MURATA UWR Technical data

FEATURES

+INPUT

COMMON

V

TRACK

/SEQUENCE

INPUT

PWM

CONTROLLER

CURRENT

SENSE

REFERENCE &

ERROR AMP

VCC

ON/OFF

CONTROL

V

OUT

TRIM

POWER

GOOD

OUTPUT

+OUTPUT

10.57

+SENSE

COMMON

■

Standard (DOSA compatible) SIP package

■

User-selectable outputs: 0.8 to 5Vdc

■

30 Amps maximum output current

■

Double lead free to RoHS standards

■

Selectable phased start-up sequencing,

tracking and pre-bias operation

■

Wide range input voltages 6 to 14Vdc

■

To 150W with overtemperature shutdown

■

Very high efficiency up to 94%

■

Fast settling, high di/dt IOUT slew rate

■

UL 60950-1, CSA-C22.2 No. 60950-1,

EN60950-1 safety approvals

■

Extensive self-protection with short circuit

“hiccup” shutdown

■

Output overvoltage/overcurrent protection

■

Input under and overvoltage shutdown

LSN2-T/30-D12 Series

DOSA-SIP, 30A POL DC/DC Converters

DESCRIPTION

These miniature point-of-load (POL) switching

DC/DCs are an ideal regulation and supply

element for distributed power and intermediate bus architectures. The converter is

fully compatible with the Distributed-power

Open Standards Alliance specification

(www.dosapower.com). LSN2-T/30-D12 can

power CPU’s, programmable logic and mixed

voltage systems with little heat and low noise.

A typical application uses a master isolated

12V DC supply and the LSN2-T/30-D12 converter for local 1.8V and 3.3V DC supplies.

All system isolation resides in the central

48V/12V bus converter supply, leaving lower

cost POL regulation right at the load. Unlike

linear regulators, the LSN2-T/30-D12 can

deliver very high power (up to 150W) in a tiny

area with no heat sinking and no external

components needed. The converter features

quick transient response (to 25µsec) and

very fast current slew rates (to 20A/µsec).

LSN2-T/30-D12 is an open-frame SIP

using advanced surface mount (SMT)

assembly and test techniques. The extraordinary performance is achieved with a fully

synchronous fixed-frequency buck topology

delivering high efficiency, tight line/load

regulation, stable no-load operation and no

output reverse conduction.

Output voltage, selected with an

external programming resistor or DC voltage into the trim pin, means OEM’s can

stock one model for multiple applications.

Also included are protection for out-oflimit voltages, currents and temperature.

Other functions: a remote On/Off control,

optional Power Good output, a phased

start-up sequence and tracking system,

and a load Sense input.

