November 2003

LM1246

150 MHz I

2

C Compatible RGB Preamplifier with Internal

512 Character OSD ROM, 512 Character RAM and 4

DACs

General Description

The LM1246 pre-amp is an integrated CMOS CRT preamp.

It has an I

the parameters necessary to directly setup and adjust the

gain and contrast in the CRT display. Brightness and bias

can be controlled through the DAC outputs, which are well

matched to the LM2479 and LM2480 integrated bias clamp

ICs. The LM1246 preamp is also designed to be compatible

with the LM246x high gain driver family.

Black level clamping of the video signal is carried out directly

on the AC coupled input signal into the high impedance

preamplifier input, thus eliminating the need for additional

clamp capacitors. Horizontal and vertical blanking of the

outputs is provided. Vertical blanking is optional and its

duration is register programmable.

The IC is packaged in an industry standard 24-lead DIP

molded plastic package.

2

C compatible interface which allows control of all

Features

n Fully addressable 512 Character OSD, simiilar in

features to the LM1237/LM1247, with selectable 2

byte character addressing or LM1247 bank select

modes

n Internal 512 character OSD ROM usable as either (a)

384 2-color plus 128 4-color characters, (b) 640 2-color

characters, or (c) some combination in between

n Internal 512 character RAM, which can be displayed as

one single or two independent windows

n Enhanced I

to allow versatile Page RAM access

2

C compatible microcontroller interface

n OSD Window Fade In/Fade Out

n OSD Half Tone Transparency

n Video Data dectection for Auto Centering & Sizing

n OSD override allows OSD messages to override video

and the use of burn-in screens with no video output.

n 4 DAC outputs (8-bit resolution) for bus controlled CRT

bias and brightness

n Spot killer which blanks the video outputs when V

falls below the specified threshold

n Suitable for use with discrete or integrated clamp, with

software configurable brightness mixer

n 4-Bit Programmable start position for internal

Horizontal Blanking

n Horizontal blanking and OSD synchronization directly

from deflection signals. The blanking can be disabled, if

desired.

n Vertical blanking and OSD synchronization directly from

deflection signals. The blanking width is register

programmable and can be disabled, if desired.

n Power Saving Mode with 65% power reduction

n Matched to LM246x driver and LM2479/80 bias IC’s

Applications

n Low end 15" and 17" bus controlled monitors with OSD

n 1024x768 displays up to 85 Hz requiring OSD capability

n Very low cost systems with LM246x driver

Character RAM and 4 DACs

LM1246 150 MHz I

2

C Compatible RGB Preamplifier with Internal 512 Character OSD ROM, 512

CC

© 2003 National Semiconductor Corporation DS200685 www.national.com

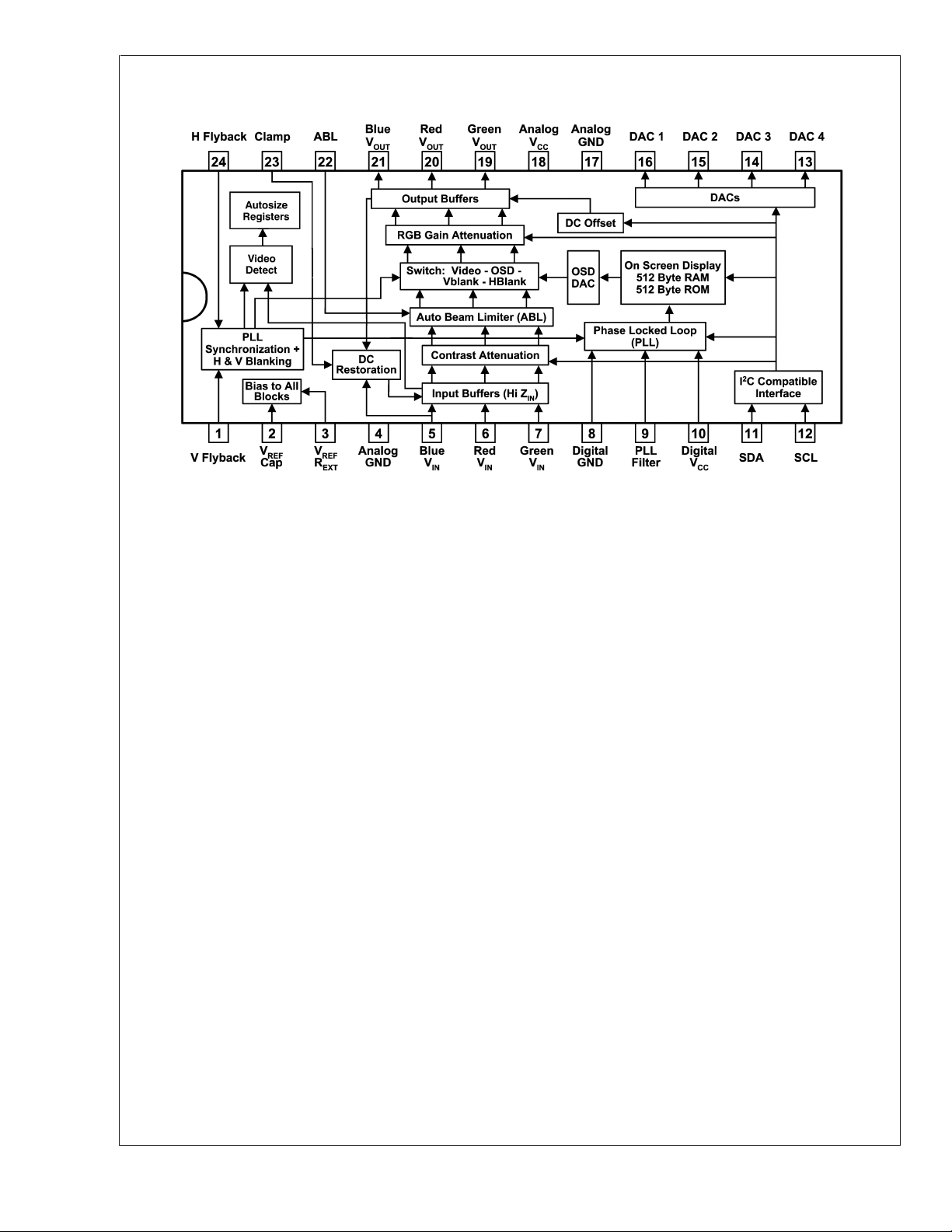

Internal Block Diagram

LM1246

20068501

FIGURE 1. Order Number LM1246AAA/NA

See NS Package Number N24D

www.national.com 2

LM1246

Absolute Maximum Ratings (Notes 1,

3)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage V

, Pins 10 and 18 6.0V

CC

Thermal Resistance to Case (θ

Junction Temperature (T

) 150˚C

J

) 32˚C/W

JC

ESD Susceptibility (Note 4) 3.0 kV

ESD Machine Model (Note 13) 350V

Storage Temperature −65˚C to +150˚C

Lead Temperature (Soldering, 10 sec.) 265˚C

Peak Video DC Output Source Current

(Any One Amp) Pins 19, 20 or 21 1.5 mA

Voltage at Any Input Pin (V

Video Inputs (pk-pk) 0.0 ≤ V

Thermal Resistance to Ambient (θ

Power Dissipation (P

)VCC+0.5 ≥ VIN≥ −0.5V

IN

) 51˚C/W

JA

)

D

IN

≤ 1.2V

Operating Ratings (Note 2)

Temperature Range 0˚C to +70˚C

Supply Voltage V

CC

Video Inputs (pk-pk) 0.0V ≤ V

4.75V ≤ VCC≤ 5.25V

≤ 1.0V

IN

(Above 25˚C Derate Based

and TJ) 2.4W

on θ

JA

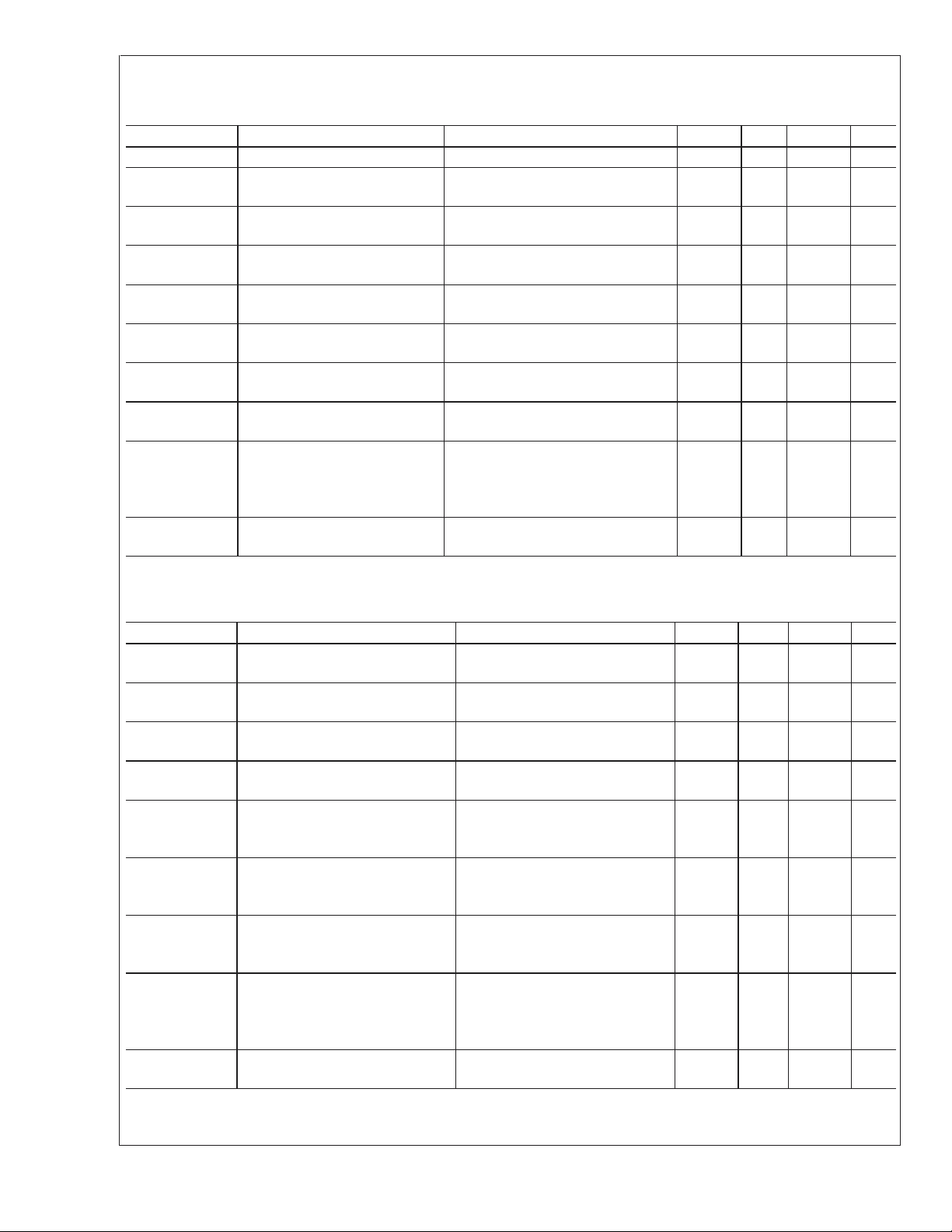

Video Signal Electrical Characteristics

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.70 V

P-P,VABL=VCC,CL

numbers refer to the definitions in Table 1. Test Settings. See (Note 7) for Min and Max parameters and (Note 6) for Typicals.

