LM117/LM317A/LM317

3-Terminal Adjustable Regulator

General Description

The LM117 series of adjustable 3-terminal positive voltage

regulators is capable of supplying in excess of 1.5A over a

1.2V to 37V output range. They are exceptionally easy to use

and require only two external resistors to set the output voltage. Further, both line and load regulation are better than

standard fixed regulators. Also, the LM117 is packaged in

standard transistor packages which are easily mounted and

handled.

In addition to higher performance than fixed regulators, the

LM117 series offers full overload protection available only in

IC's. Included on the chip are current limit, thermal overload

protection and safe area protection. All overload protection

circuitry remains fully functional even if the adjustment terminal is disconnected.

Normally, no capacitors are needed unless the device is situated more than 6 inches from the input filter capacitors in

which case an input bypass is needed. An optional output capacitor can be added to improve transient response. The

adjustment terminal can be bypassed to achieve very high

ripple rejection ratios which are difficult to achieve with standard 3-terminal regulators.

Besides replacing fixed regulators, the LM117 is useful in a

wide variety of other applications. Since the regulator is “floating” and sees only the input-to-output differential voltage,

supplies of several hundred volts can be regulated as long as

the maximum input to output differential is not exceeded, i.e.,

avoid short-circuiting the output.

Also, it makes an especially simple adjustable switching regulator, a programmable output regulator, or by connecting a

fixed resistor between the adjustment pin and output, the

LM117 can be used as a precision current regulator. Supplies

with electronic shutdown can be achieved by clamping the

adjustment terminal to ground which programs the output to

1.2V where most loads draw little current.

For applications requiring greater output current, see LM150

series (3A) and LM138 series (5A) data sheets. For the negative complement, see LM137 series data sheet.

Features

Guaranteed 1% output voltage tolerance (LM317A)

■

Guaranteed max. 0.01%/V line regulation (LM317A)

■

Guaranteed max. 0.3% load regulation (LM117)

■

Guaranteed 1.5A output current

■

Adjustable output down to 1.2V

■

Current limit constant with temperature

■

P+ Product Enhancement tested

■

80 dB ripple rejection

■

Output is short-circuit protected

■

LM117/LM317A/LM317 3-Terminal Adjustable Regulator

October 20, 2008

Typical Applications

1.2V–25V Adjustable Regulator

906301

Full output current not available at high input-output voltages

*Needed if device is more than 6 inches from filter capacitors.

†Optional—improves transient response. Output capacitors in the range

of 1μF to 1000μF of aluminum or tantalum electrolytic are commonly used

to provide improved output impedance and rejection of transients.

LM117/LM317A/LM317 Package Options

Part

Number

LM117, LM317 K TO-3 1.5A

LM317A, LM317 T TO-220 1.5A

LM317 S TO-263 1.5A

LM317A, LM317 EMP SOT-223 1.0A

LM117, LM317A, LM317 H TO-39 0.5A

LM117 E LCC 0.5A

LM317A, LM317 MDT TO-252 0.5A

Suffix Package

Current

SOT-223 vs. TO-252 (D-Pak) Packages

Scale 1:1

906354

Output

© 2008 National Semiconductor Corporation 9063 www.national.com

Connection Diagrams

Metal Can Package

LM117/LM317A/LM317

CASE IS OUTPUT

NS Package Number K02A or K02C

Surface-Mount Package

TO-3 (K)

Bottom View

Steel Package

TO-263 (S)

Top View

906330

TO-39 (H)

Metal Can Package

906331

CASE IS OUTPUT

Bottom View

NS Package Number H03A

TO-220 (T)

Plastic Package

906335

TO-263 (S)

Surface-Mount Package

Side View

906336

NS Package Number TS3B

Front View

906332

NS Package Number T03B

Ceramic Leadless

Chip Carrier (E)

Top View

NS Package Number E20A

906334

www.national.com 2

LM117/LM317A/LM317

4-Lead SOT-223 (EMP)

Front View

NS Package Number MP04A

Ordering Information

Package

TO-3

Metal Can

(K)

TO-220

3- Lead

TO-263

3- Lead

SOT-223

4- Lead

TO-39

Metal Can

(H)

LCC

TO-252

3- Lead

D-Pack

Temperature

Range

−55°C ≤ TJ ≤ +150°C

0°C ≤ TJ ≤ +125°C

−55°C ≤ TJ ≤ +150°C

−40°C ≤ TJ ≤ +125°C

0°C ≤ TJ ≤ +125°C

0°C ≤ TJ ≤ +125°C

0°C ≤ TJ ≤ +125°C

−40°C ≤ TJ ≤ +125°C

−55°C ≤ TJ ≤ +150°C

−55°C ≤ TJ ≤ +150°C

−40°C ≤ TJ ≤ +125°C

0°C ≤ TJ ≤ +125°C

−55°C ≤ TJ ≤ +150°C

0°C ≤ TJ ≤ +125°C

−40°C ≤ TJ ≤ +125°C

TO-252 (MDT)

