查询COP324C供应商

COP424C, COP425C, COP426C, COP324C, COP325C,

COP326C and COP444C, COP445C, COP344C, COP345C

Single-Chip 1k and 2k CMOS Microcontrollers

April 1992

COP424C, COP425C, COP426C, COP324C, COP325C, COP326C and COP444C, COP445C,

COP344C, COP345C Single-Chip 1k and 2k CMOS Microcontrollers

General Description

The COP424C, COP425C, COP426C, COP444C and

COP445C fully static, Single-Chip CMOS Microcontrollers

are members of the COPS

TM

family, fabricated using double-poly, silicon gate microCMOS technology. These Controller Oriented Processors are complete microcomputers

containing all system timing, internal logic, ROM, RAM, and

I/O necessary to implement dedicated control functions in a

variety of applications. Features include single supply operation, a variety of output configuration options, with an instruction set, internal architecture and I/O scheme designed to facilitate keyboard input, display output and BCD

data manipulation. The COP424C and COP444C are 28 pin

chips. The COP425C and COP445C are 24-pin versions (4

inputs removed) and COP426C is 20-pin version with 15 I/O

lines. Standard test procedures and reliable high-density

techniques provide the medium to large volume customers

with a customized microcontroller at a low end-product cost.

These microcontrollers are appropriate choices in many demanding control environments especially those with human

interface.

The COP424C is an improved product which replaces the

COP420C.

COPSTM, MicrobusTM, and MICROWIRETMare trademarks of National Semiconductor Corp.

TRI-STATE

is a registered trademark of National Semiconductor Corp.

É

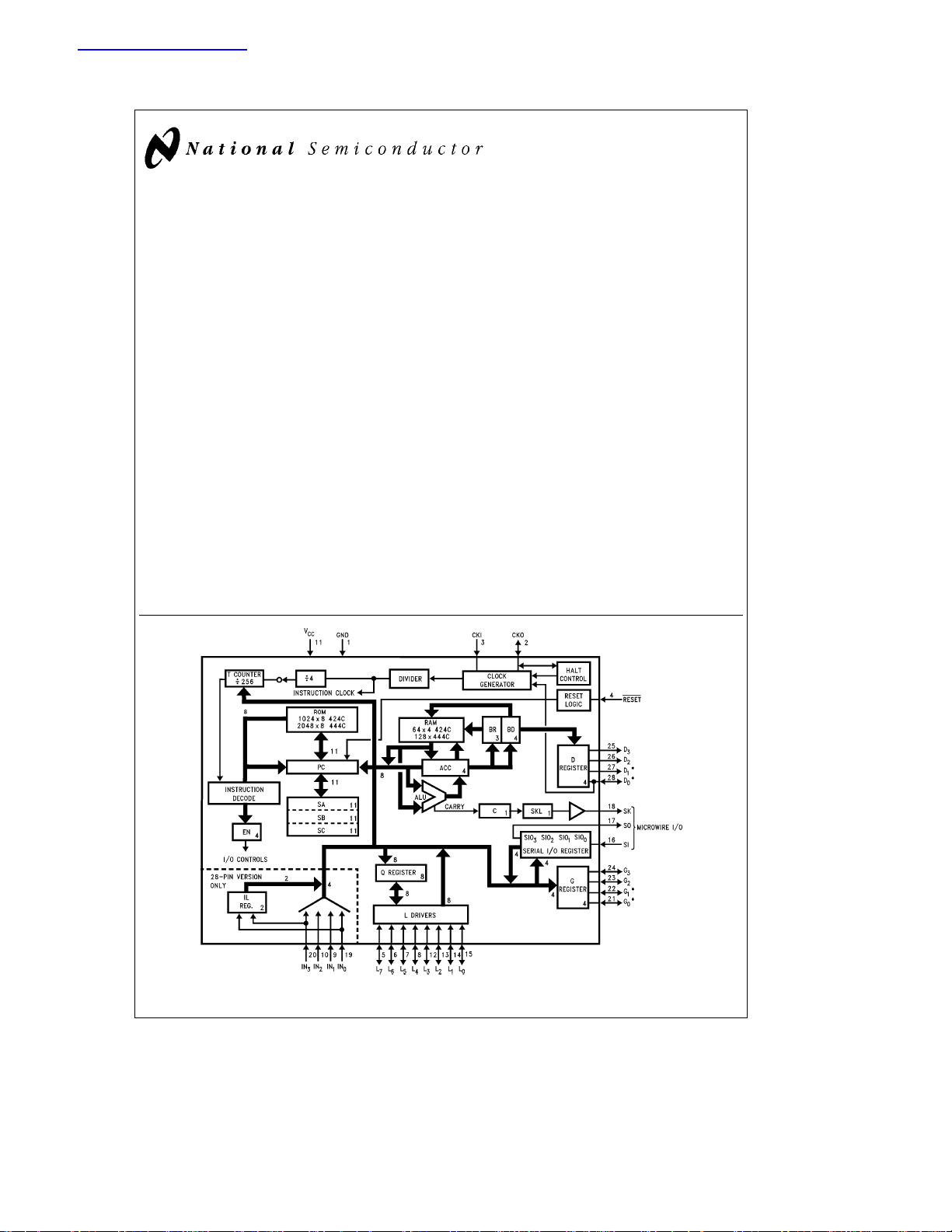

Block Diagram

Features

Y

Lowest power dissipation (50 mW typical)

Y

Fully static (can turn off the clock)

Y

Power saving IDLE state and HALT mode

Y

4 ms instruction time, plus software selectable clocks

Y

2k x 8 ROM, 128 x 4 RAM (COP444C/COP445C)

Y

1k x 8 ROM, 64 x 4 RAM (COP424C/COP425C/

COP426C)

Y

23 I/O lines (COP444C and COP424C)

Y

True vectored interrupt, plus restart

Y

Three-level subroutine stack

Y

Single supply operation (2.4V to 5.5V)

Y

Programmable read/write 8-bit timer/event counter

Y

Internal binary counter register with MICROWIRE

serial I/O capability

Y

General purpose and TRI-STATEÉoutputs

Y

LSTTL/CMOS output compatible

Y

MicrobusTMcompatible

Y

Software/hardware compatible with COP400 family

Y

Extended temperature range devices COP324C/

COP325C/COP326C and COP344C/COP345C (

a

to

85§C)

Y

Military devices (b55§Ctoa125§C) to be available

b

TM

40§C

* Not available on COP426C/COP326C

TL/DD/5259– 1

FIGURE 1

C

1995 National Semiconductor Corporation RRD-B30M105/Printed in U. S. A.

TL/DD/5259

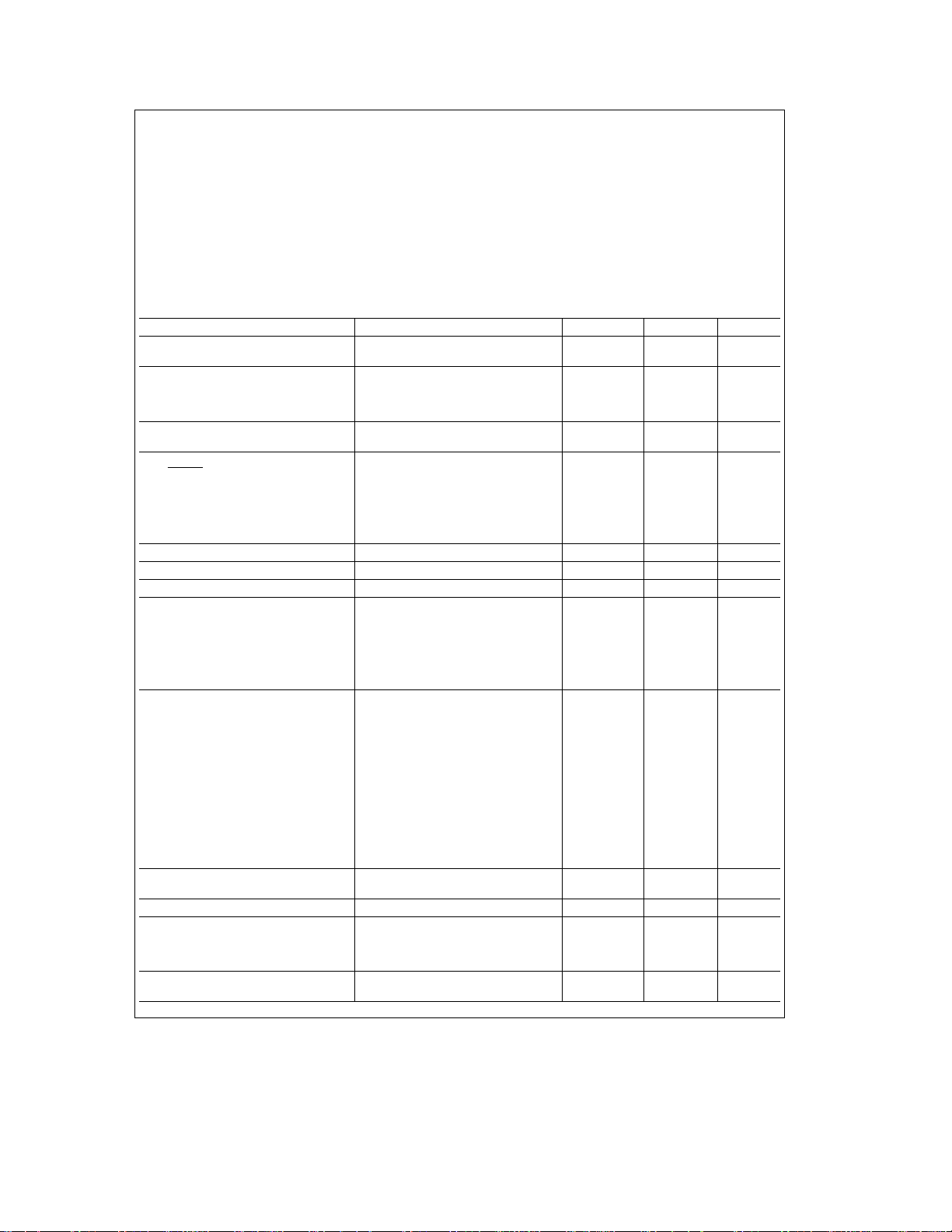

COP424C/COP425C/COP426C and COP444C/COP445C

Absolute Maximum Ratings

Note:

Supply Voltage (VCC)6V

Voltage at any Pin

b

0.3V to V

Total Allowable Source Current 25 mA

CC

a

0.3V

Total Allowable Sink Current 25 mA

Operating Temperature Range 0

Storage Temperature Range

Ctoa70§C

§

b

65§Ctoa150§C

Lead Temperature

(soldering, 10 seconds) 300

DC Electrical Characteristics 0

C

§

s

CsT

70§C unless otherwise specified

§

A

Parameter Conditions Min Max Units

Operating Voltage 2.4 5.5 V

Power Supply Ripple (Notes 4, 5) Peak to Peak 0.1 V

Supply Current V

(Note 1) V

HALT Mode Current V

(Note 2) V

Input Voltage Levels

, CKI, D0(clock input)