Symbol Parameter Conditions Min Typ Max Units

I

S

Supply Current Test Setting 1, both supplies, no

output loading. See (Note 8).

I

S-PS

V

O BLK

V

O BLK STEP

Supply Current, Power Save

Mode

Active Video Black Level Output

Voltage

Active Video Black Level Step

Test Setting 1, both supplies, no

output loading. See (Note 8).

Test Setting 4, no AC input signal, DC

offset (register 0x8438 set to 0xd5).

Test Setting 4, no AC input signal.

Size

VOMax Maximum Video Output Voltage Test Setting 3, Video in = 0.70 V

LE Linearity Error Test Setting 4, staircase input signal

(see Table 9. Page RAM Format

(9-bit mode)).

t

r

Video Rise Time (Note 5), 10% to 90%, Test Setting 4,

AC input signal.

OS

R

Rising Edge Overshoot (Note 5), Test Setting 4, AC input

signal.

t

f

Video Fall Time (Note 5), 90% to 10%, Test Setting 4,

AC input signal.

OS

F

Falling Edge Overshoot (Note 5), Test Setting 4, AC input

signal.

BW Channel Bandwidth (−3 dB) (Note 5), Test Setting 4, AC input

signal.

V

10 kHz Video Amplifier 10 kHz Isolation (Note 14), Test Setting 8. −60 dB

SEP

V

10 MHz Video Amplifier 10 MHz Isolation (Note 14), Test Setting 8. −50 dB

SEP

A

Max Maximum Voltage Gain Test Setting 8, AC input signal. 3.8 4.1 V/V

V

A

C-50% Contrast Attenuation@50% Test Setting 5, AC input signal. −5.2 dB

V

A

Min/AVMax Maximum Contrast Attenuation

V

Test Setting 2, AC input signal.

(dB)

AVG-50% Gain Attenuation@50% Test Setting 6, AC input signal. −4.0 dB

A

G-Min Maximum Gain Attenuation Test Setting 7, AC input signal. −11 dB

V

A

Match Maximum Gain Match between

V

Test Setting 3, AC input signal.

Channels

A

Track Gain Change between Channels Tracking when changing from Test

V

Setting 8 to Test Setting 5. See (Note

11).

= 8 pF, Video Outputs = 2.0 V

200 250 mA

70 95 mA

1.2 VDC

100 mVDC

P-P

4.0 4.3 V

5%

3.1 ns

2%

2.9 ns

2%

150 MHz

−20 dB

±

0.5 dB

±

0.5 dB

. Setting

P-P

www.national.com3

Video Signal Electrical Characteristics (Continued)

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.70 V

LM1246

numbers refer to the definitions in Table 1. Test Settings. See (Note 7) for Min and Max parameters and (Note 6) for Typicals.

P-P,VABL=VCC,CL

Symbol Parameter Conditions Min Typ Max Units

Vid

Threshold

V

TH ABL Control Range Upper Limit (Note 12), Test Setting 4, AC input

ABL

Video Threshold Normal Operation 80 mV

signal.

Range ABL Gain Reduction Range (Note 12), Test Setting 4, AC input

V

ABL

signal.

A

V 3.5/AV Max

A

V 2.0/AV Max

I

Active ABL Input Bias Current during

ABL

I

Max ABL Input Current Sink Capability (Note 12), Test Setting 4, AC input

ABL

ABL Gain Reduction at 3.5V (Note 12), Test Setting 4, AC input

signal. V

ABL

= 3.5V

ABL Gain Reduction at 2.0V (Note 12), Test Setting 4, AC input

signal. V

ABL

= 2.0V

(Note 12), Test Setting 4, AC input

ABL

signal. V

ABL=VABL

MIN GAIN

signal.

Max Maximum ABL Input Voltage

V

ABL

during Clamping

(Note 12), Test Setting 4, AC input

signal. I

ABL=IABL

MAX

AVABL Track ABL Gain Tracking Error Table 9. Page RAM Format (9-bit

mode), Test Setting 4, 0.7 V

signal, ABL voltage set to 4.5V and

2.5V.

R

IP

Minimum Input Resistance (pins

Test Setting 4.

5, 6, 7)

= 8 pF, Video Outputs = 2.0 V

4.8 V

2.8 V

−2 dB

−12 dB

input

P-P

20 MΩ

. Setting

P-P

10 µA

1.0 mA

V

+

CC

0.1

4.5 %

V

OSD Electrical Characteristics

Unless otherwise noted: TA= 25˚C, VCC= +5.0V. See (Note 7) for Min and Max parameters and (Note 6) for Typicals.

Symbol Parameter Conditions Min Typ Max Units

V

OSDHIGH

V

OSDHIGH

V

OSDHIGH

V

OSDHIGH

∆V

∆V

(Ch to Ch)

∆V

∆V

(White)

V

OSD-out

max Maximum OSD Level with OSD

Contrast 11

10 Maximum OSD Level with OSD

Contrast 10

01 Maximum OSD Level with OSD

Contrast 01

00 Maximum OSD Level with OSD

Contrast 00

(Black) Difference between OSD Black

OSD

Level and Video Black Level (same

channel)

BL,OSD-Video

Difference between OSD Black

Level and Video Black Level

between Channels

(White) Output Match between Channels Palette Set at 111, OSD Contrast =

OSD

Palette Set at 111, OSD Contrast =

11, RGB Gain = 96, DC Offset = 4

Palette Set at 111, OSD Contrast =

10, RGB Gain = 96, DC Offset = 4

Palette Set at 111, OSD Contrast =

01, RGB Gain = 96, DC Offset = 4

Palette Set at 111, OSD Contrast =

00, RGB Gain = 96, DC Offset = 4

Register 08=0x18, Input Video =

Black, Same Channel, Test Setting

8

Register 08=0x18, Input Video =

Black, Same Channel, Test Setting

8

11, Maximum difference between R,

G and B

OSD/VVideo

Matching of OSD to Video peak to

peak amplitude ratios between

Palette Set at 111, OSD Contrast =

10, Test Setting 4

channels, normalized to the

smallest ratio.

(Track) Output Variation between Channels OSD contrast varied from max to

min

3.85 V

3.27 V

2.70 V

1.97 V

20 mV

20 mV

3%

3%

3%

www.national.com 4

DAC Output Electrical Characteristics

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.7V, V

ABL=VCC,CL

for Min and Max parameters and (Note 6) for Typicals. DAC parameters apply to all 4 DACs.

Symbol Parameter Conditions Min Typ Max Units

V

Min DAC

V

Max DAC

Mode 00

V

Max DAC

Mode 01

∆V

Max DAC

(Temp)

∆V

Max DAC(VCC

Min Output Voltage of DAC Register Value = 0x00 0.5 0.7 V

Max Output Voltage of DAC Register Value = 0xFF,

DCF[1:0] = 00b

Max Output Voltage of DAC in

DCF Mode 01

DAC Output Voltage Variation

Register Value = 0xFF,

DCF[1:0] = 01b

<T<

0

70˚C ambient

with Temperature

) DAC Output Voltage Variation

with V

CC

VCCvaried from 4.75V to 5.25V, DAC

register set to mid-range (0x7F)

Linearity Linearity of DAC over its Range 5 %

Monotonicity Monotonicity of the DAC

Excluding Dead Zones

I

MAX

Max Load Current −1.0 1.0 mA

= 8 pF, Video Outputs = 2.0 V

3.7 4.2 V

1.85 2.35 V

±

0.5 mV/˚C

50 mV

±

0.5 LSB

. See (Note 7)

P-P

System Interface Signal Characteristics

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.7V, V

ABL=VCC,CL

for Min and Max parameters and (Note 6) for Typicals. DAC parameters apply to all 4 DACs.

