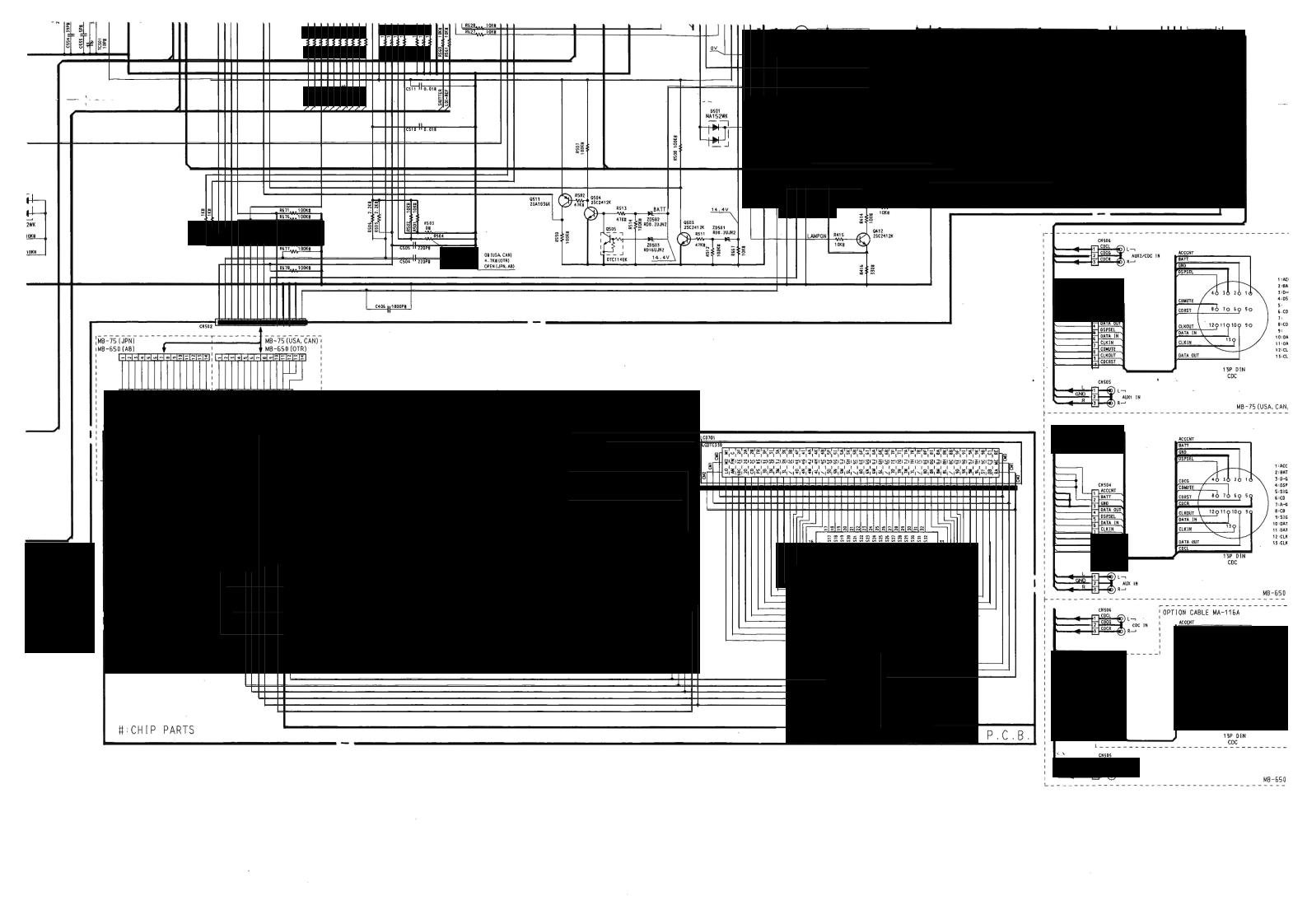

Nakamichi mb-75 Schematics

Mobile Receiver I 6 Disc Music-

Bank CD Changer

MB-75

r.Nakamichi

CONTENTS

1. |

General .............................................................................................................................................................. |

|

. |

|

|

2. |

Removal Procedures ........................................................................................................................................ |

|

|

5 |

|

|

2.1. |

Preparation .............................................................................................................. |

|

|

6 |

|

2.2. |

Top Cover Ass'y.............................................. |

...................................................................................... |

|

6 |

|

2.3. Main P.C.B. Ass'yand Front Panel Block |

.............................................................................................. |

|

7 |

|

|

2.4. |

Loading Ass'y................................................................. |

......................................................... |

|

8 |

|

2.5. |

CD P.C.B. Ass'y........................................................................................................................... |

|

|

9 |

|

2.6. |

Traverse Macha Chassis Ass'y................... |

...................................................................... |

|

10 |

|

2.7. |

Laser Pickup................................................................ |

.......................................................................... |

|

11 |

|

2.8. |

Sled Motor Ass'y........................................................................................................................ |

|

|

11 |

|

2.9. |

Feed Motor Ass'y......................................................... |

........................................................... |

|

12 |

|

2.10. |

Stocker Ass'yand Disc Holders .............................. |

|

|

13 |

|

2.11. |

Shut Arm Block and Loading FPC Ass'y... |

................................ .......................... |

15 |

|

|

2.12. |

Loading Guide Ass'y.................................................. |

..................................... |

16 |

|

3. |

Mechanical Adjustments.................................................................................................................................. |

|

|

18 |

|

|

3.1. |

Gear Position Adjustments around the Stocker Drive Gear ..... |

|

18 |

|

|

3.2. |

Disc Lock Drive Gear Positioning .................................................. |

|

........................................... |

19 |

|

3.3. |

Loading Guide R B Positioning..................................................... |

|

....................................... |

19 |

4. |

Measurement Instruments and Jigs................................................................................................................ |

|

|

20 |

|

5. |

Electrical Adjustments ..................................................................................................................................... |

|

|

21 |

|

6. |

Mechanism Ass'yand Parts List ................................... |

,................................................................................. |

25 |

||

|

6.1. |

Synthesis .............................................................. |

:....... |

............................................................ |

25 |

|

6.2. |

Front Panel Ass'y(A01) .................................. |

............................ |

.......................... ............................... |

26 |

|

6.3. |

Front Base Ass'y(A02) (USA, CAN) ..... .......................................... |

|

..................................................... |

28 |

|

6.4. |

Mechanism Ass'y(A03) ............... |

........................... ............................................................... |

29 |

|

|

6.5. |

Power Amp. Ass'y(A04) ................. |

............................ |

........................................... |

30 |

|

6.6. |

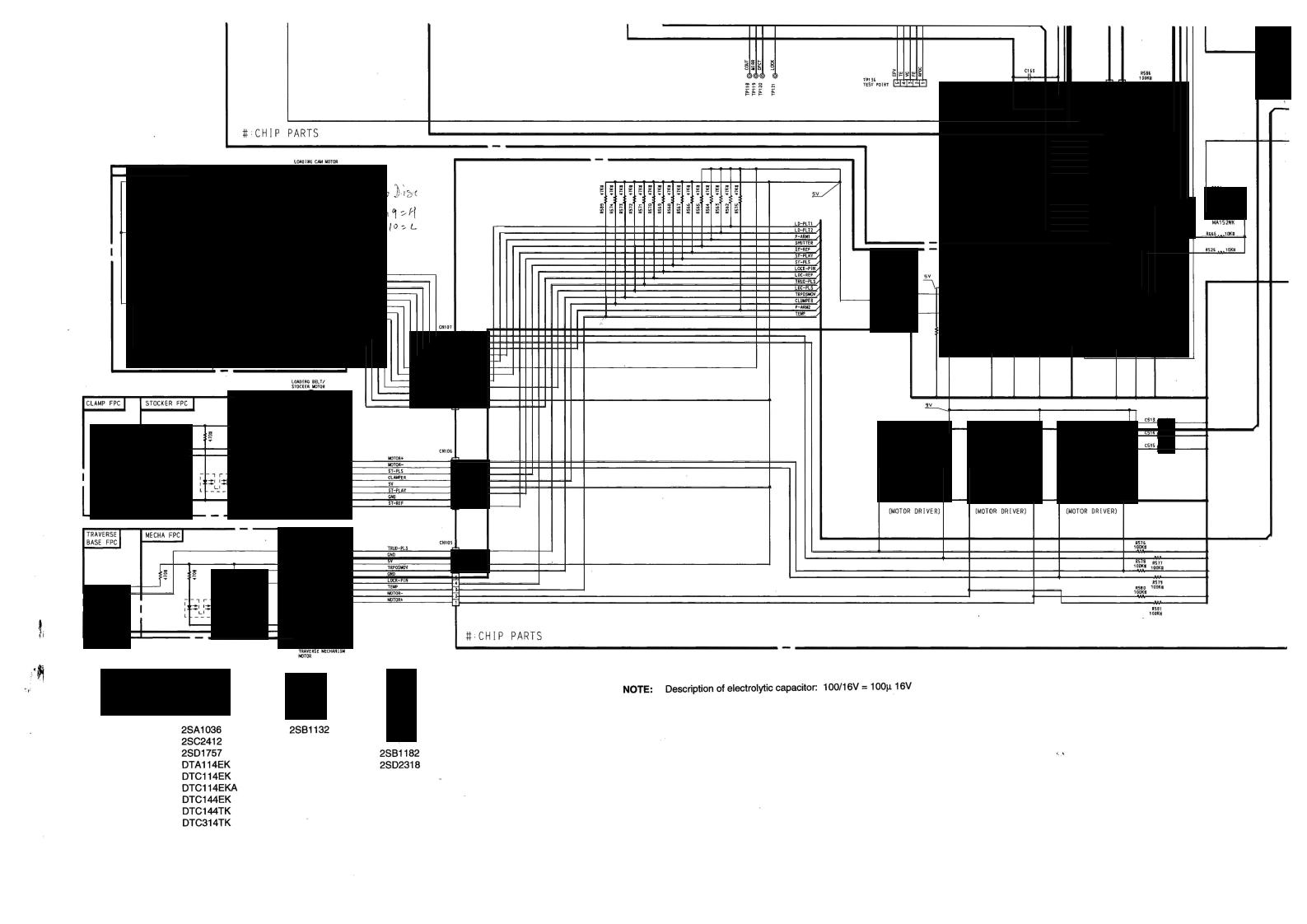

Traverse Mecha Chassis Ass'y(B01) .......... |

|

............................................................ |

31 |

|

6.7. |

Traverse Base Ass'y(B02) .................. ................................................................ |

|

................................. |

32 |

|

6.8. |

Loading Ass'y(B03) ................. |

................................................................. ............................. |