906359

Front View

906366

NS Package Number TD03B

Output

Current

1.5A LM117K STEEL LM117K STEEL P+ 50 Per Bag

1.5A LM317K STEEL LM317K STEEL P+ 50 Per Bag

Order

Number

Package

Marking

Transport

Media

Drawing

K02A

1.5A LM117K/883 LM117K/883 50 Per Bag K02C

1.5A LM317AT LM317AT P+ 45 Units/Rail

1.5A LM317T LM317T P+ 45 Units/Rail

1.5A

1.0A

1.0A

LM317S

LM317SX 500 Units Tape and Reel

LM317EMP

LM317EMPX 2k Units Tape and Reel

LM317AEMP

LM317AEMPX 2k Units Tape and Reel

LM317S P+

N01A

N07A

45 Units/Rail

1k Units Tape and Reel

1k Units Tape and Reel

T03B

TS3B

MP04A

0.5A LM117H LM117H P+ 500 Per Box

0.5A LM117H/883 LM117H/883 20 Per Tray

0.5A LM317AH LM317AH P+ 500 Per Box

H03A

0.5A LM317H LM317H P+ 500 Per Box

0.5A LM117E/883 LM117E/883 50 Units/Rail E20A

0.5A

0.5A

LM317MDT

LM317MDTX 2.5k Units Tape and Reel

LM317AMDT

LM317AMDTX 2.5k Units Tape and Reel

LM317MDT

LM317AMDT

75 Units/Rail

75 Units/Rail

TD03B

NSC

3 www.national.com

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Power Dissipation Internally Limited