Symbol Parameter Conditions Min Typ Max Units

V

VTH+

VFLYBACK Positive Switching

Vertical Blanking triggered

Guarantee

V

SPOT

Spot Killer Voltage Table 17. LM1246 Four-Color

Attribute Registers,V

Activate

V

Ref

V

(SCL, SDA) Logic Low Input Voltage −0.5 1.5 V

IL

V

(SCL, SDA) Logic High Input Voltage

IH

V

Output Voltage (pin 2) 1.25 1.45 1.65 V

Ref

IL(SCL, SDA) Logic Low Input Current SDA or SCL, Input Voltage = 0.4V

I

(SCL, SDA) Logic High Input Voltage SDA or SCL, Input Voltage = 4.5V

H

V

(SCL, SDA) Logic Low Output Voltage IO= 3 mA 0.5 V

OL

f

Min Minimum Horizontal Frequency PLL & OSD Functioning; PPL = 0 25 kHz

H

f

Max Maximum Horizontal Frequency PLL & OSD Functioning; PPL = 4 110 kHz

H

I

Max Horizontal Flyback Input Current Absolute Maximum during

HFB IN

Flyback

I

IN

I

HFB OUT

I

OUT

I

IN THRESHOLD

t

H-BLANK ON

Max Horizontal Flyback Input Current Absolute Maximum during Scan −700 µA

Peak Current during Flyback Design Value 4 mA

Peak Current during Scan Not exact - Duty Cycle Dependent −550 µA

IINH-Blank Detection Threshold 0 µA

H-Blank Time Delay - On + Zero crossing of I

output blanking start. I

t

H-BLANK OFF

H-Blank Time Delay - Off − Zero crossing of I

output blanking end. I

V

Max Maximum Video Blanking Level Test Setting 4, AC input signal 0 0.25 V

BLANK

f

FREERUN

Free Run H Frequency, Including

H Blank

t

PW CLAMP

V

CLAMP MAX

Minimum Clamp Pulse Width See (Note 15) 200 ns

Maximum Low Level Clamp

Video Clamp Functioning

Pulse Voltage

= 8 pF, Video Outputs = 2.0 V

Adjusted to

CC

to 50% of

HFB

= +1.5mA

24

to 50% of

HFB

= −100µA

24

. See (Note 7)

P-P

2.0 V

3.4 3.9 4.3 V

3.0

±

±

VCC+

0.5

10 µA

10 µA

5mA

45 ns

85 ns

42 kHz

2.0 V

LM1246

V

www.national.com5

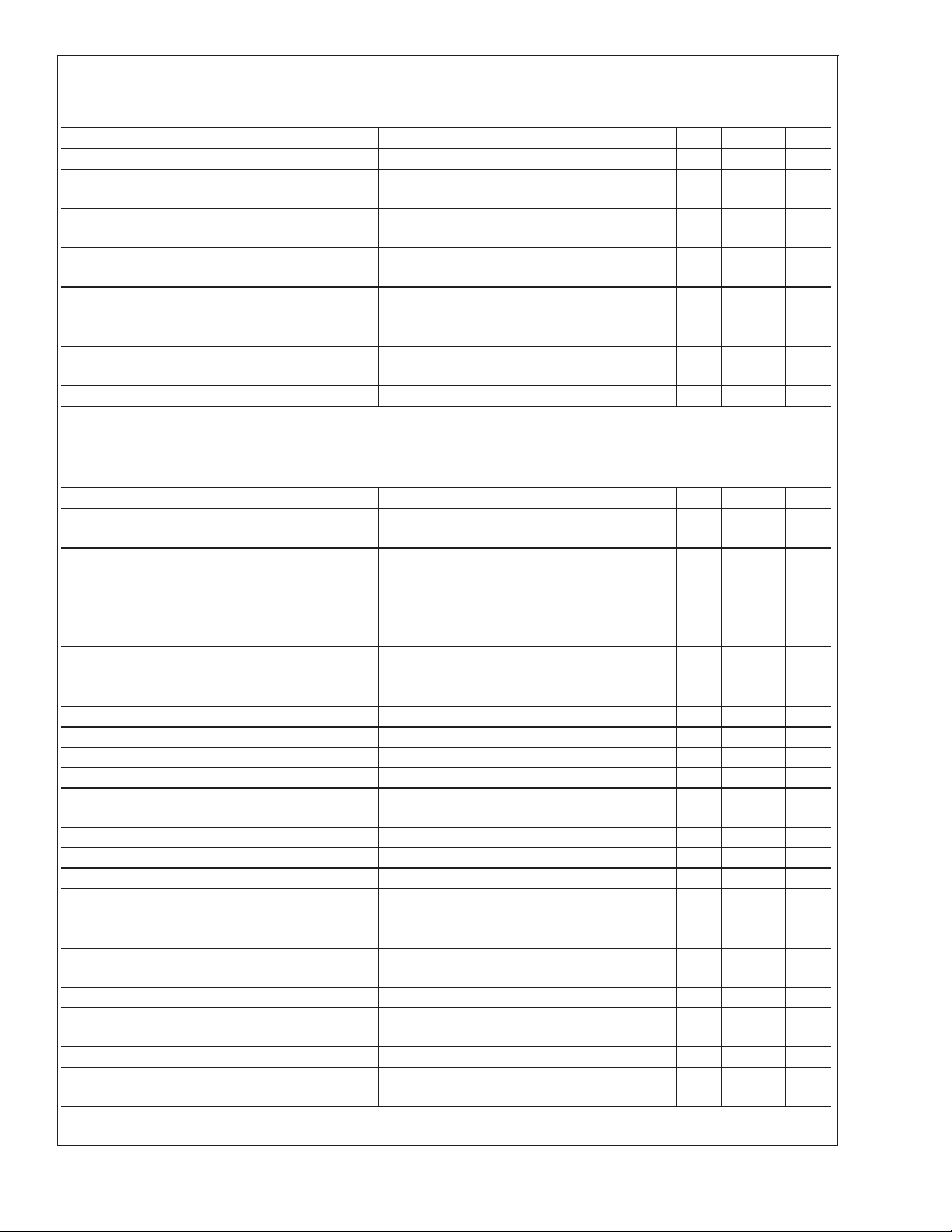

System Interface Signal Characteristics (Continued)

Unless otherwise noted: TA= 25˚C, VCC= +5.0V, VIN= 0.7V, V

LM1246

for Min and Max parameters and (Note 6) for Typicals. DAC parameters apply to all 4 DACs.

ABL=VCC,CL

Symbol Parameter Conditions Min Typ Max Units

V

CLAMP MIN

Minimum High Level Clamp

Video Clamp Functioning

Pulse Voltage

Low Clamp Gate Low Input Current V23= 2V −0.4 µA

I

CLAMP

I

High Clamp Gate High Input Current V23= 3V 0.4 µA

CLAMP

t

CLAMP-VIDEO

Note 1: Limits of Absolute Maximum Ratings indicate below which damage to the device must not occur.

Note 2: Operating Ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits.

Note 3: All voltages are measured with respect to GND, unless otherwise specified.

Note 4: Human body model, 100 pF discharged through a 1.5 kΩ resistor.

Note 5: Input from signal generator: t

Note 6: Typical specifications are specified at +25˚C and represent the most likely parametric norm.

Note 7: Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis. The guaranteed specifications apply only for the test conditions

listed. Some performance characteristics may change when the device is not operated under the listed test conditions.

Note 8: The supply current specified is the quiescent current for V

therefore all the supply current is used by the pre-amp.

Note 9: Linearity Error is the maximum variation in step height of a 16 step staircase input signal waveform with a 0.7 V

with each at least 100 ns in duration.

Note 10: dt/dV

Note 11: ∆A

gain change between any two amplifiers with the contrast set to A

amplifiers’ gains might be 12.1 dB, 11.9 dB, and 11.8 dB and change to 2.2 dB, 1.9 dB and 1.7 dB respectively for contrast set to A

gain change of 10.0 dB with a tracking change of

Note 12: The ABL input provides smooth decrease in gain over the operational range of 0 dB to −5 dB: ∆A

V

ABL MIN GAIN

Note 13: Machine Model ESD test is covered by specification EIAJ IC-121-1981. A 200 pF cap is charged to the specific voltage, then discharged directly into the

IC with no external series resistor (resistance of discharge path must be under 50Ω).

Note 14: Measure output levels of the other two undriven amplifiers relative to the driven amplifier to determine channel separation. Terminate the undriven amplifier

inputs to simulate generator loading. Repeat test at f

Note 15: A minimum pulse width of 200 ns is the guaranteed minimum for a horizontal line of 15 kHz. This limit is guaranteed by design. If a lower line rate is used

then a longer clamp pulse may be required.

Note 16: Adjust input frequency from 10 MHz (A

Note 17: Once the spot killer has been activated, the LM1246 remains in the off state until V

Time from End of Clamp Pulse to

Start of Video

<

1 ns.

r,tf

= 200*(t

CC

track is a measure of the ability of any two amplifiers to track each other and quantifies the matching of the three gain stages. It is the difference in

V

). Beyond −5 dB the gain characteristics, linearity and pulse response may depart from normal values.

5.5V–t4.5V

)/ ((t

5.5V+t4.5V

)) %/V, where: t

±

0.2 dB.

= 10 MHz for V

IN

max reference level) to the −3 dB corner frequency (f

V

Referenced to Blue, Red and Green

inputs

and 5V Dig with RL=∞. Load resistors are not required and are not used in the test circuit,

CC

is the rise or fall time at VCC= 5.5V, and t

5.5V

C−50% and measured relative to the AVmax condition. For example, at AVmax the three

V

10 MHz.

SEP

= 8 pF, Video Outputs = 2.0 V

. See (Note 7)

P-P

3.0 V

50 ns

level at the input. All 16 steps equal,

P-P

is the rise or fall time at VCC= 4.5V.

4.5V

C−50%. This yields a typical

V

= A(V

ABL

).

−3 dB

is cycled (reduced below 0.5V and then restored to 5V).