33 |

|

|

6.9. |

Clamper Ass'y(C01) .................. .............................................................................. |

|

|

34 |

|

6.10. |

Loading Guide Ass'y(C02) ........... |

|

.......................................... |

35 |

|

6.11. |

Loading Chassis Ass'y(C03) .......... .................................................................................. |

|

..... |

37 |

7. Mounting Diagrams and Parts List.................................................................................................................. |

|

|

38 |

||

|

7.1. |

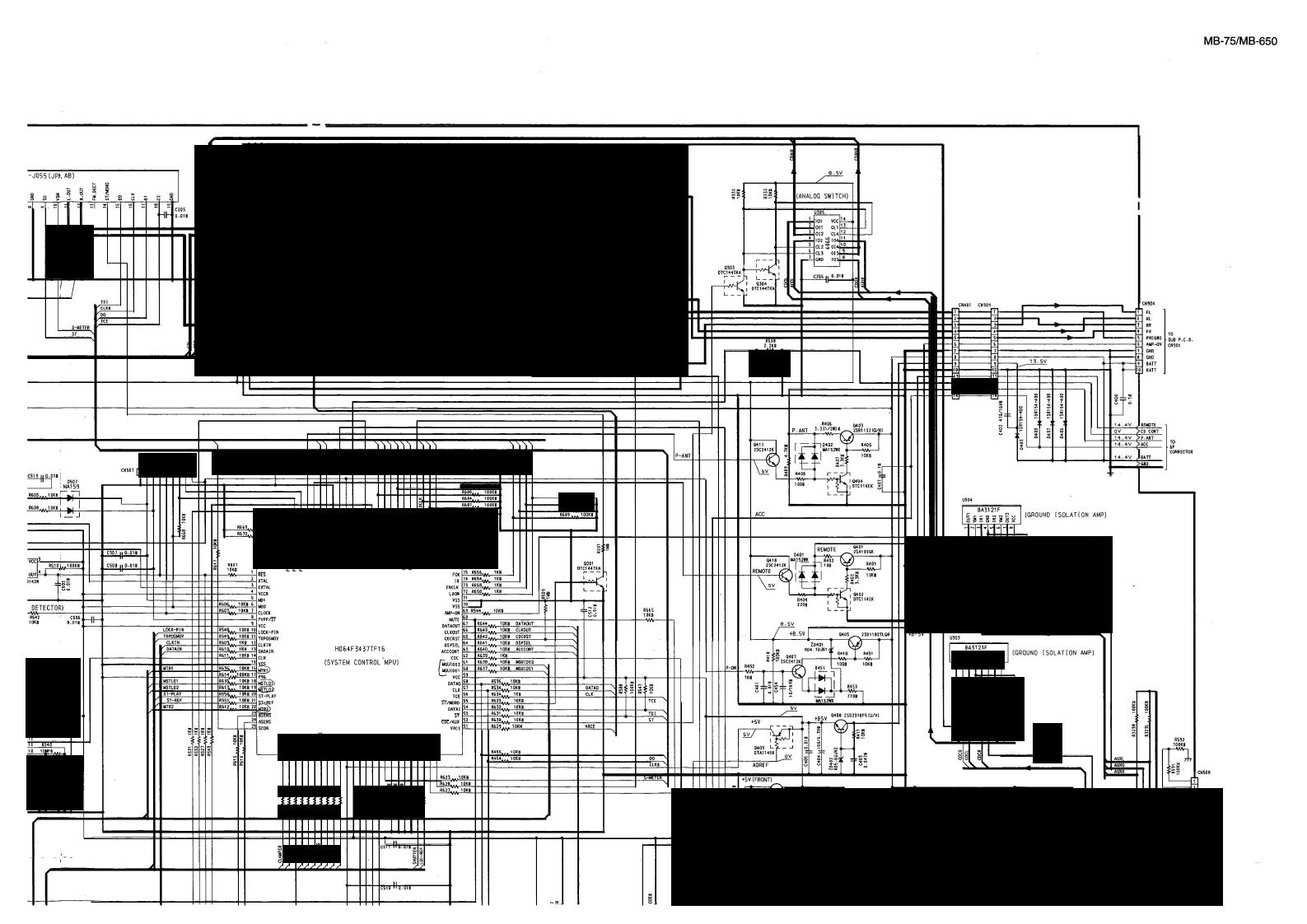

Main P.C.B. Ass'y ................................................................................................. |

|

|

38 |

|

7.2. |

Front P.C.B. Ass'y..................... |

|

....................................... |

41 |

|

7.3. |

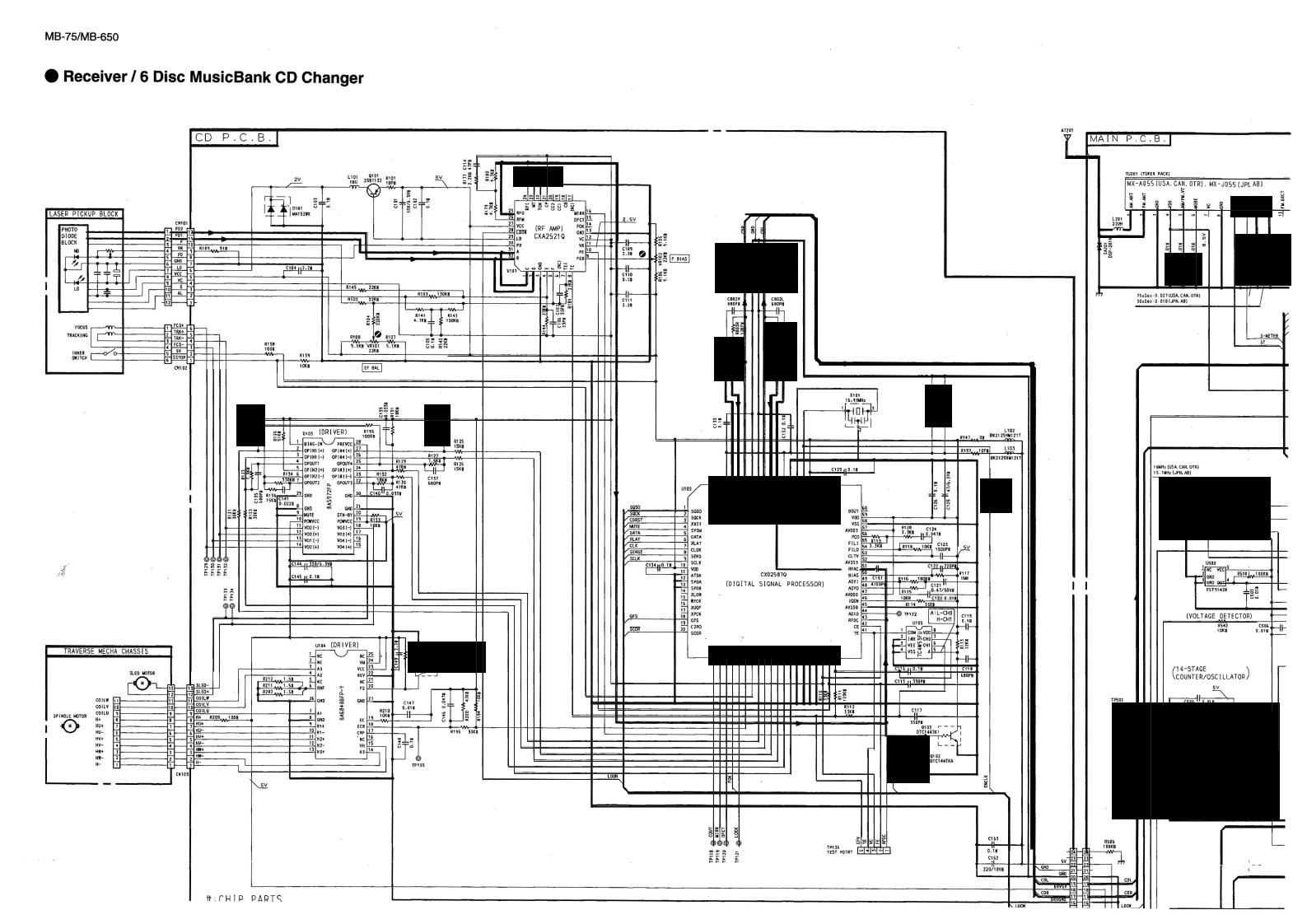

CD P.C.B. Ass'y................. |

............................................ |

42 |

|

|

7.4. |

Power Amp. Main P.C.B. Ass'y.... .............................................................................. |

|

|

42 |

|

7.5. |

Power Amp. Sub P.C.B. Ass'y........... |

.......................................................... |

42 |

|

8. |

IC Block Diagrams ............................................................................................................................................ |

|

|

47 |

|

9. |

Block Diagram ................................................................................................................................................... |

|

|

56 |

|

10. Schematic Diagrams (Power Amp. Section, For Head Unit see the attached sheet.) ................................ |

57 |

||||

Specifications |

|

|

|

||

GENERAL

1.1.Product Code V624

1.2.Destinations USA, CAN, JPN

Abbreviations for Destinations: USA - U.S.A.

