Murata

Manufacturing Co., Ltd.

Cat.No.O05E-5

CHIP COIL

CHIP COIL

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

Murata's LQ- series of chip coils consists of compact, highperformance inductors. Their innovative coil and case

structures mean low DC resistance and outstanding

!PRODUCTS GUIDE

high-frequency characteristics. The series is designed for a

variety of applications, facilitating component selection for

individual circuit requirements.

Please refer to the usage conditions;

¡Notice of Chip Coil

.................................................

P.42YP.45

¡Dimensions of Taping

.......................................................

P.46

Please refer to the usage conditions;

¡Design Kit

...............................................................

P.47YP.50

¡Information of Chip Coil

....................................................

P.51

Application

General Frequency

Range

High-frequency

Range

Chokes

Part Number

LQH1N

LQH3N

LQH (N) 4N

LQG11N

LQG21N

LQS33N

1206

1210

1812

0603

0805

1214

0402

0603

0402

0603

0603

0805

1206

1206

1206

1210

1812

0805

0805

1206

2220

1212

2525

3Y7

8Y9

10Y11

12Y13

14Y16

17Y20

21Y23

24Y27

28

29Y31

32

33Y34

35Y36

39Y41

37Y38

39Y41

Wound coil

(ferrite core)

Magnetically shielded

multilayer

Magnetically shielded

Wound coil

(air core)

Multilayer

Thin film

Wound coil

(ferrite core)

Wound coil

Magnetically shielded

multilayer

Wound coil

Magnetically shielded

LQW1608A

LQN21A

LQN1A

LQN1H

LQG10A

LQG11A

LQP10A

LQP11A

Tight

inductance

tolerance

Tight

inductance

tolerance

Structure

Dimensions Inductance Range (H)

Page

1n 10n 100n 1µ 10µ 100µ 1m 10m

(mm) (inch)

LQH1C

LQH3C

LQH4C

LQG21C

LQG21F

LQG3216F

LQN6C

LQS33C

LQS66C

3.2

1.6

3.2

2.5

4.5

3.2

2.0

1.25

3.2

3.5

2.0

1.5

3.2

1.6

3.2

1.6

3.2

1.6

4.5

3.2

6.3

6.3

3.2

2.5

3.3

3.3

2.0

1.25

2.0

1.25

1.6

0.8

1.6

0.8

1.6

0.8

1.6

0.8

1.0

0.5

1.0

0.5

5.7

5.0

3.2

1.6

1

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

LQ

(Ex.)

H 3 N 331 K

!PART NUMBERING

(Please specify the part number when ordering.)

q w e r t y34u

LQ N 21 A 10N J

q w e r t y04u

LQ G 21 N R10 K

q w e r t y10uT1i

qChip Coil

wForm .Structure

eSize

Mark

1

3

4

6

10

11

21

33

66

1608

3216

Size

3.2Z1.6mm

3.2Z2.5mm

4.5Z3.2mm

5.7Z5.0mm

1.0Z0.5mm

1.6Z0.8mm

2.0Z1.25 (1.5) mm

3.2Z3.5mm, 3.3Z3.3mm

6.3Z6.3mm

1.6Z0.8mm

3.2Z1.6mm

rCharacteristic.Applications

Mark

N

C

A

H

F

Characteristic .Applications

General use

Choke coil

Air coil

High Q

For DC power supply

line choke coil

tInductance

Example

: 330µH/331 33nH/33N

33µH/330 3.3nH/3N3

3.3µH/3R3

0.33µH/R33

uAdditional Number

iPackaging Code

(LQG21N/21C/LQP10A/11A/

LQG10A/11A/LQW1608A)

yInductance Tolerance

Mark

G

J

K

M

N

B

C

S

D

Tolerance

T02%

T05%

T10%

T20%

T30%

T0.1nH

T0.2nH

T0.3nH

T0.5nH

Mark

T1

T2

B1

Packaging

Taped (

φ180mm Reel)

Taped (φ330mm Reel)

Bulk package

Mark

H

N

S

P

G

W

Form.Structure

Wire wound with coating

Wire wound without coating

Wire wound with shielded core

Thin film

Multilayer

Horizontal wire wound

2

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

0603

LQG11A

1.2-100nH

0402

LQG10A

1.2-33nH

1206

LQN1A

8.8-100nH

LQN21A

3.3-470nH

LQP11A

1.3-33nH

LQP10A

1.0-33nH

0805

0603

0402

1206

06031206

1812

1210

0805

LQG21C

1.0-47µH 7-60mA

LQH1N

0.15-100µH

LQH3N

0.10-560µH

LQH4N

1.0-2200µH

LQG11N

47-2200nH

0805

1214

LQS33N

1.0-100µH

LQG21N

0.1-4.7µH

LQN1H

54-880nH

LQH1C

0.12-100µH 80-970mA

LQH4C

1.0-470µH 90-1080mA

LQH3C

0.15-560µH 60-1450mA

0805

LQG21F

1.0-47µH 7-220mA

1206

LQG3216F

10µH 70mA

1812

1210

1206

LQS33C

560-2200µH20-50mA

1212

LQN6C/LQS66C

0.12-10000µH 0.05-6.0A

2220 2525

LQW1608A

2.2-220nH

0603

CHIP INDUCTOR SELECTION

Application

Operating

Frequency

Less than 50MHz

Choke

Impedance Matching

or

Resonance

Greater than

100MHz

30MHz

to

150MHz

Need

Magnetical

Shield

Start

Yes

No

Chip Inductor

for

Choke Use

Chip Inductor

for

General Frequency

Chip Inductor

for

Magnetical shield

Chip Inductor

for

Ultra High Frequency

Chip Inductor

for

High Frequency

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

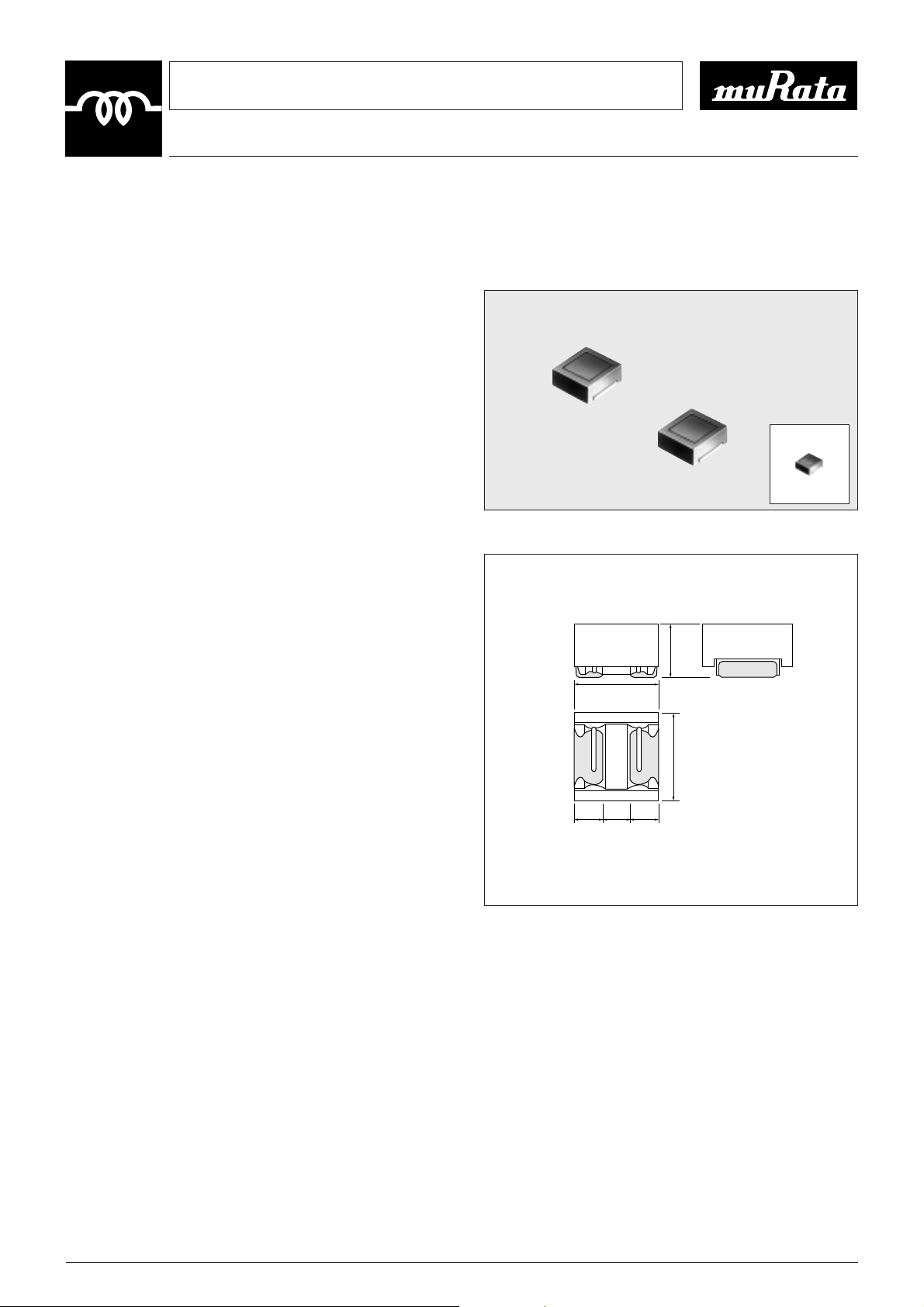

Standard Chip Coil LQH1N/LQH3N/LQH(N)4N Series

CHIP COIL

3

Wire Wound Chip Coil with High Q Value

at High Frequencies and Low DC Resistance

The chip coil LQH/LQN series consists of miniature

chip inductors wound on a special ferrite core and are

made possible by an automatic winding technique

developed by Murata. These inductors have a high Q at

high frequencies and low DC resistance, making them

very well suited to enhancing the performance of

electronic circuits in video, communications, and

audio equipment.

!FEATURES

1. There are three different inductor types: the

LQH1N,LQH3N and LQH(N)4N series. These three series

cover a wide inductance range (from 0.1µH to 2.2mH).

2. The series has outstanding frequency characteristics and

a high Q value at high frequencies.

3. The low DC resistance permits high current flow.

4. The series has excellent solder heat resistance. Both flow

and reflow soldering methods can be employed.

¡LQH1N

Miniature size (3.2Z1.6Z1.8mm) allows parallel

mounting at 2.5mm pitch. The series is suitable for

portable audio-visual equipment.

¡LQH3N

A high Q value makes this series suitable for circuits

up to 100MHz in frequency. The series is excellent for

video equipment.

¡LQH(N)4N

This series offers high inductance values

and high current capacity. At 10µH, up to 450mA

designs are possible, resulting in excellent

performance when the inductors are used as choke coils.

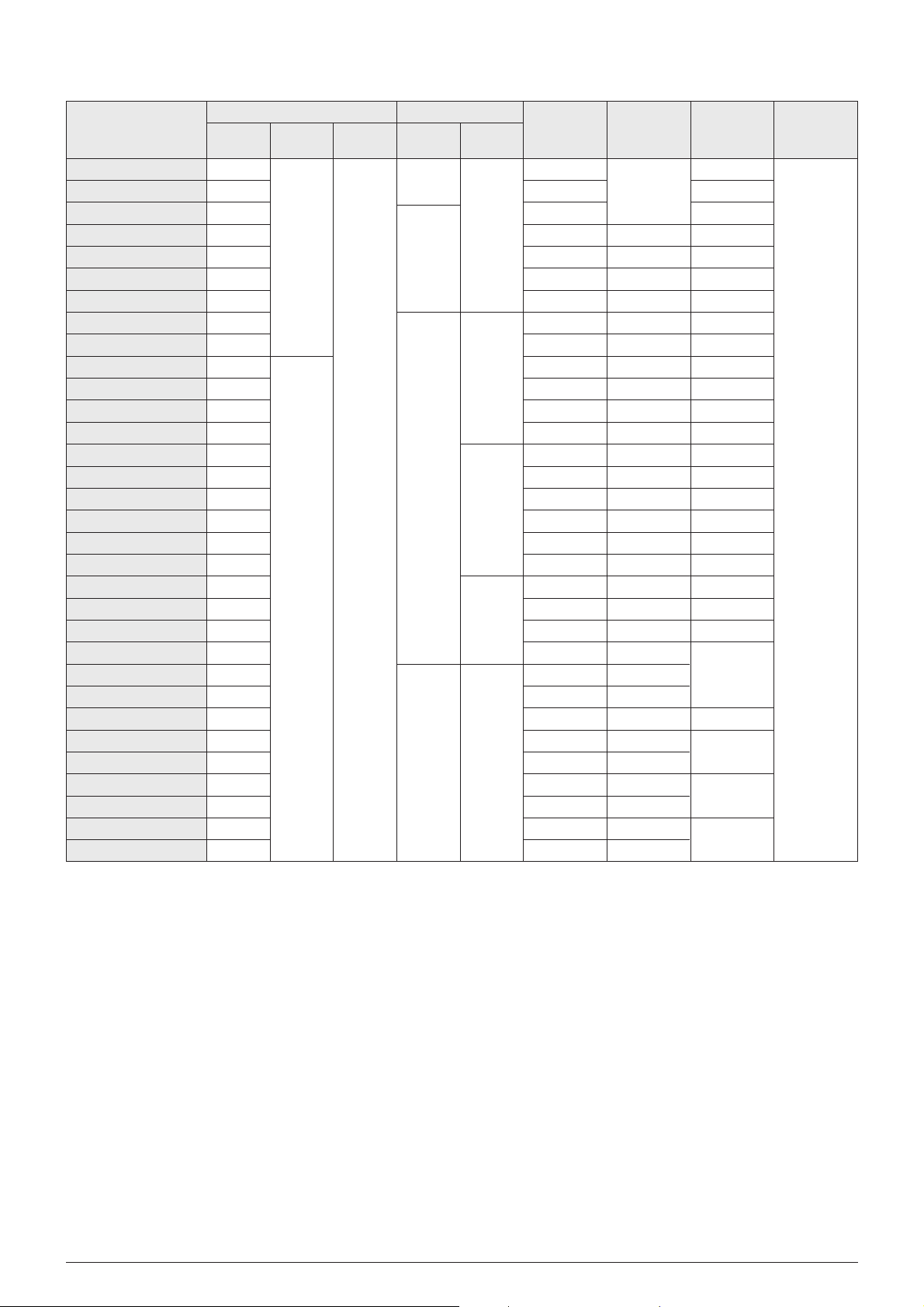

!DIMENSIONS

LQH1N Type

LQH4N/LQN4N Type

LQH3N Type

LQH1N Type

LQH3N Type

LQH4N/LQN4N Type

EIA Code:1210

2.3±0.2

3.2±0.3

1.8±0.2

1.6±0.2

1.6±0.2

0.7

min.

