between

pin 9 and pin 7, as close as possible to the LM1253A.

Pin 10—PLL Ground Ground for the PLL section of the

LM1253A. Only the PLL components connected to pin 11

should be connected to this ground pin. Pin 10 should also

be connected to the ground plane under the LM1253A. All

ground pins of the LM1253A should be connected together

by a ground plane under the LM1253A. See

shows a sample layout.

Pin 11—PLL C A resistor capacitor network is connected to

this pin. It is used to convert the charge current of the charge

pump of the PLL into a voltage that is used to control the

variable oscillator. These components should be located

very close to the LM1253A with a short ground trace to pin

10.

The recommended values are R28 = 6.2 kΩ, C23 = 0.1 µF,

and C33 = 2.2 nF. When these component values are used

the range and gain values in

Table 12

can be loaded into

register 843Eh.

Figure 29

Figure 31

, which

An example layout is shown in

the external schematic of pin 11,

Figure 31,Figure 29

Figure 15

shows the inter-

shows

nal schematic.

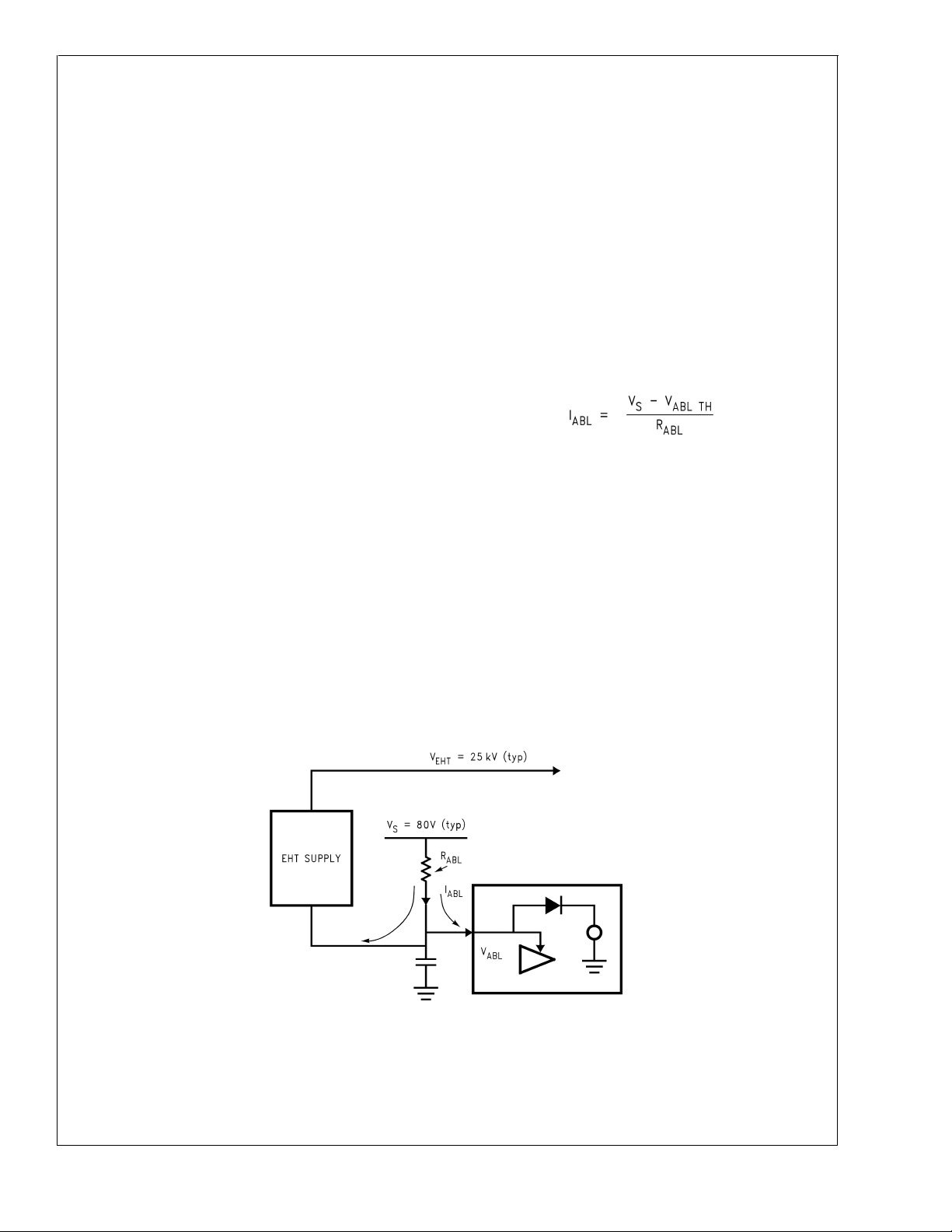

Pin 12—ABL The Auto Beam Limit control reduces the gain

of the video amplifiers in response to a control voltage proportional to the CRT beam current. The ABL acts on all three

channels in an identical manner.This is required for CRT life

and X-ray protection. The beam current limit circuit application is as shown in

Figure 7

: when no current is being drawn

by the EHT supply, current flows from the supply rail through

the ABL resistor and into the ABL input of the IC. The IC

clamps the input voltage to a low impedance voltage source

(the 5V supply rail).

When current is drawn from the EHT supply, the current

passes through the ABL resistor, and reduces the current

flowing into the ABL input of the IC.

When the EHT current is high enough, the current flowing

into the ABL input of the IC drops to zero. This current level

determines the ABL threshold and is given by:

Where:

V

is the external supply (usually the CRT driver supply rail,

S

about 80V)