CC

ABL=VABL MAX GAIN

)–A(V

ABL

=

Hexadecimal and Binary Notation

Hexadecimal numbers appear frequently throughout this

document, representing slave and register addresses, and

register values. These appear in the format “0x...”. For example, the slave address for writing the registers of the

LM1246 is hexadecimal BA, written as 0xBA. On the other

hand, binary values, where the individual bit values are

shown, are indicated by a trailing “b”. For example, 0xBA is

equal to 10111010b. A subset of bits within a register is

referred to by the bit numbers in brackets following the

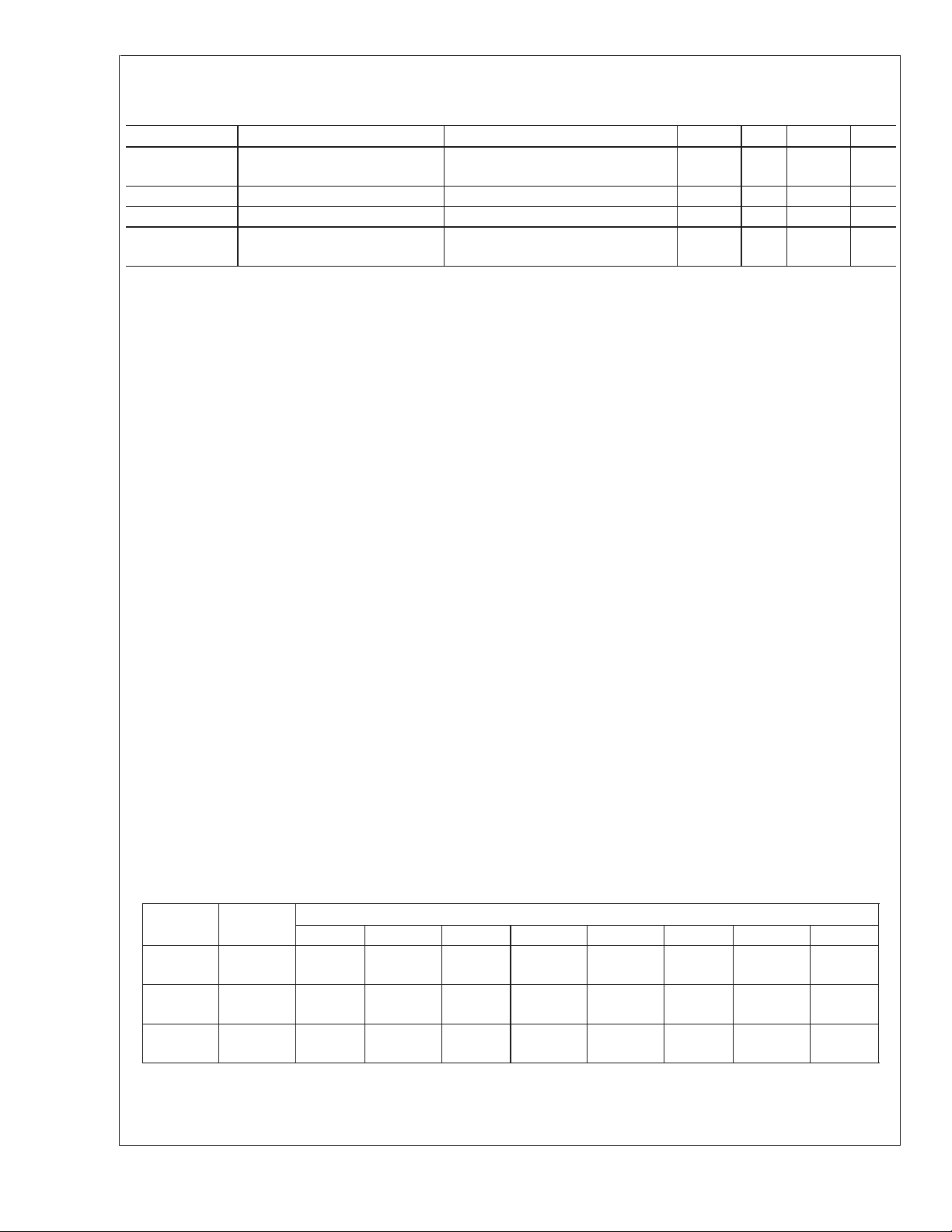

TABLE 1. Test Settings

Control No. of Bits

Contrast 7 0x7F

B, R, G

7 0x7F

Gain

DC Offset 3 0x00

1234 5678

(Max)

(Max)

0x00

Min

0x7F

(Max)

0x7F

(Max)

0x7F

(Max)

0x05 0x07

(Min)

(Max)

Compatibility with LM1237 and LM1247

www.national.com 6

register value. For example, the OSD contrast bits are the

fourth and fifth bits of register 0x8438. Since the first bit is bit

0, the OSD contrast register is 0x8438[4:3].

Register Test Settings

Table 1. Test Settings shows the definitions of the Test

Settings 1–8 referred to in the specifications sections. Each

test setting is a combination of five hexadecimal register

values, Contrast, Gain (Blue, Red, Green) and DC offset.

Test Settings

0x7F

(Max)

Set V

O

2V

P-P

0x05 0x05 0x05 0x05 0x05

0x40

(50.4%)

to

0x7F

(Max)

0x7F

(Max)

0x40

(50.4%)

0x7F

(Max)

0x00

(Min)

0x7F

(Max)

0x7F

(Max)

Compatibility with LM1237 and

LM1247

The Compatibility of the LM1246 to the LM1237 and

LM1253A is the same as that of the LM1247. Please refer to

the LM1247 datasheet for details.

(Continued)

TABLE 2. LM1253A/LM1237 Compatibility

LM1246 Pin: DAC 1 DAC 2 DAC 3 DAC 4

Assignment: Blue Green Red Brightness

LM1246

In order to maintain register compatibility with the LM1253A

and LM1237 preamplifier datasheet assignments for bias

and brightness, the color assignments are recommended as

shown in Table 2. LM1253A/LM1237 Compatibility.If

datasheet compatibility is not required, then the DAC assignments can be arbitrary.

DAC Bias Outputs

OSD vs Video Intensity

The OSD amplitude has been increased over the LM1237

level. During monitor alignment, the three gain registers are

used to achieve the desired front of screen color balance.

This also causes the OSD channels to be adjusted accordingly, since these are inserted into the video channels prior

to the gain attenuators. This provides the means to fine tune

the intensity of the OSD relative to the video as follows. If a

typical starting point for the alignment is to have the gains at

maximum (0x7F) and the contrast at 0x55, the resultant

OSD intensity will be higher than if the starting point is with

the gains at 0x55 and the contrast at maximum (0x7F). This

tradeoff allows fine tuning the final OSD intensity relative to

the video. In addition, the OSD contrast register, 0x8438

[4:3], provides 4 major increments of intensity. Together,

these allow setting the OSD intensity to the most pleasing

level.

ESD Protection

The LM1246 features a 3.0 kV ESD protection level (see

(Notes 4, 13)). This is provided by special internal circuitry

which activates when the voltage at any pin goes beyond the

supply rails by a preset amount. At that time, the protection is

applied to all the pins, including SDA and SCL.