0.7

min.

0.7

min.

2.5±0.2

3.2±0.3

2.0±0.2

2.5±0.2

2.5±0.2

0.9

±0.3

0.9

±0.3

1.3

±0.2

3.6±0.2

4.5±0.3

2.6±0.2

3.2±0.2

3.2±0.2

1.0

min.

3.2±0.2

1.0

min.

1.0

min.

EIA Code:1206

EIA Code:1812

(in mm)

4

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

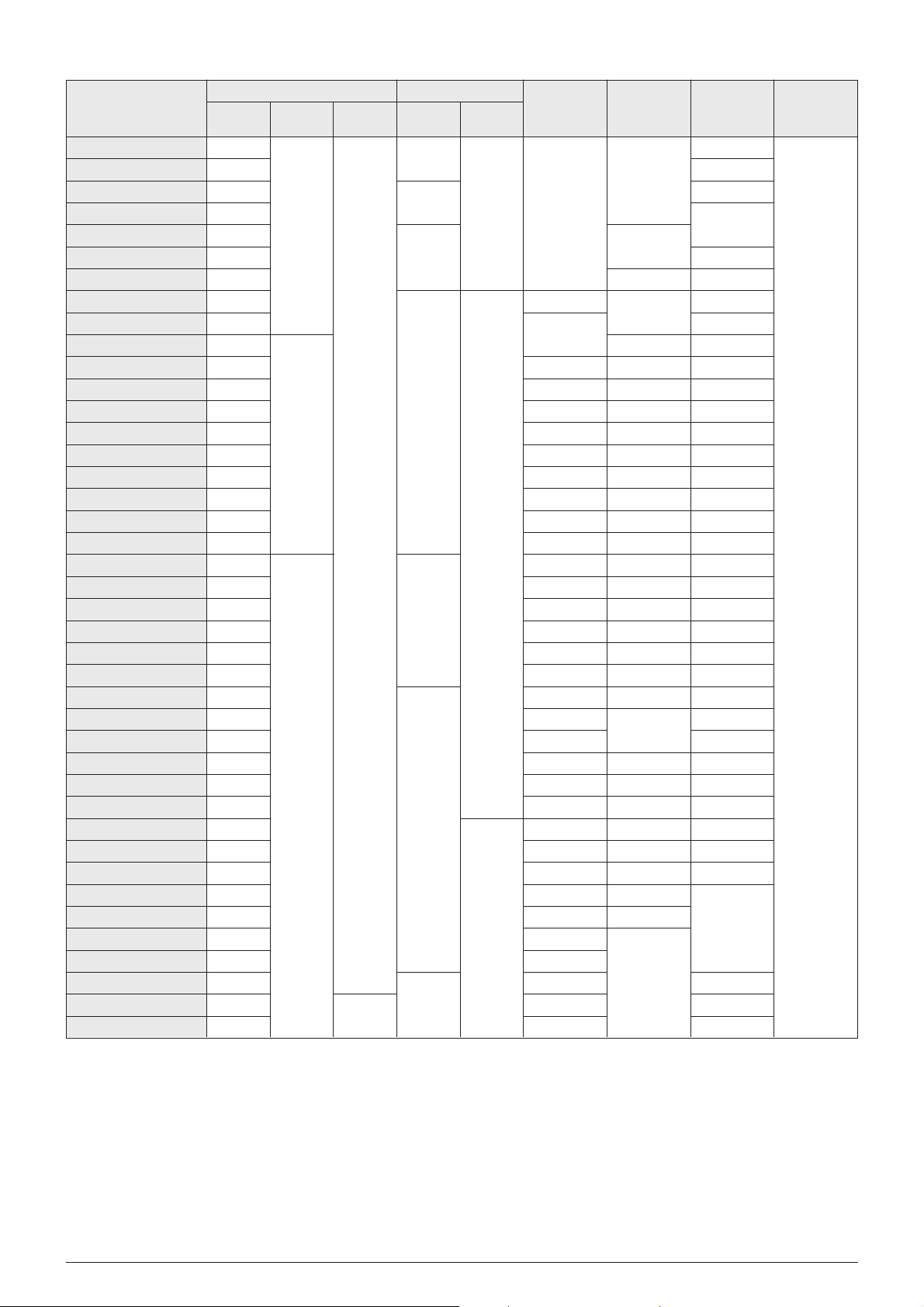

!SPECIFICATIONS

LQH1N

LQH1NR15K04 0.15

20

0.39T40% 250

LQH1NR22K04 0.22 0.43T40% 250 240

LQH1NR33K04 0.33 0.45T40% 230

LQH1NR47K04 0.47 25MHz 0.83T40% 200 215

LQH1NR56K04 0.56 T10 30 0.61T40% 180 200

LQH1NR68K04 0.68 0.67T40% 160 190

LQH1NR82K04 0.82 0.73T40% 120 185

LQH1N1R0K04 1.0 0.49T30% 100 175

LQH1N1R2K04 1.2 0.9 T30% 90 165

LQH1N1R5K(J)04 1.5

10MHz

1.0 T30% 75 155

LQH1N1R8K(J)04 1.8 1.6 T30% 60 150

LQH1N2R2K(J)04 2.2 0.7 T30% 50 140

LQH1N2R7K(J)04 2.7 0.55T30% 43 135

LQH1N3R3K(J)04 3.3 0.61T30% 38 130

LQH1N3R9K(J)04 3.9

35

1.5 T30% 35 125

Y25

LQH1N4R7K(J)04 4.7

1MHz

8MHz

1.7 T30% 31 120 to

LQH1N5R6K(J)04 5.6 1.8 T30% 28 115

W85D

LQH1N6R8K(J)04 6.8 2.0 T30% 25 110

LQH1N8R2K(J)04 8.2 2.2 T30% 23 105

LQH1N100K(J)04 10

T10

2.5 T30% 20 100

LQH1N120K(J)04 12

(T5)

5MHz

2.7 T30% 18 95

LQH1N150K(J)04 15 3.0 T30% 16 90

LQH1N180K(J)04 18 3.4 T30% 15

LQH1N220K(J)04 22 3.1 T30% 14 85

LQH1N270K(J)04 27 3.4 T30% 13

LQH1N330K(J)04 33 3.8 T30% 12 80

LQH1N390K(J)04 39 7.2 T30% 11

55

LQH1N470K(J)04 47 40 2.5MHz 8.0 T30% 10

LQH1N560K(J)04 56 8.9 T30% 9.0

50

LQH1N680K(J)04 68 9.9 T30% 8.5

LQH1N820K(J)04 82 11 T30% 7.5

45

LQH1N101K(J)04 100 12 T30% 7.0

Part Number

Inductance Q

Nominal

Value(µH)

Tolerance

(%)

Test

Frequency

Nominal

Value(min.)

Test

Frequency

DC Resistance

(Ω)

Self-resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

5

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

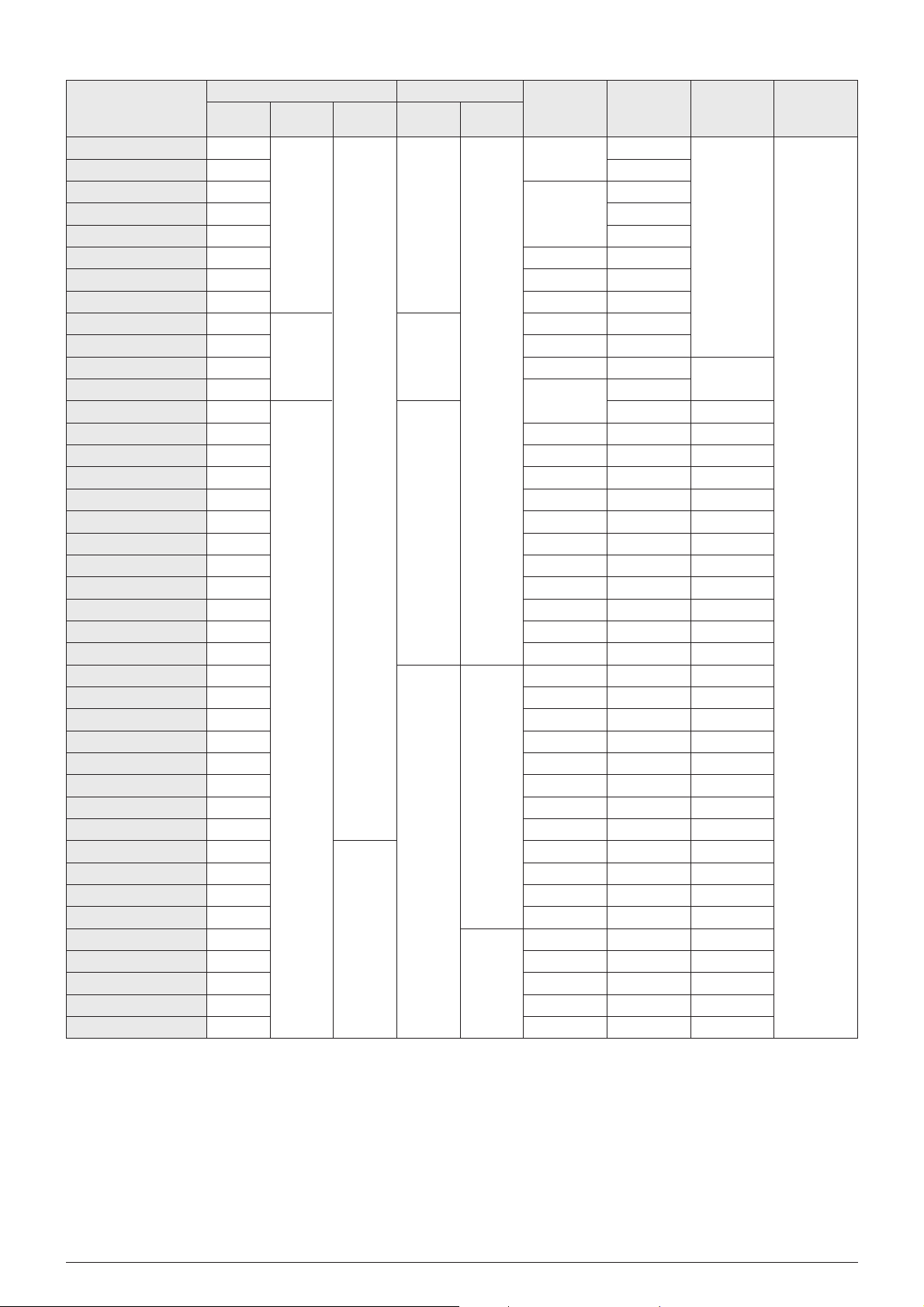

LQH3NR10M34 0.10

20

700

LQH3NR18M34 0.18

200

650

LQH3NR27M34 0.27

25

600

LQH3NR39M34 0.39 25.2MHz 0.25

530

LQH3NR56M34 0.56 T20

160

LQH3NR68M34 0.68 30 470

LQH3NR82M34 0.82 120 450

LQH3N1R0M34 1.0 0.5

100

445

LQH3N1R2M34 1.2

0.6

425

LQH3N1R5K34 1.5 75 400

LQH3N1R8K34 1.8 0.7 60 390

LQH3N2R2K34 2.2 0.8 50 370

LQH3N2R7K34 2.7 20 0.9 43 320

LQH3N3R3K34 3.3

T10

1.0 38 300

LQH3N3R9K34 3.9 1.1 35 290

LQH3N4R7K34 4.7 1.2 31 270

LQH3N5R6K34 5.6 1.3 28 250

LQH3N6R8K34 6.8 1.5 25 240

Y25

LQH3N8R2K34 8.2

1MHz 1MHz

1.6 23 225 to

LQH3N100K(J)34 10 1.8 20 190

W85D

LQH3N120K(J)34 12 2.0 18 180

LQH3N150K(J)34 15

35

2.2 16 170

LQH3N180K(J)34 18 2.5 15 165

LQH3N220K(J)34 22 2.8 14 150

LQH3N270K(J)34 27 3.1 13 125

LQH3N330K(J)34 33 3.5 12 115

LQH3N390K(J)34 39 3.9

11

110

LQH3N470K(J)34 47 4.3 100

LQH3N560K(J)34 56 4.9 10 85

LQH3N680K(J)34 68

T10

5.5 9.0 80

LQH3N820K(J)34 82

(T5)

6.2 8.5 70

LQH3N101K(J)34 100 40 7.0 8.0 80

LQH3N121K(J)34 120 8.0 7.5 75

LQH3N151K(J)34 150 9.3 7.0 70

LQH3N181K(J)34 180 10.2 6.0

LQH3N221K(J)34 220 11.8 5.5

65

LQH3N271K(J)34 270

796kHz

12.5

LQH3N331K(J)34 330 13.0

LQH3N391K(J)34 390 22.0 5.0 50

LQH3N471K(J)34 470

1kHz

50 25.0 45

LQH3N561K(J)34 560 28.0 40

Part Number

Inductance Q

Nominal

Value(µH)

Tolerance

(%)

Test

Frequency

Nominal

Value(min.)

Test

Frequency

DC Resistance

(Ωmax.)