RESET

Logic High 0.9 V

Logic Low 0.1 V

All Other Inputs

Logic High 0.7 V

Logic Low 0.2 V

Input Pull-Up Current V

e

2.4V, tce64 ms 120 mA

CC

e

5.0V, tce16 ms 700 mA

CC

e

5.0V, tce4 ms 3000 mA

V

CC

(tc is instruction cycle time)

CC

CC

CC

e

e

e

5.0V, F

2.4V, F

4.5V, V

e

0 kHz 40 mA

IN

e

0 kHz 12 mA

IN

e

0

IN

Hi-Z Input Leakage

Input Capacitance (Note 4) 7pF

Output Voltage Levels Standard Outputs

LSTTL Operation V

Logic High I

Logic Low I

CMOS Operation

Logic High I

Logic Low I

Output Current Levels (except CKO)

Sink (Note 6) V

Source (Standard Option) V

Source (Low Current Option) V

CKO Current Levels (As Clock Out)

Sink

Source

Allowable Sink/Source Current per Pin 5 mA

(Note 6)

d

4 0.3 mA

d

8V

d

16 ( 1.2 mA

d

4

d

8V

d

16 (

e

5.0Vg10%

CC

eb

100 mA 2.7 V

OH

e

400 mA 0.4 V

OL

eb

10 mAV

OH

e

10 mA 0.2 V

OL

e

4.5V, V

CC

e

2.4V, V

V

CC

e

4.5V, V

CC

e

2.4V, V

V

CC

e

4.5V, V

CC

e

2.4V, V

V

CC

e

4.5V, CKIeVCC,V

CC

e

4.5V, CKIe0V, V

CC

OUT

OUT

OUT

OUT

OUT

OUT

e

e

e

e

e

e

Allowable Loading on CKO (as HALT) 100 pF

Current Needed to Over-Ride HALT

(Note 3)

To Continue V

To Halt V

TRI-STATE or Open Drain

Leakage Current

CC

CC

e

4.5V, V

e

4.5V, V

e

0.2V

IN

e

0.7V

IN

Absolute maximum ratings indicate limits beyond

which damage to the device may occur. DC and AC electrical specifications are not ensured when operating the device at absolute maximum ratings.

CC

V

V

0V

0V

0V

0V

CC

CC

CC

CC

OUT

OUT

CC

CC

b

30

b

1

b

0.2 V

CC

1.2 mA

0.2 mA

b

0.5 mA

b

0.1 mA

b

30

b

6

e

V

CC

e

0V

0.6 mA

b

0.3 mA

b

0.6 mA

b

1.2 mA

b

2.5

CC

CC

b

330 mA

a

1 mA

b

330 mA

b

80 mA

0.7 mA

1.6 mA

a

2.5 mA

V

V

V

V

V

2

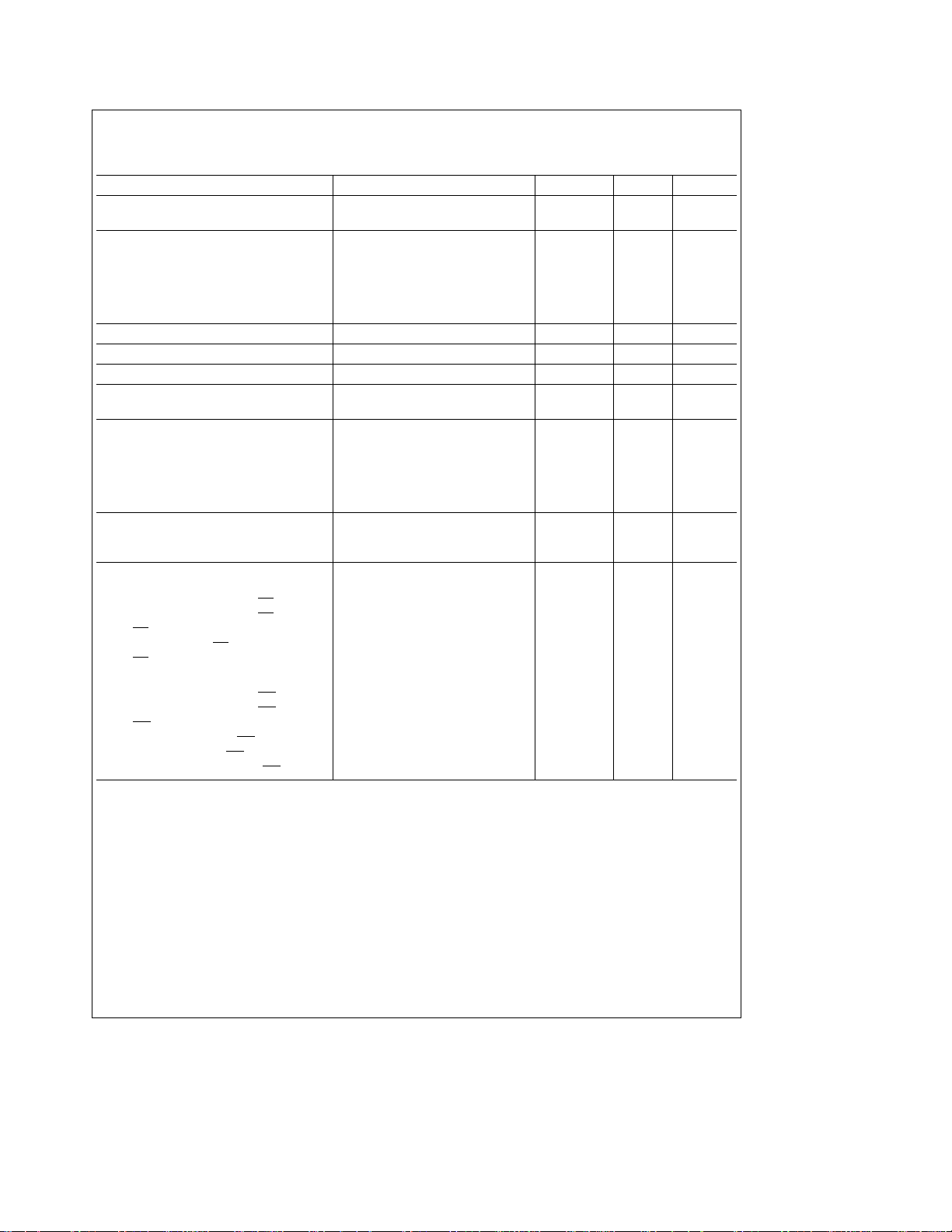

COP324C/COP325C/COP326C and COP344C/COP345C

Absolute Maximum Ratings

Note:

Supply Voltage 6V

Voltage at any Pin

b

0.3V to V

Total Allowable Source Current 25 mA

CC

a

0.3V

Total Allowable Sink Current 25 mA

b

Operating Temperature Range

Storage Temperature Range

40§Ctoa85§C

b

65§Ctoa150§C

Lead Temperature

b

40§CsT

C

§

s

a

A

(soldering, 10 seconds) 300

DC Electrical Characteristics

Parameter Conditions Min Max Units

Operating Voltage 3.0 5.5 V

Power Supply Ripple (Notes 4, 5) Peak to Peak 0.1 V

Supply Current V

(Note 1) V

HALT Mode Current V

(Note 2) V

Input Voltage Levels

, CKI, DO(clock input)

RESET

Logic High 0.9 V

Logic Low 0.1 V

All Other Inputs

Logic High 0.7 V

Logic Low 0.2 V

Input Pull-Up Current V

e

3.0V, tce64 ms 180 m A

CC

e

5.0V, tce16 ms 800 m A

CC

e

5.0V, tce4 ms 3600 m A

V

CC

(tc is instruction cycle time)

CC

CC

CC

e

e

e

5.0V, F

3.0V, F

4.5V, V

e

0 kHz 60 m A

IN

e

0 kHz 30 m A

IN

e

0

IN

Hi-Z Input Leakage

Input Capacitance (Note 4) 7pF

Output Voltage Levels Standard Outputs

LSTTL Operation V

Logic High I

Logic Low I

CMOS Operation

Logic High I

Logic Low I

Output Current Levels (except CKO)

Sink (Note 6) V

Source (Standard Option) V

Source (Low Current Option) V

CKO Current Levels (As Clock Out)

Sink

Source

Allowable Sink/Source Current per 5mA

Pin (Note 6)

d

4 0.3 mA

d

8V

d

16 ( 1.2 mA

d

4

d

8V

d

16 (

e

5.0Vg10%

CC

eb

100 mA 2.7 V

OH

e

400 mA 0.4 V

OL

eb

10 mAV

OH

e

10 mA 0.2 V

OL

e

4.5V, V

CC

e

3.0V, V

V

CC

e

4.5V, V

CC

e

3.0V, V

V

CC

e

4.5V, V

CC

e

3.0V, V

V

CC

e

4.5V, CKIeVCC,V

CC

e

4.5V, CKIe0V, V

CC

OUT

OUT

OUT

OUT

OUT

OUT

e

e

e

e

e

e

Allowable Loading on CKO (as HALT) 100 pF

Current Needed to Over-Ride HALT

(Note 3)

To Continue V

To Halt V

TRI-STATE or Open Drain

Leakage Current

CC

CC

e

4.5V, V

e

4.5V, V

e

0.2V

IN

e

0.7V

IN

Absolute maximum ratings indicate limits beyond

which damage to the device may occur. DC and AC electrical specifications are not ensured when operating the device at absolute maximum ratings.

