Page 1

• Top View..................................................4-1

• Top View(without Tray Disc).................4-1

• Bottom View ...........................................4-1

1. Holder Clamp ....................................4-2

1-1. Clamp Assembly Disc.......................4-2

1-1-1. Plate Clamp..................................4-2

1-1-2. Magnet Clamp ..............................4-2

1-1-3. Clamp Upper.................................4-2

2. Tray Disc...........................................4-2

3. Base Assembly Sled........................4-3

3-1. Gear Assembly Feed........................4-3

3-2. Gear Assembly Middle......................4-3

3-3. Gear Assembly Rack........................4-3

4. Rubber Rear ......................................4-3

5. Frame Assembly Up/Down..............4-4

6. Belt Loading......................................4-4

7. Gear Pulley .......................................4-4

8. Gear Loading....................................4-4

9. Guide Up/Down.................................4-4

10. PWB Assembly Loading................4-4

11. Base Main........................................4-4

1. Tools and Fixtures for SVC.............4-5

2. Install Process..................................4-5

3. Adjustment Process.........................4-6

1. Deck Mechanism Exploded View....4-7

CONTENTS

SECTION 4 MECHANISM

DECK MECHANISM PARTS

LOCATIONS

EXPLODED VIEW

DECK MECHANISM ADJUSTMENT

DECK MECHANISM

DISASSEMBLY

Page 2

4-1

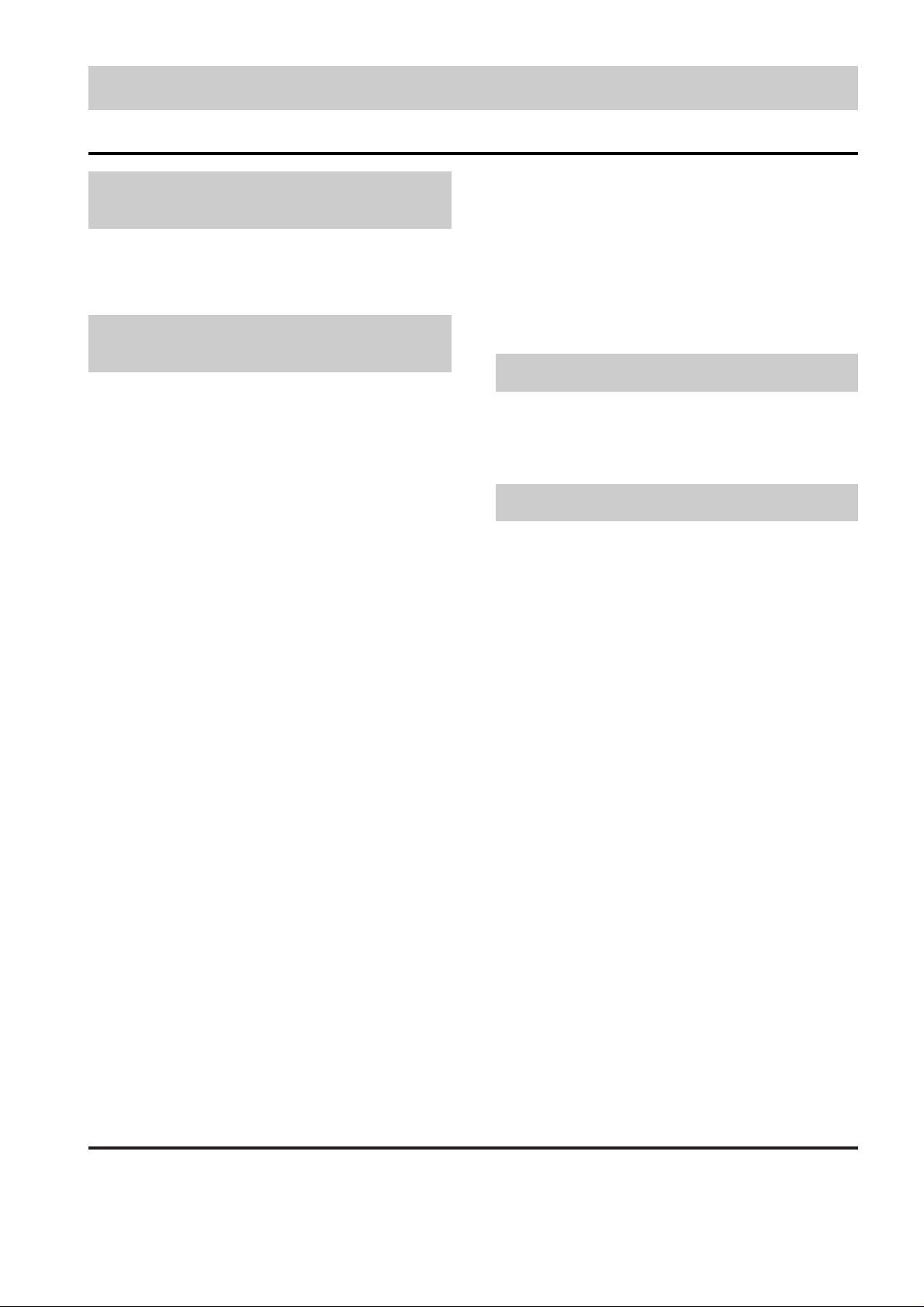

DECK MECHANISM PARTS LOCATION

Starting No.

1

1, 2

1, 2, 3

1, 2, 3, 4

1

1, 6

1, 2, 6

1, 2, 6, 8

1, 2, 6, 8,

9

1, 2, 7

1, 2, 7

1, 2

1, 2 ,13

1, 2, 13, 14

1, 2, 7, 12, 13, 14

1, 2, 13

1, 2, 7, 12, 13,

14, 15, 16, 17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Holder

Clamp

Clamp Assembly

Disc

Plate Clamp

Magnet Clamp

Clamp Upper

Tray Disc

Base Assembly Sled

Gear Assembly

Feed

Gear

Middle

Gear Assembly

Rack

Rubber Rear

Frame Assembly

Up/Down

Belt Loading

Gear Pulley

Gear Loading

Guide Up/Down

PWB Assembly

Loading

Base Main

2 Screws,

2 Locking Tabs

4 Screws,

1 Connector

1 Locking Tabs

1 Screw

1 Screw

1 Locking Tab

1 Locking Tab

1 Locking Tab

1 Hook

2Screw

2 Locking Tabs

4-1

4-1

4-1

4-1

4-1

4-2

4-3

4-3

4-3

4-3

4-3

4-4

4-4

4-4

4-4

4-4

4-4

4-4

Bottom

Bottom

Procedure

Parts Fixing Type

Figure

Disass

embly

Note

When reassembling, perform the procedure in

reverse order.

The “Bottom” on Disassembly column of above

Table indicates the part should be disassembled

at the Bottom side.

• Top View (Without Tray)

• Bottom View

• Top View (With Tray)