Self-resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

LQH3N

6

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

LQH4N1R0M04 1.0

0.20

120

LQH4N1R2M04 1.2 100

LQH4N1R5M04 1.5 85

LQH4N1R8M04 1.8

T20 20

0.30 75

LQH4N2R2M04 2.2 62 500

LQH4N2R7M04 2.7 0.32 53

LQH4N3R3M04 3.3 0.35 47

LQH4N3R9M04 3.9 0.38 41

LQH4N4R7K04 4.7 0.40 38

LQH4N5R6K04 5.6 0.47 33

LQH4N6R8K04 6.8

T10 30

0.50 31

450

LQH4N8R2K04 8.2

1MHz

0.56

27

LQH4N100K(J)04 10 23 400

LQH4N120K(J)04 12 0.62 21 380

LQH4N150K(J)04 15 0.73 19 360

LQH4N180K(J)04 18 1MHz 0.82 17 340

LQH4N220K(J)04 22 0.94 15 320

LQH4N270K(J)04 27 1.1 14 300

Y25

LQH4N330K(J)04 33

35

1.2 12 270 to

LQH4N390K(J)04 39 1.4 11 240

W85D

LQH4N470K(J)04 47 1.5 10 220

LQH4N560K(J)04 56 1.7 9.3 200

LQH4N680K(J)04 68 1.9 8.4 180

LQH4N820K(J)04 82 2.2 7.5 170

LQH4N101K(J)04 100 2.5 6.8 160

LQH4N121K(J)04 120 3.0 6.2 150

LQH4N151K(J)04 150

T10

3.7 5.5 130

LQH4N181K(J)04 180

(T5)

4.5 5.0 120

LQH4N221K(J)04 220 5.4 4.5 110

LQH4N271K(J)04 270

796kHz

6.8 4.0 100

LQH4N331K(J)04 330 8.2 3.6 95

LQH4N391K(J)04 390 9.7 3.3 90

LQH4N471K(J)04 470 40 11.8 3.0 80

LQH4N561K(J)04 560 14.5 2.7 70

LQH4N681K(J)04 680 17.0 2.5 65

LQH4N821K(J)04 820 20.5 2.2 60

LQH4N102K(J)04 1000 1kHz 25.0 2.0 50

LQH4N122K(J)04 1200 30.0 1.8 45

LQH4N152K(J)04 1500 252kHz 37.0 1.6 40

LQN4N182K(J)04 1800 45.0 1.5 35

LQN4N222K(J)04 2200 50.0 1.3 30

Part Number

Inductance Q

Nominal

Value(µH)

Tolerance

(%)

Test

Frequency

Nominal

Value(min.)

Test

Frequency

DC Resistance

(Ωmax.)

Self-resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

LQH4N/LQN4N

7

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

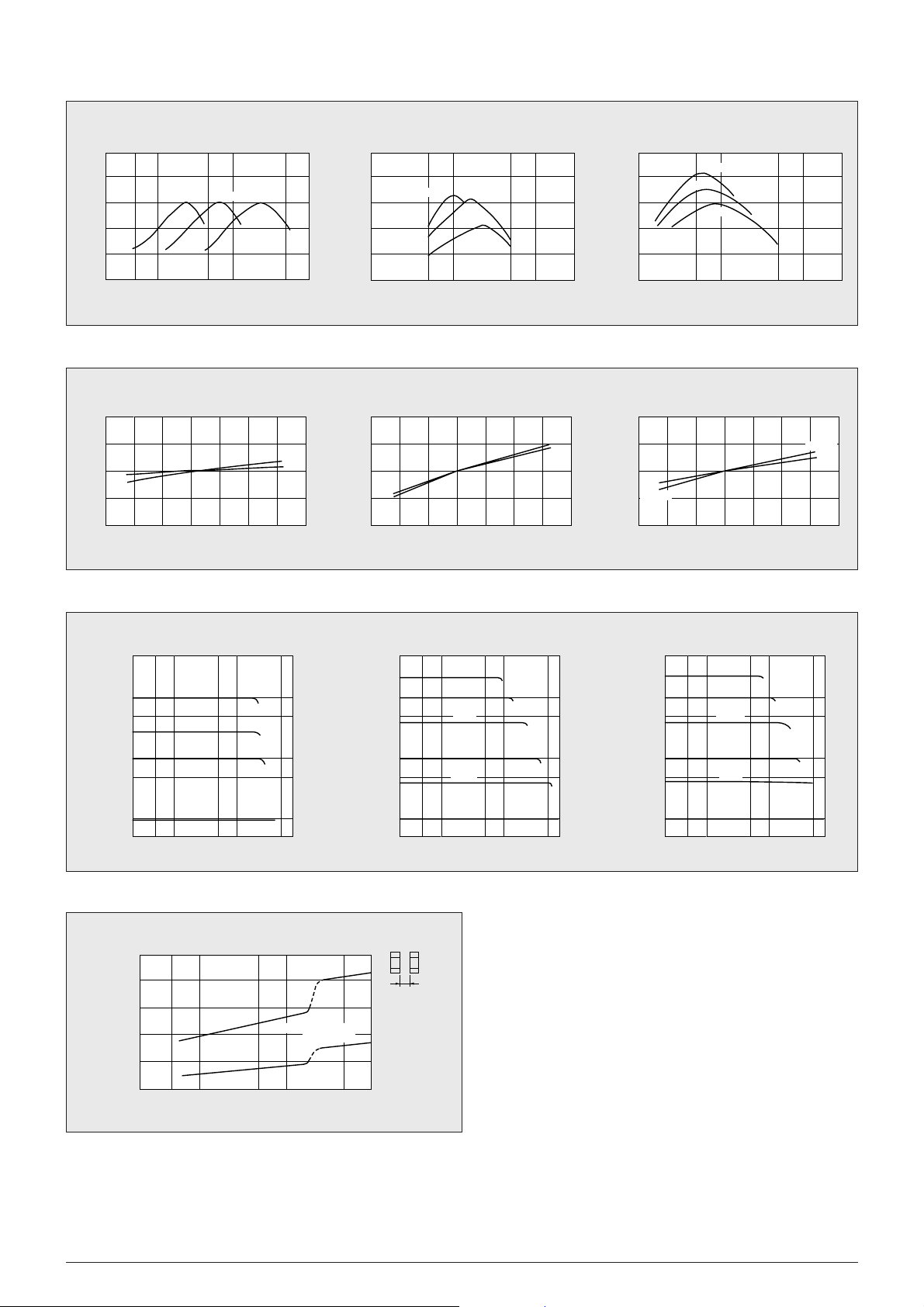

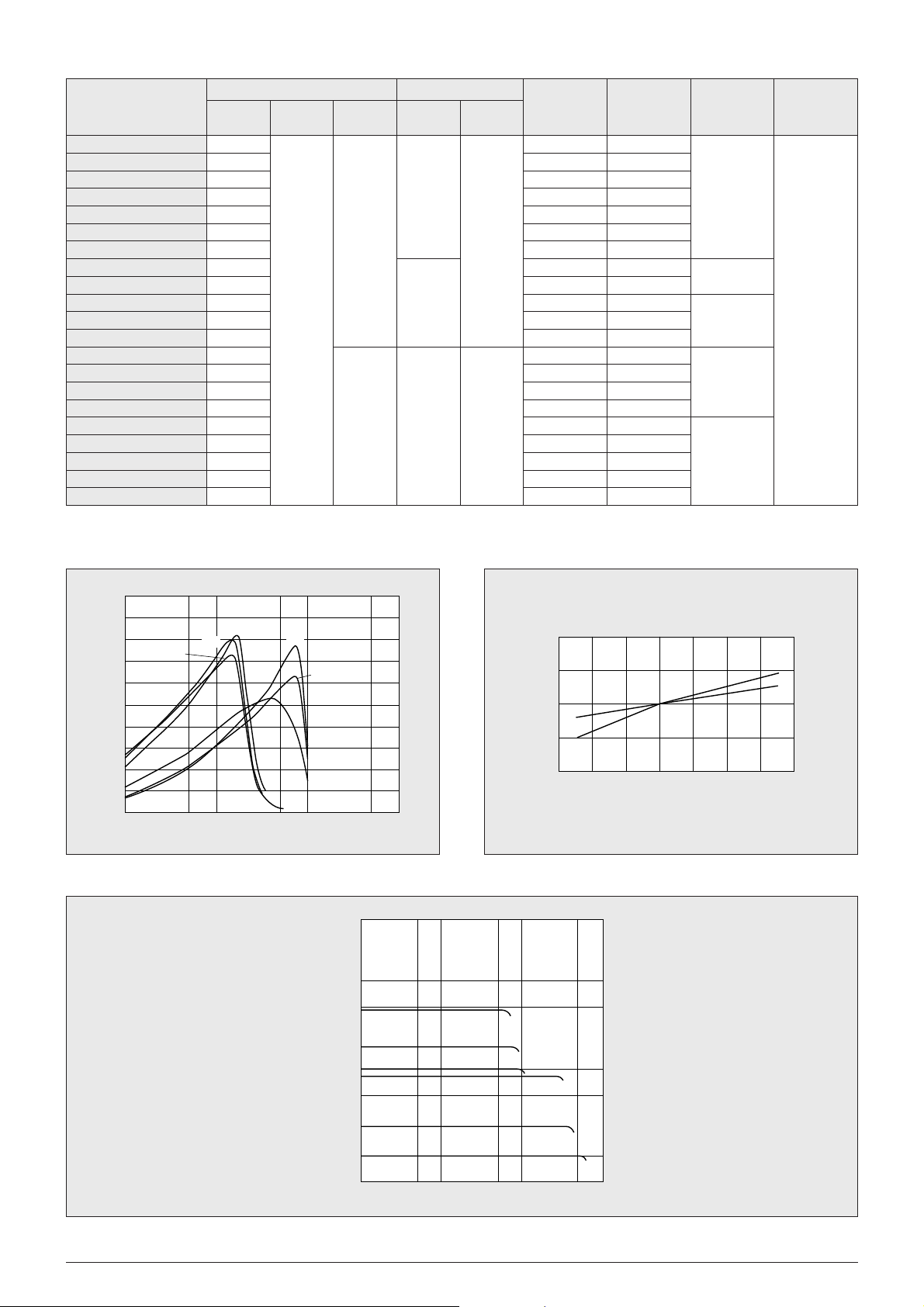

!TYPICAL ELECTRICAL CHARACTERISTICS

¡Q - Frequency Characteristics

¡Inductance - Temperature Characteristics

¡Inductance - Current Characteristics

¡Coupling Coefficient

100

80

60

40

20

0

0.1

Q

100

80

60

40

20

0

0.1

Q

100

80

60

40

20

0

Q

Frequency (MHz)

0.5 1 5 10 50 100

0.5 1

Frequency (MHz)

5 10 0.5 1

Frequency (MHz)

510

1000µH

100µH

10µH

1µH

100µH

10µH

1µH

100µH

10µH

LQH3N LQH4N/LQN4NLQH1N

LQH3N LQH4N/LQN4NLQH1N

LQH3N LQH4N/LQN4NLQH1N

10

8

6

4

2

0

0.5 1 5 10 50 100

Inductance (µH)

Coupling Coefficient (%)

R

R=0.9mm

R=2.0mm

(2.5mm Pitch Parallel

Mounting)

LQH1N

10

5

0

∆L/L (%)

-

5

-

10

-

20

020

Temperature (D)

40 60 80

100µH

1µH

500

100

50

10

Inductance (µH)

5

1

100µH

33µH

10µH

1.0µH

510 50

Current (mA)

100 500 5 10 50

10

5

0

∆L/L (%)

-

5

-

10

-

20 0 20

500

100

50

10

Inductance (µH)

5

1

40 60 80

Temperature (D)

220µH

100µH

39µH

10µH

3.9µH

1.0µH

Current (mA)

10

220µH

1.0µH

100 500 5 10 50

5

0

∆L/L (%)

-

5

-

10

10µH

1000µH

5000

1000

500

100

Inductance (µH)

50

10

-

20 0 20

Temperature (D)

2200µH

1000µH

390µH

100µH

39µH

10µH

Current (mA)

1000µH

10µH

40 60 80

100 500

!DIMENSIONS

Multilayer Chip Inductor

LQG11N

Series

CHIP COIL

8

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

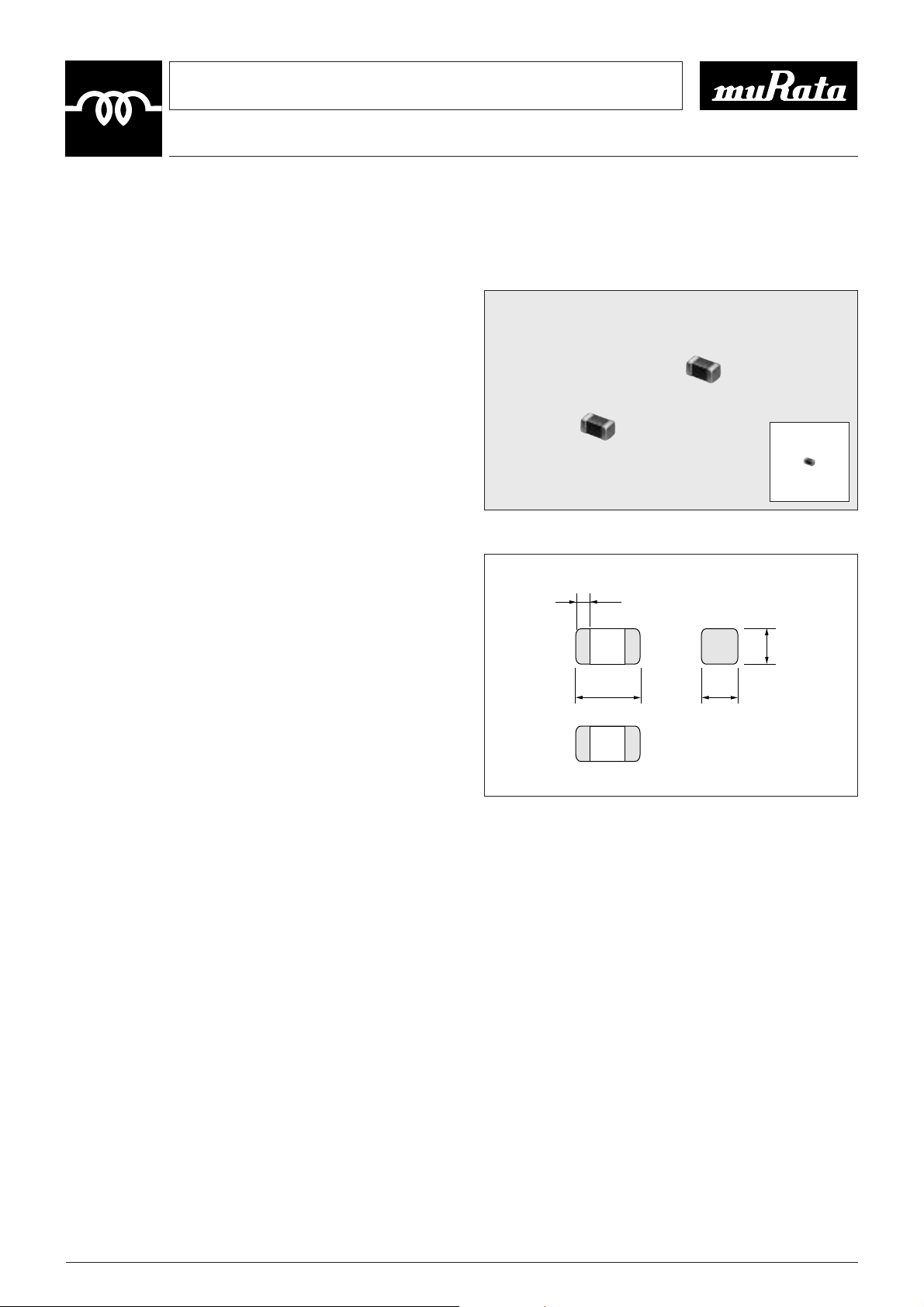

Magnetically Shielded Multilayer Chip Coil

Excellent for High Density Mounting

The LQG11N series, of magnetically shielded chip coil was

developed by using original multilayer process technology and

magnetic materials.