V

R

I

is the threshold ABL voltage of the IC

ABL TH

is the ABL resistor value

ABL

is the ABL limit

ABL

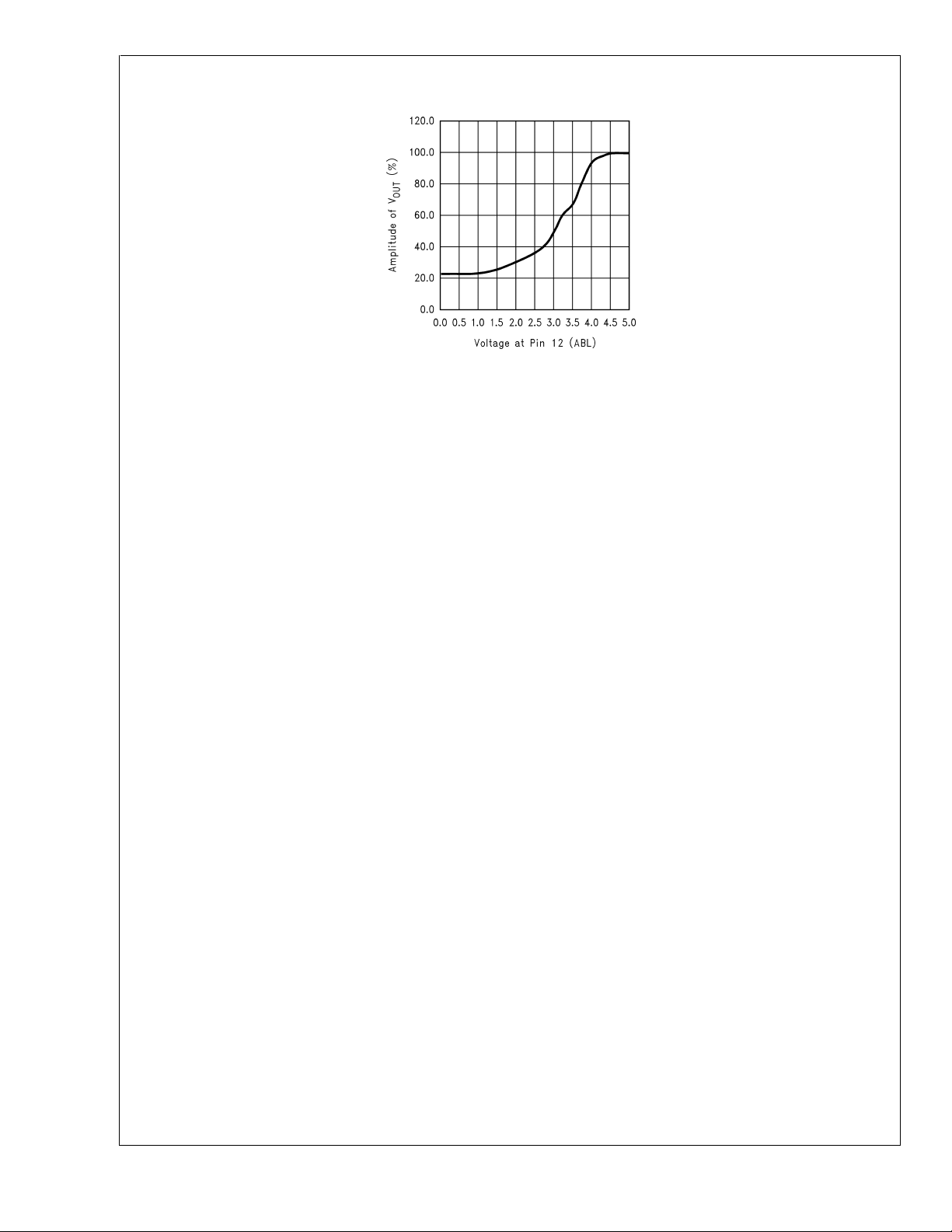

When the voltage on the ABL input drops below the ABL

threshold of the pre-amp, the gain of the pre-amp decreases,

which is shown in

Figure 8

, which reduces the beam current.

Afeedback loop is thus established which acts to prevent the

average beam current exceeding I

Figure 29

shows the external schematic of pin 12,

ABL

.

Figure 16

shows the internal schematic.

LM1253A

FIGURE 7. ABL

DS101265-12

www.national.com9

Pin Descriptions (Continued)

LM1253A

FIGURE 8. Effect of ABL Voltage on V

Pin 13—Clamp A positive going clamp signal is input on

this pin. Using this signal black level clamping of the video is

carried out directly on the input video that is AC coupled into

the high impedance preamplifier input, thus eliminating the

need for additional black level clamp capacitors.

shows the external schematic of pin 13,

internal schematic. An optional capacitor to ground may be

needed if noise interferes with the clamp signal.

Figure 17

Figure 29

shows the

DS101265-70

OUT

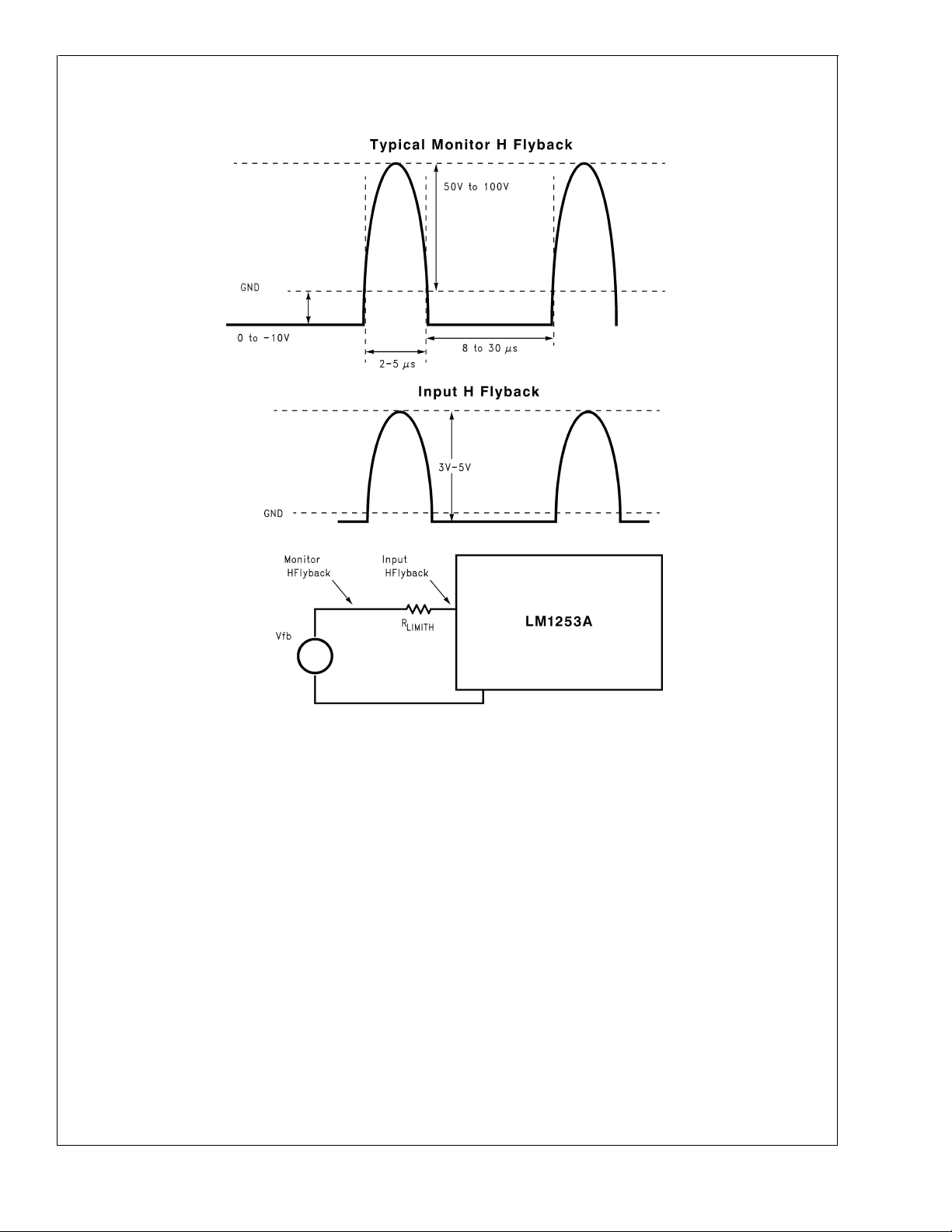

Pin 14—H Flyback H Flyback is an analog signal input from

the monitor horizontal scan. HBLANK is a digital signal derived from the horizontal flyback pulse as shown in

Figure 9

An optional capacitor and/or resistor to ground may be

needed if noise interferes with the H Flyback signal.