Input-Output Voltage Differential +40V, −0.3V

Storage Temperature −65°C to +150°C

Lead Temperature

LM117/LM317A/LM317

Metal Package (Soldering, 10 seconds) 300°C

Plastic Package (Soldering, 4 seconds) 260°C

ESD Tolerance (Note 5) 3 kV

Operating Temperature Range

LM117

LM317A

LM317

Preconditioning

Thermal Limit Burn-In All Devices 100%

−55°C ≤ TJ ≤ +150°C

−40°C ≤ TJ ≤ +125°C

0°C ≤ TJ ≤ +125°C

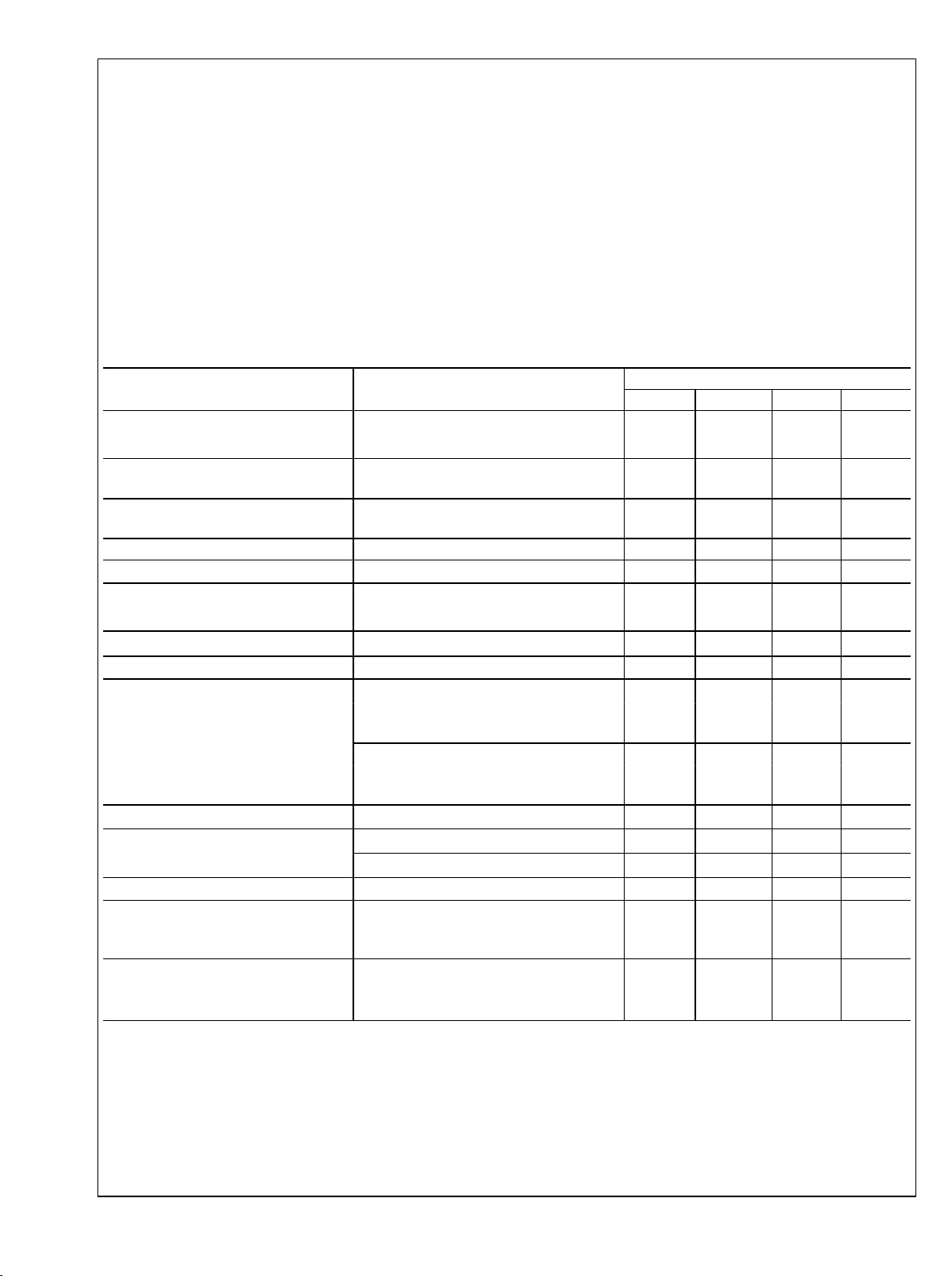

LM117 Electrical Characteristics (Note 3)

Specifications with standard type face are for TJ = 25°C, and those with boldface type apply over full Operating Temperature

Range. Unless otherwise specified, VIN − V

Parameter Conditions

Reference Voltage

Line Regulation

Load Regulation

Thermal Regulation 20 ms Pulse 0.03 0.07 %/W

Adjustment Pin Current 50 100

Adjustment Pin Current Change

Temperature Stability

Minimum Load Current

Current Limit

RMS Output Noise, % of V

OUT

Ripple Rejection Ratio

Long-Term Stability

Thermal Resistance, θ

JC

Junction-to-Case

Thermal Resistance, θ

JA

Junction-to-Ambient

(No Heat Sink)

= 5V, and I

OUT

3V ≤ (VIN − V

10 mA ≤ I

3V ≤ (VIN − V

10 mA ≤ I

10 mA ≤ I

3V ≤ (VIN − V

T

≤ TJ ≤ T

MIN

(VIN − V

OUT

(VIN − V

OUT

) ≤ 40V,

OUT

≤ I

OUT

MAX

) ≤ 40V (Note 4)

OUT

≤ I

OUT

MAX

≤ I

OUT

MAX

) ≤ 40V

OUT

MAX

) = 40V

) ≤ 15V

K Package

H, E Package

(VIN − V

OUT

) = 40V

K Package

H, E Package

10 Hz ≤ f ≤ 10 kHz

V

= 10V, f = 120 Hz, C

OUT

V

= 10V, f = 120 Hz, C

OUT

TJ = 125°C, 1000 hrs

K (TO-3) Package

H (TO-39) Package

E (LCC) Package

K (TO-3) Package

H (TO-39) Package

E (LCC) Package

= 10 mA.

OUT

(Note 4)

= 0 μF

ADJ

= 10 μF

ADJ

LM117 (Note 2)