www.national.com7

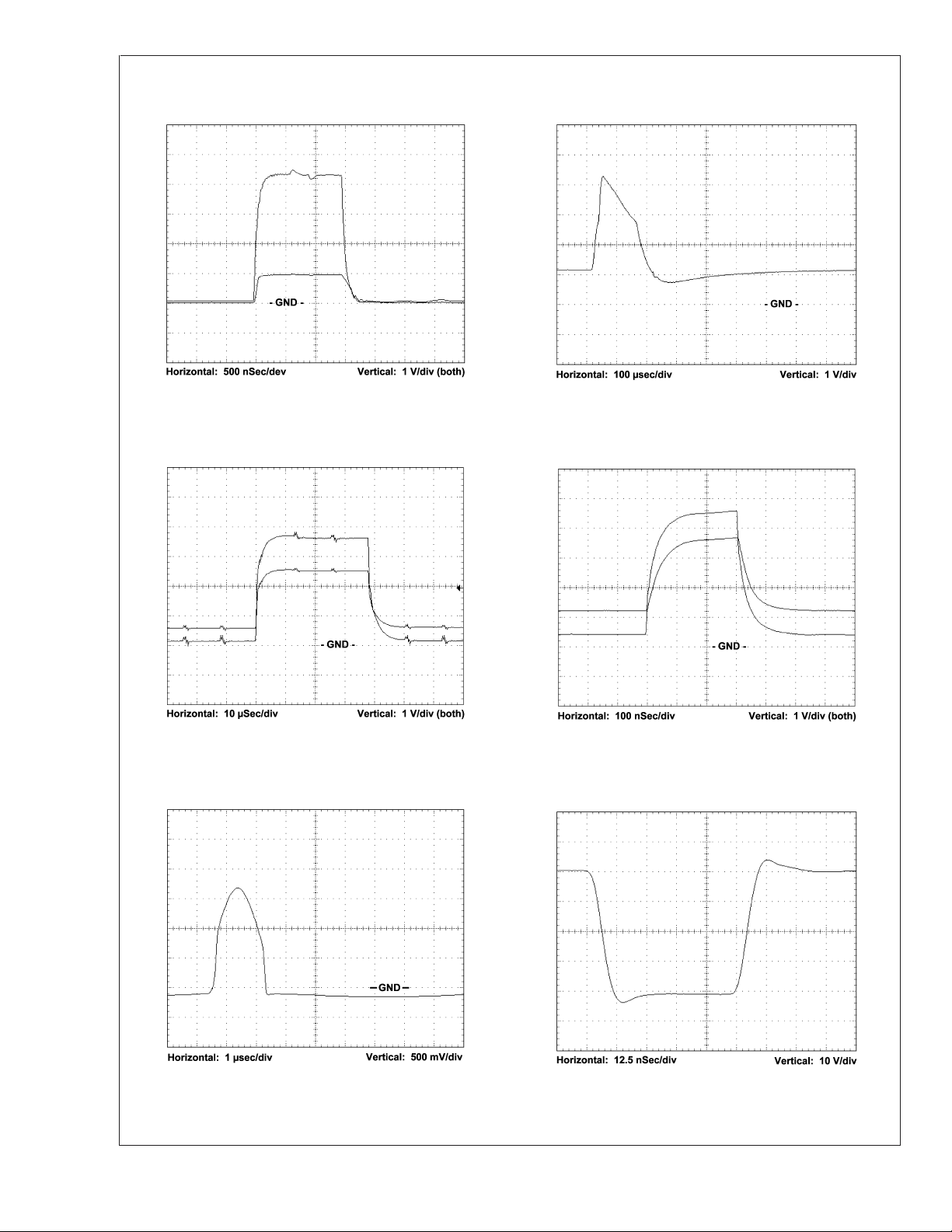

Typical Performance Characteristics V

LM1246

= 5V, TA= 25˚C unless otherwise specified

CC

FIGURE 2. Logic Horizontal Blanking

FIGURE 3. Logic Vertical Blanking

20068502

20068503

20068505

FIGURE 5. Deflection Vertical Blanking

20068506

FIGURE 6. Logic Clamp Pulse

20068504

FIGURE 4. Deflection Horizonal Blanking

www.national.com 8

20068507

FIGURE 7. Red Cathode Response

LM1246

Typical Performance Characteristics V

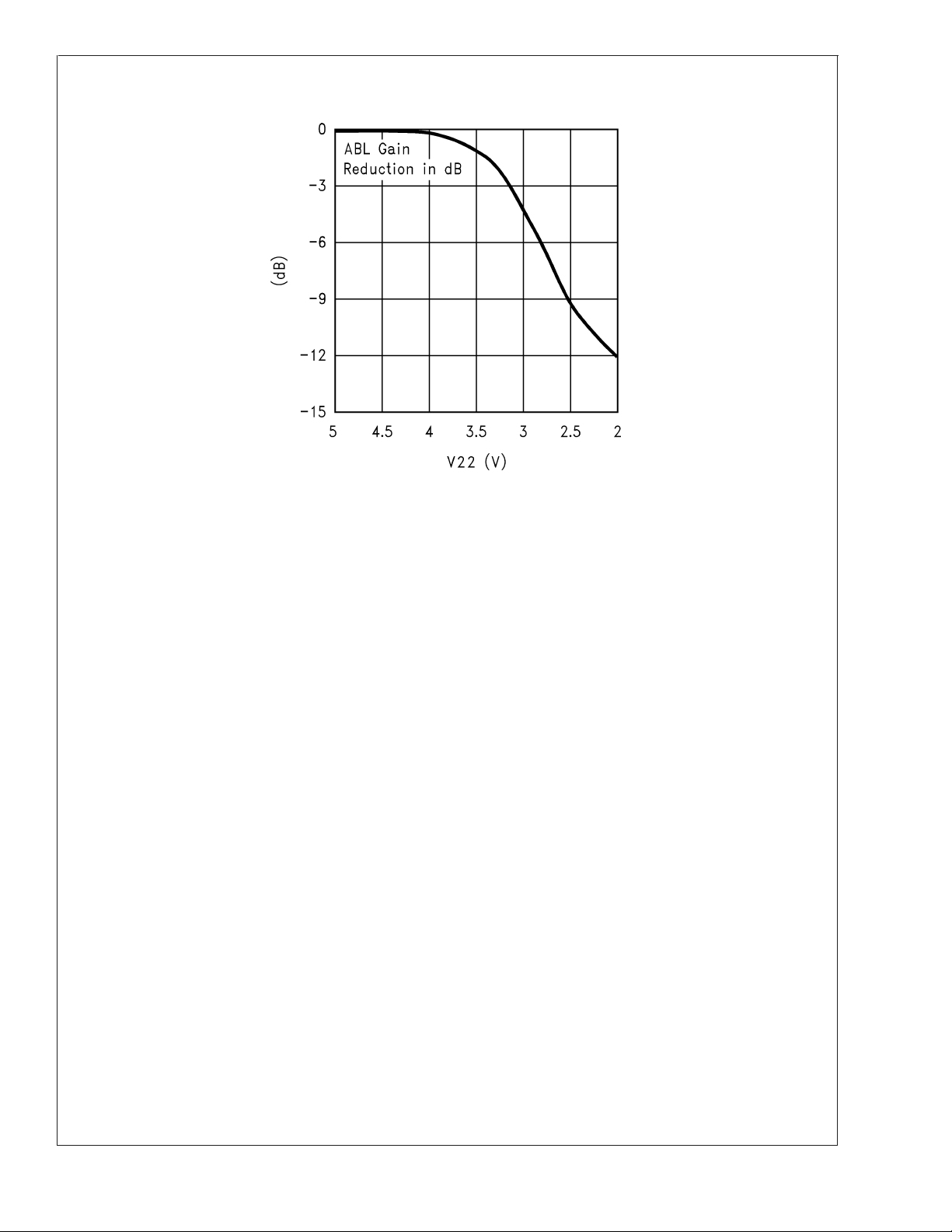

FIGURE 8. ABL Gain Reduction Curve

= 5V, TA= 25˚C unless otherwise specified (Continued)

CC

20068508

SYSTEM INTERFACE SIGNALS

The Horizontal and Vertical Blanking and the Clamping input

signals are important for proper functionality of the LM1246.

Both blanking inputs must be present for OSD synchronization. In addition, the Horizontal blanking input also assists in

setting the proper cathode black level, along with the Clamping pulse. The Vertical blanking input initiates a blanking

level at the LM1246 outputs which is programmable from 3

to 127 lines (we recommend at least 10). The start position

of the internal Horizontal blanking pulse is programmable

from 0 to 64 pixels ahead of the start position of the Horizontal flyback input. Both horizontal and vertical blanking

can be individually disabled, if desired.

Figure 2 and Figure 3 show the case where the Horizontal

and Vertical inputs are logic levels. Figure 2 shows the

smaller pin 24 voltage superimposed on the horizontal

blanking pulse input to the neck board with R

= 0.1 µF. Note where the voltage at pin 24 is clamped to

C

17

= 4.7k and

H

about 1V when the pin is sinking current. Figure 3 shows the

smaller pin 1 voltage superimposed on the vertical blanking

input to the neck board with C

jumpered and RV= 4.7k.

4

These component values correspond to the application circuit of Figure 9.

Figures 4, 5 show the case where the horizontal and vertical

inputs are from deflection. Figure 4 shows the pin 24 voltage

which is derived from a horizontal flyback pulse of 35V peak

to peak with R

= 8.2K and C17jumpered. Figure 5 shows

H

the pin 1 voltage which is derived from a vertical flyback

pulse of 55V peak to peak with C

= 1500 pF and RV= 120k.

4

Figure 6 shows the pin 23 clamp input voltage superimposed

on the neck board clamp logic input pulse. R

=1kand

31

should be chosen to limit the pin 23 voltage to about 2.5V

peak to peak. This corresponds to the application circuit

given in Figure 9.

CATHODE RESPONSE

Figure 7 shows the response at the red cathode for the

application circuit in Figures 9, 10. The input video risetime is

1.5 ns. The resulting leading edge has a 7.1 ns risetime and

a 7.6% overshoot, while the trailing edge has a 7.1 ns

risetime and a 6.9% overshoot with an LM2467 driver.

ABL GAIN REDUCTION

The ABL function reduces the contrast level of the LM1246

as the voltage on pin 22 is lowered from V

to around 2V.

CC

Figure 8 shows the amount of gain reduction as the voltage

is lowered from V

until V

reaches the knee around 3.7V, where the slope

22

(5.0V) to 2V. The gain reduction is small

CC

increases. Many system designs will require about 3 dB to

5 dB of gain reduction in full beam limiting. Additional attenuation is possible, and can be used in special circumstances.

However, in this case, video performance such as video

linearity and tracking between channels will tend to depart

from normal specifications.

OSD PHASE LOCKED LOOP

The PLL in the LM1246 has a maximum pixels per line

setting significantly higher than that of the LM1247. The

range for the LM1246 is from 704 to 1152 pixels per line, in

increments of 64. The maximum OSD pixel frequency available is 111 MHz. For example, if the horizontal scan rate is

106kHz, 1024 pixels per line would be acceptable to use,

since the OSD pixel frequency is:

Horizontal Scan Rate X PPL =

106kHz X 1024 = 108.5 MHz

www.national.com9

Typical Performance Characteristics V

LM1246

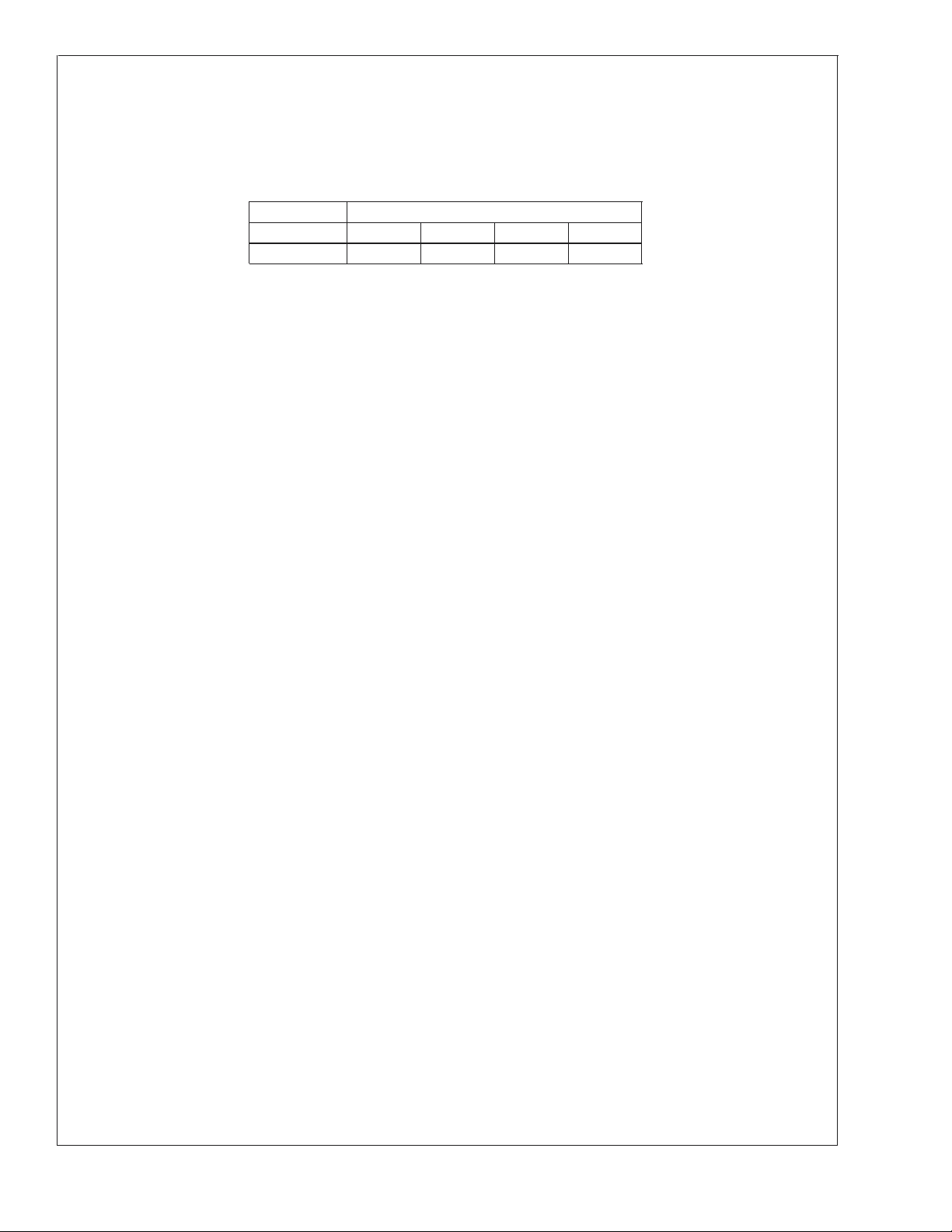

PPL=0 PPL=1 PPL=2 PPL=3 PPL=4 PPL=5 PPL=6 PPL=7

PLL Auto 25 - 110 25 - 110 25 - 110 25 - 110 25 - 110 25 - 108 25 - 102 25 - 96

TABLE 3. OSD Register Recommendations

=5V,TA= 25˚C unless otherwise specified (Continued)

