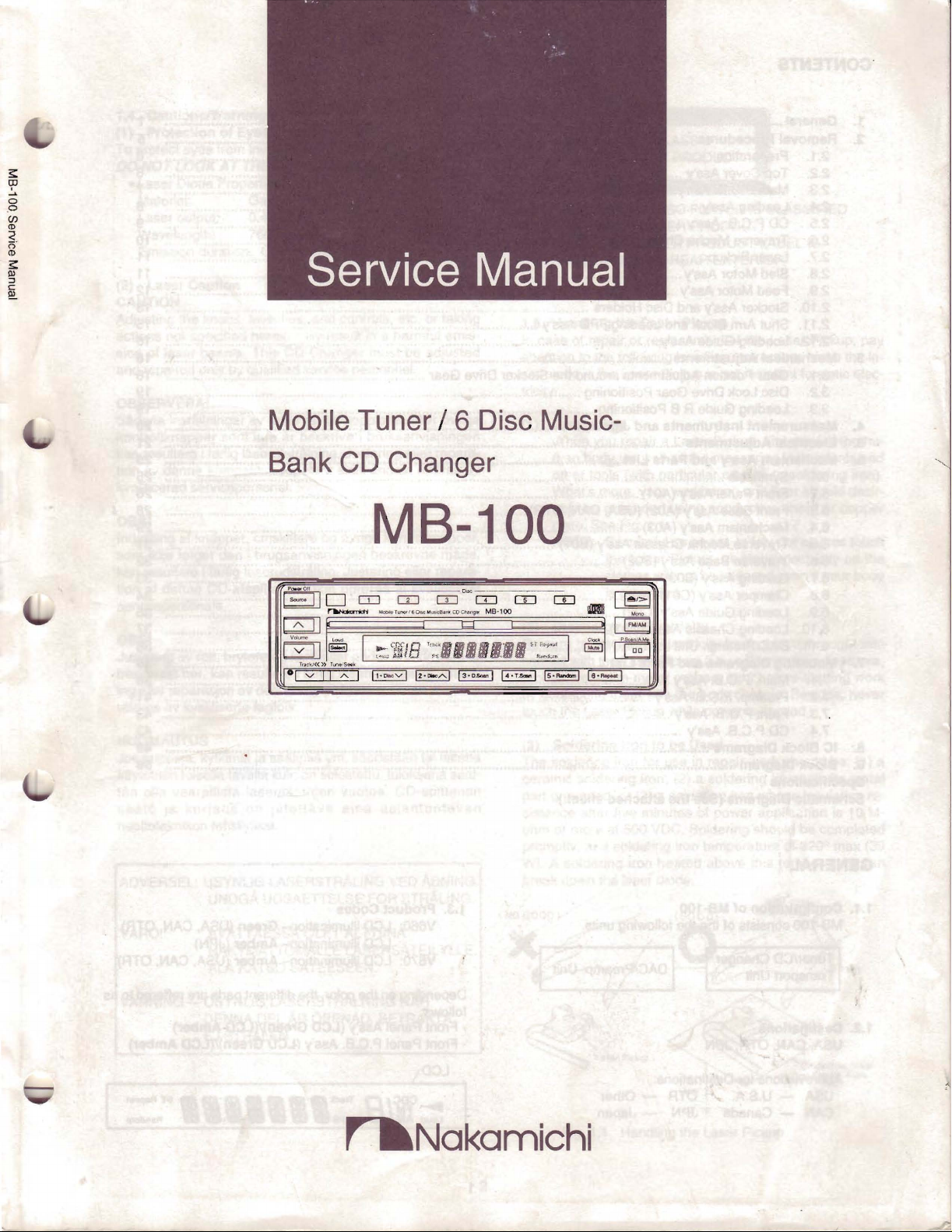

Mobile

Tuner

/ 6

Disc

Music-

Bank

CD

Changer

MB-100

r.Nakamichi

I

;<;1

CONTENTS

1.

General .

2.

Removal Procedures

2.1. Preparation .

2.2. Top Cover Ass'y

2.3. Main P.C.B. Ass'y and Front Panel Block .

2.4. Loading Ass'y .

2.5.

CD

P.C.B. Ass'y .

2.6. Traverse Mecha Chassis Ass'y .

2.7. Laser Pickup , , , .

2.8. Sled Motor Ass'y .

2.9. Feed Motor Ass'y .

2.10. Stocker Ass'y and Disc Holders .

2.11. Shut

2.12. Loading Guide Ass'y .

3.

Mechanical

3.1. Gear Position Adjustments around the Stocker Drive Gear

3.2. Disc Lock Drive Gear Positioning .

3.3. Loading Guide R B Positioning , , , .

4. Measurement

5.

Electrical

6.

Mechanism

6.1. Synthesis ,

6.2. Front Panel Ass'y (A01) .

6.3. Front Base Ass'y (A02) (USA, CAN, OTR) ,

6.4. Mechanism Ass'y (A03) , .

6.5. Traverse Mecha Chassis Ass'y (B01)

6.6.

6.7. Loading Ass'y (B03)

6.8. Clamper Ass'y (C01) .

6.9. Loading Guide Ass'y (C02) ,

6.10. Loading Chassis Ass'y (C03)

6.11. DAC/Preamp. Unit

7.

Mounting

7.1. Main P.C.B. Ass'y .

7.2. Preamp. P.C.B. Ass'y , .

7.3. Front P.C.B. Ass'y , , .

7.4.

8.

IC

Block

9.

Block

Specifications

Schematic Diagrams (See

Arm

Block and Loading

Adjustments

Instruments

Adjustments

Ass'y

and Parts

Traverse Base Ass'y (B02) , , , .

Diagrams and Parts

CD

P.C.B. Ass'y ,

Diagrams

Diagram .

and

the

attached sheet.)

List

List

Jigs

FPC

Ass'y .

,.,

..

,

1

..

5

6

6

7

8

9

'2

'3

.

..

"8

. 9

. 3

_-

__

~

.

.

..

..

..

..

..

..

..

.

..

~=-~=---

,

GENERAL

1.1.

Configuration

MB-1

00 consists of the the following units.

Tuner/CD Changer

Transport Unit

11.2.