Page 3

4-2

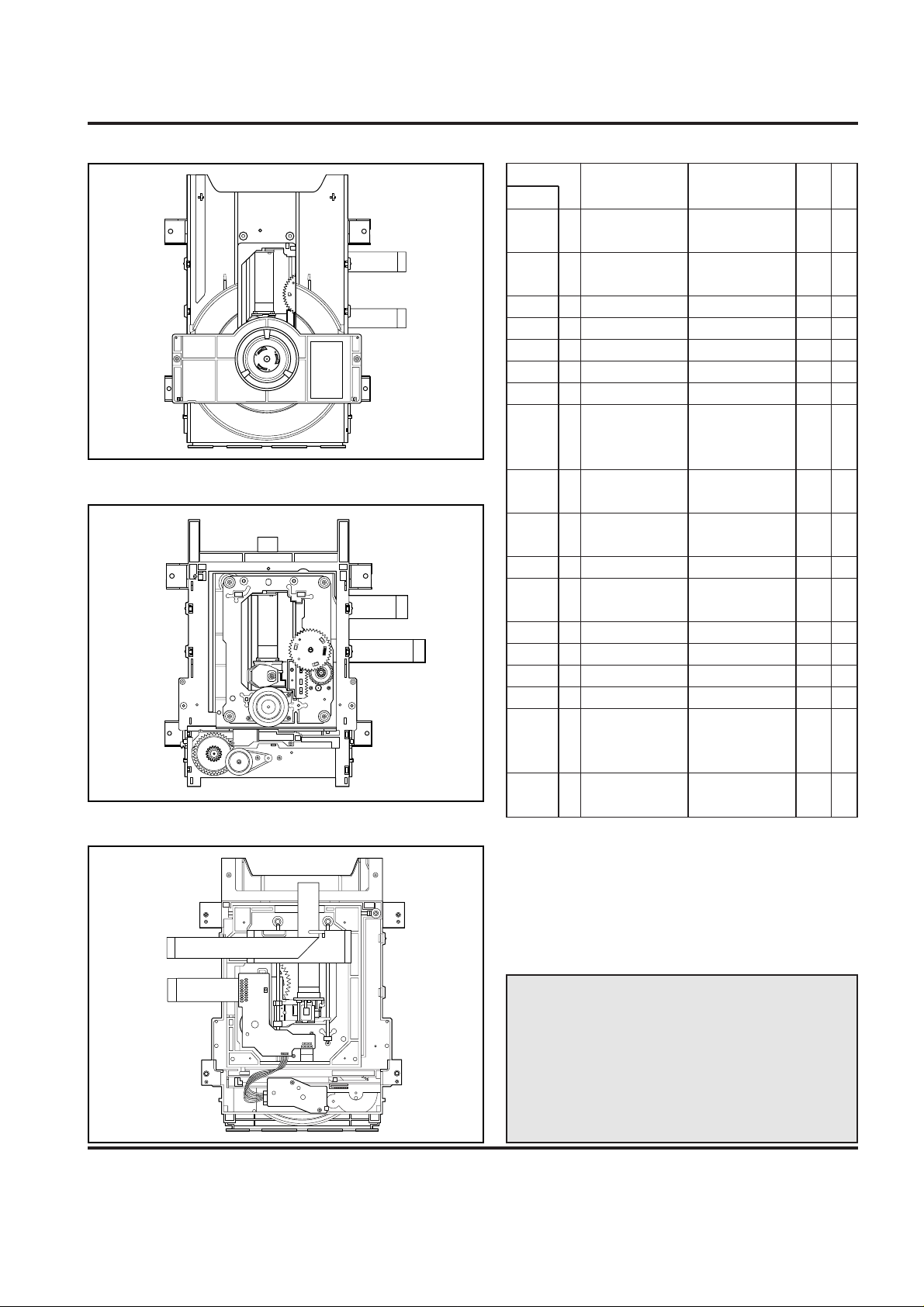

DECK MECHANISM DISASSEMBLY

1.Holder Clamp (Fig. 4-1)

1) Release 2 Screws(S1).

2) Unhook 2 Locking Tabs(L1).

3) Lift up the Holder Clamp and then separate it from the

Base Main.

1-1. Clamp Assembly Disc

1) Place the Clamp Assembly Disc as Fig. (A)

2) Lift up the Clamp Assembly Disc in direction of

arrow(A).

3) Separate the Clamp Assembly Disc from the Holder

Clamp.

1-1-1. Plate Clamp

1) Turn the Plate Clamp to counterclockwise direction and

then lift up the Plate Clamp.

1-1-2. Magnet Clamp

1-1-3.Clamp Upper

2. Tray Disc (Fig. 4-2)

1) Insert and push a Driver in the emergency eject

hole(A) at the right side, or put the Driver on the

Lever(B) of the Gear Emergency and pull the Lever(B)

in direction of arrow so that the Tray Disc is ejected

about 15~20mm.

2) Pull the Tray Disc until it is separated from the Base

Main completely.

BASE MAIN

HOLDER CLAMP

HOLDER CLAMP

CLAMP ASSEMBLY DISC

HOLDER CLAMP

PLATE CLAMP

(S1)

(S1)

(A)

(L1)

(L1)

(Fig. A)

MAGNET CLAMP

CLAMP UPPER

(B)

LEVER

BOTTOM SIDE VIEW

EMERGENCY EJECT HOLE

(A)

TRAY DISC

BASE MAIN

BASE MAIN

Fig. 4-1 Fig. 4-2

Page 4

4-3

DECK MECHANISM DISASSEMBLY

(C1)

PICK UP

ASSEMBLY

GENERAL

GEAR ASSEMBLY FEED

GEAR MIDDLE

GAER ASSEMBLY RACK

MOTOR ASSEMBLY SPINDLE

(L2)

(S2)

(S2)

(S2)

(S3)

GEAR ASSEMBLY RACK

GEAR MIDDLE

GEAR ASSEMBLY FEED

BASE PU(OUTSERT)

PICK UP ASSEMBLY GENERAL

MOTOR ASSEMBLY

SPINDLE

RUBBER REAR

(S2)