CAN - Canada JPN - Japan

1.3.Cautions/Warnings

(1)Protection of Eyes from Laser Beam

To protect eyes from invisible laser beam during servicing,

DO NOT LOOK AT THE LASER BEAM.

•Laser Diode Properties

Material: |

GaAs+GaAIAs |

Laser output: |

0.4mW Max. |

Wavelength: 760 - 800 nm

Emission duration: Continuous

(2) Laser Caution CAUTION

Adjusting the knobs, switches, and controls, etc. or taking actions not specified herein may result in a harmful emission of laser beams. This CD Changer must be adjusted and repaired only by qualified service personnel.

OBSERVERA!

Sadana installningar av rattarna, omkopplarna eller 6vriga kontrollknappar som inte ar beskriva i bruksanvisningen kan resultera i farlig laserutstralning. Justering eller reparation av denna kompaktskivspelare skall endast utf6ras av kvalificerad servicepersonal.

OBS!

lndstilling al knapper, cmskiftere og 0vrige kontrolknapper, som ikke f0lger den i brugsanvisningen beskrevne mil.de, kan resultere i farlig laserudstraling. Justering eller reparation al denno CD-afspiller ma kun udf0res al kvalificeret servicepersonale.

OBSI

Justering av rat!, brytere og kontroller andre enn de som er beskrevet her, kan resultere i farlig laserbestraling. Justering eller reparasjon av denne kompaktdiskspilleren ma bare utf0res av kvalifiserte fagfolk.

1.4. Handling the Laser Pickup

In case of repair or replacement of the Laser Pickup, pay attention to the following handling instructions since the laser diode in the Laser Pickup is not resistant to static electricity.

(1)Grounding

When you repair a Laser Pickup, first ground the human body, as well as the measuring instruments and other tools (with particular caution to soldering iron). What'smore, your workbench and floor

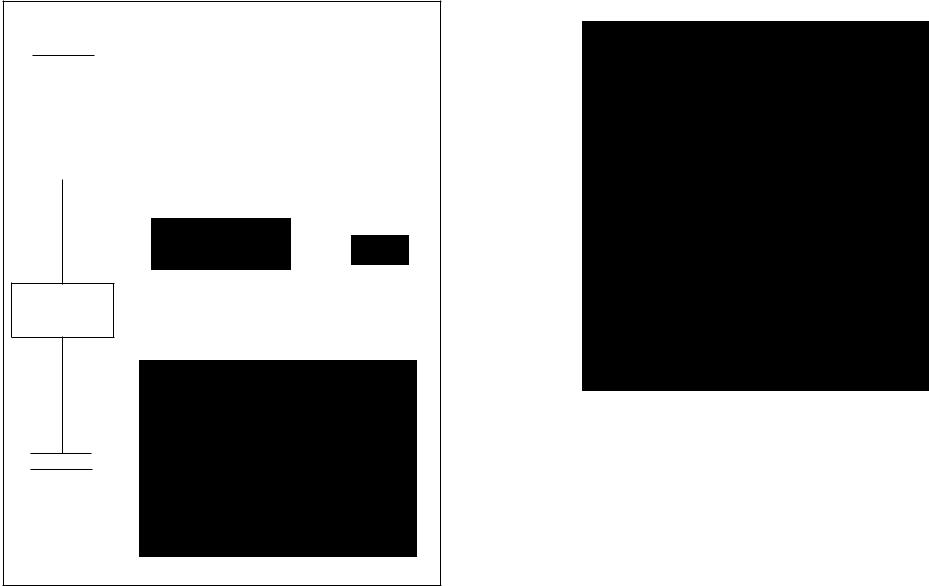

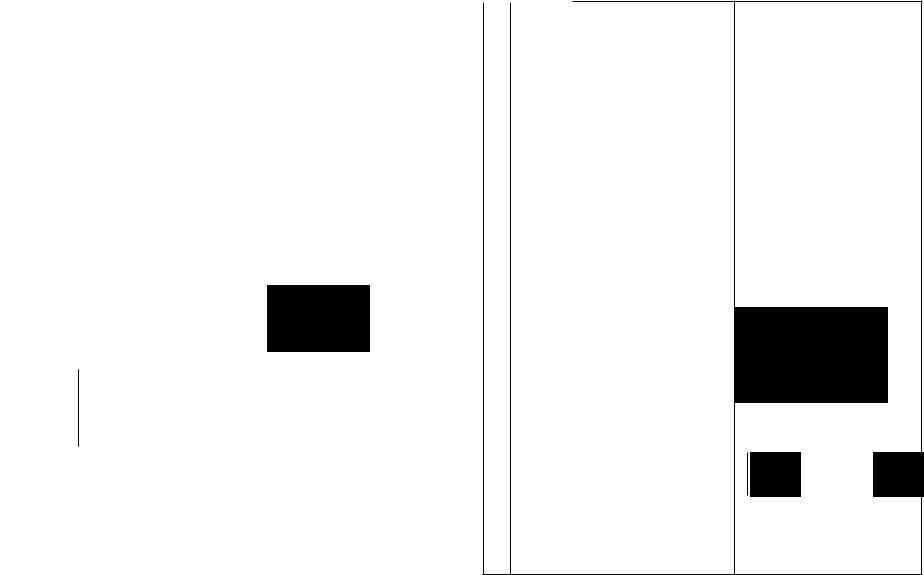

should desirably be grounded using conductive sheet or copper plate. See Fig. 1.1.

NOTE: Be careful so as not to let your |

|

clothes touch the Laser Pick~p. as |

|

static electricity on the clothes will |

. |

not be released even if your body is |

· |

grounded. |

|

HUOMAUTUS

Jos nuppeja, kytkimia ja saatimia ym, saiidetaan tai laitetta kaytetaan toisella tavalla kuin on selostettu, tuloksena saattaa olla vaarallista lasersateiden vuotoa. CD-soittimen saat6 ja korjaus on jatettava aina asiantuntevan huoltoteknikon tehtavaksi.

ADVERSEL: USYNLIG LASERSTRALING VED ABNING. UNDGA UDSAEITELSE FOR STRALING.

VARO!: |

AVAITAESSA OLET ALITllNA |

||||

|

NiiKYMiiIT6MiiLLE LASERSATEILYLLE. |

||||

|

ALA KATSO Sii.TEESEEN. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(2) Discharge of Electricity |

~ |

|

Be sure to discharge electricity from objects |

|

|

brought into contact with the Laser Pickup (i.e., |

|

|

soldering iron, tweezers, probes, volt-ohm-meter |

Loser Pickup |

|

probes, etc.) before starting work by contacting |

|

|

them with the body chassis. Besides, never touch |

IMn |

|

the Laser Pickup while power is applied. |

||

|

Conductive Sheet

or Copper Plate

Fig. 1.1 Handling the Laser Pickup

2

1.5. Shipping Procedure after Service Work

Always follow the steps below before returning the Unit.

|

START |

|

|

||

|

|

|

|

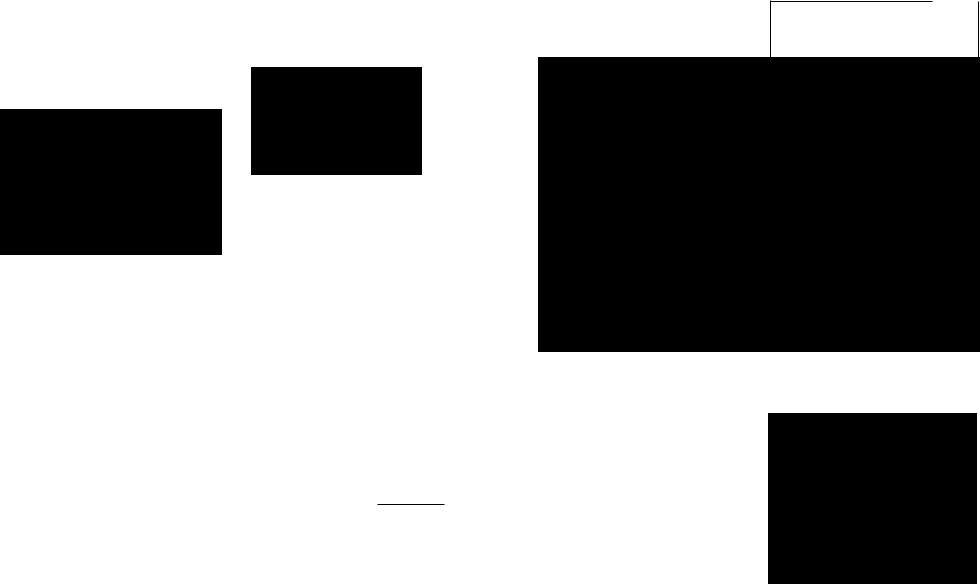

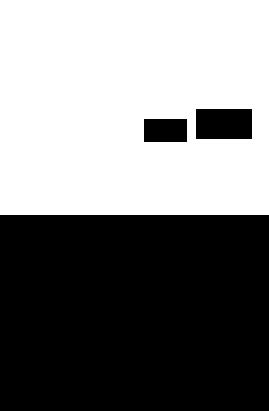

While the DISCS button is kept pressed, push the RESET button. |

|

Initialize the Mechanism. |

IDISCS I + RESET |

||||

|

|

|

|

The Unit will display the firmware version and then starts mechanism initialization. |

|

|

|

|

|

||

|

|

|

|

Turn OFF the Unit in the same order when the Unit is used in the car. Namely, discon- |

|

Disconnect the ACC line |

nect the ACC line first and then the BATT line. |

||||

first, and then BATT line. |

ACC (Red) |

I Disconnect first. |

|||

|

|

|

|

~ |

|

To fix the mechanical

parts, insert the Clamp

Arm Stopper and fasten

the U G Screws.