Min Typ Max Units

1.20 1.25 1.30 V

0.01

0.02

0.1

0.3

0.02

0.05

0.3

1

0.2 5

1 %

3.5 5 mA

1.5

0.5

2.2

0.8

3.4

1.8

0.3

0.15

0.4

0.20

A

0.003 %

65 dB

66 80 dB

0.3 1 %

2

21

°C/W

12

39

186

°C/W

88

%/V

%

μA

μA

A

www.national.com 4

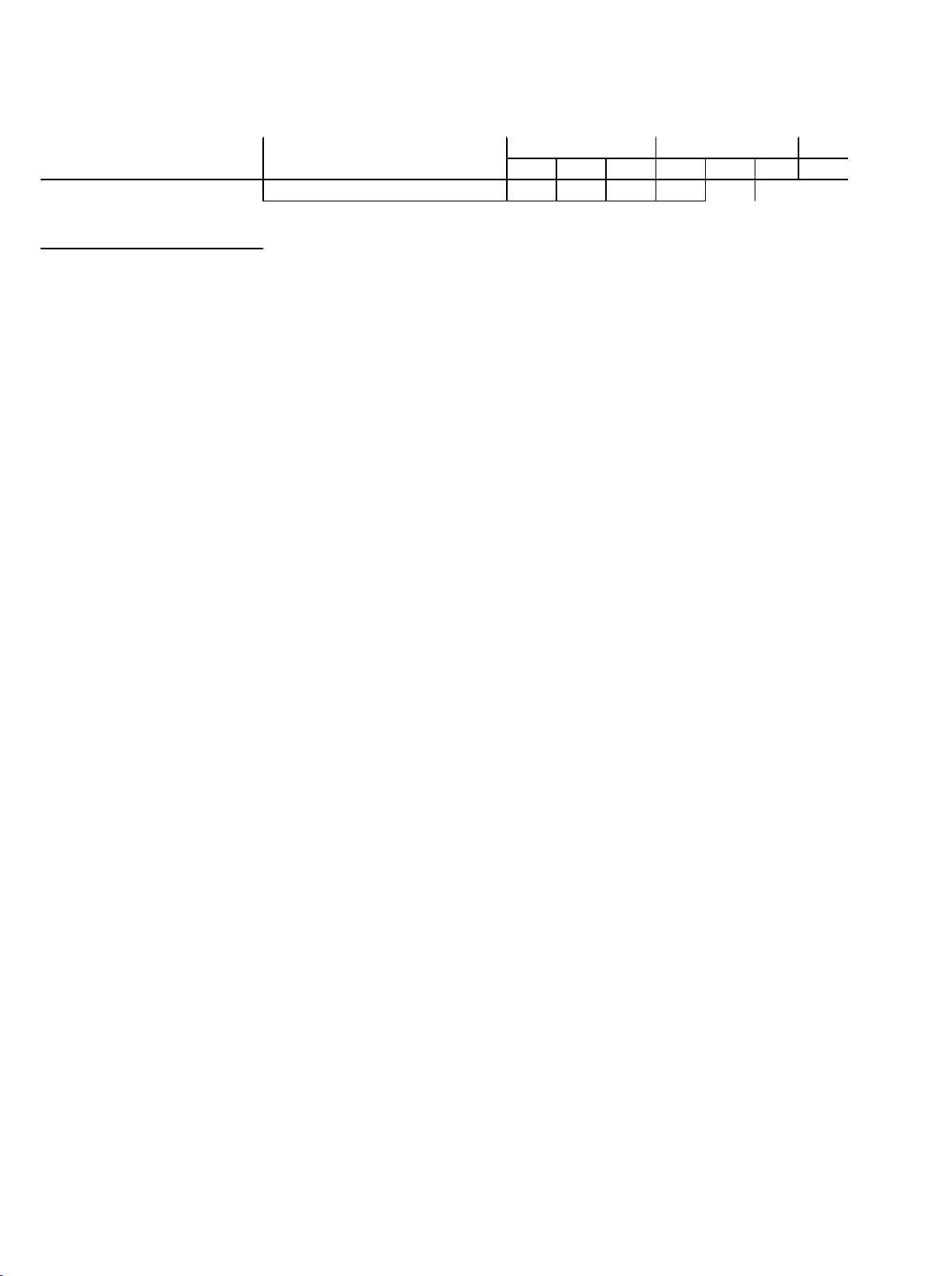

LM317A and LM317 Electrical Characteristics (Note 3)

Specifications with standard type face are for TJ = 25°C, and those with boldface type apply over full Operating Temperature

Range. Unless otherwise specified, VIN − V

Parameter Conditions

1.238 1.250 1.262 - 1.25

Reference Voltage

= 5V, and I

OUT

= 10 mA.