85§C unless otherwise specified

CC

V

V

0V

0V

0V

0V

CC

CC

CC

CC

OUT

OUT

CC

CC

b

30

b

2

b

0.2 V

CC

1.2 mA

0.2 mA

b

0.5 mA

b

0.1 mA

b

30

b

8

e

V

CC

e

0V

0.6 mA

b

0.3 mA

b

0.6 mA

b

1.2 mA

b

5

CC

CC

b

440 m A

a

2 mA

b

440 m A

b

200 m A

0.9 mA

2.1 mA

a

5 mA

V

V

V

V

V

3

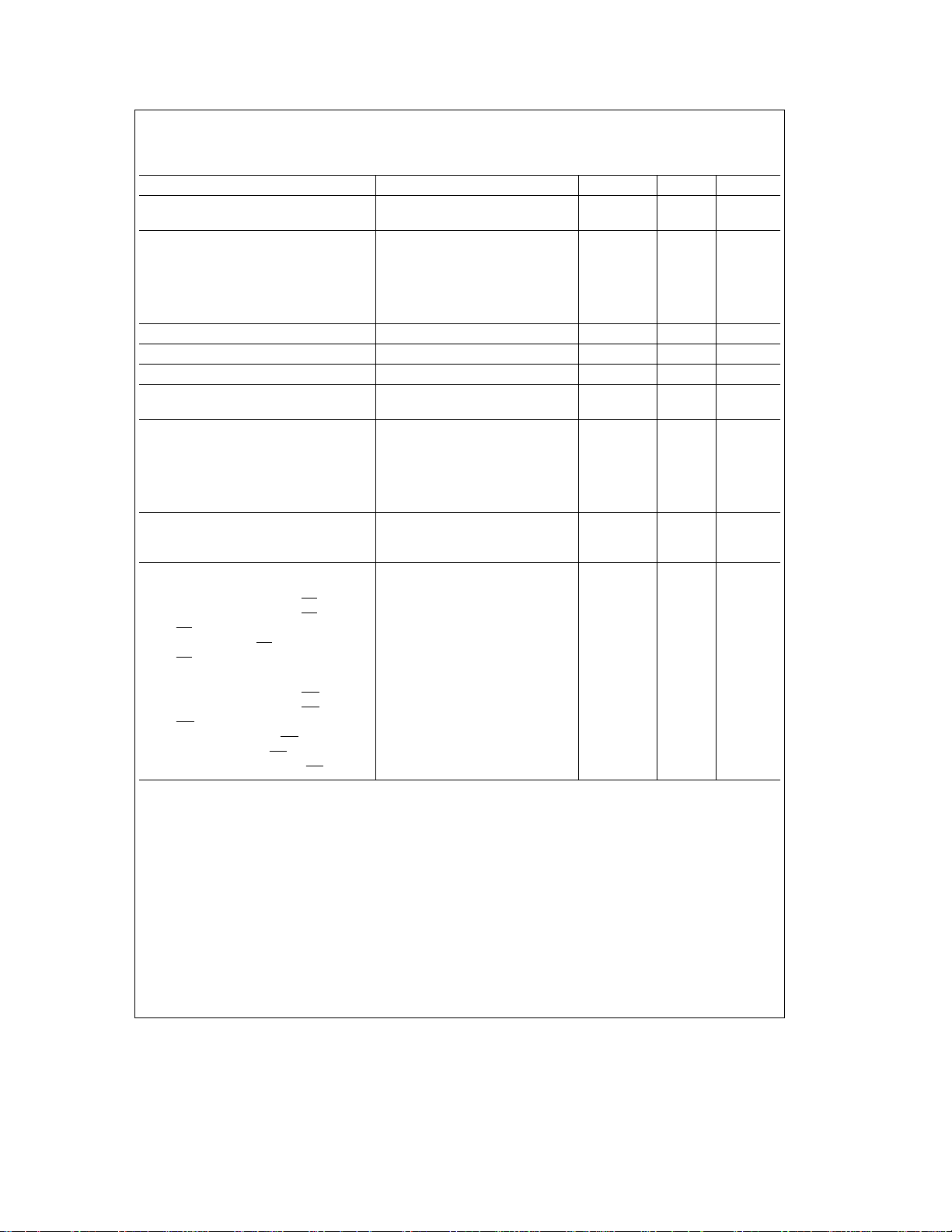

COP424C/COP425C/COP426C and COP444C/COP445C

s

AC Electrical Characteristics

0§CsT

Parameter Conditions Min Max Units

Instruction Cycle Time (tc) V

Operating CKI

Frequency

d

4 mode DC 1.0 MHz

d

8 mode V

d

16 mode ( DC 4.0 MHz

d

4 mode DC 250 kHz

d

8 mode 4.5VlV

d

16 mode ( DC 1.0 MHz

Duty Cycle (Note 4) f

Rise Time (Note 4) f

Fall Time (Note 4) f

Instruction Cycle Time Re30kg5%, V

RC Oscillator (Note 4) C

Inputs: (See

t

SETUP

t

HOLD

Figure 3

)

Output Propagation Delay V

t

PD1,tPD0

t

PD1,tPD0

Microbus Timing CLe50 pF, V

Read Operation (

Chip Select Stable before RD

Chip Select Hold Time for RDbt

RD

Pulse Widthbt

Data Delay from RD

RD

to Data FloatingbtDF(Note 4) 250 ns

Write Operation (

Chip Select Stable before WR

Chip Select Hold Time for WR

WR Pulse Widthbt

Data Set-Up Time for WR

Data Hold Time for WR

INTR Transition Time from WR

Note 1: Supply current is measured after running for 2000 cycle times with a square-wave clock on CKI, CKO open, and all other pins pulled up to VCCwith 5k

resistors. See current drain equation on page 17.

Note 2: The HALT mode will stop CKI from oscillating in the RC and crystal configurations. Test conditions: all inputs tied to V

tied to ground, all outputs low and tied to ground.

Note 3: When forcing HALT, current is only needed for a short time (approx. 200 ns) to flip the HALT flip-flop.

Note 4: This parameter is only sampled and not 100% tested. Variation due to the device included.

Note 5: Voltage change must be less than 0.5 volts ina1msperiod.

Note 6: SO output sink current must be limited to keep V

Figure 4

RR

b

Figure 5

WW

)

b

t

CSR

RCS

t

RD

)

b

t

CSW

b

t

WCS

b

t

DW

b

t

WD

b

t

WI

less than 0.2VCCwhen part is running in order to prevent entering test mode.

OL

70§C unless otherwise specified.

A

t

4.5V 4 DC ms

CC

t

l

4.5V

V

2.4V 16 DC ms

CC

t

4.5V DC 2.0 MHz

CC

t

2.4V DC 500 kHz

CC

e

4 MHz 40 60 %

1

e

4 MHz External Clock 60 ns

1

e

4 MHz External Clock 40 ns

1

e

5V

e

82 pFg5% (d4 Mode)

CC

511ms

G Inputs tc/4a.7 ms

SI Input V

All Others

t

V

4.5V 0.25 m s

CC

4.5VlV

CC

e

1.5V, C

OUT

t

V

4.5V 1.0 ms

CC

4.5VlV

CC

t

4.5V 0.3 ms

CC

( 1.7 ms

t

2.4V 1.0 ms

e

100 pF, R

L

t

2.4V 4.0 ms

e

5Vg5%

CC

e

5k

L

65 ns

20 ns

400 ns

375 ns

65 ns

20 ns

400 ns

320 ns

100 ns

700 ns

, L lines in TRI-STATE mode and

CC

4

COP324C/COP325C/COP326C and COP344C/COP345C

AC Electrical Characteristics

b

40§CsT

s

a

85§C unless otherwise specified.

A

Parameter Conditions Min Max Units

Instruction Cycle Time (tc) V

Operating CKI

Frequency

d

4 mode DC 1.0 MHz

d

8 mode V

d

16 mode ( DC 4.0 MHz

d

4 mode DC 250 kHz

d

8 mode 4.5VlV

d

16 mode ( DC 1.0 MHz

Duty Cycle (Note 4) f

Rise Time (Note 4) f

Fall Time (Note 4) f

Instruction Cycle Time Re30kg5%, V

RC Oscillator (Note 4) C

Inputs: (See

t

SETUP

t

HOLD

Figure 3

)

Output Propagation Delay V

t

PD1,tPD0

t

PD1,tPD0

Microbus Timing C

Read Operation (

Chip Select Stable before RD

Chip Select Hold Time for RDbt

RD

Pulse Widthbt

Data Delay from RD

RD

to Data FloatingbtDF(Note 4) 250 ns

Write Operation (

Chip Select Stable before WR

Chip Select Hold Time for WR

WR Pulse Widthbt

Data Set-Up Time for WR

Data Hold Time for WR

INTR Transition Time from WR

Note 1: Supply current is measured after running for 2000 cycle times with a square-wave clock on CKI, CKO open, and all other pins pulled up to VCCwith 5k

resistors. See current drain equation on page 17.

Note 2: The HALT mode will stop CKI from oscillating in the RC and crystal configurations. Test conditions: all inputs tied to V

tied to ground, all outputs low and tied to ground.

Note 3: When forcing HALT, current is only needed for a short time (approx. 200 ns) to flip the HALT flip-flop.

Note 4: This parameter is only sampled and not 100% tested. Variation due to the device included.

Note 5: Voltage change must be less than 0.5 volts ina1msperiod.

Note 6: SO output sink current must be limited to keep V

Figure 4

RR

b

Figure 5

WW

)

b

t

CSR

RCS

t

RD

)

b

t

CSW

b

t

WCS

b

t

DW

b

t

WD

b

t

WI

t

4.5V 4 DC ms

CC

t

l

4.5V

V

3.0V 16 DC ms

CC

t

4.5V DC 2.0 MHz

CC

t

3.0V DC 500 kHz

CC

e

4 MHz 40 60 %

1

e

4 MHz external clock 60 ns

1

e

4 MHz external clock 40 ns

1

e

5V

e

82 pFg5% (d4 Mode)

CC

511ms

G Inputs tc/4a.7 ms

SI Inputs V

All Others

t

V

4.5V 0.25 m s

CC

4.5VlV

CC

e

1.5V, C

OUT

t

V

4.5V 1.0 ms

CC

4.5VlV

CC

e

50 pF, V

L

t

4.5V 0.3 ms

CC

( 1.7 ms

t

3.0V 1.0 ms

e

100 pF, R

L

t

3.0V 4.0 ms

e

5Vg5%

CC

e

5k

L

65 ns

20 ns

400 ns

375 ns

65 ns

20 ns

400 ns

320 ns

100 ns

700 ns

, L lines in TRI-STATE mode and

CC

less than 0.2VCCwhen part is running in order to prevent entering test mode.