BATT (Yellow) ----- |

|

~ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DC Power |

|

|

|

|

|

|

Supply Unit |

|

|

|

14.4V |

|

|

14.4V |

0 |

|

|

GND o-!--'----- |

1 |

|

GND "- |

'--'---- |

! |

|

|

|

|

|

|

|

|

1.Insert the Clamp Arrn Stopper to lock the Clamper Ass'y.

NOTE: If it cannot be correctly inserted into the Unit, do not force to insert it.

You should correctly follow the shipping procedure again from the beginning.

2.Cover the Clamp Arm Stopper with a tape.

3.Put the Mecha Lock Caution as shown in the figure.

4.Fasten the two U G Screws from the bottom of the Unit to lock the Traverse Ass'y, passing through the Mecha Lock Caution.

3. Mecha Lock Caution

END

Fig. 1.2 Shipping Form

1.S. Handling the Laser Pickup

Schematic |

|

|

|

|

Ref. No. |

Part No. |

|

Description |

|

|

|

Package and Accessory Ass'y |

||

01 |

OF05345A |

Package Top (USA, CAN) |

||

02 |

OF05359A |

Package Top (JPN) |

1 |

|

OF05346A |

Package Bottom (USA, CAN) |

|||

03 |

OF05360A |

Package Bottom (JPN) |

|

|

OF05363A |

Inner Carton (USA, CAN) |

|||

04 |

OF05361A |

Inner Carton (JPN) |

|

|

08848838 |

6P Wire Ass'y |

|

||

05 |

OB84862C |

SP SP Cable Ass'y |

|

|

06 |

DA05321A |

Carrying Case Ass'y(USA, CAN) |

||

07 |

HA07655A |

Heat Sink Bracket Ass'y |

||

08 |

OB90462A |

Battery UM4x1 |

|

|

09OJ07417A Metal Stay (USA, CAN)

10OH07542A Panel Frame (USA, CAN)

11OH07771 A Panel Frame L (USA, CAN)

12DA05247A Remote Ass'y

13HG07456B Sleeve Ass'y(USA, CAN)

OD07031C Owner'sManual (English) 00070308 Owner'sManual (Japanese) OF05381A Soft Sheet (for Front Panel)

Fig.1.3

Schematic

Ref. No. |

Part No. |

Description |

|

OB90359A |

Masking Tape |

|

0890520A |

Fuse 250V 3A |

|

OB90525A |

Fuse NSA 250V |

|

0D06960A |

Magic Tape A |

|

OD06961A |

Magic Tape B |

|

0D06962A |

Magic Tape C |

|

OD07048A Magic Tape BK A |

|

|

0D07049A Magic Tape BK B |

|

|

DG05271 A |

Screw Kit |

|

JG04899A |

Bolt Ass'y |

|

OJ08221 B |

Connector Bracket |

|

OE00612A |

M3x6 +Pan (2A) |

|

|

(for Connector Bracket) |

|

0J07428A Rubber Cap (USA, CAN) |

|

|

0J07968B Lock Plate (USA, CAN) |

|

|

DG04858A |

Terminal Ass'yD (JPN) |

3 |

4 |

|

2.REMOVALPROCEDURES

WARNING:

Before starting disassembly, be sure to disconnect the power supply lines from a power source.

CAUTIONS:

•Before turning on the power, be sure that there is no abnormality.

•Be careful not to leave parts such as screws and washers unattached or loose inside the Unit.

•Be careful not to damage the flexible cable during service work.

•Do not excessively tighten screws.

•Do not reuse E-rings.

•Assembly should be performed in the reverse order of disassembly unless otherwise specified. However, be sure to follow the notes or procedures if written.

•Before returning the Unit, follow 1.5 "Shipping Procedure after Service Work" on page 3.

General Maintenance Tools:

•Philips screwdriver •Tweezers

•Cutting Nippers

•Soldering Iron (Ceramic one or whose metal part is grounded)

Removal Procedures:

2.1.Preparation

(1)Remove the two transportation screws (U G Screws) on the bottom, that lock the Traverse Ass'y.

Fig. 2.1

2.2. Top Cover Ass'y

Refer to Fig. 2.2.

(1)Remove the screws F01 (2 pcs.) and detach F02 (Lock Plate, 2 pcs.).

(2)Remove the screws F03 (M1 .4x3 Countersunk (Black Chromate), 2 pcs.) and detach F04 (Top Cover Ass'y). NOTE: Do not apply excessive force to the Top Cover

Ass'yas it can be deformed.

FOi F02

(} ~. l

(2)Remove the Mecha Lock Caution , tape, and Clamp Arm Stopper on the Top Cover. The Clamp Arm Stopper is used to lock the Clamper Ass'yof the Unit.

F04 Top Cover Ass'y

Fig. 2.2

5 |

6 |

2.3. Main P.C.B. Ass'yand Front Panel Block

Refer to Figs. 2.3.1 and 2.3.2.

(1)Remove the Top Cover Ass'y.See item 2.2.

(2)Remove the screws F01 (M2x1 .8 + Pan, 5 pcs.), F02 (M2.6x3 + Pan, 2 pcs.), F03 (M2.6x8 + Pan, 1 pee.) and F04 (M3x3 +Binding, 1 pee.).

(3)Gently lift the CN-501 part (the right front part) of F10 (Main P.C.B. Ass'y)to disconnect CN-501 from the CD P.C.B. Ass'yon the Mechanism Ass'y.Refer to Fig. 2.3.2.

Fig. 2.3.1

(4)While lifting F10 (Main P.C.B. Ass'y)a little, disconnect the five flexible cables F05 to F09 from CN-106, CN105, CN-508, CN-107, and CN-502 on F10 (Main P.C.B. Ass'y).

NOTE: To disconnect the flexible cable, unlock the connector lock before disconnecting it.

[Disconnecting the Flexible Cable]

(5)Remove F10 (Main P.C.B. Ass'y)while lifting its rear left cable upward.

NOTE: At this time, push the connector case "A" inward as it comes in contact with the chassis hole edge.

(6)Remove the screws F11 (M3x3 + Binding, 2 pcs.) and F12 (M1 .4x4 Countersunk, 2 pcs.) and detach F13 (Front Panel Block).

• F12 for JPN: M1.4x3 Countersunk, 2 pcs.

Fii

Main P.C.B. Ass'y

A

Fig. 2.3.2

2.4. Loading Ass;y

2.4.1. Removing the Loading Ass'y

Refer to Fig. 2.4.1.

(1)Remove the Main P.C.B. Ass'y.See 2.3 "Main P.C.B. Ass'yand Front Panel Block".

(2)Remove the screws F01 (M1.7x2 + Pan (Black Chromate), 2 pcs.), F02 (M17 STC Lock Screw, 2 pcs.) and F03 (M2x2 Countersunk, 2 pcs.).

(3)Carefully disengage the cut washer F04 (Cut Washer 1.6x3.5x0.125) to disengage F05 (Loading Ass'y)from the main body.

(4)While lifting the right side of F05 (Loading Ass'y)((!)), carefully remove it as shown by the arrow <2:1.

NOTE: While removing, do not damage the flexible cables and other parts.

F05 Loading Ass'y

Fig. 2.4.1

2.4.2. Installing the Loading Ass'y

Refer to Fig. 2.4.2.

Install the Loading Ass'yby reversing the removal procedure. However, pay attention to the following points.

•Pay special attention so as not to let fail the four white caps (Stocker Screw Topl of the Loading Ass'y.

NOTE: If it falls, recheck the position of the Stocker Screw Gears. Refer to Fig. 2. 10.3 for correct po- sitions.

•To allow installation of the Loading Ass'y,move the Traverse Ass'ytoward the front of the Unit. See "How To Move the Traverse Ass'y"on the right column.

•Set F06 (Stocker Clutch Plate) in place before installing the Loading Ass'yas F06 (Stocker Clutch Plate) can move freely.

How To Move the Traverse Ass1y

While pushing the part "A" backward, turn the gear of the Feed Motor Ass'ywith your finger tip in the direction as shown by the arrow to move the Traverse Ass'yforward. To move it backward, turn the gear in reverse.