OUT

LM317A LM317

Min Typ Max Min Typ Max Units

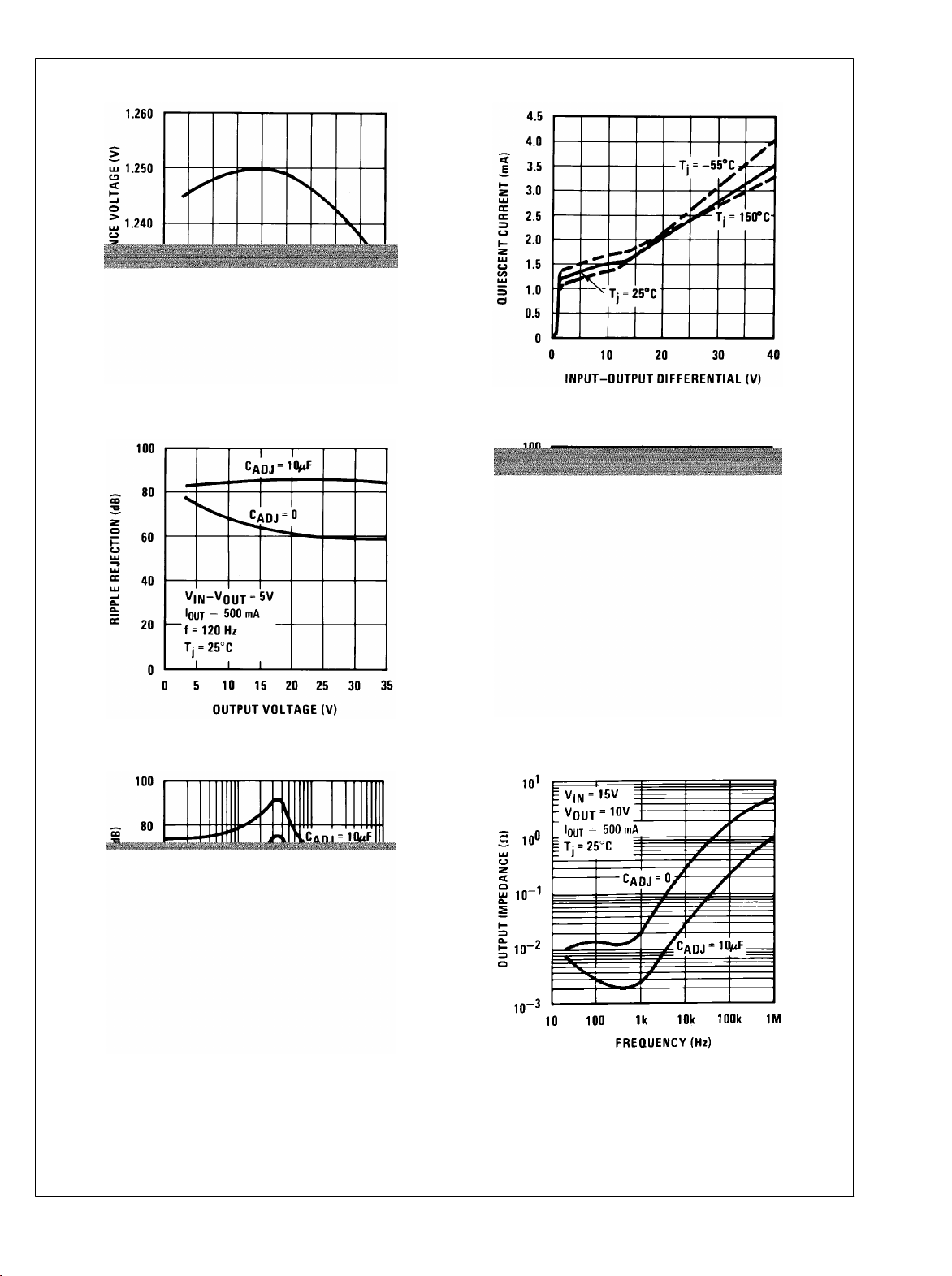

Typical Performance Characteristics Output Capacitor = 0 μF unless otherwise noted

LM117/LM317A/LM317

Adjustment Current

Load Regulation

906337

Current Limit

906338

Dropout Voltage

906339

V

vs VIN, V

OUT

www.national.com 6

OUT

= V

REF

906367

V

OUT

vs VIN, V

OUT

906340

= 5V

906368

LM117/LM317A/LM317

Temperature Stability

Ripple Rejection

906341

Minimum Operating Current

906342

Ripple Rejection

Ripple Rejection

906343

906345

906344

Output Impedance

906346

7 www.national.com

Line Transient Response

LM117/LM317A/LM317

Load Transient Response

906347

906348

www.national.com 8

LM117/LM317A/LM317

Application Hints

In operation, the LM117 develops a nominal 1.25V reference

voltage, V

The reference voltage is impressed across program resistor

R1 and, since the voltage is constant, a constant current I

then flows through the output set resistor R2, giving an output

voltage of

, between the output and adjustment terminal.

REF

906305

FIGURE 1.

(1)

aluminum electrolytic) on the output swamps this effect and

insures stability. Any increase of the load capacitance larger

than 10 μF will merely improve the loop stability and output

impedance.