CC

If 1152 pixels per line is being used, the horizontal scan rate

would have to be lower than 106 kHz in order to not exceed

the maximum OSD pixel frequency of 111 MHz. The maxi-

and at scan rates outside these ranges, the performance of

the loop will be improved if these recommendations are

followed.

mum number of vertical video lines that may be used is 1536

lines as in a 2048x1536 display. The LM1246 has a PLL

Auto feature, which will automatically select an internal PLL

frequency range setting that will guarantee optimal OSD

locking for any horizontal scan rate. This offers improved

PLL performance and eliminates the need for PLL register

settings determined by the user. To initialize the PLL Auto

feature, set bits, 0x843E[1:0] to 0 for pre-calibration, which

takes one vertical scan period to complete, and must be

done while the video is blanked. Subsequently, set

0x843E[6] to 1, which must also be done while the video is

blanked. Table 3. OSD Register Recommendations shows

PLL Auto Mode Initialization Sequence

Blank video

•

In PLL manual mode, set PLL range (0x843E[1:0]) to 0

•

Wait for at least one vertical period or vertical sync pulse

•

to pass

Set 0x843E[6] to 1 to activate the Auto mode

•

Wait for at least one vertical period or vertical sync pulse

•

to pass

Unblank video

•

the recommended horizontal scan rate ranges (in kHz) for

each pixels per line register setting, 0x8401[7:5]. These

ranges are recommended for chip ambient temperatures of

o

Cto70oC, and the recommended PLL filter values are

0

6.2kohms, 0.01uF, and 1000pF as shown in the schematic.

While the OSD PLL will lock for other register combinations

This Sequence must be done by the microcontroller at sys-

tem power up, as well as each time there is a horizontal line

rate change from the video source, for the PLL Auto mode to

function properly.

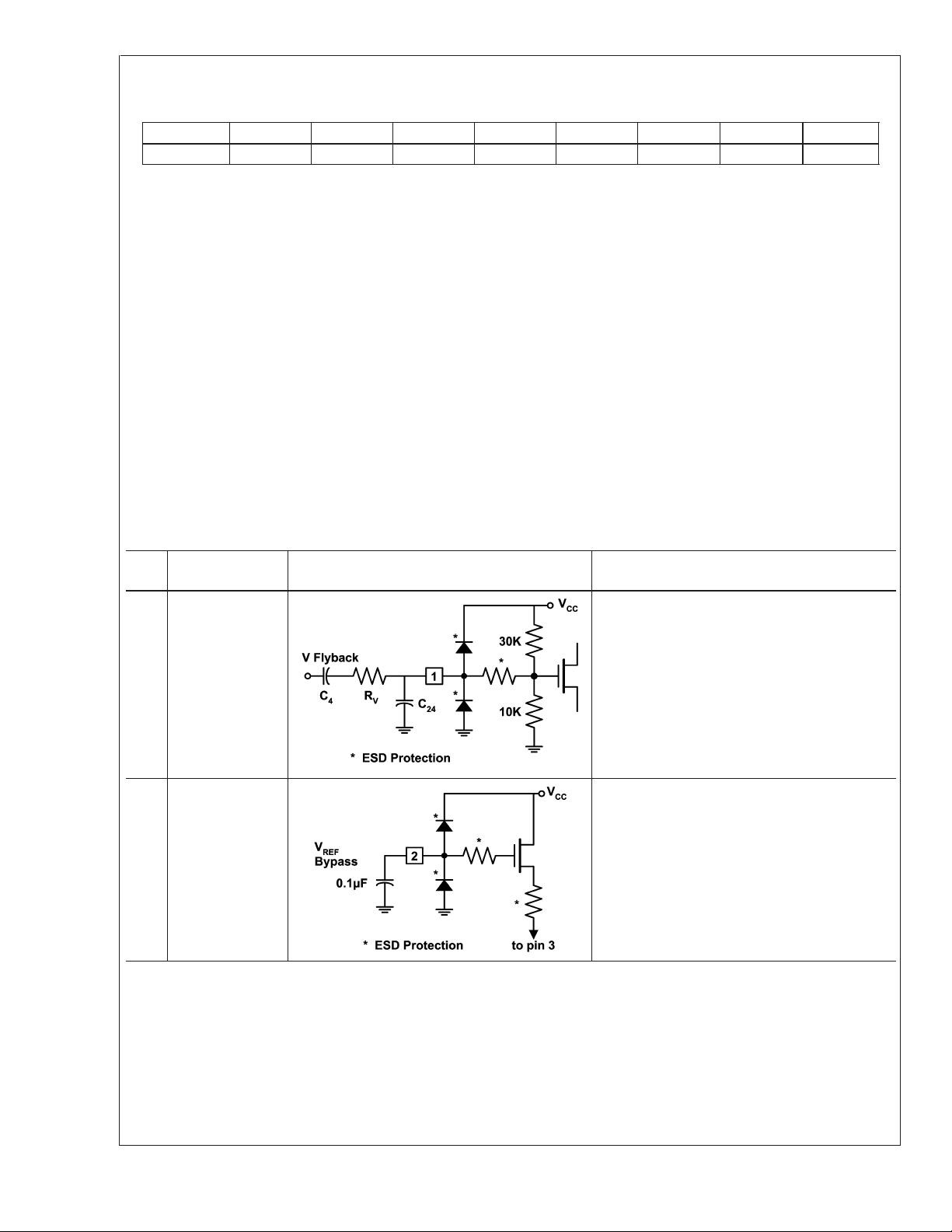

Pin Descriptions and Application Information

Pin

No.

1 V Flyback Required for OSD synchronization and is also

2V

Pin Name Schematic Description

used for vertical blanking of the video outputs.

The actual switching threshold is about 35% of

. For logic level inputs C4can be a jumper,

V

CC

but for flyback inputs, an AC coupled

differentiator is recommended, where R

enough to prevent the voltage at pin 1 from

exceeding V

or going below GND. C4should

CC

be small enough to flatten the vertical rate ramp

at pin 1. C

Bypass Provides filtering for the internal voltage which

REF

may be needed to reduce noise.

24

sets the internal bias current in conjunction with

. A minimum of 0.1 µF is recommended for

R

EXT

proper filtering. This capacitor should be placed

as close to pin 2 and the pin 4 ground return as

possible.

V

is large

www.national.com 10

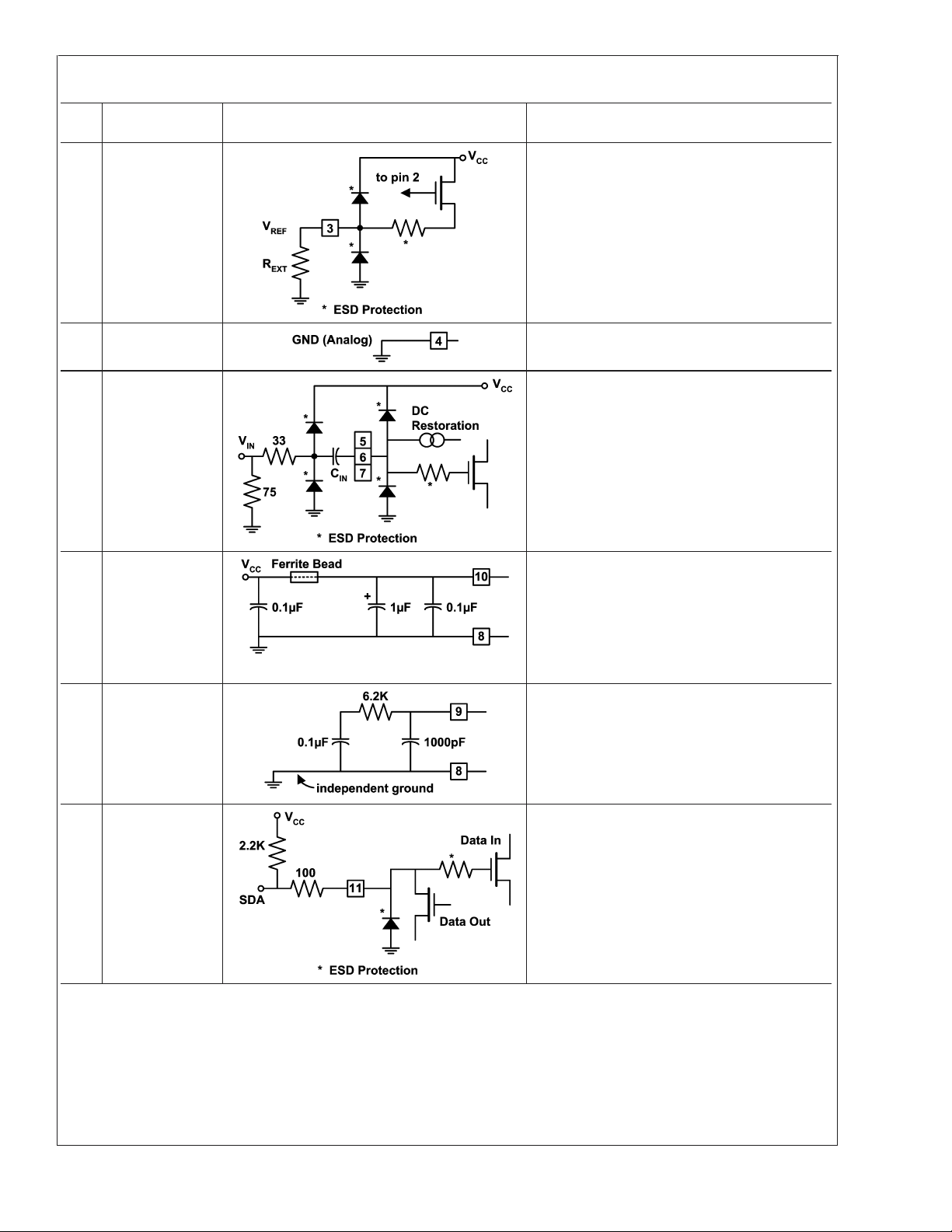

Pin Descriptions and Application Information (Continued)

LM1246

Pin

No.

