Multiteria CS Parts List

A.

B.

C.

D.

A.

1.

2.

a.

3.

4.

5.

6.

a.

7.

8.

9.

A.

1.

a.

b.

c.

a.

b.

c.

a.

b.

c.

B.

1.

2.

3.

C.

1.

a.

b.

c.

2.

3.

TABLE OF CONTENTS

I. PRODUCT DESCRIPTION 1

II. TYPICAL APPLICATIONS 1

Tray Assembly 1

Plate Assembly 1

Tray Return 1

Dish and Rack Bussing 1

III. INSTALLATION REQUIREMENTS 1

Mechanical 1

Slider Bed 1

Vertical Height Adjustment 1

Motorized systems 1

b. Gravity (rollers/skate wheels) 1

Self-Cleaning Return 1

Roller Return 2

Belt Assembly - Hinge Type (CI-Series) 2

Belt Assembly - Chain Type (CB-Series) 2

Stringing the Slat Belt 2

Belt Assembly - Fabric Type (CF-Series) 2

Belt Assembly - Cord Type (CC-Series) 3

Power Roller 3

IV. OPERATION 3

Main Conveyor Control Console 3

Disconnect Switch 3

2. Speed Control 3

3. Conveyor Stop Switch 3

4. Conveyor Start Switch 3

5. Conveyor Wash Switch 3

Belt Wash 3

Belt Rinse 3

Auto or Off 3,4

6. Low Detergent (optional) 4

7. Limit Switch 4

On 4

Off 4

Auto Index 4

8. Power Rollers 4

9. Auto Plate Rinse 4

Auto 4,5

On 5

10. Visual Indicators 5

Remote Controls 5

Limit and Safety Switches 5

Off 5

Conveyor Start Switch 5

Conveyor Stop Switch 5

Momentary Switch 5

Limit Switches 5

Photoelectric Sensor 5

Arm Switch Type 5

Pressure Type 5

Anti-Jam Switch 5,6

Drive Door Safety (optional) 6

ii

D.

Motor Control Adjustments 6

E.

1.

2.

2.

A.

1.

2.

3.

B.

1.

2.

C.

1.

2.

3.

4.

D.

1.

2.

a.

b.

c.

3.

A.

B.

1.

2.

3.

Water Usage 6

Slat Belt Conveyors 6

Cordveyor 6

Auto Plate Rinse 6

V. MAINTENANCE 6

Cleaning 6

Drip Pan - for Slat Type Belt 6

Scrap Basket (Tank) 6,7

Scrap Basket (Tail) 7

Detergent Pump Housing/Bottle 7

Detergent Pump Housing 7

Detergent Bottle 7

Access for Servicing 7

Hinged Side Panel 7

Removable Side Panel 7

Upper Access Panel 8

Drive Housing 8

Routine Servicing 8

Gear Box 8

Visual Inspection 8

Slat type belt 8

Fabric type belt 8

Cord type belt 8

Drive Chain 9

VI. PARTS LIST 10-14

VII. WARRANTY 15

Specific Supplements

Component Layout (internal control panel)

Wiring Diagrams

P.L.C. I/O Map

Conveyor Master

Liquid-tit Layout

iii

I. PRODUCT DESCRIPTION

Your AVTEC Conveyor is a custom engineered

member of the AVTEC Conveyor Product Group.

This manual is intended to describe the product,

its applications, installation, operation and

maintenance. Since each of our products is

engineered and manufactured specifically for you,

this manual is written in general terms and may

describe options that do not apply to your

conveyor. Specific "As Built" shop drawings are

included with your conveyor for reference.

CAUTION: This equipment is electrically driven

by a motor that is of sufficient power to cause

personal injury if improperly or recklessly

used. There are a number of safety features

engineered into the design and construction of

this product, but common sense precautions

[i.e., avoid wearing loose clothing, jewelry, etc.]

and alertness should be practiced at all times.

These conveyors are intended primarily to move

trays or racks of dishware and/or utensils.

Transporting of individual items such as flatware

and direct food contact is not recommended.

II. TYPICAL APPLICATIONS

A. Tray Assembly

Empty trays are loaded on one end of the

conveyor belt or cords and, as they progress

along the length of the conveyor, selected food

items and condiments are placed on the trays.