Destinations

USA, CAN, OTR, JPN

Abbreviations for Destinations:

USA U.S.A. OTR

CAN

- Canada JPN - Japan

of

MB-100

DAC/Preamp. Unit

- Other

1.3. Product Codes

V660: LCD illumination- Gree

LCD

illumination-

V670:

LCD

illumination- Ambe

on

the

Depending

follows:

. Front Panel Ass'y (LCD Green)/(LC

. Front Panel P.C.B. Ass'y (LCD

color, the different

Ambe'

Greel"

1

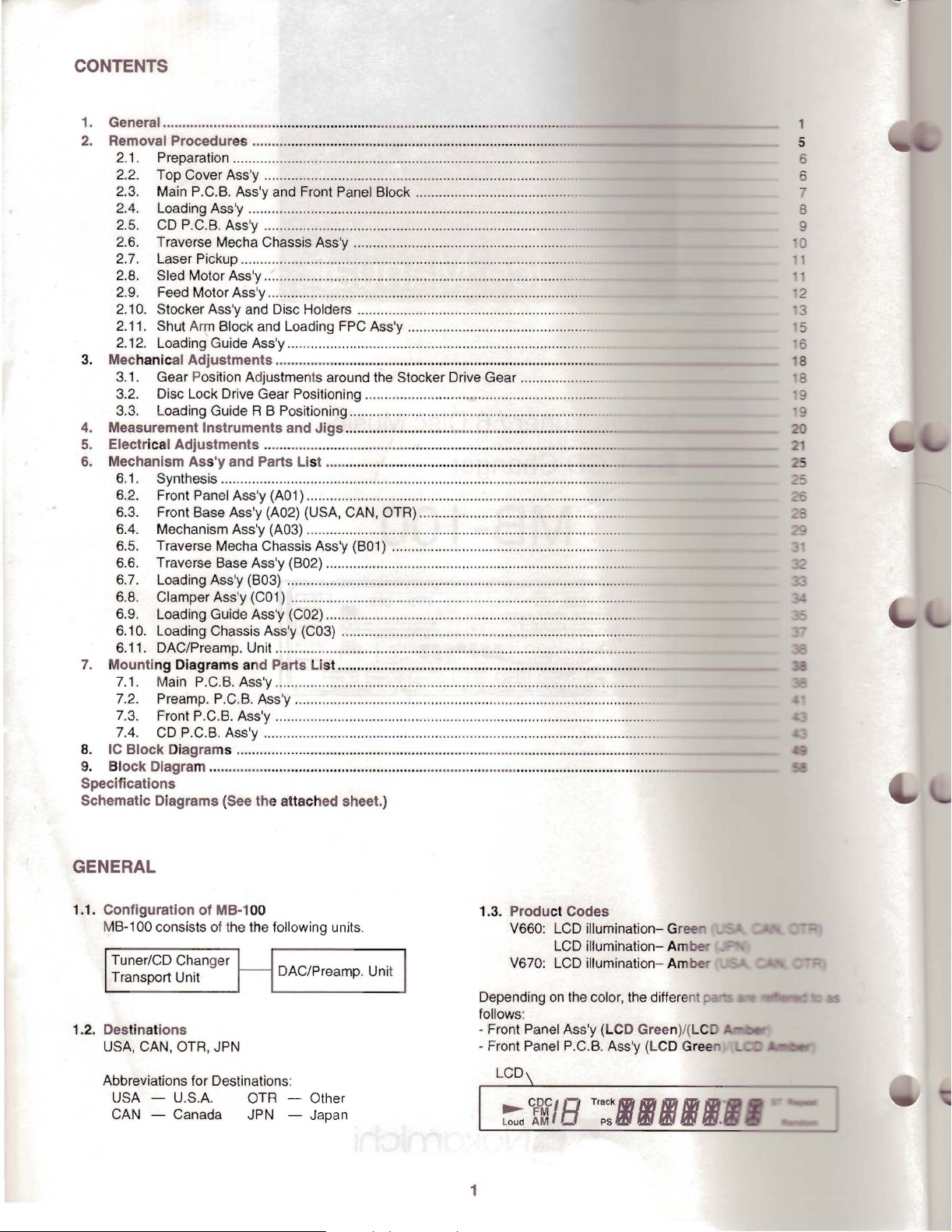

Removal Procedures:

2.1. Preparation

(1)

Remove the two transportation screws

on

the bottom, that lock lhe Traverse Ass"j.

(U

G Screws)

(2)

Remove the Mecha Lock

Arm Stopper

per

is

U

on

used to lock the Clamper Ass'y

G Screw

Caution,

the Top Cover. The Clamp Arm Stop-

lape, and Clamp

of

the Unit.