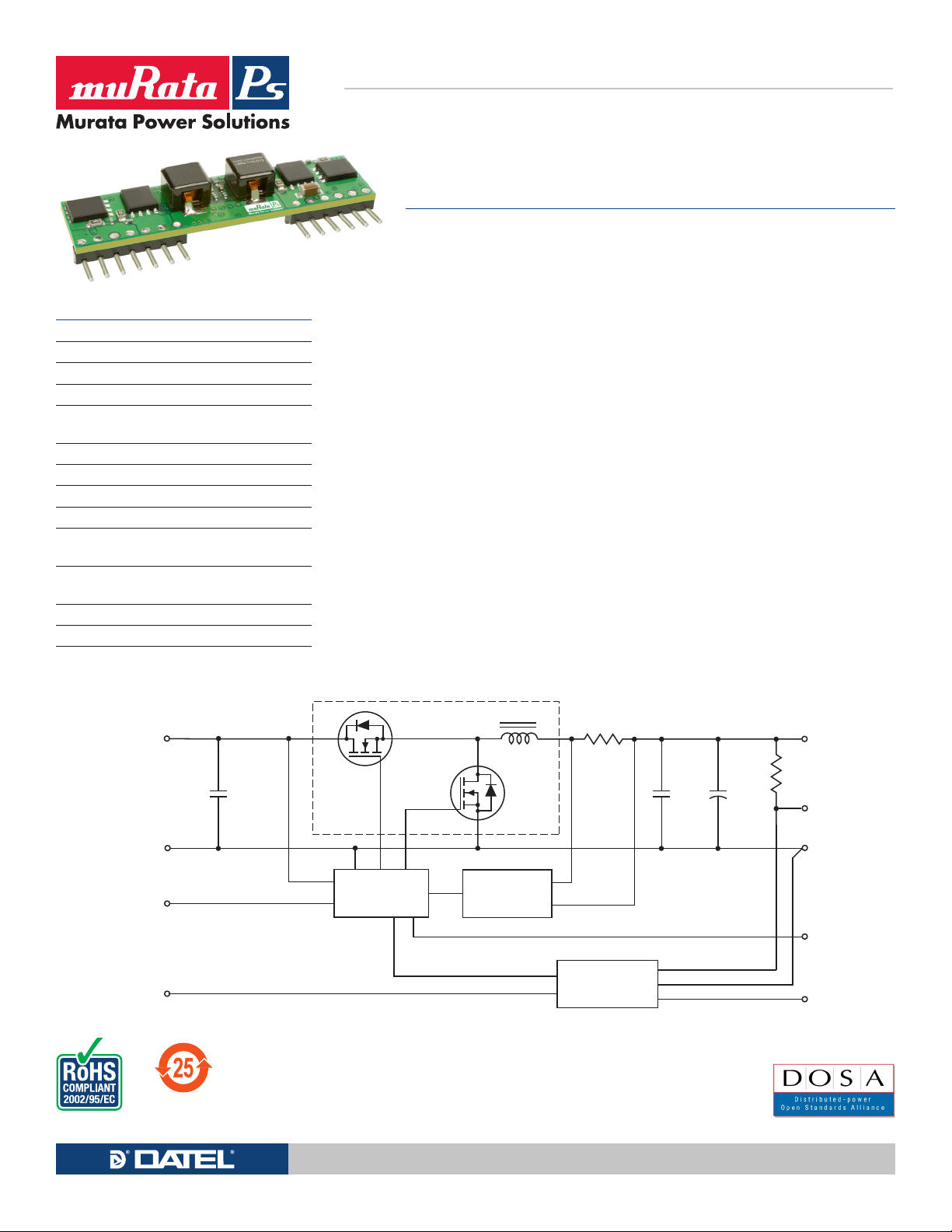

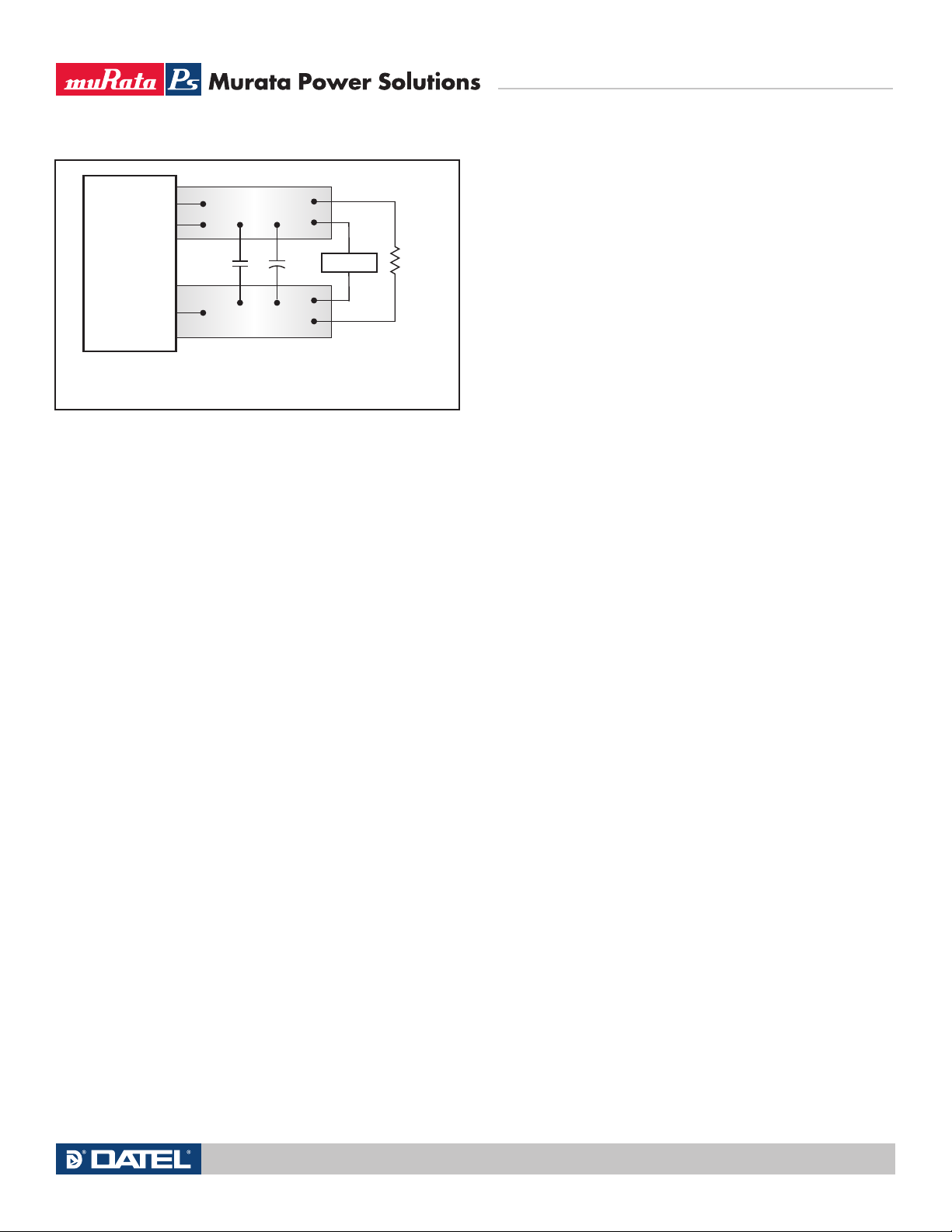

Typical topology is shown.

For full details go to

www.murata-ps.com/rohs

➀

➀ Only one phase of two is shown.