The horizontal flyback from the monitor must be a clean signal. There should be no ringing or other noise on the flyback.

.

www.national.com 10

Pin Descriptions (Continued)

LM1253A

FIGURE 9. H Flyback Input Pulse

R

is set to limit the input current into the IC to a maxi-

LIMITH

mum value of +1 mA during flyback and −150 µA during normal forward scan. For example if an h flyback with a peak of

100V is used, R

= 100 kΩ.The internal input imped-

LIMITH

ance of pin 14 is low to limit the maximum voltage swing at

the input to within the supply rail and ground. The IC interface circuit creates a digital signal from this waveform, which

is used as the blanking signal, and termed HBLANK. This

signal is used by the video amplifier for blanking the video

and by the OSD generator as the horizontal sync reference

for the PLL.

Loss of the horizontal flyback pulse implies that the monitor

is not scanning, and therefore no image is being displayed.

The HBLANK pulse is still required by the LM2453 CRT

driver in order to maintain correct bias conditions in the CRT

until the power supplies are switched off, but video will be set

at black level to prevent front of screen problems, using the

NO_VID line. See also the

Loss of Horizontal Flyback

sec-

tion.

Figure 29

shows the external schematic of pin 14,

Figure 18

shows the internal schematic.

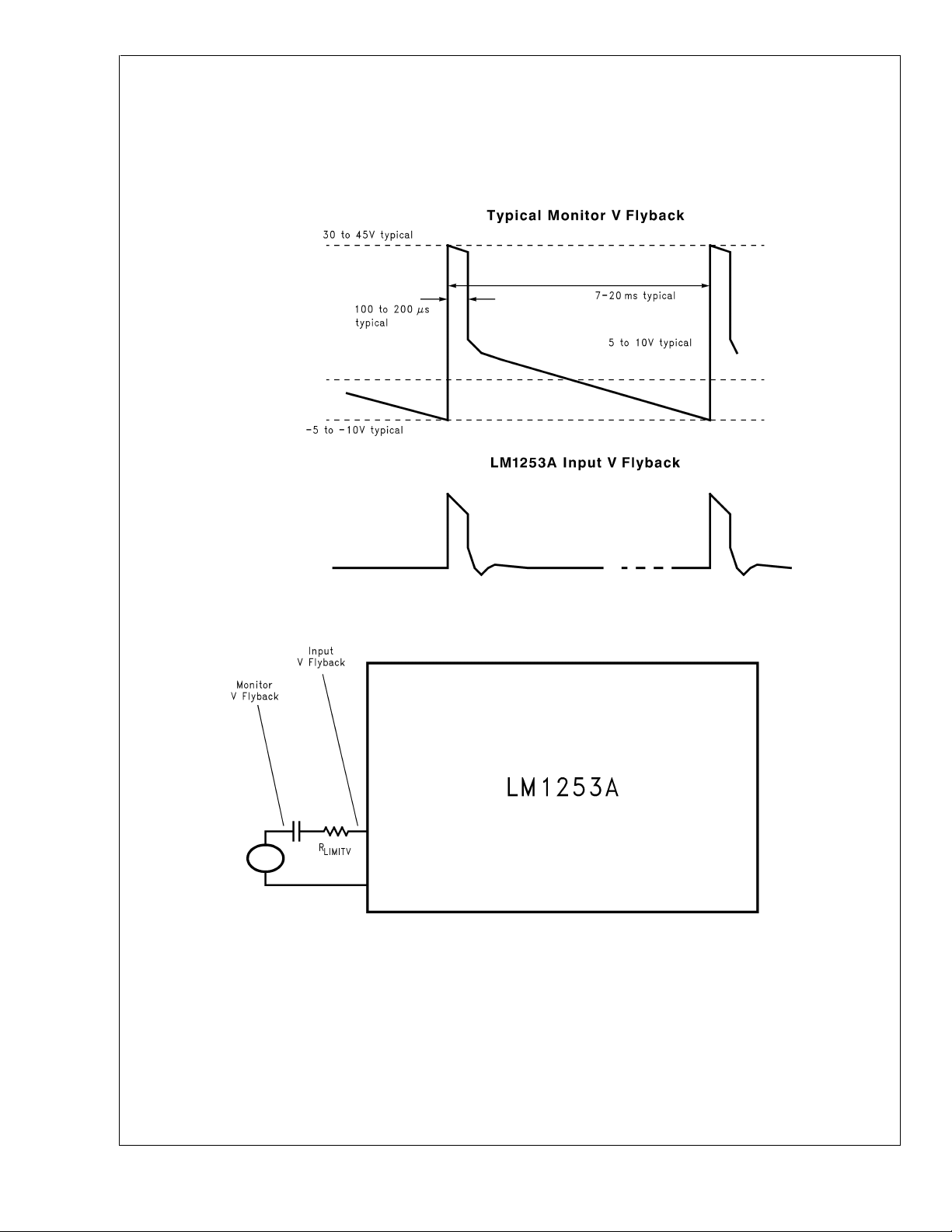

Pin 15—V Flyback This is an analog signal from the moni-

tor vertical scan. The analog waveform is AC coupled and

fed to the input of the IC via a current limiting resistor to pre-

DS101265-13

vent the positive and negative excursions of the signal causing excessive current or voltage swing at the input to the IC.

See

R

LIMITV

Figure 10

.

is set to limit the maximum input voltage swing into

the IC to less than the supply rails. The input to the IC is

positive edge triggered, and ignores the falling edge. Because of horizontal rate noise on the waveform, the input

buffer incorporates hysteresis, triggering at a positive going

threshold of V

and a negative going threshold of V

VTH+

VTH

The input buffer produces a digital signal VSTART which is

used to start the VBLANK timer. The positive rising edge of

VSTART sets a counter timer, which counts horizontal periods using the HBLANK signal. The timer resets VBLANK

when it reaches the value preset in the register VCOUNT

(set by the micro-controller over I

2

C). While the output

VBLANK is active, an AND function prevents any further

transitions on the VSTART waveform from retriggering the

counter.