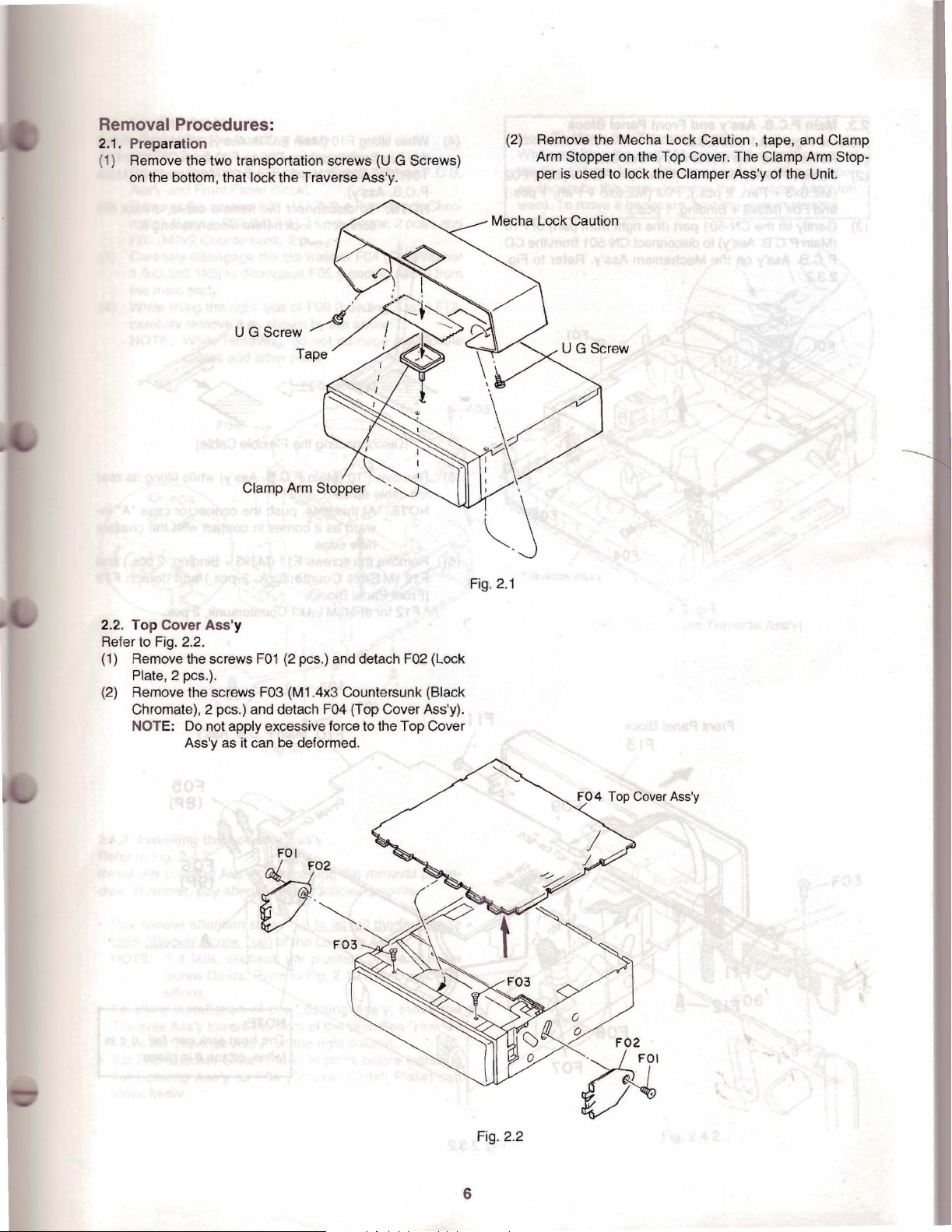

2.2. Top Cover Ass'y

Refer to Fig. 2.2.

(1) Remove the screws

Plate, 2 pes.).

(2)

Remove the screws F03 (M1.4x3 Countersunk (Black

Chromate), 2 pes.) and detach

NOTE:

Do

not apply excessive force to the Top Cover

Ass'y as

it

FO~

can

(2

pcs.) and detach F02 (Lock

F04

(Top Cover Ass'y).

be

deformed.

FOI

tl°~

Fig.

2.1

F04

Top Cover Ass'y

c

Fig. 2.2

6

11<0~

o

F02

~'

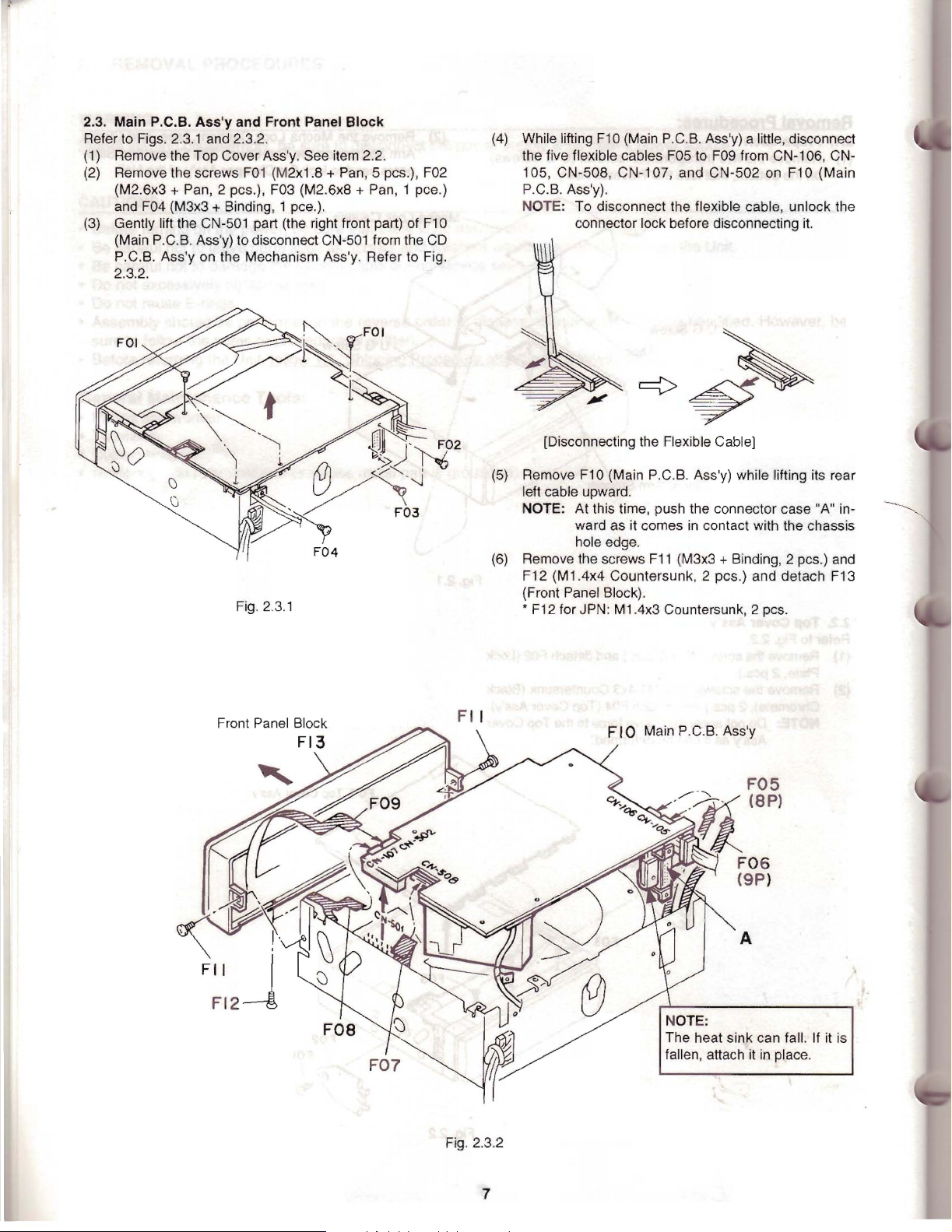

2.3. Main p.e.B. Ass'y and Front Panel Block

Refer to Figs.

(1)

Remove

(2)

Remove

2.3.1

and 2.3.2.

the Top

Cover

the screws

Ass'y. See item 2.2.

F01

(M2x1.8 + Pan,S pcs.),

(M2.6x3 + Pan, 2 pes.), F03 (M2.6x8 + Pan, 1 pee.)

and F04 (M3x3 + Binding, 1 pce.).

(3)

Gently lift Ihe CN-501 part (the right front part)

(Main P.C.B. Ass'y) to disconnect

CN-501

from the

P.C.B. Ass'y on the Mechanism Ass'y. Refer to Fig.

2.3.2.

of

F02

F10

CD

(4)

While lifting

the

five flexible cables F05

F10

(Main P.C.B. Ass'y) a little, disconnect

to

FOg

from

CN-1

105, CN-508, CN-107, and CN-502 on F10 (Main

P.C.B. Ass'y).

NOTE: To disconnect the flexible cable, unlock the

connector lock before disconnecting

06,

it.

CN-

Fig. 2.3.1

FII

(5)

(Disconnecting

Remove

F10 (Main P.C.B. Ass'y) while lifting its rear

the

Flexible Cable]

left cable upward.