Trays are then off-loaded from the conveyor

and transported to the serving location.

B. Plate Assembly

Individual plates are placed on the conveyor belt

and selected food items are placed on the

plates. These plates are then off-loaded at the

end of the conveyor and transported to the

serving area.

C. Tray Return

Soiled dishes and trays are placed on the

conveyor belt or cords and transported from the

dining area to the dishwashing area, where they

are scrapped and otherwise prepared for the

dish-washing machine.

D. Dish and Rack Bussing

These conveyors can be single or double belt

width design and transport plates, utensils and

racks of soiled hollowware, from the scrapping

areas to the dishwashing machine. Dishware

can be stacked and transported without racks.

III. INSTALLATION REQUIREMENTS

General directions are provided attached to the

conveyor system on the drive housing, at time of

shipping.

A. Mechanical

1. Slider Bed

In most applications field joints are intended

to be fully welded, ground and polished to

meet both operational and aesthetic

requirements. When a conveyor is to be

used in a generally dry environment, field

joints may be bolted. To assemble, slide the

sections of the conveyor together and align

the edges, then clamp sections and bolt

together using hardware provided. Remove

clamps. [See Fig. 3.1]

Fig. 3.1

2. Vertical Height Adjustment

a. Motorized systems

Permanently located conveyors should be

leveled to within 1/16" from side to side

and 1/32" per foot from end to end.

[Example: An 8'-0" long conveyor section

the maximum deviation between the

highest and lowest points should not

exceed 1/4".] This adjustment can be

made by adjusting the feet up and down

as required.

b. Gravity (rollers/skate wheels)

Gravity fed conveyors include drain

connections, with the drain towards the

terminus-end. Floor conditions may limit

adjustment, and puddling may occur. (It

must be wiped clean)

NOTE: When using mobile conveyors, care

should be taken to operate the conveyor on a

relatively level section of floor.