[How to move the Traverse Ass'y]

7 |

8 |

2.5. CD P.C.B. Ass'y

2.5.1. Removing the CD P.C.B. Ass'y Refer to Figs. 2.5.1 and 2.5.2.

(1)Remove the Loading Ass'y.See 2.4 "Loading Ass'y".

(2) Be sure that the Traverse Ass'yis in the front position. (If not, move it by referring to "How To Move the Traverse Ass'y"in 2.4 "Loading Ass'y".)

(3) Remove the screws F01 (M2.6x3 + Pan (Black Chromate), 2 pcs.).

(4) Disconnect the flexible cables F02 and F03 from the CD P.C.B. Ass'y.

(5) Lift F05 (CD P.C.B. Ass'y)and short the laser diode shorting lands "A" on the flexible cable F04.

NOTE: Use the ceramic soldering iron or the soldering iron whose metal part is grounded.

Fig. 2.5.1

F05 CD P.C.B. Ass'y

Fig. 2.5.2

2.6. Traverse Mecha Chassis Ass'y

2.6.1. Removing the Traverse Mecha Chassis Ass'y Refer to Fig. 2.6.

(1)Remove the CD P.C.B. Ass'y.See 2.5 "CD P.C.B. Ass'y".

(2)Remove the screws F01 (M1. 7x1 .6 + Pan (Black. Chromate), 2 pcs.) and detach F02 (Guide PL Block).

(3)Remove the C-ring F03 (1 pee.), washers F04 (Washer 2.6x5x0.5, 2 pcs.), F05 (Thrust Ring, 3 pcs.), and F06 (Lock Guide Top, 3 pcs.).

(4)Remove F07 (Traverse Mecha Chassis Ass'y)from the dampers of the main body.

The four springs F08-F1 o are fallen.

NOTE: Be sure which spring should be mounted on which damper as there are three kinds of springs.

2.6.2. Installing the Traverse Mecha Chassis Ass'y Install the Traverse Mecha Chassis Ass'yby reversing the removal procedure. However, pay attention to the following points.

• Mount the correct spring on each damper.

FOB |

F09 |

FIO |

•Securely insert the Traverse Mecha Chassis Ass'yinto the four dampers.

Fig. 2.6

g |

10 |

2.7. Laser Pickup

2.7.1. Removing the Laser Pickup

Refer to Fig. 2.7.

(1)Remove the Traverse Mecha Chassis Ass'y.See 2.6 "Treverse Mecha Chassis Ass'y".

(2)Remove the screws F01 (M1 .7x1 .8 Countersunk, 3 pcs.) and detach F02 (Spindle Motor Ass'y).

(3)Remove the screws F03 (M1 x1 .5 + Pan (Black Chromate), 2 pcs.) and the washers F04 (Plastic Washer 1.3x3.3x0.3).

(4)Remove the screws F05 (M1.4x1.4 +Pan (Black Chromate), 2 pcs.) and detach F06 (Thrust Bracket Block).

(5)Remove the cut washer (Cut Washer 1.6x3.5x0.5) and detach F08 (Pickup Block).

2.8. Sled Motor Ass'y

Refer to Fig. 2.8.

(1)Remove the Traverse Macha Chassis Ass'y.See 2.6 ''TraverseMacha Chassis Ass'y".

(2)Remove the screws F01 (M1.7x1.8 Countersunk, 3 pcs.) and detach F02 (Spindle Motor Ass'y).

(3)Remove the screws F03 (M2x1.8 + Countersunk, 2 pcs.), F04 (M1x1.5 +Pan (Black Chromate), 1 pee.), and the washer F05 (Plastic Washer 1.3x3.3x0.3).

(4)Remove F06 (Sled Motor Ass'y)and F07 (Sled Belt, 2 pcs.)

(6)Remove the screws F09 (M1 .7x1 .6 +Pan (Black Chromate), 2 pcs.) and F10 (Pickup Feed Spring) and pull out F11 (Pickup Feed Shaft Ass'y)from F12 (Pickup).

2.7.2. Installing a Laser Pickup

Install the Pickup by reversing the removal procedure. NOTES: 1. As a Laser Pickup is packed in a conductive

pack, do not take it out of the pack until you need it.

2.Do not unsolder the shorting lands on the flexible cable of the pickup in this stage. It should be removed after inserting the flexible cable into the CD P.C.B. Ass'yas described in 2.5.2 "Installing the CD P.C.B. Ass'y".

Fig. 2.7

Fig. 2.8

2.9. Feed Motor Ass'y

2.9.1. Removing the Feed Motor Ass'y Refer to Figs. 2.9.1 to 2.9.3.

(1)Remove the Loading Ass'y.See 2.4 "Loading Ass'y".

(2)Be sure that the Traverse Ass'yis in the front position. (If not, move it by hand. See "How To Move the Traverse Ass'y"in 2.4 "Loading Ass'y".)

(3)Remove the screws F01 (M1 .7x1 .6 + Pan (Black Chromate), 2 pcs. ).

(4)Unsolder the flexible cable (unsolder three places).

(5)Unhook the spring F02 (Disc Lock Arm Spring).

(6)Remove the screws F03 (M2x2 Countersunk (Black Chromate), 2 pcs.) and F04 (BT2x3.5 Countersunk (Black Chromate), 2 pcs.).

(7)Peel off F05 (Feed Motor Spacer) that sticks the flexible cable onto the chassis, then remove F06 (Feed Motor Ass'y).

2.9.2 Installing the Feed Motor Ass'y

Install the Feed Motor Ass'yby reversing the removal procedure. However, pay attention to the following points.

•Insert the flexible cable of the Feed Motor Ass'y(part "A") between the chassis and the flexible cable "B" as shown in Fig. 2.9.3.

•Stick F05 (Feed Motor Spacer) on the original place.

•When tightening the screws F01, slide the flexible cable toward the front as shown by the arrow in Fig. 2.9.1.

Fig. 2.9.1 |

Fig. 2.9.2 |

|

Fig. 2.9.3

11 |

12 |

|

2.1 O. Stocker Ass'yand Disc Holders

2.10.1. Removing the Stocker Ass'yand Disc Holders

Reier to Fig. 2.10.1.

(1)Remove the Loading Ass'y.See 2.4 "Loading Ass'y".

(2)Remove F01 (Stocker Screw Top, 4 pcs.).

(3)Carefully remove F02 (Stocker Ass'y).

(4)By turning the lour Stocker Screw Gears little by little in turn, remove the six Disc Holders from the Stocker Screw Gears one by one.

Disc Holder

Stocker Screw Gear

Fig.2.10.1

2.10.2. Installing the Stocker Ass'yand Disc Holders

Refer to Figs. 2.10.2 and 2.10.3.

(1)While turning the lour Stocker Screw Gears little by little in turn, insert each Disc Holder one by one.

•As shown in Fig. 2.10.2, leave space of approx. 2 mm (approx. equivalent to the Disc Holder'sthickness) at the free end of the Stocker Screw Gears.

•Insert the Disc Holders without space between them. When you try to insert the 5th Disc Holder, the first one will apart approx. 1O mm as shown in Fig. 2.10.2.

(to be continued on the next page)

Stocker Screw Gear@~

Approx.2 mm

|

_i |

1st Disc Holder |

T |

|

|

|

I |

|

Stocker Screw Gear |

2nd Disc Holder ~(Nospace) |

|

|

~ |

5th Disc Holder

6th Disc Holder (The last one)

Fig. 2.10.2

(2)When installing the Stocker Ass'yin the chassis, align the position of the gear of each Stocker Screw Gear as shown in Fig. 2.10.3.

1)Before installing the Stocker Screw Gears in the chassis, be sure the large Stocker Drive Gear po- sition is correct.

•The holes "A", "B", and "C" on the Stocker Drive Gears should align with corresponding marks "a", "b", and "C".

•If not, turn the large Stocker Drive Gear by hand to correct its position, while depressing the part "D" with your finger tip as shown in the figure. (By pressing the part "D", the Stocker Drive Gear can turn.)

2)Aligning the two Stocker Screw Gear~: Align the mark (projection) on the gear of the Stocker Screw Gear wjth the mark fho!e\ on the lame Stocker Drive Gear as shown in the figure. NOTE: Since the mark (projection) on the gear is

difficult to find, it is a good idea to reflect light to find it.

3)Aligning the two Stocker Screw Gear at the rear: Align the mark (projection) on the gear of the Stocker Screw Gear with the mark (hole\ on the chassis as shown in the figure.

Gear of the Stocker Screw Gear

Mark on the chassis

Fig. 2.10.3

13 |

14 |

2.11. Shut Arm Block and Loading FPC Ass'y

Refer to Fig. 2.11.

2.11.1. Removing the Shut Arm Block and Loading FPC

Ass'y

(1)Remove the Loading Ass'y.See 2.4 "Loading Ass'y".

(2)Remove the screws F01 (M2x1 .8 + Pan (Black Chromate), 3 pcs.) and detach F02 (Shut Arm Block) by shifting it to the right in Fig. 2.11.

(3)Remove the screws F03 (M2x1 .8 + Pan (Black Chromate), 1 pee.) and F04 (M2x2.5 + Pan, 1 pee.) that fasten F05 (Loading FPC Ass'y).

(The Loading FPC Ass'yare soldered to the motor terminals.)

2.11.2. Installing the Shut Arm Block and Loading FPC

Ass'y

(1)Fasten F05 (Loading FPC Ass'y)with the screws in the following order.

1)Fasten the center screw F04 and then right and left screws F03 and F01.

2)Loosen the center screw F04 once and then refasten it.