Compact size is suitable for high density mounting.

Shielded construction is not affected by interference from

peripheral components.

!FEATURES

1. Magnetically shielded structure provides excellent

characteristics in cross talk and magnetic coupling.

2. Compact size (1.6Z0.8mm) and light weight.

3. The external electrodes with nickel barrier structure provide

excellent solder heat resistance. Both flow and reflow

soldering can be applicable.

!APPLICATIONS

¡Resonance circuit, traps, filter circuits and RF choke in

telecommunication equipments, cordless phones, radio

equipments.

(in mm)

0.4±0.2

1.6±0.15

0.8±0.15

0.8±0.15

9

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

¡Inductance-Frequency Characteristics

!SPECIFICATIONS

!TYPICAL ELECTRICAL CHARACTERISTICS

¡Q-Frequency Characteristics

Part Number

LQG11N47NM00

LQG11N68NM00

LQG11N82NM00

LQG11NR10K00

LQG11NR12K00

LQG11NR15K00

LQG11NR18K00

LQG11NR22K00

LQG11NR27K00

LQG11NR33K00

LQG11NR39K00

LQG11NR47K00

LQG11NR56K00

LQG11NR68K00

LQG11NR82K00

LQG11N1R0K00

LQG11N1R2K00

LQG11N1R5K00

LQG11N1R8K00

LQG11N2R2K00

Inductance Q

DC

Resistance

(Ω max.)

Self-resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (nH)

Nominal

Value(min.)

Test Frequency

(MHz)

1047

1068

1082

1100

1120

1150

1180

1220

1270

1330

1390

1470

1560

1680

1820

1000

1200

1500

1800

2200

Tolerance

(%)

T20

T10

10

15

35

50

25

10

0.30

0.50

0.60

0.80

0.85

1.00

1.35

1.55

1.70

2.10

0.60

0.80

0.95

1.15

260

250

245

240

205

180

165

150

136

125

110

105

95

90

85

75

65

60

55

50

50

35

25

15

Y25 to W85D

Measuring instrument Q : HP4291A+16192A Measuring instrument L : HP4291A+16192A

80

60

2200nH

40

Q

820nH

20

0

1 10 100 1000

100nH

47nH

Frequency (MHz)

10000

2200nH

1000

Inductance (nH)

100

1

1 10 100 1000

Frequency (MHz)

820nH

100nH

47nH

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!DIMENSIONS

Multilayer Chip Coil

LQG21N

Series

CHIP COIL

10

Magnetically Shielded Multilayer Chip Coil

Low Drift Excellent for High Density Mounting

The LQG21N series consists of magnetically shielded chip

coils developed using original Murata multilayer process

technology and magnetic materials.

The coils occupy one quarter the volume of conventional

chip coils and feature high reliability.

!FEATURES

1. Magnetically shielded structure provides excellent

crosstalk characteristics.

2. Compact (2.0Z1.25mm) and lightweight.

3. Low inductance drift resulting from

soldering,environmentaltests, etc.

4. Outstanding solder heat resistance. Either flow or reflow

soldering can be used.

!APPLICATIONS

¡Hard-disk drives

¡Audio-Visual equipment

¡Telecommunications equipment

Part Number T

LQG21NR10K10Y2R2K10 0.85T0.2

LQG21N2R7K10Y4R7K10 1.25T0.2

(in mm)

EIA Code:0805

2.0±0.3 1.25±0.2

T

0.5±0.3

11

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!SPECIFICATIONS

Part Number

Inductance Q

Nominal

Value(µH)

Tolerance

(%)

Test

Frequency

Nominal

Value(min.)

Test

Frequency

DC Resistance

(Ω max.)

Self-resonant

Frequency

(MHz min.)

Operating

Temp. Range

!TYPICAL ELECTRICAL CHARACTERISTICS

¡Q - Frequency Characteristics

¡Inductance - Temperature Characteristics

¡Inductance - Current Characteristics

Allowable

Current

(mA)

LQG21NR10K10 0.10 0.26 340

LQG21NR12K10 0.12 0.29 310

LQG21NR15K10 0.15 0.32 270

LQG21NR18K10 0.18 20 0.35 250 250

LQG21NR22K10 0.22 0.38 220

LQG21NR27K10 0.27 25MHz 25MHz 0.42 200

LQG21NR33K10 0.33 0.48 180

LQG21NR39K10 0.39 0.53 165

200

LQG21NR47K10 0.47 0.57 150

LQG21NR56K10 0.56 25 0.63 140 Y40

LQG21NR68K10 0.68 T10 0.72 125 150 to

LQG21NR82K10 0.82 0.81 115 W85D

LQG21N1R0K10 1.0 0.40 107

LQG21N1R2K10 1.2 0.47 97

50

LQG21N1R5K10 1.5 0.50 87

LQG21N1R8K10 1.8 0.57 80

LQG21N2R2K10 2.2 10MHz 45 10MHz 0.63 71

LQG21N2R7K10 2.7 0.69 66

LQG21N3R3K10 3.3 0.80 59 30

LQG21N3R9K10 3.9 0.89 53

LQG21N4R7K10 4.7 1.00 47

1

0.5

0.1

5

10

50

5051 10 100 500

Inductance (

µH)

Current (mA)

4.7µH

1.8µH

1.0µH

0.22µH

0.10µH

0.82µH

100

80

60

Q

40

20

0

4R7

1 10 100 1000

1R0

1R8

Frequency (MHz)

R10

R22

R82

10

5

0

L/L(%)

-5

-10

-20 0 20 40 60 80

Temperature (°C)

0.1µH

4.7µH

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!DIMENSIONS

Small Tolerance Chip Coil

LQS33N

Series for Oscillation Circuits

CHIP COIL

12

High Q, Magnetically Shielded Chip Coil with Tight Inductance

Tolerance (T2%), Perfect in Oscillation Circuits

The LQS33N series consists of closed, magnetically

shielded chip inductors wound on ferrite bobbins developed

by Murata.

Their high Q value virtually eliminates interference with

nearby circuits. This, combined with their tight inductance

tolerance, makes these chip inductors excellent in resonant

circuits.

!FEATURES

1. The coil's outstanding stability yields a reduction in

inductor tolerance to within T2%.

2. Its high Q (typically greater than 80) is present at all

inductance values and is the basis of this chip coil's

outstanding low loss circuit characteristics.

3. The ferrite core shielding structure both eliminates

external interference and facilitates high mounting

density.

4. Small inductance variation with respect to temperature

change makes these coils applicable in traps or LC filters

for stable frequency characteristics.

5.

This series is thin and compact, with a thickness of merely

1.8mm.

(in mm)

EIA Code:1214

1.8±0.2

+0.3

3.2

-0.2

0.7

min.

0.7

min.

min.

+0.3

-0.2

3.5

0.7

13

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!TYPICAL ELECTRICAL CHARACTERISTICS

¡Q - Frequency Characteristics ¡Inductance - Temperature Characteristics

¡Inductance - Current Characteristics

!SPECIFICATIONS

Part Number

Inductance Q

Nominal

Value(µH)

Tolerance

(%)

Test

Frequency

Peak Value

(Typ.)

Min.

Value

Test

Frequency

DC

Resistance

(Ω)

Self-resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

80

100

60

40

20

0

120

5050.1 0.5 1 10 100

Frequency (MHz)

Q

1.0µH

100µH

10µH

¡Coupling Coefficient

LQS33N1R0G(J)04 1.0 0.19T30% 120

LQS33N1R2G(J)04 1.2

85

0.22T30% 100

70

LQS33N1R5G(J)04 1.5 0.26T30% 80

LQS33N1R8G(J)04 1.8 0.28T30% 70

LQS33N2R2G(J)04 2.2 0.33T30% 60

LQS33N2R7G(J)04 2.7 0.39T30% 55

50

LQS33N3R3G(J)04 3.3 7.96 60 7.96 0.43T30% 50

LQS33N3R9G(J)04 3.9

MHz MHz

0.45T30% 45

LQS33N4R7G(J)04 4.7 0.52T30% 40

LQS33N5R6G(J)04 5.6 0.56T30% 37

30

LQS33N6R8G(J)04 6.8 90 0.62T30% 35

LQS33N8R2G(J)04 8.2 T2 0.69T30% 32 Y25

LQS33N100G(J)04 10 (T5) 0.94T30% 30 to

LQS33N120G(J)04 12 1.1 T30% 27

15

W85D

LQS33N150G(J)04 15

70

1.2 T30% 25

LQS33N180G(J)04 18 1.3 T30% 23

LQS33N220G(J)04 22 1.5 T30% 20

LQS33N270G(J)04 27

2.52 2.52

1.7 T30% 18

LQS33N330G(J)04 33

MHz

95

MHz

2.4 T30% 16

LQS33N390G(J)04 39 2.6 T30% 15

LQS33N470G(J)04 47 3.0 T30% 14 10

LQS33N560G(J)04 56 80 3.3 T30% 13

LQS33N680G(J)04 68

100

5.3 T30% 12

LQS33N820G(J)04 82 5.8 T30% 11

LQS33N101G(J)04 100 6.6 T30% 10

10

5

L/L

0

(%)

-5

-10

-20 0 20 40 60 80

Temperature (°C)

500

100

50

µH)

10

Inductance (

5

1

100µH

4.7µH

2.2µH

1.0µH

Current (mA)

47µH

22µH

10µH

505 10 100 500

10

8

6

4

2

Coupling Coefficient (%)

0

Inductance (

µH

)

100µH

1mm

501 5 10 100

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

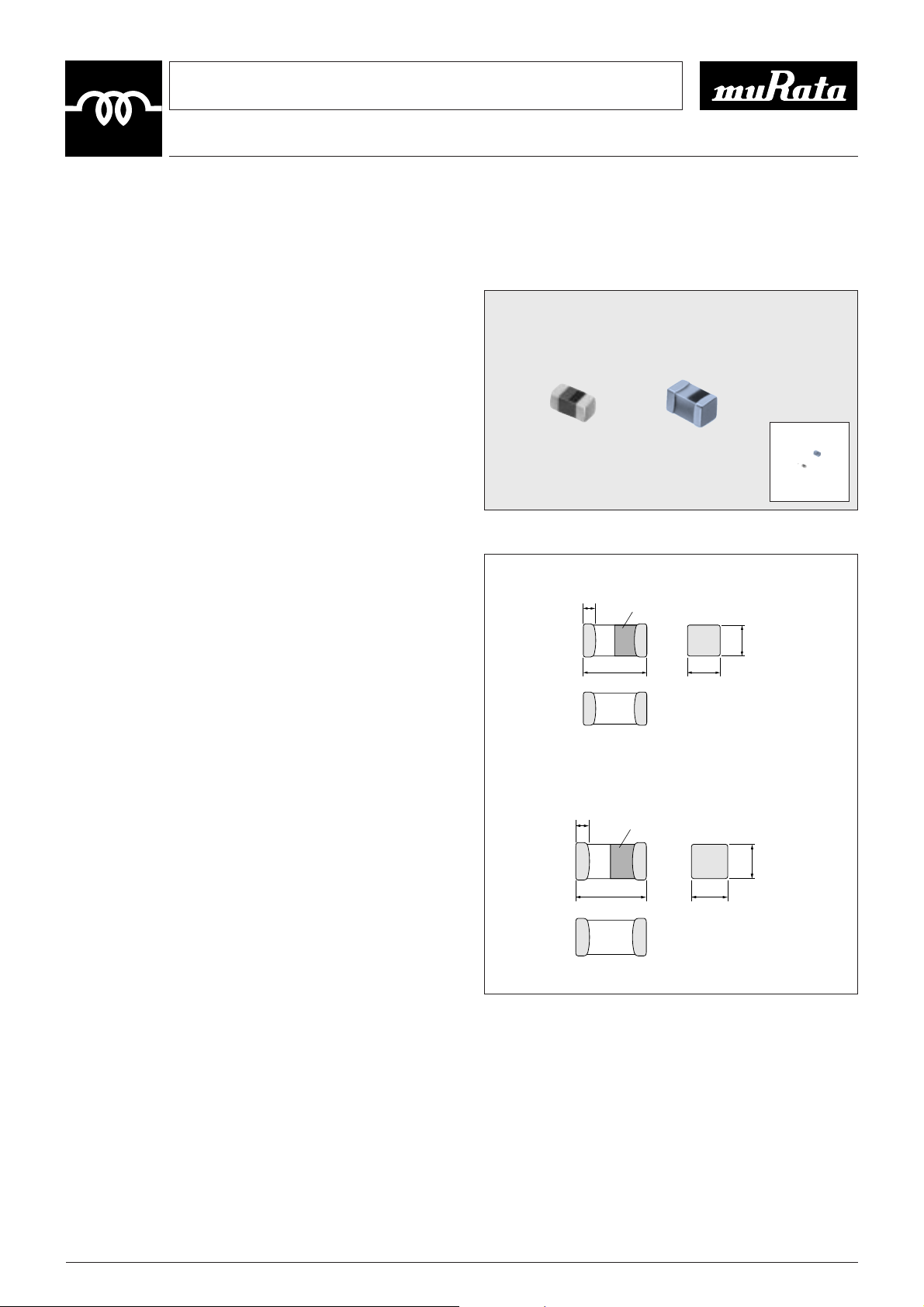

!DIMENSIONS

Multilayer Chip Inductor

LQG10A/11A

Series for High Frequency

CHIP COIL

14

High-Q, Stable Inductance in High Frequency Range Small

Size Multilayer Chip Inductor for High Frequency Range

The LQG10A/11A series are chip inductors specifically

designed for high frequency applications. The LQG10A/11A

series is designed to realize stable characteristics in high

frequency range applying integrated multilayer process. The

integrated multilayer process enables a wide range of

inductance values with tight tolerance.