The positive edge of the VSTART signal is initially transmitted through to VBLANK through an OR function, as the timer

may take up to one horizontal line period to begin timing the

duration of the pulse. The application must ensure that the

.

www.national.com11

Pin Descriptions (Continued)

VFLYBACKvertical flyback pulse is kept high during that ini-

LM1253A

tial period to prevent the output VBLANK from switching between high and low states.

Loss of vertical flyback pulse implies that the monitor is not

scanning, and therefore no image is being displayed. The

VBLANK pulses are still required by the LM2453 CRT driver

in order to maintain correct bias conditions in the CRT until

the power supplies are switched off, but video will be set at

black level to prevent front of screen problems, using the

NO_VID line. See also the

section.

Figure 19

Figure 29

shows the external schematic of pin 15,

shows the internal schematic.

Loss of Vertical Flyback Pulse

FIGURE 10. Vertical Flyback Input Pulse

Pin 16—SDA The I

2

C data line. A pull up resistor of about

2kΩshould be connected between this pin and +5V.A300Ω

resistor should be connected in series with the data line to

protect the IC against arcing.

schematic of pin 16,

Pin 17—SCL The I

Figure 20

2

C clock line. A pull up resistor of about

Figure 29

shows the external

shows the internal schematic.

2kΩshould be connected between this pin and +5V.A300Ω

resistor should be connected in series with the clock line to

protect the IC against arcing.

schematic of pin 17,

www.national.com 12

Figure 20

Figure 29

shows the external

shows the internal schematic.

DS101265-5

Pin 18 — Digital Ground Ground for the OSD section of the

LM1253A. All ground pins of the LM1253A should be connected together by a ground plane under the LM1253A. See

Figure 31

, which shows a sample layout.

Pin 19 —Digital Supply 5V supply for the OSD section of

the LM1253A. A 0.1 µF capacitor should be connected between pin 18 and pin 19, as close as possible to the

LM1253A.

LM1253A

Pin Descriptions (Continued)

Pin 20 —Digital Supply 5V supply for the OSD section of

the LM1253A. Pins 19 and 20 should be tied together under

normal operating conditions.

Pin 21—Analog Supply 5V supply for the video section of

the preamp. A 0.1 µF capacitor should be connected between pin 21 and pin 22, as close as possible to the

LM1253A.

Pin 22—Analog Ground Ground for the video section of

the LM1253A. All ground pins of the LM1253A should be

connected together by a ground plane under the LM1253A.

See

Figure 31

Pin 23, 24, and 25— Green, Red, and Blue Video Out

These pins output the red, green, and blue video information

in the VideoPlex format. These pins are connected to the

LM2453 using as short of traces as possible. An inductor

should be in series with the trace between the preamp and

CRT driver. The value of this inductor depends on the board

layout.

23, 24, and 25,

Pin 26—V

referenced to is output on this pin. A 0.1 µF capacitor should

be connected between this pin and ground and be located

close to the LM1253A. This pin is connected to the V

of the LM2453. A 0.1 µF capacitor also needs to be connected very close to the LM2453. A 100 µF capacitor should

also be connected to this trace.

ternal schematic of pin 26,

schematic.

Pin 27—Analog Ground Ground for the band gap reference section of the LM1253A. All ground pins of the

LM1253A should be connected together by a ground plane

under the LM1253A. See

layout.

Pin 28 — Analog Supply 5V supply for the band gap reference section of the preamp. A 0.1 µF capacitor should be

connected between pin 27 and pin 28, as close as possible

to the LM1253A. See

out.

, which shows a sample layout.

Figures 29, 30

REF

show the external schematic of pins

Figure 21

shows the internal schematic.

Out The voltage that the VideoPlex signal is

Figures 29, 30

Figure 31

Figure 31

Figure 22

, which shows a sample lay-

shows the internal

, which shows a sample

pin

REF

show the ex-

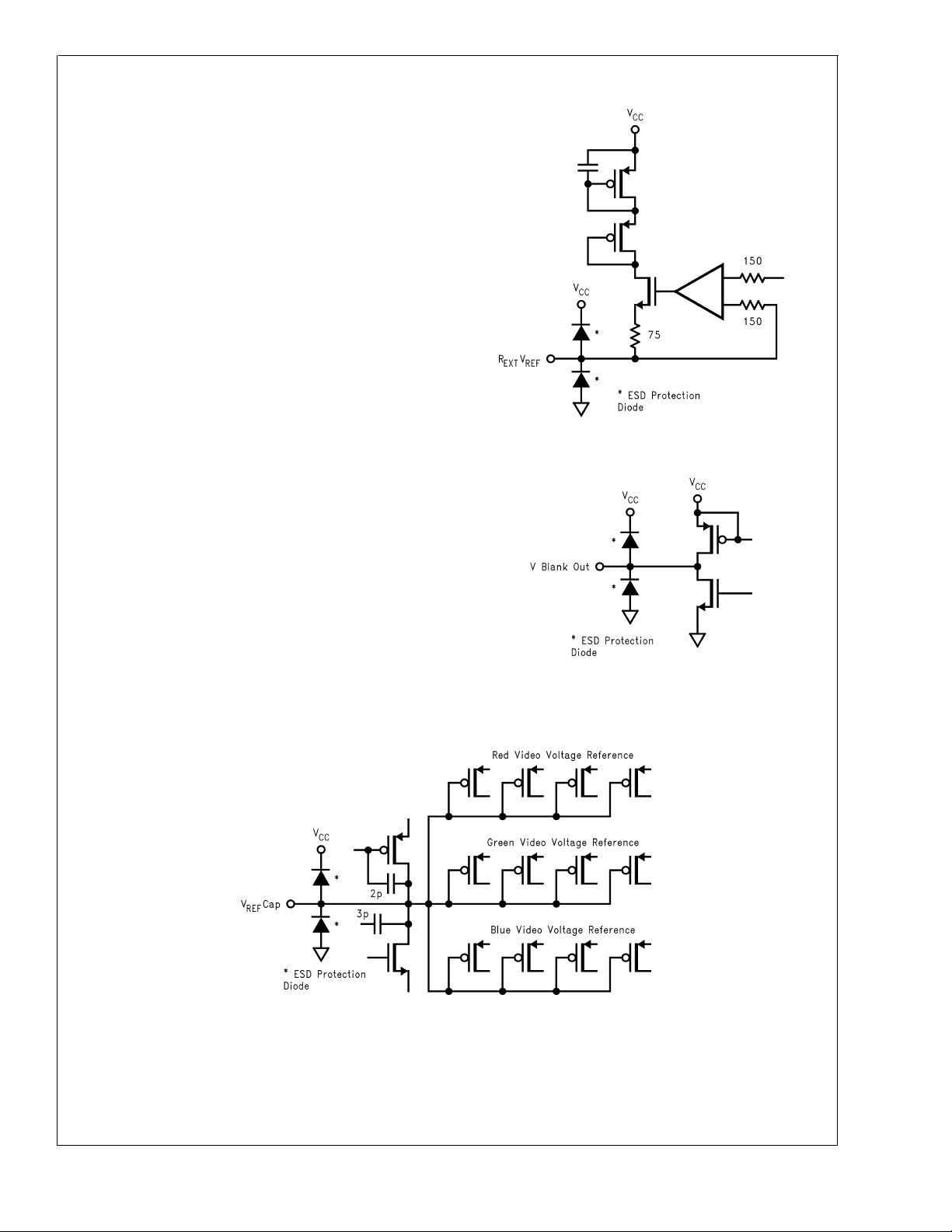

Input/Output Schematics

FIGURE 11. Pin 1 (R

FIGURE 12. Pin 2 (V Blank Out)