3V

Pin Name Schematic Description

REF

4 Analog Input

Ground

5

Blue Video In

6

7

8

10

Red Video In

Green Video In

Digital Ground

PLL V

CC

9 PLL Filter

External resistor, 10k 1%, sets the internal bias

current level for optimum performance of the

LM1247. This resistor should be placed as close

to pin 3 and the pin 4 ground return as possible.

This is the ground for the input analog portions

of the LM1247 internal circuitry.

These video inputs must be AC coupled with a

.0047 µF cap. Internal DC restoration is done at

these inputs. A series resistor of about 33Ω and

external ESD protection diodes should also be

used for protection from ESD damage.

The ground pin should be connected to the rest

of the circuit ground by a short but independent

PCB trace to prevent contamination by

extraneous signals. The V

isolated from the rest of the V

pin should be

CC

line by a ferrite

CC

bead and bypassed to pin 8 with an electrolytic

capacitor and a high frequency ceramic.

Recommended topology and values are shown

to the left. It is recommended that both filter

branches be bypassed to the independent

ground as close to pin 8 as possible. Great care

should be taken to prevent external signals from

2

coupling into this filter from video, I

C, etc.

11 SDA

The I2C compatible data line. A pull-up resistor

of about 2 kΩ should be connected between this

pin and V

. A resistor of at least 100Ω should

CC

be connected in series with the data line for

additional ESD protection.

www.national.com11

Pin Descriptions and Application Information (Continued)

LM1246

Pin

No.

12 SCL The I2C compatible clock line. A pull-up resistor

Pin Name Schematic Description

of about 2 kΩ should be connected between this

pin and V

. A resistor of at least 100Ω should

CC

be connected in series with the clock line for

additional ESD protection.

13

14

15

16

17

18

19

20

21

DAC 4 Output

DAC 2 Output

DAC 3 Output

DAC 1 Output

Ground

V

CC

Green Output

Red Output

Blue Output

DAC outputs for cathode cut-off adjustments and

brightness control. DAC 4 can be set to change

the outputs of the other three DACs, acting as a

brightness control. The DAC values and the

2

special DAC 4 function are set through the I

C

compatible bus. A resistor of at least 100Ω

should be connected in series with these outputs

for additional ESD protection.

Ground pin for the output analog portion of the

LM1247 circuitry, and power supply pin for all

the analog of the LM1247. Note the

recommended charge storage and high

frequency capacitors which should be as close to

pins 17 and 18 as possible.

These are the three video output pins. They are

intended to drive the LM246x family of cathode

drivers. Nominally, about 2V peak to peak will

produce 40V peak to peak of cathode drive.

22 ABL

www.national.com 12

The Automatic Beam Limiter input is biased to

the desired beam current limit by R

and normally keeps D

forward biased. When

INT

ABL

and V

the current resupplying the CRT capacitance

(averaged by C

) exceeds this limit, then D

ABL

begins to turn off and the voltage at pin 22

begins to drop. The LM1247 then lowers the

gain of the three video channels until the beam

current reaches an equilibrium value.

BB

INT

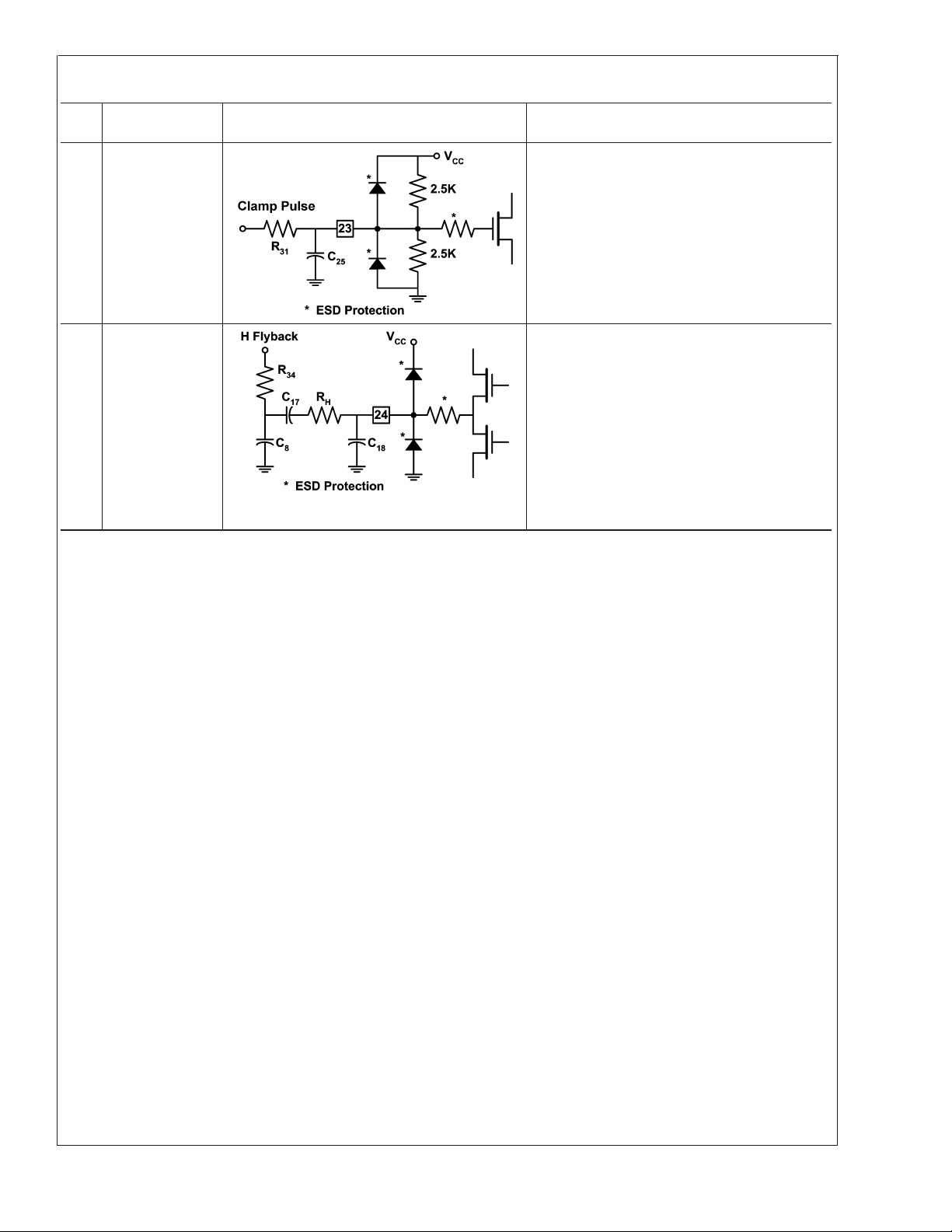

Pin Descriptions and Application Information (Continued)

LM1246

Pin

No.

Pin Name Schematic Description

23 CLAMP This pin accepts either TTL or CMOS logic

levels. The internal switching threshold is

approximately one-half of V

series resistor, R

, of about 1K is recommended

31

. An external

CC

to avoid overdriving the input devices. In any

event, R

must be large enough to prevent the

EXT

voltage at pin 23 from going higher than V

below GND.

24 H Flyback

Proper operation requires current reversal. R

should be large enough to limit the peak current

at pin 24 to about +4 ma during blanking, and

−500 µA during scan. C

is usually needed for

17

logic level inputs and should be large enough to

make the time constant, R

larger than the horizontal period. R

HC17

significantly

and C8are

34

typically 300Ω and 330 pF when the flyback

waveform has ringing and needs filtering. C

may be needed to filter extraneous noise and

can be up to 100 pF.