NOTE: At this time, push the connector case "A" in-

ward as it comes

in

contact with the chassis

hole edge.

(6)

Remove

the screws

F11

(M3x3 + Binding, 2 pes.) and

F12 (M1.4x4 Countersunk, 2 pcs.) and detach F13

(Front Panel Block).

* F12 for JPN: M1.4x3 Countersunk, 2 pcs.

FlO

Main P.C.B. Ass'y

Fig.

2.3.2

7

A

NOTE:

The heat sink can fall.

fallen, attach

it

in

place.

If

it

is

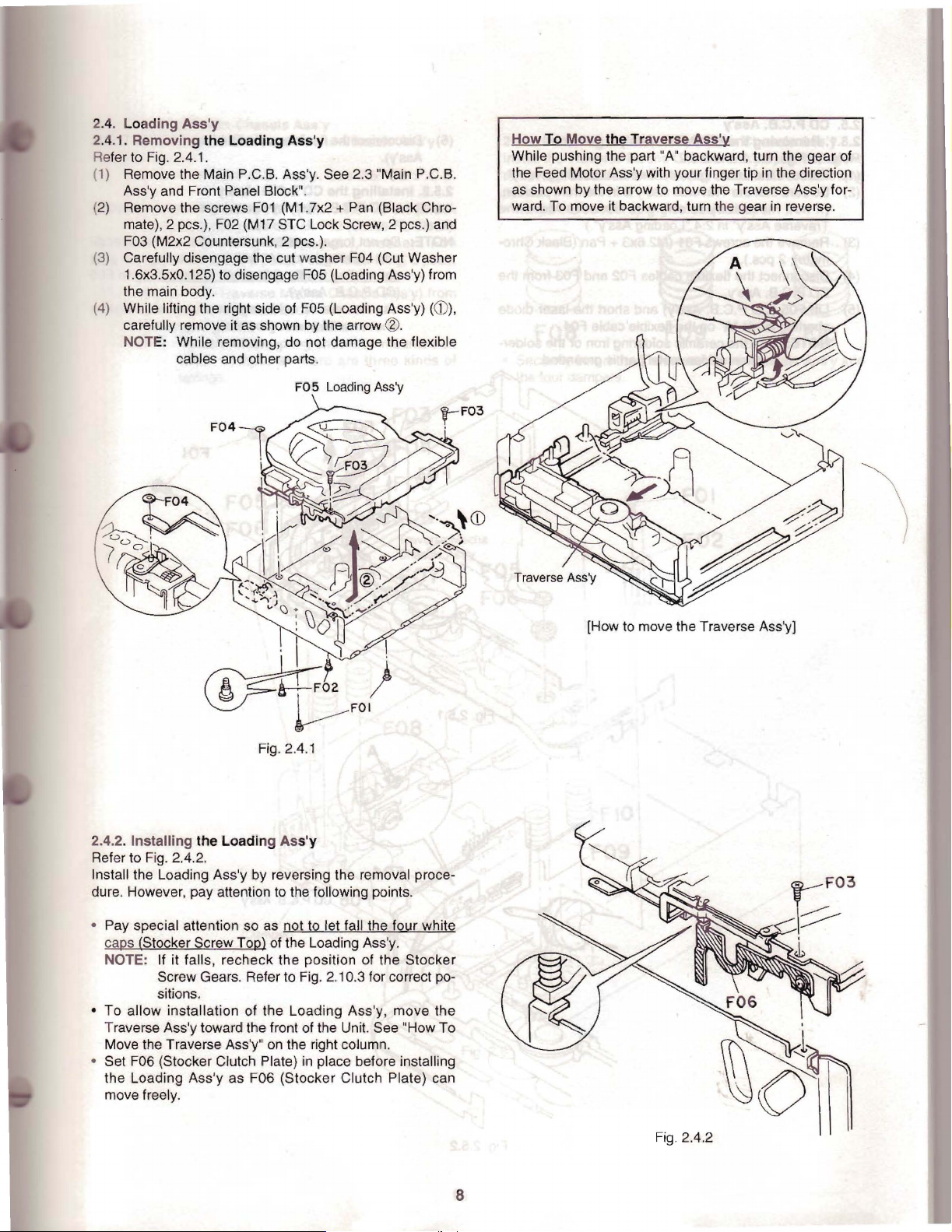

2.4.

Loading

2.4.1. Removing the Loading

Refer to Fig. 2.4.1.

(1) Remove the Main P.C.B. Ass'y. See 2.3 "Main P.C.B.

Ass'y and Front Panel Block".

2)

Remove the screws

mate), 2 pes.),

F03

(3)

Carefully disengage the cut washer

1.6x3.5xO.125) to disengage

the main body.

(4) While lifting the right side of F05 (Loading Ass'y)

carefully remove

NOTE: While removing,

Ass'y

Ass'y

F01

(M1.7x2 + Pan (Black Chro-

F02

(M17 STC Lock Screw, 2 pes.) and

(M2x2 Countersunk, 2 pes.).

F05

it

as shown

cables and other parts.

by

do

not damage the flexible

F05

F04

(Cut Washer

(Loading Ass'y) from

(CD),

the arrow

Loading

(2).

Ass'y

How To Move the Traverse

While pushing the part "A" backward, turn the gear of

the

Feed Motor Ass'y with your finger

as shown by the arrow to move the Traverse Ass'y forward. To move

it

backward, turn the gear

Ass'y

Np

in

the direction

in

reverse.

Fig,.

2.4.1

2.4.2. Installing the 'Loading

Refer to Fig. 2.4.2.

install the Loading, Ass'y

dure. However, pay attention to the following points.

• Pay special attention so as not to let fall the four white

caps (Stocker Screw Top) of the

NOTE: if it falls, recheck the position of the Stocker

Screw Gears. Refer to Fig. 2.10.3 for correct posiNons.

• To allow installation of the Loading, Ass'y, move the

Traverse Ass'y toward the front of the Unit. See "How To

Move the Traverse Ass'y"

• Set F06 (Stocker Clutch Plate) in place before installing

the Loading Ass'y as F06 (Stocker Clutch Plate) can

move freely.

Ass'y

by

reversing the removal proce-

loading

on

the right column.

Ass'y.

[How to move the Traverse Ass'y)

~oln

Fig.