EXTVREF

DS101265-14

)

DS101265-15

FIGURE 13. Pin 3 (V

REF

DS101265-16

Cap)

www.national.com13

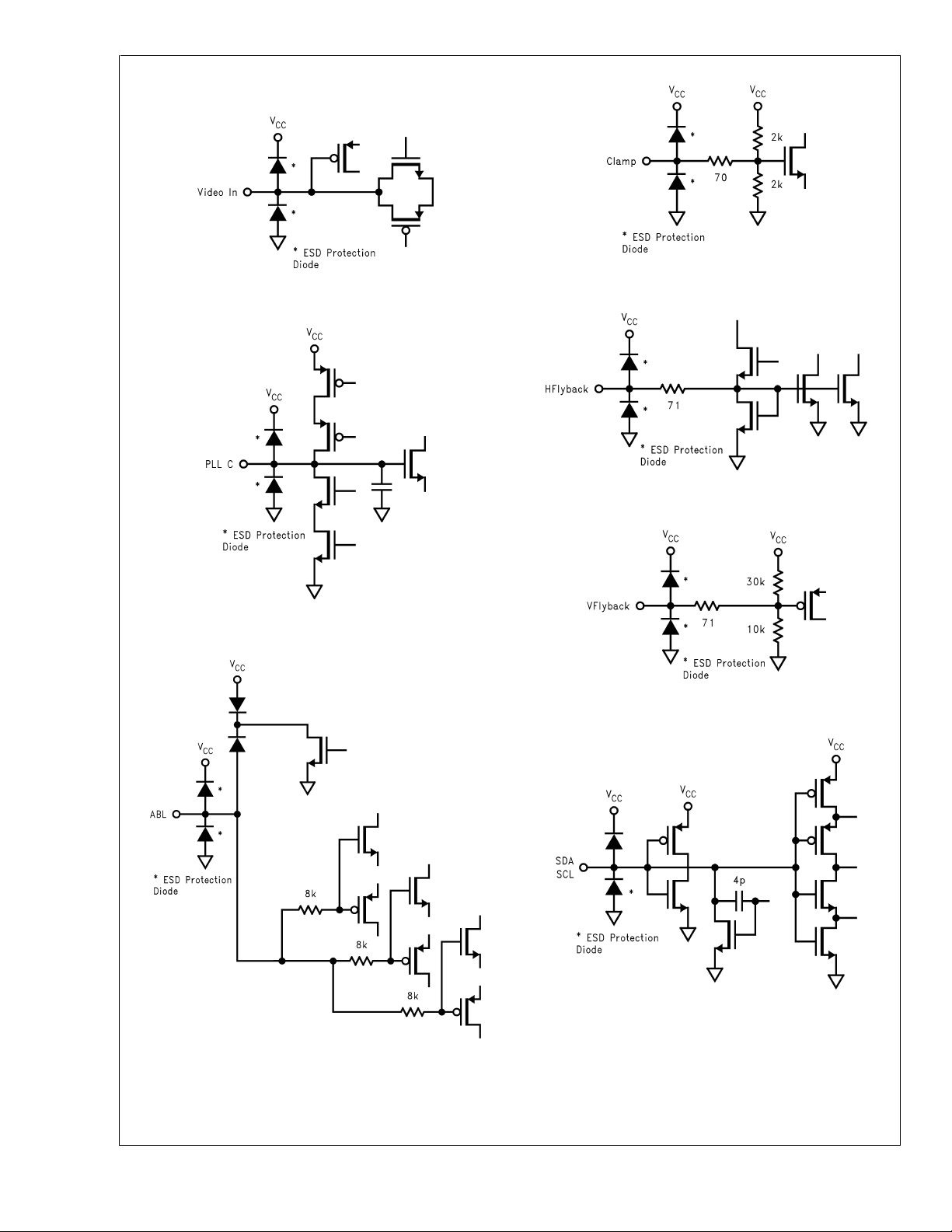

Input/Output Schematics (Continued)

LM1253A

DS101265-17

FIGURE 14. Pins 4, 5, and 6 (Video In)

DS101265-18

FIGURE 15. Pin 11 (PLL C)

DS101265-20

FIGURE 17. Pin 13 (Clamp)

DS101265-21

FIGURE 18. Pin 14 (H Flyback)

DS101265-22

FIGURE 19. Pin 15 (V Flyback)

DS101265-19

FIGURE 16. Pin 12 (ABL)

www.national.com 14

DS101265-23

FIGURE 20. Pins 16 and 17 (SDA and SCL)