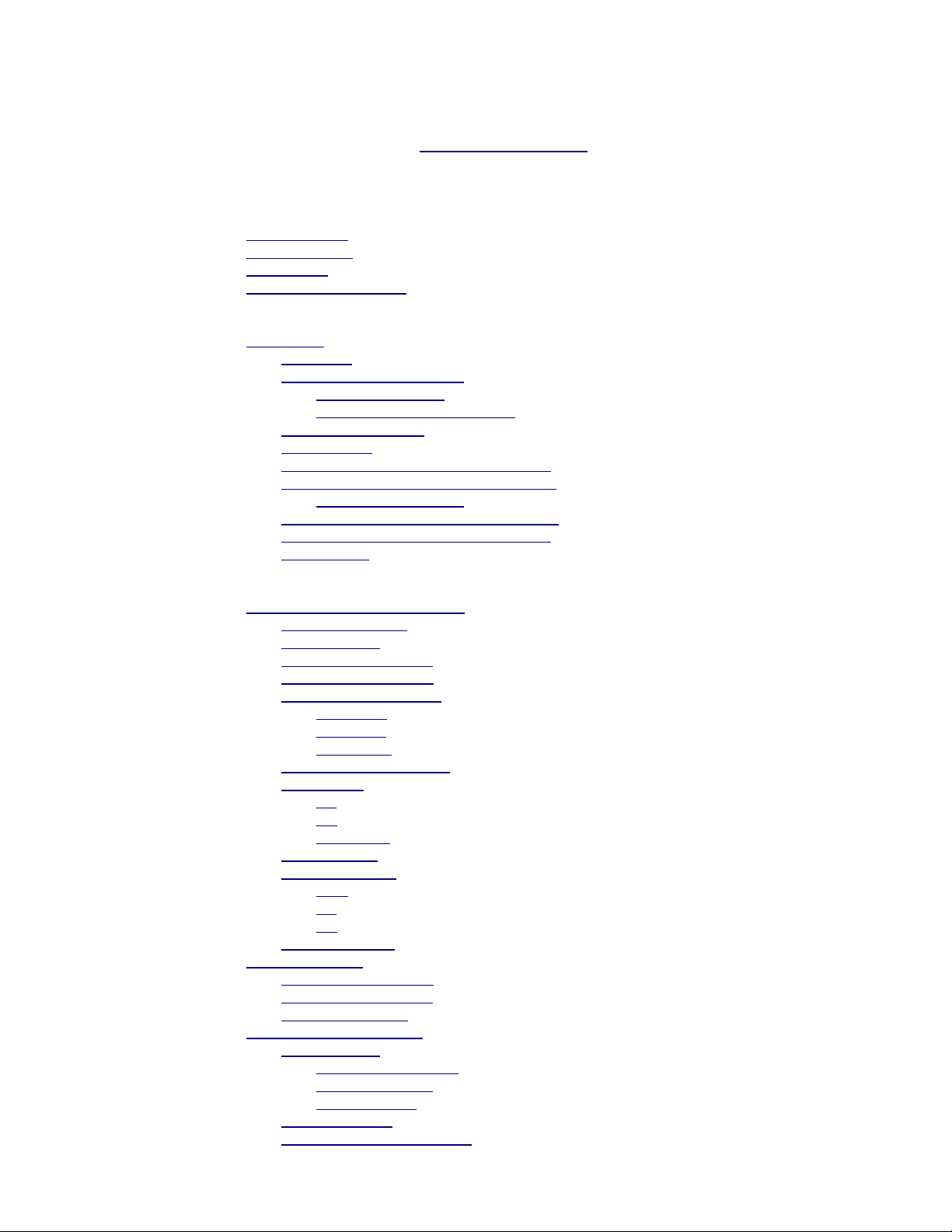

3. Self Cleaning return

On conveyors equipped with a self-cleaning

return system, it is important to align the

return pan at all field joints and seal the

seam with 100% silicon during installation to

insure proper belt operation. [See Fig. 3.2]

At the initial time of installation these pans

should be wiped free of construction debris

prior to initial start-up.

4

Fig. 3.2

4. Roller Return

On conveyors equipped with a roller return,

feed the belt over all rollers. Slight tension on

the belt should allow the ends to come

together and still leave slack under the slider

bed. [See Fig. 3.3].