OL

5

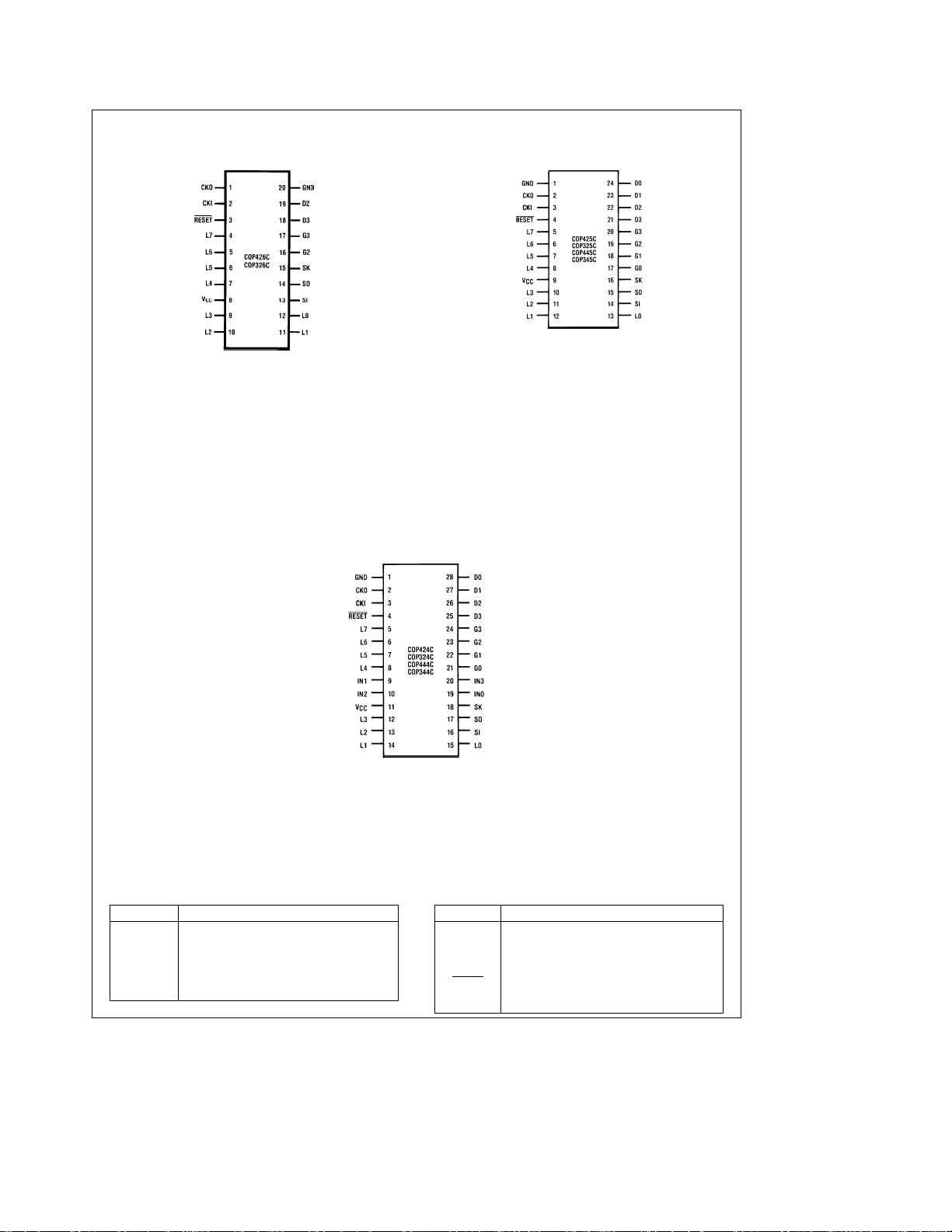

Connection Diagrams

DIP and S.O. Wide

DIP and S.O. Wide

Top View

TL/DD/5259– 16

Order Number COP326C-XXX/D

or COP426C-XXX/D

See NS Hermetic Package D20A

(Prototype Package Only)

Order Number COP326C-XXX/N

or COP426C-XXX/N

See NS Molded Package N20A

Order Number COP326C-XXX/WM

or COP426C-XXX/WM

See NS Surface Mount Package M20B

Order Number COP324C-XXX/D, COPC324-XXX/WM, COP344C-XXX/D,

COP424C-XXX/D, COPC424-XXX/WM or COP444C-XXX/D

See NS Hermetic Package D28C

Order Number COP324C-XXX/N, COP344C-XXX/N, COPC344-XXX/WM,

COP424C-XXX/N, COP444C-XXX/N or COPC444-XXX/WM

See NS Molded Package N28B

Pin Description

L7– L0 8-bit bidirectional port with TRI-STATE

G3– G0 4-bit bidirectional I/O port

D3– D0 4-bit output port

IN3– IN0 4-bit input port (28-pin package only)

SI Serial input or counter input

SO Serial or general purpose output

Order Number COP325C-XXX/D, COP445C-XXX/D,

Order Number COP325C-XXX/N, COP345C-XXX/N,

Order Number COP325C-XXX/WM, COP345C-XXX/WM,

Dual-In-Line Package

Top View

(Prototype Package Only)

FIGURE 2

Pin Description

SK Logic controlled clock output

CKI Chip oscillator input

CKO Oscillator output, HALT I/O port or general

RESET

V

CC

GND Ground

6

Top View

TL/DD/5259– 2

COP425C-XXX/D or COP345C-XXX/D

See NS Hermetic Package D24C

(Prototype Package Only)

COP425C-XXX/N or COP445C-XXX/N

See NS Molded Package N24A

COP425C-XXX/WM or COP445C-XXX/WM

See NS Surface Mount Package M24B

TL/DD/5259– 3

purpose input

Reset input

Most positive power supply

Functional Description

The internal architecture is shown in

are illustrated in simplified form to depict how the various

logic elements communicate with each other in implementing the instruction set of the device. Positive logic is used.

When a bit is set, it is a logic ‘‘1’’, when a bit is reset, it is a

logic ‘‘0’’.

For ease of reading only the COP424C/425C/COP426C/

444C/445C are referenced; however, all such references

apply equally to COP324C/325C/COP326C/344C/345C.

PROGRAM MEMORY

Program Memory consists of ROM, 1024 bytes for the

COP424C/425C/426C and 2048 bytes for the COP444C/

445C. These bytes of ROM may be program instructions,

constants or ROM addressing data.

ROM addressing is accomplished by a 11-bit PC register

which selects one of the 8-bit words contained in ROM. A

new address is loaded into the PC register during each instruction cycle. Unless the instruction is a transfer of control

instruction, the PC register is loaded with the next sequential 11-bit binary count value.

Three levels of subroutine nesting are implemented by a

three level deep stack. Each subroutine call or interrupt

pushes the next PC address into the stack. Each return

pops the stack back into the PC register.

DATA MEMORY

Data memory consists of a 512-bit RAM for the COP444C/

445C, organized as 8 data registers of 16

RAM addressing is implemented by a 7-bit B register whose

upper 3 bits (Br) select 1 of 8 data registers and lower 4 bits

(Bd) select 1 of 16 4-bit digits in the selected data register.

Data memory consists of a 256-bit RAM for the COP424C/

425C/426C, organized as 4 data registers of 16

digits. The B register is 6 bits long. Upper 2 bits (Br) select 1

of 4 data registers and lower 4 bits (Bd) select 1 of 16 4-bit

digits in the selected data register. While the 4-bit contents

of the selected RAM digit (M) are usually loaded into or

from, or exchanged with, the A register (accumulator), it

may also be loaded into or from the Q latches or T counter

or loaded from the L ports. RAM addressing may also be

performed directly by the LDD and XAD instructions based

upon the immediate operand field of these instructions.

The Bd register also serves as a source register for 4-bit

data sent directly to the D outputs.

Figure 1

. Data paths

c

4-bit digits.

c

4-bits

INTERNAL LOGIC

The processor contains its own 4-bit A register (accumulator) which is the source and destination register for most I/O,

arithmetic, logic, and data memory access operations. It can

also be used to load the Br and Bd portions of the B register, to load and input 4 bits of the 8-bit Q latch or T counter,

to input 4 bits of L I/O ports data, to input 4-bit G, or IN

ports, and to perform data exchanges with the SIO register.

A 4-bit adder performs the arithmetic and logic functions,

storing the results in A. It also outputs a carry bit to the 1-bit

C register, most often employed to indicate arithmetic overflow. The C register in conjunction with the XAS instruction

and the EN register, also serves to control the SK output.

The 8-bit T counter is a binary up counter which can be

loaded to and from M and A using CAMT and CTMA instructions. When the T counter overflows, an overflow flag will be

set (see SKT and IT instructions below). The T counter is

cleared on reset. A functional block diagram of the timer/

counter is illustrated in

Four general-purpose inputs, IN3-IN0, are provided. IN1,

IN2 and IN3 may be selected, by a mask-programmable option as Read Strobe, Chip Select, and Write Strobe inputs,

respectively, for use in Microbus application.

The D register provides 4 general-purpose outputs and is

used as the destination register for the 4-bit contents of Bd.

In the dual clock mode, D0 latch controls the clock selection

(see dual oscillator below).

The G register contents are outputs to a 4-bit general-purpose bidirectional I/O port. G0 may be mask-programmed

as an output for Microbus applications.

The Q register is an internal, latched, 8-bit register, used to

hold data loaded to or from M and A, as well as 8-bit data

from ROM. Its contents are outputted to the L I/O ports

when the L drivers are enabled under program control. With

the Microbus option selected, Q can also be loaded with the

8-bit contents of the L I/O ports upon the occurrence of a

write strobe from the host CPU.

The 8 L drivers, when enabled, output the contents of

latched Q data to the L I/O port. Also, the contents of L may

be read directly into A and M. As explained above, the

Microbus option allows L I/O port data to be latched into the

Q register.

Figure 10a

.

7

Functional Description (Continued)

The SIO register functions as a 4-bit serial-in/serial-out shift

register for MICROWIRE I/O and COPS peripherals, or as a

binary counter (depending on the contents of the EN register). Its contents can be exchanged with A.

The XAS instruction copies C into the SKL latch. In the

counter mode, SK is the output of SKL; in the shift register

mode, SK outputs SKL ANDed with the clock.

EN is an internal 4-bit register loaded by the LEI instruction.