Figure 1. LSN2 -T/30-D12 Series Simplified Schematic

www.murata-ps.com Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000

MDC_LSN2-T/30-D12 Series.B12 Page 1 of 17

LSN2-T/30-D12 Series

DOSA-SIP, 30A POL DC/DC Converters

➀

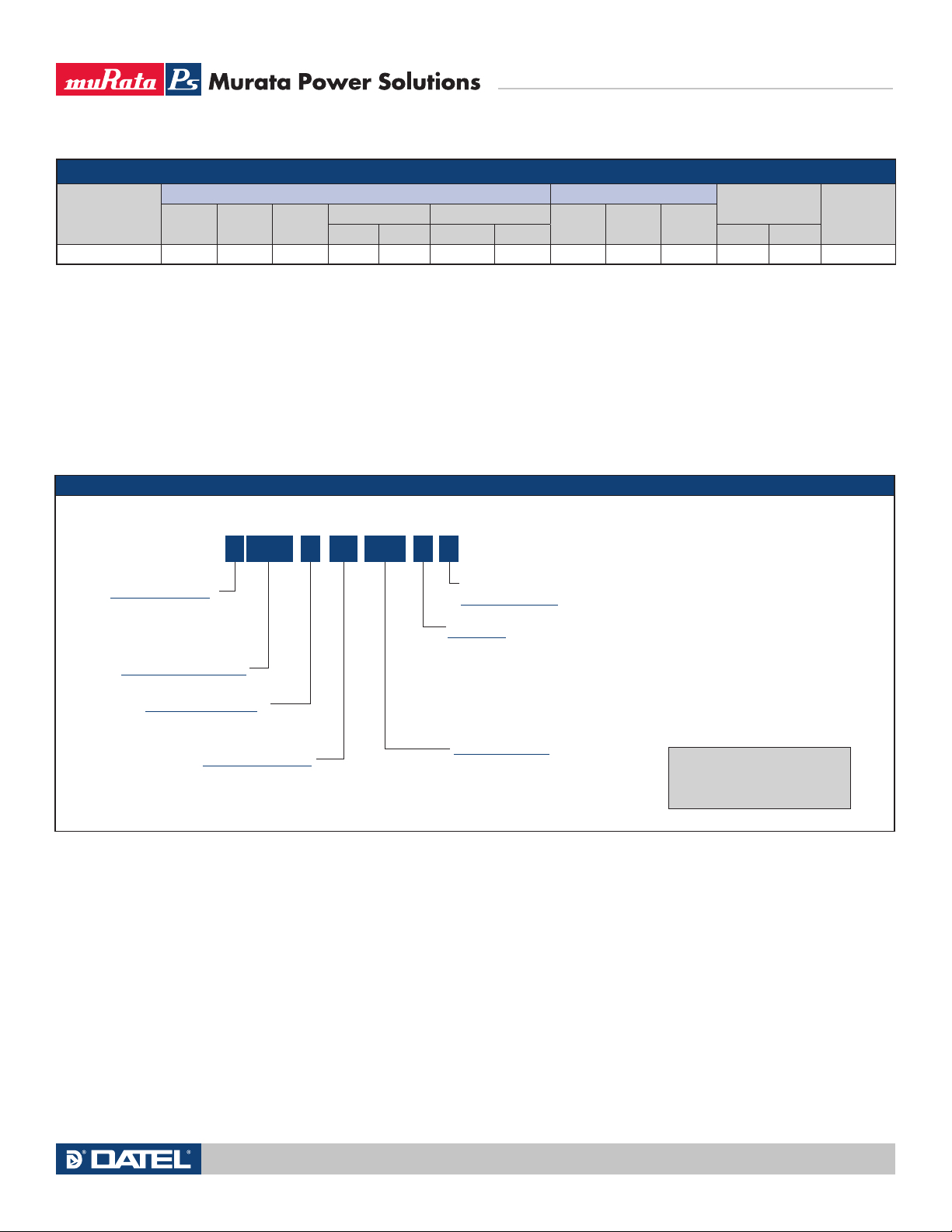

PERFORMANCE SPECIFICATIONS AND ORDERING GUIDE

Model ➆

LSN2-T/30-D12-C 0.8-5 30 150 25 50 ±0.1% ±0.1% 12 6-14 200/11.1 93% 94% B13, P71

➀ Typical at Ta = +25°C under nominal line voltage and full-load conditions, unless noted. All

models are tested and specified with external 22µF tantalum input and output 0.01//0.1//10µF

capacitors. These capacitors are necessary to accommodate our test equipment and may not

be required to achieve specified performance in your applications. See I/O Filtering and

Noise Reduction.

➁ Ripple/Noise (R/N) is tested/specified over a 20MHz bandwidth for Vo u t > 3.63V and may be

reduced with external filtering. See I/O Filtering and Noise Reduction for details.

VOUT

(Volts)

IOUT

(Amps)

Power

(Watts)

PART NUMBER STRUCTURE

Output Input

R/N (mVp-p) ➁ Regulation (max.)

Typ. Max. Line Load

➂

VIN Nom.

(Volts)

➂ These devices have no minimum-load requirements and will regulate under no-load conditions.

Regulation specifications describe the output-voltage deviation as the line voltage or load is

varied from its nominal/midpoint value to either extreme.

➃ Nominal line voltage, no-load/full-load conditions.

➄ LSN2-T/30-D12 efficiencies are shown at 5Vo u t .

➅ Input range is 6-14V if Vo u t ≤3.63V. For Vo u t > 3.63V, the input range is 7–14V.

➆ Please refer to the Part Number Structure for additional options when ordering.

Range➅

(Volts)

IIN ➃

(mA/A)

Efficiency

Min. Typ.

➄

Package

(Case/

Pinout)

Output Configuration:

L = Unipolar

Low Voltage

Non-Isolated Through-hole

Nominal Output Voltage:

0.8-5 Volts

Maximum Rated Output

Current in Amps

L SN2 -

/

30 G

D12- -T

C

RoHS-6 hazardous

substance compliant

Power Good:

Blank = Omitted (default)

G = Installed (special quantity orders required)

Input Voltage Range:

D12 = 7-14 Volts (12V nominal)

Note:

Some model number combinations may not be available. Contact

Murata Power Solutions.

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_LSN2-T/30-D12 Series.B12 Page 2 of 17