(2)Shift the Shut Arm Block to the right in Fig. 2.11. Then, assemble it to the Shut Arm Rack of the Loading Ass'y. In this case, assemble it so that 3 teeth of the Shut Arm Rack comes out as shown when the Shut Arm is set free (set vertically).

Fig. 2.11

2.12. Loading Guide Ass'y

2.12.1. Preparation Before Removing the Loading GuideAss'y

It is required to position the Clamper Ass'yof the Loading Ass'yin the clamp (chucking) position before removing the Loading Guide Ass'y.Otherwise, the Loading Guide Ass'y cannot be installed to the loading chassis.

To position the Clamper Ass'yto the clamp (chucking) position, follow the steps below:

(1)Check if the Clamper Ass'yis in the clamp (chucking) position as shown in Fig. 2.12.1.

If not, proceed to step (2).

(2)Connect two batteries (3.0 V) between the terminals of the Loading Motor Ass'y.As you apply the voltage to the Loading Motor Ass'y,the loading mechanism will move. So, set the Clamper Ass'yto the clamp (chucking) position or near position.

Loading Motor Ass'y

Connect two ==D dry-cell batteries

(3.0V)

2.12.2. Removing the Loading Guide Ass'y

Refer to Fig. 2. 12.1.

(1)Remove the Shut Arm Block and Loading FPC Ass'y. See 2.11 "Shut Arm Block and Loading FPC Ass'y".

(2)Remove the cut washer F01 (Cut Washer 2.1x5x0.125) and pull out F02 (GearTBL 2).

(3)Remove the screw F03 (M2x2.5 + Pan (Black Chromate)) and detach F04 (P Arm Guide).

(4)Remove the screws F05 (M2x3 + Pan (Black Chromate), 5 pcs), disengage F06 (Cut Washer 1.2x3x 0.125), and detach F07 (Loading Guide Ass'y)by lifting it upward.

To separate F07 (Loading Guide Ass'y)from the Loading Chassis Ass'y,it is required to unsolder the flexible cable from the Loading Motor Ass'y.

[Connecting battery to turn the Loading Motor Ass'y]

Loading Guide Ass'y

Loading Motor Ass'y

Loading Chassis Ass'y

Clamper Ass'yin the clamp (chucking) position

B

Fig. 2.12.1

15 |

16 |

2.12.3. Installing the Loading Guide Ass'y

When installing the Loading Guide Ass'yin the Loading Chassis Ass'y,follow the steps below:

Note that the 3 places "A"-"B", "C"-"D" and "E"-"F" (see Figs. 2.12.1 and 2.12.2) must be correctly positioned.

(1)First, temporarily mount the Plate LG R of the Loading Guide Ass'yon the Loading Chassis Ass'ywith two screws "G", as it can move freely and come in contact with other parts. Refer to Fig. 2.12.2.

(2)Turn the movable Plate PLS Sub Ass'y"H" to bring it to the position shown in Fig. 2.12.2.

(3)Insert the shaft "A" of the Loading Guide Ass'yinto the hole "B" of the gear train on the Loading Chassis Ass'y.(After insertion, the Loading Guide Ass'ywill float from the Loading Chassis Ass'ya little.)

Loading Guide Ass'y

Loading Chassis Ass'y

(4)While opening the Loading Guide L outward, align the hole "C" of the Plate PLS Sub Ass'ywith the pin "D" of the Loading Guide Ass'yand, at the same time, align the pin "E" of the Plate PLS Sub Ass'ywith the hole "F" of the Loading Guide Ass'y.Then, engage them each other.

(5)Move the part "I" in the direction shown by the arrow. Then, be sure that the Loading Guide Ass'yis securely seated to the Loading Chassis Ass'y.

(6)Fasten the cut washer F06 and 5 screws F05 to mount the Loading Guide Ass'y.

Loading Guide L

A

c

F

E

Fig. 2.12.2

3.MECHANICAL ADJUSTMENTS

3.1. Gear Position Adjustments around the Stocker Drive Gear

Refer to Fig. 3.1.

NOTE: To turn the large Stocker Drive Gear, depress the part "A" with your finger tip as shown in Fig. 3.1.

3.1.1.Positioning the STCD Gear and Disc Lock SG The STCD Gear and two Disc Lock SGs must be positioned as shown in Fig. 3.1.

3.1.2.Positioning the Stocker Screw Gears

The four Stocker Screw Gears must be positioned as shown in Fig. 3.1.

(1)Aligning the two Stocker Screw Gear at the front: Align the mark (projection) on the gear of the Stocker

Screw Gear with the mark lholel on the lame Stocker

Drive Gear as shown in the figure.

NOTE: Since the mark (projection) on the gear is difficult to find, it is a good idea to reflect light to find it.

(2)Aligning the two Stocker Screw Gear~: Align the mark (projection) on the gear of the Stocker

Screw Gear with the mark lholel on the chassjs as shown in the figure.

For details, refer to 2.10.2 "Installing the Stocker Ass'yand Disc Holders".

Gear of the Stocker Screw Gear

Mark on the chassis

Fig. 3.1

17 |

18 |

3.2. Disc Lock Drive Gear Positioning

(1)Lower the Disc Lock Sleeve until it reaches the lowest position. Namely, turn the Disc Lock Drive Gear fully clockwise until it stops.

(2)Install the Disc Lock Plate so that its 3rd tooth engages with the Disc Lock Drive Gear as shown in Fig. 3.2.

Disc Lock Plate

Disc Lock Drive Gear

Disc Lock Sleeve

Fig. 3.2

3.3. Loading Guide R B Positioning

Install the Loading Guide R B so that its gear is engaged with the P Arm Gear as shown in Fig. 3.3.

In this case, be sure that the Loading Guide R B is fully pushed against the Loading Plate R Sub Ass'y.

Loading Plate R Sub Ass'y

Loading Guide R B

Vertical position

Fig. 3.3

4.MEASUREMENT INSTRUMENTS AND JIGS

(1)Oscilloscope (40 MHz or more)

(2)DC Power Supply Unit(+14.4 V DC)

(3)DC Power Supply Unit (+5 V DC)

(4)ABEX Test Disc TCD-725A (DA09193A)

(5)ABEX Test Disc TCD-784 (DA09195A)

(6)CD-ROM Test Unit (DA09190A)

(7)Test Unit Cable (DA05322A)

(8)Tracking Offset Meter LTM-9055 or LE 9055A (Leader Electronics Corp.)

0 |

|

|

|

|

|

|

-rl |

|||||||||||||

|

|

|

|

12:.c·~ |

|

T/F |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

W1 ON |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T-OSC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

TE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

EFV |

|

|

|

|

|

|

|

|

|

|

|

|

E-F |

|

|

|||||

F-OSC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||

FE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

SL-DAV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+5V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

RF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+5V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

> |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ud |

|

|

|

|

"'co |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

();,::: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

02 |

|

|

|

|

~ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

2SC2240 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RF |

|

|

|

|

|

|

|

|

|

|

|

|

|

C3 |

a:~"' |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

0.1 |

|

|

|

GND |

|||||||||||

|

|

... 0 |

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

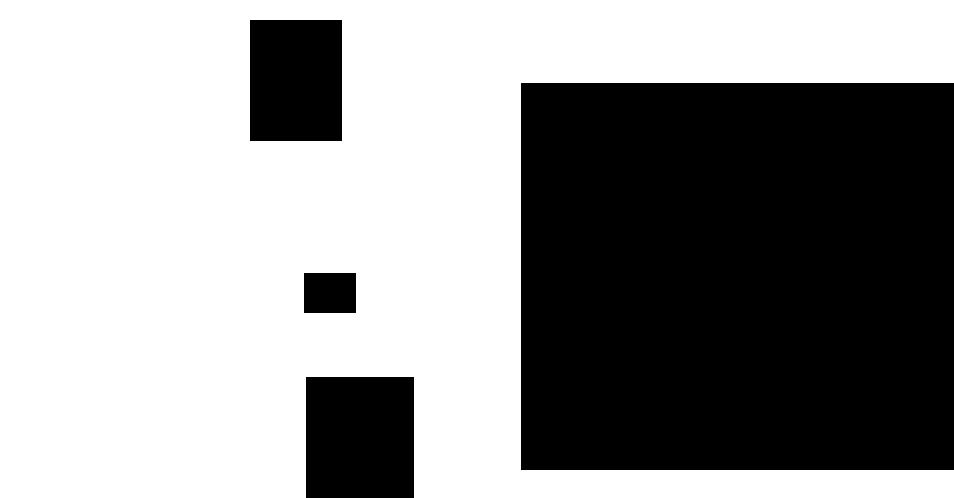

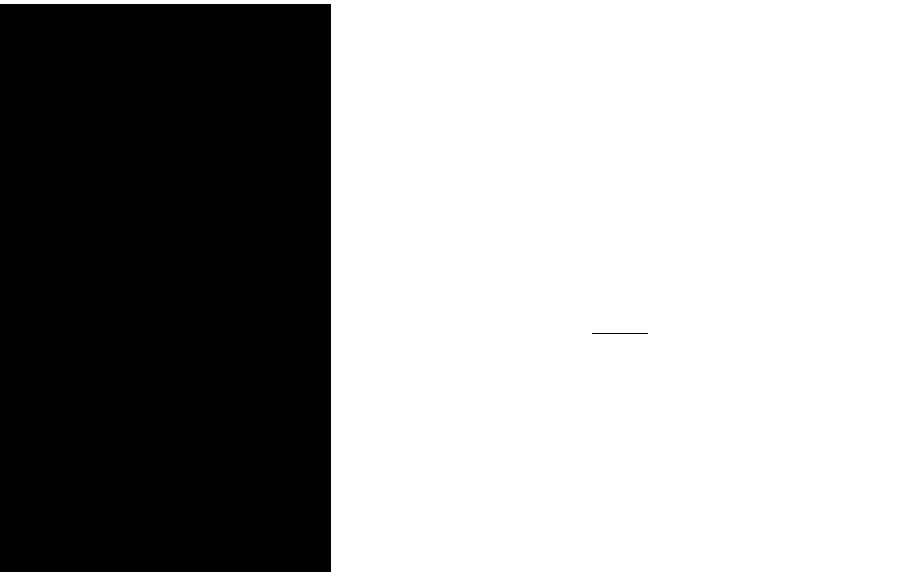

Fig. 4.1 CD-ROM Test Unit

19 |

20 |

5.ELECTRICAL ADJUSTMENTS

NOTES:

1. Preset position of the semi-fixed volumes:

When the CD P.C.B. Ass'yor semi-fixed volume VR101 or VR102 is replaced with new one, preset the semi-fixed volumes to their mechanical center positions before starting adjustment.