The state of each bit of this register selects or deselects the

particular feature associated with each bit of the EN register:

0. The least significant bit of the enable register, EN0, selects the SIO register as either a 4-bit shift register or a

4-bit binary counter. With EN0 set, SIO is an asynchronous binary counter, decrementing its value by one upon

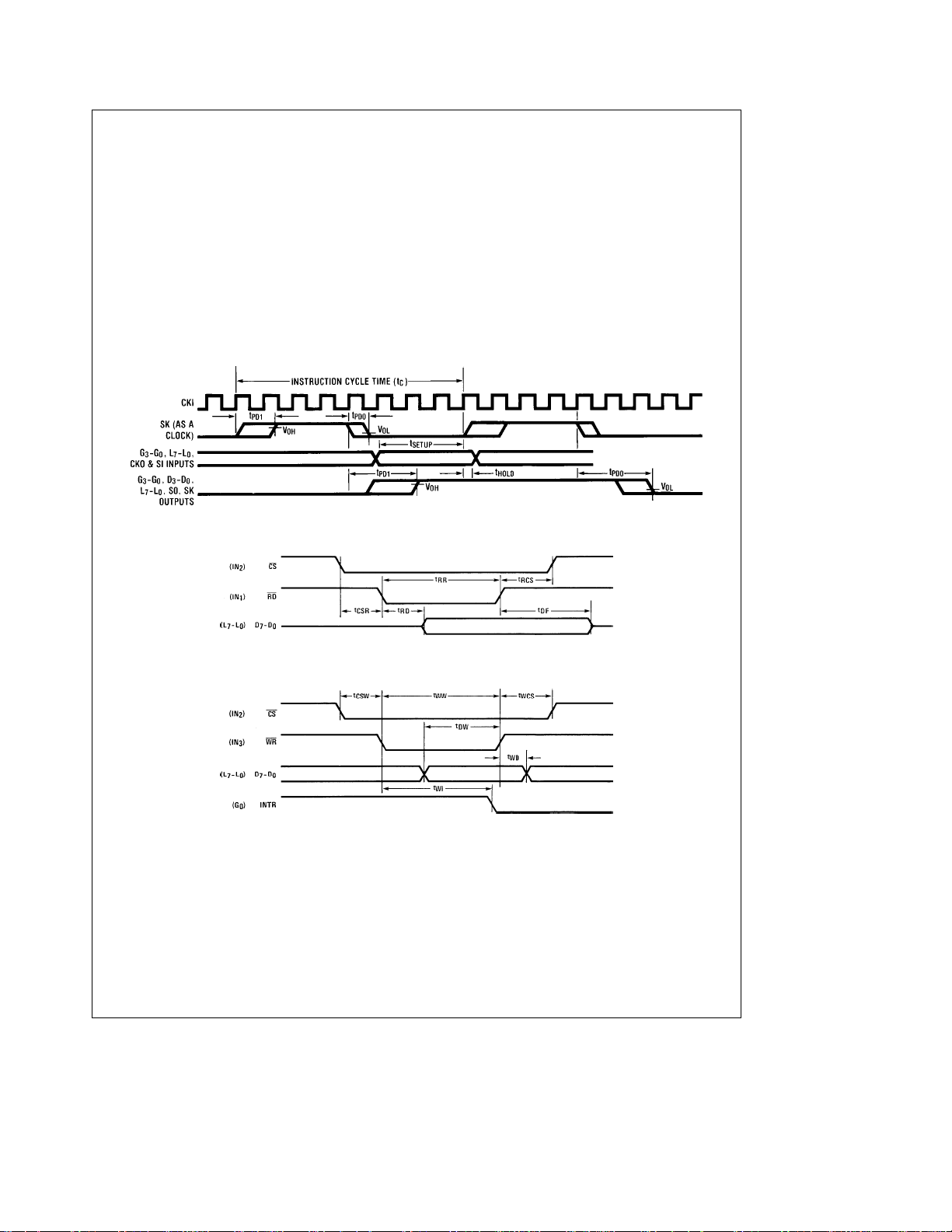

FIGURE 3. Input/Output Timing Diagrams (divide by 8 mode)

each low-going pulse (‘‘1’’ to ‘‘0’’) occurring on the SI

input. Each pulse must be at least two instruction cycles

wide. SK outputs the value of SKL. The SO output equals

the value of EN3. With EN0 reset, SIO is a serial shift

register left shifting 1 bit each instruction cycle time. The

data present at SI goes into the least significant bit of

SIO. SO can be enabled to output the most significant bit

of SIO each cycle time. The SK outputs SKL ANDed with

the instruction cycle clock.

1. With EN1 set, interrupt is enabled. Immediately following

an interrupt, EN1 is reset to disable further interrupts.

2. With EN2 set, the L drivers are enabled to output the data

in Q to the L I/O port. Resetting EN2 disables the L drivers, placing the L I/O port in a high-impedance input

state.

TL/DD/5259– 4

FIGURE 4. Microbus Read Operation Timing

FIGURE 5. Microbus Write Operation Timing

8

TL/DD/5259– 5

TL/DD/5259– 6

Functional Description (Continued)

3. EN3, in conjunction with EN0, affects the SO output. With

EN0 set (binary counter option selected) SO will output

the value loaded into EN3. With EN0 reset (serial shift

register option selected), setting EN3 enables SO as the

output of the SIO shift register, outputting serial shifted

data each instruction time. Resetting EN3 with the serial

shift register option selected disables SO as the shift register output; data continues to be shifted through SIO and

can be exchanged with A via an XAS instruction but SO

remains set to ‘‘0’’.

INTERRUPT

The following features are associated with interrupt procedure and protocol and must be considered by the programmer when utilizing interrupts.

a. The interrupt, once recognized as explained below,

pushes the next sequential program counter address

a

(PC

1) onto the stack. Any previous contents at the bottom of the stack are lost. The program counter is set to

hex address 0FF (the last word of page 3) and EN1 is

reset.

b. An interrupt will be recognized only on the following con-

ditions:

1. EN1 has been set.

2. A low-going pulse (‘‘1’’ to ‘‘0’’) at least two instruction

cycles wide has occurred on the IN

3. A currently executing instruction has been completed.

4. All successive transfer of control instructions and suc-

cessive LBIs have been completed (e.g. if the main

program is executing a JP instruction which transfers

program control to another JP instruction, the interrupt

will not be acknowledged until the second JP instruction has been executed).

c. Upon acknowledgement of an interrupt, the skip logic

status is saved and later restored upon popping of the

stack. For example, if an interrupt occurs during the execution of ASC (Add with Carry, Skip on Carry) instruction

which results in carry, the skip logic status is saved and

program control is transferred to the interrupt servicing

routine at hex address 0FF. At the end of the interrupt

routine, a RET instruction is executed to pop the stack

and return program control to the instruction following the

original ASC. At this time, the skip logic is enabled and

skips this instruction because of the previous ASC carry.

Subroutines should not be nested within the interrupt

service routine, since their popping of the stack will enable any previously saved main program skips, interfering

with the orderly execution of the interrupt routine.

1

input.

d. The instruction at hex address 0FF must be a NOP.

e. An LEI instruction may be put immediately before the

RET instruction to re-enable interrupts.

MICROBUS INTERFACE

The COP444C/424C has an option which allows it to be

used as a peripheral microprocessor device, inputting and

outputting data from and to a host microprocessor (m P).

IN1, IN2 and IN3 general purpose inputs become Microbus

compatible read-strobe, chip-select, and write-strobe lines,

respectively. IN1 becomes RD

Ð a logic ‘‘0’’ on this input

will cause Q latch data to be enabled to the L ports for input

to the uP. IN2 becomes CS

Ð a logic ‘‘0’’ on this line selects the COP444C/424C as the uP peripheral device by

enabling the operation of the RD

and WR lines and allows

for the selection of one of several peripheral components.

IN3 becomes WR

Ð a logic ‘‘0’’ on this line will write bus

data from the L ports to the Q latches for input to the

COP444C/424C. G0 becomes INTR a ‘‘ready’’ output, reset

by a write pulse from the uP on the WR

line, providing the

‘‘handshaking’’ capability necessary for asynchronous data

transfer between the host CPU and the COP444C/424C.

This option has been designed for compatibility with National’s Microbus Ð a standard interconnect system for 8-bit

parallel data transfer between MOS/LSI CPUs and interfacing devices. (See Microbus National Publication.) The functioning and timing relationships between the signal lines affected by this option are as specified for the Microbus interface, and are given in the AC electrical characteristics and

shown in the timing diagrams (

of the COP444C/424C to the Microbus is shown in

Figures 4

and5). Connection

Figure 6

TL/DD/5259– 7

FIGURE 6. Microbus Option Interconnect

.

TABLE I. Enable Register Modes Ð Bits EN0 and EN3

EN0 EN3 SIO SI SO SK

0 0 Shift Input to Shift 0 If SKLe1,SKeclock

e

0 1 Shift Input to Shift Serial If SKL

Register Register If SKL

Register Register out If SKL

1 0 Binary Input to 0 SK

0,SKe0

e

1,SKeclock

e

0,SKe0

e

SKL

Counter Counter

1 1 Binary Input to 1 SKeSKL

Counter Counter

9

Functional Description (Continued)

INITIALIZATION

The internal reset logic will initialize the device upon powerup if the power supply rise time is less than 1 ms and if the

operating frequency at CKI is greater than 32 kHz, otherwise the external RC network shown in

connected to the RESET

pin (the conditions in

must be met). The RESET pin is configured as a Schmitt

trigger input. If not used, it should be connected to V

Initialization will occur whenever a logic ‘‘0’’ is applied to the

RESET

input, providing it stays low for at least three instruc-

tion cycle times.

Note: If CKI clock is less than 32 kHz, the internal reset logic (option

Ý

29e1) MUST be disabled and the external RC circuit must be used.

FIGURE 7. Power-Up Circuit

Upon initialization, the PC register is cleared to 0 (ROM address 0) and the A, B, C, D, EN, IL, T and G registers are

cleared. The SKL latch is set, thus enabling SK as a clock

output. Data Memory (RAM) is not cleared upon initialization. The first instruction at address 0 must be a CLRA

(clear A register).

Figure 7

must be

Figure 7

CC

TL/DD/5259– 8

TIMER

The timer can be operated as a time-base counter.

The instruction cycle frequency generated from CKI passes

through a 2-bit divide-by-4 prescaler. The output of this prescaler increments the 8-bit T counter thus providing a 10-bit

timer. The pre-scaler is cleared during execution of a CAMT

instruction and on reset.

.

For example, using a 4 MHz crystal with a divide-by-16 option, the instruction cycle frequency of 250 kHz increments

the 10-bit timer every 4 ms. By presetting the counter and

detecting overflow, accurate timeouts between 16 ms

(4 counts) and 4.096 ms (1024 counts) are possible. Longer

timeouts can be achieved by accumulating, under software

control, multiple overflows.

HALT MODE

The COP444C/445C/424C/425C/426C is a FULLY STATIC circuit; therefore, the user may stop the system oscillator

at any time to halt the chip. The chip may also be halted by

the HALT instruction or by forcing CKO high when it is

mask-programmed as an HALT I/O port. Once in the HALT

mode, the internal circuitry does not receive any clock signal and is therefore frozen in the exact state it was in when

halted. All information is retained until continuing. The chip

may be awakened by one of two different methods:

Continue function: by forcing CKO low, if it mask-pro-

#

grammed as an HALT I/O port, the system clock is reenabled and the circuit continues to operate from the

point where it was stopped.

Restart: by forcing the RESET pin low (see Initializa-

#

tion).

Crystal or Resonator

Crystal Component Values

Value R1 R2 C1(pF) C2(pF)

32 kHz 220k 20M 30 6–36

455 kHz 5k 10M 80 40

2.096 MHz 2k 1M 30 6– 36

4.0 MHz 1k 1M 30 6 –36

FIGURE 8. Oscillator Component Values

RC Controlled Oscillator (g5% R,g5% C)

RC

30k 82 pF 5 –11 m s

60k 100 pF 12 –24 ms 2.4– 4.5V

Note: 15ksRs150k

sCs

150 pF

50 pF

Cycle

Time

10

TL/DD/5259– 9

V

CC

t

4.5V

Functional Description (Continued)

The HALT mode is the minimum power dissipation state.