Fig. 3.3

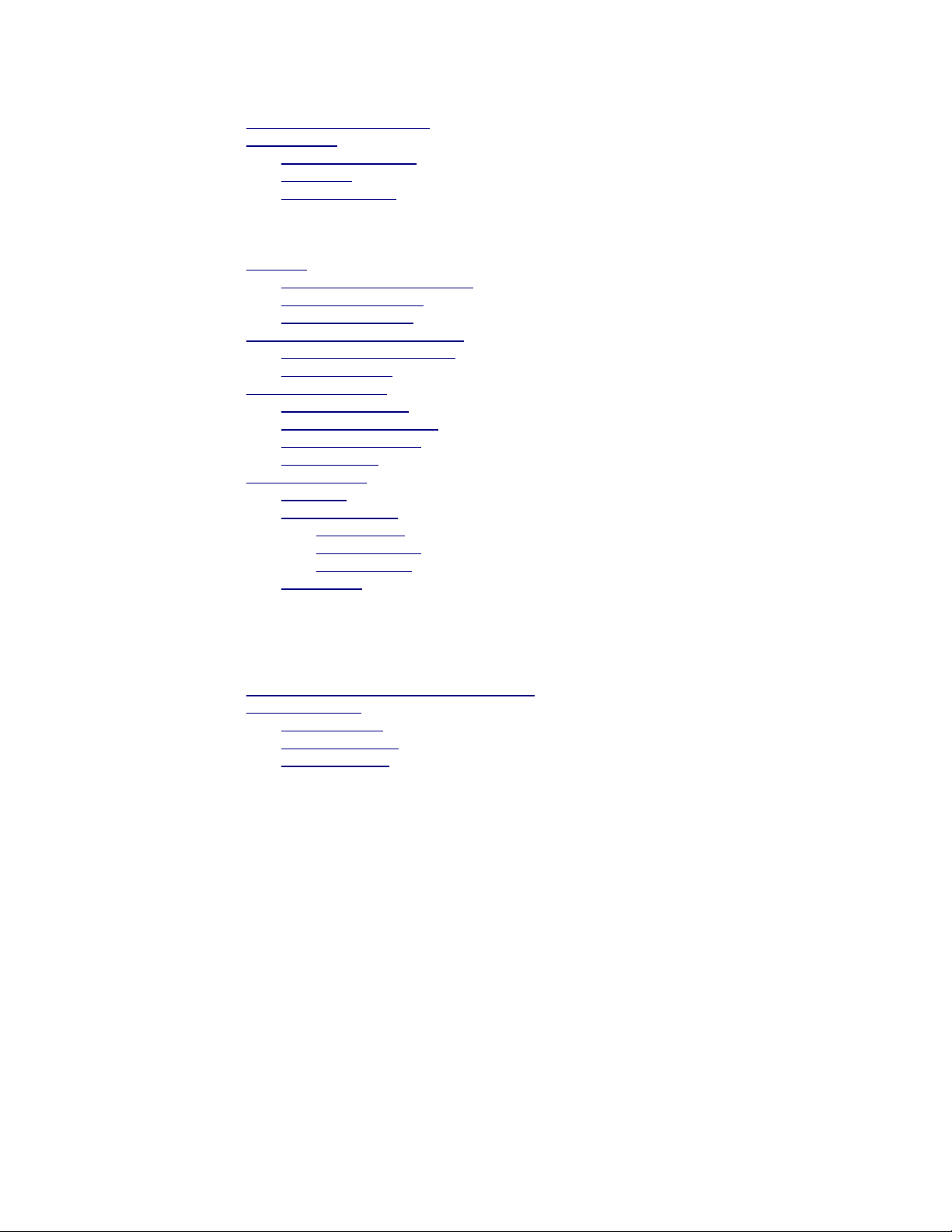

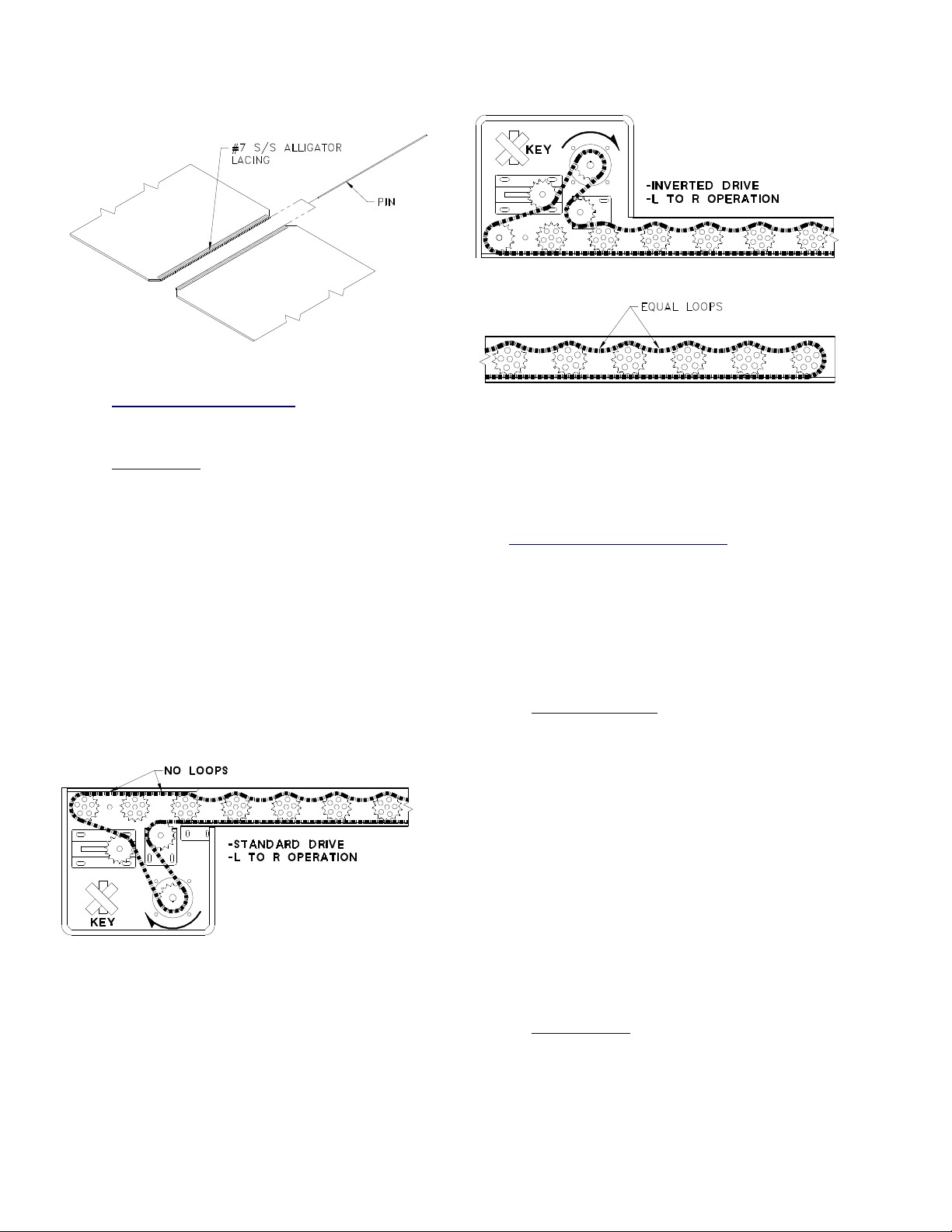

5. Belt Assembly - Hinge Type

With hinge type belts, align the ends of the

belt and insert pin. To disassemble, simply

remove the pin. [See Fig. 3.4].