LSN2-T/30-D12 Series

DOSA-SIP, 30A POL DC/DC Converters

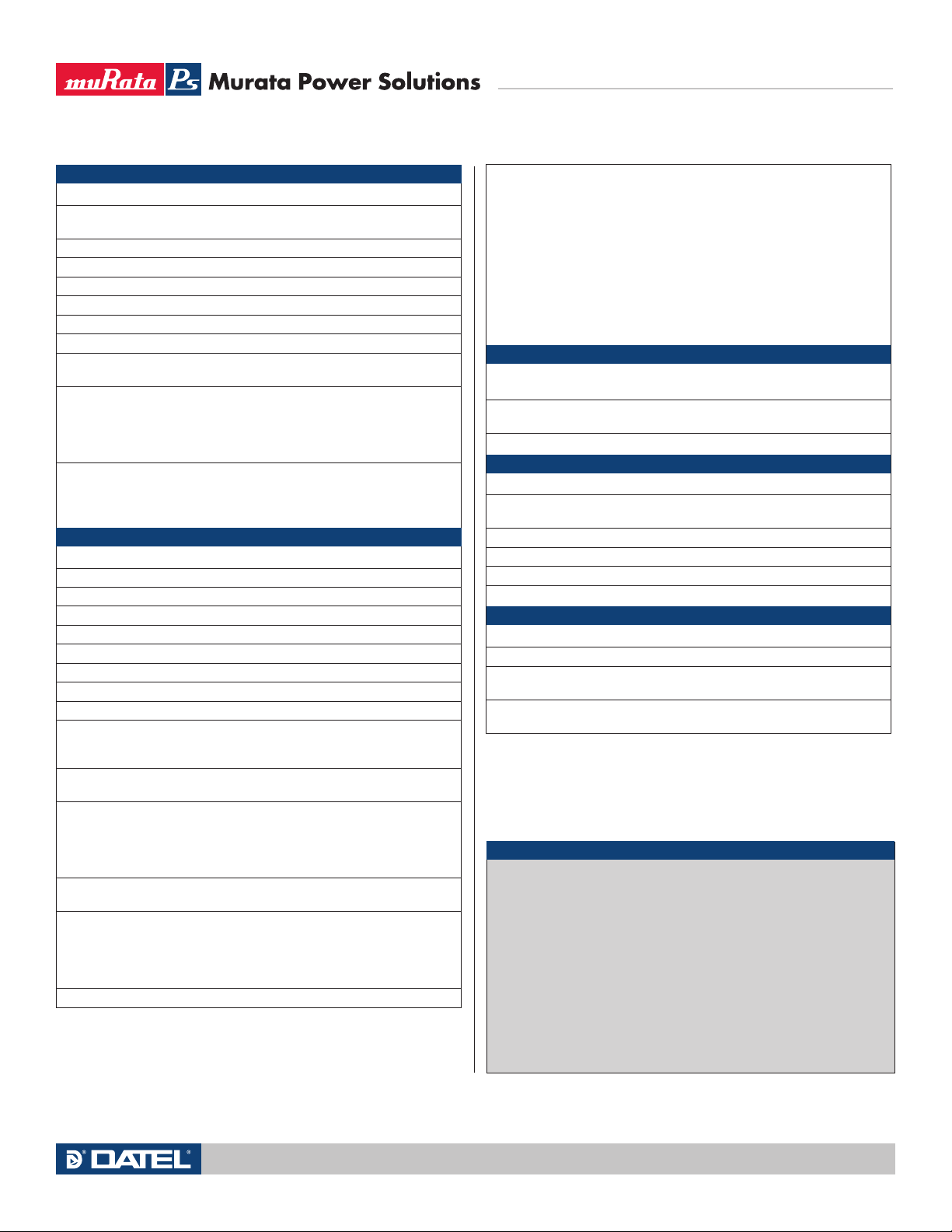

Performance/Functional Specifications

Input

(1)

Input Voltage Range See Ordering Guide

Isolation Not isolated. Input and output

Commons are internally connected.

Start-Up Voltage 5.5 Volts

Undervoltage Shutdown 5.2 Volts

Overvoltage Shutdown None

Reflected (Back) Ripple Current

(2)

20mAp-p

Internal Input Filter Type Capacitive

Reverse Polarity Protection See fuse information

Input Current:

Full Load Conditions See Ordering Guide

Inrush Transient 0.4A2sec

Shutdown Mode (Off, UV, OT) 5mA

Output Short Circuit 60mA

No Load, 5VOUT 200mA

Low Line (VIN = VMIN, 5VOUT) 18.8 Amps

Remote On/Off Control:

(5)

Negative Logic (No suffix) ON = 0 to +0.5V max.

OFF = +2V min. to +14V max.

Current 1 mA max.

Output

Voltage Output Range See Ordering Guide

Minimum Loading No minimum load

Accuracy (50% load) ±1.5% of Vnominal

Voltage Adjustment Range

(13)

See Ordering Guide

Overvoltage Protection None

Temperature Coefficient ±0.02% per °C of Vo u t range

Ripple/Noise (20 MHz bandwidth) See Ordering Guide

Line/Load Regulation (See Tech. Notes) See Ordering Guide

(8)

(10)

Efficiency See Ordering Guide

Maximum Capacitive Loading

(15)

Cap-ESR = 0.001 to 0.01W 5,000µF

Cap-ESR > 0.01W 10,000µF

Current Limit Inception 48 Amps (cold star tup)

(98% of VOUT setting) 42 Amps (after warm up)

Short Circuit Mode

Short Circuit Current Output 600mA

Protection Method

(6)

(14)

Hiccup autorecovery on overload removal

Short Circuit Duration Continuous, no damage

(output shorted to ground)

Pre-bias Startup

(16)

Converter will start up if the external

output voltage is less than VNOMINAL

Sequencing

Slew Rate 2V max. per millisecond

Startup delay until sequence start 10 milliseconds

Tracking accuracy, rising input Vout= ±200mV of Sequence In

Tracking accuracy, falling input Vo u t = ±400mV of Sequence In

Remote Sense to Vo u t 0.5V max.

(7)

Power Good Output

(15)

Configuration Positive-true open drain FET with internal

10 Kilohm pullup to +5 Vdc

Operation TRUE (power is okay) = High, approx. 5Vdc

FALSE (power is not ready) = Low, < 1V typ.,

while DC/DC is powered

External sink current 4.5 mA max. (< 1mA is recommended

to retain Vpg < 1V)

FALSE conditions (OR’d) Soft start is active, Tracking is active, output

is greater than ±10% out of regulation,

overcurrent, or overtemperature

Forced Load Share Accuracy 1% of Io u t (5 parallel units)

Dynamic Characteristics

Dynamic Load Response 60µsec to within ±2% of final value

(50-100-50% step, di/dt = 20A/msec)

Start-Up Time 7mS for VOUT = nominal

(VIN on to VOUT regulated or On/Off to VOUT)

Switching Frequency 520 ±50kHz

Environmental

Calculated MTBF

(4)

4, 018, 248 Hours

Operating Temperature Range –40 to +85°C with derating

See Derating Curves

Operating PC Board Temperature –40 to +100°C max.