Note: If the user has selected dual-clock with D0 as external

oscillator (option 30

running with the D0 clock, the HALT mode Ð either

hardware or software Ð will NOT be entered. Thus,

the user should switch to the CKI clock to HALT. Alternatively, the user may stop the D0 clock to minimize power.

CKO PIN OPTIONS

a. Two-pin oscillator Ð (Crystal). See

In a crystal controlled oscillator system, CKO is used as

an output to the crystal network. The HALT mode may be

entered by program control (HALT instruction) which

forces CKO high, thus inhibiting the crystal network. The

circuit can be awakened only by forcing the RESET

a logic ‘‘0’’ (restart).

b. One-pin oscillator Ð (RC or external). See

If a one-pin oscillator system is chosen, two options are

available for CKO:

CKO can be selected as the HALT I/O port. In that

#

case, it is an I/O flip-flop which is an indicator of the

HALT status. An external signal can over-ride this pin

to start and stop the chip. By forcing a high level to

CKO, the chip will stop as soon as CKI is high and

CKO output will stay high to keep the chip stopped if

the external driver returns to high impedance state.

By forcing a low level to CKO, the chip will continue

and CKO will stay low.

As another option, CKO can be a general purpose in-

#

put, read into bit 2 of A (accumulator) upon execution

of an INIL instruction.

OSCILLATOR OPTIONS

There are four basic clock oscillator configurations available

as shown by

a. Crystal Controlled Oscillator. CKI and CKO are connect-

ed to an external crystal. The instruction cycle time equals

the crystal frequency optionally divided by 4, 8 or 16.

b. External Oscillator. The external frequency is optionally

divided by 4, 8 or 16 to give the instruction cycle time.

CKO is the HALT I/O port or a general purpose input.

Figure 8

e

2) AND the COP444C/424C is

Figure 9A

.

.

Figure 9B

pin to

.

c. RC Controlled Oscillator. CKI is configured as a single pin

RC controlled Schmitt trigger oscillator. The instruction

cycle equals the oscillation frequency divided by 4. CKO

is the HALT I/O port or a general purpose input.

d. Dual oscillator. By selecting the dual clock option, pin D0

is now a single pin oscillator input. Two configurations are

available: RC controlled Schmitt trigger oscillator or external oscillator.

The user may software select between the D0 oscillator

(in that case, the instruction cycle time equals the D0

oscillation frequency divided by 4) by setting the D0 latch

high or the CKI (CKO) oscillator by resetting D0 latch low.

Note that even in dual clock mode, the counter, if maskprogrammed as a time-base counter, is always connected to the CKI oscillator.

For example, the user may connect up to a 1 MHz RC

circuit to D0 for faster processing and a 32 kHz watch

crystal to CKI and CKO for minimum current drain and

time keeping.

Note: CTMA instruction is not allowed when chip is running

from D0 clock.

Figures 10A

with and without Dual clock.

COP445C AND COP425C 24-PIN PACKAGE OPTION

If the COP444C/424C is bonded in a 24-pin package, it becomes the COP445C/425C, illustrated in

tion diagrams. Note that the COP445C/425C does not contain the four general purpose IN inputs (IN3 –IN0). Use of

this option precludes, of course, use of the IN options, interrupt feature, external event counter feature, and the

Microbus option which uses IN1 –IN3. All other options are

available for the COP445C/425C.

Note: If user selects the 24-pin package, options 9, 10, 19

COP426C 20-PIN PACKAGE OPTION

If the COP425C is bonded as 20-pin device it becomes the

COP426C. Note that the COP426C contains all the

COP425C pins except D

and

10B

show the clock and timer diagrams

Figure 2

and 20 must be selected as a ‘‘0’’ (load to V

IN inputs). See option list.

, and G1.

0,D1,G0

, Connec-

on the

CC

Block Diagram (Continued)

TL/DD/5259– 10

FIGURE 9A. Halt Mode Ð Two-Pin Oscillator

11

Block Diagram (Continued)

FIGURE 9B. Halt Mode Ð One-Pin Oscillator

FIGURE 10A. Clock and Timer without Dual-Clock

TL/DD/5259– 11

TL/DD/5259– 12

FIGURE 10B. Clock and Timer with Dual-Clock

12

TL/DD/5259– 13

Instruction Set

Table II is a symbol table providing internal architecture, instruction operan and operation symbols used in the instruction set table.

TABLE II. Instruction Set Table Symbols

Symbol Definition

Internal Architecture Symbols

A 4-bit accumulator

B 7-bit RAM address register (6-bit for COP424C)

Br Upper 3 bits of B (register address)

(2-bit for COP424C)

Bd Lower 4 bits of B (digit address)

C 1-bit carry register

D 4-bit data output port

EN 4-bit enable register

G 4-bit general purpose I/O port

IL two 1-bit (IN0 and IN3) latches

IN 4-bit input port

L 8-bit TRI-STATE I/O port

M 4-bit contents of RAM addressed by B

PC 11-bit ROM address program counter

Q 8-bit latch for L port

SA,SB,SC 11-bit 3-level subroutine stack

SIO 4-bit shift register and counter

SK Logic-controlled clock output

SKL 1-bit latch for SK output

T 8-bit timer

Table III provides the mnemonic, operand, machine code

data flow, skip conditions and description of each instruction.

Instruction Operand Symbols

d 4-bit operand field, 0 –15 binary (RAM digit select)

r 3(2)-bit operand field, 0 –7(3) binary

(RAM register select)

a 11-bit operand field, 0 – 2047 (1023)

y 4-bit operand field, 0 –15 (immediate data)

RAM(x) RAM addressed by variable x

ROM(x) ROM addressed by variable x

Operational Symbols

a

Plus

b

Minus

x

Replaces

Ý

Is exchanged with

e

Is equal to

One’s complement of A

A

Z

Exclusive-or

: Range of values

Mnemonic Operand

ARITHMETIC INSTRUCTIONS

ASC 30

ADD 31

ADT 4A

AISC y 5

CASC 10

CLRA 00

COMP 40

NOP 44

RC 32

SC 22

XOR 02

Hex Language

Code Code Conditions

TABLE III. COP444C/445C Instruction Set

Machine

Data Flow

(Binary)

0011À0000ÀAaCaRAM(B)xA Carry Add with Carry, Skip on

À

0011À0001

À

0100À1010

À

b

0101Ày

À

0001À0000

À

0000À0000

À

0100À0000

À

0100À0100ÀNone None No Operation

À

0011À0010

À

0010À0010

À

0000À0010ÀAZRAM(B)xA None Exclusive-OR RAM with A

À

Carry

x

C Carry

AaRAM(B)xA None Add RAM to A

À

Aa10

x

A None Add Ten to A

À

À

À

À

À

À

À

10

AayxA Carry Add Immediate. Skip on

AaRAM(B)aCxA Carry Complement and Add with

Carry

x

C Carry, Skip on Carry

0xA None Clear A

AxA None Ones complement of A to A

‘‘0’’xC None Reset C

‘‘1’’xC None Set C

13

Skip

Carry (yi0)

Description

Instruction Set (Continued)

Table III. COP444C/445C Instruction Set (Continued)

Mnemonic Operand

Hex Language

Code Code Conditions

TRANSFER CONTROL INSTRUCTIONS

JID FFÀ1111À1111

JMP a 6

JP a

JSRP a

JSR a 6

b

bb

bb

bb

bb

b

bb

RET 48À0100À1000

RETSK 49À0100À1001

HALT 33À0011À0011

38À0011À1000

IT 33À0011À0011

39À0011À1001

MEMORY REFERENCE INSTRUCTIONS

CAMT 33À0011À0011

3FÀ0011À1111

CTMA 33À0011À0011

2FÀ0010À1111

CAMQ 33À0011À0011

3CÀ0011À1100

CQMA 33À0011À0011

2CÀ0010À1100

LD r

b

LDD r,d 23À0010À0011

bb

LQID BFÀ1011À1111

RMB 0 4CÀ0100À1100

145

242

343

SMB 0 4DÀ0100À1101

147

246

34B

Machine

(Binary)

0110À0Àa

À

a

7:0

À

a

6:0

À1À

(pages 2,3 only)

or

a

5:0

À11À

(all other pages)

a

5:0

À10À

0110À1Àa

À

a

7:0

À

5À00ÀrÀ0101

e

(r

0:3) BrZrxBr Exclusive-OR Br with r

À0ÀrÀdÀ

0100À0101

À

0100À0010

À

0100À0011

À

0100À0111

À

0100À0110

À

0100À1011

À

Data Flow

ROM (PC

À

axPC None Jump

10:8

À

A,M)xPC

10:8

Skip

None Jump Indirect (Notes 1, 3)

7:0

Description

À

axPC

À

À

À

10:8

À

À

À

À

6:0

axPC

5:0

PCa1xSAxSBxSC None Jump to Subroutine Page

00010

x

PC

PC

10:6

5:0

a

x

PCa1xSAxSBxSC None Jump to Subroutine

axPC

SCxSBxSAxPC None Return from Subroutine

SCxSBxSAxPC Always Skip Return from Subroutine

À

À

À

À

AxT

À

À

À

À

À

À

À

À

À

À

À

À

À

À

À

À

À

À

À

7:4

RAM(B)xT

T

x

7:4

T

x

3:0

AxQ

RAM(B)xQ

Q

7:4

Q

3:0

3:0

RAM(B)

A None Copy T to RAM, A (Note 9)

7:4

3:0

x

RAM(B) None Copy Q to RAM, A

x

A

RAM(B)xA None Load RAM into A,

RAM(r,d)xA None Load A with RAM pointed

ROM(PC

SB

0xRAM(B)

0xRAM(B)

0xRAM(B)

0xRAM(B)

1xRAM(B)

1xRAM(B)

1xRAM(B)

1xRAM(B)

,A,M)xQ None Load Q Indirect (Note 3)

10:8

x

SC

0

1

2

3

0

1

2

3

None Jump within Page (Note 4)

(Note 5)

on Return then Skip

None HALT Processor

IDLE till Timer

None Overflows then Continues

None Copy A, RAM to T

None Copy A, RAM to Q

to directly by r,d

None Reset RAM Bit

None Set RAM Bit

14

Instruction Set (Continued)

Table III. COP444C/445C Instruction Set (Continued)

Mnemonic Operand

Hex Language

Code Code Conditions

MEMORY REFERENCE INSTRUCTIONS (Continued)

STII y 7

Xr

b

b

6

XAD r,d 23

bb

XDS r

XIS r

b

7

b

4

REGISTER REFERENCE INSTRUCTIONS

CAB 50

CBA 4E

LBI r,d

bb

33

bb

LEI y 33

b

6

XABR 12

TEST INSTRUCTIONS

SKC 20

SKE 21

SKGZ 33

21

SKGBZ 33

001

111

203

313

SKMBZ 0 01

111

203

313

SKT 41

Machine

(Binary)

0111Ày

À

00ÀrÀ0110ÀRAM(B)ÝA None Exchange RAM with A,

À

e

0:3) BrZrxBr Exclusive-OR Br with r

(r

0010À0011

À

À1ÀrÀdÀ

0111

À00ÀrÀ

e

0:3) Bdb1xBd decrements and Decrement Bd.