2.Connecting Measurement Instruments:

Connect measurement instruments to the CD P.C.B. Ass'yas shown in Fig. 5.1. Fig. 5.1 also shows the parts location tor adjustment.

|

|

|

|

|

DC Power |

|

To the Unit |

BATT |

|

|

Supply Unit |

||

|

|

|

|

|||

[ |

|

ACC |

|

|

|

14.4V |

|

GND |

|

|

|

||

|

|

|

|

GND |

||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

To Chassis |

|

|

|

|

|||||

|

|

|

|

CD-ROM Test Unit |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SW1 SW2 |

|

|

|

|

||

|

|

|

|

|

©E-F |

|

Tracking |

||||

" -------- + - iu8 |

|

~OFFB~ |

|

Offset Meter |

|||||||

|

(Vose |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Test Unit Cable |

|

|

Tracking |

(VvM |

|

|

|||||

|

|

|

|

||||||||

|

|

|

|

|

|

ON |

|

|

|||

|

|

|

|

|

+5V GND |

(VRF |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DC Power |

|

|

|

|

|

|

|

|

||

|

Supply Unit |

|

|

|

|

|

|

|

|

||

|

5V 0 - |

|

|

|

|

|

|

|

|||

|

4 --------- ' |

|

|

|

|

|

|

||||

|

GNDO--l-~~~~~~-' |

|

|

|

|

||||||

|

|

Fig. 5.1 Measurement Instrument Connecting Diagram |

|

|

|||||||

|

|

|

|

||||||||

STEP |

|

|

ITEM |

|

SIGNAL |

|

|

OUTPUT |

|

|

|

ADJUST- |

REMARKS |

|||||||||

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

SOURCE |

|

CONNECTION |

|

|

MENT |

|

||||||||||

|

|

|

|

|

|

|

|

|

See Fig. 5.1. |

|

|

|

|

|

|

1. To access to the semi-fixed volumes on the CD |

||||||

|

|

Preparation |

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P.C.B. Ass'y,remove the Front Panel Block and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

then carefully place it on the Unit. (See item 2.3.) |

|

|

|

|

|

|

Test Unit Cable |

|

|

|

|

CD-ROM Test Unit |

|

2. Disconnect the original BP cable from the CD- |

|||||||||

|

|

|

|

ToTP136 |

|

|

|

|

|

|

|

1 SWI SW2 |

ROM Test Unit. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

~OFFB~ |

3. Connect one end of the additional Test Unit Cable |

||||||||

|

|

|

|

(CD P.C.B. Ass'y) |

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tracking |

|

|

|

|

to the BP connector of the CD-ROM Test Unit. |

||

|

|

|

|

|

|

|

To Chassis |

|

|

|

|

|

|

|

|

|

|

4. Connect the other end of the additional Test Unit |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

ON |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cable to the TP136 connector on the CD P.C.B. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+SV GND |

|

|

|

|

Ass'y. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5. Connect the Ground Wire with Clip of the CD- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ROM Test Unit to the chassis of the Unit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

To Power Supply |

6. Connect +5V and GND wires of the CD-ROM Test |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unit to a +5V DC power supply unit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. Supply +14.4V DC to the ACC and BATT lines of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the Unit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

EFM Signal |

|

ABEX Test Disc |

Oscilloscope |

|

CD P.C.B. |

1. Set SW1 of the CD-ROM Test Unit to Tracking |

||||||||||||||

|

|

Adjustment |

|

TCD-784 |

to RF Connector |

|

VR102 |

ON position and SW2 to OFF (center) position. |

||||||||||||||

|

|

|

|

|

|

|

|

|

of the CD-ROM |

|

|

|

|

|

2. Play back the first track of the test disc (within 1 |

|||||||

|

|

|

|

|

|

|

|

|

Test Unit |

|

|

|

|

|

minute). |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. Adjust VR102 until waveform amplitude becomes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

maximum and the waveform becomes clear (not |

|

|

SW1: TRACKING ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

thick) as shown below: |

||||||

|

|

SW2:0FF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-r |

||

|

|

|

CD-ROM Test Unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

SWI |

SW2 |

@E-F |

|

|

|

|

|

|

|

|

|

|

|

|

|

0.75-1.20Vp·p |

||

|

|

|

|

goffB~ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

Tracking |

@osc |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

ON |

|

|

@VM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

@RF |

|

|

|

|

Oscilloscope |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oscilloscope Setting: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connecting Diagram |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AC Mode, 0.2 V/div, 0.5 µs/div |

|||||

4. Stop the test disc.

21 |

22 |

|

STEP |

|

ITEM |

|

SIGNAL |

OUTPUT |

ADJUST· |

|

REMARKS |

|

|

|

|

STEP |

ITEM |

SIGNAL |

OUTPUT |

ADJUST· |

|

REMARKS |

|

|||||||||

|

|

|

|

|

|

SOURCE |

CONNECTION |

MENT |

|

|

|

|

|

|

|

|

|

|

SOURCE |

CONNECTION |

MENT |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

3 |

|

E·FBalance |

ABEX Test Disc |

Tracking Offset |

CD P.C.B. |

1. |

Set SW1 of the CD-ROM Test Unit to Tracking |

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

3. |

Disconnect the ACC and BATT power lines in |

||||||||||||||||||||

|

|

ON position and SW2 to OFF (center) position. |

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

Adjustment |

TCD·784 |

|

Meter to E·F |

VR101 |

|

|

|

|

|

|

|

|

|

that order to set the Unit to the Standby state. |

|||||||||||||

|

|

|

|

|

|

|

|

|

Connector |

|

|

2. |

Connect a tracking offset meter to the E-F |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• First, disconnect the ACC power line. |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

connector of the CD-ROM Test Unit, and set the |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

of the CD·ROM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Test Unit |

|

|

|

switches of the meter as follows: |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•Sensitivity switch: |

HIGH (right side) |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

SW1: TRACKING ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

• Level switch: |

MEASURE (left side) |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

SW2:0FF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

•Center switch: |

MEASURE (center position) |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

CD-ROM Test Unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

3. |

Set SW1 of the CD-ROM Test Unit to Tracking |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

SW1 |

SW2 |

0 E·F ..._ |

H------, |

|

|

|

OFF position and play back the first track of the |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

gOFF |

8 |

~ |

|

|

|

test disc. |

|

|

|

|

|

|

|

|

|

|

|

|

•Next, disconnect the BATT power line. |

||||||

|

|

|

|

|

|

|

@osc |

|

|

|

|

|

Then, within several seconds, adjust VR101 to |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

Tracking |

|

|

|

|

|

|

|

|

obtain OV ± 50mV DC on the meter located in the |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

ON |

|

|

|

@vM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DC Power |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

center of the Tracking Offset Meter. |

|

|

|

|

|

|

|

|

|

Supply Unit |

||||

|

|

|

|

|

|

|

|

@RF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(After several seconds, the sound output will be |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

stopped though the test disc turns.) |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Tracking Offset Meter LTM·9055 or LE·9055A |

|

|

|

-,_. |

+,.. |

I |

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. |

Before returning the Unit, insert the Clamp Arm |

||||||

|

|

|

~rrn@rn1;1 |

|

4. |

|

|

|

|||||||||||||||||||||

|

|

|

|

Set SW1 of the CD-ROM Test Unit to ON position |

|

|

|

|

|

|

|

|

U G Screws to lock the Traverse Ass'y.For |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. ''%"'l |

'47."'. |

|

|

|

|

|

|

|

|

Stopper to lock the Clamper Arm and fasten the |

||||

|

|

|

00 |

|

. J~ • |

l:i:J |

|

|

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

and repeat from step 3 until adjustment is com- |

|

|

|

|

|

|

|

|

details, see 1.5 "Shipping Procedure after |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pleted. |

|

|

|

|

|

|

|

|

|

|

|

|

Service Work" on page 3. |

|

|

|

|

|

|

|

|

|

|

.\Read this meter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

Connecting Diagram |

|

|

|

|

|

5. |

After adjustment, perlorm "EFM Signal Adjust· |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

ment" in step 2. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mecha Lock Caution |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6. Stop the test disc. |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

Operation |

ABEX Test Disc |

|

|

|

|

|

Make sure that no noise nor track-jumping is found in |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