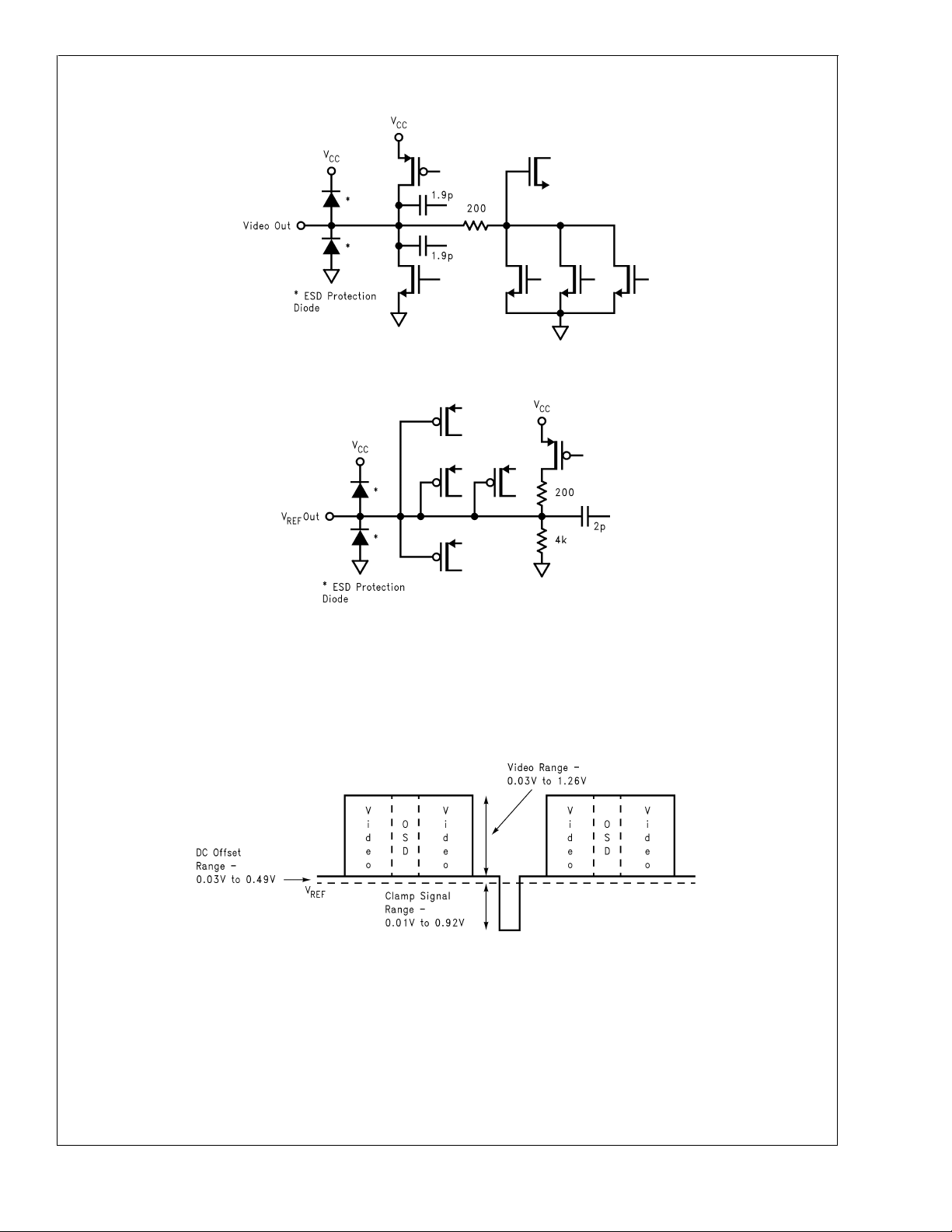

Input/Output Schematics (Continued)

FIGURE 21. Pins 23, 24, and 25 (Video Out)

LM1253A

DS101265-24

FIGURE 22. Pin 26 V

National VideoPlex Video System

The LM1253A CRT Pre-Amp in conjunction with the LM2453

CRT driver uses the National VideoPlex multiplexed video

FIGURE 23. National VideoPlex Video Signal (Pre-Amp Output)

The response of the LM2453 CRT driver to the VideoPlex

signal from the LM1253A Pre-Amp is shown in

Note that there are two sections in the video signal; the video

information is above V

and the clamp information is be-

REF

Figure 24

DS101265-25

Out

REF

signal to send the video signal and DC clamp level from the

pre-amp to the CRT driver. The basic signal scheme is

shown in

low V

.

LM2453 for an arbitrary video waveform from the LM1253A

is shown in

Figure 23

. The signals on the video out and clamp pins of the

REF

.

Figure 25

DS101265-26

.

www.national.com15

National VideoPlex Video System (Continued)

LM1253A

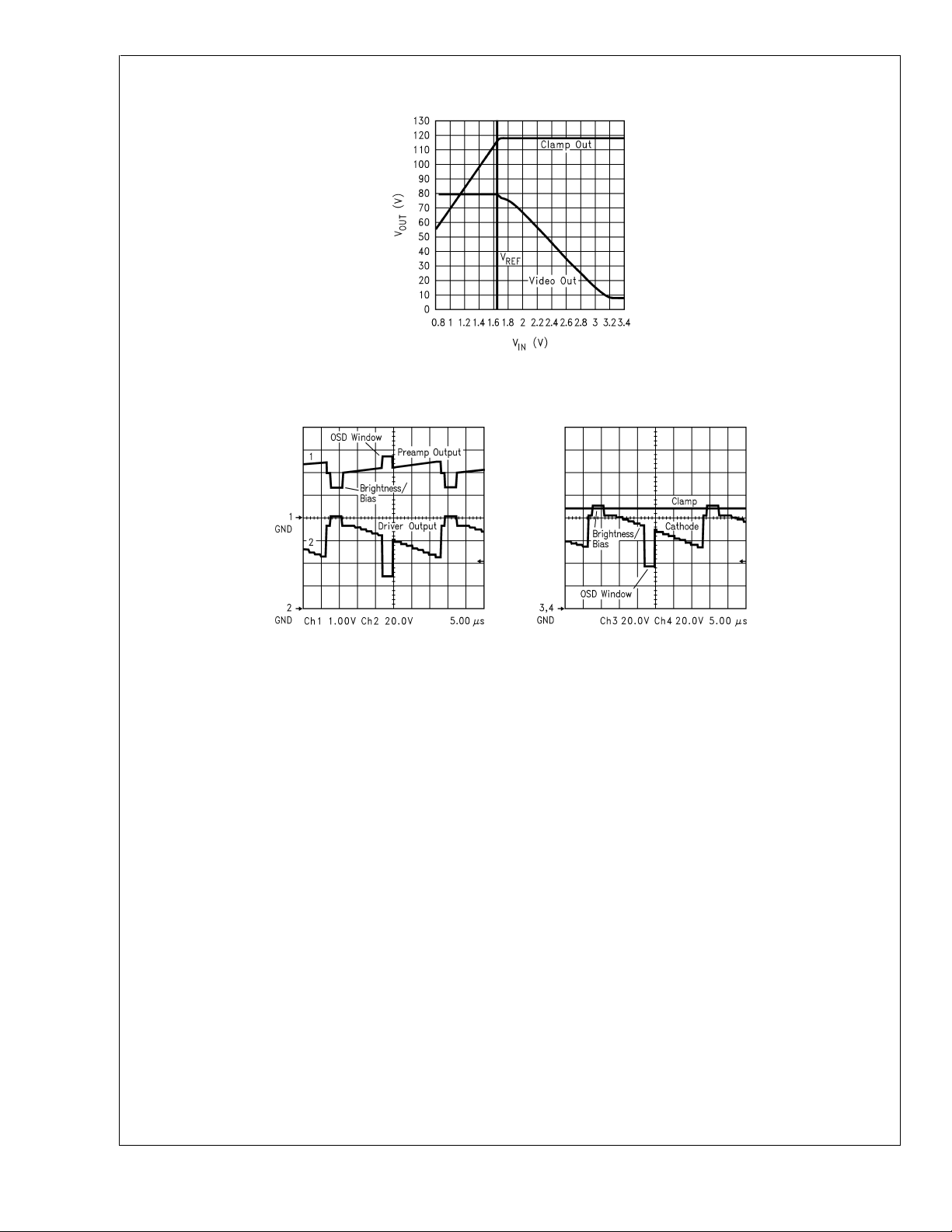

FIGURE 24. DC I/O Transfer Characteristics for the LM2453 CRT Driver

(Test Conditions: V

REF

= 1.65V, V

DS101265-27

= 80V, VBB= 8V)