!FEATURES

1. High-Q, stable inductance in high frequency is achieved

by the unique low-capacitance structure. It is suitable for

mobile communication equipment.

2. The small size of LQG10A (1.0Z0.5Z0.5mm) is ideal for

small mobile equipment.

3. The external electrodes with nickel barrier structure

provide excellent solder heat resistance.

!APPLICATIONS

¡High frequency circuit of telecommunication equipment

such as CDMA, DECT, PHS, PCS, PCN, GSM and DCS.

LQG10A

LQG11A

LQG10A LQG11A

(in mm)

EIA Code:0603

EIA Code:0402

0.25±0.1

Direection Indicator

0.5±0.1

0.3±0.2

1.0±0.1

Direction Indicator

1.6±0.15

0.5±0.1

0.8±0.15

0.8±0.15

15

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!SPECIFICATIONS

LQG10A

LQG11A

Part Number

LQG10A1N2S00

LQG10A1N5S00

LQG10A1N8S00

LQG10A2N2S00

LQG10A2N7S00

LQG10A3N3S00

LQG10A3N9S00

LQG10A4N7S00

LQG10A5N6S00

LQG10A6N8J00

LQG10A8N2J00

LQG10A10NJ00

LQG10A12NJ00

LQG10A15NJ00

LQG10A18NJ00

LQG10A22NJ00

LQG10A27NJ00

LQG10A33NJ00

Inductance Q

DC

Resistance

(Ω max.)

Self-

resonant

Frequency

(MHz min)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value

(nH)

Tolerance

Test

Frequency

(MHz)

800MHz

(typ.)

Nominal

Value

(min.)

01.2

01.5

01.8

02.2

02.7

03.3

03.9

04.7

05.6

06.8

08.2

10.0

12.0

15.0

18.0

22.0

27.0

33.0

T0.3nH

T5%

100

35

33

31

30

29

30

29

29

31

30

31

30

29

28

27

23

1GHz

(typ.)

38

34

33

32

33

32

34

33

32

31

27

24

8

Test

Frequency

(MHz)

500MHz

(typ.)

100

25

24

22

23

24

23

22

0.10

0.15

0.17

0.19

0.19

0.23

0.26

0.29

0.33

0.35

0.41

0.46

0.51

0.58

0.67

6000

5300

4200

3600

3200

2800

2300

2100

1800

1600

1500

200

Y40

to

W85

D

Inductance Q

Part Number

LQG11A1N2S00 1.2

LQG11A1N5S00 1.5

0.10

LQG11A1N8S00 1.8

LQG11A2N2S00 2.2

6000

LQG11A2N7S00 2.7 T0.3nH

LQG11A3N3S00 3.3 0.15

LQG11A3N9S00 3.9

LQG11A4N7S00 4.7

0.20

LQG11A5N6S00 5.6

5000

LQG11A6N8J(K)00 6.8

LQG11A8N2J(K)00 8.2

0.25

4000

LQG11A10NJ(K)00 10 0.30 3500

Y40

LQG11A12NJ(K)00 12

100 12 100

0.35 3000

300

to

LQG11A15NJ(K)00 15 0.40 2800

W85D

LQG11A18NJ(K)00 18 0.45 2600

LQG11A22NJ(K)00 22

T5%

0.50 2300

LQG11A27NJ(K)00 27

(T10%)

0.55 2000

LQG11A33NJ(K)00 33 0.60 1700

LQG11A39NJ(K)00 39 0.65 1500

LQG11A47NJ(K)00 47 0.70 1200

LQG11A56NJ(K)00 56 0.75 1100

LQG11A68NJ(K)00 68 0.80 1000

LQG11A82NJ(K)00 82 0.85 900

LQG11AR10J(K)00 100 0.90 800

Nominal

Value

(nH)

Tolerance

Test

Frequency

(MHz)

Nominal

Value

(min.)

Test

Frequency

(MHz)

DC

Resistance

(Ω max.)

Self-

resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp.

Range

16

!TYPICAL ELECTRICAL CHARACTERISTICS

"Q-Frequency Characteristics "Inductance - Frequency Characteristics

Measuring instrument Q : HP8720C, SMA connector

(MM1215-3CC)

Measuring instrument L : HP8720C, SMA connector

(MM1215-3CC)

LQG10A LQG10A

100

1000

10000

Frequency (MHz)

200

160

120

80

40

0

Q

3.3nH

10nH

68nH

100 1000 10000

Frequency (MHz)

1000

100

10

1

Inductance (nH)

68nH

10nH

3.3nH

LQG11A LQG11A

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

100

80

1.5nH

60

Q

40

20

0

100

33nH

1000

Frequency (MHz)

4.7nH

12nH

10000

1000

100

10

Inductance (nH)

1

100 1000 10000

33nH

12nH

Frequency (MHz)

4.7nH

1.5nH

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!DIMENSIONS

Thin Film Chip Coil

LQP10A/LQP11A

Series for High Frequency

CHIP COIL

17

Tight Inductance Tolerance Chip Coil for High Frequency Application

Small Size and Tight Inductance Tolerance (T0.2nH or T2%)

The LQP10A/LQP11A series consists of chip coils with a

tight inductance tolerance (T0.2nH or T2%) achieved even

in low inductance region.

!FEATURES

1. Tight inductance tolerance (T0.2nH, T2%) realized by

thin-film technology enables assemble with no tuning.

2. High self resonant frequency due to low stray capacitance

and close inductance distribution provide stable

inductance in high frequency circuit such as

telecommunication equipment.

3. The external electrodes with nickel barrier structure

provide excellent solder heat resistance.

¡LQP10A

Ultra-Small size 0402 inductor which is low, and lightest

weight (half of multilayer type) in the world enables to

miniaturize mobile telephone.

¡LQP11A

Small size of 0603 (LQP11A) is suitable for small hand

held equipment, especially for card size equipment.

!APPLICATIONS

¡High frequency circuit of telecommunication equipment,

such as DECT, PHS, PCS, PCN, GSM, DCS and CDMA.

¡Impedance Matching—Power-AMP Module (PA), SAW

filter

¡Resonance circuits—VCO

The appearance of coil pattern depends on the part number.

LQP11ALQP10A

1.6±0.15

0.2 min.

0.8±0.15

0.5T0.1

1.0T0.15

0.25T0.1

0.5T0.15

0.35T0.1

1.6±0.15

0.2 min.

0.8±0.15

0.5T0.1

1.0T0.15

0.25T0.1

0.5T0.15

0.35T0.1

Use plastic tweezers when treating with tweezers.

LQP10A

LQP11A

(in mm)

EIA Code : 0603

EIA Code : 0402

18

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!SPECIFICATIONS

LQG10A

Part Number

LQP10A1N0B(C)00

LQP10A1N1B(C)00

LQP10A1N2B(C)00

LQP10A1N3B(C)00

LQP10A1N5B(C)00

LQP10A1N6B(C)00

LQP10A1N8B(C)00

LQP10A2N0B(C)00

LQP10A2N2B(C)00

LQP10A2N4B(C)00

LQP10A2N7B(C)00

LQP10A3N0B(C)00

LQP10A3N3B(C)00

LQP10A3N6B(C)00

LQP10A3N9B(C)00

LQP10A4N3B(C)00

LQP10A4N7B(C)00

LQP10A5N1B(C)00

LQP10A5N6B(C)00

LQP10A6N2B(C)00

LQP10A6N8B(C)00

LQP10A7N5B(C)00

LQP10A8N2B(C)00

LQP10A9N1B(C)00

LQP10A10NG(J)00

LQP10A12NG(J)00

LQP10A15NG(J)00

LQP10A18NG(J)00

LQP10A22NG(J)00

LQP10A27NG(J)00

LQP10A33NG(J)00

Inductance Q

DC

Resistance

(Ω max.)

Self-resonant

Frequency

(MHz min)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value

(nH)

Tolerance

Test

Frequency

(MHz)

Typical

@1GHz

Min.

Value

1.0

1.1

1.2

1.3

1.5

1.6

1.8

2.0

2.2

2.4

2.7

3.0

3.3

3.6

3.9

4.3

4.7

5.1

5.6

6.2

6.8

7.5

8.2

9.1

10.0

12.0

15.0

18.0

22.0

27.0

33.0

T0.1nH

(T0.2nH)

T2%

(T5%)

500

50

45

40

35

30

28

29

26

25

22

21

13

Test

Frequency

(MHz)

500

0.1

0.2

0.3

0.2

0.3

0.4

0.5

0.6

0.7

0.9

1.1

1.3

1.6

1.8

2.0

2.6

3.1

3.8

6000

5500

4500

3700

3300

3100

2800

2500

2100

400

390

280

220

280

220

190

170

160

140

130

110

100

90

80

70

60

Y40

to

W85D

19

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

LQG11A

Part Number

LQP11A1N3C00

LQP11A1N5C00

LQP11A1N8C00

LQP11A2N2C00

LQP11A2N7C00

LQP11A3N3C00

LQP11A3N9C00

LQP11A4N7C00

LQP11A5N6C00

LQP11A6N8C00

LQP11A8N2C00

LQP11A10NG00

LQP11A12NG00

LQP11A15NG00

LQP11A18NG00

LQP11A22NG00

LQP11A27NG00

LQP11A33NG00

LQP11A39NG00

LQP11A47NG00

LQP11A56NG00

LQP11A68NG00

LQP11A82NG00

LQP11AR10G00

Inductance Q

DC

Resistance

(Ω max.)

Self-resonant

Frequency

(MHz min)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value

(nH)

Tolerance

Test

Frequency

(MHz)

Peak

Value

(Typ.)

Min.

Value

01.3

01.5

01.8

02.2

02.7

03.3

03.9

04.7

05.6

06.8

08.2

10.0

12.0

15.0

18.0

22.0

27.0

33.0

39.0

47.0

56.0

68.0

82.0

100.00

T0.2nH

T2%

500

160

140

120

100

190

185

180

175

165

163

157

155

150

143

139

138

132

130

128

126

128

1

27

125

17

Test

Frequency

(MHz)

500

300

0.3

0.4

0.5

0.6

0.7

0.8

1.0

1.3

1.5

1.9

2.4

2.8

2.2

3.4

3.5

4.6

6.1

6000

5900

5200

4700

4300

3600

3400

3000

2700

2300

2100

1900

1700

1400

1200

1000

900

800

700

300

250

200

150

100

50

Y40

to

W85D

20

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!TYPICAL ELECTRICAL CHARACTERISTICS

"Q-Frequency Characteristics "Inductance - Frequency Characteristics

LQP10A

LQP11A

LQP10A

LQP11A

100

80

60

Q

40

20

0

100 1000 10000

200

160

120

Q

80

40

0

100 1000 10000

Frequency (MHz)

33nH

100nH

Frequency (MHz)

2.2nH

4.7nH

8.2nH

15nH

33nH

15nH

68nH

6.8nH

1.5nH

3.3nH

100

10

1

100 1000 10000

1000

100

Inductance (nH) Inductance (nH)

10

1

100 1000 10000

33nH

15nH

8.2nH

4.7nH

2.2nH

Frequency (MHz)

100nH

68nH

33nH

15nH

Frequency (MHz)

6.8nH

3.3nH

1.5nH

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

Wire Wound Chip Coil

LQW1608A

Series for High Frequency

CHIP COIL

21

!DIMENSIONS

High-Q and Tight Inductance Tolerance (T0.2nH or T2%)

Ultra Small Wire Wound Air-core Chip Coil

The LQW1608A series which consists of air-core chip coil

using a miniature alumina core.

The tight inductance tolerance (T0.2nH, T2%) is available

due to Murata's original winding technology. The series has

high Q value and high self resonant frequency in high

frequency range. It is suitable for high frequency circuits

which are used in telecommunication equipment.

!FEATURES

1. Horizontal winding structure enables tight inductance

tolerance (T0.2nH, T2%). Stable circuit operation is

possible.

2. Broad range of inductance (3.9nH to 220nH).

3. The subminiature dimensions (1.6Z0.8mm) allow high

density mounting.

4. The high self resonant frequency realizes high-Q value

and stable inductance at high frequency.

5. Low DC resistance design is ideal for low loss, high

output and low power consumption.

4. Resin-coated surface enables excellent mounting.

!APPLICATIONS

¡High frequency circuit in telecommunication equipment,

such as DECT, PHS, PCS, PCN, GSM and CDMA.