2.4.2

8

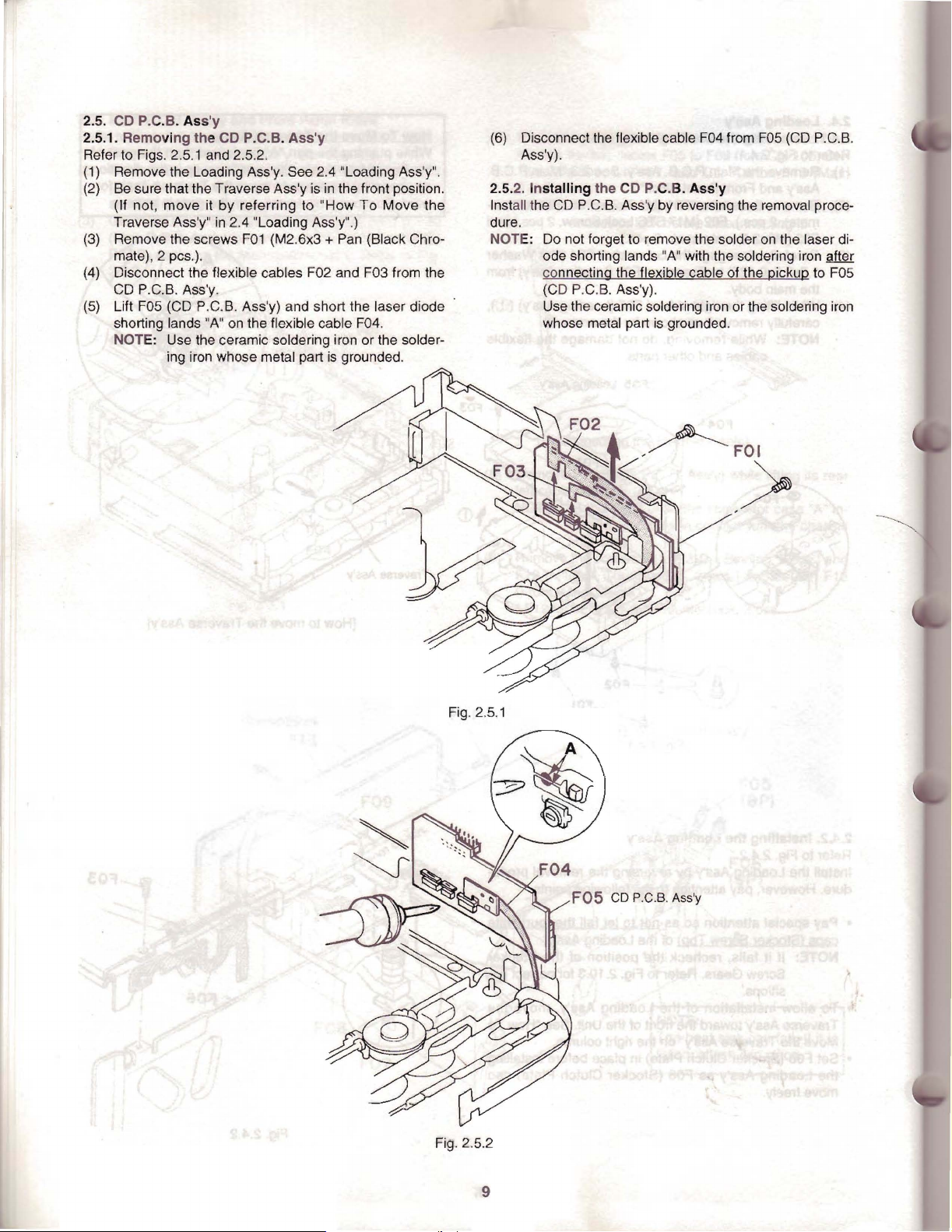

2.5. CD P.C.B.

2.5.1. Removing the CD P.C.B.

Refer to Figs.

(1)

Remove the Loading Ass'y. See 2.4 "Loading Ass'y".

(2)

Be

sure that the Traverse Ass'y is

(If not, move it by referring to "How

Traverse Ass'y"

(3)

Remove the screws

mate), 2 pes.).

(4) Disconnect the flexible cabtes F02 and F03 from the

CD

(5)

Lift F05 (CD P.C.B. Ass'y) and short the laser diode

shorting lands

NOTE: Use the ceramic soldering iron or the solder-

Ass'y

2.5.1

and 2.5.2.

in

2.4 "Loading Ass'y".)

F01

P.C.B. Ass'y.

"A"

on

the flexible cable

ing iron whose metal part

Ass'y

in

(M2.6x3 +

the front position.

To

Move the

Pan

(Black Chro-

F04.

is

grounded.

(6)

Disconnect

Ass'y).

Installing the CD P.C.B.

2.5.2.

Install the

dure.

NOTE:

Do

ode shorting lands

connecting the flexible cable of the pickup to F05

(CD P.C.B. Ass'y).

Use the ceramic soldering iron

whose metal part

the

CD

P.C.B. Ass'y by reversing the removal proce-

not forget to remove the solder

flexible cable

"A"

with the soldering iron after

is

grounded.

F04

Ass'y

from

F05

(CD P.C.B.

on

the laser di-

or

the soldering iron

Fig.

2.5.1

F05

CD P.C.B. Ass'y

,/----.