(r

0100ÀRAM(B)ÝA Bd Exchange RAM with A

À00ÀrÀ

e

0:3) Bda1xBd increments and Increment Bd,

(r

0101À0000

À

0100À1110

À

(d–1)

À00ÀrÀ

e

0:3: not a LBI (Note 6)

(r

e

0,9:15)

d

or

0011À0011

À

À1ÀrÀdÀ

(any r, any d)

0011À0011

À

0110Ày

À

0001À0010

À

0010À0000

À

0010À0001

À

0011À0011

À

0010À0001

À

0011À0011

À

0000À0001

À

0001À0001

À

0000À0011

À

0001À0011

À

0000À0001

À

0001À0001

À

0000À0011

À

0001À0011

À

0100À0001

À

Data Flow

yxRAM(B) None Store Memory Immediate

À

À

À

À

À

À

a

1xBd 1 and Increment Bd

Bd

RAM(r,d)ÝA None Exchange A with RAM

RAM(B)

Ý

A Bd Exchange RAM with A

Z

rxBr past 0 Exclusive-OR Br with r

Br

Z

rxBr past 15 Exclusive-OR Br with r

Br

AxBd None Copy A to Bd

BdxA None Copy Bd to A

r,dxB Skip until Load B Immediate with r,d

Skip

Description

Pointed to Directly by r,d

À

yxEN None Load EN Immediate (Note 7)

À

À

AÝBr None Exchange A with Br (Note 8)

À

À

À

À

À

1st byte Skip if G Bit is Zero

À

À

À

2nd byte

À

* G

À

À

À

À

À

À

Ce‘‘1’’ Skip if C is True

AeRAM(B) Skip if A Equals RAM

e

G

0 Skip if G is Zero

3:0

e

G

0

0

e

G

0

1

e

G

0

2

e

0

3

RAM(B)

RAM(B)

RAM(B)

RAM(B)

0

1

2

3

(all 4 bits)

e

0 Skip if RAM Bit is Zero

e

0

e

0

e

0

A time-base Skip on Timer

counter carry (Note 3)

has occurred

since last test

15

Instruction Set (Continued)

Table III. COP444C/445C Instruction Set (Continued)

Mnemonic Operand

Hex Language

Code Code Conditions

INPUT/OUTPUT INSTRUCTIONS

ING 33

2A

ININ 33

28

INIL 33

29

INL 33

2E

OBD 33

3E

OGI y 33

b

5

OMG 33

3A

XAS 4F

Note 1: All subscripts for alphabetical symbols indicate bit numbers unless explicitly defined (e.g., Br and Bd are explicitly defined). Bits are numbered 0 to N where

0 signifies the least significant bit (low-order, right-most bit). For example, A

Note 2: The ININ instruction is not available on the 24-pin packages since these devices do not contain the IN inputs.

Note 3: For additional information on the operation of the XAS, JID, LQID, INIL, and SKT instructions, see below.

Note 4: The JP instruction allows a jump, while in subroutine pages 2 or 3, to any ROM location within the two-page boundary of pages 2 or 3. The JP instruction,

otherwise, permits a jump to a ROM location within the current 64-word page. JP may not jump to the last word of a page.

Note 5: A JSRP transfers program control to subroutine page 2 (0010 is loaded into the upper 4 bits of P). A JSRP may not be used when in pages 2 or 3. JSRP

may not jump to the last word in page 2.

Note 6: LBI is a single-byte instruction if d

e.g., to load the lower four bits of B(Bd) with the value 9 (1001

instruction should equal 15 (1111

Note 7: Machine code for operand field y for LEI instruction should equal the binary value to be latched into EN, where a ‘‘1’’ or ‘‘0’’ in each bit of EN corresponds

with the selection or deselection of a particular function associated with each bit. (See Functional Description, EN Register.)

Note 8: For 2K ROM devices, A

Note 9: Do not use CTMA instruction when dual-clock option is selected and part is running from D

e

).

2

Ý

Br (0xA3). For 1K ROM devices, AÝBr (0,0xA3, A2).

Machine

Data Flow

Skip

Description

(Binary)

0011À0011ÀGxA None Input G Ports to A

À

0010À1010

À

0011À0011ÀINxA None Input IN Inputs to A

À

0010À1000

À

0011À0011

À

0010À1001

À

0011À0011ÀL

À

0010À1110

À

0011À0011

À

0011À1110

À

0011À0011ÀyxG None Output to G Ports

À

0101Ày

À

0011À0011

À

0011À1010

À

0100À1111ÀAÝSIO, CxSKL None Exchange A with SIO

À

0, 9, 10, 11, 12, 13, 14, or 15. The machine code for the lower 4 bits equals the binary value of the ‘‘d’’ data

À

À

IL3, CKO,‘‘0’’, IL

À

x

A None Input IL Latches to A

0

À

x

RAM(B) None Input L Ports to RAM,A

7:4

L

x

A

3:0

À

BdxD None Output Bd to D Outputs

À

(Note 2)

(Note 3)

À

À

RAM(B)xG None Output RAM to G Ports

À

Immediate

À

(Note 3)

indicates the most significant (left-most) bit of the 4-bit A register.

3

), the lower 4 bits of the LBI instruction equal 8 (10002). To load 0, the lower 4 bits of the LBI

2

clocks.

0

minus 1

,

16

Description of Selected Instructions

XAS INSTRUCTION

XAS (Exchange A with SIO) copies C to the SKL latch and

exchanges the accumulator with the 4-bit contents of the

SIO register. The contents of SIO will contain serial-in/serial-out shift register or binary counter data, depending on the

value of the EN register. If SIO is selected as a shift register,

an XAS instruction can be performed once every 4 instruction cycles to effect a continuous data stream.

LQID INSTRUCTION

LQID (Load Q Indirect) loads the 8-bit Q register with the

contents of ROM pointed to by the 11-bit word

PC10:PC8,A,M. LQID can be used for table lookup or code

conversion such as BCD to seven-segment. The LQID instruction ‘‘pushes’’ the stack (PC

and replaces the least significant 8 bits of the PC as follows:

A

x

PC(7:4), RAM(B)xPC(3:0), leaving PC(10), PC(9)

and PC(8) unchanged. The ROM data pointed to by the new

address is fetched and loaded into the Q latches. Next, the

stack is ‘‘popped’’ (SC

xSBxSAx

saved value of PC to continue sequential program execution. Since LQID pushes SB

of SC are lost.

Note: LQID uses 2 instruction cycles if executed, one if skipped.

JID INSTRUCTION

JID (Jump Indirect) is an indirect addressing instruction,

transferring program control to a new ROM location pointed

to indirectly by A and M. It loads the lower 8 bits of the ROM

address register PC with the contents of ROM addressed by

the 11-bit word, PC10:8,A,M. PC10,PC9 and PC8 are not

affected by JID.

Note: JID uses 2 instruction cycles if executed, one if skipped.

SKT INSTRUCTION

The SKT (Skip On Timer) instruction tests the state of the T

counter overflow latch (see internal logic, above), executing

the next program instruction if the latch is not set. If the

latch has been set since the previous test, the next program

instruction is skipped and the latch is reset. The features

associated with this instruction allow the processor to generate its own time-base for real-time processing, rather than

relying on an external input signal.

Note: If the most significant bit of the T counter is a 1 when a CAMT instruc-

tion loads the counter, the overflow flag will be set. The following

sample of codes should be used when loading the counter:

; load T counterCAMT

; skip if overflow flag is set and reset itSKT

NOP

IT INSTRUCTION

The IT (idle till timer) instruction halts the processor and

puts it in an idle state until the time-base counter overflows.

This idle state reduces current drain since all logic (except

the oscillator and time base counter) is stopped.

INIL INSTRUCTION

INIL (Input IL Latches to A) inputs 2 latches, IL3 and IL0,

CKO and 0 into A. The IL3 and IL0 latches are set if a lowgoing pulse (‘‘1’’ to ‘‘0’’) has occurred on the IN3 and IN0

inputs since the last INIL instruction, provided the input

pulse stays low for at least two instruction cycles. Execution

of an INIL inputs IL3 and IL0 into A3 and A0 respectively,

a

1xSAxSBxSC)

PC), restoring the

x

SC, the previous contents

and resets these latches to allow them to respond to subsequent low-going pulses on the IN3 and IN0 lines. If CKO is

mask programmed as a general purpose input, an INIL will

input the state of CKO into A2. If CKO has not been so

programmed, a ‘‘1’’ will be placed in A2. A0 is input into A1.

IL latches are cleared on reset. IL latches are not available

on the COP445C/425C, and COP426C.

INSTRUCTION SET NOTES

a. The first word of a program (ROM address 0) must be a

CLRA (Clear A) instruction.

b. Although skipped instructions are not executed, they are

still fetched from the program memory. Thus program

paths take the same number of cycles whether instructions are skipped or executed except for JID, and LQID.

c. The ROM is organized into pages of 64 words each. The

Program Counter is a 11-bit binary counter, and will count

through page boundaries. If a JP, JSRP, JID, or LQID is

the last word of a page, it operates as if it were in the next

page. For example: a JP located in the last word of a

page will jump to a location in the next page. Also, a JID

or LQID located in the last word of every fourth page (i.e.

hex address 0FF, 1FF, 2FF, 3FF, 4FF, etc.) will access

data in the next group of four pages.

Note: The COP424C/425C/426C needs only 10 bits to address its ROM.

Therefore, the eleventh bit (P10) is ignored.

Power Dissipation

The lowest power drain is when the clock is stopped. As the

frequency increases so does current. Current is also lower

at lower operating voltages. Therefore, the user should run

at the lowest speed and voltage that his application will allow. The user should take care that all pins swing to full

supply levels to insure that outputs are not loaded down and

that inputs are not at some intermediate level which may

draw current. Any input with a slow rise or fall time will draw

additional current. A crystal or resonator generated clock

input will draw additional current. An R/C oscillator will draw

even more current since the input is a slow rising signal.