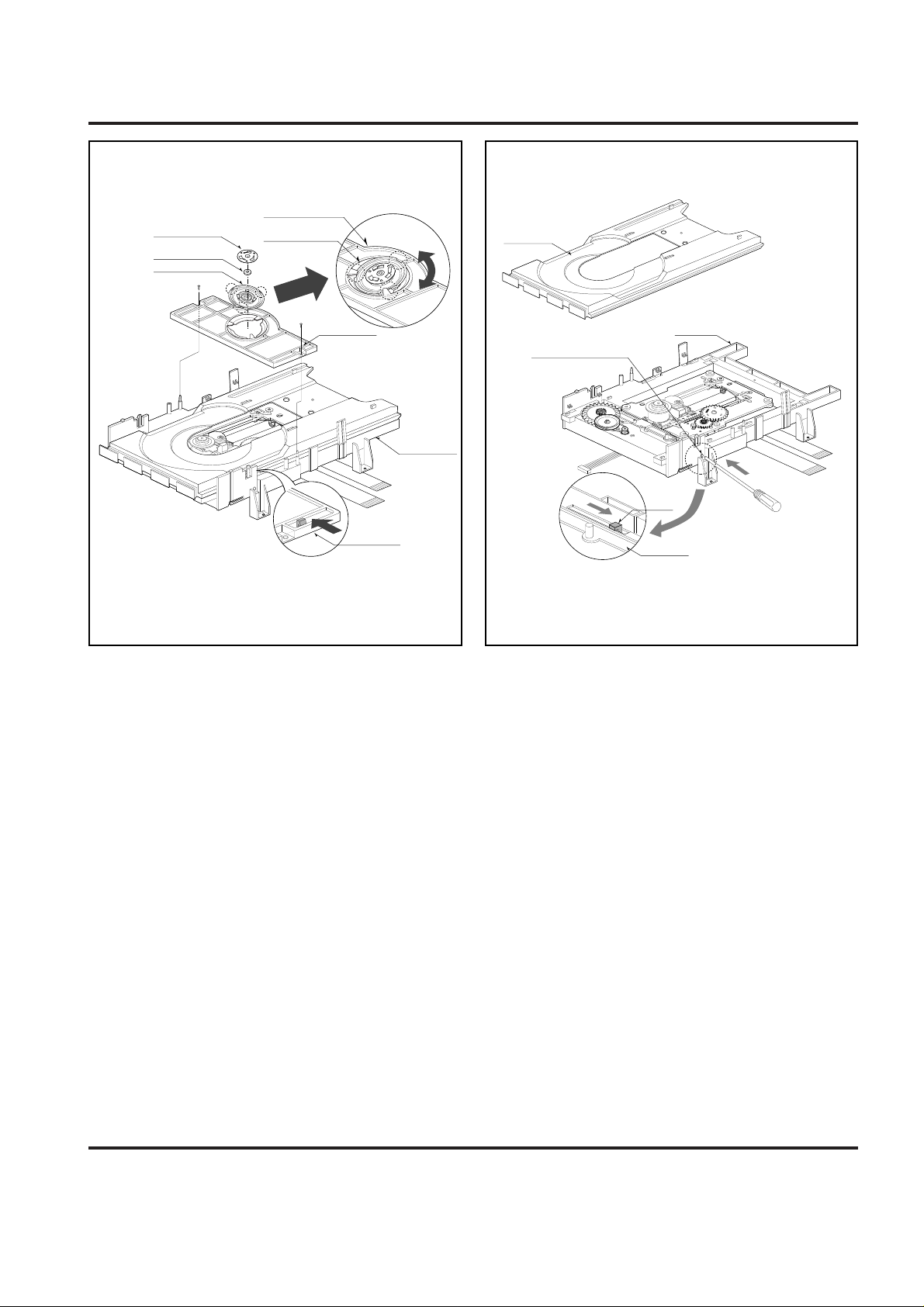

3.Base Assembly Sled (Fig. 4-3)

1) Release 4 Screw(S2).

2) Disconnect the FFC Connector(C1)

3-1. Gear Assembly Feed

1) Unhook the Locking Tab(L2) in direction of arrow.

3-2. Gear Middle

3-3. Gear Assembly Rack

1) Release the Scerw(S3)

4. Rubber Rear (Fig. 4-3)

Fig. 4-3

Page 5

4-4

DECK MECHANISM DISASSEMBLY

(B)

(S5)

(L6)

(L4)

(L5)

(A)

(L3)

(A)

(L6)

(H1)

(L6)

FIG. (B)

GUIDE UP/DOWN

BASE MAIN

BASE MAIN

PWB ASSEMBLY LOADING

GEAR LOADING

BELT LOADING

FRAME ASSEMBLY UP/DOWN

GUIDE UP/DOWN

GUIDE UP/DOWN

GUIDE UP/DOWN

(A)

(B)

(S4)

FIG. (C)

FIG. (A)

(B)

(C)

GEAR PULLEY

Fig. 4-4

5. Frame Assembly Up/Down

Put the Base Main face down(Bottom Side)

1) Release the Screw(S4)

2) Unlock the Locking Tab(L3) in direction of arrow and

then lift up the Frame Assembly Up/Down to separate

it from the Base Main.

• When reassembling move the Guide Up/Down in direction

of arrow(C) until it is positioned as Fig.(C).