FOI

>

Fig. 2.5.2

9

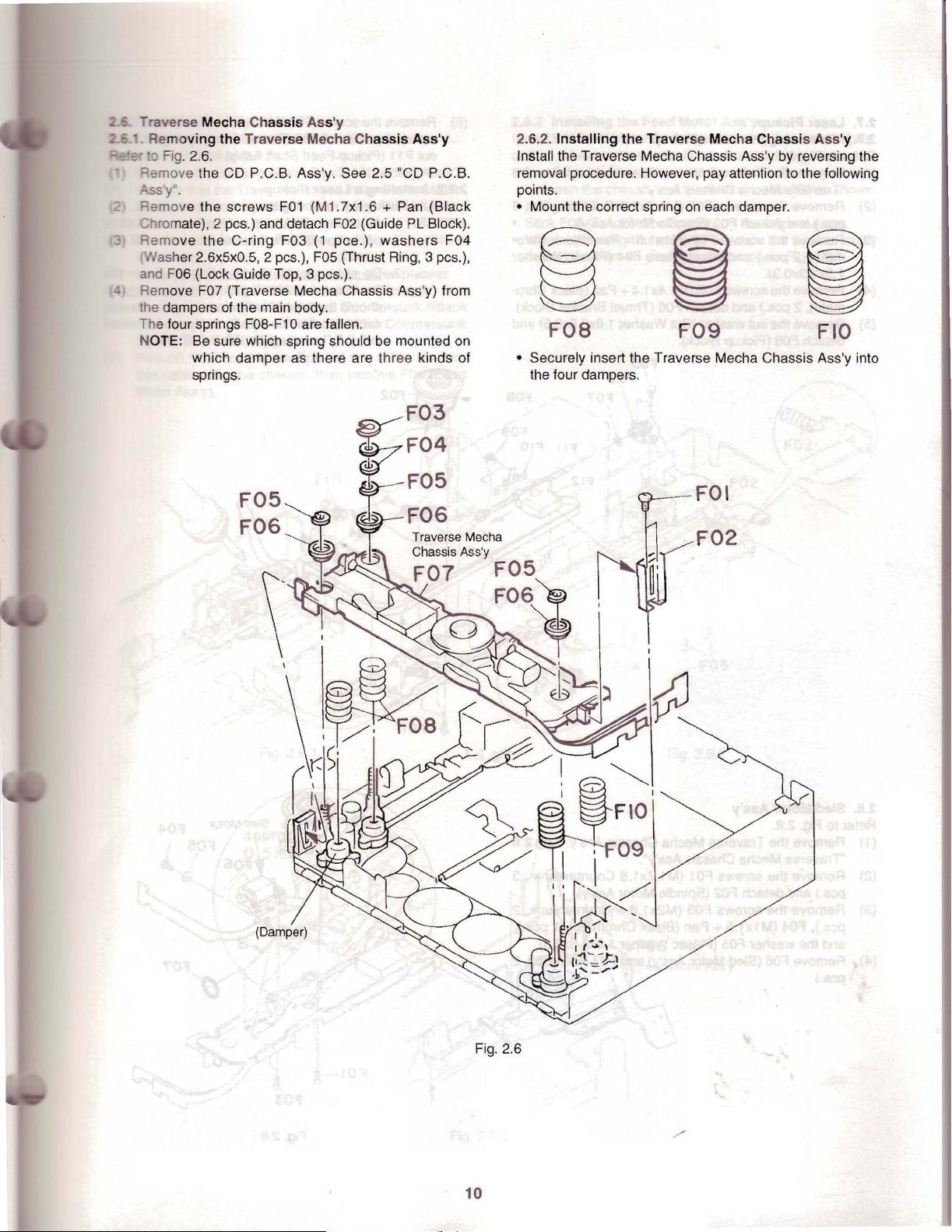

Traverse Mecha Chassis Ass'y

..

Removing the Traverse Mecha Chassis Ass'y

o

Fig.

2.6.

>:1emove

ssy.

8emove

Chromate), 2 pes.) and detach

8emove

and

Remove

the dampers

The four springs F08-F10 are fallen.

NOTE: Be sure which spring should be mounted on

the CD P.C.B. Ass'y. See 2.5 "CD P.C.B.

the screws

the Coring F03

asher 2.6x5xO.5, 2 pes.), F05 (Thrust Ring, 3 pes.).

F06

(Lock Guide Top. 3 pes.).

FO?

(Traverse Mecha Chassis Ass'y) from

of

which

springs.

F01

(M1.7x1.6 + Pan (Black

(1

the main body,

damper

as there are three kinds of

F02

(Guide

pee.),

PL

Block).

washers

F04

2.6.2. Installing the Traverse Mecha Chassis Ass'y

Install the Traverse Mecha Chassis Ass'y by reversing the

removal procedure. However, pay attention to the following

points.

• Mount the correct spring

Foe

• Securely insert the Traverse Mecha Chassis Ass'y into

the four dampers.

on

each damper.

F09

FlO

F02

Fig. 2.6

10

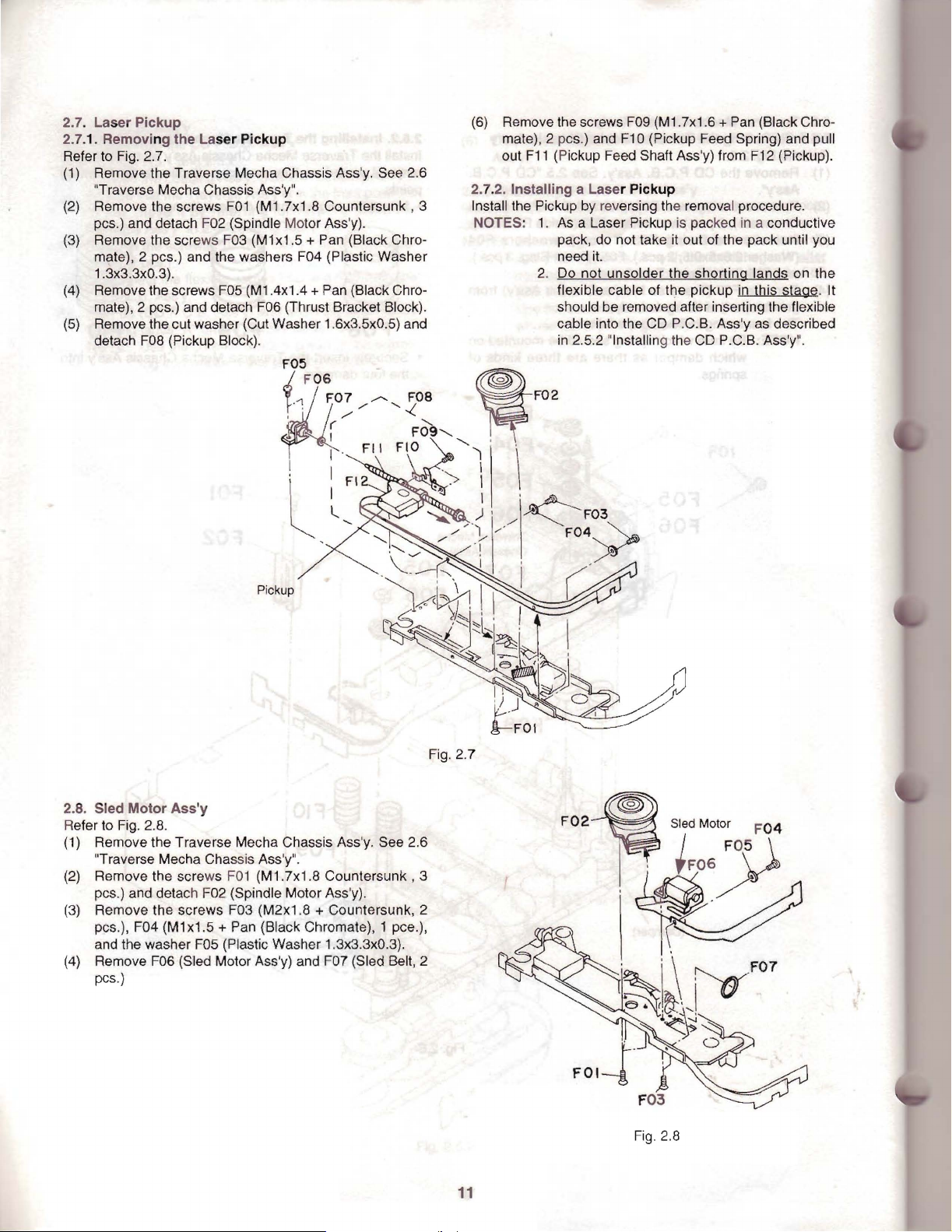

2.7. Laser Pickup

2.7.1. Removing the Laser Pickup

Refer to

(1) Remove the Traverse Mecha Chassis Ass'y. See 2.6

(2)

(3) Remove the screws

(4)

(5) Remove the cut washer (Cut Washer 1.6x3.5xO.5) and

Fig.