1

LOAD REGULATION

The LM117 is capable of providing extremely good load regulation but a few precautions are needed to obtain maximum

performance. The current set resistor connected between the

adjustment terminal and the output terminal (usually 240Ω)

should be tied directly to the output (case) of the regulator

rather than near the load. This eliminates line drops from appearing effectively in series with the reference and degrading

regulation. For example, a 15V regulator with 0.05Ω resistance between the regulator and load will have a load regulation due to line resistance of 0.05Ω × IL. If the set resistor is

connected near the load the effective line resistance will be

0.05Ω (1 + R2/R1) or in this case, 11.5 times worse.

Figure 2 shows the effect of resistance between the regulator

and 240Ω set resistor.

Since the 100μA current from the adjustment terminal represents an error term, the LM117 was designed to minimize

I

and make it very constant with line and load changes. To

ADJ

do this, all quiescent operating current is returned to the output establishing a minimum load current requirement. If there

is insufficient load on the output, the output will rise.

EXTERNAL CAPACITORS

An input bypass capacitor is recommended. A 0.1μF disc or

1μF solid tantalum on the input is suitable input bypassing for

almost all applications. The device is more sensitive to the

absence of input bypassing when adjustment or output capacitors are used but the above values will eliminate the

possibility of problems.

The adjustment terminal can be bypassed to ground on the

LM117 to improve ripple rejection. This bypass capacitor prevents ripple from being amplified as the output voltage is

increased. With a 10 μF bypass capacitor 80dB ripple rejection is obtainable at any output level. Increases over 10 μF do

not appreciably improve the ripple rejection at frequencies

above 120Hz. If the bypass capacitor is used, it is sometimes

necessary to include protection diodes to prevent the capacitor from discharging through internal low current paths and

damaging the device.

In general, the best type of capacitors to use is solid tantalum.

Solid tantalum capacitors have low impedance even at high

frequencies. Depending upon capacitor construction, it takes

about 25 μF in aluminum electrolytic to equal 1μF solid tantalum at high frequencies. Ceramic capacitors are also good

at high frequencies; but some types have a large decrease in

capacitance at frequencies around 0.5 MHz. For this reason,

0.01 μF disc may seem to work better than a 0.1 μF disc as

a bypass.

Although the LM117 is stable with no output capacitors, like

any feedback circuit, certain values of external capacitance

can cause excessive ringing. This occurs with values between 500 pF and 5000 pF. A 1 μF solid tantalum (or 25 μF

906306

FIGURE 2. Regulator with Line Resistance in Output Lead

With the TO-3 package, it is easy to minimize the resistance

from the case to the set resistor, by using two separate leads

to the case. However, with the TO-39 package, care should

be taken to minimize the wire length of the output lead. The

ground of R2 can be returned near the ground of the load to

provide remote ground sensing and improve load regulation.

PROTECTION DIODES

When external capacitors are used with any IC regulator it is

sometimes necessary to add protection diodes to prevent the

capacitors from discharging through low current points into

the regulator. Most 10 μF capacitors have low enough internal

series resistance to deliver 20A spikes when shorted. Although the surge is short, there is enough energy to damage

parts of the IC.

When an output capacitor is connected to a regulator and the

input is shorted, the output capacitor will discharge into the

output of the regulator. The discharge current depends on the

value of the capacitor, the output voltage of the regulator, and

the rate of decrease of VIN. In the LM117, this discharge path

is through a large junction that is able to sustain 15A surge

with no problem. This is not true of other types of positive

regulators. For output capacitors of 25 μF or less, there is no

need to use diodes.

The bypass capacitor on the adjustment terminal can discharge through a low current junction. Discharge occurs when

either the input, or the output, is shorted. Internal to the LM117

is a 50Ω resistor which limits the peak discharge current. No

protection is needed for output voltages of 25V or less and 10

μF capacitance. Figure 3 shows an LM117 with protection

9 www.national.com

diodes included for use with outputs greater than 25V and

high values of output capacitance.

LM117/LM317A/LM317

D1 protects against C1

D2 protects against C2

FIGURE 3. Regulator with Protection Diodes

HEATSINK REQUIREMENTS

The LM317 regulators have internal thermal shutdown to protect the device from over-heating. Under all operating conditions, the junction temperature of the LM317 should not

exceed the rated maximum junction temperature (TJ) of 150°

C for the LM117, or 125°C for the LM317A and LM317. A

heatsink may be required depending on the maximum device

power dissipation and the maximum ambient temperature of

the application. To determine if a heatsink is needed, the

power dissipated by the regulator, PD, must be calculated:

PD = ((VIN − V

Figure 4 shows the voltage and currents which are present in

the circuit.