Check |

TCD-725A |

|

|

|

|

|

the following programs of the test disc. |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To select the desired program, press FWD. Skip |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(»)button or REV. Skip(«) button of the Control |

|

|

|

|

|

Tape |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Button Unit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Interruption 600 µm: |

4th program |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Black dot 500 µm: |

|

8th program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Simulated fingerprint: |

13th program |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Termination |

|

|

|

|

|

|

|

|

|

1. |

Eject the test disc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. |

Perform the "Initialization" as follows: |

|

|

|

|

|

Clamp Arm Stopper |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

While pressing and holding the DISC6 button, |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

press the RESET button. |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(The firmware version will be displayed and then |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

initialization begins.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IDiscs I+ RESET Button |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(to be continued) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 |

24 |

6.MECHANISM ASS'YAND PARTS LIST

6.1. Synthesis

02

04

Fig. 6.1

6.2. Front Panel Ass'y(A01)

6.2.1. Front Panel Ass'y(USA, CAN)

|

|

|

Fig. 6.2.1 |

For USA, CAN |

|

|

|

|

6.1. Synthesis |

|

|

|

|

|

|

|

|

Schematic |

|

|

|

|

Schematic |

|

Description |

|

Ref. No. |

Part No. |

Description |

|

Q'ty |

Ref. No. |

Part No. |

Q'ty |

|

|

--- |

|

|

|

|

|

|

|

|

Synthesis |

|

|

L10 |

OE04100A |

M1 .4x4 Countersunk (Black Chromate) 2 |

||

|

|

|

|

|||||

01 |

OC204BOC |

Clamp Arm Stopper |

1 |

|

|

(USA, CAN) |

|

|

|

|

|

|

|||||

02 |

OC20365E |

Top Cover |

1 |

|

|

|

|

|

03 |

OJ08184A |

Insulator Main A |

1 |

6.2.1. Front Panel AS$'y(A01) {USA, CAN) |

|

|||

04 |

BA09853A |

Main P.C.B. Ass'y(USA, CAN) |

1 |

Schematic |

|

|

|

|

|

BA09854A |

Main P.C.B. Ass'y(JPN) |

1 |

|

|

|

||

05 |

BA09859A |

Connector FPC Ass'y |

1 |

Ref.No. |

Part No. |

Description |

Q'ty |

|

06 |

OJ08185A |

Insulator Main B |

1 |

~ HA07641A |

Front Panel Ass'y(USA, CAN) |

1 |

||

07 |

OJ08124A |

Lock Plale (USA, CAN) |

2 |

|

|

|

|

|

08 |

HA07651A |

Power Amp. Ass'y |

1 |

01 |

HA07779A |

Front Panel Sub Ass'y |

1 |

|

09 |

OJ08196A |

Label Protector |

1 |

02 |

OH07802A |

Release Knob |

1 |

|

10 |

OJ06068A |

Clip |

1 |

03 |

OH07792A |

Up/Down Knob |

1 |

|

11 |

HA07641A |

Fron! Panel Ass'y(USA, CAN) |

1 |

04 |

OH07790A |

Source Knob |

1 |

|

12 |

HA07642A |

Front Panel Ass'y(JPN) |

1 |

05 |

OH07809A |

Reset Knob |

1 |

|

HA07610A |

Fron! Base Ass'y(USA, PAN) |

1 |

06 |

OH07797A |

Preset Knob |

1 |

||

13 |

OB84524A |

Cap |

4 |

07 |

OH07795A |

TU/PA Knob |

1 |

|

14 |

OB84910A |

RCA Ass'yAux1 |

1 |

08 |

OH07793A |

Eject Knob |

1 |

|

15 |

OB84911A |

RCA Ass'yAux2 |

1 |

09 |

OH07784D |

Disc Select Knob 1 |

1 |

|

16 |

OB84912A |

13P DIN Ass'y |

1 |

10 |

OH07785D |

Disc Select Knob 2 |

1 |

|

17 |

CA10130A |

Mechanism Ass'y |

1 |

11 |

OH07786D |

Disc Select Knob 3 |

1 |

|

18 |

OD07059B |

Macha Lock Caution |

1 |

12 |

OH07787D |

Disc Select Knob 4 |

1 |

|

L01 |

OE04109A |

M2x1.8 +Pan |

5 |

13 |

OH07788D |

Disc Select Knob 5 |

1 |

|

L02 |

OE04047A |

M3x3 + Binding |

3 |

14 |

OH07789D |

Disc Select Knob 6 |

1 |

|

L03 |

OE04057A |

M5x6 Countersunk (USA, CAN) |

2 |

15 |

OJ08165A |

LED Filter |

1 |

|

L04 |

OE04046A |

M2.6x3+ Pan |

2 |

16 |

BA09861A |

Front P.C.B Ass'y |

1 |

|

LOS |

OE04036A |

M2.6x8 +Pan |

1 |

17 |

OJ08194B |

Conductor Sheet B |

1 |

|

L06 |

OE03070A |

M2.6x6 + Binding |

1 |

18 |

OJ08120A |

Release Spring |

1 |

|

L07 |

OC20447B |

U G Screw |

2 |

19 |

OJ08160A |

Lock Arm R |

1 |

|

LOB |

OE00986A |

M3x10 + Binding |

2 |

20 |

OJ08161A |

Lock Pin L |

2 |

|

L09 |

OE04053A |

M1 .4x3 Countersunk |

2 |

21 |

OJ08162B |

Lock Spring L |

2 |

|

|

|

(Black Chromate) (USA, CAN) |

|

|

22 |

OH07749E |

Rear Cover |

1 |

|

OE04053A |

M1 .4x3 Countersunk |

|

|

L01 |

OE03814A |

PT2x8 +Binding (Black Chromate) |

3 |

|

|

(Black Chromate) (JPN) |

|

|

|

|

|

|

25 |

26 |

6.2.2. Front Panel Ass'y(JPN)

Fig. 6.2.2 For JPN

6.2.2. Front Panel Ass'y{A01) (JPN) |

|

||||

Schematic |

|

|

|

|

|

Ref~. No. |

~Part N |

|

Description |

||

|

HA07642A |

i;;F,;;;o:;nt;-;'.P;:a:!'ne:::I7A-,.ss'y-(-JP_N ) |

|||

01 |

HA07780A |

F I |

|

|

|

03 |

OH07792A |

Ur~~ Panel Sub Ass'y |

|||

OH07790A |

S~ur~w~n~~ob |

||||

02 |

|

|

|

|

|

04 |

OH07809A |

Reset Knob |

|

||

05 |

OH07797A |

Preset Knob |

|||

06 |

OH07795A |

TU/PA Knob |

|||

07 |

g~g~m~ |

Eject Knob |

|

||

08 |

OH07785D |

g1sc Select Knob 1 |

|||

09 |

OH07786D |

D~sc ~elect |

Knob 2 |

||

10 |

OH07787D |

|

~SC |

elect Knob 3 |

|

11 |

OH0778BD |

Disc Select Knob 4 |

|||

1314 |

~:r::f |

E~;;:=~1 |

~~~g~ |

||

12 |

|

|

|

|

|

15 |

BA09867A |

F |

|

er |

|

OJ08195B |

|

rant P.C.B. Ass'y |

|||

16 |

HG07635B |

g~:mdu~orSheet C |

|||

17 |

088491 |

|

isc.Guide Ass'y |

||

18 |

OE0381:~ |

Flexible Wire 14P |

|||

L01 |

|

PT2x8 |

+ Binding (Black Chromate) |

||

6.3. Front Base Ass'y(A02) (USA, CAN)

03

Fig. 6.3 For USA, CAN

6.3. Front Base Ass'y(A02

Schematic

Ref~. No.

01

02

03

04

05

L01

) (USA, CAN)

PartN_o. Description

HA07610A FF,;;;~;:::7-,--.,------

ront Base Ass•y (USA, CAN)

~g~~~~ Push Button

HG07634C Push Button Spring

OJOB176A ~~mt ~~se Sub Ass'y

BA09865A F C Fixing Plate

OE04048A p~;~:~~:nss•y

27 |

28 |

6.4. Mechanism Ass'y(A03)

01 (803)---tc:.

Loading Ass'y

1S (802)

Traverse Base Ass'y

32

L02

LOS

LO& ~LOS

1~~18

Fig. 6.4

6.5. Power Amp. Ass'y(A04)

L01

L01

Fig. 6.5

6.4. Mechanism Ass'y(A03) |

|

|

|

|

|

|

|

|

|

|

||

Schematic |

|

|

|

Q'ty |

Schematic |

|

|

|

|

|

|

|

Ref. No. |

Part No. |

_Dc_e:..cs.:.ccn"'·p_tio n |

_ |

Ref. No. |

Part No. |

|

Description |

|

|

Q'ty |

||

~CA10130A |

Mechanism Ass'y |

|

1 |

L01 |

OE04087A |

Cut Washer 1.6x3.5x0.125 |

|

|

||||

01 |

CA10105A |

Loading Ass'y |

|

1 |

L02 |

OE03499A |

M2x2 Countersunk (Black Chromate) |

|

|

|||

|

L03 |

OE04120A |

C-Ring |

|

|

|||||||

02 |

OC20357A |

Thrust Ring |

|

3 |

|

|

||||||

|

L04 |

OE04124A |

Washer 2.6x5x0.5 |

|

|

|||||||

03 |

OC20170A |

Lock Guide Top |

|

3 |

|

|