2.7.

"Traverse Mecha Chassis Ass'y".

Remove the screws

pes.) and detach F02 (Spindle Motor Ass'y).

mate), 2 pes.) and the washers F04 (Plastic Washer

1.3x3.3xO.3).

Remove the screws F05 (M1.4x1.4 + Pan (Black Chro-

mate), 2 pes.) and detach F06 (Thrust Bracket Block).

detach F08 (Pickup Block).

F01

(M1.7x1.8 Countersunk, 3

F03

(M1

x1.5 + Pan (Black Chro-

(6)

Remove the screws

mate), 2 pes.) and F10 (Pickup Feed Spring) and

out

F11

(Pickup Feed Shaft Ass'y) from

FOg

(M1.7x1.6 + Pan (Black Chro-

2.7.2. Installing a Laser Pickup

Install the Pickup

NOTES:

by

reversing the removal procedure.

1.

As

a Laser Pickup is packed

pack, do not take

need

it.

2.

Do not unsolder the shorting lands on the

flexible cable of the pickup

should be removed after inserting the fleXible

cable into the CD P.C.B. Ass'y

in

2.5.2 "Installing the

it

out of the pack

CD

P.C.B. Ass'y".

F12

(Pickup).

in

a conductive

unti,l

in

this stage. It

as

described

pUll

you

2.8. Sled Motor Ass'y

Refer to

(1) Remove the Traverse Mecha Chassis Ass'y. See 2.6

(2)

(3)

(4)

Fig.

2.8.

"Traverse Mecha Chassis Ass'y".

Remove the screws

pes.) and detach

Remove the screws F03 (M2x1.8 + Countersunk, 2

pes.), F04

and the washer F05 (Plastic Washer 1.3x3.3xO.3).

Remove F06 (Sled Motor Ass'y) and Fa? (Sled Belt, 2

pes.)

(M1

F01

(M1.7x1.8 Countersunk, 3

F02

(Spindle Motor Ass'y).

x1.5 + Pan (Black Chromate), 1 pee.),

Fig.

2.7

11

Fig.

2.8

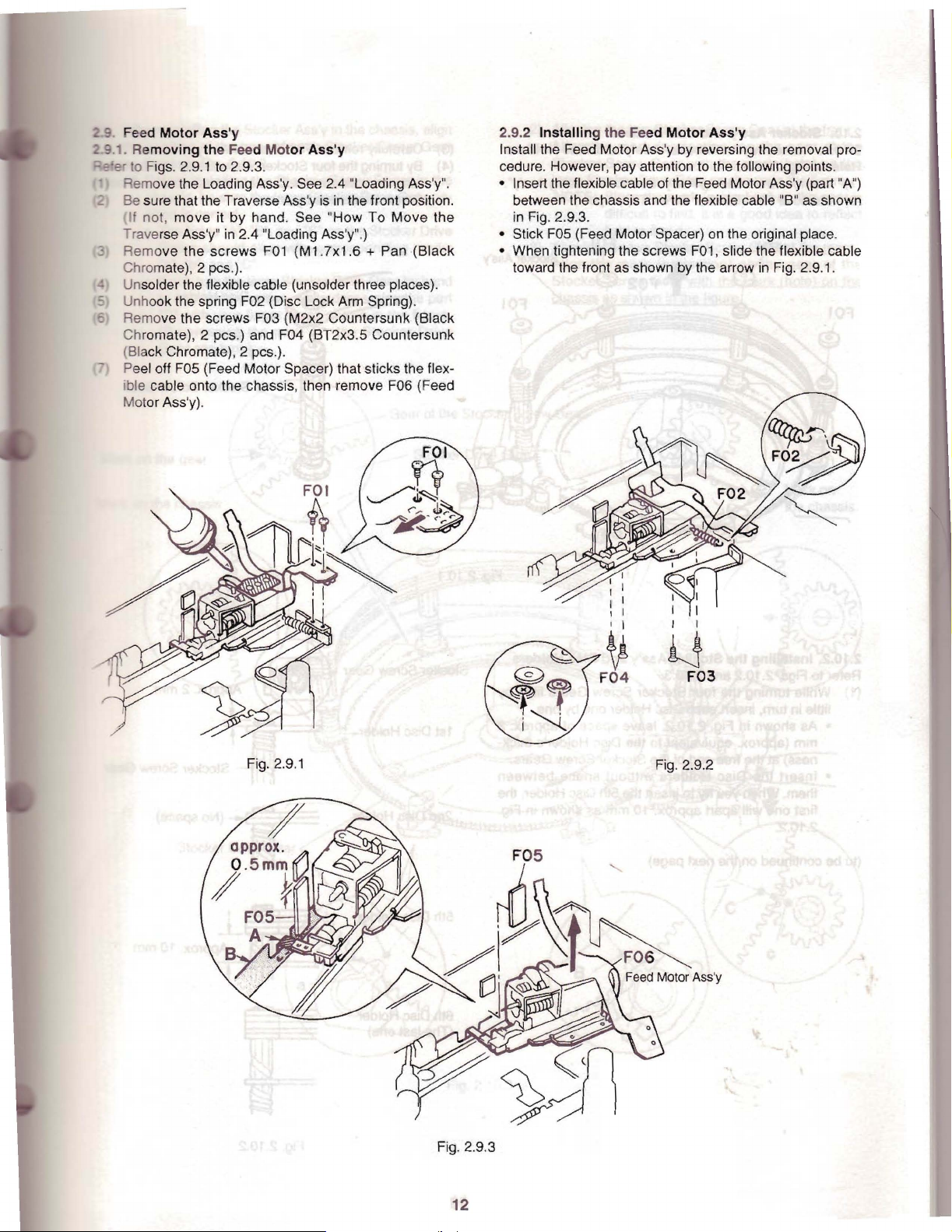

Feed Motor

9.1. Removing the Feed

_'e to Figs.

>:1emove

Be sure that the Traverse Ass'y is in the front position.

If not, move it by hand. See "How To

Traverse Ass'y"

Remove the screws

Chromate), 2 pes.).

Unsolder the flexible cable (unsolder three places).

Unhook the spring F02 (Disc Lock Arm Spring).