(12)

Storage Temperature Range –55 to +125°C

Thermal Protection/Shutdown +115°C

Relative Humidity To 85°C/85% RH, non-condensing

Physical

Outline Dimensions See Mechanical Specifications

Weight 0.28 ounces (7.8 grams)

Electromagnetic Interference FCC part 15, class B, EN55022

(conducted and radiated) (may need external filter)

Safety Designed to meet UL/cUL 60950-1,

ABSOLUTE MAXIMUM RATINGS

CSA-C22.2 No.60950-1,

IEC/EN 60950-1

Input Voltage (Continuous or transient) +15 Volts

On/Off Control 0V min. to + Vin max.

Input Reverse Polarity Protection See Fuse section

Output Current (7) Current-limited. Devices can withstand

sustained short circuit without damage.

Storage Temperature –55 to +125°C

Lead Temperature (soldering 10 sec. max.) +280°C

These are stress ratings. Exposure of devices to any of these conditions may adversely

affect long-term reliability. Proper operation under conditions other than those listed in the

Performance/Functional Specifications Table is not implied.

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_LSN2-T/30-D12 Series.B12 Page 3 of 17

Performance/Functional Specification Notes:

#

).

6

).

#

"53

,

"53

#).X§&%32M7 K(Z

#

"53

§&%32M7 K(Z

,

"53

§(

).054

#/--/.

#522%.4

02/"%

4/

/3#),,/3#/0%

n

(1) Specifications are typical at +25°C, Vin = nominal (+12V), Vo u t = nominal (+5V), full

load, external caps and natural convection unless otherwise indicated.

All models are tested and specified with external 0.01 || 0.1 || 10µF ceramic/tantalum

output capacitors and a 22µF external input capacitor. All capacitors are low ESR

types. These capacitors are necessary to accommodate our test equipment and may

not be required to achieve specified performance in your applications. All models are

stable and regulate within spec under no-load conditions.

(2) Input Back Ripple Current is tested and specified over a 5Hz to 20MHz bandwidth.

Input filtering is Cin = 2 x 100µF tantalum, Cb u s = 1000µF electrolytic, Lb u s = 1µH.

(3) Note that Maximum Power Derating curves indicate an average current at nominal

input voltage. At higher temperatures and/or lower airflow, the DC/DC converter will

tolerate brief full current outputs if the total RMS current over time does not exceed the

Derating curve.

(4) Mean Time Before Failure is calculated using the Telcordia (Belcore) SR-332

Method 1, Case 3, ground fixed conditions, TPCBOARD = +25°C, full output load,

natural air convection.

(5) The On/Off Control may be driven with external logic or by applying appropriate exter-

nal voltages which are referenced to –Input Common. The On/Off Control Input should

use either an open collector/open drain transistor or logic gate.

(6) Short circuit shutdown begins when the output voltage degrades approximately 2%

from the selected setting.

(7) If Sense is connected remotely at the load, up to 0.5 Volts difference is allowed between

the Sense and +Vo u t pins to compensate for ohmic voltage drop in the power lines.

A larger voltage drop may cause the converter to exceed maximum power dissipation.

LSN2-T/30-D12 Series

DOSA-SIP, 30A POL DC/DC Converters

(8) Output noise may be further reduced by adding an external filter. See I/O Filtering and

Noise Reduction.

(9) All models are fully operational and meet published specifications, including “cold start”

at –40°C. At full power, the package temperature of all on-board components must not

exceed +128°C.

(10) Regulation specifications describe the deviation as the line input voltage or output load

current is varied from a nominal midpoint value to either extreme.

(11) Other input or output voltage ranges will be reviewed under scheduled quantity special

order.

(12) Maximum PC board temperature is measured with the sensor in the center.

(13) Do not exceed maximum power specifications when adjusting the output trim.

(14) After short circuit shutdown, if the load is partially removed such that the load still

exceeds the overcurrent (OC) detection, the converter will remain in hiccup restart mode.

(15) Static Discharge CAUTION: The Power Good output connects directly to the PWM

controller. Be sure to use proper grounding techniques to avoid damaging the converter.

Power Good is not valid when using Sequence/Tracking.

(16) The maximum output capacitive loads depend on the the Equivalent Series Resistance

(ESR) of theexternal output capacitor. Larger caps will reduce output noise but may

slow transient response or degrade dynamic performance. Use only as much output filtering as needed and no more. Thoroughly test your system under full load, especially

with low-ESR ceramic capacitors.

(17) Do not use Pre-bias startup and sequencing together. See the Technical Notes below.

I/O Filtering and Noise Reduction

All models in the LSN2-T/30-D12 Series are tested and specified with external

0.01 || 0.1 || 10µF ceramic/tantalum output capacitors and a 22µF tantalum

input capacitor. These capacitors are necessary to accommodate our test

equipment and may not be required to achieve desired performance in your

application. The LSN2-T/30-D12’s are designed with high-quality, high-performance internal I/O caps, and will operate within spec in most applications with

no additional external components.

In particular, the LSN2-T/30-D12’s input capacitors are specified for low

ESR and are fully rated to handle the units’ input ripple currents. Similarly, the

internal output capacitors are specified for low ESR and full-range frequency

response.

In critical applications, input/output ripple/noise may be further reduced using

filtering techniques, the simplest being the installation of external I/O caps.