• When reassembling insert (A) portion of the Frame

Assembly Up/Down in the (B) portion of the Guide

Up/Down as Fig.(B)

6. Belt Loading(Fig. 4-4)

Put the Base Assembly Main on original position(Top Side)

7. Gear pulley (Fig. 4-4)

1) Unlock the Locking Tab(L4) in direction of arrow(B) and

then separate the Gear Pulley from the Base Main.

8. Gear Loading (Fig. 4-4)

9. Guide Up/Down (Fig. 4-4)

1) Move the Guide Up/Down in direction of arrow(A) as

Fig.(A)

2) Push the Locking Tab(L5) down and then lift up the

Guide Up/Down to separate it from the Base Main.

When reassembling place the Guide Up/Down as Fig.(C)

and move it in direction arrow(B) until it is locked by the

Locking Tab(L5). And confirm the Guide Up/Down as Fig.(A)

10. PWB Assembly Loading

Put the Base Main face down(Bottom Side)

1) Release 2 Screws(S5)

2) Unkool the Loading Motor Connector (C2) from the

Hook (H1) on the Base Main.

3) Unlock 2 Locking Tabs(L6) and separate the PWB

Assembly Loading from the Base Main.

11. Base Main(Fig. 4-4)

Note

Note

Note

Note

Note

Page 6

4-5

DECK MECHANISM ADJUSTMENT

1. Tools and Fixtures for SVC

• For SVC Program Down-Load

• For T-Skew and R-Skew Adjustment

2. Install Process

1. Connect Fig. 1, 2, 3 as Fig. 7.

2. Plug out the Power cord of DVD set.

3. Connect FFC Cable(Fig.2) to the Connector on DVD Set(Fig.8)

4. Connect Printer Cable(Fig.1) to the P.C.Printer Port (LPT1).

5. Plug in the DVD Power cord.

6. Press the Menu key on Remocon.

7. Confirm No.1 LED(RED Color) of Jig board is ON. (Fig.9)

8. Perform The S/W for Down-load at P.C.

9. Open the Program File for Adjusting(Fig.10)

10. Click the Down-load Icon and perform Program Down-load.

11. Displayed remaining time.

12. Confirm LED No.1(RED) and No.2(GREEN) is ON.

13. Plug out the DVD Set Power cord.

14. Disconnect the FFC Cable.

Fig.1. Printer Cable Fig.2. FFC Cable (15 pin) Fig.3. Jig Board

Fig.4. Deviation Disc (0.8mm)

Fig.5. L-Wrench(3mm) Fig.6. RCA Jack Fig.7. Connecting Method

RED

GREEN

RED

Rom Size

File Help

16MBit

6M Bit

LPT1

Manual

953826Bytes

md _bas_ntsc.bin

LPT2

Port

FILE NAME

OPEN

DOWN LOAD

CLOSE

Fig.8. FFC Cable Connecting

Fig.9. Jig Board LED ConditionFig.10. Adjusting Program File Open

Page 7

MEMO

4-6

DECK MECHANISM ADJUSTMENT

3. Adjustment Procedure

1. Insert Disc(Only Open/Close Key Pressing)

2. Wait Until the Sector Display is about 200,000 (Fig.11)

3. Adjust R-Skew adjusting Point until the Error rate has

Minimum rate with L-wrench (3mm).

4. Adjust T-Skew Adjusting Point until the Error rate has

Minimum rate.

5. Repeat No. 3, 4 adjusting procedure until the Error rate

have Minimum rate.

6. Error rate; SVC-3561 Disc=below 30 and TDV-533

Disc=below 100. If not, Please confirm Play ability on

screen.

# You can watch the screen when pressing the Stop key

after the Adjusting is finished, Then perform Play and

Scan/Skip operation at Chapter1 and Chapter16 and

confirm screen condition, normal or abnormal.

• Please obtain these software for Adjusting through our

Global Cyber Service Center(GCSC).

• The location is http://biz.lgservice.com

& Web Site for End users

& Software updates

& Product : DVD Player

& Search.

R-SKEW ADJUSTING HOLE

T-SKEW ADJUSTING HOLE

Fig.12. Adjusting Method

Fig.11. Adjusting Screen Display

0045

SECTOR : 200145

0065

CURRENT PICK UP POSITION

ERROR RATE SIZE

ERROR RATE (HEXADEAMAL)

AVERAGE ERROR RATE

Page 8

4-7 4-8

EXPLODED VIEWS

1. Deck Mechanism Exploded View

002

001

003

004

429

429

026

018

008

009

016

012

430

430

430

432

020

430

011

017

014

013

015

431

A01

A02

A03

430

Loading...

Loading...