CC1

FIGURE 25. LM2453 Input and Output Waveforms

ESD and Arc-Over Protection

The LM1253A incorporates full ESD protection with special

consideration given to maximizing arc-over robustness. The

monitor designer must still use good circuit design and PCB

layout techniques. The human body model ESD susceptibility of the LM1253A is 2 kV,however many monitor manufacturers are now testing their monitors to the level 4 of the IEC

801-2 specification which requires the monitor to survive an

8 kV discharge. External ESD protection is needed to survive this level of ESD. The LM1253A provides excellent protection against both ESD and arc-over, but this is not a substitute for good PCB layout.

Figure 26

LM1253A. This provides the best protection against ESD.

When this protection is combined with good PCB layout the

LM1253A will easily survive the IEC 801-2 level 4 testing

(8 kV ESD). It is strongly recommended that the protection

diodes be added as shown in

has a maximum capacitance of 4 pF which will have little effect on the response of the video system due to the low impedance of the input video.

The ESD cells of the LM1253A also provide good protection

against arc-over, however good PCB layout is necessary.

The LM1253A should not be exposed directly to the voltages

that may occur during arc-over. The main vulnerability of the

LM1253A to arc-over is though the ground traces on the

PCB. For proper protection all ground connections associated with the LM1253A, including the grounds to the bypass

show the recommended input protection for the

Figure 26

. The 1N4148 diode

DS101265-28

capacitors, must have short returns to the ground pins. Asignificant ground plane should be used to connect all the

LM1253A grounds.

Figure 31

, which shows the demo board

layout, is an excellent example of an effective ground plane.

The list below should be followed to ensure a PCB with good

grounding:

All grounds associated with the LM1253A should be con-

•

nected together through a large ground plane.

CRT driver ground is connected to the video pre-amp

•

ground at one point.

CRTand arc protection grounds are connected directly to

•

the chassis or main ground. There is no arc-over current

flow from these grounds through the LM1253A grounds.

Input signal traces for SDA, SCL, H Flyback, V Flyback,

•

Clamp should be kept away from the LM2453 and all

traces that an arc can travel on.

Output signal traces of the LM1253A (video, V

•

V

) should be kept away from traces that carry the out-

REF

BLANK

put signals of the LM2453.

If any one of the above suggestions is not followed the

LM1253A may become more vulnerable to arc-over. Improper grounding is by far the most common cause of a

video pre-amp failure during arc-over.

,

www.national.com 16

LM1253A

ESD and Arc-Over Protection

(Continued)

DS101265-29

FIGURE 26. Recommended Video Input ESD Protection

2

The I

C specification recommends that the SDA and SCL

pins should be protected from arc-over.This is done by adding a resistor in series with each pin.

the resistors are connected to the SDA and SCL lines.

FIGURE 27. Recommended Arc-Over Protection for

SDA and SCL Pins

Figure 27

DS101265-30

shows how

Pre-Amp Functional Description

Figure 1

video signal is input to the LM1253A through the circuit

shown in

rectly on the AC coupled input signal at the input of the high

impedance buffer amplifier, thus eliminating the need for

black level clamp capacitors. The following sections then

modify the input video signal:

•

•

•

•

•

•

•

•

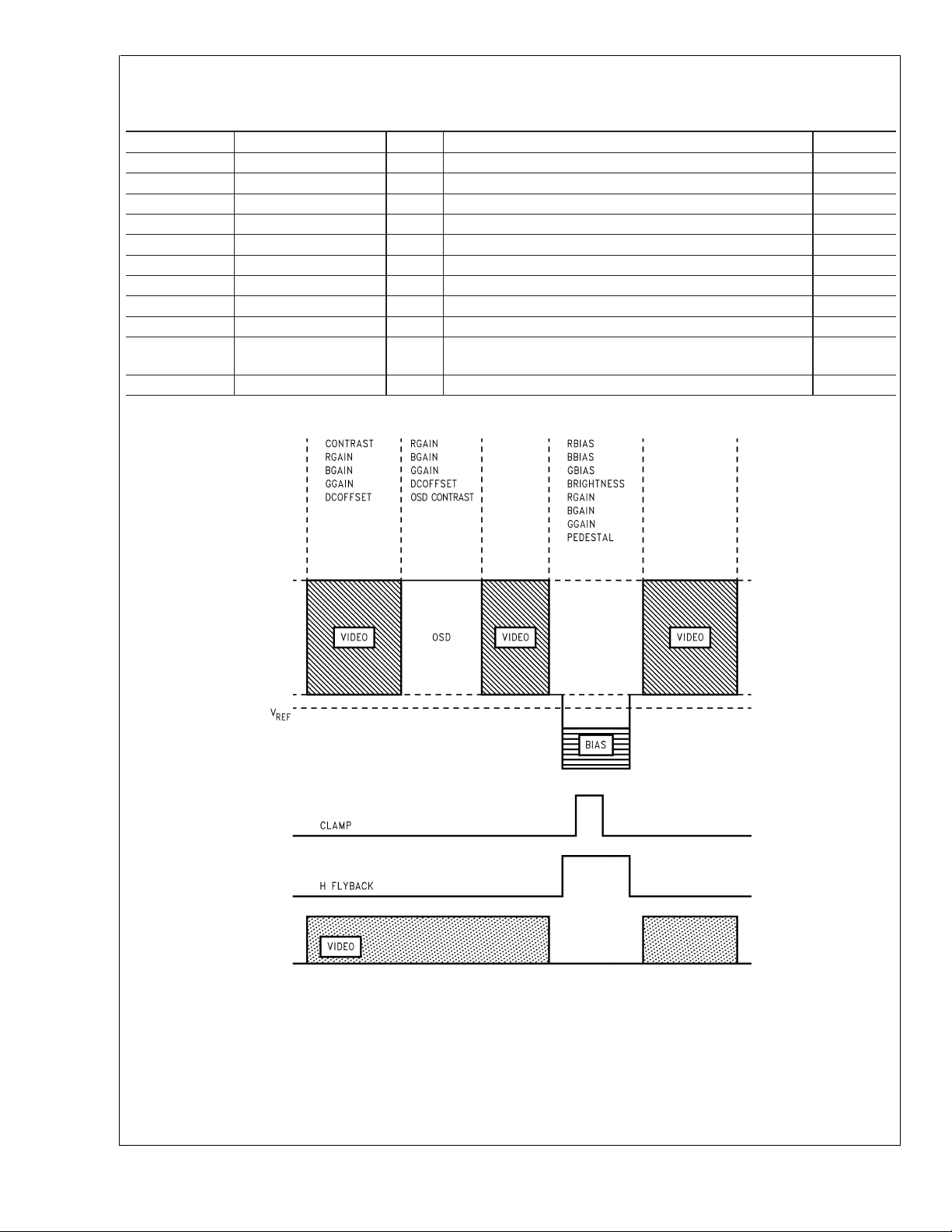

The above sections use the registers shown in

ure 28

signal each register controls.

shows the block diagram of the LM1253A. The

Figure 26

Contrast Attenuator—Sets the contrast level of the video

signal for all three channels.