External input capacitors serve primarily as energy-storage devices. They

minimize high-frequency variations in input voltage (usually caused by IR drops

in conductors leading to the DC/DC) as the switching converter draws pulses of

current. Input capacitors should be selected for bulk capacitance (at appropriate frequencies), low ESR, and high rms-ripple-current ratings. The switching

nature of modern DC/DCs requires that the dc input voltage source have low ac

impedance at the frequencies of interest. Highly inductive source impedances

can greatly affect system stability. Your specific system configuration may

necessitate additional considerations.

TECHNICAL NOTES

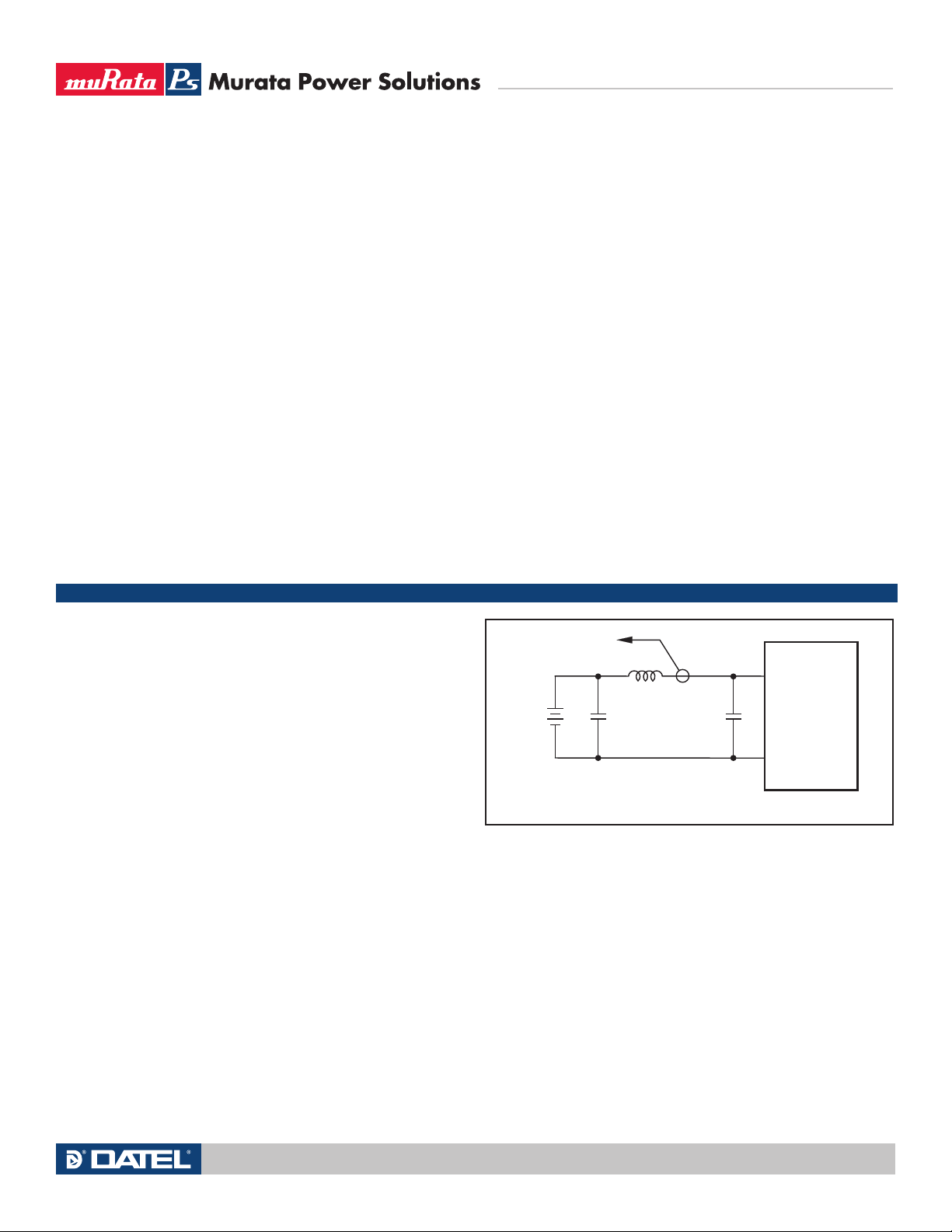

Figure 2. Measuring Input Ripple Current

Output ripple/noise (also referred to as periodic and random deviations or

PARD) may be reduced below specified limits with the installation of additional

external output capacitors. Output capacitors function as true filter elements

and should be selected for bulk capacitance, low ESR, and appropriate frequency response. Any scope measurements of PARD should be made directly

at the DC/DC output pins with scope probe ground less than 0.5" in length.

All external capacitors should have appropriate voltage ratings and be located

as close to the converters as possible. Temperature variations for all relevant

parameters should be taken into consideration.

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_LSN2-T/30-D12 Series.B12 Page 4 of 17

Figure 3. Measuring Output Ripple/Noise (PARD)

#

#§&#%2!-)#

#§&4!.4!,5,/!$).#(%3MM&2/--/$5,%

#

2

,/!$

#/00%2342)0

#/00%2342)0

3#/0%

/54054

#/--/.

3%.3%

The most effective combination of external I/O capacitors will be a function of your line voltage and source impedance, as well as your particular load

and layout conditions. Our Applications Engineers can recommend potential

solutions and discuss the possibility of our modifying a given device’s internal

filtering to meet your specific requirements. Contact our Applications Engineering Group for additional details.

Input Fusing

Most applications and or safety agencies require the installation of fuses at the

inputs of power conversion components. The LSN2-T/30-D12 Series are not

internally fused. Therefore, if input fusing is mandatory, either a normal-blow

or a slow-blow fuse with a value no greater than twice the maximum input current calculated at low line with the converter’s minimum efficiency should be

installed within the ungrounded input path to the converter.