¡Impedance Matching—Power-AMP Module (PA), SAW

filter

¡Resonance circuits—VCO

1.6T0.2 0.8T0.3

0.8T0.2

0.2T0.1

0.3T0.1 0.3T0.1

0.4max.

(in mm)

22

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!SPECIFICATIONS

Part Number

LQW1608A2N2D00

LQW1608A3N6D(C)00

LQW1608A3N9D(C)00

LQW1608A4N3D(C)00

LQW1608A4N7D00

LQW1608A5N6D(C)00

LQW1608A6N2D(C)00

LQW1608A6N8D(C)00

LQW1608A7N5D00

LQW1608A8N2D00

LQW1608A8N7D00

LQW1608A9N1D00

LQW1608A9N5D00

LQW1608A10NJ(G)00

LQW1608A11NJ(G)00

LQW1608A12NJ(G)00

LQW1608A13NJ(G)00

LQW1608A15NJ(G)00

LQW1608A16NJ(G)00

LQW1608A18NJ(G)00

LQW1608A20NJ(G)00

LQW1608A22NJ(G)00

LQW1608A24NJ(G)00

LQW1608A27NJ(G)00

LQW1608A30NJ(G)00

LQW1608A33NJ(G)00

LQW1608A36NJ(G)00

LQW1608A39NJ(G)00

LQW1608A43NJ(G)00

LQW1608A47NJ(G)00

LQW1608A51NJ(G)00

LQW1608A56NJ(G)00

LQW1608A62NJ(G)00

LQW1608A68NJ(G)00

LQW1608A72NJ(G)00

LQW1608A75NJ(G)00

LQW1608A82NJ(G)00

LQW1608A91NJ(G)00

LQW1608AR10J(G)00

LQW1608AR11J(G)00

LQW1608AR12J(G)00

LQW1608AR13J(G)00

LQW1608AR15J(G)00

LQW1608AR16J(G)00

LQW1608AR18J(G)00

LQW1608AR20J(G)00

LQW1608AR22J(G)00

Inductance Q

DC

Resistance

(Ω max.)

Self-

resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value

(nH)

Tolerance

Test

Frequency

(MHz)

800

(MHz)

Typical

1.5

(GHz)

Typical

Nominal

Value

(min.)

102.2

103.6

103.9

104.3

104.7

105.6

106.2

106.8

107.5

108.2

108.7

109.1

109.5

110.6

111.6

112.6

113.6

115.6

116.6

118.6

120.6

122.6

124.6

127.6

130.6

133.6

136.6

139.6

143.6

147.6

151.6

156.6

162.6

168.6

172.6

175.6

182.6

191.6

100.6

110.6

120.6

130.6

150.6

160.6

180.6

200.6

220.6

T0.5nH

T0.5nH

(T0.2nH)

T0.5nH

T0.5nH

(T0.2nH)

T0.5nH

T5%

(T2%)

100

80

75

80

85

90

85

80

75

70

65

60

110

95

100

105

95

90

75

60

55

50

Y

16

25

35

40

38

34

32

25

Test

Frequency

(MHz)

300

(MHz)

Typical

250

200

150

100

45

50

55

50

45

0.049

0.059

0.082

0.11

0.13

0.16

0.17

0.21

0.23

0.26

0.29

0.33

0.35

0.51

0.38

0.56

0.60

0.64

0.68

1.2

1.3

1.4

1.5

2.1

2.2

2.4

2.5

6000

5500

4900

4600

3800

3700

3300

3200

2900

2800

2700

2600

2500

2400

2300

2200

2100

2050

2000

1900

1800

1350

1600

1450

1400

1350

1300

1250

1200

700

850

750

650

600

550

500

440

420

400

380

370

360

280

340

270

250

230

220

200

180

170

160

150

140

120

Y25

to

W85

D

23

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!TYPICAL ELECTRICAL CHARACTERISTICS

"Q-Frequency Characteristics "Inductance - Frequency Characteristics

Measuring instrument Q : HP4291A + 16193A Measuring instrument L : HP4291A + 16193A

160

140

120

100

Q

80

60

40

20

0

10 100 1000 10000

Frequency (MHz)

8.7nH

20nH

47nH

110nH

220nH

1000

100

Inductance (nH)

10

1

10 100 1000 10000

Frequency (MHz)

220nH

100nH

470nH

20nH

8.7nH

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

Wire Wound Chip Coil

LQN21A/LQN1A

Series for High Frequency

CHIP COIL

24

!DIMENSIONS

Small Winding-type Air-core Chip Coil with High Q

value at High Frequencies and Low DC Resistance

The LQN21A/LQN1A series consists of air-core chip coil

using a sub-miniature alumina core as a bobbin. The high Q

value at high frequencies and high self-resonant frequencies

make this coil perfect for use in the high frequency circuits

of communications equipment.

!FEATURES

1. LQN21A series covers inductance range from 3.3nH to

470nH.

2. Their high self-resonant frequency characteristic yields a

high Q value and highly stable inductance at high

frequencies.

3. Low DC resistance design enables to handle higher

allowable current.

4. The series has excellent solder heat resistance.

Both flow and reflow soldering methods can be employed.

¡LQN21Axxxx04

Inductance tolerance T0.5nH (8.2nH max.), T5% (10nH

to 220nH) and T10% (270nH to 470nH) are realized.

The sub miniature dimensions (2.0Z1.5mm) allow high

density mounting.

¡LQN21A (Tight inductance tolerance)

Tight inductance tolerance of T2% is available.

¡LQN21Axxxx44

LQN21Axxxx44 using thick wire (f0.12mm) has higher Q

value than existing LQN21A series. Low DC resistance

design enables to handle higher current.

LQN21Axxxx44 covers inductance range from 2.7nH to

27nH.

¡LQN1A

Miniature size (3.2Z1.6Z1.8mm) allows parallel mounting

at 2.5mm pitch.

Inductance tolerance T5% realized.

!APPLICATIONS

¡High frequency circuit in telecommunication equipment,

such as DECT, PHS, PCS, PCN, GSM and CDMA.

¡Impedance Matching—Power-AMP Module (PA), SAW

filter

¡Resonance circuits—VCO

LQN1ALQN21A

2.0T0.2

0.5

min.

0.5

min.

0.5

min.

1.5T0.2

1.5T0.2

1.7

1.5T0.2

W0.08

Y0.1

2.3T0.2 1.6T0.2

3.2T0.3

1.8T0.2

1.6T0.2

0.7

min.

0.7

min.

0.7

min.

LQN21A

LQN1A

EIA Code : 0805

EIA Code : 1206

(in mm)

25

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!SPECIFICATIONS

LQN21Axxxx04

LQN21A (Tight inductance tolerance)

Part Number

LQN21A3N3D04

LQN21A6N8D(K)04

LQN21A8N2D(K)04

LQN21A10NJ(K)04

LQN21A12NJ(K)04

LQN21A15NJ(K)04

LQN21A18NJ(K)04

LQN21A22NJ(K)04

LQN21A27NJ(K)04

LQN21A33NJ(K)04

LQN21A39NJ(K)04

LQN21A47NJ(K)04

LQN21A56NJ(K)04

LQN21A68NJ(K)04

LQN21A82NJ(K)04

LQN21AR10J(K)04

LQN21AR12J(K)04

LQN21AR15J(K)04

LQN21AR18J(K)04

LQN21AR22J(K)04

LQN21AR27K04

LQN21AR33K04

LQN21AR39K04

LQN21AR47K04

Inductance

Q *1

DC

Resistance

(Ω max.)

*2

Self-resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value

(nH)

Tolerance

Test

Frequency

(MHz)

Peak Value

(Typ.)

Min.

Value

Test

Frequency

(MHz)

113.3

116.8

118.2

110

112

115

118

122

127

133

139

147

156

168

182

100

120

150

180

220

270

330

390

470

T0.5nH

T0.5nH

(T10%)

T5%

(T10%)

T10%

100

10

70

80

65

70

65

80

65

70

65

60

70

50

45

50

10

20

30

40

30

35

15

250

200

150

100

25.2

0.05

0.11

0.12

0.03

0.11

0.12

0.10

0.09

0.17

0.15

0.09

0.23

0.26

0.23

0.42

0.38

0.40

0.47

0.71

0.70

2.00

2.20

2.50

2.80

6000

5400

3900

3300

3200

2700

2600

2100

2300

1900

1700

1600

1500

1200

1100

1900

1750

1350

1700

1500

1550

1500

1400

1350

1910

1680

1630

1320

1680

1630

1690

1720

1540

1570

1730

1450

1430

1460

1320

1350

1320

1390

1250

1240

1190

1180

1170

1160

Y25

to

W85

D

Part Number

Inductance

Q *1

DC

Resistance

(Ω max.)

*2

Self-resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value

(nH)

Tolerance

Test

Frequency

(MHz)

Peak Value

(Typ.)

Min.

Value

Test

Frequency

(MHz)

133

139

147

156

168

182

100

120

150

180

220

T2%

100

65

80

65

70

65

60

55

50

55

50

40

35

40

30

35

250

200

150

100

0.15

0.09

0.23

0.26

0.23

0.42

0.55

0.40

0.68

0.71

0.70

1900

1700

1600

1500

1200

1100

1900

1750

1350

1700

1500

570

730

450

430

460

320

270

320

260

250

240

Y25

to

W85

D

LQN21A33NG04

LQN21A39NG04

LQN21A47NG04

LQN21A56NG04

LQN21A68NG04

LQN21A82NG04

LQN21AR10G04

LQN21AR12G04

LQN21AR15G04

LQN21AR18G04

LQN21AR22G04

*1 Measured with LCR meter YHP4191A, measuring tap 16193A.

*2 Measured with Network Analyzer HP8753C.

26

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

LQN21Axxxx44

LQN1A

Part Number

Inductance Q

DC

Resistance

(Ω max.)

Self-

resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value

(nH)

Tolerance

Test

Frequency

(MHz)

Nominal

Value

(min.)

Test

Frequency

(MHz)

800MHz

(Typ.)

12.7

13.1

13.3

15.6

16.8

18.6

10.8

12.8

15.8

18.8

21.8

27.8

T0.5nH

T5%

T10%

100

20

35

40

250

185

195

185

100

105

195

1.5GHz

(Typ.)

120

110

115

100

90

75

65

45

0.02

0.03

0.04

0.05

0.06

6000

5400

3900

3300

3200

3100

2600

2200

1800

1900

1800

1700

1500

1400

1300

1320

1100

1000

1950

1900

Y25

to

W85

D

LQN21A2N7D44

LQN21A3N1D44

LQN21A3N3D44

LQN21A5N6D44

LQN21A6N8D44

LQN21A8N6D44

LQN21A10NJ44

LQN21A12NK44

LQN21A15NK44

LQN21A18NK44

LQN21A21NK44

LQN21A27NK44

Part Number

Inductance Q

DC

Resistance

(Ω)

Self-resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (nH)

Tolerance

(%)

Test

Frequency

Peak Value

(Typ.)

Min.

Value

Test

Frequency

118.8

114.7

117

123

127

133

139

147

156

164

184

100

T5

(T10)

100MHz

100

190

180

170

50

60

436MHz

0.029T40%

0.035T40%

0.037T40%

0.046T40%

0.051T40%

0.057T40%

0.067T40%

0.110T40%

0.140T40%

0.180T40%

0.280T40%

0.300T40%

1000

1900

750

680

650

590

560

530

490

380

330

290

240

230

Y25

to

W85D

LQN1A8N8J(K)04

LQN1A15NJ(K)04

LQN1A17NJ(K)04

LQN1A23NJ(K)04

LQN1A27NJ(K)04

LQN1A33NJ(K)04

LQN1A39NJ(K)04

LQN1A47NJ(K)04

LQN1A56NJ(K)04

LQN1A64NJ(K)04

LQN1A84NJ(K)04

LQN1AR10J(K)04

27

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

"Inductance-Frequency Characteristics

!TYPICAL ELECTRICAL CHARACTERISTICS

"Q-Frequency Characteristics

LQN21Axxxx44

LQN21Axxxx04

100

80

60

Q

40

20

0

1 105 50 500 5000100 1000 10000

330nH

470nH

220nH

Frequency (MHz)

LQN21Axxxx44

150

120

90

Q

60

3.3nH

12nH

33nH

10nH

100

50

40

30

Inductance (nH)

20

10

0

10 10050 500 50001000 10000

Frequency (MHz)

27nH

12nH

3.3nH

30

0

10 10050 500 50001000 10000

Frequency (MHz)

27nH

LQN1A

120

100

80

Q

60

40

20

0

10 50 100 500 1000 5000

Frequency (MHz)

39nH

100nH

8.8nH

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

High Q Chip Coil

LQN1H

for High Frequency

CHIP COIL

28

!DIMENSIONS

Wire Wound Chip Coil with High Q from

30MHz to 150MHz and Stable Inductance

The LQN1H series consists of wire wound chip coils

which use ferrite cores for high frequency application. Their

high Q values from 30MHz to 150MHz and low DC

resistance make them suitable in high-frequency resonator

circuits.

!FEATURES

1. Same dimensions as LQN1A/LQH1N/LQH1C series

enables design flexibility.

2. Broad range of inductance 54 to 880nH.

3. High Q value and stable inductance at high frequency

(30MHz to 150MHz).

4. Both flow and reflow soldering methods are applicable

due to excellent solder heat resistance.

5. Miniature size (3.2Z1.6Z1.8mm) allows parallel mounting

at 2.5mm pitch.

!APPLICATIONS

¡Voltage controlled oscillators, traps, and filter circuits in

mobile communication equipments, cordless phones,

various radio equipment, FM radio turners, TV turners

(VHF low), VIF circuits.

!TYPICAL ELECTRICAL CHARACTERISTICS

¡Q-Frequency Characteristics

!SPECIFICATIONS

(in mm)

EIA Code : 1206

Part Number

Inductance Q

DC

Resistance

(Ω)

Self-resonant

Frequency

(MHz min.)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (nH)

Tolerance

(%)

Test

Frequency

Peak Value

(Typ.)

Min.