or

CC

H

18

www.national.com13

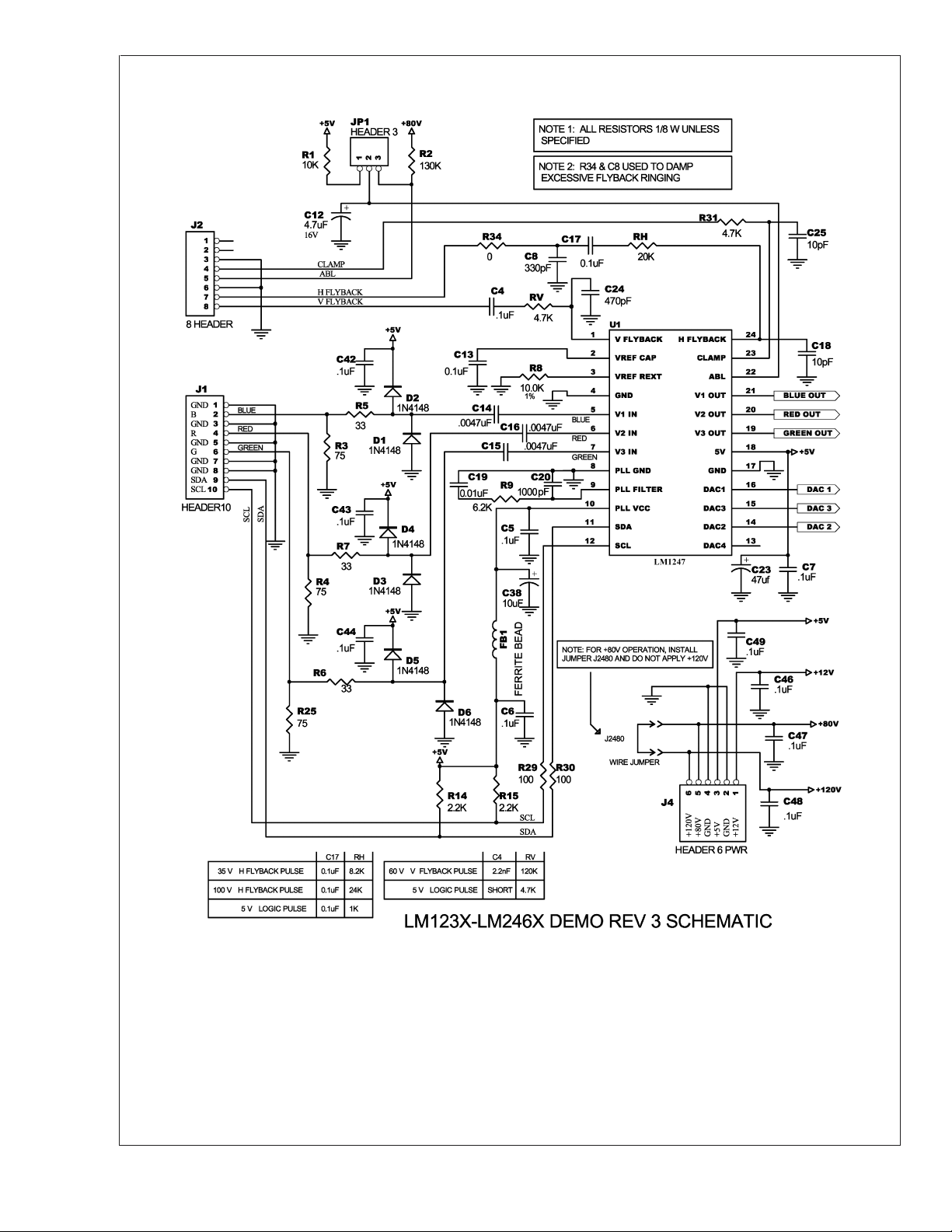

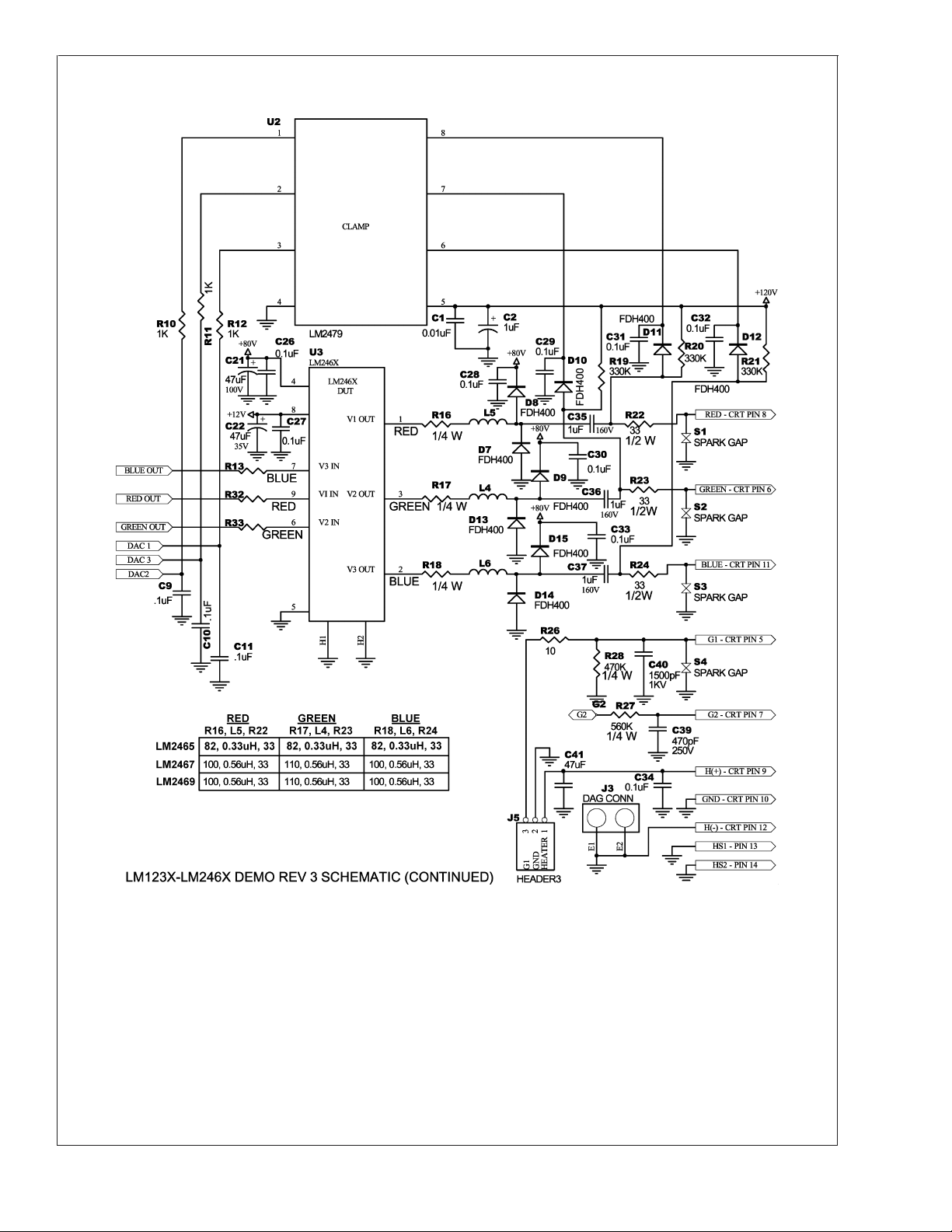

Schematic Diagram

LM1246

FIGURE 9. LM123x/LM124x-LM246x Demo Board Schematic

www.national.com 14

20068524

Schematic Diagram

LM1246

FIGURE 10. LM123x/LM124x-LM246x Demo Board Schematic (continued)

20068525

www.national.com15

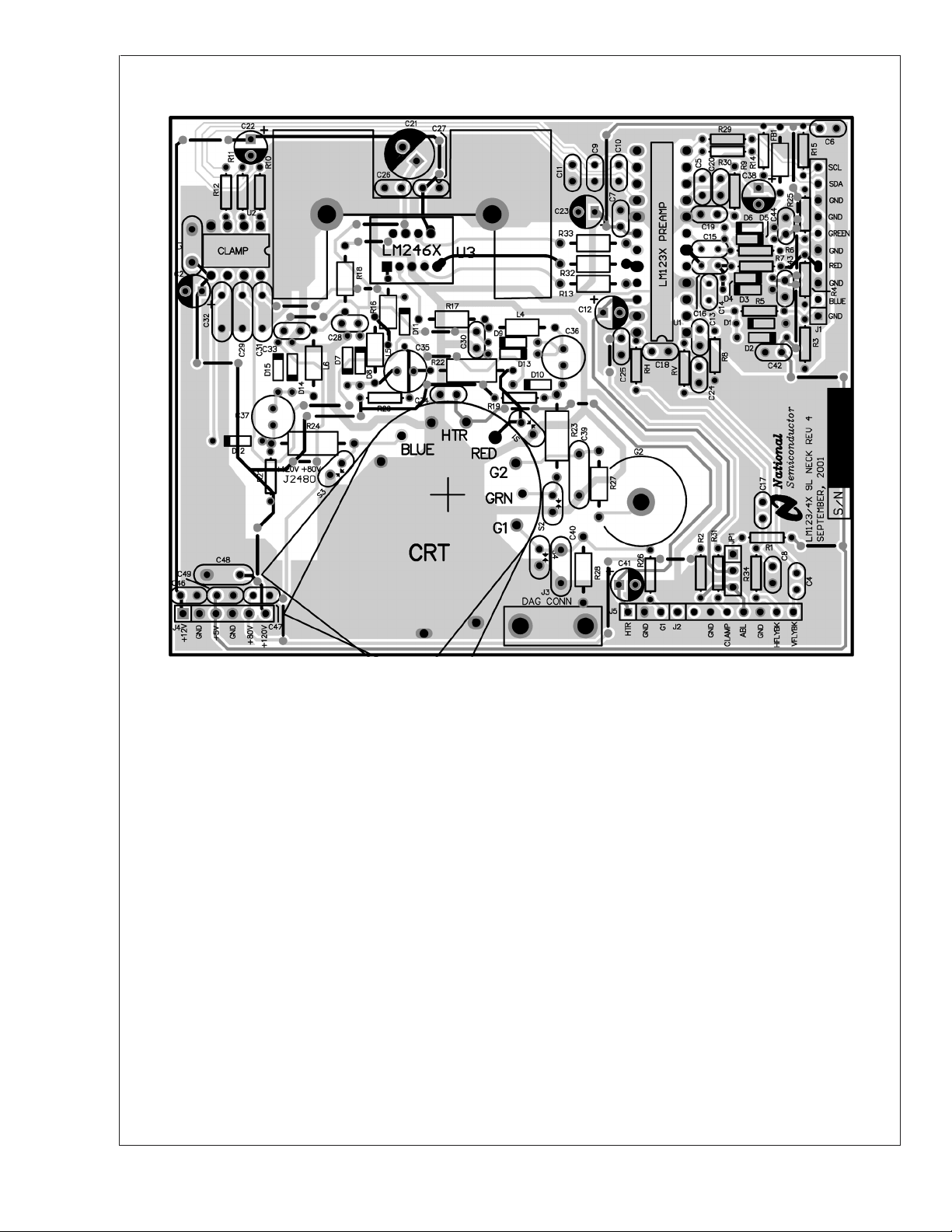

PCB Layout

LM1246

FIGURE 11. LM123x/LM124x-LM246x Demo Board Layout

20068526

www.national.com 16

Loading...

Loading...