Safety Considerations

LSN2-T/30-D12 SIPs are non-isolated DC/DC converters. In general, all DC/DC’s

must be installed, including considerations for I/O voltages and spacing/separation requirements, in compliance with relevant safety-agency specifications

(usually UL/IEC/EN60950-1).

In particular, for a non-isolated converter’s output voltage to meet SELV

(safety extra low voltage) requirements, its input must be SELV compliant. If the

output needs to be ELV (extra low voltage), the input must be ELV.

Input Overvoltage and Reverse-Polarity Protection

LSN2-T/30-D12 SIP Series DC/DCs do not incorporate either input overvoltage

or input reverse-polarity protection. Input voltages in excess of the specified

absolute maximum ratings and input polarity reversals of longer than “instantaneous” duration can cause permanent damage to these devices.

LSN2-T/30-D12 Series

DOSA-SIP, 30A POL DC/DC Converters

The On/Off to VOUT Start-Up Time assumes the converter is turned off via the

On/Off Control with the nominal input voltage already applied to the converter.

The specification defines the interval between the time at which the converter

is turned on and the fully loaded output voltage enters and remains within its

specified accuracy band. See Typical Performance Curves.

Remote Sense

LSN2-T/30-D12 Series offer an output sense function.

enables point-of-use regulation for overcoming moderate IR drops in conductors and/or cabling. Since these are non-isolated devices whose inputs and

outputs usually share the same ground plane, sense is provided only for the

+Output.

The remote sense line is part of the feedback control loop regulating the

DC/DC converter’s output. The sense line carries very little current and consequently requires a minimal cross-sectional-area conductor. As such, it is not a

low-impedance point and must be treated with care in layout and cabling. Sense

lines should be run adjacent to signals (preferably ground), and in cable and/or

discrete-wiring applications, twisted-pair or similar techniques should be used.

To prevent high frequency voltage differences between VOUT and Sense, we

recommend installation of a 1000pF capacitor close to the converter.

The sense function is capable of compensating for voltage drops between

the +Output and +Sense pins that do not exceed 10% of VOUT.

[VOUT(+) – Common] – [Sense(+) – Common] ≤ 10%VOUT

Power derating (output current limiting) is based upon maximum output current and voltage at the converter’s output pins. Use of trim and sense functions

can cause the output voltage to increase, thereby increasing output power

beyond the LSN2-T/30-D12’s specified rating. Therefore:

(VOUT at pins) x (IOUT) ≤ rated output power

The internal 10.5W resistor between +Sense and +Output (see Figure 1)

serves to protect the sense function by limiting the output current flowing

through the sense line if the main output is disconnected. It also prevents

output voltage runaway if the sense connection is disconnected.

Note: If the sense function is not used for remote regulation, +Sense

must be tied to +Output at the DC/DC converter pins.

Remote On/Off Control

Normally this input is controlled by the user’s external transistor or relay. With

simple external circuits, it may also be selected by logic outputs. Please note

however that the actual control threshold levels vary somewhat with the PWM

supply and therefore are best suited to “open collector” or “open drain” type

logic. The On/Off control takes effect only when appropriate input power has

been applied and stabilized (approximately 7msec).

The sense function

Start-Up Time

The VIN to VOUT Start-Up Time is the interval between the time at which a ramp-

ing input voltage crosses the lower limit of the specified input voltage range

and the fully loaded output voltage enters and remains within its specified

accuracy band. Actual measured times will vary with input source impedance,

external input capacitance, and the slew rate and final value of the input voltage

as it appears to the converter.

For negative polarity, the default operation leaves this pin open (unconnected)

or LOW. The output will then always be on (enabled) whenever appropriate input

power is applied.

Dynamic control of the On/Off must be capable of sinking or sourcing the

control current (approximately 1mA max.) and not overdrive the input greater

than the +VIN power input. Always wait for the input power to stabilize before

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_LSN2-T/30-D12 Series.B12 Page 5 of 17