Auto Beam Limit—Reduces the gain of all three video

amplifiers in response to a control voltage proportional to

the CRT beam current.

Gain Attenuator —Separately sets the gain for each

video channel.

Brightness—Sets the brightness for all three channels.

Bias—Adds an offset to the brightness controls for all

three video channels.

Pedestal—Adds a dc voltage offset to the brightness

control, in order that bi-directional control of the brightness control is always possible at all bias voltage settings.

Source Select—Switches between the input video signal

and the analog OSD signal generated by the 3 bit pallet

DAC control block.

DC Offset—Adds a dc voltage offset to all three video

outputs.

. Black level clamping is carried out di-

Table 2.Fig-

shows which section of the output video and clamp

www.national.com17

Pre-Amp Functional Description (Continued)

LM1253A

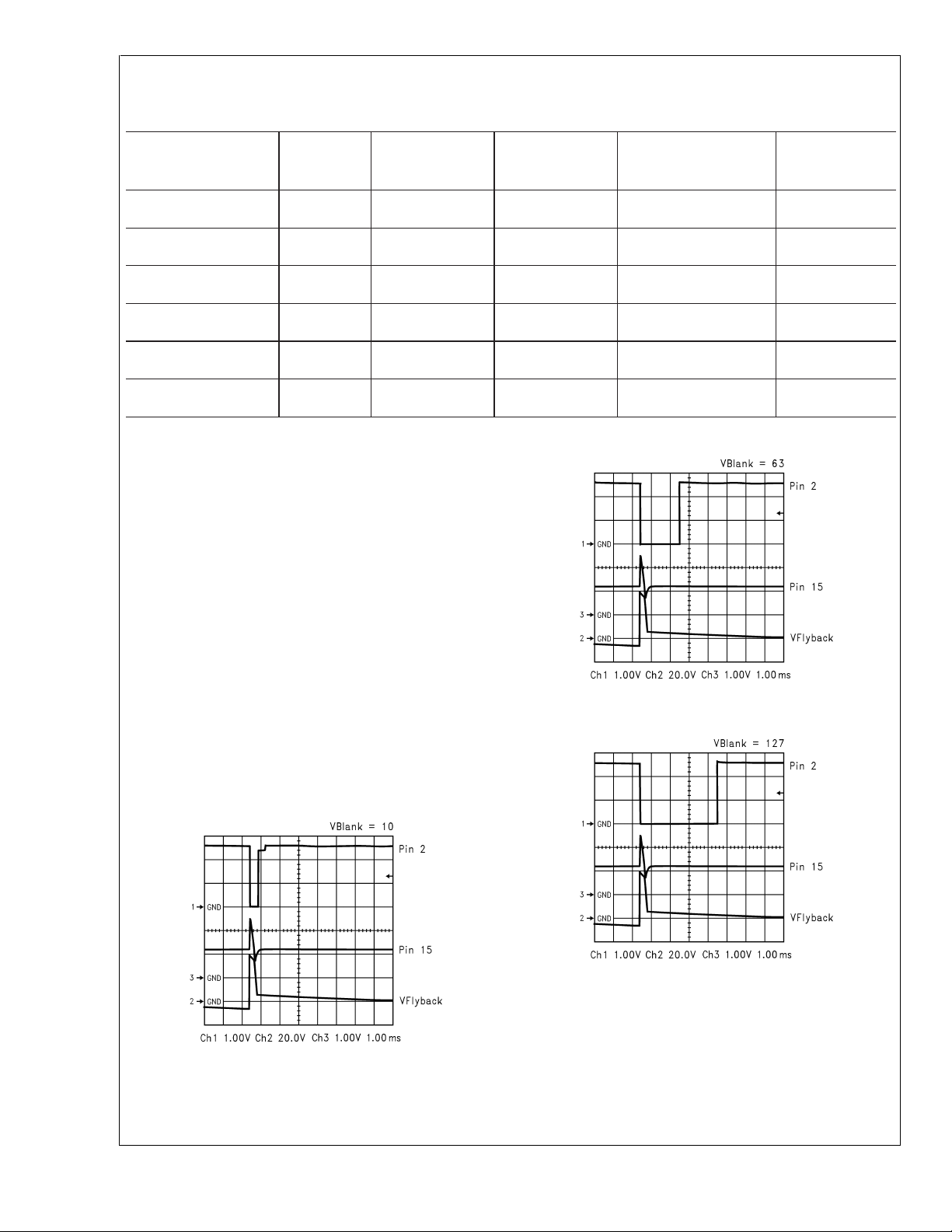

TABLE 2. Registers Controlling the Output Video and Clamp Signal

Parameter Address Size Description Default

BGAIN 8430h 7 Bit Blue Channel Gain 60h

GGAIN 8431h 7 Bit Green Channel Gain 60h

RGAIN 8432h 7 Bit Red Channel Gain 60h

CONTRAST 8433h 7 Bit Overall Gain of All Three Channels 60h

BBIAS 8434h 8 Bit Blue Bias Clamp Pulse Amplitude 80h

GBIAS 8435h 8 Bit Green Bias Clamp Pulse Amplitude 80h

RBIAS 8436h 8 Bit Red Bias Clamp Pulse Amplitude 80h

BRIGHTNESS 8437h 8 Bit Amplitude of Brightness Clamp Pulse of All 3 Channels 80h

PEDESTAL 8438h Bits 7–5 3 Bit Offset to the Brightness Control 4h

OSD

8438h Bits 4–3 2 Bit OSD Gain 2h

CONTRAST

DC OFFSET 8438h Bits 2–0 3 Bit Active Video DC Offset of All 3 Channels 4h

FIGURE 28. Register Control of the Output Video and Clamp Signal

An active horizontal blanking signal is added to the video at

the output, giving excellent smear performance, and preventing video content dependent DC bias offsets as a result

of high frequency over shoot.

www.national.com 18

DS101265-31

The outputs are referenced to a DC level (V

) produced by

REF

the LM1253A preamp, and so are guaranteed to provide

stable DC operating levels within the system without the

need for additional external feedback components.

Loading...

Loading...