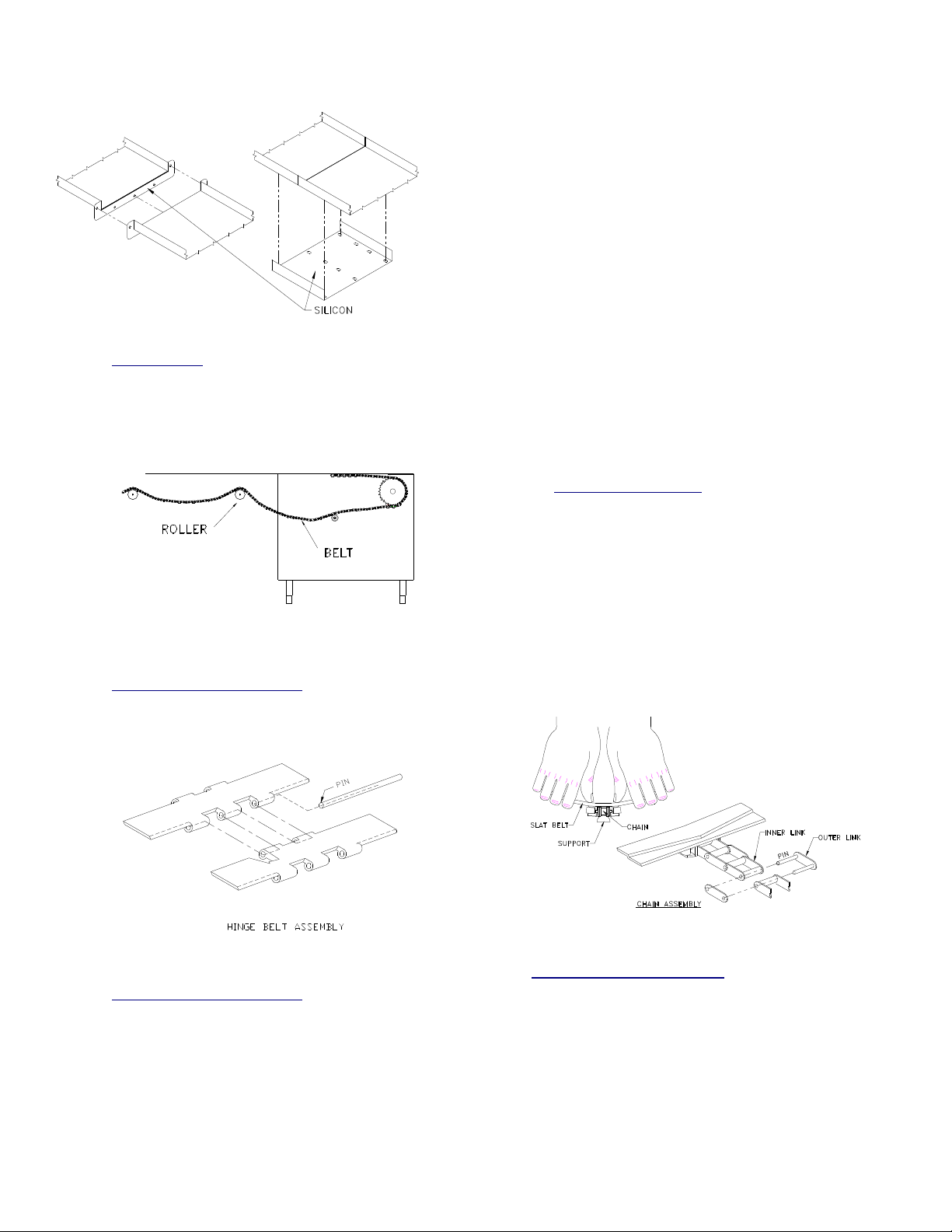

removing the slat from the stainless steel

chain, simply place your thumbs on the

center of the slat with your fingers gripping

the leading edge and “arch” the slat away

from the chain while pulling upward.

When attaching a slat to the chain, bend the

slat upward a fair amount, position the slat

carefully so the small bevels in the slat lugs

align with the extended pins of the chain and

press downward.

The chain must be supported from

underneath with some object such as a

screw driver, handle, or tube.

Service people find that the slat can be

replaced most easily right over the drive

sprocket just before the belt goes down into

the drive/wash tank. Do not HAMMER the

slat onto the chain, it only ruins the slat and

is liable to come off at a later date.

[See Fig. 3.5]

a. Stringing the Slat Belt

To string the belt, loosen the drive

sprocket flange bearing locking collet

which allows the sprocket to run freely.

Install the belt and connect it together

(per fig. 3.4 or 3.5) Center the sprocket

by pushing it against alignment hub and

tighten the locking collet securely. Test

belt alignment by briefly running the

system. Any slippage or realignment

must be immediately addressed to

prevent damage.

Fig. 3.4

6. Belt Assembly - Chain Type

For belts with integral drive chain and

removable individual slats, the links and

slats required for assembly are shipped

loose. To assemble, draw the inner links

together then inserting the outer links, snap

in place. Links can be press-fit together

using channel locks or vise grips. In

Fig. 3.5

7. Belt Assembly - Fabric Type

With fabric type belts, align the ends of the

belt and insert pin. To disassemble, simply

remove the pin. [See Fig. 3.7].

5

Fig. 3.7

8. Belt Assembly - Cord Type

See welding instruction cut sheet, at end of

manual.

9. Power Roller

Before start-up, the power roller chain must

be realigned. Turn the main sprocket

counter-clockwise (Right to Left operation),

or clockwise (Left to Right operation) until

chain is tight on bottom of sprockets [See

Fig. 3.8 and 3.9]. Loop the chain on top of

the sprockets to take up all excess slack, as

show in Fig. 3.10. For standard drives

(motor on bottom) the chain will not loop for

the first three (3) rollers over the drive

housing [see Fig 3.8]. Be sure to start up the

Power Rollers to verify the correct direction

of the motor, before installing the key. The

motor should turn in the same direction as

mentioned above. The key will be taped to

the inside of the motor housing.

Fig. 3.9

Fig. 3.10

IV

. OPERATION

A control wiring diagram of your specific conveyor

is included at the end of this manual. The

following is a brief, verbal description of the

electrical related features of your unit.

A. Main Conveyor Control Console

Due to the variety of system options some of

the noted controls may not apply to your

system. In the event that the system includes

more than one conveyor, there may be

duplicate sets of controls (one per conveyor).

The controls will be labeled for the appropriate

system.

1. Disconnect Switch

The Disconnect Switch, mounted on the

Conveyor Control Panel, is used only when

servicing the AVTEC conveyor. To remove

power from the conveyor and the

components within the Conveyor Control

Panel, rotate the handle counter-clockwise

so that it is in the off position.

The Disconnect Switch must be in the "Off"

position in order to open or close the front

plate of the Conveyor Control Panel. When

it is in the "Off" position, a lock may be

Fig. 3.8

installed in the handle to prevent the switch

from being turned back on. Turn the handle

to the on position in order to restore power to

the conveyor and the Conveyor Control

Panel.

2. Speed Control

The speed control knob is located on the

main control panel and is clearly labeled.

Turn the knob clockwise to increase the

speed of the conveyor belt. Turn the knob

counter-clockwise to reduce the speed of the

conveyor belt.

6

Loading...

Loading...