LSN2-T/30-D12 Series

+INPUT

+V

CONTROLLER

SMALL

SIGNAL

TRANSISTOR

HI = ON

LO = OFF

SHUTDOWN

SIGNAL

GROUND

COMMON

ON/OFF

CONTROL

DOSA-SIP, 30A POL DC/DC Converters

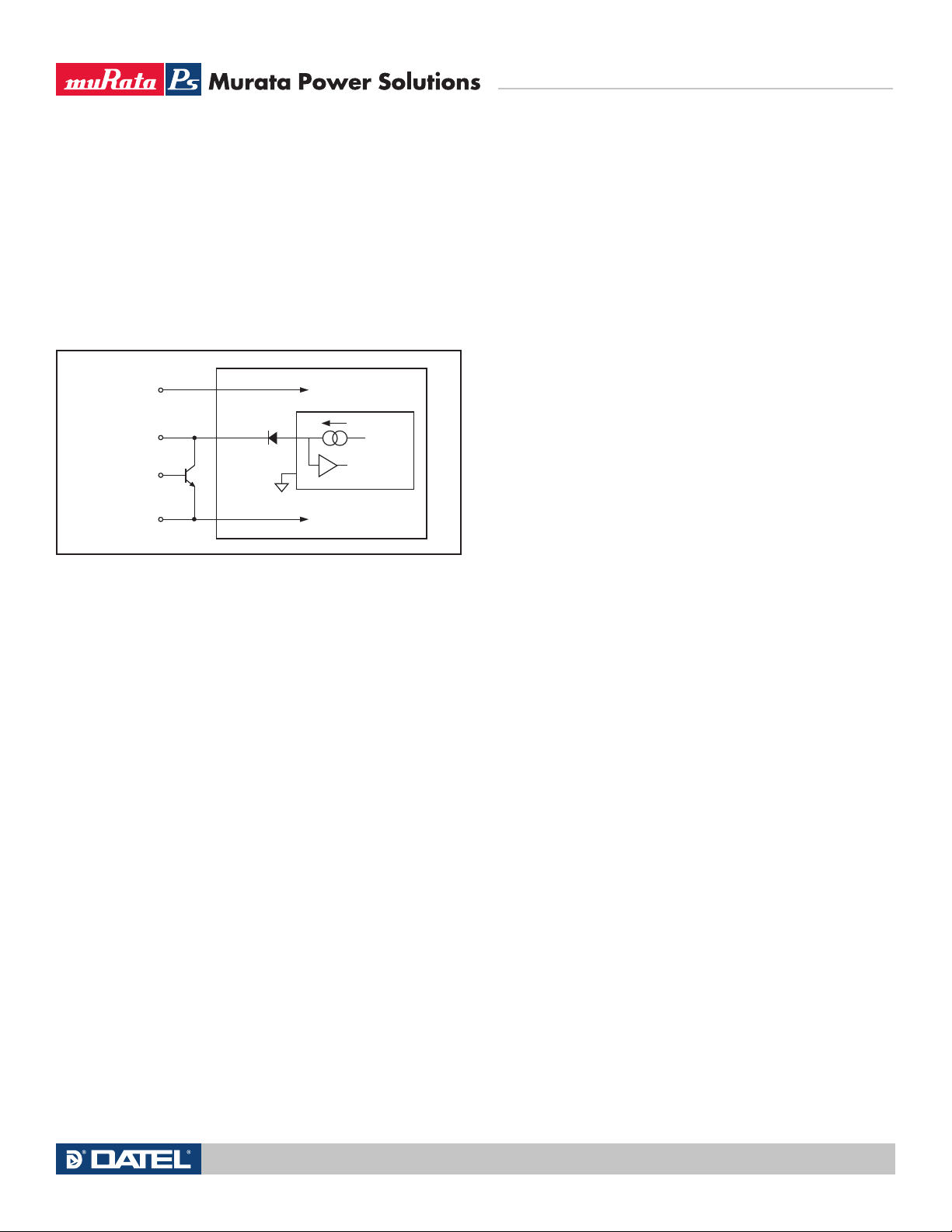

activating the On/Off control. Be aware that a delay of several milliseconds

occurs (see specifications) between activation of the control and the resulting

change in the output.

Power-up Sequencing

If a controlled start-up of one or more LSN2-T/30-D12 Series DC/DC converters

is required, or if several output voltages need to be powered-up in a given

sequence, the On/Off control pin can be driven with an external open collector

device as per Figure 4.

Figure 4. On/Off Control Using An External Open Collector Driver

Output Overvoltage Protection

LSN2-T/30-D12 SIP Series DC/DC converters do not incorporate output

overvoltage protection. In the extremely rare situation in which the device’s

feedback loop is broken, the output voltage may run to excessively high levels

(VOUT = VIN). If it is absolutely imperative that you protect your load against

any and all possible overvoltage situations, voltage limiting circuitry must be

provided external to the power converter.

Output Overcurrent Detection

Overloading the power converter’s output for an extended time will invariably

cause internal component temperatures to exceed their maximum ratings

and eventually lead to component failure. High-current-carrying components

such as inductors, FET’s and diodes are at the highest risk. LSN2-T/30-D12

SIP Series DC/DC converters incorporate an output overcurrent detection and

shutdown function that serves to protect both the power converter and its load.

If the output current exceeds it maximum rating by typically 50% or if the

output voltage drops to less than 98% of it original value, the LSN2-T/30-D12’s

internal overcurrent-detection circuitry immediately turns off the converter,

which then goes into a “hiccup” mode. While hiccupping, the converter will

continuously attempt to restart itself, go into overcurrent, and then shut down.

Once the output short is removed, the converter will automatically restart itself.

Output Reverse Conduction

Many DC/DCs using synchronous rectification suffer from Output Reverse

Conduction. If those devices have a voltage applied across their output before

a voltage is applied to their input (this typically occurs when another power

supply starts before them in a power-sequenced application), they will either

fail to start or self destruct. In both cases, the cause is the “freewheeling” or

“catch” FET biasing itself on and effectively becoming a short circuit.

LSN2-T/30-D12 SIP DC/DC converters do not suffer from Output Reverse

Conduction. They employ proprietary gate drive circuitry that makes them

immune to moderate applied output overvoltages.

Thermal Considerations and Thermal Protection

The typical output-current thermal-derating curves shown below enable

designers to determine how much current they can reliably derive from each

model of the LSN2-T/30-D12 SIPs under known ambient-temperature and airflow conditions. Similarly, the curves indicate how much air flow is required to

reliably deliver a specific output current at known temperatures.

The highest temperatures in LSN2-T/30-D12 SIPs occur at their output

inductor, whose heat is generated primarily by I2R losses. The derating curves

were developed using thermocouples to monitor the inductor temperature and

varying the load to keep that temperature below +110°C under the assorted

conditions of air flow and air temperature. Once the temperature exceeds

+115°C (approx.), the thermal protection will disable the converter. Automatic

restart occurs after the temperature has dropped below +110°C.

As you may deduce from the derating curves and observe in the efficiency

curves on the following pages, LSN2-T/30-D12 SIPs maintain virtually constant

efficiency from half to full load, and consequently deliver very impressive

temperature performance even if operating at full load.

Lastly, when LSN2-T/30-D12 SIPs are installed in system boards, they are

obviously subject to numerous factors and tolerances not taken into account

here. If you are attempting to extract the most current out of these units under

demanding temperature conditions, we advise you to monitor the outputinductor temperature to ensure it remains below +110°C at all times.

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_LSN2-T/30-D12 Series.B12 Page 6 of 17

Loading...

Loading...