If using an external squarewave oscillator, the following

equation can be used to calculate operating current drain.

e

a

I

I

CO

where I

quiescent leakage current (from curve)

CKI frequency in MegaHertz

chip V

divide by option selected

For example at 5 volts VCCand 400 kHz (divide by 4)

I

CO

I

CO

At 2.4 volts VCCand 30 kHz (divide by 4)

I

CO

I

CO

Vc40cFiaVc1400cFi/Dv

Q

e

chip operating current drain in microamps

CO

in volts

CC

e20a

5c40c0.4a5c1400c0.4/4

e20a80a

e6a

e6a

700e800 mA

2.4c40c0.03a2.4c1400c0.03/4

2.88a25.2e34.08 mA

17

Power Dissipation (Continued)

If an IT instruction is executed, the chip goes into the IDLE

mode until the timer overflows. In IDLE mode, the current

drain can be calculated from the following equation:

e

a

Ici

I

Vc40cFi

Q

c

CC

ToaTi

and 400 kHz

To

a

Ici

c

Ti

ToaTi

For example, at 5 volts V

Icie20a5c40c0.4e100 mA

The total average current will then be the weighted average

of the operating current and the idle current:

e

I

Ita

CO

e

where: Ita

total average current

e

I

operating current

CO

Icieidle current

Toeoperating time

e

idle time

Ti

I/O OPTIONS

Outputs have the following optional configurations, illustrated in

Figure 11

:

a. Standard Ð A CMOS push-pull buffer with an N-channel

device to ground in conjunction with a P-channel device

to V

, compatible with CMOS and LSTTL.

CC

b. Low Current Ð This is the same configuration as a.

above except that the sourcing current is much less.

c. Open Drain Ð An N-channel device to ground only, allow-

ing external pull-up as required by the user’s application.

d. Standard TRI-STATE L Output Ð A CMOS output buffer

similar to a. which may be disabled by program control.

e. Low-Current TRI-STATE L Output Ð This is the same as

d. above except that the sourcing current is much less.

f. Open-Drain TRI-STATE L Output Ð This has the N-chan-

nel device to ground only.

All inputs have the following options:

g. Input with on chip load device to V

CC

.

h. Hi-Z input which must be driven by the users logic.

When using either the G or L I/O ports as inputs, a pull-up

device is necessary. This can be an external device or the

following alternative is available: Select the low-current output option. Now, by setting the output registers to a logic

‘‘1’’ level, the P-channel devices will act as the pull-up load.

Note that when using the L ports in this fashion the Q registers must be set to a logic ‘‘1’’ level and the L drivers MUST

BE ENABLED by an LEI instruction (see description above).

All output drivers use one or more of three common devices

numbered 1 to 3. Minimum and maximum current (I

V

) curves are given in

OUT

vices to allow the designer to effectively use these I/O con-

Figure 12

for each of these de-

OUT

and

figurations.

a. Standard Push-Pull Output b. Low Current Push-Pull Output c. Open-Drain Output

d. Standard TRI-STATE ‘‘L’’ Output e. Low Current TRI-STATE

‘‘L’’ Output

g. Input with Load

f. Open Drain TRI-STATE

‘‘L’’ Output

h. Hi-Z Input

FIGURE 11. Input/Output Configurations

18

TL/DD/5259– 14

Power Dissipation (Continued)

Minimum Sink Current

Standard

Minimum Source Current

Low Current Option

Minimum Source Current

COP444C/424C/445C/425C

Low Current Option

Maximum Source Current

COP344C/345C/324C/325C

Low Current Option

Maximum Source Current Maximum Quiescent Current

FIGURE 12. Input/Output Characteristics

Option List

The COP444C/445C/424C/425C/COP426C mask-programmable options are assigned numbers which correspond with the COP444C/424C pins.

The following is a list of options. The options are programmed at the same time as the ROM pattern to provide

the user with the hardware flexibility to interface to various

I/O components using little or no external circuitry.

PLEASE FILL OUT THE OPTION TABLE on the next page.

Xerox the option data and send it in with your disk or

EPROM.

e

Option 1

Option 2: CKO Pin

Option 3: CKI input

0: Ground Pin Ð no options available

e

0: clock generator output to crystal/resonator

e

1: HALT I/O port

e

2: general purpose input with load device to V

e

3: general purpose input, high-Z

e

0: Crystal controlled oscillator input divide by 4

e

1: Crystal controlled oscillator input divide by 8

e

2: Crystal controlled oscillator input divide by 16

e

4: Single-pin RC controlled oscillator (divide by 4)

e

5: External oscillator input divide by 4

e

6: External oscillator input divide by 8

e

7: External oscillator input divide by 16

CC

Option 4: RESET

e

0: load device to V

e

1: Hi-Z input

input

CC

Option 5: L7 Driver

e

0: Standard TRI-STATE push-pull output

e

1: Low-current TRI-STATE push-pull output

e

2: Open-drain TRI-STATE output

Option 6: L6 Driver Ð (same as option 5)

Option 7: L5 Driver Ð (same as option 5)

Option 8: L4 Driver Ð (same as option 5)

Option 9: IN1 input

e

0: load device to V

e

1: Hi-Z input

CC

Option 10: IN2 input Ð (same as option 9)

Option 11e0: VCCPin Ð no option available

Option 12: L3 Driver Ð (same as option 5)

Option 13: L2 Driver Ð (same as option 5)

Option 14: L1 Driver Ð (same as option 5)

Option 15: L0 Driver Ð (same as option 5)

Option 16: SI input Ð (same as option 9)

Option 17: SO Driver

e

0: Standard push-pull output

e

1: Low-current push-pull output

e

2: Open-drain output

19

TL/DD/5259– 15

Option List (Continued)

Option 18: SK Driver Ð (same as option 17)

Option 19: IN0 Input Ð (same as option 9)

Option 20: IN3 Input Ð (same as option 9)

Option 21: G0 I/O Port Ð (same as option 17)

Option 22: G1 I/O Port Ð (same as option 17)

Option 23: G2 I/O Port Ð (same as option 17)

Option 24: G3 I/O Port Ð (same as option 17)

Option 25: D3 Output Ð (same as option 17)

Option 26: D2 Output Ð (same as option 17)

Option 27: D1 Output Ð (same as option 17)

Option 28: D0 Output Ð (same as option 17)

Option 29: Internal Initialization Logic

e

0: Normal operation

e

1: No internal initialization logic

Option 30: Dual Clock

e

0: Normal operation

e

1: Dual Clock. D0 RC oscillator

e

2: Dual Clock. D0 ext. clock input

(opt.Ý28 muste2)

(

Option 31: Timer

e

0: No Option Available

Option 32: Microbus

e

0: Normal

e

1: Microbus (opt.Ý31 muste0)

Option 33: COP bonding

(1k and 2K Microcontroller)

e

0: 28-pin package

e

1: 24-pin package

e

2: Same die purchased in both

24 and 28 pin version.

(1K Microcontroller only)

e

3: 20-pin package

e

4: 28- and 20-pin package

e

5: 24- and 20-pin package

e

6: 28-, 24- and 20-pin package

Note:Ðif opt.

e

must

0Ðif opt.Ý33e3, 4, 5 or 6 then opt.Ý9, 10, 19,

20, 21, 22, 30 and 32 must

Option Table

The following option information is to be sent to National along with the EPROM.

Ý

33e1 or 2 then opt.Ý9, 10, 19, 20 and 32

e

0.

OPTION 1 VALUE

OPTION 2 VALUE

OPTION 3 VALUE

OPTION 4 VALUE

OPTION 5 VALUE

OPTION 6 VALUE

OPTION 7 VALUE

OPTION 8 VALUE

OPTION 9 VALUE

OPTION 10 VALUE

OPTION 11 VALUE

OPTION 12 VALUE

OPTION 13 VALUE

OPTION 14 VALUE

OPTION 15 VALUE

OPTION 16 VALUE

OPTION DATA

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

0 IS: GROUND PIN

IS: CKO PIN

IS: CKI INPUT

IS: RESET INPUT

IS: L(7) DRIVER

IS: L(6) DRIVER

IS: L(5) DRIVER

IS: L(4) DRIVER

IS: IN1 INPUT

IS: IN2 INPUT

IS: VCC PIN

IS: L(3) DRIVER

IS: L(2) DRIVER

IS: L(1) DRIVER

IS: L(0) DRIVER

IS: SI INPUT

OPTION 17 VALUE

OPTION 18 VALUE

OPTION 19 VALUE

OPTION 20 VALUE

OPTION 21 VALUE

OPTION 22 VALUE

OPTION 23 VALUE

OPTION 24 VALUE

OPTION 25 VALUE

OPTION 26 VALUE

OPTION 27 VALUE

OPTION 28 VALUE

OPTION 29 VALUE

OPTION 30 VALUE

OPTION 31 VALUE

OPTION 32 VALUE

OPTION 33 VALUE

OPTION DATA

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

0 IS: TIMER

IS: SO DRIVER

IS: SK DRIVER

IS: IN0 INPUT

IS: IN3 INPUT

IS: G0 I/O PORT

IS: G1 I/O PORT

IS: G2 I/O PORT

IS: G3 I/O PORT

IS: D3 OUTPUT

IS: D2 OUTPUT

IS: D1 OUTPUT

IS: D0 OUTPUT

IS: INT INIT LOGIC

IS: DUAL CLOCK

IS: MICROBUS

IS: COP BONDING

20

21

Physical Dimensions inches (millimeters)

20-Lead Hermetic Dual-In-Line Package (D)

Order Number COP326C-XXX/D, COP426C-XXX/D

NS Package Number D20A

24-Lead Hermetic Dual-In-Line Package (D)

Order Number COP425C-XXX/D, COP325C-XXX/D,

COP445C-XXX/D, COP345C-XXX/D

NS Package Number D24C

22

Physical Dimensions inches (millimeters) (Continued)

28-Lead Hermetic Dual-In-Line Package (D)

Order Number COP424C-XXX/D, COP324C-XXX/D,

COP444C-XXX/D, COP344C-XXX/D

NS Package Number D28C

20-Lead Molded Dual-In-Line Package (N)

Order Number COP426C-XXX/N and COP326C-XXX/N

NS Package Number N20A

23

Physical Dimensions inches (millimeters) (Continued)

24-Lead Molded Dual-In-Line Package (N)

Order Number COP425C-XXX/N, COP325C-XXX/N,

COP445C-XXX/N, COP345C-XXX/N

NS Package Number N24A

28-Lead Molded Dual-In-Line Package (N)

Order Number COP424C-XXX/N, COP324C-XXX/N,

COP344C, COP345C Single-Chip 1k and 2k CMOS Microcontrollers

LIFE SUPPORT POLICY

COP444C-XXX/N, COP344C-XXX/N

NS Package Number N28B

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

COP424C, COP425C, COP426C, COP324C, COP325C, COP326C and COP444C, COP445C,

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

Fax: 1(800) 737-7018 English Tel: (

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Fran3ais Tel: (

Italiano Tel: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

a

49) 0-180-532 78 32 Hong Kong

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

Loading...

Loading...