Value

Test

Frequency

154

195

145

215

290

390

500

610

750

880

T10

T10

(T5)

1MHz

65

75

80

85

90

50

60

100MHz

0.035T30%

0.047T30%

0.061T30%

0.115T30%

0.175T30%

0.265T30%

0.445T30%

0.485T30%

0.795T30%

0.865T30%

800

650

500

430

360

300

270

240

220

200

920

790

700

520

420

330

260

250

190

180

Y25

to

W85

D

LQN1H54NK04

LQN1H95NK04

LQN1HR14K(J)04

LQN1HR21K(J)04

LQN1HR29K(J)04

LQN1HR39K(J)04

LQN1HR50K(J)04

LQN1HR61K(J)04

LQN1HR75K(J)04

LQN1HR88K(J)04

2.3T0.2 1.6T0.2

100

80

60

Q

40

20

0

1 5 10 50 100 500 1000

Frequency (MHz)

R21

R88

54N

3.2T0.3

0.7

0.7

min.

min.

1.6T0.2

0.7

min.

1.8T0.2

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

Miniature Chip Coil

LQH1C/LQH3C/LQH4C

Series for Power Line Choke

CHIP COIL

29

!DIMENSIONS

Miniature Chip Coil for Power Line Choke Has High Current

Capacity, Low DC Resistance, Large Inductance

The LQH1C, LQH3C and LQH4C series consist of

miniature chip coils with low DC resistance, high current

capacity, and high impedance characteristics.

These features are made possible by the development of

Murata's innovative automatic winding techniques. They are

excellent for use as choke coils in DC power supply circuits.

!FEATURES

1. The LQH1C, LQH3C and LQH4C series have an open

magnetic structure. The series have a combined

inductance range of 0.12µH to 560µH and are applicable

in a wide variety of applications.

2. The series exhibit low voltage drops and small variations

in inductance with respect to temperature rise and DC

current level. This makes them excellent for use as power

supply line choke coils.

3. The series has excellent solder heat resistance. Both flow

and reflow soldering methods can be employed.

¡LQH1C

Miniature size (3.2Z1.6Z1.8mm) allows parallel mounting

at 2.5mm pitch. Despite their small size, at 0.12µH these

coils have a maximum current rating of 970mA.

¡LQH3C

The low DC resistance means high current and high

inductance.

For inductance ranging from 0.15µH to 10µH, LQH3C

coils have very low DC resistance.

¡LQH4C

The LQH4C has miniature size 4.5mmZ3.2mm and

realized low height 2.8mm max.

LQH1C Type LQH3C Type LQH4C Type

LQH1C Type

LQH3C

xx24 Series

LQH3C

xx34 Series

EIA Code : 1206

EIA Code : 1210

EIA Code : 1210

LQH4C Type

2.3±0.2

3.2±0.3

0.7

min.

0.7

min.

0.7

min.

1.6±0.2

1.8±0.2

1.6±0.2

0.7

min.

0.7

min.

0.7

min.

2.5±0.2

3.2±0.3

2.5±0.2

2.0±0.2

2.5±0.2

2.5±0.2

3.2±0.3

0.9

±0.3

1.3

±0.2

0.9

±0.3

2.5±0.2

2.0±0.2

2.5±0.2

3.6±0.2

4.5±0.3

2.6±0.2

3.2±0.2

3.2±0.2

1.0

min.

3.2±0.2

1.0

min.

1.0

min.

EIA Code : 1812

(in mm)

30

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!SPECIFICATIONS

LQH1C

LQH3C

LQH4C

Part Number

Inductance

Self-resonant Frequency (MHz)

DC

Resistance

(Ω)

Typ.

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (µH)

Tolerance

(%)

Test

Frequency

100.15

100.27

100.47

101.0

102.2

104.7

110

101.0

102.2

104.7

110

122

147

100

220

330

390

470

560

T20

T10

T20

T10

1MHz

1kHz

10.028T30%

10.034T30%

10.042T30%

10.060T30%

10.097T30%

10.150T30%

10.300T30%

10.090T30%

10.130T30%

10.200T30%

10.440T30%

10.710T30%

11.310T30%

13.510T30%

18.410T30%

10.010T30%

17.010T30%

19.010T30%

22.010T30%

680

490

370

200

120

177

150

150

100

166

140

127

119

113

108.5

107.0

106.6

106.2

105.7

Min.

400

250

150

100

164

143

126

196

164

143

126

119

115

110

106.8

105.6

105.0

1450

1250

1100

1000

1790

1650

1450

1800

1600

1450

1300

1250

1170

1100

1170

1160

Y25

to

W85

D

LQH3CR15M24

*

LQH3CR27M24

*

LQH3CR47M24

*

LQH3C1R0M24

*

LQH3C2R2M24

*

LQH3C4R7M24

*

LQH3C100K24

*

LQH3C1R0M34

LQH3C2R2M34

LQH3C4R7M34

LQH3C100K34

LQH3C220K34

LQH3C470K34

LQH3C101K34

LQH3C221K34

LQH3C331K34

LQH3C391K34

LQH3C471K34

LQH3C561K34

Part Number

Inductance

Self-resonant Frequency (MHz)

DC

Resistance

(Ω)

Typ.

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (µH)

Tolerance

(%)

Test

Frequency

100.12

100.22

100.47

101.0

102.2

104.7

110

122

147

100

T20

T10

1MHz

10.08T40%

10.10T40%

10.15T40%

10.28T30%

10.41T30%

10.65T30%

11.30T30%

13.00T30%

18.00T30%

12.00T30%

900

570

310

190

110

167

142

126

118

112

Min.

250

180

100

150

131

120

114

110

117

970

850

700

510

430

340

230

160

100

180

Y25

to

W85

D

LQH1CR12M04

LQH1CR22M04

LQH1CR47M04

LQH1C1R0M04

LQH1C2R2M04

LQH1C4R7M04

LQH1C100K04

LQH1C220K04

LQH1C470K04

LQH1C101K04

Part Number

Inductance

Self-resonant

Frequency (MHz)

DC

Resistance

(Ω max.)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (µH)

Tolerance

(%)

Test

Frequency

101.0

101.5

102.2

103.3

104.7

106.8

110

115

122

133

147

168

100

150

220

330

470

T20

T10

1MHz

1kHz

0.08

0.09

0.11

0.13

0.15

0.20

0.24

0.32

0.62

1.02

1.12

1.72

2.22

3.52

4.02

6.82

8.52

100

185

160

147

135

130

123

120

115

112

110

108.4

106.8

105.5

104.5

103.6

103.0

1080

1000

1900

1800

1750

1720

1650

1570

1420

1310

1280

1220

1190

1130

1110

1100

1090

Y25

to

W85D

LQH4C1R0M04

LQH4C1R5M04

LQH4C2R2M04

LQH4C3R3M04

LQH4C4R7M04

LQH4C6R8M04

LQH4C100K04

LQH4C150K04

LQH4C220K04

LQH4C330K04

LQH4C470K04

LQH4C680K04

LQH4C101K04

LQH4C151K04

LQH4C221K04

LQH4C331K04

LQH4C471K04

*Low DC Resistance type.

31

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

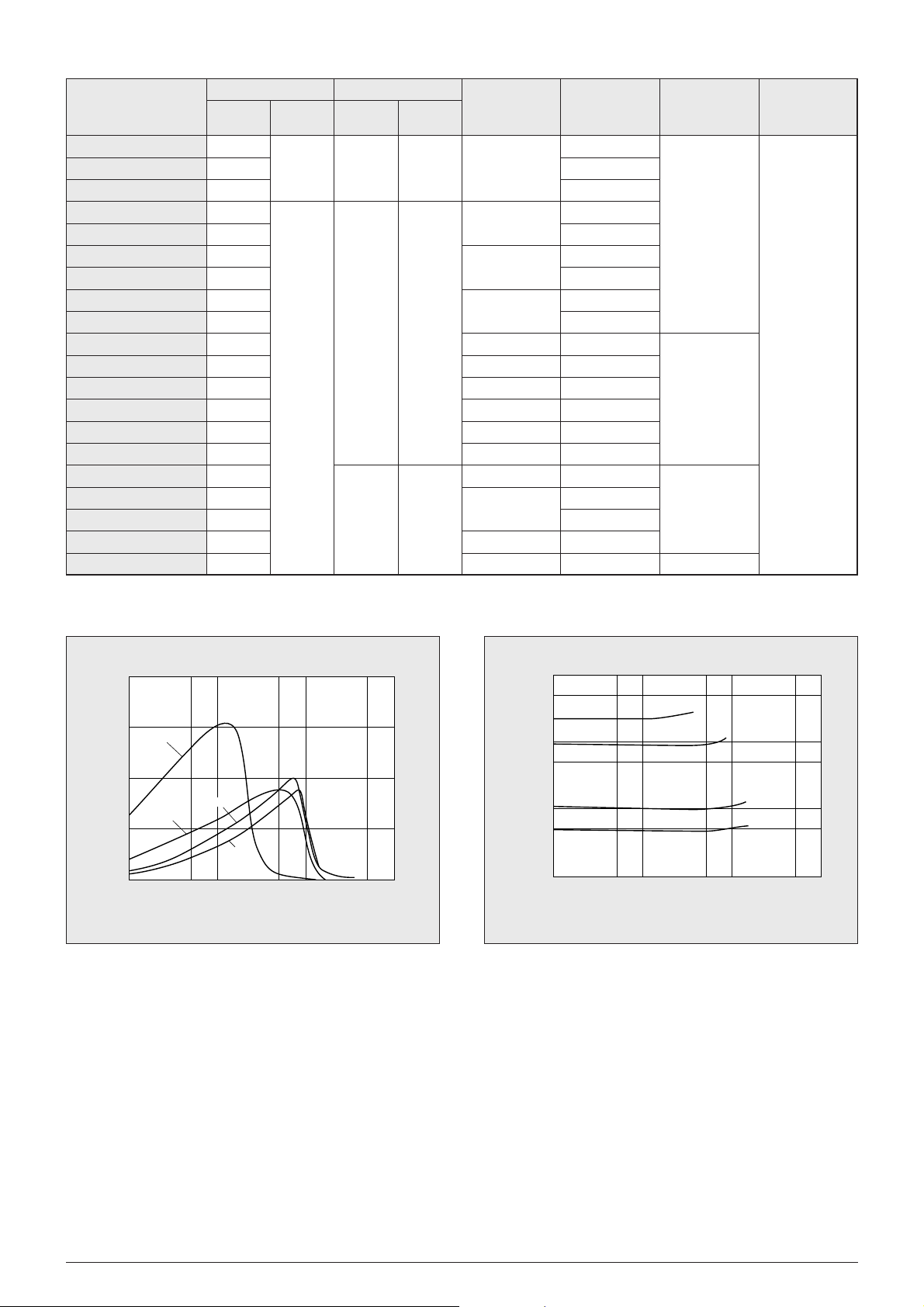

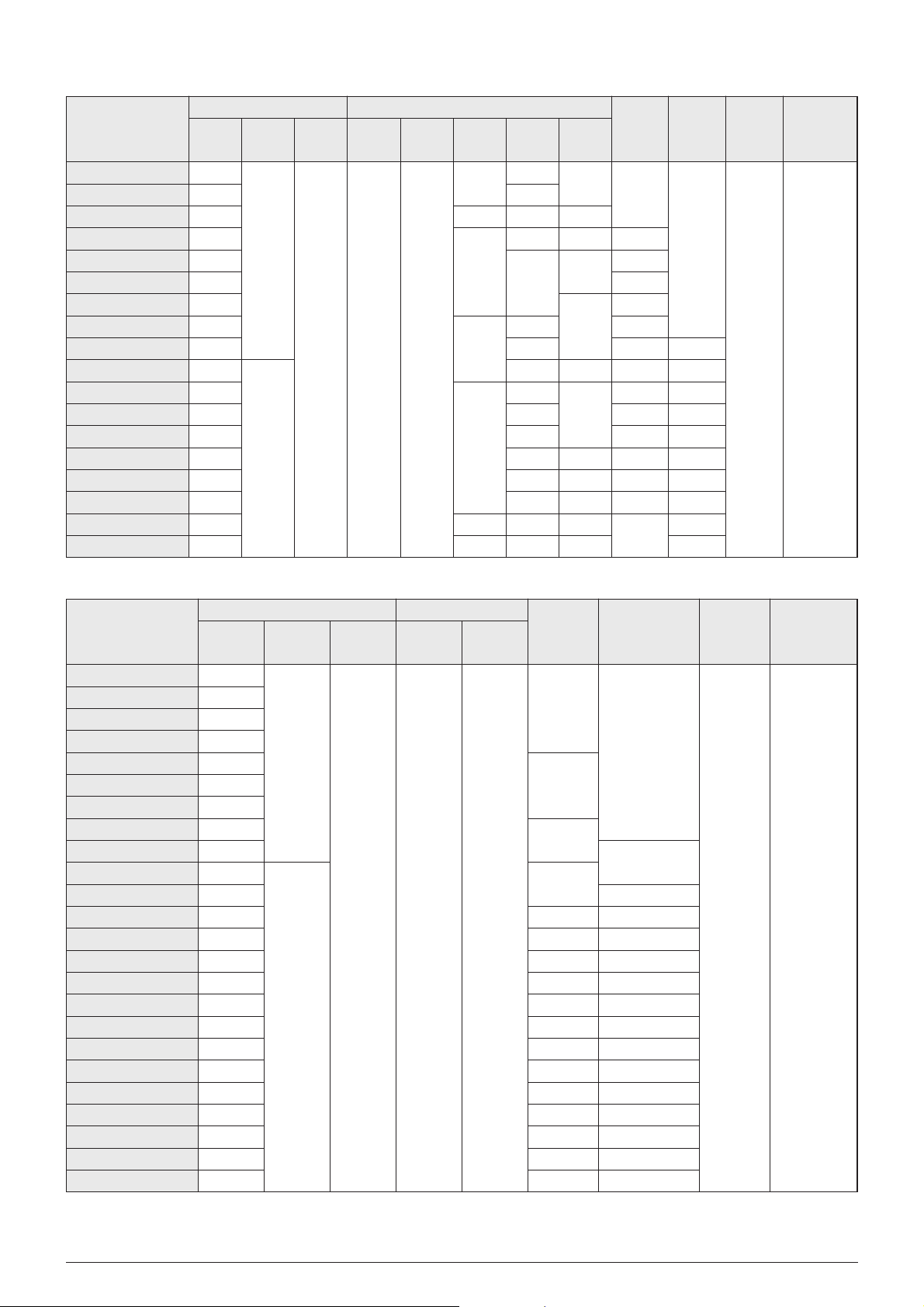

!TYPICAL ELECTRICAL CHARACTERISTICS

"Direct Current Characteristics

!TYPICAL ELECTRICAL CHARACTERISTICS

"Impedance - Frequency Characteristics

1000

100

10

1

0.1

0.01

0.01 0.1 1

Fequency (MHz)