The next parameter which must be calculated is the maximum

allowable temperature rise, T

T

R(MAX)

where T

(150°C for the LM117, or 125°C for the LM317A/LM317), and

T

A(MAX)

encountered in the application.

is the maximum allowable junction temperature

J(MAX)

is the maximum ambient temperature which will be

Using the calculated values for T

allowable value for the junction-to-ambient thermal resistance

(θJA) can be calculated:

θJA = (T

) × IL) + (VIN × IG) (3)

OUT

:

R(MAX)

= T

− T

J(MAX)

R(MAX)

A(MAX)

and PD, the maximum

R(MAX)

/ PD) (5)

906307

(2)

(4)

906360

FIGURE 4. Power Dissipation Diagram

If the calculated maximum allowable thermal resistance is

higher than the actual package rating, then no additional work

is needed. If the calculated maximum allowable thermal resistance is lower than the actual package rating either the

power dissipation (PD) needs to be reduced, the maximum

ambient temperature T

mal resistance (θJA) must be lowered by adding a heatsink,

needs to be reduced, the ther-

A(MAX)

or some combination of these.

If a heatsink is needed, the value can be calculated from the

formula:

θHA ≤ (θJA - (θCH + θJC)) (6)

where (θCH is the thermal resistance of the contact area between the device case and the heatsink surface, and θJC is

thermal resistance from the junction of the die to surface of

the package case.

When a value for θ

heatsink must be selected that has a value that is less than,

is found using the equation shown, a

(H−A)

or equal to, this number.

The θ

ufacturer in the catalog, or shown in a curve that plots tem-

rating is specified numerically by the heatsink man-

(H−A)

perature rise vs power dissipation for the heatsink.

HEATSINKING SURFACE MOUNT PACKAGES

The TO-263 (S), SOT-223 (EMP) and TO-252 (MDT) packages use a copper plane on the PCB and the PCB itself as a

heatsink. To optimize the heat sinking ability of the plane and

PCB, solder the tab of the package to the plane.

HEATSINKING THE SOT-223 PACKAGE

Figure 5 and Figure 6 show the information for the SOT-223

package. Figure 6 assumes a θ

copper and 51°C/W for 2 ounce copper and a maximum junc-

of 74°C/W for 1 ounce

(J−A)

tion temperature of 125°C. Please see AN-1028 for thermal

enhancement techniques to be used with SOT-223 and

TO-252 packages.

www.national.com 10

LM117/LM317A/LM317

906357

FIGURE 5. θ

FIGURE 6. Maximum Power Dissipation vs T

vs Copper (2 ounce) Area for the

(J−A)

SOT-223 Package

SOT-223 Package

906358

AMB

for the

HEATSINKING THE TO-263 PACKAGE

Figure 7 shows for the TO-263 the measured values of θ

for different copper area sizes using a typical PCB with 1

−A)

ounce copper and no solder mask over the copper area used

for heatsinking.

As shown in Figure 7, increasing the copper area beyond 1

square inch produces very little improvement. It should also

be observed that the minimum value of θ

package mounted to a PCB is 32°C/W.

for the TO-263

(J−A)

906355

FIGURE 7. θ

vs Copper (1 ounce) Area for the TO-263

(J−A)

Package

As a design aid, Figure 8 shows the maximum allowable power dissipation compared to ambient temperature for the

TO-263 device (assuming θ

junction temperature is 125°C).

(J

FIGURE 8. Maximum Power Dissipation vs T

TO-263 Package

is 35°C/W and the maximum

(J−A)

906356

AMB

for the

HEATSINKING THE TO-252 PACKAGE

If the maximum allowable value for θJA is found to be ≥103°

C/W (Typical Rated Value) for TO-252 package, no heatsink

is needed since the package alone will dissipate enough heat

to satisfy these requirements. If the calculated value for θ

falls below these limits, a heatsink is required.

JA

As a design aid, Table 1 shows the value of the θJA of TO-252

for different heatsink area. The copper patterns that we used

to measure these θJAs are shown at the end of the Application

Notes Section. Figure 9 reflects the same test results as what

are in Table 1.

Figure 10 shows the maximum allowable power dissipation

vs. ambient temperature for the TO-252 device. Figure 11

shows the maximum allowable power dissipation vs. copper

area (in2) for the TO-252 device. Please see AN-1028 for

thermal enhancement techniques to be used with SOT-223

and TO-252 packages.