Remove the screws F03 (M2x2 Countersunk (Black

Chromate), 2 pes.) and F04 (BT2x3.5 Countersunk

(Black Chromate), 2 pes.).

Peel off F05 (Feed Motor Spacer) that sticks the flexible cable onto the chassis, then remove F06 (Feed

Motor Ass'y).

Ass'y

Motor

Ass'y

2.9.1

to

2.9.3.

the Loading Ass'y. See 2.4 "Loading Ass'y".

Move

in

2.4 "Loading Ass'y".)

F01

(M

1.

7x1.6

+ Pan ·(Black

the

2.9.2 Installing the Feed Motor

Install the Feed Motor Ass'y by reversing the removal procedure. However, pay attention to the following points.

• Insert the flexible cable

between the chassis and

in

Fig.

2.9.3.

• Stick F05 (Feed Motor Spacer)

• When tightening the screws F01, slide the flexible cable

the

toward

front as shown by the arrow

of

Ass'y

the Feed Motor Ass'y (part "A")

the

flexible cable "8" as shown

on

the original place.

in

Fig. 2.9.1.

Fig. 2.9.1

I

I

I

I

V

F04

I

I

I

I I

W

F03

Fig. 2.9.2

Fig. 2.9.3

12

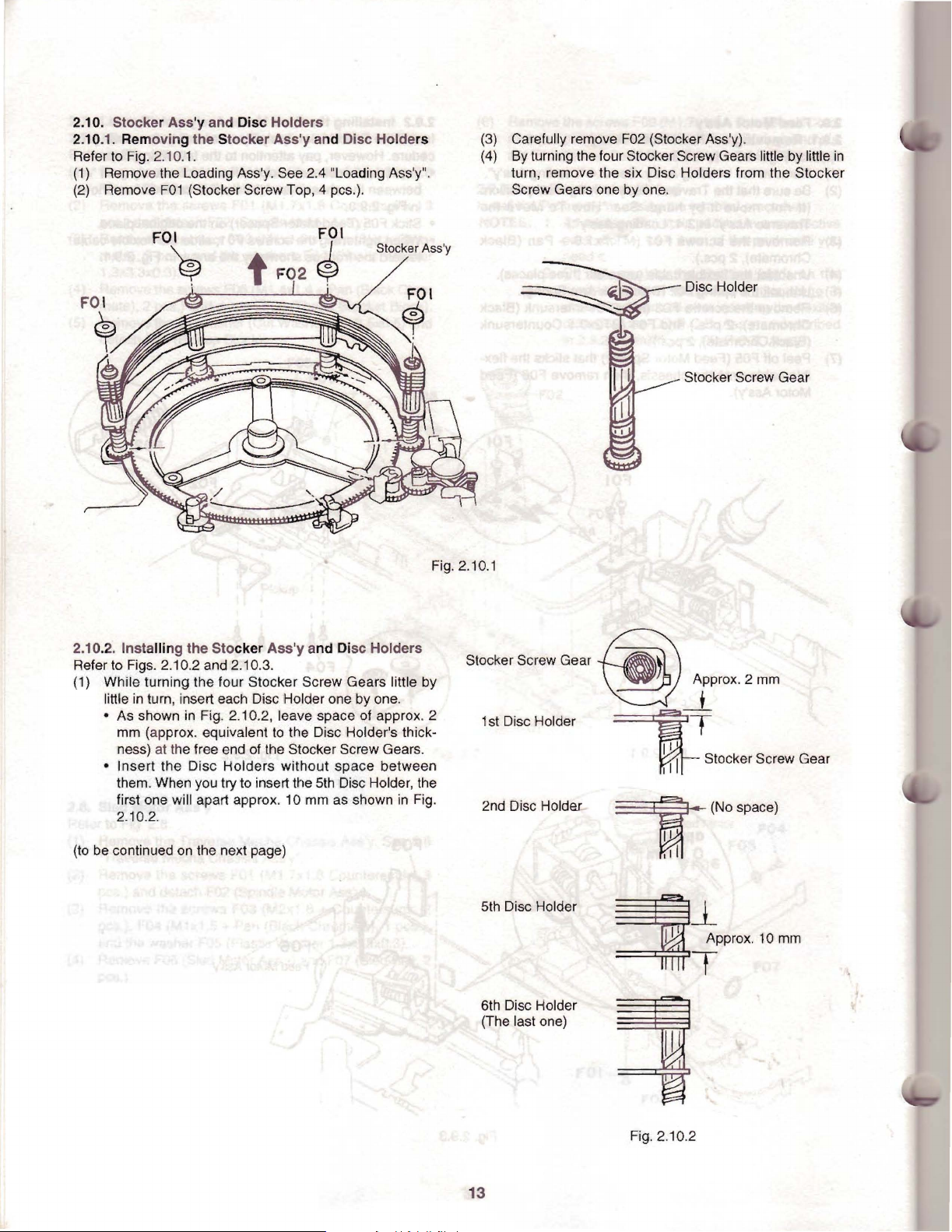

2.10.

Stocker

2.10.1. Removing

Refer

to

(1)

Remove the Loading Ass'y. See 2.4 "Loading Ass'y".

(2)

Remove

Ass'y

Fig. 2.10.1.

FOl

and Disc

the

Stocker

(Stocker Screw Top, 4 pcs.).

Holders

Ass'y

and Disc

Holders

(3)

Carefully remove

(4)

By

turning the four Stocker Screw Gears little by little

turn, remove the six Disc Holders from the Stocker

Screw Gears one by one.

F02

(Stocker Ass'y).

in

FOI

~

2.10.2.

Refer to Figs. 2.10.2 and 2.10.3.

(1) Whi'le turning the four Stocker Screw Gears little by

(to

Installing

little

in

• As shown

mm (approx. equivalent

ness)

• Insert the Disc Holders without space between

them. When you try to insert the

lirst one will apart approx.

2.10.2.

be continued on the next page)

the

tum, insert each Disc Holder one by one.

in

Fig. 2.10.2, leave space at approx. 2

at

the free end of the Stocker Screw Gears.

t

Stocker

Ass'y

FOI

F02

~

and

to

the Disc Holder's thick-

5th

10

mm

Stocker

Disc

Holders

Disc Holder, the

as shown

in

Ass'y

Fig.

Fig. 2.10.1

Stocke' SC'ew

1st

2nd Disc

Ge"

Disc Holder

Holdar~

@

,:

,-

III

I

II

II

,iI

Disc Holder

Stocker Screw Gear

Approx. 2

mm

+

-Stocker Screw Gear

(No space)

5th Disc Holder

6th Disc Holder

(The last one)

13

~PCOX10mm

Fig. 2.10.2

Loading...

Loading...