Impedance (kΩ)Impedance (kΩ)

10 100 1000

1000

100

10

1

0.1

0.01

0.01 0.1 1

Fequency (MHz)

Impedance (kΩ)

Fequency (MHz)

10 100 1000

1.0µH

100µH

10µH

1.0µH

100µH

10µH

0.01 0.1 1 10010

100

1000

10

1

0.1

0.01

1000

1.0µH

100µH

10µH

LQH1C

LQH3C

LQH4C

LQH1C

LQH3C

LQH4C

100µH

10µH

1.0µH

5 10 50

DC Current (mA)

100µH

10µH

1.0µH

100 500

1000

100

Inductance (µH)

100

10

Inductance (µH)

1

10

1

0.1

101

DC Current (mA)

1000

100

10

Inductance (µH)

1

0.1

1 10 100 100001000

DC Current (mA)

100 1000

100µH

10µH

1.0µH

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

Multilayer Chip Coil

LQG21C

Series

CHIP COIL

32

!DIMENSIONS

Low DC Resistance Choke for Power Lines Has

Magnetically Shielded Structure

The LQG21C series consists of magnetically shielded

chip coil developed with original Murata multilayer process

technology and incorporating magnetic materials. It has less

than half the DC resistance of our conventional multilayer

chip coils as well as high inductance.

!FEATURES

1. The inductors have very low DC resistance.

2. The series has an inductance range of 1.0µH to 47µH.

3. Magnetically shielded structure provides excellent

crosstalk characteristics.

4. Compact (2.0Z1.25mm) and lightweight.

5. Outstanding solder heat resistance. Either flow or reflow

soldering methods can be employed.

!APPLICATIONS

¡Power lines (for choke use)

!TYPICAL ELECTRICAL CHARACTERISTICS

¡Impedance-Frequency Characteristics

!SPECIFICATIONS

Part Number

Inductance

Self-resonant Frequency (MHz)

DC

Resistance

(Ω max.)

Typ.

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (µH)

Tolerance

(%)

Test

Frequency

1.0

2.2

4.7

10.0

22.0

47.0

T30

1MHz

0.10

0.17

0.30

0.50

0.65

1.20

150

100

70

45

20

-

Min.

75.0

50.0

35.0

24.0

16.0

07.5

60

40

30

15

13

07

Y40

to

W85

D

LQG21C1R0N00

LQG21C2R2N00

LQG21C4R7N00

LQG21C100N00

LQG21C220N00

LQG21C470N00

Part Number

LQG21C1R0N00Y100N00

LQG21C220N00Y470N00

T

0.85T0.2

1.25T0.2

(in mm)

EIA Code : 0805

2.0T0.3 1.25T0.2

10000

1000

100

Impedance (Ω)

10

1

1 10 100 1000

47µH

22µH

10µH

4.7µH

2.2µH

1.0µH

Frequency (MHz)

0.5T0.3

T

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

Multilayer Chip Coil

LQG21F

Series

CHIP COIL

33

!DIMENSIONS

Magnetically Shielded Multilayer Chip Coil for

Choke with Excellent Direct Current Characteristics

LQG21F series consists of magnetically shielded chip

coils based on Murata's technologies of multilayer process

and magnetic materials. Excellent direct current

characteristics are realized by using magnetic materials

which have excellent saturation characteristics. The

inductance of LQG21F is four times as large as that of

conventional items.

!FEATURES

1. LQG21F series is suitable for power line choke because

of its excellent direct current characteristics. The series

has larger rated current (60mA at 10µH) than

conventional rated current.

2. Low DC resistance is realized.

3. The cross talk characteristics are excellent because of

the use of magnetically shielded structure.

4. Small size (2.0Z1.25mm) and light weight.

5. The series has excellent solder heat resistance. Both flow

and reflow soldering can be employed.

!APPLICATIONS

¡Circuits for DC power line choke of telecommunication

equipment such as DVC, digital camera, PDA, MD and

DVD-RAM.

!SPECIFICATIONS

EIA Code : 0805

(in mm)

Part Number

LQG21F1R0N00Y2R2N00

LQG21F4R7N00Y470N00

T

0.85T0.2

1.25T0.2

Part Number

Inductance

Self-resonant

Frequency

(MHz Min.)

DC

Resistance

(Ω T30%)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (µH)

Tolerance

(%)

Test

Frequency

11.0

12.2

14.7

10.0

22.0

47.0

T30

1MHz

0.20

0.28

0.30

0.50

0.35

0.60

105.5

170.5

125.5

115.5

115.5

107.5

220

150

80

60

13

7

Y40

to

W85

D

LQG21F1R0N00

LQG21F2R2N00

LQG21F4R7N00

LQG21F100N00

LQG21F220N00

LQG21F470N00

0.5±0.3

2.0±0.2

T

1.25±0.2

34

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

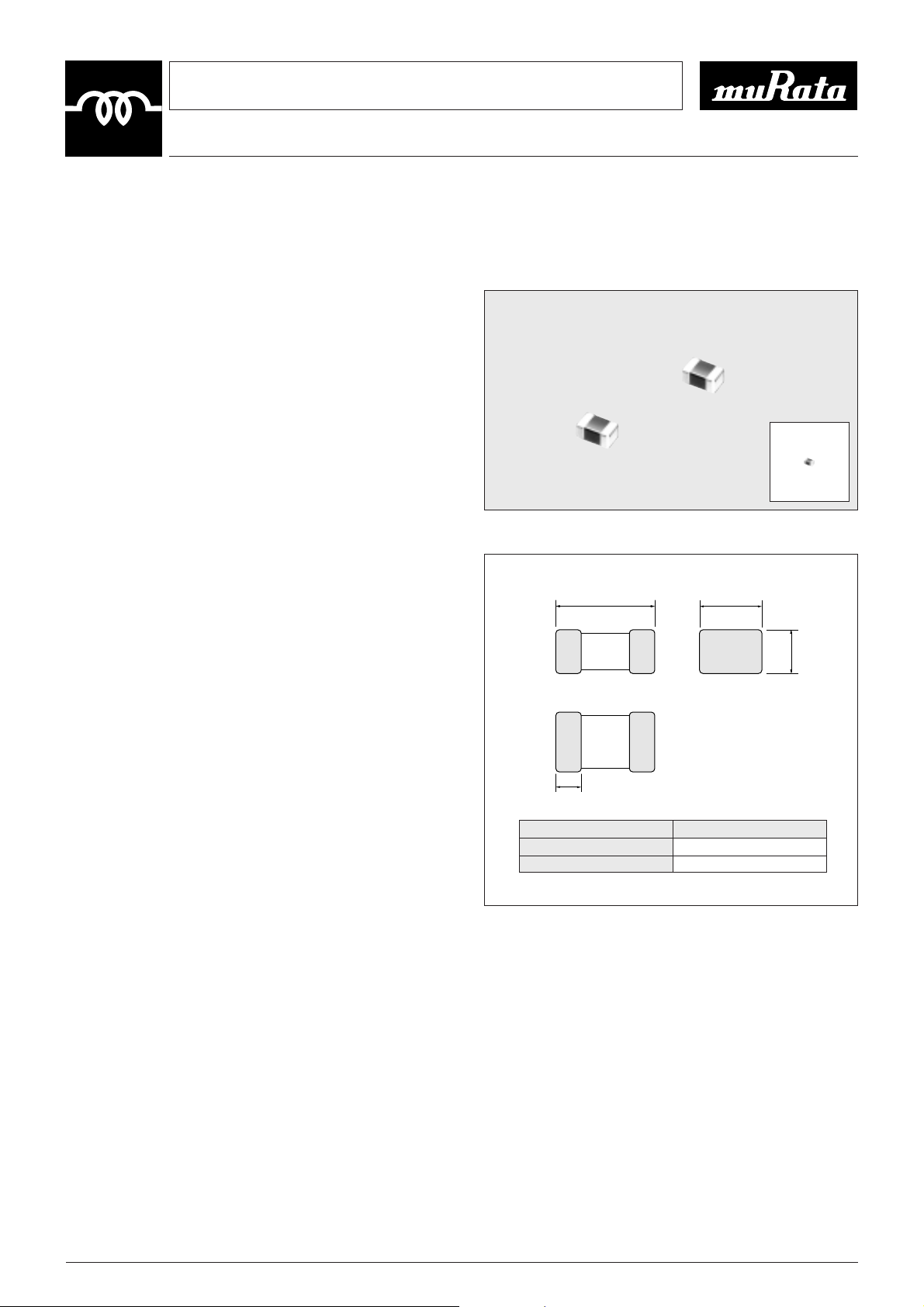

!TYPICAL ELECTRICAL CHARACTERISTICS

¡Impedance Frequency Characteristics ¡Direct Current Characteristics

100000

10000

10µH

1000

100

Impedance (Ω)

10

1

1.0µH

1 10 100 1000

22µH

47µH

4.7µH

2.2µH

Frequency (MHz) DC Current (mA)

100

47µH

22µH

10µH

10

4.7µH

2.2µH

1.0µH

Inductance (µH)

1

0.1

1 10 100 1000

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

Multilayer Chip Coil

LQG3216F

Series

CHIP COIL

35

!DIMENSIONS

Magnetically Shielded Multilayer Thin Type Chip Coil

with Excellent Direct Current Characteristics

LQG3216F series consists of magnetically shielded chip

coils based on Murata's technologies of multilayer process

and magnetic materials. Excellent direct current

characteristics and low DC resistance are realized by using

magnetic materials which have excellent saturation

characteristics and high permeability.

!FEATURES

1. LQG3216F series is suitable for power line choke

because of its excellent direct current characteristics and

large rated current. (70mA at 10µH)

2. Low DC resistance is realized.

3. The cross talk characteristics are excellent because of

magnetically shielded structure.

4. Low profile 1.0mm.

5. The series has excellent solder heat resistance. Both flow

and reflow soldering can be employed.

!APPLICATIONS

¡Circuits for DC power line choke of telecommunication

equipments such as PDA, Note-PC, digital camera, PDA,

DVC, MD and DVD-RAM.

!SPECIFICATIONS

(in mm)

Part Number

Inductance

Self-resonant

Frequency

(MHz Min.)

DC

Resistance

(Ω max.)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (µH)

Tolerance

(%)

Test

Frequency

10

T20

1MHz

0.50 20 70

Y40 to W85

D

LQG3216F100M00

0.7±0.3

3.2±0.2

0.2

±

1.0

1.6±0.2

36

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!TYPICAL ELECTRICAL CHARACTERISTICS

¡Impedance Frequency Characteristics ¡Direct Current Characteristics

10000

1000

100

100

Impedance (Ω)

10

1

1 10 100 1000

Frequency (MHz)

10

Inductance (µH)

1

1 10 100

DC Current (mA)

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

Magnetically Shielded Choke Coil

LQS33C

Series

CHIP COIL

37

!DIMENSIONS

Small Size, Low Profile and Magnetically Shielded Chip Coil for Choke

Excellent for EL Back Light Driver Circuit

!FEATURES

1. Low profile dimension (2.1mm max.) and small size of

1212 (3.3Z3.3mm) is suitable for portable equipment.

2. The series have low DC Resistance.

3. LQS33C series have large inductance of 560µH to

2200µH.

4. Magnetically shielded structure prevents interference

occurring between peripheral components.

!APPLICATIONS

¡For EL back light driver circuit

!SPECIFICATIONS

2.1 max.

3.3±0.3

3.3±0.3

0.9

±0.3

1.3

±0.2

0.9

±0.3

(in mm)

Part Number

Inductance

Self-resonant

Frequency

(MHz Min.)

DC

Resistance

(Ω T30%)

Allowable

Current

(mA)

Operating

Temp. Range

Nominal

Value (µH)

Tolerance

(%)

Test

Frequency

560

680

1000

1500

2200

T30

100kHz

110kHz

07.8

09.1

11.0

23.0

28.0

3.0

2.6

2.1

1.7

1.5

50

40

30

25

20

Y25

to

W85

D

LQS33C561N34

LQS33C681N34

LQS33C102N34

LQS33C152N34

LQS33C222N34

EIA Code : 1212

38

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

!TYPICAL ELECTRICAL CHARACTERISTICS

¡Impedance Frequency Characteristics ¡Direct Current Characteristics

1000

100

10

1

Impedance (kΩ)

0.1

0.01

10 100 1000 10000

LQS33C222N34

LQS33C102N34

LQS33C561N34

Frequency (kHz)

10000

LQS33C222N34

1000

Inductance (µH)

100

LQS33C102N34

LQS33C561N34

10

1 10 100

DC Current (mA)

This is the PDF file of catalog No.O05E-5. No.O05E5.pdf 00.3.15

Large Current Choke Coil

LQN6C/LQS66C

Series

CHIP COIL

39

!DIMENSIONS

Choke Coil for DC/DC Converters and DC Power Lines with

Low DC Resistance, Large Current Capacity and Large Inductance

The LQN6C/LQS66C series are choke coils which have

achieved low direct current resistance, large current

capacity and large inductance by using high performance

thick wire wrapping technology.

Because the LQS66C series has a shielded construction, it

can be mounted in high density without interference

occurring between peripheral components.

They are optimum for use as choke coils in DC/DC