11 www.national.com

Layout Copper Area Thermal Resistance

Top Side (in2)* Bottom Side (in2)

1 0.0123 0 103

2 0.066 0 87

3 0.3 0 60

LM117/LM317A/LM317

4 0.53 0 54

5 0.76 0 52

6 1.0 0 47

7 0.066 0.2 84

8 0.066 0.4 70

9 0.066 0.6 63

10 0.066 0.8 57

11 0.066 1.0 57

12 0.066 0.066 89

13 0.175 0.175 72

14 0.284 0.284 61

15 0.392 0.392 55

16 0.5 0.5 53

Note:

* Tab of device attached to topside of copper.

TABLE 1. θJA Different Heatsink Area

(θJA°C/W) TO-252

FIGURE 9. θJA vs 2oz Copper Area for TO-252

www.national.com 12

906361

906363

FIGURE 10. Maximum Allowable Power Dissipation vs. Ambient Temperature for TO-252

LM117/LM317A/LM317

906362

FIGURE 11. Maximum Allowable Power Dissipation vs. 2oz Copper Area for TO-252

13 www.national.com

906364

FIGURE 12. Top View of the Thermal Test Pattern in Actual Scale

LM117/LM317A/LM317

FIGURE 13. Bottom View of the Thermal Test Pattern in Actual Scale

Schematic Diagram

906365

906308

15 www.national.com

Typical Applications

5V Logic Regulator with Electronic Shutdown*

LM117/LM317A/LM317

†Solid tantalum

*Discharges C1 if output is shorted to ground

High Stability 10V Regulator

*Min. output ≊ 1.2V

Slow Turn-On 15V Regulator

906309

Adjustable Regulator with Improved Ripple Rejection

906303

906311

906310

www.national.com 16

High Current Adjustable Regulator

LM117/LM317A/LM317

‡Optional—improves ripple rejection

†Solid tantalum

*Minimum load current = 30 mA

0 to 30V Regulator

906313

Full output current not available at high input-output voltages

906312

Power Follower

906314

17 www.national.com

LM117/LM317A/LM317

5A Constant Voltage/Constant Current Regulator

†Solid tantalum

*Lights in constant current mode

1A Current Regulator

906316

1.2V–20V Regulator with Minimum Program Current

906317

906315

*Minimum load current ≊ 4 mA

High Gain Amplifier

906318

www.national.com 18

Low Cost 3A Switching Regulator

LM117/LM317A/LM317

†Solid tantalum

*Core—Arnold A-254168-2 60 turns

906319

4A Switching Regulator with Overload Protection

†Solid tantalum

*Core—Arnold A-254168-2 60 turns

906320

Precision Current Limiter

906321

19 www.national.com

LM117/LM317A/LM317

Tracking Preregulator

906322

Current Limited Voltage Regulator

(Compared to LM117's higher current limit)

—At 50 mA output only ¾ volt of drop occurs in R3 and R

Adjusting Multiple On-Card Regulators with Single Control*

*All outputs within ±100 mV

†Minimum load—10 mA

906323

4

906324

www.national.com 20

AC Voltage Regulator

12V Battery Charger

LM117/LM317A/LM317

906325

Use of RS allows low charging rates with fully charged battery.

50mA Constant Current Battery Charger

906326

906327

21 www.national.com

LM117/LM317A/LM317

Adjustable 4A Regulator

Current Limited 6V Charger

*Sets peak current (0.6A for 1Ω)

**The 1000μF is recommended to filter out input transients

906329

*Sets maximum V

906328

Digitally Selected Outputs

906302

OUT

www.national.com 22

Physical Dimensions inches (millimeters) unless otherwise noted

LM117/LM317A/LM317

TO-3 Metal Can Package (K)

NS Package Number K02A

TO-3 Metal Can Package (K)

Mil-Aero Product

NS Package Number K02C

23 www.national.com

LM117/LM317A/LM317

TO-39 Metal Can Package (H)

NS Package Number H03A

3-Lead TO-220 (T)

NS Package Number T03B

www.national.com 24

3-Lead TO-263 (S)

NS Package Number TS3B

LM117/LM317A/LM317

Ceramic Leadless Chip Carrier (E)

NS Package Number E20A

25 www.national.com

LM117/LM317A/LM317

4-Lead SOT-223 (EMP)

NS Package Number MP04A

3-Lead D-Pack (MDT)

NS Package Number TD03B

www.national.com 26

Notes

LM117/LM317A/LM317

27 www.national.com

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

LM117/LM317A/LM317 3-Terminal Adjustable Regulator

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

www.national.com

National Semiconductor

Americas Technical

Support Center

Email: support@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Loading...

Loading...